مقدمة: الإبحار في السوق العالمية لمعرفة تكلفة مولد التيار المتردد

في سوق السيارات الديناميكي اليوم، يعد فهم تكلفة مولد التيار المتردد أمرًا ضروريًا للمشترين بين الشركات الذين يتطلعون إلى اتخاذ قرارات شراء مستنيرة. يمكن أن يكون الحصول على مولدات التيار المتردد التي تلبي متطلبات السيارة المحددة مهمة شاقة، خاصة عند النظر في الاختلافات في الأنواع والتطبيقات والأسعار في مختلف المناطق، بما في ذلك إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. يهدف هذا الدليل إلى إزالة الغموض عن التعقيدات المحيطة بتكاليف مولد التيار المتردد من خلال تقديم نظرة عامة شاملة للعوامل التي تؤثر على التسعير، مثل نوع السيارة وطرازها، ومتطلبات الأمبير، والاختلافات بين الوحدات الجديدة والمعاد تصنيعها.

علاوة على ذلك، سوف نستكشف الآثار المترتبة على أداء مولد التيار المتردد على تشغيل السيارة، مع تسليط الضوء على أهمية الاستبدال في الوقت المناسب لتجنب الأعطال الكهربائية المتتالية. سيستفيد المشترون بين الشركات من رؤى حول عمليات فحص الموردين، مما يضمن تعاملهم مع المصنعين والموزعين ذوي السمعة الطيبة الذين يتوافقون مع احتياجاتهم التشغيلية. يُمكِّن هذا الدليل المشترين الدوليين من خلال تزويدهم بالمعرفة اللازمة للتنقل بثقة في سوق المولدات الكهربائية العالمية، مما يؤدي في النهاية إلى اتخاذ قرارات شراء أفضل تعزز موثوقية السيارة وكفاءتها التشغيلية. سواء كنت في البرازيل أو فيتنام أو في أي مكان بينهما، فإن فهم الفروق الدقيقة في تكاليف مولدات التيار المتردد سيجعل عملك التجاري في وضع النجاح في مشهد تنافسي.

جدول المحتويات

- نظرة على تكلفة المولد كم يكلف المولد المصنعين والموردين

- مقدمة: الإبحار في السوق العالمية لمعرفة تكلفة مولد التيار المتردد

- فهم مقدار تكلفة مولد التيار المتردد أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لكمية تكلفة مولد التيار المتردد

- 3 نقاط ألم شائعة للمستخدمين حول ‘كم تكلفة المولد’ وحلولها

- دليل اختيار المواد الاستراتيجية لمعرفة تكلفة مولد التيار المتردد

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لكمية تكلفة مولد التيار المتردد

- دليل عملي للمصادر: قائمة تدقيق خطوة بخطوة لـ ‘كم تبلغ تكلفة المولد’

- تحليل شامل للتكلفة والتسعير لمصادر التكلفة والتسعير لمقدار تكلفة المولد المولد

- تحليل البدائل: مقارنة كم تكلفة المولد مع الحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية لكمية تكلفة المولد الكهربائي

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع كم يكلف مولد التيار المتردد

- الأسئلة المتداولة (FAQs) لمشتري B2B عن تكلفة مولد التيار المتردد

- استنتاج المصادر الاستراتيجية والتوقعات بشأن تكلفة مولد التيار المتردد

- إخلاء مسؤولية هام وشروط الاستخدام

فهم مقدار تكلفة مولد التيار المتردد أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولدات الجديدة | مكونات جديدة تماماً، تأتي عادةً مع ضمان | شركات تصنيع السيارات، وورش التصليح | الإيجابيات: موثوقية عالية، أحدث التقنيات. السلبيات: تكلفة مقدمة أعلى. |

| المولدات المعاد تصنيعها | أعيد بناؤها من قطع مستعملة، وتم اختبارها للتأكد من جودتها | تجار قطع غيار السيارات بالتجزئة والكراجات | الإيجابيات: فعالة من حيث التكلفة وجيدة النوعية. السلبيات: قد يكون لها ضمان محدود. |

| مولدات كهربائية عالية الإنتاج | مصممة للمركبات عالية الأداء، خرج أمبيرية أعلى | فرق السباقات ومتاجر الأداء | الإيجابيات: مصدر طاقة محسّن، مثالي للتعديلات. السلبيات: أكثر تكلفة، وقد يتطلب تركيباً محدداً. |

| المولدات أحادية السلك | أسلاك مبسطة، عادةً للطرازات القديمة | مرممو السيارات الكلاسيكية وأسواق السيارات القديمة | الإيجابيات: تركيب أسهل وتكلفة أقل. السلبيات: ميزات محدودة، قد لا تلبي متطلبات الطاقة الحديثة. |

| مولدات الديزل | مصممة لمحركات الديزل، بنية متينة | الآلات الثقيلة والمركبات التجارية | الإيجابيات: تصميم قوي ومناسب للتطبيقات عالية الطلب. السلبيات: أثقل وزناً، ويحتمل أن تكون الصيانة أعلى. |

ما هي خصائص المولدات الجديدة؟

يتم تصنيع مولدات المولدات الجديدة من الصفر، مما يضمن استيفاءها لأحدث المواصفات ومعايير الأداء. وعادةً ما تأتي مع ضمانات توفر راحة البال للمشترين من الشركات. هذه المكونات مناسبة للشركات التي تركز على الجودة والموثوقية، مثل شركات تصنيع السيارات وورش التصليح. عند الشراء، ضع في اعتبارك متطلبات السيارة المحددة وإمكانية الأداء على المدى الطويل، على الرغم من الاستثمار الأولي الأعلى.

كيف يمكن المقارنة بين المولدات المعاد تصنيعها؟

يتم تجديد المولدات المعاد تصنيعها من قطع مستعملة وتخضع لاختبارات صارمة لضمان الجودة. وهي توفر حلاً فعالاً من حيث التكلفة للشركات مثل تجار قطع غيار السيارات بالتجزئة والكراجات، حيث تكون قيود الميزانية ضرورية. وعلى الرغم من أنها توفر توازناً جيداً بين الأداء والسعر، يجب أن يكون المشترون على دراية بقيود الضمان والتباين المحتمل في الجودة. من الضروري الحصول على هذه القطع من موردين ذوي سمعة جيدة لضمان الموثوقية.

ما الذي يجب أن تعرفه عن المولدات عالية الإنتاجية؟

تم تصميم المولدات عالية الإنتاجية خصيصاً للمركبات عالية الأداء، حيث توفر أمبيرية متزايدة لدعم المتطلبات الكهربائية الإضافية. وهي ضرورية لفرق السباقات وورش الأداء حيث تتطلب السيارات المعدلة أنظمة طاقة معززة. وعلى الرغم من أنها توفر مزايا كبيرة في إمداد الطاقة، إلا أنه يجب على المشترين الموازنة بين المزايا مقابل التكاليف المرتفعة وتعقيدات التركيب المحتملة. إن فهم النظام الكهربائي للسيارة أمر بالغ الأهمية عند التفكير في هذه المولدات.

لماذا تختار المولدات ذات السلك الواحد؟

تعمل مولدات المولدات أحادية السلك على تبسيط عملية التركيب من خلال توصيل سلك واحد، مما يجعلها مثالية للسيارات القديمة ومُجددي السيارات الكلاسيكية. تميل هذه المولدات إلى أن تكون أقل تكلفة من نظيراتها متعددة الأسلاك، ولكن يجب على الشركات أن تأخذ بعين الاعتبار ما إذا كانت قادرة على تلبية متطلبات الطاقة الحديثة. هذه المولدات هي الأنسب للأسواق المتخصصة حيث يتم إعطاء الأولوية للبساطة والتكلفة على الميزات المتقدمة.

كيف تختلف مولدات الديزل؟

صُممت مولدات الديزل للتطبيقات الشاقة، حيث توفر أداءً قويًا لمحركات الديزل الموجودة في المركبات التجارية والآلات الثقيلة. متانتها تجعلها الخيار المفضل للشركات العاملة في البيئات الصعبة. وعلى الرغم من أنها توفر موثوقية وإنتاجية عالية، إلا أن المفاضلة قد تتضمن تصميمًا أثقل واحتياجات صيانة أعلى. يجب على المشترين تقييم المتطلبات المحددة لتطبيقاتهم لضمان التوافق والفعالية.

التطبيقات الصناعية الرئيسية لكمية تكلفة مولد التيار المتردد

| الصناعة/القطاع | التطبيق المحدد لتكلفة مولد التيار المتردد | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | تقدير تكلفة خطوط تجميع المركبات | وضع ميزانية دقيقة لتكاليف الإنتاج | المواصفات الخاصة بموديلات السيارات وأنواعها المختلفة |

| الطاقة المتجددة | توريد المولدات لأنظمة طاقة الرياح والطاقة الشمسية | يضمن توليد الطاقة وتخزينها بشكل موثوق | التوافق مع الأنظمة الحالية والمعايير الدولية |

| معدات البناء | المولدات البديلة للماكينات الثقيلة | تقليل وقت التعطل إلى الحد الأدنى والحفاظ على الكفاءة التشغيلية | مواصفات الخدمة الشاقة وخيارات الضمان |

| النقل واللوجستيات | المولدات لمركبات الأسطول | تعزيز موثوقية وسلامة عمليات النقل | اتفاقيات الشراء بالجملة وسمعة الموردين |

| الصناعة البحرية | المولدات الكهربائية للسفن والمنصات البحرية | يضمن إمدادات طاقة ثابتة للعمليات الحرجة | الامتثال للوائح التنظيمية البحرية والمعايير البيئية |

كيف يتم استخدام ‘كم تكلفة مولد التيار المتردد’ في صناعة السيارات؟

في قطاع تصنيع السيارات، يعد فهم تكلفة المولدات الكهربائية أمرًا بالغ الأهمية لوضع الميزانية أثناء تجميع السيارات. يساعد التقدير الدقيق للتكلفة الشركات المصنعة على تخصيص الموارد بفعالية، مما يضمن بقاء خطوط الإنتاج فعالة ومربحة. يجب أن يأخذ المشترون في الاعتبار المتطلبات المحددة لمختلف طرازات السيارات، بما في ذلك أنماط التيار الكهربائي والتركيب، لضمان التوافق. بالإضافة إلى ذلك، يعد توفير مصادر المولدات التي تتوافق مع معايير الجودة العالمية أمرًا ضروريًا للعمليات العالمية، لا سيما في الأسواق الناشئة مثل أفريقيا وأمريكا الجنوبية.

