Introduction: Navigating the Global Market for aftermarket starters

Navigating the complexities of the global market for aftermarket starters presents a unique challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality aftermarket starters requires a nuanced understanding of product specifications, supplier reliability, and cost-effectiveness. As vehicles become increasingly sophisticated, the importance of selecting the right starter—whether for automotive, marine, or industrial applications—cannot be overstated.

This comprehensive guide aims to empower international B2B buyers by providing an in-depth exploration of various types of aftermarket starters, their applications across different industries, and actionable strategies for vetting suppliers. Buyers will learn how to assess the quality of starter components, understand the implications of OEM standards, and navigate the intricacies of pricing to secure optimal value.

By addressing critical aspects such as performance testing, warranty considerations, and environmental factors, this guide equips buyers with the insights needed to make informed purchasing decisions. Ultimately, understanding the global aftermarket starter landscape will enable businesses to enhance operational efficiency, reduce downtime, and maximize their return on investment. As you delve into this resource, you will gain the knowledge necessary to confidently navigate the aftermarket starter market and ensure your fleet remains reliable and efficient.

جدول المحتويات

- Top 5 Aftermarket Starters Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for aftermarket starters

- Understanding aftermarket starters Types and Variations

- Key Industrial Applications of aftermarket starters

- 3 Common User Pain Points for ‘aftermarket starters’ & Their Solutions

- Strategic Material Selection Guide for aftermarket starters

- In-depth Look: Manufacturing Processes and Quality Assurance for aftermarket starters

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘aftermarket starters’

- Comprehensive Cost and Pricing Analysis for aftermarket starters Sourcing

- Alternatives Analysis: Comparing aftermarket starters With Other Solutions

- Essential Technical Properties and Trade Terminology for aftermarket starters

- Navigating Market Dynamics and Sourcing Trends in the aftermarket starters Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of aftermarket starters

- Strategic Sourcing Conclusion and Outlook for aftermarket starters

- إخلاء مسؤولية هام وشروط الاستخدام

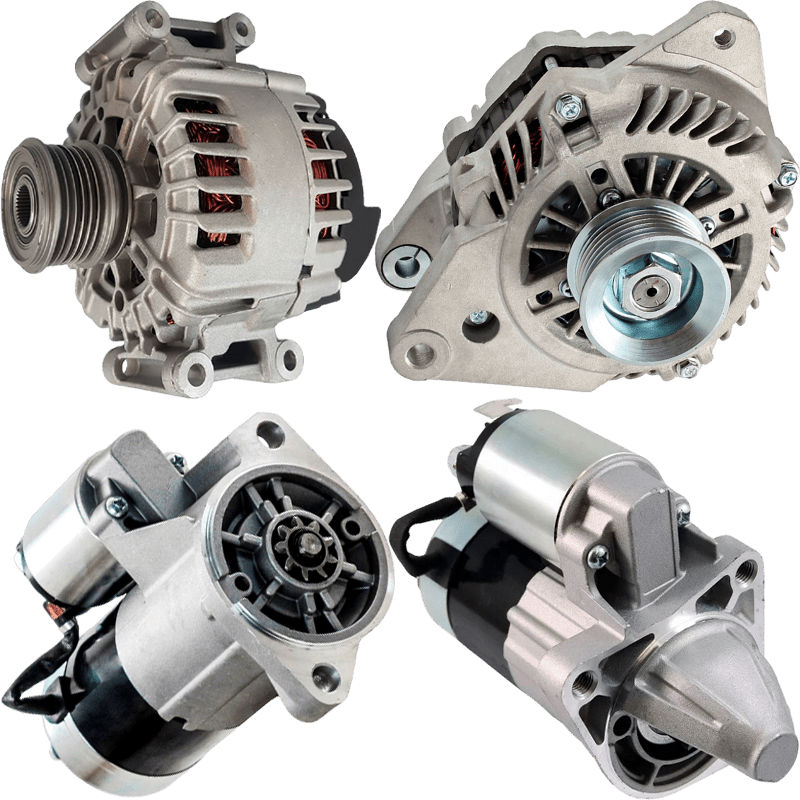

Understanding aftermarket starters Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| Standard Aftermarket | OEM specifications, competitive pricing, basic functionality | التصليحات العامة للسيارات | الإيجابيات: فعالة من حيث التكلفة ومتوفرة على نطاق واسع. السلبيات: قد تفتقر إلى الميزات المتقدمة. |

| High-Performance | Enhanced torque, lightweight materials, optimized for racing | Performance vehicles, motorsport applications | الإيجابيات: Superior performance, reliability under stress. السلبيات: Higher cost, may not be suitable for everyday use. |

| مُعاد تصنيعه | Recycled components, rigorous testing, environmentally friendly | Cost-sensitive markets, fleet maintenance | الإيجابيات: Eco-friendly, lower price point. السلبيات: التباين المحتمل في الجودة. |

| Marine Starters | Designed for harsh environments, corrosion-resistant materials | السفن البحرية، قوارب الصيد | الإيجابيات: Durability in extreme conditions, specialized designs. السلبيات: Higher maintenance due to marine environment. |

| المبتدئين المتخصصين | Custom designs for unique applications (e.g., motorcycles, ATVs) | Niche markets, specialized vehicles | الإيجابيات: Tailored solutions, specific performance needs. السلبيات: Limited availability, potentially higher costs. |

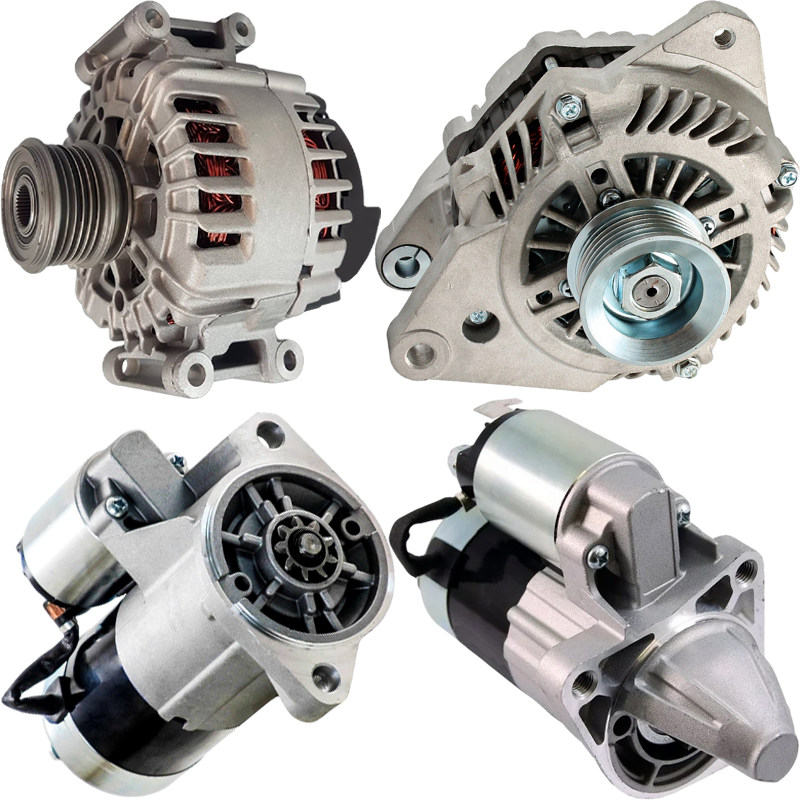

What Are the Key Characteristics of Standard Aftermarket Starters?

