مقدمة: التنقل في السوق العالمية لكيفية اختبار الملف اللولبي لبادئ التشغيل

في العالم المعقد لمكونات السيارات، يعد فهم كيفية اختبار الملف اللولبي لبادئ التشغيل أمرًا بالغ الأهمية لضمان موثوقية السيارة وأدائها. بالنسبة للمشترين الدوليين بين الشركات، لا سيما أولئك الذين يعملون في أسواق متنوعة مثل إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، يمكن أن يشكل الحصول على ملفات لولبية موثوقة لبادئ التشغيل تحديًا كبيرًا. إن القدرة على التشخيص الدقيق لمشاكل ملفات لولبية بادئ التشغيل لا تقلل فقط من وقت التعطل بل تقلل أيضًا من تكاليف الإصلاح، مما يجعلها مهارة حيوية لمحترفي السيارات والشركات على حد سواء.

يتعمق هذا الدليل الشامل في الجوانب الأساسية لاختبار ملفات لولبية بادئ التشغيل، ويغطي أنواعًا مختلفة وتطبيقاتها عبر طرازات السيارات المختلفة، والخطوات الحاسمة التي ينطوي عليها الاختبار الفعال. كما يركز على أهمية فحص الموردين، مما يساعد المشترين على تحديد المصنعين والموزعين ذوي السمعة الطيبة الذين يستوفون المعايير الدولية. وعلاوة على ذلك، يقدم الدليل رؤى حول اعتبارات التكلفة وأفضل الممارسات للحصول على مكونات عالية الجودة.

من خلال تمكين المشترين بين الشركات بالمعرفة حول إجراءات الاختبار وتقييم الموردين، يسهل هذا الدليل اتخاذ قرارات شراء مستنيرة. سواء كنت في البرازيل أو نيجيريا أو في أي مكان آخر، فإن القدرة على تقييم ملفات لولبية بادئ التشغيل بفعالية يمكن أن تعزز الكفاءة التشغيلية وتساهم في النجاح الشامل لأعمالك في مجال السيارات. استفد من هذا المورد لتبحر في تعقيدات السوق العالمية بثقة ودقة.

جدول المحتويات

- قائمة المصنعين والموردين لأعلى 3 كيفية اختبار الملف اللولبي لبدء التشغيل

- مقدمة: التنقل في السوق العالمية لكيفية اختبار الملف اللولبي لبادئ التشغيل

- فهم كيفية اختبار الملف اللولبي لبدء التشغيل أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لكيفية اختبار الملف اللولبي لبادئ التشغيل

- 3 نقاط ألم شائعة للمستخدمين حول ‘كيفية اختبار الملف اللولبي لبادئ التشغيل’ وحلولها

- دليل اختيار المواد الاستراتيجية لكيفية اختبار الملف اللولبي لبدء التشغيل

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لكيفية اختبار الملف اللولبي لبادئ التشغيل

- دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘كيفية اختبار الملف اللولبي لبادئ التشغيل’

- تحليل شامل للتكاليف والتسعير لكيفية اختبار الملف اللولبي لبادئ التشغيل تحديد المصادر

- تحليل البدائل: مقارنة كيفية اختبار الملف اللولبي لبادئ التشغيل مع الحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية لكيفية اختبار الملف اللولبي لبدء التشغيل

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع كيفية اختبار الملف اللولبي لبادئ التشغيل

- الأسئلة المتداولة (FAQs) لمشتري B2B حول كيفية اختبار الملف اللولبي لبادئ التشغيل

- خاتمة المصادر الاستراتيجية والتوقعات لكيفية اختبار الملف اللولبي لبدء التشغيل

- إخلاء مسؤولية هام وشروط الاستخدام

فهم كيفية اختبار الملف اللولبي لبدء التشغيل أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| الفحص البصري | فحص سريع للضرر المادي والتوصيلات | ورش إصلاح السيارات، صيانة الأساطيل | الإيجابيات: سريع وسهل; السلبيات: قد تتغاضى عن المشكلات الداخلية. |

| الاختبار الكهربائي باستخدام مقياس متعدد | يقيس الجهد والتيار عبر الأطراف | موردو المكونات الكهربائية، تصليح السيارات | الإيجابيات: دقيق; السلبيات: يتطلب معرفة تقنية. |

| اختبار الحمل | تقييم أداء الملف اللولبي تحت الحمل | الآلات الثقيلة وصيانة المركبات التجارية | الإيجابيات: شامل; السلبيات: تستغرق وقتاً أطول. |

| اختبار منضدة الملف اللولبي | يعزل الملف اللولبي لإجراء فحوصات متعمقة للوظائف | خدمات التصليح المتخصصة، شركات تصنيع السيارات | الإيجابيات: التشخيص التفصيلي; السلبيات: يتطلب معدات متخصصة. |

| الاختبار المقارن | مقارنة الأداء بوحدة جيدة معروفة | مراقبة الجودة في التصنيع وموردي قطع الغيار | الإيجابيات: فعالة لضمان الجودة; السلبيات: يحتاج إلى الوصول إلى الوحدات الوظيفية. |

ما هي الخصائص الرئيسية للفحص البصري لاختبار الملف اللولبي لبادئ التشغيل؟

الفحص البصري هو أبسط طريقة لتقييم الملف اللولبي لبادئ التشغيل. يبحث الفنيون عن علامات واضحة للتآكل أو التآكل أو الوصلات المفكوكة. هذه الطريقة مناسبة بشكل خاص لورش إصلاح السيارات وعمليات صيانة الأساطيل، حيث تكون السرعة ضرورية. في حين أنها تسمح بإجراء تقييمات سريعة، إلا أنها قد تفوت الأعطال الكهربائية الكامنة، مما يجعلها أقل موثوقية للتشخيص الشامل. يجب على المشترين النظر في الكفاءة الزمنية لهذه الطريقة مقابل إمكانية إغفالها للمشاكل الحرجة.

كيف يعمل الاختبار الكهربائي بالمقياس المتعدد لتقييم الملف اللولبي؟

يتضمن الاختبار الكهربائي باستخدام مقياس متعدد قياس الجهد والتيار عند أطراف الملف اللولبي. هذه الطريقة دقيقة للغاية ويمكنها تحديد المشاكل الكهربائية بفعالية. إنها مثالية لتطبيقات B2B مثل إصلاح السيارات وتوريد المكونات الكهربائية، حيث يكون التشخيص الدقيق أمرًا بالغ الأهمية. ومع ذلك، تتطلب هذه الطريقة مستوى معينًا من الخبرة الفنية، مما قد يستلزم تدريب أو توظيف فنيين مهرة، مما يزيد من تكاليف التشغيل.

ما أهمية اختبار الحمولة للآليات الثقيلة والمركبات التجارية؟

يعمل اختبار الحمل على تقييم أداء الملف اللولبي في ظل ظروف التشغيل، مما يجعله أمرًا حيويًا لصيانة الآلات الثقيلة والمركبات التجارية. تضمن هذه الطريقة قدرة الملف اللولبي على التعامل مع متطلبات المحركات الأكبر حجمًا وهي ذات أهمية خاصة للصناعات التي تعتمد على المعدات الثقيلة. على الرغم من أنها توفر رؤى شاملة حول وظائف الملف اللولبي، إلا أن اختبار الحمل يستغرق وقتًا أطول وقد يتطلب أدوات متخصصة، وهو ما قد يشكل عائقًا لبعض الشركات.

ما هي فوائد اختبار مقعد الملف اللولبي في الإصلاحات المتخصصة؟

يعمل اختبار منضدة الملف اللولبي على عزل الملف اللولبي لإجراء فحوصات تفصيلية لوظائفه، مما يجعله خياراً مفضلاً لخدمات الإصلاح المتخصصة ومصنعي السيارات. تسمح هذه الطريقة بإجراء تحليل شامل لأداء الملف اللولبي دون تداخل من المكونات الأخرى. وعلى الرغم من أنها توفر تشخيصات متعمقة، إلا أنها تتطلب معدات متخصصة، مما قد يمثل استثماراً كبيراً للشركات الصغيرة. يجب أن يوازن المشترون بين فوائد الاختبار التفصيلي مقابل تكلفة المعدات والتدريب.

كيف يعزز الاختبار المقارن مراقبة الجودة في التصنيع؟

يتضمن الاختبار المقارن تقييم أداء الملف اللولبي مقابل وحدة جيدة معروفة، مما يوفر معيارًا لضمان الجودة. هذه الطريقة مفيدة بشكل خاص للمصنعين وموردي قطع الغيار الذين يركزون على الحفاظ على معايير عالية. فهي تسمح بالتعرف السريع على الوحدات المعيبة قبل وصولها إلى السوق. ومع ذلك، يتطلب هذا النهج إمكانية الوصول إلى الملفات اللولبية الوظيفية، وهو ما قد لا يكون ممكنًا دائمًا لجميع الشركات. يجب على المشترين النظر في الآثار المترتبة على هذا الشرط في تخطيطهم التشغيلي.

التطبيقات الصناعية الرئيسية لكيفية اختبار الملف اللولبي لبادئ التشغيل

| الصناعة/القطاع | تطبيق محدد لكيفية اختبار الملف اللولبي لبدء التشغيل | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| إصلاح السيارات | اختبار الملف اللولبي لبدء التشغيل في صيانة المركبات | يقلل من وقت التعطل عن طريق التشخيص السريع لمشكلات بدء التشغيل | الحاجة إلى أدوات تشخيص وتدريب موثوق بها |

| الآلات الثقيلة | ضمان عمل الملف اللولبي لبدء التشغيل في معدات الإنشاءات | تعزيز الكفاءة التشغيلية وتقليل تكاليف الإصلاح | توافر معدات اختبار قوية للبيئات القاسية |

| الزراعة | التحقق من أداء الملف اللولبي في الجرارات والحصادات | يقلل من أعطال المعدات أثناء فترات الحصاد الحرجة | التوافق مع مختلف طرازات الآلات الزراعية |

| النقل | صيانة مركبات الأسطول من خلال اختبار الملف اللولبي | زيادة موثوقية الأسطول وتقليل الأعطال غير المتوقعة | الوصول إلى خيارات الشراء بالجملة لقطع الغيار والأدوات |

| التعدين | اختبار الملفات اللولبية في مركبات ومعدات التعدين | يضمن السلامة والاستمرارية التشغيلية في المواقع النائية | الحاجة إلى معدات اختبار متينة ومناسبة للظروف الوعرة |

كيف يتم استخدام ‘كيفية اختبار الملف اللولبي لبدء التشغيل’ في صناعة إصلاح السيارات؟

في قطاع إصلاح السيارات، يعد اختبار الملفات اللولبية لبادئ التشغيل أمرًا بالغ الأهمية لتشخيص مشاكل بدء التشغيل في المركبات. يمكن للميكانيكيين أن يحددوا بسرعة ما إذا كان العطل يكمن في الملف اللولبي أو البطارية أو محرك بدء التشغيل، مما يوفر الوقت وتكاليف العمالة. يجب على المشترين الدوليين، خاصة من مناطق مثل إفريقيا وأمريكا الجنوبية، التفكير في الحصول على أدوات تشخيص موثوقة وموارد تدريب لضمان تقديم الخدمة بكفاءة. تعزز القدرة على معالجة أعطال الملف اللولبي على الفور من رضا العملاء وولائهم، وهو أمر حيوي في الأسواق التنافسية.