ما هو دور المولدات الكهربائية في تطبيقات الطاقة المتجددة؟

في تطبيقات الطاقة المتجددة، مثل أنظمة الطاقة الشمسية وطاقة الرياح، تُعد المولدات الكهربائية محورية لتحويل الطاقة الميكانيكية إلى طاقة كهربائية. تحتاج الشركات إلى تقييم تكلفة المولدات لضمان تشغيل أنظمة الطاقة الخاصة بها بشكل موثوق وفعال. يجب أن يركز المشترون في هذا القطاع على تحديد مصادر المولدات التي تلبي متطلبات الجهد والتيار الكهربائي المحددة، بالإضافة إلى التوافق مع أنظمة الطاقة الحالية. علاوة على ذلك، فإن فهم اللوائح المحلية والمعايير الدولية أمر بالغ الأهمية للشركات العاملة في أسواق متنوعة، بما في ذلك أوروبا والشرق الأوسط.

ما أهمية استبدال المولد في معدات البناء؟

بالنسبة لصناعة معدات البناء، تؤثر تكلفة المولدات بشكل مباشر على ميزانيات الصيانة. غالبًا ما تعتمد الآلات الثقيلة على مولدات كهربائية قوية لتعمل على النحو الأمثل، ويمكن أن تؤدي عمليات الاستبدال في الوقت المناسب إلى تقليل وقت التعطل بشكل كبير. يجب على المشترين إعطاء الأولوية للمشترين في الحصول على مولدات المولدات الثقيلة التي يمكنها تحمل ظروف العمل القاسية مع ضمان الامتثال لمواصفات الشركة المصنعة. بالإضافة إلى ذلك، فإن النظر في خيارات الضمان يمكن أن يوفر قيمة وأمانًا طويل الأجل للشركات العاملة في مناطق مثل البرازيل وفيتنام، حيث تكون موثوقية المعدات أمرًا بالغ الأهمية.

كيف تعمل المولدات على تحسين العمليات في مجال النقل والخدمات اللوجستية؟

في قطاع النقل والخدمات اللوجستية، تُعد تكلفة مولدات التيار المتردد أمرًا حيويًا للحفاظ على موثوقية أسطول المركبات. يمكن أن يؤدي تعطل مولد التيار المتردد إلى اضطرابات تشغيلية، مما يؤثر على جداول التسليم ورضا العملاء. يجب على الشركات النظر بعناية في اتفاقيات التوريد التي تسمح بالشراء بالجملة لتقليل التكاليف مع ضمان جودة المولدات. علاوة على ذلك، يمكن أن تؤدي المواءمة مع الموردين ذوي السمعة الطيبة الذين يفهمون الاحتياجات المحددة لمركبات الأساطيل إلى تعزيز الكفاءة التشغيلية في مختلف الأسواق الدولية.

ما هي الآثار المترتبة على المولدات في الصناعة البحرية؟

في الصناعة البحرية، تُعد المولدات الكهربائية ضرورية لضمان إمدادات طاقة ثابتة على السفن والمنصات البحرية. تعد تكلفة هذه المكونات أمرًا بالغ الأهمية لوضع ميزانية الصيانة وضمان سلامة العمليات البحرية. يجب أن يأخذ المشترون في الاعتبار الحصول على مولدات تتوافق مع اللوائح البحرية والمعايير البيئية الصارمة، خاصة في المياه الدولية. سيساعد فهم متطلبات الطاقة المحددة للتطبيقات البحرية الشركات على اتخاذ قرارات شراء مستنيرة، مما يعزز في النهاية موثوقية عملياتها في الأسواق العالمية المتنوعة.

3 نقاط ألم شائعة للمستخدمين حول ‘كم تكلفة المولد’ وحلولها

السيناريو 1: فهم تباين تكلفة المولدات عبر الأسواق المختلفة

المشكلة: غالبًا ما يواجه المشترون بين الشركات تحديات كبيرة في فهم تباين تكلفة المولدات عبر المناطق المختلفة. على سبيل المثال، قد يجد المشتري في أمريكا الجنوبية أن سعر نفس المولد أعلى بكثير من سعره في أوروبا بسبب اختلاف تكاليف سلسلة التوريد، وتعريفات الاستيراد، وظروف السوق المحلية. يمكن أن يؤدي عدم الوضوح هذا إلى مشاكل في وضع الميزانية وقرارات سيئة بشأن المخزون، خاصةً عند الحصول على قطع غيار لأسطول من المركبات.

الحل: وللتغلب على هذا التعقيد، يجب على المشترين بين الشركات إجراء بحث شامل للسوق خاص بمنطقتهم. يمكن أن يوفر استخدام مزيج من رؤى الموردين المحليين وقواعد بيانات الأسعار الدولية صورة أكثر دقة لسوق المولدات الكهربائية. بالإضافة إلى ذلك، فإن إقامة علاقات مع موردين متعددين يمكن أن يوفر نفوذاً في المفاوضات، مما يضمن للمشترين الوصول إلى أسعار تنافسية. من المفيد أيضًا مراعاة تكاليف الشحن والمناولة عند تقييم إجمالي النفقات. يمكن أن يساعد إنشاء مصفوفة مقارنة التكاليف التي تتضمن عوامل مثل الضمان ودعم الخدمة وأوقات التسليم في اتخاذ قرارات مستنيرة تتماشى مع قيود الميزانية.

السيناريو 2: توفير مولدات عالية الجودة دون المساومة على التكلفة

المشكلة: تتمثل إحدى المشاكل الشائعة التي تواجه المشترين من الشركات في إغراء اختيار مولدات التيار المتردد منخفضة التكلفة لتوفير المال، مما قد يؤدي إلى مشاكل في الجودة والموثوقية. على سبيل المثال، قد يبدو في البداية أن الحصول على مولدات التيار المتردد المعاد تصنيعها بسعر منافس فعال من حيث التكلفة؛ ومع ذلك، قد لا تفي هذه القطع بالمواصفات المطلوبة، مما يؤدي إلى زيادة معدلات الأعطال والإصلاحات اللاحقة. وهذا أمر مثير للقلق بشكل خاص بالنسبة للشركات التي تعتمد على وقت تشغيل المركبات في عملياتها.

الحل: وللتغلب على هذا التحدي، يجب على المشترين إعطاء الأولوية للجودة على التوفير في التكلفة الأولية. يمكن أن يؤدي إجراء العناية الواجبة على الموردين من خلال مراجعة شهاداتهم وعروض الضمان وملاحظات العملاء إلى توفير رؤى حول موثوقية المولدات. من المستحسن أيضًا النظر في التكلفة الإجمالية للملكية، والتي تشمل تكاليف الإصلاح المحتملة ووقت التعطل. يمكن أن يساعد تنفيذ إجراءات تشغيل قياسية لفحص الجودة عند استلام المولدات على ضمان تركيب الأجزاء التي تفي بالمواصفات المطلوبة فقط. علاوة على ذلك، يمكن أن يؤدي التفاوض على خصومات الشراء بالجملة مع الموردين الموثوق بهم إلى تخفيف التكاليف مع ضمان الجودة.

السيناريو 3: إدارة الأثر المالي لأعطال المولدات الكهربائية

المشكلة: غالبًا ما يستخف المشترون من الشركات بالآثار المالية المترتبة على أعطال المولدات، والتي يمكن أن تؤدي إلى نفقات غير مخطط لها وتعطلات تشغيلية. على سبيل المثال، إذا تعرضت إحدى مركبات الأسطول لعطل في مولد التيار المتردد، فإن ذلك لا يؤدي فقط إلى تكبد تكاليف الإصلاح، بل يؤدي أيضًا إلى فقدان الإنتاجية وخسائر محتملة في الإيرادات أثناء فترة التعطل. هذا السيناريو مهم بشكل خاص للشركات في قطاعات مثل الخدمات اللوجستية والنقل، حيث تكون موثوقية المركبات ذات أهمية قصوى.

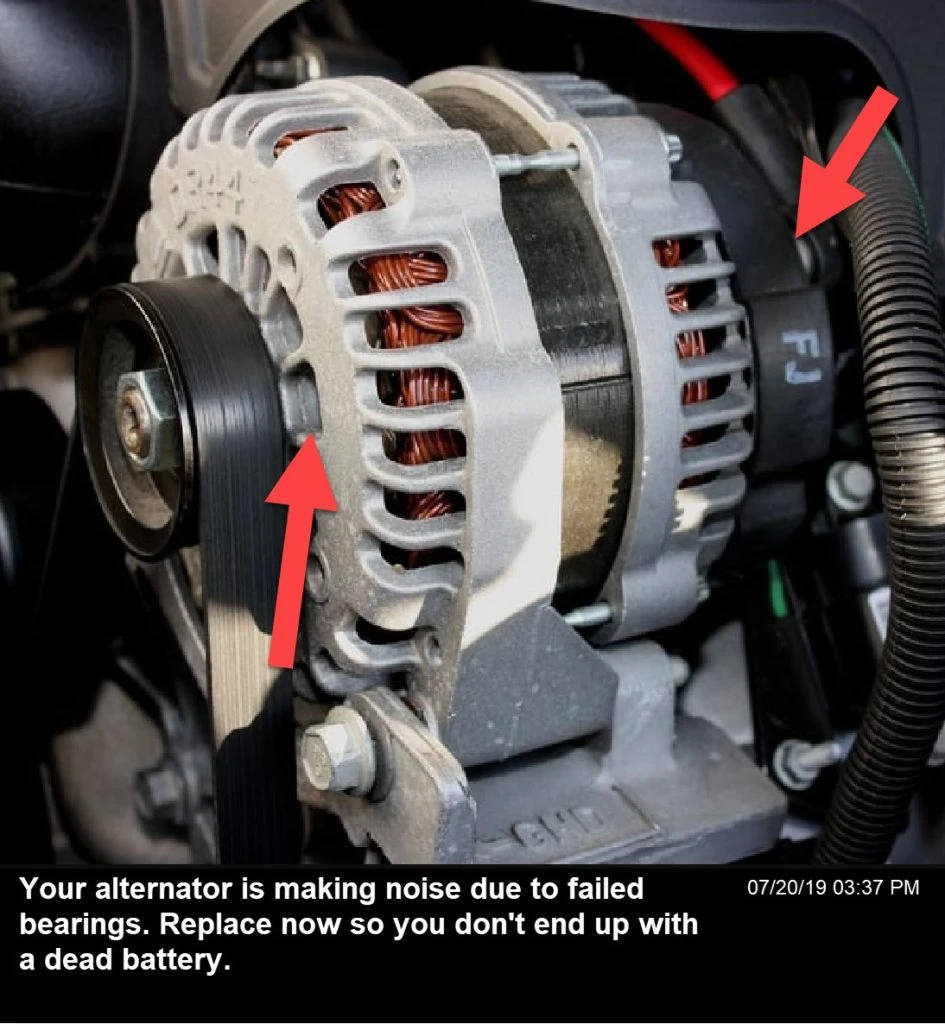

الحل: لإدارة التأثير المالي لأعطال المولد بفعالية، يجب على الشركات تنفيذ استراتيجية صيانة استباقية تتضمن فحوصات وتشخيصات منتظمة للنظام الكهربائي، بما في ذلك المولد. يمكن أن يساعد وضع جدول صيانة يتماشى مع متوسط العمر الافتراضي لمولدات التيار المتردد في التخفيف من الأعطال غير المتوقعة. بالإضافة إلى ذلك، فإن الاستثمار في تدريب الموظفين على كيفية التعرف على العلامات المبكرة لمشاكل المولد - مثل الأضواء الخافتة أو الأصوات غير المعتادة - يمكن أن يمنع حدوث مشاكل أكثر خطورة في المستقبل. كما أن إنشاء ميزانية احتياطية للإصلاحات الطارئة يمكن أن يساعد أيضًا في تخفيف الضربة المالية عند حدوث أعطال، مما يضمن عدم انقطاع العمليات.

