Introduction: Navigating the Global Market for how do you know if the starter relay is bad

In the complex landscape of automotive maintenance, understanding how to determine if the starter relay is bad is crucial for businesses that rely on vehicle fleets. A malfunctioning starter relay can lead to unexpected downtime, impacting productivity and operational efficiency. This comprehensive guide delves into the various signs of a failing starter relay, including symptoms that may point to related issues such as a defective solenoid or electrical faults.

International B2B buyers, especially those in Africa, South America, the Middle East, and Europe, will find valuable insights on different types of starter relays, their applications across various vehicle models, and the nuances of supplier vetting to ensure quality purchases. Additionally, this guide explores cost factors and provides tips for negotiating with suppliers effectively.

By equipping decision-makers with the knowledge to identify starter relay issues and understand their implications, this resource empowers informed purchasing decisions. Buyers will be better positioned to maintain their fleets, minimize repair costs, and ensure that their vehicles are always ready to perform. Whether you are sourcing components for a fleet of delivery trucks in Saudi Arabia or assessing supplier reliability in Germany, this guide serves as an essential tool for navigating the global market of automotive parts.

جدول المحتويات

- Top 3 How Do You Know If The Starter Relay Is Bad Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do you know if the starter relay is bad

- Understanding how do you know if the starter relay is bad Types and Variations

- Key Industrial Applications of how do you know if the starter relay is bad

- 3 Common User Pain Points for ‘how do you know if the starter relay is bad’ & Their Solutions

- Strategic Material Selection Guide for how do you know if the starter relay is bad

- In-depth Look: Manufacturing Processes and Quality Assurance for how do you know if the starter relay is bad

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you know if the starter relay is bad’

- Comprehensive Cost and Pricing Analysis for how do you know if the starter relay is bad Sourcing

- Alternatives Analysis: Comparing how do you know if the starter relay is bad With Other Solutions

- Essential Technical Properties and Trade Terminology for how do you know if the starter relay is bad

- Navigating Market Dynamics and Sourcing Trends in the how do you know if the starter relay is bad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do you know if the starter relay is bad

- Strategic Sourcing Conclusion and Outlook for how do you know if the starter relay is bad

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding how do you know if the starter relay is bad Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| No Response on Ignition | Engine fails to turn over; no sound or lights. | ورش إصلاح السيارات، خدمات الأساطيل | الإيجابيات: تشخيص سهل; السلبيات: May indicate multiple issues. |

| صوت نقرة واحدة | A single click from the relay; starter fails to engage. | Vehicle maintenance, automotive parts suppliers | الإيجابيات: Often indicates a solenoid issue; السلبيات: Requires further testing. |

| بدء التشغيل المتقطع | Occasional successful starts; inconsistent behavior. | Automotive diagnostics, service centers | الإيجابيات: Identifies potential underlying problems; السلبيات: صعوبة التشخيص. |

| Starter Engages Continuously | Starter runs without key being turned; potential damage. | Automotive repair facilities, parts distributors | الإيجابيات: Clear indication of solenoid failure; السلبيات: Risk of engine damage if ignored. |

| Electrical Corruption Signs | Visible damage to wiring or blown fuses; erratic electrical behavior. | موردو المكونات الكهربائية وخدمات التشخيص | الإيجابيات: Can prevent further damage; السلبيات: قد يتطلب استكشاف الأخطاء وإصلاحها على نطاق واسع. |

What Are the Characteristics of No Response on Ignition?

The absence of any response when the ignition key is turned is a primary indicator of a faulty starter relay. This condition often points to issues with the relay itself or other components like the battery or ignition switch. For B2B buyers, particularly those in automotive repair or fleet services, understanding this symptom allows for quick identification and efficient solutions, minimizing downtime for clients.

How Does a Single Click Sound Indicate a Problem?

When a single click is heard upon turning the ignition, it suggests that the starter relay or solenoid is attempting to engage but is failing to provide the necessary power to the starter motor. This symptom is crucial for automotive maintenance providers and parts suppliers, as it can guide them to recommend specific components for testing or replacement. Buyers should consider the reliability of parts and the expertise of technicians when addressing this issue.

Why Is Intermittent Starting a Concern?

Intermittent starting issues can complicate diagnostics, as they may be caused by a range of problems, including a failing starter relay. This unpredictability can frustrate fleet managers and automotive service centers, leading to potential customer dissatisfaction. B2B buyers should focus on sourcing high-quality diagnostic tools and training for technicians to effectively address these challenges.

What Does Continuous Engagement of the Starter Indicate?

If the starter engages continuously without the key being turned, it is a clear sign of a malfunctioning solenoid or relay. This condition can lead to significant engine damage if not addressed promptly. For automotive repair facilities, understanding the implications of this symptom is essential for providing timely and effective repairs, thereby enhancing customer trust and service reliability.

How Do Electrical Corruption Signs Affect Starter Relay Function?

Visible signs of electrical corruption, such as damaged wiring or blown fuses, can severely impact the performance of a starter relay. These issues often require comprehensive diagnostics and may lead to more extensive repairs. B2B buyers in electrical component supply should prioritize sourcing durable and reliable parts while ensuring that technicians are equipped to handle complex electrical issues, ultimately reducing the risk of recurring problems.