ما أهمية اختبار الملف اللولبي لبادئ التشغيل في الماكينات الثقيلة؟

في الآلات الثقيلة، وخاصةً في مجال الإنشاءات، يعد اختبار الملفات اللولبية لبادئ التشغيل أمرًا ضروريًا للحفاظ على وظائف المعدات. يمكن أن يؤدي الملف اللولبي المعطل إلى تعطل المعدات، مما يؤدي إلى تعطل مكلف. من خلال تنفيذ بروتوكولات اختبار منتظمة، يمكن للشركات تعزيز الكفاءة التشغيلية وتقليل تكاليف الإصلاح. يجب أن يركز المشترون في هذا القطاع على توفير أدوات تشخيص قوية يمكنها تحمل الظروف الصعبة المعتادة في مواقع البناء، مما يضمن طول العمر والموثوقية.

ما الدور الذي يلعبه اختبار الملف اللولبي البادئ في الزراعة؟

في القطاع الزراعي، يعد ضمان عمل الملفات اللولبية لبدء التشغيل في الجرارات والحصادات بشكل صحيح أمرًا بالغ الأهمية خلال فترات ذروة التشغيل. يمكن أن تؤدي الأعطال إلى تأخيرات خلال أوقات الزراعة أو الحصاد الحاسمة، مما يؤثر على الإنتاجية والربحية. يجب على المزارعين والشركات الزراعية البحث عن حلول اختبار متوافقة مع مختلف طرازات الآلات لتبسيط عمليات الصيانة. يساعد هذا النهج الاستباقي على تقليل أعطال المعدات ويضمن سير العمليات بسلاسة خلال المواسم التي يكثر فيها الطلب.

كيف يعزز اختبار الملف اللولبي لبادئ التشغيل عمليات النقل؟

بالنسبة لشركات النقل، لا سيما تلك التي تدير أساطيل المركبات، يعد اختبار الملفات اللولبية لبدء التشغيل أمرًا حيويًا للحفاظ على موثوقية المركبة. يمكن أن تمنع الفحوصات المنتظمة الأعطال غير المتوقعة، والتي يمكن أن تعطل الخدمات اللوجستية وتؤدي إلى خسائر مالية كبيرة. يجب على المشترين بين الشركات في هذا القطاع إعطاء الأولوية لتوريد أدوات التشخيص التي تسمح بإجراء اختبارات فعالة وإصلاحات سريعة. بالإضافة إلى ذلك، فإن إقامة علاقات مع الموردين الذين يقدمون خيارات الشراء بالجملة يمكن أن يؤدي إلى توفير التكاليف وتحسين إدارة الأسطول.

لماذا من المهم اختبار الملفات اللولبية لبادئ التشغيل في تطبيقات التعدين؟

في صناعة التعدين، تُعد وظيفة المركبات والمعدات ذات أهمية قصوى لضمان السلامة والاستمرارية التشغيلية. يساعد اختبار الملفات اللولبية لبدء التشغيل على منع تعطل المعدات في المواقع النائية، حيث يمكن أن تكون عمليات الإصلاح صعبة وتستغرق وقتًا طويلاً. يجب أن تستثمر الشركات في معدات اختبار متينة مصممة للظروف الوعرة لضمان دقة التشخيص. يعد الحصول على أدوات موثوقة يمكنها تحمل البيئات القاسية أمرًا ضروريًا للحفاظ على معايير الإنتاجية والسلامة في عمليات التعدين.

3 نقاط ألم شائعة للمستخدمين حول ‘كيفية اختبار الملف اللولبي لبادئ التشغيل’ وحلولها

السيناريو 1: صعوبة في تشخيص السبب الجذري لمشاكل البدء

المشكلة: غالبًا ما يواجه العاملون في مجال إصلاح السيارات تحديات عند تشخيص مشاكل بدء التشغيل في السيارات. ويواجه العديد من الفنيين صعوبة في تحديد ما إذا كانت المشكلة تكمن في الملف اللولبي لبدء التشغيل، أو البطارية، أو محرك بدء التشغيل نفسه. قد يؤدي عدم اليقين هذا إلى إهدار الوقت والموارد، خاصةً عندما يتم استبدال الأجزاء دون داعٍ. قد يشعر المشترون أيضًا بالإحباط إذا كان فريقهم يفتقر إلى الأدوات أو المعرفة المناسبة لإجراء اختبارات شاملة، مما يؤدي إلى التأخير في تقديم الخدمة وعدم رضا العملاء.