دليل اختيار المواد الاستراتيجية لمعرفة تكلفة مولد التيار المتردد

ما هي المواد الشائعة المستخدمة في المولدات الكهربائية وانعكاساتها من حيث التكلفة؟

عند النظر في تكلفة المولدات الكهربائية، تلعب المواد المستخدمة في بنائها دورًا مهمًا في تحديد كل من الأداء والتسعير. ويمكن أن يساعد فهم الخصائص والمزايا والعيوب والآثار المترتبة على المشترين الدوليين في اتخاذ قرارات الشراء الاستراتيجية.

كيف يؤثر النحاس على أداء المولد وتكلفته؟

النحاس هو المادة الأساسية المستخدمة في المولدات الكهربائية، خاصةً في اللفات والتوصيلات الكهربائية. وتضمن الموصلية الكهربائية الممتازة له توليد الطاقة بكفاءة وأقل قدر من فقدان الطاقة.

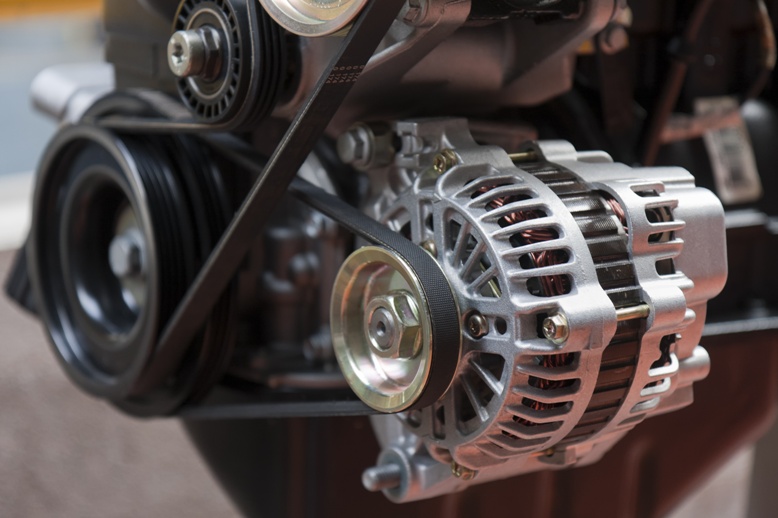

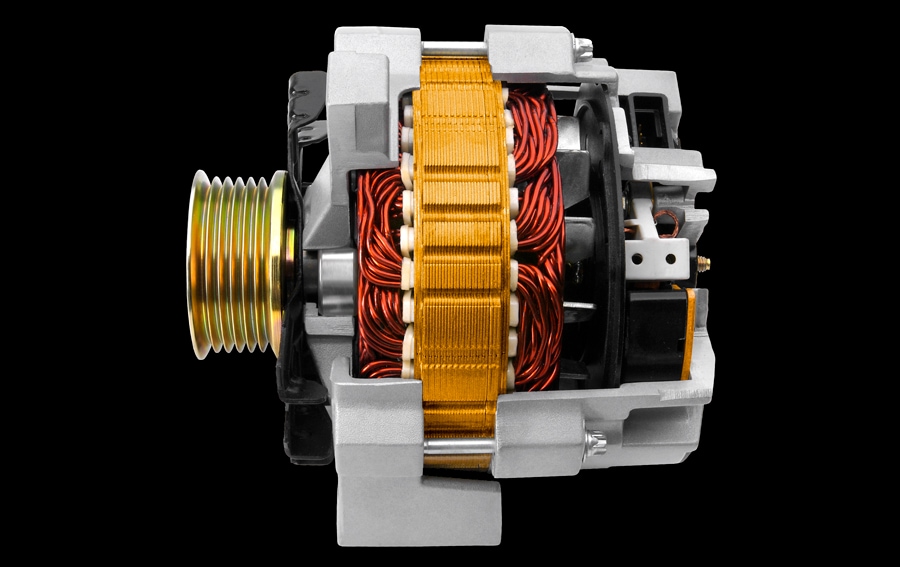

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

الخصائص الرئيسية: يمكن للنحاس أن يتحمل درجات الحرارة العالية ويتمتع بمقاومة جيدة للتآكل، مما يجعله مناسبًا لتطبيقات السيارات حيث تنتشر الحرارة والرطوبة.

الإيجابيات والسلبيات: وتساهم متانة النحاس في طول عمر المولدات الكهربائية، ولكنها تأتي بتكلفة أعلى مقارنة بالبدائل مثل الألومنيوم. تعقيد التصنيع معتدل، حيث يتطلب النحاس معالجة متخصصة أثناء الإنتاج.

التأثير على التطبيق: إن توافق النحاس مع الأحمال الكهربائية العالية يجعله مثاليًا للمركبات الحديثة التي تتطلب طاقة كبيرة لمختلف الأنظمة الإلكترونية.

اعتبارات للمشترين الدوليين: ومن الضروري الامتثال للمعايير الدولية مثل ASTM B170 للأسلاك النحاسية. كما يجب على المشترين في مناطق مثل أفريقيا وأمريكا الجنوبية النظر في خيارات التوريد المحلية لتخفيف تكاليف الاستيراد.

ما الدور الذي يلعبه الألومنيوم في تصنيع المولد؟

غالبًا ما يستخدم الألومنيوم كبديل فعال من حيث التكلفة للنحاس في بناء المولدات المترددة، وخاصة في الدوار والمبيت.

الخصائص الرئيسية: يتميز الألومنيوم بخفة الوزن والتوصيل الحراري الجيد، مما يساعد في تبديد الحرارة.

الإيجابيات والسلبيات: وعلى الرغم من أن الألومنيوم أقل تكلفة وأسهل في العمل، إلا أن توصيله الكهربائي المنخفض مقارنة بالنحاس يمكن أن يؤدي إلى انخفاض الكفاءة. قد تؤثر هذه المفاضلة على الأداء العام للمولد، خاصة في التطبيقات عالية الطلب.

التأثير على التطبيق: يعد الألومنيوم مناسباً للمركبات خفيفة الوزن أو التطبيقات التي يكون فيها توفير الوزن أمراً بالغ الأهمية، ولكنه قد لا يؤدي بشكل جيد في سيناريوهات الحمولة العالية.

اعتبارات للمشترين الدوليين: إن الامتثال لمعايير مثل DIN 1725 لسبائك الألومنيوم أمر بالغ الأهمية. يجب على المشترين تقييم السوق المحلي لأسعار الألومنيوم وتوافره، خاصةً في مناطق مثل الشرق الأوسط حيث يتم الحصول على الألومنيوم عادةً من مصادره.

كيف يساهم الفولاذ في السلامة الهيكلية للمولدات؟

يُستخدم الفولاذ بشكل شائع في الغلاف والمكونات الهيكلية لمولدات التيار المتردد، مما يوفر القوة والمتانة.

الخصائص الرئيسية: يوفر الفولاذ قوة شد عالية ومقاومة للتشوه تحت الضغط، مما يجعله مناسباً لحماية المكونات الداخلية.

الإيجابيات والسلبيات: وتتمثل الميزة الرئيسية للفولاذ في متانته، ولكنه أثقل من الألومنيوم، مما قد يؤثر على الوزن الإجمالي للمركبة. كما أن تعقيد التصنيع أعلى بسبب الحاجة إلى التصنيع الآلي واللحام.

التأثير على التطبيق: إن متانة الفولاذ تجعله مثالياً للاستخدامات الشاقة، ولكن قد يكون وزنه عيباً في السيارات ذات الأداء العالي.

اعتبارات للمشترين الدوليين: من المهم الامتثال لمعايير مثل ASTM A36 للصلب الهيكلي. يجب على المشترين النظر في الآثار المترتبة على تكاليف الشحن للمواد الأثقل، خاصة في المناطق ذات قدرات التصنيع المحلية المحدودة.

ما هو دور البلاستيك في مكونات المولد؟

يتم استخدام البلاستيك بشكل متزايد في المكونات غير الهيكلية لمولدات الكهرباء، مثل العوازل والأغلفة الخاصة بالتوصيلات الكهربائية.

الخصائص الرئيسية: يتميز البلاستيك بخفة وزنه ومقاومته للتآكل، مما يجعله مناسباً لمختلف الظروف البيئية.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

الإيجابيات والسلبيات: على الرغم من أن البلاستيك فعّال من حيث التكلفة وخفيف الوزن، إلا أنه قد لا يتحمل درجات الحرارة العالية مثل المعادن. يمكن أن تختلف متانتها بشكل كبير بناءً على نوع البلاستيك المستخدم.

التأثير على التطبيق: يمكن أن يساعد البلاستيك في تقليل الوزن الإجمالي للمولّد، ولكن قد تقيد القيود الحرارية الخاصة به من الاستخدام في التطبيقات عالية الأداء.

اعتبارات للمشترين الدوليين: يجب على المشترين التأكد من امتثال المكونات البلاستيكية لمعايير مثل ISO 9001 لإدارة الجودة. وفي أسواق مثل أوروبا، حيث اللوائح البيئية صارمة، قد يكون الحصول على المواد البلاستيكية الصديقة للبيئة أولوية أيضاً.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

جدول ملخص الاعتبارات المادية للمولدات الكهربائية

| المواد | حالة الاستخدام النموذجية لمقدار تكلفة المولدات الكهربائية | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | الملفات والتوصيلات الكهربائية | توصيلية ومتانة ممتازة | تكلفة أعلى مقارنة بالبدائل | عالية |

| الألومنيوم | الدوار والمبيت | خفيفة الوزن وفعالة من حيث التكلفة | موصلية أقل من النحاس | متوسط |

| الصلب | المكونات الهيكلية | قوة ومتانة عالية | أثقل وزناً، مما يؤثر على وزن السيارة | متوسط |

| بلاستيك | العوازل والمكونات غير الهيكلية | خفيف الوزن ومقاوم للتآكل | القيود الحرارية والمتانة المتغيرة | منخفض |

في الختام، يؤثر اختيار المواد في تصنيع المولدات بشكل كبير على الأداء والتكلفة والملاءمة لمختلف التطبيقات. يجب على المشترين الدوليين النظر في المعايير المحلية وخيارات التوريد لتحسين استراتيجيات الشراء الخاصة بهم.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لكمية تكلفة مولد التيار المتردد

ما هي المراحل الرئيسية في عملية تصنيع المولدات الكهربائية؟

ينطوي تصنيع المولدات على عدة مراحل حاسمة، كل منها مصمم لضمان أن المنتج النهائي يفي بمعايير الأداء ومعايير الجودة المطلوبة. ويمكن أن يساعد فهم هذه المراحل المشترين بين الشركات على تقييم موثوقية الموردين المحتملين وفعالية تكلفتهم.

