مقدمة: الإبحار في السوق العالمية كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

عند مواجهة السيناريو المحبط لسيارة لا تعمل، فإن تحديد ما إذا كانت المشكلة تكمن في البطارية أو مولد التيار المتردد يمكن أن يكون تحديًا شاقًا لمشتري الأعمال التجارية في قطاع السيارات. إن فهم كيفية تشخيص هذه المكونات بدقة أمر بالغ الأهمية، حيث لا يؤثر ذلك على تكاليف الإصلاح فحسب، بل يؤثر أيضًا على إدارة المخزون وعلاقات الموردين. يتعمق هذا الدليل الشامل في تعقيدات تحديد أعطال البطارية مقابل أعطال مولد التيار المتردد، ويقدم رؤى حول الأعراض والأدوار التشغيلية وأفضل الممارسات لاستكشاف الأعطال وإصلاحها.

يغطي استكشافنا مجموعة من الموضوعات المهمة، بما في ذلك علامات مشاكل البطاريات ومولدات التيار المتردد، وأحدث أدوات التشخيص المتوفرة في السوق، والاستراتيجيات الفعالة للحصول على قطع غيار السيارات عالية الجودة. بالإضافة إلى ذلك، نقدم إرشادات حول فحص الموردين لضمان الموثوقية والفعالية من حيث التكلفة، وهو أمر حيوي بشكل خاص للمشترين الذين يعملون في أسواق دولية متنوعة مثل إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، بما في ذلك اللاعبين الرئيسيين مثل البرازيل وألمانيا.

من خلال تزويد المشترين في مجال الأعمال التجارية بالمعرفة اللازمة للتمييز بين مشاكل البطارية ومشاكل مولد التيار المتردد، يمكّن هذا الدليل من اتخاذ قرارات شراء مستنيرة، مما يؤدي في النهاية إلى تعزيز الكفاءة التشغيلية ورضا العملاء. من خلال الرؤى القابلة للتنفيذ وتوصيات الخبراء، ستكون مستعدًا جيدًا للتنقل في تعقيدات تشخيص السيارات والمشتريات في المشهد التنافسي الحالي.

جدول المحتويات

- أعلى 2 كيف يمكنني معرفة ما إذا كانت البطارية أو المولد قائمة المصنعين والموردين

- مقدمة: الإبحار في السوق العالمية كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

- فهم كيف يمكنني معرفة ما إذا كانت المشكلة في البطارية أو مولد التيار المتردد أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

- 3 نقاط ألم شائعة لدى المستخدمين حول ‘كيف يمكنني معرفة ما إذا كانت المشكلة في البطارية أو مولد التيار المتردد’ وحلولها

- دليل اختيار المواد الإستراتيجية لكيفية معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لكيفية معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

- دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد’

- تحليل شامل للتكلفة والتسعير لكيفية معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد مصدر

- تحليل البدائل: مقارنة كيف يمكنني معرفة ما إذا كانت المشكلة في البطارية أو المولد مع حلول أخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية لكيفية معرفة ما إذا كانت البطارية أو مولد التيار المتردد

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع البطارية أو مولد التيار المتردد

- الأسئلة المتداولة (FAQs) لمشتري B2B عن كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

- خاتمة المصادر الاستراتيجية والتوقعات لكيفية معرفة ما إذا كانت المشكلة في البطارية أو المولد

- إخلاء مسؤولية هام وشروط الاستخدام

فهم كيف يمكنني معرفة ما إذا كانت المشكلة في البطارية أو مولد التيار المتردد أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| علامات تعطل البطارية | بطء في تدوير المحرك، أضواء خافتة، ضوضاء نقر | ورش إصلاح السيارات، خدمات الأساطيل | الإيجابيات: سهل التشخيص؛ مشاكل شائعة. السلبيات: يمكن أن يؤدي إلى استبدالات متكررة إذا لم تتم إدارتها. |

| علامات تعطل المولد | وميض الأضواء، وضوء لوحة العدادات التحذيري، ورائحة الاحتراق | صيانة المركبات التجارية | الإيجابيات: التحديد المبكر يمكن أن يمنع حدوث الأعطال. السلبيات: قد تكون هناك حاجة إلى إصلاحات أكثر تعقيداً. |

| المشكلات المتقطعة | يبدأ التشغيل بشكل جيد في يوم، ويعاني في اليوم التالي؛ سلوك كهربائي غير منتظم | إدارة الأسطول، شركات الخدمات اللوجستية | الإيجابيات: يساعد في تخطيط الصيانة؛ يقلل من وقت التعطل. السلبيات: قد يتطلب التشخيص أدوات متخصصة. |

| اختبار البطارية مقابل اختبار المولد | اختبار احترافي لكلا النظامين | مزودو خدمات السيارات | الإيجابيات: التشخيص الدقيق يوفر التكاليف ويمنع عمليات الاستبدال غير الضرورية. السلبيات: قد تتكبد رسوم التشخيص. |

| العوامل البيئية | تأثير درجة الحرارة على عمر البطارية وأداء مولد التيار المتردد | موردو قطع غيار السيارات، الورش | الإيجابيات: تساعد المعرفة في اختيار المنتج. السلبيات: قد يتطلب صيانة إضافية في الظروف القاسية. |

كيف يمكن أن تؤثر علامات فشل البطارية على عمليات B2B؟

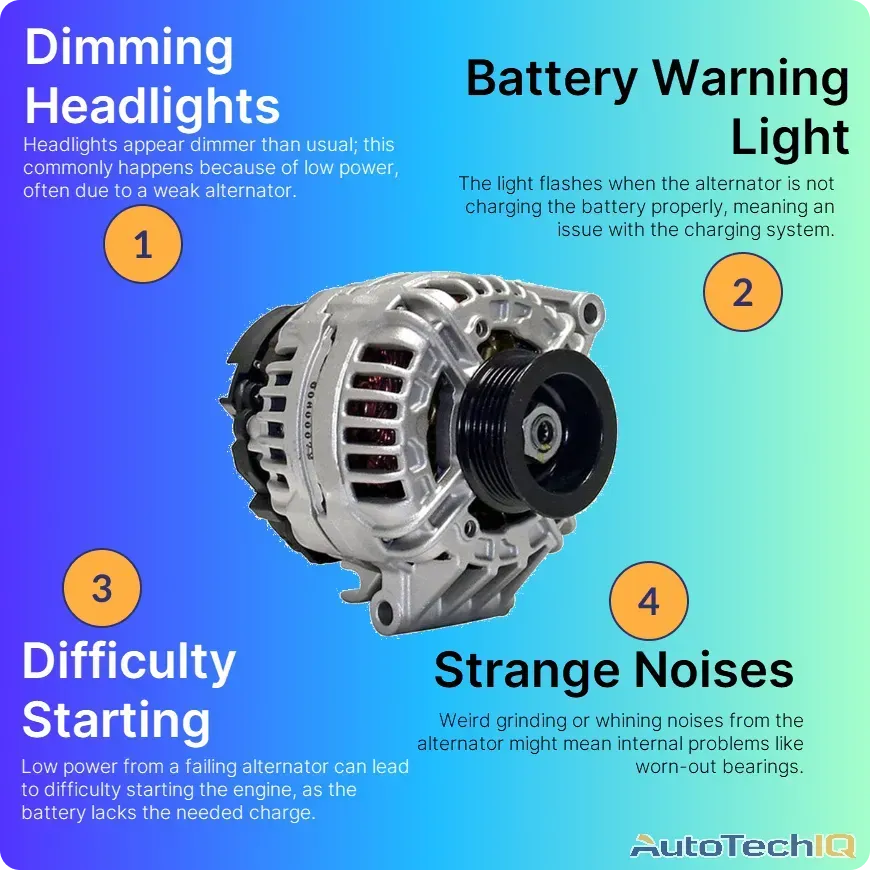

تُعدّ علامات تعطل البطارية مؤشرات حاسمة للشركات العاملة في مجال إصلاح السيارات أو خدمات الأساطيل. تشمل الأعراض الشائعة بطء دوران المحرك والأضواء الخافتة، والتي تشير إلى ضعف البطارية. يسمح فهم هذه العلامات للشركات بإدارة المخزون بفعالية وجدولة الصيانة في الوقت المناسب. ومع ذلك، يمكن أن تؤدي عمليات الاستبدال المتكررة للبطاريات إلى زيادة التكاليف التشغيلية، مما يجعل من الضروري للشركات الاستثمار في بطاريات عالية الجودة ومراعاة العوامل البيئية التي قد تسرّع من تآكل البطارية.

ما هي المؤشرات الرئيسية لفشل المولد؟

يمكن أن يؤدي التعرف على علامات تعطل المولد إلى تعزيز موثوقية المركبات التجارية بشكل كبير. تعد الأضواء الوامضة وإشارات التحذير في لوحة العدادات مؤشرات أساسية على أن المولد قد لا يعمل بشكل صحيح. يمكن أن يمنع الاكتشاف المبكر لهذه المشكلات الأعطال غير المتوقعة والإصلاحات المكلفة. ومع ذلك، فإن تشخيص مشاكل المولد قد ينطوي على إصلاحات أكثر تعقيدًا، مما قد يرهق الميزانيات إذا لم يتم معالجتها على الفور.

كيف تؤثر المشكلات المتقطعة على موثوقية السيارة؟

يمكن أن تؤدي المشكلات المتقطعة، حيث تعمل السيارة دون مشاكل في يوم واحد وتعاني في اليوم التالي، إلى خلق حالة من عدم اليقين بالنسبة لإدارة الأسطول وشركات الخدمات اللوجستية. يشير هذا السلوك غير المنتظم في كثير من الأحيان إلى وجود تناقضات في البطارية أو المولد. ويسمح تحديد هذه الأنماط للشركات بجدولة الصيانة الاستباقية، وبالتالي تقليل مخاطر تعطل السيارة. ومع ذلك، قد يتطلب تشخيص هذه المشكلات أدوات متخصصة، مما يزيد من تكاليف الصيانة الإجمالية.

