Introduction: Navigating the Global Market for headlight installation cost

In today’s competitive automotive landscape, accurately navigating the global market for headlight installation costs is crucial for B2B buyers. The challenge lies not only in sourcing the right components at the best price but also in understanding the diverse types of headlight systems available, from traditional halogen bulbs to advanced LED assemblies. Each option presents unique pricing structures and installation requirements, which can vary significantly based on vehicle models and regional standards.

This comprehensive guide delves into the intricacies of headlight installation costs, providing a thorough analysis of various headlight types, their applications, and the factors influencing pricing. We will also explore essential supplier vetting strategies to ensure quality and compliance with safety regulations. By equipping international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—specifically Germany and Vietnam—with actionable insights, this guide empowers informed purchasing decisions.

Understanding these dynamics not only helps mitigate unexpected costs but also enhances operational efficiency and safety standards in the automotive sector. Whether you’re looking to optimize your supply chain or ensure compliance with local regulations, this guide serves as your roadmap to effectively manage headlight installation costs in a global marketplace.

جدول المحتويات

- Top 1 Headlight Installation Cost Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for headlight installation cost

- Understanding headlight installation cost Types and Variations

- Key Industrial Applications of headlight installation cost

- 3 Common User Pain Points for ‘headlight installation cost’ & Their Solutions

- Strategic Material Selection Guide for headlight installation cost

- In-depth Look: Manufacturing Processes and Quality Assurance for headlight installation cost

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘headlight installation cost’

- Comprehensive Cost and Pricing Analysis for headlight installation cost Sourcing

- Alternatives Analysis: Comparing headlight installation cost With Other Solutions

- Essential Technical Properties and Trade Terminology for headlight installation cost

- Navigating Market Dynamics and Sourcing Trends in the headlight installation cost Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of headlight installation cost

- Strategic Sourcing Conclusion and Outlook for headlight installation cost

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding headlight installation cost Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| Halogen Bulb Replacement | Inexpensive, widely available, short lifespan (500-1,000 hours) | الورش العامة لإصلاح السيارات | الإيجابيات: منخفضة التكلفة وسهلة التركيب. السلبيات: عمر افتراضي قصير، سطوع أقل. |

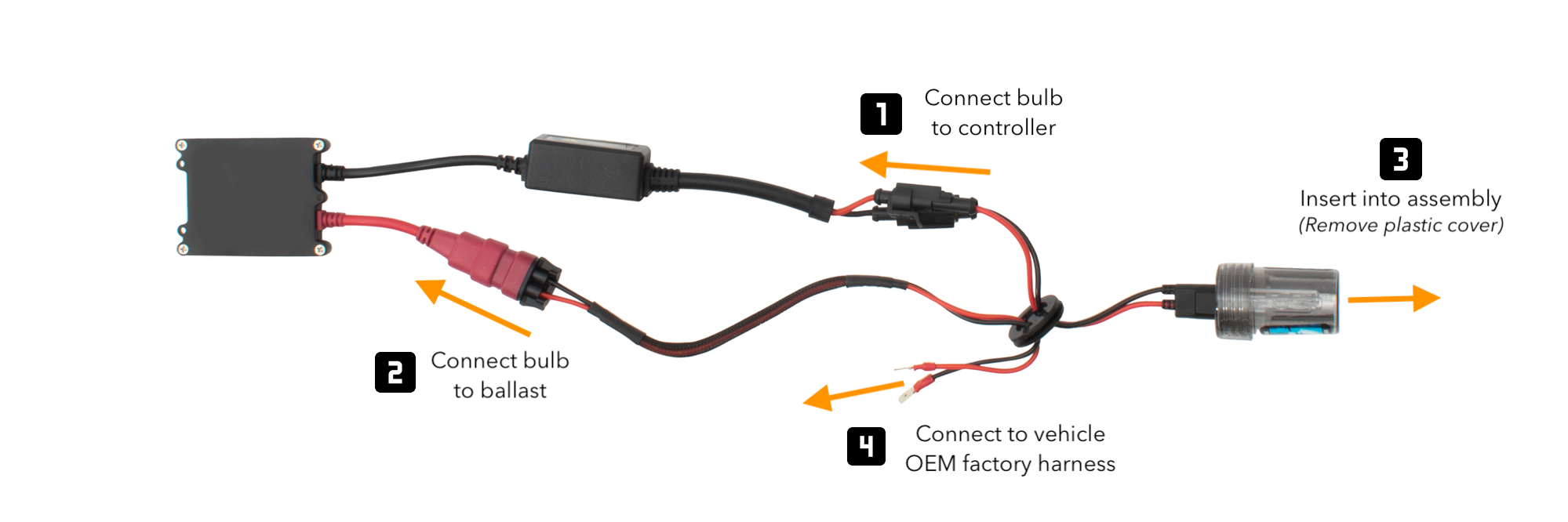

| HID Bulb Replacement | Brighter than halogen, requires ballast, longer lifespan (2,000-3,000 hours) | Luxury vehicle service centers | الإيجابيات: Enhanced visibility, longer lifespan. السلبيات: Higher cost, installation complexity. |

| LED Headlight Assembly | Long-lasting (30,000 hours), energy-efficient, often sealed units | High-end automotive dealerships | الإيجابيات: Excellent visibility, low power consumption. السلبيات: High replacement costs, potential warranty issues. |

| Complete Headlight Module | Sealed units, includes advanced features like adaptive lighting | Specialty automotive repair shops | الإيجابيات: Comprehensive solution, integrates advanced technology. السلبيات: Very high costs, complex installation. |

| أطقم ترميم المصابيح الأمامية | DIY kits for lens clarity, affordable, requires maintenance | Car detailing businesses, auto parts retailers | الإيجابيات: Cost-effective, improves safety. السلبيات: Requires time and skill, may not last long without proper care. |

What Are the Key Characteristics of Halogen Bulb Replacements?

