Introduction: Navigating the Global Market for where is the starter located

In the complex landscape of automotive parts procurement, understanding where the starter is located in various vehicle models is crucial for international B2B buyers. Sourcing the right starter not only ensures optimal vehicle performance but also mitigates downtime and repair costs. This guide delves into the intricacies of starter locations across a diverse range of vehicles, providing essential insights into their design, applications, and the common challenges faced when sourcing these critical components.

Buyers from Africa, South America, the Middle East, and Europe—regions with varying automotive needs and market dynamics—will find this guide invaluable. It covers a comprehensive scope, including types of starters, common applications in different vehicle types, and supplier vetting processes to identify reliable partners. Additionally, we will discuss cost factors and offer actionable strategies for making informed purchasing decisions that align with your business objectives.

By equipping B2B buyers with the knowledge to navigate the global market effectively, this guide empowers you to overcome sourcing challenges, ensuring that you can procure the right starter for your needs without unnecessary delays or complications. Whether you are in Saudi Arabia, Brazil, or beyond, understanding where the starter is located in each vehicle model can significantly enhance your procurement strategy and operational efficiency.

جدول المحتويات

- Top 3 Where Is The Starter Located Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for where is the starter located

- Understanding where is the starter located Types and Variations

- Key Industrial Applications of where is the starter located

- 3 Common User Pain Points for ‘where is the starter located’ & Their Solutions

- Strategic Material Selection Guide for where is the starter located

- In-depth Look: Manufacturing Processes and Quality Assurance for where is the starter located

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘where is the starter located’

- Comprehensive Cost and Pricing Analysis for where is the starter located Sourcing

- Alternatives Analysis: Comparing where is the starter located With Other Solutions

- Essential Technical Properties and Trade Terminology for where is the starter located

- Navigating Market Dynamics and Sourcing Trends in the where is the starter located Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of where is the starter located

- Strategic Sourcing Conclusion and Outlook for where is the starter located

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding where is the starter located Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| Front-Wheel Drive (FWD) | Located between engine and transmission, often on the left side. | Passenger vehicles, compact cars. | Pros: Easier access; Cons: Limited to specific models. |

| Rear-Wheel Drive (RWD) | Positioned below the exhaust manifold, usually on the passenger side. | Trucks, SUVs, performance vehicles. | Pros: Robust design; Cons: Complex access for replacements. |

| Top-Mounted Starters | Found on top of the engine, often under the intake manifold. | High-performance engines, some imports. | Pros: Compact placement; Cons: Difficult accessibility. |

| Hidden Starters | Inaccessible without significant disassembly (e.g., under intake manifold). | Specialty vehicles, older models. | Pros: Space-saving; Cons: High labor costs for replacement. |

| Integrated Starter Systems | Starters combined with other engine components. | Electric and hybrid vehicles. | Pros: Enhanced efficiency; Cons: Higher replacement costs. |

What Are the Characteristics of Front-Wheel Drive (FWD) Starters?