لماذا يعد الاختبار الاحترافي مهماً لتشخيص البطارية والمولد؟

يعد الاختبار الاحترافي لكل من البطارية ومولد التيار المتردد ضرورياً للتشخيص الدقيق والصيانة الفعالة من حيث التكلفة. يمكن لمقدمي خدمات السيارات استخدام معدات متخصصة لتحديد السبب الجذري لمشاكل بدء التشغيل، مما يساعد الشركات على تجنب الاستبدال غير الضروري للأجزاء. على الرغم من أن خدمات التشخيص قد تنطوي على رسوم إضافية، إلا أن الاستثمار يؤتي ثماره عادةً من خلال تعزيز موثوقية السيارة وتقليل وقت التعطل.

كيف تؤثر العوامل البيئية على أداء البطارية والمولد؟

يمكن أن تؤثر العوامل البيئية، مثل درجات الحرارة القصوى، بشكل كبير على عمر البطاريات ومولدات التيار المتردد وأدائها. بالنسبة للشركات العاملة في المناطق ذات المناخ القاسي، فإن فهم هذه التأثيرات أمر حيوي لاختيار المنتجات المناسبة وتخطيط جداول الصيانة. في حين أن هذه المعرفة يمكن أن تساعد في اتخاذ قرارات شراء مستنيرة، إلا أنها قد تتطلب أيضًا جهود صيانة إضافية لضمان الأداء الأمثل في الظروف الصعبة.

التطبيقات الصناعية الرئيسية لـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

| الصناعة/القطاع | تطبيق محدد لكيفية معرفة ما إذا كانت المشكلة في البطارية أو المولد | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| إصلاح السيارات | تشخيص المشاكل الكهربائية في السيارة أثناء الصيانة والإصلاحات | تعزيز كفاءة الخدمة ورضا العملاء | توفر أدوات التشخيص، وتدريب الفنيين، وتكلفة قطع الغيار |

| النقل واللوجستيات | ضمان موثوقية الأسطول من خلال فحص البطارية ومولد التيار المتردد | تقليل وقت التعطل والتكاليف التشغيلية، وتحسين سلامة الأسطول | خيارات الشراء بالجملة للبطاريات ومولدات التيار المتردد وموثوقية المورد |

| الآلات الثقيلة | فحوصات الصيانة الدورية لمعدات البناء أو المعدات الزراعية | منع الأعطال المكلفة وإطالة عمر المعدات | ضمان جودة القطع، والتوافق مع طرازات ماكينات محددة |

| الطاقة المتجددة | تقييم أنظمة تخزين البطاريات في تطبيقات الطاقة الشمسية أو طاقة الرياح | تحسين كفاءة تخزين الطاقة وموثوقية النظام | تحديد مصادر البطاريات المتوافقة وفهم لوائح الطاقة المحلية |

| وسائل النقل العام | الفحوصات الروتينية للحافلات والقطارات للتأكد من موثوقية التشغيل | ضمان سلامة الركاب وتقليل انقطاع الخدمة إلى أدنى حد ممكن | الامتثال لمعايير السلامة، وتحديد مصادر المكونات المتينة للبيئات عالية الاستخدام |

كيف يمكنني معرفة ما إذا كانت المشكلة في البطارية أو المولد في إصلاح السيارات؟

في مجال إصلاح السيارات، يواجه الفنيون في كثير من الأحيان مركبات تظهر عليها أعراض الأعطال الكهربائية. من خلال فهم كيفية التفريق بين مشاكل البطارية ومشاكل المولد الكهربائي، يمكن لورش الإصلاح توفير تشخيصات دقيقة وحلول في الوقت المناسب. على سبيل المثال، قد تحتاج السيارة التي تواجه صعوبة في تشغيلها إلى استبدال بسيط للبطارية، بينما قد يشير وميض الأضواء إلى تعطل المولد. لا تعزز هذه المعرفة كفاءة الخدمة فحسب، بل تزيد أيضاً من رضا العملاء، حيث يقدّر العملاء الحلول السريعة والفعالة.

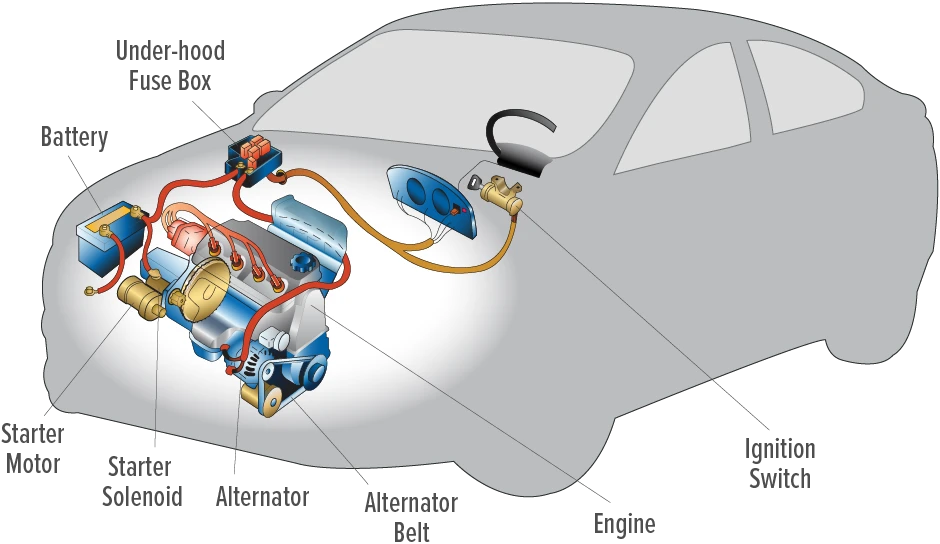

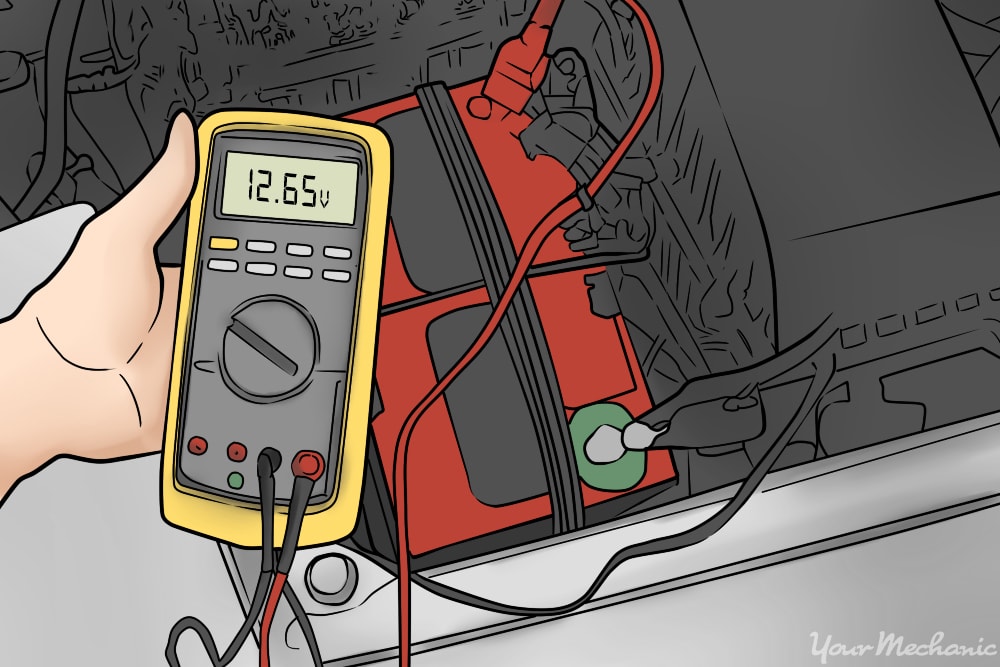

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

ما الدور الذي يلعبه تشخيص البطارية والمولد في النقل والخدمات اللوجستية؟

في قطاع النقل والخدمات اللوجستية، يُعد الحفاظ على موثوقية الأسطول أمرًا بالغ الأهمية. إن التشخيص المنتظم للبطاريات ومولدات التيار المتردد في المركبات يساعد مديري الأساطيل على تجنب الأعطال غير المتوقعة التي يمكن أن تؤدي إلى تأخيرات مكلفة. على سبيل المثال، قد يؤدي تعطّل مركبة الأسطول عن العمل بسبب نفاد البطارية إلى توقف العمليات، مما يؤثر على جداول التسليم. من خلال تنفيذ الفحوصات الروتينية، يمكن للشركات تقليل وقت التعطل إلى الحد الأدنى وتقليل التكاليف التشغيلية وتحسين السلامة العامة، مما يضمن سير عملياتها اللوجستية بسلاسة.

ما مدى أهمية صيانة البطارية والمولد للآلات الثقيلة؟

يعتمد مشغّلو الآلات الثقيلة في قطاعي الإنشاءات والزراعة على معداتهم لأداء مهامهم بكفاءة. يعد تشخيص مشاكل البطارية ومولد التيار المتردد أمرًا بالغ الأهمية لمنع الأعطال المكلفة التي يمكن أن توقف العمليات. على سبيل المثال، يمكن أن يؤدي تعطل الماكينات عن العمل بسبب مشكلة في البطارية إلى تأخير المشروع. من خلال الحصول على قطع غيار عالية الجودة وضمان تدريب الفنيين على التشخيص الكهربائي، يمكن للشركات إطالة عمر معداتها وتجنب التداعيات المالية للإصلاحات غير المخطط لها.

ما أهمية تقييم البطاريات في تطبيقات الطاقة المتجددة؟

في قطاع الطاقة المتجددة، لا سيما مع أنظمة الطاقة الشمسية وطاقة الرياح، فإن فعالية حلول تخزين البطاريات أمر حيوي. ويضمن تشخيص ما إذا كانت البطارية أو المولد معطلة أم لا أن تعمل أنظمة الطاقة بأعلى كفاءة. على سبيل المثال، إذا فشلت بطارية الطاقة الشمسية في الاحتفاظ بالشحن، فقد يؤدي ذلك إلى تعطيل إمدادات الطاقة. يجب على المشترين في هذا القطاع التأكد من حصولهم على بطاريات متوافقة وفهم لوائح الطاقة المحلية لتحسين أنظمتهم من أجل الموثوقية والأداء.

