Introduction: Navigating the Global Market for lifespan of an alternator

In the competitive landscape of the automotive sector, understanding the lifespan of an alternator is crucial for international B2B buyers looking to optimize their procurement strategies. The alternator, a key component in vehicle electrical systems, plays a vital role in ensuring vehicles operate efficiently. However, sourcing reliable alternators that meet varying market demands and conditions presents a significant challenge for buyers, especially in regions like Africa, South America, the Middle East, and Europe, where vehicle usage and maintenance practices differ widely.

This comprehensive guide explores the intricacies of alternator lifespan, covering various types, applications, and performance indicators. It delves into factors that influence durability, such as environmental conditions and vehicle types, while also providing insights into effective supplier vetting processes. Additionally, it addresses cost considerations, helping buyers make informed decisions that align with their operational budgets and quality standards.

By equipping international B2B buyers with actionable insights, this guide empowers them to navigate the complexities of sourcing alternators effectively. With a focus on understanding product specifications, maintenance practices, and market trends, buyers can mitigate risks associated with poor-quality parts and ensure the longevity and reliability of their vehicle fleets. Whether you are based in Nigeria, Brazil, or any other region, this guide serves as an essential resource for strategic procurement and enhanced operational efficiency.

جدول المحتويات

- Top 1 Lifespan Of An Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for lifespan of an alternator

- Understanding lifespan of an alternator Types and Variations

- Key Industrial Applications of lifespan of an alternator

- 3 Common User Pain Points for ‘lifespan of an alternator’ & Their Solutions

- Strategic Material Selection Guide for lifespan of an alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for lifespan of an alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘lifespan of an alternator’

- Comprehensive Cost and Pricing Analysis for lifespan of an alternator Sourcing

- Alternatives Analysis: Comparing lifespan of an alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for lifespan of an alternator

- Navigating Market Dynamics and Sourcing Trends in the lifespan of an alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of lifespan of an alternator

- Strategic Sourcing Conclusion and Outlook for lifespan of an alternator

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding lifespan of an alternator Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولدات القياسية | متوسط عمر افتراضي يبلغ 7 سنوات أو 150,000 ميل | General automotive sectors | الإيجابيات: فعالة من حيث التكلفة ومتوفرة على نطاق واسع. السلبيات: May require frequent replacements. |

| المولدات عالية الأداء | Enhanced durability, designed for extreme conditions | Motorsport, heavy machinery | الإيجابيات: Longer lifespan, better efficiency. السلبيات: تكلفة أولية أعلى. |

| المولدات المعاد تصنيعها | أعيد بناؤها من قطع مستعملة، وتم اختبارها للتأكد من جودتها | Budget-conscious buyers | الإيجابيات: منخفضة التكلفة وصديقة للبيئة. السلبيات: التباين المحتمل في الجودة. |

| مولدات التيار المتردد للخدمة الشاقة | Built to withstand extreme loads and harsh environments | Commercial vehicles, industrial equipment | الإيجابيات: Exceptional durability, reliable under stress. السلبيات: Heavier, may be overkill for light vehicles. |

| المولدات الذكية | Integrated with advanced electronics for optimal performance | السيارات الكهربائية والأنظمة الهجينة | الإيجابيات: Improved efficiency, real-time diagnostics. السلبيات: أكثر تعقيدًا، وتكاليف إصلاح أعلى. |

