Introduction: Navigating the Global Market for what is the starter

In the dynamic landscape of automotive components, understanding what a starter motor is and its critical role in vehicle operation is essential for international B2B buyers. Sourcing reliable starter motors that meet diverse automotive needs presents challenges, particularly in regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide delves into the intricacies of starter motors, exploring their types, applications, and the factors influencing their performance.

As a pivotal device that initiates the engine’s operation, the starter motor is not just about functionality; it’s about ensuring reliability and efficiency in various vehicle models. Buyers will gain insights into the various types of starter motors, including traditional, gear reduction, and integrated systems, enabling them to make informed decisions based on specific vehicle requirements.

Furthermore, this guide addresses the critical aspects of supplier vetting, enabling buyers to identify trustworthy manufacturers and distributors. Cost analysis will also be provided, highlighting how to balance quality with budget constraints without compromising on performance. By empowering B2B buyers with this knowledge, we aim to facilitate informed purchasing decisions that align with regional demands and technological advancements in the automotive sector.

جدول المحتويات

- Top 4 What Is The Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for what is the starter

- Understanding what is the starter Types and Variations

- Key Industrial Applications of what is the starter

- 3 Common User Pain Points for ‘what is the starter’ & Their Solutions

- Strategic Material Selection Guide for what is the starter

- In-depth Look: Manufacturing Processes and Quality Assurance for what is the starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is the starter’

- Comprehensive Cost and Pricing Analysis for what is the starter Sourcing

- Alternatives Analysis: Comparing what is the starter With Other Solutions

- Essential Technical Properties and Trade Terminology for what is the starter

- Navigating Market Dynamics and Sourcing Trends in the what is the starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of what is the starter