كيف تستفيد وسائل النقل العام من التشخيص الكهربائي؟

يجب على أنظمة النقل العام إعطاء الأولوية للموثوقية التشغيلية لضمان سلامة الركاب ورضاهم. يمكن أن تمنع الفحوصات المنتظمة للحافلات والقطارات للتأكد من سلامة البطارية ومولد التيار المتردد من انقطاع الخدمة الذي يزعج الركاب. فالحافلة التي تتعطل عن العمل بسبب مشكلة في البطارية لا تؤدي فقط إلى تعطيل الجداول الزمنية بل يمكن أن تضر بسمعة مزود الخدمة. من خلال الحصول على مكونات متينة والالتزام بمعايير السلامة، يمكن لوكالات النقل العام تعزيز موثوقيتها وجودة خدماتها.

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

3 نقاط ألم شائعة لدى المستخدمين حول ‘كيف يمكنني معرفة ما إذا كانت المشكلة في البطارية أو مولد التيار المتردد’ وحلولها

السيناريو 1: صعوبة في تشخيص مشاكل البطارية مقابل مشاكل المولد

المشكلة:

غالبًا ما يواجه المشترون من الشركات العاملة في مجال إصلاح السيارات حالات تتعطل فيها مركبات الأسطول أو الآلات عن العمل، مما يؤدي إلى تعطلها عن العمل. عندما يتم استدعاء الفنيين لتشخيص المشكلة، قد يواجهون صعوبة في تحديد ما إذا كانت المشكلة تكمن في البطارية أو المولد. وقد يؤدي هذا الالتباس إلى استبدال غير ضروري لقطع الغيار وزيادة التكاليف وإطالة وقت التعطل. بالنظر إلى الاستثمار في صيانة المركبات وأهمية تقليل الأعطال إلى الحد الأدنى، فإن التشخيص الدقيق للسبب الجذري أمر بالغ الأهمية للشركات التي تعتمد على أساطيلها.

الحل:

للتمييز بفعالية بين مشاكل البطارية ومشاكل المولدات، قم بتنفيذ نهج تشخيصي منهجي. ابدأ بتوجيه الفنيين إلى مراقبة وتسجيل أعراض السيارة. على سبيل المثال، إذا كان المحرك يدور ببطء ولكن في النهاية يبدأ في العمل، فهذا يشير على الأرجح إلى ضعف البطارية. وعلى العكس من ذلك، إذا تعطلت السيارة بعد وقت قصير من بدء التشغيل، فقد لا يقوم المولد بشحن البطارية بشكل فعال. يمكن أن يساعد استخدام أدوات التشخيص، مثل مقياس متعدد، في قياس جهد البطارية وإخراج المولد. يجب أن تقرأ البطارية المشحونة بالكامل حوالي 12.6 فولت، في حين يجب أن يظهر المولد السليم ما بين 13.7 إلى 14.7 فولت عند تشغيل المحرك. من خلال إنشاء قائمة مرجعية موحدة لاستكشاف الأعطال وإصلاحها والاستثمار في تدريب الفنيين، يمكن للشركات تحسين دقة التشخيص وتقليل تكاليف الإصلاح غير الضرورية.

السيناريو 2: الأعطال الكهربائية المتكررة في الأساطيل

المشكلة:

يدير العديد من مشتري B2B أساطيل السيارات التي تعتمد بشكل كبير على أنظمة كهربائية مختلفة للتشغيل، من الإضاءة إلى أجهزة المساعدة على الملاحة. إذا بدأت المركبات تعاني من أعطال كهربائية متكررة، فقد يكون من الصعب تحديد ما إذا كانت المشكلة ناتجة عن تقادم البطاريات أو تعطل مولدات التيار المتردد. لا يؤثر ذلك على موثوقية السيارة فحسب، بل يؤثر أيضًا على السلامة، حيث يمكن أن يؤدي الأداء الكهربائي غير المنتظم إلى مواقف خطيرة على الطريق.

الحل:

وضع جدول صيانة استباقي يتضمن عمليات فحص منتظمة لكل من نظامي البطارية ومولد التيار المتردد. تشجيع مديري أساطيل السيارات على تثقيف السائقين حول علامات المشاكل الكهربائية، مثل المصابيح الخافتة أو الملحقات المعطلة. تنفيذ بروتوكول اختبار روتيني، حيث يقوم الفنيون أثناء الصيانة المجدولة بتقييم سلامة البطاريات ومولدات التيار المتردد. يمكن أن يتضمن ذلك اختبار خرج المولد في ظروف التحميل وفحص التآكل في أطراف البطارية. من خلال اعتماد نهج الصيانة الوقائية، يمكن للشركات التخفيف من مخاطر الأعطال غير المتوقعة وضمان بقاء مركباتها آمنة وموثوقة.

السيناريو 3: التشخيص الخاطئ الذي يؤدي إلى زيادة تكاليف الإصلاح

المشكلة:

في بيئة إصلاح السيارات سريعة الوتيرة، يمكن أن يؤدي التشخيص الخاطئ لمشاكل البطارية أو مولد التيار المتردد إلى إهدار تكاليف العمالة وقطع الغيار. بالنسبة للمشترين من الشركات الذين يديرون مراكز خدمة، فإن المخاطر كبيرة؛ فالتشخيص الخاطئ لا يحبط العملاء فحسب، بل يمكن أن يضر بسمعتهم أيضًا. عندما يستبدل الفني عن طريق الخطأ مولد التيار المتردد الذي يعمل عن طريق الخطأ بدلاً من البطارية المعطوبة، فإن ذلك يؤدي إلى نفقات غير ضرورية وعدم رضا العملاء.

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

الحل:

لمكافحة التشخيص الخاطئ، استثمر في معدات التشخيص المتقدمة التي يمكنها اختبار كل من البطارية ومولد التيار المتردد بدقة في دفعة واحدة. يمكن لأدوات مثل أجهزة اختبار البطارية المزودة بقدرات اختبار المولد المدمجة أن تبسّط عملية التشخيص وتوفر نتائج واضحة. بالإضافة إلى ذلك، يجب تنفيذ برامج تدريبية تركز على الأنظمة الكهربائية لجميع الفنيين، مع التركيز على أهمية فهم كيفية تفاعل البطاريات ومولدات التيار المتردد. يمكن أن يؤدي تشجيع الفنيين على إجراء فحوصات واختبارات شاملة قبل إجراء أي عمليات استبدال إلى تقليل معدلات التشخيص الخاطئ بشكل كبير. من خلال تعزيز دقة التشخيص، يمكن لمراكز الخدمة تحسين الكفاءة التشغيلية وخفض التكاليف وتعزيز ثقة العملاء من خلال خدمة موثوقة.

دليل اختيار المواد الإستراتيجية لكيفية معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

ما هي المواد المستخدمة عادة في تطبيقات البطاريات والمولدات؟

عند تقييم ما إذا كانت مشكلة السيارة تنبع من البطارية أو مولد التيار المتردد، فإن فهم المواد المستخدمة في هذه المكونات أمر بالغ الأهمية. ويحلل هذا القسم المواد الشائعة المستخدمة في البطاريات ومولدات التيار المتردد، مع التركيز على خصائصها ومزاياها وعيوبها واعتباراتها بالنسبة للمشترين الدوليين من الشركات.

كيف يؤثر الرصاص على أداء البطارية في المركبات؟

الرصاص هو المادة الأساسية المستخدمة في بطاريات الرصاص الحمضية التقليدية. وله خصائص كهروكيميائية ممتازة، مما يسمح بتخزين الطاقة وإطلاقها بكفاءة.

- الخصائص الرئيسية: يتميز الرصاص بكثافة عالية وموصلية جيدة، مما يجعله مناسباً لتخزين الطاقة. ويعمل بفعالية في نطاق درجة حرارة تتراوح بين -20 درجة مئوية و60 درجة مئوية.

- إيجابيات وسلبيات: بطاريات الرصاص غير مكلفة نسبياً في التصنيع ولها عملية إعادة تدوير راسخة. ومع ذلك، فهي ثقيلة ويمكن أن تكون حساسة لدرجات الحرارة القصوى، مما قد يؤثر على الأداء.

- التأثير على التطبيق: توافق الرصاص مع مختلف تطبيقات السيارات موثق بشكل جيد، ولكنه قد يتآكل مع مرور الوقت، مما يؤثر على الأداء.

- اعتبارات محددة للمشترين الدوليين: في مناطق مثل أفريقيا وأمريكا الجنوبية، حيث تشيع التقلبات في درجات الحرارة، من الضروري ضمان صيانة بطاريات الرصاص بشكل جيد. ومن الضروري أيضاً الامتثال للوائح البيئية المحلية المتعلقة بالتخلص من الرصاص.

ما الدور الذي يلعبه النحاس في وظيفة المولد؟

يُستخدم النحاس على نطاق واسع في أسلاك ولفائف المولدات الكهربائية بسبب توصيلها الكهربائي الفائق.

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

- الخصائص الرئيسية: يتميز النحاس بتوصيل كهربائي ممتاز، مع مقاومة منخفضة تسمح بنقل الطاقة بكفاءة. ويمكنه تحمل درجات حرارة تصل إلى 200 درجة مئوية دون تدهور كبير.

- إيجابيات وسلبيات: تعمل الموصلية العالية للنحاس على تحسين أداء المولدات، مما يجعلها أكثر كفاءة. ومع ذلك، فإن النحاس أغلى ثمناً من بدائل مثل الألومنيوم، ويمكن أن يتآكل إذا لم يتم عزله بشكل صحيح.

- التأثير على التطبيق: إن توافق النحاس مع الأنظمة الكهربائية لا مثيل له، ولكن قابليته للتآكل تستلزم طلاءات واقية، خاصة في البيئات الرطبة أو الساحلية.

- اعتبارات محددة للمشترين الدوليين: في أوروبا، يمكن أن يؤثر الامتثال لمعايير مثل DIN على اختيار النحاس مقابل الألومنيوم في المولدات الكهربائية. قد يحتاج المشترون من الشرق الأوسط أيضًا إلى النظر في تأثير درجات الحرارة المرتفعة على أداء النحاس.

كيف يمكن مقارنة الألومنيوم كمادة لمكونات البطارية والمولد؟

يُستخدم الألومنيوم بشكل متزايد في تطبيقات السيارات، بما في ذلك بعض أغلفة البطاريات وأغطية المولدات.

