مقدمة: الإبحار في السوق العالمية لقطع غيار المولدات الكهربائية

في المشهد المتطور باستمرار لصناعة السيارات العالمية، يمكن أن يمثل الحصول على قطع غيار المولدات عالية الجودة تحديات كبيرة للمشترين من الشركات بين الشركات، خاصةً أولئك الذين يعملون في أسواق متنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. بينما تسعى الشركات جاهدة لتلبية الطلب المتزايد على الأداء الموثوق للمركبات، يصبح فهم تعقيدات مواصفات قطع غيار المولدات وقدرات الموردين واتجاهات السوق الإقليمية أمرًا ضروريًا. تم تصميم هذا الدليل لإلقاء الضوء على تعقيدات الحصول على قطع غيار مولدات التيار المتردد، حيث يقدم رؤى حول مختلف الأنواع والتطبيقات والفروق الدقيقة لكل من الخيارات الجديدة والمعاد تصنيعها.

من خلال هذا المورد الشامل، سيجد المشترون الدوليون معلومات قيّمة حول كيفية فحص الموردين بفعالية، وتقييم معايير الجودة، والتعامل مع اعتبارات التكلفة. نحن نتعمق في عوامل مهمة مثل تصنيفات التيار، وأنواع الجهد، والتوافق مع مختلف طرازات السيارات وموديلاتها، مما يضمن أنك مجهز لاتخاذ قرارات شراء مستنيرة. من خلال معالجة الاحتياجات والتحديات المحددة التي تواجهها الشركات في مناطق مثل فيتنام والبرازيل، يمكّن هذا الدليل المشترين من الشركات من تحسين استراتيجيات الشراء الخاصة بهم. ويهدف في النهاية إلى تسهيل الوصول إلى قطع غيار المولدات عالية الجودة، مما يضمن الكفاءة التشغيلية والموثوقية في أداء المركبات في مختلف الأسواق.

جدول المحتويات

- قائمة موردي ومصنعي أجزاء المولد 1 الأعلى 1

- مقدمة: الإبحار في السوق العالمية لقطع غيار المولدات الكهربائية

- فهم أنواع أجزاء المولد وأشكاله المختلفة

- التطبيقات الصناعية الرئيسية لجزء المولد المتردد

- 3 نقاط ألم شائعة لدى المستخدمين لـ ‘جزء المولد’ وحلولها

- دليل اختيار المواد الاستراتيجية لجزء المولد

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لجزء المولد الكهربائي

- دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘جزء المولد’

- تحليل شامل للتكاليف والتسعير لتحديد مصادر قطع غيار المولدات

- تحليل البدائل: مقارنة جزء المولد مع الحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية لجزء المولد الكهربائي

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع أجزاء المولدات الكهربائية

- الأسئلة المتداولة (FAQs) لمشتري قطع غيار مولد التيار المتردد بين الشركات

- استنتاج وتوقعات التوريد الاستراتيجي لجزء المولد المتردد

- إخلاء مسؤولية هام وشروط الاستخدام

فهم أنواع أجزاء المولد وأشكاله المختلفة

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولدات الجديدة | مكونات جديدة تماماً، ذات أداء أعلى في العادة | تصنيع السيارات، خدمات أساطيل السيارات | الإيجابيات: أداء موثوق؛ تغطية ضمان موثوق به. السلبيات: تكلفة أولية أعلى. |

| المولدات المعاد تصنيعها | أعيد بناؤها من قطع مستعملة، وغالباً ما تكون معتمدة | محلات التصليح، والشركات ذات التكلفة العالية | الإيجابيات: تكلفة أقل؛ صديقة للبيئة. السلبيات: التباين المحتمل في الجودة. |

| مولدات كهربائية عالية الإنتاج | تصنيفات أمبيرية أعلى، مصممة للاستخدامات الصعبة | مركبات عالية الأداء، آلات ثقيلة | الإيجابيات: زيادة إمداد الطاقة؛ يدعم ترقيات ما بعد البيع. السلبيات: قد يتطلب الأمر إجراء تعديلات. |

| المولدات المزودة بمنظمات خارجية | تنظيم الجهد الذي يتم التعامل معه خارج الوحدة | السيارات المتخصصة والترميمات القديمة | الإيجابيات: ترقيات أسهل؛ قابلة للتخصيص. السلبيات: تركيب أكثر تعقيداً. |

| المولدات بدون فرش | بدون فراشي وتقليل البلى والتلف | التطبيقات الصناعية والسفن البحرية | الإيجابيات: عمر افتراضي أطول؛ صيانة أقل. السلبيات: تكلفة أعلى؛ توافق محدد. |

ما هي المولدات الجديدة ولماذا هي مهمة لمشتري B2B؟

المولدات الجديدة عبارة عن مكونات جديدة تم تصنيعها لتلبية مواصفات الشركة المصنعة للمعدات الأصلية أو تتجاوزها. وهي مثالية للشركات التي تعطي الأولوية للموثوقية وتغطية الضمان، مثل شركات تصنيع السيارات وخدمات الأساطيل. يجب أن يأخذ المشترون في الاعتبار الاستثمار الأولي، حيث أن هذه الوحدات عادةً ما تأتي بسعر أعلى مقارنة بالخيارات المعاد تصنيعها. ومع ذلك، فإن ضمان الأداء وطول العمر يجعلها خياراً مفضلاً للتطبيقات الحرجة.

كيف تقدم المولدات المعاد تصنيعها قيمة للشركات ذات التكلفة العالية؟

يتم إعادة بناء المولدات المعاد تصنيعها من مكونات مستعملة وغالباً ما تكون معتمدة لتلبية معايير أداء محددة. هذا الخيار شائع بين ورش التصليح والشركات التي تتطلع إلى تقليل النفقات. على الرغم من أن الوحدات المعاد تصنيعها أقل تكلفة بشكل عام، إلا أنه يجب على المشترين توخي الحذر بشأن جودة وموثوقية الأجزاء. إن التأكد من أن الشركة المعاد تصنيعها تتمتع بسمعة جيدة يمكن أن يخفف من المخاطر المرتبطة بالتباين المحتمل في الجودة.

ما هي فوائد المولدات عالية الإنتاجية لتطبيقات الأداء؟

توفر المولدات عالية الإنتاجية معدلات أمبيرية متزايدة، مما يجعلها مناسبة للمركبات عالية الأداء والآلات الثقيلة التي تتطلب طاقة كهربائية إضافية. ستجد الشركات العاملة في تعديلات ما بعد البيع أو تشغيل المعدات ذات المتطلبات الكهربائية العالية هذه المولدات مفيدة. في حين أنها توفر مزايا كبيرة في إمداد الطاقة، يجب أن يدرك المشترون أن التركيب قد يتطلب تعديلات لاستيعاب الإنتاج الأعلى.

لماذا تختار المولدات المزودة بمنظمات خارجية للتطبيقات المتخصصة؟

توفر المولدات المزودة بمنظمات خارجية مستوى من المرونة يمكن أن يكون مفيداً للمركبات المتخصصة أو عمليات الترميم القديمة. يتيح هذا التصميم ترقيات أسهل وخيارات تخصيص أسهل. ومع ذلك، يمكن أن يكون تعقيد التركيب عائقاً لبعض الشركات. إن فهم المتطلبات المحددة والتوافق مع الأنظمة الحالية أمر بالغ الأهمية لنجاح عملية الشراء.

ما المزايا التي توفرها المولدات بدون فرش للتطبيقات الصناعية؟

تم تصميم المولدات بدون فرش بدون فرش، مما يؤدي إلى تقليل التآكل والتلف وإطالة العمر الافتراضي. وهي مناسبة بشكل خاص للتطبيقات الصناعية والسفن البحرية حيث تكون الموثوقية وانخفاض الصيانة أمرًا بالغ الأهمية. على الرغم من أنها تأتي بتكلفة أعلى وتتطلب توافقًا محددًا، إلا أن التوفير طويل الأجل في الصيانة والاستبدال يجعلها خيارًا جذابًا للشركات التي تركز على الكفاءة التشغيلية.

التطبيقات الصناعية الرئيسية لجزء المولد المتردد

| الصناعة/القطاع | التطبيق المحدد لجزء المولد المولد | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | تشغيل الأنظمة الكهربائية للمركبات | يضمن التشغيل الموثوق للأنظمة الحرجة | التوافق مع طرازات محددة من المركبات ومتطلبات الجهد الكهربائي |

| الطاقة المتجددة | مولدات توربينات الرياح | يحول الطاقة الميكانيكية إلى طاقة كهربائية | تصنيفات المتانة والكفاءة للبيئات القاسية |

| معدات البناء | تشغيل الآلات الثقيلة | توفر طاقة ثابتة للأنظمة الهيدروليكية | متطلبات الأمبيرية بناءً على مواصفات الماكينات |

| الصناعة البحرية | تشغيل الأنظمة الكهربائية على متن الطائرة | تعزيز موثوقية الملاحة والسلامة | مواصفات مقاومة التآكل والمواصفات البحرية |

| الزراعة | تشغيل أنظمة الري بالطاقة | يدعم الإدارة الفعالة للمياه وإنتاجية المحاصيل | استقرار الجهد في ظل ظروف الحمل المتغيرة |

كيف يتم استخدام جزء المولد في صناعة السيارات؟

في قطاع تصنيع السيارات، تعتبر مولدات التيار المتردد ضرورية لتشغيل الأنظمة الكهربائية للسيارة، مثل الإضاءة والإشعال ووحدات التحكم الإلكترونية. يضمن المولد الموثوق به أن تظل البطارية مشحونة وأن تعمل جميع المكونات الكهربائية على النحو الأمثل. بالنسبة لمشتري B2B، يعد التوافق مع طرازات معينة من السيارات أمرًا ضروريًا، إلى جانب اعتبارات متطلبات الجهد وتقييمات التيار الكهربائي. يمكن أن يؤدي التأكد من أن المولد يفي بمواصفات الشركة المصنعة للمعدات الأصلية إلى منع الأعطال وتعزيز رضا العملاء.