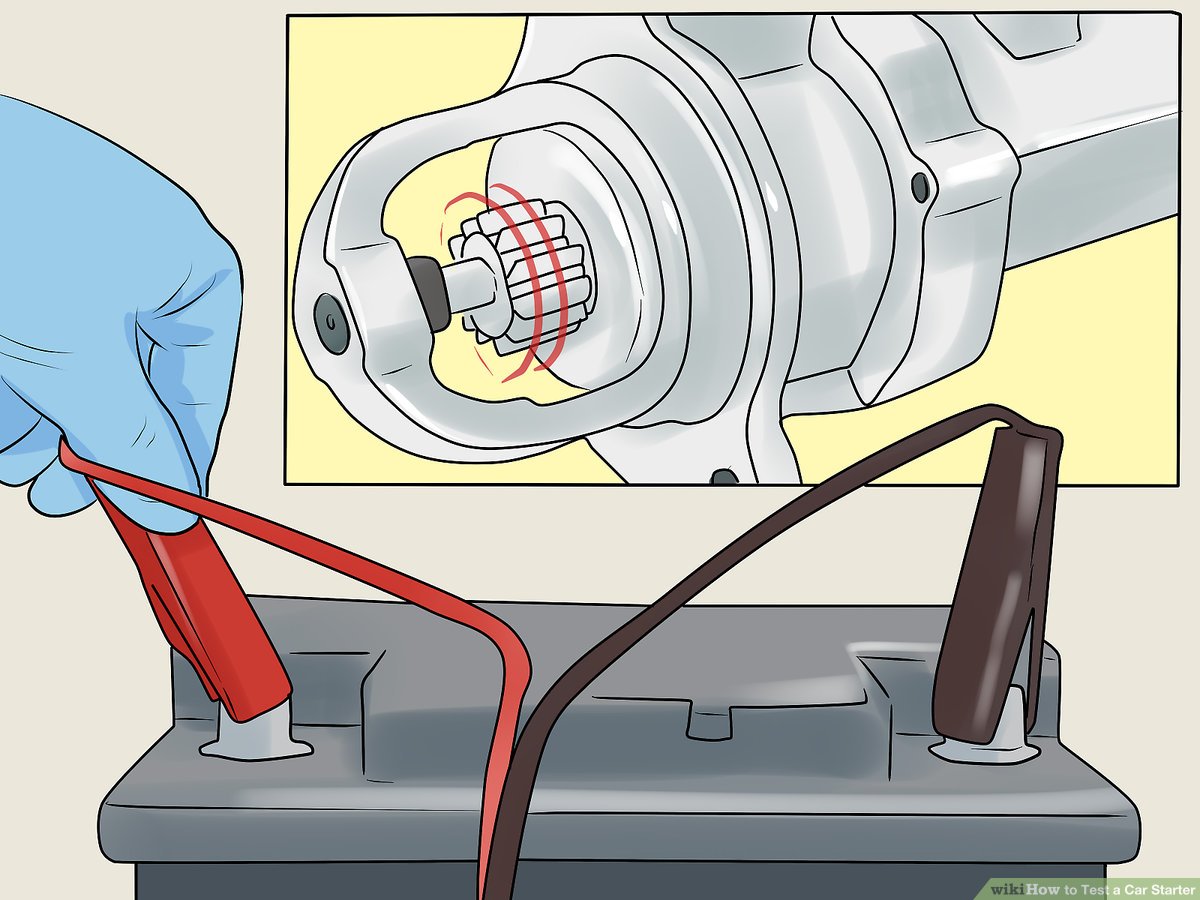

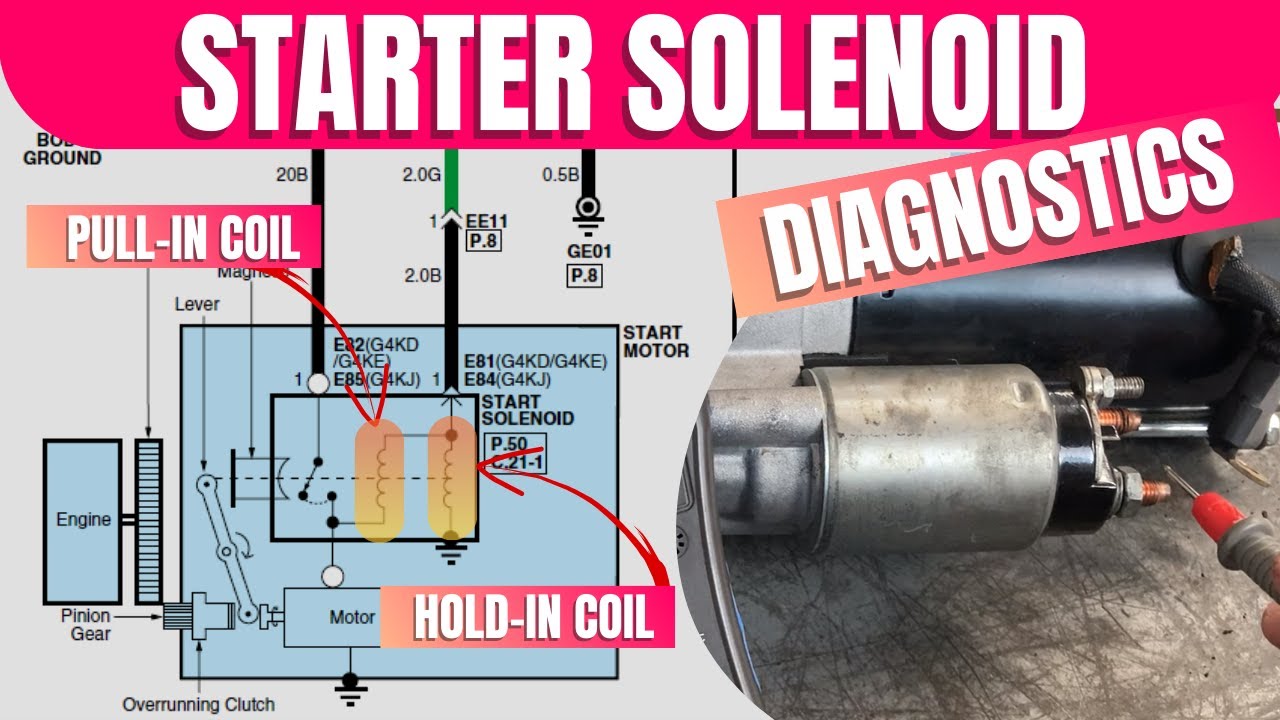

الحل: لتشخيص مشاكل بدء التشغيل بفعالية، من الضروري تنفيذ نهج اختبار منهجي. ابدأ بالتأكد من تدريب الفنيين على استخدام مقياس متعدد أو مصباح اختبار بشكل صحيح. قم بتثقيفهم حول كيفية فحص جهد البطارية أولاً؛ يجب أن تقرأ البطارية السليمة حوالي 12.6 فولت عند السكون. إذا كان جهد البطارية منخفضًا، فقد تحتاج ببساطة إلى الشحن أو الاستبدال. بعد ذلك، قم بإرشاد الفنيين لفحص التيار في الملف اللولبي لبدء التشغيل باستخدام مصباح الاختبار، والتأكد مما إذا كانت الطاقة تصل إلى الملف اللولبي قبل تحديد ما إذا كان الملف اللولبي نفسه معطوباً. لا يوفر هذا الاختبار المنظم الوقت فحسب، بل يعزز أيضًا دقة التشخيص، مما يؤدي في النهاية إلى تحسين جودة الخدمة وثقة العملاء.

السيناريو 2: إجراءات الاختبار غير المتسقة عبر الفنيين

المشكلة: في ورش السيارات الكبيرة أو مراكز الخدمة الكبيرة، قد يكون لدى الفنيين المختلفين إجراءات مختلفة لاختبار الملفات اللولبية لبادئ التشغيل. قد يؤدي هذا التناقض إلى حدوث ارتباك ونتائج غير موثوقة، مما يؤثر على كفاءة العمليات وجودة الخدمة المقدمة للعملاء. قد يجد المشترون من الشركات صعوبة في توحيد العمليات عبر فرقهم، مما يؤدي إلى احتمال حدوث خطأ في التشخيص وتكرار الإصلاحات التي تحبط العملاء.

الحل: لمعالجة هذه المشكلة، قم بإنشاء بروتوكول اختبار موحد لجميع الفنيين لاتباعه. قم بإنشاء دليل تفصيلي خطوة بخطوة أو قائمة مراجعة توضح عملية اختبار الملفات اللولبية لبادئ التشغيل، بما في ذلك المخططات ونصائح استكشاف الأخطاء وإصلاحها. قم بإجراء دورات تدريبية حيث يمكن للفنيين ممارسة هذه الإجراءات تحت الإشراف، مما يضمن أن يكون الجميع على نفس الصفحة. استفد من التكنولوجيا، مثل مقاطع الفيديو التعليمية أو الكتيبات الرقمية، لتعزيز التعلم وتحسين الاحتفاظ بها. من خلال توحيد الإجراءات، يمكن لورشة العمل لديك تحقيق قدر أكبر من الاتساق في التشخيص، مما يؤدي إلى تعزيز الكفاءة التشغيلية وزيادة رضا العملاء.

السيناريو 3: توريد قطع غيار عالية الجودة لملفات لولبية بادئ الحركة

المشكلة: عندما يتقرر وجود عطل في الملف اللولبي لبادئ التشغيل، غالبًا ما يواجه المشترون من الشركات تحديات في الحصول على قطع غيار عالية الجودة. في بعض المناطق، قد يكون هناك وصول محدود إلى موردين موثوقين أو مجموعة واسعة من المنتجات التي يمكن أن تؤدي إلى الارتباك بشأن القطع التي يجب اختيارها. وتعتبر هذه المشكلة ملحة بشكل خاص في الأسواق الدولية حيث يعتبر ضمان الجودة والتوافق مع المركبات المحلية من الشواغل الهامة.

الحل: للتأكد من أنك تحصل على قطع غيار عالية الجودة، قم بإقامة علاقات مع موردين ذوي سمعة جيدة متخصصين في مكونات السيارات. قم بإجراء بحث شامل عن الموردين وخذ بعين الاعتبار عوامل مثل سمعتهم وسياسات الضمان ومراجعات العملاء. عند طلب قطع الغيار، قم بتوفير مواصفات تفصيلية لضمان توافقها مع السيارات في مجموعة خدماتك. ضع في اعتبارك الاستثمار في اتفاقيات الشراء بالجملة لتأمين أسعار وتوافر أفضل. بالإضافة إلى ذلك، شجع الفنيين لديك على توثيق مواصفات القطع التي يستبدلونها بشكل متكرر، مما يسمح لفريق المشتريات لديك بتبسيط الطلبات المستقبلية. من خلال التركيز على الجودة والاتساق في التوريد، يمكنك تقليل وقت التعطل إلى أدنى حد ممكن وضمان أن تظل خدمات الإصلاح لديك تنافسية وموثوقة.

دليل اختيار المواد الاستراتيجية لكيفية اختبار الملف اللولبي لبدء التشغيل

ما هي المواد الشائعة المستخدمة في اختبار الملفات اللولبية البادئة؟

عند النظر في المواد المستخدمة لاختبار الملفات اللولبية البادئة، من الضروري تقييم خصائصها وأدائها وملاءمتها لمختلف التطبيقات. فيما يلي تحليلات لأربع مواد شائعة مستخدمة في هذا السياق، مع التركيز على خصائصها الرئيسية ومزاياها وعيوبها واعتباراتها المحددة للمشترين الدوليين من الشركات.

صورة توضيحية تتعلق بكيفية اختبار الملف اللولبي لبدء التشغيل

1. النحاس

الخصائص الرئيسية: النحاس عالي التوصيل، مما يجعله خياراً ممتازاً للتطبيقات الكهربائية. وتصل درجة انصهاره إلى 1,984 درجة فهرنهايت (1,085 درجة مئوية) ويتميز بمقاومة جيدة للتآكل، خاصةً عندما يكون مطلياً.

إيجابيات وسلبيات: الميزة الأساسية للنحاس هي الموصلية الكهربائية الفائقة التي تضمن نقل الطاقة بكفاءة. ومع ذلك، فهو مكلف نسبياً مقارنة بمواد أخرى مثل الألومنيوم. بالإضافة إلى ذلك، يمكن أن يكون النحاس عرضة للأكسدة، مما قد يؤثر على الأداء ما لم تتم معالجته بشكل صحيح.

التأثير على التطبيق: النحاس مثالي للتوصيلات في الملفات اللولبية لبدء التشغيل حيث تكون هناك حاجة إلى تيار عالي. إن توافقه مع مختلف الوسائط يجعله متعدد الاستخدامات، ولكن الأكسدة في البيئات الرطبة يمكن أن تؤدي إلى حدوث أعطال.

اعتبارات للمشترين الدوليين: يجب على المشترين من مناطق مثل أفريقيا وأمريكا الجنوبية مراعاة التوافر المحلي وتقلبات الأسعار. والامتثال لمعايير مثل ASTM B170 (للأسلاك النحاسية) أمر بالغ الأهمية لضمان الجودة.

2. الألومنيوم

الخصائص الرئيسية: يوفر الألومنيوم توازنًا جيدًا بين التوصيلية والوزن، حيث تبلغ درجة انصهاره 1221 درجة فهرنهايت (660.3 درجة مئوية). كما أنه مقاوم للتآكل، خاصة في البيئات المؤكسدة.

إيجابيات وسلبيات: إن الطبيعة الخفيفة للألومنيوم تجعل من السهل التعامل معه وتركيبه، مما يقلل من تكاليف العمالة. ومع ذلك، فإن موصلية الألومنيوم أقل من موصلية النحاس، مما قد يستلزم أسلاكاً ذات مقاس أكبر للحصول على نفس السعة الحالية.

التأثير على التطبيق: الألومنيوم مناسب للاستخدامات التي يكون فيها الوزن مصدر قلق، مثل مكونات السيارات. كما أنه متوافق مع مختلف السوائل، على الرغم من أنه يجب توخي الحذر لتجنب التآكل الجلفاني عند استخدامه مع المعادن غير المتشابهة.

اعتبارات للمشترين الدوليين: في مناطق مثل الشرق الأوسط، حيث يمكن أن ترتفع درجات الحرارة، تكون الخصائص الحرارية للألومنيوم مفيدة في مناطق مثل الشرق الأوسط. يجب على المشترين التأكد من الامتثال لمعايير مثل ASTM B221 لسحب الألومنيوم.

3. الفولاذ

الخصائص الرئيسية: يُعرف الفولاذ بقوته ومتانته، حيث تبلغ درجة انصهاره حوالي 2,500 درجة فهرنهايت (1,370 درجة مئوية). وهو أقل توصيلًا من النحاس والألومنيوم ولكنه يوفر خصائص ميكانيكية ممتازة.

إيجابيات وسلبيات: الصلب فعال من حيث التكلفة ومتين للغاية، مما يجعله مناسباً للمكونات الهيكلية. ومع ذلك، فهو عرضة للصدأ والتآكل، خاصةً في البيئات الرطبة، ما لم يتم طلاؤه أو معالجته بشكل صحيح.

التأثير على التطبيق: غالبًا ما يستخدم الفولاذ في مبيت الملفات اللولبية لبدء التشغيل نظرًا لقوته. غير أن انخفاض توصيله يعني أنه ليس مثالياً للتوصيلات الكهربائية.

اعتبارات للمشترين الدوليين: يجب أن يكون المشترون في أوروبا على دراية بالامتثال لمعايير مثل EN 10025 لمنتجات الصلب. قد تكون معالجات مقاومة التآكل ضرورية في المناخات الرطبة، مثل تلك الموجودة في أجزاء من البرازيل ونيجيريا.

4. المركبات البلاستيكية

الخصائص الرئيسية: مركبات البلاستيك خفيفة الوزن وغير موصلة للكهرباء ويمكنها تحمل مجموعة من درجات الحرارة، تصل عادةً إلى 300 درجة فهرنهايت (149 درجة مئوية). وهي مقاومة للتآكل الكيميائي.