ما هي الخصائص الرئيسية للمولدات القياسية؟

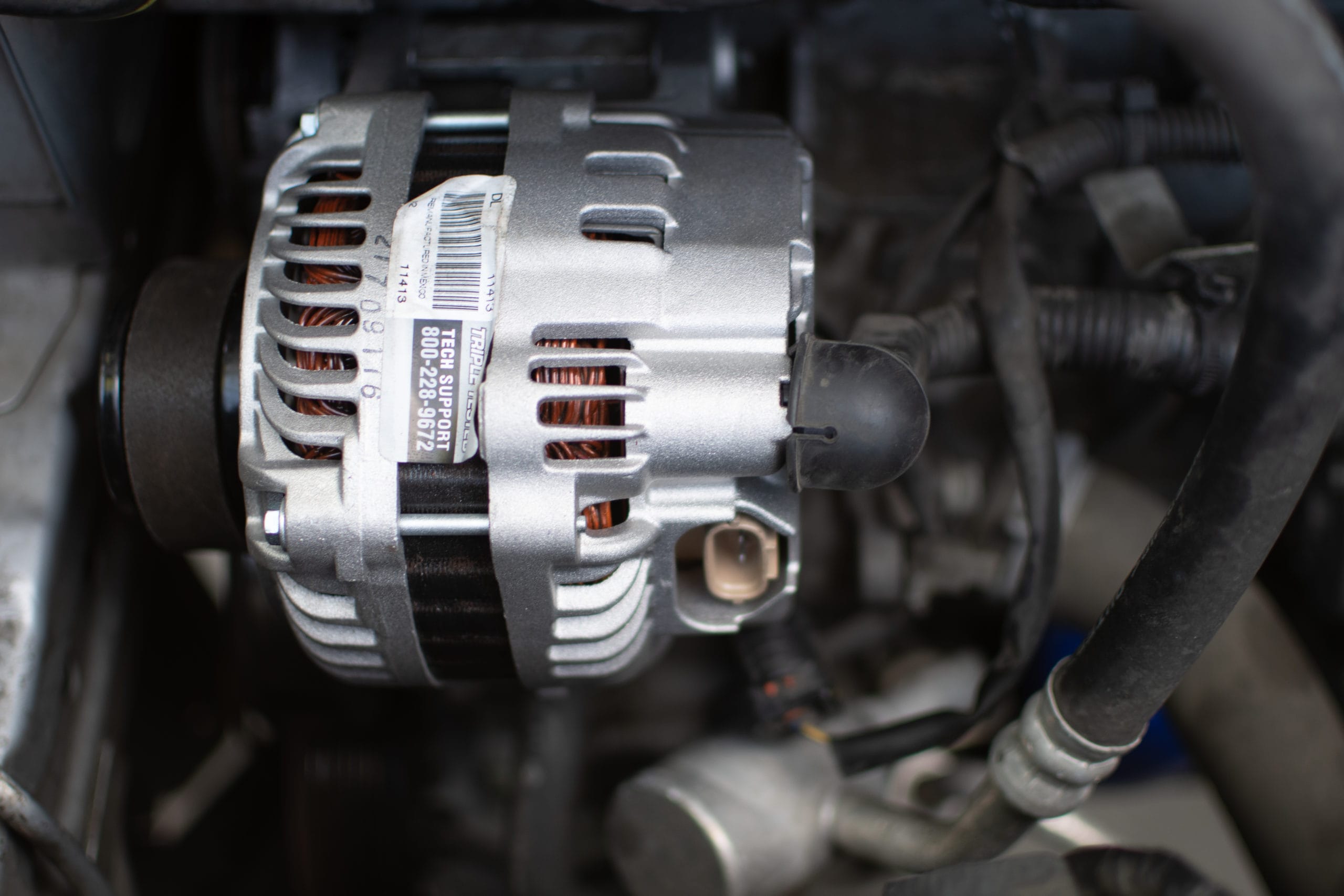

Standard alternators are the most common type found in vehicles, typically offering a lifespan of around seven years or 150,000 miles. They are designed to meet the basic electrical demands of everyday vehicles, making them suitable for general automotive applications. B2B buyers should consider factors such as the reliability of the manufacturer and warranty options, as these can significantly impact long-term operational costs. While they are cost-effective, businesses should prepare for potential replacements as they age.

Illustrative image related to lifespan of an alternator

How Do High-Performance Alternators Differ from Standard Ones?

High-performance alternators are engineered for durability and efficiency, often extending their lifespan beyond that of standard models. They are particularly beneficial in applications like motorsport and heavy machinery, where reliability under extreme conditions is crucial. B2B buyers should evaluate the specific needs of their operations, as the higher initial investment can be justified by reduced downtime and lower maintenance costs in demanding environments.

ما الذي يجب أن يعرفه المشترون عن المولدات المعاد تصنيعها؟

Remanufactured alternators are an economical choice for businesses looking to minimize costs without sacrificing quality. They are rebuilt from used components and subjected to rigorous testing to ensure performance standards. This option is particularly appealing to budget-conscious buyers in sectors where vehicles are frequently in use. However, variability in quality can be a concern, so sourcing from reputable suppliers is essential to mitigate risks.

In What Situations Are Heavy-Duty Alternators Necessary?

Heavy-duty alternators are designed to withstand higher loads and harsh operational conditions, making them ideal for commercial vehicles and industrial applications. Their exceptional durability ensures reliability even under stress, which is critical for businesses that rely on heavy machinery. While they may be heavier and more expensive, the investment can lead to significant savings in maintenance and replacement costs over time.

What Advantages Do Smart Alternators Offer for Electric Vehicles?

Smart alternators integrate advanced electronics that enhance performance and efficiency, making them particularly suitable for electric and hybrid vehicles. They provide real-time diagnostics and adapt to varying electrical demands, which can improve overall vehicle efficiency. B2B buyers should consider the complexity and potential repair costs associated with these systems, as they may require specialized knowledge for maintenance. Despite the higher upfront costs, the long-term benefits often outweigh the initial investment for businesses focused on sustainability and performance.

Illustrative image related to lifespan of an alternator

Key Industrial Applications of lifespan of an alternator

| الصناعة/القطاع | Specific Application of lifespan of an alternator | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | Production of electric vehicles (EVs) | Ensures reliability and longevity of vehicle performance | Quality standards for alternators, sourcing from reputable suppliers |

| الزراعة | Powering irrigation systems and farm machinery | تعزيز الكفاءة التشغيلية وتقليل وقت التعطل | Durability in harsh environments, compatibility with existing systems |

| البناء | Supporting heavy machinery and equipment | Minimizes maintenance costs and maximizes equipment uptime | Robust design, local support for service and parts availability |

| الطاقة المتجددة | التكامل في أنظمة الطاقة الشمسية وطاقة الرياح | Increases system reliability and reduces maintenance frequency | Performance under variable conditions, warranty and service options |

| النقل واللوجستيات | إدارة الأسطول وصيانة المركبات | Improves vehicle reliability, reducing unexpected breakdowns | Supply chain efficiency, availability of spare parts and service support |

How is the lifespan of an alternator critical in automotive manufacturing?

In the automotive manufacturing sector, particularly with the rise of electric vehicles (EVs), the lifespan of an alternator is vital. It ensures that the vehicle’s electrical systems remain functional over time, contributing to overall vehicle reliability. Buyers in this sector must consider quality standards and the reputation of suppliers, as a longer-lasting alternator can significantly reduce warranty claims and maintenance costs. Furthermore, manufacturers should prioritize sourcing alternators that comply with international standards to facilitate global market access.

Why is alternator lifespan important for agricultural applications?

In agriculture, the lifespan of an alternator is crucial for powering irrigation systems and farm machinery. A reliable alternator ensures that equipment operates efficiently, reducing the risk of downtime during critical planting and harvesting seasons. Buyers in this sector should look for alternators designed to withstand harsh environmental conditions, including dust and moisture. Additionally, compatibility with existing systems and ease of maintenance are key considerations, as they can impact overall farm productivity.

What role does alternator lifespan play in construction?

In the construction industry, alternators are essential for powering heavy machinery and equipment. A long-lasting alternator minimizes maintenance costs and maximizes equipment uptime, which is critical for meeting project deadlines. Construction companies should prioritize sourcing robust alternators that can endure the rigorous demands of construction sites. Local support for service and parts availability is also important, as it ensures quick repairs and reduced downtime.

How does alternator lifespan affect renewable energy systems?

For renewable energy systems, such as solar and wind, the lifespan of an alternator is pivotal in maintaining system reliability. A durable alternator reduces the frequency of maintenance and enhances the overall efficiency of energy generation. Buyers in this sector should seek alternators that perform well under variable environmental conditions, ensuring consistent power output. Additionally, warranty and service options should be evaluated to ensure long-term support for these critical systems.

Illustrative image related to lifespan of an alternator

Why is the lifespan of an alternator significant in transportation and logistics?