ما الدور الذي يلعبه جزء المولد في تطبيقات الطاقة المتجددة؟

في الطاقة المتجددة، وخاصة في مولدات توربينات الرياح، تقوم المولدات بتحويل الطاقة الميكانيكية إلى طاقة كهربائية بكفاءة. ويُعد هذا التحويل أمرًا حيويًا لدمج مصادر الطاقة المتجددة في الشبكة وضمان إنتاج طاقة ثابت. بالنسبة للمشترين الدوليين، يعد الحصول على مولدات المولدات ذات المتانة والكفاءة العالية أمرًا بالغ الأهمية، خاصة في المناطق ذات الظروف الجوية القاسية. وتُعد القدرة على تحمل البيئات القاسية مع الحفاظ على الأداء من الاعتبارات المهمة للمشتريات.

كيف يعمل جزء المولد على تحسين العمليات في معدات البناء؟

في صناعة الإنشاءات، تعتمد الماكينات الثقيلة على المولدات لتشغيل الأنظمة الهيدروليكية والمكونات الكهربائية المختلفة. يضمن المولد القوي تشغيل هذه الماكينات بسلاسة، مما يقلل من وقت التعطل وتكاليف الصيانة. يجب أن يركز المشترون على متطلبات التيار الكهربائي التي تمليها مواصفات الماكينات، مما يضمن قدرة المولد على التعامل مع الأحمال القصوى دون عطل. هذه الموثوقية أمر بالغ الأهمية للحفاظ على الإنتاجية في مواقع البناء.

ما أهمية جزء المولد للتطبيقات البحرية؟

في الصناعة البحرية، تعد المولدات ضرورية لتشغيل الأنظمة الكهربائية على متن السفينة، بما في ذلك معدات الملاحة والاتصالات والسلامة. يعزز المولد الموثوق به من سلامة وكفاءة العمليات البحرية، خاصةً في البيئات البحرية الصعبة. يجب أن يأخذ المشترون في الاعتبار الحصول على مولدات كهربائية تفي بالمواصفات البحرية، بما في ذلك مقاومة التآكل والقدرة على العمل بفعالية في الظروف الرطبة. هذه العوامل حيوية لضمان طول عمر المعدات وموثوقيتها.

كيف يدعم جزء المولد المتردد العمليات الزراعية؟

في الزراعة، غالبًا ما تُستخدم المولدات في تشغيل أنظمة الري، والتي تعتبر بالغة الأهمية لإدارة المياه وإنتاجية المحاصيل. يضمن المولد الذي يمكن الاعتماد عليه تشغيل هذه الأنظمة باستمرار، خاصة خلال مواسم ذروة الري. عند تحديد مصادر المولدات للتطبيقات الزراعية، من الضروري التركيز على استقرار الجهد والأداء في ظل ظروف الأحمال المختلفة. يمكن أن تؤثر هذه الموثوقية بشكل كبير على الإنتاجية الإجمالية للمزارع، مما يجعلها اعتبارًا رئيسيًا للمشترين في هذا القطاع.

3 نقاط ألم شائعة لدى المستخدمين لـ ‘جزء المولد’ وحلولها

السيناريو 1: توريد مولدات عالية الجودة في أسواق متنوعة

المشكلة: غالبًا ما يواجه المشترون بين الشركات في مناطق مثل أفريقيا أو أمريكا الجنوبية صعوبات في الحصول على مولدات الطاقة المتجددة عالية الجودة بسبب تجزئة السوق. قد تفتقر هذه المناطق إلى إمكانية الوصول المستمر إلى موردين موثوقين، مما يؤدي إلى مخاوف بشأن أصالة المنتج وموثوقية الأداء ودعم الضمان. بالإضافة إلى ذلك، يمكن أن تؤدي الاختلافات في متطلبات الجهد ومواصفات التيار الكهربائي إلى زيادة تعقيد قرار الشراء، حيث يجب على المشترين ضمان التوافق مع طرازات ومعدات المركبات المتنوعة.

الحل: وللتغلب على هذه التحديات، يجب على المشترين إقامة علاقات مع موردين ذوي سمعة طيبة ولديهم سجل حافل في أسواقهم. ويمكن أن يشمل ذلك الاستفادة من المنصات الإلكترونية المتخصصة في قطع غيار السيارات، حيث يمكن للمشترين تصفية الخيارات بناءً على سمعة العلامة التجارية ومواصفات المنتج. بالإضافة إلى ذلك، يمكن أن يوفر التعامل مع الموزعين المحليين رؤى حول النماذج الشائعة والبدائل الموثوقة. يجب على المشترين أيضاً طلب عينات أو مواصفات تفصيلية للمنتج قبل الشراء بالجملة لضمان التوافق مع متطلباتهم التشغيلية. كما يمكن أن يساعد التواصل المنتظم مع الموردين حول أحدث معايير الصناعة وابتكارات المنتجات في اتخاذ قرارات مستنيرة.

السيناريو 2: إدارة المخزون واضطرابات سلسلة التوريد

المشكلة: يواجه العديد من المشترين بين الشركات تحديات في إدارة المخزون، لا سيما عندما يتعلق الأمر بمولدات الكهرباء. يمكن أن يؤدي تذبذب الطلب إلى زيادة المخزون أو نقصه، مما يؤثر على التدفق النقدي والكفاءة التشغيلية. وعلاوة على ذلك، يمكن أن تؤدي اضطرابات سلسلة التوريد - مثل التأخير في الشحن أو التخليص الجمركي - إلى تفاقم هذه المشكلات، مما يترك الشركات بدون مكونات حيوية عندما تكون في أمس الحاجة إليها.

الحل: يمكن أن يؤدي تطبيق نظام قوي لإدارة المخزون إلى تخفيف هذه المشاكل بشكل كبير. يجب على المشترين اعتماد ممارسات المخزون في الوقت المناسب (JIT) لمواءمة مستويات المخزون مع الطلب الفعلي بشكل أفضل. كما يمكن أن يساعد التعاون مع الموردين لتحديد مهل زمنية موثوقة وحد أدنى للطلب في التخفيف من مخاطر نفاد المخزون. بالإضافة إلى ذلك، يمكن أن يؤدي تنويع سلسلة التوريد من خلال الحصول على الموردين من موردين متعددين إلى إنشاء شبكة أمان ضد الاضطرابات. ستضمن المراجعة المنتظمة لبيانات المبيعات وتعديل الطلبات وفقاً لذلك أن تظل مستويات المخزون على النحو الأمثل، وبالتالي تعزيز الكفاءة التشغيلية الإجمالية.

السيناريو 3: فهم المواصفات التقنية والتوافقية

المشكلة: غالبًا ما يواجه المشترون من الشركات صعوبة في فهم المواصفات الفنية لمولدات الكهرباء، مما قد يؤدي إلى شراء قطع غيار خاطئة. يمكن أن يؤدي عدم التوافق في مواصفات الجهد أو التيار الكهربائي أو البكرة إلى إرجاع مكلف ووقت تعطل مكلف. وهذا أمر بالغ الأهمية بشكل خاص في الأسواق الدولية حيث قد تختلف المصطلحات الفنية، مما يسبب مزيدًا من الارتباك وسوء الفهم.

الحل: ولمواجهة هذه المشكلة، يجب على المشترين استثمار الوقت في تدريب فرق المشتريات لديهم على الجوانب الفنية لمولدات التيار المتردد. يمكن أن يشمل ذلك فهم الاختلافات بين الوحدات الجديدة والمعاد تصنيعها، وأنواع منظمات الجهد، وتصنيفات الأمبيرات المختلفة. يمكن أن يساعد استخدام كتالوجات المنتجات التفصيلية وأوراق المواصفات في توضيح الخيارات. علاوة على ذلك، يمكن أن يوفر الانخراط المباشر مع المصنعين أو الخبراء الفنيين أثناء عملية الشراء رؤى قيمة ويضمن أن المولدات المختارة تلبي الاحتياجات المحددة للمركبات أو المعدات التي تتم صيانتها. كما أن بناء قاعدة بيانات شاملة للمشتريات السابقة وأدائها يمكن أن يكون بمثابة مرجع للطلبات المستقبلية، مما يعزز اتخاذ قرارات أفضل.