Halogen bulbs are the most common type of headlight replacement, known for their affordability and ease of installation. Typically ranging from $10 to $40, they are suitable for a wide variety of vehicles, making them a go-to option for general automotive repair shops. While they offer decent illumination, their relatively short lifespan of 500 to 1,000 hours can lead to frequent replacements, which may not be ideal for businesses focused on long-term vehicle maintenance.

How Do HID Bulb Replacements Differ from Halogen Options?

High-Intensity Discharge (HID) bulbs deliver significantly brighter light than halogen options and are often used in luxury vehicles. Priced around $150 per bulb, they require a ballast for operation and have a lifespan of 2,000 to 3,000 hours. This makes them suitable for luxury vehicle service centers that prioritize high-quality lighting solutions. However, their installation can be complex, which may necessitate professional assistance, adding to the overall cost for B2B buyers.

Why Choose LED Headlight Assemblies for Modern Vehicles?

LED headlight assemblies are increasingly standard in newer vehicles due to their energy efficiency and longevity, lasting up to 30,000 hours. While replacement costs can range from $50 to $200 per pair, the advanced technology often necessitates the purchase of a complete assembly, which can be significantly more expensive. B2B buyers, particularly those in high-end automotive dealerships, should consider the investment as a long-term solution, despite the initial high costs.

What Are the Advantages of Complete Headlight Modules?

Complete headlight modules are sealed units that often come with advanced features like adaptive lighting and auto-leveling. These modules can be quite expensive, sometimes costing over $1,000, making them suitable for specialty automotive repair shops that cater to high-end vehicles. While they provide a comprehensive solution, the complexity of their installation can pose challenges, requiring skilled technicians and potentially leading to increased labor costs.

How Do Headlight Restoration Kits Benefit B2B Buyers?

Headlight restoration kits are an affordable solution for improving the clarity of cloudy lenses. Priced around $25, these kits are ideal for car detailing businesses and auto parts retailers looking to offer cost-effective maintenance solutions. While they can significantly enhance safety and visibility, they require a degree of DIY skill and time investment. Buyers should be aware that without proper care, the benefits may diminish over time, impacting customer satisfaction.

Key Industrial Applications of headlight installation cost

| الصناعة/القطاع | Specific Application of headlight installation cost | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | Routine headlight bulb replacements | Increased customer satisfaction and retention | Quality of replacement parts, availability of skilled labor |

| إدارة الأسطول | Bulk headlight assembly replacements | Cost savings through bulk purchasing and reduced downtime | Supplier reliability, warranty terms, and installation support |

| وسائل النقل العام | Upgrading public transport vehicles’ lighting systems | Enhanced safety for passengers and reduced accident rates | Compliance with local regulations, durability of components |

| Construction & Mining | Heavy equipment headlight replacements | Improved visibility and safety in hazardous environments | Compatibility with machinery, sourcing of durable materials |

| Export Vehicle Parts | Sourcing headlight components for international markets | Competitive pricing and adherence to local standards | Understanding of international shipping regulations and tariffs |

How is headlight installation cost relevant for automotive repair shops?

Automotive repair shops frequently handle routine headlight bulb replacements, which can significantly impact customer satisfaction. The cost of headlight installation can vary based on the type of bulb and the complexity of the job. Shops need to ensure they source high-quality bulbs that meet safety standards, as well as provide skilled labor for installation. This reliability helps build trust and encourages repeat business from customers who prioritize safety and performance in their vehicles.

What role does headlight installation cost play in fleet management?

For fleet management companies, managing headlight installation costs is crucial for maintaining operational efficiency. Regular bulk replacements of headlight assemblies can lead to significant cost savings and minimize vehicle downtime. Companies should consider sourcing from reliable suppliers who offer warranties and support services to ensure that fleets remain operational and compliant with safety standards. This proactive approach helps avoid unexpected expenses and enhances the overall safety of fleet operations.

Illustrative image related to headlight installation cost

Why is headlight installation cost important for public transportation?

Public transportation agencies must prioritize the safety of their passengers, making headlight installation costs a critical factor in vehicle maintenance. Upgrading lighting systems to modern, efficient options can improve visibility and significantly reduce accident rates. Agencies need to ensure compliance with local regulations regarding vehicle safety and lighting standards. Sourcing durable components that can withstand heavy use is essential for maintaining service quality and safety in public transit.

How does headlight installation cost impact construction and mining industries?

In the construction and mining sectors, proper visibility is vital for safety in hazardous environments. The cost of replacing headlights on heavy equipment can be significant, but it is necessary to prevent accidents and ensure worker safety. Companies must consider compatibility with their machinery and the durability of sourced materials, as these factors directly influence operational efficiency. Investing in quality headlight systems can mitigate risks associated with poor visibility, ultimately protecting both workers and equipment.

What considerations should be made for exporting vehicle parts related to headlight installation costs?

For businesses involved in exporting vehicle parts, understanding headlight installation costs is essential for competitive pricing in international markets. Sourcing components that adhere to local safety standards while maintaining affordability can enhance marketability. Companies must navigate international shipping regulations and tariffs, ensuring that their supply chain is efficient and compliant. This strategic approach can position exporters favorably in diverse markets, such as those in Africa, South America, the Middle East, and Europe.