- Strategic Sourcing Conclusion and Outlook for what is the starter

- إخلاء مسؤولية هام وشروط الاستخدام

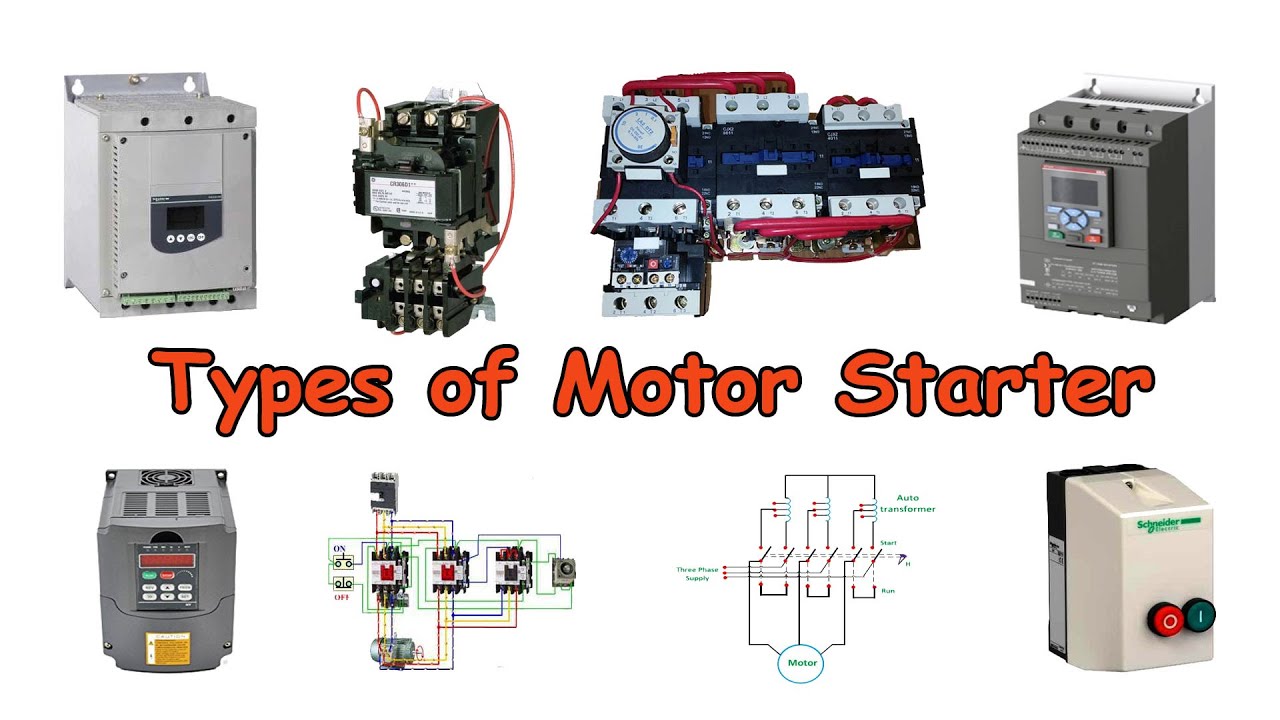

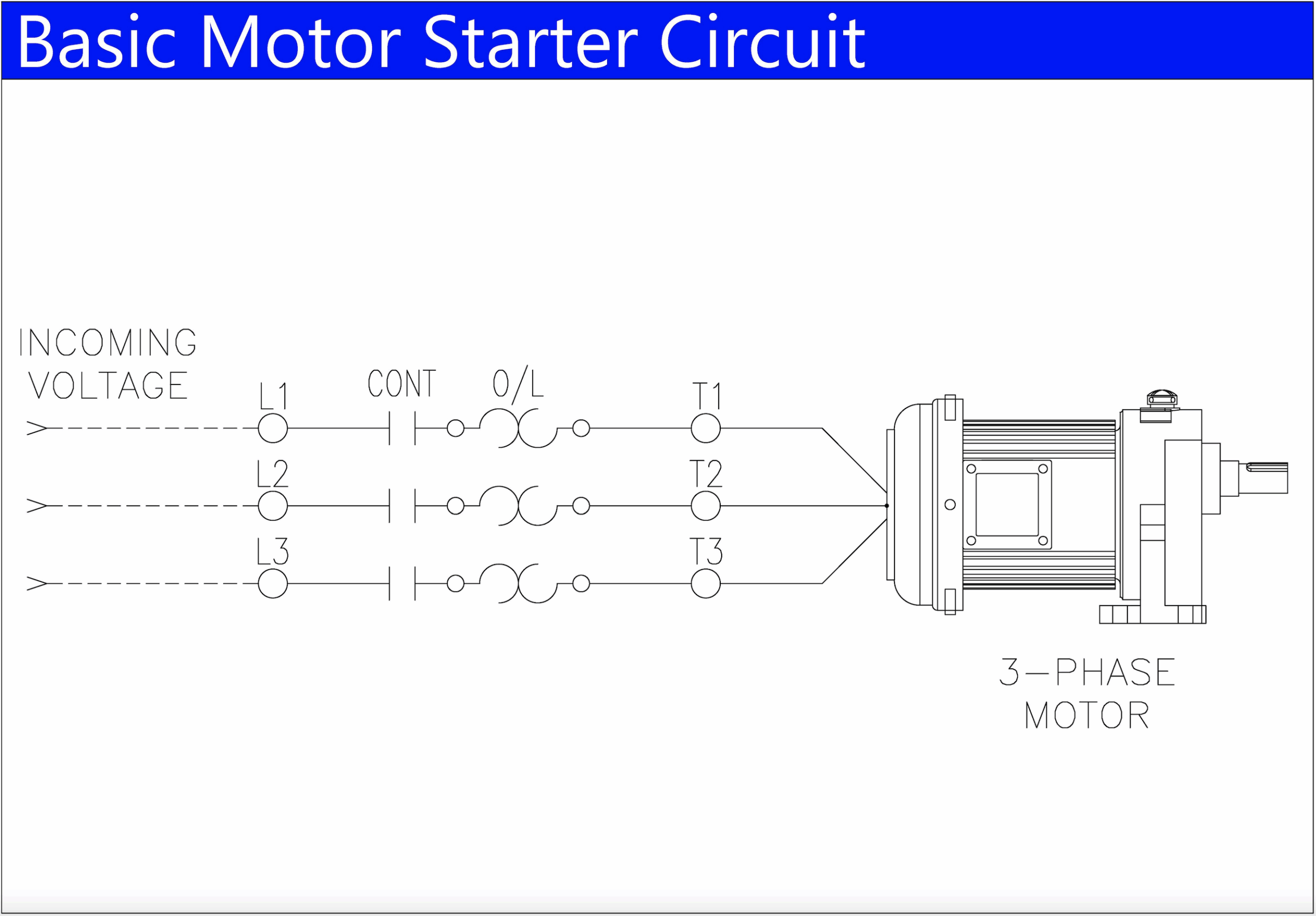

Understanding what is the starter Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| مبدئ تقليدي | Utilizes a direct current electric motor, engages via solenoid. | Automotive repair and replacement. | الإيجابيات: متوفر على نطاق واسع، فعال من حيث التكلفة. السلبيات: Limited lifespan, prone to wear. |

| بادئ الحركة بعزم دوران عالٍ | Designed for high-performance engines, offers greater torque. | Racing and heavy machinery. | الإيجابيات: Enhanced performance, reliable in demanding conditions. السلبيات: تكلفة أعلى، قد تتطلب تعديلات. |

| محرك بدء بتقليل التروس | Incorporates gears to amplify torque while reducing size. | Commercial vehicles, marine engines. | الإيجابيات: Compact design, efficient power use. السلبيات: أكثر تعقيداً، واحتمال تآكل التروس. |

| محرك بدء دائم المغناطيس | Uses permanent magnets for improved efficiency and response. | Electric and hybrid vehicles. | الإيجابيات: Lightweight, quick engagement. السلبيات: More expensive, less common. |

| مولد بدء التشغيل المدمج (ISG) | Combines starter and generator functions, suitable for hybrid systems. | Hybrid and electric vehicle production. | الإيجابيات: توفير المساحة وتحسين كفاءة استهلاك الوقود. السلبيات: يمكن أن يؤدي التعقيد إلى ارتفاع تكاليف الإصلاح. |

ما هي خصائص المبتدئين التقليديين ومدى ملاءمتهم للمشترين B2B؟

Conventional starters are the most common type found in internal combustion engine vehicles. They operate using a simple electric motor and solenoid mechanism to engage the engine. For B2B buyers, these starters are suitable due to their availability and affordability, making them ideal for automotive repair shops and parts distributors. When purchasing, consider the compatibility with various vehicle models and the expected lifespan, as these starters may require frequent replacement in high-use environments.

How Do High Torque Starters Differ and What Are Their Applications?

High torque starters are specifically engineered for high-performance engines, providing greater torque to start engines under demanding conditions, such as in racing or heavy machinery applications. These starters are essential for businesses involved in motorsport or heavy-duty vehicle maintenance. Buyers should assess the performance requirements of their applications and be prepared for a higher upfront investment, as well as potential modifications needed for installation.

What Makes Gear Reduction Starters a Popular Choice for Commercial Use?

Gear reduction starters utilize a gear system to increase torque output while minimizing size, making them particularly advantageous for commercial vehicles and marine engines. Their compact design allows for installation in tight spaces, which is a significant benefit for fleet operators and repair shops. When considering these starters, buyers should evaluate the complexity of installation and the potential for gear wear, which may necessitate additional maintenance.

Why Are Permanent Magnet Starters Gaining Popularity in Electric Vehicles?

Permanent magnet starters leverage permanent magnets to enhance efficiency and response time, making them a preferred choice for electric and hybrid vehicles. This technology appeals to manufacturers focused on innovation and sustainability. B2B buyers should weigh the benefits of reduced weight and faster engagement against the higher cost and limited availability compared to conventional starters.

How Do Integrated Starter Generators (ISG) Benefit Hybrid Vehicles?

Integrated Starter Generators combine the functions of a starter and generator, offering significant advantages for hybrid systems by improving fuel efficiency and reducing space requirements. This technology is increasingly relevant for manufacturers and suppliers in the hybrid vehicle market. Buyers must consider the complexity of ISG systems, as they may incur higher repair costs and require specialized knowledge for maintenance, making them a strategic investment for forward-thinking businesses.

