مقدمة: الإبحار في السوق العالمي ل que es el solenoide

في المشهد التنافسي اليوم، فإن فهم ما هو السولينويد أمر بالغ الأهمية للمشترين من الشركات الذين يبحثون عن حلول موثوقة للتحكم في السوائل والأتمتة. ومع تزايد اعتماد الصناعات في جميع أنحاء أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا على الملفات اللولبية لتحقيق الكفاءة التشغيلية، فإن الحصول على المكونات المناسبة يمكن أن يشكل تحديات كبيرة. يهدف هذا الدليل إلى إزالة الغموض عن الملف اللولبي، وتقديم رؤى حول أنواعه وتطبيقاته والعوامل الحاسمة التي يجب مراعاتها عند اختيار المورد.

من خلال هذا المورد الشامل، سوف نستكشف من خلال هذا المورد الشامل تصميمات الملفات اللولبية المختلفة، ووظائفها في مختلف الصناعات، وكيفية مساهمتها في تحويل الطاقة الكهربائية إلى حركة ميكانيكية. كما سنتعمق أيضًا في تعقيدات فحص الموردين، واعتبارات التكلفة، وأحدث التطورات التكنولوجية التي يمكن أن تؤثر على قرارات الشراء الخاصة بك.

من خلال تزويد المشترين الدوليين من الشركات برؤى قابلة للتنفيذ وتوصيات الخبراء، يمكّنك هذا الدليل من اتخاذ قرارات مستنيرة تعزز قدراتك التشغيلية. وسواء كنت تعمل في قطاع السيارات أو الهيدروليك أو أي قطاع آخر يستخدم الملفات اللولبية، فإن فهم هذه المكونات ضروري لزيادة الكفاءة وضمان الجودة في عمليات الشراء الخاصة بك. دعنا نتعرف على تعقيدات السوق العالمية للملفات اللولبية معًا، مما يضمن لك العثور على أفضل الحلول المصممة خصيصًا لتلبية احتياجات عملك.

جدول المحتويات

- قائمة المُصنِّعين والموردين لأعلى 2 Que Es El Solenoide قائمة المصنعين والموردين

- مقدمة: الإبحار في السوق العالمي ل que es el solenoide

- فهم que es que es el solenoide أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لمصطلح que es el solenoide

- 3 نقاط ألم شائعة لدى المستخدمين ‘que es el solenoide’ وحلولها

- دليل اختيار المواد الاستراتيجية ل que es el solenoide

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لمصنع que es el solenoide

- دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة ‘que es el solenoide’

- تحليل شامل للتكلفة والتسعير لمصادر que es el solenoide Sourcing

- تحليل البدائل: مقارنة que es el solenoide مع الحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية ل que es el solenoide

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع que es el solenoide

- الأسئلة المتداولة (FAQs) لمشتري B2B من que es el solenoide

- استنتاجات وتوقعات التوريد الاستراتيجي لـ que es el solenoide

- إخلاء مسؤولية هام وشروط الاستخدام

فهم que es que es el solenoide أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| الملفات اللولبية الكهرومغناطيسية | تعمل باستخدام المجالات الكهرومغناطيسية؛ متعددة الاستخدامات. | التحكم في السوائل في التدفئة والتهوية وتكييف الهواء والسيارات. | الإيجابيات: دقة عالية; السلبيات: حساسة للتقلبات الكهربائية. |

| الملفات اللولبية الهوائية | مصممة لأنظمة ضغط الهواء؛ تصميم قوي. | الأتمتة الصناعية والتعبئة والتغليف. | الإيجابيات: متينة; السلبيات: يقتصر على التطبيقات الهوائية. |

| الملفات اللولبية الهيدروليكية | خصيصًا للتحكم في السوائل؛ الضغط العالي. | الآلات الثقيلة ومعدات البناء. | الإيجابيات: يتعامل مع معدلات التدفق العالية; السلبيات: حجم ووزن أكبر. |

| الملفات اللولبية التناسبية | تحكم متغير في معدلات التدفق؛ تعديلات دقيقة. | الروبوتات وماكينات التحكم الرقمي باستخدام الحاسوب. | الإيجابيات: دقة عالية; السلبيات: أكثر تعقيداً وتكلفة. |

| ملفات لولبية قابلة للإغلاق | تحافظ على الوضع بدون طاقة مستمرة؛ موفرة للطاقة. | أنظمة الأمان والأقفال الذكية. | الإيجابيات: استهلاك منخفض للطاقة; السلبيات: وقت استجابة أبطأ. |

ما هي الملفات اللولبية الكهرومغناطيسية وتطبيقاتها؟

الملفات اللولبية الكهرومغناطيسية هي النوع الأكثر شيوعًا، حيث تستخدم المجالات الكهرومغناطيسية لتحويل الطاقة الكهربائية إلى حركة ميكانيكية. إن تعدد استخداماتها يجعلها مناسبة لمجموعة متنوعة من التطبيقات، خاصة في أنظمة التحكم في السوائل في صناعات التدفئة والتهوية وتكييف الهواء والسيارات. يجب على المشترين النظر في حساسية الملف اللولبي للتقلبات الكهربائية، والتي يمكن أن تؤثر على الأداء، وضمان التوافق مع الأنظمة الحالية.

كيف تعمل الملفات اللولبية الهوائية في الأتمتة الصناعية؟

الملفات اللولبية الهوائية مصممة خصيصًا لأنظمة ضغط الهواء وغالبًا ما توجد في تطبيقات الأتمتة الصناعية والتعبئة والتغليف. يسمح تصميمها القوي بتحمل البيئات القاسية. وعلى الرغم من أنها متينة وموثوقة، إلا أنها تقتصر على التطبيقات الهوائية، والتي قد لا تناسب جميع احتياجات المشترين. يجب على الشركات تقييم متطلبات ضغط الهواء المحددة لعملياتها عند اختيار هذه الملفات اللولبية.

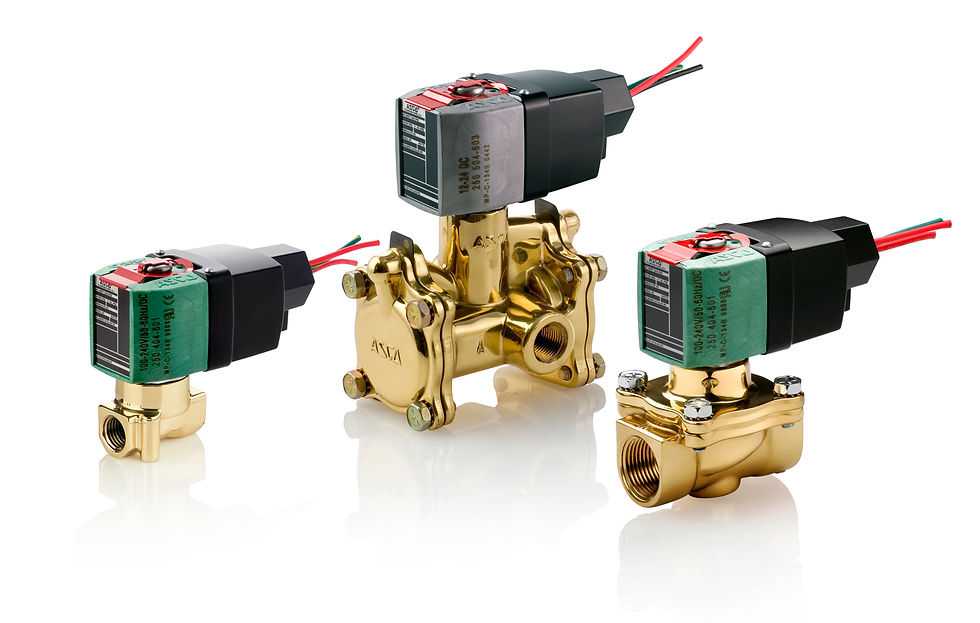

ما هي الميزات الرئيسية للملفات اللولبية الهيدروليكية؟

صُممت الملفات اللولبية الهيدروليكية لإدارة التحكم في السوائل، خاصةً في ظروف الضغط العالي، مما يجعلها لا غنى عنها في الآلات الثقيلة ومعدات البناء. وتعد قدرتها على التعامل مع معدلات التدفق العالية ميزة كبيرة في البيئات الصعبة. ومع ذلك، يجب على المشترين المحتملين أن يكونوا على دراية بحجمها ووزنها الأكبر، مما قد يؤثر على التركيب والاندماج في الأنظمة الحالية.

لماذا تختار الملفات اللولبية التناسبية للتحكم الدقيق؟

تسمح الملفات اللولبية التناسبية بالتحكم المتغير في معدلات التدفق، مما يجعلها مثالية للتطبيقات في الروبوتات وماكينات التحكم الرقمي باستخدام الحاسوب التي تتطلب تعديلات دقيقة. وعلى الرغم من أنها توفر دقة عالية، إلا أن تعقيدها وتكلفتها المرتفعة قد يثني بعض المشترين. من الضروري أن تقوم الشركات بتقييم التوازن بين احتياجات الدقة وقيود الميزانية عند التفكير في هذه الملفات اللولبية.