إيجابيات وسلبيات: الميزة الأساسية لمركبات البلاستيك هي مقاومتها للعوامل البيئية، مما يجعلها مناسبة لمختلف التطبيقات. غير أنها قد لا تتحمل درجات الحرارة العالية بنفس فعالية المعادن، وقد تكون قوتها الميكانيكية أقل.

التأثير على التطبيق: غالباً ما تستخدم مركبات البلاستيك في المكونات العازلة في الملفات اللولبية لبدء التشغيل. وهي توفر حماية ممتازة ضد العوامل البيئية ولكنها قد لا تكون مناسبة للتطبيقات عالية الإجهاد.

اعتبارات للمشترين الدوليين: يجب أن يتأكد المشترون من أن المركبات البلاستيكية تفي بالمعايير ذات الصلة، مثل ISO 9001 لإدارة الجودة. وفي المناطق ذات درجات الحرارة القصوى، ينبغي تقييم الحدود الحرارية لهذه المواد في المناطق ذات درجات الحرارة القصوى.

جدول ملخص اختيار المواد

| المواد | حالة استخدام نموذجية لكيفية اختبار الملف اللولبي لبادئ التشغيل | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | التوصيلات الكهربائية في الملفات اللولبية | موصلية كهربائية فائقة | باهظة الثمن وعرضة للأكسدة | عالية |

| الألومنيوم | أسلاك ومكونات خفيفة الوزن | خفيفة الوزن ومقاومة للتآكل | موصلية أقل من النحاس | متوسط |

| الصلب | مبيت هيكلي للملفات اللولبية | فعالة من حيث التكلفة ومتينة | عرضة للصدأ والتآكل | منخفض |

| المركبات البلاستيكية | المكونات العازلة | مقاومة للعوامل البيئية | قوة ميكانيكية أقل | متوسط |

يوفر هذا التحليل رؤى حول المواد المناسبة لاختبار الملفات اللولبية لبدء التشغيل، مما يساعد المشترين من الشركات على اتخاذ قرارات مستنيرة بناءً على الأداء والتكلفة والاعتبارات الإقليمية.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لكيفية اختبار الملف اللولبي لبادئ التشغيل

ما هي المراحل الرئيسية لتصنيع الملف اللولبي لبدء التشغيل؟

تنطوي عملية تصنيع الملف اللولبي لبادئ التشغيل على عدة مراحل حاسمة، كل منها مصمم لضمان عمل الملف اللولبي بشكل موثوق في ظل ظروف مختلفة. وتشمل هذه المراحل إعداد المواد والتشكيل والتجميع والتشطيب.

-

تحضير المواد: تبدأ عملية التصنيع باختيار مواد عالية الجودة، وهي عادةً النحاس للمكونات الكهربائية، والمعادن المتينة للمبيت. ويجب على الموردين التأكد من أن هذه المواد تفي بمعايير محددة لضمان التوصيل والمتانة. يبدأ ضمان الجودة هنا، مع إجراء عمليات فحص للمواد الخام للتأكد من مطابقتها للمعايير الدولية مثل ISO 9001.

-

تشكيل: في هذه المرحلة، يتم تشكيل المواد الخام في المكونات الضرورية. بالنسبة للملفات اللولبية، يتضمن ذلك عمليات مثل الختم أو التصنيع الآلي لإنشاء مبيت الملف اللولبي والمكونات الداخلية. وغالبًا ما يتم استخدام تقنيات التصنيع المتقدمة، مثل التصنيع باستخدام الحاسب الآلي، لتحقيق أبعاد دقيقة، وهو أمر بالغ الأهمية لأداء الملف اللولبي.

-

الجمعية: بمجرد تشكيل جميع المكونات، يتم تجميعها. وتتطلب هذه المرحلة عمالة ماهرة أو أتمتة لضمان توافق مكونات الملف اللولبي معًا بشكل صحيح. يتكون كل ملف لولبي عادةً من ملف كهرومغناطيسي ومكبس ومبيت. عملية التجميع أمر بالغ الأهمية، حيث أن أي اختلال في المحاذاة يمكن أن يؤدي إلى حدوث خلل.

-

التشطيب: بعد التجميع، تخضع الملفات اللولبية لعمليات تشطيب، بما في ذلك المعالجة السطحية والطلاء. هذه الخطوة ضرورية لمنع التآكل وتعزيز طول عمر الملف اللولبي. قد تتضمن فحوصات الجودة خلال هذه المرحلة فحوصات بصرية واختبارات وظيفية للتأكد من أن الملف اللولبي يعمل على النحو المنشود.

كيف تؤثر المعايير الدولية على ضمان الجودة في تصنيع الملف اللولبي البادئ؟

يعد ضمان الجودة جانبًا حيويًا من جوانب تصنيع الملفات اللولبية البادئة، مما يضمن أن المنتجات تفي بمعايير السلامة والأداء. تشمل المعايير الدولية الرئيسية ISO 9001، التي تحدد متطلبات أنظمة إدارة الجودة، والمعايير الخاصة بالصناعة مثل علامة CE في أوروبا ومعايير API في قطاع النفط والغاز.

-

آيزو 9001: يشدد هذا المعيار على اتباع نهج موجه نحو العمليات في إدارة الجودة، مع التركيز على رضا العملاء والتحسين المستمر. ويجب على المصنعين وضع إجراءات موثقة والاحتفاظ بسجلات للامتثال لضمان استيفاء منتجاتهم للمتطلبات المحددة.

-

علامة CE: بالنسبة للمصنعين الذين يستهدفون السوق الأوروبية، فإن علامة CE أمر بالغ الأهمية. فهي تشير إلى أن المنتج يتوافق مع معايير الاتحاد الأوروبي للسلامة والصحة وحماية البيئة. ينطوي الحصول على شهادة CE على اختبارات وتوثيق صارمين، وهو ما يمكن أن يكون عاملًا قيمًا للتمييز في الأسواق التنافسية.

-

معايير API: بالنسبة للملفات اللولبية المستخدمة في صناعة النفط والغاز، من الضروري الالتزام بمعايير API. تضمن هذه المعايير قدرة المنتجات على تحمل ظروف التشغيل القاسية والحفاظ على الموثوقية بمرور الوقت.

ما هي نقاط التحقق من مراقبة الجودة في تصنيع الملف اللولبي لبدء التشغيل؟

يتم دمج نقاط التحقق من مراقبة الجودة (QC) في جميع مراحل عملية التصنيع لضمان استيفاء كل ملف لولبي للمواصفات المطلوبة. وتشمل نقاط التحقق هذه عادةً مراقبة الجودة الواردة (IQC) ومراقبة الجودة أثناء العملية (IPQC) ومراقبة الجودة النهائية (FQC).

-

مراقبة الجودة الواردة (IQC): تتضمن نقطة الفحص الأولية هذه فحص المواد الخام والمكونات عند وصولها إلى منشأة التصنيع. ويعد التأكد من أن المواد تفي بالمعايير المحددة مسبقًا أمرًا بالغ الأهمية، حيث أن أي عيوب في هذه المرحلة يمكن أن تنتشر خلال عملية التصنيع.

-

مراقبة الجودة أثناء الإنتاج (IPQC): أثناء التصنيع، تراقب IPQC عمليات التجميع والتشكيل. ويتم إجراء عمليات تفتيش واختبارات منتظمة لتحديد أي انحرافات عن معايير الجودة. يساعد هذا النهج الاستباقي على اكتشاف المشكلات المحتملة مبكرًا، مما يقلل من مخاطر وصول المنتجات المعيبة إلى السوق.

-

مراقبة الجودة النهائية (FQC): بعد مرحلتي التجميع والتشطيب، تتضمن مراقبة الجودة النوعية اختبارًا شاملاً للملفات اللولبية النهائية. وقد يشمل ذلك الاختبار الوظيفي، واختبارات المتانة، وتقييمات الأداء الكهربائي للتحقق من أن كل ملف لولبي يعمل بشكل صحيح في ظل ظروف مختلفة.

ما هي طرق الاختبار الشائعة الاستخدام للملفات اللولبية البادئة؟

لضمان أداء وموثوقية الملفات اللولبية لبادئ التشغيل، يستخدم المصنعون عدة طرق اختبار أثناء عملية مراقبة الجودة. وتشمل الطرق الشائعة ما يلي:

-

الاختبارات الكهربائية: يتضمن ذلك التحقق من الاستمرارية والمقاومة في دائرة الملف اللولبي. وغالباً ما يستخدم مقياس متعدد لقياس الجهد والتيار، والتأكد من أن الملف اللولبي ينشط بشكل صحيح عند التعشيق.

-

الاختبار الوظيفي: تخضع الملفات اللولبية لاختبارات تشغيلية لمحاكاة ظروف العالم الحقيقي. يتحقق هذا الاختبار من أن الملف اللولبي يقوم بتعشيق محرك بدء التشغيل بفعالية ويستجيب بدقة لإشارات الإشعال.

-

اختبار البيئة: يقيّم هذا الاختبار أداء الملف اللولبي في ظل درجات الحرارة ومستويات الرطوبة القصوى. هذه الظروف مهمة بشكل خاص للأسواق الدولية حيث يمكن أن تختلف العوامل البيئية بشكل كبير.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

بالنسبة للمشترين بين الشركات، لا سيما في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، فإن التحقق من ممارسات مراقبة الجودة لدى الموردين أمر بالغ الأهمية لضمان موثوقية المنتج. إليك بعض الاستراتيجيات:

-

تدقيق الموردين: إن إجراء عمليات تدقيق منتظمة للموردين يمكن أن يوفر نظرة ثاقبة لعمليات التصنيع وممارسات ضمان الجودة الخاصة بهم. ويشمل ذلك مراجعة الوثائق المتعلقة بشهادات الأيزو وإجراءات الاختبار والامتثال للمعايير الدولية.

-

تقارير الجودة: يمكن أن يساعد طلب تقارير مفصلة عن الجودة المشترين على فهم تدابير مراقبة الجودة التي ينفذها الموردون. وينبغي أن تتضمن هذه التقارير بيانات عن معدلات العيوب، ونتائج الاختبارات، وأي إجراءات تصحيحية تم اتخاذها استجابة لمشاكل الجودة.

