Introduction: Navigating the Global Market for how do you know if alternator or battery is bad

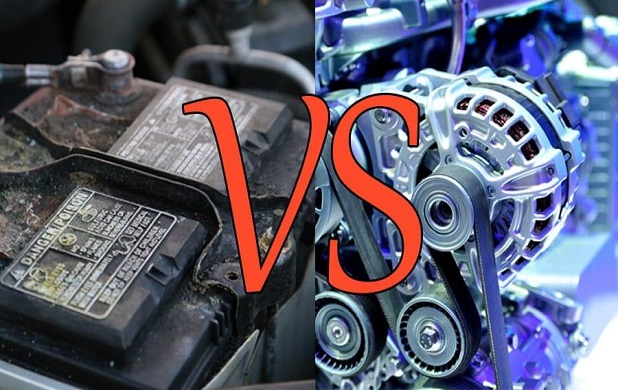

In the complex landscape of automotive maintenance, understanding how to identify whether an alternator or battery is faulty is crucial for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. As businesses rely on their vehicle fleets for operational efficiency, the challenge lies in effectively diagnosing electrical issues that could lead to costly downtime. This guide delves into the intricacies of distinguishing between a bad alternator and a depleted battery, equipping buyers with the knowledge to make informed purchasing decisions.

The comprehensive scope of this guide encompasses various types of batteries and alternators, their specific applications in different vehicle models, and essential considerations for supplier vetting. Additionally, we will explore cost implications and maintenance best practices that can enhance the lifespan of these critical components. By arming B2B buyers with actionable insights, this guide not only simplifies the decision-making process but also fosters strategic partnerships with reliable suppliers.

With the automotive sector’s rapid evolution and the increasing demand for efficient energy solutions, understanding the nuances of battery and alternator performance is more vital than ever. Empower your business with the expertise to identify potential issues early, ensuring operational continuity and reducing the risk of unexpected expenses.

جدول المحتويات

- Top 2 How Do You Know If Alternator Or Battery Is Bad Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do you know if alternator or battery is bad

- Understanding how do you know if alternator or battery is bad Types and Variations

- Key Industrial Applications of how do you know if alternator or battery is bad

- 3 Common User Pain Points for ‘how do you know if alternator or battery is bad’ & Their Solutions

- Strategic Material Selection Guide for how do you know if alternator or battery is bad

- In-depth Look: Manufacturing Processes and Quality Assurance for how do you know if alternator or battery is bad

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you know if alternator or battery is bad’

- Comprehensive Cost and Pricing Analysis for how do you know if alternator or battery is bad Sourcing

- Alternatives Analysis: Comparing how do you know if alternator or battery is bad With Other Solutions

- Essential Technical Properties and Trade Terminology for how do you know if alternator or battery is bad

- Navigating Market Dynamics and Sourcing Trends in the how do you know if alternator or battery is bad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do you know if alternator or battery is bad

- Strategic Sourcing Conclusion and Outlook for how do you know if alternator or battery is bad

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding how do you know if alternator or battery is bad Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| تعطل البطارية | No response when starting, slow cranking, clicking | Automotive service centers, fleet management | الإيجابيات: سهل التشخيص; السلبيات: May require frequent replacements. |

| Alternator Failure | Dim lights, electrical accessories malfunctioning | Vehicle repair shops, automotive parts suppliers | الإيجابيات: Can be tested while vehicle is running; السلبيات: Complex diagnostics may be needed. |

| Combined Failure | Symptoms of both battery and alternator issues | Commercial vehicle maintenance, logistics firms | الإيجابيات: Identifies simultaneous issues; السلبيات: Higher repair costs. |

| اختبار الجهد | Voltage readings below specifications | Quality control in automotive manufacturing | الإيجابيات: Precise diagnosis; السلبيات: يتطلب معدات متخصصة. |

| Warning Light Diagnostics | Dashboard warning lights indicating electrical issues | Fleet management systems, automotive diagnostics | الإيجابيات: تعريف سريع; السلبيات: May not pinpoint the exact issue. |

How to Identify Battery Failure in Vehicles

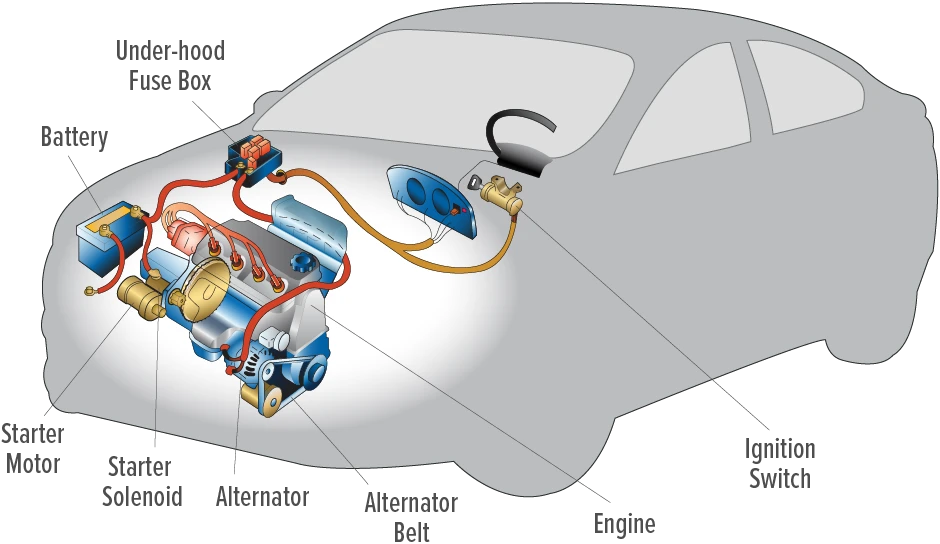

Battery failure is typically characterized by a vehicle that does not respond when attempting to start. This can manifest as a complete lack of sound or a clicking noise when the ignition is engaged. For B2B buyers, particularly in automotive service centers or fleet management, understanding these symptoms is crucial for efficient diagnosis and repair. Frequent battery replacements can be a cost concern, so investing in high-quality batteries and maintenance practices is advisable to extend battery life.