ما هي فوائد الملفات اللولبية القابلة للإغلاق في أنظمة الأمان؟

الملفات اللولبية ذات الإغلاق فريدة من نوعها من حيث قدرتها على الحفاظ على موضعها بدون طاقة مستمرة، مما يجعلها موفرة للطاقة ومثالية لتطبيقات مثل أنظمة الأمان والأقفال الذكية. يعد استهلاكها المنخفض للطاقة ميزة كبيرة؛ ومع ذلك، قد يكون وقت استجابتها أبطأ مقارنة بالأنواع الأخرى. يجب أن يوازن المشترون بين مزايا كفاءة الطاقة والحاجة المحتملة للتشغيل الأسرع في تطبيقاتهم الخاصة.

التطبيقات الصناعية الرئيسية لمصطلح que es el solenoide

| الصناعة/القطاع | تطبيق محدد ل que es el solenoide | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | التحكم في أنظمة سحب الوقود والهواء | يعزز كفاءة المحرك ويقلل من الانبعاثات | الموثوقية، وتحمل درجات الحرارة، والتوافق مع أنظمة المحرك. |

| المكونات الهيدروليكية | التحكم في السوائل في الماكينات الهيدروليكية | تحسين الكفاءة التشغيلية وتقليل وقت التعطل | مقاومة التآكل، ومعدلات الضغط، وآليات الختم المناسبة. |

| معالجة المياه | صمامات آلية لتنظيم تدفق المياه | يضمن ثبات جودة المياه وسلامة التشغيل | الامتثال للوائح البيئية والمتانة ضد التعرض للمواد الكيميائية. |

| التصنيع | الأتمتة في خطوط التجميع | زيادة الإنتاجية وتقليل تكاليف العمالة | الدقة في التشغيل ووقت الاستجابة والتكامل مع الأنظمة الحالية. |

| أنظمة التدفئة والتهوية وتكييف الهواء | تنظيم تدفق غاز التبريد في وحدات تكييف الهواء | يحسن كفاءة الطاقة وأداء النظام | تصنيفات استهلاك الطاقة، وسرعة الاستجابة، وجودة المواد من أجل المتانة. |

كيف يتم استخدام ‘que es el solenoide’ في صناعة السيارات؟

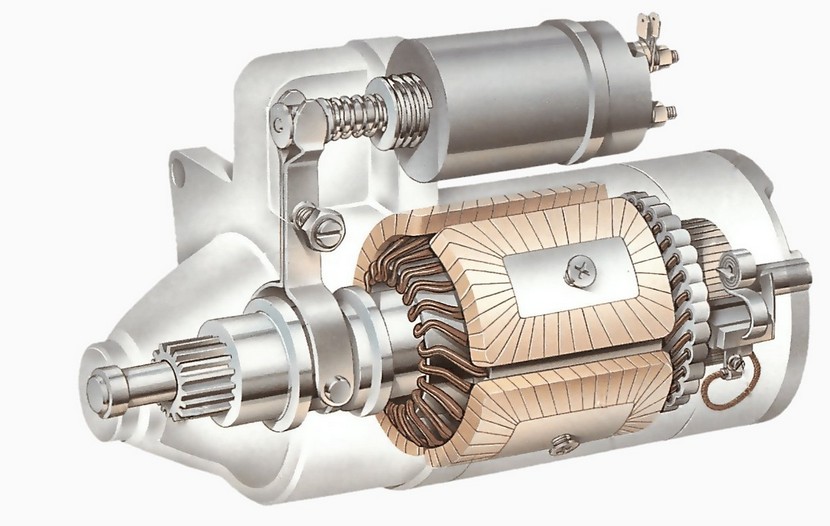

في قطاع السيارات، تلعب الملفات اللولبية دورًا حاسمًا في التحكم في أنظمة سحب الوقود والهواء، والتي تعتبر حيوية لأداء المحرك. من خلال تنظيم تدفق هذه المكونات الأساسية بدقة، تعمل الملفات اللولبية على تحسين كفاءة المحرك وتقليل الانبعاثات، وهو أمر مهم بشكل متزايد بسبب اللوائح البيئية الصارمة. بالنسبة للمشترين الدوليين، يعد الحصول على الملفات اللولبية ذات الموثوقية العالية وتحمل درجات الحرارة أمرًا بالغ الأهمية، خاصة في المناطق ذات الظروف الجوية القاسية.

ما هو الدور الذي تلعبه الملفات اللولبية في المكونات الهيدروليكية؟

في الأنظمة الهيدروليكية، يتم استخدام الملفات اللولبية للتحكم في تدفق السوائل، مما يسهل تشغيل الآلات مثل الحفارات والرافعات الشوكية. تضمن آلية التحكم هذه تشغيل الأنظمة الهيدروليكية بكفاءة، مما يقلل من وقت التعطل وتكاليف الصيانة. يجب على المشترين إعطاء الأولوية للملفات اللولبية التي توفر مقاومة للتآكل وتصنيفات ضغط مناسبة، خاصة في القطاعات الصناعية السائدة في أمريكا الجنوبية والشرق الأوسط، حيث تكون ظروف التشغيل القاسية شائعة.

كيف يتم دمج الملفات اللولبية في معالجة المياه؟

في منشآت معالجة المياه، تُستخدم الملفات اللولبية في الصمامات الآلية لتنظيم تدفق المياه، مما يضمن جودة المياه وسلامتها بشكل متسق. وتساعد هذه الأجهزة في إدارة توزيع المياه المعالجة، مما يجعلها ضرورية للعمليات الفعالة. يجب على المشترين في هذا القطاع مراعاة الامتثال للوائح البيئية ومتانة الملفات اللولبية ضد التعرض للمواد الكيميائية، خاصة في مناطق مثل أفريقيا حيث جودة المياه أمر بالغ الأهمية.

لماذا تعتبر الملفات اللولبية مهمة في أتمتة التصنيع؟

في مجال التصنيع، تُعد الملفات اللولبية جزءًا لا يتجزأ من عمليات الأتمتة على خطوط التجميع، مما يسمح بالتحكم الدقيق في العمليات المختلفة. تزيد هذه الأتمتة من الإنتاجية وتقلل من تكاليف العمالة بشكل كبير، مما يجعلها استثمارًا مناسبًا للشركات. عند تحديد مصادر الملفات اللولبية، يجب على الشركات المصنعة التركيز على الدقة في التشغيل ووقت الاستجابة، وضمان التوافق مع أنظمة الأتمتة الحالية لتحسين كفاءة الإنتاج.

كيف تعمل الملفات اللولبية على تحسين أداء نظام التدفئة والتهوية وتكييف الهواء (HVAC)؟

في أنظمة التدفئة والتهوية وتكييف الهواء، تُستخدم الملفات اللولبية لتنظيم تدفق المبردات، وهو أمر بالغ الأهمية للحفاظ على الأداء الأمثل للنظام. من خلال ضمان تدفق المبردات بشكل صحيح، تعمل الملفات اللولبية على تحسين كفاءة الطاقة وموثوقية النظام بشكل عام. يجب على المشترين تقييم الملفات اللولبية استنادًا إلى تصنيفات استهلاك الطاقة وجودة المواد، خاصةً في أوروبا حيث معايير كفاءة الطاقة صارمة، مما يضمن حلول تدفئة وتكييف وتدفئة وتهوية وتبريد وتدفئة وتكييف فعالة وطويلة الأمد.

3 نقاط ألم شائعة لدى المستخدمين ‘que es el solenoide’ وحلولها

السيناريو 1: صعوبة اختيار الملف اللولبي المناسب لتطبيقات محددة

المشكلة: غالبًا ما يواجه المشترون من الشركات صعوبة في تحديد الملف اللولبي الأنسب لاحتياجات تطبيقاتهم الخاصة. مع وجود مجموعة كبيرة من الملفات اللولبية المتاحة، بما في ذلك مختلف الأحجام وتصنيفات الطاقة والتكوينات، قد يكون من الصعب اختيار ملف لولبي يلبي المواصفات الفنية والمتطلبات التشغيلية لأنظمتهم. وهذا يمكن أن يؤدي إلى تأخير في الجداول الزمنية للمشروع وزيادة التكاليف بسبب الطلبات غير الصحيحة أو المعدات التي لا تعمل كما هو متوقع.

الحل: لتبسيط عملية الاختيار، يجب أن يبدأ المشترون بإجراء تقييم شامل للاحتياجات. ويتضمن ذلك فهم متطلبات التطبيق المحددة، مثل نوع السائل الذي يتم التحكم فيه (سائل أو غاز)، وتصنيفات الضغط، والظروف البيئية (درجة الحرارة والرطوبة). يمكن أن يكون التعاون مع الشركات المصنعة أو الموردين الذين يقدمون الدعم الفني لا يقدر بثمن. يمكنهم تقديم رؤى حول التصميم المناسب للملف اللولبي ومتطلبات الجهد والتوافق مع الأنظمة الحالية. بالإضافة إلى ذلك، فإن إنشاء قائمة مرجعية تحدد المواصفات الرئيسية يمكن أن يساعد المشترين على تضييق نطاق خياراتهم بشكل فعال.

السيناريو 2: التحديات المتعلقة بتركيب الملف اللولبي والتكامل

المشكلة: بعد شراء الملفات اللولبية، يواجه العديد من مشتري B2B صعوبات أثناء مرحلتي التركيب والتكامل. يمكن أن يؤدي التركيب غير الصحيح إلى حدوث أعطال أو مخاطر تتعلق بالسلامة أو حتى تلف الملف اللولبي والأنظمة المتصلة به. علاوةً على ذلك، يمكن أن يؤدي اختلاف المعايير عبر الصناعات والمناطق الجغرافية إلى تعقيد عملية الدمج، خاصةً بالنسبة للمشترين الدوليين.

