Introduction: Navigating the Global Market for vehicle starter motor

Navigating the complexities of sourcing vehicle starter motors can be a daunting task for international B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. The starter motor is an essential component in vehicle systems, responsible for initiating the engine’s operation. Buyers often face challenges such as identifying the right specifications, understanding the various types available, and selecting reliable suppliers amid fluctuating costs and quality standards.

This comprehensive guide aims to equip B2B buyers with the necessary insights to make informed purchasing decisions in the vehicle starter motor market. It covers a wide range of topics, including the different types of starter motors suited for various applications, detailed supplier vetting processes, and an analysis of cost factors that influence procurement. By addressing these critical areas, the guide empowers buyers to navigate the global market effectively, ensuring they select the best starter motors that meet their operational needs.

With a focus on actionable strategies and expert recommendations, this guide serves as a valuable resource for businesses looking to enhance their supply chain efficiency while minimizing risks associated with sourcing. Whether you are a small automotive company or a large-scale distributor, understanding the nuances of the starter motor market will enable you to secure quality products that drive your business forward.

جدول المحتويات

- Top 5 Vehicle Starter Motor Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for vehicle starter motor

- Understanding vehicle starter motor Types and Variations

- Key Industrial Applications of vehicle starter motor

- 3 Common User Pain Points for ‘vehicle starter motor’ & Their Solutions

- Strategic Material Selection Guide for vehicle starter motor

- In-depth Look: Manufacturing Processes and Quality Assurance for vehicle starter motor

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘vehicle starter motor’

- Comprehensive Cost and Pricing Analysis for vehicle starter motor Sourcing

- Alternatives Analysis: Comparing vehicle starter motor With Other Solutions

- Essential Technical Properties and Trade Terminology for vehicle starter motor

- Navigating Market Dynamics and Sourcing Trends in the vehicle starter motor Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of vehicle starter motor

- Strategic Sourcing Conclusion and Outlook for vehicle starter motor

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding vehicle starter motor Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| محرك بدء بتقليل التروس | Uses gears to increase torque while reducing motor size | المركبات التجارية والآلات الثقيلة | الإيجابيات: Compact size, efficient torque output. السلبيات: أكثر تعقيداً، ويحتمل أن تكون تكاليف الإصلاح أعلى. |

| محرك بدء دائم المغناطيس | Utilizes permanent magnets for efficient operation | Passenger vehicles, motorcycles | الإيجابيات: Lightweight, higher efficiency. السلبيات: Limited torque in extreme conditions. |

| Solenoid Starter | Features a solenoid to engage the starter and disengage post-start | تطبيقات السيارات القياسية | الإيجابيات: Reliable engagement, easy to replace. السلبيات: Can wear out over time, requires precise alignment. |

| مشغل عالي الأداء | Designed for racing or high-performance vehicles | Motorsports, specialized vehicles | الإيجابيات: Superior torque, lightweight design. السلبيات: Higher cost, may not be suitable for everyday use. |

| مشغّل/بديل مدمج | Combines starter and alternator functions into one unit | Mild hybrids, electric vehicles | الإيجابيات: Space-saving, improved fuel efficiency. السلبيات: Complex installation, higher replacement costs. |

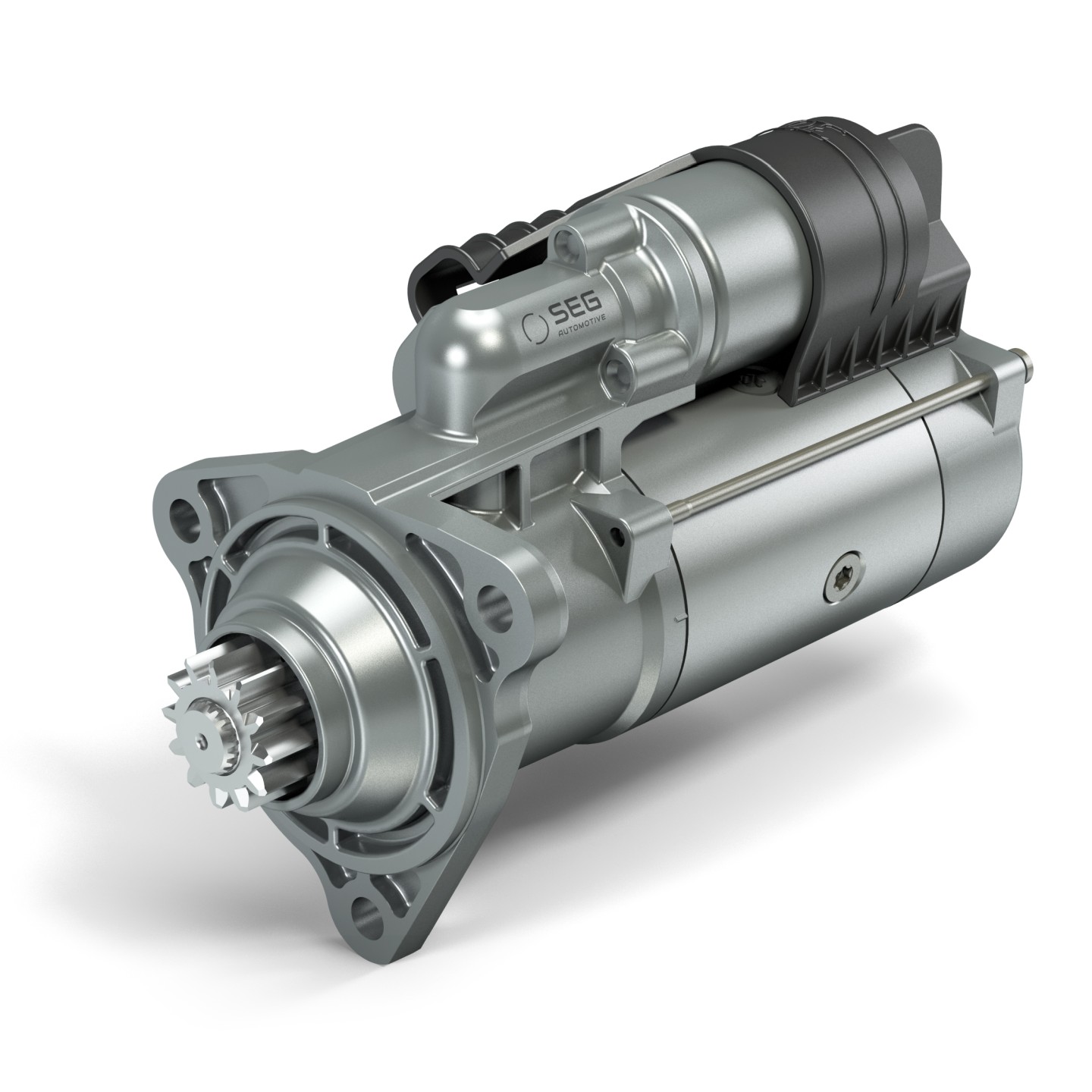

What are Gear Reduction Starters and Their B2B Relevance?

Gear reduction starters leverage a gear system to amplify torque while minimizing the motor’s physical size. This design is particularly beneficial for commercial vehicles and heavy machinery, where space is at a premium but high torque is necessary for engine cranking. B2B buyers should consider the complexity of these systems, as repairs may require specialized knowledge, potentially increasing maintenance costs.