Standard aftermarket starters are designed to meet OEM specifications, ensuring compatibility with a wide range of vehicles. They typically provide reliable performance at a competitive price point, making them ideal for general automotive repairs. B2B buyers should consider the warranty and return policies when purchasing these starters, as they can vary significantly among suppliers. While they are cost-effective, these starters may lack advanced features found in high-performance alternatives.

How Do High-Performance Starters Differ from Standard Options?

High-performance starters are engineered for enhanced torque and efficiency, often utilizing lightweight materials to reduce strain on the vehicle’s electrical system. These starters are particularly suited for performance vehicles and motorsport applications where reliability under high-stress conditions is crucial. B2B buyers in sectors focused on racing or specialized automotive applications should weigh the benefits of superior performance against the higher costs associated with these products.

What Should B2B Buyers Know About Remanufactured Starters?

Remanufactured starters are an eco-friendly option that involves recycling components while adhering to rigorous testing standards. These starters provide a cost-effective solution for businesses operating on tight budgets, such as fleet maintenance providers. However, B2B buyers must be cautious about the variability in quality, as not all remanufactured products meet the same standards. Ensuring suppliers offer solid warranties and quality assurance can mitigate these risks.

Why Are Marine Starters Essential for Marine Applications?

Marine starters are specifically designed to withstand harsh environments, featuring corrosion-resistant materials that ensure longevity in saltwater conditions. These starters are critical for marine vessels and fishing boats, where reliability is paramount. B2B buyers in the marine industry should prioritize suppliers that offer specialized marine starters with robust warranties, as the cost of failure at sea can be significant. Maintenance considerations are also essential due to the unique challenges of marine environments.

What Are the Benefits of Specialty Starters for Niche Markets?

Specialty starters cater to unique applications, such as motorcycles and ATVs, and are tailored to meet specific performance and fitment needs. These products are ideal for businesses in niche markets that require customized solutions. B2B buyers should evaluate the availability of these starters and consider potential lead times, as they may not be as readily available as standard options. While the costs can be higher, the tailored performance benefits often justify the investment.

Key Industrial Applications of aftermarket starters

| الصناعة/القطاع | Specific Application of aftermarket starters | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | Replacement starters for passenger vehicles | حلول فعالة من حيث التكلفة لصيانة المركبات | OEM compatibility, warranty, and performance guarantees |

| معدات زراعية | Starters for tractors and farming machinery | Enhanced reliability in demanding conditions | Durability under extreme temperatures and heavy usage |

| الصناعة البحرية | Starters for outboard and inboard engines | Increased performance and longevity in marine environments | Resistance to corrosion and water exposure |

| الآلات الصناعية | Starters for heavy-duty equipment | Improved uptime and operational efficiency | Availability of parts for various machinery brands |

| البناء | Starters for construction vehicles and machinery | Minimized downtime through reliable starting systems | الامتثال للوائح والمعايير المحلية |

How Are Aftermarket Starters Used in the Automotive Sector?

In the automotive industry, aftermarket starters are crucial for replacing worn-out or malfunctioning components in passenger vehicles. Businesses benefit from cost-effective solutions that maintain vehicle performance without the premium price tag of OEM parts. Buyers must ensure that the starters are compatible with specific vehicle models and come with warranties to safeguard against defects. Performance guarantees are essential, particularly for international buyers who may face logistical challenges in sourcing reliable replacements.

What Role Do Aftermarket Starters Play in Agricultural Equipment?

Aftermarket starters are vital for tractors and other agricultural machinery, ensuring reliable operation in often harsh conditions. These components must withstand extreme temperatures and heavy usage, which are common in farming environments. The value lies in their enhanced reliability, reducing the risk of equipment failure during critical planting or harvesting periods. Buyers should prioritize sourcing durable starters that meet the specific requirements of their machinery and consider local climate conditions when selecting components.