3 Common User Pain Points for ‘headlight installation cost’ & Their Solutions

Scenario 1: High Replacement Costs for Complex Headlight Systems

المشكلة:

B2B buyers often face the challenge of sourcing headlight replacements for modern vehicles equipped with advanced lighting systems. The complexity of these systems means that replacement parts can vary significantly in price, with complete assemblies for high-end models reaching thousands of dollars. This unpredictability can strain budgets, especially for fleet managers or automotive service providers who must manage multiple vehicle repairs. Additionally, the need for specialized labor to install these components can further escalate costs, making it difficult to provide accurate estimates to clients or stakeholders.

الحل:

To navigate these high replacement costs, it is essential to establish relationships with reliable suppliers who can offer competitive pricing on headlight assemblies and parts. Conduct thorough market research to identify vendors that specialize in OEM and aftermarket parts, ensuring they provide quality products compliant with international safety standards. Additionally, consider bulk purchasing agreements with suppliers to negotiate discounts based on volume. For installation, invest in training for your technicians to ensure they are proficient in handling complex headlight systems, which can reduce labor costs in the long run. By developing a systematic approach to sourcing and installing headlight components, businesses can better manage expenses and maintain a competitive edge.

Scenario 2: Confusion Over Headlight Bulb Types and Compatibility

المشكلة:

Many buyers encounter confusion when selecting the appropriate headlight bulbs due to the wide variety of options available, including halogen, HID, and LED. Each type has different specifications, costs, and installation requirements. For automotive repair shops, this confusion can lead to incorrect purchases, wasted time, and dissatisfied customers. This scenario is particularly challenging in markets where vehicle models vary greatly, and the wrong bulb can result in safety issues or operational inefficiencies.

Illustrative image related to headlight installation cost

الحل:

To combat this confusion, develop a comprehensive database of vehicle specifications that includes the correct bulb types and compatible parts for various makes and models. This resource can be used by staff during the purchasing process to ensure accurate selections. Additionally, provide training sessions to educate employees about the differences between headlight types, their benefits, and installation processes. Collaborating with trusted manufacturers who can supply detailed product information and support can also enhance your team’s knowledge base. Finally, consider implementing a customer feedback system to capture insights on bulb performance, which can help refine your inventory and improve service offerings.

Scenario 3: The Impact of Diminished Headlight Performance on Safety and Compliance

المشكلة:

In many regions, including parts of Africa and South America, regulatory compliance regarding vehicle safety is becoming increasingly strict. Diminished headlight performance due to age or damage can not only pose safety risks but also lead to failed inspections, resulting in costly repairs and downtime. For B2B buyers managing fleets or automotive services, ensuring that all vehicles meet safety standards is critical, yet often challenging when dealing with outdated or poorly maintained headlight systems.

الحل:

Implement a proactive headlight maintenance program that includes regular inspections and timely replacements. Educate clients about the importance of headlight performance for safety and compliance, using data to illustrate the risks of neglecting this aspect of vehicle maintenance. Utilize headlight restoration kits as a cost-effective solution for restoring cloudy lenses, which can enhance visibility and safety. Additionally, create partnerships with local workshops to facilitate quick repairs or replacements, ensuring that compliance is maintained without significant downtime. By prioritizing headlight maintenance, businesses can enhance safety, improve customer satisfaction, and reduce compliance-related penalties.

Strategic Material Selection Guide for headlight installation cost

What Are the Key Materials Impacting Headlight Installation Costs?

When considering headlight installation costs, the choice of materials plays a crucial role in determining both performance and expenses. Below, we analyze four common materials used in headlight assemblies and their implications for B2B buyers, particularly those operating in diverse international markets.

How Do Plastics Influence Headlight Cost and Performance?

الخصائص الرئيسية: Plastics, particularly polycarbonate, are lightweight and have good impact resistance, making them suitable for headlight lenses. They can withstand a range of temperatures but may not be as resistant to UV degradation unless treated.

الإيجابيات والسلبيات: The primary advantage of plastics is their lower manufacturing cost and ease of shaping into complex designs. However, they can be prone to scratching and yellowing over time, which may necessitate replacement or restoration. This can lead to additional costs for buyers if not managed properly.

Illustrative image related to headlight installation cost

التأثير على التطبيق: Plastics are compatible with various automotive lighting technologies, including halogen, HID, and LED. However, they may require protective coatings to enhance UV resistance.

اعتبارات للمشترين الدوليين: Compliance with international standards such as ASTM or DIN is essential, especially in regions with stringent automotive regulations. Buyers should also consider the environmental impact of plastic waste, which is increasingly becoming a concern in markets like Europe.

What Role Do Metals Play in Headlight Assembly Costs?

الخصائص الرئيسية: Metals such as aluminum and steel are often used in the structural components of headlight assemblies. They offer excellent strength and durability, withstanding high temperatures and mechanical stress.

الإيجابيات والسلبيات: Metals provide a robust framework that can enhance the overall longevity of the headlight assembly. However, they are heavier and may increase the overall cost of the assembly due to higher material and manufacturing expenses. Corrosion resistance can also vary, requiring additional coatings or treatments.

Illustrative image related to headlight installation cost

التأثير على التطبيق: Metals are essential for ensuring the integrity of headlight assemblies, especially in vehicles exposed to harsh environmental conditions. They are compatible with various lighting technologies but may require careful design to prevent overheating.

اعتبارات للمشترين الدوليين: Compliance with corrosion resistance standards is vital, especially in regions with high humidity or saline environments, such as coastal areas in Africa and South America. Buyers should ensure that the materials meet local regulatory requirements.

How Do Glass Components Affect Headlight Installation Costs?

الخصائص الرئيسية: Glass is often used for high-end headlight lenses due to its optical clarity and resistance to scratching. It can withstand high temperatures but is more fragile than plastic.