- الخصائص الرئيسية: يتميز الألومنيوم بخفة وزنه ومقاومته للتآكل، وتبلغ درجة انصهاره حوالي 660 درجة مئوية. يمكن أن يعمل بفعالية في مجموعة من درجات الحرارة، مما يجعله متعدد الاستخدامات.

- إيجابيات وسلبيات: يمكن لطبيعة الألمنيوم خفيفة الوزن أن تحسن كفاءة استهلاك الوقود في المركبات. ومع ذلك، فهو أقل توصيلاً من النحاس، مما قد يؤثر على الأداء الكهربائي في المولدات الكهربائية.

- التأثير على التطبيق: إن مقاومة الألومنيوم للتآكل تجعله مناسبًا للبيئات ذات الرطوبة العالية أو التعرض للمياه المالحة، ولكن قد يتطلب توصيله المنخفض أحجام أسلاك أكبر.

- اعتبارات محددة للمشترين الدوليين: قد يفضّل المشترون في مناطق مثل ألمانيا الألومنيوم لخصائصه خفيفة الوزن، بينما قد يركز المشترون في أفريقيا على فعالية التكلفة ومقاومة التآكل.

ما هي فوائد استخدام المواد المركبة في تكنولوجيا البطاريات؟

بدأت المواد المركبة في الظهور كبدائل في تكنولوجيا البطاريات، خاصة في بطاريات الليثيوم أيون المتقدمة.

- الخصائص الرئيسية: يمكن تصميم المواد المركبة هندسيًا للحصول على خصائص أداء محددة، مثل تعزيز الثبات الحراري وخصائص الوزن الخفيف.

- إيجابيات وسلبيات: توفر كثافة طاقة محسنة ويمكن تصميمها لتناسب تطبيقات محددة. ومع ذلك، يمكن أن يكون إنتاج المركبات أكثر تكلفة وقد يتطلب عمليات تصنيع متخصصة.

- التأثير على التطبيق: إن قدرة المواد المركبة على التكيف تجعلها مناسبة للتطبيقات عالية الأداء، ولكن تكلفتها قد تحد من اعتمادها على نطاق واسع في الأسواق ذات الميزانية المحدودة.

- اعتبارات محددة للمشترين الدوليين: في مناطق مثل أمريكا الجنوبية، حيث يتطور الابتكار بسرعة، قد يكون الطلب على تقنيات البطاريات المتقدمة في صالح المواد المركبة، شريطة أن تفي بالمعايير المحلية.

جدول ملخص لخص خواص المواد لتطبيقات البطاريات والمولدات

| المواد | حالة الاستخدام النموذجية لكيفية معرفة ما إذا كانت المشكلة في البطارية أو المولد | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الرصاص | بطاريات الرصاص الحمضية لبدء تشغيل المحركات | إعادة التدوير الفعالة من حيث التكلفة والراسخة | ثقيلة وحساسة للحرارة | منخفض |

| النحاس | الأسلاك واللفات في مولدات التيار المتردد | موصلية كهربائية ممتازة | أغلى ثمناً وأكثر عرضة للتآكل | عالية |

| الألومنيوم | أغلفة البطاريات وأغطية المولدات خفيفة الوزن | مقاومة للتآكل وخفيفة الوزن | موصلية أقل من النحاس | متوسط |

| مركب | بطاريات الليثيوم أيون المتقدمة | خصائص أداء مصممة خصيصًا | ارتفاع تكاليف الإنتاج وتعقيده | عالية |

يوفر هذا التحليل للمشترين بين الشركات رؤى قابلة للتنفيذ في اختيار المواد للبطاريات ومولدات الكهرباء، مما يضمن اتخاذ قرارات مستنيرة تتماشى مع الاحتياجات التشغيلية والاعتبارات الإقليمية.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لكيفية معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

ما هي عمليات التصنيع الرئيسية للبطاريات والمولدات؟

يُعد فهم عمليات تصنيع البطاريات ومولدات التيار المتردد أمرًا بالغ الأهمية بالنسبة للمشترين من الشركات الذين يسعون إلى تمييز المنتجات عالية الجودة في سوق تنافسية. ينطوي إنتاج هذه المكونات على عدة مراحل، تتطلب كل منها الدقة والالتزام بالمعايير الدولية لضمان الموثوقية والأداء.

كيف يتم تحضير المواد لتصنيع البطاريات والمولدات؟

المرحلة الأولى في تصنيع كل من البطاريات ومولدات التيار المتردد هي إعداد المواد. بالنسبة للبطاريات، يتضمن ذلك عادةً الحصول على رصاص وحمض ومواد كيميائية أخرى عالية الجودة. ويتم تنقية الرصاص وتشكيله في شبكات، بينما يتم خلط الحمض بالتركيز المطلوب. وفي المولدات المترددة، يتم تحضير مواد مثل النحاس للملفات والألومنيوم للأغلفة ومواد بلاستيكية مختلفة للعوازل.

تشمل التقنيات الرئيسية في هذه المرحلة ما يلي:

- عمليات التنقية: التأكد من خلو المواد المستخدمة من الملوثات التي يمكن أن تؤثر على الأداء.

- اختبار المواد: إجراء اختبارات مثل قوة الشد والتوصيل للتأكد من مطابقة المواد للمواصفات.

ما هي تقنيات التشكيل المستخدمة في إنتاج البطاريات والمولدات؟

بمجرد تجهيز المواد، تكون الخطوة التالية هي التشكيل.

-

تشكيل البطارية: تتضمن تجميع شبكات الرصاص ووضع المواد النشطة. ثم تُملأ الخلايا بعد ذلك بالكهرباء وتخضع لعملية شحن أولية لتنشيط التفاعل الكيميائي الضروري لتشغيل البطارية.

-

تشكيل المولد: ويشمل ذلك لف الأسلاك النحاسية حول قلب الجزء الثابت وتجميع مكونات الدوار. الدقة في اللف أمر بالغ الأهمية، حيث أن أي عدم اتساق يمكن أن يؤدي إلى عدم الكفاءة أو الفشل في المجال.

تشمل التقنيات المستخدمة في هذه المرحلة ما يلي:

- ماكينات اللف الآلي: لضمان الاتساق في لف الملفات، وهو أمر بالغ الأهمية للأداء.

- القولبة والصب: لإنشاء العلب والمكونات الهيكلية الأخرى، مما يضمن المتانة ومقاومة الحرارة.

كيف يتم إجراء التجميع للبطاريات والمولدات؟

مرحلة التجميع هي المرحلة التي يتم فيها تجميع المكونات المختلفة معًا لإنشاء منتج وظيفي.

-

تجميع البطارية: ويشمل ذلك تركيب الفواصل والأطراف والغلق النهائي لعلبة البطارية. تضمن مراقبة الجودة في هذه المرحلة عدم وجود تسربات وأن البطارية يمكنها تحمل الاهتزازات والتغيرات في درجات الحرارة.

-

مجموعة المولد: يتضمن دمج الدوّار، والجزء الثابت، ومنظم الجهد، والمقوِّم. يجب تركيب كل مكون بإحكام لمنع حدوث عطل تشغيلي.

تشمل التقنيات الرئيسية ما يلي:

- خطوط التجميع الروبوتية: تعزيز الدقة وتقليل الأخطاء البشرية أثناء عملية التجميع.

- الفحوصات اليدوية: غالباً ما يقوم الفنيون المهرة بإجراء الفحوصات النهائية لضمان تجميع جميع المكونات بشكل صحيح.

ما هي عمليات التشطيب المهمة للبطاريات والمولدات؟

تتضمن مرحلة التشطيب وضع الطلاءات الواقية والاختبار النهائي لضمان جاهزية المنتج للسوق.

-

تشطيب البطارية: غالباً ما يتم طلاء البطاريات بطبقة واقية لمنع التآكل. بالإضافة إلى ذلك، تخضع لدورات شحن نهائية لضمان استيفائها لمعايير الأداء.

-

تشطيب المولد: قد يشمل ذلك طلاء أو طلاء المبيت بأكسيد الألومنيوم لمنع التآكل وتحسين المظهر الجمالي.

تشمل تقنيات التشطيب الشائعة ما يلي:

- الطلاء الكهربائي: لمقاومة التآكل، خاصة في أطراف البطاريات.

- اختبارات التدوير الحراري: لمحاكاة ظروف التشغيل القاسية وضمان الموثوقية.

ما هي إجراءات مراقبة الجودة الضرورية في تصنيع البطاريات والمولدات؟

يعد ضمان الجودة جزءًا لا يتجزأ من التصنيع، خاصةً بالنسبة للمكونات الحرجة مثل البطاريات ومولدات الطاقة الكهربائية. يساعد تنفيذ عمليات مراقبة الجودة القوية على التخفيف من المخاطر المرتبطة بأعطال المنتجات، مما يضمن حصول المشترين من الشركات على منتجات موثوقة.

ما هي المعايير الدولية ذات الصلة لضمان الجودة؟

يجب على المصنعين الالتزام بالمعايير الدولية مثل ISO 9001، والتي تحدد أنظمة إدارة الجودة لضمان الاتساق في جودة المنتج. بالإضافة إلى ذلك، قد تنطبق المعايير الخاصة بالصناعة مثل علامة CE في أوروبا ومواصفات API لمكونات السيارات.

كيف يتم تنفيذ نقاط فحص مراقبة الجودة في عملية التصنيع؟

يتم إنشاء نقاط فحص لمراقبة الجودة في جميع مراحل عملية التصنيع لضمان استيفاء المنتجات للمعايير المحددة.

-

مراقبة الجودة الواردة (IQC): يتضمن ذلك فحص المواد الخام قبل دخولها خط الإنتاج للتأكد من مطابقتها للمواصفات المطلوبة.

-

مراقبة الجودة أثناء الإنتاج (IPQC): تساعد الفحوصات المنتظمة أثناء الإنتاج على تحديد المشكلات مبكرًا، مما يقلل من مخاطر وصول المنتجات المعيبة إلى السوق.

-

مراقبة الجودة النهائية (FQC): في هذه المرحلة، تخضع المنتجات المكتملة لاختبارات صارمة، بما في ذلك اختبارات الأداء وتقييمات السلامة.