Illustrative image related to vehicle starter motor

How Do Permanent Magnet Starters Differ in Application?

Permanent magnet starters employ permanent magnets to create a magnetic field, offering efficient operation and reduced weight. These starters are predominantly found in passenger vehicles and motorcycles, making them ideal for B2B buyers in the automotive sector. Buyers should evaluate the environmental conditions in which the starter will operate, as performance may decline in extreme temperatures due to torque limitations.

Why Choose Solenoid Starters for Standard Automotive Needs?

Solenoid starters are characterized by their reliable engagement mechanism, which utilizes a solenoid to connect the battery to the starter motor. Commonly used in standard automotive applications, these starters are easy to replace and maintain. B2B buyers should be aware of the wear and tear on solenoids over time, necessitating regular inspections to ensure optimal performance and prevent unexpected failures.

What Advantages Do High-Performance Starters Offer?

High-performance starters are engineered for racing and other high-demand applications, providing superior torque and reduced weight. These starters are essential for motorsports and specialized vehicles where performance is critical. B2B buyers must weigh the benefits against the higher costs and assess whether the increased performance justifies the investment for their specific applications.

What are the Benefits and Challenges of Integrated Starter/Alternator Systems?

Integrated starter/alternator systems combine the functions of a starter and an alternator, making them suitable for mild hybrids and electric vehicles. This design not only saves space but also enhances fuel efficiency. For B2B buyers, the complexity of installation and the potential for higher replacement costs should be key considerations when evaluating this technology for their fleets or automotive offerings.

Key Industrial Applications of vehicle starter motor

| الصناعة/القطاع | Specific Application of vehicle starter motor | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | Production of passenger and commercial vehicles | Ensures reliable engine startup, enhancing vehicle reliability and customer satisfaction | Quality assurance, compatibility with various engine types, and compliance with international standards |

| معدات زراعية | Starting systems for tractors and harvesters | Improves operational efficiency and reduces downtime during critical farming periods | Durability in harsh environments, availability of spare parts, and support for diverse agricultural machinery |

| عمليات التعدين | Starter motors for heavy-duty mining vehicles | Enhances operational reliability in remote locations and extreme conditions | Robustness, ability to handle high torque demands, and supplier reliability for timely delivery |

| النقل واللوجستيات | Starter motors in fleet vehicles for logistics companies | Reduces maintenance costs and ensures timely deliveries | Cost-effectiveness, warranty terms, and compatibility with fleet management systems |

| مركبات الطاقة المتجددة | Integrated starter motors in electric and hybrid vehicles | Supports the transition to sustainable transport solutions and meets regulatory requirements | Innovation in technology, adherence to environmental standards, and supplier expertise in electric systems |

How Are Vehicle Starter Motors Used in Automotive Manufacturing?

In the automotive manufacturing sector, vehicle starter motors are integral to the assembly of both passenger and commercial vehicles. They are responsible for initiating engine operation, which is crucial for quality control and performance testing during production. For international buyers, especially in regions like Europe and South America, sourcing starter motors that comply with stringent safety and quality standards is essential. Additionally, manufacturers must consider compatibility with various engine types to ensure seamless integration into their production lines.

What Role Do Starter Motors Play in Agriculture Equipment?

Starter motors are vital in agricultural machinery such as tractors and harvesters, where they enable reliable engine startup. This is especially important during peak farming seasons when operational efficiency is critical. Buyers from Africa and South America must prioritize sourcing starter motors that are durable and can withstand harsh environmental conditions. The availability of spare parts and after-sales support is also a key consideration, as it directly impacts the uptime of essential farming equipment.

How Are Starter Motors Applied in Mining Operations?

In mining operations, heavy-duty vehicles rely on robust starter motors to ensure reliable performance in extreme conditions. These starter motors must be capable of handling high torque demands while functioning in remote locations where maintenance may be challenging. International buyers, particularly from the Middle East, should focus on sourcing starter motors that are built to withstand the rigors of mining environments, emphasizing supplier reliability for timely delivery and support.

Why Are Starter Motors Important for Transportation & Logistics?

Transportation and logistics companies depend on starter motors in their fleet vehicles to minimize maintenance costs and ensure timely deliveries. A reliable starter motor can significantly reduce the risk of vehicle breakdowns, which is crucial for maintaining operational efficiency. Buyers must consider the cost-effectiveness of starter motors, warranty terms, and compatibility with fleet management systems when sourcing these components, particularly in competitive markets across Europe and South America.

What Innovations Are Emerging in Renewable Energy Vehicles?

In the growing sector of renewable energy vehicles, integrated starter motors are becoming increasingly important for electric and hybrid models. These systems support the transition to sustainable transport solutions while meeting evolving regulatory requirements. Buyers looking to invest in this technology should prioritize innovation, adherence to environmental standards, and supplier expertise in electric systems to ensure they remain competitive in the rapidly changing automotive landscape.

3 Common User Pain Points for ‘vehicle starter motor’ & Their Solutions

Scenario 1: Difficulty in Diagnosing Starter Motor Issues

المشكلة:

B2B buyers often face the challenge of accurately diagnosing starter motor failures in their fleets or inventory. A common scenario involves vehicles that exhibit symptoms such as clicking sounds when attempting to start, which can be misleading. Buyers may struggle to determine if the issue lies with the starter motor, the battery, or the wiring. This uncertainty can lead to unnecessary replacement costs and downtime, affecting operational efficiency and profitability.

الحل:

To effectively diagnose starter motor issues, B2B buyers should invest in diagnostic tools that can test electrical systems comprehensively. A multimeter can help check the battery voltage and ensure that it is adequately charged. Moreover, utilizing a starter motor tester can provide specific insights into the starter’s performance, allowing for quick identification of faults. Buyers should also implement a standardized troubleshooting protocol for their technicians, which includes checking battery connections, examining wiring integrity, and testing the solenoid operation. By adopting these practices, businesses can reduce misdiagnosis rates and ensure that only faulty components are replaced, ultimately saving time and money.

Scenario 2: Sourcing Quality Starter Motors for Diverse Applications

المشكلة:

International buyers often encounter difficulties in sourcing high-quality starter motors that meet the specific demands of various vehicle models and operating conditions. This issue is exacerbated when dealing with different manufacturers and standards, leading to a mismatch between the starter motors procured and the vehicles in their fleet. Inconsistent quality can result in high failure rates, increased maintenance costs, and reliability issues.

الحل:

To address sourcing challenges, B2B buyers should establish strong relationships with reputable manufacturers and distributors known for their quality assurance processes. Conducting thorough research to identify suppliers with certifications such as ISO 9001 can provide confidence in the reliability of the products. Additionally, buyers should leverage platforms that offer detailed specifications and compatibility information, ensuring that the starter motors are suitable for their vehicle types. Engaging in pilot testing with a small batch of starter motors before full-scale procurement can also help gauge performance and compatibility, minimizing risk and ensuring that operational standards are met.

Scenario 3: Managing Inventory and Replacement Costs

المشكلة:

Managing inventory levels of starter motors can be a daunting task for B2B buyers, especially when balancing the need for quick replacements against the risk of overstocking. Fluctuating demand can lead to situations where businesses either run out of starter motors when they are urgently needed or find themselves with excess stock that ties up capital. This inventory mismanagement can significantly impact cash flow and operational efficiency.