In transportation and logistics, the lifespan of an alternator directly impacts fleet management and vehicle maintenance. A reliable alternator reduces the likelihood of unexpected breakdowns, which can lead to costly delays and lost revenue. Companies in this sector should focus on supply chain efficiency when sourcing alternators, ensuring that spare parts and service support are readily available. This proactive approach helps maintain vehicle reliability and enhances overall operational efficiency.

3 Common User Pain Points for ‘lifespan of an alternator’ & Their Solutions

Scenario 1: Unexpected Alternator Failures During Operations

المشكلة: B2B buyers, especially in logistics and transportation industries, often face unexpected alternator failures that can halt operations. These failures can lead to costly downtimes, disrupt supply chains, and affect customer satisfaction. For instance, a fleet manager in Nigeria may encounter a scenario where multiple delivery trucks are sidelined due to alternator issues, leading to delayed deliveries and potential loss of contracts. This unpredictability can stem from a lack of comprehensive maintenance protocols and insufficient knowledge about the lifespan of alternators.

الحل: To mitigate the risk of sudden alternator failures, it is crucial to implement a proactive maintenance strategy that includes regular inspections and replacements based on the alternator’s expected lifespan. B2B buyers should establish a maintenance schedule that accounts for the specific operating conditions of their vehicles, such as load capacity, frequency of use, and environmental factors. Investing in quality alternators with proven durability and sourcing them from reputable suppliers can significantly reduce the likelihood of premature failures. Additionally, training staff on the signs of alternator wear and tear can empower them to take timely action, thus minimizing downtime.

Scenario 2: Costly Repairs Due to Ignored Warning Signs

المشكلة: Many B2B buyers overlook the early warning signs of a failing alternator, resulting in costly repairs and increased operational expenses. For example, a construction company in Brazil may ignore dimming headlights or strange noises from the engine, only to face a complete alternator failure that requires not just a replacement but also damages to other electrical components. This neglect can significantly inflate repair costs and lead to unnecessary delays in project timelines.

Illustrative image related to lifespan of an alternator

الحل: B2B buyers should prioritize regular training for their maintenance teams on identifying and addressing early warning signs of alternator failure. Implementing a checklist that includes monitoring for symptoms such as fluctuating voltage, unusual noises, and dashboard warning lights can help catch issues before they escalate. Establishing a partnership with a trusted automotive service provider can also facilitate routine diagnostics and timely interventions. Additionally, investing in diagnostic tools that monitor the vehicle’s electrical system can provide real-time data, allowing for proactive measures that prevent costly repairs.

Scenario 3: Difficulty in Sourcing Reliable Alternators

المشكلة: Sourcing high-quality alternators that meet specific operational needs can be a daunting task for B2B buyers, particularly in regions with less established automotive supply chains, such as the Middle East. A manufacturing company may struggle to find alternators that not only fit their vehicles but also offer the durability required for heavy use. This challenge can lead to extended search times, increased costs, and potential operational delays.

الحل: To overcome sourcing difficulties, B2B buyers should develop a network of reliable suppliers who specialize in automotive parts, particularly alternators. Conducting thorough research and leveraging industry connections can help identify reputable manufacturers that offer high-quality products at competitive prices. Additionally, buyers should specify their requirements clearly, including the intended application, load demands, and any environmental conditions the alternator will face. Establishing long-term partnerships with suppliers can also lead to better pricing, improved product availability, and access to the latest innovations in alternator technology. Regularly reviewing supplier performance and seeking feedback from maintenance teams can further enhance sourcing strategies and ensure that only the best products are integrated into operations.

Strategic Material Selection Guide for lifespan of an alternator

What Are the Key Materials Used in Alternator Manufacturing?

When selecting materials for alternator components, several factors influence their lifespan, including temperature resistance, corrosion resistance, and overall durability. Here, we analyze four common materials used in alternator construction: aluminum, copper, steel, and plastic.

How Does Aluminum Impact the Lifespan of an Alternator?

Aluminum is frequently used in alternator housings due to its lightweight and excellent thermal conductivity. It typically withstands temperatures up to 150°C and is resistant to corrosion, making it suitable for various environments.

الإيجابيات: Aluminum’s lightweight nature contributes to improved fuel efficiency in vehicles. Additionally, its resistance to rust and corrosion extends the lifespan of the alternator, particularly in humid or coastal regions.

السلبيات: While aluminum is durable, it can be less robust than steel under high stress or impact conditions. The manufacturing process for aluminum can also be more complex, potentially increasing production costs.

التأثير على التطبيق: Aluminum is compatible with electrical components and provides a good barrier against environmental factors, making it ideal for automotive applications.

اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM and ISO is crucial. In regions like Africa and South America, where road conditions can be harsh, aluminum’s lightweight properties may be beneficial, but buyers should ensure that the alloy used meets local durability expectations.

ما الدور الذي يلعبه النحاس في كفاءة المولد؟

Copper is predominantly used for wiring and windings within alternators due to its superior electrical conductivity, which is essential for efficient power generation. It can handle high temperatures up to 200°C, making it suitable for high-performance applications.

الإيجابيات: The high conductivity of copper minimizes energy loss, enhancing the alternator’s efficiency. Its durability ensures a long lifespan when properly insulated.

السلبيات: Copper is more expensive than aluminum and can be prone to corrosion if not adequately protected. The weight of copper can also contribute to overall vehicle weight, which may be a concern for some manufacturers.

التأثير على التطبيق: Copper’s excellent conductivity makes it ideal for applications requiring high power output, but its weight and cost must be considered in the overall design.

اعتبارات للمشترين الدوليين: Buyers should be aware of the copper supply chain and pricing fluctuations, especially in regions like the Middle East, where import tariffs may affect overall costs.

Illustrative image related to lifespan of an alternator

كيف يساهم الفولاذ في السلامة الهيكلية للمولدات؟

Steel is often used in the fabrication of alternator brackets and internal components due to its high strength and durability. It can withstand high temperatures and pressures, making it suitable for demanding automotive environments.

الإيجابيات: Steel’s robustness ensures that alternator components can endure significant mechanical stress, contributing to the overall reliability of the alternator.

السلبيات: The heavier weight of steel can negatively impact vehicle efficiency. Additionally, steel is susceptible to rust and corrosion if not treated properly, which can shorten the alternator’s lifespan.