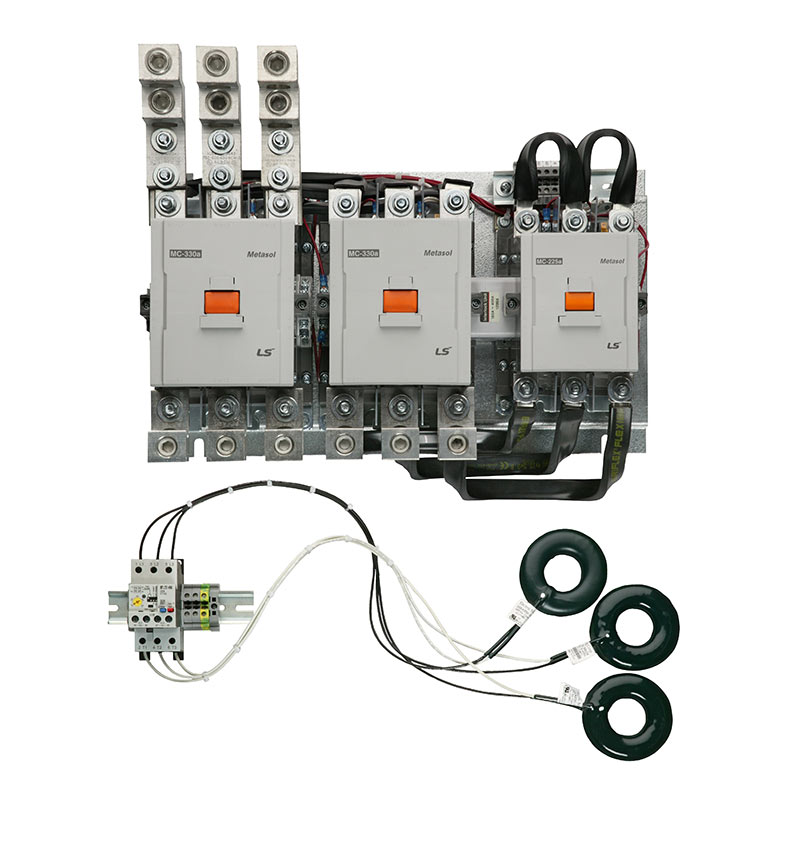

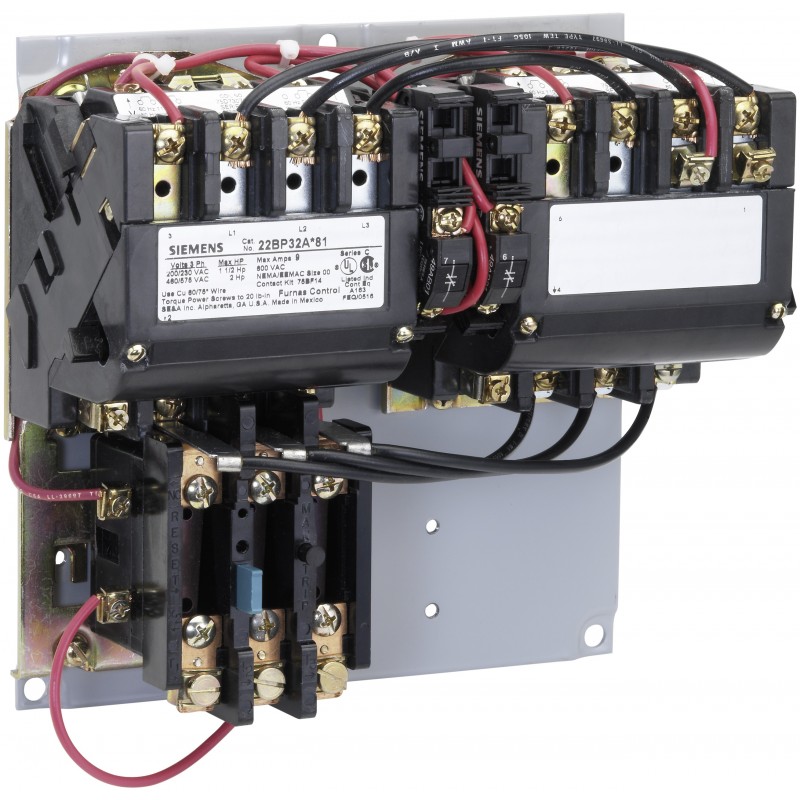

Illustrative image related to what is the starter

Key Industrial Applications of what is the starter

| الصناعة/القطاع | Specific Application of what is the starter | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | التكامل في خطوط التجميع لإنتاج المركبات | Enhances production efficiency and reliability of vehicle starts | Quality certifications, compatibility with various engine types |

| المعدات الثقيلة | Starter motors for construction machinery | Ensures quick and reliable engine starts for operational uptime | Durability under extreme conditions, availability of spare parts |

| الصناعة البحرية | Use in marine engines for boats and ships | Critical for the reliability of engines in harsh marine environments | Resistance to corrosion, compliance with maritime regulations |

| معدات زراعية | Starter motors in tractors and harvesters | Supports agricultural productivity by ensuring equipment readiness | Reliability, ease of maintenance, and local support services |

| أنظمة الطاقة المتجددة | Integration in wind turbines and solar trackers | Facilitates the efficient startup of energy generation systems | Compatibility with renewable energy setups, efficiency ratings |

How is ‘what is the starter’ utilized in automotive manufacturing?

In the automotive manufacturing industry, starter motors are integral to assembly lines, ensuring that vehicles can be reliably started during production testing. A malfunctioning starter can lead to production delays, impacting overall efficiency. Buyers in this sector should prioritize sourcing starter motors that meet specific quality certifications and are compatible with a range of engine types, as this can significantly reduce downtime during assembly.

What role do starter motors play in heavy equipment operations?

Heavy equipment, such as bulldozers and excavators, relies on robust starter motors for engine ignition. These motors must perform reliably in harsh environments, where dust, vibration, and temperature extremes can affect performance. For B2B buyers, sourcing durable starter motors that can withstand these conditions is crucial. Additionally, ensuring the availability of spare parts for maintenance can enhance operational uptime, which is vital for construction projects.

How are starter motors critical in the marine industry?

In the marine sector, starter motors are essential for the ignition of both recreational and commercial vessels. The reliability of these motors is paramount, as a failure can lead to significant safety risks and operational losses. Buyers should focus on starter motors that offer resistance to corrosion and comply with maritime regulations. This ensures long-term performance in challenging marine environments, enhancing the safety and reliability of marine operations.

What is the importance of starter motors in agricultural equipment?

In agriculture, starter motors are vital for tractors and harvesters, ensuring that machinery is ready for use during critical planting and harvesting seasons. A reliable starter motor minimizes downtime, directly impacting agricultural productivity. Buyers should consider the reliability and ease of maintenance when sourcing starter motors, as local support services can significantly affect operational efficiency, especially in remote farming locations.

How do starter motors contribute to renewable energy systems?

Starter motors are increasingly being integrated into renewable energy systems, such as wind turbines and solar trackers, to facilitate efficient startup operations. These motors ensure that energy generation systems can quickly respond to environmental changes, maximizing energy capture. When sourcing starter motors for renewable applications, buyers should prioritize compatibility with existing systems and efficiency ratings to ensure optimal performance in energy generation.

3 Common User Pain Points for ‘what is the starter’ & Their Solutions

Scenario 1: Understanding Starter Motor Specifications for Diverse Applications

المشكلة: B2B buyers often struggle to identify the correct specifications for starter motors suitable for their vehicles or machinery. With a variety of models available and distinct requirements depending on the engine type, voltage, and intended use, buyers may inadvertently select an incompatible starter. This can lead to operational inefficiencies, increased downtime, and ultimately, financial losses. For instance, a logistics company in Nigeria may need starters for a fleet of trucks but lacks clarity on the differences between heavy-duty and light-duty starters.

الحل: To overcome this challenge, buyers should begin by conducting thorough research on the specific requirements of their vehicles or machinery. Utilize technical resources such as OEM (Original Equipment Manufacturer) manuals or reliable online databases that detail starter motor specifications. Engage with suppliers who offer expert consultations to ensure compatibility. Additionally, consider utilizing starter motors that come with detailed installation guides and troubleshooting tips. This proactive approach not only aids in selecting the right product but also enhances the overall efficiency of fleet operations.

Scenario 2: Troubleshooting Starter Motor Failures in Diverse Conditions

المشكلة: B2B buyers frequently face the issue of starter motor failures, especially in regions with extreme weather conditions, such as the Middle East or parts of Africa. A common scenario involves a fleet of construction vehicles that fails to start due to heat-related stress on starter components. Buyers may find it challenging to diagnose whether the issue lies with the starter, battery, or electrical connections, leading to unnecessary replacements and costs.

الحل: Implement a systematic troubleshooting protocol to accurately identify the root cause of starter failures. Start by checking the battery’s voltage and charge state, as many starter issues stem from inadequate power supply. Next, inspect the starter motor for any signs of wear, such as overheating or mechanical failure. Investing in high-quality starters designed for high-temperature environments can mitigate these issues. Collaborate with suppliers who provide robust warranty programs and support, ensuring that replacements are straightforward and cost-effective. Regular maintenance checks and training for staff on the proper handling of starter systems can further enhance reliability and reduce downtime.

Scenario 3: Cost-Effectiveness of Starter Motor Maintenance and Replacement

المشكلة: For many B2B buyers, the cost associated with starter motor maintenance and replacement can be a significant concern, particularly for companies operating on tight margins. In regions like South America, where budgets may be constrained, companies may opt for cheaper, lower-quality starters that could lead to more frequent breakdowns and higher long-term costs. This decision can create a cycle of recurring expenses that undermine profitability.