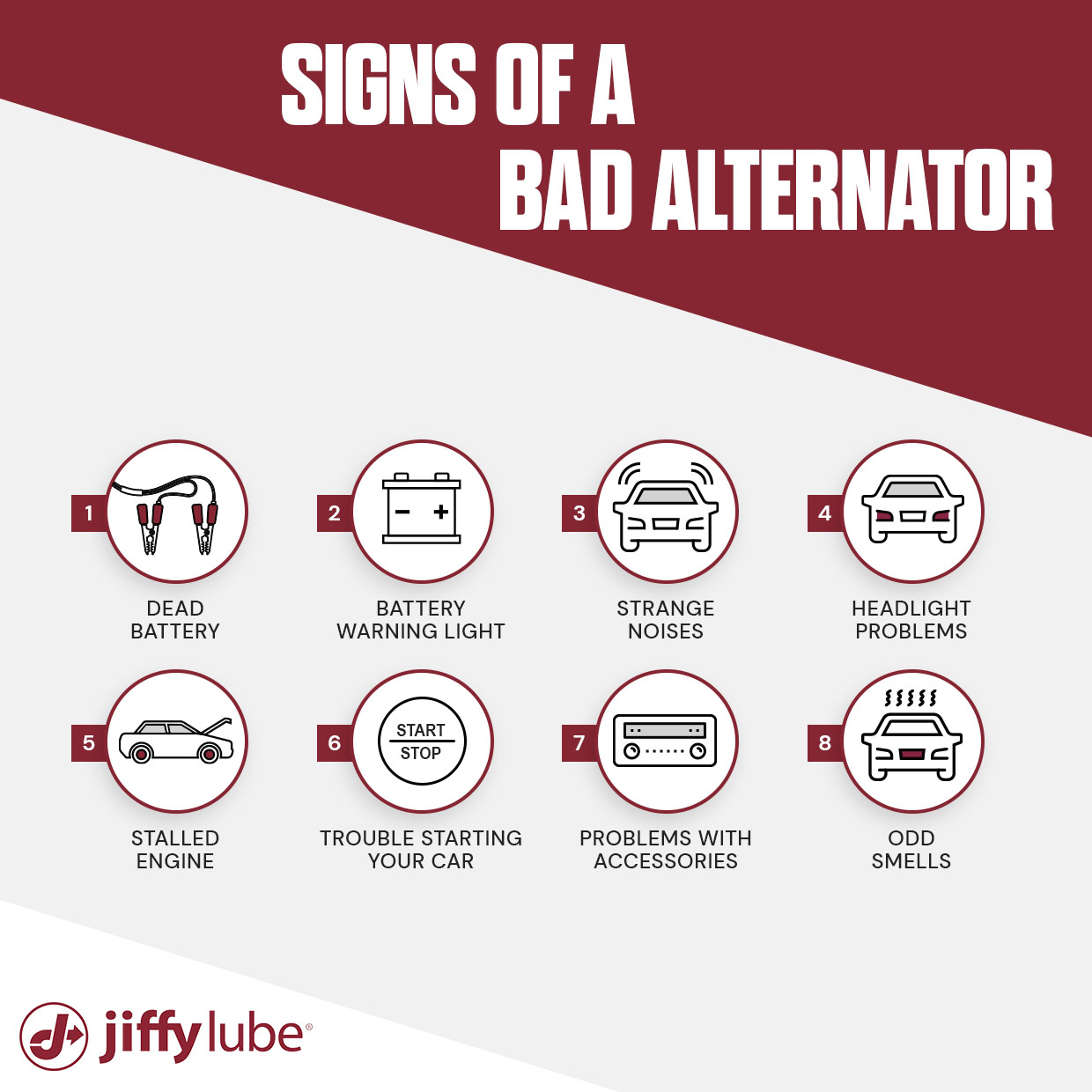

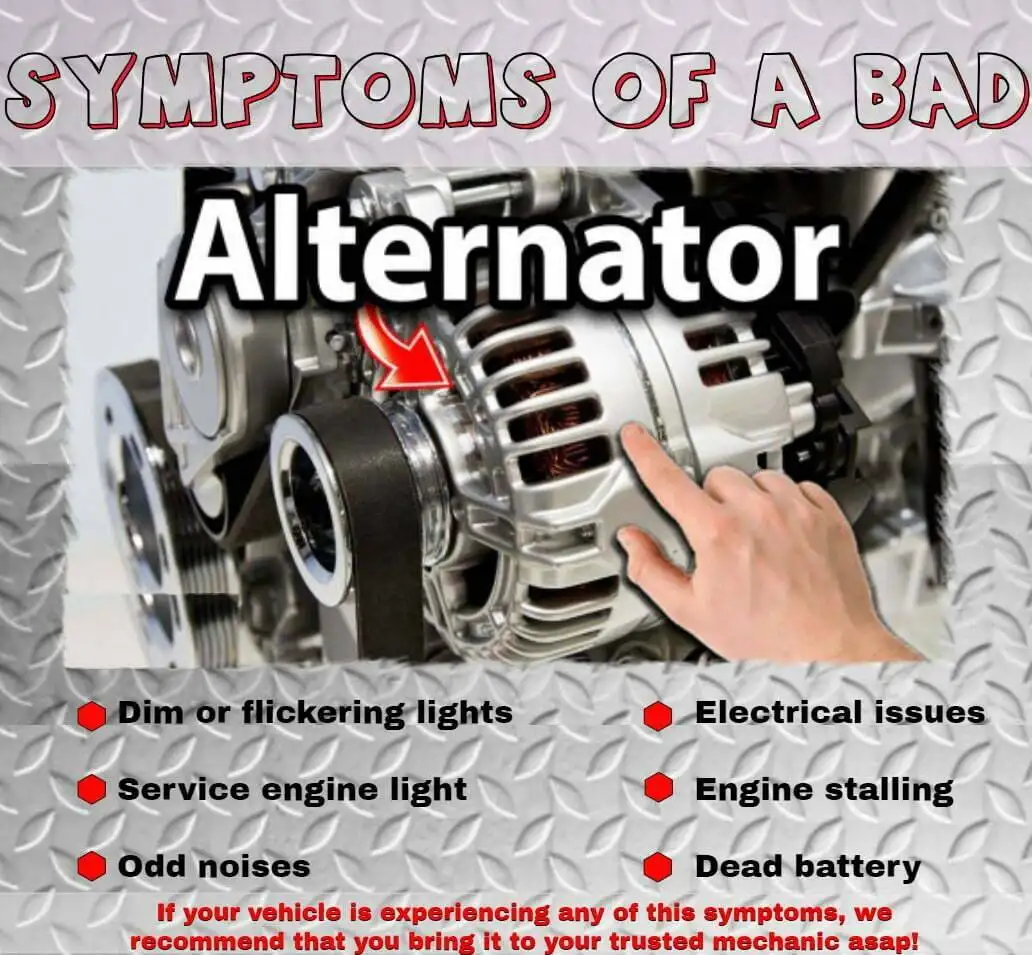

Recognizing Alternator Failure Symptoms

An alternator failure usually presents itself through dimming or flickering lights and malfunctioning electrical accessories. For businesses operating vehicle repair shops or supplying automotive parts, recognizing these signs can lead to timely repairs and improved customer satisfaction. While alternator diagnostics can be straightforward, they may require specialized tools, which can increase initial costs for buyers. However, the ability to test the alternator while the vehicle is running can streamline the repair process.