التأثير على التطبيق: Steel components are ideal for high-stress applications, but manufacturers must ensure proper coatings or treatments to prevent corrosion.

اعتبارات للمشترين الدوليين: Compliance with DIN and JIS standards is essential for steel components. In regions with high humidity, such as parts of Africa and South America, corrosion-resistant coatings are recommended.

What Benefits Does Plastic Offer in Alternator Design?

Plastic is increasingly used in alternators for non-structural components, such as covers and insulation. It offers a lightweight alternative while providing sufficient thermal and electrical insulation.

الإيجابيات: The use of plastic reduces overall weight, which can enhance vehicle performance. Additionally, plastics can be molded into complex shapes, allowing for innovative designs.

السلبيات: Plastic is generally less durable than metals and can degrade over time, especially when exposed to high temperatures or UV light.

Illustrative image related to lifespan of an alternator

التأثير على التطبيق: While suitable for insulating purposes, plastic’s limitations in strength and durability must be considered in the design phase.

اعتبارات للمشترين الدوليين: Buyers should ensure that plastics meet relevant standards for automotive applications, especially in regions with extreme temperatures, such as the Middle East.

جدول ملخص لاختيار المواد للمولدات الكهربائية

| المواد | Typical Use Case for lifespan of an alternator | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | المساكن والمكونات الهيكلية | خفيف الوزن ومقاوم للتآكل | أقل متانة من الفولاذ | متوسط |

| النحاس | الأسلاك واللفات | موصلية كهربائية عالية | Expensive and heavy | عالية |

| الصلب | الأقواس والمكونات الداخلية | قوة ومتانة عالية | عرضة للصدأ | متوسط |

| بلاستيك | الأغطية والعزل | خفيف الوزن وقابل للتشكيل | أقل متانة من المعادن | منخفض |

By understanding the properties and implications of these materials, B2B buyers can make informed decisions that enhance the performance and longevity of alternators in various applications across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for lifespan of an alternator

ما هي المراحل الرئيسية لتصنيع المولد؟

The manufacturing process of an alternator is intricate and comprises several critical stages that ensure its durability and reliability. Each phase plays a vital role in determining the lifespan of the alternator, making it essential for B2B buyers to understand these processes.

كيف يتم تحضير المواد لتصنيع المولد؟

The first step in alternator production involves careful material preparation. High-grade materials such as aluminum, copper, and steel are commonly used due to their excellent conductivity and durability. The selection of materials is crucial, as they directly impact the alternator’s efficiency and lifespan.

Illustrative image related to lifespan of an alternator

Manufacturers typically conduct thorough material inspections to ensure that only the highest quality materials are used. This may involve checking for purity levels, tensile strength, and resistance to corrosion. Non-destructive testing methods, such as ultrasonic testing, can also be employed to identify any defects in the materials before they are processed.

ما هي تقنيات التشكيل المستخدمة في إنتاج المولد؟

Once the materials are prepared, the next phase is forming. This includes several processes such as casting, machining, and stamping.

-

اختيار الممثلين This method is often used for the alternator housing, where molten metal is poured into molds to create the desired shape.

-

التصنيع الآلي: Precision machining is essential for components like the rotor and stator. This process involves cutting, drilling, and grinding to achieve the exact dimensions and tolerances required for optimal performance.

-

الختم: Stamping is commonly used for the production of various metal parts, including brackets and end plates. This technique allows for high-volume production with minimal waste.

Each of these techniques must adhere to strict tolerances to ensure compatibility between the alternator components, which is vital for overall performance and longevity.

كيف يتم التجميع في تصنيع المولدات الكهربائية؟

The assembly stage is where all the individual components come together to form a complete alternator. This process typically includes:

-

تكامل المكونات: Skilled technicians or automated systems assemble the rotor, stator, bearings, and other critical parts.

-

الأسلاك: The electrical connections are made with precision to ensure proper current flow. High-quality insulation is used to prevent short circuits and other electrical failures.

-

الاختبار أثناء التجميع: During assembly, preliminary tests are often conducted to verify the functionality of individual components, such as electrical resistance and mechanical integrity.

This phase is crucial for ensuring that each alternator meets the necessary performance standards before moving on to the finishing stage.

ما هي عمليات التشطيب التي يتم تطبيقها على المولدات؟

Finishing processes enhance the alternator’s performance and durability. This may include:

-

المعالجة السطحية: Techniques such as anodizing or powder coating are applied to prevent corrosion and wear, particularly for components exposed to harsh environments.

-

Final Assembly Testing: Once the alternator is fully assembled, it undergoes rigorous final testing. This may involve checking voltage output, current flow, and overall operational efficiency.

-

Quality Assurance Documentation: Every alternator that passes the final tests is documented, which is crucial for traceability and quality assurance purposes.

What Quality Control Measures Are Implemented in Alternator Manufacturing?

Quality control (QC) is a critical aspect of alternator manufacturing, particularly for international B2B buyers who require assurance of product reliability and compliance with industry standards.

Which International Standards Are Relevant for Alternator QC?

Manufacturers often adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards ensures that manufacturers have processes in place to consistently deliver quality products.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for components used in automotive applications are essential. These certifications not only validate the quality of the alternators but also facilitate easier entry into international markets.

Illustrative image related to lifespan of an alternator

ما هي نقاط التحكم الرئيسية في الجودة في إنتاج المولدات الكهربائية؟

يتم دمج نقاط فحص مراقبة الجودة في جميع مراحل عملية التصنيع:

-

مراقبة الجودة الواردة (IQC): At this stage, raw materials are inspected for defects and compliance with specifications before they enter production.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During the manufacturing stages, real-time monitoring is performed to catch any deviations from quality standards early. This involves regular inspections and testing of components.

-

مراقبة الجودة النهائية (FQC): After assembly, a comprehensive evaluation is conducted to ensure the finished product meets all performance and safety requirements.

These checkpoints are designed to minimize defects and enhance the overall quality of the alternators produced.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

B2B buyers can take several steps to verify a supplier’s quality control practices:

-

عمليات تدقيق الموردين: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality management systems. This helps ensure that they adhere to international standards and best practices.

