Introduction: Navigating the Global Market for various parts of car

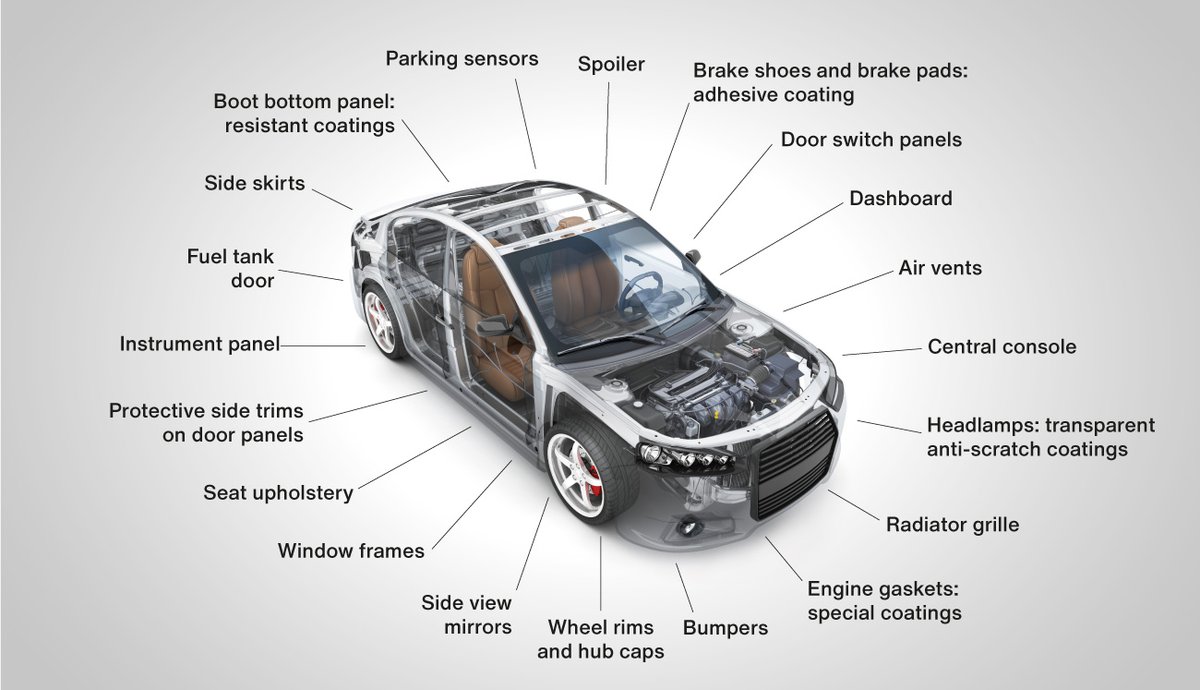

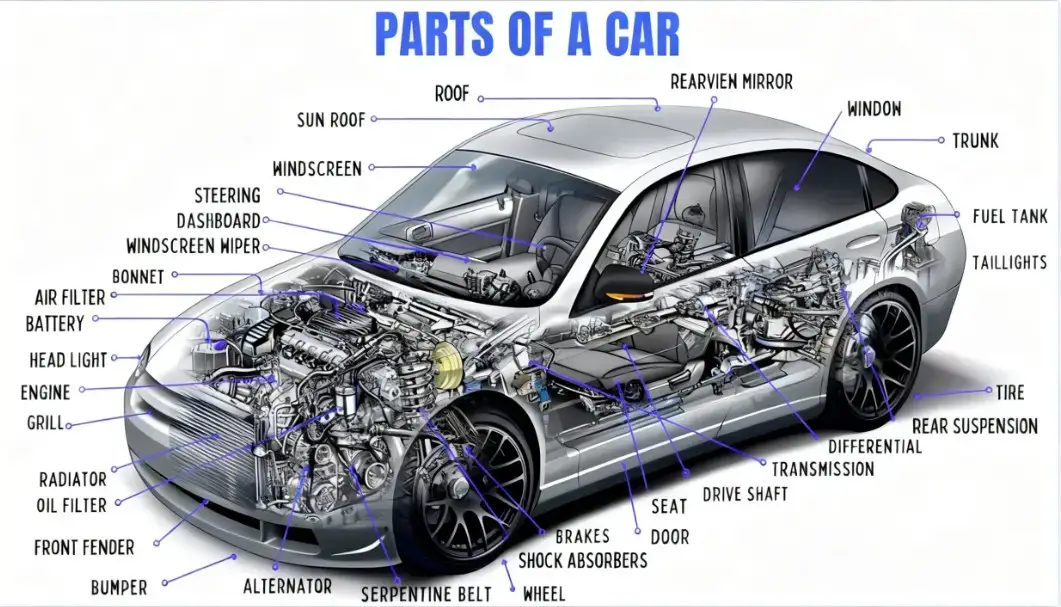

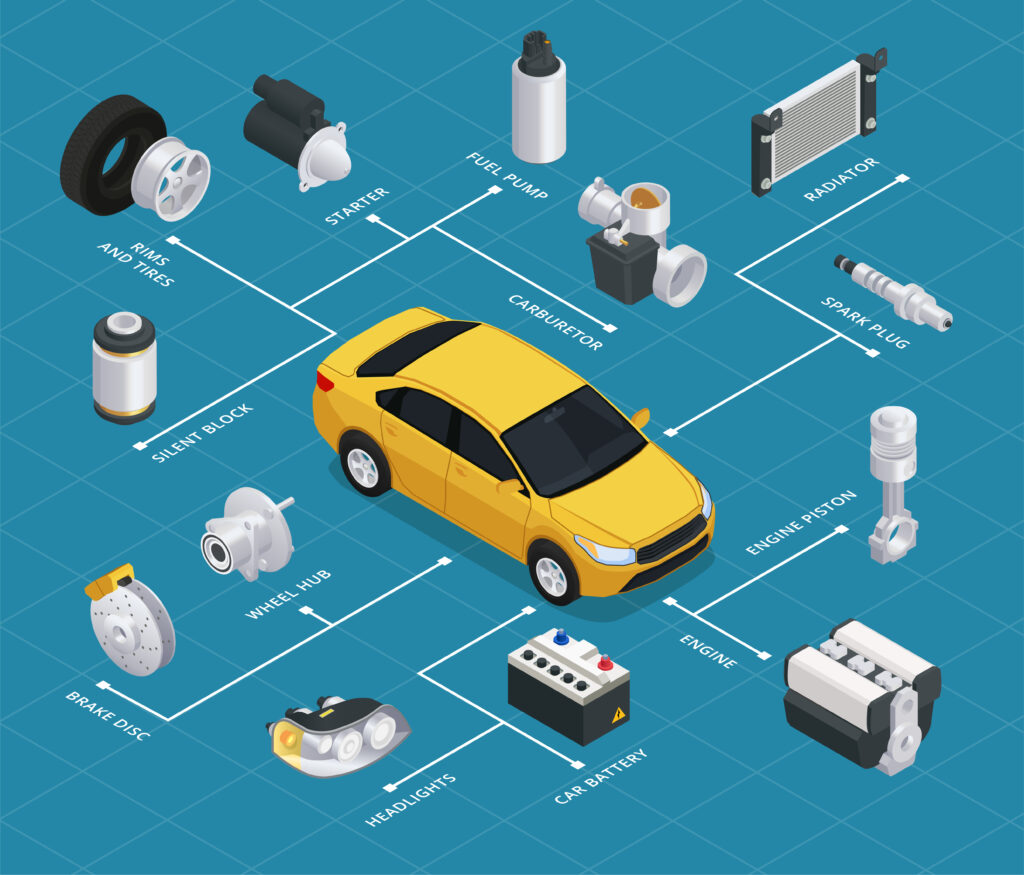

Navigating the global market for various car parts can be a daunting task for B2B buyers, particularly in emerging regions like Africa, South America, the Middle East, and Europe. With the automotive industry evolving rapidly, sourcing high-quality components such as engines, transmissions, and braking systems requires not only an understanding of the products but also insight into market dynamics and supplier capabilities. This guide is designed to demystify the complexities of the automotive parts sector, covering a comprehensive range of topics including types of parts, their applications, and the nuances of supplier vetting.

In addition to detailing the essential components that make up modern vehicles, this guide offers actionable insights on evaluating suppliers, understanding pricing structures, and recognizing trends that could impact purchasing decisions. By equipping international B2B buyers with the knowledge to make informed choices, we aim to enhance their procurement strategies and optimize their supply chains. Whether you are a distributor looking to expand your inventory or a manufacturer seeking reliable components, this guide serves as a valuable resource to help you navigate the intricacies of the global automotive parts market with confidence.