ما هي طرق الاختبار الشائعة المستخدمة في مراقبة جودة البطارية والمولد؟

تختلف طرق الاختبار حسب المكون، ولكنها تشمل بشكل عام ما يلي:

- اختبار الحمل: لتقييم قدرة البطارية على توصيل التيار في ظروف التحميل.

- الاختبارات الكهربائية: بالنسبة لمولدات المولدات، يعد اختبار خرج الجهد وتدفق التيار أمرًا ضروريًا لضمان الأداء السليم.

- اختبار البيئة: لتقييم الأداء في ظل الظروف القاسية، بما في ذلك التغيرات في درجات الحرارة والرطوبة.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

بالنسبة للمشترين الدوليين بين الشركات B2B، فإن التحقق من عمليات مراقبة الجودة لدى الموردين أمر بالغ الأهمية لضمان موثوقية المنتج. وفيما يلي بعض الاستراتيجيات:

-

عمليات تدقيق الموردين: يمكن أن يساعد إجراء عمليات تدقيق منتظمة للموردين في التحقق من الامتثال لمعايير الجودة وعمليات التصنيع.

-

طلب تقارير مراقبة الجودة: يجب على الموردين تقديم وثائق توضح بالتفصيل تدابير مراقبة الجودة ونتائج الاختبارات التي يجرونها، والتي يمكن مراجعتها لتحقيق الشفافية.

-

عمليات التفتيش من طرف ثالث: يمكن أن يوفر إشراك خدمات الفحص من طرف ثالث تقييمًا غير متحيز لعمليات التصنيع وضمان الجودة الخاصة بالمورد.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

يجب أن يكون المشترون الدوليون، لا سيما من مناطق متنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، على دراية بالفروق الدقيقة المحددة في مراقبة الجودة:

-

الامتثال التنظيمي: قد يكون للمناطق المختلفة لوائح تنظيمية مختلفة فيما يتعلق بمكونات السيارات. يجب على المشترين التأكد من امتثال الموردين للوائح المحلية في أسواقهم.

-

الاعتبارات الثقافية: يمكن أن يؤدي فهم السياق الثقافي للموردين إلى تحسين التواصل والتعاون، مما يؤدي إلى نتائج أفضل من حيث الجودة.

-

حواجز اللغة: يمكن أن يساعد ضمان توفر الوثائق الفنية بلغات متعددة في تجنب سوء الفهم في توقعات الجودة.

من خلال فهم عمليات التصنيع ومقاييس ضمان الجودة المرتبطة بالبطاريات ومولدات الكهرباء، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة، مما يضمن لهم الاستثمار في مكونات موثوقة وعالية الجودة لتلبية احتياجاتهم.

دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد’

لمساعدة مشتري B2B في تشخيص ما إذا كانت المشاكل في سياراتهم نابعة من البطارية أو مولد التيار المتردد، يوفر هذا الدليل العملي للمصادر قائمة مرجعية خطوة بخطوة. يُعد فهم الاختلافات بين هذه المكونات أمراً حيوياً للحفاظ على أداء السيارة وضمان الكفاءة التشغيلية. اتبع هذا الدليل لاتخاذ قرارات مستنيرة من شأنها توفير الوقت والموارد في نهاية المطاف.

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

الخطوة 1: تحديد الأعراض الشائعة

قبل الاستعانة بأدوات أو خدمات التشخيص، تعرّف على الأعراض الشائعة المرتبطة بأعطال البطارية ومولد التيار المتردد. عادةً ما يشير بطء دوران المحرك أو ضجيج النقر إلى ضعف البطارية، بينما تشير الأضواء الخافتة وتنبيهات لوحة العدادات إلى وجود مشاكل في المولد. سيؤدي التعرف على هذه العلامات إلى تبسيط عملية التقييم.

الخطوة 2: تقييم احتياجات معدات التشخيص

تقييم معدات التشخيص المطلوبة لتحديد السبب الجذري للمشكلة. تشمل الأدوات الأساسية أجهزة القياس المتعددة لاختبار الجهد، وأجهزة اختبار البطارية، وأجهزة اختبار المولد. تأكد من قدرة المعدات على التعامل مع الجهد والمواصفات الخاصة بالمركبات التي تديرها، حيث سيعزز ذلك من الدقة في تشخيص المشاكل.

الخطوة 3: حدد المواصفات الفنية الخاصة بك

بمجرد معرفة الأعراض والأدوات اللازمة، حدد المتطلبات الفنية المحددة للمعدات أو الخدمات التي تحتاجها. ضع في اعتبارك عوامل مثل التوافق مع مختلف طرازات المركبات وسهولة الاستخدام ودقة البيانات. هذه الخطوة ضرورية لضمان أن الحلول التي تشتريها ستلبي احتياجاتك التشغيلية بفعالية.

الخطوة 4: تقييم الموردين المحتملين

قبل الالتزام بمورّد ما، قم بإجراء بحث شامل للتحقق من موثوقيته وخبرته. اطلب ملفات تعريف الشركة ودراسات حالة ومراجع من صناعات أو مناطق مشابهة. ابحث عن الموردين الذين يقدمون ضمانات ودعم ما بعد البيع، حيث يمكن أن يكون ذلك مؤشراً على الجودة وخدمة العملاء.

الخطوة 5: التحقق من الشهادات والامتثال

تأكد من أن أدوات أو خدمات التشخيص التي تفكر فيها معتمدة ومتوافقة مع معايير الصناعة ذات الصلة. ابحث عن شهادات مثل ISO أو لوائح السيارات المحلية التي تثبت التزام المورد بالجودة والسلامة. هذه الخطوة ضرورية للتخفيف من المخاطر المرتبطة بالمنتجات دون المستوى المطلوب.

الخطوة 6: طلب عينات أو عروض توضيحية

إن أمكن، اطلب عينات من معدات التشخيص أو عروض توضيحية للخدمات. يتيح لك ذلك تقييم الأداء وسهولة الاستخدام بشكل مباشر. انتبه إلى مدى سهولة توفير المعدات لقراءات واضحة، بالإضافة إلى مدى سهولة معالجة المورد لأي أسئلة أو مخاوف.

الخطوة 7: قارن الأسعار والشروط

وأخيراً، قم بإجراء مقارنة أسعار بين الموردين المختارين. انظر إلى ما هو أبعد من التكلفة الأولية؛ ضع في اعتبارك شروط الضمان واتفاقيات الخدمة والوفورات المحتملة على المدى الطويل من المنتجات الموثوقة. يضمن لك هذا التقييم الشامل اتخاذ قرار فعال من حيث التكلفة يتماشى مع ميزانيتك التشغيلية وتوقعات الجودة.

من خلال اتباع قائمة المراجعة هذه، يمكن للمشترين بين الشركات التعامل بفعالية مع تعقيدات تشخيص مشاكل البطاريات ومولدات التيار المتردد، مما يضمن حصولهم على الأدوات والخدمات المناسبة لاحتياجاتهم.

تحليل شامل للتكلفة والتسعير لكيفية معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد مصدر

ما هي مكونات التكلفة الرئيسية في الحصول على حلول تشخيص البطارية والمولد؟

عند البحث عن حلول لتشخيص مشاكل البطاريات ومولدات التيار المتردد، فإن فهم هيكل التكلفة أمر ضروري لإدارة الميزانية بفعالية. تشمل مكونات التكلفة الرئيسية المواد والعمالة ونفقات التصنيع العامة والأدوات ومراقبة الجودة (QC) والخدمات اللوجستية وهامش المورد.

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

-

المواد: تتأثر تكلفة المواد بالمكونات المستخدمة في أدوات التشخيص. يمكن أن تؤدي أجهزة الاستشعار والإلكترونيات عالية الجودة التي توفر قراءات دقيقة إلى زيادة التكاليف بشكل كبير. وقد يقدم الموردون مستويات جودة مختلفة، مما يؤثر على الأسعار.

-

العمل: الفنيون المهرة ضروريون لتجميع أدوات التشخيص وتقديم الخدمة. يمكن أن تختلف تكاليف العمالة بشكل كبير بناءً على المنطقة والخبرة المطلوبة وقوانين العمل في مختلف البلدان. على سبيل المثال، قد تكون تكاليف العمالة أقل في أمريكا الجنوبية مقارنةً بأوروبا، مما يؤثر على السعر الإجمالي للخدمة.

-

تكاليف التصنيع العامة: ويشمل ذلك التكاليف المتعلقة بتشغيل مرافق الإنتاج، مثل المرافق والإيجار. يمكن لعمليات التصنيع الفعالة أن تقلل من التكاليف العامة، مما يؤدي إلى تسعير أفضل للمشترين.

-

الأدوات: قد يكون الاستثمار في الأدوات المتخصصة للتشخيص كبيراً. وقد ينقل الموردون هذه التكاليف إلى المشترين، لا سيما إذا كانوا يقدمون حلولاً متقدمة ومخصصة.

-

مراقبة الجودة (QC): تضمن إجراءات مراقبة الجودة الصارمة استيفاء أدوات التشخيص لمعايير محددة. يمكن أن تضيف هذه العملية إلى التكلفة الإجمالية ولكنها ضرورية للحفاظ على الموثوقية، خاصة في المناطق ذات الظروف البيئية المتفاوتة.

-

اللوجستيات: يمكن أن تختلف تكاليف الشحن والمناولة بناءً على الوجهة وحجم الطلب. يجب على المشترين الدوليين مراعاة الآثار المترتبة على التأخير في الشحن والرسوم الجمركية ورسوم المناولة عند حساب التكاليف الإجمالية.

-

الهامش: عادةً ما يدرج الموردون هامش ربح في أسعارهم. ويمكن أن يساعد فهم معيار السوق للهوامش في مختلف المناطق في المفاوضات.

كيف تؤثر العوامل المؤثرة في الأسعار على تكلفة أدوات تشخيص البطارية والمولد؟

يمكن أن تؤثر عدة عوامل على أسعار تشخيص البطاريات ومولدات التيار المتردد، خاصةً بالنسبة للمشترين الدوليين من الشركات.

-

الحجم/الحد الأدنى للطلب: غالباً ما يؤدي طلب كميات أكبر إلى خفض تكاليف الوحدة الواحدة. وينبغي للمشترين تقييم احتياجاتهم والنظر في الشراء بالجملة لزيادة كفاءة التكلفة إلى أقصى حد.