Illustrative image related to vehicle starter motor

الحل:

Implementing an inventory management system tailored for automotive parts can help B2B buyers streamline their processes. This system should incorporate demand forecasting tools that analyze historical data and trends to predict future needs accurately. Additionally, adopting a just-in-time (JIT) inventory strategy can minimize holding costs while ensuring that starter motors are available when needed. Establishing a partnership with a reliable supplier that offers flexible ordering options and rapid delivery can further enhance responsiveness. Regularly reviewing inventory turnover rates and adjusting stock levels based on performance metrics will allow businesses to maintain optimal inventory levels, ultimately reducing costs and improving service levels.

Strategic Material Selection Guide for vehicle starter motor

What Are the Common Materials Used in Vehicle Starter Motors?

In the manufacturing of vehicle starter motors, material selection is crucial for ensuring optimal performance, durability, and cost-effectiveness. Here, we analyze four common materials used in starter motor components: steel, aluminum, copper, and plastic composites. Each material has distinct properties, advantages, and limitations that influence their application in starter motors.

How Does Steel Perform in Vehicle Starter Motors?

Steel is a widely used material in the construction of starter motors, particularly for housing and gear components.

- الخصائص الرئيسية: Steel exhibits high tensile strength and excellent wear resistance, making it suitable for high-torque applications. It can withstand significant mechanical stress and has a temperature rating of up to 300°C, depending on the alloy used.

- إيجابيات وسلبيات: The durability of steel is a significant advantage; however, it is heavier than other materials, which can affect overall vehicle weight. Additionally, steel is prone to corrosion unless properly treated, which can be a concern in humid or saline environments.

- التأثير على التطبيق: Steel’s strength is critical for components like the pinion gear and housing, which must endure repeated engagement and disengagement cycles.

- اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM A36 or DIN 17100 is essential. Buyers should also consider corrosion resistance treatments, especially in regions with high humidity or salt exposure, such as coastal areas in South America or the Middle East.

What Are the Advantages of Aluminum in Starter Motors?

Aluminum is increasingly popular for starter motor components due to its lightweight properties.

- الخصائص الرئيسية: Aluminum has a lower density than steel, making it easier to handle and install. It also offers good corrosion resistance and can operate effectively at temperatures up to 150°C.

- إيجابيات وسلبيات: The primary advantage of aluminum is its weight reduction, which can improve vehicle efficiency. However, its lower strength compared to steel means it may not be suitable for all components, particularly those subject to high torque.

- التأثير على التطبيق: Aluminum is often used for housings and end plates, where weight savings are critical without compromising performance.

- اعتبارات للمشترين الدوليين: Buyers should ensure compliance with standards such as ASTM B211 for aluminum alloys. The cost of aluminum can be higher than steel, so buyers must weigh performance benefits against budget constraints.

Why Is Copper Essential for Electrical Components in Starter Motors?

Copper is a key material for electrical connections and windings in starter motors due to its excellent conductivity.

- الخصائص الرئيسية: Copper has a high electrical conductivity rating, making it ideal for components that require efficient power transmission. It can handle temperatures up to 200°C without significant degradation.

- إيجابيات وسلبيات: The primary advantage of copper is its superior conductivity, which enhances starter motor efficiency. However, copper is more expensive than aluminum and can be prone to corrosion if not properly insulated.

- التأثير على التطبيق: Copper is critical for the solenoid and winding connections, where efficient electrical flow is essential for performance.

- اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM B170 is important. Buyers should also consider the implications of copper prices, which can fluctuate based on market demand.

How Do Plastic Composites Fit into Starter Motor Design?

Plastic composites are increasingly used in starter motors for non-structural components.

- الخصائص الرئيسية: These materials offer good insulation properties and can operate effectively at temperatures up to 120°C. They are also lightweight and resistant to corrosion.

- إيجابيات وسلبيات: The main advantage of plastic composites is their versatility and low weight. However, they may not withstand high mechanical stress, limiting their use to non-load-bearing components.

- التأثير على التطبيق: Plastic composites are often used for covers and insulation, providing protection against environmental factors without adding significant weight.

- اعتبارات للمشترين الدوليين: Compliance with standards such as ISO 9001 for quality management is essential. Buyers should also evaluate the long-term durability of plastic components in their specific operating environments.

Summary Table of Material Selection for Vehicle Starter Motors

| المواد | Typical Use Case for vehicle starter motor | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الصلب | Housing, gears | قوة ومتانة عالية | أثقل وزناً، وعرضة للتآكل | متوسط |

| الألومنيوم | Housings, end plates | خفيفة الوزن ومقاومة جيدة للتآكل | قوة أقل من الفولاذ | عالية |

| النحاس | التوصيلات الكهربائية، اللفات | موصلية كهربائية ممتازة | أعلى تكلفة، وعرضة للتآكل | عالية |

| المركبات البلاستيكية | الأغطية، والعزل | Lightweight, corrosion resistant | قوة ميكانيكية محدودة | منخفض |

This guide provides international B2B buyers with a comprehensive overview of material options for vehicle starter motors, highlighting the importance of material properties, advantages, and compliance considerations in different regional markets.

Illustrative image related to vehicle starter motor

In-depth Look: Manufacturing Processes and Quality Assurance for vehicle starter motor

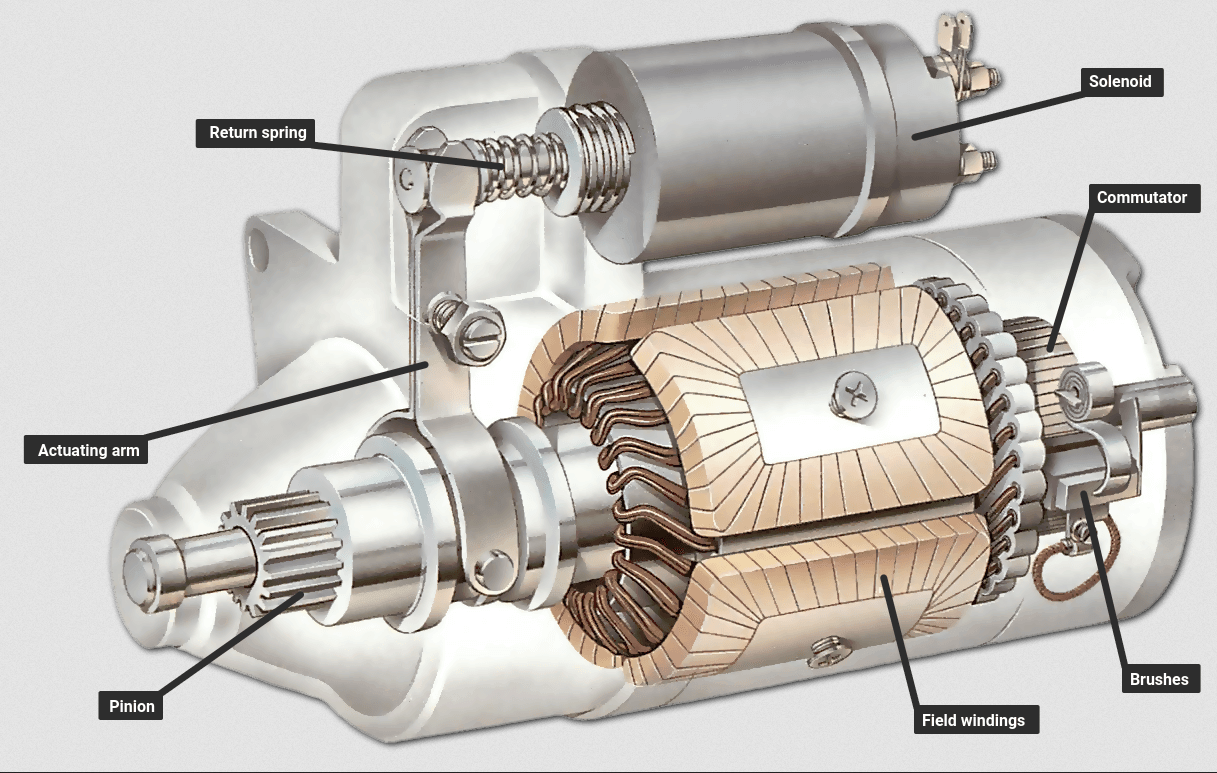

What Are the Main Stages of Manufacturing a Vehicle Starter Motor?