جدول المحتويات

- A Look at Various Parts Of Car Manufacturers & Suppliers

- Introduction: Navigating the Global Market for various parts of car

- Understanding various parts of car Types and Variations

- Key Industrial Applications of various parts of car

- 3 Common User Pain Points for ‘various parts of car’ & Their Solutions

- Strategic Material Selection Guide for various parts of car

- In-depth Look: Manufacturing Processes and Quality Assurance for various parts of car

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘various parts of car’

- Comprehensive Cost and Pricing Analysis for various parts of car Sourcing

- Alternatives Analysis: Comparing various parts of car With Other Solutions

- Essential Technical Properties and Trade Terminology for various parts of car

- Navigating Market Dynamics and Sourcing Trends in the various parts of car Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of various parts of car

- Strategic Sourcing Conclusion and Outlook for various parts of car

- إخلاء مسؤولية هام وشروط الاستخدام

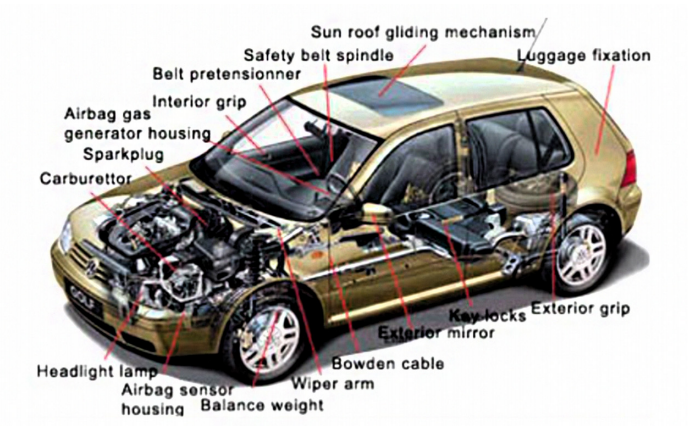

Understanding various parts of car Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| محرك الاحتراق الداخلي | Comprises parts like pistons, crankshaft, and camshaft. | تصنيع السيارات وإصلاحها | الإيجابيات: High power output; widely used. السلبيات: Higher emissions; requires regular maintenance. |

| أنظمة الإرسال | Includes manual, automatic, and CVT types. | Vehicle assembly, aftermarket parts | الإيجابيات: Varying levels of driver control; improved fuel efficiency. السلبيات: يمكن أن يؤدي التعقيد إلى ارتفاع تكاليف الإصلاح. |

| أنظمة التعليق | Encompasses front and rear suspension components. | Parts suppliers, vehicle tuning | الإيجابيات: Enhances ride comfort and handling. السلبيات: Can be costly to replace; affects vehicle dynamics. |

| الأنظمة الكهربائية | Comprises battery, alternator, and ignition components. | Vehicle electrification, OEM parts | الإيجابيات: Essential for modern vehicle functionality; supports advanced features. السلبيات: Can be expensive; potential for electrical issues. |

| أنظمة العادم | Includes catalytic converters, mufflers, and tailpipes. | Emissions control, aftermarket parts | الإيجابيات: Reduces harmful emissions; improves engine efficiency. السلبيات: May require frequent replacement; performance impact if not optimized. |

What are the Key Characteristics of Internal Combustion Engines for B2B Buyers?

Internal combustion engines (ICE) serve as the powerhouse of traditional vehicles, featuring components such as pistons, crankshafts, and camshafts. These engines are suitable for a wide range of applications, from passenger vehicles to heavy machinery. B2B buyers should consider the engine’s power output and emissions standards, as regulations vary significantly across regions, particularly in Africa and Europe. Ensuring compatibility with local environmental regulations is crucial for manufacturers and aftermarket suppliers.

How Do Different Transmission Systems Impact Vehicle Performance?

Transmission systems, including manual, automatic, and continuously variable transmissions (CVTs), play a vital role in vehicle performance. Manual transmissions offer driver control, while automatic and CVT systems enhance driving ease and fuel efficiency. B2B buyers should assess the specific needs of their target market, as preferences for driver engagement versus convenience can differ significantly across regions. Additionally, understanding the complexity and potential repair costs associated with each type is essential for informed purchasing decisions.

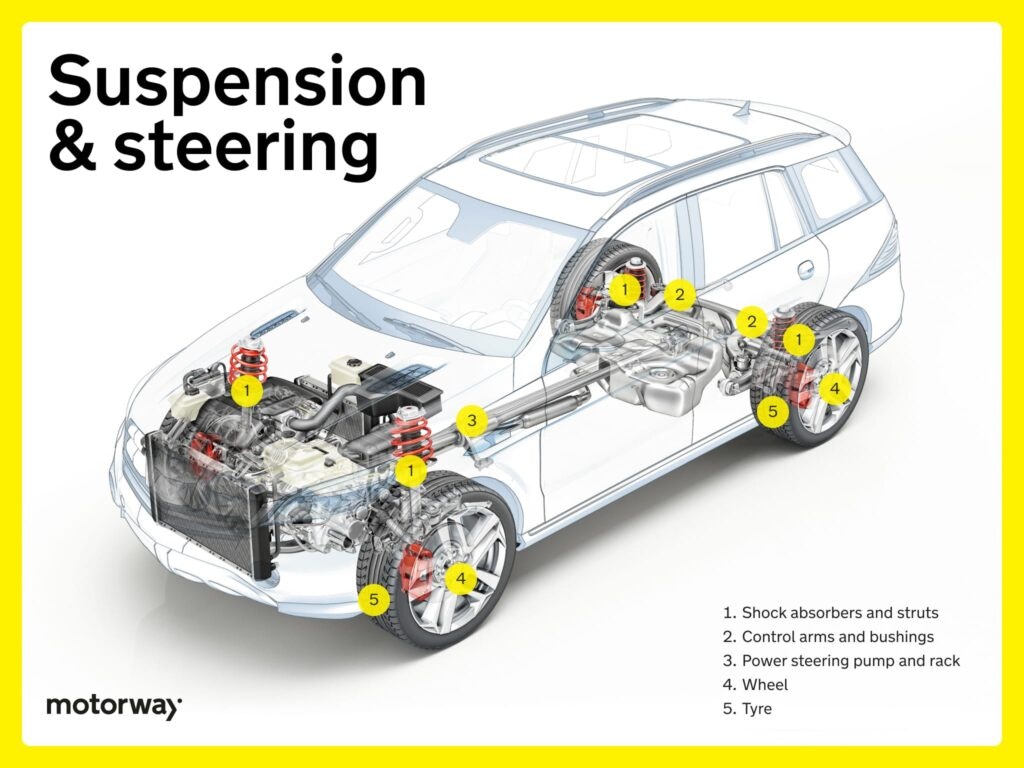

Why is Suspension System Quality Important for Vehicle Comfort and Safety?

Suspension systems are critical for vehicle handling and passenger comfort, comprising various components that absorb shocks and maintain tire contact with the road. B2B buyers in the automotive industry should prioritize high-quality suspension parts, as they directly affect ride quality and safety. The suitability of different suspension types can vary based on vehicle applications, from heavy-duty trucks to luxury sedans. Buyers must also consider the long-term costs associated with maintenance and replacements, as high-quality systems can reduce overall operational costs.