-

المواصفات والتخصيص: يمكن أن تترتب على الحلول المخصصة المصممة خصيصًا لأنواع معينة من المركبات أو الاحتياجات الإقليمية تكاليف إضافية. وينبغي على المشترين الموازنة بين فوائد التخصيص وقيود الميزانية.

-

شهادات المواد والجودة: قد تكون المواد والشهادات عالية الجودة (مثل معايير المنظمة الدولية لتوحيد المقاييس) ذات جودة أعلى (مثل معايير المنظمة الدولية لتوحيد المقاييس) ذات تكلفة عالية. ومع ذلك، فإن الاستثمار في الأدوات المعتمدة يمكن أن يقلل من التكاليف التشغيلية على المدى الطويل بسبب انخفاض الأعطال ومطالبات الضمان.

-

عوامل الموردين: تلعب سمعة المورد وموثوقيته دوراً حاسماً في التسعير. وقد يتقاضى الموردون الراسخون رسوماً أعلى نظراً لسجلهم الحافل بالإنجازات، لكنهم غالباً ما يقدمون دعماً وموثوقية أفضل.

-

مصطلحات التجارة الدولية: يمكن أن يؤثر اختيار شروط التجارة الدولية بشكل كبير على إجمالي تكاليف الإنزال. وينبغي للمشترين فهم الآثار المترتبة على مصطلحات مثل فوب (FOB) (مجاناً على ظهر السفينة) أو سيف (التكلفة والتأمين والشحن) لتقدير التكاليف الإجمالية بشكل أفضل.

ما هي أفضل نصائح للمشتري للتفاوض على التكاليف في حلول البطاريات والمولدات؟

بالنسبة للمشترين الدوليين بين الشركات، لا سيما في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، يتطلب التفاوض على التكاليف بفعالية تخطيطاً استراتيجياً:

-

إجراء أبحاث السوق: إن فهم السوق المحلية والدولية يمكن أن يوفر لك ميزة أثناء المفاوضات. ويمكن أن تساعد معرفة أسعار المنافسين في تحديد نطاق عادل للمفاوضات.

-

تقييم التكلفة الإجمالية للملكية (TCO): ضع في اعتبارك ليس فقط التكاليف الأولية ولكن أيضًا التكاليف التشغيلية طويلة الأجل المرتبطة بأدوات التشخيص. وقد يؤدي الاستثمار الأولي الأعلى قليلاً إلى انخفاض تكاليف الصيانة والاستبدال.

-

التفاوض على شروط الدفع: يمكن أن تحسن شروط الدفع المرنة من التدفق النقدي وتجعل عمليات الشراء الكبيرة أكثر جدوى. ناقش خيارات الدفع بالتقسيط أو الخصومات على المدفوعات المبكرة.

-

تقييم اللوائح المحلية: كن على علم بأي رسوم أو ضرائب استيراد قد تؤثر على الأسعار. ففهمها يمكن أن يساعد في التفاوض على صفقات شاملة أفضل مع الموردين.

-

بناء العلاقات: يمكن أن تؤدي إقامة علاقة طويلة الأمد مع الموردين إلى أسعار أفضل بمرور الوقت. وغالباً ما تؤدي الثقة والولاء إلى شروط مواتية للمشترين المتكررين.

إخلاء المسؤولية بشأن الأسعار الإرشادية

يمكن أن تتقلب أسعار أدوات تشخيص البطاريات ومولدات التيار المتردد بناءً على ظروف السوق واستراتيجيات تسعير الموردين والعوامل الاقتصادية الإقليمية. لذلك، من الضروري أن يتواصل المشترون مباشرةً مع الموردين للحصول على معلومات التسعير الأكثر دقة وحداثة المصممة خصيصًا لتلبية احتياجاتهم وظروفهم الخاصة.

تحليل البدائل: مقارنة كيف يمكنني معرفة ما إذا كانت المشكلة في البطارية أو المولد مع حلول أخرى

مقدمة: استكشاف البدائل لتشخيص مشاكل البطارية أو المولد

عند مواجهة التحدي المتمثل في تشخيص مشاكل السيارة، خاصةً تلك المتعلقة بالبطارية ومولد التيار المتردد، غالباً ما تبحث الشركات عن حلول فعالة وموثوقة. إن فهم الاختلافات بين هذه المكونات أمر بالغ الأهمية لتجنب الإصلاحات والتكاليف غير الضرورية. يبحث هذا القسم في الطريقة التقليدية لتقييم ما إذا كانت المشكلة تكمن في البطارية أو مولد التيار المتردد مقابل حلين بديلين للتشخيص: أدوات تشخيص السيارات وخدمات السيارات الاحترافية.

جدول المقارنة

| جانب المقارنة | كيف يمكنني معرفة ما إذا كانت المشكلة في البطارية أو المولد | أدوات تشخيص السيارات | خدمات السيارات الاحترافية |

|---|---|---|---|

| الأداء | التعرف على الأعراض الأساسية؛ قد يؤدي إلى تشخيص خاطئ | دقة عالية؛ بيانات شاملة عن أداء النظام | تشخيص الخبراء بالمعدات؛ فرصة منخفضة للخطأ |

| التكلفة | منخفضة التكلفة؛ نهج "اصنعها بنفسك" في المقام الأول | تكلفة معتدلة؛ تتطلب شراء أدوات | تكلفة أعلى؛ تشمل رسوم العمالة والتشخيص |

| سهولة التنفيذ | فحوصات بسيطة؛ لا تتطلب أدوات خاصة | تتطلب معرفة لتفسير البيانات؛ قد تحتاج إلى تدريب | بسيطة بالنسبة للمستخدم؛ تعتمد على خبرة الفنيين |

| الصيانة | الحد الأدنى؛ لا يتطلب سوى مهارات الملاحظة | يحتاج إلى تحديثات دورية للبرامج والمعايرة | لا شيء مطلوب؛ يعتمد على مزود الخدمة |

| أفضل حالة استخدام | فحوصات سريعة وغير رسمية للمشكلات البسيطة | تحليل مفصل للمشكلات المعقدة | التشخيص الشامل للمشاكل الخطيرة |

تفصيل البدائل

كيف يمكنني معرفة ما إذا كانت المشكلة في البطارية أو المولد

تعتمد هذه الطريقة على التعرف على الأعراض المرتبطة بأعطال البطارية أو مولد التيار المتردد، مثل بطء دوران المحرك أو تعتيم الأضواء أو أضواء التحذير في لوحة العدادات. في حين أن هذه الطريقة يمكن أن تكون فعالة من حيث التكلفة ومباشرة، إلا أنها غالبًا ما تفتقر إلى الدقة، مما يؤدي إلى احتمال حدوث خطأ في التشخيص. بالنسبة للشركات ذات الخبرة التقنية المحدودة، قد تؤدي هذه الطريقة إلى استبدال قطع غيار غير ضرورية وزيادة وقت التوقف عن العمل.

أدوات تشخيص السيارات

توفر أدوات تشخيص السيارات، مثل الماسحات الضوئية OBD-II، تحليلاً أكثر تفصيلاً لأداء السيارة ويمكنها تحديد المشاكل في كل من البطارية ومولد التيار المتردد بدقة عالية. يمكن لهذه الأدوات قراءة رموز الأعطال ومراقبة البيانات في الوقت الحقيقي، مما يوفر رؤى حول النظام الكهربائي للسيارة. ومع ذلك، فهي تأتي بتكاليف معتدلة وتتطلب من المستخدمين بعض المعرفة التقنية لتفسير النتائج بفعالية. بالإضافة إلى ذلك، قد تحتاج هذه الأدوات إلى تحديثات أو معايرة دورية، ما يزيد من عبء الصيانة الإجمالي.

خدمات السيارات الاحترافية

يوفر الاستعانة بخدمات السيارات الاحترافية أعلى مستوى من الدقة في التشخيص، حيث يستخدم الفنيون المدربون معدات متخصصة لتقييم مشاكل السيارة. يستبعد هذا الخيار التخمين الذي ينطوي عليه تشخيص مشاكل البطارية أو مولد التيار المتردد، مما يضمن حصول الشركات على حلول موثوقة ودقيقة. ومع ذلك، تكون التكلفة أعلى بشكل عام بسبب رسوم العمالة والتشخيص. بالنسبة للشركات التي تعطي الأولوية لوقت التشغيل والموثوقية، يمكن أن يؤدي الاستثمار في الخدمات الاحترافية إلى توفير الوقت والموارد في نهاية المطاف من خلال معالجة المشكلات بشكل صحيح من المرة الأولى.

الخاتمة: اختيار الحل المناسب لاحتياجات عملك التجاري

يعتمد اختيار الطريقة المناسبة لتشخيص مشاكل البطارية أو مولد التيار المتردد على عوامل مختلفة، بما في ذلك الميزانية والخبرة الفنية ومدى إلحاح المشكلة. قد تجد الشركات التي لديها معرفة أساسية بالسيارات أن طريقة التعرف على الأعراض مفيدة لإجراء فحوصات سريعة، بينما قد يستفيد من يحتاجون إلى تحليل شامل من أدوات تشخيص السيارات. للحصول على نتائج أكثر دقة وموثوقية، خاصة في الحالات الحرجة، فإن خدمات السيارات الاحترافية هي الخيار الأفضل. من خلال تقييم هذه البدائل، يمكن للمشترين من الشركات اتخاذ قرارات مستنيرة تتماشى مع احتياجاتهم التشغيلية وتضمن بقاء سياراتهم موثوقة وفعالة.

الخصائص التقنية الأساسية والمصطلحات التجارية لكيفية معرفة ما إذا كانت البطارية أو مولد التيار المتردد

ما هي الخصائص التقنية الرئيسية التي يجب مراعاتها عند تشخيص مشاكل البطارية أو المولد؟

عند تقييم ما إذا كانت مشكلة السيارة تنبع من البطارية أو مولد التيار المتردد، فإن فهم الخصائص التقنية المهمة يمكن أن يساعد مشتري B2B بشكل كبير في اتخاذ قرارات مستنيرة. فيما يلي بعض المواصفات الأساسية التي يجب مراعاتها:

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

-

أمبير التدوير البارد (CCA)

– التعريف: يقيس CCA قدرة البطارية على تشغيل المحرك في درجات الحرارة الباردة. وهو يشير إلى مقدار التيار الذي يمكن للبطارية توصيله لمدة 30 ثانية عند درجة حرارة 0 درجة فهرنهايت (-18 درجة مئوية) مع الحفاظ على جهد لا يقل عن 7.2 فولت.