الحل: لمواجهة تحديات التركيب هذه، يجب على المشترين إعطاء الأولوية لإرشادات التركيب التفصيلية من الشركة المصنعة للملف اللولبي. وينبغي أن تتضمن هذه الإرشادات الرسوم البيانية والأدوات الموصى بها والتعليمات خطوة بخطوة المصممة خصيصاً للطراز المحدد. كما أن الاستعانة بخدمات التركيب الاحترافية أو التشاور مع مهندسين متخصصين في أنظمة التحكم في السوائل يمكن أن يوفر شبكة أمان ضد الأخطاء المحتملة. علاوة على ذلك، يمكن أن يؤدي الاستثمار في الدورات التدريبية للفريق الفني إلى تعزيز فهمهم لتكامل الملف اللولبي، مما يؤدي إلى عمليات تركيب أكثر سلاسة وكفاءة تشغيلية طويلة الأجل.

السيناريو 3: مشاكل الصيانة والموثوقية مع الملفات اللولبية

المشكلة: كثيرًا ما يواجه مشترو B2B مشكلات في الموثوقية مع الملفات اللولبية، خاصةً في التطبيقات عالية الطلب حيث يُتوقع أن تعمل بشكل مستمر. يمكن أن تؤدي عوامل مثل البلى والتلف والتعرض البيئي والاستخدام غير السليم إلى أعطال متكررة، مما يؤدي إلى تعطلها وزيادة التكاليف التشغيلية. غالبًا ما يتفاقم التحدي في المناطق التي تقل فيها إمكانية الوصول إلى موارد أو خبرات الصيانة.

الحل: للتخفيف من مشاكل الموثوقية، من الضروري تنفيذ جدول صيانة استباقي. يجب أن يشمل ذلك عمليات الفحص والتنظيف والاختبار المنتظمة للملفات اللولبية لضمان عملها على النحو الأمثل. يجب على المشترين أيضًا التفكير في الحصول على ملفات لولبية مصممة لتحقيق المتانة والأداء العالي في بيئاتهم الخاصة. يمكن للمصنعين الذين يقدمون ضمانات ممتدة أو اتفاقيات خدمة أن يوفروا راحة بال إضافية. وبالإضافة إلى ذلك، فإن إقامة علاقة قوية مع الموردين يمكن أن يسهل الوصول بشكل أسرع إلى قطع الغيار والدعم الفني عند ظهور مشاكل، مما يضمن الحد الأدنى من التعطيل للعمليات.

دليل اختيار المواد الاستراتيجية ل que es el solenoide

ما هي المواد المستخدمة عادة في تصنيع الملف اللولبي؟

عند اختيار مواد للملفات اللولبية، من الضروري مراعاة خصائصها وكيفية تأثيرها على الأداء في التطبيقات المختلفة. هنا، نقوم بتحليل أربع مواد شائعة تستخدم في بناء الملف اللولبي: النحاس والفولاذ المقاوم للصدأ والألومنيوم والبلاستيك. لكل مادة خصائص مميزة تؤثر على المتانة والتكلفة والملاءمة لتطبيقات محددة.

كيف يؤثر النحاس على أداء الملف اللولبي؟

النحاس هو المادة الأكثر استخدامًا على نطاق واسع في لف الأسلاك في الملفات اللولبية نظرًا لتوصيلها الكهربائي الممتاز. وتسمح هذه الخاصية بتدفق التيار بكفاءة، وهو أمر ضروري لتوليد مجال مغناطيسي قوي. يتراوح معدل درجة حرارة النحاس عادةً من -40 درجة مئوية إلى 200 درجة مئوية، مما يجعله مناسبًا للعديد من البيئات.

الإيجابيات: النحاس متين للغاية ومقاوم للتآكل عند معالجته بشكل صحيح. وتكلفته المنخفضة نسبياً مقارنة بالمواد الموصلة الأخرى تجعله خياراً جذاباً للمصنعين.

السلبيات: ومع ذلك، يمكن أن يكون النحاس ثقيلًا وقد لا يكون مناسبًا للتطبيقات التي تتطلب مكونات خفيفة الوزن. وبالإضافة إلى ذلك، يمكن أن يكون عرضة للأكسدة إذا لم يتم تغليفه أو معالجته، مما قد يؤثر على الأداء بمرور الوقت.

التأثير على التطبيق: النحاس متوافق مع مختلف الوسائط، بما في ذلك الماء والغازات، ولكن يجب توخي الحذر في البيئات المسببة للتآكل.

اعتبارات للمشترين الدوليين: إن الامتثال لمعايير مثل ASTM B3 (الأسلاك النحاسية) أمر بالغ الأهمية. وينبغي للمشترين في مناطق مثل أفريقيا والشرق الأوسط التأكد من قدرة الموردين على الوفاء بالمعايير المحلية.

ما الدور الذي يلعبه الفولاذ المقاوم للصدأ في تصميم الملف اللولبي؟

غالبًا ما يستخدم الفولاذ المقاوم للصدأ في مبيت الملف اللولبي والمكونات الهيكلية الأخرى. إن مقاومته للتآكل وقوته تجعله مثاليًا للبيئات القاسية، خاصةً في قطاعي السيارات والقطاع الهيدروليكي.

الإيجابيات: تعمل متانة الفولاذ المقاوم للصدأ ومقاومته للصدأ والتآكل على إطالة عمر الملفات اللولبية، خاصة في التطبيقات الخارجية أو الصناعية.

السلبيات: العيب الأساسي هو ارتفاع تكلفته مقارنة بالمواد الأخرى مثل الألومنيوم أو البلاستيك. وبالإضافة إلى ذلك، فإن الفولاذ المقاوم للصدأ أثقل، وهو ما قد لا يكون مثاليًا لجميع الاستخدامات.

التأثير على التطبيق: يناسب الفولاذ المقاوم للصدأ التعامل مع السوائل العنيفة، بما في ذلك الزيوت والمواد الكيميائية، مما يجعله خيارًا مفضلاً في العديد من الصناعات.

اعتبارات للمشترين الدوليين: يجب أن يبحث المشترون عن الامتثال لمعايير مثل ASTM A276 لدرجات الفولاذ المقاوم للصدأ. من الضروري فهم التفضيلات الإقليمية لدرجات المواد، خاصة في أوروبا وأمريكا الجنوبية.

كيف يقارن الألومنيوم لتطبيقات الملف اللولبي؟

يعد الألومنيوم خيارًا شائعًا آخر، خاصةً بالنسبة لأغطية ومكونات الملف اللولبي. إنه خفيف الوزن ويتميز بمقاومة جيدة للتآكل، مما يجعله مناسبًا لمختلف التطبيقات.

الإيجابيات: تسمح الطبيعة خفيفة الوزن للألومنيوم بتخفيض الوزن الإجمالي للنظام، وهو ما يمكن أن يكون بالغ الأهمية في تطبيقات السيارات والفضاء. كما أنه فعال من حيث التكلفة وسهل التصنيع.

السلبيات: ومع ذلك، فإن الألومنيوم أقل متانة من الفولاذ المقاوم للصدأ وقد لا يعمل بشكل جيد في التطبيقات ذات درجات الحرارة العالية. وقد يكون انخفاض قوته عاملاً مقيدًا في بعض التصميمات.

التأثير على التطبيق: يتوافق الألومنيوم بشكل عام مع السوائل والغازات غير المسببة للتآكل، ولكن يجب توخي الحذر عند استخدامه مع الوسائط العدوانية.

اعتبارات للمشترين الدوليين: يجب على المشترين التأكد من الامتثال لمعايير مثل ASTM B221 لسحب الألومنيوم. كما يمكن أن يؤثر فهم تفضيلات السوق المحلية لدرجات الألومنيوم على قرارات الشراء.

ما المزايا التي يقدمها البلاستيك في تصنيع الملف اللولبي؟

يتزايد استخدام المواد البلاستيكية، مثل البولي أميد (النايلون) أو البولي كربونات، في تطبيقات الملف اللولبي، خاصةً في المكونات غير الهيكلية.

الإيجابيات: البلاستيك خفيف الوزن ومقاوم للتآكل ويمكن تصنيعه بتكلفة أقل. كما أنها عوازل ممتازة، مما يمكن أن يعزز أداء الملفات اللولبية.

السلبيات: القيد الرئيسي هو انخفاض درجات الحرارة والضغط مقارنةً بالمعادن. قد لا تكون المواد البلاستيكية مناسبة للتطبيقات عالية الضغط أو التعرض لدرجات الحرارة القصوى.

التأثير على التطبيق: تُعد المكونات البلاستيكية مثالية للتطبيقات التي تتضمن وسائط غير عدائية، ولكن الاختيار الدقيق ضروري لضمان التوافق مع سوائل معينة.

اعتبارات للمشترين الدوليين: من المهم الامتثال لمعايير مثل ASTM D638 للمواد البلاستيكية. يجب على المشترين أيضًا مراعاة تأثير الاختلافات في درجات الحرارة الإقليمية على أداء البلاستيك.