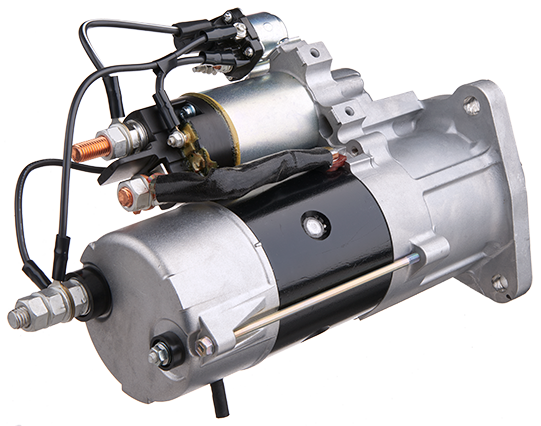

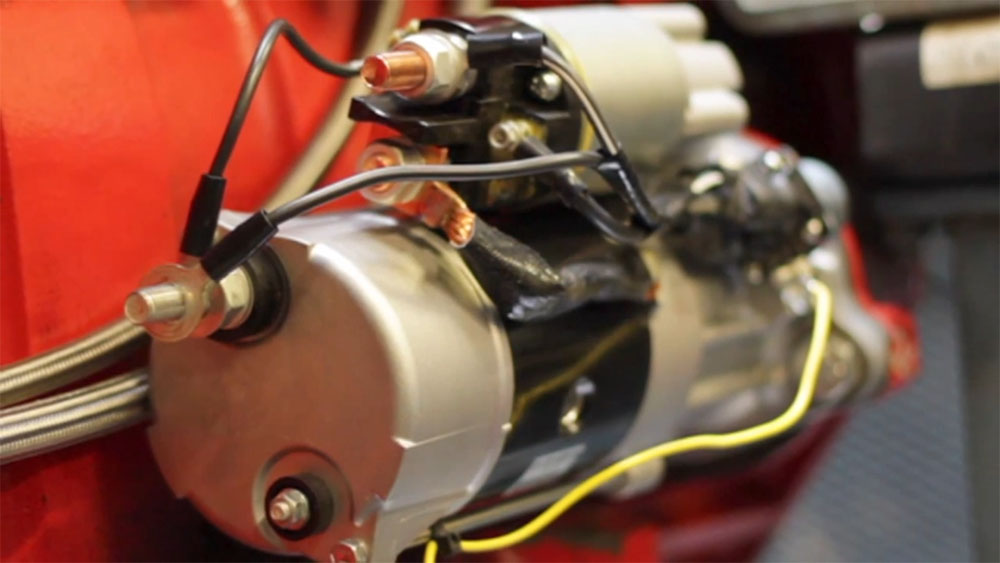

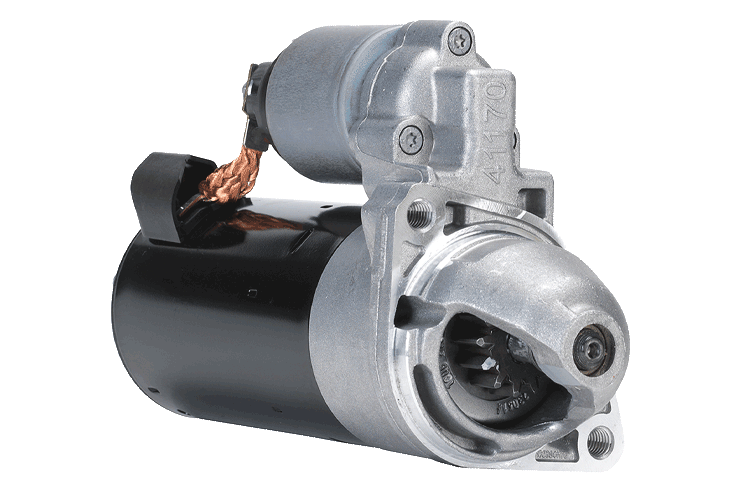

Illustrative image related to aftermarket starters

How Do Aftermarket Starters Benefit the Marine Industry?

In the marine sector, aftermarket starters are essential for both outboard and inboard engines, providing the necessary power for reliable engine starts. The unique demands of marine environments necessitate components that are resistant to corrosion and water exposure. Businesses benefit from increased performance and longevity, which are crucial for minimizing downtime on the water. Buyers must consider sourcing options that offer robust warranties and ensure compliance with marine safety standards.

Why Are Aftermarket Starters Important for Industrial Machinery?

Heavy-duty industrial machinery relies on aftermarket starters for efficient operation and reduced downtime. These starters are engineered to perform under demanding conditions, providing improved uptime and operational efficiency. Businesses benefit from the ability to source starters that fit a variety of machinery brands, ensuring compatibility and performance. Key considerations for buyers include the availability of parts, adherence to industry standards, and the reputation of the supplier.

How Do Aftermarket Starters Enhance Construction Equipment Performance?

In the construction industry, aftermarket starters are critical for the reliable operation of vehicles and machinery. They help minimize downtime, which is essential for maintaining project timelines and productivity. The value lies in their ability to provide dependable starting systems that withstand the rigors of construction sites. Buyers should ensure that the starters comply with local regulations and standards, as well as evaluate the supplier’s capacity to deliver timely replacements in case of failure.

3 Common User Pain Points for ‘aftermarket starters’ & Their Solutions

Scenario 1: Difficulty in Identifying Compatible Aftermarket Starters

المشكلة: One of the primary challenges B2B buyers face when sourcing aftermarket starters is ensuring compatibility with a diverse range of vehicles. With numerous makes, models, and specifications, buyers often find themselves overwhelmed by the variations in starter designs. This can lead to costly purchasing mistakes, increased downtime, and customer dissatisfaction if the wrong part is ordered, especially in regions with a high demand for specific vehicle types.

Illustrative image related to aftermarket starters

الحل: To mitigate this issue, buyers should leverage advanced part-finding tools provided by reputable suppliers. These tools allow users to filter products by vehicle type, model year, and even engine specifications. Additionally, it’s crucial to maintain an updated database of OEM part numbers and cross-reference them with aftermarket options. Establishing a relationship with reliable suppliers who can provide detailed product specifications and support can also enhance the purchasing process. Regular training for purchasing staff on the nuances of various starter systems can further reduce errors and improve overall sourcing efficiency.

Scenario 2: Concerns Over Quality and Reliability of Aftermarket Starters

المشكلة: Quality assurance is a significant concern when dealing with aftermarket starters. Buyers often worry that these components may not meet OEM standards, leading to performance issues and increased warranty claims. This is particularly true for buyers in regions where the climate can severely affect starter performance, such as extreme heat in the Middle East or cold in parts of Europe. Poor-quality starters can result in higher replacement costs and damage to customer relationships.

الحل: Buyers should prioritize sourcing aftermarket starters from manufacturers that provide transparent quality assurance processes. Look for suppliers who conduct rigorous testing, such as high-voltage testing of armatures and field coils, and who offer guarantees or warranties on their products. It’s beneficial to request samples and conduct independent tests if necessary. Establishing partnerships with manufacturers that have a proven track record of producing reliable components can also help mitigate risks. Additionally, consider investing in training for your team to understand quality indicators and testing standards in the aftermarket parts industry.

Illustrative image related to aftermarket starters

Scenario 3: The Challenge of Balancing Cost and Performance

المشكلة: B2B buyers frequently struggle with the dilemma of balancing cost against performance when purchasing aftermarket starters. In a competitive market, the pressure to minimize expenses can lead to compromising on quality, which may affect the long-term reliability and efficiency of the starters. This is particularly challenging in emerging markets where price sensitivity is high, yet the need for durable and dependable components remains critical.

الحل: To navigate this challenge, buyers should adopt a value-based purchasing strategy rather than solely focusing on the lowest price. Conduct thorough market research to identify suppliers that offer a balance of quality and affordability. Engage in discussions with manufacturers about their production processes to understand the materials used and their impact on performance. Implement a tiered pricing strategy that allows for bulk purchasing discounts without sacrificing quality. Additionally, consider forming a buying group with other businesses to increase purchasing power while ensuring access to high-quality aftermarket starters. Regularly evaluate supplier performance and customer feedback to make informed decisions and adjustments to sourcing strategies.

Strategic Material Selection Guide for aftermarket starters

When selecting materials for aftermarket starters, understanding the properties, advantages, and limitations of various materials is crucial for ensuring optimal performance and longevity. This guide analyzes four common materials used in the manufacturing of aftermarket starters, focusing on their properties, pros and cons, and specific considerations for international B2B buyers.

Illustrative image related to aftermarket starters

What Are the Key Properties of Copper in Aftermarket Starters?

Copper is a highly conductive material, often used for electrical terminals and windings in starters. Its excellent electrical conductivity ensures efficient current flow, which is essential for reliable starter performance. Copper also exhibits good corrosion resistance, particularly when plated, making it suitable for various environmental conditions.

الإيجابيات والسلبيات: While copper is durable and provides superior conductivity, it is also relatively expensive compared to other metals. Its manufacturing complexity can increase costs, especially when precision machining is required.

التأثير على التطبيق: Copper’s high conductivity makes it ideal for applications requiring rapid electrical response, such as in high-performance automotive starters.

اعتبارات للمشترين الدوليين: Buyers from regions like Europe and the Middle East should ensure compliance with standards like ASTM B187 for copper products. In Africa and South America, sourcing copper may be influenced by local availability and pricing fluctuations.

Why is Steel a Common Choice for Starter Housings?

Steel, particularly carbon steel, is frequently used for starter housings due to its strength and durability. It can withstand high temperatures and pressures, making it suitable for automotive applications where heat dissipation is critical.

الإيجابيات والسلبيات: Steel is cost-effective and readily available, but it can be prone to corrosion if not properly treated. Additionally, its weight may impact the overall efficiency of the starter system.

Illustrative image related to aftermarket starters

التأثير على التطبيق: Steel housings provide robust protection for internal components, ensuring longevity even in harsh environments.