The manufacturing process for vehicle starter motors involves several key stages, each critical to ensuring the final product meets quality and performance standards. Understanding these stages can help B2B buyers assess the capabilities of potential suppliers and the reliability of their products.

1. Material Preparation: What Materials Are Used in Starter Motor Manufacturing?

The first stage involves the selection and preparation of materials. Starter motors typically utilize a combination of metals and plastics. The primary materials include:

- النحاس: تستخدم للملفات بسبب توصيلها الممتاز.

- الصلب: Commonly used for the housing and other structural components.

- الألومنيوم: Often employed for lighter components to enhance performance and efficiency.

- Insulation materials: Such as nylon and PVC, which are essential for electrical insulation.

Quality assurance begins at this stage, as sourcing high-grade materials is crucial for durability and performance. Suppliers should provide documentation verifying the material specifications to ensure compliance with international standards.

2. Forming: How Are Starter Motor Components Shaped?

The forming process includes various techniques to shape the components of the starter motor. Common methods include:

- الختم: Used to create flat components like end plates and covers from sheets of metal.

- التصنيع الآلي: Precision machining processes, such as turning and milling, are used to manufacture complex parts like the armature and pinion gear.

- القولبة بالحقن: This technique is used for producing plastic components, including housings and insulation parts.

Each method requires specialized machinery and skilled labor to ensure precise tolerances. Monitoring for defects during this stage is critical, as any discrepancies can lead to failures in the final assembly.

3. Assembly: What Are the Key Steps in Assembling a Starter Motor?

The assembly of starter motors is a meticulous process that combines various components into a functional unit. Key steps in this phase include:

- اللف: The copper wire is wound around the armature, creating electromagnetic fields necessary for motor function.

- Component Fitting: All parts, including the solenoid, pinion gear, and housing, are fitted together. Proper alignment is essential to prevent mechanical failures.

- Soldering and Electrical Connections: Connections are made to ensure electrical continuity and reliability.

Quality checks during assembly, such as torque measurements and alignment verification, help ensure that the starter motor functions correctly under operational conditions.

4. Finishing: What Surface Treatments Are Applied to Starter Motors?

Finishing processes enhance the durability and performance of starter motors. Common finishing techniques include:

- الطلاء: Protective coatings, such as powder coating or electroplating, are applied to prevent corrosion and wear.

- Balancing: Dynamic balancing of the armature is performed to reduce vibrations during operation, which can lead to premature wear.

- الاختبار: Final testing involves running the starter motor under load conditions to verify performance specifications.

Finishing not only improves longevity but also ensures compliance with international standards, making products more appealing to international buyers.

What International Standards and Quality Control Measures Are Relevant for Starter Motors?

Quality assurance in starter motor manufacturing is governed by several international standards. Understanding these can help B2B buyers ensure they are sourcing reliable products.

1. What Are the Key International Standards for Starter Motor Quality?

- آيزو 9001: This standard focuses on quality management systems and is crucial for ensuring consistent quality throughout the manufacturing process.

- علامة CE: Required for products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- معايير API: While primarily associated with the petroleum industry, API standards can also apply to certain components of automotive manufacturing, particularly in terms of performance testing.

These certifications provide assurance that the manufacturer adheres to recognized quality management practices.

2. What Quality Control Checkpoints Should Be Considered?

Quality control should encompass several checkpoints throughout the manufacturing process:

- مراقبة الجودة الواردة (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- مراقبة الجودة أثناء الإنتاج (IPQC): Continuous monitoring during manufacturing to catch defects early.

- مراقبة الجودة النهائية (FQC): Comprehensive testing of the finished product before it is shipped to ensure it meets performance specifications.

Implementing these checkpoints helps in identifying issues early, thus reducing waste and ensuring the final product is reliable.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

B2B buyers can take several steps to verify the quality control processes of their suppliers:

1. What Audit Processes Can Be Implemented?

Conducting regular audits of suppliers is crucial for maintaining quality standards. Audits should assess:

- Manufacturing processes.

- Compliance with international standards.

- Documentation of quality control procedures.

These audits can be performed by the buyer or through third-party organizations specializing in quality assurance.

2. How Can Testing and Inspection Reports Be Utilized?

Requesting testing and inspection reports from suppliers can provide insights into their quality control practices. Reports should include:

Illustrative image related to vehicle starter motor

- Results from performance tests.

- Documentation of compliance with international standards.

- Records of any deviations and corrective actions taken.

Buyers should ensure that suppliers are transparent about their quality assurance processes and willing to provide necessary documentation.

What Nuances Should International B2B Buyers Consider?

For buyers in regions such as Africa, South America, the Middle East, and Europe, several nuances must be considered:

- الامتثال التنظيمي: Ensure that products comply with local regulations, which may vary significantly between regions.

- الاختلافات الثقافية: Understanding local business practices can enhance communication and build stronger supplier relationships.

- الخدمات اللوجستية وسلسلة التوريد: Consider the logistics of importing components, as shipping times and costs can impact overall procurement strategies.

By keeping these factors in mind, international buyers can better navigate the complexities of sourcing vehicle starter motors while ensuring high quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vehicle starter motor’

In the competitive landscape of automotive parts procurement, sourcing a reliable vehicle starter motor is crucial for ensuring operational efficiency and customer satisfaction. This guide provides a structured approach to help B2B buyers navigate the complexities of sourcing starter motors, focusing on key considerations that can influence the quality and reliability of the product.

Illustrative image related to vehicle starter motor

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Clearly outlining your technical requirements is the first step in sourcing a starter motor. Consider factors such as the vehicle’s make, model, and engine type, as these will determine the specific starter motor needed. Additionally, assess the voltage and torque specifications to ensure compatibility with your vehicle systems.

الخطوة 2: البحث عن الموردين المحتملين

Conduct thorough research to identify potential suppliers who specialize in starter motors. Look for manufacturers or distributors with a strong reputation in the industry. Utilize online directories, trade shows, and industry forums to gather insights and feedback on suppliers’ reliability and product quality.

الخطوة 3: تقييم شهادات الموردين

Before making a commitment, verify that potential suppliers hold relevant certifications. Certifications such as ISO 9001 indicate adherence to quality management standards. Inquire about compliance with local and international regulations, especially if you are sourcing from regions with different safety and environmental standards.