جدول ملخص لاختيار المواد للملفات اللولبية

| المواد | حالة الاستخدام النموذجية ل que es el solenoide | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | اللفات الكهربائية في الملفات اللولبية | موصلية ممتازة | عرضة للأكسدة | منخفض |

| الفولاذ المقاوم للصدأ | مبيت للملفات اللولبية | متانة عالية ومقاومة عالية للتآكل | تكلفة أعلى، أثقل | عالية |

| الألومنيوم | مبيتات ومكونات خفيفة الوزن | خفيفة الوزن وفعالة من حيث التكلفة | أقل قوة، وأقل متانة | متوسط |

| بلاستيك | المكونات غير الهيكلية | خفيفة الوزن ومنخفضة التكلفة | درجات حرارة/ضغط أقل | منخفض |

يوفر دليل اختيار المواد الاستراتيجية هذا رؤى قيمة للمشترين الدوليين من الشركات الذين يفكرون في تطبيقات الملف اللولبي في مختلف الصناعات. إن فهم خصائص ومزايا وقيود كل مادة سيسهل اتخاذ قرارات شراء مستنيرة مصممة خصيصًا لتلبية الاحتياجات التشغيلية المحددة.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لمصنع que es el solenoide

ما هي المراحل الرئيسية في عملية تصنيع الملفات اللولبية؟

تُعد عملية تصنيع الملفات اللولبية جانبًا حاسمًا يؤثر على أدائها وموثوقيتها في مختلف التطبيقات، بدءًا من أنظمة السيارات وحتى الأتمتة الصناعية. يساعد فهم مراحل الإنتاج المشترين بين الشركات على تقييم الموردين بفعالية.

تحضير المواد: ما هي المواد المستخدمة في تصنيع الملف اللولبي؟

تتضمن المرحلة الأولى في عملية التصنيع اختيار مواد عالية الجودة ضرورية لأداء الملف اللولبي. وعادةً ما يتم استخدام الأسلاك النحاسية للملف بسبب توصيلها الممتاز. وغالباً ما يُصنع القلب من مواد مغناطيسية حديدية، مثل الحديد أو الفولاذ، لتعزيز المجال المغناطيسي الذي يولده الملف. وبالإضافة إلى ذلك، تعتبر المواد العازلة ضرورية لمنع حدوث ماس كهربائي وضمان تشغيل الملف اللولبي بأمان.

يجب على مشتري B2B الاستفسار عن مصدر هذه المواد وجودتها، لأنها تؤثر بشكل مباشر على كفاءة الملف اللولبي وعمره الافتراضي.

كيف تتم عملية التشكيل للملفات اللولبية؟

بمجرد تجهيز المواد، تبدأ مرحلة التشكيل، والتي تتضمن لف السلك النحاسي حول القلب المغناطيسي الحديدي. ويتم ذلك عادةً باستخدام آلات اللف الآلية التي تضمن الدقة والاتساق. يمكن أن يؤثر عدد اللفات وضيق اللف بشكل كبير على قوة المجال المغناطيسي للملف اللولبي.

في بعض الحالات، قد يستخدم المصنعون تقنيات مثل القطع بالليزر أو التصنيع باستخدام الحاسب الآلي لتشكيل المكونات بدقة قبل التجميع. هذه المرحلة ضرورية للحفاظ على المواصفات المطلوبة لتحقيق الأداء الأمثل.

ما الذي تنطوي عليه عملية التجميع في إنتاج الملف اللولبي؟

يعد تجميع الملفات اللولبية عملية دقيقة تجمع المكونات المشكلة في وحدة وظيفية. وتشمل الخطوات الرئيسية ما يلي:

- إدخال الملف: يتم وضع الملف الملف الملفوف بعناية على القلب.

- التجميع الميكانيكي: يتم دمج المكونات الإضافية، مثل النوابض والأذرع لضمان الحركة والوظيفة المناسبة.

- التوصيلات الكهربائية: يتم توصيل الأسلاك بالملف، مما يتيح تدفق التيار الكهربائي.

تُعد مراقبة الجودة في هذه المرحلة أمرًا حيويًا، حيث يمكن أن يؤدي التجميع غير السليم إلى حدوث أعطال في الميدان. يجب على المشترين بين الشركات أن يسألوا عن تقنيات التجميع وخبرة القوى العاملة لضمان الحفاظ على معايير عالية.

ما هي تقنيات التشطيب المستخدمة في تصنيع الملف اللولبي؟

تتضمن مرحلة التشطيب وضع طلاءات أو معالجات لتعزيز متانة الملف اللولبي وأدائه. وقد يشمل ذلك:

- الطلاء الكهربائي: لمنع التآكل وتحسين التوصيل.

- الطلاء العازل: لحماية التوصيلات الكهربائية وضمان السلامة.

- الاختبار والمعايرة: التعديلات النهائية لضمان استيفاء الملف اللولبي لمعايير الأداء المحددة.

لا تعمل تقنيات التشطيب على تعزيز الكفاءة التشغيلية للملف اللولبي فحسب، بل تعزز أيضًا موثوقيته في بيئات متنوعة، مما يجعل من الضروري للمشترين الدوليين فهم هذه العمليات.

صورة توضيحية متعلقة ب que es el solenoide

ما هي إجراءات ضمان الجودة الضرورية لمصنعي الملف اللولبي؟

يعد ضمان الجودة (QA) جانبًا حاسمًا في عملية تصنيع الملف اللولبي، خاصةً بالنسبة للمشترين الدوليين من الشركات الذين يحتاجون إلى منتجات موثوقة.

ما هي المعايير الدولية التي يجب على المشترين بين الشركات أخذها في الاعتبار؟

هناك العديد من المعايير الدولية التي تحكم جودة الملفات اللولبية، حيث تعتبر المواصفة القياسية ISO 9001 هي الأكثر شهرة لأنظمة إدارة الجودة. يشير الامتثال لمعيار ISO 9001 إلى أن الشركة المصنعة تتبع بروتوكولات صارمة لضمان الجودة. وبالإضافة إلى ذلك، فإن الشهادات الخاصة بالصناعة، مثل علامة CE للأسواق الأوروبية ومعايير API لتطبيقات النفط والغاز، تعتبر حاسمة لضمان سلامة المنتج وموثوقيته.

يجب على المشترين بين الشركات إعطاء الأولوية للموردين الذين يمكنهم تقديم دليل على الامتثال لهذه المعايير، لأن ذلك يعكس التزامهم بالجودة.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في إنتاج الملف اللولبي؟

تعتبر نقاط التحقق من مراقبة الجودة (QC) في جميع مراحل عملية التصنيع ضرورية للحفاظ على معايير عالية. وتشمل نقاط فحص مراقبة الجودة الشائعة ما يلي:

- مراقبة الجودة الواردة (IQC): فحص المواد الخام عند وصولها للتأكد من مطابقتها للمواصفات.

- مراقبة الجودة أثناء الإنتاج (IPQC): مراقبة عملية التصنيع لتحديد المشكلات وتصحيحها في الوقت الفعلي.

- مراقبة الجودة النهائية (FQC): إجراء اختبار شامل للمنتجات النهائية للتحقق من الأداء مقابل المواصفات.

يجب على المشترين بين الشركات أن يسألوا الموردين المحتملين عن عمليات مراقبة الجودة الخاصة بهم وكيفية توثيق هذه الفحوصات.

ما هي طرق الاختبار الشائعة المستخدمة لضمان جودة الملف اللولبي؟

يستخدم المصنعون طرق اختبار مختلفة لضمان أداء الملف اللولبي كما هو متوقع. وتشمل الاختبارات الشائعة ما يلي:

- الاختبارات الكهربائية: للتحقق من المقاومة المناسبة والاستمرارية في الملف.

- اختبار المجال المغناطيسي: للتحقق من قوة وانتظام المجال المغناطيسي المتولد.

- الاختبار الوظيفي: لتقييم تشغيل الملف اللولبي في ظل ظروف مختلفة.

يمكن للمشترين بين الشركات طلب تقارير مفصلة عن هذه الاختبارات للتأكد من أن المنتجات التي يشترونها تلبي احتياجاتهم التشغيلية.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

يعد التحقق من ممارسات مراقبة الجودة للموردين المحتملين أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات، خاصة في الأسواق المتنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

ما هي ممارسات التدقيق التي يجب على المشترين تنفيذها؟

يمكن أن يوفر إجراء عمليات التدقيق للموردين المحتملين نظرة ثاقبة على عمليات التصنيع ومراقبة الجودة الخاصة بهم. وينبغي على المشترين النظر في كل من عمليات التدقيق الأولية والمتابعة الدورية لضمان الامتثال المستمر لمعايير الجودة. وتشمل المجالات الرئيسية التي يجب التركيز عليها أثناء عمليات التدقيق ما يلي:

- عمليات التصنيع: تقييم كفاءة وموثوقية تقنيات الإنتاج.

- التوثيق: مراجعة سجلات توريد المواد، ودفعات الإنتاج، وعمليات التفتيش على مراقبة الجودة.

- الشهادات: التأكد من أن المورد يحتفظ بالشهادات ذات الصلة ويلتزم بمعايير الصناعة.