-

طلب تقارير الجودة: Buyers should request detailed quality reports, including results from IQC, IPQC, and FQC processes. These documents can provide transparency regarding the supplier’s commitment to quality.

-

عمليات التفتيش من طرف ثالث: Engaging third-party inspection services can offer an additional layer of assurance. Independent inspectors can verify compliance with industry standards and assess the overall quality of the alternators.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different markets may have varying regulatory requirements, and what is considered standard practice in one region may not be acceptable in another.

-

الاعتبارات الثقافية: Buyers should be aware of cultural differences that may affect supplier relationships. Building trust and clear communication can facilitate smoother transactions.

-

الامتثال التنظيمي: Familiarizing oneself with the specific regulatory requirements in the buyer’s country can help in selecting suppliers that are compliant with local laws.

-

التوثيق وإمكانية التتبع: Ensuring that suppliers maintain comprehensive documentation of their quality control processes is crucial for accountability. This can also aid in future warranty claims or product recalls.

By understanding the manufacturing processes and quality assurance measures involved in alternator production, B2B buyers can make informed decisions, ensuring they procure reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lifespan of an alternator’

In the competitive landscape of automotive parts procurement, understanding the lifespan of an alternator is crucial for B2B buyers. This guide serves as a comprehensive checklist to ensure you make informed decisions when sourcing alternators for your business, ultimately enhancing your supply chain efficiency and product reliability.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Start by clearly defining the technical specifications required for the alternators you intend to procure. Consider factors such as power output, size, and compatibility with specific vehicle models. These specifications will help you narrow down potential suppliers and ensure that the alternators meet the performance needs of your clients.

الخطوة 2: Research the Expected Lifespan

Understanding the expected lifespan of alternators is vital. Typically, alternators can last between 7 to 10 years or approximately 150,000 miles, but this can vary based on usage and maintenance. Inquire about the average lifespan of the products from different suppliers, and consider how their offerings compare to industry standards.

الخطوة 3: تقييم الموردين المحتملين

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers who have a proven track record of reliability and quality in their alternator offerings, as this will significantly impact your business operations.

الخطوة 4: Verify Quality Standards and Certifications

Ensure that potential suppliers adhere to recognized quality standards and certifications. Look for ISO certifications or compliance with regional automotive industry standards. This step is crucial as it guarantees that the alternators have undergone rigorous testing, ensuring safety and performance.

الخطوة 5: Assess Warranty and Support Services

Evaluate the warranty terms offered by suppliers for their alternators. A comprehensive warranty can indicate the manufacturer’s confidence in their product and provide peace of mind for your business. Additionally, inquire about after-sales support services, such as installation assistance and troubleshooting guidance, which can be invaluable.

الخطوة 6: طلب عينة من المنتجات

Before finalizing a bulk order, request samples of the alternators you intend to purchase. This allows you to assess the quality, functionality, and compatibility with your existing systems. Testing samples in real-world conditions can help identify any potential issues before committing to a larger order.

الخطوة 7: إنشاء قنوات اتصال واضحة

Maintain open lines of communication with your suppliers throughout the sourcing process. Clear communication ensures that any potential issues can be addressed promptly and that you receive updates regarding production timelines, shipping, and any changes in specifications. This collaborative approach will foster a stronger partnership and improve your overall procurement experience.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing alternators, ensuring they select high-quality products that meet their operational needs while optimizing their supply chain.

Comprehensive Cost and Pricing Analysis for lifespan of an alternator Sourcing

ما هي المكونات الرئيسية لتكلفة شراء المولدات الكهربائية؟

When sourcing alternators, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

المواد: The core components of an alternator—such as copper windings, magnets, and casings—greatly influence the overall cost. High-quality materials may lead to a higher upfront investment but can significantly enhance longevity and performance.

-

العمل: Labor costs can vary significantly based on geographical location and manufacturing practices. In regions with lower labor costs, such as parts of Africa or South America, the manufacturing expense can be reduced, but this might impact the quality if not managed properly.

-

تكاليف التصنيع العامة: This encompasses indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing practices can help minimize these costs, potentially leading to more competitive pricing.

-

الأدوات: Tooling costs are associated with the machinery and tools required for production. Custom tooling can increase initial costs but may be necessary for specific alternator designs or large volume orders.

-

مراقبة الجودة (QC): Implementing stringent QC measures ensures that the alternators meet required specifications and certifications. While this adds to the cost, it can prevent future expenses related to failures and warranty claims.

-

اللوجستيات: Transportation and shipping costs are critical, especially for international transactions. Factors such as distance, shipping method, and Incoterms can significantly influence logistics costs.

-

الهامش: The profit margin varies by supplier and market conditions. Buyers should be aware of the typical margins in their region to negotiate effectively.

كيف تؤثر العوامل المؤثرة في الأسعار على تكاليف المولد؟

Several factors can influence the pricing of alternators, especially in international markets.

-

الحجم/الحد الأدنى للطلب: Minimum order quantities (MOQs) can lead to discounts. Bulk purchases typically lower the per-unit price, making it essential for buyers to assess their needs accurately.

-

المواصفات/التخصيص: Custom specifications can increase costs. Buyers should weigh the benefits of tailored products against the potential for higher prices and longer lead times.

-

المواد: The choice of materials directly impacts pricing. Premium materials may enhance performance but also elevate costs. Balancing quality and price is essential for long-term value.

-

الجودة/الشهادات: Products with recognized quality certifications may carry higher prices, but they often provide assurance of reliability. Buyers should consider the long-term implications of investing in certified products.

-

عوامل الموردين: Supplier reputation, reliability, and service capabilities can influence pricing. Engaging with established suppliers may come at a premium but can offer better support and lower risk.

-

مصطلحات التجارة الدولية: Understanding Incoterms is crucial for international buyers. They dictate shipping responsibilities and costs, impacting the total landed cost of the alternators.

What Tips Can Help Buyers Optimize Costs in Alternator Sourcing?

For B2B buyers, especially from emerging markets in Africa, South America, the Middle East, and Europe, strategic sourcing can yield significant savings.

-

التفاوض: Leverage volume purchasing to negotiate better terms. Being informed about market rates and competitor pricing can enhance negotiating power.