-

عمليات التفتيش من قبل أطراف ثالثة: يمكن أن يضيف إشراك وكالات التفتيش الخارجية طبقة إضافية من الضمان. ويمكن لهذه المنظمات المستقلة إجراء عمليات التدقيق والاختبار نيابة عن المشترين، مما يضمن استيفاء المنتجات لمعايير الجودة المحددة قبل الشحن.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

يجب على المشترين الدوليين بين الشركات التعامل مع العديد من الفروق الدقيقة في مراقبة الجودة عند الحصول على الملفات اللولبية لبدء التشغيل. وتشمل العوامل التي يجب مراعاتها ما يلي:

صورة توضيحية تتعلق بكيفية اختبار الملف اللولبي لبدء التشغيل

-

الامتثال التنظيمي: من الضروري فهم المشهد التنظيمي في السوق المستهدفة. فقد يكون للمناطق المختلفة متطلبات محددة لاعتماد المنتج ومعايير السلامة والأثر البيئي.

-

الاعتبارات الثقافية: يجب على المشترين أن يكونوا على دراية بالاختلافات الثقافية التي قد تؤثر على التواصل والتوقعات فيما يتعلق بالجودة. ويمكن أن يؤدي بناء علاقات قوية مع الموردين إلى تيسير التفاهم والتعاون بشكل أفضل.

-

الخدمات اللوجستية وسلسلة التوريد: تمتد مراقبة الجودة إلى ما هو أبعد من التصنيع لتشمل الخدمات اللوجستية. وضمان مناولة المنتجات ونقلها بشكل صحيح أمر بالغ الأهمية للحفاظ على الجودة في جميع مراحل سلسلة التوريد.

وختامًا، يعد فهم عمليات التصنيع وممارسات ضمان الجودة للملفات اللولبية لبادئات التشغيل أمرًا ضروريًا للمشترين بين الشركات. ومن خلال النظر في مراحل التصنيع، والمعايير الدولية ذات الصلة، ونقاط التحقق من مراقبة الجودة، وطرق الاختبار، واستراتيجيات التحقق، يمكن للمشترين اتخاذ قرارات مستنيرة عند الحصول على هذه المكونات الهامة.

دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘كيفية اختبار الملف اللولبي لبادئ التشغيل’

لضمان كفاءة وفعالية شراء الأدوات والمعدات اللازمة لاختبار الملفات اللولبية لبادئ التشغيل، اتبع هذا الدليل العملي للتوريد المصمم للمشترين من الشركات. ستساعدك قائمة المراجعة هذه على التنقل في عملية الاختيار، مما يضمن حصولك على المنتجات المناسبة لتلبية احتياجاتك التشغيلية.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

ضع متطلبات فنية واضحة للأدوات والمعدات التي تحتاجها لاختبار الملفات اللولبية لبادئ التشغيل. حدد أنواع المركبات التي ستعمل معها وقياسات الجهد والتيار المتوقعة. سيرشدك هذا الوضوح في اختيار الموردين الذين يقدمون منتجات متوافقة مع متطلباتك.

- نطاق الجهد: تأكد من قدرة الأدوات على التعامل مع مستويات الجهد الكهربائي المعتادة للمركبات في السوق الذي تتواجد فيه.

- دقة القياس: ابحث عن أجهزة ذات تصنيفات دقة عالية لضمان نتائج اختبار موثوقة.

الخطوة 2: البحث عن أوراق اعتماد الموردين

تحقق من الموردين المحتملين للتحقق من مصداقيتهم وموثوقيتهم. ركز على الموردين الذين يتمتعون بسجل حافل في صناعة السيارات وأولئك الذين يقدمون دليلاً على ضمان الجودة من خلال الشهادات.

- الشهادات: تحقق من شهادات الأيزو أو معايير إدارة الجودة المماثلة التي تؤكد التزامها بالجودة.

- الخبرة في المجال: من المرجح أن يفهم الموردون الذين يتمتعون بخبرة واسعة احتياجاتك ويقدمون حلولاً مصممة خصيصاً لك.

الخطوة 3: تقييم جودة المنتج ومتانته

تقييم جودة ومتانة المنتجات المعروضة. يجب أن تتحمل الأدوات والمعدات المستخدمة في تشخيص السيارات الاستخدام المنتظم وظروف العمل القاسية.

صورة توضيحية تتعلق بكيفية اختبار الملف اللولبي لبدء التشغيل

- تركيبة المادة: استفسر عن المواد المستخدمة في تصنيع معدات الاختبار. المواد عالية الجودة تؤدي إلى منتجات تدوم طويلاً.

- الضمان والدعم: يشير الضمان القوي ودعم العملاء المتجاوب إلى ثقة الشركة المصنعة في منتجاتها.

الخطوة 4: قارن الأسعار وشروط الدفع

اجمع عروض الأسعار من عدة موردين لفهم أسعار السوق للأدوات والمعدات التي تحتاجها. تأكد من مراعاة شروط وأحكام الدفع لتحسين التدفق النقدي.

- التكلفة الإجمالية للملكية: انظر إلى ما هو أبعد من السعر الأولي. ضع في اعتبارك عوامل مثل الصيانة والإصلاحات المحتملة وطول عمر المعدات.

- خيارات دفع مرنة: يمكن أن يساعدك الموردون الذين يقدمون شروط دفع مرنة في إدارة ميزانيتك بشكل أكثر فعالية.

الخطوة 5: طلب عروض توضيحية أو عينات

قبل الانتهاء من عملية الشراء، اطلب عروضًا توضيحية أو عينات من الأدوات. سيتيح لك ذلك تقييم وظائفها وسهولة استخدامها في سيناريوهات العالم الحقيقي.

- اختبار عملي: تأكد من أن الأدوات تلبي المعايير التشغيلية الخاصة بك وتتناسب بشكل جيد مع سير العمل الحالي لديك.

- ملاحظات من الفنيين: قم بإشراك الفنيين في عملية التقييم لجمع رؤى حول سهولة الاستخدام والفعالية.

الخطوة 6: تحقق من المراجعات والمراجع

ابحث عن المراجعات والشهادات من الشركات الأخرى التي اشترت أدوات مماثلة. يمكن أن توفر التعليقات الواقعية رؤى قيمة حول موثوقية المورد وأداء المنتج.

صورة توضيحية تتعلق بكيفية اختبار الملف اللولبي لبدء التشغيل

- المراجعات الخاصة بالصناعة: ركز على المراجعات من الشركات في قطاعك لضمان ملاءمتها لاحتياجاتك الخاصة.

- مراجع مباشرة: لا تتردد في أن تطلب من الموردين مراجع من عملاء سابقين. فالتحدث مباشرة مع هؤلاء العملاء يمكن أن يوفر لك رؤى أعمق.

الخطوة 7: الانتهاء من اختيار الموردين

بعد تقييم جميع المعلومات التي تم جمعها، اتخذ قرارًا مستنيرًا بشأن المورد الخاص بك. تأكد من توافقهم مع أهداف شركتك وقيمها على المدى الطويل.

- إمكانات الشراكة طويلة الأجل: ضع في اعتبارك ما إذا كان المورد يمكن أن ينمو مع عملك ويدعم احتياجاتك المستقبلية.

- الاتفاقيات التعاقدية: مراجعة جميع الشروط التعاقدية لضمان وضوح الجداول الزمنية للتسليم والتسعير ودعم ما بعد البيع.

من خلال اتباع هذه الخطوات، يمكن للمشترين بين الشركات تبسيط عملية الشراء لاختبار الملفات اللولبية لبداية التشغيل، مما يضمن اختيار الأدوات والموردين المناسبين لتعزيز كفاءتهم التشغيلية.

تحليل شامل للتكاليف والتسعير لكيفية اختبار الملف اللولبي لبادئ التشغيل تحديد المصادر

عند تحليل التكاليف والتسعير لتوريد المواد والمكونات لاختبار الملفات اللولبية لبادئ التشغيل، من الضروري تحليل مكونات التكلفة المختلفة وفهم العوامل المؤثرة التي تؤثر على التسعير. ستساعد هذه النظرة العامة الشاملة المشترين الدوليين بين الشركات في اتخاذ قرارات شراء مستنيرة.

صورة توضيحية تتعلق بكيفية اختبار الملف اللولبي لبدء التشغيل

ما هي مكونات التكلفة الرئيسية في الحصول على مواد اختبار الملف اللولبي لبدء التشغيل؟

-

المواد: تشمل المواد الأساسية المستخدمة في اختبار ملفات لولبية بادئ التشغيل المكونات الكهربائية مثل الأسلاك والموصلات والملفات اللولبية نفسها. يمكن أن تؤثر جودة هذه المواد بشكل كبير على الأداء والمتانة، مما يؤدي إلى اختلافات في التكلفة. على سبيل المثال، قد تكون الأسلاك النحاسية عالية الجودة أغلى من الألومنيوم ولكنها توفر توصيلًا أفضل.

-

العمل: تشمل تكاليف العمالة الأجور المدفوعة للفنيين والمهندسين المشاركين في عملية الاختبار. العمالة الماهرة ضرورية لضمان دقة الاختبار ومراقبة الجودة. واعتمادًا على المنطقة، يمكن أن تختلف تكاليف العمالة بشكل كبير؛ على سبيل المثال، قد تكون العمالة أقل تكلفة في أمريكا الجنوبية مقارنة بأوروبا.

-

تكاليف التصنيع العامة: يشمل ذلك التكاليف غير المباشرة المرتبطة بالإنتاج، مثل المرافق والإيجار والمصروفات الإدارية. قد تحتاج الشركات ذات النفقات العامة التصنيعية المرتفعة إلى رفع أسعار منتجاتها للحفاظ على الربحية.

-

الأدوات: تشير تكاليف الأدوات إلى النفقات المتكبدة للأدوات المتخصصة اللازمة لاختبار الملفات اللولبية. وقد يشمل ذلك أجهزة قياس الفولتميتر ومصابيح الاختبار وغيرها من معدات التشخيص. يمكن أن يؤدي الاستثمار في الأدوات عالية الجودة إلى تحسين دقة الاختبار وكفاءته.

-

مراقبة الجودة (QC): يتطلب ضمان استيفاء المنتجات للمعايير المحددة عملية قوية لمراقبة الجودة. ويمكن أن تضيف التكاليف المرتبطة بالاختبار والفحص إلى السعر الإجمالي. ويجب على المشترين البحث عن الموردين الذين يلتزمون بشهادات الجودة الدولية لضمان موثوقية المنتج.

-

اللوجستيات: تُعد تكاليف النقل والتخزين أمراً بالغ الأهمية، خاصة بالنسبة للشحنات الدولية. يمكن أن تؤثر عوامل مثل مسافة الشحن وطريقة الشحن (جواً أو بحراً أو براً) والرسوم الجمركية على التكاليف اللوجستية. يمكن للتخطيط اللوجستي الفعال أن يخفف من بعض هذه النفقات.