دليل اختيار المواد الاستراتيجية لجزء المولد

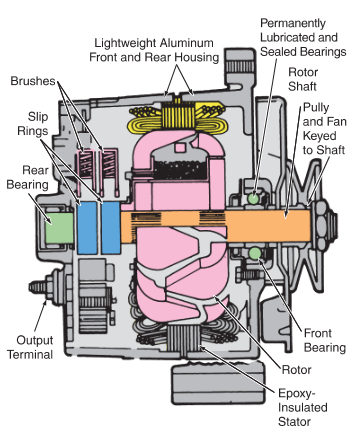

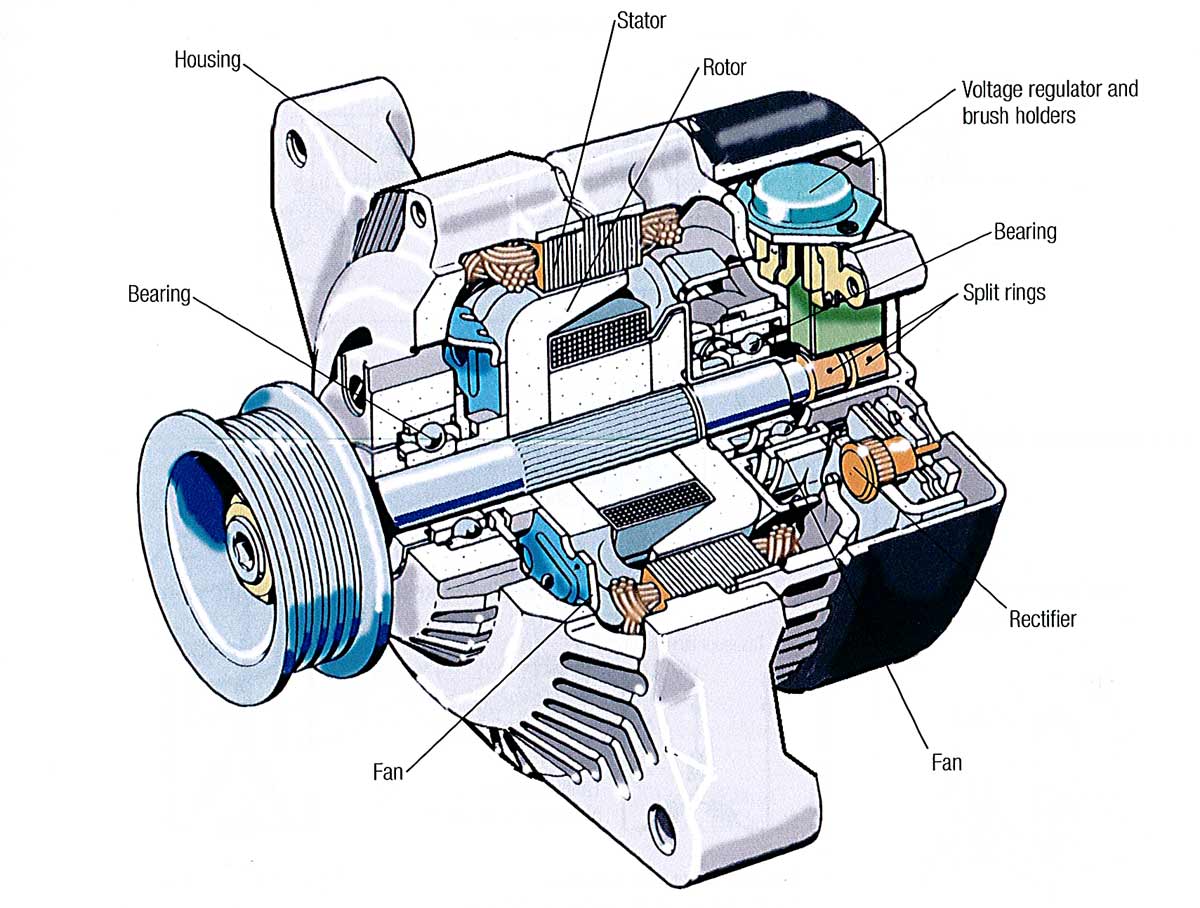

ما هي المواد المستخدمة عادة في أجزاء المولد؟

يعد اختيار المواد المناسبة لأجزاء مولد التيار المتردد أمرًا بالغ الأهمية لضمان الأداء والمتانة والامتثال للمعايير الدولية. فيما يلي، نحلل أدناه العديد من المواد الشائعة المستخدمة في المولدات، مع التركيز على خصائصها ومزاياها وعيوبها والآثار المترتبة على المشترين الدوليين من الشركات.

الألومنيوم: خيار خفيف الوزن ومقاوم للتآكل

يُستخدم الألومنيوم على نطاق واسع في علب ومكونات المولدات بسبب مقاومته الممتازة للتآكل وطبيعته خفيفة الوزن. وعادةً ما تبلغ درجة حرارته حوالي 150 درجة مئوية (302 درجة فهرنهايت) ويمكنه تحمل الضغط المعتدل.

الإيجابيات: كما أن كثافة الألومنيوم المنخفضة تجعله مثاليًا للتطبيقات التي يكون فيها الوزن مصدر قلق، مما يساهم في كفاءة استهلاك الوقود بشكل عام. ومن السهل نسبياً تصنيعها وتشكيلها، مما يسمح بتصميمات معقدة.

السلبيات: وعلى الرغم من أن الألومنيوم متين، إلا أنه قد يكون أقل متانة من المعادن الأخرى في الظروف القاسية. كما يمكن أن تكون تكلفته أعلى من بعض البدائل، خاصةً بالنسبة للسبائك عالية الجودة.

التأثير على التطبيق: يتوافق الألومنيوم مع مختلف الوسائط، بما في ذلك سوائل السيارات، مما يجعله مناسبًا لتطبيقات السيارات.

اعتبارات للمشترين الدوليين: يجب على المشترين من مناطق مثل أفريقيا وأمريكا الجنوبية التأكد من الامتثال لمعايير مثل ASTM B221 لسحب الألومنيوم. وبالإضافة إلى ذلك، قد يختلف توافر سبائك الألومنيوم حسب المنطقة، مما يؤثر على المهل الزمنية.

الفولاذ: خيار قوي وفعال من حيث التكلفة

يشيع استخدام الفولاذ، وخاصةً الفولاذ الكربوني، في مكونات المولد مثل الأقواس والأعمدة نظرًا لقوته ومتانته العالية. يمكن أن يتحمل الفولاذ درجات الحرارة والضغوط العالية، وعادةً ما تصل درجة حرارته إلى 300 درجة مئوية (572 درجة فهرنهايت).

الإيجابيات: قوة الشد العالية للصلب تجعله مناسبًا للاستخدامات الشاقة. كما أنه غير مكلف نسبيًا مقارنةً بالمعادن الأخرى، مما يجعله خيارًا فعالاً من حيث التكلفة للمصنعين.

السلبيات: إن الفولاذ عرضة للتآكل ما لم تتم معالجته أو طلاؤه بشكل صحيح. كما أنه أثقل من الألومنيوم، مما قد يؤثر على الوزن الإجمالي للمركبة وكفاءتها.

التأثير على التطبيق: متانة الفولاذ تجعله مناسبًا للتطبيقات عالية الإجهاد، ولكن قابليته للصدأ يمكن أن تحد من استخدامه في البيئات ذات الرطوبة العالية أو التعرض للمواد المسببة للتآكل.

اعتبارات للمشترين الدوليين: يجب على المشترين البحث عن الامتثال لمعايير مثل ASTM A36 للصلب الهيكلي. يمكن أن يختلف التوفر والتكلفة بشكل كبير بين المناطق، مما يؤثر على استراتيجيات الشراء.

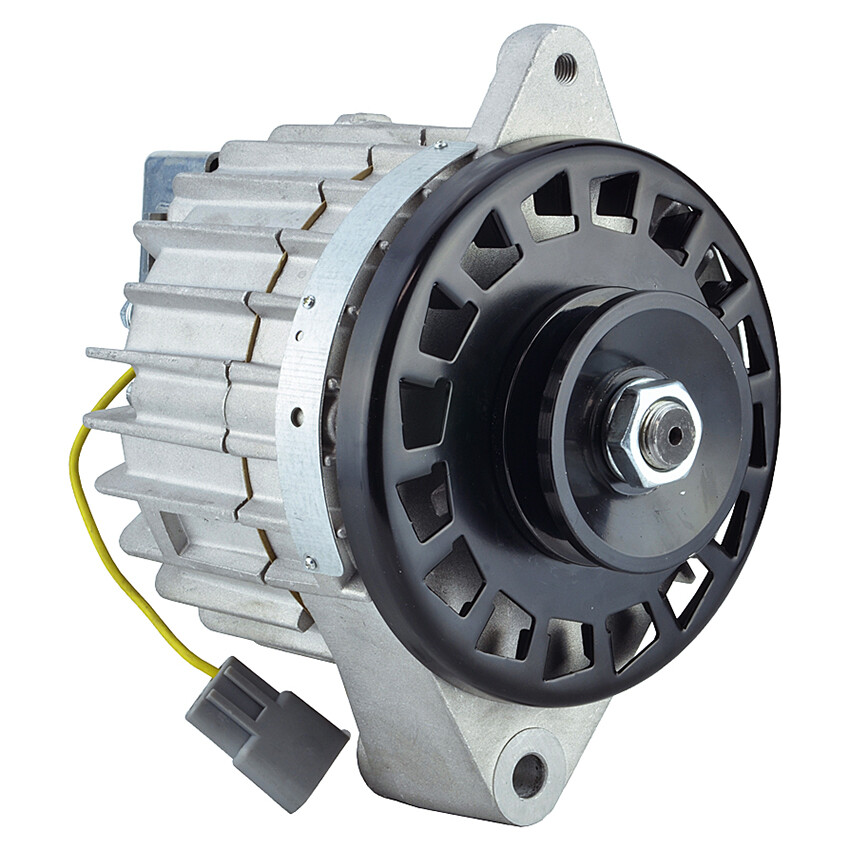

صورة توضيحية متعلقة بجزء المولد

النحاس: الموصل الكهربائي

يُستخدم النحاس في المقام الأول في لفات المولدات والتوصيلات الكهربائية نظراً لخصائصه الممتازة في التوصيل الكهربائي والحراري. ويمكن أن يعمل بفعالية في درجات حرارة تصل إلى 200 درجة مئوية (392 درجة فهرنهايت).

الإيجابيات: تضمن الموصلية الفائقة للنحاس نقل الطاقة بكفاءة، وهو أمر بالغ الأهمية لأداء المولد. كما أنه يتمتع بمقاومة جيدة للتآكل، خاصةً عندما يكون مطلياً.