Illustrative image related to vehicle starter motor

الخطوة 4: طلب عينات من المنتجات

Always request samples of the starter motors before placing a bulk order. Testing samples allows you to assess the quality, performance, and compatibility with your vehicles. This step is vital to avoid costly mistakes and ensure that the product meets your specifications.

الخطوة 5: فهم سياسات الضمان والإرجاع

Review the warranty terms and return policies offered by the supplier. A robust warranty indicates confidence in the product’s durability and performance. Additionally, understanding the return process will help mitigate risks associated with defective products or incorrect orders.

الخطوة 6: التفاوض على الأسعار وشروط الدفع

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing and payment terms. Consider factors such as bulk order discounts and payment flexibility. Ensure that the agreed terms align with your budget and cash flow requirements.

الخطوة 7: وضع خطة التواصل

Effective communication is key to a successful sourcing relationship. Establish clear lines of communication with your supplier to address any questions or concerns promptly. Regular updates on order status and delivery timelines will help you manage expectations and ensure a smooth procurement process.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for vehicle starter motors, ensuring they procure high-quality products that meet their operational needs. Proper planning and careful evaluation can lead to successful partnerships and improved vehicle performance.

Comprehensive Cost and Pricing Analysis for vehicle starter motor Sourcing

What Are the Key Cost Components in Sourcing Vehicle Starter Motors?

When sourcing vehicle starter motors, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

المواد: The raw materials, such as copper for windings, steel for housing, and plastic for insulation, significantly impact costs. Prices can fluctuate based on global commodity markets, so buyers should monitor trends to anticipate price changes.

-

العمل: Labor costs vary by region and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing, but this can sometimes compromise quality.

-

تكاليف التصنيع العامة: This includes utilities, rent, and operational costs incurred during production. Efficient manufacturing processes can help reduce overhead and ultimately lower prices.

-

الأدوات: The initial investment in tools and machinery is a significant upfront cost. Custom tooling for specialized starter motors may raise costs but can lead to better product quality and performance.

-

مراقبة الجودة (QC): Ensuring that starter motors meet specifications and certifications is crucial. Stringent QC processes add to manufacturing costs but are necessary for reliable performance, particularly in markets with high safety standards.

-

اللوجستيات: Shipping and handling fees can vary significantly based on distance and mode of transport. Incoterms also influence logistics costs, which can be a critical factor for international buyers.

-

الهامش: Supplier margins must also be factored into the total cost. Pricing strategies can vary widely, with some suppliers offering lower margins to gain market share while others prioritize quality and service.

How Do Price Influencers Impact Starter Motor Sourcing?

Several factors influence the pricing of vehicle starter motors, and understanding these can lead to better procurement decisions.

-

الحجم/الحد الأدنى للطلب: Purchasing in larger volumes often results in lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) that align with their inventory needs while maximizing cost efficiency.

-

المواصفات والتخصيص: Customized starter motors designed for specific vehicle models or performance requirements can increase costs. Buyers must weigh the benefits of customization against budget constraints.

-

جودة المواد والشهادات: High-quality materials and industry certifications (e.g., ISO, TS16949) can increase costs but are essential for reliability and compliance in many markets.

-

عوامل الموردين: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge a premium, but their products often come with quality assurances that mitigate risk.

-

مصطلحات التجارة الدولية: The chosen Incoterms determine the responsibilities of buyers and sellers in shipping. Understanding these terms can help buyers avoid unexpected costs and delays.

What Are Some Effective Buyer Tips for Negotiating Starter Motor Prices?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several strategies for effective negotiation and cost management.

-

استراتيجيات التفاوض: Be prepared to negotiate on price, terms, and delivery schedules. Suppliers may be willing to offer discounts for longer-term contracts or larger orders.

-

التركيز على كفاءة التكلفة: Consider the Total Cost of Ownership (TCO), which encompasses not just the purchase price but also installation, maintenance, and potential downtime. A lower initial price may not always equate to lower TCO.

-

فهم الفروق الدقيقة في الأسعار: Be aware of regional pricing differences influenced by local market conditions, currency fluctuations, and trade tariffs. This knowledge can enhance negotiation leverage.

-

بناء العلاقات: Cultivating long-term relationships with suppliers can lead to better pricing and service. Suppliers may offer preferential pricing or priority during shortages to established clients.

الخلاصة

While indicative prices may vary based on the factors discussed, B2B buyers should focus on understanding the comprehensive cost structure, price influencers, and effective negotiation strategies when sourcing vehicle starter motors. This informed approach can lead to better purchasing decisions and enhanced supplier relationships.

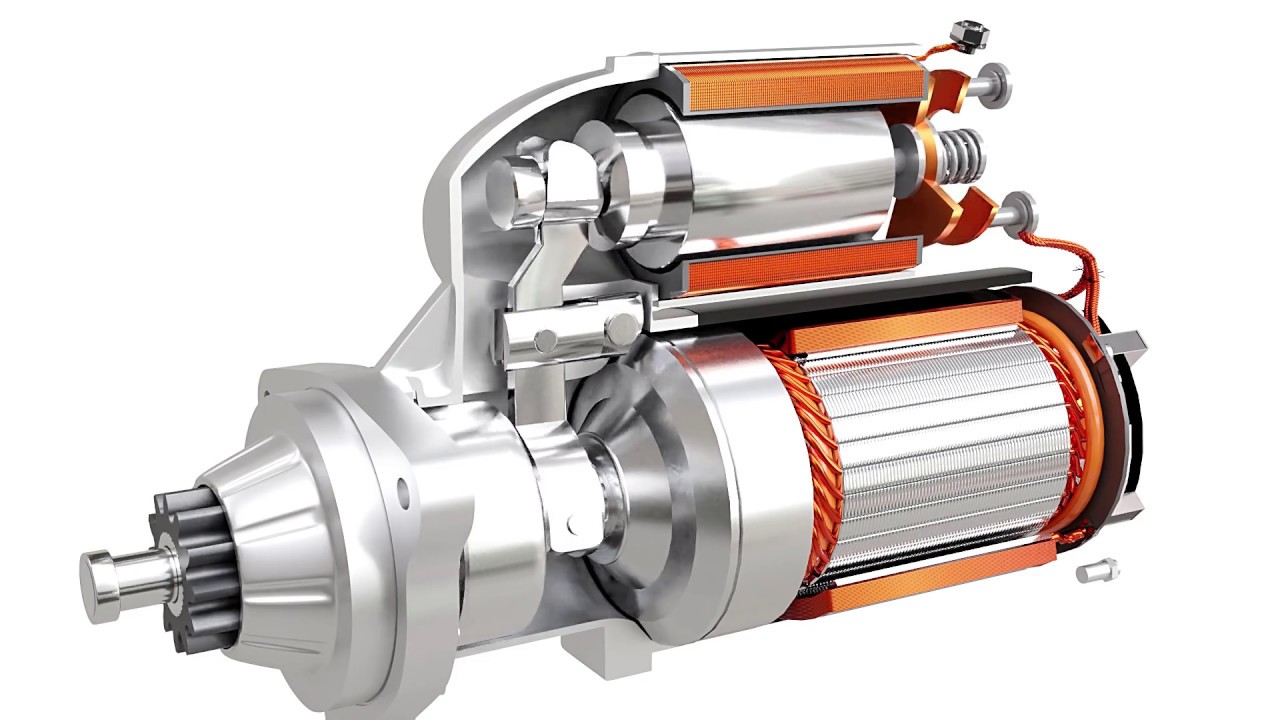

Alternatives Analysis: Comparing vehicle starter motor With Other Solutions

Exploring Alternatives to Vehicle Starter Motors

In the automotive industry, the vehicle starter motor is a crucial component that initiates the engine’s operation. However, as technology evolves, alternative solutions are emerging that may offer distinct advantages for various applications. This section will compare the traditional vehicle starter motor with two viable alternatives: the Integrated Starter-Generator (ISG) system and manual starting methods, particularly in the context of different markets and applications.