Illustrative image related to headlight installation cost

الإيجابيات والسلبيات: The clarity of glass provides superior light transmission, enhancing visibility. However, its fragility can lead to higher replacement costs if damaged. Additionally, glass components may require more complex manufacturing processes, increasing costs.

التأثير على التطبيق: Glass is particularly well-suited for high-performance lighting systems, such as those found in luxury vehicles. It is compatible with various lighting technologies but may not be as versatile as plastics in design.

اعتبارات للمشترين الدوليين: Buyers should be aware of the transportation costs associated with glass components, as they are more prone to breakage. Compliance with safety standards for automotive glass is also crucial, especially in Europe and the Middle East.

Illustrative image related to headlight installation cost

What Are the Advantages of Composite Materials in Headlight Assemblies?

الخصائص الرئيسية: Composite materials combine plastics and metals, offering a balance of lightweight properties and structural integrity. They often have enhanced resistance to UV light and impact.

الإيجابيات والسلبيات: Composites can reduce overall weight, which may improve vehicle fuel efficiency. However, they can be more expensive to manufacture and may require specialized processing techniques.

التأثير على التطبيق: Composites are increasingly used in modern vehicles for their versatility and performance benefits. They are compatible with a wide range of lighting systems, making them a popular choice for manufacturers.

Illustrative image related to headlight installation cost

اعتبارات للمشترين الدوليين: Understanding the supply chain for composite materials is essential, as sourcing may vary by region. Buyers should also consider the lifecycle impact of composites, especially in environmentally conscious markets.

Summary Table of Material Considerations for Headlight Installation Costs

| المواد | Typical Use Case for headlight installation cost | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| بلاستيك | Headlight lenses and assemblies | خفيفة الوزن وفعالة من حيث التكلفة | عرضة للخدش والتدهور بسبب الأشعة فوق البنفسجية | منخفض |

| Metals | Structural components of headlight assemblies | قوة ومتانة عالية | Heavier and potentially more expensive | متوسط |

| زجاج | High-end headlight lenses | Superior light transmission | Fragile and higher replacement costs | عالية |

| المركبات | Modern vehicle headlight assemblies | Balanced properties and lightweight | تعقيد التصنيع العالي | متوسطة إلى عالية |

This analysis provides valuable insights for B2B buyers in various international markets, helping them make informed decisions regarding headlight installation costs and material selection.

In-depth Look: Manufacturing Processes and Quality Assurance for headlight installation cost

What Are the Key Stages in the Manufacturing Process of Headlight Assemblies?

The manufacturing of headlight assemblies involves several critical stages, each designed to ensure the final product meets safety and quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

تحضير المواد: This initial stage involves sourcing high-quality materials such as polycarbonate or acrylic for the lens, aluminum or plastic for the housing, and various electrical components. Suppliers must provide materials that meet international quality standards to ensure durability and performance.

-

تشكيل: In this stage, the raw materials are shaped into components. For lenses, processes like injection molding or blow molding are commonly used. The precision in this phase is crucial, as any imperfections can affect the light output and overall performance of the headlight.

-

الجمعية: The assembly process involves integrating various components, including the lens, housing, bulbs (halogen, HID, or LED), and wiring. Automated systems often assist in this phase to enhance efficiency and consistency. Quality control measures are implemented here to ensure that all components fit correctly and function as intended.

-

التشطيب: The final stage involves applying coatings to the lens to enhance clarity and protect against UV damage, as well as assembling the final product. This may include additional testing for light output and durability before the product is packaged for distribution.

What International Standards Should B2B Buyers Consider for Quality Assurance?

For B2B buyers, understanding international quality standards is essential when sourcing headlight assemblies. The most relevant standards include ISO 9001, which focuses on quality management systems, and specific automotive standards such as ISO/TS 16949. Additionally, regional standards such as CE marking in Europe and API certifications can also be relevant.

-

آيزو 9001: This standard ensures that manufacturers have quality management systems in place that consistently produce products that meet customer and regulatory requirements.

-

ISO/TS 16949: Specifically for the automotive industry, this standard focuses on continuous improvement, defect prevention, and the reduction of variation and waste in the supply chain.

-

علامة CE: In Europe, CE marking indicates that the product meets EU safety, health, and environmental protection requirements, which is crucial for headlight assemblies used in vehicles.

-

API Certification: While more common in the oil and gas industry, API standards can sometimes apply to automotive components, particularly those involving lubrication and electrical systems.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في عملية التصنيع؟

Quality control (QC) is vital in ensuring that headlight assemblies are reliable and safe. The following checkpoints are commonly utilized throughout the manufacturing process:

Illustrative image related to headlight installation cost

-

مراقبة الجودة الواردة (IQC): At this initial checkpoint, raw materials and components are inspected upon arrival to ensure they meet specified standards. This includes checking for physical dimensions, material properties, and compliance with relevant certifications.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During the manufacturing process, various inspections occur to ensure that each stage meets quality standards. This may include monitoring temperature and pressure during forming and assessing assembly alignment.

-

مراقبة الجودة النهائية (FQC): After assembly, a comprehensive evaluation is conducted. This includes functional testing of the headlight’s brightness, durability testing under various conditions, and verification against regulatory compliance.

What Common Testing Methods Are Used in Headlight Assembly Quality Assurance?

Various testing methods are employed to ensure that headlight assemblies perform safely and effectively:

-

اختبار القياس الضوئي: This method evaluates the light output and distribution patterns of headlight assemblies. It ensures that the lights meet required brightness levels and do not cause glare to oncoming drivers.