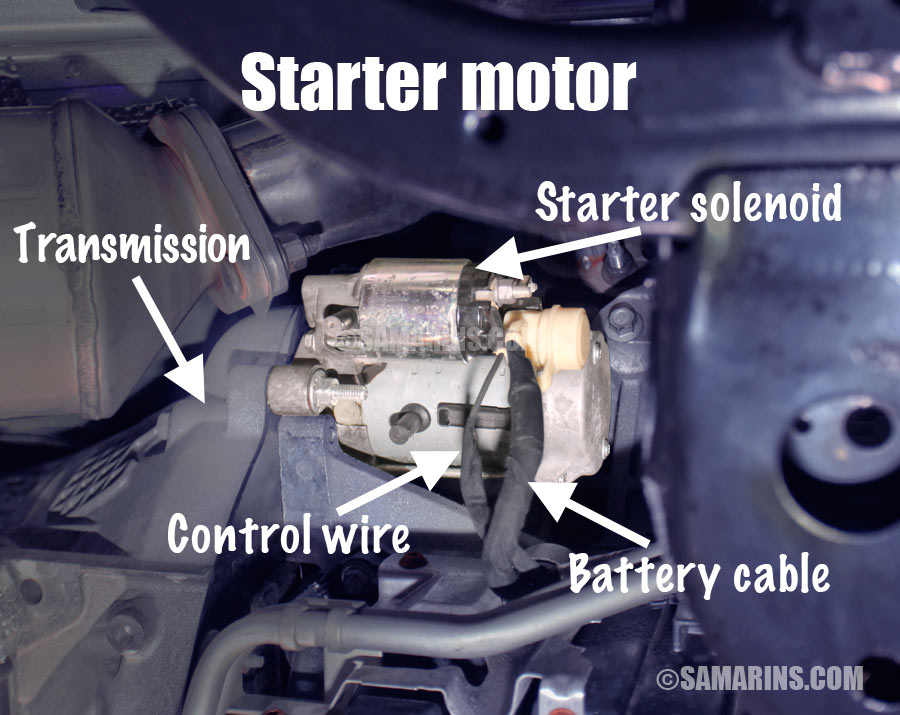

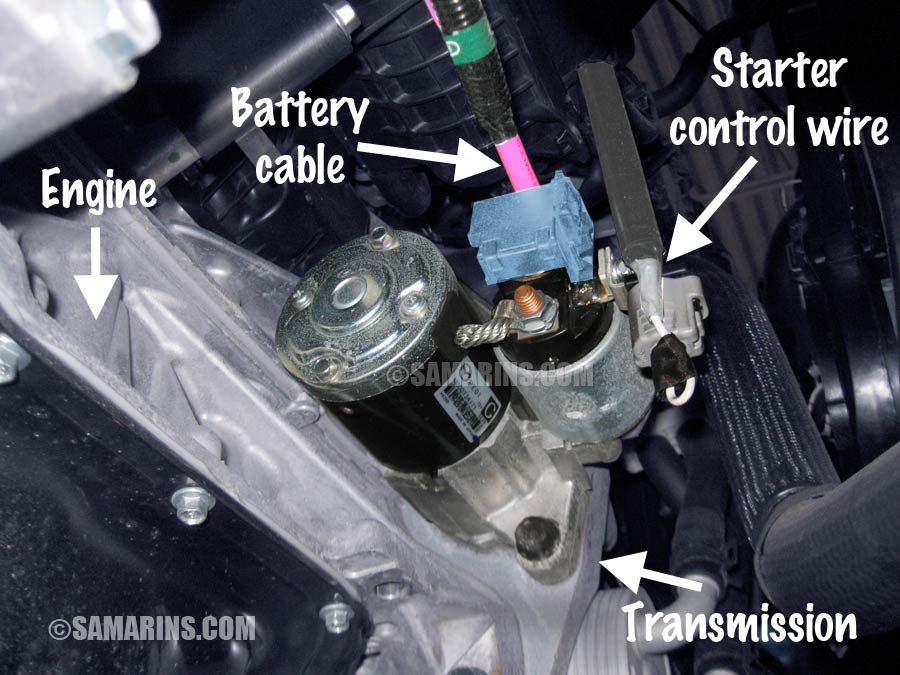

Front-wheel drive vehicles typically have their starters situated between the engine and transmission, specifically on the driver’s side. This configuration allows for easier access during maintenance, making it a favorable option for passenger vehicles and compact cars. B2B buyers should consider the ease of replacement and the availability of parts, as FWD starters are generally standardized across many makes and models, facilitating bulk purchasing.

How Do Rear-Wheel Drive (RWD) Starters Differ?

In rear-wheel drive vehicles, starters are usually located below the exhaust manifold on the passenger side. This design is common in trucks, SUVs, and performance vehicles. While RWD starters are known for their robust construction, accessing them can be complicated, often requiring the removal of other components. Buyers in this segment should evaluate the labor costs associated with replacement and the availability of compatible starter models for specific vehicle types.

What Are the Advantages of Top-Mounted Starters?

Top-mounted starters are positioned on the upper side of the engine, often hidden beneath the intake manifold. This design is prevalent in high-performance engines and some imported vehicles. While this placement can optimize space, it significantly complicates access for repairs or replacements. B2B buyers should weigh the benefits of performance enhancements against the potential for increased labor costs when considering these starter systems.

What Challenges Do Hidden Starters Present?

Hidden starters are those that require extensive disassembly to access, such as those located under the intake manifold. This is often seen in specialty vehicles and older models. While they can save space and contribute to engine design, the difficulty in accessing these starters can lead to high labor costs during maintenance. B2B buyers must be prepared for these challenges and consider the long-term service implications when investing in such vehicles.

How Do Integrated Starter Systems Function?

Integrated starter systems combine the starter with other engine components, common in electric and hybrid vehicles. These systems enhance efficiency and reduce weight but come with higher replacement costs due to their specialized nature. B2B buyers focusing on electric or hybrid technologies should assess the total cost of ownership, including maintenance and potential upgrades, to make informed purchasing decisions.

Key Industrial Applications of where is the starter located

| الصناعة/القطاع | Specific Application of where is the starter located | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | Ensuring accurate installation of starters in assembly lines | Reduces production delays and enhances vehicle reliability | Quality of components, supplier reliability, and lead times |

| إصلاح السيارات | Diagnosing starter issues in service centers | Increases customer satisfaction through efficient repairs | Availability of OEM vs aftermarket parts, warranty options |

| إدارة الأسطول | Regular maintenance checks on fleet vehicles | تقليل وقت التعطل إلى الحد الأدنى وتعزيز الكفاءة التشغيلية | Bulk purchasing agreements and long-term supplier relationships |

| معدات البناء | Starter location knowledge for heavy machinery maintenance | Ensures timely repairs, reducing project delays | Compatibility with various equipment models and parts availability |

| الآلات الزراعية | Identifying starter placement for tractors and harvesters | Enhances machinery uptime and productivity in the field | Sourcing durable components that withstand harsh conditions |

How is the Starter Location Critical in Automotive Manufacturing?

In the automotive manufacturing sector, knowing the starter’s location is essential for efficient assembly line operations. Accurate installation directly impacts vehicle performance and reliability. For businesses, this means fewer recalls and enhanced customer trust. Buyers must consider the quality of components sourced, ensuring they meet OEM specifications, while also evaluating supplier reliability to prevent production delays.

What Role Does Starter Location Play in Automotive Repair Services?

In automotive repair services, technicians rely on their understanding of starter locations to diagnose issues quickly. A well-located starter facilitates efficient repairs, leading to higher customer satisfaction. B2B buyers in this sector should prioritize sourcing options that offer both OEM and aftermarket parts, taking into account warranty options and service support to ensure long-term reliability.

Why is Starter Location Important for Fleet Management?

For fleet management, knowledge of starter locations is vital during regular maintenance checks. Proper maintenance minimizes vehicle downtime, which is crucial for maximizing operational efficiency. B2B buyers should establish bulk purchasing agreements with suppliers to secure consistent availability of starter components, ensuring that repairs can be executed swiftly and effectively.

How Does Starter Location Affect Construction Equipment Maintenance?

In the construction industry, understanding where starters are located in heavy machinery is critical for timely maintenance. Delays in repairs can lead to project setbacks, affecting overall productivity. Buyers should focus on sourcing parts compatible with various equipment models while ensuring that suppliers can provide quick turnaround times on orders to minimize equipment downtime.

What is the Significance of Starter Location in Agricultural Machinery?

For agricultural machinery, knowing the starter’s location helps farmers and technicians quickly address issues that may arise in the field. Ensuring that machinery operates efficiently is key to maintaining productivity during crucial planting and harvesting seasons. B2B buyers must seek durable components that can withstand the rigors of agricultural use, ensuring reliable performance in demanding environments.

3 Common User Pain Points for ‘where is the starter located’ & Their Solutions

Scenario 1: Difficulty Locating the Starter in Complex Engine Designs

المشكلة:

B2B buyers often face challenges when attempting to locate the starter in vehicles with intricate engine layouts. This complexity is particularly evident in models with front-wheel drive configurations, where the starter may be hidden between the engine and transmission. Additionally, different manufacturers have varying designs, such as placing starters beneath intake manifolds or near exhaust components. This inconsistency can lead to frustration, wasted time, and potential damage if the wrong components are accessed during maintenance or repair.