| جانب المقارنة | Vehicle Starter Motor | Integrated Starter-Generator (ISG) | Manual Starting Methods |

|---|---|---|---|

| الأداء | High torque for quick engine start | Provides both starting and regenerative capabilities | Relies on physical effort; variable performance |

| التكلفة | Moderate initial cost; replacement costs can be high | Higher initial cost; potential savings through fuel efficiency | Very low cost, but labor-intensive |

| سهولة التنفيذ | Standard installation in modern vehicles | Requires integration with hybrid/electric systems | Simple but requires operator skill |

| الصيانة | Regular checks needed; can fail due to wear | Generally low maintenance; integrated with vehicle systems | Minimal maintenance; dependent on user skill |

| أفضل حالة استخدام | Conventional vehicles needing reliable starts | السيارات الهجينة والكهربائية لتحقيق الكفاءة | Vintage or specialty vehicles with no electrical systems |

تحليل متعمق للبدائل

Integrated Starter-Generator (ISG) System

The ISG system combines the functions of a starter motor and an alternator, offering a compact solution that improves fuel efficiency and reduces emissions. This technology is particularly beneficial for hybrid and electric vehicles where energy recovery during braking is essential. The ISG provides seamless transitions between starting the engine and generating electricity, which enhances overall vehicle performance. However, the initial investment is significantly higher than traditional starter motors, making it less attractive for budget-conscious buyers or in markets with lower vehicle turnover.

Manual Starting Methods

Manual starting methods, such as hand cranking, were common before the advent of electric starters. While they are incredibly cost-effective and require minimal equipment, they demand physical effort and skill from the operator. This method is primarily applicable to vintage cars, specialty vehicles, or in regions where electrical systems are unreliable. However, the reliance on human effort can lead to inconsistent performance and user fatigue, making it less practical for everyday use in modern contexts.

الخلاصة: كيفية اختيار الحل المناسب لاحتياجاتك

When selecting the right starting solution for your vehicles, consider the specific requirements of your operations and the market environment. If you are dealing with conventional vehicles, the traditional starter motor remains a reliable choice. For hybrid or electric vehicle fleets, the ISG system offers enhanced efficiency and performance, albeit at a higher cost. Meanwhile, manual methods may serve niche markets effectively but may not meet the demands of modern automotive standards. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their operational needs and budget constraints, ensuring optimal vehicle performance and cost-efficiency.

Essential Technical Properties and Trade Terminology for vehicle starter motor

What Are the Essential Technical Properties of a Vehicle Starter Motor?

When sourcing vehicle starter motors, understanding their technical properties is crucial for ensuring compatibility and reliability in automotive applications. Here are several key specifications to consider:

-

درجة المواد: Starter motors are typically made from high-grade steel and aluminum. Steel offers durability and strength, while aluminum provides lightweight characteristics, which can improve vehicle efficiency. In B2B procurement, selecting the appropriate material grade is essential for performance longevity and resistance to wear, especially in challenging environments prevalent in regions like Africa and South America.

-

تصنيف عزم الدوران: This specification indicates the amount of rotational force the starter motor can generate. A higher torque rating is necessary for starting larger engines, such as those found in trucks or heavy machinery. B2B buyers must assess the torque requirements of their specific applications to ensure the starter motor can effectively start the engine under varying conditions.

-

المواصفات الكهربائية: This includes voltage (commonly 12V or 24V) and current ratings (measured in amps). The correct voltage ensures compatibility with the vehicle’s electrical system, while adequate current ratings are critical for the motor’s efficiency and performance. For international buyers, understanding these specifications helps avoid costly mismatches that could lead to operational failures.

-

نطاق درجة الحرارة: Starter motors must operate effectively within a specified temperature range. Motors designed for extreme climates, whether hot or cold, are essential for reliable performance. This is particularly significant in regions with fluctuating temperatures, influencing the selection process for B2B purchasers.

-

مستويات التسامح: Precise tolerances in manufacturing ensure that components fit correctly and operate smoothly. Tighter tolerances often lead to better performance and reliability, which is crucial for high-volume applications. Buyers should evaluate tolerance levels to ensure they meet the operational demands of their vehicles.

What Are Common Trade Terms Related to Vehicle Starter Motors?

Understanding trade terminology is essential for effective communication and negotiation in the automotive parts industry. Here are some common terms that B2B buyers should be familiar with:

-

OEM (الشركة المصنعة للمعدات الأصلية): This term refers to the original manufacturer of the starter motor or its components. OEM parts are often preferred for their guaranteed compatibility and quality. B2B buyers should consider OEM parts when aiming for reliability and performance consistency in their vehicle fleets.

-

MOQ (الحد الأدنى لكمية الطلب): This refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for budget management and inventory planning, especially for international buyers looking to import starter motors in bulk.

-

طلب عرض أسعار (RFQ): An RFQ is a document sent to suppliers to request pricing and terms for specific products. This process helps buyers compare offers and negotiate better deals. B2B buyers should utilize RFQs to streamline their procurement processes and ensure they receive competitive pricing.

-

شروط التجارة الدولية (Incoterms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and delivery responsibilities, particularly in cross-border transactions.

-

المهلة الزمنية: This term indicates the time required from placing an order to receiving the product. Understanding lead times is crucial for supply chain management and planning, allowing buyers to align their inventory levels with production schedules effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement strategies and operational efficiencies in sourcing vehicle starter motors.