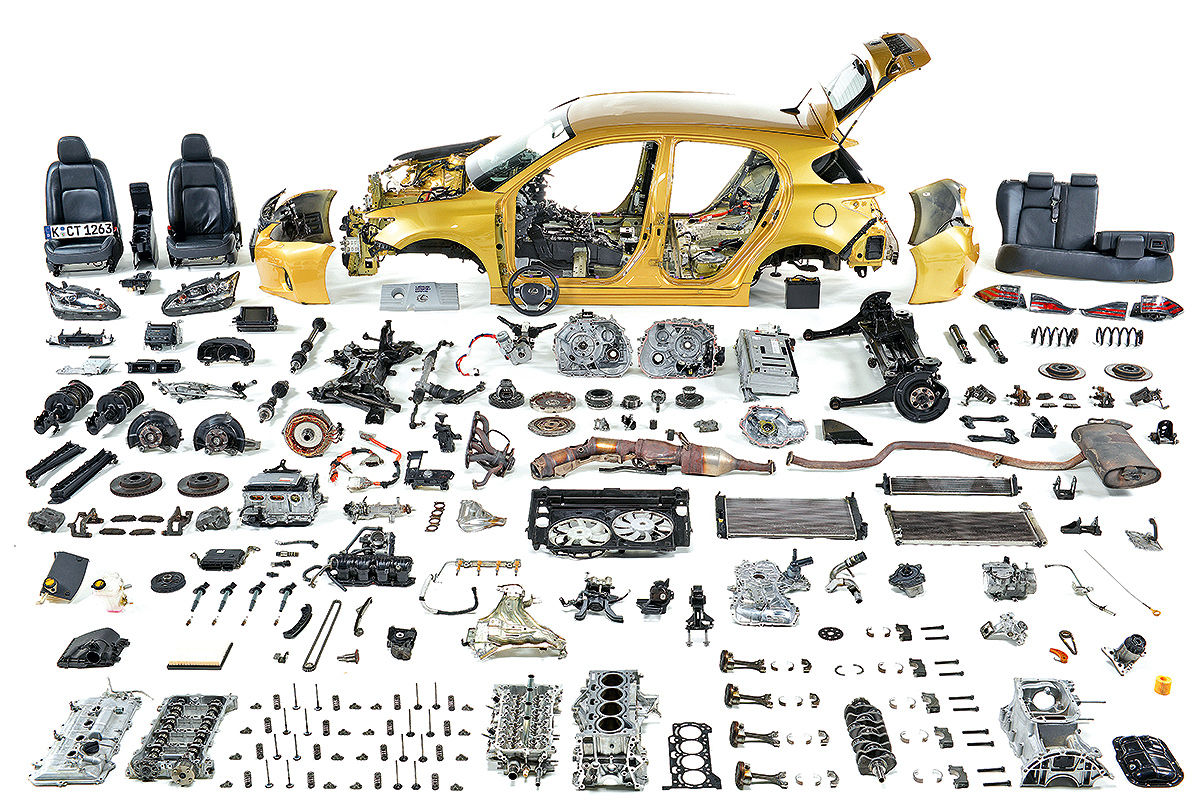

Illustrative image related to various parts of car

What Role Do Electrical Systems Play in Modern Vehicles?

The electrical systems of vehicles, including batteries, alternators, and ignition components, are fundamental to their operation and functionality. As vehicles become more electrified, B2B buyers should focus on sourcing reliable electrical components that support advanced features such as infotainment systems and driver-assistance technologies. The growing trend towards electric and hybrid vehicles necessitates a keen understanding of evolving electrical requirements and the associated costs. Buyers should also be aware of the potential for electrical failures and the importance of quality assurance in component selection.

How Do Exhaust Systems Contribute to Emission Control and Performance?

Exhaust systems, which include catalytic converters, mufflers, and tailpipes, are essential for controlling vehicle emissions and optimizing engine performance. For B2B buyers, understanding the regulatory landscape regarding emissions is critical, especially in regions with stringent environmental laws. The choice of exhaust system can impact vehicle performance, and buyers should consider the trade-offs between emission control and power output. Additionally, the longevity and maintenance requirements of exhaust components should be factored into purchasing decisions to ensure compliance and performance efficiency.

Key Industrial Applications of various parts of car

| الصناعة/القطاع | Specific Application of various parts of car | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | Engine components supply for vehicle assembly | Ensures production efficiency and quality control | موثوقية المورد، والامتثال للمعايير الدولية، وفعالية التكلفة. |

| Automotive Aftermarket | Replacement parts for vehicle maintenance and repairs | Increases vehicle longevity and customer satisfaction | Quality certifications, warranty provisions, and availability of parts. |

| إدارة الأسطول | Parts for maintenance of commercial vehicle fleets | يقلل من وقت التعطل وتكاليف الصيانة | Bulk purchasing options, service agreements, and logistics efficiency. |

| تطوير السيارات الكهربائية | Components for hybrid and electric vehicles | Supports innovation and sustainability initiatives | Compatibility with existing systems, technological advancements, and supplier expertise. |

| التصدير والتجارة | Sourcing parts for resale in international markets | Expands market reach and revenue potential | Understanding of import/export regulations, tariffs, and local demand trends. |

How Are Engine Components Used in Automotive Manufacturing?

In automotive manufacturing, engine components such as pistons, crankshafts, and camshafts are essential for assembling reliable vehicles. These parts must meet stringent quality standards to ensure safety and performance. For international buyers, particularly in regions like Africa and South America, sourcing from suppliers who can guarantee compliance with local regulations is crucial. Additionally, manufacturers should consider the supplier’s ability to provide consistent delivery and support to maintain production schedules.

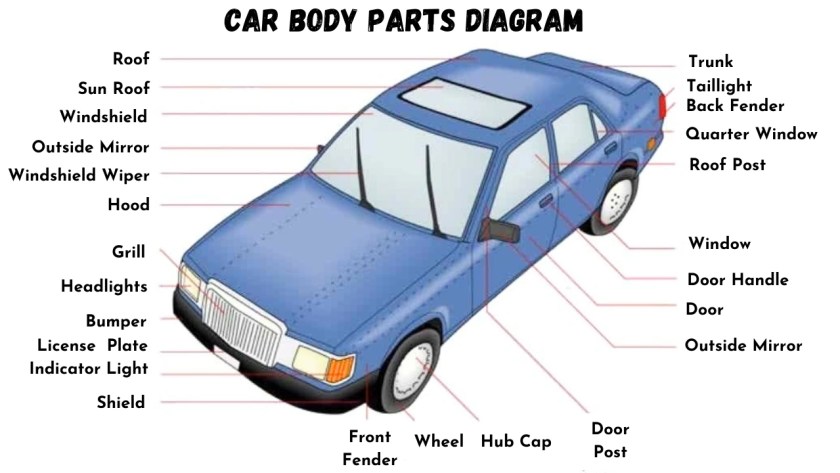

Illustrative image related to various parts of car

Why Are Replacement Parts Important for the Automotive Aftermarket?

Replacement parts play a vital role in the automotive aftermarket by enabling vehicle maintenance and repair. Components like brake pads, filters, and batteries are frequently replaced to ensure vehicles operate safely and efficiently. For businesses in the Middle East and Europe, sourcing high-quality aftermarket parts can enhance customer satisfaction and loyalty. Buyers should prioritize suppliers that offer warranties and have a reputation for quality, as these factors significantly influence the longevity of the parts and the overall vehicle performance.

How Do Fleet Management Companies Benefit from Car Parts?

Fleet management companies rely on a steady supply of various car parts to maintain their vehicles and minimize downtime. Components such as suspension systems and transmission parts are critical for ensuring that commercial vehicles operate smoothly. For international buyers, particularly in emerging markets, negotiating bulk purchasing agreements can lead to significant cost savings. Furthermore, establishing partnerships with suppliers who can provide timely deliveries and technical support is essential to maintain operational efficiency.

What Role Do Components Play in Electric Vehicle Development?

In the burgeoning field of electric vehicle (EV) development, components such as battery systems and electric drive units are crucial. These parts must not only be efficient but also compatible with existing automotive technologies. For B2B buyers in Europe and South America, selecting suppliers with expertise in EV technology can accelerate innovation and support sustainability goals. It is important to assess the technological capabilities of suppliers and their commitment to research and development in order to stay competitive in the rapidly evolving EV market.

How Does Export and Trade Affect Sourcing Car Parts?

In the context of global trade, sourcing car parts for resale in international markets can be a lucrative opportunity. Businesses must navigate complex import/export regulations, tariffs, and local market demands, particularly in regions like Africa and Brazil. Understanding these dynamics helps businesses identify profitable opportunities and mitigate risks. Buyers should seek suppliers who are knowledgeable about international trade practices and can provide insights into market trends, ensuring a competitive edge in sourcing strategies.

3 Common User Pain Points for ‘various parts of car’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Parts

المشكلة: Many B2B buyers in the automotive sector struggle with sourcing high-quality car parts that meet both performance and regulatory standards. This issue is especially prevalent in emerging markets, where inconsistent supplier reliability can lead to delays, increased costs, and compromised vehicle safety. Buyers often find themselves overwhelmed by a multitude of suppliers offering various parts, but lacking clear information on quality, warranty terms, and compatibility with specific vehicle models.

الحل: To effectively source quality car parts, B2B buyers should prioritize building relationships with reputable suppliers who have a proven track record. Conducting thorough research on potential suppliers, including reading reviews and checking certifications, is essential. Buyers can also leverage industry networks and attend trade shows to connect with manufacturers and distributors who specialize in high-quality components. Additionally, implementing a standardized parts catalog can help streamline the selection process, ensuring that all components meet the necessary specifications. Establishing clear communication about expectations regarding quality and compliance can further enhance partnerships and lead to better sourcing outcomes.