الحل:

To effectively address this issue, buyers should prioritize access to detailed service manuals specific to each vehicle model. These manuals typically include diagrams and step-by-step instructions on locating the starter motor. Furthermore, leveraging online platforms that specialize in automotive repair can offer insights into common starter locations for various makes and models. Buyers should also consider investing in diagnostic tools that can assist in identifying engine layouts quickly. By systematically researching starter placements and understanding the specific vehicle’s architecture, businesses can streamline their repair processes and reduce labor costs associated with misdiagnosis or inefficient repairs.

Scenario 2: Costly Repairs Due to Inaccessible Starters

المشكلة:

Many vehicles feature starters positioned in hard-to-reach areas, which can significantly increase repair costs. For example, certain models require the removal of various components, such as the intake manifold or exhaust parts, to access the starter. This not only escalates labor time but can also lead to additional costs if further components are damaged during disassembly. B2B buyers, especially those managing fleets or repair shops, must contend with the financial implications of such repairs, which can hinder operational efficiency and profitability.

الحل:

To mitigate these costs, B2B buyers should focus on training their technicians in efficient repair techniques specific to each vehicle type. This includes familiarizing staff with the most common vehicle models they encounter and the specific challenges associated with each starter location. Investing in specialized tools, such as angled wrenches or ratchet extensions, can also facilitate easier access to difficult-to-reach starters. Additionally, maintaining a database of service procedures for frequently serviced models can improve workflow efficiency, allowing technicians to complete repairs more swiftly and accurately, thus minimizing labor costs.

Scenario 3: Misdiagnosis of Starter Issues Leading to Unnecessary Replacements

المشكلة:

B2B buyers frequently encounter situations where symptoms of starter failure are misdiagnosed due to a lack of understanding of starter locations and function. Symptoms such as clicking sounds or slow cranking can often be attributed to battery issues or electrical failures rather than the starter itself. Misdiagnosis leads to unnecessary part replacements, resulting in wasted resources and diminished trust from clients, particularly in competitive markets like automotive repair.

الحل:

To combat misdiagnosis, it is essential for B2B buyers to implement a structured diagnostic protocol that emphasizes comprehensive testing of both the battery and starter system before concluding that the starter is at fault. This can include voltage drop tests, checking for loose connections, and ensuring the battery is adequately charged. Moreover, providing ongoing training for technicians on the electrical systems of vehicles can enhance their diagnostic capabilities. Encouraging the use of diagnostic scanners that can provide fault codes related to the starting system can also help in pinpointing issues accurately. By fostering a culture of thorough diagnostics, businesses can reduce unnecessary repairs, save costs, and enhance customer satisfaction.

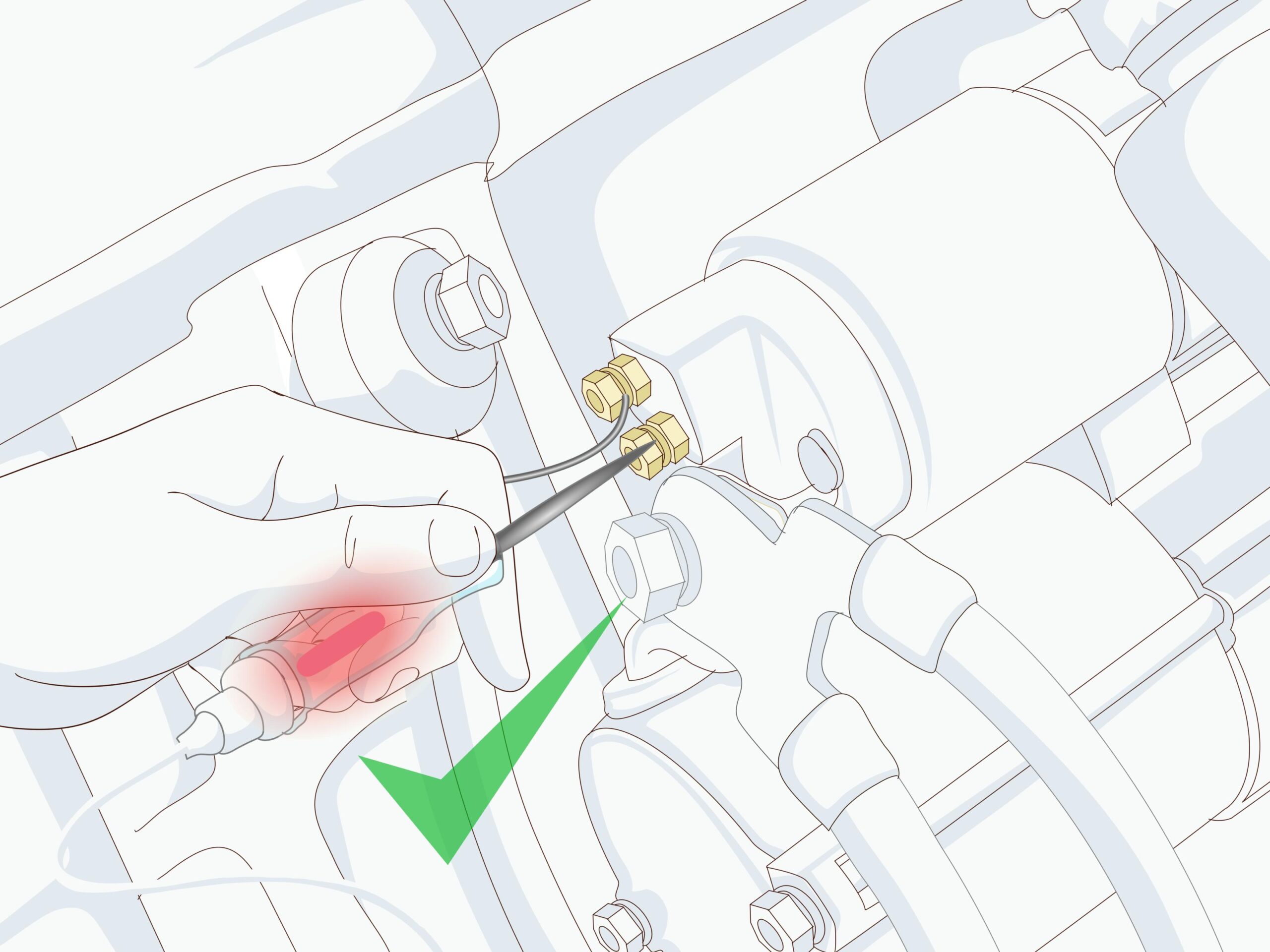

Illustrative image related to where is the starter located

Strategic Material Selection Guide for where is the starter located

What Are the Common Materials Used in Starter Locations?