اعتبارات للمشترين الدوليين: Compliance with standards such as DIN 17100 for carbon steel is essential for buyers in Germany and other European countries. Buyers in the Middle East should also consider the effects of humidity and temperature on steel components.

How Does Aluminum Enhance Starter Performance?

Aluminum is increasingly used in starter components due to its lightweight properties and good corrosion resistance. It is often utilized in the construction of starter end caps and housings, where weight savings can lead to improved vehicle efficiency.

الإيجابيات والسلبيات: The lightweight nature of aluminum reduces the overall weight of the starter, enhancing vehicle performance. However, aluminum is less durable than steel and may not withstand extreme conditions as effectively.

Illustrative image related to aftermarket starters

التأثير على التطبيق: Aluminum is particularly beneficial in applications where weight is a critical factor, such as in racing or high-performance vehicles.

اعتبارات للمشترين الدوليين: Buyers should ensure that aluminum components meet standards like JIS H 2000 in Japan or similar standards in Europe. Additionally, sourcing aluminum may be subject to tariffs or trade regulations in various regions.

What Role Does Plastic Play in Aftermarket Starters?

Plastic materials, particularly high-performance polymers, are often used for non-structural components such as covers and insulators. These materials provide excellent electrical insulation and can be engineered to withstand a range of temperatures.

الإيجابيات والسلبيات: Plastics are lightweight and resistant to corrosion, making them suitable for various applications. However, they may not offer the same level of durability as metals under extreme conditions.

التأثير على التطبيق: Plastic components can enhance the overall efficiency of starters by reducing weight and providing effective insulation.

اعتبارات للمشترين الدوليين: Compliance with international standards for plastics, such as ISO 1043, is essential for ensuring quality and performance, especially for buyers in Europe and the Middle East.

Summary Table of Material Selection for Aftermarket Starters

| المواد | Typical Use Case for aftermarket starters | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | Electrical terminals and windings | موصلية ممتازة | ارتفاع التكلفة وتعقيد التصنيع | عالية |

| الصلب | Starter housings | قوية ومتينة | Prone to corrosion if untreated | متوسط |

| الألومنيوم | End caps and housings | خفيف الوزن ومقاوم للتآكل | أقل متانة من الفولاذ | متوسط |

| بلاستيك | المكونات غير الهيكلية | Lightweight and insulated | أقل متانة في الظروف القاسية | منخفض |

This strategic material selection guide provides valuable insights for B2B buyers in the aftermarket starter industry, enabling informed decisions that align with performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for aftermarket starters

What Are the Key Stages in the Manufacturing Process of Aftermarket Starters?

The manufacturing of aftermarket starters involves several critical stages, each designed to ensure the final product meets high-performance standards and durability requirements. Understanding these stages can help B2B buyers make informed decisions when sourcing from suppliers.

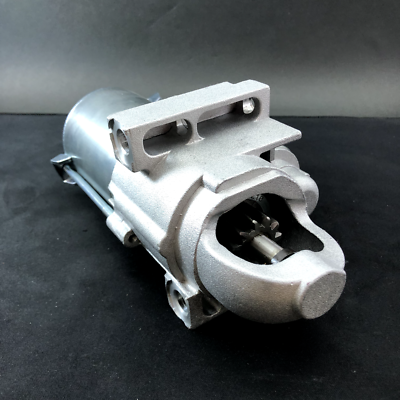

Material Preparation: What Are the Essential Components for Starters?

The first step in the manufacturing process is the preparation of raw materials. High-quality materials such as copper, steel, and durable plastics are essential for the components of a starter. For instance, copper is often used for terminals to ensure optimal electrical conductivity, while high-grade steel is used for the housing and internal gears to withstand operational stresses.

To ensure material integrity, suppliers may perform metallurgical testing to assess tensile strength and durability. This stage also includes the procurement of components like brushes, solenoids, and bearings from trusted manufacturers, which are often sourced globally to meet various specifications.

Illustrative image related to aftermarket starters

التشكيل: كيف يتم تشكيل مكونات المبتدئين؟

Once materials are prepared, they undergo various forming processes. Techniques such as stamping, machining, and die-casting are commonly employed to create the individual components of starters. For example, the armature and field coils are typically produced through precision machining to ensure exact dimensions and a perfect fit.

Advanced forming techniques, such as injection molding, are used for plastic components. This process allows for complex shapes that contribute to the overall efficiency of the starter. Quality control during this stage includes visual inspections and dimensional checks to ensure compliance with design specifications.

Assembly: What Quality Checks Are Performed During Assembly?

After forming, the assembly process begins. Components are meticulously assembled, often using automated machinery combined with skilled labor to ensure precision. Each starter typically undergoes a multi-step assembly process, including the installation of the armature, field coils, solenoids, and housing.

During assembly, various quality checkpoints are implemented. In-Process Quality Control (IPQC) checks are crucial at this stage to identify any defects early on. Common checks include torque measurements on bolts and fasteners to ensure they meet specified tolerances, as well as functional tests to verify the assembly’s integrity.

Finishing: What Final Touches Ensure Performance and Reliability?

The finishing stage involves treatments that enhance the durability and performance of the starter. This may include surface treatments like plating or painting to prevent corrosion, as well as the application of seals to protect against dust and moisture. These treatments are particularly important for starters used in harsh environments, such as agricultural or marine applications.

Illustrative image related to aftermarket starters

At this stage, final quality assurance tests are performed. Functional testing simulates actual operating conditions to ensure the starter performs under various temperatures and loads. This is essential for ensuring reliability, especially in regions with extreme weather conditions.

How Is Quality Assurance Implemented in Aftermarket Starter Manufacturing?

Quality assurance (QA) is a vital aspect of manufacturing aftermarket starters, ensuring that products meet international standards and customer expectations. B2B buyers should familiarize themselves with the QA processes to assess the reliability of potential suppliers.

What International Standards Guide Quality Assurance?

Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 ensures that manufacturers have robust processes in place for consistent quality throughout production.

Illustrative image related to aftermarket starters

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for oil and gas applications may also apply. These certifications not only enhance product credibility but also provide assurance of adherence to specific safety and performance criteria.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة؟

Quality control in the manufacturing process typically includes several checkpoints, namely:

-

مراقبة الجودة الواردة (IQC): This initial checkpoint evaluates the quality of raw materials and components received from suppliers. Materials must meet predefined specifications before they can be used in production.

-

مراقبة الجودة أثناء الإنتاج (IPQC): Conducted during the manufacturing process, IPQC involves regular inspections and tests to catch defects before they affect the final product. This includes dimensional checks and functional tests.

-

مراقبة الجودة النهائية (FQC): Before the starters are packaged and shipped, FQC ensures that each unit meets all performance and safety standards. This may include functional testing and visual inspections.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

To ensure the reliability of suppliers, B2B buyers should actively verify their quality assurance practices. Here are some effective methods:

What Audits and Reports Should Buyers Request?

Buyers can request regular audit reports from suppliers to gain insight into their quality management processes. Audits may cover compliance with international standards, testing procedures, and overall manufacturing practices.