Scenario 2: Managing Inventory and Supply Chain Challenges

المشكلة: Inventory management is a critical concern for B2B buyers dealing with various car parts, especially when faced with fluctuating demand and supply chain disruptions. Delays in receiving parts can halt production lines or repair services, leading to lost revenue and dissatisfied customers. Moreover, keeping excessive stock can tie up capital and increase storage costs, making it crucial for buyers to find a balance.

الحل: Implementing an inventory management system that utilizes just-in-time (JIT) principles can significantly mitigate these challenges. By forecasting demand based on historical sales data and market trends, buyers can optimize their inventory levels to align closely with actual needs. Collaborating with suppliers to establish reliable delivery schedules and maintaining open lines of communication can also help ensure timely replenishment of stock. Additionally, adopting technology solutions, such as inventory tracking software, allows buyers to gain real-time insights into stock levels and automate reordering processes. This proactive approach not only enhances efficiency but also reduces the risk of stockouts or overstocking.

Scenario 3: Navigating Regulatory Compliance and Environmental Standards

المشكلة: B2B buyers often face the complex challenge of navigating varying regulatory compliance and environmental standards across different regions. This is particularly relevant for parts such as catalytic converters and exhaust systems, which are subject to strict emission regulations. Non-compliance can result in hefty fines, legal issues, and reputational damage, making it imperative for buyers to understand the specific requirements of the markets they operate in.

الحل: To effectively manage compliance challenges, B2B buyers should invest in a comprehensive understanding of the regulatory landscape within their target markets. This can be achieved through continuous education and resources such as industry publications and regulatory agency updates. Collaborating with legal experts or compliance consultants can provide valuable insights into local regulations and help buyers make informed decisions when sourcing parts. Additionally, working exclusively with manufacturers who prioritize compliance and provide documentation for their products can streamline the procurement process. Establishing a compliance checklist for parts can also help ensure that all purchased components meet the necessary standards, ultimately protecting the buyer’s business and enhancing its reputation in the market.

Strategic Material Selection Guide for various parts of car

When selecting materials for various parts of a car, it is essential to consider the specific properties and performance requirements of each component. Different materials can significantly influence the durability, cost, and manufacturing complexity of automotive parts. Below, we analyze four common materials used in automotive applications, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Steel in Automotive Parts?

Steel is widely used in the automotive industry due to its excellent strength-to-weight ratio and versatility. It can withstand high temperatures and pressures, making it suitable for components like the chassis, engine block, and suspension parts. Steel’s corrosion resistance can be enhanced through galvanization or coatings, making it more durable in harsh environments.

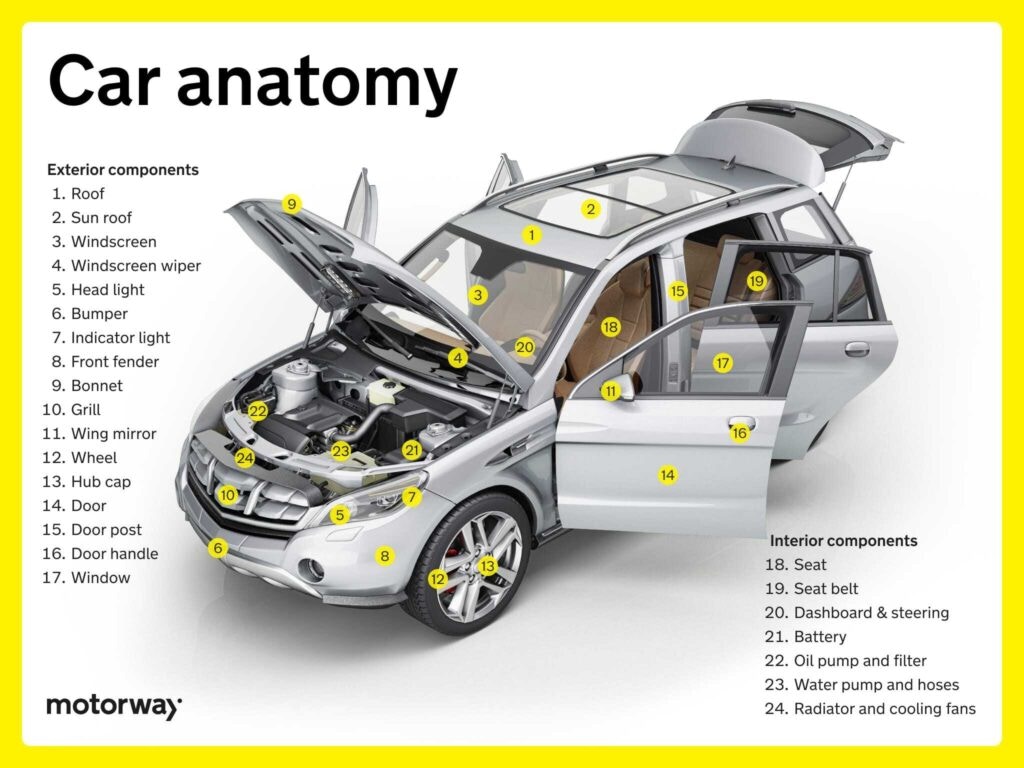

Illustrative image related to various parts of car

الإيجابيات: Steel is relatively inexpensive and readily available, which makes it a cost-effective choice for manufacturers. Its high tensile strength ensures long-lasting performance, especially in structural applications.

السلبيات: The primary drawback of steel is its susceptibility to rust if not properly treated. Additionally, the manufacturing processes for steel components can be complex, requiring specialized equipment and techniques.

التأثير على التطبيق: Steel is compatible with various media, including fuels and lubricants, but care must be taken to ensure that protective coatings are applied to prevent corrosion.

اعتبارات للمشترين الدوليين: Buyers from regions such as Africa and South America should ensure compliance with local and international standards, such as ASTM and DIN, to ensure quality and safety.

How Does Aluminum Enhance Performance in Automotive Applications?

Aluminum is increasingly favored in the automotive sector for its lightweight properties and resistance to corrosion. It is commonly used in engine components, wheels, and body panels. Aluminum can withstand high temperatures, making it suitable for parts that operate under significant thermal stress.

Illustrative image related to various parts of car

الإيجابيات: The lightweight nature of aluminum contributes to improved fuel efficiency and handling. It also offers excellent corrosion resistance, reducing maintenance costs over the vehicle’s lifespan.

السلبيات: Aluminum can be more expensive than steel, and its lower strength compared to steel may require thicker sections or reinforcements in certain applications. The manufacturing process can also be more complex, particularly for high-performance parts.

التأثير على التطبيق: Aluminum is compatible with various automotive fluids and does not corrode easily, making it ideal for components exposed to moisture.

اعتبارات للمشترين الدوليين: Compliance with JIS standards is crucial for buyers in Asia, while European buyers may prioritize adherence to EU regulations regarding material safety and environmental impact.

Illustrative image related to various parts of car

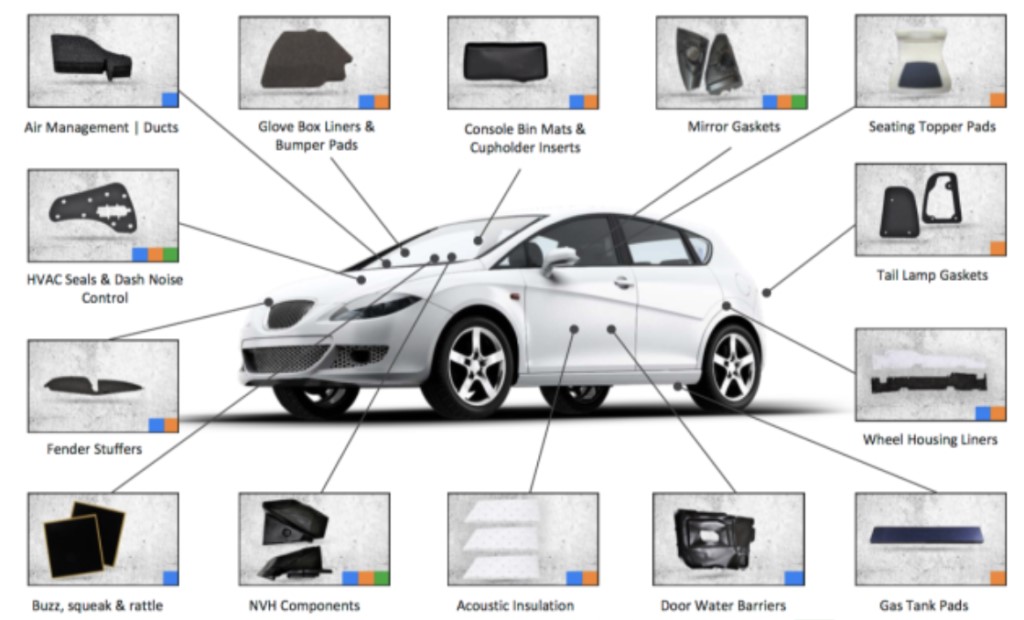

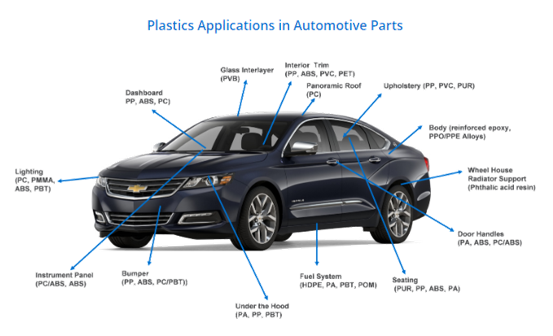

What Role Does Plastic Play in Automotive Parts Manufacturing?