1. تحضير المواد: ما هي المواد المستخدمة في إنتاج المولد؟

تبدأ عملية التصنيع بالاختيار الدقيق للمواد الخام وإعدادها. وتشمل المكونات الرئيسية للمولدات الكهربائية ما يلي:

- الأسلاك النحاسية: ضروري لملف الجزء الثابت والدوّار، ويتم اختيار النحاس لتوصيله الكهربائي الممتاز.

- ألواح الصلب: تُستخدم هذه الألواح في مجموعة الجزء الثابت، ويتم تكديسها وعزلها لإنشاء المجال المغناطيسي اللازم لتوليد الكهرباء.

- علب من الألومنيوم أو البلاستيك: تحمي هذه المواد المكونات الداخلية من العوامل البيئية والأضرار الميكانيكية.

قبل الإنتاج، تخضع المواد لفحوصات جودة صارمة للتأكد من مطابقتها للمواصفات اللازمة. وتتضمن هذه المرحلة التحقق من التركيب الكيميائي والخصائص الفيزيائية للمواد، والتي يمكن أن تؤثر على الأداء العام للمولد.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

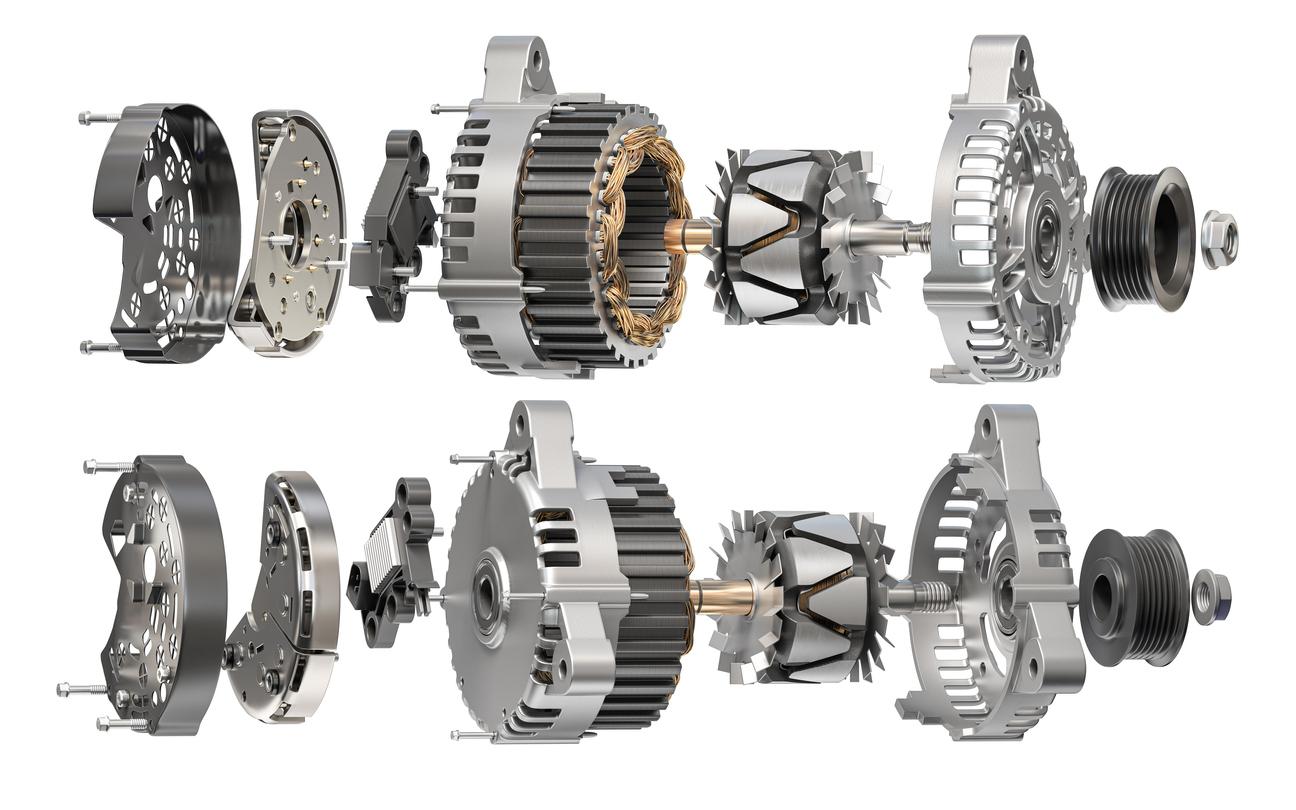

2. التشكيل: كيف يتم تشكيل مكونات المولد وتجميعها؟

تتضمن مرحلة التشكيل تشكيل المواد المحضرة إلى المكونات المطلوبة للمولد. ويشمل ذلك:

- تشكيل الجزء الثابت والدوّار: يتم ختم الصفائح الفولاذية في أشكال محددة ويتم لفها بأسلاك نحاسية. ويتم أيضاً تشكيل الدوار ولفه لإنشاء المجالات الكهرومغناطيسية اللازمة.

- التصنيع الآلي: قد تخضع المكونات لعمليات تصنيع آلي لتحقيق أبعاد دقيقة، مما يضمن توافقها معًا بسلاسة.

وغالبًا ما يتم استخدام تقنيات متقدمة مثل التصنيع باستخدام التحكم العددي بالكمبيوتر (CNC) لتعزيز الدقة وقابلية التكرار. وتعتبر هذه الدقة حاسمة بالنسبة لأداء المولد وخاصة فيما يتعلق بإخراج الجهد والكفاءة.

3. التجميع: ما هي التقنيات المستخدمة لتجميع المولدات؟

عملية التجميع هي المرحلة التي يتم فيها تجميع المكونات الفردية معًا لتشكيل المولد الكامل. تتضمن هذه المرحلة عادةً ما يلي:

- تكامل المكونات: يتم تجميع الجزء الثابت والدوار والثنائيات والمكونات الأخرى داخل المبيت. ويجب أن يضمن التجميع أن التوصيلات الكهربائية آمنة لمنع حدوث أعطال.

- الختم والعزل: المكونات محكمة الغلق للحماية من الرطوبة والملوثات التي يمكن أن تضعف الأداء. يتم استخدام مواد عازلة لمنع حدوث قصور كهربائي.

الجودة أثناء التجميع أمر بالغ الأهمية؛ فالتركيب غير السليم يمكن أن يؤدي إلى عدم الكفاءة أو العطل الميكانيكي، مما يؤدي في النهاية إلى زيادة تكاليف الاستبدال.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

4. التشطيب: كيف يتم إعداد المولد للسوق؟

تتضمن مرحلة التشطيب عمليات تحسين مظهر المولد وحمايته من العوامل البيئية. قد تتضمن هذه المرحلة:

- معالجة السطح: قد تخضع المكونات لعملية طلاء بأكسيد الألومنيوم أو مسحوق الطلاء لتحسين المتانة ومقاومة التآكل.

- الفحص والاختبار النهائي: يخضع كل مولد لاختبارات صارمة لضمان استيفائه لمعايير الأداء. ويشمل ذلك فحوصات للإخراج الكهربائي والثبات الميكانيكي ومستويات الضوضاء.

ما هي معايير مراقبة الجودة لتصنيع المولدات؟

يعد ضمان الجودة أمرًا حيويًا في ضمان أداء المولدات بشكل موثوق وآمن. يجب أن يكون المشترون من الشركات على دراية بالمعايير الدولية ذات الصلة والمعايير الخاصة بالصناعة.

المعايير الدولية: كيف تؤثر الأيزو 9001 وغيرها على الجودة؟

ISO 9001 هو معيار معترف به على نطاق واسع لإدارة الجودة يحدد أفضل الممارسات لعمليات التصنيع. ويضمن الامتثال لمعيار الأيزو 9001 أن تحافظ الشركات المصنعة على جودة متسقة وتحسن عملياتها باستمرار.

وبالإضافة إلى ذلك، قد تنطبق شهادات مثل CE (المطابقة الأوروبية) وAPI (معهد البترول الأمريكي) اعتمادًا على الاستخدام المقصود للمولد. تشير هذه الشهادات إلى أن المنتجات تفي بمتطلبات السلامة والأداء المحددة، والتي يمكن أن تكون حاسمة بالنسبة للمشترين الدوليين.

نقاط التحقق من مراقبة الجودة: ما هي مراحل مراقبة الجودة الرئيسية؟

يتم دمج نقاط فحص مراقبة الجودة في جميع مراحل عملية التصنيع لاكتشاف العيوب في وقت مبكر. وتشمل نقاط الفحص الشائعة ما يلي:

- مراقبة الجودة الواردة (IQC): يتم فحص المواد عند وصولها للتأكد من مطابقتها للمواصفات.

- مراقبة الجودة أثناء الإنتاج (IPQC): تساعد عمليات الفحص المستمرة أثناء التصنيع في تحديد المشكلات في الوقت الفعلي.

- مراقبة الجودة النهائية (FQC): تخضع المولدات المكتملة لاختبارات صارمة، بما في ذلك الاختبارات الوظيفية والفحوصات البصرية.

تساعد نقاط الفحص هذه على تقليل العيوب وضمان وصول المنتجات عالية الجودة فقط إلى السوق.

ما هي طرق الاختبار الشائعة الاستخدام في إنتاج المولد؟

يعد الاختبار جانبًا مهمًا لضمان جودة المولدات الكهربائية. وتشمل الطرق الشائعة ما يلي:

- الاختبارات الكهربائية: التحقق من خرج الجهد وسعة التيار لضمان عمل المولد ضمن الحدود المحددة.

- الاختبارات الميكانيكية: تقييم متانة المكونات من خلال اختبارات الإجهاد وتحليل الاهتزازات.

- اختبار البيئة: تعريض المولدات لدرجات حرارة ورطوبة قصوى لتقييم أدائها في ظل ظروف مختلفة.

تساعد هذه الاختبارات على ضمان قدرة المولدات على تحمل ظروف التشغيل في العالم الحقيقي، وهو أمر مهم بشكل خاص للمشترين في المناخات المتنوعة.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

عند الحصول على مولدات الكهرباء، يجب على المشترين بين الشركات التحقق بنشاط من ممارسات مراقبة الجودة للموردين المحتملين. وتشمل الاستراتيجيات الرئيسية ما يلي:

- تدقيق الموردين: يمكن أن يوفر إجراء عمليات التدقيق الموقعي نظرة ثاقبة على عمليات التصنيع وإجراءات ضمان الجودة لدى المورد. وتساعد هذه الملاحظة المباشرة على تحديد المخاطر المحتملة.

- طلب تقارير الجودة: يجب على الموردين تقديم وثائق لعمليات مراقبة الجودة الخاصة بهم، بما في ذلك الشهادات، ونتائج الاختبارات، والامتثال للمعايير الدولية.