-

الفعالية من حيث التكلفة: Analyze total cost of ownership (TCO) rather than just upfront costs. Consider factors such as lifespan, warranty, and maintenance to determine the true value.

-

الفروق الدقيقة في التسعير: Be aware of regional pricing variances. Economic conditions, local demand, and currency fluctuations can affect pricing structures.

-

علاقات الموردين: Building strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming market changes.

-

أبحاث السوق: Regularly conduct market research to stay updated on trends, new technologies, and emerging suppliers that may offer competitive advantages.

إخلاء المسؤولية

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and consult with multiple suppliers to obtain accurate pricing tailored to your needs.

Alternatives Analysis: Comparing lifespan of an alternator With Other Solutions

Understanding Alternatives to the Lifespan of an Alternator

When considering the lifespan of an alternator, it is essential to evaluate alternative solutions that can deliver similar performance in automotive electrical systems. This analysis will focus on two alternatives: أنظمة إدارة البطاريات (BMS) و Hybrid Energy Systems (HES). Each solution has distinct characteristics that affect performance, cost, and maintenance, which are crucial for B2B buyers in sectors such as automotive manufacturing and fleet management.

جدول المقارنة

| جانب المقارنة | Lifespan Of An Alternator | نظام إدارة البطارية (BMS) | Hybrid Energy System (HES) |

|---|---|---|---|

| الأداء | 7 سنوات / 150,000 ميل | Enhances battery lifespan and efficiency | Combines multiple energy sources for optimal performance |

| التكلفة | استثمار أولي معتدل | Higher upfront costs but reduced long-term battery replacement expenses | Significant initial investment; potential savings in fuel and maintenance |

| سهولة التنفيذ | التركيب القياسي في المركبات | Requires integration with battery systems; may need expert installation | Complex installation; requires compatible components and systems |

| الصيانة | Routine checks; potential replacements after lifespan | Minimal maintenance; regular software updates needed | High maintenance due to multiple components; requires specialized knowledge |

| أفضل حالة استخدام | Standard vehicles and fleets | Electric and hybrid vehicles for optimal battery life | Electric, hybrid, and commercial vehicles needing efficiency in energy use |

تفصيل البدائل

أنظمة إدارة البطاريات (BMS)

Battery Management Systems are designed to optimize the performance and lifespan of batteries, particularly in electric and hybrid vehicles. By monitoring and managing the charging and discharging cycles, BMS can significantly extend battery life and enhance overall efficiency. The primary advantage of a BMS is its ability to minimize battery degradation, leading to lower replacement costs over time. However, the initial investment can be higher than a standard alternator setup, and implementation may require specialized knowledge to integrate effectively with existing vehicle systems.

Hybrid Energy Systems (HES)

Hybrid Energy Systems incorporate various energy sources, such as internal combustion engines and electric batteries, to provide power to vehicles. This approach allows for greater efficiency and reduced fuel consumption, especially in commercial applications. While the performance can be superior due to the combination of energy sources, the initial cost of implementing an HES can be substantial. Maintenance may also be more complex due to the integration of multiple systems, requiring specialized technicians. However, the long-term savings on fuel and maintenance can justify the upfront investment for fleet operators and businesses focused on sustainability.

الخلاصة: كيفية اختيار الحل المناسب لاحتياجاتك

When selecting the appropriate solution for your automotive electrical needs, consider the specific requirements of your operation, including vehicle type, budget constraints, and maintenance capabilities. If you’re managing a standard fleet, the lifespan of an alternator may suffice. However, for businesses looking to enhance efficiency and reduce long-term costs, investing in a Battery Management System or Hybrid Energy System could yield significant benefits. Evaluate the total cost of ownership, including installation, maintenance, and potential savings, to make an informed decision that aligns with your operational goals.

Essential Technical Properties and Trade Terminology for lifespan of an alternator

What Are the Key Technical Properties That Affect the Lifespan of an Alternator?

Understanding the technical properties of an alternator is crucial for international B2B buyers looking to make informed purchasing decisions. Here are several critical specifications to consider:

Illustrative image related to lifespan of an alternator

-

درجة المواد

The materials used in manufacturing alternators significantly influence their durability and performance. High-grade materials such as aluminum and copper are often used due to their excellent conductivity and resistance to corrosion. For B2B buyers, selecting alternators made from superior materials can lead to longer lifespans and reduced maintenance costs. -

التسامح

Tolerance refers to the allowable variation in the dimensions and characteristics of alternator components. High tolerance levels ensure that parts fit together correctly, reducing wear and tear over time. In a B2B context, understanding tolerance specifications helps buyers assess quality and compatibility with existing systems, minimizing the risk of premature failure. -

Output Rating

The output rating, measured in amperes (A), indicates the maximum electrical load an alternator can handle. Higher output ratings are essential for vehicles equipped with advanced electronics. B2B buyers should evaluate output ratings to ensure that the alternator can meet the electrical demands of the vehicles they support, particularly in regions with high electronic usage. -

آلية التبريد

Alternators often employ cooling mechanisms, such as vented designs or integrated cooling fans, to prevent overheating during operation. Efficient cooling extends the lifespan of an alternator by preventing thermal damage. For international buyers, understanding the cooling capabilities is vital, especially in hot climates where overheating is a common issue. -

جودة التحمل

The quality of the bearings used in an alternator impacts its operational smoothness and lifespan. High-quality bearings reduce friction and wear, enhancing performance. B2B buyers should prioritize alternators with superior bearing materials to ensure reliability and longevity, particularly in heavy-duty applications.

What Are Common Trade Terms Related to Alternators That B2B Buyers Should Know?

Familiarity with trade terminology is essential for effective communication and decision-making in the B2B marketplace. Here are several common terms relevant to alternator procurement:

-

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to products made by the same company that manufactures the original components for a vehicle. B2B buyers often prefer OEM alternators for their guaranteed compatibility and reliability, ensuring that the product meets the same specifications as the original part. -

MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory effectively and negotiate better pricing. Buyers should be aware of MOQs to ensure they can meet supplier requirements without overcommitting resources. -

طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products, such as alternators. This process allows buyers to compare offers and make informed purchasing decisions. Crafting a detailed RFQ can lead to better pricing and terms, making it a vital tool for B2B transactions. -

مصطلحات التجارة الدولية

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in a transaction, including shipping and logistics. Familiarity with Incoterms is essential for B2B buyers to understand the cost implications and risks associated with shipping alternators, especially when importing from different regions. -

الضمان

A warranty is a guarantee provided by the manufacturer regarding the performance and durability of a product. Understanding warranty terms is crucial for B2B buyers, as it reflects the manufacturer’s confidence in their product and can provide financial protection against defects or premature failures.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing alternators, ultimately leading to enhanced operational efficiency and cost-effectiveness in their businesses.