Understanding Combined Failure Scenarios

When both the battery and alternator exhibit symptoms of failure, it complicates the diagnosis. This combined failure often results in a vehicle that starts but dies shortly after, indicating a potential charging issue. For businesses in commercial vehicle maintenance or logistics, identifying these simultaneous failures can lead to increased repair costs and longer downtime. B2B buyers should be prepared for comprehensive diagnostics and consider investing in training for technicians to better handle these situations.

Importance of Voltage Testing in Diagnostics

Voltage testing is a critical diagnostic tool for identifying battery and alternator issues. A voltage reading below specifications can indicate a failing component. For automotive manufacturers and parts suppliers, ensuring quality control through voltage testing can prevent costly returns and enhance customer trust. While the precision of voltage testing is a significant advantage, it does require specialized equipment, which may represent an upfront investment for businesses.

Utilizing Warning Light Diagnostics for Quick Identification

Dashboard warning lights are essential for quickly identifying electrical system issues. A battery-shaped warning light often indicates problems with the charging system, which can be crucial for fleet management systems and automotive diagnostics. While this method allows for rapid identification of potential issues, it may not provide the exact cause, necessitating further investigation. B2B buyers should ensure their teams are trained to interpret warning lights accurately to minimize downtime and repair costs.

Key Industrial Applications of how do you know if alternator or battery is bad

| الصناعة/القطاع | Specific Application of how do you know if alternator or battery is bad | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| إصلاح السيارات | Diagnostic services to assess battery and alternator health | Reduces downtime for vehicles, ensuring customer satisfaction | Quality diagnostic tools, technician training, parts availability |

| النقل واللوجستيات | Fleet maintenance programs focusing on battery and alternator diagnostics | Enhances fleet reliability, reducing costs associated with breakdowns | Access to bulk diagnostic equipment, efficient supply chains |

| الزراعة | Equipment maintenance for tractors and harvesters | Minimizes operational disruptions during critical farming periods | Durable equipment, local support, and parts availability |

| البناء | Maintenance of heavy machinery and vehicles | Ensures machinery uptime, maximizing productivity on job sites | Robust diagnostic solutions, service agreements, local sourcing |

| وسائل النقل العام | Regular checks on buses and transport vehicles | Improves safety and reliability, enhancing public trust | Compliance with local regulations, reliable parts sourcing |

How is the Knowledge of Alternator and Battery Health Applied in Automotive Repair?

In the automotive repair industry, understanding how to diagnose issues with batteries and alternators is crucial. Service centers often offer diagnostic services that can quickly identify whether a vehicle’s failure to start is due to a dead battery or a malfunctioning alternator. This knowledge allows mechanics to provide accurate solutions, reducing vehicle downtime and enhancing customer satisfaction. For international buyers, sourcing quality diagnostic tools and ensuring technicians are well-trained is essential to maintain service standards.

How Do Transportation and Logistics Companies Benefit from Battery and Alternator Diagnostics?

In the transportation and logistics sector, maintaining a fleet of vehicles is critical for operational efficiency. Regular diagnostics on batteries and alternators can prevent unexpected breakdowns, thereby enhancing fleet reliability. By implementing robust maintenance programs, companies can reduce costs associated with vehicle repairs and ensure timely deliveries. International buyers should consider the availability of bulk diagnostic equipment and efficient supply chains to streamline their maintenance processes.

What Role Does Battery and Alternator Knowledge Play in Agriculture?

Agricultural machinery, such as tractors and harvesters, relies heavily on functional batteries and alternators to operate efficiently. Understanding how to diagnose potential issues can minimize operational disruptions during peak farming seasons. For buyers in this sector, sourcing durable diagnostic equipment and ensuring local support for parts and services is vital to maintaining machinery uptime and productivity.

How is Battery and Alternator Health Managed in Construction?

In the construction industry, heavy machinery and vehicles are essential for project completion. Regular maintenance checks on batteries and alternators can prevent machinery failures that could delay projects. Companies benefit from maximizing productivity on job sites through consistent equipment uptime. Buyers should focus on robust diagnostic solutions, service agreements, and local sourcing to ensure that their machinery remains operational.

Why is Knowledge of Battery and Alternator Issues Important for Public Transportation?

Public transportation systems must prioritize the safety and reliability of their vehicles. Regular checks on buses and transport vehicles for battery and alternator health can significantly improve operational reliability and enhance public trust. For international buyers, compliance with local regulations regarding vehicle maintenance and reliable sourcing of parts is crucial to maintaining fleet safety and efficiency.

3 Common User Pain Points for ‘how do you know if alternator or battery is bad’ & Their Solutions

Scenario 1: Difficulty in Diagnosing Electrical Issues in Fleets

المشكلة: Many B2B buyers, especially those managing fleets of vehicles, face significant challenges when diagnosing electrical issues. A common scenario occurs when multiple vehicles exhibit symptoms such as difficulty starting, dimming lights, or erratic electronic behavior. Fleet managers often struggle to determine whether these issues stem from failing batteries or alternators. This uncertainty can lead to costly downtime, misdiagnosis, and unnecessary parts replacement, ultimately affecting operational efficiency and profitability.

الحل: To effectively diagnose whether the problem lies with the battery or alternator, fleet managers should implement a systematic troubleshooting process. Begin by conducting voltage tests using a multimeter to assess both the battery and alternator’s performance. A fully charged battery should read approximately 12.6 volts. If the voltage is below this level, the battery may be failing. Next, start the vehicle and measure the voltage at the battery terminals again; it should range between 13 and 14.5 volts if the alternator is functioning correctly. If these readings are inconsistent, it may indicate a failing alternator. Additionally, consider investing in diagnostic tools that can streamline this process across the fleet, reducing the time spent on each vehicle and improving maintenance scheduling.

Scenario 2: Overlooking Preventive Maintenance Strategies

المشكلة: In the fast-paced world of B2B operations, preventive maintenance often takes a back seat. Companies may neglect regular checks of their vehicles’ electrical systems, leading to unexpected failures. This oversight can manifest in scenarios where vehicles suddenly fail to start or experience electrical malfunctions while on the road. Such disruptions not only incur repair costs but can also result in lost business opportunities and damage to reputation due to unreliable service delivery.