ما مدى أهمية عمليات التفتيش من طرف ثالث لضمان الجودة؟

يمكن أن يضيف إشراك خدمات الفحص من طرف ثالث مستوى إضافي من الضمان للمشترين بين الشركات. يمكن لهذه المنظمات المستقلة إجراء تقييمات غير متحيزة لعمليات التصنيع وجودة المنتج الخاصة بالمورد. وهذا مهم بشكل خاص في التجارة الدولية، حيث قد توجد اختلافات في المعايير والممارسات.

يجب على المشترين النظر في دمج عمليات التفتيش من طرف ثالث في استراتيجية الشراء الخاصة بهم للتخفيف من المخاطر المرتبطة بجودة المنتج.

صورة توضيحية متعلقة ب que es el solenoide

الخاتمة: ضمان الجودة في توريد الملف اللولبي

تُعد عمليات التصنيع ومقاييس ضمان الجودة للملفات اللولبية من العوامل الحاسمة التي تؤثر على أدائها وموثوقيتها. من خلال فهم المراحل الرئيسية للتصنيع، ومعايير الجودة ذات الصلة، وطرق التحقق الفعالة، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة عند الحصول على الملفات اللولبية من الموردين الدوليين. يضمن إعطاء الأولوية للموردين ذوي الممارسات القوية لمراقبة الجودة حصول الشركات على منتجات عالية الجودة تلبي احتياجاتها التشغيلية.

دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة ‘que es el solenoide’

في العالم المعقد للمكونات الصناعية، تلعب الملفات اللولبية دورًا محوريًا في مختلف التطبيقات، لا سيما في أنظمة إدارة السوائل. تهدف قائمة المراجعة هذه إلى توجيه المشترين بين الشركات من خلال الخطوات الأساسية لتوريد الملفات اللولبية بفعالية، مما يضمن اتخاذ قرارات مستنيرة تلبي متطلباتهم التشغيلية.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

حدد بوضوح المواصفات الفنية اللازمة لتطبيقات الملف اللولبي لديك. ضع في اعتبارك عوامل مثل متطلبات الجهد، وإخراج القوة، والظروف البيئية (مثل درجة الحرارة والرطوبة). هذه الخطوة مهمة للغاية لأنها تضع خط أساس لعملية الشراء الخاصة بك وتضمن التوافق مع الأنظمة الحالية.

صورة توضيحية متعلقة ب que es el solenoide

الخطوة 2: البحث عن أنواع مختلفة من الملفات اللولبية

تعرّف على الأنواع المختلفة من الملفات اللولبية المتوفرة في السوق. تشمل الفئات الرئيسية ما يلي:

– الملفات اللولبية ذات المفعول المباشر: مناسبة للتطبيقات التي تتطلب استجابة فورية.

– ملفات لولبية تعمل بالطيار: مثالية لمعدلات التدفق الأكبر أو أنظمة الضغط العالي.

وسيساعدك فهم هذه الاختلافات في اختيار الملف اللولبي الذي يناسب احتياجات تطبيقك المحدد.

الخطوة 3: تقييم الموردين المحتملين

قبل الالتزام، من الأهمية بمكان فحص الموردين بدقة. اطلب ملفات تعريف الشركة، ودراسات الحالة، والمراجع من المشترين في صناعة أو منطقة مماثلة. ابحث عن:

– الخبرة في هذا المجال: الموردون الذين يتمتعون بسجل حافل في قطاعك.

– السمعة: يمكن أن توفر المراجعات والشهادات عبر الإنترنت نظرة ثاقبة حول الموثوقية وجودة الخدمة.

الخطوة 4: التحقق من شهادات الموردين

تأكد من أن الموردين الذين اخترتهم يستوفون شهادات ومعايير الصناعة ذات الصلة، مثل الامتثال لمعايير ISO أو CE. هذه الخطوة ضرورية لضمان جودة المنتج وسلامته. تشير الشهادات إلى أن المورد يلتزم بلوائح الصناعة، والتي يمكن أن تكون مهمة بشكل خاص في قطاعات مثل السيارات أو الأدوية.

الخطوة 5: طلب عينات للاختبار

اطلب من الموردين عينات من الملفات اللولبية التي تفكر فيها. يتيح لك اختبار العينات في بيئتك التشغيلية تقييم الأداء والموثوقية والتوافق مع أنظمتك. انتبه لجوانب مثل وقت الاستجابة والمتانة وسهولة التكامل.

صورة توضيحية متعلقة ب que es el solenoide

الخطوة 6: قارن الأسعار والشروط

بمجرد تضييق نطاق خياراتك، قارن بين هياكل التسعير وشروط الدفع. انظر إلى ما هو أبعد من التكلفة الأولية؛ ضع في اعتبارك التكلفة الإجمالية للملكية، بما في ذلك الصيانة ووقت التعطل المحتمل. تأكد من أن الشروط مواتية وتتوافق مع قيود ميزانيتك.

الخطوة 7: إنشاء دعم ما بعد البيع والضمان

استفسر عن دعم ما بعد البيع وشروط الضمان التي يقدمها المورد. من الضروري وجود نظام دعم قوي لمعالجة أي مشاكل قد تنشأ بعد الشراء. ابحث عن الموردين الذين يقدمون المساعدة الفنية ولديهم سياسة ضمان واضحة، مما يضمن لك اللجوء إلى الموردين في حالة تعطل المنتج.

من خلال اتباع قائمة المراجعة هذه، يمكن للمشترين بين الشركات التنقل في عملية شراء الملفات اللولبية بثقة، مما يضمن اختيار المنتجات المناسبة لاحتياجاتهم الخاصة مع بناء علاقات مع موردين ذوي سمعة طيبة.

تحليل شامل للتكلفة والتسعير لمصادر que es el solenoide Sourcing

يعد فهم هيكل التكلفة وديناميكيات تسعير الملفات اللولبية أمرًا بالغ الأهمية للمشترين الدوليين من الشركات على مستوى العالم، خاصةً المشترين من أسواق متنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. يفصل هذا التحليل المكونات الرئيسية التي تؤثر على تسعير الملفات اللولبية ويقدم رؤى قيمة للتوريد الفعال من حيث التكلفة.

ما هي مكونات التكلفة الرئيسية في تصنيع الملف اللولبي؟

-

المواد: تشمل المواد الأساسية المستخدمة في إنتاج الملف اللولبي الأسلاك النحاسية للملفات، والقلب المغناطيسي الحديدي، وأنواع مختلفة من البلاستيك أو المعادن للإسكان. يمكن أن تؤثر التقلبات في أسعار المواد الخام بشكل كبير على التكاليف الإجمالية. على سبيل المثال، غالبًا ما تكون أسعار النحاس متقلبة بسبب الطلب العالمي وانقطاع سلسلة التوريد.

-

العمل: تختلف تكاليف العمالة حسب المنطقة ويمكن أن تتأثر بمستوى المهارة المطلوبة لعمليات التجميع ومراقبة الجودة. في البلدان ذات تكاليف العمالة المرتفعة، قد يحتاج المصنعون إلى الموازنة بين الجودة والقدرة على تحمل التكاليف، مما قد يؤثر على سعر المنتج النهائي.

-

تكاليف التصنيع العامة: ويشمل ذلك التكاليف المتعلقة بالمرافق وصيانة المعدات وعمليات المصنع. ويمكن لعمليات التصنيع الفعالة أن تساعد في تقليل النفقات العامة، مما يؤثر على القدرة التنافسية لأسعار الملفات اللولبية.

-

الأدوات: يمكن أن تكون الأدوات المخصصة لتصميمات ملفات لولبية محددة تكلفة مقدمة كبيرة. قد يتكبد المشترون الذين يبحثون عن مواصفات فريدة من نوعها تكاليف أدوات أعلى، والتي يمكن استهلاكها على مدى عمليات إنتاج أكبر.

-

مراقبة الجودة (QC): يضمن تنفيذ عمليات مراقبة الجودة الصارمة موثوقية المنتج، خاصة في التطبيقات الحرجة. ومع ذلك، فإن هذا يضيف إلى هيكل التكلفة الإجمالي. يمكن أن تضيف الشهادات (مثل ISO) أيضًا إلى التكاليف ولكنها ضرورية للامتثال في العديد من الصناعات.

-

اللوجستيات: تتأثر تكاليف الشحن بوسيلة النقل والمسافة وأي تعريفات أو رسوم مطبقة في البلد المستورد. ويمكن أن تساعد الإدارة اللوجستية الفعالة في تقليل هذه التكاليف.

-

الهامش: عادة ما يطبق المصنعون هامشاً لتغطية المخاطر وضمان الربحية. ويمكن أن يختلف هذا الهامش بناء على المنافسة في السوق والقيمة المتصورة للملف اللولبي.

ما الذي يؤثر على تسعير الملفات اللولبية؟

هناك عدة عوامل يمكن أن تؤثر على تسعير الملفات اللولبية بخلاف هيكل التكلفة الأساسي:

-

الحجم/الحد الأدنى للطلب: يمكن أن يؤثر الحد الأدنى لكميات الطلبات (MOQ) على التسعير؛ فعادةً ما تؤدي الطلبات الأكبر إلى انخفاض تكاليف الوحدة بسبب وفورات الحجم.

-

المواصفات والتخصيص: قد تأتي الملفات اللولبية المصممة خصيصًا والمصممة خصيصًا لتطبيقات محددة بسعر أعلى. ويجب على المشترين تحديد متطلباتهم بوضوح لتجنب التكاليف غير المتوقعة.