-

اختبار المتانة: This involves subjecting headlight assemblies to extreme temperatures, humidity, and vibration to simulate real-world conditions. The goal is to assess how well the assemblies hold up over time.

-

الاختبارات الكهربائية: For headlight assemblies that include electrical components, tests are conducted to ensure proper function and safety. This includes checking for short circuits and verifying that the electrical connections are secure.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Here are some strategies to consider:

-

تدقيق الموردين: Conducting regular audits of potential suppliers is a critical step. This includes reviewing their manufacturing processes, quality control measures, and compliance with international standards.

-

طلب تقارير الجودة: Suppliers should provide detailed quality reports that outline their testing procedures, results, and any corrective actions taken in response to failures. This documentation is essential for transparency.

-

عمليات التفتيش من قبل أطراف ثالثة: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can be particularly valuable for international suppliers, where buyers may not have direct oversight.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance:

-

فهم المعايير الإقليمية: Familiarity with local regulations and standards is crucial. For example, European buyers must ensure compliance with CE marking, while buyers in Africa may face different regulatory requirements.

-

الخدمات اللوجستية ومخاطر سلسلة التوريد: International shipping can introduce risks that affect product quality. Delays, temperature fluctuations, and handling can impact sensitive components like headlight assemblies. Buyers should work with suppliers who have robust logistics strategies.

-

Cultural and Communication Differences: Effective communication is vital when dealing with international suppliers. Misunderstandings can lead to quality issues, so establishing clear expectations and regular communication channels is essential.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing headlight assemblies, ensuring that they invest in products that meet the highest safety and performance standards.

Illustrative image related to headlight installation cost

Practical Sourcing Guide: A Step-by-Step Checklist for ‘headlight installation cost’

مقدمة

This guide provides a comprehensive checklist for B2B buyers looking to understand and manage the costs associated with headlight installation. Given the variety of headlight types and the complexities of installation, following these steps will ensure a well-informed procurement process, ultimately leading to safer vehicles and satisfied customers.

الخطوة 1: تقييم متطلبات مركبتك

Understanding the specific needs of your fleet or inventory is crucial. Different vehicles require different headlight types, such as halogen, HID, or LED. Make sure to gather information on the make, model, year, and trim level of each vehicle to ensure you source the correct components.

- الاعتبارات الرئيسية: Certain vehicles may require entire headlight assemblies instead of just bulbs, which can significantly impact costs.

الخطوة 2: Define Your Budget Parameters

Establish a clear budget for headlight installation, including both parts and labor. The cost can vary widely—from $10 for a simple bulb replacement to several thousand dollars for advanced lighting systems.

Illustrative image related to headlight installation cost

- Cost Breakdown: Include potential additional costs such as labor, which can range from $30 to $300, especially for complex installations requiring bumper removal.

الخطوة 3: تحديد الموردين الموثوق بهم

Research and select suppliers who specialize in automotive lighting solutions. Reliable suppliers will offer quality parts that meet regulatory standards and have a good reputation in the industry.

- Supplier Verification: Request certifications and check for compliance with local regulations, particularly focusing on suppliers who provide products with DOT certification.

الخطوة 4: Evaluate Installation Options

Decide whether to perform the installation in-house or outsource it to professionals. If you opt for in-house installation, ensure your team is adequately trained.

- Training Resources: Consider investing in training programs or materials to equip your team with the necessary skills for safe and efficient installation.

الخطوة 5: مراجعة سياسات الضمان والإرجاع

Before finalizing your purchase, carefully review the warranty and return policies offered by suppliers. This is critical in the automotive industry, where the quality of parts can vary significantly.

- ما الذي يجب البحث عنه: Ensure the warranty covers defects and installation issues, and understand the return process in case the components do not meet your expectations.

الخطوة 6: Plan for Future Maintenance

Incorporate a maintenance schedule to regularly check and replace headlight components as needed. This proactive approach can prevent safety issues and enhance the longevity of your vehicles.

- Maintenance Tips: Keep an inventory of common replacement parts on hand and consider using restoration kits for cloudy lenses to extend the life of headlight assemblies.

الخطوة 7: Compare Total Cost of Ownership (TCO)

Beyond the initial purchase price, consider the total cost of ownership for different headlight types. LED lights may be more expensive upfront but offer longer lifespans and lower energy consumption, reducing overall costs.

- Long-Term Savings: Analyze the lifespan and performance of various options to make informed decisions that align with your operational budget and safety standards.

By following this structured checklist, B2B buyers can effectively navigate the complexities of headlight installation costs, ensuring they make informed decisions that enhance vehicle safety and operational efficiency.

Comprehensive Cost and Pricing Analysis for headlight installation cost Sourcing

What Are the Key Cost Components in Headlight Installation?

When analyzing the costs associated with headlight installation, several components contribute to the overall expenditure. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control, logistics, and margins.

المواد: The type of headlight chosen significantly affects material costs. Halogen bulbs are generally less expensive, ranging from $10 to $40 per unit, while high-intensity discharge (HID) and LED bulbs can cost significantly more, sometimes exceeding $150 for a single unit. The complexity of the headlight assembly can also drive up material costs, especially for vehicles requiring advanced lighting systems.

Illustrative image related to headlight installation cost

العمل: Labor costs vary based on the region and the complexity of the installation. Simple bulb replacements can cost around $30 to $100 when performed by a professional, while more complicated installations, such as those requiring bumper removal, can escalate to several hundred dollars. Labor rates may differ significantly across markets, particularly between developed and developing regions.