When considering the materials used in the construction of starters, it is essential to analyze their properties, advantages, and limitations, especially from a B2B perspective. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must also consider compliance with local standards and the specific demands of their markets.

Steel: The Traditional Choice for Starter Components

Steel is often the primary material used in the construction of starter motors due to its high strength and durability. It can withstand significant mechanical stress and is resistant to deformation under high pressure.

الإيجابيات: Steel’s robustness makes it ideal for high-performance applications, and its cost-effectiveness is a significant advantage for manufacturers.

السلبيات: However, steel is susceptible to corrosion, which can be a critical issue in humid or coastal environments. Additionally, the manufacturing process can be complex, requiring precise machining and finishing.

التأثير على التطبيق: Steel starters are compatible with various engine types and can handle the rigors of different media, including high temperatures during engine operation.

Illustrative image related to where is the starter located

اعتبارات للمشترين الدوليين: Buyers in regions with high humidity or saline environments should prioritize corrosion-resistant coatings or consider alternatives. Compliance with ASTM standards for steel quality is crucial, particularly in Europe and the Middle East.

الألومنيوم: بديل خفيف الوزن

Aluminum is increasingly being used for starter housings due to its lightweight nature and good thermal conductivity.

الإيجابيات: The reduced weight of aluminum starters can improve overall vehicle efficiency and performance. Furthermore, aluminum is naturally resistant to corrosion, making it suitable for various environments.

السلبيات: On the downside, aluminum is less durable than steel and may not withstand high-stress applications as effectively. Its cost can also be higher, depending on the alloy used.

Illustrative image related to where is the starter located

التأثير على التطبيق: Aluminum starters are particularly effective in applications requiring reduced weight, such as in racing or high-performance vehicles.

اعتبارات للمشترين الدوليين: Buyers should ensure that the aluminum used meets international standards such as ISO or DIN. In regions like Brazil and Saudi Arabia, where extreme temperatures can affect performance, selecting the right aluminum alloy is crucial.

Plastic Composites: The Emerging Material

Plastic composites are gaining traction in starter motor applications due to their lightweight and corrosion-resistant properties.

الإيجابيات: These materials can be molded into complex shapes, allowing for innovative designs that reduce weight and improve performance. They are also resistant to many chemicals, making them suitable for various automotive environments.

السلبيات: However, plastic composites may not withstand high temperatures as well as metals, which can limit their application in high-performance engines. They can also be more expensive to produce.

التأثير على التطبيق: Plastic composites are particularly useful in applications where weight savings are critical, but their thermal limitations must be considered.

اعتبارات للمشترين الدوليين: Buyers should verify that the plastic materials comply with automotive industry standards and are suitable for the specific environmental conditions in their region.

Copper: Essential for Electrical Connections

Copper is often used for electrical connections within starters due to its excellent conductivity.

الإيجابيات: Copper’s high electrical conductivity ensures efficient power transfer, which is crucial for starter performance. It is also relatively resistant to corrosion when properly treated.

السلبيات: The primary drawback of copper is its cost, which can be significantly higher than other materials. Additionally, copper is relatively heavy compared to alternatives like aluminum.

التأثير على التطبيق: Copper is essential in applications where electrical efficiency is paramount, but its weight can be a consideration in overall design.

اعتبارات للمشترين الدوليين: Compliance with electrical standards is vital, particularly in regions with stringent regulations, such as the EU. Buyers should also consider the impact of copper prices on overall costs.

جدول ملخص

| المواد | Typical Use Case for where is the starter located | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الصلب | Starter housing and components | قوة ومتانة عالية | عرضة للتآكل | متوسط |

| الألومنيوم | علب بدء التشغيل خفيفة الوزن | خفيف الوزن ومقاوم للتآكل | أقل متانة تحت الضغط العالي | عالية |

| المركبات البلاستيكية | Housing and non-load bearing components | خفيف الوزن وقابل للتشكيل | مقاومة حرارية محدودة | متوسط |

| النحاس | Electrical connections within the starter | موصلية ممتازة | High cost and relatively heavy | عالية |

This analysis provides a comprehensive overview of the materials used in starter motors, focusing on their properties, advantages, and considerations for international B2B buyers. Understanding these factors is crucial for making informed purchasing decisions that align with specific market needs and conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for where is the starter located

What Are the Main Stages of Manufacturing for Starters?

Manufacturing starters involves a series of well-defined processes that ensure the final product meets the necessary performance and quality standards. The key stages include material preparation, forming, assembly, and finishing. Each stage is crucial in delivering a reliable starter motor that meets the demands of various automotive applications.

Illustrative image related to where is the starter located

كيف يتم تحضير المواد لتصنيع البادئ؟

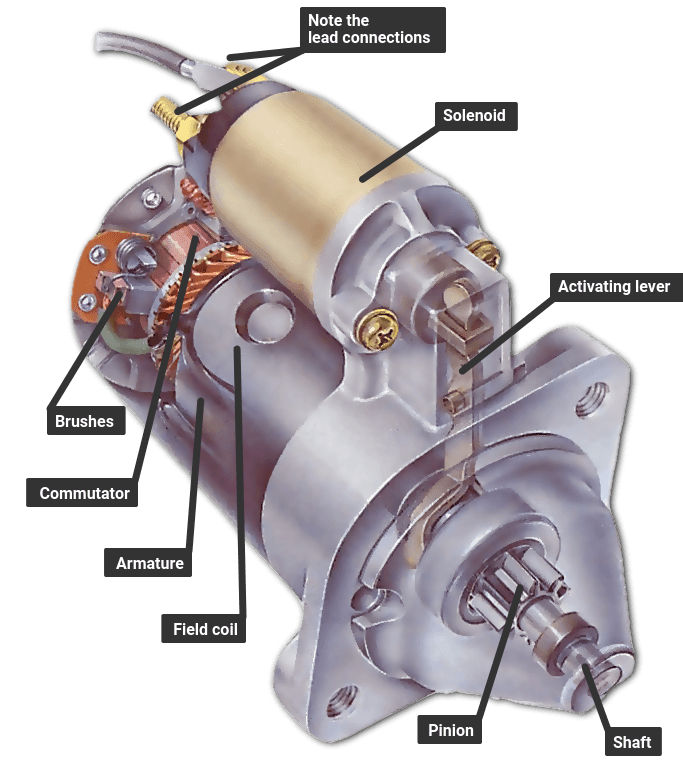

The manufacturing process begins with the selection of high-quality materials. Typically, starter motors are made from a combination of metals, including steel for the housing and copper for the windings. The materials must be sourced from reputable suppliers, ensuring they meet the required specifications for durability and performance.