Plastics, particularly engineering-grade polymers, are used extensively in automotive interiors, exterior components, and under-the-hood applications. These materials are lightweight, can be molded into complex shapes, and offer good resistance to chemicals and temperature variations.

الإيجابيات: The primary advantages of plastics include their lightweight nature and flexibility in design. They can reduce overall vehicle weight, contributing to better fuel economy.

السلبيات: Plastics may not provide the same level of structural integrity as metals and can be susceptible to UV degradation if not properly treated. Additionally, they may have limitations in high-temperature applications.

التأثير على التطبيق: Plastics are compatible with various automotive fluids, but specific grades must be chosen to ensure performance in high-temperature or high-pressure environments.

اعتبارات للمشترين الدوليين: Buyers should be aware of the varying regulations regarding plastic materials in different regions, particularly concerning recyclability and environmental impact.

Illustrative image related to various parts of car

Why is Composite Material Gaining Popularity in Automotive Design?

Composite materials, such as carbon fiber and fiberglass, are becoming increasingly popular in high-performance automotive applications due to their exceptional strength-to-weight ratio. They are commonly used in luxury cars and racing vehicles for body panels and structural components.

الإيجابيات: Composites offer superior weight savings and can significantly enhance vehicle performance. Their resistance to corrosion and fatigue makes them suitable for demanding environments.

السلبيات: The primary disadvantage is the high cost of composite materials and the complexity of the manufacturing processes involved, which can limit their use in mass-market vehicles.

التأثير على التطبيق: Composites are compatible with various automotive fluids but require careful consideration regarding bonding and assembly techniques.

اعتبارات للمشترين الدوليين: Buyers should ensure that composite materials meet specific industry standards, such as those set by ASTM, to guarantee performance and safety.

جدول ملخص لاختيار المواد لقطع غيار السيارات

| المواد | Typical Use Case for various parts of car | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الصلب | Chassis, engine block, suspension parts | قوة ومتانة عالية | عرضة للتآكل | منخفض |

| الألومنيوم | Engine components, wheels, body panels | خفيف الوزن ومقاوم للتآكل | تكلفة أعلى وقوام أقل | متوسط |

| بلاستيك | Interior components, exterior parts | تصميم خفيف الوزن ومرن | Lower structural integrity | منخفض |

| مركب | Body panels, structural components | نسبة قوة إلى وزن استثنائية | التكلفة العالية والتصنيع المعقد | عالية |

This strategic material selection guide provides valuable insights for international B2B buyers looking to optimize their automotive parts sourcing and manufacturing processes. Understanding the properties and implications of each material will facilitate informed decision-making and enhance product performance.

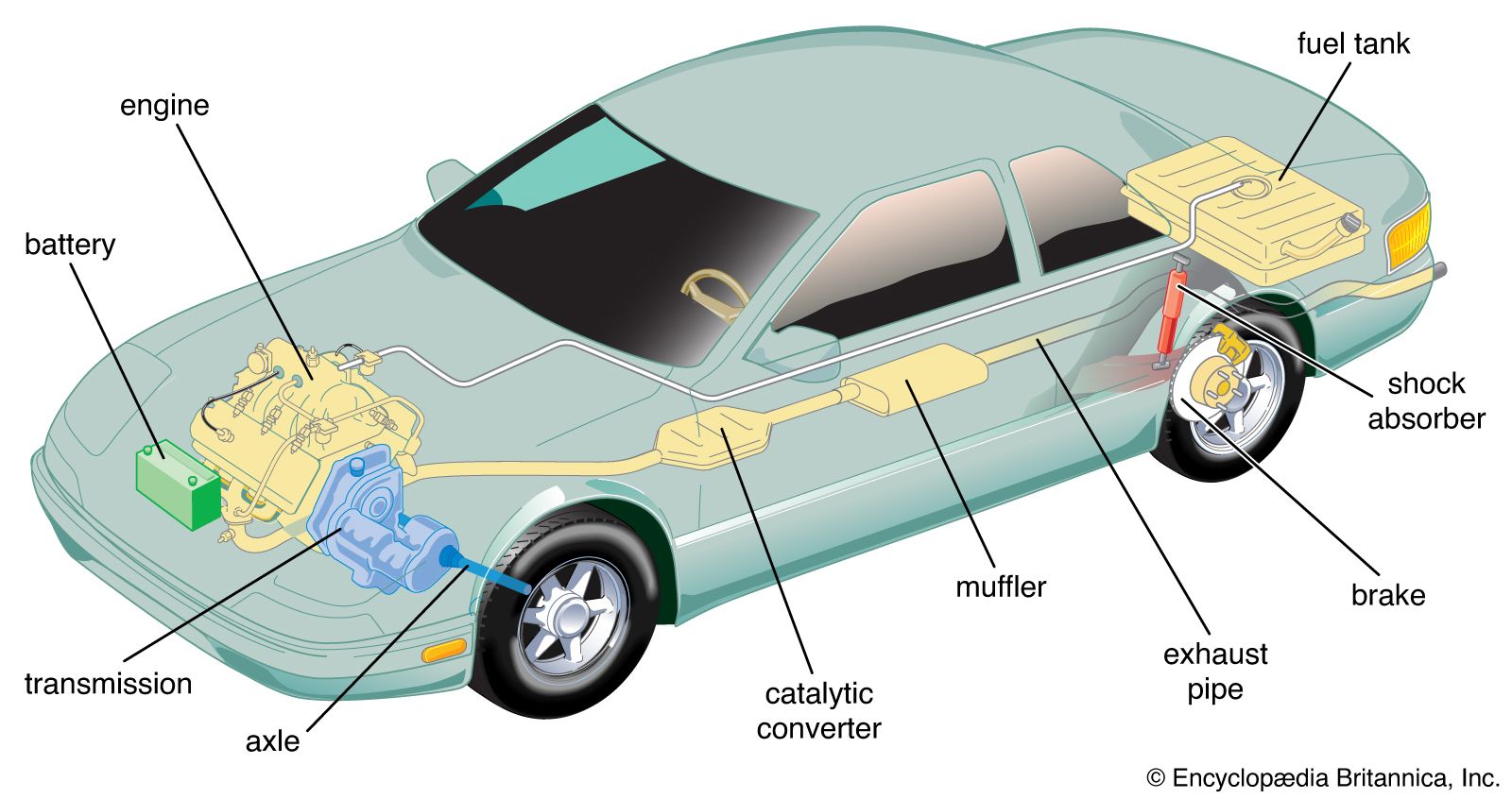

In-depth Look: Manufacturing Processes and Quality Assurance for various parts of car

What Are the Key Stages in the Manufacturing Process of Automotive Parts?

The manufacturing process for automotive parts typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring that the final product meets the high standards required in the automotive industry.

How Is Material Prepared for Automotive Parts Manufacturing?

Material preparation is the first step in the production of automotive components. This involves selecting high-quality raw materials, such as metals (steel, aluminum) and polymers, that will be used in the manufacturing process. Suppliers often conduct thorough inspections of incoming materials to ensure they meet specified standards. This is crucial for B2B buyers, as the quality of raw materials directly impacts the performance and durability of the final parts.

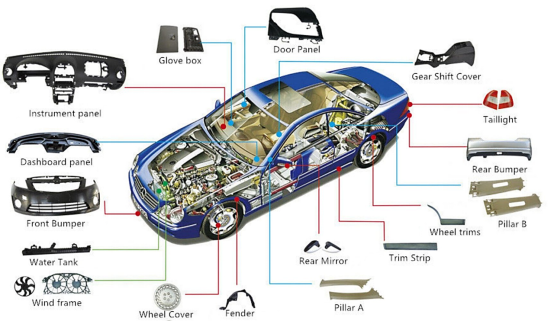

Illustrative image related to various parts of car

Once the materials are sourced, they undergo processes like cutting, machining, and heat treatment to achieve the desired dimensions and properties. For instance, steel components may be tempered to enhance their strength, while aluminum parts might be anodized to improve corrosion resistance.