الحل: To manage costs effectively, buyers should adopt a value-based purchasing strategy rather than focusing solely on the initial price of starter motors. Consider the long-term performance, warranty options, and supplier reliability when making purchases. Investing in high-quality starters may come with a higher upfront cost but can lead to lower maintenance needs and enhanced durability. Establish relationships with reputable suppliers who can offer competitive pricing on bulk orders or long-term contracts. Additionally, integrating predictive maintenance practices can help identify potential starter issues before they escalate, ultimately saving costs associated with emergency repairs and downtime. By focusing on total cost of ownership, buyers can make informed decisions that support both operational efficiency and budgetary constraints.

Strategic Material Selection Guide for what is the starter

ما هي المواد التي تستخدم عادة في محركات التشغيل؟

When it comes to the manufacturing of starter motors, the choice of materials is crucial for ensuring performance, durability, and cost-effectiveness. Below, we analyze four common materials used in starter motors, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

1. فولاذ

الخصائص الرئيسية:

Steel is known for its high tensile strength and durability, which makes it suitable for components that experience significant mechanical stress. It can withstand high temperatures and pressures, making it ideal for the harsh environment of an engine.

الإيجابيات والسلبيات:

Steel’s primary advantage is its strength and resistance to deformation. However, it is prone to corrosion unless treated, which can affect longevity. Manufacturing complexity is moderate, requiring specific processes for shaping and finishing.

التأثير على التطبيق:

Steel is compatible with various automotive fluids and can withstand the thermal cycling associated with engine operation. However, untreated steel can corrode in humid or saline environments, which is a concern in coastal areas or regions with high humidity.

اعتبارات للمشترين الدوليين:

Buyers should ensure compliance with standards such as ASTM A36 or DIN 17100 for structural steel. In regions like Africa and South America, where environmental conditions may vary, selecting corrosion-resistant steel or applying protective coatings is advisable.

2. الألومنيوم

الخصائص الرئيسية:

Aluminum is lightweight and has excellent corrosion resistance due to its natural oxide layer. It can handle moderate temperatures and pressures, making it suitable for various automotive applications.

الإيجابيات والسلبيات:

The primary advantage of aluminum is its lightweight nature, which can improve overall vehicle efficiency. However, it has lower tensile strength compared to steel, which may limit its use in high-stress applications. Manufacturing processes for aluminum can be more complex and costly.

التأثير على التطبيق:

Aluminum’s resistance to corrosion makes it suitable for environments with exposure to moisture. However, it may not perform as well under extreme mechanical stress, which could be a limitation in high-performance applications.

اعتبارات للمشترين الدوليين:

Buyers should be aware of compliance with standards like ASTM B221 for aluminum extrusions. In regions like the Middle East, where temperatures can soar, ensuring that aluminum components can withstand thermal expansion is crucial.

Illustrative image related to what is the starter

3. نحاس

الخصائص الرئيسية:

Copper is an excellent conductor of electricity and has good thermal conductivity. It is also resistant to corrosion, making it suitable for electrical connections within starter motors.

الإيجابيات والسلبيات:

The key advantage of copper is its electrical efficiency, which is critical for starter motors that require high current to function. However, copper is relatively expensive and can be heavy compared to alternatives like aluminum.

التأثير على التطبيق:

Copper’s compatibility with electrical systems is unmatched, ensuring reliable performance. However, its weight can be a disadvantage in applications where reducing mass is a priority.

اعتبارات للمشترين الدوليين:

Compliance with standards such as ASTM B170 for copper wire is essential. In regions like Europe, where recycling and sustainability are emphasized, sourcing recycled copper may be a preferred option.

Illustrative image related to what is the starter

4. المركبات البلاستيكية

الخصائص الرئيسية:

Plastic composites are lightweight and can be engineered for specific thermal and chemical resistance properties. They can withstand moderate temperatures and pressures, depending on the formulation.

الإيجابيات والسلبيات:

The main advantage of plastic composites is their lightweight nature and versatility in design. However, they may not be suitable for high-stress applications and can degrade under extreme temperatures or exposure to certain chemicals.

التأثير على التطبيق:

Plastic composites can be used for non-structural components in starter motors, such as housings or covers. Their chemical resistance can be advantageous in environments with exposure to automotive fluids.

Illustrative image related to what is the starter

اعتبارات للمشترين الدوليين:

Buyers should ensure compliance with standards like ISO 1043 for plastic materials. In regions with stringent regulations on materials, such as Europe, verifying the environmental impact of plastics used is important.

جدول ملخص لاختيار المواد لمحركات التشغيل

| المواد | Typical Use Case for what is the starter | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الصلب | المكونات الهيكلية | قوة ومتانة عالية | عرضة للتآكل | متوسط |

| الألومنيوم | مكونات خفيفة الوزن | مقاومة ممتازة للتآكل | قوة شد أقل | عالية |

| النحاس | التوصيلات الكهربائية | موصلية كهربائية فائقة | Relatively high cost | عالية |

| المركبات البلاستيكية | المكونات غير الهيكلية | خفيفة الوزن ومتعددة الاستخدامات | Limited high-stress applications | متوسط |

This material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions based on performance, cost, and regional considerations.

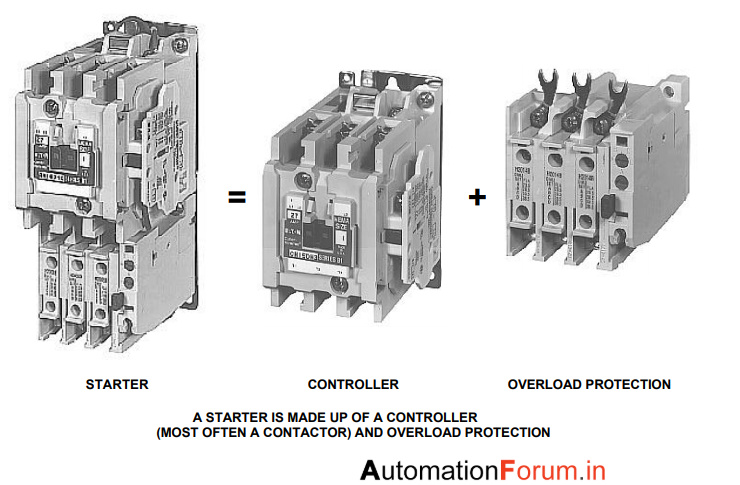

In-depth Look: Manufacturing Processes and Quality Assurance for what is the starter

ما هي المراحل الرئيسية في عملية تصنيع محركات التشغيل؟

The manufacturing of starter motors involves several critical stages, each designed to ensure the final product meets stringent performance and reliability standards. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to what is the starter

How is Material Prepared for Starter Motor Manufacturing?

Material preparation is the first step in the manufacturing process. The primary materials used in starter motors are high-grade steel, copper, and various alloys for electrical components. Suppliers must ensure that these materials meet international quality standards, such as ASTM or ISO specifications, to guarantee durability and performance.