- إشراك مفتشي الطرف الثالث: يمكن أن يوفر استخدام خدمات الفحص من طرف ثالث تقييمًا غير متحيز لجودة المنتج قبل الشحن، مما يضمن استيفاء المولدات للمواصفات المطلوبة.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين؟

يجب أن يكون المشترون الدوليون بين الشركات، لا سيما من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، على دراية بالفروق الدقيقة المحددة في مراقبة الجودة. وقد تشمل هذه الفروق ما يلي:

- الامتثال التنظيمي: قد يكون للمناطق المختلفة أنظمة مختلفة فيما يتعلق بالمكونات الكهربائية. ومن الضروري فهم هذه المتطلبات لتجنب المشاكل القانونية واللوجستية.

- الاختلافات الثقافية في توقعات الجودة: يجب أن يكون المشترون على دراية بأن معايير الجودة قد تختلف من ثقافة إلى أخرى، مما يؤثر على توقعات الأداء والمتانة.

- التحديات اللوجستية: يمكن أن يؤدي الشحن الدولي إلى مخاطر، مثل التلف أثناء النقل. يعد ضمان التغليف والتأمين القوي أمرًا حيويًا للتخفيف من هذه المخاطر.

من خلال فهم عمليات التصنيع وممارسات ضمان الجودة هذه، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة عند الحصول على مولدات الكهرباء، مما يضمن في النهاية حصولهم على منتجات عالية الجودة تلبي احتياجاتهم التشغيلية.

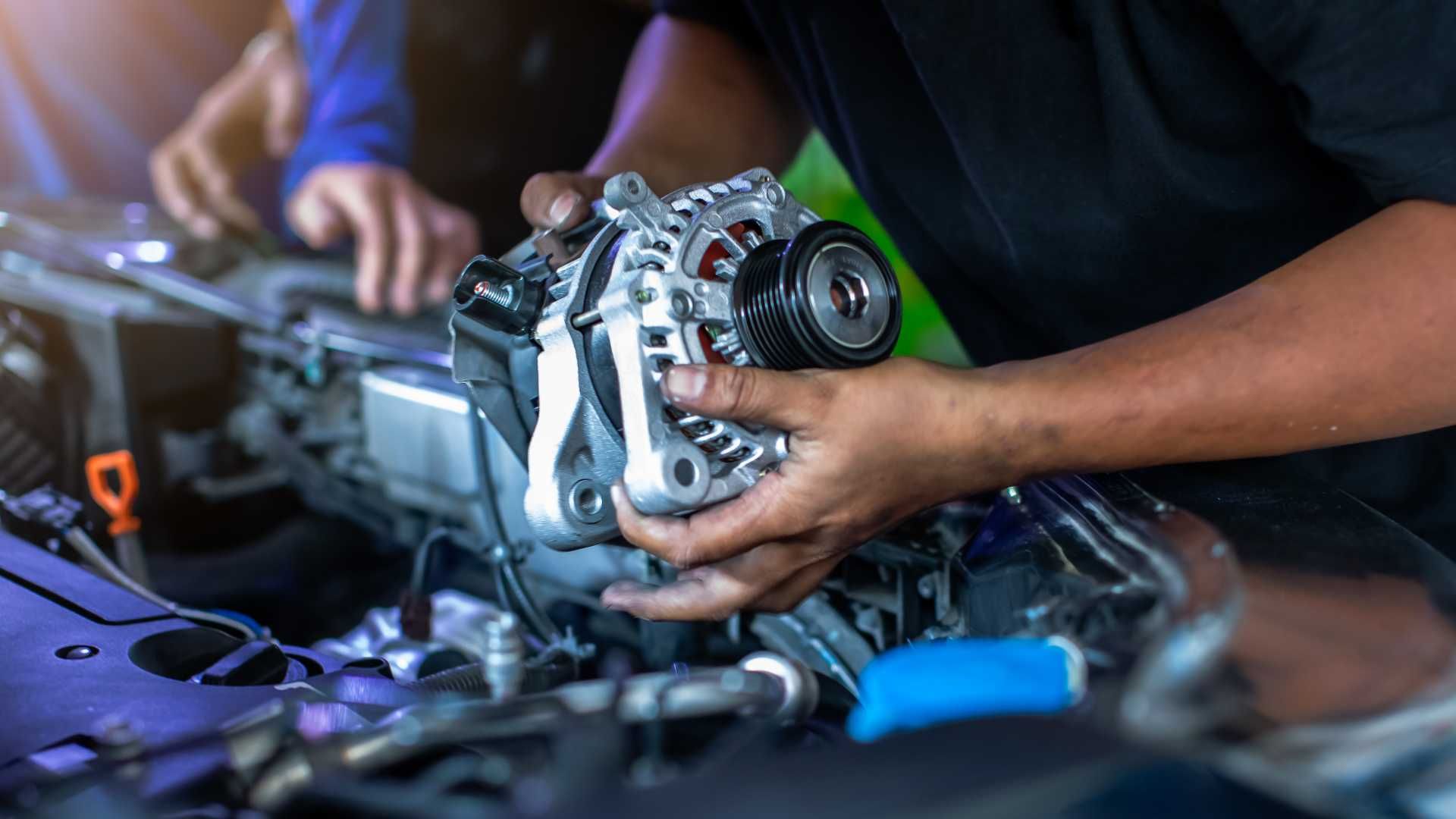

دليل عملي للمصادر: قائمة تدقيق خطوة بخطوة لـ ‘كم تبلغ تكلفة المولد’

في صناعة السيارات، يعد فهم تكلفة مولدات التيار المتردد أمرًا بالغ الأهمية للشركات العاملة في صيانة السيارات أو إصلاحها أو تصنيعها. يوفر هذا الدليل قائمة مرجعية عملية للمشترين بين الشركات لشراء مولدات التيار المتردد بفعالية واتخاذ قرارات شراء مستنيرة.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

قبل البدء في عملية الشراء، من الضروري أن تحدد بوضوح المواصفات الفنية لمولدات التيار المتردد التي تحتاج إليها. يتضمن ذلك عوامل مثل الطراز والموديل وحجم المحرك للمركبات التي تقوم بخدمتها، بالإضافة إلى قوة التيار المطلوبة. إن فهم هذه التفاصيل يضمن لك الحصول على المولدات الصحيحة التي تلبي احتياجاتك التشغيلية.

- ضع في اعتبارك الاختلافات: قد تتطلب المركبات المختلفة أنواعاً محددة من المولدات، مثل تكوينات ذات سلك واحد أو 3 أسلاك.

- تقييم متطلبات الطاقة: قم بتقييم الحمل الكهربائي للمركبات لتحديد الأمبيرية اللازمة.

الخطوة 2: أسعار سوق الأبحاث

قم بإجراء بحث شامل عن أسعار السوق الحالية لمولدات التيار المتردد. يمكن أن تتفاوت الأسعار بشكل كبير بناءً على عوامل مثل العلامة التجارية والنوع (جديد مقابل معاد التصنيع) والضمان المقدم. من خلال جمع بيانات الأسعار، يمكنك وضع ميزانية وتحديد الأسعار التنافسية.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

- المقارنة المعيارية: قارن الأسعار بين عدة موردين لتحديد خط أساس.

- ضع في اعتبارك التكلفة الإجمالية: ضع في اعتبارك تكاليف الشحن ورسوم الاستيراد والتركيب المحتملة.

الخطوة 3: تقييم شهادات الموردين

عند اختيار الموردين، فإن التحقق من شهاداتهم أمر بالغ الأهمية لضمان الجودة والموثوقية. ابحث عن الموردين الحاصلين على شهادات الصناعة ذات الصلة، مثل ISO أو ما يعادلها، والتي يمكن أن تشير إلى الالتزام بمعايير الجودة.

- طلب الوثائق: اسأل الموردين عن وثائق الاعتماد وعمليات ضمان الجودة الخاصة بهم.

- سمعة الصناعة: ابحث عن مراجعات الموردين وملاحظات الشركات الأخرى في مجال عملك.

الخطوة 4: تقييم خيارات الضمان والدعم

قم بتقييم شروط الضمان ودعم العملاء المقدم من الموردين. يمكن للضمان القوي حماية استثمارك وتقليل التكاليف المستقبلية المحتملة المرتبطة بالقطع المعيبة.

- مدة الضمان: قارن بين مدة الضمانات المقدمة على مولدات التيار المتردد الجديدة والمعاد تصنيعها.

- دعم ما بعد البيع: تأكد من أن المورد يوفر الدعم الفني الكافي وسياسات الإرجاع في حالة وجود عيوب.

الخطوة 5: طلب عينات أو إجراء اختبار

قبل الانتهاء من عملية الشراء، اطلب عينات أو قم بإجراء اختبارات على المولدات التي تنوي شراءها. يمكن أن يساعد الاختبار في التأكد مما إذا كانت المنتجات تلبي مواصفاتك وتوقعات الأداء الخاصة بك.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

- مقاييس الأداء: تحقق من خرج الجهد والمتانة في ظروف مختلفة.

- فحوصات التوافق: تأكد من ملاءمة المولدات بشكل صحيح مع المركبات المخصصة لها.

الخطوة 6: التفاوض على الشروط والأحكام

بمجرد تحديد المورد المناسب، يحين وقت التفاوض على شروط وأحكام الشراء. ويشمل ذلك السعر وشروط الدفع ومواعيد التسليم وسياسات الإرجاع.

- اتفاقيات طويلة الأجل: النظر في التفاوض للحصول على خصومات الشراء بالجملة أو عقود التوريد طويلة الأجل.

- المرونة في الشروط: استهدف شروط دفع مواتية تتماشى مع احتياجات التدفق النقدي لديك.

الخطوة 7: وضع اللمسات الأخيرة على طلب الشراء

بعد الاتفاق على الشروط، ضع اللمسات الأخيرة على طلب الشراء مع توثيق جميع التفاصيل ذات الصلة بوضوح. تأكد من أن كلا الطرفين يفهمان المواصفات والجداول الزمنية للتسليم وترتيبات الدفع لتجنب النزاعات المستقبلية.

- تحقق مرة أخرى من التفاصيل: تحقق من أن جميع المواصفات والشروط تنعكس بدقة في الطلب.

- الاحتفاظ بالسجلات: احتفظ بنسخ من جميع المراسلات والاتفاقيات للرجوع إليها في المستقبل.

من خلال اتباع هذه الخطوات، يمكن للمشترين بين الشركات التعامل مع تعقيدات شراء مولدات التيار المتردد، مما يضمن اتخاذ قرارات مستنيرة تعزز الكفاءة التشغيلية وتحافظ على موثوقية السيارة.

تحليل شامل للتكلفة والتسعير لمصادر التكلفة والتسعير لمقدار تكلفة المولد المولد

ما هي مكونات التكلفة الرئيسية التي تؤثر على تسعير المولد؟

عند توريد مولدات الكهرباء، يعد فهم هيكل التكلفة أمرًا ضروريًا للمشترين بين الشركات. وتشمل مكونات التكلفة الأساسية المواد، والعمالة، ونفقات التصنيع العامة، والأدوات، ومراقبة الجودة، والخدمات اللوجستية، وهوامش الربح.