نفقات التصنيع الزائدة والأدوات: Overhead costs include expenses related to production facilities, equipment maintenance, and utilities. Tooling costs are also relevant, particularly for custom or specialized headlight designs. Investing in quality tooling can lead to better efficiency and reduced long-term costs.

مراقبة الجودة (QC): Ensuring that headlight products meet safety standards incurs additional costs. QC processes are essential for maintaining product reliability and compliance, especially when dealing with international markets that may have varying standards and regulations.

اللوجستيات: Transportation costs can fluctuate based on distance, shipping methods, and Incoterms. For international buyers, understanding these logistics costs is crucial for budgeting effectively. Costs may vary significantly between regions such as Africa, South America, and Europe.

Illustrative image related to headlight installation cost

الهامش: Suppliers typically apply a markup to their costs to ensure profitability. This margin can vary based on market demand, competition, and the perceived value of the product.

What Influences Pricing in Headlight Installation?

Several factors influence the pricing of headlight installations, including volume or minimum order quantities (MOQs), specifications, materials used, quality certifications, supplier-related factors, and Incoterms.

الحجم/الحد الأدنى للطلب: Purchasing in bulk can lead to significant discounts. Suppliers often provide better pricing for larger orders, making it advantageous for businesses looking to reduce per-unit costs.

Illustrative image related to headlight installation cost

المواصفات والتخصيص: Custom specifications can lead to higher costs, particularly if unique designs or features are required. Buyers should weigh the benefits of customization against the potential for increased expenses.

المواد والجودة: The choice of materials directly impacts pricing. Higher-quality materials often come with a higher price tag but may offer better durability and performance, resulting in a lower Total Cost of Ownership (TCO) over time.

الشهادات: Products that comply with international safety and quality standards may incur additional costs. However, these certifications can enhance marketability and ensure compliance in various regions.

Illustrative image related to headlight installation cost

عوامل الموردين: The reliability, reputation, and location of suppliers can significantly affect pricing. Engaging with reputable suppliers who adhere to quality standards can mitigate risks associated with product failures.

مصطلحات التجارة الدولية: Understanding Incoterms is essential for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can have a substantial impact on overall costs.

What Are Some Tips for Buyers to Optimize Headlight Installation Costs?

B2B buyers can adopt several strategies to optimize costs associated with headlight installations.

التفاوض: Effective negotiation can yield better pricing and terms. Building strong relationships with suppliers can create opportunities for discounts and favorable payment terms.

الفعالية من حيث التكلفة: Assessing the Total Cost of Ownership is crucial. While initial costs may be lower for cheaper bulbs, consider the lifespan and performance to avoid frequent replacements.

الفروق الدقيقة في الأسعار للمشترين الدوليين: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local market conditions. These factors can significantly affect pricing and should be factored into any purchasing decision.

Illustrative image related to headlight installation cost

إخلاء المسؤولية عن الأسعار الإرشادية: Pricing for headlight installation can vary widely based on numerous factors, including vehicle type, market conditions, and supplier relationships. Therefore, it is essential for buyers to conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing headlight installation cost With Other Solutions

Understanding Alternatives to Headlight Installation Costs

In the realm of automotive maintenance, understanding the cost implications of headlight installation is crucial for B2B buyers. However, there are alternative solutions that may offer comparable benefits while varying significantly in cost and implementation. This section delves into the alternatives to traditional headlight installation, allowing businesses to make informed decisions based on their specific needs and circumstances.

جدول المقارنة

| جانب المقارنة | Headlight Installation Cost | أطقم ترميم المصابيح الأمامية | Upgraded Lighting Technologies |

|---|---|---|---|

| الأداء | High; depends on bulb type | Moderate; restores clarity | Very High; enhanced visibility |

| التكلفة | $20 – $3,000+ | $25 – $150 | $50 – $7,000+ |

| سهولة التنفيذ | Moderate; may require professionals | Easy; DIY options available | Moderate; often requires professional installation |

| الصيانة | منخفضة؛ استبدلها حسب الحاجة | Moderate; periodic restoration | Low; long-lasting solutions |

| أفضل حالة استخدام | Complete replacement needed | Restoring cloudy lenses | High-performance lighting upgrades |

تفصيل البدائل

1. Headlight Restoration Kits

Headlight restoration kits offer a cost-effective solution for vehicles with cloudy or dull lenses. Typically priced between $25 and $150, these kits allow users to restore headlight clarity, improving performance without replacing the entire assembly. The ease of implementation is a significant advantage, as many kits are designed for DIY use, requiring minimal tools and skills. However, while restoration can enhance visibility temporarily, it may not provide a long-term solution if the headlight assembly itself is failing. Businesses focused on budget-friendly maintenance may find these kits appealing, but they should be aware of the potential need for more frequent restorations.

2. Upgraded Lighting Technologies

Investing in upgraded lighting technologies, such as high-intensity discharge (HID) or light-emitting diode (LED) systems, can significantly enhance a vehicle’s visibility and safety on the road. The cost for these upgrades can range from $50 to over $7,000, depending on the vehicle and the complexity of installation. While the initial investment is higher, these technologies often provide better performance and longevity compared to traditional halogen bulbs. However, installation can be more complex, sometimes requiring professional assistance. For businesses prioritizing safety and performance, upgraded lighting technologies may be the most effective solution, albeit at a higher upfront cost.

Conclusion: Making the Right Choice for Your Business

Selecting the appropriate headlight solution involves evaluating multiple factors, including cost, performance, and ease of implementation. B2B buyers must consider their specific operational needs and budget constraints. For organizations that frequently manage vehicle fleets, investing in upgraded lighting technologies may yield long-term benefits despite higher initial costs. Conversely, those looking for immediate savings might opt for headlight restoration kits or standard bulb replacements. Ultimately, the right choice will align with the business’s goals, ensuring safety and efficiency on the road.