Additionally, asking for third-party inspection reports can provide an unbiased assessment of the supplier’s quality control measures. Independent inspections can help verify that the products meet the required specifications and standards.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين؟

For international buyers, particularly those from regions like Africa, South America, and the Middle East, understanding local regulations and standards is crucial. Different countries may have specific certification requirements or quality expectations. Buyers should ensure that their suppliers are knowledgeable about these regulations and can provide the necessary documentation.

Furthermore, establishing strong communication with suppliers can facilitate better understanding and compliance with quality standards. Regular updates and feedback loops can help ensure that both parties are aligned on quality expectations.

Conclusion: Making Informed Decisions in Sourcing Aftermarket Starters

Understanding the manufacturing processes and quality assurance measures for aftermarket starters is vital for B2B buyers. By focusing on material quality, production techniques, and rigorous QA standards, buyers can source reliable products that meet their operational needs. Engaging with suppliers who prioritize quality will ultimately lead to better performance and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aftermarket starters’

مقدمة

This practical sourcing guide is designed to assist B2B buyers in navigating the complexities of procuring aftermarket starters. With a focus on quality, reliability, and cost-effectiveness, this checklist provides actionable steps to ensure you make informed purchasing decisions that meet your operational needs.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Before beginning your search, clearly outline the technical requirements for the starters you need. This includes understanding the voltage, type (gear reduction vs. direct drive), and compatibility with specific vehicle makes and models. Precise specifications will help streamline your sourcing process and ensure that you only consider products that meet your operational needs.

الخطوة 2: البحث في اتجاهات السوق والتسعير

Stay informed about current market trends and pricing structures for aftermarket starters. Analyze the average price range and understand what constitutes a fair price based on quality and brand reputation. This knowledge will empower you to negotiate better deals and avoid overpaying for subpar products.

Illustrative image related to aftermarket starters

الخطوة 3: تقييم الموردين المحتملين

Thoroughly vet potential suppliers to ensure they meet your standards for quality and reliability. Request company profiles, product certifications, and references from other businesses in your industry. Look for suppliers with proven track records and positive customer feedback to mitigate risks associated with sourcing.

- Check for OEM Standards: Ensure that the starters comply with Original Equipment Manufacturer (OEM) specifications for quality and fitment.

- Assess Production Capabilities: Understand the supplier’s manufacturing processes and quality control measures.

الخطوة 4: التحقق من شهادات الموردين

Confirm that your chosen suppliers hold relevant industry certifications that demonstrate their commitment to quality. Certifications such as ISO 9001 can indicate a supplier’s adherence to international quality management standards. This step is crucial for ensuring that the products you receive will meet your performance expectations.

الخطوة 5: طلب عينات للاختبار

Before making a bulk purchase, request samples of the starters for testing. Evaluate their performance under real-world conditions to ensure they meet your operational requirements. This hands-on approach allows you to verify the quality and functionality of the products before committing to a larger order.

الخطوة 6: تقييم سياسات الضمان والإرجاع

Review the warranty and return policies offered by your suppliers. A robust warranty indicates confidence in product quality and provides peace of mind in case of defects. Look for terms that are favorable to you, such as extended warranties or hassle-free returns, to safeguard your investment.

الخطوة 7: إنشاء قنوات اتصال واضحة

Effective communication is key to a successful procurement process. Establish clear lines of communication with your suppliers to address any questions or concerns promptly. This proactive approach will foster a strong business relationship and facilitate smoother transactions throughout the sourcing process.

Illustrative image related to aftermarket starters

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing landscape for aftermarket starters, ensuring they obtain high-quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for aftermarket starters Sourcing

What are the Key Cost Components in Aftermarket Starters?

Understanding the cost structure of aftermarket starters is crucial for B2B buyers looking to optimize their procurement strategies. The primary cost components include:

-

المواد: Quality of raw materials directly impacts performance and longevity. High-grade copper for terminals and robust alloys for housing are common, which can significantly elevate costs. Sourcing materials locally can help mitigate some import costs, especially for international buyers.

-

العمل: Labor costs vary widely based on geographic location and manufacturing practices. Countries with lower labor costs may offer competitive pricing, but this can affect quality. It’s essential to balance cost with the expertise of the workforce in producing reliable starters.

-

تكاليف التصنيع العامة: This encompasses utilities, facility costs, and indirect labor. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

-

الأدوات: Initial tooling costs can be significant, especially for custom designs. Buyers should inquire about the tooling setup and any associated costs, particularly for unique specifications.

-

مراقبة الجودة (QC): Rigorous testing and quality assurance processes ensure that each starter meets performance standards. While this adds to the cost, it is a necessary investment to reduce warranty claims and returns.

-

اللوجستيات: Transportation costs are vital, especially for international shipments. Factors such as distance, mode of transport, and customs duties can influence the final cost significantly.

-

الهامش: Suppliers typically build a margin into their pricing to cover risks and ensure profitability. Understanding the average market margin can help buyers negotiate better deals.

What Influences Pricing in Aftermarket Starters?

Several factors can influence the pricing of aftermarket starters:

-

الحجم والحد الأدنى لكمية الطلب (MOQ): Larger orders often lead to lower per-unit costs. Buyers should assess their needs carefully and consider bulk purchasing to leverage better pricing.

-

المواصفات والتخصيص: Custom-built starters tailored to specific vehicle models or performance requirements can incur higher costs. Buyers should clearly outline their needs to avoid unnecessary expenses.

-

جودة المواد والشهادات: Premium materials and certifications (like ISO or OEM standards) can increase costs but are often worth the investment for enhanced reliability and performance.

-

عوامل الموردين: Supplier reputation, manufacturing capabilities, and delivery reliability are crucial. Established suppliers may charge a premium, but their products often come with better support and warranty terms.

-

مصطلحات التجارة الدولية: Understanding the chosen Incoterms (e.g., FOB, CIF) is essential for calculating total landed costs. This affects pricing structures significantly, especially in international transactions.

What Tips Can Help Buyers Navigate Pricing Nuances?

-

التفاوض: Leverage competitive quotes from multiple suppliers to negotiate better terms. Building long-term relationships can also yield favorable pricing adjustments over time.

-

التركيز على التكلفة الإجمالية للملكية (TCO): Consider not just the initial purchase price but also the long-term costs associated with maintenance, warranty, and potential failures. Investing in higher-quality starters can lead to lower overall costs.

-

فهم الفروق الدقيقة في التسعير للمشترين الدوليين: Be aware of currency fluctuations, import tariffs, and local market conditions. Engaging with local suppliers in regions like Africa, South America, or the Middle East can provide valuable insights and potentially lower costs.

-

ابق على اطلاع: Keep abreast of market trends and technological advancements in starter manufacturing. This knowledge can empower buyers to make informed decisions and anticipate price changes.

-

طلب عينات: Before committing to large orders, request samples to evaluate quality and performance. This can prevent costly mistakes and ensure that the products meet your standards.

إخلاء المسؤولية بشأن الأسعار

While this analysis provides a comprehensive overview of cost and pricing factors, actual prices may vary based on specific circumstances, supplier negotiations, and market conditions. Always conduct thorough due diligence before finalizing any procurement decisions.