السلبيات: النحاس أغلى من الألومنيوم والصلب، مما قد يؤثر على تكاليف الإنتاج الإجمالية. بالإضافة إلى ذلك، يمكن أن يكون وزنه عيباً في التطبيقات التي يكون فيها توفير الوزن ضرورياً.

التأثير على التطبيق: النحاس متوافق مع مختلف الوسائط الكهربائية، مما يجعله مثاليًا للمكونات الكهربائية في المولدات.

اعتبارات للمشترين الدوليين: ومن الضروري الامتثال لمعايير مثل ASTM B170 للأسلاك النحاسية. يجب على المشترين أيضًا مراعاة تذبذب أسعار النحاس في الأسواق العالمية، مما قد يؤثر على وضع الميزانية.

مركبات البلاستيك: بديل حديث

يتم استخدام المركبات البلاستيكية بشكل متزايد في المكونات غير الهيكلية لمولدات الكهرباء، مثل العلب والعوازل. يمكن أن تتحمل درجات حرارة تصل إلى 120 درجة مئوية (248 درجة فهرنهايت) وتوفر مقاومة جيدة للمواد الكيميائية.

الإيجابيات: المركبات البلاستيكية خفيفة الوزن ويمكن تشكيلها في أشكال معقدة، مما يقلل من تكاليف التصنيع. كما أنها توفر عزلًا كهربائيًا ممتازًا.

السلبيات: في حين أنها مقاومة للتآكل، قد لا تتحمل المركبات البلاستيكية الضغوط الميكانيكية العالية بنفس فعالية المعادن. كما يمكن أن تكون متانتها على المدى الطويل مصدر قلق في البيئات القاسية.

التأثير على التطبيق: تعد هذه المواد مناسبة للتطبيقات التي يكون فيها العزل الكهربائي أمرًا بالغ الأهمية، ولكن خواصها الميكانيكية قد تحد من استخدامها في المكونات الحاملة.

اعتبارات للمشترين الدوليين: يعد الامتثال للمعايير الدولية للمواد البلاستيكية، مثل ISO 1043 للمواد البلاستيكية، أمرًا بالغ الأهمية. يجب على المشترين أيضًا مراعاة التأثير البيئي وخيارات إعادة التدوير للمركبات البلاستيكية.

جدول ملخص خواص المواد

| المواد | حالة الاستخدام النموذجي لجزء المولد | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | العلب، والمكونات | خفيف الوزن ومقاوم للتآكل | أقل قوة في الظروف القاسية | متوسط |

| الصلب | الأقواس، الأعمدة | قوة عالية وفعالة من حيث التكلفة | عرضة للتآكل | منخفض |

| النحاس | اللفات والتوصيلات الكهربائية | موصلية ممتازة | تكلفة أعلى، أثقل | عالية |

| المركبات البلاستيكية | المكونات غير الهيكلية | خفيف الوزن وعزل جيد | قوة ميكانيكية محدودة | متوسط |

يوفر هذا الدليل رؤى قيمة للمشترين من الشركات في اختيار المواد المناسبة لقطع غيار المولدات، مما يضمن الأداء الأمثل مع الالتزام بالمعايير الدولية والتفضيلات الإقليمية.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لجزء المولد الكهربائي

ما هي المراحل الرئيسية في عملية تصنيع أجزاء المولد؟

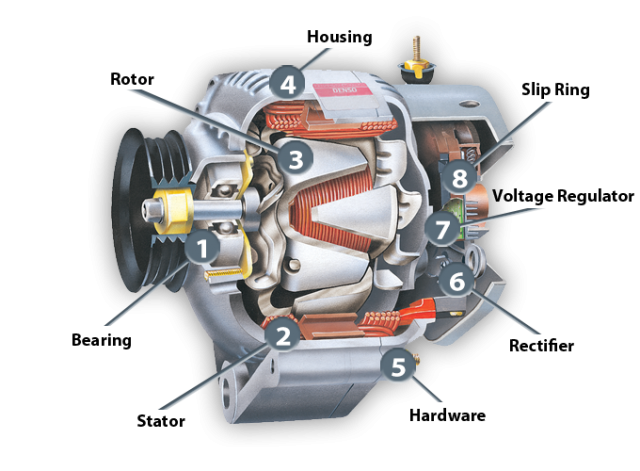

تتضمن عملية تصنيع أجزاء مولد التيار المتردد عدة مراحل حاسمة، كل منها مصممة لضمان أن المنتج النهائي يلبي معايير الأداء والجودة الصارمة.

-

تحضير المواد: تتضمن الخطوة الأولى الحصول على المواد الخام عالية الجودة، والتي تشمل عادةً معادن مثل الألومنيوم والنحاس والصلب. ويتم فحص هذه المواد بعناية للتأكد من نقائها ومطابقتها لمواصفات الصناعة. ثم يتم قطعها وتشكيلها في الأشكال اللازمة لمزيد من المعالجة.

-

تشكيل: تتضمن هذه المرحلة تشكيل المواد المحضرة في مكونات محددة للمولد. ويشيع استخدام تقنيات مثل الصب بالقالب والختم والتشغيل الآلي. على سبيل المثال، غالبًا ما يتم إنتاج القواطع والدوّارات من خلال التصنيع الآلي الدقيق لضمان تفاوتات تحمل محكمة، والتي تعتبر ضرورية لكفاءة المولد ومتانته.

-

الجمعية: بمجرد تشكيل المكونات الفردية، يتم تجميعها في وحدة المولد النهائية. وقد يشمل ذلك تركيب منظم الجهد والمحامل والبكرات. يتم استخدام خطوط التجميع المؤتمتة بشكل متزايد لتعزيز الدقة والسرعة، على الرغم من أن التجميع اليدوي لا يزال يلعب دورًا مهمًا في ضمان الجودة.

-

التشطيب: تتضمن المرحلة النهائية في عملية التصنيع معالجات تشطيبات مختلفة مثل الطلاء أو الطلاء أو الطلاء. لا تعزز هذه العمليات المظهر الجمالي للمولد فحسب، بل توفر أيضًا الحماية ضد التآكل والتآكل. يتم إجراء عمليات فحص شاملة خلال هذه المرحلة لاكتشاف أي عيوب قبل تعبئة المنتج للشحن.

كيف يتم دمج ضمان الجودة في عملية تصنيع أجزاء المولد؟

يعد ضمان الجودة (QA) أمرًا ضروريًا في تصنيع أجزاء المولد لضمان الموثوقية والامتثال للمعايير الدولية.

-

المعايير الدولية: تلتزم العديد من الشركات المصنعة بمعيار الأيزو 9001، الذي يضع إطار عمل لأنظمة إدارة الجودة. ويشير الامتثال لهذا المعيار إلى أن الشركة المصنعة قد استوفت معايير الجودة الصارمة في عملياتها.

-

الشهادات الخاصة بالصناعة: اعتمادًا على التطبيق، قد تحتاج المولدات أيضًا إلى الامتثال لشهادات صناعية محددة مثل CE (المطابقة الأوروبية) للمنتجات التي تباع في السوق الأوروبية أو معايير معهد البترول الأمريكي (API) للأجزاء المستخدمة في تطبيقات النفط والغاز. توفر هذه الشهادات طبقة إضافية من الضمانات فيما يتعلق بجودة المنتجات وسلامتها.

-

نقاط مراقبة الجودة: يتم دمج العديد من نقاط التفتيش خلال عملية التصنيع:

– مراقبة الجودة الواردة (IQC): يتضمن ذلك فحص المواد الخام عند وصولها للتأكد من استيفائها للمعايير المحددة.

– مراقبة الجودة أثناء الإنتاج (IPQC): خلال مراحل التصنيع، يتم إجراء عمليات فحص مستمرة لتحديد العيوب في وقت مبكر من العملية.

– مراقبة الجودة النهائية (FQC): قبل تغليف المولدات الكهربائية، يتم إجراء عمليات الفحص النهائي للتأكد من أن المنتجات تعمل بشكل صحيح وتفي بجميع المواصفات. -

طرق الاختبار الشائعة: يتم استخدام طرق اختبار مختلفة للتحقق من أداء وموثوقية أجزاء المولد. ويشمل ذلك الاختبارات الكهربائية لقياس جهد الخرج والتيار، واختبارات التدوير الحراري لتقييم مقاومة الحرارة، واختبارات الاهتزاز لتقييم المتانة في ظل ظروف التشغيل.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

بالنسبة للمشترين الدوليين بين الشركات، خاصةً في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، فإن التحقق من ممارسات مراقبة الجودة لدى الموردين أمر بالغ الأهمية لضمان موثوقية قطع غيار المولدات.

-

تدقيق الموردين: يمكن أن يوفر إجراء عمليات التدقيق للموردين المحتملين نظرة ثاقبة على عمليات التصنيع وتدابير مراقبة الجودة الخاصة بهم. ويمكن للمشترين تقييم ما إذا كان الموردون يتبعون المعايير الدولية وأفضل الممارسات.

-

تقارير الجودة: يمكن أن يساعد طلب تقارير الجودة التفصيلية من الموردين المشترين على فهم بروتوكولات الاختبار الخاصة بهم ونتائج عمليات التفتيش السابقة. وينبغي أن تتضمن هذه التقارير بيانات عن معدلات العيوب والامتثال للشهادات وأي إجراءات تصحيحية تم اتخاذها.

-

عمليات التفتيش من قبل أطراف ثالثة: يمكن للاستعانة بخدمات التفتيش من طرف ثالث أن يوفر تقييماً غير متحيز لعمليات مراقبة الجودة لدى المورد. ويمكن لعمليات التفتيش هذه أن تكون مفيدة بشكل خاص عند التعامل مع الموردين في المناطق التي قد يكون للمشترين فيها معرفة محدودة بممارسات التصنيع المحلية.