Key Industrial Applications of how do you know if the starter relay is bad

| الصناعة/القطاع | Specific Application of how do you know if the starter relay is bad | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | Diagnosing starter relay issues in customer vehicles | Enhances service reliability and customer satisfaction | Access to quality diagnostic tools and replacement parts |

| Heavy Machinery Operations | Maintenance of construction and agricultural machinery | Minimizes downtime and ensures operational efficiency | Availability of specialized components for various machinery |

| Fleet Management Services | Regular checks on fleet vehicles’ starter systems | Reduces operational costs through proactive maintenance | Bulk purchasing options and reliable supply chains |

| لوجستيات النقل والمواصلات | Ensuring reliability of delivery trucks and logistics vehicles | Increases fleet reliability and on-time deliveries | Compatibility with diverse vehicle models and brands |

| Industrial Equipment Rental | Maintenance checks on rental equipment like generators and compressors | Ensures safety and reliability for end-users | Quick access to parts and technical support |

How Can Automotive Repair Shops Benefit from Understanding Starter Relay Issues?

In automotive repair shops, diagnosing starter relay problems is crucial for ensuring that customer vehicles operate efficiently. By recognizing symptoms such as clicking noises or intermittent starting issues, technicians can quickly identify and address the root cause of the problem. This not only enhances service reliability but also improves customer satisfaction, as timely repairs can prevent further complications. For international buyers, sourcing quality diagnostic tools and reliable replacement parts is essential to maintain high service standards.

Why Is Understanding Starter Relay Issues Important in Heavy Machinery Operations?

In heavy machinery operations, such as construction and agriculture, understanding how to identify starter relay failures can significantly minimize downtime. Equipment like excavators and tractors relies heavily on functional starter systems to operate effectively. Recognizing the signs of a bad starter relay can lead to timely maintenance, ensuring that machinery remains operational and productive. Buyers in these sectors should focus on sourcing specialized components that cater to the specific needs of their machinery.

How Do Fleet Management Services Enhance Operations by Diagnosing Starter Relay Problems?

Fleet management services benefit from a comprehensive understanding of starter relay issues by implementing regular checks on their vehicles. This proactive approach helps in reducing operational costs associated with unexpected breakdowns and repairs. Identifying potential problems early ensures that vehicles remain reliable, which is critical for on-time deliveries and overall customer satisfaction. For international buyers, bulk purchasing options and establishing reliable supply chains are key considerations to maintain fleet efficiency.

What Role Does Knowledge of Starter Relay Issues Play in Transportation Logistics?

In the transportation logistics sector, ensuring the reliability of delivery trucks is paramount. Understanding how to diagnose starter relay issues allows logistics companies to maintain their fleet effectively, thus increasing overall reliability and ensuring timely deliveries. Buyers should prioritize sourcing components that are compatible with a wide range of vehicle models, as this flexibility can enhance the efficiency of maintenance operations.

How Can Industrial Equipment Rental Companies Benefit from Starter Relay Diagnostics?

For industrial equipment rental companies, understanding how to identify starter relay issues is essential for maintaining the safety and reliability of rental equipment like generators and compressors. Regular maintenance checks can prevent equipment failures that could disrupt client operations. Quick access to replacement parts and technical support is vital for these businesses to ensure that they can provide reliable equipment to their customers, enhancing their reputation in the market.

3 Common User Pain Points for ‘how do you know if the starter relay is bad’ & Their Solutions

Scenario 1: Inconsistent Starting Issues with Heavy Machinery

المشكلة: B2B buyers in industries such as construction or agriculture often rely on heavy machinery to maintain productivity. A faulty starter relay can lead to inconsistent starting, where equipment may start one day but fail the next. This unpredictability not only halts operations but also leads to costly downtime and delays in project timelines. Furthermore, the inability to diagnose the problem quickly can exacerbate frustrations among operators who depend on these machines daily.

الحل: To address this issue, establish a routine diagnostic check for your starter relays as part of your equipment maintenance program. Educate your maintenance teams on the signs of a failing starter relay, such as a single click sound when attempting to start or intermittent starting issues. Implement a checklist that includes checking the relay’s connections for corrosion and ensuring that the wiring is intact. Sourcing high-quality replacement relays from reputable suppliers can also minimize future issues. Additionally, consider investing in a diagnostic tool that can help identify electrical issues in real time, allowing for quicker resolutions and less downtime.

Scenario 2: Confusion Between Starter Relay and Solenoid

المشكلة: Many B2B buyers, particularly in the automotive sector, face confusion regarding the differences between starter relays and solenoids. This confusion can lead to incorrect troubleshooting, resulting in unnecessary replacements and increased costs. For companies that rely on fleets, misdiagnosing these components can lead to prolonged vehicle downtime, affecting service delivery and customer satisfaction.

الحل: To mitigate this confusion, it’s essential to create a comprehensive training program for your technical staff that outlines the distinctions between starter relays and solenoids. Provide visual aids and hands-on training to help them recognize the components and their functions. Additionally, develop a clear protocol for diagnosing issues, emphasizing the need to check both components during troubleshooting. Investing in a detailed service manual or access to an online resource specific to your fleet can serve as a handy reference, ensuring that your team can make informed decisions quickly.

Scenario 3: Unexpected Repairs and Cost Management

المشكلة: B2B buyers often struggle with the financial implications of unexpected repairs caused by failing starter relays. Without proper diagnostics, companies may incur significant costs due to emergency repairs, which can include towing, labor, and parts. This unpredictability complicates budget management and can hinder financial planning, especially for small to medium-sized enterprises that may operate on tighter margins.