Quality control begins at this stage with Incoming Quality Control (IQC), where the materials are inspected for defects. This inspection may include physical tests for hardness and tensile strength, as well as chemical composition analysis. Ensuring the materials are of the highest quality is crucial, as any flaws can lead to premature failure of the starter motor.

What Forming Techniques Are Used in Starter Motor Production?

Once materials are prepared, the next stage is forming. This involves shaping the components of the starter motor through various techniques, including stamping, machining, and casting.

-

الختم: This process is commonly used for producing the starter motor’s casing and other metallic parts. High-speed presses are utilized to cut and shape metal sheets into precise forms, ensuring consistency across production runs.

-

التصنيع الآلي: Critical components such as the armature and rotor are often manufactured using CNC (Computer Numerical Control) machines. This technique allows for high precision and tight tolerances, which are essential for the efficient operation of the starter motor.

-

الصب: For parts that require complex shapes, casting techniques are employed. This involves pouring molten metal into molds to create components that would be difficult or impossible to fabricate through machining alone.

How is the Assembly Process Conducted for Starter Motors?

The assembly stage is where all the individual components come together to form a complete starter motor. This process typically follows a systematic approach:

-

التجميع الفرعي: Components such as the solenoid, armature, and pinion gear are first assembled separately. Each sub-assembly undergoes its own quality checks to ensure they function correctly.

-

Main assembly: The sub-assemblies are then integrated into the final product. This stage requires skilled technicians to ensure that components fit together perfectly and that all electrical connections are secure.

-

Final assembly checks: After the starter motor is fully assembled, it is subjected to a series of functional tests. These tests may include checking the motor’s torque output and ensuring the solenoid engages and disengages properly.

ما هي عمليات التشطيب المطبقة على محركات التشغيل؟

Finishing processes are crucial for enhancing the durability and appearance of starter motors. These may include:

Illustrative image related to what is the starter

-

معالجة السطح: Components may undergo treatments such as galvanization or powder coating to prevent corrosion and improve aesthetic appeal. This is especially important for markets in humid or corrosive environments, such as parts of Africa and South America.

-

Quality Control (QC) Inspections: After finishing, the starter motors are subject to Final Quality Control (FQC) inspections. These inspections verify that the product meets all specifications and is free from defects before shipment.

What International Standards Govern Quality Assurance for Starter Motors?

Quality assurance in the manufacturing of starter motors is governed by a variety of international standards. The most prominent of these is ISO 9001, which outlines the requirements for a quality management system (QMS). Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO certifications, industry-specific standards such as CE marking (for European markets) and API (American Petroleum Institute) certifications are also relevant. These certifications indicate that the starter motors comply with safety, health, and environmental protection standards.

How Are Quality Control Checkpoints Implemented During Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that any issues are identified and addressed promptly. These include:

-

مراقبة الجودة الواردة (IQC): This initial checkpoint occurs when materials arrive at the facility. It ensures that all incoming materials meet specified quality standards.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During the manufacturing stages, IPQC checks are performed to monitor the quality of components as they are being formed and assembled. This may involve testing dimensions, electrical conductivity, and mechanical properties.

-

مراقبة الجودة النهائية (FQC): Before the starter motors are shipped, FQC inspections are conducted. This involves functional testing of the complete starter motor, ensuring it meets performance criteria and is free from defects.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are several strategies:

-

تدقيق الموردين: Conducting on-site audits allows buyers to assess the supplier’s manufacturing processes and quality control measures firsthand. This can include reviewing documentation, inspecting facilities, and observing production lines.

-

تقارير الجودة: Requesting quality assurance reports can provide insight into a supplier’s QC practices. These reports should detail the results of various inspections and tests conducted throughout the manufacturing process.

-

عمليات التفتيش من قبل أطراف ثالثة: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality management system. These services often conduct random inspections and provide detailed reports on compliance with industry standards.

-

الشهادات: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 or CE marking. This not only indicates adherence to quality standards but also reflects a commitment to continuous improvement.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

International B2B buyers must navigate various nuances when it comes to quality control. Different regions may have specific standards, regulations, and expectations. For instance, buyers from Europe may prioritize CE compliance, while those from the Middle East might focus on local regulations.

Illustrative image related to what is the starter

Understanding these nuances is vital for successful partnerships. Buyers should engage in open communication with suppliers to clarify expectations and requirements. Additionally, being aware of potential language barriers and cultural differences can facilitate smoother interactions and ensure that quality standards are consistently met.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for starter motors is essential for B2B buyers. By prioritizing quality control and supplier verification, buyers can ensure they are sourcing reliable and high-performing products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is the starter’

To assist international B2B buyers in procuring starter motors, this practical sourcing guide outlines essential steps to ensure a successful purchase. By following this checklist, buyers can confidently navigate the complexities of sourcing starter motors for their specific needs.

Illustrative image related to what is the starter

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Establishing clear technical specifications is fundamental to ensure compatibility with your vehicle or machinery. Identify key parameters such as voltage, power requirements, and the type of starter motor (e.g., gear reduction or direct drive). This will help you narrow down your options and avoid costly errors in procurement.

الخطوة 2: Research Market Trends and Suppliers

Conduct thorough market research to understand current trends in starter motors. Investigate suppliers specializing in automotive parts in your region, particularly in Africa, South America, the Middle East, and Europe. Pay attention to emerging technologies, such as integrated starter-generator systems, which may offer advanced solutions.

الخطوة 3: تقييم الموردين المحتملين

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, case studies, and references from previous clients, especially those within your industry. Look for suppliers with proven experience in manufacturing or distributing starter motors, as well as a solid reputation for quality and reliability.

- تحقق من الشهادات: Ensure that suppliers comply with international quality standards, such as ISO certifications.

- Assess warranty terms: A robust warranty can indicate confidence in the product’s quality and longevity.

الخطوة 4: طلب عينات للاختبار

Obtaining samples of the starter motors you are considering can provide invaluable insights into their quality and performance. Test these samples under real-world conditions to assess their reliability and compatibility with your existing systems. Pay attention to torque output, noise levels, and engagement mechanisms.

الخطوة 5: التفاوض على الأسعار والشروط

Once you’ve identified suitable suppliers and tested their products, initiate negotiations to secure the best pricing and terms. Discuss bulk purchasing discounts, payment terms, and delivery schedules. Understanding the total cost of ownership, including installation and maintenance, will help you make a financially sound decision.

الخطوة 6: Verify After-Sales Support and Services

Reliable after-sales support is crucial for a successful procurement process. Confirm that your supplier offers comprehensive support, including installation assistance, technical advice, and access to spare parts. A supplier with strong after-sales service can significantly reduce downtime and maintenance costs in the long run.

الخطوة 7: Finalize the Purchase and Monitor Performance

After selecting a supplier and finalizing the agreement, proceed with the purchase. Monitor the performance of the starter motors closely after installation to ensure they meet your specifications and operational needs. Regular feedback to your supplier can foster a strong relationship and lead to better service in future transactions.

By following these steps, B2B buyers can ensure a streamlined and effective sourcing process for starter motors, ultimately leading to enhanced operational efficiency and reduced costs.

Illustrative image related to what is the starter

Comprehensive Cost and Pricing Analysis for what is the starter Sourcing

What Are the Key Cost Components of Sourcing a Starter Motor?