-

الهامش: وأخيراً، يقوم الموردون بتضمين هامش ربح في هيكل التسعير الخاص بهم. وقد يختلف هذا الهامش اختلافاً كبيراً تبعاً للمنافسة في السوق وسمعة الموردين والقيمة المتصورة للمنتج.

ما هي العوامل التي تؤثر على تسعير حلول اختبار الملف اللولبي لبادئ التشغيل؟

-

الحجم والحد الأدنى لكمية الطلب (MOQ): يؤدي ارتفاع أحجام الطلبات عادةً إلى انخفاض تكاليف الوحدة الواحدة. وينبغي للمشترين أن يتفاوضوا على التسعير بالجملة لزيادة كفاءة التكلفة إلى أقصى حد.

-

المواصفات والتخصيص: قد تترتب على الحلول المخصصة تكاليف إضافية، لأنها غالباً ما تتطلب مواد أو أدوات متخصصة. وينبغي للمشترين تقييم ما إذا كان التخصيص ضرورياً لعملياتهم.

-

الجودة والشهادات: المنتجات التي تأتي بشهادات جودة معترف بها (مثل ISO، CE) قد تفرض أسعارًا أعلى. ومع ذلك، فإن ضمان الجودة يمكن أن يقلل من التكاليف طويلة الأجل المرتبطة بالأعطال أو الاستبدال.

-

عوامل الموردين: يمكن أن تؤثر موثوقية الموردين وسمعتهم على التسعير. فقد يفرض الموردون الراسخون أسعاراً أعلى نظراً لسجلهم الحافل بالإنجازات، بينما قد يعرض الموردون الجدد أسعاراً أقل لكسب حصة في السوق.

-

مصطلحات التجارة الدولية: فهم شروط الشحن والتسليم (Incoterms) أمر بالغ الأهمية للمشترين الدوليين. فالشروط المختلفة يمكن أن تؤثر على التكلفة الإجمالية للرسو بما في ذلك من هو المسؤول عن الشحن والتأمين والتعريفات.

ما هي النصائح الفعالة للمشتري للحصول على حلول اختبار الملف اللولبي لبدء التشغيل؟

-

التفاوض: الانخراط في مفاوضات مع الموردين لتأمين أسعار أفضل، خاصة بالنسبة لطلبات الشراء بالجملة. كما يمكن أن يؤدي بناء علاقات طويلة الأجل إلى شروط مواتية.

-

كفاءة التكلفة: ضع في اعتبارك التكلفة الإجمالية للملكية (TCO) بدلاً من السعر المقدم فقط. قد يؤدي الاستثمار الأولي الأعلى في المكونات عالية الجودة إلى تحقيق وفورات في الصيانة والاستبدال بمرور الوقت.

-

الفروق الدقيقة في الأسعار للمشترين الدوليين: كن على دراية بتقلبات العملة ورسوم الاستيراد واللوائح المحلية التي قد تؤثر على الأسعار. وينبغي للمشترين في مناطق مثل أفريقيا وأمريكا الجنوبية أن يضعوا في اعتبارهم أيضاً تأثير الظروف الاقتصادية المحلية على أسعار الموردين.

-

إخلاء المسؤولية عن الأسعار الإرشادية: اطلب دائمًا عروض أسعار رسمية من الموردين حيث يمكن أن تختلف الأسعار الإرشادية بناءً على ظروف السوق والمتطلبات المحددة.

من خلال فهم مكونات التكلفة ومؤثرات التسعير هذه، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة عند الحصول على المواد والخدمات اللازمة لاختبار الملفات اللولبية لبداية التشغيل، مما يضمن تحقيق الجودة وكفاءة التكلفة.

تحليل البدائل: مقارنة كيفية اختبار الملف اللولبي لبادئ التشغيل مع الحلول الأخرى

استكشاف بدائل لاختبار الملف اللولبي لبدء التشغيل

في قطاع السيارات، لا سيما بالنسبة للمشترين من الشركات في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، يعد الاختبار الفعال للملفات اللولبية لبادئ التشغيل أمرًا بالغ الأهمية. في حين أن الطريقة التقليدية لاختبار الملف اللولبي توفر نتائج موثوقة، توجد العديد من الحلول البديلة التي قد تناسب الاحتياجات أو التفضيلات التشغيلية المحددة بشكل أفضل. فيما يلي، نقارن أدناه الطريقة التقليدية لاختبار الملف اللولبي لبادئ التشغيل مع بديلين قابلين للتطبيق: استخدام مقياس متعدد واستخدام أداة تشخيص احترافية.

| جانب المقارنة | كيفية اختبار الملف اللولبي لبدء التشغيل | البديل 1: استخدام مقياس متعدد | البديل 2: أداة التشخيص الاحترافية |

|---|---|---|---|

| الأداء | موثوقة لتشخيص مشاكل الملف اللولبي بمؤشرات واضحة (صوت طقطقة وضوء). | فعال لقياس الجهد والتيار، ولكنه يتطلب معرفة بالأنظمة الكهربائية. | يوفر تشخيصاً شاملاً، بما في ذلك اختبار الملف اللولبي وأنظمة السيارة الأخرى. |

| التكلفة | منخفضة التكلفة-تتطلب في المقام الأول أدوات أساسية (مصباح اختبار، فولتميتر). | متوسط التكلفة - يمكن أن تتراوح أجهزة القياس المتعددة من غير المكلفة إلى المكلفة حسب الميزات. | قد تكون الأدوات الاحترافية عالية التكلفة باهظة الثمن وقد تتطلب تدريباً لاستخدامها بفعالية. |

| سهولة التنفيذ | يتطلب معرفة أساسية بالسيارات؛ بسيطة ومباشرة إذا تم اتباع التعليمات. | متوسط؛ فهم كيفية قياس الجهد وتفسير القراءات أمر ضروري. | عالية؛ عادةً ما تكون سهلة الاستخدام ولكنها قد تتطلب تدريباً لفهم مخرجات التشخيص. |

| الصيانة | الحد الأدنى من الصيانة؛ الأدوات بشكل عام متينة وتدوم طويلاً. | منخفض؛ تتطلب أجهزة القياس المتعدد معايرة واستبدال البطارية من حين لآخر. | معتدلة؛ قد تتطلب أدوات التشخيص تحديثات البرامج والعناية المناسبة لضمان طول العمر الافتراضي. |

| أفضل حالة استخدام | مثالية للميكانيكيين الذين يعملون بأنفسهم أو ورش التصليح الصغيرة ذات الموارد المحدودة. | مناسب للفنيين الذين يحتاجون إلى تشخيصات كهربائية مفصلة لأنظمة متعددة. | الأفضل للورش الكبيرة أو الوكلاء الذين يحتاجون إلى تشخيص شامل للمركبة. |

تفصيل البدائل

باستخدام مقياس متعدد:

المقياس المتعدد هو أداة متعددة الاستخدامات يمكنها قياس الجهد والتيار والمقاومة، مما يجعله بديلاً ممتازاً لاختبار الملف اللولبي لبدء التشغيل. وتشمل مزاياه قدرته على توفير قراءات كهربائية دقيقة، والتي يمكن أن تساعد في تشخيص ليس فقط الملف اللولبي ولكن أيضاً المكونات الكهربائية الأخرى في السيارة. ومع ذلك، تتطلب هذه الطريقة مستوى معيناً من الخبرة؛ حيث يجب أن يفهم المستخدمون كيفية توصيل المقياس المتعدد بشكل صحيح وتفسير قراءاته. بالإضافة إلى ذلك، على الرغم من أن الاستثمار الأولي في جهاز القياس المتعدد قد يكون أعلى من أدوات الاختبار الأساسية، إلا أنه يمكن اعتباره حلاً فعالاً من حيث التكلفة للورش التي تحتاج إلى إجراء اختبارات كهربائية مختلفة.

أداة تشخيصية احترافية:

توفر أدوات التشخيص الاحترافية بديلاً متقدماً لاختبار الملفات اللولبية لبادئ التشغيل وأنظمة السيارة الأخرى. يمكن أن توفر هذه الأجهزة تحليلاً متعمقاً ورموزاً للأخطاء يمكن أن تحدد المشكلات التي تتجاوز الملف اللولبي فقط. وتتمثل الميزة الرئيسية في الطبيعة الشاملة للتشخيص، والتي يمكن أن تؤدي إلى إصلاحات أسرع وأكثر دقة. ومع ذلك، يمكن أن تكون تكلفة هذه الأدوات باهظة بالنسبة للشركات الصغيرة، وغالباً ما تتطلب تدريباً لاستخدامها بفعالية. وهذا يجعلها الأنسب لورش السيارات الكبيرة أو الوكلاء الذين لديهم الميزانية والحاجة إلى قدرات تشخيصية شاملة.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

بالنسبة لمشتري B2B الذين يتطلعون إلى اختبار الملفات اللولبية لبادئ التشغيل، يعتمد القرار بين الطرق التقليدية والبدائل على عدة عوامل، بما في ذلك الميزانية والخبرة الفنية ونطاق الخدمات المقدمة. في حين أن الطريقة القياسية متاحة وفعالة لتلبية الاحتياجات الأساسية، فإن البدائل مثل أجهزة القياس المتعددة وأدوات التشخيص الاحترافية توفر وظائف إضافية قد تعزز الكفاءة التشغيلية. في نهاية المطاف، فإن تقييم المتطلبات المحددة لورشة العمل الخاصة بك وأنواع المركبات التي تتم خدمتها سيرشدك في اختيار حل الاختبار الأنسب.

صورة توضيحية تتعلق بكيفية اختبار الملف اللولبي لبدء التشغيل

الخصائص التقنية الأساسية والمصطلحات التجارية لكيفية اختبار الملف اللولبي لبدء التشغيل

ما هي الخصائص التقنية الأساسية عند اختبار الملف اللولبي لبادئ التشغيل؟

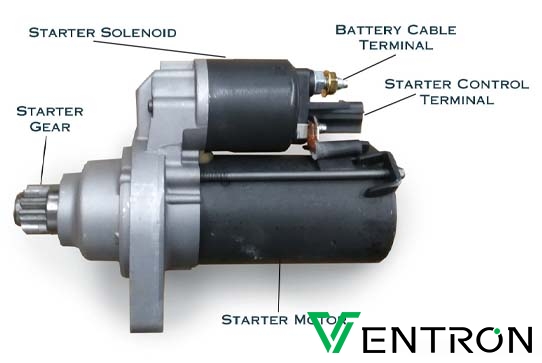

عند اختبار الملف اللولبي لبادئ التشغيل، هناك العديد من الخصائص التقنية المهمة لضمان التشخيص الدقيق والإصلاحات الفعالة. يمكن لفهم هذه الخصائص أن يساعد مشتري B2B على اتخاذ قرارات مستنيرة بشأن تحديد مصادر ملفات لولبية بادئ الحركة واستخدامها في عملياتهم.