-

التحقق من الشهادات: يجب على المشترين التحقق من صحة الشهادات التي يدعيها الموردون. وقد ينطوي ذلك على التحقق من هيئات أو منظمات التصديق للتأكد من أن شهادات الموردين سارية وصالحة.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين بين الشركات؟

يجب على المشترين الدوليين بين الشركات التعامل مع مختلف الفروق الدقيقة عندما يتعلق الأمر بمراقبة الجودة في شراء قطع غيار المولدات:

-

الامتثال التنظيمي: قد يكون للمناطق المختلفة لوائح تنظيمية مختلفة فيما يتعلق بالمكونات الكهربائية. وفهم هذه اللوائح أمر بالغ الأهمية لضمان إمكانية بيع المنتجات واستخدامها بشكل قانوني في الأسواق المستهدفة.

-

الاختلافات الثقافية والإقليمية: يجب أن يكون المشترون على دراية بالاختلافات الثقافية والتشغيلية التي قد تؤثر على ممارسات مراقبة الجودة. فعلى سبيل المثال، قد يعطي الموردون في مناطق مختلفة الأولوية لجوانب مختلفة من الجودة، متأثرين بمتطلبات السوق المحلية وقدرات التصنيع.

-

التواصل: التواصل الواضح فيما يتعلق بتوقعات ومعايير الجودة أمر ضروري. وينبغي للمشترين أن يتأكدوا من أن مواصفاتهم مفهومة جيداً من قبل الموردين لتجنب التباين في جودة الإنتاج.

-

الشراكات طويلة الأجل: يمكن أن تؤدي إقامة علاقات طويلة الأجل مع موردين موثوقين إلى تحسين مراقبة الجودة بمرور الوقت. فمع بناء الثقة، من المرجح أن يعطي الموردون الأولوية لمعايير الجودة الخاصة بالمشتري ويستثمرون في التحسينات لتلبية تلك التوقعات.

من خلال فهم عمليات التصنيع وتدابير ضمان الجودة التي ينطوي عليها إنتاج أجزاء المولدات، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة تعزز كفاءة سلسلة التوريد وموثوقية المنتج.

دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘جزء المولد’

لمساعدة المشترين بين الشركات في الحصول على قطع غيار المولدات بفعالية، يوفر هذا الدليل قائمة مراجعة خطوة بخطوة تحدد الإجراءات الهامة التي يجب اتخاذها أثناء عملية الشراء. سيساعدك اتباع هذه الخطوات على ضمان اختيار المنتجات والموردين المناسبين، وبالتالي تقليل المخاطر وتعزيز الكفاءة التشغيلية.

صورة توضيحية متعلقة بجزء المولد

الخطوة 1: حدد المواصفات الفنية الخاصة بك

حدد بوضوح المتطلبات الفنية لأجزاء المولد التي تحتاجها. تعتبر المواصفات مثل الأمبيرية والجهد ونوع البكرة ضرورية للتوافق مع الأنظمة الحالية. ويساعد هذا الوضوح الموردين على تقديم عروض أسعار دقيقة ويقلل من مخاطر استلام منتجات غير مناسبة.

- المواصفات الرئيسية التي يجب مراعاتها:

- تصنيفات القدرة (على سبيل المثال، 90 أمبير، 120 أمبير)

- متطلبات الجهد (على سبيل المثال، 12 فولت، 24 فولت)

- أنواع البكرات وتكويناتها

الخطوة 2: البحث عن الموردين المحتملين

قم بإجراء بحث شامل لتحديد الموردين ذوي السمعة الطيبة المتخصصين في قطع غيار المولدات. ابحث عن الشركات التي لديها سجل حافل في مناطق السوق المستهدفة، مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

- موارد للبحث:

- أدلة الصناعة والجمعيات التجارية

- الأسواق عبر الإنترنت ومراجعات الموردين

- توصيات من نظراء في القطاع

الخطوة 3: تقييم شهادات الموردين

تحقق من حصول الموردين المحتملين على شهادات ومعايير الصناعة ذات الصلة. يمكن أن تشير الشهادات إلى الالتزام بالجودة والسلامة، وهو أمر بالغ الأهمية لمكونات السيارات.

- ابحث عن شهادات مثل:

- ISO 9001 لإدارة الجودة

- IATF 16949 لجودة السيارات IATF 16949

- الامتثال للوائح والمعايير المحلية

الخطوة 4: طلب عينات وإجراء الاختبارات

قبل تقديم طلب بالجملة، اطلب عينات من أجزاء المولد لاختبارها. هذه الخطوة ضرورية لضمان مطابقة المنتجات للمواصفات ومعايير الجودة الخاصة بك.

صورة توضيحية متعلقة بجزء المولد

- اعتبارات الاختبار:

- الأداء الوظيفي تحت الحمل

- المتانة والموثوقية في ظروف التشغيل

- التوافق مع الأنظمة الحالية

الخطوة 5: التفاوض على الشروط والأسعار

بمجرد تحديد الموردين المناسبين والتحقق من صحة منتجاتهم، ادخل في مفاوضات لتأمين شروط مواتية. ناقش الأسعار وشروط الدفع وجداول التسليم وشروط الضمان.

- النقاط الرئيسية للتفاوض بشأنها:

- خصومات على الطلبات بالجملة

- خيارات الدفع (على سبيل المثال، الدفع مقدمًا أو بشروط صافية)

- سياسات الإرجاع للأجزاء المعيبة

الخطوة 6: وضع خطة تواصل واضحة

حافظ على خطوط اتصال مفتوحة مع المورد الذي اخترته طوال عملية الشراء. يساعد التواصل الفعال على معالجة أي مشاكل محتملة على الفور ويضمن توافق الطرفين على التوقعات.

- أفضل ممارسات التواصل:

- عقد اجتماعات تحديث منتظمة

- استخدام لغة واضحة وموجزة في جميع المراسلات

- توثيق جميع الاتفاقيات والتغييرات كتابةً

الخطوة 7: مراقبة تنفيذ الطلبات ومراقبة الجودة

بعد تقديم طلبك، راقب عملية التنفيذ عن كثب. ضع تدابير لمراقبة الجودة لفحص المنتجات عند وصولها، والتأكد من مطابقتها للمواصفات المتفق عليها.

- خطوات مراقبة الجودة:

- إجراء فحص بصري للتحقق من عدم وجود تلف

- التحقق من الكميات مقابل طلب الشراء

- إجراء الاختبارات الوظيفية حسب الضرورة

من خلال الالتزام بقائمة المراجعة هذه، يمكن للمشترين بين الشركات تبسيط عملية توريد قطع غيار المولدات، مما يؤدي في النهاية إلى سلاسل توريد أكثر موثوقية وأداء أفضل للمنتج.

تحليل شامل للتكاليف والتسعير لتحديد مصادر قطع غيار المولدات

ما هي مكونات التكلفة الرئيسية لتوريد أجزاء المولد؟

عند الحصول على قطع غيار المولدات، يعد فهم هيكل التكلفة أمرًا بالغ الأهمية للمشترين بين الشركات. وتشمل مكونات التكلفة الأساسية ما يلي:

-

المواد: يؤثر اختيار المواد بشكل كبير على التكلفة. فالمعادن عالية الجودة واللفائف النحاسية واللدائن القوية شائعة في تصنيع المولدات الكهربائية. وتتقلب الأسعار بناءً على أسواق المعادن العالمية والدرجات المحددة المطلوبة.

-

العمل: تختلف تكاليف العمالة حسب المنطقة ويمكن أن تكون كبيرة، خاصة في البلدان ذات معايير الأجور الأعلى. وفي المقابل، فإن التوريد من مناطق ذات تكاليف عمالة أقل قد يقلل من النفقات الإجمالية ولكنه قد يؤثر على الجودة.

-

تكاليف التصنيع العامة: يشمل ذلك تكاليف مثل المرافق والإيجار والنفقات الإدارية المرتبطة بمرافق الإنتاج. يمكن أن تساعد عمليات التصنيع الفعالة في تقليل هذه النفقات العامة.

-

الأدوات: يمكن أن تكون الأدوات المخصصة لتصميمات محددة لمولدات المولدات استثمارًا مقدمًا كبيرًا. ومع ذلك، يتم إطفاء هذه التكلفة على مدى فترة الإنتاج، مما يجعلها أكثر اقتصاداً بالنسبة للأحجام الكبيرة.

-

مراقبة الجودة (QC): إن ضمان موثوقية المولدات أمر حيوي، خاصة في تطبيقات السيارات. يمكن أن تضيف عمليات مراقبة الجودة إلى التكاليف ولكنها ضرورية للحفاظ على المعايير والشهادات.

-

اللوجستيات: يمكن أن تتفاوت تكاليف الشحن والمناولة تفاوتًا كبيرًا بناءً على المسافة بين المورد والمشتري، وطرق الشحن، والرسوم الجمركية المرتبطة بها. وتؤدي شروط التجارة الدولية دوراً حاسماً في تحديد من يتحمل هذه التكاليف.

-

الهامش: يضيف الموردون عادةً هامش ربح إلى تكاليفهم. ويمكن أن يختلف هذا الهامش حسب المنافسة والطلب في السوق ووضع الموردين.

كيف يؤثر الحجم والتخصيص على التسعير؟

يعد الحجم والحد الأدنى لكمية الطلب (MOQ) من العوامل المؤثرة الهامة في التسعير في توريد المولدات. غالبًا ما تؤدي الطلبات ذات الحجم الأكبر إلى انخفاض تكاليف الوحدة بسبب وفورات الحجم. قد يقدم الموردون خصومات على الطلبات الأكبر، مما قد يقلل بشكل كبير من التكلفة الإجمالية.