Navigating Market Dynamics and Sourcing Trends in the lifespan of an alternator Sector

What Are the Key Market Dynamics Affecting the Lifespan of an Alternator?

The global alternator market is currently experiencing significant transformation driven by technological advancements, changing consumer preferences, and increasing regulatory standards. Notably, the lifespan of an alternator typically ranges between seven years or 150,000 miles, but several factors influence this duration. For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed purchasing decisions.

Illustrative image related to lifespan of an alternator

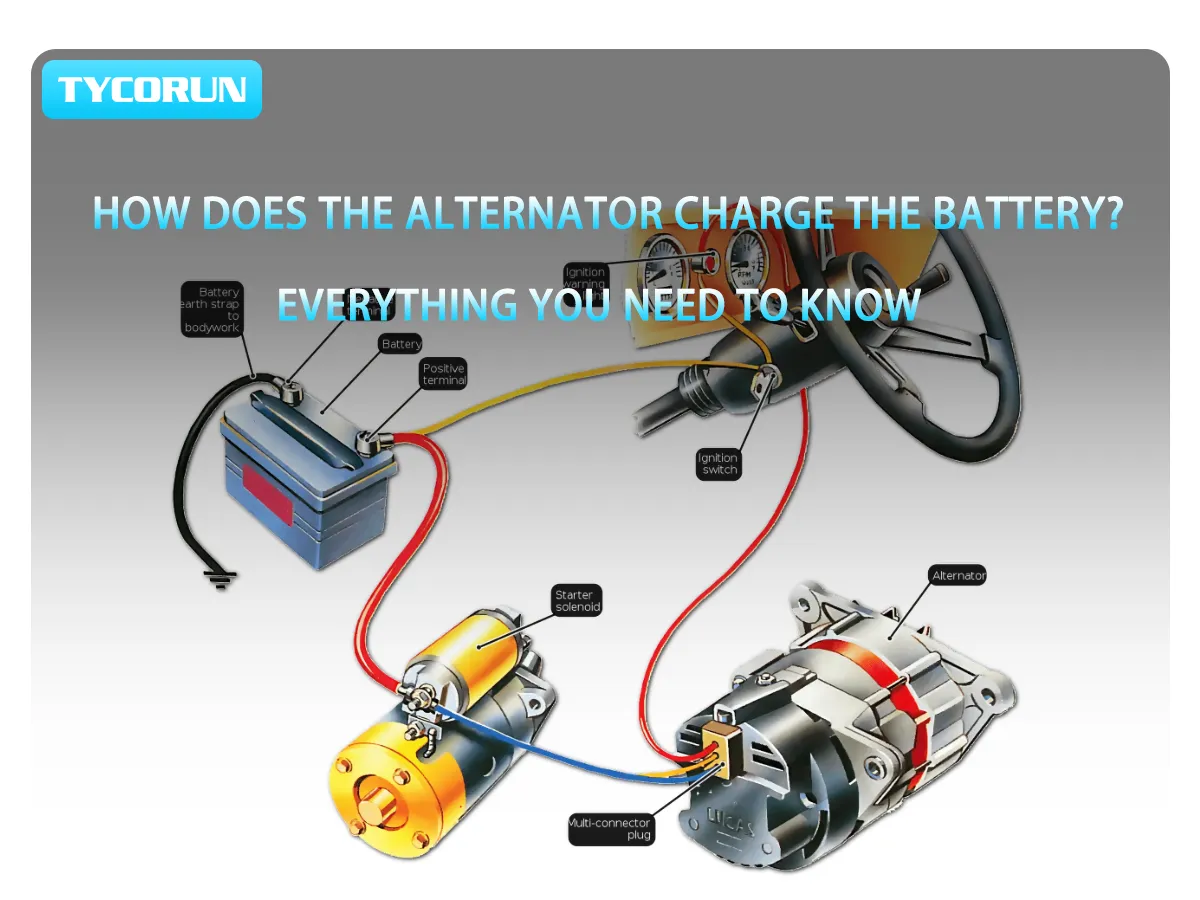

Emerging technologies like electric vehicles (EVs) are reshaping the alternator landscape. As automakers pivot towards EVs, traditional alternators may face reduced demand; however, hybrid models still require efficient alternators, maintaining market relevance. Additionally, the rise of smart technologies in vehicles is leading to higher electrical demands, necessitating more robust alternator designs capable of sustaining longevity under increased loads. International B2B buyers should consider sourcing alternators that incorporate advanced materials and designs for enhanced durability.

Moreover, global supply chain challenges, exacerbated by geopolitical tensions and the COVID-19 pandemic, have underscored the importance of reliable sourcing. Buyers are increasingly looking for suppliers that can offer transparency in their sourcing practices and demonstrate the capability to deliver quality parts consistently. Understanding local market conditions, such as the demand for specific vehicle types and the prevalence of electrical systems, can further guide sourcing strategies.

How Can Sustainability and Ethical Sourcing Impact the Lifespan of an Alternator?

As the automotive industry evolves, so does the imperative for sustainability and ethical sourcing within the alternator sector. The environmental impact of alternators—particularly regarding resource extraction and manufacturing processes—cannot be overlooked. B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices, thus ensuring that the materials used in alternators are sourced responsibly.

Ethical supply chains are essential for mitigating the risks associated with labor exploitation and environmental degradation. Buyers should seek suppliers that are certified by recognized ‘green’ organizations, which often require adherence to strict environmental regulations and ethical labor practices. Certifications such as ISO 14001 can indicate a supplier’s commitment to minimizing their ecological footprint.