الحل: To mitigate these risks, B2B buyers should develop a robust preventive maintenance program tailored to monitor battery and alternator health. Schedule routine inspections that include testing battery voltage and alternator output as part of regular service intervals. Employing battery maintainers or trickle chargers can help ensure batteries are always charged, especially for vehicles that may sit idle for extended periods. Additionally, educate staff on the importance of recognizing early signs of battery or alternator issues, such as dimming lights or strange electrical behavior. Proactive measures not only extend the life of these components but also enhance overall fleet reliability.

Scenario 3: Navigating Warranty and Replacement Confusion

المشكلة: B2B buyers often encounter confusion regarding warranties and the appropriate time to replace batteries and alternators. With various suppliers and manufacturers providing different warranty terms, it can be challenging to determine whether a component is still covered or if it is more cost-effective to replace it. This ambiguity can lead to delayed decisions, resulting in further complications, including prolonged vehicle downtime and increased repair costs.

الحل: To navigate these complexities, B2B buyers should maintain detailed records of all vehicle components, including purchase dates, warranties, and service history. This documentation will help track when batteries and alternators are due for inspection or replacement based on their expected lifespan, which typically ranges from three to five years for batteries and up to seven years for alternators. When a vehicle shows signs of electrical failure, refer back to these records before making a replacement decision. Engage with suppliers to clarify warranty details, and consider establishing relationships with trusted local mechanics or service providers who can provide insights on component longevity and replacement timing. By being organized and informed, businesses can make timely decisions that minimize downtime and maintain operational efficiency.

Strategic Material Selection Guide for how do you know if alternator or battery is bad

What Materials Are Commonly Used in Diagnosing Alternator and Battery Issues?

When diagnosing issues related to alternators and batteries, several materials are commonly utilized in the tools and equipment. Understanding the properties, advantages, and limitations of these materials can help international B2B buyers make informed purchasing decisions.

Illustrative image related to how do you know if alternator or battery is bad

What Are the Key Properties of Copper in Electrical Diagnostics?

Copper is a widely used material in electrical diagnostics due to its excellent conductivity. It has a high-temperature rating, typically up to 200°C, and offers good corrosion resistance, especially when coated. Copper wiring is essential for multimeters and other diagnostic tools used to measure voltage and current in batteries and alternators.

إيجابيات وسلبيات: Copper is highly durable and provides excellent electrical performance, making it suitable for high-load applications. However, it is relatively expensive compared to alternatives like aluminum, and manufacturing processes can be complex due to the need for proper insulation and protection against corrosion.

التأثير على التطبيق: In applications involving automotive diagnostics, copper ensures accurate readings, which are crucial for identifying whether a battery or alternator is at fault.

اعتبارات للمشترين الدوليين: Buyers from regions like Africa and South America should be aware of local regulations regarding copper usage, as well as the potential for price fluctuations based on global copper markets. Compliance with standards such as ASTM and IEC is also essential.

How Does Aluminum Compare for Diagnostic Equipment?

Aluminum is another common material used in diagnostic tools, particularly in the construction of housings and frames for multimeters and other equipment. It has a lower conductivity than copper but is lighter and more cost-effective.

إيجابيات وسلبيات: Aluminum is resistant to corrosion and is easier to manufacture into various shapes, making it versatile for different applications. However, its lower conductivity can lead to less accurate readings in high-current applications, which may be a concern in battery and alternator diagnostics.

التأثير على التطبيق: While aluminum is suitable for non-critical components, it may not be the best choice for wiring or connections that require high electrical performance.

اعتبارات للمشترين الدوليين: Buyers in Europe, particularly Germany, may prefer aluminum for its lightweight properties, but they should ensure that the material meets local standards for electrical applications.

What Role Does Plastic Play in Battery and Alternator Diagnostics?

Plastic is often used for insulation and housing in diagnostic tools. It offers good electrical insulation properties and is lightweight, making it easy to handle.

إيجابيات وسلبيات: Plastic is generally low-cost and can be molded into complex shapes, which is beneficial for ergonomic designs. However, it may not withstand high temperatures or harsh environmental conditions as effectively as metals, leading to potential durability concerns.

التأثير على التطبيق: In battery and alternator diagnostics, plastic components can help protect sensitive electronics from short circuits and environmental damage.

اعتبارات للمشترين الدوليين: Buyers should ensure that the plastic materials used in diagnostic tools comply with regulations such as RoHS (Restriction of Hazardous Substances) in Europe and similar standards in other regions.

Why Is Rubber Important for Seals and Insulation?

Rubber is often used in seals and insulation for diagnostic tools to protect against moisture and dust, which can affect performance.

إيجابيات وسلبيات: Rubber is flexible and provides excellent sealing properties, making it ideal for protecting sensitive components. However, it can degrade over time, especially when exposed to extreme temperatures or chemicals.

التأثير على التطبيق: In battery and alternator diagnostics, rubber seals ensure that tools remain functional in various environments, enhancing their lifespan.

Illustrative image related to how do you know if alternator or battery is bad

اعتبارات للمشترين الدوليين: Buyers should consider the climate of their region when selecting rubber components, as different formulations may be required for high-temperature or humid conditions.

Summary Table of Material Selection for Diagnosing Alternator and Battery Issues

| المواد | Typical Use Case for how do you know if alternator or battery is bad | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | Wiring in multimeters and diagnostic tools | موصلية ممتازة | التكلفة العالية والتصنيع المعقد | عالية |

| الألومنيوم | Housings and frames for diagnostic equipment | خفيفة الوزن وفعالة من حيث التكلفة | توصيل أقل | متوسط |

| بلاستيك | Insulation and housing for electronic components | Low-cost and moldable | قد يتحلل تحت درجات الحرارة المرتفعة | منخفض |

| المطاط | Seals and insulation for moisture protection | Excellent sealing properties | Can degrade over time | متوسط |

This analysis provides a comprehensive overview of the materials commonly used in diagnosing alternator and battery issues, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how do you know if alternator or battery is bad

What Are the Main Stages in the Manufacturing Process of Alternators and Batteries?

Understanding the manufacturing processes of alternators and batteries is crucial for B2B buyers seeking quality products. These components play a vital role in the automotive industry, and their reliability is paramount. The manufacturing process typically involves several key stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Alternators and Batteries?

Material preparation is the foundation of the manufacturing process. For alternators, critical components include copper wire for windings, steel for the housing, and various electronic components for voltage regulation. In battery manufacturing, lead, sulfuric acid, and plastic for the casing are essential materials. Suppliers must ensure that all materials meet specific international standards, such as ISO 9001, to guarantee quality and safety.

Illustrative image related to how do you know if alternator or battery is bad

What Forming Techniques Are Used in Manufacturing?