يؤثر التخصيص أيضًا على الأسعار. يمكن أن تؤدي المواصفات الفريدة أو التعديلات على التصميمات القياسية إلى زيادة تعقيد التصنيع والتكاليف. يجب أن يوازن المشترون بين الشركات بين فوائد التخصيص مقابل الزيادات المحتملة في الأسعار. يمكن أن يساعد التأكد من أن المواصفات واضحة في تخفيف التكاليف غير المتوقعة.

ما الدور الذي تلعبه الجودة والاعتماد في التسعير؟

الجودة والاعتماد من العوامل الحاسمة التي تؤثر على الأسعار. المولدات التي تفي بمعايير أو شهادات صناعية محددة (مثل علامة ISO أو علامة CE) غالبًا ما تكون أسعارها أعلى بسبب ضمان الموثوقية والسلامة. يجب على المشترين النظر في الآثار طويلة الأجل المترتبة على الاستثمار في المنتجات المعتمدة، لأنها قد تقلل من المخاطر المتعلقة بفشل المنتج.

ما هي استراتيجيات التفاوض الفعالة للمشترين الدوليين؟

بالنسبة للمشترين الدوليين بين الشركات B2B، فإن التفاوض أمر ضروري. وفيما يلي بعض الاستراتيجيات:

- الاستفادة من العلاقات: يمكن أن يؤدي بناء علاقات قوية مع الموردين إلى تحسين الأسعار والشروط.

- فهم ظروف السوق: إن الاطلاع على اتجاهات السوق، وتكاليف المواد، وأسعار المنافسين يمكن أن يمنح المشترين ميزة في المفاوضات.

- مناقشة شروط الدفع: يمكن في بعض الأحيان التفاوض على شروط دفع مرنة في بعض الأحيان، مما يمكن أن يحسن التدفق النقدي ويقلل من التكاليف المقدمة.

ما الذي يجب على المشترين مراعاته فيما يتعلق بالتكلفة الإجمالية للملكية (TCO)؟

تتجاوز التكلفة الإجمالية للملكية (TCO) سعر الشراء الأولي وتتضمن التكاليف المرتبطة بالصيانة ووقت التعطل والتخلص من المنتجات في نهاية عمرها الافتراضي. عند تقييم موردي المولدات، ضع في اعتبارك أداء وموثوقية منتجاتهم على المدى الطويل. قد يكون لمولدات المولدات ذات الجودة العالية تكلفة أعلى مقدمًا ولكن يمكن أن تؤدي إلى انخفاض تكاليف الصيانة والاستبدال بمرور الوقت.

ما هي الفروق الدقيقة في التسعير التي يجب أن يكون المشترون الدوليون على دراية بها؟

يجب أن يكون المشترون الدوليون على دراية بالعديد من الفروق الدقيقة في الأسعار:

- تقلبات العملة: يمكن أن تؤثر أسعار الصرف على التكاليف النهائية، خاصة إذا كانت المعاملات تتم بعملات مختلفة.

- رسوم الاستيراد والتعريفات الجمركية: يمكن أن يؤثر ذلك بشكل كبير على التكلفة الإجمالية لمولدات التيار المتردد ويجب أخذها في الحسبان في إجمالي النفقات.

- الخدمات اللوجستية وأوقات التسليم: قد تؤدي فترات الشحن الممتدة إلى زيادة تكاليف الاحتفاظ بالمخزون، مما يؤثر على الميزانية الإجمالية.

الخاتمة: لماذا من المهم فهم ديناميكيات التسعير؟

إن فهم ديناميكيات التكلفة والتسعير الشاملة لتوريد قطع غيار المولدات أمر ضروري للمشترين بين الشركات. من خلال النظر في جميع مكونات التكلفة والعوامل المؤثرة واستراتيجيات التفاوض الفعالة، يمكن للمشترين اتخاذ قرارات مستنيرة لا تقتصر على تحسين عمليات الشراء الخاصة بهم فحسب، بل تعزز أيضًا قدرتهم التنافسية الشاملة في السوق.

تحليل البدائل: مقارنة جزء المولد مع الحلول الأخرى

عند تقييم ‘جزء المولد’ في سياق توليد الطاقة وتطبيقات السيارات، من الضروري أن يأخذ المشترون في الاعتبار الحلول البديلة التي يمكن أن تحقق أهدافًا مماثلة. سيقارن هذا التحليل بين جزء المولد التقليدي وبديلين قابلين للتطبيق: الجزء المولد التقليدي مولد التيار المستمر و أنظمة الطاقة الشمسية. يقدم كل بديل مزايا وعيوب فريدة من نوعها، والتي يمكن أن تؤثر بشكل كبير على عملية صنع القرار بالنسبة للمشترين في أسواق متنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

جدول المقارنة

| جانب المقارنة | جزء المولد | مولد التيار المستمر | أنظمة الطاقة الشمسية |

|---|---|---|---|

| الأداء | كفاءة عالية؛ تحوّل الطاقة الميكانيكية إلى طاقة كهربائية بفعالية. | كفاءة معتدلة؛ تقوم بتحويل الطاقة الميكانيكية، ولكنها أقل كفاءة من المولدات الحديثة. | ناتج متغير؛ اعتماداً على ضوء الشمس، يمكن أن يتذبذب الأداء. |

| التكلفة | استثمار أولي منخفض إلى متوسط بشكل عام؛ تتوفر خيارات إعادة التصنيع. | تكلفة أولية أعلى بسبب المكونات والتركيب. | تكاليف مقدمة عالية؛ ومع ذلك، من الممكن تحقيق وفورات طويلة الأجل في فواتير الطاقة. |

| سهولة التنفيذ | تركيب بسيط نسبياً؛ متوافق مع معظم السيارات. | قد يكون التركيب معقداً ويتطلب فنيين مهرة. | تتطلب مساحة كافية للألواح الشمسية؛ ويمكن أن يتفاوت التركيب من حيث التعقيد. |

| الصيانة | تتطلب فحوصات دورية؛ صيانة منخفضة إذا تم تركيبها بشكل صحيح. | يلزم إجراء الصيانة الدورية لضمان الأداء الأمثل. | الحد الأدنى من الصيانة؛ تنظيف اللوحات وفحص التوصيلات في المقام الأول. |

| أفضل حالة استخدام | مثالية للمركبات والآلات التقليدية التي تتطلب طاقة موثوقة. | مناسبة للمناطق النائية التي لا تتوفر فيها مصادر الطاقة التقليدية. | الأفضل لحلول الطاقة المستدامة، خاصة في المناطق المشمسة. |

تفصيل البدائل

مولد التيار المستمر

يعد مولد التيار المستمر بديلاً تقليديًا تم استخدامه على نطاق واسع في تطبيقات مختلفة. تكمن ميزته الأساسية في قدرته على إنتاج خرج ثابت من التيار المباشر، مما يجعله مناسبًا لتطبيقات صناعية محددة. ومع ذلك، فإن كفاءته أقل عمومًا من كفاءة المولدات الحديثة، مما يؤدي إلى إنتاج طاقة أقل لنفس المدخلات الميكانيكية. بالإضافة إلى ذلك، يمكن أن تكون عملية تركيب مولدات التيار المستمر معقدة، وتتطلب معرفة متخصصة، مما قد يزيد من التكاليف الإجمالية والأطر الزمنية للتنفيذ.

أنظمة الطاقة الشمسية

تعمل أنظمة الطاقة الشمسية على تسخير الطاقة من الشمس وتحويلها إلى طاقة كهربائية من خلال الخلايا الكهروضوئية. ويحظى هذا الحل بشعبية متزايدة في المناطق التي تتمتع بأشعة الشمس الوفيرة، مما يوفر مصدر طاقة مستدام وصديق للبيئة. يمكن أن يكون الاستثمار الأولي لأنظمة الطاقة الشمسية كبيراً، بما في ذلك تكاليف الألواح والمحولات والتركيب. ومع ذلك، مع مرور الوقت، يمكن للمستخدمين الاستفادة من وفورات كبيرة في تكاليف الطاقة. كما أن الصيانة منخفضة نسبياً، وتتضمن في المقام الأول تنظيف الألواح وإجراء فحوصات بين الحين والآخر، مما يجعلها خياراً خالياً من المتاعب بمجرد إعدادها. ومع ذلك، فإن الاعتماد على ضوء الشمس يعني أن إنتاج الطاقة يمكن أن يكون غير متناسق، خاصة أثناء الطقس الغائم أو في الليل.

الخلاصة

يتضمن اختيار حل الطاقة المناسب دراسة متأنية للاحتياجات والظروف المحددة. فبالنسبة للمشترين من الشركات بين الشركات (B2B)، يوفر ‘جزء المولد’ حلاً موثوقاً وفعالاً من حيث التكلفة للمركبات والمعدات التقليدية، في حين أن مولد التيار المستمر قد يناسب تطبيقات صناعية محددة تتطلب تياراً مباشراً. من ناحية أخرى، تقدم أنظمة الطاقة الشمسية بديلاً مستدامًا يمكن أن يحقق وفورات على المدى الطويل ولكنه يتطلب استثمارًا مقدمًا أعلى ويعتمد على الظروف البيئية. وفي نهاية المطاف، سيتوقف الاختيار الأفضل على عوامل مثل المتطلبات التشغيلية وقيود الميزانية ومشهد الطاقة في منطقة التشغيل. من خلال الموازنة بين هذه البدائل و‘الجزء المولد’، يمكن للمشترين اتخاذ قرارات مستنيرة تتماشى مع أهدافهم الاستراتيجية.