Once the materials are selected, they undergo preparation processes such as cutting, machining, and surface treatment. These steps are essential for creating components with precise dimensions, which is vital for the effective functioning of the starter motor. For instance, machined parts must fit together seamlessly to avoid operational failures.

What Techniques Are Used in Forming Starters?

Forming is the next stage in the manufacturing process. Techniques like stamping, die-casting, and injection molding are commonly employed to create the various components of the starter motor.

- الختم is often used to manufacture the outer casing, allowing for high-volume production with consistent quality.

- Die-casting is utilized for components requiring complex shapes and high strength, such as the motor housing.

- Injection molding is generally reserved for plastic components, which may include covers or insulating parts.

These forming techniques not only enhance the efficiency of production but also contribute to the overall quality of the starter motor, ensuring it can withstand the harsh conditions of automotive use.

Illustrative image related to where is the starter located

How Is the Assembly Process Managed for Starters?

The assembly of the starter motor is a critical phase that requires precision and attention to detail. This process typically involves several key steps:

-

تكامل المكونات: Individual parts, including the armature, field coils, and housing, are brought together. This stage requires skilled labor or automated systems to ensure that components fit together without gaps or misalignments.

-

التوصيلات الكهربائية: Proper connections between the battery terminals and the motor are established. This is crucial for ensuring the starter receives adequate power when engaged.

-

Testing Before Final Assembly: Before sealing the motor, preliminary tests are conducted to check for electrical continuity and mechanical functionality. This step helps identify any issues that could lead to failures down the line.

What Finishing Techniques Are Applied to Starters?

Once assembled, the starter motor undergoes finishing processes that enhance its durability and performance. These processes may include:

- طلاء: Applying protective coatings to prevent corrosion and wear. Common materials used for coating include zinc and powder coatings.

- الاختبار النهائي: Each starter must undergo a series of performance tests, including load tests and durability assessments, to ensure they meet or exceed industry standards.

Finishing processes are essential for providing the starter with a long service life, which is particularly important for B2B buyers focused on reliability and cost-effectiveness.

ما هي ممارسات ضمان الجودة الضرورية في التصنيع المبتدئ؟

Quality assurance (QA) is an integral part of the manufacturing process for starters. It ensures that each product meets stringent performance and safety standards before it reaches the market.

ما هي المعايير الدولية ذات الصلة بضمان الجودة؟

Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction.

Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards may apply, particularly for starters used in specialized applications such as heavy-duty vehicles.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة؟

Quality control (QC) checkpoints are established at various stages of the manufacturing process. These typically include:

- مراقبة الجودة الواردة (IQC): Inspects raw materials upon arrival to ensure they meet specified requirements.

- مراقبة الجودة أثناء الإنتاج (IPQC): Ongoing inspections during manufacturing to monitor processes and detect any deviations in real-time.

- مراقبة الجودة النهائية (FQC): Comprehensive testing of the finished product to confirm it meets all operational and safety standards before shipping.

These checkpoints are crucial for maintaining high-quality standards and preventing defective products from reaching customers.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital. Here are some effective methods:

- عمليات التدقيق: Conduct regular audits of suppliers to assess their adherence to quality standards and practices. This can include both scheduled and surprise audits.

- تقارير الجودة: Request detailed quality reports that outline the results of inspections and tests performed during the manufacturing process.

- عمليات التفتيش من طرف ثالث: Engage third-party inspection agencies to evaluate the manufacturing processes and quality control measures in place. This adds an extra layer of assurance regarding product quality.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

International B2B buyers should be aware of specific nuances that may affect quality control. These can include:

- الامتثال التنظيمي: Different regions may have varying regulatory requirements for automotive components. Understanding these regulations is crucial for ensuring compliance.

- الاختلافات الثقافية: Communication styles and business practices can vary significantly across regions, impacting the effectiveness of quality control measures.

- Logistics Challenges: Transporting starters across international borders may introduce risks that affect product quality. Implementing robust logistics and handling protocols is essential.

By being proactive and informed, B2B buyers can navigate these challenges effectively and ensure they source high-quality starters that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘where is the starter located’

To assist B2B buyers in effectively sourcing information about the location of starters in various vehicles, this guide outlines a practical checklist. Understanding where the starter is located is essential for maintenance, repair, and procurement of replacement parts. This guide provides a structured approach to ensure you gather all necessary information efficiently.

الخطوة 1: Identify Vehicle Types and Models

Understanding the specific types of vehicles you will be working with is crucial. Different vehicles, such as sedans, SUVs, or trucks, have varied starter locations based on their design and drivetrain configuration. Make a list of the models you frequently encounter to streamline your sourcing efforts.

الخطوة 2: Research Starter Locations for Each Model

Once you have identified the vehicle types, research the typical starter locations for each model. For instance, front-wheel-drive vehicles usually have starters positioned between the engine and transmission, often under the left cylinder bank. This knowledge is critical for accurate part replacement and can influence purchasing decisions.

الخطوة 3: Gather Technical Specifications

Document the technical specifications related to the starter for each vehicle model. This includes dimensions, power ratings, and compatibility with other components. Accurate specifications ensure that the starters you source will fit and function properly, reducing the risk of returns or malfunctions.

الخطوة 4: Verify Supplier Expertise and Experience

Select suppliers who have a proven track record in providing starter parts for the specific vehicle models you are dealing with. Look for suppliers with certifications and endorsements from automotive organizations. This verification ensures that you are sourcing high-quality, reliable components.

الخطوة 5: طلب معلومات مفصلة عن المنتج

When considering potential suppliers, request detailed product information, including installation guides and warranty details. Understanding the installation process and the warranty can help you assess the overall value of the product and anticipate any potential issues during installation.