-

المواد: تؤثر المواد الأساسية المستخدمة في مولدات التوليد، مثل النحاس للملفات والصلب للدوار والجزء الثابت، بشكل كبير على التكاليف. يمكن أن تتقلب أسعار هذه المواد بناءً على طلب السوق وتوافرها، مما قد يؤدي إلى تفاوت أسعار المولدات.

-

العمل: تختلف تكاليف العمالة حسب المنطقة التي يتم فيها إنتاج المولد. قد تقدم البلدان ذات تكاليف العمالة المنخفضة أسعاراً أكثر تنافسية، ولكن هذا قد يؤثر على الجودة.

-

تكاليف التصنيع العامة: ويشمل ذلك التكاليف المرتبطة بعمليات المصنع، مثل المرافق والصيانة والإدارة. ويمكن لعمليات التصنيع الفعالة أن تقلل من هذه التكاليف، وبالتالي من سعر المولد.

-

الأدوات: يمكن أن يكون الاستثمار في المعدات والأدوات المتخصصة لإنتاج نماذج محددة من المولدات كبيراً. وقد يؤدي تصنيع أدوات مخصصة لمواصفات فريدة من نوعها إلى ارتفاع التكاليف، والتي غالباً ما يتم تمريرها إلى المشتري.

-

مراقبة الجودة: عمليات مراقبة الجودة الصارمة ضرورية لضمان الموثوقية والأداء. وفي حين أن الضمان عالي الجودة يمكن أن يزيد من التكاليف، إلا أنه يمكن أن يقلل أيضاً من احتمال حدوث أعطال، وهو أمر بالغ الأهمية بالنسبة للمشترين من الشركات.

-

اللوجستيات: يمكن أن تختلف تكاليف الشحن بشكل كبير بناءً على المسافة من الشركة المصنعة إلى المشتري. يجب على المشترين الدوليين مراعاة رسوم الشحن والرسوم الجمركية والتأخيرات المحتملة في التسليم، وكلها يمكن أن تؤثر على السعر النهائي.

-

الهامش: يضيف الموردون عادةً هامش ربح لتغطية تكاليفهم وتحقيق الربحية. ويمكن أن يختلف هذا الهامش حسب المنافسة في السوق والطلب.

ما هي العوامل المؤثرة في أسعار المولدات في مجال التوريد بين الشركات؟

يمكن أن تؤثر عدة عوامل على أسعار المولدات، خاصةً بالنسبة للمشترين الدوليين:

-

الحجم/الحد الأدنى لكمية الطلب: يمكن أن يؤدي الشراء بالجملة في كثير من الأحيان إلى انخفاض أسعار الوحدة الواحدة. وينبغي أن يتفاوض المشترون للحصول على أسعار أفضل على أساس الحجم المتوقع.

-

المواصفات والتخصيص: قد تتكبد المولدات المصممة لماركات وموديلات سيارات معينة تكاليف إضافية. وستؤثر الميزات أو التعديلات المخصصة على الأسعار أيضاً.

-

جودة المواد والشهادات: قد تأتي المولدات التي تمتثل لمعايير أو شهادات جودة أعلى (مثل ISO) بسعر أعلى. وينبغي على المشترين تقييم ما إذا كانت التكلفة الإضافية تتماشى مع متطلبات الجودة الخاصة بهم.

-

عوامل الموردين: يمكن أن تؤثر سمعة المورد وموثوقيته أيضًا على التسعير. فقد يفرض الموردون الراسخون أسعاراً أعلى بسبب قيمة علامتهم التجارية وسجلهم الحافل.

-

مصطلحات التجارة الدولية: إن فهم شروط الشحن أمر بالغ الأهمية. فالشروط المتفق عليها تملي المسؤوليات بين البائع والمشتري فيما يتعلق بالشحن والتأمين والتعريفات الجمركية، مما قد يؤثر على التكاليف الإجمالية.

ما هي النصائح التي يمكن أن تساعد مشتري B2B في التفاوض على أسعار أفضل للمولدات؟

بالنسبة للمشترين الدوليين، لا سيما من أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، يمكن أن يؤدي التفاوض بفعالية إلى تحقيق وفورات كبيرة:

-

فهم التكلفة الإجمالية للملكية (TCO): تقييم ليس فقط سعر الشراء ولكن أيضًا التكاليف طويلة الأجل المرتبطة بالصيانة والضمان والأعطال المحتملة. قد لا يكون السعر الأولي المنخفض هو الخيار الأكثر فعالية من حيث التكلفة إذا كانت الجودة دون المستوى.

-

الاستفادة من علاقات الموردين: يمكن أن يؤدي بناء علاقات قوية مع الموردين إلى أسعار أفضل وشروط مواتية وخدمة ذات أولوية.

-

طلب عينات: قبل الالتزام بطلبات كبيرة، اطلب عينات لتقييم الجودة. وهذا يمكن أن يمنع حدوث أخطاء مكلفة في عمليات الشراء بالجملة.

-

كن على دراية بالفروق الدقيقة في التسعير: قد يكون للمناطق المختلفة استراتيجيات تسعير مختلفة بناءً على ظروف السوق المحلية. ويمكن أن يساعد فهم هذه الفروق الدقيقة المشترين على التفاوض بفعالية.

-

ابق على اطلاع على اتجاهات السوق: إن مواكبة تكاليف المواد وقضايا سلسلة التوريد العالمية يمكن أن توفر ميزة أثناء المفاوضات، مما يسمح للمشترين بتوقيت مشترياتهم بشكل أكثر استراتيجية.

إخلاء المسؤولية

الأسعار المذكورة في هذا التحليل إرشادية ويمكن أن تتقلب بناءً على عوامل مختلفة، بما في ذلك ظروف السوق واستراتيجيات تسعير الموردين ومتطلبات المشتري المحددة. يوصى بإجراء بحث شامل للسوق والتعامل مباشرةً مع الموردين للحصول على عروض أسعار دقيقة مصممة خصيصًا لتلبية احتياجاتك.

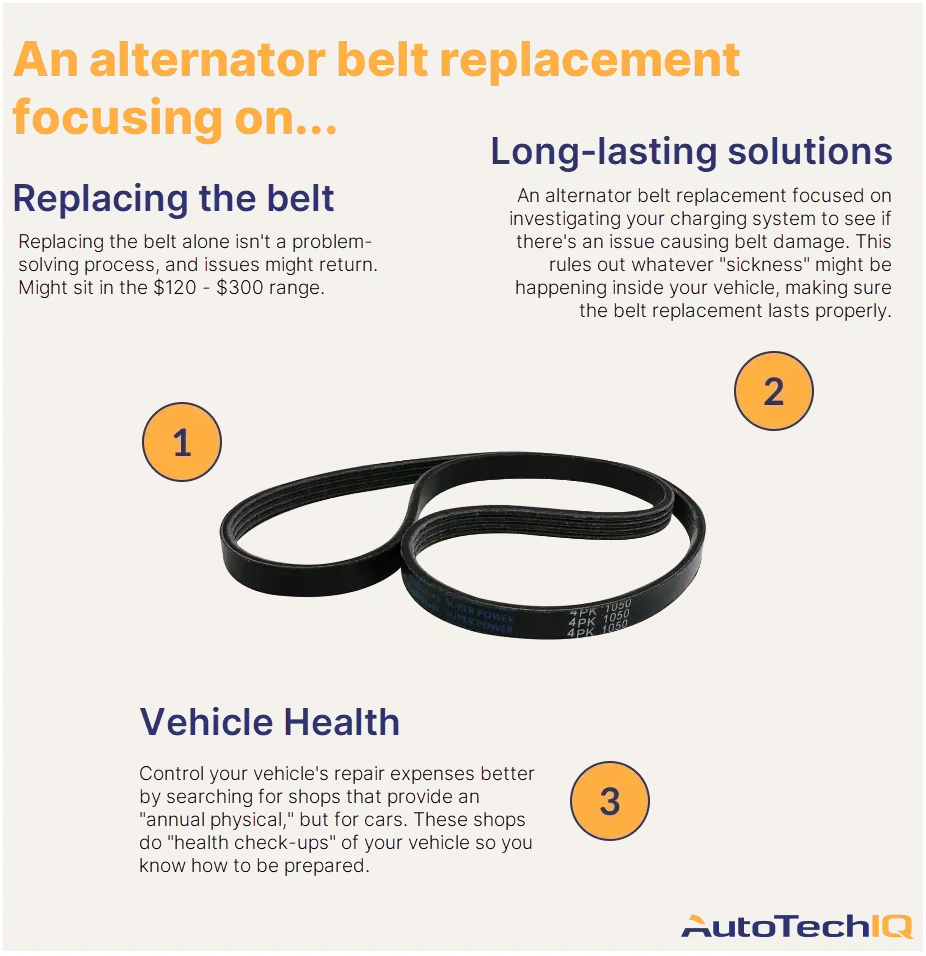

تحليل البدائل: مقارنة كم تكلفة المولد مع الحلول الأخرى

استكشاف بدائل المولدات في الأنظمة الكهربائية للسيارات

في صناعة السيارات، يعد مولد التيار المتردد مكونًا حاسمًا مسؤولاً عن تحويل الطاقة الميكانيكية إلى طاقة كهربائية، مما يضمن عمل الأنظمة الكهربائية المختلفة بشكل صحيح. ومع ذلك، يمكن النظر في بدائل مختلفة لتطبيقات محددة، لا سيما في السياقات التي قد لا تكون فيها المولدات التقليدية الحل الأكثر كفاءة أو فعالية من حيث التكلفة. يقارن هذا التحليل تكاليف وفوائد المولدات التقليدية مقابل بديلين قابلين للتطبيق: أنظمة البطاريات وأنظمة الطاقة الشمسية.

| جانب المقارنة | كم تبلغ تكلفة المولد | أنظمة البطاريات | أنظمة الطاقة الشمسية |

|---|---|---|---|

| الأداء | 100 - 1,000 دولار أمريكي | 150 - 800 دولار أمريكي | 1,000 - 3,000 دولار أمريكي |

| التكلفة | يمكن أن يضيف التركيب والعمالة 50-200 دولار أمريكي | يلزم الاستبدال المنتظم (2-5 سنوات) | استثمار أولي مرتفع، وتكلفة منخفضة على المدى الطويل |

| سهولة التنفيذ | معتدل؛ يتطلب تركيباً احترافياً | سهل الاستبدال ولكن يحتاج إلى مراقبة | معقد؛ يتطلب التثبيت والإعداد |

| الصيانة | معتدل؛ عادةً ما تكون الصيانة منخفضة | عالية؛ تتطلب فحوصات واستبدالات منتظمة | منخفضة؛ تحتاج إلى الحد الأدنى من الصيانة |

| أفضل حالة استخدام | المركبات التقليدية التي تحتاج إلى طاقة موثوقة | السيارات الكهربائية أو الأنظمة الهجينة | المركبات خارج الشبكة أو المركبات المستدامة |