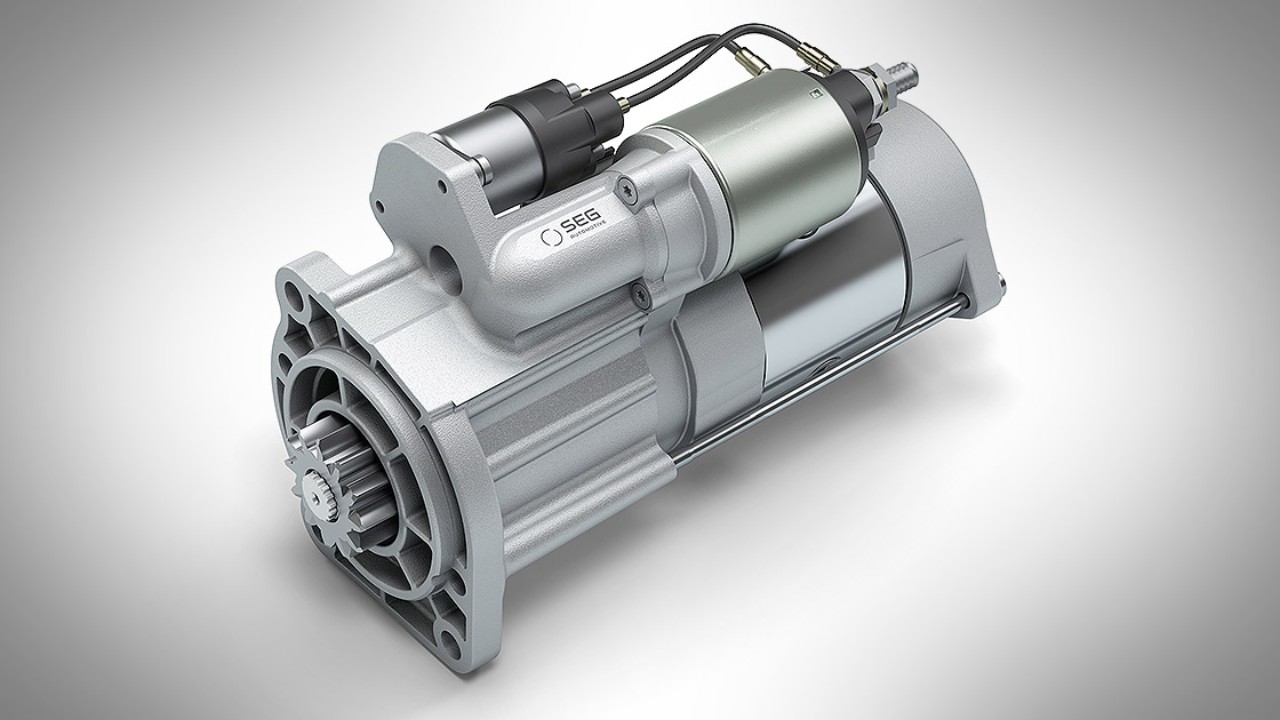

Navigating Market Dynamics and Sourcing Trends in the vehicle starter motor Sector

What Are the Key Market Trends Influencing the Vehicle Starter Motor Sector?

The global vehicle starter motor market is experiencing significant transformation driven by several factors. One of the primary drivers is the increasing demand for electric vehicles (EVs) and hybrids, which often utilize more sophisticated starter systems. This trend is particularly relevant for B2B buyers in regions like Africa and South America, where the automotive industry is rapidly evolving. Manufacturers are increasingly integrating starter motors with alternators in mild hybrid vehicles, improving energy efficiency and performance.

Another key trend is the push towards automation and digitalization within the automotive supply chain. B2B buyers can leverage advanced technologies such as predictive analytics and Internet of Things (IoT) to optimize sourcing strategies and inventory management. These technologies enhance forecasting accuracy, enabling companies to respond swiftly to market fluctuations and consumer demands.

Illustrative image related to vehicle starter motor

Sourcing trends are also shifting towards localization. International buyers are increasingly favoring suppliers who can offer quick turnaround times and lower transportation costs. This is especially true in Europe, where stringent environmental regulations are pushing companies to reconsider their supply chains. Buyers should seek suppliers who can provide transparency in their sourcing practices, ensuring compliance with local laws and regulations.

How Can Sustainability and Ethical Sourcing Impact the Vehicle Starter Motor Supply Chain?

Sustainability is becoming a cornerstone of sourcing strategies in the vehicle starter motor sector. The environmental impact of traditional manufacturing processes is prompting B2B buyers to seek out suppliers who prioritize sustainable practices. This includes the use of recycled materials and energy-efficient production methods, which not only reduce carbon footprints but also align with consumer preferences for eco-friendly products.

Ethical sourcing is equally crucial. Buyers should prioritize suppliers who adhere to fair labor practices and provide transparency in their supply chains. The importance of certifications like ISO 14001 for environmental management and ethical sourcing certifications cannot be overstated. Such certifications reassure buyers that suppliers are committed to sustainable practices and social responsibility.

Incorporating sustainability into sourcing decisions can also enhance brand reputation, especially in markets like Europe and North America, where consumers increasingly favor brands with strong environmental commitments. Companies that lead in sustainability are better positioned to attract investment and maintain customer loyalty, making ethical sourcing a vital consideration for international B2B buyers.

Illustrative image related to vehicle starter motor

What Is the Historical Context of Vehicle Starter Motors and Its Relevance to Today’s Market?

The vehicle starter motor has a rich history, originating in the early 20th century with Charles Kettering’s invention in 1911. This innovation revolutionized vehicle design by eliminating the need for manual cranking, leading to the widespread adoption of electric starters in automobiles. Over the decades, starter motors have evolved, incorporating advancements in technology and materials that enhance efficiency and reliability.

Understanding this evolution is significant for B2B buyers today. As starter motors have become integral to modern engine management systems, familiarity with their historical development can provide insights into current trends, such as the integration of starter motors with alternators in hybrid vehicles. This knowledge equips buyers to make informed decisions when sourcing components, ensuring they align with the latest technological advancements and market demands.

In summary, navigating the vehicle starter motor sector requires a keen understanding of market dynamics, an emphasis on sustainability, and awareness of historical context. By leveraging these insights, international B2B buyers can position themselves strategically within this evolving landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of vehicle starter motor

-

How do I solve starter motor issues in vehicles?

To address starter motor issues, first confirm that the battery is fully charged and connections are clean and secure. If the starter clicks but does not turn, the solenoid or internal components may be faulty. Testing the starter at an auto parts store can help determine if it needs replacement. If the starter functions intermittently, it may be due to overheating or worn-out internal parts. Regular maintenance and timely replacement of worn components can prevent future issues, ensuring reliable vehicle operation. -

ما هو أفضل محرك تشغيل للمركبات الثقيلة؟

The best starter motor for heavy-duty vehicles should provide high torque and durability under extreme conditions. Look for models specifically designed for heavy-duty applications, as they often feature robust construction and enhanced electrical components to handle increased demands. Brands known for heavy-duty starters include Bosch, Denso, and Delco Remy. Additionally, consider factors such as compatibility with the vehicle’s specifications, warranty, and availability of service parts to ensure long-term reliability. -

ما هي العوامل التي يجب أن آخذها في الاعتبار عند شراء محركات بدء التشغيل من الخارج؟

When sourcing starter motors internationally, consider the supplier’s reputation, quality certifications, and compliance with industry standards. Check for reviews and testimonials from other B2B buyers to gauge reliability. Additionally, assess the supplier’s ability to provide timely delivery, competitive pricing, and robust after-sales support. Understanding local regulations regarding imports, tariffs, and taxes is crucial to avoid unexpected costs. Always request samples or prototypes before placing larger orders to verify quality. -

ما هو الحد الأدنى لكميات الطلب (MOQ) لمحركات بدء التشغيل؟

MOQs for starter motors can vary significantly based on the supplier and the type of motor being sourced. Many manufacturers set MOQs to ensure cost-efficiency in production and shipping. Generally, MOQs can range from 50 to 500 units, depending on the supplier’s capabilities and your specific requirements. It’s advisable to negotiate the MOQ with the supplier, especially if you are a smaller buyer or if you wish to test the market before committing to larger quantities. -

How can I ensure quality assurance (QA) for starter motors?