الخطوة 6: تقييم التوافر ومدة التسليم

Evaluate the availability of starters and the lead times for delivery from your selected suppliers. Quick access to parts can be crucial for minimizing downtime in repair situations. Ensure that suppliers can meet your timelines, especially if you are operating in regions with longer shipping durations.

Illustrative image related to where is the starter located

الخطوة 7: مقارنة الأسعار والتكلفة الإجمالية للملكية

Finally, compare the pricing structures of different suppliers, taking into account not just the initial purchase price but also the total cost of ownership. This includes shipping, potential duties, and any additional fees. A lower initial price may not always equate to a better deal if other costs are significantly higher.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing starters, ensuring they procure the right parts for their specific needs while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for where is the starter located Sourcing

When sourcing starters for vehicles, international B2B buyers should consider a comprehensive analysis of costs and pricing structures that influence their purchasing decisions. Understanding the cost components and price influencers is essential for making informed procurement choices, especially in regions like Africa, South America, the Middle East, and Europe.

ما هي مكونات التكلفة الرئيسية في التوريد المبدئي؟

-

المواد: The primary cost driver in starter manufacturing is the quality of raw materials used. Common materials include high-grade steel for the housing, copper for windings, and various alloys for internal components. Sourcing these materials globally may lead to fluctuations in pricing based on regional availability and market demand.

-

العمل: Labor costs vary significantly across different regions. For instance, countries with lower labor costs may offer competitive pricing but could compromise on quality. Conversely, manufacturers in Europe may charge higher due to skilled labor forces. Understanding local labor markets can help buyers evaluate potential partners.

-

تكاليف التصنيع العامة: This includes costs related to facility maintenance, utilities, and general administrative expenses. Efficient manufacturing processes can reduce overhead, but buyers should ensure that quality is not compromised in the quest for lower costs.

-

الأدوات: The initial investment in tooling for starter production can be substantial. Custom tooling designed for specific vehicle models can lead to higher upfront costs but may provide better long-term value through improved production efficiency.

-

مراقبة الجودة (QC): Implementing robust QC processes ensures that starters meet industry standards and certifications. While this adds to the cost, it is crucial for reducing the risk of failures, which can lead to costly warranty claims and loss of reputation.

-

اللوجستيات: Transportation and shipping costs can significantly affect the total cost of ownership. Factors such as distance, mode of transportation, and customs duties should be considered, especially for international shipments.

-

الهامش: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers gauge whether they are receiving fair pricing.

كيف تؤثر العوامل المؤثرة في الأسعار على مصادر المبتدئين؟

-

الحجم والحد الأدنى لكميات الطلبات (MOQ): Suppliers often provide discounts for bulk purchases. Buyers should negotiate MOQs that align with their inventory management strategies to optimize costs.

-

المواصفات والتخصيص: Custom starters designed for specific vehicle models or performance requirements can lead to higher costs. Buyers should weigh the benefits of customization against budget constraints.

-

الجودة والشهادات: Products that meet international quality standards, such as ISO certifications, may come at a premium. However, investing in higher-quality starters can reduce long-term maintenance costs.

-

عوامل الموردين: The reputation and reliability of suppliers can influence pricing. Established suppliers with a history of performance may command higher prices, but the assurance of quality and service can justify the cost.

-

مصطلحات التجارة الدولية: Understanding Incoterms is essential for international transactions. They dictate the responsibilities of buyers and sellers, impacting logistics costs and risk management.

What Are the Buyer Tips for Cost-Efficiency in Starter Sourcing?

-

التفاوض على الأسعار: Leverage volume commitments to negotiate better pricing with suppliers. Building long-term relationships can lead to favorable terms.

-

تقييم التكلفة الإجمالية للملكية: Consider not just the purchase price but also installation, maintenance, and potential failure costs. A slightly higher upfront cost may lead to lower total costs over the product’s lifespan.

-

فهم الفروق الدقيقة في التسعير الإقليمي: Pricing can vary significantly by region due to economic conditions, import tariffs, and local demand. Buyers should research these factors to make informed decisions.

-

ابق على اطلاع على اتجاهات السوق: Being aware of fluctuations in material costs and global supply chain issues can help buyers anticipate price changes and plan their sourcing strategies accordingly.

In conclusion, a thorough analysis of the cost structure and pricing dynamics surrounding starter sourcing can empower international B2B buyers to make strategic decisions that enhance operational efficiency and reduce costs. Understanding these elements is crucial for navigating the complexities of the automotive parts market.

Alternatives Analysis: Comparing where is the starter located With Other Solutions

In the automotive industry, understanding the placement of the starter motor is essential for efficient vehicle maintenance and repair. However, there are various alternatives and methods to consider when addressing issues related to starting systems. This analysis will compare the traditional understanding of “where is the starter located” with alternative starting solutions such as push-button ignition systems and remote start technologies.

جدول المقارنة

| جانب المقارنة | Where Is The Starter Located | Push-Button Ignition System | Remote Start Technology |

|---|---|---|---|

| الأداء | Reliable, directly engages engine | Quick and efficient, enhances convenience | Convenient, ideal for pre-heating/cooling |

| التكلفة | Moderate (starter replacement: $100-$400) | Higher initial cost, typically $200-$600 | Higher initial cost, typically $300-$800 |

| سهولة التنفيذ | Requires mechanical knowledge for access | تركيب بسيط، وغالباً ما يتم التوصيل والتشغيل | Moderate complexity; may require professional installation |

| الصيانة | Regular checks needed, can be labor-intensive | Minimal maintenance, generally reliable | Requires periodic updates for remote features |

| أفضل حالة استخدام | Standard vehicles requiring traditional start | Modern vehicles prioritizing convenience | Cold climates or areas where pre-conditioning is advantageous |

تفصيل البدائل

1. Push-Button Ignition System

Push-button ignition systems have become increasingly popular in modern vehicles. They offer a seamless start experience where drivers can start their engines with the push of a button, eliminating the need for a traditional key. The primary advantage of this system is convenience; it allows for quick starts without fumbling for keys. However, the initial cost can be higher than standard ignition systems, and the installation may require modifications to the vehicle’s electrical system. For B2B buyers focusing on modern fleet management or vehicle upgrades, this solution enhances user experience but may necessitate a budget for installation and maintenance.