Alternatives Analysis: Comparing aftermarket starters With Other Solutions

Exploring Alternatives to Aftermarket Starters

In the automotive industry, aftermarket starters provide a cost-effective solution for vehicle owners seeking reliable performance. However, several alternatives also exist that can serve similar functions. Understanding these options allows B2B buyers to make informed decisions based on their specific needs, budgets, and operational contexts. Below, we compare aftermarket starters with two viable alternatives: OEM (Original Equipment Manufacturer) Starters و Starter Repair Kits.

| جانب المقارنة | محركات بدء التشغيل في سوق قطع الغيار | مشغلات OEM | Starter Repair Kits |

|---|---|---|---|

| الأداء | High-quality materials ensure reliability and longevity. | Designed for specific models, often offering superior performance. | Performance depends on the quality of components used in repairs. |

| التكلفة | Typically 30% less than OEM, providing significant savings. | Generally higher due to brand and warranty factors. | Cost-effective but varies based on part quality. |

| سهولة التنفيذ | Easy to source and install, widely available. | Direct fit for vehicles but may require professional installation. | Requires technical knowledge for assembly and installation. |

| الصيانة | Low maintenance; designed for durability. | Regular maintenance may be necessary depending on usage. | Maintenance depends on the quality of repairs; potential for issues if done improperly. |

| أفضل حالة استخدام | Ideal for budget-conscious consumers needing reliable performance. | Best for high-performance vehicles or where warranty is critical. | Suitable for DIY enthusiasts or those looking to save money on repairs. |

What Are the Advantages and Disadvantages of OEM Starters?

OEM starters are manufactured by the original car makers, ensuring a perfect fit and performance tailored to specific vehicle models. الإيجابيات include superior reliability, adherence to manufacturer specifications, and often better performance under extreme conditions. However, they come at a premium price, which may not be justifiable for all buyers. Additionally, OEM starters may have longer lead times due to sourcing directly from manufacturers, which can be a drawback for urgent replacements.

How Do Starter Repair Kits Compare?

Starter repair kits provide an economical solution for those looking to extend the life of their existing starter motor. These kits typically include all necessary components for a DIY repair, allowing for significant cost savings compared to purchasing a new starter. الإيجابيات include lower upfront costs and the ability to customize repairs based on specific component failures. However, the سلبيات include the need for technical knowledge and skills for effective installation. Poor-quality components can lead to performance issues, making this option less reliable than aftermarket or OEM starters.

Making the Right Choice: How Can B2B Buyers Select the Best Starter Solution?

When choosing between aftermarket starters, OEM starters, and starter repair kits, B2B buyers should assess their specific needs, such as budget constraints, performance requirements, and installation capabilities. Aftermarket starters offer a balance of quality and cost, making them suitable for a wide range of applications. In contrast, OEM starters may be preferable for high-performance vehicles where reliability is paramount. Meanwhile, starter repair kits can be an appealing choice for those with mechanical expertise looking to minimize repair costs. Ultimately, the decision should align with the operational goals, maintenance capabilities, and financial considerations of the buyer’s business.

Essential Technical Properties and Trade Terminology for aftermarket starters

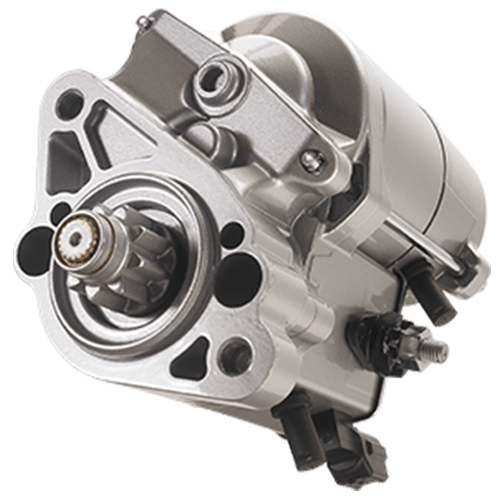

What Are the Key Technical Properties of Aftermarket Starters?

Understanding the technical properties of aftermarket starters is essential for B2B buyers to ensure they select products that meet quality and performance standards. Here are some critical specifications to consider:

1. درجة المواد

The material grade of a starter significantly affects its durability and performance. High-quality materials, such as premium-grade steel and copper, are essential for components like the armature, field coils, and terminals. Choosing starters made from superior materials ensures longer service life and reliability, reducing the frequency of replacements and maintenance costs.

2. تصنيف عزم الدوران

Torque rating refers to the amount of rotational force a starter can produce to crank the engine. This specification is crucial, especially in demanding environments or for high-performance vehicles. A higher torque rating means the starter can handle larger engines or operate efficiently under various conditions, including extreme temperatures, which is particularly important in regions with diverse climates.

3. جهد التشغيل

Most automotive starters operate at 12 volts, but some applications may require higher voltages. Understanding the operating voltage is vital for compatibility with the vehicle’s electrical system. Starters that can withstand fluctuations in voltage without compromising performance are preferable, as they minimize the risk of electrical failures.

4. Fitment and Compatibility (OEM Standards)

Aftermarket starters must meet Original Equipment Manufacturer (OEM) specifications for fitment. This ensures that the starter will integrate seamlessly with the vehicle’s existing systems. For B2B buyers, sourcing starters that adhere to OEM standards reduces the risk of installation issues and enhances customer satisfaction.

5. Testing and Quality Assurance

A rigorous testing protocol is essential for ensuring the reliability of aftermarket starters. Look for products that have undergone comprehensive testing for performance, including high-voltage tests and endurance tests. This validation provides assurance of quality and can lead to lower return rates and higher customer trust.

6. Sealed Housings and Bearings

Sealed housings protect internal components from moisture, dirt, and debris, which can significantly extend the lifespan of the starter. High-quality bearings reduce friction, enhancing efficiency and performance. For B2B buyers, investing in starters with these features means fewer replacements and lower overall operational costs.

Illustrative image related to aftermarket starters

What Are the Common Trade Terms in the Aftermarket Starters Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in the aftermarket starters market. Here are some common terms that B2B buyers should know:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to the original manufacturer of a vehicle’s parts. In the aftermarket context, it signifies products that are designed to meet or exceed the specifications of the original components. Understanding OEM standards helps buyers ensure they are selecting high-quality replacements that fit properly.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ is the minimum number of units a supplier requires for a single order. Knowing the MOQ helps buyers plan their inventory and manage costs effectively. It is particularly important for international buyers who may need to balance shipping costs against order size.

3. طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. By issuing an RFQ, buyers can compare offers from multiple suppliers, ensuring they obtain the best value for their purchases. This process is critical for budget management in B2B transactions.

4. شروط التجارة الدولية (Incoterms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is essential for international transactions, as they clarify who is responsible for costs and risks during transport.

5. المهلة الزمنية

Lead time refers to the time it takes from placing an order to delivery. For B2B buyers, understanding lead times is crucial for inventory management and ensuring that they can meet customer demands promptly.