تفصيل البدائل

أنظمة البطاريات

تزداد شعبية أنظمة البطاريات، وخاصة بطاريات الليثيوم أيون، في السيارات الكهربائية والهجينة. وهي توفر مصدر طاقة مدمج وفعال ولكنها تأتي مع مجموعة من التحديات الخاصة بها. على الرغم من أن التكلفة الأولية قد تكون أقل من تكلفة نظام المولدات الكهربائية، إلا أن البطاريات تتطلب عادةً استبدالها كل سنتين إلى 5 سنوات، وهو ما يمكن أن يتراكم مع مرور الوقت. الصيانة ضرورية أيضاً؛ فالفحوصات المنتظمة ضرورية لضمان الأداء الأمثل. ومع ذلك، توفر أنظمة البطاريات قدرات ممتازة لتخزين الطاقة، مما يجعلها مثالية للسيارات الكهربائية التي تعتمد على الطاقة المخزّنة.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

أنظمة الطاقة الشمسية

تمثّل أنظمة الطاقة الشمسية بديلاً مبتكراً لمولدات الطاقة التقليدية، خاصةً للمركبات المصممة لتحقيق الاستدامة. تعمل هذه الأنظمة على تسخير الطاقة الشمسية لشحن البطاريات، والتي يمكنها بعد ذلك تشغيل الأنظمة الكهربائية في السيارة. وفي حين أن الاستثمار الأولي أعلى بكثير، يمكن أن تؤدي أنظمة الطاقة الشمسية إلى تحقيق وفورات كبيرة بمرور الوقت نظراً لانخفاض تكاليفها التشغيلية والحد الأدنى من متطلبات الصيانة. ومع ذلك، فإن تعقيد التركيب والحاجة إلى أشعة الشمس الكافية يمكن أن يحدّ من إمكانية تطبيقها العملي في مناطق معينة أو لتطبيقات محددة. وهي الأنسب للمركبات خارج الشبكة أو تلك المصممة للمستهلكين المهتمين بالبيئة.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

عند التفكير في أفضل حل للطاقة لتطبيقات السيارات، يجب على مشتري B2B تقييم متطلباتهم المحددة، مثل توقعات الأداء وقيود التكلفة وقدرات الصيانة. تظل المولدات التقليدية خيارًا يمكن الاعتماد عليه للسيارات التقليدية، بينما قد تكون أنظمة البطاريات أكثر ملاءمة للتطبيقات الكهربائية أو الهجينة. بالنسبة لأولئك الذين يعطون الأولوية للاستدامة، توفر أنظمة الطاقة الشمسية بديلاً مستقبلياً، وإن كانت تكلفتها الأولية أعلى. في نهاية المطاف، يجب أن يتماشى القرار مع السياق التشغيلي والأهداف طويلة الأجل للأعمال، مما يضمن أن الحل المختار يلبي الاحتياجات الفورية وإمكانات النمو المستقبلية.

الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية لكمية تكلفة المولد الكهربائي

ما هي الخصائص التقنية الرئيسية للمولدات التي تؤثر على التكلفة؟

عند النظر في تكلفة المولد الكهربائي، تلعب العديد من المواصفات المهمة دورًا مهمًا في تحديد كل من السعر والملاءمة لتطبيقات محددة. يمكن أن يساعد فهم هذه الخصائص مشتري B2B على اتخاذ قرارات شراء مستنيرة.

1. تصنيف الأمبيرية

يشير تصنيف الأمبيرية لمولد التيار المتردد إلى قدرة الخرج الكهربائي الخاصة به، مقاسة بالأمبير. يمكن لمولدات التيار الأعلى أن تدعم المزيد من الأجهزة والأنظمة الكهربائية داخل السيارة، مما يجعلها أكثر ملاءمة للسيارات الحديثة المجهزة بالإلكترونيات المتقدمة. يجب على مشتري B2B النظر في المتطلبات الكهربائية لسيارتهم لتجنب التحميل الزائد أو الاستخدام الناقص لمولد التيار المتردد، مما قد يؤدي إلى عطل سابق لأوانه.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

2. نمط التركيب

يشير نمط التركيب إلى كيفية تأمين المولد داخل حجرة المحرك. تتطلب المركبات المختلفة تكوينات تركيب محددة، ويمكن أن يؤدي اختيار نمط غير صحيح إلى تركيب ووظيفة غير مناسبة. بالنسبة للمشترين الدوليين، يعد فهم متطلبات التركيب لطرازات السيارات المختلفة أمرًا بالغ الأهمية لضمان التوافق وتجنب التكاليف الإضافية المرتبطة بالتعديلات.

3. ناتج الجهد

عادةً ما ينتج مولد التيار المتردد القياسي للسيارات بين 13.5 و14.5 فولت. يعد نطاق الجهد هذا ضروريًا لشحن بطارية السيارة وتشغيل الأنظمة الكهربائية. يمكن أن يؤدي المولد الذي لا يفي بمواصفات الجهد هذه إلى استنزاف البطارية أو تعطل النظام الكهربائي. يجب على مشتري B2B التحقق من خرج الجهد عند الحصول على مولدات المولدات للتأكد من أنها تلبي احتياجاتهم التشغيلية.

4. تركيب المواد

يؤثر التركيب المادي للمولد، وخاصة المحتوى النحاسي في اللفات على متانته وأدائه. قد تتكبد المولدات ذات المواد عالية الجودة تكاليف أعلى ولكنها توفر عمر خدمة أطول وموثوقية أعلى. بالنسبة لمشتري B2B، يمكن أن يقلل الاستثمار في المواد عالية الجودة من تكرار الاستبدال، مما يؤدي في النهاية إلى خفض تكاليف التشغيل على المدى الطويل.

5. فترة الضمان

يمكن أن تختلف فترة الضمان المقدمة مع المولد بشكل كبير بين الشركات المصنعة. غالبًا ما تعكس فترة الضمان الأطول الثقة في متانة المنتج وأدائه. يجب على مشتري B2B النظر في شروط الضمان كجزء من تقييمهم للتكاليف، حيث يمكن أن تخفف من النفقات المستقبلية المتعلقة بالإصلاحات أو الاستبدال.

ما هي المصطلحات التجارية الشائعة المتعلقة بتكاليف المولد؟

إن الإلمام بالمصطلحات الخاصة بالصناعة أمر ضروري للمشترين في مجال الأعمال بين الشركات، خاصة عند التفاوض على الأسعار وفهم مواصفات المنتج.

1. OEM (الشركة المصنعة للمعدات الأصلية)

يشير مصطلح OEM إلى القطع المصنوعة من قبل الشركة المصنعة الأصلية للسيارة. وغالباً ما تكون أسعار مولدات التيار المتردد المصنوعة من OEM أعلى بسبب توافقها المضمون وجودتها. وعادةً ما يفضل المشترون قطع غيار OEM من أجل الموثوقية، خاصةً في التطبيقات عالية المخاطر حيث يمكن أن يؤدي تعطلها إلى تعطل كبير.

2. MOQ (الحد الأدنى لكمية الطلب)

موك هو أصغر كمية من المنتج الذي يرغب المورد في بيعه. يعد فهم موك أمرًا ضروريًا للمشترين بين الشركات، خاصةً عند الحصول على مولدات الكهرباء للأساطيل أو المركبات المتعددة. قد يقدم الموردون أسعارًا أفضل لكل وحدة للطلبات الأكبر، مما يجعل من المهم تقييم التكلفة الإجمالية مقابل الكمية المطلوبة.

3. طلب عرض أسعار (RFQ)

طلب عروض الأسعار عبارة عن مستند رسمي يتم إرساله إلى الموردين لطلب تسعير وتوافر منتجات محددة. بالنسبة لمولدات الكهرباء، يمكن أن يساعد طلب عرض الأسعار المشترين من الشركات على جمع أسعار وشروط تنافسية من موردين متعددين، مما يسهل اتخاذ قرارات الشراء المستنيرة.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

4. مصطلحات التجارة الدولية

المصطلحات التجارية الدولية هي مصطلحات تجارية دولية تحدد مسؤوليات المشترين والبائعين في الشحن الدولي. يعد فهم شروط التجارة الدولية مثل FOB (مجانًا على متن الطائرة) أو CIF (التكلفة والتأمين والشحن) أمرًا بالغ الأهمية للمشترين بين الشركات لتوضيح تكاليف الشحن والمخاطر المرتبطة بشراء المولدات الكهربائية من الموردين في الخارج.

5. سوق ما بعد البيع

يشير سوق ما بعد البيع إلى القطع والملحقات التي تباع للمركبات بعد البيع الأصلي. يمكن لمولدات ما بعد البيع أن توفر بدائل فعالة من حيث التكلفة لقطع غيار المعدات الأصلية، ولكن يجب على المشترين تقييم الجودة والتوافق لتجنب المشاكل المحتملة.

من خلال فهم هذه الخصائص التقنية الأساسية والمصطلحات التجارية، يمكن للمشترين بين الشركات التعامل مع تعقيدات شراء مولدات الكهرباء، مما يضمن اتخاذ قرارات مستنيرة تتماشى مع احتياجاتهم التشغيلية وقيود الميزانية.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع كم يكلف مولد التيار المتردد

ما هي محركات السوق الرئيسية التي تؤثر على تكاليف المولدات؟

يتأثر السوق العالمي لمولدات التيار المتردد بشكل كبير بالعديد من العوامل التي تحدد الأسعار والتوافر. ويُعد ارتفاع إنتاج المركبات، خاصة في المناطق النامية مثل أفريقيا وأمريكا الجنوبية، محركًا أساسيًا. يتزايد الطلب على الأنظمة الكهربائية الموثوقة في المركبات، مما يؤدي إلى زيادة الحاجة إلى مولدات التيار المتردد. بالإضافة إلى ذلك، فإن التحول نحو السيارات الكهربائية (EVs) يخلق شريحة جديدة من السوق. يتم تكييف المولدات الكهربائية التقليدية أو استبدالها بأنظمة أكثر تقدمًا قادرة على تلبية متطلبات الطاقة في السيارات الكهربائية، مما قد يؤدي إلى تغيير هياكل التسعير.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

تلعب التقنيات الناشئة أيضًا دورًا محوريًا في اتجاهات التوريد. يكتسب استخدام تحليلات البيانات وإنترنت الأشياء في إدارة سلسلة التوريد زخمًا متزايدًا، مما يسمح للمشترين باتخاذ قرارات مستنيرة استنادًا إلى بيانات في الوقت الفعلي فيما يتعلق بقدرات الإنتاج وظروف السوق. ويكتسب هذا الاتجاه أهمية خاصة بالنسبة للمشترين الدوليين الذين يجب عليهم التعامل مع اللوائح والمعايير المختلفة عبر المناطق.