الخصائص التقنية الأساسية والمصطلحات التجارية لجزء المولد الكهربائي

ما هي الخصائص التقنية الرئيسية لأجزاء المولد؟

يعد فهم المواصفات الفنية الأساسية لقطع غيار المولدات أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات، خاصةً عند الحصول على المكونات لمختلف التطبيقات، من السيارات إلى الآلات الصناعية. فيما يلي بعض الخصائص الرئيسية التي يجب مراعاتها:

-

الأمبيرية (A): تشير هذه المواصفات إلى الحد الأقصى للتيار الكهربائي الذي يمكن أن ينتجه المولد. تتراوح التصنيفات الشائعة من 90 إلى 300 أمبير. إن معرفة الأمبيرية المطلوبة أمر حيوي، حيث أن الإنتاج غير الكافي يمكن أن يؤدي إلى تعطل النظام، في حين أن المعدلات الزائدة قد تهدر الطاقة وتزيد من التكاليف.

-

الجهد (فولت): تعمل المولدات عادةً بجهد 12 فولت أو 24 فولت أو 32 فولت. هذه المواصفات ضرورية للتوافق مع الأنظمة الكهربائية التي سيتم استخدام المولدات فيها. يساعد ضمان الجهد الصحيح على تجنب تلف المكونات المتصلة ويضمن الأداء الأمثل.

-

نوع البكرة وتكوينها: يؤثر نوع البكرة (على سبيل المثال، البكرة التقليدية أو المفككة، أو القابض) وقطرها على تكامل المولد مع المحرك. يؤثر عدد الأخاديد أيضًا على توافق الحزام. يضمن الاختيار المناسب نقل الطاقة بكفاءة ويقلل من البلى على كل من المولد وسير القيادة.

-

نوع المنظم: يمكن أن تحتوي المولدات على منظمات جهد داخلية أو خارجية تتحكم في جهد الخرج لمنع التقلبات. ويعتمد الاختيار بين هذه الأنواع على تصميم النظام ومتطلبات الموثوقية. يعمل المنظم الداخلي على تبسيط التركيب، بينما يمكن أن يوفر المنظم الخارجي تحكمًا أكثر دقة.

-

طريقة التبريد: تعد طريقة التبريد، التي عادةً ما يتم تبريدها بالهواء، أمرًا بالغ الأهمية للحفاظ على درجات حرارة التشغيل المثلى. يمكن أن يؤدي ارتفاع درجة الحرارة إلى انخفاض الكفاءة والفشل المبكر. يساعد فهم متطلبات التبريد في اختيار المولد المناسب للظروف البيئية المحددة.

-

القطبية: تعمل المولدات عادةً بقطبية سالبة، ولكن قد تتطلب بعض التطبيقات قطبية موجبة. هذه المواصفات ضرورية لضمان التوافق مع البنية الكهربائية للمركبة أو النظام، وبالتالي منع حدوث تلف محتمل.

ما هي المصطلحات التجارية الشائعة المتعلقة بأجزاء المولد؟

الإلمام بمصطلحات الصناعة يمكن أن يعزز بشكل كبير التواصل والتفاوض بين المشترين والموردين. فيما يلي بعض المصطلحات الشائعة الاستخدام في تجارة قطع غيار المولدات:

-

OEM (الشركة المصنعة للمعدات الأصلية): يشير هذا المصطلح إلى القطع المصنوعة من قبل الشركة المصنعة للمعدات الأصلية. وغالباً ما تكون قطع غيار المعدات الأصلية مفضلة بسبب توافقها المضمون وجودتها. وينبغي للمشترين النظر في قطع غيار المعدات الأصلية للتطبيقات التي تكون فيها الموثوقية أمرًا بالغ الأهمية.

-

MOQ (الحد الأدنى لكمية الطلب): تشير هذه المواصفات إلى أصغر كمية من المنتج الذي يرغب المورد في بيعه. ويُعدّ فهم موك أمرًا بالغ الأهمية لتخطيط الميزانية وإدارة المخزون، لا سيما بالنسبة للشركات الصغيرة أو الشركات الناشئة.

-

طلب عرض أسعار (RFQ): طلب عرض الأسعار هو مستند يتم إرساله إلى الموردين لطلب تسعير وشروط لقطع غيار أو خدمات محددة. ويمكن أن يساعد إنشاء طلب عرض أسعار شامل المشترين في الحصول على عروض أسعار تنافسية وضمان حصولهم على أفضل قيمة لمشترياتهم.

-

مصطلحات التجارة الدولية: وهي اختصار للمصطلحات التجارية الدولية، وهي شروط تجارية موحدة تحدد مسؤوليات المشترين والبائعين في المعاملات الدولية. يساعد الإلمام بشروط إنكوترمز المشترين على فهم تكاليف الشحن ونقل المخاطر والتزامات التسليم، مما يسهل التجارة الدولية بشكل أكثر سلاسة.

-

المهلة الزمنية: يشير هذا المصطلح إلى الوقت المستغرق من تقديم الطلب إلى استلام المنتج. وفهم المهل الزمنية أمر ضروري لإدارة المشاريع وجدولتها بفعالية، لا سيما في الصناعات التي يمكن أن يكون فيها وقت التعطل مكلفاً.

-

الضمان: الضمان هو ضمان من الشركة المصنعة فيما يتعلق بجودة وأداء جزء المولد. إن معرفة شروط الضمان يمكن أن تساعد المشترين على تقييم المخاطر والتأكد من أن لديهم حق الرجوع في حالة وجود عيوب أو أعطال.

من خلال فهم هذه الخصائص التقنية والشروط التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة وتبسيط عمليات الشراء وضمان نجاح دمج أجزاء المولدات في عملياتهم.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع أجزاء المولدات الكهربائية

ما هي اتجاهات السوق الرئيسية التي تؤثر على قطاع أجزاء المولدات؟

يشهد قطاع قطع غيار المولدات تغيرات كبيرة مدفوعة بديناميكيات السوق العالمية والتقدم التكنولوجي. يتمثل أحد المحركات الرئيسية في الطلب المتزايد على المولدات عالية الكفاءة التي تلبي متطلبات الطاقة في السيارات الحديثة. ويؤدي ظهور السيارات الكهربائية (EVs) إلى إعادة تشكيل استراتيجيات التوريد، حيث يسعى المصنعون إلى الحصول على مولدات ذات معدلات أمبيرية أعلى لدعم الأنظمة الكهربائية المحسنة. وعلاوة على ذلك، فإن دمج التقنيات الذكية في مكونات السيارات يدفع الموردين إلى الاستثمار في عمليات التصنيع المبتكرة التي تتضمن قدرات إنترنت الأشياء والذكاء الاصطناعي.

صورة توضيحية متعلقة بجزء المولد

يعطي المشترون الدوليون بين الشركات، وخاصة في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، الأولوية بشكل متزايد للموردين الذين يوفرون المرونة في التوريد. ويتجلى هذا الاتجاه بشكل خاص في أسواق مثل فيتنام والبرازيل، حيث يمكن للشراكات المحلية أن تخفف من التحديات اللوجستية وتقلل من المهل الزمنية. يؤدي ظهور المنصات الرقمية لتوريد قطع غيار المولدات إلى تبسيط عمليات الشراء، مما يسمح للمشترين بمقارنة المنتجات والأسعار وبيانات اعتماد الموردين بسهولة.

علاوة على ذلك، يتزايد التركيز على المكونات المعاد تصنيعها. ويدرك المشترون فعالية التكلفة والاستدامة في الحصول على مولدات التيار المتردد المعاد تصنيعها، والتي غالبًا ما تأتي مع ضمانات ويمكن أن تلبي معايير الجودة الصارمة. ونتيجة لذلك، يكتسب الموردون الذين يمكنهم تقديم مواصفات مفصلة للمنتج وإثبات الامتثال لشهادات الجودة الدولية ميزة تنافسية.

كيف يمكن أن تؤثر الاستدامة والتوريد الأخلاقي على استراتيجية التوريد بين الشركات لقطع غيار المولدات؟

أصبحت الاستدامة حجر الزاوية في قطاع قطع غيار المولدات، حيث تدفع المخاوف البيئية كلاً من المصنعين والمشترين إلى إعادة التفكير في استراتيجيات التوريد. يمكن أن يكون لإنتاج مولدات التيار المتردد تأثير بيئي كبير، خاصةً فيما يتعلق باستهلاك الطاقة وتوليد النفايات. ولذلك، يجب على المشترين إعطاء الأولوية للموردين الذين يستخدمون ممارسات التصنيع المستدامة، مثل تقليل آثار الكربون وتقليل النفايات من خلال إعادة التدوير وإعادة استخدام المواد.

كما أن التوريد الأخلاقي يكتسب زخمًا متزايدًا، حيث تدرك الشركات بشكل متزايد أهمية الشفافية في سلاسل التوريد الخاصة بها. ويُشجَّع المشترون على الاستفسار عن ممارسات الموردين في مجال العمالة والتزامهم بالمعايير الأخلاقية. ويكتسب هذا الأمر أهمية خاصة في المناطق التي يمكن أن تتفاوت فيها ظروف العمل بشكل كبير. يمكن أن تكون شهادات مثل ISO 14001 (الإدارة البيئية) وISO 9001 (إدارة الجودة) بمثابة مؤشرات على التزام المورد بالممارسات الأخلاقية.

بالإضافة إلى ذلك، يمكن أن يؤدي استخدام المواد “الخضراء” في إنتاج المولدات الكهربائية - مثل المعادن القابلة لإعادة التدوير والطلاءات الصديقة للبيئة - إلى تعزيز جاذبية المورد. من خلال مواءمة استراتيجيات التوريد الخاصة بهم مع الاستدامة وممارسات التوريد الأخلاقية، لا يمكن للمشترين بين الشركات تلبية المتطلبات التنظيمية فحسب، بل يمكنهم أيضًا تعزيز سمعة علامتهم التجارية بين المستهلكين المهتمين بالبيئة.