6. فترة الضمان

The warranty period is the duration during which a manufacturer guarantees the performance and quality of a starter. A longer warranty period often indicates confidence in product durability and can influence purchasing decisions, as it adds value and reduces potential future costs for buyers.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance their purchasing strategy and ultimately contribute to their business’s success.

Navigating Market Dynamics and Sourcing Trends in the aftermarket starters Sector

What Are the Key Trends Shaping the Aftermarket Starters Market?

The aftermarket starters sector is witnessing significant growth driven by various global factors. The rise in vehicle ownership in emerging markets, particularly in Africa and South America, is a primary driver. As more vehicles hit the roads, the demand for replacement parts, including starters, is expected to surge. Furthermore, advancements in automotive technology, such as electric vehicles (EVs) and hybrid models, are influencing sourcing trends. International B2B buyers must adapt to these innovations by seeking suppliers who offer compatible aftermarket starters that meet evolving technical specifications.

Another critical trend is the increasing shift towards online procurement platforms. B2B buyers are leveraging e-commerce to access a broader range of products and suppliers, enabling them to compare prices and quality easily. This shift is particularly pronounced in regions like Europe and the Middle East, where digital adoption is high. Moreover, buyers are increasingly prioritizing suppliers that provide detailed product information, testing certifications, and customer support to enhance their purchasing decisions.

How Can Sustainability and Ethical Sourcing Impact Aftermarket Starters?

In today’s market, sustainability and ethical sourcing are no longer optional; they are essential for maintaining competitive advantage. B2B buyers are becoming more conscious of the environmental impact of their purchasing decisions, particularly regarding the materials used in aftermarket starters. Suppliers that utilize recycled materials and adhere to environmentally friendly manufacturing processes are gaining traction. This shift is evident in the growing demand for products that are certified ‘green,’ which not only help reduce waste but also resonate with eco-conscious consumers.

Furthermore, ethical supply chains are becoming a significant consideration for buyers. Transparency in sourcing and manufacturing practices is critical, especially in regions like Europe, where regulations around sustainability are stringent. Buyers should prioritize suppliers who can demonstrate their commitment to ethical practices, such as fair labor conditions and environmentally responsible resource extraction. By aligning with such suppliers, businesses can enhance their brand reputation and appeal to a broader audience.

What Is the Evolution of Aftermarket Starters and Its Relevance to B2B Buyers?

The evolution of aftermarket starters can be traced back to the early 20th century when the first electric starter was introduced. Initially, starters were mechanical devices that relied on hand cranks, which proved to be cumbersome and inefficient. The introduction of electric starters revolutionized the automotive industry, leading to the widespread adoption of internal combustion engines. Over the decades, starter technology has advanced significantly, with improvements in materials and design leading to enhanced performance and reliability.

For B2B buyers, understanding this evolution is crucial. The advancements in starter technology mean that today’s aftermarket starters are not only more efficient but also more durable, offering better value for money. Buyers should seek suppliers who stay at the forefront of these technological advancements, ensuring that they are sourcing products that meet contemporary performance standards. Additionally, familiarity with the historical context can help buyers appreciate the importance of quality and innovation in the aftermarket starters they choose to procure.

Frequently Asked Questions (FAQs) for B2B Buyers of aftermarket starters

-

How do I solve issues with aftermarket starter compatibility?

To ensure compatibility with your vehicle, always provide the specific make, model, and year when sourcing aftermarket starters. Use a detailed part number if available, as many suppliers have advanced search tools on their websites. Additionally, consult the supplier’s catalog or customer service to confirm fitment. If possible, request samples or detailed specifications before placing a bulk order to avoid mismatches that could lead to costly returns or installation delays. -

What is the best quality assurance process for sourcing aftermarket starters?

Look for suppliers that implement rigorous quality control measures, such as multipoint testing, material inspections, and adherence to OEM standards. Ask potential suppliers about their testing protocols for starters, including voltage and performance tests. Certifications such as ISO 9001 can also indicate a commitment to quality. Establishing a clear communication channel for feedback and issues will further enhance the quality assurance process and ensure long-term satisfaction. -

What are the typical payment terms for purchasing aftermarket starters in B2B transactions?

Payment terms can vary widely based on the supplier and the buyer’s creditworthiness. Common terms include net 30, net 60, or even upfront payments for first-time orders. International buyers should also consider currency fluctuations and potential import duties when negotiating payment terms. Establishing a clear agreement on payment methods—such as bank transfers, letters of credit, or payment platforms—can facilitate smoother transactions. -

How can I verify the reliability of an aftermarket starter supplier?

Conduct thorough research on potential suppliers by checking their online presence, customer reviews, and industry reputation. Request references from other businesses that have sourced products from them. Additionally, consider visiting their facilities if possible, or conducting virtual audits to assess their manufacturing capabilities and quality control processes. Engaging in trade shows or industry conferences can also provide insights into a supplier’s standing in the market. -

What is the minimum order quantity (MOQ) for aftermarket starters?

MOQs can differ significantly among suppliers, often based on product type and manufacturing processes. Typically, MOQs range from a few units to several hundred. It’s advisable to discuss your specific needs with the supplier to negotiate terms that suit your business model. Some suppliers may offer flexibility for first-time buyers or bulk orders, so it’s worth exploring options that can minimize inventory costs. -

What logistics considerations should I keep in mind when importing aftermarket starters?

Key logistics considerations include shipping methods, customs clearance, and lead times. Determine whether air freight or sea freight is more suitable based on urgency and cost. Understand the import regulations in your country to avoid unexpected delays or fines. Collaborate with freight forwarders experienced in automotive parts to streamline the process and ensure compliance with all legal requirements. -

How can I customize aftermarket starters to meet specific requirements?

Many suppliers offer customization options, such as different voltage ratings, housing designs, or branding. When seeking customized solutions, provide detailed specifications and expected performance criteria. Engage in discussions with the supplier’s engineering team to explore feasible modifications. Be aware that customization may affect lead times and pricing, so ensure these factors align with your business needs. -

What are the benefits of sourcing remanufactured starters versus new aftermarket starters?

Remanufactured starters often present a cost-effective alternative to new units, providing significant savings without compromising quality. They undergo rigorous testing to ensure they meet or exceed OEM standards. Additionally, sourcing remanufactured parts can be more environmentally sustainable, as they utilize recycled materials. However, ensure you verify the supplier’s remanufacturing processes and warranty offerings to safeguard your investment.