– أهمية B2B: بالنسبة للشركات في المناطق الأكثر برودة، يضمن اختيار بطاريات ذات تصنيف CCA أعلى أداءً موثوقاً خلال أشهر الشتاء، مما يقلل من وقت التعطل وتكاليف الصيانة. -

السعة الاحتياطية (RC)

– التعريف: يشير RC إلى المدة التي يمكن لبطارية مشحونة بالكامل أن تحافظ على الحد الأدنى من الجهد (10.5 فولت على الأقل) تحت حمل محدد (عادةً 25 أمبير).

– أهمية B2B: تُعد البطارية ذات الترددات العالية ضرورية لمشغلي الأساطيل الذين يعتمدون على المركبات لفترات طويلة دون إعادة الشحن، مما يضمن الكفاءة التشغيلية ويقلل من احتمال حدوث أعطال غير متوقعة. -

ناتج الجهد

– التعريف: إن خرج الجهد القياسي لبطاريات السيارات هو 12 فولت، في حين أن خرج المولدات عادةً يتراوح بين 13.5 إلى 14.5 فولت عند تشغيل المحرك.

– أهمية B2B: يعد فهم خرج الجهد أمرًا بالغ الأهمية للشركات التي تقوم بتصنيع أو توريد المكونات الكهربائية، حيث يساعد في تصميم أنظمة متوافقة وضمان الأداء الأمثل. -

دورة حياة البطارية

– التعريف: يشير هذا إلى عدد دورات الشحن والتفريغ الكاملة التي يمكن أن تمر بها البطارية قبل أن تتضاءل قدرتها بشكل كبير.

– أهمية B2B: تتيح معرفة دورة حياة البطاريات للشركات إدارة المخزون بفعالية، والتخطيط لعمليات الاستبدال، وتقليل الاضطرابات التشغيلية إلى الحد الأدنى. -

المقاومة الداخلية

– التعريف: وهي معارضة تدفق التيار داخل البطارية، والتي يمكن أن تؤثر على كفاءتها وأدائها.

– أهمية B2B: بالنسبة للمصنعين والموردين، يمكن أن يساعد فهم المقاومة الداخلية في مراقبة الجودة وتطوير المنتجات، مما يضمن أن البطاريات تلبي معايير الأداء.

ما هي المصطلحات التجارية التي يجب أن يعرفها مشترو B2B فيما يتعلق بمشاكل البطارية والمولد؟

يعد فهم المصطلحات الصناعية أمرًا بالغ الأهمية للتواصل الفعال واتخاذ القرارات في قطاع السيارات. فيما يلي بعض المصطلحات الشائعة ذات الصلة بتشخيص البطارية ومولد التيار المتردد:

-

OEM (الشركة المصنعة للمعدات الأصلية)

– التعريف: يشير مصطلح OEM إلى القطع المصنوعة من قبل الشركة المصنعة الأصلية للسيارة، مما يضمن التوافق والموثوقية.

– الصلة بالموضوع: غالباً ما يفضل المشترون بين الشركات قطع الغيار الأصلية للحفاظ على تغطية الضمان وضمان الأداء الأمثل للسيارة. -

MOQ (الحد الأدنى لكمية الطلب)

– التعريف: موك هو أصغر كمية من المنتج يرغب المورد في بيعها.

– الصلة بالموضوع: معرفة موك يساعد الشركات على تخطيط مشترياتها من المخزون وإدارة التدفق النقدي بفعالية. -

طلب عرض أسعار (RFQ)

– التعريف: طلب عرض الأسعار هو مستند يتم إرساله إلى الموردين لطلب تسعير وشروط لمنتجات محددة.

– الصلة بالموضوع: يسمح استخدام طلبات عروض الأسعار للمشترين بين الشركات بمقارنة العروض والتفاوض على شروط أفضل، مما يؤدي إلى توفير التكاليف. -

شروط التجارة الدولية (Incoterms)

– التعريف: وهي مصطلحات تجارية موحدة تحدد مسؤوليات المشترين والبائعين في المعاملات الدولية.

– الصلة بالموضوع: يساعد الإلمام بشروط التجارة الدولية المشترين من الشركات على فهم مسؤوليات الشحن والتكاليف وإدارة المخاطر في المعاملات عبر الحدود. -

تغطية الضمان

– التعريف: يشير هذا إلى الضمان المقدم من الشركة المصنعة فيما يتعلق بأداء المنتج وعمره الافتراضي.

– الصلة بالموضوع: يعد فهم شروط الضمان أمرًا ضروريًا للمشترين بين الشركات لحماية استثماراتهم وضمان موثوقية المنتج.

من خلال فهم هذه الخصائص التقنية والمصطلحات التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات أكثر استنارة فيما يتعلق بتشخيص البطاريات ومولدات التيار المتردد، مما يؤدي في النهاية إلى تحسين الكفاءة التشغيلية وخفض التكاليف.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع البطارية أو مولد التيار المتردد

ما هي ديناميكيات السوق الحالية والاتجاهات الرئيسية التي تؤثر على توريد البطاريات والمولدات؟

يشهد قطاع السيارات تحولاً كبيرًا مدفوعًا بالتقدم التكنولوجي وتغير سلوكيات المستهلكين. يركّز المشترون الدوليون من الشركات على نحو متزايد على توفير مصادر موثوقة لمكونات السيارات، بما في ذلك البطاريات ومولدات التيار المتردد، لا سيما من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. ومن المحركات الرئيسية لهذا الاتجاه هو ارتفاع عدد السيارات الكهربائية والهجينة، والتي تتطلب تقنيات بطاريات وأنظمة شحن أكثر تطوراً. ومع سعي الدول لإيجاد حلول نقل أكثر مراعاة للبيئة، يزداد الطلب على البطاريات عالية السعة والمتانة.

كما تعمل التقنيات الناشئة مثل إنترنت الأشياء (إنترنت الأشياء) على إعادة تشكيل المشهد. يمكن لأدوات التشخيص الذكية الآن توفير رؤى في الوقت الفعلي حول صحة البطارية ومولد التيار المتردد، مما يسمح للشركات بإدارة الصيانة بشكل استباقي وتقليل وقت التعطل. يعد هذا التحول نحو اتخاذ القرارات المستندة إلى البيانات أمرًا بالغ الأهمية بالنسبة للمشترين من الشركات الذين يهدفون إلى تعزيز الكفاءة التشغيلية.

بالإضافة إلى ذلك، تأثرت ديناميكيات سلسلة التوريد العالمية بالاضطرابات الأخيرة، مما دفع الشركات إلى البحث عن المزيد من الموردين المحليين لضمان توافر المنتجات بشكل ثابت. ويعطي المشترون الآن الأولوية للشراكات مع المصنعين الذين يُظهرون الموثوقية وضمان الجودة في عروض البطاريات ومولدات التيار المتردد. ويؤدي التركيز على الاستدامة أيضًا إلى تشكيل استراتيجيات التوريد، حيث تسعى الشركات إلى التوافق مع الموردين الذين يلتزمون بالممارسات الصديقة للبيئة.

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

كيف تؤثر الاستدامة والتوريد الأخلاقي على عملية شراء البطاريات والمولدات؟

أصبح التأثير البيئي لمكونات السيارات، وخاصة البطاريات ومولدات التيار المتردد، مصدر قلق محوري للمشترين الدوليين من الشركات. فمع تحول صناعة السيارات نحو التحول نحو الكهرباء، يخضع توريد المواد الخام مثل الليثيوم والكوبالت والنيكل للتدقيق بسبب آثارها البيئية والأخلاقية المحتملة. يدرك المشترون بشكل متزايد أهمية سلاسل التوريد الأخلاقية ويبحثون عن موردين يعطون الأولوية لممارسات التوريد المسؤولة.

إن دمج الاستدامة في استراتيجيات المشتريات لا يعالج المخاوف البيئية فحسب، بل يعزز سمعة العلامة التجارية أيضًا. وتبحث الشركات الآن عن شهادات ‘خضراء’ تضمن أن المواد المستخدمة في البطاريات ومولدات الطاقة المتجددة يتم الحصول عليها بطريقة مسؤولة. ويشمل ذلك البحث عن الموردين الذين يمكنهم إثبات امتثالهم للمعايير البيئية الدولية، مثل ISO 14001، وأولئك الذين يشاركون في مبادرات إعادة التدوير للتخفيف من النفايات.

وعلاوة على ذلك، يؤثر الدفع نحو ممارسات الاقتصاد الدائري على كيفية تعامل الشركات مع المصادر. فالمشترون مهتمون بالموردين الذين يقدمون برامج استرجاع للبطاريات والمولدات الكهربائية المستعملة، مما يسهل دورة حياة أكثر استدامة لهذه المنتجات. من خلال التوافق مع الموردين الذين يتشاركون الالتزام بالاستدامة، يمكن للشركات تقليل بصمتها البيئية مع تلبية طلب المستهلكين المتزايد على المنتجات الصديقة للبيئة.

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

كيف تطور سوق البطاريات والمولدات بمرور الوقت؟

يعكس تطور سوق البطاريات ومولدات التيار المتردد التغيرات الأوسع نطاقاً في تكنولوجيا السيارات وتوقعات المستهلكين. تاريخياً، كانت بطاريات الرصاص الحمضية تهيمن على السوق بسبب قدرتها على تحمل التكاليف والموثوقية. ولكن، مع تقدم تكنولوجيا السيارات، ظهرت الحاجة إلى حلول طاقة أكثر كفاءة وأطول عمراً. وقد أدى ذلك إلى ظهور بطاريات الليثيوم أيون التي أصبحت الآن هي المعيار في السيارات الكهربائية والطرازات الهجينة.

وبالمثل، تطورت المولدات من أجهزة ميكانيكية بسيطة إلى مكونات متطورة قادرة على إدارة الأنظمة الكهربائية المعقدة في السيارات الحديثة. وقد أدى التحول نحو المزيد من الوظائف الإلكترونية في السيارات إلى زيادة الطلب على المولدات عالية الأداء التي يمكن أن تدعم أنظمة مساعدة السائق المتقدمة (ADAS) والتكنولوجيا داخل السيارة.