وعلاوة على ذلك، يؤثر تقلب تكاليف المواد الخام، مثل النحاس والصلب، على الأسعار الإجمالية لمولدات التيار المتردد. يجب أن يظل المشترون متيقظين فيما يتعلق بظروف السوق لتحسين استراتيجيات الشراء. كما يمكن أن يؤثر فهم ديناميكيات الموردين المحليين والتعريفات التجارية المحتملة على قرارات التوريد، خاصة بالنسبة للصفقات الدولية التي تشمل مناطق مثل أوروبا والشرق الأوسط.

كيف تشكل الاستدامة والتوريد الأخلاقي سوق المولدات الكهربائية؟

أصبحت الاستدامة ذات أهمية متزايدة في قطاع مولدات التيار المتردد، حيث تدفع المخاوف البيئية الشركات إلى تبني ممارسات توريد أخلاقية. تتعرض صناعة السيارات لضغوط لتقليل بصمتها الكربونية، وهو ما يمتد إلى توريد المكونات مثل مولدات الكهرباء. ويميل المشترون بين الشركات إلى الشراكة مع الشركات المصنعة التي تعطي الأولوية للمواد والعمليات الصديقة للبيئة، مثل تلك التي تستخدم المعادن المعاد تدويرها أو الطاقة المتجددة في الإنتاج.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

لا يمكن المبالغة في أهمية سلاسل التوريد الأخلاقية. فالشركات التي تُظهر التزاماً بالمسؤولية الاجتماعية غالباً ما تكتسب ميزة تنافسية. ويشمل ذلك ضمان ممارسات العمل العادلة داخل سلسلة التوريد والامتثال للمعايير البيئية الدولية. يمكن لشهادات مثل ISO 14001، التي تركز على أنظمة الإدارة البيئية الفعالة، أن توفر ضمانات للمشترين فيما يتعلق باستدامة مورديهم.

مع ارتفاع الطلب على الشهادات والمواد “الخضراء”، يركز المصنعون بشكل متزايد على تأثير دورة حياة منتجاتهم. هذا الاتجاه ليس مفيدًا للبيئة فحسب، بل يمكن أن يعزز أيضًا سمعة العلامة التجارية وولاء العملاء، مما يؤثر في نهاية المطاف على قرارات الشراء في مجال الأعمال التجارية بين الشركات.

ما هي التطورات التاريخية التي شكلت سوق المولدات الحالية؟

يعود تطور مولد التيار المتردد إلى أوائل القرن العشرين عندما انتقلت السيارات من الأنظمة الكهربائية البسيطة إلى تكوينات أكثر تعقيدًا تتطلب مصادر طاقة موثوقة. في البداية، تم استخدام المولدات، ولكن إدخال المولد في الستينيات أحدث ثورة في الأنظمة الكهربائية للسيارات. وقد سمح هذا التحول بتوليد طاقة وقدرات شحن أكثر كفاءة، مما أدى إلى انتشار استخدام المولدات على نطاق واسع في السيارات الحديثة.

على مر العقود، أدى التقدم في التكنولوجيا على مر العقود إلى ظهور مولدات كهربائية أكثر تطورًا يمكنها التعامل مع المتطلبات الكهربائية المتزايدة للمركبات المعاصرة، بما في ذلك انتشار الأجهزة والأنظمة الإلكترونية. يعد هذا السياق التاريخي أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات، حيث إن فهم تطور مولدات التيار المتردد يمكن أن يوفر رؤى حول الاتجاهات الحالية والتطورات المستقبلية، مما يتيح استراتيجيات أفضل للتوريد واتخاذ القرارات.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

وباختصار، يتشكل سوق المولدات الكهربائية من خلال العديد من العوامل، بما في ذلك التطورات التكنولوجية واعتبارات الاستدامة والتطورات التاريخية، وكلها تلعب دورًا حيويًا في توجيه المشترين الدوليين بين الشركات في جهودهم الشرائية.

الأسئلة المتداولة (FAQs) لمشتري B2B عن تكلفة مولد التيار المتردد

-

كم تبلغ تكلفة مولد التيار المتردد عادةً عند الشراء بالجملة؟

يمكن أن تختلف تكلفة مولد التيار المتردد اختلافًا كبيرًا بناءً على عدة عوامل، بما في ذلك نوع السيارة وطرازها، ونوع المولد (جديد مقابل معاد تصنيعه)، والكمية المشتراة. في المتوسط، يمكن للمشترين بالجملة أن يتوقعوا أن يدفعوا ما بين $100 و$500 لكل وحدة، اعتمادًا على هذه العوامل. بالإضافة إلى ذلك، قد يؤدي التفاوض مع الموردين للحصول على طلبيات أكبر إلى الحصول على أسعار أفضل، خاصة إذا كان بإمكانك إقامة شراكة طويلة الأجل. -

ما العوامل التي تؤثر على سعر مولد التيار المتردد؟

تؤثر العديد من العوامل على سعر مولد التيار المتردد، بما في ذلك سنة السيارة وطرازها وطرازها ومواصفات المحرك. يلعب تصنيف الأمبيرية أيضاً دوراً حاسماً، حيث أن مولدات المولدات ذات الإنتاجية الأعلى عادةً ما تكون أكثر تكلفة بسبب زيادة المواد المستخدمة في التصنيع. تشمل الاعتبارات الأخرى خيارات الضمان، وما إذا كان المولد جديدًا أو معاد تصنيعه، وتوافر القطع، مما قد يؤثر على تكاليف سلسلة التوريد. -

ما الذي يجب أن آخذه في الاعتبار عند شراء المولدات الكهربائية من الموردين الدوليين؟

عند التوريد الدولي لمولدات الكهرباء، ضع في اعتبارك موثوقية المورد، وشهادات الجودة، وقدراته الإنتاجية. تحقق من خبرتهم في التصدير إلى منطقتك، خاصةً فيما يتعلق بالامتثال للوائح المحلية. بالإضافة إلى ذلك، قم بتقييم قدرتهم على تلبية احتياجاتك المحددة، مثل خيارات التخصيص والحد الأدنى لكميات الطلبات (MOQs)، لضمان سلاسة عملية الشراء. -

هل توجد خيارات تخصيص متاحة لمولدات التيار المتردد؟

يقدم العديد من الموردين خيارات تخصيص لمولدات المولدات لتلبية متطلبات محددة. قد يتضمن ذلك تعديلات على خرج الأمبير أو تكوينات التركيب أو التوصيلات الكهربائية. عند مناقشة التخصيص، كن واضحًا بشأن مواصفات سيارتك واحتياجات الأداء لضمان قدرة المورد على تقديم منتج يلبي توقعاتك. -

ما هي شروط الدفع المستخدمة عادةً لشراء المولدات الكهربائية؟

يمكن أن تختلف شروط الدفع لشراء المولدات حسب المورد، ولكن الخيارات الشائعة تشمل الدفع مقدمًا، والدفع الجزئي عند تأكيد الطلب، والدفع عند التسليم. قد يقدم بعض الموردين أيضًا شروطًا ائتمانية للعملاء الراسخين. من الضروري التفاوض على شروط مواتية تتماشى مع تدفقاتك النقدية مع ضمان ارتياح المورد للترتيب. -

كيف يمكنني فحص الموردين للتأكد من جودة المولدات؟

لفحص الموردين للتحقق من جودة المولدات، اطلب عينات وقم بإجراء فحوصات شاملة. ابحث عن الموردين الحاصلين على شهادات صناعية مثل ISO 9001، والتي تشير إلى الالتزام بمعايير إدارة الجودة. وبالإضافة إلى ذلك، ابحث عن مراجع من الشركات الأخرى التي حصلت على مصادر من المورد وتحقق من المراجعات عبر الإنترنت لقياس سمعتها وموثوقيتها. -

ما هي الاعتبارات اللوجستية عند استيراد المولدات الكهربائية؟

عند استيراد المولدات الكهربائية، ضع في اعتبارك طرق الشحن وعمليات التخليص الجمركي والتعريفات أو الرسوم المحتملة. قم بتقييم خبرة المورد في الشحن الدولي وقدرته على توفير الوثائق اللازمة للجمارك. من الحكمة أيضًا العمل مع شريك لوجستي يمكنه المساعدة في التعامل مع هذه التعقيدات وضمان التسليم في الوقت المناسب إلى موقعك. -

ما هي إجراءات ضمان الجودة التي يجب أن أتوقعها من موردي مولدات التيار المتردد؟

يجب على موردي مولدات المولدات ذات السمعة الطيبة تنفيذ تدابير صارمة لضمان الجودة، بما في ذلك اختبار الأداء الكهربائي والمتانة والامتثال لمعايير الصناعة. استفسر عن عمليات مراقبة الجودة الخاصة بهم، مثل اختبار الدُفعات وعروض الضمان. يمكن أن يشير الضمان القوي إلى ثقة المورد في منتجه، مما يوفر ضمانًا إضافيًا للجودة عند الشراء.

نظرة على تكلفة المولد كم يكلف المولد المصنعين والموردين

لم نتمكن من التحقق من عدد كافٍ من الموردين لمعرفة تكلفة مولد التيار المتردد لإنشاء قائمة في الوقت الحالي.

استنتاج المصادر الاستراتيجية والتوقعات بشأن تكلفة مولد التيار المتردد

في الختام، يعد فهم الآثار المترتبة على تكلفة استبدال المولدات أمرًا بالغ الأهمية بالنسبة للمشترين الدوليين من الشركات الذين يتنقلون في أسواق متنوعة. يتراوح نطاق التكلفة لمولدات التيار المتردد عادةً من $100 إلى $1000، ويتأثر ذلك بعوامل مثل مواصفات السيارة ومتطلبات الأمبيرات والاختيار بين القطع الجديدة والمعاد تصنيعها. يلعب التوريد الاستراتيجي دوراً محورياً في ضمان تحسين عمليات الشراء من حيث الجودة والفعالية من حيث التكلفة. من خلال الاستفادة من العلاقات مع الموردين ذوي السمعة الطيبة، يمكن للشركات تأمين مكونات عالية الجودة تلبي متطلباتها التشغيلية مع تقليل التكاليف العامة إلى الحد الأدنى.

بالنسبة للمشترين في إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، فإن البقاء على اطلاع على أحدث الاتجاهات في توريد قطع غيار السيارات سيعزز الميزة التنافسية. ضع في اعتبارك استكشاف الشراكات مع الموزعين المحليين الذين يفهمون ديناميكيات السوق الإقليمية ويمكنهم تقديم رؤى قيمة حول الأسعار والتوافر.

مع استمرار تطور صناعة السيارات، لن تؤدي استراتيجيات التوريد الاستباقية إلى التخفيف من المخاطر المرتبطة باضطرابات سلسلة التوريد فحسب، بل ستؤدي أيضًا إلى زيادة الربحية. اغتنم الفرصة لتحسين عمليات الشراء والاستثمار في علاقات قوية مع الموردين لضمان مرونة أعمالك واستجابتها لتغيرات السوق.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.