What Techniques Are Employed in the Forming Stage?

The forming stage is where raw materials are transformed into the required shapes and sizes. Common techniques include:

-

الختم: Used for flat sheet metal parts, stamping involves pressing a die onto the material to cut or shape it. This method is efficient for high-volume production and ensures consistency in part dimensions.

-

اختيار الممثلين For complex shapes, casting techniques such as sand casting or die casting are employed. Molten metal is poured into a mold, allowing it to solidify into the desired shape. This method is particularly useful for engine blocks and other intricate components.

-

القولبة بالحقن: This technique is widely used for producing plastic parts. Polymer granules are heated until molten and then injected into molds. This allows for high precision and repeatability in manufacturing.

These forming techniques require careful control to maintain quality and minimize defects, making them essential considerations for B2B buyers when evaluating suppliers.

How Are Automotive Parts Assembled?

The assembly stage involves the integration of various components into a complete part or system. This process can vary significantly depending on the complexity of the part. For example, assembling an engine involves intricate steps, such as fitting pistons into the cylinder block and installing the crankshaft.

Automation plays a significant role in modern assembly lines, with robotic systems used for repetitive tasks such as welding and fastening. This not only enhances precision but also improves efficiency and reduces labor costs. B2B buyers should consider suppliers with advanced assembly capabilities, as this can lead to better quality control and quicker turnaround times.

Illustrative image related to various parts of car

What Finishing Processes Are Important for Automotive Parts?

Finishing processes are crucial for enhancing the aesthetic and functional properties of automotive parts. Common finishing techniques include:

-

طلاء: Parts may be coated with paints, powder, or other materials to improve their appearance and resistance to environmental factors. This is particularly important for exterior components exposed to harsh conditions.

-

التلميع: For parts that require a smooth surface finish, polishing is essential. This can enhance both the appearance and performance of components like mirrors and chrome fittings.

-

فحص الجودة: Throughout the finishing stage, quality checks are performed to ensure that the finished products meet all specifications and standards.

B2B buyers should look for suppliers that implement rigorous finishing processes, as this can significantly influence the longevity and performance of automotive parts.

What Quality Assurance Standards Should Automotive Parts Meet?

Quality assurance (QA) is critical in the automotive industry to ensure safety, reliability, and compliance with international standards. B2B buyers must understand the various QA standards that apply to automotive parts, including:

Illustrative image related to various parts of car

-

ISO 9001: This international standard focuses on quality management systems and is widely recognized in the automotive sector. Suppliers certified to ISO 9001 demonstrate their commitment to quality and continuous improvement.

-

علامة CE: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

-

معايير واجهة برمجة التطبيقات: The American Petroleum Institute (API) sets standards for lubricants and engine oils, crucial for engine performance and longevity.

كيف يتم إنشاء نقاط التحقق من مراقبة الجودة؟

Quality control (QC) checkpoints are essential throughout the manufacturing process to identify defects and ensure compliance with standards. The typical QC checkpoints include:

-

مراقبة الجودة الواردة (IQC): This involves inspecting raw materials before they are used in production. Suppliers should have a robust IQC process to ensure only quality materials are processed.

-

مراقبة الجودة أثناء الإنتاج (IPQC): Conducted during manufacturing, IPQC checks are crucial for detecting issues early in the production cycle. Techniques such as statistical process control (SPC) are often used here.

-

مراقبة الجودة النهائية (FQC): This is the last step before parts are shipped. FQC involves comprehensive inspections and tests to confirm that parts meet all specifications and quality standards.

B2B buyers should inquire about the QC processes used by suppliers, including the types of tests performed and the frequency of inspections.

What Common Testing Methods Are Used for Automotive Parts?

Testing methods are vital for verifying the performance and safety of automotive parts. Common testing methods include:

-

الاختبار الميكانيكي: This includes tensile tests, fatigue tests, and impact tests to assess the strength and durability of materials.

-

Dimensional Testing: Ensures that parts meet specified tolerances using tools like calipers and coordinate measuring machines (CMM).

-

الاختبار الوظيفي: For critical components like brakes and engines, functional tests simulate real-world conditions to ensure reliability and performance.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

B2B buyers should adopt a proactive approach to verify supplier quality control measures. This can include:

-

عمليات تدقيق الموردين: Conducting regular audits of suppliers to assess their manufacturing processes, quality control systems, and compliance with international standards.

-

تقارير الجودة: Requesting quality reports that detail inspection results, defect rates, and corrective actions taken by the supplier.

-

عمليات التفتيش من طرف ثالث: Engaging independent inspection agencies can provide unbiased assessments of supplier quality and adherence to standards.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين؟

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Factors such as regional regulations, certification requirements, and cultural differences can impact supplier relationships and quality assurance practices.

Illustrative image related to various parts of car

Buyers should ensure that their suppliers understand and comply with local standards while also adhering to international requirements. This dual compliance can significantly reduce risks associated with quality issues and enhance the reliability of the supply chain.

In conclusion, a comprehensive understanding of manufacturing processes and quality assurance standards is essential for B2B buyers in the automotive industry. By focusing on material preparation, forming techniques, assembly, and finishing processes, along with robust quality control measures, buyers can ensure they source high-quality automotive parts that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘various parts of car’

In the competitive landscape of the automotive industry, sourcing various car parts requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This guide provides a comprehensive checklist to assist B2B buyers in procuring essential automotive components.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Establishing clear technical specifications is crucial before initiating the sourcing process. This includes understanding the part’s function, compatibility with existing systems, and any relevant industry standards. Specific details such as dimensions, materials, and performance requirements should be documented to avoid mismatches later in the procurement cycle.

الخطوة 2: إجراء أبحاث السوق

Thorough market research enables buyers to identify potential suppliers and understand pricing structures. Analyze trends in the automotive parts market and gather data on suppliers’ reputations and product offerings. Utilize online platforms, industry reports, and trade shows to gather insights and build a shortlist of potential vendors.

الخطوة 3: تقييم الموردين المحتملين

Before committing to any supplier, a thorough evaluation is necessary. Request company profiles, case studies, and references from other buyers, especially those in your target regions. Pay attention to factors such as production capacity, delivery timelines, and customer service responsiveness.

- Check for Industry Certifications: Ensure suppliers hold relevant certifications (e.g., ISO 9001) that demonstrate their commitment to quality.

- Assess Financial Stability: A financially stable supplier is less likely to face disruptions that could impact your supply chain.

الخطوة 4: Request Samples and Quality Assurance

Requesting samples of the car parts you intend to purchase is an essential step. This allows you to assess the quality and fit of the components before making a bulk order. Evaluate the samples against your specifications and consider conducting tests to verify performance standards.

- تنفيذ تدابير مراقبة الجودة: Establish criteria for quality checks and ensure that suppliers are willing to comply with these standards throughout the production process.

الخطوة 5: التفاوض على الشروط والأسعار

Once you have identified a suitable supplier, enter negotiations to establish favorable terms. This includes pricing, minimum order quantities, payment terms, and delivery schedules. A well-structured agreement can help mitigate risks and ensure a smooth transaction.

- Consider Long-Term Partnerships: Building a long-term relationship with a supplier can lead to better pricing and priority service, enhancing your overall procurement strategy.

الخطوة 6: Plan for Logistics and Distribution

Effective logistics planning is vital for timely delivery of car parts. Coordinate with suppliers to understand their shipping capabilities and timelines. Evaluate potential customs and import regulations that may affect delivery, especially when sourcing internationally.

- Assess Shipping Costs and Options: Compare various shipping methods and their costs to find the most efficient solution that meets your timeline and budget.

الخطوة 7: مراقبة أداء الموردين

After procurement, it’s important to continuously monitor supplier performance. Regularly review delivery timelines, quality of parts received, and responsiveness to issues. This ongoing evaluation can help in making informed decisions for future sourcing.

Illustrative image related to various parts of car

By following this structured checklist, B2B buyers can enhance their sourcing process for various car parts, ensuring they secure high-quality components that meet their operational needs while optimizing costs.

Comprehensive Cost and Pricing Analysis for various parts of car Sourcing

ما هي مكونات التكلفة الرئيسية في توريد قطع غيار السيارات؟

When analyzing the cost structure for sourcing various car parts, several fundamental components must be considered. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

المواد: The choice of materials significantly impacts the overall cost. For instance, high-quality steel or specialized composites used in engine components will increase material costs. Buyers should consider the trade-off between cost and durability when selecting materials for their specific needs.