Additionally, the use of recyclable materials and energy-efficient manufacturing processes not only aligns with corporate social responsibility (CSR) initiatives but also enhances the overall longevity of the product. By investing in alternators made from sustainable materials, companies can ensure higher durability and reduced lifecycle costs, ultimately benefiting their bottom line.

What Is the Historical Context of Alternators in the Automotive Industry?

The alternator, as a critical component of the automotive electrical system, has evolved significantly since its introduction in the early 1960s. Initially, vehicles relied on generators, which were less efficient and less reliable than modern alternators. The shift to alternators marked a turning point, as they provided a more consistent power supply and improved battery charging capabilities.

Over the decades, advancements in technology have led to the development of high-output alternators, designed to meet the increasing electrical demands of modern vehicles equipped with numerous electronic systems. This evolution not only enhanced performance but also extended the lifespan of alternators, making them more resilient to wear and tear.

In summary, understanding the historical context of alternators provides B2B buyers with insights into the technological advancements that have shaped the current market. By leveraging this knowledge, buyers can make more informed decisions regarding sourcing and maintenance practices that align with contemporary market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of lifespan of an alternator

-

How do I determine the lifespan of an alternator for my fleet?

To assess the lifespan of an alternator for your fleet, consider factors such as the average age of the vehicles, typical usage patterns, and maintenance history. Generally, alternators last between 5 to 7 years or around 150,000 miles, but this can vary based on the quality of the alternator and the electrical load placed on it. Regular inspections and monitoring of performance indicators, such as dimming lights or electrical failures, can help anticipate replacement needs, minimizing downtime and ensuring operational efficiency. -

What is the best way to source high-quality alternators for international distribution?

To source high-quality alternators for international distribution, prioritize suppliers with a proven track record and reputable certifications. Look for manufacturers that adhere to international quality standards, such as ISO 9001. Conduct thorough due diligence, including visiting manufacturing facilities if possible, and request samples for testing. Establishing long-term relationships with reliable suppliers can ensure consistent quality and availability, particularly for B2B transactions across diverse markets. -

ما العوامل التي يجب أن أضعها في الاعتبار عند فحص مورِّدي مولدات التيار المتردد؟

When vetting alternator suppliers, consider their production capacity, quality control measures, and customer service reputation. Evaluate their experience in exporting to your target regions, as knowledge of local regulations and logistical challenges is crucial. Request client references and assess their responsiveness to inquiries. Additionally, consider their ability to customize products according to your specific needs, as flexibility can be a significant advantage in B2B partnerships. -

How can I customize alternators to meet my specific requirements?

Customization of alternators typically involves working closely with the supplier to define your specific needs, such as output capacity, size, and features. Discuss any unique specifications, including environmental considerations relevant to your region, such as humidity or dust exposure. Ensure the supplier has the capability to produce customized products and inquire about minimum order quantities (MOQs) for bespoke designs. Regular communication throughout the design and production phases can help ensure the final product meets your expectations. -

ما هو الحد الأدنى المعتاد لكميات الطلبات (MOQ) لمولدات التيار المتردد؟

Minimum order quantities for alternators can vary significantly by supplier and the type of alternator required. Typically, MOQs may range from 50 to 500 units, depending on whether the alternators are standard or customized. It’s essential to discuss MOQs upfront with potential suppliers to align your purchasing strategy with their production capabilities. Smaller orders may be possible for certain suppliers, but this could affect pricing and lead times. -

ما هي شروط الدفع التي يجب أن أتوقعها عند توريد مولدات الكهرباء على المستوى الدولي؟

Payment terms can vary widely among suppliers and depend on the country of origin. Common arrangements include payment in advance, net 30, or letter of credit. It is advisable to negotiate terms that align with your cash flow needs while considering the supplier’s requirements. Always confirm the currency of the transaction and any potential fees associated with international wire transfers. Establishing clear payment terms upfront can help prevent misunderstandings and foster a stronger business relationship. -

كيف يمكنني التأكد من ضمان جودة المولدات التي أشتريها؟

To ensure quality assurance for your alternator purchases, establish clear quality standards and performance metrics with your suppliers. Request documentation of quality control processes, including testing protocols and certifications. Consider implementing a third-party inspection service to evaluate products before shipment. Additionally, maintain open lines of communication with suppliers to address any quality concerns promptly and facilitate continuous improvement. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد المولدات الكهربائية؟

When importing alternators, logistics considerations include shipping methods, customs regulations, and lead times. Assess the most efficient shipping options based on your timeline and budget, whether by air or sea. Familiarize yourself with import tariffs and regulations in your country to avoid unexpected costs or delays. Partnering with a reliable freight forwarder can streamline the logistics process, ensuring timely delivery and compliance with all necessary documentation and regulations.

Top 1 Lifespan Of An Alternator Manufacturers & Suppliers List

1. Gurnee Chrysler Jeep Dodge Ram – Alternator Solutions

المجال: gurneechryslerjeepdodgeram.com

مسجل: 2015 (10 سنوات)

مقدمة: The alternator is a crucial component of a vehicle that functions as a generator, using the engine as a source of energy to power the car’s electrical system. Common issues with alternators include the car not starting, devices failing to charge, dim headlights, a burning rubber smell, a battery warning light on the dashboard, and whining noises after starting the car. An alternator typically last…

Strategic Sourcing Conclusion and Outlook for lifespan of an alternator

In conclusion, understanding the lifespan of an alternator is crucial for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. With an average lifespan of around seven years or 150,000 miles, the longevity of an alternator is influenced by factors such as quality, vehicle condition, and electrical load. Buyers should prioritize sourcing high-quality alternators and consider the implications of aftermarket modifications that could strain these components.

Strategic sourcing is not merely about cost but ensuring reliability and performance. By establishing partnerships with reputable manufacturers and suppliers, businesses can enhance their operational efficiency and reduce unexpected downtimes associated with alternator failures.

As the automotive industry continues to evolve, the demand for durable and efficient alternators will only increase. Now is the time for B2B buyers to assess their sourcing strategies and align with suppliers who can provide high-quality products and exceptional service. Investing in reliable alternators today will yield long-term benefits, ensuring operational continuity and customer satisfaction in the competitive marketplace.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

Illustrative image related to lifespan of an alternator

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.