-

الجودة والشهادات: يمكن أن تؤدي معايير الجودة العالية أو الشهادات المحددة إلى رفع السعر. يجب على المشترين أن يوازنوا بين أهمية هذه العوامل وقيود ميزانيتهم.

-

عوامل الموردين: يمكن أن تؤثر سمعة الموردين وموثوقيتهم على التسعير. وقد يفرض الموردون الراسخون أسعاراً أعلى بسبب مستويات الجودة والخدمة المتصورة.

-

مصطلحات التجارة الدولية: فهم شروط الشحن (Incoterms) أمر حيوي. فهي تحدد المسؤوليات المتعلقة بالتكاليف والمخاطر، والتي يمكن أن تؤثر بشكل كبير على إجمالي التكاليف التي تم إنزالها.

ما هي النصائح الفعالة للمشتري من أجل التوريد الفعال من حيث التكلفة؟

-

التفاوض: إشراك الموردين في مناقشات حول الأسعار، خاصة بالنسبة للطلبات الكبيرة. فالعديد من الموردين منفتحون على التفاوض، لا سيما إذا رأوا إمكانية إقامة شراكات طويلة الأجل.

-

التركيز على التكلفة الإجمالية للملكية (TCO): لا تأخذ في الاعتبار سعر الشراء فقط ولكن أيضاً الصيانة والمتانة وكفاءة الطاقة للملفات اللولبية. وقد تكون التكلفة الأولية الأعلى مبررة بانخفاض تكاليف التشغيل بمرور الوقت.

-

فهم الفروق الدقيقة في الأسعار: يجب أن يكون المشترون الدوليون على دراية بتقلبات أسعار العملات، وتعريفات الاستيراد، وظروف السوق المحلية التي يمكن أن تؤثر على الأسعار.

-

تنويع الموردين: تجنب الاعتماد على مورد واحد. فاستكشاف موردين متعددين يمكن أن يوفر نفوذاً في المفاوضات ويساعد على إيجاد أفضل نسبة بين السعر والجودة.

-

الجودة على السعر: إعطاء الأولوية للجودة لتقليل الأعطال المحتملة والتكاليف المرتبطة بها على المدى الطويل. وقد تؤدي الخيارات الأرخص إلى ارتفاع تكاليف الاستبدال والصيانة.

الخلاصة

يُعد فهم هيكل التكلفة وديناميكيات التسعير للملفات اللولبية أمرًا ضروريًا للمشترين الدوليين بين الشركات. من خلال النظر في مكونات التكلفة المختلفة والمؤثرات السعرية والنصائح الاستراتيجية للتوريد، يمكن للمشترين اتخاذ قرارات مستنيرة تتماشى مع احتياجات أعمالهم وقيود ميزانيتهم. تذكر دائمًا أن الأسعار الإرشادية يمكن أن تتقلب، لذا فإن البحث المستمر في السوق أمر حيوي لتأمين أفضل الصفقات.

تحليل البدائل: مقارنة que es el solenoide مع الحلول الأخرى

مقدمة: استكشاف بدائل الملفات اللولبية

في مجال التحكم في السوائل والتشغيل الآلي، تعمل الملفات اللولبية كمكونات حاسمة، حيث تقوم بتحويل الطاقة الكهربائية إلى حركة ميكانيكية. ومع ذلك، يمكن أن تحقق تقنيات بديلة مختلفة أهدافًا مماثلة، وتقدم مزايا وعيوبًا فريدة من نوعها. يعد فهم هذه البدائل أمرًا ضروريًا لمشتري B2B الذين يسعون إلى تحسين عملياتهم مع مراعاة الأداء والتكلفة وسهولة التنفيذ.

جدول المقارنة: الميزات الرئيسية للملفات اللولبية والبدائل

| جانب المقارنة | Que Es El Solenoide | البديل 1 الاسم البديل 1: المشغلات الهوائية | البديل 2 الاسم البديل 2: الصمامات الآلية |

|---|---|---|---|

| الأداء | دقة وموثوقية عالية في التحكم في السوائل | سرعة وقوة عالية للأنظمة الكبيرة | تحكم متعدد الاستخدامات مع خيارات قابلة للبرمجة |

| التكلفة | تكلفة أولية معتدلة؛ وفورات طويلة الأجل | تكلفة أولية أقل بشكل عام؛ تكاليف تشغيلية أعلى | استثمار أولي أعلى؛ إمكانية تحقيق وفورات في الطاقة |

| سهولة التنفيذ | تركيب بسيط ومباشر؛ يتطلب إعداداً كهربائياً | تكامل بسيط؛ يتطلب إمداد الهواء | تركيب أكثر تعقيداً؛ يتطلب تركيباً كهربائياً وميكانيكياً |

| الصيانة | منخفضة الصيانة؛ متينة | صيانة معتدلة؛ صيانة نظام الهواء | صيانة معتدلة؛ تآكل ميكانيكي بمرور الوقت |

| أفضل حالة استخدام | مثالية للتحكم الدقيق في السوائل في أنظمة السيارات والأنظمة الهيدروليكية | الأفضل للتطبيقات التي تتطلب تشغيلًا سريعًا | مناسبة للأنظمة المعقدة التي تحتاج إلى تحكم قابل للبرمجة |

تفصيل البدائل

البديل 1: المشغلات الهوائية

تستخدم المشغلات الهوائية الهواء المضغوط لتوليد الحركة، مما يجعلها خيارًا شائعًا للتطبيقات التي تتطلب تشغيلًا سريعًا. وهي تتفوق في البيئات التي تكون فيها السرعة أولوية، مثل خطوط التصنيع والتعبئة والتغليف. في حين أن تكلفتها الأولية أقل بشكل عام مقارنةً بالملفات اللولبية، إلا أن التكاليف التشغيلية يمكن أن تكون أعلى بسبب الحاجة المستمرة لإمدادات الهواء والتسريبات المحتملة للهواء. بالإضافة إلى ذلك، قد تتطلب الأنظمة الهوائية صيانة منتظمة لضمان الأداء الأمثل، مما قد يؤثر على الكفاءة التشغيلية الإجمالية.

البديل 2: الصمامات الآلية

تدمج الصمامات الآلية محركات كهربائية للتحكم في تدفق السوائل، مما يوفر براعة في التطبيقات التي تتطلب منطقًا وأتمتة قابلة للبرمجة. وهي تسمح بالتحكم الدقيق في معدلات التدفق ويمكن دمجها بسهولة في الأنظمة المؤتمتة. ومع ذلك، عادةً ما تنطوي الصمامات الآلية عادةً على استثمار مقدم أعلى وقد تتطلب تركيبات أكثر تعقيدًا مقارنةً بالملفات اللولبية. وعلى الرغم من ذلك، فإنها يمكن أن تؤدي إلى توفير الطاقة على المدى الطويل، لا سيما في الأنظمة التي يكون فيها التحكم الدقيق والمراقبة أمرًا بالغ الأهمية.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

يتطلب اختيار التقنية المناسبة للتحكم في السوائل تحليلاً شاملاً للاحتياجات والقيود التشغيلية المحددة. في حين أن الملفات اللولبية توفر دقة وموثوقية عالية، فإن البدائل مثل المشغلات الهوائية والصمامات الآلية قد توفر فوائد من حيث السرعة وقابلية البرمجة. يجب على مشتري B2B النظر في عوامل مثل الاستثمار الأولي ومتطلبات الصيانة وأفضل حالات الاستخدام عند اتخاذ قرارهم. من خلال مواءمة خيارات التكنولوجيا مع الأهداف التشغيلية، يمكن للشركات تعزيز الكفاءة وتحسين عملياتها بفعالية.

الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية ل que es el solenoide

ما هي الخصائص التقنية الرئيسية للملف اللولبي؟

يعد فهم الخصائص التقنية الأساسية للملف اللولبي أمرًا بالغ الأهمية لمشتري B2B في صناعات مثل السيارات والمكونات الهيدروليكية والتحكم في السوائل. فيما يلي بعض المواصفات الهامة التي يجب مراعاتها:

-

درجة المواد

تؤثر المواد المستخدمة في بناء الملف اللولبي بشكل كبير على متانته وأدائه. وتشمل المواد الشائعة النحاس للأسلاك والمواد المغناطيسية الحديدية للقلب. تضمن المواد عالية الجودة توصيلية ومقاومة أفضل للتآكل، وهو أمر حيوي لطول العمر، خاصة في البيئات القاسية. -

مقاومة اللفائف

تقاس مقاومة الملف بالأوم، وتشير مقاومة الملف إلى مقدار المقاومة التي يوفرها الملف اللولبي للتيار الكهربائي. تسمح المقاومة المنخفضة بتدفق تيار أعلى، مما قد يعزز الأداء. من المهم بالنسبة للمشترين مطابقة مقاومة الملف مع مصدر الطاقة لضمان التشغيل الأمثل دون ارتفاع درجة الحرارة. -

الحث

يقيس معامل الحث المعبر عنه بوحدة الهنري (H)، قدرة الملف اللولبي على تخزين الطاقة في مجال مغناطيسي. تؤثر هذه الخاصية على السرعة التي يمكن أن يعمل بها الملف اللولبي. بالنسبة للتطبيقات التي تتطلب تشغيلًا سريعًا، يفضل الملف اللولبي ذو الحث المنخفض، حيث يمكنه الاستجابة بسرعة للإشارات الكهربائية. -

تصنيف القوة

تشير هذه المواصفات إلى القوة القصوى التي يمكن أن يبذلها الملف اللولبي عند تنشيطه. يعد فهم تصنيف القوة أمرًا ضروريًا للتطبيقات التي تتطلب تحكمًا دقيقًا في تدفق السوائل أو الحركة الميكانيكية. يجب على المشترين اختيار الملفات اللولبية ذات تصنيفات القوة المناسبة لتلبية متطلبات تطبيقاتهم المحددة. -

جهد التشغيل

تم تصميم الملفات اللولبية لتعمل عند مستويات جهد محددة، تتراوح عادةً من 5 فولت إلى 230 فولت. يعد اختيار الجهد الصحيح أمرًا بالغ الأهمية لضمان التشغيل الموثوق به ومنع التلف. يجب على المشترين ضمان التوافق مع المواصفات الكهربائية لنظامهم لتجنب مشاكل الأداء. -

وقت الاستجابة

هذا هو الوقت الذي يستغرقه الملف اللولبي للتنشيط بمجرد تشغيل الطاقة. يعد زمن الاستجابة الأقصر أمرًا حاسمًا في التطبيقات التي تتطلب تشغيل/إيقاف تشغيل سريع. يجب على المشترين النظر في وقت الاستجابة المناسب لاحتياجاتهم التشغيلية لضمان الكفاءة.