الحل: To manage these costs effectively, implement a proactive maintenance strategy that includes regular inspections of starter relays and associated components. Schedule maintenance checks at intervals recommended by the manufacturer, and keep detailed records of all repairs and replacements. This data can help identify patterns that may signal an impending failure, allowing for preemptive actions before a complete breakdown occurs. Additionally, consider establishing partnerships with local repair shops or mechanics who can offer competitive rates for routine checks and emergency repairs, thus reducing the financial burden when issues arise.

Strategic Material Selection Guide for how do you know if the starter relay is bad

What Are the Common Materials Used in Starter Relay Applications?

When evaluating the performance and reliability of starter relays, the choice of materials is crucial. Various materials can influence the relay’s functionality, durability, and overall performance. Below are analyses of three common materials used in starter relay applications, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Copper in Starter Relay Manufacturing?

Copper is a widely used material in electrical components, including starter relays, due to its excellent conductivity. It typically operates effectively within a temperature range of -40°C to +200°C, making it suitable for diverse automotive environments. Additionally, copper offers good corrosion resistance when treated, which is vital for longevity in various climates.

الإيجابيات:

– High electrical conductivity ensures efficient power transmission.

– Ductility allows for complex shapes, enhancing design flexibility.

– Relatively low cost compared to other conductive materials.

السلبيات:

– Susceptible to oxidation if not properly coated, which can lead to performance issues.

– Heavier than some alternatives, which may affect overall relay weight.

– Requires careful handling during manufacturing to avoid damage.

التأثير على التطبيق:

Copper’s compatibility with various media makes it an ideal choice for electrical connections in starter relays. However, oxidation in humid environments can lead to failures, necessitating protective coatings.

اعتبارات للمشترين الدوليين:

In regions like Europe and the Middle East, compliance with standards such as DIN and ASTM is essential. Buyers should also consider the local availability of copper and the potential for price fluctuations based on global market conditions.

كيف يمكن مقارنة الألومنيوم كمادة لمرحلات بدء التشغيل؟

Aluminum is another common material utilized in starter relay applications, particularly for housings and structural components. It has a lower weight than copper and operates effectively within a temperature range of -50°C to +150°C. Aluminum is also naturally resistant to corrosion, which is beneficial in automotive applications.

الإيجابيات:

– Lightweight, contributing to overall vehicle efficiency.

– Excellent corrosion resistance without requiring additional coatings.

– Cost-effective compared to copper in bulk applications.

السلبيات:

– Lower electrical conductivity than copper, which may affect performance in high-power applications.

– Less ductile, making it challenging to form intricate designs.

– Can be more expensive to machine due to its hardness.

التأثير على التطبيق:

Aluminum’s lightweight nature makes it suitable for applications where weight reduction is critical. However, its lower conductivity may necessitate larger cross-sectional areas for electrical components.

اعتبارات للمشترين الدوليين:

Buyers in regions such as South America and Africa should be aware of local machining capabilities and the potential need for specialized tools to work with aluminum effectively.

What Role Does Plastic Play in Starter Relay Design?

Plastic materials, particularly thermoplastics, are often used for insulation and housing in starter relays. These materials can withstand temperatures ranging from -40°C to +120°C and offer excellent electrical insulation properties.

الإيجابيات:

– Lightweight and cost-effective, reducing overall manufacturing costs.

– Good electrical insulation, preventing short circuits.

– Versatile in terms of design and can be molded into complex shapes.

Illustrative image related to how do you know if the starter relay is bad

السلبيات:

– Limited temperature tolerance compared to metals, which may affect reliability in extreme conditions.

– Susceptible to degradation from UV exposure and certain chemicals.

– May not provide adequate structural support for heavy-duty applications.

التأثير على التطبيق:

Plastic’s insulating properties are crucial for preventing electrical shorts in starter relays. However, its limitations in extreme environments necessitate careful selection based on application conditions.

اعتبارات للمشترين الدوليين:

In regions like Germany, compliance with RoHS and REACH regulations is critical when sourcing plastic materials. Buyers should also consider the environmental impact of plastic disposal and recycling.

جدول ملخص لاختيار المواد لمرحلات بدء التشغيل

| المواد | Typical Use Case for how do you know if the starter relay is bad | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | التوصيلات الكهربائية في مرحلات بدء التشغيل | موصلية كهربائية عالية | عرضة للأكسدة | متوسط |

| الألومنيوم | المكونات السكنية والهيكلية | خفيف الوزن ومقاوم للتآكل | موصلية أقل من النحاس | متوسط |

| بلاستيك | العزل والإسكان | عزل كهربائي ممتاز | تحمل محدود لدرجات الحرارة | منخفض |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in starter relays, enabling informed decisions that align with their operational needs and regional compliance standards.

Illustrative image related to how do you know if the starter relay is bad

In-depth Look: Manufacturing Processes and Quality Assurance for how do you know if the starter relay is bad

What Are the Key Manufacturing Processes for Starter Relays?

When it comes to the manufacturing of starter relays, understanding the main stages involved is crucial for B2B buyers seeking quality assurance in their purchases. The manufacturing process typically involves several key stages: material preparation, forming, assembly, and finishing.