Essential Technical Properties and Trade Terminology for headlight installation cost

What Are the Key Technical Properties Related to Headlight Installation Costs?

When evaluating headlight installation costs, understanding the technical properties involved is crucial for B2B buyers. Here are some essential specifications to consider:

1. درجة المواد

The materials used in headlight assemblies significantly impact durability and performance. Common materials include polycarbonate and acrylic for lenses, while housings may be made from aluminum or high-grade plastics. Higher-grade materials resist UV damage and impact, ensuring longevity and reducing the frequency of replacements. For B2B buyers, investing in higher-quality materials may lead to lower long-term costs and improved customer satisfaction.

2. Light Output (Lumens)

Light output is measured in lumens and indicates the brightness of the headlight. Different types of bulbs (halogen, HID, LED) provide varying lumen outputs, affecting visibility and safety. For instance, LED headlights can produce more lumens than halogen bulbs while consuming less energy. Understanding light output helps businesses meet safety standards and regulations, making it a critical consideration for buyers in the automotive industry.

3. Lifespan (Hours)

The lifespan of a headlight bulb is often measured in hours and varies widely among types. Halogen bulbs typically last 500 to 1,000 hours, while LEDs can reach up to 30,000 hours. This longevity translates into reduced maintenance costs and fewer replacement cycles, making it an essential factor for B2B buyers looking to optimize operational efficiency and cost-effectiveness.

4. Voltage and Power Consumption

Headlight systems operate at specific voltage levels, typically 12V in automotive applications. Power consumption, measured in watts, indicates how much energy the headlight uses. Understanding these specifications helps businesses gauge energy efficiency, which can lead to cost savings in electrical consumption over time. This is particularly relevant for fleet operators aiming to minimize operational costs.

5. Beam Pattern and Adjustability

The beam pattern determines how light is distributed on the road. Proper adjustment is crucial for maximizing visibility without causing glare for other drivers. Features like adaptive lighting and auto-leveling can enhance safety and performance. B2B buyers should prioritize products that offer adjustable beam patterns to comply with local regulations and enhance user safety.

Illustrative image related to headlight installation cost

What Are Common Trade Terms Related to Headlight Installation Costs?

Navigating the technical landscape of headlight installation costs also involves understanding industry-specific terminology. Here are several key terms:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the vehicle’s original manufacturer. These components generally guarantee compatibility and performance, often justifying higher costs. B2B buyers should consider OEM parts for reliability and warranty assurance, particularly in high-stakes applications.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory and cash flow effectively. For headlight assemblies, an MOQ can help ensure that buyers receive the best pricing while maintaining adequate stock.

3. طلب عرض أسعار (RFQ)

An RFQ is a formal process through which buyers request pricing information from suppliers. For headlight installation costs, submitting an RFQ can help businesses compare prices and services, ensuring they secure the best possible deal.

Illustrative image related to headlight installation cost

4. شروط التجارة الدولية (Incoterms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers engaged in cross-border transactions, as they can significantly impact the overall cost of headlight installations.

5. فترة الضمان

The warranty period is the duration during which a product is guaranteed against defects. Knowing the warranty terms for headlight assemblies can help buyers mitigate risks associated with defective products and ensure long-term satisfaction.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding headlight installation costs, leading to better procurement strategies and enhanced operational efficiency.

Illustrative image related to headlight installation cost

Navigating Market Dynamics and Sourcing Trends in the headlight installation cost Sector

What Are the Current Market Dynamics Influencing Headlight Installation Costs?

The global market for headlight installation costs is shaped by several dynamic factors. Notably, the shift towards advanced lighting technologies such as LEDs and HIDs is driving up replacement costs. As vehicles become increasingly equipped with sophisticated lighting systems that offer improved visibility and safety features, the complexity of installation and repair has also escalated. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these trends is crucial. For instance, the labor costs associated with replacing modern headlight assemblies can vary significantly based on local regulations and skill availability.

Furthermore, the trend towards modular designs in headlight assemblies means that buyers must be prepared for higher upfront costs, even as these systems often promise longer lifespans and reduced maintenance needs. The emergence of online platforms for sourcing automotive parts has also changed how B2B buyers approach procurement, enabling them to compare prices and suppliers with greater ease. In regions where vehicle maintenance infrastructure is still developing, partnerships with local suppliers who understand the nuances of the market can be invaluable.

How Is Sustainability Shaping the Sourcing of Headlight Installation Costs?

Sustainability is becoming an essential consideration in the sourcing of headlight installation components. The environmental impact of automotive manufacturing and waste management is prompting buyers to seek out suppliers who prioritize ethical sourcing and sustainable practices. This includes the use of recyclable materials in headlight assemblies and bulbs, as well as the implementation of energy-efficient manufacturing processes.

B2B buyers should look for suppliers that possess relevant green certifications, which can provide assurance of the ethical standards upheld in their operations. Additionally, the adoption of sustainable practices can lead to long-term cost savings, as energy-efficient products typically have lower operational costs over their lifetimes. As consumers increasingly demand environmentally responsible products, businesses that align with these values may also benefit from enhanced brand reputation and customer loyalty.

What Is the Historical Context Behind Headlight Installation Costs?

Historically, headlight systems were simpler and more uniform, primarily consisting of incandescent bulbs that were easy and inexpensive to replace. However, as automotive technology has evolved, so too have the complexities of headlight systems. The introduction of halogen, HID, and now LED technology has transformed the landscape, often resulting in higher costs for both parts and labor.