Once materials are prepared, they undergo forming processes. For alternators, winding the copper wire around the stator is a critical step, often done using automated winding machines to ensure precision and efficiency. The rotor is then formed, typically through stamping and machining processes to achieve the required dimensions.

In battery production, lead is cast into grids and pasted with active materials. The formation of lead-acid batteries involves a chemical process where the active materials interact with sulfuric acid, creating the necessary electrochemical environment. Each technique must adhere to strict industry standards to ensure product performance and longevity.

How Are Alternators and Batteries Assembled?

Assembly is where the components come together to create a functional product. For alternators, this involves integrating the stator, rotor, and rectifier into a single unit. Skilled technicians often perform this task, ensuring that all connections are secure and meet specifications. The assembly process for batteries includes placing the lead grids into the casing, filling them with electrolyte, and sealing them properly to prevent leaks.

What Finishing Processes Are Essential for Quality?

Finishing processes are crucial for enhancing the durability and aesthetic appeal of alternators and batteries. For alternators, this may involve painting, coating for corrosion resistance, and testing for electrical performance. Battery finishing includes ensuring proper sealing and labeling, as well as conducting final inspections to confirm that the product meets safety standards.

Illustrative image related to how do you know if alternator or battery is bad

What Are the Key Quality Assurance Practices in Alternator and Battery Manufacturing?

Quality assurance (QA) is vital in ensuring that alternators and batteries perform reliably over time. Manufacturers must implement various QA practices throughout the production process, adhering to international standards such as ISO 9001, CE, and other relevant certifications.

How Do International Standards Influence Quality Assurance?

International standards provide a framework for quality management systems. ISO 9001, for instance, outlines requirements for consistent quality in manufacturing processes. Compliance with these standards is essential for B2B buyers, particularly in international markets, as they ensure that products meet specific safety and performance criteria.

In addition to ISO standards, CE marking is crucial for products sold in the European market, indicating compliance with health, safety, and environmental protection standards. B2B buyers should verify that suppliers hold these certifications, as they reflect a commitment to quality and safety.

ما هي نقاط التحقق الحرجة لمراقبة الجودة؟

Quality control (QC) checkpoints are established at various stages of the manufacturing process to identify defects early. Typical checkpoints include:

- مراقبة الجودة الواردة (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specifications.

- مراقبة الجودة أثناء الإنتاج (IPQC): Continuous monitoring during the manufacturing process helps identify issues before they escalate. This may include testing electrical components and inspecting assembly techniques.

- مراقبة الجودة النهائية (FQC): The final inspection ensures that the finished products meet all quality standards and performance metrics.

By implementing these checkpoints, manufacturers can reduce defects and improve overall product quality.

What Common Testing Methods Are Used for Alternators and Batteries?

Testing is an essential aspect of quality assurance in alternator and battery manufacturing. Common testing methods include:

- الاختبارات الكهربائية: For alternators, this involves checking voltage output and current under load conditions. For batteries, testing includes measuring voltage and capacity to ensure they meet specifications.

- الاختبار الحراري: Assessing how components perform under extreme temperatures can reveal weaknesses in design or materials.

- اختبار المتانة: Simulating real-world conditions through stress tests helps evaluate the longevity and reliability of alternators and batteries.

B2B buyers should seek suppliers that employ comprehensive testing protocols to ensure that products meet performance expectations.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

B2B buyers must take proactive steps to verify the quality control measures of their suppliers. Here are some effective strategies:

Illustrative image related to how do you know if alternator or battery is bad

- إجراء عمليات تدقيق للموردين: Regular audits can help assess the manufacturing processes and quality assurance practices of suppliers. This includes reviewing documentation, inspecting facilities, and observing production methods.

- Request Quality Control Reports: Suppliers should provide detailed reports outlining their QC processes, testing results, and compliance with international standards.

- الاستعانة بخدمات التفتيش من قبل أطراف ثالثة: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. These inspections can be particularly beneficial for international buyers who may not have the resources to conduct on-site evaluations.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

International B2B buyers must navigate various quality control nuances when sourcing alternators and batteries. Different regions may have unique regulatory requirements, such as specific certifications or testing protocols. For instance, European buyers should pay attention to CE marking, while buyers in the Middle East may need to consider local standards.

Additionally, language barriers and differing business practices can complicate communication with suppliers. Establishing clear expectations regarding quality standards and certifications is essential to ensure a smooth procurement process.

By understanding these manufacturing and quality assurance processes, B2B buyers can make informed decisions when sourcing alternators and batteries, ultimately leading to improved product reliability and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you know if alternator or battery is bad’

مقدمة

In the automotive industry, understanding whether a vehicle’s electrical issue stems from a faulty alternator or a dead battery is crucial for effective maintenance and repair. This guide provides a systematic approach for B2B buyers to assess and procure the right tools and resources necessary for diagnosing and resolving these common electrical problems. By following these steps, you can ensure your operations are efficient, cost-effective, and reliable.

Illustrative image related to how do you know if alternator or battery is bad

Step 1: Identify Symptoms of Electrical Issues

Understanding the symptoms associated with battery and alternator failures is the first step in diagnosing the problem. Common signs include dimming headlights, slow engine cranking, and unusual electrical behavior in vehicle accessories. Recognizing these symptoms early can save time and reduce repair costs by allowing you to address issues before they escalate.

Step 2: Define Your Diagnostic Tools Requirements

Before sourcing diagnostic tools, outline the specific requirements based on the types of vehicles you service. Tools such as multimeters, battery testers, and alternator testers are essential for accurate diagnostics. Ensure that the tools you select can handle the voltage and amperage specifications of the vehicles in your market, particularly if you’re dealing with heavy-duty or commercial vehicles.

الخطوة 3: تقييم الموردين المحتملين

Thoroughly vet potential suppliers for the diagnostic tools you need. Request company profiles, product certifications, and references from other businesses in your region or industry. This evaluation ensures you partner with reliable suppliers who offer quality products that meet your operational needs.

Illustrative image related to how do you know if alternator or battery is bad

Step 4: Check for Technical Support and Training

When procuring diagnostic equipment, consider suppliers that provide technical support and training. Having access to knowledgeable support can facilitate proper tool usage and troubleshooting. This is especially important for teams unfamiliar with advanced diagnostic equipment, as proper training can enhance operational efficiency.

Step 5: Assess Warranty and Return Policies

Before finalizing your purchase, review the warranty and return policies offered by suppliers. A robust warranty indicates the supplier’s confidence in their products and provides peace of mind for your investment. Flexible return policies also allow you to address any issues or mismatches in equipment without incurring additional costs.

Step 6: Consider Regional Compliance and Certification

Ensure that the tools and equipment you are sourcing comply with local regulations and industry standards. This is particularly relevant in international markets, where certification requirements can vary significantly. Verify that the products are certified for use in your specific geographic region to avoid potential legal issues and ensure safety.