1. درجة المواد

تؤثر المواد المستخدمة في بناء الملف اللولبي لبادئ التشغيل بشكل كبير على متانته وأدائه. وعادةً ما تكون الملفات اللولبية مصنوعة من النحاس أو الألومنيوم عالي الجودة للمكونات الكهربائية، في حين أن المبيت قد يكون مصنوعًا من البلاستيك أو المعادن المقاومة للحرارة. وتؤثر درجة المواد على قدرة الملف اللولبي على تحمل الحرارة والتآكل، وهو أمر بالغ الأهمية لطول العمر، خاصة في البيئات القاسية الشائعة في مناطق مثل أفريقيا وأمريكا الجنوبية.

2. التصنيف الحالي

يشير التصنيف الحالي، الذي يقاس بالأمبير، إلى الحد الأقصى للتيار الكهربائي الذي يمكن للملف اللولبي التعامل معه دون ارتفاع درجة الحرارة أو التعطل. على سبيل المثال، قد يكون للملف اللولبي النموذجي لبادئ تشغيل السيارات تصنيف تيار يتراوح بين 30 إلى 200 أمبير. يعد فهم التصنيف الحالي أمرًا حيويًا لضمان التوافق مع النظام الكهربائي للمركبة، وبالتالي منع الأعطال المحتملة التي يمكن أن تؤدي إلى إصلاحات مكلفة أو تعطل.

3. قيمة المقاومة

المقاومة، التي تقاس بالأوم، هي خاصية رئيسية أخرى. يجب أن يُظهر الملف اللولبي قيمة مقاومة محددة عند اختباره، مما يشير إلى قدرته على نقل الطاقة الكهربائية بكفاءة من البطارية إلى بادئ التشغيل. يمكن أن تشير قيم المقاومة المرتفعة جدًا أو المنخفضة جدًا إلى وجود خلل في الملف اللولبي. يعد هذا القياس ضروريًا لمشتري B2B المشاركين في إصلاح السيارات أو تصنيعها، حيث إنه يرتبط مباشرة بأداء الملف اللولبي.

4. نطاق درجة حرارة التشغيل

ويحدد نطاق درجة حرارة التشغيل درجات الحرارة التي يمكن للملف اللولبي أن يعمل خلالها بفعالية. تعتبر الملفات اللولبية المصممة لدرجات الحرارة القصوى بالغة الأهمية في المناطق ذات درجات الحرارة المحيطة المرتفعة، مما يضمن أداءً موثوقاً تحت الضغط. يجب على المشترين مراعاة هذه الخاصية عند اختيار الملفات اللولبية للمركبات التي تعمل في مناخات متنوعة.

5. تصنيف الجهد الكهربائي

يشير تصنيف الجهد إلى الجهد الكهربائي الذي تم تصميم الملف اللولبي ليعمل عنده، وعادةً ما يكون حوالي 12 فولت لتطبيقات السيارات. هذا التصنيف ضروري لضمان عمل الملف اللولبي بشكل صحيح داخل النظام الكهربائي للسيارة. يمكن أن يؤدي عدم تطابق تصنيفات الجهد الكهربائي إلى أعطال في النظام، مما يجعل من الضروري للمشترين التحقق من التوافق مع الأنظمة الحالية.

ما هي المصطلحات الشائعة المستخدمة في صناعة الملف اللولبي لبدء التشغيل؟

يعد فهم المصطلحات الخاصة بالصناعة أمرًا بالغ الأهمية للتواصل الفعال واتخاذ القرار في شراء الملفات اللولبية البادئة. فيما يلي بعض المصطلحات الأساسية التي كثيراً ما نصادفها في مجال الأعمال التجارية:

1. OEM (الشركة المصنعة للمعدات الأصلية)

يشير مصطلح OEM إلى القطع المصنوعة من قبل الشركة المصنعة الأصلية للمركبة أو المكون الأصلي. في سياق الملفات اللولبية لبادئ التشغيل، عادةً ما تكون قطع غيار OEM ذات جودة أعلى وملاءمة أفضل من بدائل ما بعد البيع. غالباً ما يفضل المشترون قطع غيار OEM لضمان التوافق والموثوقية.

2. MOQ (الحد الأدنى لكمية الطلب)

موك هو أصغر عدد من الوحدات التي يرغب المورد في بيعها. هذا المصطلح مهم بشكل خاص للمشترين بين الشركات الذين يحتاجون إلى إدارة المخزون والتكاليف بفعالية. ويمكن أن يساعد فهم موك في تخطيط المشتريات والمفاوضات مع الموردين.

3. طلب عرض أسعار (RFQ)

طلب عرض الأسعار هو مستند يتم إرساله إلى الموردين لطلب تسعير وشروط لمنتجات أو خدمات محددة. بالنسبة للشركات التي تقوم بتوريد ملفات لولبية لبدء التشغيل، يتيح لها إصدار طلب عرض أسعار مقارنة العروض واختيار أفضل مورد على أساس السعر والجودة وشروط التسليم.

4. مصطلحات التجارة الدولية

تحدد شروط التجارة الدولية أو الشروط التجارية الدولية مسؤوليات المشترين والبائعين في التجارة الدولية. توضح هذه الشروط مسؤوليات الشحن والتأمين ونقل المخاطر. يعد فهم شروط إنكوترمز أمرًا حيويًا للمشترين بين الشركات، خاصةً عند استيراد ملفات لولبية بادئ الحركة من بلدان مختلفة.

5. المهلة الزمنية

تشير المهلة الزمنية إلى الوقت المستغرق من تقديم الطلب إلى استلام البضائع. في صناعة السيارات، يمكن أن يساعد فهم المهل الزمنية الشركات على إدارة سلاسل التوريد الخاصة بها بفعالية وتقليل وقت التعطل المرتبط بإصلاح المركبات.

من خلال الإلمام بهذه الخصائص التقنية والمصطلحات الصناعية، يمكن للمشترين بين الشركات التعامل مع تعقيدات توريد واختبار الملفات اللولبية البادئة بكفاءة أكبر، مما يؤدي في النهاية إلى تحسين نتائجهم التشغيلية.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع كيفية اختبار الملف اللولبي لبادئ التشغيل

ما هي الديناميكيات الحالية للسوق والاتجاهات الرئيسية في قطاع اختبار الملف اللولبي لبدء التشغيل؟

يشهد السوق العالمي لمكونات السيارات، ولا سيما قطاع الملف اللولبي لبدء التشغيل، تحولاً كبيرًا مدفوعًا بعوامل مختلفة. يؤدي تزايد عدد المركبات على الطريق، إلى جانب الطلب المتزايد على حلول إصلاح السيارات الفعالة، إلى زيادة الحاجة إلى إجراءات اختبار فعالة. وفي مناطق مثل إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا على وجه الخصوص، هناك تركيز متزايد على التوريد المحلي لتقليل المهل الزمنية والتكاليف. يتزايد تفضيل المشترين الدوليين بين الشركات للموردين الذين يقدمون أدوات تشخيص متقدمة وموارد تدريب، مما يعزز قدرتهم على استكشاف مشكلات الملف اللولبي لبادئ التشغيل وإصلاحها.

تعمل التقنيات الناشئة على إعادة تشكيل المشهد، حيث تكتسب الابتكارات مثل أجهزة التشخيص التي تدعم إنترنت الأشياء زخماً كبيراً. توفر هذه الأدوات تحليلات في الوقت الفعلي، مما يسمح للفنيين بإجراء اختبارات أكثر دقة وبالتالي تبسيط عمليات الإصلاح. بالإضافة إلى ذلك، يسهّل ظهور منصات التجارة الإلكترونية سهولة الوصول إلى المكونات المتخصصة ومعدات الاختبار، مما يتيح للمشترين الحصول على المنتجات مباشرةً من الشركات المصنعة أو الموزعين. كما يعكس الاتجاه المتزايد لإعادة التدوير وإعادة التصنيع أيضاً تحولاً نحو الاستدامة، مما يشجع الشركات على اعتبار الملفات اللولبية المجددة كخيارات قابلة للتطبيق.

كيف تؤثر الاستدامة والمصادر الأخلاقية على سوق اختبار الملف اللولبي لبدء التشغيل؟

أصبحت الاستدامة من الاعتبارات الحاسمة في صناعة قطع غيار السيارات، بما في ذلك قطاع اختبار الملف اللولبي لبدء التشغيل. يتطلب التأثير البيئي لمكونات السيارات، بدءًا من التصنيع وحتى التخلص منها، التركيز على سلاسل التوريد الأخلاقية. ويعطي المشترون بين الشركات الأولوية بشكل متزايد للموردين الذين يلتزمون بالممارسات المستدامة، مثل استخدام مواد صديقة للبيئة وتقليل النفايات في عمليات الإنتاج. ويكتسب هذا الاتجاه أهمية خاصة في المناطق التي تتطور فيها الأطر التنظيمية لفرض معايير بيئية أكثر صرامة.

إن التوريد الأخلاقي لا يعزز صورة العلامة التجارية للشركة فحسب، بل يعزز أيضًا الثقة والولاء بين العملاء. يمكن لشهادات مثل ISO 14001 لأنظمة الإدارة البيئية وغيرها من العلامات ‘الخضراء’ أن تؤثر بشكل كبير على قرارات الشراء. من خلال التوافق مع الموردين الذين يعطون الأولوية للاستدامة، يمكن للشركات تحسين ملفاتها الخاصة بالمسؤولية الاجتماعية للشركات مع إمكانية الوصول إلى أسواق جديدة تقدر الممارسات الأخلاقية. وعلاوة على ذلك، يدفع التحول نحو السيارات الكهربائية (EVs) والتكنولوجيا الهجينة الشركات المصنعة إلى إعادة التفكير في استراتيجيات التوريد الخاصة بها، مع التركيز على المواد المستدامة التي تلبي المتطلبات المتطورة لمشهد السيارات.

ما هو السياق التاريخي للملفات اللولبية البادئة واختبارها؟

لقد تطور الملف اللولبي لبادئ التشغيل بشكل كبير منذ نشأته في أوائل القرن العشرين. في البداية، كانت هذه المكونات في البداية عبارة عن أجهزة ميكانيكية تعتمد على التشغيل اليدوي لتشغيل محرك البادئ. ومع تقدم تكنولوجيا السيارات، تحولت الملفات اللولبية إلى آليات كهربائية، مما سمح بتشغيل أكثر موثوقية وكفاءة. وكان هذا التطور حاسماً في تعزيز أداء السيارة وموثوقيتها.