When sourcing starter motors for automotive applications, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

المواد: The quality of raw materials significantly affects the cost. Key materials include steel, copper, and various plastics. High-quality materials may lead to higher initial costs but can result in better durability and performance, thus reducing long-term costs.

-

العمل: Labor costs vary by region and can significantly impact overall pricing. Skilled labor is essential for quality assembly and testing processes. Countries with lower labor costs may offer competitive pricing, but ensure that the quality of work meets international standards.

-

تكاليف التصنيع العامة: This encompasses indirect costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can lower these costs, which can be passed on to the buyer.

-

الأدوات: The initial investment in tooling for production can be substantial. Custom tools for specific starter motor designs increase costs. However, these costs can be amortized over larger production volumes, making it essential to consider the minimum order quantity (MOQ) when negotiating prices.

-

مراقبة الجودة (QC): Implementing stringent QC measures ensures that the starter motors meet safety and performance standards. While QC can add to the cost, it is a crucial investment to prevent defects that could lead to costly recalls or warranty claims.

-

اللوجستيات: Transportation costs can vary based on distance, shipping method, and customs duties. For international buyers, understanding Incoterms is vital for calculating total landed costs, which include shipping and handling.

-

الهامش: Suppliers typically add a profit margin to their costs. This margin can vary based on market competition and the perceived value of the product.

ما هي العوامل التي تؤثر على تسعير محركات بدء التشغيل؟

Several factors influence the pricing of starter motors, particularly for international B2B buyers:

-

الحجم والحد الأدنى لكمية الطلب (MOQ): Larger orders generally result in lower per-unit costs due to economies of scale. Negotiating MOQs can lead to significant savings.

-

المواصفات والتخصيص: Custom specifications can increase costs due to the need for specialized tooling and materials. Be clear about your requirements to avoid unexpected price hikes.

-

جودة المواد والشهادات: Higher quality materials or certifications (like ISO or IATF) can increase costs but often justify the investment through improved reliability and performance.

-

عوامل الموردين: The reputation and reliability of suppliers affect pricing. Established suppliers may charge more due to their track record, but they can also provide better warranties and support.

-

مصطلحات التجارة الدولية: Understanding the terms of sale is crucial. Prices may appear lower from suppliers who quote FOB (Free On Board) but can increase significantly once shipping, insurance, and customs are factored in.

What Are Some Buyer Tips for Sourcing Starter Motors?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, consider the following tips:

-

التفاوض على الشروط: Don’t hesitate to negotiate pricing and payment terms. Suppliers may offer discounts for early payments or larger orders.

-

التركيز على التكلفة الإجمالية للملكية (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, warranty, and potential failures. A lower initial cost may lead to higher TCO if quality is compromised.

-

فهم الفروق الدقيقة في الأسعار: Be aware of currency fluctuations and their impact on pricing, especially for long-term contracts. Consider hedging strategies or agreements that can mitigate this risk.

-

إجراء عمليات تدقيق الموردين: If possible, conduct audits or request references to ensure suppliers adhere to quality standards. This can prevent costly issues down the line.

-

ابق على اطلاع على اتجاهات السوق: Keep abreast of global market trends, such as supply chain disruptions or shifts in material costs, which can impact pricing.

إخلاء المسؤولية بشأن الأسعار الإرشادية

Prices for starter motors can vary widely based on the factors outlined above. It’s essential to conduct thorough market research and obtain multiple quotes to ensure competitive pricing. Always clarify all costs involved to avoid unexpected expenses.

Alternatives Analysis: Comparing what is the starter With Other Solutions

Exploring Alternatives to the Starter Motor: What Are Your Options?

In the automotive sector, understanding the alternatives to traditional starter motors is crucial for B2B buyers seeking efficient solutions. Starter motors are essential for igniting internal combustion engines, but advancements in technology have introduced various alternative methods. This section compares the traditional starter motor with two alternatives: the Integrated Starter Generator (ISG) and the Flywheel Starter System. Each alternative presents unique advantages and challenges that can influence purchasing decisions.

Illustrative image related to what is the starter

| جانب المقارنة | What Is The Starter | مولد بدء التشغيل المدمج (ISG) | نظام تشغيل الحذافة |

|---|---|---|---|

| الأداء | High torque for engine ignition | Provides smooth start and regenerative capabilities | Instant engagement with no delay |

| التكلفة | استثمار أولي معتدل | Higher upfront cost due to complexity | Cost-effective in the long run |

| سهولة التنفيذ | التركيب القياسي | يتطلب تركيبًا متخصصًا | Simple integration in existing systems |

| الصيانة | Requires regular checks and replacements | Lower maintenance but complex parts can fail | الحد الأدنى من الصيانة المطلوبة |

| أفضل حالة استخدام | المركبات التقليدية | Mild hybrid and electric vehicles | High-performance racing or specialized vehicles |

What Are the Pros and Cons of an Integrated Starter Generator (ISG)?

The Integrated Starter Generator combines the functions of a starter motor and an alternator, making it particularly beneficial for mild hybrid vehicles. This system allows for smoother engine starts and contributes to fuel efficiency by enabling regenerative braking. However, the complexity of the ISG can lead to higher initial costs and specialized installation requirements. While maintenance is generally lower compared to traditional starter motors, the intricate components can be more challenging to repair if they fail.

How Does the Flywheel Starter System Compare to Traditional Starters?

The Flywheel Starter System is designed for quick engagement, providing an instantaneous start to the engine without the delay typical of conventional starter motors. This technology is commonly used in high-performance applications, such as racing, where every millisecond counts. While the initial investment may be lower, the system’s suitability is limited to specific use cases, making it less versatile for everyday vehicles. Maintenance is also minimal, which can be an attractive feature for businesses focusing on performance and reliability.

كيف ينبغي للمشترين بين الشركات اختيار الحل المناسب؟

When selecting the appropriate starting solution, B2B buyers must consider several factors including the type of vehicles they are servicing, budget constraints, and maintenance capabilities. Understanding the specific needs of their fleet or target market is essential. For conventional vehicles, traditional starter motors are still a reliable choice. However, for businesses looking to invest in future technologies, the Integrated Starter Generator may offer long-term benefits through improved efficiency. The Flywheel Starter System, while niche, is ideal for high-performance applications where rapid engine engagement is critical.

In summary, the choice between traditional starter motors and their alternatives should align with operational goals, cost considerations, and maintenance capabilities. By evaluating these aspects, buyers can make informed decisions that enhance the efficiency and reliability of their automotive solutions.