كيف يتم تحضير المواد لتصنيع مرحل البادئ؟

The first stage in the manufacturing process is material preparation. Manufacturers often source high-quality materials such as copper for electrical contacts, plastic for casings, and steel for internal components. The selection of materials is critical, as it directly impacts the relay’s durability and performance. Suppliers should provide Material Safety Data Sheets (MSDS) to verify the quality and safety of these materials.

ما هي تقنيات التشكيل المستخدمة في إنتاج مرحل البادئ؟

After material preparation, the forming stage involves shaping the materials into the desired components. Techniques such as stamping and injection molding are commonly employed. Stamping is used to create metal parts, while injection molding is utilized for plastic housings. Both methods require precise tooling and machinery to ensure dimensional accuracy and consistency, which are essential for the relay’s functionality.

How Is Assembly Conducted in Starter Relay Manufacturing?

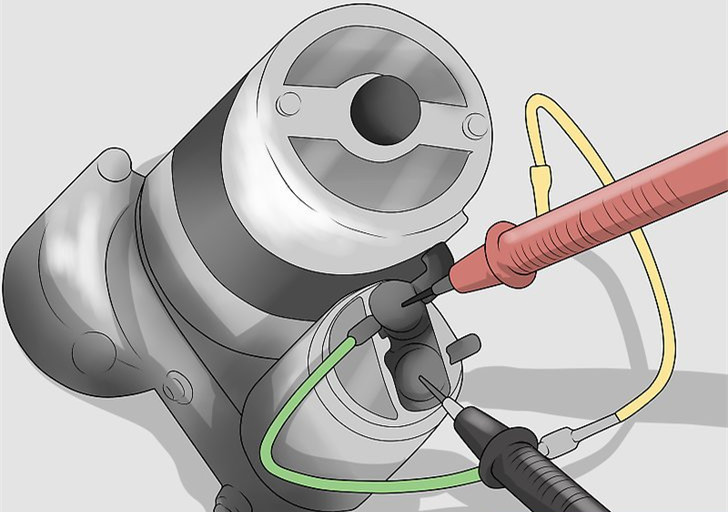

Assembly is a critical phase where individual components are brought together to create the final product. This stage often involves automated assembly lines that enhance efficiency and reduce human error. Key processes include soldering electrical connections, installing components into the relay housing, and conducting initial functionality tests to ensure that the relay operates as intended. For B2B buyers, understanding the assembly process is vital, as it affects the reliability and longevity of the starter relays.

What Finishing Techniques Are Applied to Starter Relays?

The finishing stage includes surface treatments and quality checks before the product is packaged. Techniques such as coating for corrosion resistance and labeling for identification are common. This stage also typically involves visual inspections and functional testing to ensure that each relay meets the required specifications. For buyers, a thorough understanding of these finishing processes can help in assessing the overall quality of the product.

How Is Quality Assurance Implemented in Starter Relay Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, especially for critical components like starter relays. Effective QA measures ensure that products meet international standards and satisfy customer requirements.

What International Standards Govern Starter Relay Quality Assurance?

Manufacturers often adhere to international quality standards such as ISO 9001, which outlines the criteria for an effective quality management system. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific standards like CE marking in Europe or API certifications for automotive components may also apply, depending on the market.

What Are the Key Quality Control Checkpoints in Starter Relay Production?

Quality control (QC) checkpoints are vital for ensuring that the manufacturing process meets quality standards. Typically, these checkpoints include:

- مراقبة الجودة الواردة (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications before production begins.

- مراقبة الجودة أثناء الإنتاج (IPQC): During manufacturing, periodic checks are conducted to monitor processes and detect defects early.

- مراقبة الجودة النهائية (FQC): After assembly, the finished product undergoes rigorous testing to confirm its functionality and reliability.

For B2B buyers, understanding these checkpoints can guide them in selecting suppliers who prioritize quality.

What Common Testing Methods Are Used for Starter Relays?

Testing methods vary but typically include:

- الاختبارات الكهربائية: To verify that the relay can handle the specified voltage and current levels.

- الاختبار الوظيفي: To ensure that the relay operates correctly under simulated conditions.

- اختبار المتانة: To assess how the relay performs under extreme conditions, such as temperature variations and vibrations.

These testing methods help identify any potential issues before the relays reach the market.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

For international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks.

What Steps Can Buyers Take to Verify Supplier QC?

-

عمليات التدقيق: Conducting supplier audits can provide insights into their manufacturing processes and quality control measures. Audits should assess compliance with international standards and the effectiveness of their QC checkpoints.

-

تقارير الجودة: Requesting detailed quality reports can help buyers understand the supplier’s history of quality issues and their resolutions. These reports should include data on defect rates, customer complaints, and corrective actions taken.

-

عمليات التفتيش من طرف ثالث: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages of production, from material sourcing to final product testing.

ما هي الفروق الدقيقة في مراقبة الجودة والشهادات بالنسبة للمشترين الدوليين؟

International buyers must be aware of regional certification requirements that may differ significantly. For example, CE marking is essential for products sold in the European market, while other regions may have their own certification standards. Understanding these nuances can help buyers ensure compliance and avoid costly delays in their supply chains.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing starter relays, ultimately ensuring the reliability and performance of their automotive applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you know if the starter relay is bad’

The purpose of this guide is to equip B2B buyers with a practical checklist for identifying signs of a faulty starter relay or solenoid. Understanding these components is crucial for ensuring optimal vehicle performance and making informed purchasing decisions.