مع استمرار السوق في التكيف مع التقنيات الناشئة ومتطلبات الاستدامة، يجب على المشترين بين الشركات البقاء على اطلاع على هذه التغييرات. يمكن أن يوفر فهم السياق التاريخي لتطوير البطاريات ومولدات التيار المتردد رؤى قيمة في استراتيجيات التوريد المستقبلية، مما يمكّن المشترين من اتخاذ قرارات مستنيرة تتماشى مع التطورات التكنولوجية واتجاهات السوق.

الأسئلة المتداولة (FAQs) لمشتري B2B عن كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

-

كيف يمكنني تحديد ما إذا كانت مشكلة سيارتي في البطارية أم في المولد؟

لتحديد ما إذا كانت المشكلة تكمن في البطارية أو مولد الكهرباء، راقب الأعراض عن كثب. غالباً ما يشير بطء دوران المحرك أو ضجيج النقر عند محاولة تشغيل المحرك إلى وجود مشكلة في البطارية، بينما يشير خفوت المصابيح الأمامية أو أضواء التحذير في لوحة العدادات إلى وجود مشكلة في المولد. يمكن أن يساعد أيضاً إجراء عملية التشغيل السريع؛ إذا كانت السيارة تعمل لفترة وجيزة ثم توقفت، فهذا يشير إلى عطل في المولد. يمكن للصيانة والاختبار الدوري لكلا المكونين أن يمنع التشخيص الخاطئ والتكاليف غير الضرورية. -

ما هي العلامات الرئيسية التي تشير إلى تعطل البطارية؟

تتضمن المؤشرات الشائعة لفشل البطارية بطء تشغيل المحرك، واستمرار إضاءة أضواء التحذير في لوحة العدادات، وتورم أو تسرب من علبة البطارية. إذا احتاجت سيارتك إلى عمليات تشغيل متكررة أو كان أداؤها غير متناسق في بدء التشغيل، فهذه علامات مهمة على تلف البطارية. بالإضافة إلى ذلك، إذا لاحظت وجود رائحة بيض فاسد، فهذا يشير إلى وجود تسرّب في البطارية ومن الضروري استبدالها فوراً لمنع حدوث المزيد من الضرر. -

ما هي أعراض تعطل مولد التيار المتردد؟

عادةً ما تظهر على المولد المتعطل أعراض مثل الأضواء الخافتة أو الوامضة والسلوك غير المنتظم للملحقات الكهربائية ورائحة احتراق المطاط بسبب ارتفاع درجة الحرارة. إذا استنزفت البطارية على الرغم من القيادة الأخيرة، فهذا يشير إلى أن المولد لا يعيد شحن البطارية بشكل كافٍ. كما يمكن أن تشير أضواء التحذير في لوحة العدادات، وخاصة الأيقونة التي تظهر على شكل بطارية، إلى وجود مشاكل في المولد. يمكن أن تساعد عمليات الفحص المنتظمة في اكتشاف هذه المشاكل مبكراً. -

ما الذي يجب أن أضعه في الاعتبار عند الحصول على البطاريات ومولدات التيار المتردد لشركتي؟

عند الحصول على البطاريات ومولدات الكهرباء، ضع في اعتبارك عوامل مثل جودة المنتج والتوافق مع طرازات السيارات المختلفة وموثوقية المورد. من المهم فحص الموردين من خلال التحقق من شهاداتهم، ومراجعات العملاء، ودعم ما بعد البيع. بالإضافة إلى ذلك، استفسر عن الضمانات وسياسات الإرجاع، حيث يمكن أن تؤثر بشكل كبير على قرار الشراء ورضاك على المدى الطويل. -

كيف يمكنني تخصيص طلبات البطارية أو مولد التيار المتردد لتلبية احتياجاتي الخاصة؟

لتخصيص الطلبات، قم بإبلاغ الموردين المحتملين بمتطلباتك المحددة بوضوح. يتضمن ذلك تفاصيل عن الجهد والحجم والسعة وأي ميزات خاصة تحتاجها. العديد من المصنعين على استعداد لتلبية الطلبات المخصصة، خاصةً بالنسبة للمشتريات بالجملة. احرص على مناقشة الحد الأدنى لكميات الطلبات (MOQs) والمهل الزمنية للتوافق مع استراتيجية إدارة المخزون لديك. -

ما هي شروط الدفع التي يجب أن أتفاوض بشأنها مع الموردين للبطاريات ومولدات التيار المتردد؟

التفاوض على شروط دفع مواتية أمر بالغ الأهمية لإدارة التدفق النقدي. وتتضمن الشروط الشائعة صافي 30 أو صافي 60 أو حتى صافي 90 يوماً، حسب علاقتك مع المورد وحجم طلباتك. ضع في اعتبارك مناقشة خيارات الخصومات على الدفعات المبكرة أو جداول الدفع المرنة، خاصةً إذا كنت تقدم طلبات كبيرة. تأكد دائماً من توثيق الشروط في اتفاقية الشراء لتجنب سوء الفهم. -

كيف يمكنني التأكد من ضمان الجودة (QA) للبطاريات ومولدات التيار المتردد؟

تنفيذ عملية قوية لضمان الجودة من خلال مطالبة الموردين بتقديم مواصفات المنتج ونتائج الاختبارات وشهادات الامتثال. يمكن أن تساعد عمليات التدقيق المنتظمة لعملية التصنيع والمنتجات النهائية في الحفاظ على معايير الجودة. ضع في اعتبارك وضع سياسة إرجاع للسلع المعيبة والحفاظ على التواصل المفتوح مع الموردين من أجل حل سريع لأي مشاكل تنشأ بعد الشراء. -

ما هي الاعتبارات اللوجستية المهمة عند استيراد البطاريات ومولدات التيار المتردد؟

عند استيراد البطاريات ومولدات الكهرباء، ركز على العوامل اللوجستية مثل طرق الشحن واللوائح الجمركية ومهل الشحن. تأكد من أن مورديك على دراية بمتطلبات الشحن الدولي، خاصة بالنسبة للمواد الخطرة مثل البطاريات. خطط للتأخيرات المحتملة من خلال بناء أوقات احتياطية في سلسلة التوريد الخاصة بك. بالإضافة إلى ذلك، ضع في اعتبارك الآثار المترتبة على التعريفات والرسوم الجمركية على التكاليف الإجمالية، واعمل مع شركاء لوجستيين يمكنهم التعامل مع هذه التعقيدات بكفاءة.

أعلى 2 كيف يمكنني معرفة ما إذا كانت البطارية أو المولد قائمة المصنعين والموردين

1. على الصعيد الوطني - رؤى المولدات على الصعيد الوطني

المجال: blog.nationwide.com

تاريخ التسجيل: 1994 (31 عامًا)

مقدمة: المولد: يعمل على تشغيل السيارة عند تشغيل المحرك، ويشحن البطارية، ويدوم طوال عمر السيارة ولكنه قد يحتاج إلى الإصلاح أو الاستبدال بسبب البلى. تشمل علامات تلف المولد: الأضواء الداخلية الخافتة، والمصابيح الأمامية الخافتة أو شديدة السطوع، والضوضاء المزعجة، ورائحة الاحتراق. البطارية: تعمل على تخزين الطاقة، وتشغيل المحرك، وتوصيل الكهرباء إلى نظام الإشعال، وتعمل مع المولد البديل.

2. بروتير - خدمات السيارات والإطارات الفاخرة

المجال: protyre.co.uk

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: تقدم شركة Protyre مجموعة من خدمات السيارات بما في ذلك فحص البطارية وتركيب الإطارات وصيانة وصيانة السيارات. وتوفر الشركة إطارات فاخرة من علامات تجارية مثل ميشلان وبيريللي وجوديير وبريجستون، بالإضافة إلى خيارات متوسطة المدى من فايرستون وآفون وسوميتومو وهانكوك وإطارات اقتصادية من أوفيشن وبدجيت وأوتوجريب. يمكن حجز الخدمات عبر الإنترنت أو عبر الهاتف، ويمكن للعملاء...

خاتمة المصادر الاستراتيجية والتوقعات لكيفية معرفة ما إذا كانت المشكلة في البطارية أو المولد

في التعامل مع تعقيدات تشخيص ما إذا كانت مشاكل السيارة نابعة من البطارية أو مولد التيار المتردد، يمكن للمشترين الدوليين من الشركات الحصول على رؤى قيمة تعزز الكفاءة التشغيلية وإدارة التكاليف. يمكن أن يؤدي فهم الأعراض المميزة المرتبطة بكل مكوّن - مثل بطء دوران المحرك الذي يشير إلى فشل البطارية أو الأضواء الخافتة التي تشير إلى وجود مشكلة في المولد - إلى منع الاستبدال غير الضروري للقطع والتأخير في الخدمة. تُمكِّن هذه المعرفة الشركات من اتخاذ قرارات مستنيرة، مما يضمن الأداء الأمثل للمركبة وتقليل وقت التعطل إلى الحد الأدنى.

يؤدي التوريد الاستراتيجي دوراً حاسماً في هذه العملية، حيث إنه يمكّن الشركات من إقامة شراكات مع موردين ومقدمي خدمات موثوقين يمكنهم تقديم مكونات وخبرات عالية الجودة في مجال السيارات. يمكن أن تؤدي إقامة علاقات قوية مع موردين موثوق بهم في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا إلى تحسين الأسعار وتوافر قطع الغيار في الوقت المناسب وتحسين جودة الخدمة.

واستشرافاً للمستقبل، من الضروري أن يعطي المشترون من الشركات الأولوية للتثقيف في مجال صيانة المركبات وتشخيص مكوناتها. فمن خلال الاستثمار في التدريب والموارد، يمكن للشركات تعزيز ثقافة الإدارة الاستباقية للمركبات. لا يعزز هذا النهج من الموثوقية التشغيلية فحسب، بل يهيئ الشركات أيضاً للتكيف بسرعة مع متطلبات السوق المتطورة. تواصل مع الخبراء والموردين المحليين اليوم لضمان بقاء أسطولك جاهزاً وفعالاً على الطريق.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

صورة توضيحية متعلقة بـ كيف يمكنني معرفة ما إذا كانت بطاريتي أو مولد التيار المتردد

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.