-

العمل: Labor costs vary by region and can be influenced by local wage standards and the complexity of manufacturing processes. Skilled labor may come at a premium, especially in regions with stringent quality requirements.

-

تكاليف التصنيع العامة: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive prices.

-

الأدوات: Tooling costs can be substantial, particularly for custom parts. Buyers should inquire about the tooling required for specific components, as this can add to the upfront investment.

-

مراقبة الجودة: QC measures are vital for ensuring that parts meet required specifications. Enhanced QC processes can raise costs but are necessary for maintaining safety and performance standards.

-

اللوجستيات: Transportation and warehousing play a crucial role in the final pricing of car parts. Understanding the logistics involved, including shipping methods and costs, is essential for accurate budgeting.

-

الهامش: Finally, suppliers will include a margin to cover risks and ensure profitability. This margin can vary widely based on the supplier’s market position and the complexity of the part.

كيف تؤثر العوامل المؤثرة في الأسعار على توريد قطع غيار السيارات؟

Several factors influence pricing, making it essential for buyers to understand the dynamics at play:

-

الحجم/الحد الأدنى للطلب: Larger orders typically lead to lower per-unit costs. Establishing a minimum order quantity (MOQ) can help suppliers manage production efficiently while providing buyers with better pricing.

-

المواصفات والتخصيص: Customized parts often come at a premium. Buyers should clearly define specifications to avoid unnecessary costs associated with changes or redesigns.

-

جودة المواد والشهادات: Parts that require specific certifications (e.g., ISO, IATF) may incur higher costs. Buyers should assess whether these certifications are necessary for their market.

-

عوامل الموردين: The reliability and reputation of suppliers can influence pricing. Established suppliers may charge more due to their track record of quality and delivery.

-

مصطلحات التجارة الدولية: Understanding the terms of shipping and delivery can significantly impact the total cost. Incoterms dictate responsibilities between buyers and sellers, affecting logistics costs and risks.

What Are the Best Negotiation and Cost-Efficiency Strategies for Buyers?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, implementing strategic approaches can enhance cost efficiency:

-

التفاوض على الشروط: Buyers should be prepared to negotiate on price, payment terms, and delivery schedules. Establishing long-term relationships can lead to better terms over time.

-

التكلفة الإجمالية للملكية (TCO): Evaluate the TCO rather than just the upfront price. Consider factors such as maintenance, durability, and potential downtime, which can significantly affect overall costs.

-

فهم الفروق الدقيقة في الأسعار: International buyers must be aware of currency fluctuations, import duties, and local regulations that can influence pricing. Engaging local experts can provide valuable insights.

-

Leverage Technology: Utilizing digital platforms for sourcing can streamline communication and reduce lead times, contributing to overall cost savings.

By understanding these components and strategies, B2B buyers can make informed decisions, optimizing their sourcing of car parts to align with their operational needs and budget constraints.

Illustrative image related to various parts of car

إخلاء المسؤولية: الأسعار والتكاليف المذكورة إرشادية ويمكن أن تختلف بناءً على ظروف السوق ومفاوضات الموردين ومتطلبات المشتري المحددة.

Alternatives Analysis: Comparing various parts of car With Other Solutions

Exploring Alternatives to Traditional Car Parts

In the automotive industry, understanding the various parts of a car is crucial for maintaining performance and safety. However, as technology evolves, alternative solutions and methods emerge that can offer similar functionalities. This analysis compares traditional car parts against alternative technologies that can enhance vehicle performance and efficiency.

| جانب المقارنة | Various Parts Of Car | البديل 1 الاسم البديل 1 | البديل 2 الاسم البديل 2 |

|---|---|---|---|

| الأداء | High reliability and performance | السيارة الكهربائية (EV) | الأنظمة الهجينة |

| التكلفة | Moderate to high initial investment | Higher upfront costs | Moderate initial costs |

| سهولة التنفيذ | Established manufacturing processes | Requires charging infrastructure | Requires dual systems |

| الصيانة | Regular checks and replacements needed | انخفاض احتياجات الصيانة | احتياجات صيانة معتدلة |

| أفضل حالة استخدام | Ideal for traditional combustion engines | Urban commuting | السفر لمسافات طويلة |

What are the Pros and Cons of Electric Vehicles as an Alternative?

Electric Vehicles (EVs) represent a significant shift in automotive technology. They offer high reliability and performance while reducing emissions. However, the upfront costs can be considerably higher than traditional vehicles, and the need for a comprehensive charging infrastructure can be a barrier in regions with limited access to electric stations. On the maintenance front, EVs generally require less frequent servicing compared to traditional vehicles, as they have fewer moving parts. Overall, EVs are best suited for urban commuting, where charging stations are readily available.

Illustrative image related to various parts of car

How Do Hybrid Systems Compare to Traditional Car Parts?

Hybrid systems combine traditional internal combustion engines with electric propulsion. This dual approach allows for improved fuel efficiency and lower emissions, making hybrids an attractive alternative. The initial investment is moderate compared to full EVs, but still higher than conventional vehicles. Hybrids require a more complex maintenance routine due to their dual systems, which can be a downside. They excel in long-distance travel, offering the flexibility of gasoline and electric power, making them suitable for diverse driving conditions.

Conclusion: How Should B2B Buyers Choose the Right Automotive Solution?

When selecting between traditional car parts and alternative solutions, B2B buyers must consider their specific operational needs and the regional market landscape. Factors such as performance requirements, cost considerations, ease of implementation, and maintenance capabilities play a crucial role in decision-making. By evaluating these aspects, buyers can determine the most suitable option that aligns with their business goals and customer demands, ensuring they invest in a solution that meets both current and future automotive trends.

Essential Technical Properties and Trade Terminology for various parts of car

ما هي الخصائص التقنية الأساسية لقطع غيار السيارات؟

Understanding the technical properties of car components is vital for B2B buyers to ensure they procure parts that meet quality and performance standards. Here are some critical specifications to consider:

-

درجة المواد

The material grade refers to the quality and composition of the materials used in car parts, such as steel, aluminum, or composite materials. Higher-grade materials typically offer better durability, corrosion resistance, and performance. For example, automotive steel grades like ASTM A572 are often used in structural components due to their strength and weldability. Selecting the right material grade is crucial for ensuring long-lasting components that meet safety standards and reduce maintenance costs. -

التسامح

Tolerance indicates the allowable variation in dimensions for manufactured parts. For instance, a tolerance of ±0.01 mm means the actual dimension can vary by one hundredth of a millimeter. Precise tolerances are essential in parts such as engine components and transmission systems, where even minor deviations can lead to performance issues or failure. Understanding tolerance requirements helps buyers ensure parts fit correctly and function as intended, which is particularly important in high-performance applications. -

Heat Treatment Specification

Many metal parts undergo heat treatment to enhance their mechanical properties, such as hardness and strength. Specifications like quenching and tempering processes are crucial for components like gears and axles, which experience high stress. Buyers should inquire about the heat treatment processes used to ensure they are acquiring parts that can withstand operational demands, particularly in heavy-duty applications. -

Finish Type

The finish type refers to the surface treatment applied to car parts, which can impact corrosion resistance, friction, and aesthetics. Common finishes include anodizing, powder coating, and galvanizing. A well-defined finish specification ensures that parts not only meet functional requirements but also align with branding and design standards. For instance, powder-coated parts are often preferred for their durability and visual appeal. -

Load Rating

Load rating is a critical property for components like suspension systems and wheel bearings, indicating the maximum load a part can safely carry. Understanding load ratings helps buyers select appropriate components based on vehicle weight, intended use, and performance requirements. This knowledge is particularly crucial for B2B buyers in sectors such as commercial transportation, where safety and reliability are paramount.

ما هي المصطلحات التجارية الشائعة في صناعة قطع غيار السيارات؟

Familiarity with industry jargon enhances communication and transaction efficiency in B2B environments. Here are some key terms:

Illustrative image related to various parts of car

-

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are typically designed to fit and perform as intended, ensuring compatibility and reliability. B2B buyers often prefer OEM parts for their quality assurance, although they may come at a premium compared to aftermarket alternatives. -

MOQ (الحد الأدنى لكمية الطلب)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory effectively and negotiate better pricing. Setting an appropriate MOQ can also help suppliers streamline production and reduce costs, making it a critical term in procurement discussions. -

طلب عرض أسعار (RFQ)

An RFQ is a formal document that buyers send to suppliers to request pricing and terms for specific products. It often includes details about specifications, quantities, and delivery timelines. Using RFQs can help buyers compare offers from multiple suppliers, facilitating informed purchasing decisions. -

شروط التجارة الدولية (Incoterms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) clarify who bears the costs and risks at various stages of the shipping process. Familiarity with Incoterms is crucial for B2B buyers to understand shipping responsibilities and avoid misunderstandings. -

سوق ما بعد البيع

The aftermarket refers to parts and accessories sold after the original vehicle purchase. These components can range from performance upgrades to replacement parts. Understanding the aftermarket landscape allows buyers to explore alternative sourcing options, often at lower costs, while ensuring they meet quality standards.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right parts for their automotive needs.