الخطوة 1: Understand the Function of Starter Relays and Solenoids

Before diving into diagnostics, familiarize yourself with how starter relays and solenoids work. These components act as electromagnetic switches that enable low-power signals to trigger high-power circuits, facilitating the engine starting process. Knowing their roles helps in accurately diagnosing issues and communicating effectively with suppliers.

الخطوة 2: Identify Symptoms of a Faulty Starter Relay

Recognizing the signs of a bad starter relay is essential. Common symptoms include the engine failing to start, a single click sound when turning the key, or intermittent starting issues. Document these symptoms meticulously, as they provide critical information to technicians and suppliers when sourcing replacements.

الخطوة 3: Define Technical Specifications for Replacement Parts

Clarify the specifications needed for the starter relay or solenoid you intend to purchase. This includes voltage ratings, compatibility with vehicle models, and whether you need a relay or solenoid. Precise specifications ensure that the sourced component will fit and function correctly within your vehicle’s electrical system.

Illustrative image related to how do you know if the starter relay is bad

الخطوة 4: البحث عن الموردين المحتملين

Conduct thorough research to identify reputable suppliers of starter relays and solenoids. Look for suppliers with a strong track record in the automotive parts industry and positive reviews from previous clients. Consider their experience with your specific vehicle models and their ability to meet your technical requirements.

الخطوة 5: التحقق من شهادات الموردين ومعايير الجودة

Before making any purchases, ensure that potential suppliers adhere to relevant quality standards and certifications. This might include ISO certifications or compliance with local automotive regulations. Valid certifications indicate that the supplier follows industry best practices, reducing the risk of acquiring subpar components.

الخطوة 6: Request Samples or Product Documentation

Once you’ve narrowed down potential suppliers, request samples or detailed product documentation. This can include datasheets, installation guides, and warranty information. Evaluating these documents helps ensure the quality and compatibility of the components with your vehicle.

الخطوة 7: Establish a Reliable After-Sales Support System

After selecting a supplier, confirm the availability of after-sales support. Reliable customer service can assist with installation issues, warranty claims, and any potential defects. Establishing a solid support system will enhance your confidence in the product and the supplier’s commitment to quality.

By following this checklist, B2B buyers can ensure they make informed decisions when sourcing starter relays and solenoids, ultimately enhancing their operational efficiency and vehicle reliability.

Comprehensive Cost and Pricing Analysis for how do you know if the starter relay is bad Sourcing

What Are the Key Cost Components for Sourcing Information on Starter Relay Issues?

Understanding the costs associated with sourcing information on how to identify a bad starter relay involves several components. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the desired profit margin.

Illustrative image related to how do you know if the starter relay is bad

-

المواد: The primary materials include electronic components such as relays and solenoids, wiring harnesses, and connectors. The quality and specifications of these materials can significantly influence costs. For example, sourcing high-quality, certified components will typically incur higher upfront costs but may result in lower failure rates and increased reliability.

-

العمل: Labor costs encompass the expertise required for assembling and testing starter relays. Skilled technicians may command higher wages, but their proficiency can lead to reduced error rates and improved production efficiency.

-

تكاليف التصنيع العامة: This includes expenses related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, thus positively impacting the overall pricing structure.

-

الأدوات: Custom tooling for specific starter relay designs can be a substantial initial investment. However, if economies of scale are achieved through higher production volumes, these costs can be amortized over a larger number of units, reducing the per-unit cost.

-

مراقبة الجودة (QC): Implementing stringent QC measures ensures that defective units are minimized. While this may increase operational costs, it is essential for maintaining a good reputation and customer satisfaction, particularly in international markets.

-

اللوجستيات: Shipping and handling costs must be considered, especially for international buyers. Factors such as distance, shipping method, and customs duties can all affect the final price.

-

الهامش: Suppliers typically add a profit margin to cover their costs and generate profit. Understanding the competitive landscape can help buyers gauge whether the margin is reasonable.

How Do Price Influencers Affect the Cost of Sourcing Information on Starter Relay Problems?

Several factors influence pricing for sourcing information on starter relay issues, particularly for international B2B buyers.

-

الحجم/الحد الأدنى للطلب: Minimum Order Quantities (MOQ) can significantly affect pricing. Ordering in bulk often leads to better per-unit pricing, which is particularly advantageous for businesses anticipating high demand.

-

المواصفات/التخصيص: Custom specifications can lead to increased costs due to the need for specialized materials or manufacturing processes. However, tailored solutions can enhance performance, making them worthwhile investments.

-

المواد: The choice of materials has a direct impact on pricing. High-quality, durable materials may cost more upfront but can reduce Total Cost of Ownership (TCO) by lowering replacement frequency and maintenance costs.

-

الجودة/الشهادات: Components that come with industry certifications may command a premium price. However, they often provide peace of mind and assurance of reliability, which is particularly critical for automotive applications.

-

عوامل الموردين: The reputation, reliability, and service level of the supplier can influence pricing. Established suppliers with a track record of quality may charge more, but the long-term savings from fewer defects can justify the investment.

-

مصطلحات التجارة الدولية: Understanding shipping terms and responsibilities can affect overall costs. Different Incoterms dictate who bears the cost and risk at various points in the shipping process, which can have significant financial implications.