Step 7: Plan for Ongoing Maintenance and Calibration

Once you’ve procured your diagnostic tools, establish a plan for regular maintenance and calibration. This step is vital to ensure the accuracy and reliability of your equipment over time. Schedule routine checks and calibrations based on the manufacturer’s recommendations to maintain optimal performance in your diagnostic processes.

By following this checklist, B2B buyers can make informed decisions in sourcing the right tools and resources to effectively diagnose alternator and battery issues, ultimately improving service quality and operational efficiency.

Comprehensive Cost and Pricing Analysis for how do you know if alternator or battery is bad Sourcing

What Are the Key Cost Components in Sourcing Components for Battery and Alternator Diagnosis?

When evaluating the costs associated with sourcing components related to diagnosing battery and alternator issues, several key cost components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

Illustrative image related to how do you know if alternator or battery is bad

-

المواد: The raw materials used in producing diagnostic tools, such as multimeters and battery testers, significantly impact the overall cost. These materials can range from basic electronic components to specialized parts that meet specific industry standards.

-

العمل: Labor costs encompass the wages paid to workers involved in the design, assembly, and quality assurance processes. In regions with higher labor costs, such as Europe, these expenses can be substantial, while lower labor markets, such as parts of Africa and South America, may offer cost advantages.

-

تكاليف التصنيع العامة: This includes indirect costs associated with production, such as facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize these overhead costs, impacting overall pricing.

-

الأدوات: Investment in tooling is necessary for the production of diagnostic equipment. This upfront cost can be significant but is essential for ensuring consistent quality and efficiency in manufacturing.

-

مراقبة الجودة (QC): Ensuring that products meet safety and performance standards involves additional costs. Quality control processes can include testing and certification, which are crucial for maintaining product reliability and customer satisfaction.

-

اللوجستيات: Transportation and warehousing costs play a critical role in the total cost structure. International shipping can be complex, particularly with varying import duties and regulations across regions, impacting overall pricing.

-

الهامش: Suppliers typically include a profit margin in their pricing to account for risk and operational costs. Understanding market dynamics can help buyers negotiate better deals.

What Factors Influence Pricing for Battery and Alternator Diagnostic Tools?

Several factors influence the pricing of diagnostic tools for battery and alternator issues, which can vary significantly based on the buyer’s needs and market conditions.

-

الحجم/الحد الأدنى للطلب: The volume of the order often affects pricing. Higher volumes may lead to discounts, while smaller orders might incur higher per-unit costs due to lower economies of scale.

-

المواصفات/التخصيص: Customization requests can increase costs. Buyers should carefully consider their needs and whether standard products could suffice, potentially reducing expenses.

-

المواد: The choice of materials impacts both performance and price. High-quality materials may yield better durability and reliability but could increase upfront costs.

-

الجودة/الشهادات: Products that meet certain industry certifications often command higher prices. Buyers should assess whether these certifications are necessary for their market.

-

عوامل الموردين: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer higher prices due to their brand value and assurance of quality.

-

مصطلحات التجارة الدولية: Understanding Incoterms is crucial in international trade, as they define responsibilities for shipping costs, insurance, and tariffs. This knowledge helps buyers calculate the total landed cost of products.

What Are Essential Buyer Tips for Sourcing Battery and Alternator Diagnostic Tools?

To maximize value when sourcing battery and alternator diagnostic tools, international B2B buyers should consider several strategies:

-

التفاوض: Leverage market knowledge to negotiate better pricing. Establishing long-term relationships with suppliers can lead to better terms and pricing over time.

-

الفعالية من حيث التكلفة: Assess the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and operational expenses. This comprehensive view helps in making informed purchasing decisions.

-

الفروق الدقيقة في الأسعار للمشترين الدوليين: Be aware of currency fluctuations and local market conditions that can affect pricing. Understanding regional differences in demand and supply can help in negotiating better deals.

-

تقييم الموردين: Conduct thorough evaluations of potential suppliers, focusing on their reliability, quality of products, and service capabilities. This diligence can prevent costly mistakes and ensure consistent product quality.

-

Market Trends: Stay updated on market trends and technological advancements, as these can impact both pricing and product availability. Awareness of these trends can aid in strategic sourcing decisions.

By keeping these cost components, pricing influencers, and buyer tips in mind, international B2B buyers can make more informed decisions when sourcing diagnostic tools for battery and alternator issues.

Alternatives Analysis: Comparing how do you know if alternator or battery is bad With Other Solutions

مقدمة في الحلول البديلة لتشخيص المشاكل الكهربائية

In the automotive sector, diagnosing whether a vehicle’s electrical issues stem from a failing alternator or a dead battery is crucial. While knowing how to differentiate between these two components is vital for effective repairs, there are alternative solutions that can aid in this process. These alternatives can provide additional insights, enhance diagnostic accuracy, or streamline maintenance processes, ultimately benefiting B2B buyers in the automotive repair industry.

جدول المقارنة

| جانب المقارنة | How Do You Know If Alternator Or Battery Is Bad | جهاز اختبار حمل البطارية | On-Board Diagnostic Tools |

|---|---|---|---|

| الأداء | Provides clear symptoms and diagnostic steps | Accurate testing of battery capacity | تشخيص شامل للمركبة |

| التكلفة | Low-cost, mainly requires basic tools | Moderate (around $30-$100) | Higher (ranging from $50 to several hundred) |

| سهولة التنفيذ | Simple, requires minimal training | Requires understanding of load testing | User-friendly, often plug-and-play |

| الصيانة | Low maintenance, but depends on user knowledge | Periodic calibration needed | Software updates needed |

| أفضل حالة استخدام | Quick initial assessment of issues | Battery condition verification | Comprehensive system diagnosis |

تفصيل البدائل

1. Battery Load Tester

A battery load tester is a device specifically designed to assess the condition of a vehicle’s battery. By applying a controlled load to the battery while measuring voltage, it provides an immediate reading of the battery’s health. This method is particularly effective for determining whether a battery can hold a charge under load, making it a reliable alternative for B2B buyers focused on battery diagnostics.

الإيجابيات: Battery load testers offer precise measurements, allowing for informed decisions about battery replacement. They are relatively easy to use and provide immediate results.

السلبيات: While effective, they require some understanding of how to interpret load test results. Additionally, they do not diagnose alternator issues, meaning they must be used in conjunction with other diagnostic methods.

2. On-Board Diagnostic Tools

On-board diagnostic (OBD) tools connect directly to a vehicle’s computer system, providing a comprehensive overview of all electronic components, including the battery and alternator. These tools can read fault codes and give insights into the vehicle’s overall electrical system health, making them a versatile option for automotive professionals.