Top 5 Aftermarket Starters Manufacturers & Suppliers List

1. OEM Starters – Reliability vs. Aftermarket

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: Aftermarket starters are generally less reliable compared to OEM starters. OEM starters are more expensive but are known to work better and last longer. Some users have reported that aftermarket starters can be a gamble; they may last long enough to be satisfactory, but others may fail prematurely. Warranties on aftermarket parts do not guarantee reliability, as replacing a failed starter multiple…

2. Discount Starter and Alternator – Starter Fits Infiniti QX60 2.5L Hybrid

المجال: خصمstarterandalternator.com

تاريخ التسجيل: 2004 (21 عامًا)

مقدمة: [{‘name’: ‘Starter Fits Infiniti QX60 2.5L Hybrid’, ‘model_years’: ‘2014-2018’, ‘SKU’: ‘10972N_DSA-1’, ‘condition’: ‘New’, ‘MSRP’: ‘$119.06’}, {‘name’: ‘New Starter Fits Ford Fusion / Mercury Milan 3.0L’, ‘model_years’: ‘2006-2009’, ‘SKU’: ‘17945N_DSA-PS-1’, ‘condition’: ‘New’, ‘MSRP’: ‘$99.06’}, {‘name’: ‘New Starter Fits Lincoln Zephyr 3.0L’, ‘model_years’: ‘2006’, ‘SKU’: ‘17945N_DSA-PS-2’, ‘con…

3. Compustar – Remote Car Starters

المجال: كومبوستار

تاريخ التسجيل: 1995 (30 عامًا)

مقدمة: Compustar Remote Car Starters are compatible with all vehicles and offer features such as: 2-Way LCD and LED remotes, 1-Way remotes, smartphone control, water-resistant designs, and various remote ranges up to 3 miles. Key models include PRO T13, PRO R5, and CS4900S-KIT, with prices starting at $449.99 including installation. The systems provide all-weather comfort, upgraded security options, and …

4. Starter Options – Jeep Wrangler TJ

المجال: wranglertjforum.com

مسجل: 2015 (10 سنوات)

مقدمة: 1. Vehicle: 1999 Jeep Wrangler TJ SE 2.5L automatic

2. Starter Options:

– Aftermarket brands: BBB Industries, Remy, FVP (Price range: $108–177 CAD)

– Remanufactured: AC Delco starter ($185 CAD)

– Denso remanufactured starter ($243 CAD with a $95 core charge refund)

3. Recommendations:

– Denso is preferred for starters, alternators, and radiators.

– Local rebuilders may offer bette…

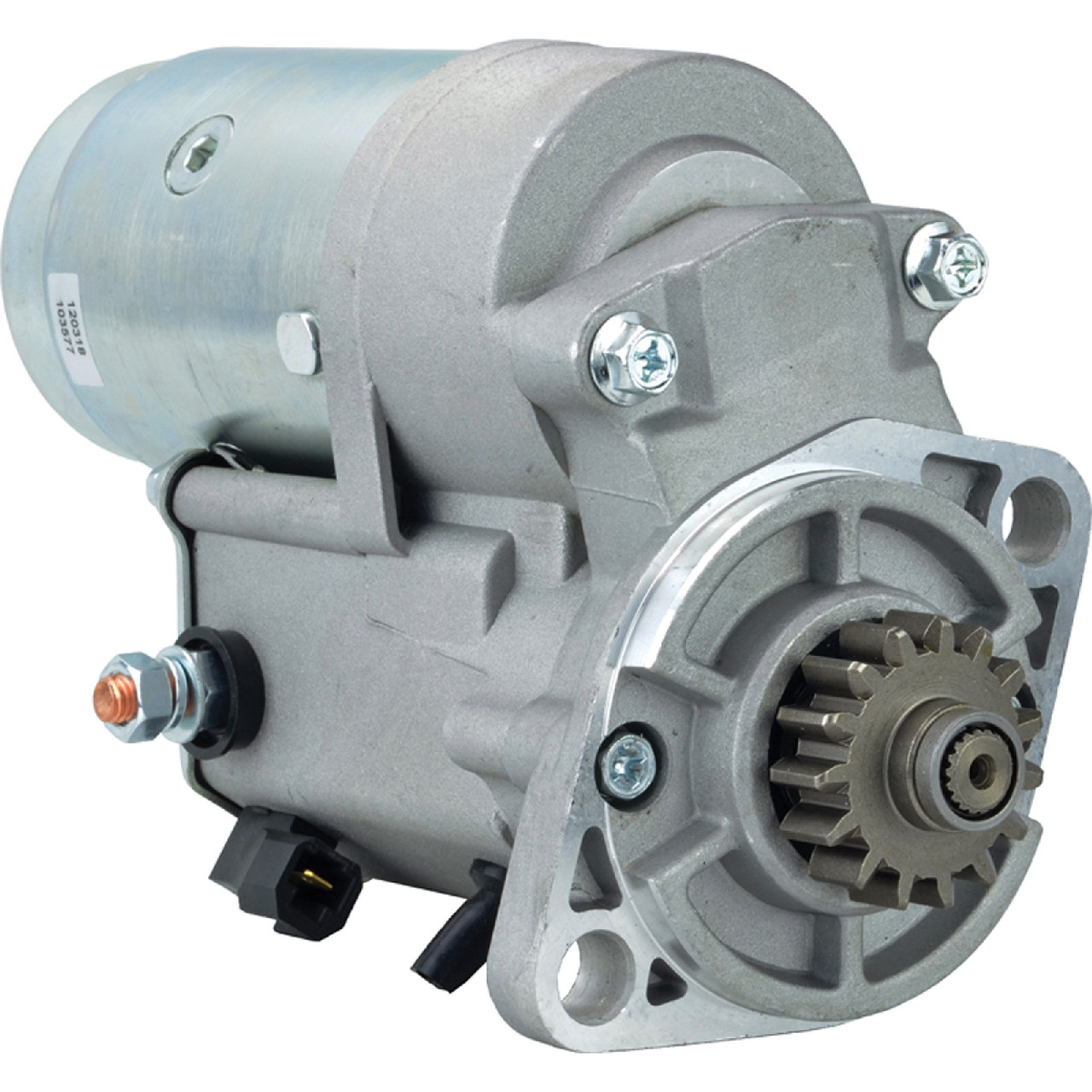

5. Aftermarket Starters – Key Brands and Models

المجال: redpowermagazine.com

مسجل: 2000 (25 سنة)

مقدمة: Aftermarket starter recommendations include brands such as DB Electrical, EMS Global, Uni Point, Hy Capacity, BBB, Wilson, and A&I. A specific Delco starter model number mentioned is 1107867, which is noted as a direct fit replacement for the Lucas starter. The Wilson starter is made in Mexico, which is preferred over Chinese-made starters. Users have shared experiences of rebuilding original star…

Strategic Sourcing Conclusion and Outlook for aftermarket starters

In today’s competitive landscape, strategic sourcing of aftermarket starters is pivotal for maximizing operational efficiency and cost-effectiveness. High-quality starters not only enhance vehicle performance but also extend service life, translating into significant savings for businesses in diverse sectors—from automotive to marine. By leveraging relationships with reputable suppliers who prioritize OEM standards and rigorous testing, buyers can ensure they receive reliable products that meet their specific needs.

Moreover, understanding the nuances of aftermarket parts—including the benefits of remanufactured components—can offer substantial economic advantages. As global markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, it is essential for B2B buyers to stay ahead by sourcing products that align with both performance standards and sustainability practices.

Looking forward, the aftermarket starter industry is poised for innovation. Engaging with suppliers who embrace advanced technologies and eco-friendly practices will not only enhance product offerings but also contribute to a sustainable future. As you navigate your sourcing strategy, consider the long-term benefits of investing in quality starters that support your operational goals while fostering a greener economy. Take action today to secure your supply chain and drive your business forward.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.