What Buyer Tips Should International B2B Buyers Consider When Sourcing Starter Relay Information?

-

التفاوض: Buyers should engage suppliers in discussions about pricing, especially when purchasing in volume. Negotiating terms can lead to more favorable pricing structures.

-

الفعالية من حيث التكلفة: Evaluate the Total Cost of Ownership rather than just the purchase price. Consider factors such as reliability, warranty, and potential downtime costs associated with sourcing lower-quality components.

-

الفروق الدقيقة في الأسعار للمشترين الدوليين: When sourcing from regions such as Africa, South America, the Middle East, and Europe, be aware of local market conditions, currency fluctuations, and potential tariffs. These factors can significantly impact the final cost.

-

إخلاء المسؤولية عن الأسعار الإرشادية: Keep in mind that prices can fluctuate based on market demand, availability of materials, and other economic factors. Always request updated quotes and be prepared for negotiations.

By understanding these cost components, price influencers, and buyer strategies, international B2B buyers can make informed decisions when sourcing information on how to identify a bad starter relay.

Alternatives Analysis: Comparing how do you know if the starter relay is bad With Other Solutions

In the automotive sector, understanding whether a starter relay is malfunctioning is crucial for ensuring vehicle reliability and performance. However, there are alternative methods and technologies that can be employed to diagnose starting issues. This analysis compares the traditional approach of diagnosing a faulty starter relay against two alternative solutions: using a multimeter and implementing an OBD-II diagnostic tool.

| جانب المقارنة | How Do You Know If The Starter Relay Is Bad | استخدام جهاز القياس المتعدد | OBD-II Diagnostic Tool |

|---|---|---|---|

| الأداء | Effective for identifying relay issues | Accurate readings for electrical faults | Provides detailed error codes |

| التكلفة | Generally low cost (testing tools) | Affordable; requires basic tools | Moderate cost; tool purchase required |

| سهولة التنفيذ | Requires knowledge of automotive systems | يتطلب معرفة أساسية بالكهرباء | User-friendly; minimal training needed |

| الصيانة | Minimal; mostly one-time checks | Requires user to maintain tools | Software updates needed occasionally |

| أفضل حالة استخدام | Vehicles with starting problems | DIY enthusiasts and professional mechanics | Fleet management and larger operations |

How Does Using a Multimeter Compare to Knowing if the Starter Relay is Bad?

Using a multimeter is a straightforward alternative for diagnosing electrical issues in vehicles, including starter relays. This method allows users to measure voltage, resistance, and continuity across various components. The primary advantage of this approach is its accuracy in pinpointing electrical faults, which can help determine if the relay is indeed the issue or if other components are to blame. However, it requires a certain level of electrical knowledge and skill, which may not be readily available to all users. Additionally, while the multimeter is relatively low-cost, it does require some maintenance and care to ensure accurate readings.

How Does an OBD-II Diagnostic Tool Offer a Different Approach?

An OBD-II diagnostic tool is another effective method for diagnosing starting problems in vehicles. This technology connects to the vehicle’s onboard computer system and retrieves error codes that indicate specific issues, including those related to the starter relay. The primary benefit of this method is its ease of use; even those with limited technical knowledge can interpret the codes with the help of user-friendly software. However, the initial investment in an OBD-II scanner can be moderate, which may deter some users. Additionally, while it provides a broad overview of system health, it may not offer the granularity that a multimeter provides in diagnosing specific electrical issues.

Conclusion: How Should B2B Buyers Choose the Right Diagnostic Method?

When considering the best approach to diagnose starter relay issues, B2B buyers should evaluate their specific operational needs and available expertise. If precision and detailed electrical diagnostics are required, investing in a multimeter may be the best route. Conversely, for businesses managing a fleet or requiring quick diagnostics across multiple vehicles, an OBD-II tool may provide the most value. Ultimately, the choice will depend on factors such as cost, ease of use, and the technical capabilities of the personnel involved. By aligning the chosen method with operational requirements, buyers can enhance vehicle reliability and reduce downtime effectively.

Illustrative image related to how do you know if the starter relay is bad

Essential Technical Properties and Trade Terminology for how do you know if the starter relay is bad

What Are the Key Technical Properties to Consider When Evaluating a Starter Relay?

When assessing a starter relay for potential failure, several technical properties are critical to ensure optimal performance and reliability. Understanding these specifications can aid B2B buyers in making informed purchasing decisions.

-

Electrical Rating

The electrical rating of a starter relay specifies the maximum current and voltage it can handle. Typically, this ranges from 12V to 24V systems, with current ratings often between 30A to 100A. Selecting a relay with the appropriate rating is crucial to prevent overheating and potential failure, which can lead to costly downtime. -

تكوين جهة الاتصال

The contact configuration refers to the arrangement of the relay’s internal contacts, which can be normally open (NO) or normally closed (NC). Understanding the configuration is vital for compatibility with various ignition systems, ensuring that the relay can effectively manage the electrical flow required to start the engine. -

المتانة ودرجة المواد

The materials used in the construction of the starter relay, such as the housing and internal components, significantly affect its lifespan and performance. Common materials include high-grade plastics and copper contacts. A relay made from durable materials can withstand harsh environments, making it suitable for diverse climates, particularly in regions like Africa and the Middle East. -