الإيجابيات: OBD tools offer a thorough analysis of the vehicle’s electrical systems, including real-time data monitoring and historical fault codes. They can simplify troubleshooting for various issues beyond just the battery and alternator.

السلبيات: The initial investment can be substantial, especially for advanced diagnostic tools. They may require training or experience to maximize their capabilities, which could be a barrier for some B2B buyers.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

For B2B buyers in the automotive repair sector, selecting the right diagnostic solution depends on various factors, including budget, ease of use, and the specific needs of their operations. While knowing how to determine whether an alternator or battery is at fault remains a fundamental skill, integrating tools like battery load testers and OBD devices can enhance diagnostic efficiency and accuracy. By weighing the advantages and limitations of each option, businesses can better position themselves to address customer needs and improve service delivery in the competitive automotive market.

Essential Technical Properties and Trade Terminology for how do you know if alternator or battery is bad

What Key Technical Properties Should You Consider When Diagnosing Battery or Alternator Issues?

When assessing whether a battery or alternator is malfunctioning, understanding specific technical properties is crucial. Here are several critical specifications to keep in mind:

1. ناتج الجهد

The voltage output of a battery should ideally be around 12.6 volts when fully charged. For alternators, the output typically ranges from 13 to 14.5 volts while the engine is running. Monitoring these voltage levels is vital for identifying issues; for instance, a voltage below 12.4 volts in a battery indicates a potential failure. This property is essential for B2B buyers, as it informs the necessary specifications when sourcing replacement parts.

2. Ampere Rating

Batteries and alternators are rated based on their amperage capacity. A standard automotive battery usually delivers between 400 to 600 amps for starting, while alternators can range from 130 to 200 amps for most passenger vehicles. Understanding these ratings helps businesses determine compatibility with various vehicle types and ensures that the components can handle the electrical load required for optimal performance.

3. أمبير التدوير البارد (CCA)

CCA measures a battery’s ability to start an engine in cold temperatures. A battery with higher CCA ratings is better suited for vehicles in colder climates, making this a critical property for international buyers in regions with extreme weather. Knowing the CCA can guide procurement decisions for batteries that meet specific operational needs.

4. السعة الاحتياطية (RC)

Reserve capacity refers to the duration a battery can supply power without being recharged, typically measured in minutes. This is particularly important for businesses that operate in areas where vehicle downtime can result in significant losses. A battery with a higher RC allows for extended use of electrical systems during alternator failure, thus enhancing operational reliability.

Illustrative image related to how do you know if alternator or battery is bad

5. الإدارة الحرارية

Both batteries and alternators generate heat during operation. Proper thermal management specifications, such as maximum operating temperature, are essential for ensuring longevity and efficiency. This property is crucial for B2B buyers focused on maintaining performance in high-temperature environments, which can be common in regions like Africa and the Middle East.

What Trade Terminology Should You Be Aware Of When Sourcing Battery and Alternator Components?

Familiarizing yourself with industry jargon can streamline procurement processes and enhance communication with suppliers. Here are several key terms:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM parts are components made by the original manufacturer of the vehicle. Sourcing OEM batteries and alternators ensures compatibility and reliability, which is essential for maintaining vehicle performance.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for businesses to manage inventory effectively and avoid overstocking or understocking essential components.

Illustrative image related to how do you know if alternator or battery is bad

3. طلب عرض أسعار (RFQ)

An RFQ is a formal document sent to suppliers requesting pricing information for specific products. Utilizing RFQs is a strategic approach for B2B buyers to compare costs and terms from different vendors, ensuring they obtain the best value.

4. شروط التجارة الدولية (Incoterms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to navigate shipping logistics, costs, and risks associated with purchasing battery and alternator components across borders.

5. فترة الضمان

This term refers to the timeframe during which a manufacturer guarantees the performance and quality of a product. Knowledge of warranty periods is vital for businesses to assess the long-term value of components like batteries and alternators and to minimize the risk of unexpected failures.

By understanding these essential properties and trade terms, B2B buyers can make informed decisions when diagnosing battery or alternator issues, ensuring they select the right components for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the how do you know if alternator or battery is bad Sector

Market Overview & Key Trends: What Are the Global Drivers Affecting Battery and Alternator Diagnostics?

The market for diagnosing battery and alternator issues is influenced by several global drivers, including the increasing reliance on advanced automotive technologies and the growing importance of vehicle uptime in commercial operations. With the proliferation of electric and hybrid vehicles, the demand for reliable power management systems has surged. This has led to an uptick in B2B demand for diagnostic tools and services that can accurately assess battery and alternator health.

Emerging technologies such as IoT sensors and machine learning algorithms are revolutionizing how businesses approach vehicle diagnostics. These technologies enable real-time monitoring of battery and alternator performance, allowing for predictive maintenance that can preempt failures before they lead to costly downtimes. International buyers, particularly in regions like Africa, South America, and the Middle East, are increasingly sourcing advanced diagnostic equipment that leverages these technologies to maintain their fleets more efficiently.

Moreover, the expansion of e-commerce platforms has made it easier for businesses to access high-quality diagnostic tools and replacement parts from various global suppliers. In Europe, for instance, there is a strong emphasis on quality and reliability, leading to a preference for suppliers who can demonstrate compliance with stringent automotive standards. This shift is driving a more competitive landscape, compelling suppliers to innovate and offer better value propositions to B2B buyers.

Sustainability & Ethical Sourcing in B2B: Why Should Businesses Consider Environmental Impact When Sourcing Battery and Alternator Diagnostics?

Sustainability is becoming a pivotal concern in the automotive sector, particularly regarding battery and alternator sourcing. The environmental impact of battery production and disposal is significant, with traditional lead-acid batteries posing recycling challenges. As a result, B2B buyers are increasingly looking for suppliers that prioritize sustainability through ethical sourcing practices and environmentally friendly materials.

The rise of “green” certifications and standards is reshaping how businesses approach procurement. Suppliers who offer eco-friendly alternatives, such as lithium-ion batteries or sustainable materials for alternators, are gaining traction among conscientious buyers. Additionally, the use of recycled components in manufacturing not only reduces waste but can also enhance a company’s brand image, making it more appealing to customers who value sustainability.

Furthermore, businesses are recognizing the importance of ethical supply chains. Engaging with suppliers that uphold labor rights and environmental regulations is essential for mitigating risks associated with unethical practices. This trend is particularly prominent in regions like Europe, where consumers are increasingly demanding transparency from brands regarding their sourcing methods. For international B2B buyers, aligning with suppliers that prioritize sustainability and ethical practices can lead to long-term partnerships and enhanced corporate reputation.