In the past two decades, regulatory changes have also influenced headlight designs, pushing manufacturers towards more efficient and longer-lasting solutions. Today, B2B buyers must navigate a more intricate market characterized by a diverse range of products and installation requirements, making informed sourcing decisions more critical than ever. Understanding these historical shifts can provide valuable insights into current pricing structures and market expectations, particularly for international buyers seeking to optimize their procurement strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of headlight installation cost

-

How do I calculate the total cost of headlight installation for my fleet?

To accurately calculate the total cost of headlight installation for your fleet, consider the type of headlight bulbs required (halogen, HID, or LED), the number of vehicles, and the labor costs associated with installation. Typically, halogen bulbs are the most economical, while LEDs or HIDs can be significantly more expensive. Don’t forget to account for any additional costs related to replacing headlight assemblies or restoring lenses. It’s advisable to get quotes from multiple suppliers to ensure competitive pricing. -

ما هو أفضل نوع من المصابيح الأمامية للمركبات التجارية؟

For commercial vehicles, LED headlights are often the best choice due to their longevity, energy efficiency, and superior brightness. They typically last longer than halogen or HID bulbs, reducing replacement frequency and maintenance costs. However, initial costs can be higher. It’s essential to consider the specific needs of your vehicles, such as visibility requirements and environmental conditions, when making your selection. Consulting with industry experts can also provide tailored recommendations. -

How can I ensure quality when sourcing headlight replacements internationally?

To ensure quality when sourcing headlight replacements from international suppliers, consider the following steps: verify that the supplier adheres to international quality standards (such as ISO certifications), request product samples for testing, and review customer feedback and testimonials. Additionally, conducting a factory audit can help assess the supplier’s production processes and quality control measures. Establishing a clear quality assurance protocol in your contracts can further safeguard your interests. -

What are the typical minimum order quantities (MOQs) for headlight installations?

Minimum order quantities (MOQs) for headlight installations can vary widely based on the supplier and the type of headlights being sourced. Generally, MOQs can range from 100 to 1,000 units for bulk orders. It’s important to communicate your needs directly with suppliers to negotiate MOQs that align with your purchasing capabilities. Some suppliers may offer flexibility for new clients or larger contracts. -

ما هي شروط الدفع التي يجب أن أتوقعها عند الحصول على المصابيح الأمامية دولياً؟

Payment terms for international sourcing of headlights typically include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit of 30-50% upfront, with the balance due upon shipment or delivery. It’s crucial to clarify payment terms in advance and ensure they are documented in your contract to avoid misunderstandings. Additionally, consider using secure payment methods to protect your transactions. -

How can I vet suppliers for headlight installation projects?

Vetting suppliers for headlight installation projects involves a thorough assessment of their capabilities, reputation, and compliance with industry standards. Start by checking their business credentials, including registration and relevant certifications. Look for reviews or ratings from previous clients, and request references. Engaging in direct communication can also provide insights into their customer service and responsiveness. Utilizing platforms that specialize in supplier ratings can aid in making informed decisions. -

What logistics considerations should I keep in mind when importing headlights?

When importing headlights, several logistics considerations are critical. Assess shipping options based on cost, delivery speed, and reliability. Ensure compliance with local regulations regarding automotive parts to avoid customs delays. Additionally, factor in potential tariffs and duties that may apply upon importation. Collaborating with a logistics provider experienced in international shipping can streamline the process and help navigate any challenges. -

How do I handle warranty and return issues for headlights purchased internationally?

Handling warranty and return issues for internationally sourced headlights requires clear communication with your supplier. Ensure that warranty terms are explicitly stated in your purchase agreement, including the duration and coverage of the warranty. Establish a return policy that outlines the process for defective products, including shipping responsibilities and timelines. Maintaining detailed records of all transactions and communications will facilitate smoother resolutions should issues arise.

Top 1 Headlight Installation Cost Manufacturers & Suppliers List

1. Xenon Pro – Headlight Replacement Cost Guide

المجال: xenonpro.com

مسجل: 2013 (12 سنة)

مقدمة: Headlight Replacement Cost Guide: 1. Factory Halogen Bulb Replacement Cost: $30 – $50 per pair, Lifespan: 1,000+ hours. 2. Factory Xenon HID Bulb Replacement Cost: $50 – $150 per bulb, Lifespan: 10,000+ hours. 3. Factory LED Bulb Replacement Cost: N/A (entire assembly must be replaced), Lifespan: 30,000+ hours. 4. LED Conversion Kit Cost: $60 – $200, Lifespan: 5,000+ hours. 5. Xenon HID Conversion…

Strategic Sourcing Conclusion and Outlook for headlight installation cost

The landscape of headlight installation costs presents both challenges and opportunities for international B2B buyers. Understanding the varying costs associated with different types of headlight systems—ranging from economical halogen bulbs to advanced LED assemblies—allows businesses to make informed purchasing decisions. Strategic sourcing is essential not only for cost management but also for ensuring compliance with safety standards and enhancing vehicle reliability.

As the automotive industry increasingly shifts towards sophisticated lighting technologies, sourcing high-quality components can mitigate long-term expenses. Buyers should prioritize suppliers who offer durable products and robust warranties, as these factors significantly impact total cost of ownership. Additionally, considering the geographical variances in supply chains, establishing relationships with reliable local suppliers can streamline operations and reduce lead times.

Looking ahead, the demand for advanced lighting solutions is set to grow. By investing in strategic sourcing practices today, businesses can position themselves for future success in a competitive market. We encourage international buyers, especially from regions like Africa, South America, the Middle East, and Europe, to leverage these insights to enhance their procurement strategies and drive operational excellence.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.