2. Remote Start Technology

Remote start technology allows drivers to start their vehicles from a distance, which is especially beneficial in extreme weather conditions. This system can pre-heat or cool the cabin, providing comfort before entering the vehicle. The performance is highly regarded for convenience, but the cost is generally higher than traditional starter systems. Installation may also require professional assistance, adding to the overall expense. For businesses operating in regions with severe weather, investing in remote start technology can improve the utility of their fleet vehicles, although buyers must weigh the benefits against installation costs.

الخلاصة

When choosing the right starting solution, B2B buyers must consider various factors such as cost, performance, and ease of implementation. Traditional starter motors are reliable and cost-effective for standard vehicles, while push-button ignition systems and remote start technologies offer enhanced convenience and comfort. Ultimately, the decision will depend on the specific needs of the business, the types of vehicles in use, and the driving conditions they face. By analyzing these alternatives, businesses can make informed choices that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for where is the starter located

What Are the Key Technical Properties Related to the Location of Starters?

Understanding the technical properties associated with starter locations is crucial for international B2B buyers in the automotive sector. These specifications not only affect the performance and compatibility of starters but also influence maintenance and repair decisions.

1. Mounting Position

The mounting position of the starter is essential as it varies between vehicle designs. Typically, starters are located between the engine and transmission, often positioned below the left cylinder bank on the driver’s side for front-wheel-drive vehicles. For rear-wheel-drive vehicles, they are usually found below the exhaust manifold on the passenger side. Knowing the precise mounting position helps in ensuring compatibility with the vehicle’s design during procurement.

2. مواصفات عزم الدوران

Torque specifications are critical for ensuring that the starter is securely fastened to avoid vibrations or dislodgment during operation. Each vehicle model will have specific torque requirements for the starter bolts, which can range from 20 to 50 Nm. Understanding these specifications is vital for manufacturers and suppliers to ensure the durability and reliability of the starter installation.

3. التصنيفات الكهربائية

Starters operate on a 12-volt electrical system, but the amperage can vary based on the vehicle’s requirements. Most starters draw between 100 to 200 amps during cranking. Suppliers should ensure that the starters meet or exceed the electrical ratings specified by the vehicle manufacturer to prevent overheating or failure.

4. تركيب المواد

The material used in the construction of the starter impacts its performance and longevity. Common materials include high-grade steel for the casing and copper for the windings. Using quality materials minimizes the risk of corrosion and wear, which is especially important in regions with harsh climates, such as parts of Africa and South America.

5. Heat Resistance Ratings

Starters are often located near hot engine components, making heat resistance a crucial property. Components should be rated for high-temperature operation, typically above 100°C (212°F). This is particularly relevant for buyers in regions with high ambient temperatures, ensuring that starters will perform reliably without overheating.

6. Size and Weight Constraints

The physical dimensions and weight of the starter can impact installation and vehicle performance. Buyers must consider the size specifications to ensure they fit within the designated space in the engine compartment, especially for compact or specialized vehicles.

ما هي المصطلحات التجارية الشائعة المتعلقة بموقع المبتدئين؟

Familiarity with industry terminology is vital for B2B buyers to navigate procurement and logistics effectively.

1. OEM (الشركة المصنعة للمعدات الأصلية)

This term refers to companies that produce parts that are sold under the vehicle manufacturer’s brand. OEM starters typically offer higher reliability and compatibility, which is a key consideration for buyers looking to maintain vehicle integrity.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory costs and ensure they meet their procurement needs without overstocking.

3. طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of products. For buyers, crafting a detailed RFQ for starters ensures that they receive competitive quotes that meet their specifications.

4. شروط التجارة الدولية (Incoterms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping. Understanding Incoterms is vital for B2B transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transport.

5. قطع غيار ما بعد البيع

Aftermarket parts refer to components made by companies other than the OEM. Buyers often consider these for cost-effective solutions but must assess compatibility with the vehicle’s starter location.

6. شروط الضمان

Warranty terms outline the conditions under which a product will be repaired or replaced. Understanding warranty terms is essential for buyers to gauge the reliability of the starters they are purchasing.

In summary, a comprehensive understanding of the technical properties and trade terminology surrounding starter locations is essential for B2B buyers in the automotive sector. This knowledge aids in making informed decisions that ensure the compatibility and reliability of starter components across various vehicle types.

Navigating Market Dynamics and Sourcing Trends in the where is the starter located Sector

What Are the Current Market Dynamics and Key Trends for Starter Locations?

The global automotive market is witnessing significant shifts, driven by technological advancements and the demand for efficient vehicle performance. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, it is crucial to understand these dynamics to make informed sourcing decisions. The starter motor, integral to vehicle ignition systems, is increasingly being engineered for compactness and efficiency. This trend reflects a broader industry push towards lightweight components that enhance fuel efficiency and reduce emissions.

Emerging sourcing trends reveal a growing reliance on digital platforms for procurement, as buyers seek to streamline their supply chains and enhance operational efficiency. E-commerce platforms are being utilized more frequently to access a wide array of starter models from various manufacturers globally. Additionally, the integration of data analytics in inventory management allows for better forecasting and demand planning, which is vital for maintaining optimal stock levels of starter motors.

Moreover, the shift towards electric vehicles (EVs) is influencing starter design and manufacturing. As manufacturers pivot towards hybrid and fully electric models, understanding the location and functionality of starters in these vehicles becomes essential for B2B buyers. This transition is not only a response to regulatory pressures but also aligns with consumer preferences for sustainable transportation options.

How Can Sustainability and Ethical Sourcing Impact the Starter Industry?

In today’s B2B landscape, sustainability and ethical sourcing are more than just buzzwords; they are pivotal to corporate strategies. For buyers in the starter motor sector, understanding the environmental impact of sourcing practices is critical. The production of automotive components, including starters, often involves processes that can generate significant waste and emissions. Therefore, partnering with manufacturers who prioritize sustainability can lead to a more responsible supply chain.

Buyers should look for suppliers who have obtained ‘green’ certifications, indicating a commitment to environmentally friendly practices. This includes using recyclable materials in starter manufacturing and implementing energy-efficient production processes. Furthermore, the adoption of ethical labor practices in the supply chain is paramount, ensuring that all workers involved in the production of automotive parts are treated fairly and humanely.