مقاومة اللفائف

Coil resistance is a measure of the electrical resistance of the relay’s coil. It typically ranges from 50 to 100 ohms. This property impacts the amount of current required to activate the relay. A low coil resistance can allow for quicker engagement but may consume more power, whereas a higher resistance may be energy-efficient but slower to respond. -

نطاق درجة حرارة التشغيل

The operating temperature range indicates the ambient temperatures within which the relay can function correctly. Many automotive relays operate effectively between -40°C to 85°C. Understanding this range is essential for applications in extreme environments, ensuring reliability and reducing the risk of failure. -

نوع التثبيت

The mounting type defines how the relay is installed within a vehicle. Common mounting types include plug-in, surface mount, or bracket mount. Knowing the mounting type is crucial for compatibility with existing vehicle systems and simplifies the installation process.

What Trade Terminology Should B2B Buyers Understand When Sourcing Starter Relays?

Familiarity with industry jargon is essential for B2B buyers to navigate the procurement process effectively. Here are some key terms to consider:

-

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the original manufacturer of the vehicle. Sourcing OEM starter relays ensures compatibility and reliability, making it an important consideration for businesses focused on quality. -

MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for inventory management and cost efficiency, particularly for companies looking to maintain a steady supply of starter relays. -

طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers to obtain pricing and terms for specific products. Crafting an effective RFQ can help buyers compare offerings and negotiate better deals, ensuring they secure the best value for starter relays. -

شروط التجارة الدولية (Incoterms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery obligations, which are crucial for smooth logistics. -

قطع غيار ما بعد البيع

Aftermarket parts are components manufactured by companies other than the OEM. While often more cost-effective, understanding the quality and compatibility of aftermarket starter relays is essential to ensure they meet operational standards. -

المهلة الزمنية

Lead time refers to the time taken from placing an order to delivery. Knowing the lead time for starter relays can assist businesses in planning their inventory and ensuring they have the necessary components to avoid production delays.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing starter relays, ensuring they select the right components for their automotive needs.

Navigating Market Dynamics and Sourcing Trends in the how do you know if the starter relay is bad Sector

Market Overview & Key Trends: How Do You Know If the Starter Relay Is Bad?

The automotive sector is witnessing transformative changes driven by technological advancements and shifting consumer preferences. For B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing strategies. One significant driver is the increasing reliance on advanced diagnostic tools that streamline the identification of starter relay issues. These tools leverage artificial intelligence and machine learning to provide real-time insights, reducing downtime and enhancing operational efficiency.

Moreover, the global push towards electrification in vehicles is reshaping the starter relay landscape. As more manufacturers transition to electric vehicles (EVs), traditional starter systems are evolving, demanding new sourcing strategies and an understanding of how these components function in hybrid systems. International buyers must stay abreast of these technological shifts, as they impact not only product specifications but also pricing and availability.

Emerging trends also include the rise of e-commerce platforms for automotive parts, allowing B2B buyers easier access to a wider range of suppliers. This digital transformation fosters competitive pricing, improved supply chain transparency, and enhanced supplier relationships. In regions like Saudi Arabia and Germany, where automotive aftermarket services are growing, understanding local regulations and standards becomes increasingly important for successful sourcing.

How Can Sustainability & Ethical Sourcing Impact the ‘How Do You Know If the Starter Relay Is Bad’ Sector?

Sustainability is no longer a peripheral concern but a core component of strategic sourcing in the automotive sector. B2B buyers are increasingly prioritizing suppliers that adhere to environmentally responsible practices, particularly in the sourcing of starter relay components. The production and disposal of automotive parts can significantly impact the environment, prompting a shift towards more sustainable materials and manufacturing processes.

Buyers should look for suppliers who utilize recycled materials and have certifications such as ISO 14001, which demonstrates a commitment to environmental management. Additionally, the use of eco-friendly packaging and logistics practices contributes to reducing the carbon footprint associated with automotive parts distribution.

Ethical sourcing is equally important, as consumers and businesses alike demand transparency in supply chains. Ensuring that components are sourced from suppliers who uphold labor rights and fair trade practices not only enhances brand reputation but also aligns with the values of increasingly conscientious consumers. By prioritizing sustainability and ethical sourcing, B2B buyers can mitigate risks associated with environmental regulations and social responsibility, leading to long-term operational benefits.

What Is the Brief Evolution/History of the Starter Relay in Automotive Systems?

The starter relay has evolved significantly since its inception in the early 20th century. Initially, starter systems were rudimentary, relying on simple mechanical switches to engage the starter motor. As automotive technology advanced, the need for more reliable and efficient systems led to the development of electromagnetic relays. These devices allowed a low-power ignition signal to control a high-power circuit, essential for starting modern engines.

In the latter half of the 20th century, the introduction of electronic ignition systems further refined the functionality of starter relays. With the advent of computerized engine management systems, relays became integral components that enabled precise control over the starter motor, improving overall vehicle performance and reliability.

Today, with the rise of hybrid and electric vehicles, starter relays continue to adapt, showcasing the automotive industry’s commitment to innovation. Understanding this evolution helps B2B buyers appreciate the technical specifications and sourcing needs of modern starter relays, ensuring they make informed purchasing decisions aligned with current market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of how do you know if the starter relay is bad

-

How do I know if the starter relay is failing?