ما هي المصطلحات التجارية الشائعة المتعلقة بالملفات اللولبية؟

يتضمن الإبحار في مشهد B2B التعرف على المصطلحات الرئيسية في هذا المجال. فيما يلي بعض المصطلحات الشائعة ذات الصلة بشكل خاص بمشتريات الملف اللولبي:

-

OEM (الشركة المصنعة للمعدات الأصلية)

يشير المصنع الأصلي إلى الشركة التي تنتج قطع غيار أو معدات قد يتم تسويقها من قبل مصنع آخر. في سياق الملفات اللولبية، يمكن أن يساعد فهم العلاقات مع مصنعي المعدات الأصلية المشترين على تحديد الموردين الموثوق بهم وضمان التوافق مع الأنظمة الحالية. -

MOQ (الحد الأدنى لكمية الطلب)

موك هو أصغر كمية من المنتج يرغب المورد في بيعها. ومعرفة موك هو أمر ضروري للمشترين لتقييم احتياجات المخزون وتجنب الإفراط في التخزين أو النقص في الطلب، مما قد يؤثر على التدفق النقدي والكفاءة التشغيلية. -

طلب عرض أسعار (RFQ)

طلب عرض الأسعار هو عملية رسمية يطلب فيها المشتري عروض أسعار من الموردين. وبالنسبة لمشتريات الملف اللولبي، فإن إصدار طلب عرض أسعار يتيح للمشترين مقارنة التكاليف والمواصفات، مما يضمن اتخاذ قرارات شراء مستنيرة. -

شروط التجارة الدولية (Incoterms)

تحدد شروط التجارة الدولية مسؤوليات المشترين والبائعين في المعاملات الدولية. إن الإلمام بهذه الشروط يساعد المشترين على فهم تكاليف الشحن وإدارة المخاطر ومسؤوليات التسليم، وهي أمور بالغة الأهمية عند الحصول على الملفات اللولبية من الموردين العالميين. -

المهلة الزمنية

المهلة الزمنية هي الفترة بين تقديم الطلب واستلام البضائع. ويُعد فهم المهل الزمنية أمرًا حيويًا لتخطيط المخزون وجداول الإنتاج، خاصةً في الصناعات التي تلعب فيها الملفات اللولبية دورًا حاسمًا في الكفاءة التشغيلية. -

معايير الاعتماد

تشير معايير الشهادات، مثل علامة ISO أو علامة CE، إلى الامتثال للوائح السلامة والجودة. يجب على المشترين إعطاء الأولوية للموردين الذين يستوفون معايير الاعتماد ذات الصلة لضمان موثوقية المنتج وسلامته في تطبيقاتهم.

من خلال فهم هذه الخصائص التقنية والشروط التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة عند اختيار الملفات اللولبية لتطبيقاتهم المحددة، مما يضمن الأداء الأمثل والموثوقية في عملياتهم.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع que es el solenoide

ما هي ديناميكيات السوق الحالية والاتجاهات الرئيسية التي تؤثر على قطاع الملف اللولبي؟

يشهد قطاع الملف اللولبي مرحلة تحول مدفوعة بالتطورات التكنولوجية وتغير متطلبات السوق. تشمل الدوافع العالمية الرئيسية زيادة أتمتة الصناعات، والاستثمارات المتزايدة في البنية التحتية الذكية، والحاجة المتزايدة لأنظمة التحكم في السوائل الفعالة في قطاعات مثل السيارات والتصنيع والتدفئة والتهوية وتكييف الهواء. على وجه الخصوص، تخلق الطفرة في إنتاج السيارات الكهربائية فرصًا جديدة لتطبيقات الملف اللولبي، لا سيما في التحكم في أنظمة السوائل وإدارة المحرك.

يشهد المشترون الدوليون بين الشركات، خاصةً من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، اتجاهًا نحو دمج قدرات إنترنت الأشياء في تقنيات الملف اللولبي. ويتيح هذا الدمج إمكانية المراقبة والتحكم في الوقت الفعلي، مما يعزز الكفاءة التشغيلية ويقلل من الهدر. بالإضافة إلى ذلك، يتجه المصنعون نحو التخصيص، حيث يقدمون حلول الملف اللولبي المصممة خصيصًا لتلبية متطلبات الصناعة المحددة، وبالتالي زيادة القدرة التنافسية في السوق العالمية.

وتكشف اتجاهات التوريد الناشئة عن تفضيل متزايد للموردين الذين لا يستطيعون توفير منتجات عالية الجودة فحسب، بل أيضًا الدعم الفني القوي وأوقات التسليم السريعة. يتطلع المشترون بشكل متزايد إلى إقامة شراكات طويلة الأجل مع المصنعين الذين يظهرون المرونة والاستجابة لظروف السوق المتغيرة، خاصة في المناطق المتقلبة. ويتعزز هذا الاتجاه من خلال رقمنة عمليات الشراء، مما يسمح باختيار الموردين بشكل أكثر انسيابية وكفاءة.

كيف تشكل الاستدامة والمصادر الأخلاقية سوق الملف اللولبي؟

أصبحت الاستدامة نقطة محورية في صناعة الملفات اللولبية، مع تزايد الضغط من كل من المستهلكين والهيئات التنظيمية لتقليل الآثار البيئية. وغالبًا ما ينطوي إنتاج الملفات اللولبية على مواد وعمليات يمكن أن تشكل مخاطر بيئية؛ ومن ثم، تعطي الشركات الأولوية للممارسات المستدامة. ويشمل ذلك الحصول على المواد القابلة لإعادة التدوير أو المشتقة من مصادر مستدامة، والحد من استهلاك الطاقة أثناء التصنيع، وتقليل النفايات من خلال تقنيات إنتاج أكثر كفاءة.

تُعد سلاسل التوريد الأخلاقية أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات الذين يتزايد وعيهم بمصادر مكوناتهم. وقد أصبحت شهادات مثل ISO 14001 للإدارة البيئية والالتزام بمعايير المسؤولية الاجتماعية ضرورية. يميل المشترون بشكل أكبر إلى التعاون مع الموردين الذين يمكنهم إثبات التزامهم بالتوريد الأخلاقي، مما يضمن الحفاظ على ممارسات العمل والمعايير البيئية في جميع مراحل سلسلة التوريد.

وعلاوة على ذلك، ومع تشديد اللوائح العالمية المتعلقة بالتأثير البيئي، فإن الشركات التي تستثمر في الشهادات والمواد ‘الخضراء’ تكون في وضع أفضل لتلبية معايير الامتثال وتلبية احتياجات المستهلكين المهتمين بالبيئة. هذا التحول لا يعزز سمعة العلامة التجارية فحسب، بل يمكن أن يؤدي أيضًا إلى توفير التكاليف من خلال تحسين كفاءة الموارد والحد من النفايات.

صورة توضيحية متعلقة ب que es el solenoide

ما هو السياق التاريخي لصناعة الملف اللولبي الذي يؤثر على الممارسات الحالية بين الشركات؟

تطورت تكنولوجيا الملف اللولبي بشكل كبير منذ نشأتها في القرن التاسع عشر. وكانت تستخدم في البداية في المقام الأول في أنظمة التلغراف، وتحولت الملفات اللولبية إلى مكونات حيوية في مختلف التطبيقات، من أنظمة السيارات إلى الأتمتة الصناعية. شهد القرن العشرين إدخال المبادئ الكهرومغناطيسية التي وسّعت من استخدام الملفات اللولبية في التحكم في الصمامات والمشغلات، مما أدى إلى أنظمة أكثر تطوراً للتحكم في السوائل.