Additionally, sourcing from suppliers who utilize renewable energy sources in their manufacturing processes can significantly reduce the carbon footprint associated with starter production. Such initiatives not only enhance a company’s brand reputation but can also lead to cost savings in the long run, as many consumers and businesses are now favoring eco-conscious suppliers.

What Is the Historical Evolution of Starter Motors in the Automotive Industry?

The starter motor has undergone substantial evolution since its inception in the early 20th century. Originally, vehicles relied on hand cranks to initiate engine ignition, a labor-intensive process that required considerable physical effort. The introduction of the electric starter motor in the 1910s revolutionized the automotive industry, making vehicle operation more accessible and convenient.

As automotive technology advanced, so did the design and functionality of starter motors. Initially positioned near the flywheel, starters have now been engineered to accommodate various engine layouts, including front-wheel and rear-wheel drives. This adaptability reflects the growing complexity of modern vehicles and the need for compact, high-performance components.

Today, the focus is on integrating advanced technologies into starter systems, such as improved torque capabilities and enhanced durability. As the industry moves towards electrification, the design of starters is evolving to meet the demands of hybrid and electric vehicles, ensuring that they remain a critical component in the future of automotive innovation. Understanding this evolution helps B2B buyers appreciate the importance of sourcing quality starter motors that align with modern automotive standards.

Frequently Asked Questions (FAQs) for B2B Buyers of where is the starter located

-

How do I identify the location of the starter in different vehicle types?

The starter’s location can vary significantly based on the vehicle’s design and drivetrain layout. In front-wheel drive vehicles, it typically resides between the engine and transmission, often on the driver’s side. For rear-wheel drive models, it may be found beneath the exhaust manifold on the passenger side. Understanding the specific layout of the vehicle is crucial for efficient sourcing and replacement. Consult the vehicle’s service manual or diagrams provided by manufacturers for precise locations. -

What is the best way to access the starter for replacement?

Accessing the starter can differ by vehicle model. Generally, you’ll need to disconnect the battery and lift the vehicle for better access, often requiring car jacks and stands. Some models may necessitate the removal of components like the intake manifold or exhaust parts, which can complicate the process. It’s advisable to research specific access methods for the vehicle type in question to avoid unnecessary labor costs and delays. -

What factors should I consider when sourcing starters for international trade?

When sourcing starters internationally, consider factors such as compatibility with local vehicle models, quality certifications, and supplier reliability. Ensure that the components meet regional standards and regulations, particularly in markets like Africa and South America, where vehicle types may differ. Evaluate suppliers based on their track record, production capabilities, and ability to provide customization options for specific needs. -

How can I verify the quality of starters from potential suppliers?

To verify the quality of starters, request samples and check for industry certifications like ISO or TS16949, which indicate adherence to quality management standards. Conduct audits or inspections at the supplier’s facility if possible, and seek feedback from other B2B buyers. Additionally, consider establishing quality assurance protocols, including testing for performance and durability prior to bulk purchases. -

What are common payment terms in international B2B transactions for automotive parts?

Common payment terms vary widely but often include options such as advance payment, letter of credit, or payment upon delivery. In the automotive parts sector, many suppliers may require a deposit before production, with the balance due upon shipping. It’s essential to negotiate clear terms that protect both parties and facilitate smooth transactions. Be aware of currency exchange implications and transaction fees that may affect the final cost. -

What is the minimum order quantity (MOQ) for starters when sourcing from suppliers?

Minimum order quantities (MOQs) for starters can vary based on the supplier and the specific part being ordered. Typically, MOQs may range from 50 to 500 units, depending on the supplier’s production capabilities and the part’s demand. When negotiating, inquire about the potential for lower MOQs, especially for new or specialized models, to minimize initial investment risks. -

How can I ensure timely logistics and delivery of starters?

To ensure timely logistics and delivery, establish clear communication with your suppliers regarding shipping schedules and lead times. Utilize reliable freight forwarding services and consider shipping options that best suit your timeline and budget. It’s beneficial to track shipments closely and maintain a buffer stock to manage unexpected delays, especially in regions with unpredictable shipping conditions. -

What customization options are available for starters, and how do I request them?

Customization options for starters may include variations in size, performance specifications, or specific design features tailored to unique vehicle models. When requesting customization, provide detailed specifications and performance requirements to the supplier. Discuss potential design modifications and ensure that the supplier has the capability to produce customized parts without significant delays or cost increases.

Top 3 Where Is The Starter Located Manufacturers & Suppliers List

1. Reddit – Engine Starter Replacement Guide

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: Starter location: under the intake manifold on the right side of the engine, low on the engine. It resembles a big can with a smaller can as a sidecar. If it works when hit, it likely needs replacement. Replacement is generally inexpensive and easy.

2. Facebook – Exhaust Heat Shield

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: This company, Facebook – Exhaust Heat Shield, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Cadillac – 2006 SRX Starter Location & Replacement

المجال: 2carpros.com

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: 2006 Cadillac SRX 3.6L 6 Cylinder Starter Location: Left side of the engine, behind the A/C compressor by the catalytic converter. Replacement Instructions: 1. Loosen the exhaust if necessary, but avoid unless absolutely needed. 2. Use a long handled 3/8″ ratchet or breaker bar to relieve tension on the belt and remove it from the A/C compressor pulley. 3. Remove the A/C compressor by taking out 3…

Strategic Sourcing Conclusion and Outlook for where is the starter located

In summary, understanding the location and accessibility of a vehicle’s starter is crucial for efficient maintenance and repair. The starter typically resides between the engine and transmission, often positioned in challenging areas that vary across vehicle makes and models. International B2B buyers should prioritize sourcing high-quality starter components from reliable manufacturers to ensure optimal performance and longevity.

Strategic sourcing not only enhances the reliability of automotive operations but also mitigates risks associated with supply chain disruptions. By engaging with trusted suppliers, businesses can secure essential components that meet stringent quality standards, ultimately driving operational efficiency.

Looking ahead, as the automotive industry continues to evolve, particularly with advancements in electric vehicles and hybrid technology, the demand for reliable starter systems will remain paramount. We encourage international buyers from regions such as Africa, South America, the Middle East, and Europe to leverage this knowledge in their sourcing strategies. By doing so, you can position your operations for sustained success and growth in a competitive marketplace. Explore your sourcing options today and ensure your automotive offerings remain top-notch.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.