Brief Evolution/History: How Has Battery and Alternator Diagnostics Evolved Over Time?

The evolution of battery and alternator diagnostics has significantly changed over the past few decades. Initially, mechanical systems dominated, where technicians relied on manual checks and simple tools to diagnose issues. However, as automotive technology advanced, so did the diagnostic methods. The introduction of computerized systems allowed for more precise assessments, leading to the development of sophisticated diagnostic equipment that utilizes electronic data to pinpoint faults.

In recent years, the integration of IoT and artificial intelligence has further transformed the landscape. These technologies facilitate remote diagnostics and continuous monitoring, enabling businesses to adopt proactive maintenance strategies. The shift from reactive to predictive maintenance not only improves operational efficiency but also enhances the longevity of vehicles, making modern diagnostics an essential component for B2B buyers in the automotive sector.

This historical context illustrates the importance of staying updated with technological advancements and sourcing innovative solutions that can address the evolving needs of the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of how do you know if alternator or battery is bad

-

How do I determine if my vehicle’s battery or alternator is failing?

To diagnose whether the issue lies with your battery or alternator, start by observing the symptoms. A dead battery typically results in the vehicle not starting at all, or it may produce a clicking sound when you turn the key. Conversely, if the car starts but dies shortly after, it may indicate a failing alternator that isn’t recharging the battery. Additionally, check for dimming lights or fluctuating electrical accessories, which can signal alternator problems. Using a multimeter can help measure battery voltage; a healthy battery should read around 12.6 volts or higher. -

What should I look for when sourcing batteries or alternators for my fleet?

When sourcing batteries or alternators for your fleet, focus on quality, compatibility, and performance ratings. Look for suppliers that provide detailed specifications, including voltage, amperage, and expected lifespan. Additionally, consider their warranty and return policies as indicators of reliability. It’s essential to ensure that the parts are compatible with your vehicles to avoid costly replacements. Engaging with suppliers who offer customization options can also be beneficial, especially for unique fleet requirements. -

What is the best way to prevent battery or alternator issues in commercial vehicles?

Regular maintenance is key to preventing battery or alternator issues in commercial vehicles. Schedule periodic inspections to check for corrosion on battery terminals and ensure connections are secure. Encourage drivers to take longer trips occasionally, as short trips can deplete the battery without allowing it to recharge fully. Consider installing trickle chargers for vehicles that are not used frequently. Additionally, keeping an eye on warning lights and addressing them promptly can help prevent more significant issues. -

How can I verify the reliability of a supplier for automotive batteries and alternators?

To verify the reliability of a supplier, conduct thorough research by checking their industry reputation, customer reviews, and certifications. Request case studies or references from other businesses in your sector to assess their reliability and service quality. Additionally, inquire about their manufacturing processes and quality control measures to ensure they meet international standards. It’s also beneficial to visit their facilities, if possible, to get a firsthand look at their operations. -

ما هي شروط الدفع الشائعة في معاملات B2B الدولية لقطع غيار السيارات؟

Payment terms can vary significantly in international B2B transactions. Common practices include upfront payment, net 30 or net 60 terms, or a letter of credit for larger orders. It’s essential to clarify these terms with your supplier before finalizing the agreement. Additionally, consider using escrow services for higher-value transactions to protect both parties. Ensure that the payment method is secure and suits your cash flow requirements, and be aware of any currency exchange implications. -

What is the minimum order quantity (MOQ) for batteries and alternators in international trade?

The minimum order quantity (MOQ) for batteries and alternators can vary widely depending on the supplier and the specific product. Generally, MOQs can range from a few dozen to several hundred units. When negotiating with suppliers, express your needs clearly and see if they can accommodate lower MOQs for trial orders. Some suppliers may offer flexibility, especially if you establish a long-term partnership. Always evaluate the total cost implications of the MOQ to ensure it aligns with your inventory strategy. -

How can I ensure quality assurance (QA) for automotive parts sourced internationally?

To ensure quality assurance (QA) for internationally sourced automotive parts, establish clear specifications and standards that the products must meet. Request samples before placing large orders and consider third-party inspection services to verify the quality of the products upon arrival. It’s also beneficial to ask for certifications such as ISO or other relevant quality standards. Regular communication with your supplier regarding quality expectations and feedback can foster a culture of quality and reliability. -

What logistics considerations should I keep in mind when importing automotive batteries and alternators?

When importing automotive batteries and alternators, logistics considerations include shipping regulations, import duties, and handling requirements for hazardous materials, as batteries often fall under this category. Ensure that your logistics partner is experienced in dealing with automotive parts and understands the complexities of international shipping. Plan for potential delays in customs clearance and have a strategy for warehousing and distribution once the products arrive. Additionally, consider the total landed cost, including freight, insurance, and taxes, to make informed purchasing decisions.

Top 2 How Do You Know If Alternator Or Battery Is Bad Manufacturers & Suppliers List

1. Reddit – Power System Insights

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: The battery provides power to all electronics on board, including the starter. The alternator charges the battery when the engine is running. The starter uses power from the battery to turn over the engine. Symptoms of a dead battery include no power at all, while a failing alternator may be indicated by a battery light on the dash when the engine is running.

2. Protyre – Tyres and Vehicle Services

المجال: protyre.co.uk

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: Protyre offers a range of services including battery checks, tyre fitting, MOTs, and vehicle servicing. They provide premium tyres from brands like Michelin, Pirelli, Goodyear, and Bridgestone, as well as mid-range and economy options. Customers can book services online or over the phone, and they have an extensive network of garages staffed by qualified fitters. Protyre also offers free safety ch…

Strategic Sourcing Conclusion and Outlook for how do you know if alternator or battery is bad

In summary, understanding whether a battery or alternator is at fault is essential for maintaining vehicle reliability and efficiency. Key indicators such as dimming lights, slow cranking, and warning lights can help diagnose issues early, preventing costly downtime. For businesses, investing in the right diagnostic tools and establishing relationships with reliable suppliers can streamline the repair process and enhance operational productivity.

Strategic sourcing not only ensures access to high-quality automotive parts but also fosters partnerships that can lead to cost savings and improved service delivery. By identifying trusted suppliers and leveraging their expertise, companies can make informed decisions that enhance their fleet management.

As we look to the future, the automotive landscape is evolving rapidly, with advancements in electric vehicles and smart technology. B2B buyers from Africa, South America, the Middle East, and Europe should embrace these changes by staying informed and adaptable. Engaging with innovative suppliers will be crucial to navigating these developments effectively. Let us prioritize proactive maintenance and strategic sourcing to ensure your operations remain resilient and efficient.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.