في النصف الأخير من القرن العشرين، ومع ازدياد تعقيد المركبات، برزت الحاجة إلى طرق اختبار فعالة. بدأ الفنيون في تطوير إجراءات تشخيصية لتقييم وظائف الملف اللولبي، مما أدى إلى إنشاء معدات اختبار متخصصة. واليوم، أدى دمج التكنولوجيا الرقمية في تشخيص السيارات إلى زيادة تحسين طرق الاختبار هذه، مما أتاح إجراء تقييمات أسرع وأكثر دقة لأداء الملف اللولبي لبادئ التشغيل. يمكن أن يساعد فهم هذا السياق التاريخي مشتري B2B على تقدير التطورات في تقنيات الاختبار وأهمية الحصول على مكونات عالية الجودة تلبي المعايير الحديثة.

الأسئلة المتداولة (FAQs) لمشتري B2B حول كيفية اختبار الملف اللولبي لبادئ التشغيل

-

1. كيف يمكنني حل المشاكل المتعلقة بخلل في الملف اللولبي لبادئ التشغيل؟

لمعالجة المشاكل المتعلقة بالملف اللولبي لبدء التشغيل، تحقق أولاً من مستوى شحن البطارية؛ يمكن أن تتسبب البطارية الضعيفة في تعطل الملف اللولبي. بعد ذلك، استخدم مصباح اختبار لفحص الطاقة في أطراف الملف اللولبي عند تشغيل الإشعال. إذا كانت الطاقة موجودة ولكن مفتاح التشغيل لا يعمل، فقد يحتاج الملف اللولبي إلى الاستبدال. إذا لم تكن هناك طاقة، افحص التوصيلات والأسلاك بحثًا عن أعطال. اتبع دائماً بروتوكولات السلامة واستشر متخصصاً إذا لم تكن متأكداً من إجراءات الاختبار. -

2. ما هي أفضل طريقة للحصول على ملفات لولبية لبدء التشغيل لشركتي؟

عند الحصول على ملفات لولبية لبادئ التشغيل، ضع في اعتبارك الموردين المتخصصين في مكونات السيارات والذين يتمتعون بسمعة طيبة في منطقتك. ابحث عن الشركات المصنعة الحاصلة على شهادات مثل ISO 9001، والتي تشير إلى الالتزام بالجودة. بالإضافة إلى ذلك، قم بتقييم مجموعة منتجاتهم، وخيارات التخصيص، والقدرة على تلبية متطلباتك الخاصة. كما أن المشاركة في المعارض التجارية والمعارض الصناعية يمكن أن توفر لك معلومات عن الموردين ذوي السمعة الطيبة. -

3. كيف يمكنني التحقق من جودة ملفات لولبية بادئ التشغيل قبل الشراء؟

لضمان الجودة، اطلب عينات وقم بإجراء الاختبارات وفقًا لمعايير الصناعة. تحقق من الشهادات وعمليات ضمان الجودة من الشركة المصنعة. بالإضافة إلى ذلك، ضع في اعتبارك مراجعات العملاء وشهاداتهم لقياس موثوقية المنتج. من المفيد أيضًا الاستفسار عن شروط الضمان وسياسات الإرجاع، حيث يمكن أن يشير ذلك إلى ثقة الشركة المصنعة في منتجاتها. -

4. ما الذي يجب أن أضعه في الاعتبار فيما يتعلق بالحد الأدنى لكميات الطلبات (MOQ) للملفات اللولبية لبداية التشغيل؟

يمكن أن يختلف الحد الأدنى لكميات الطلبات بشكل كبير بين الموردين. من الضروري تقييم احتياجات عملك وقدرات إدارة المخزون قبل الالتزام. قد يقدم بعض الموردين مرونة في الحد الأدنى للكميات المطلوبة للمشترين لأول مرة أو الطلبات بالجملة. تفاوض على الشروط التي تتماشى مع توقعات الطلب لديك، وفكر في إقامة علاقة للطلبات المستقبلية لتسهيل الحصول على شروط أفضل. -

5. كيف يمكنني ضمان تسليم الملفات اللولبية البادئة في الوقت المناسب في التجارة الدولية؟

لضمان التسليم في الوقت المناسب، اختر الموردين الذين لديهم شبكات لوجستية راسخة وسجلات حافل في مجال الشحن الدولي. ناقش طرق الشحن وأوقات التسليم المقدرة وعمليات التخليص الجمركي مقدماً. من المستحسن أيضاً استخدام إنكوترمز لتوضيح المسؤوليات المتعلقة بتكاليف الشحن والمخاطر. يمكن أن يساعد التواصل المنتظم مع الموردين أثناء عملية الشحن في الحد من التأخيرات المحتملة. -

6. ما هي شروط الدفع القياسية في التجارة الدولية لقطع غيار السيارات؟

وغالباً ما تتضمن شروط الدفع القياسية خيارات مثل خطابات الاعتماد أو التحويلات البنكية أو باي بال. واعتماداً على سياسات المورد وعلاقتك، يمكنك أيضاً التفاوض على شروط الدفع الصافي، مثل 30 أو 60 يوماً بعد التسليم. تأكد دائماً من أن شروط الدفع محددة بوضوح في اتفاقية الشراء لتجنب النزاعات. بالإضافة إلى ذلك، فكر في استخدام خدمات الضمان للمعاملات عالية القيمة لتأمين استثمارك. -

7. كيف يمكنني تخصيص ملفات لولبية لبدء التشغيل لتناسب طرازات معينة من المركبات؟

يتضمن التخصيص عادةً العمل عن كثب مع الشركة المصنعة لتحديد تغييرات التصميم أو اختيار المواد أو تحسينات الأداء. قدم المواصفات التفصيلية المتعلقة بطرازات السيارة المعنية، بما في ذلك الأبعاد والمتطلبات الكهربائية والتوافق. تقدم العديد من الشركات المصنّعة الدعم التصميمي والهندسي، والذي يمكن أن يكون ذا قيمة كبيرة في تطوير منتج يلبي احتياجاتك الفريدة. -

8. ما هو الدور الذي يلعبه ضمان الجودة (QA) في توريد الملفات اللولبية البادئة؟

يعد ضمان الجودة أمرًا بالغ الأهمية في توريد الملفات اللولبية لبداية التشغيل، حيث إنه يضمن أن المنتجات تلبي معايير السلامة والأداء. قم بإشراك الموردين الذين يطبقون عمليات صارمة لضمان الجودة، بما في ذلك الاختبارات وعمليات الفحص في مراحل الإنتاج المختلفة. اطلب توثيق بروتوكولات ضمان الجودة وأي شهادات تثبت صحة عملياتهم. يمكن أن يؤدي الالتزام القوي بضمان الجودة إلى تقليل مخاطر العيوب وتعزيز رضا العملاء.

قائمة المصنعين والموردين لأعلى 3 كيفية اختبار الملف اللولبي لبدء التشغيل

1. ريديت - كابل تشغيل الملف اللولبي

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: كابل بدء التشغيل بالملف اللولبي، جهاز قياس متعدد، بطارية، ملف لولبي لبدء التشغيل

2. ويكي هاو - الملف اللولبي لبدء التشغيل

المجال: wikihow.com

تاريخ التسجيل: 2004 (21 عامًا)

مقدمة: الملف اللولبي لبادئ التشغيل هو آلية بسيطة تنقل التيار الكهربائي من البطارية إلى بادئ التشغيل، وتشغل محرك بادئ التشغيل لبدء تشغيل المحرك. وعادة ما يكون أسطواني الشكل ويقع بالقرب من مكان التقاء المحرك وناقل الحركة، مع وجود أسطوانة أصغر متصلة به. يحتوي الملف اللولبي على طرفين، أحدهما متصل بالبطارية. يتضمن الفحص التحقق من وجود صوت طقطقة مع...

3. LinkedIn – الملف اللولبي المبدئي

المجال: linkedin.com

تاريخ التسجيل: 2002 (23 عامًا)

مقدمة: الملف اللولبي لبادئ التشغيل هو مفتاح كهرومغناطيسي يقوم بتعشيق محرك بادئ التشغيل عند تشغيل مفتاح الإشعال على وضع “بدء التشغيل”. وهو يتحكم بالتيار العالي اللازم لتشغيل محرك البادئ بأمان، مما يضمن تعشيق وفصل نظيفين لتقليل التآكل والتلف. تشمل أعراض تلف الملف اللولبي لبادئ التشغيل التالف صعوبة بدء تشغيل المحرك، وانخفاض أداء التسارع، وتعطل المحرك تلقائياً.

خاتمة المصادر الاستراتيجية والتوقعات لكيفية اختبار الملف اللولبي لبدء التشغيل

في الختام، يعد الاختبار الفعال للملف اللولبي بادئ التشغيل ضرورياً لضمان الأداء الأمثل للسيارة وتقليل تكاليف الإصلاح. من خلال اتباع نهج منهجي - تحديد موقع الملف اللولبي لبادئ التشغيل، والتحقق من تدفق التيار، وتقييم مقاومة التيار - يمكن للمشترين تحديد السبب الجذري لمشاكل بدء التشغيل بسرعة. هذا لا يعزز الكفاءة التشغيلية فحسب، بل يعزز أيضًا علاقات أفضل مع الموردين من خلال تمكين المناقشات المستنيرة حول قطع الغيار واحتياجات الصيانة.

يلعب التوريد الاستراتيجي دورًا حيويًا في هذه العملية، حيث يتيح للشركات تحديد الموردين الموثوق بهم لملفات لولبية عالية الجودة لبدء التشغيل والمكونات المرتبطة بها. من خلال التعامل مع المصنعين والموزعين الموثوقين، يمكن للشركات أن تضمن أنها تستثمر في المنتجات التي توفر طول العمر والموثوقية، مما يؤدي في النهاية إلى تقليل وقت التعطل وزيادة الإنتاجية.

بينما تتعامل مع تعقيدات توريد قطع غيار السيارات، فكّر في استكشاف الشراكات مع الموردين الذين يفهمون المتطلبات الفريدة لمنطقتك. اغتنم الفرصة لتبسيط عملية الشراء وتعزيز قدرتك التنافسية. يمكننا معاً دفع صناعة السيارات إلى الأمام، وتعزيز الابتكار والنمو في جميع أنحاء إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. اتخذ الخطوة التالية في تحسين عملياتك من خلال إعطاء الأولوية للتوريد الاستراتيجي لاحتياجاتك من الملف اللولبي لبادئ التشغيل اليوم.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.