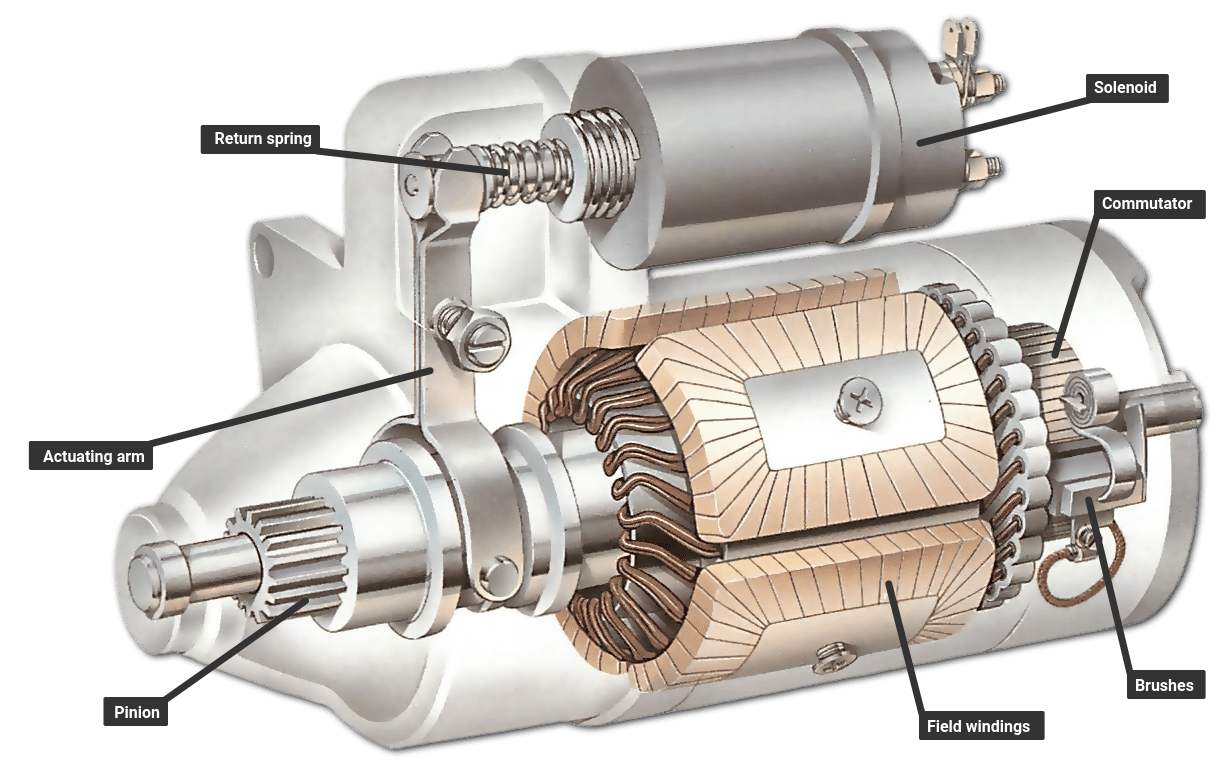

Essential Technical Properties and Trade Terminology for what is the starter

ما هي الخصائص التقنية الرئيسية لمحرك التشغيل؟

Understanding the essential technical properties of a starter motor is crucial for B2B buyers, particularly when evaluating quality and compatibility for various applications. Here are several critical specifications to consider:

1. درجة المواد

The materials used in starter motors significantly affect their durability and performance. Common materials include high-grade steel for the housing and copper or aluminum for the windings. High-quality materials ensure better conductivity and resistance to wear, which is vital for parts that experience high torque and frequent engagement. For international buyers, sourcing from manufacturers who adhere to specific material standards can ensure longevity and reliability.

2. تصنيف عزم الدوران

The torque rating of a starter motor indicates its ability to turn the engine over. Typically measured in Newton-meters (Nm), a higher torque rating means the starter can handle larger engines or more demanding conditions. For B2B buyers, understanding the torque requirements of the engines they are working with helps in selecting the appropriate starter motor, ensuring optimal performance.

3. جهد التشغيل

Most automotive starter motors operate on 12V systems, but some applications may require 24V or other configurations. Knowing the operating voltage is essential for ensuring compatibility with the vehicle’s electrical system. Buyers should confirm the voltage requirements to avoid potential failures that could result from mismatched components.

4. التيار المستهلك

The current draw, typically measured in Amperes (A), indicates how much electricity the starter motor consumes during operation. A motor with a high current draw may require larger gauge wiring and can impact battery performance. B2B buyers need to consider the current specifications to ensure the starter motor fits within the overall power management system of the vehicle.

Illustrative image related to what is the starter

5. آلية المشاركة

The engagement mechanism, often a pinion gear that meshes with the flywheel, is critical for ensuring a reliable start. Understanding the type of engagement system (e.g., solenoid-driven or permanent magnet) helps in assessing the motor’s reliability and efficiency. Buyers should look for products with proven engagement systems to minimize maintenance and replacement costs.

ما هي المصطلحات التجارية الشائعة المتعلقة بمحركات التشغيل؟

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms that buyers should know:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the same manufacturer that produced the original components for a vehicle. Purchasing OEM starter motors ensures compatibility and performance equivalent to the factory-installed part. This is particularly important for businesses that prioritize quality and reliability.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory management and cost calculations. Buyers should negotiate MOQs that align with their operational needs to avoid excess stock or shortages.

3. طلب عرض أسعار (RFQ)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. In the context of starter motors, submitting an RFQ can facilitate competitive pricing and help buyers assess the market. Crafting a detailed RFQ ensures that suppliers provide comprehensive and relevant information.

4. شروط التجارة الدولية (Incoterms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Knowledge of Incoterms helps B2B buyers understand their liabilities and costs when importing starter motors from international suppliers. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for effective logistics management.

5. فترة الضمان

The warranty period is the duration during which a manufacturer guarantees the performance of the starter motor. Understanding the warranty terms helps buyers evaluate the risk associated with their investment. A longer warranty period typically indicates greater confidence in product reliability, which can be a deciding factor in the purchasing process.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding starter motor procurement, ensuring they select the right products for their needs while optimizing their supply chain efficiency.

Navigating Market Dynamics and Sourcing Trends in the what is the starter Sector

What Are the Key Market Dynamics and Trends Affecting the Starter Sector?

In recent years, the global automotive market has undergone significant transformations, particularly in the starter motor sector. Key drivers include the increasing demand for electric and hybrid vehicles, which necessitate advanced starter systems capable of managing higher loads and providing seamless integration with electric components. As emerging markets in Africa and South America expand their automotive industries, the need for reliable starter motors is also rising. Countries like Nigeria and Brazil are investing heavily in local manufacturing, presenting opportunities for international B2B buyers to source components locally while ensuring compliance with regional standards.

Additionally, technological advancements are reshaping sourcing trends. The integration of IoT (Internet of Things) technology in automotive systems is enhancing starter motor functionality, allowing for predictive maintenance and improved performance tracking. This trend is particularly relevant for B2B buyers looking to invest in smart automotive solutions. Furthermore, manufacturers are increasingly focusing on modular designs that facilitate easier replacements and upgrades, appealing to businesses that prioritize efficiency and cost-effectiveness in their supply chains.

How Does Sustainability Influence Sourcing in the Starter Motor Sector?

Sustainability has become a critical factor in the sourcing of automotive components, including starter motors. The environmental impact of manufacturing processes, such as carbon emissions and waste generation, is under heightened scrutiny from both consumers and regulatory bodies. B2B buyers are encouraged to seek suppliers that prioritize sustainable practices, such as using recycled materials or minimizing energy consumption during production.

Ethical sourcing is equally important, as companies strive to build responsible supply chains that respect labor rights and promote fair trade. Certifications like ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) are increasingly valued among international buyers, providing assurance that suppliers adhere to recognized sustainability standards. Additionally, the adoption of ‘green’ materials in the manufacturing of starter motors can enhance a company’s brand reputation, appealing to environmentally conscious consumers and stakeholders.