To ensure quality assurance for starter motors, request detailed quality control processes from your supplier. This should include testing protocols for performance, durability, and safety standards. Certifications such as ISO 9001 can indicate a commitment to quality management. Additionally, consider third-party inspections before shipment to verify that products meet agreed specifications. Establishing clear communication regarding quality expectations upfront will help mitigate risks associated with defective products. -

What payment terms are common in international trade for starter motors?

Common payment terms in international trade for starter motors often include options like Letter of Credit (LC), advance payment, or payment upon receipt of goods. Many suppliers prefer a 30% deposit upfront, with the remaining balance due before shipment or upon delivery. It’s essential to clarify payment terms in the contract to avoid misunderstandings. Using secure payment methods can also protect both parties and ensure a smooth transaction process. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد محركات بدء التشغيل؟

When importing starter motors, consider shipping methods, customs clearance, and delivery timelines. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure that your supplier provides all necessary documentation, including invoices, packing lists, and certificates of origin. Familiarize yourself with the import regulations of your country to avoid delays at customs. Collaborating with a reliable freight forwarder can streamline the logistics process and enhance efficiency. -

How can I evaluate potential suppliers for starter motors?

To evaluate potential suppliers for starter motors, begin by researching their industry experience and expertise. Request references from other clients and assess their production capacity and technology. Visit their manufacturing facility if possible, or opt for virtual tours to gauge their operations. Additionally, review their certifications, warranty policies, and after-sales support. Conducting thorough due diligence will help you select a supplier that aligns with your quality and service expectations.

Top 5 Vehicle Starter Motor Manufacturers & Suppliers List

1. هاينز – محركات بدء التشغيل

المجال: us.haynes.com

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: هذه الشركة، Haynes – Starter Motors، هي كيان بارز في السوق. للحصول على تفاصيل محددة عن المنتجات، يوصى بزيارة موقعها الإلكتروني مباشرة.

2. AutoElectro – Starter Motors

المجال: autoelectro.co.uk

تاريخ التسجيل: 1999 (26 عامًا)

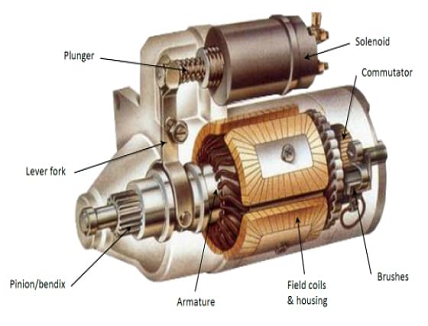

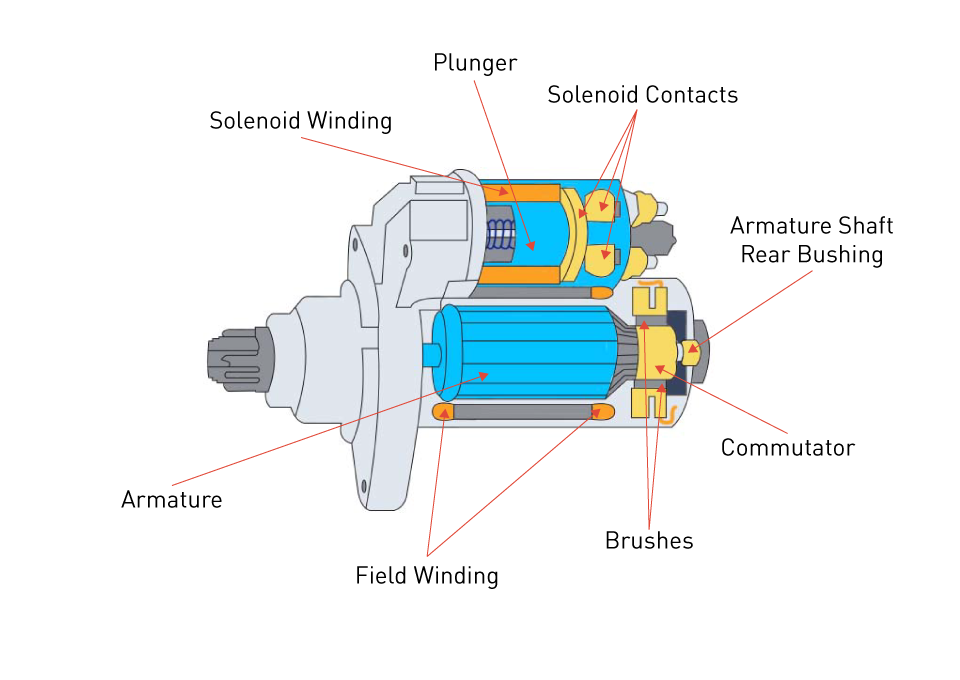

مقدمة: محركات البادئ مسؤولة عن قلب المحرك أثناء الاشتعال، مما يسمح بدخول الهواء والوقود للاحتراق. تشمل المكونات الرئيسية ما يلي:

- حديد التسليح: مغناطيس كهرومغناطيسي مركب على عمود الإدارة، مصنوع من قلب حديد لين مصفح مع حلقات موصل.

- مقوم التيار: جزء من العمود الذي يقوم بتوصيل الكهرباء من خلال الفرش.

– Brushes: Conduct electricity by making contact with the …

3. RAC – Starter Motor

المجال: rac.co.uk

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: Starter Motor: An electric component essential for starting the engine in internal combustion vehicles. It engages the engine’s rotation when the ignition is activated. Common issues leading to failure include broken solenoids, mechanical issues, electrical faults, overheating, and wear and tear. Location: Typically found at the back of the engine, lower part of the housing. Lifespan: Generally la…

4. 1A Auto – Starters

المجال: 1aauto.com

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: Starters are small electric motors that engage with the engine’s flywheel to crank the engine and start the combustion cycle. There are different types of starters: inertia starters, pre-engaged starters, and gear reduction starters. Inertia starters engage the ring gear as the pinion threads out, while pre-engaged starters use a solenoid to push the pinion out before starting the motor. Gear redu…

5. Adair and Sons – Starter Motor Services

المجال: adairandsons.com

مسجل: 2023 (2 سنة)

مقدمة: Adair and Sons offers professional automotive services, including starter motor diagnostics and repairs. Their team of qualified mechanics in Round Rock, TX, specializes in handling issues related to starter motors and other ignition system components. They provide quality services to both local and neighboring regions, ensuring customer satisfaction. The company is located at 1001 Sam Bass Rd, Ro…

Strategic Sourcing Conclusion and Outlook for vehicle starter motor

As the demand for reliable vehicle starter motors continues to rise globally, strategic sourcing has become imperative for businesses seeking to enhance their supply chains. Leveraging insights into the mechanics and functionality of starter motors can aid in making informed purchasing decisions. It is crucial for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, to prioritize quality suppliers that can provide durable products tailored to their specific market needs.

Illustrative image related to vehicle starter motor

Understanding the common causes of starter motor failure, such as mechanical wear and electrical issues, allows buyers to select components that ensure longevity and performance. Additionally, establishing relationships with manufacturers that offer comprehensive testing and after-sales support can mitigate risks associated with sourcing.

Looking ahead, the vehicle starter motor market is poised for growth, driven by advancements in automotive technology and increasing vehicle electrification. Now is the time for B2B buyers to align their sourcing strategies with innovative suppliers that can provide cutting-edge starter motor solutions. Engage with potential partners who can enhance your operational efficiency and product reliability, ensuring your business remains competitive in this evolving landscape.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.