مع تقدم الصناعات، تطورت أيضًا تقنيات التصنيع والمواد المستخدمة في إنتاج الملف اللولبي. وقد سمح إدخال التصميم بمساعدة الحاسوب (CAD) والمواد المتقدمة بمزيد من الدقة والكفاءة في تطبيقات الملف اللولبي. ويستمر هذا التطور في تشكيل توقعات المشترين بين الشركات اليوم، الذين لا يطلبون الوظائف فحسب، بل أيضًا الموثوقية والقدرة على التكيف في الملفات اللولبية التي يشترونها. ويُعد فهم هذا السياق التاريخي أمرًا بالغ الأهمية للمشترين الذين يسعون إلى الإبحار في المشهد المعقد لتوريد الملفات اللولبية وتوقع الاتجاهات المستقبلية في هذه الصناعة.

الأسئلة المتداولة (FAQs) لمشتري B2B من que es el solenoide

-

كيف أختار الملف اللولبي المناسب لاستخدامي؟

ينطوي اختيار الملف اللولبي المناسب على تقييم المتطلبات المحددة للتطبيق الخاص بك، بما في ذلك نوع السائل الذي يتم التحكم فيه، وضغط التشغيل، وزمن الاستجابة المطلوب. ضع في اعتبارك مواصفات الجهد والتيار للملف اللولبي لضمان التوافق مع نظامك الكهربائي. بالإضافة إلى ذلك، قم بتقييم الأبعاد المادية لضمان ملاءمتها لتصميم نظامك. يمكن أن يساعد التعاون مع الموردين الذين يقدمون خيارات التخصيص أيضًا في تكييف الملف اللولبي وفقًا لاحتياجاتك الدقيقة. -

ما هي التطبيقات الشائعة للملفات اللولبية في مختلف الصناعات؟

تُستخدم الملفات اللولبية على نطاق واسع في العديد من الصناعات، بما في ذلك السيارات والمكونات الهيدروليكية والهوائية والهوائية والتصنيع. في قطاع السيارات، تتحكم الملفات اللولبية في تدفق الغازات والسوائل، بينما في الهيدروليكا، تتحكم في حركة السوائل. وتشمل التطبيقات الأخرى التحكم في الصمامات في أنظمة الري، والأتمتة في الماكينات الصناعية، وأنظمة التدفئة والتهوية وتكييف الهواء للتحكم في الهواء. يمكن أن يساعدك فهم الاحتياجات المحددة لمجال عملك على تحديد أفضل حلول الملف اللولبي. -

ما هي خيارات التخصيص المتاحة للملفات اللولبية؟

تقدم العديد من الشركات المصنعة إمكانية التخصيص للملفات اللولبية، مما يسمح لك بتعديل عوامل مثل مقاومة الملف، وتصنيفات الجهد، والتكوينات الميكانيكية. ويمكن أن يمتد التخصيص أيضًا إلى المواد المستخدمة، خاصةً للتطبيقات التي تنطوي على سوائل أكالة. إن مناقشة متطلباتك المحددة مع الموردين ستمكنك من استكشاف الخيارات المتاحة وضمان أن الملف اللولبي يلبي احتياجاتك التشغيلية بفعالية. -

ما هو الحد الأدنى لكميات الطلب (MOQ) للملفات اللولبية؟

يمكن أن تختلف كميات الطلبات الدنيا للملفات اللولبية اختلافًا كبيرًا بين الموردين وتعتمد على عوامل مثل تعقيد تصميم الملف اللولبي والمواد المستخدمة. وبوجه عام، يمكن أن تتراوح الكميات المطلوبة من بضع قطع إلى عدة مئات من الوحدات. يُنصح بالتواصل مباشرةً مع الموردين المحتملين لفهم سياسات موك الخاصة بهم واستكشاف إمكانيات الطلبات الأصغر، خاصةً للنماذج الأولية أو مراحل المشروع الأولية. -

كيف يمكنني ضمان جودة الملفات اللولبية من الموردين الدوليين؟

لضمان الجودة عند الحصول على ملفات لولبية من موردين دوليين، اطلب شهادات المنتج ووثائق الامتثال، مثل شهادات ISO أو CE. يمكن أن يوفر إجراء عمليات تدقيق الموردين ومراجعة شهادات العملاء أيضًا رؤى حول عمليات التصنيع الخاصة بهم. بالإضافة إلى ذلك، ضع في اعتبارك تنفيذ تدابير ضمان الجودة، مثل عمليات التفتيش من طرف ثالث، للتحقق من أن الملفات اللولبية تفي بمواصفاتك قبل الشحن. -

ما هي شروط الدفع التي يجب أن أتوقعها عند توريد الملفات اللولبية دولياً؟

يمكن أن تختلف شروط الدفع اختلافاً كبيراً بين الموردين الدوليين، وعادةً ما تتراوح بين الدفعات المقدمة إلى صافي 30 أو صافي 60 يوماً بعد التسليم. قد يقدم بعض الموردين خطابات اعتماد أو خدمات ضمان للطلبات الكبيرة. من المهم توضيح شروط الدفع مقدماً والنظر في التفاوض على الشروط التي تتماشى مع متطلبات التدفق النقدي لديك. تأكد دائماً من توثيق الشروط المتفق عليها في عقدك. -

ما هي الاعتبارات اللوجستية التي يجب مراعاتها عند استيراد الملفات اللولبية؟

عند استيراد الملفات اللولبية، ضع في اعتبارك العوامل اللوجستية مثل طرق الشحن والمهل الزمنية واللوائح الجمركية. اختر وكيل شحن موثوقًا به على دراية بمتطلبات الاستيراد في بلد المقصد لضمان سلاسة العبور. بالإضافة إلى ذلك، ضع في اعتبارك الرسوم والتعريفات المحتملة التي قد تنطبق على شحنتك. التخطيط للحالات الطارئة، مثل التأخير أو التلف أثناء النقل، ضروري أيضاً للحفاظ على سلامة سلسلة التوريد الخاصة بك. -

كيف يمكنني التحقق من سمعة مورد الملف اللولبي؟

للتحقق من سمعة أحد الموردين، ابدأ بالبحث في تاريخ أعمالهم ومراجعات العملاء. يمكن أن توفر المنصات الإلكترونية والمنتديات الصناعية والجمعيات التجارية على الإنترنت معلومات قيّمة عن موثوقيتها وجودة خدماتها. بالإضافة إلى ذلك، فكِّر في التواصل مع العملاء السابقين للحصول على شهادات العملاء. يمكن أن يساعدك حضور المعارض التجارية في المجال أيضاً على إقامة علاقات مباشرة وقياس مكانة المورد في السوق.

قائمة المُصنِّعين والموردين لأعلى 2 Que Es El Solenoide قائمة المصنعين والموردين

1. Tameson - Solenoides y Válvulas

المجال: تامسون

مقدمة: إن وحدة الطاقة المنفردة عبارة عن بوبينا من الألامب تولد معسكرًا مغناطيسيًا في حالة تنشيطها، مما يسمح أو يمنع تدفق الفلوجو عبر قناة منفردة. تشتمل مكوناتها على: 1) بوبينا: قطعة من الكوبري مسجّلة في محيط دائرة حديدية مغناطيسية. 2) Núcleo estacionario: سيليندرو حديدي مغناطيسي. 3) أنيلو دي سومبريدو: تقليل الخراب والاهتزاز. 4) المنتجع: يكرس الذراع في موضعه...

2. Autodoc - Solenoide de Arranque

المجال: autodoc.es

مقدمة: هذه الشركة، Autodoc - Solenoide de Arranque، هي كيان بارز في السوق. للحصول على تفاصيل محددة عن المنتج، يُنصح بزيارة موقعها الإلكتروني مباشرةً.

استنتاجات وتوقعات التوريد الاستراتيجي لـ que es el solenoide

في الختام، يعد فهم الميكانيكا الأساسية والتطبيقات المتنوعة للملفات اللولبية أمرًا ضروريًا لمشتري B2B في المشهد التنافسي اليوم. تلعب الملفات اللولبية دورًا حاسمًا في مختلف الصناعات، لا سيما في أنظمة التحكم في السوائل في تطبيقات السيارات والتطبيقات الهيدروليكية والهوائية. توفر قدرتها على تحويل الطاقة الكهربائية إلى حركة ميكانيكية مزايا كبيرة في الأتمتة والكفاءة، مما يجعلها لا غنى عنها في الهندسة الحديثة.

يمكن أن يؤدي التوريد الاستراتيجي للملفات اللولبية إلى تحقيق وفورات كبيرة في التكاليف وتحسين الأداء التشغيلي وتحسين جودة المنتج. ومن خلال الشراكة مع المصنعين والموردين الموثوقين، يمكن للشركات ضمان تزويدها بمكونات عالية الجودة مصممة خصيصًا لتلبية احتياجاتها الخاصة. ومع تطور الأسواق، سيستمر الطلب على الحلول المبتكرة في النمو، مما يؤكد على أهمية اختيار تكنولوجيا الملف اللولبي المناسبة.

واستشرافًا للمستقبل، ينبغي على المشترين الدوليين بين الشركات من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا أن يستكشفوا بنشاط الشراكات التي تعطي الأولوية للجودة والتخصيص. لن يؤدي تبني ممارسات التوريد الاستراتيجية هذه إلى تبسيط العمليات فحسب، بل سيؤدي أيضًا إلى تهيئة الشركات لتحقيق النجاح على المدى الطويل في سوق عالمية مترابطة بشكل متزايد. تعامل مع الموردين ذوي الخبرة اليوم لإطلاق الإمكانات الكاملة لتكنولوجيا الملف اللولبي لعملياتك.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

صورة توضيحية متعلقة ب que es el solenoide

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.