To determine if the starter relay is failing, listen for a single click when turning the ignition key, which suggests the relay is attempting to engage but may not be functioning properly. If nothing happens at all, it could indicate a complete failure. Intermittent starting issues or the engine starting without turning the key are also signs of a bad relay. It is essential to conduct a thorough electrical check, including examining the wiring and connections, to confirm the relay’s condition. -

What are the symptoms of a bad starter solenoid versus a relay?

While both the starter solenoid and relay serve similar functions, their symptoms differ. A faulty solenoid may produce a single click or repeated clicking sounds, indicating it is trying to engage but failing. In contrast, a bad relay might prevent any sound or action from the starter. If the vehicle occasionally starts, this could point to a failing solenoid. For precise diagnosis, it is advisable to consult an automotive technician who can test both components effectively. -

What should I consider when sourcing starter relays internationally?

When sourcing starter relays internationally, consider factors such as product quality, compliance with local regulations, and the reputation of the supplier. Verify the supplier’s credentials and certifications to ensure they meet industry standards. Additionally, assess the compatibility of the relays with your specific vehicle models. Engaging in due diligence, such as requesting samples and product specifications, can help mitigate risks associated with international procurement. -

What are the minimum order quantities (MOQs) for starter relays from suppliers?

Minimum order quantities (MOQs) for starter relays can vary significantly based on the supplier and the type of relay. Some suppliers may offer flexible MOQs for smaller businesses, while others may require larger orders to maintain cost efficiency. It is advisable to communicate directly with potential suppliers to negotiate MOQs that align with your purchasing needs and budget constraints. Understanding the implications of MOQs on your inventory management is crucial for effective sourcing. -

What payment terms should I expect when buying starter relays internationally?

Payment terms for international purchases of starter relays can differ among suppliers, typically ranging from upfront payments to net 30 or net 60 days after delivery. Some suppliers may also accept letters of credit or escrow services to ensure security for both parties. It is essential to clarify payment terms before finalizing any agreements and consider the impact of currency exchange rates and transaction fees on your overall costs. -

How can I ensure the quality of starter relays I import?

To ensure the quality of imported starter relays, implement a robust quality assurance (QA) process. This may include conducting pre-shipment inspections, obtaining certificates of conformity, and reviewing product samples. Collaborating with suppliers who have established QA protocols and certifications can also enhance confidence in product quality. Additionally, consider building long-term relationships with reliable suppliers to foster mutual trust and continuous quality improvement. -

What are the logistics considerations when importing starter relays?

Logistics play a crucial role in the timely and cost-effective importation of starter relays. Assess shipping options, including air and sea freight, to determine the most suitable method based on urgency and budget. Understand customs regulations and duties that may apply to your shipments to avoid unexpected costs. Partnering with a reliable logistics provider can help streamline the import process and ensure compliance with international shipping standards. -

How do I handle potential disputes with international suppliers?

Handling potential disputes with international suppliers requires clear communication and documentation. Establish a written agreement outlining terms, conditions, and expectations before proceeding with orders. In case of disputes, try to resolve issues amicably through direct negotiation. If necessary, consider mediation or arbitration as alternatives to litigation, as they can be more cost-effective and less time-consuming. Keeping records of all communications and transactions can also support your position in any dispute resolution process.

Top 3 How Do You Know If The Starter Relay Is Bad Manufacturers & Suppliers List

1. Aliontimer – Key Relays and Timers

المجال: aliontimer.com

مسجل: 2016 (9 سنوات)

مقدمة: 1. مرحل الحماية - المكونات الحرجة لشبكة الطاقة الكهربائية 2. مرحل عائم - التحكم التلقائي في إمدادات المياه والصرف الصحي 3. مرحل الموقت المعياري - جزء أساسي من التحكم في المحرك 4. مرحل الموقت متعدد الوظائف - مرحل تأخير الموقت متعدد النطاقات

2. Jeep – Patriot Starting Issues

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: سيارة جيب باتريوت 2008؛ المشكلة: السيارة لا تعمل؛ الأعراض: جميع الأضواء والراديو تعمل، ضوضاء طقطقة واحدة عند محاولة تشغيل السيارة؛ المشاكل المحتملة: فتيل مرحل بدء التشغيل أو مفتاح التشغيل بحاجة إلى استبدال.

3. Facebook – Common Bad Starter Symptoms

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: This company, Facebook – Common Bad Starter Symptoms, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for how do you know if the starter relay is bad

As you navigate the complexities of automotive component sourcing, recognizing the signs of a faulty starter relay is crucial for maintaining operational efficiency. Key indicators, such as a lack of response when turning the ignition, single or repeated clicks, and intermittent starting issues, can guide you in diagnosing potential relay or solenoid failures. Understanding the differences between these components can also streamline your procurement process, ensuring you source the right parts for your vehicles.

Strategic sourcing is not just about cost savings; it’s about building long-term partnerships with suppliers who understand the nuances of your market. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, establishing reliable supply chains can significantly enhance your operational resilience. As you seek quality components, prioritize suppliers who offer not only competitive pricing but also expertise in automotive technologies.

Looking ahead, investing in robust sourcing strategies will empower your business to respond swiftly to maintenance needs, ultimately enhancing your fleet’s reliability and performance. Engage with trusted suppliers today to secure the essential parts that keep your operations running smoothly.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.