ما هو السياق التاريخي لمحركات التشغيل وتطورها؟

The inception of the starter motor can be traced back to the early 20th century, with Charles Kettering’s invention in 1911 marking a pivotal moment in automotive engineering. This innovation eliminated the need for manual cranking, revolutionizing vehicle operation and enhancing safety. Over the decades, starter motors have evolved from simple mechanical systems to sophisticated electronic devices integrated with modern vehicle technology.

Today, the trend towards hybrid and electric vehicles is pushing the boundaries of starter motor design. Manufacturers are now developing integrated systems that combine starter and generator functions, reflecting a shift towards more compact and efficient automotive technologies. This evolution not only highlights the importance of staying current with technological advancements but also underscores the necessity for B2B buyers to engage with suppliers who are at the forefront of innovation in the automotive sector.

In conclusion, navigating the complexities of the starter motor market requires an understanding of both the historical context and the modern dynamics that shape sourcing strategies. By prioritizing sustainability and technological advancements, international B2B buyers can position themselves competitively in an ever-evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of what is the starter

-

How do I solve starter motor problems in my vehicles?

To address starter motor issues, begin by ensuring that the battery is fully charged and that all electrical connections are clean and secure. If the starter motor is still unresponsive or makes a clicking sound, it may indicate a faulty solenoid or a worn-out starter. Conduct a thorough inspection of the starter motor’s internal components, such as bearings and armature windings, as these can also fail over time. If necessary, remove the starter for testing at a local auto parts store to determine if it requires repair or replacement. -

What is the best starter motor for commercial vehicles?

When selecting a starter motor for commercial vehicles, consider factors such as torque requirements, durability, and compatibility with your specific engine type. Look for starter motors that are designed to withstand heavy-duty usage and extreme conditions, often found in commercial applications. Brands that have proven reliability and performance in the commercial sector, along with strong warranties, should be prioritized. Collaborate with suppliers who specialize in heavy-duty parts to ensure you receive a product that meets your operational needs. -

How can I vet suppliers for starter motors in international trade?

To effectively vet suppliers for starter motors, start by assessing their experience in the automotive parts industry and their reputation in the market. Request certifications, such as ISO 9001, which indicate quality management practices. Additionally, check references and customer reviews to gauge reliability and service quality. Conducting site visits or utilizing third-party inspection services can further ensure that their manufacturing processes meet your standards, especially when sourcing from regions like Africa or South America. -

What are common payment terms for purchasing starter motors internationally?

Payment terms in international trade can vary widely, but common practices include upfront payment, letters of credit, or payment upon delivery. For larger orders, consider negotiating partial payments, such as a deposit before production and the balance upon completion or shipment. Ensure that the payment method chosen is secure and offers protection against fraud. Be aware of currency exchange implications and potential tariffs that may affect the total cost. -

ما هو الحد الأدنى لكمية الطلب (MOQ) لمحركات التشغيل؟

Minimum order quantities (MOQs) for starter motors can vary by supplier and depend on the type of motor and customization options. Generally, MOQs can range from 50 to 500 units. If you are a smaller buyer, inquire about flexibility in MOQs or consider consolidating orders with other businesses to meet the supplier’s requirements. Discussing your specific needs with potential suppliers may lead to negotiations that can accommodate your purchasing capabilities. -

How can I ensure quality assurance (QA) for starter motors?

To ensure quality assurance for starter motors, request detailed product specifications and performance standards from your supplier. Implement a quality control process that includes pre-shipment inspections, which can involve checking for defects and ensuring compliance with industry standards. Consider partnering with suppliers that offer warranties or guarantees on their products, as this demonstrates confidence in their quality. Regular audits of supplier facilities can also help maintain high-quality standards. -

What logistics considerations should I keep in mind when sourcing starter motors?

When sourcing starter motors internationally, logistics play a crucial role in ensuring timely delivery. Evaluate shipping options, including air freight for urgent needs or sea freight for cost-effective bulk shipments. Factor in customs regulations and potential tariffs that could affect delivery times and costs. Establish clear communication with your logistics provider to track shipments and address any issues promptly, ensuring that you maintain a steady supply of starter motors for your operations. -

Can I customize starter motors for specific applications?

Yes, many suppliers offer customization options for starter motors to meet specific application requirements. Customizations can include modifications to torque ratings, housing materials, or electrical specifications. When approaching suppliers, clearly outline your technical needs and performance expectations. Additionally, verify the supplier’s capabilities to handle custom orders, including lead times and costs associated with such modifications. This proactive approach can help you secure the most suitable starter motors for your unique applications.

Top 4 What Is The Starter Manufacturers & Suppliers List

1. هاينز – محركات بدء التشغيل

المجال: us.haynes.com

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: هذه الشركة، Haynes – Starter Motors، هي كيان بارز في السوق. للحصول على تفاصيل محددة عن المنتجات، يوصى بزيارة موقعها الإلكتروني مباشرة.

2. Pueblo Tires – Car Starters

المجال: pueblotires.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: Car starters are electrical motors responsible for starting a vehicle’s engine. They receive a significant amount of electricity from the battery. When the ignition key is turned, the battery sends an electrical current to the starter solenoid, which powers the starter. A small gear extends from the starter to engage the vehicle’s flywheel, turning it and subsequently the crankshaft to start the e…

3. RAC – Starter Motors

المجال: rac.co.uk

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: Starter motor is an electric component essential for starting the engine in internal combustion vehicles. It works by receiving an electrical signal when the ignition is engaged, activating the starter motor and cranking the engine. Common causes of failure include broken solenoids, mechanical issues, electrical faults, overheating, and wear and tear. The starter motor is typically located at the …

4. eBay – Starters

المجال: ebay.com

تاريخ التسجيل: 1995 (30 عامًا)

مقدمة: Starters are electric motors that spin the engine over to start combustion. They typically last over 150,000 miles with proper maintenance. Signs of a bad starter include the engine not turning over, slow cranking, unusual noises, or smoking. Replacing a starter is a simple task requiring basic tools and can be done in an afternoon. The cost of a new starter starts around $200, and it’s recommende…

Strategic Sourcing Conclusion and Outlook for what is the starter

In summary, understanding the role and functionality of starter motors is essential for international B2B buyers operating in automotive sectors. A starter motor is not merely a component; it is the critical link that initiates the engine’s operation, thereby influencing the overall efficiency and reliability of vehicles. Recognizing the factors that can lead to starter motor failure—such as wear and tear, electrical issues, or battery problems—can guide buyers in making informed purchasing decisions, ultimately reducing downtime and maintenance costs.

Strategic sourcing plays a pivotal role in securing quality starter motors that meet specific operational needs. By establishing relationships with reliable suppliers, buyers can ensure consistent availability of high-quality products and potentially negotiate better pricing terms. This proactive approach is particularly beneficial for businesses in emerging markets across Africa, South America, the Middle East, and Europe, where the demand for reliable automotive parts is on the rise.

As the automotive industry continues to evolve with advancements in technology, including the rise of electric and hybrid vehicles, it is imperative for buyers to stay ahead of trends and innovations in starter motor technology. Engage with suppliers who are not only knowledgeable about current products but also forward-thinking in their approach to new developments. Take action today to enhance your supply chain resilience and drive operational excellence in your business.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.

Illustrative image related to what is the starter