Navigating Market Dynamics and Sourcing Trends in the various parts of car Sector

What Are the Key Market Dynamics and Sourcing Trends for Car Parts?

The automotive parts market is undergoing significant transformation driven by several global trends. A major factor is the shift towards electrification, as electric vehicles (EVs) gain market share. This transition is prompting international B2B buyers, particularly in regions like Africa and South America, to explore sourcing opportunities in EV components, including batteries and electric drivetrains. Additionally, the rise of connected vehicles has led to increased demand for advanced electronic parts, such as sensors and infotainment systems, reshaping sourcing strategies and supplier relationships.

Emerging technologies like blockchain and AI are also influencing sourcing trends. Blockchain offers enhanced transparency in supply chains, which is crucial for buyers seeking reliable partners. AI-driven analytics can optimize inventory management and demand forecasting, allowing B2B buyers to make data-driven decisions that minimize costs and improve efficiency. In markets like Europe, where regulatory pressures are high, compliance with safety and environmental standards is becoming a focal point for procurement processes.

Moreover, international buyers are increasingly seeking local suppliers to mitigate risks associated with global supply chain disruptions. This trend is particularly evident in markets like Brazil and Vietnam, where local sourcing can enhance responsiveness and reduce lead times. As the automotive landscape evolves, B2B buyers must stay agile and informed to capitalize on these emerging trends.

How Can Sustainability and Ethical Sourcing Impact the Car Parts Industry?

Sustainability is no longer just a buzzword; it has become a critical consideration for B2B buyers in the automotive parts sector. The environmental impact of manufacturing processes and raw materials is under scrutiny, prompting companies to adopt more sustainable practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing carbon footprints and implementing eco-friendly manufacturing processes.

Ethical sourcing is also gaining prominence, as consumers and regulators demand transparency in supply chains. For B2B buyers, this means selecting suppliers that adhere to ethical labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and Fair Trade for ethical labor practices are becoming essential benchmarks. Buyers should look for suppliers who can provide evidence of these certifications, ensuring that their sourcing decisions align with broader corporate social responsibility goals.

Additionally, the use of ‘green’ materials, such as recycled plastics and bio-based composites, is on the rise. Sourcing parts made from sustainable materials not only helps in meeting regulatory requirements but also enhances brand reputation among environmentally conscious consumers. As sustainability continues to shape the automotive landscape, B2B buyers who prioritize ethical sourcing will be well-positioned to thrive in this evolving market.

What Historical Trends Have Influenced Current Car Parts Sourcing Strategies?

The history of the automotive parts industry reveals a trajectory of adaptation and innovation. Initially dominated by mechanical components, the sector has seen a shift towards electronic and software-based parts, particularly with the advent of the digital age. The introduction of advanced manufacturing technologies, such as 3D printing and robotics, has revolutionized production processes, enabling faster prototyping and reduced costs.

In the past, sourcing strategies were heavily reliant on a few key suppliers, often located in regions with established automotive industries. However, recent global events, including trade tensions and the COVID-19 pandemic, have prompted a reevaluation of these strategies. B2B buyers are now more inclined to diversify their supply chains, seeking out suppliers across various regions to mitigate risks and enhance flexibility.

Understanding this historical context allows international buyers to make informed decisions about sourcing car parts in today’s complex landscape. By learning from past trends, companies can better navigate the current challenges and seize opportunities for growth in the automotive parts market.

Frequently Asked Questions (FAQs) for B2B Buyers of various parts of car

-

كيف يمكنني ضمان جودة قطع غيار السيارات عند التوريد من الخارج؟

To ensure the quality of car parts when sourcing internationally, start by vetting suppliers through their certifications, customer reviews, and industry reputation. Request samples to assess the quality firsthand and inquire about their quality assurance processes. Establish clear specifications and standards that the parts must meet. It’s also beneficial to conduct factory audits or use third-party inspection services to verify that the products adhere to international quality standards before making a purchase. -

ما هي أفضل طريقة للعثور على موردين موثوقين لقطع غيار السيارات؟

The best way to find reliable suppliers for car parts involves leveraging multiple channels. Begin with industry trade shows and exhibitions, where you can meet suppliers face-to-face. Online marketplaces and B2B directories can also provide valuable insights and contacts. Networking within industry forums and seeking recommendations from other businesses can yield trustworthy leads. Lastly, consider using sourcing agents who specialize in the automotive sector to help identify reputable suppliers. -

What are the typical minimum order quantities (MOQs) for car parts?

Minimum order quantities (MOQs) for car parts can vary significantly based on the supplier, type of part, and customization requirements. Generally, MOQs can range from as low as 50 to several thousand units. It’s crucial to discuss your specific needs with potential suppliers, as many are willing to negotiate MOQs, especially for new relationships or long-term contracts. Understanding the supplier’s production capabilities and inventory levels can also aid in determining feasible order sizes. -

What payment terms should I expect when sourcing car parts?

Payment terms in the automotive parts industry can vary widely but typically include options like 30% upfront payment with the balance due upon delivery or net 30 days after receipt. Some suppliers may offer more favorable terms for larger orders or established relationships. Always clarify payment methods accepted, such as wire transfers or letters of credit, and ensure that all terms are documented in the purchase agreement to avoid misunderstandings. -

How can I customize car parts for my specific requirements?

To customize car parts for your specific requirements, start by clearly defining your needs and specifications, including materials, dimensions, and performance criteria. Communicate these details to potential suppliers, who may offer customization options or suggest modifications to existing parts. It’s essential to collaborate closely during the design and prototyping phases to ensure the final product meets your expectations. Additionally, be prepared for potential lead time extensions and cost implications associated with custom manufacturing. -

ما هي الاعتبارات اللوجستية التي يجب مراعاتها عند استيراد قطع غيار السيارات؟

When importing car parts, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder with experience in handling automotive shipments to navigate international shipping complexities. Be aware of import duties, taxes, and compliance with local regulations in your destination country. Additionally, ensure that the supplier provides necessary documentation, including packing lists and certificates of origin, to facilitate smooth customs clearance. -

What are the common challenges faced when sourcing car parts internationally?

Common challenges in sourcing car parts internationally include language barriers, cultural differences, and variations in quality standards. Additionally, fluctuating currency exchange rates can impact pricing. Delays in shipping and customs clearance may also pose risks to timely delivery. To mitigate these issues, establish clear communication channels with suppliers, conduct thorough research on regulations, and build strong relationships to enhance collaboration and problem-solving capabilities. -

How can I stay informed about the latest trends in automotive parts?

To stay informed about the latest trends in automotive parts, regularly engage with industry publications, blogs, and news sites that focus on automotive technology and market insights. Joining professional associations and participating in industry conferences can provide valuable networking opportunities and access to expert opinions. Social media platforms and online forums are also excellent resources for real-time updates and discussions. Subscribing to newsletters from leading manufacturers and distributors can further keep you updated on innovations and market shifts.

A Look at Various Parts Of Car Manufacturers & Suppliers

Could not verify enough suppliers for various parts of car to create a list at this time.

Strategic Sourcing Conclusion and Outlook for various parts of car

In navigating the complexities of the automotive parts market, strategic sourcing emerges as a critical approach for international B2B buyers. Understanding the intricacies of various car components—from engines and transmissions to braking systems and electrical parts—enables buyers to make informed decisions that enhance operational efficiency and reduce costs. Engaging with reputable suppliers who offer high-quality parts ensures not only compliance with safety standards but also contributes to the longevity and reliability of vehicles.

For businesses in Africa, South America, the Middle East, and Europe, cultivating relationships with manufacturers and distributors can provide a competitive edge. By leveraging regional strengths and understanding local market dynamics, buyers can optimize their supply chains and reduce lead times.

Looking ahead, the automotive industry is poised for transformation with advancements in electric vehicles and sustainable technologies. As these trends unfold, now is the time for B2B buyers to reassess their sourcing strategies, align with innovative suppliers, and prepare for a future where adaptability and sustainability are paramount. Embrace the opportunity to enhance your procurement processes and drive your business forward in this evolving landscape.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.