كيف تطور قطاع أجزاء المولدات بمرور الوقت؟

شهد قطاع أجزاء المولدات الكهربائية تطورًا كبيرًا منذ نشأته. فقد صُممت المولدات في البداية لتحويل الطاقة الميكانيكية إلى طاقة كهربائية لبطاريات المركبات، ثم تحولت المولدات إلى مكونات متطورة تدعم الأنظمة الكهربائية المعقدة في المركبات الحديثة. وقد شكّل الانتقال من مولدات التيار المباشر (DC) إلى مولدات التيار المتردد (AC) تحولاً محوريًا، مما أتاح زيادة الكفاءة والموثوقية.

في العقود الأخيرة، أدى دمج التكنولوجيا في تصميم المولدات إلى إحداث ثورة في هذا القطاع. وقد أتاح إدخال منظمات الجهد التي يتم التحكم فيها بواسطة المعالجات الدقيقة والمولدات الذكية تحسين الأداء وإدارة الطاقة. ومع تبنّي صناعة السيارات للكهربة والاستدامة، من المتوقع أن يتوسع دور المولد الكهربائي، مما يجعله مكونًا حاسمًا في مستقبل النقل.

من خلال فهم ديناميكيات واتجاهات السوق هذه، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة عند الحصول على قطع غيار المولدات، مما يضمن الحفاظ على قدرتهم التنافسية في مشهد سريع التطور.

الأسئلة المتداولة (FAQs) لمشتري قطع غيار مولد التيار المتردد بين الشركات

-

كيف يمكنني تحديد جزء المولد المناسب لاستخدامي؟

لاختيار جزء المولد المناسب، ضع في اعتبارك المواصفات الرئيسية مثل الجهد (على سبيل المثال، 12 فولت، 24 فولت)، وتصنيف الأمبيرية (يتراوح من 90 أمبير إلى أكثر من 300 أمبير)، ونوع البكرة المطلوبة (على سبيل المثال، حزام أفعواني أو حزام على شكل V). بالإضافة إلى ذلك، قم بتقييم مدى التوافق مع مركبتك أو آلتك، بما في ذلك الطراز والطراز. يمكن أن يساعدك أيضًا التعامل مع الموردين للحصول على أوراق البيانات الفنية وكتالوجات المنتجات في توضيح أي مولد يلبي احتياجاتك التشغيلية على أفضل وجه. -

ما هي أفضل طريقة لفحص مورد قطع غيار المولدات؟

عند فحص الموردين، أعط الأولوية للموردين الذين يتمتعون بسمعة طيبة وخبرة كبيرة في مجال عملك. تحقق من الشهادات مثل معايير ISO ومراجعات العملاء لقياس الموثوقية. اطلب مراجع وتقييم قدرتهم على تلبية متطلباتك المحددة، بما في ذلك عمليات ضمان الجودة والجداول الزمنية للتسليم ودعم ما بعد البيع. كما قد يوفر إجراء زيارات ميدانية أو عمليات تدقيق للموقع رؤى قيمة حول عملياتهم. -

ما هو الحد الأدنى المعتاد لكميات الطلبات (MOQs) لقطع غيار المولدات؟

يمكن أن يختلف الحد الأدنى لكميات الطلب لقطع غيار المولدات اختلافًا كبيرًا حسب المورد ونوع المنتج. بشكل عام، يتراوح الحد الأدنى للكميات المطلوبة من 10 وحدات إلى أكثر من 100 وحدة للطلبات بالجملة. ويُنصح بمناقشة طلبات موك مباشرةً مع الموردين، حيث قد يقدمون مرونة بناءً على احتياجاتك الشرائية أو يضعون شروطًا مختلفة للعملاء الجدد مقابل الحسابات القائمة. -

كيف يمكنني ضمان جودة قطع غيار المولدات التي أستوردها؟

لضمان جودة قطع غيار المولدات المستوردة، اطلب مواصفات وشهادات شاملة للمنتج من الموردين. تنفيذ عملية ضمان الجودة التي تشمل فحص العينات قبل الشراء بالجملة. يمكن أن يساعد استخدام خدمات الفحص من طرف ثالث في التحقق من الامتثال للمعايير الدولية. ضع سياسات واضحة للإرجاع وشروط ضمان واضحة لحماية استثمارك. -

ما هي شروط الدفع المقبولة عادةً عند توريد قطع غيار المولدات على المستوى الدولي؟

غالباً ما تتضمن شروط الدفع للمشتريات الدولية خيارات مثل الدفع مقدماً أو خطابات الاعتماد أو الدفع عند التسليم. قد يقدم بعض الموردين شروطًا صافية (على سبيل المثال، صافي 30 أو صافي 60 يومًا) للعلاقات القائمة. من المهم مناقشة طرق الدفع والاتفاق عليها مسبقاً لتجنب النزاعات المحتملة وضمان سلاسة عملية الشراء. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في الحسبان عند استيراد قطع غيار المولدات؟

عند استيراد قطع غيار المولدات، ضع في اعتبارك طرق الشحن (الشحن الجوي مقابل الشحن البحري)، واللوائح الجمركية، والتعريفات التي قد تنطبق على بلد الوجهة. تأكد من وجود شركاء لوجستيين موثوقين يمكنهم التعامل مع الوثائق وتوفير معلومات التتبع. ضع في الحسبان المهل الزمنية للشحن والتخليص الجمركي لتتماشى مع جداولك التشغيلية. -

هل يمكنني تخصيص أجزاء المولد لتلبية احتياجات محددة؟

يقدم العديد من الموردين خيارات التخصيص لأجزاء المولدات، بما في ذلك التعديلات على الجهد والأمبير وأنواع البكرات. لبدء التخصيص، قدم مواصفات مفصلة وناقش متطلباتك مع المورد. ضع في اعتبارك أن الطلبات المخصصة قد تنطوي على مهل زمنية أطول وربما تكاليف أعلى، لذا خطط وفقًا لذلك. -

ما الذي يجب أن أعرفه عن سياسات الضمان والإرجاع لقطع غيار المولدات؟

من الضروري فهم سياسات الضمان والإرجاع عند الحصول على قطع غيار المولدات. يقدم معظم الموردين ضمانات تغطي العيوب في المواد والتصنيع لفترة محددة. تعرّف على الشروط، بما في ذلك ما يتم تغطيته، وعملية تقديم المطالبة، وأي شروط قد تبطل الضمان. بالإضافة إلى ذلك، قم بتوضيح سياسة الإرجاع للمنتجات غير المرضية للتخفيف من المخاطر.

قائمة موردي ومصنعي أجزاء المولد 1 الأعلى 1

1. دي بي للكهرباء - مولدات كهربائية عالية الجودة

المجال: dbelectrical.com

مسجل: 2000 (25 سنة)

مقدمة: مولدات كهربائية عالية الجودة بأسعار منخفضة؛ شحن مجاني في نفس اليوم لأكثر من $50 في الولايات المتحدة الأمريكية/48 ولاية؛ معايير OEM للجودة والتركيب؛ تشمل الميزات إيبوكسي عالي الحرارة، ومقومات شديدة التحمل، ومنظمات عالية الجودة، ومحامل جيدة التصميم، وشحوم عالية الحرارة؛ برنامج اختبار صارم متعدد النقاط لكل طراز؛ توفر عادةً ما يصل إلى 30% من أسعار بيع المعدات الأصلية بالتجزئة؛ مناسبة لمختلف أنواع...

استنتاج وتوقعات التوريد الاستراتيجي لجزء المولد المتردد

ما هي النقاط الأساسية للتوريد الاستراتيجي لقطع غيار المولدات؟

في المشهد التنافسي لمكونات السيارات، يبرز التوريد الاستراتيجي لقطع غيار المولدات كعامل محوري للنجاح. يجب على المشترين الدوليين، لا سيما من الأسواق الناشئة في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، إعطاء الأولوية للموردين الذين لا يقدمون منتجات عالية الجودة فحسب، بل أيضًا الموثوقية والقدرة على التكيف مع احتياجات السوق المحلية. من خلال التركيز على العلامات التجارية الراسخة والخيارات المعاد تصنيعها، يمكن للشركات تحسين سلاسل التوريد الخاصة بها مع إدارة التكاليف بفعالية.

وعلاوة على ذلك، فإن فهم المواصفات المختلفة - مثل الأمبير والجهد وأنواع البكرات - يمكّن المشترين من اتخاذ قرارات مستنيرة تتماشى مع متطلباتهم التشغيلية. يمكن أن يؤدي التعاون مع الموردين الذين يقدمون ضمانات شاملة ودعمًا إلى تعزيز تجربة الشراء الإجمالية، مما يضمن طول عمر وأداء المولدات.

كيف يمكن للمشترين الدوليين الاستعداد للاتجاهات المستقبلية في توريد المولدات الكهربائية؟

مع استمرار قطاع السيارات في التطور، فإن مواكبة الاتجاهات السائدة مثل الكهرباء والاستدامة أمر بالغ الأهمية. يجب على المشترين استكشاف الشراكات التي لا تلبي المتطلبات الحالية فحسب، بل تتماشى أيضًا مع الابتكارات المستقبلية. سيؤدي التعامل مع الموردين الذين يستثمرون في الممارسات المستدامة والتقنيات المتقدمة إلى وضع الشركات في وضع إيجابي في سوق سريع التغير.

في الختام، إن التوريد الاستراتيجي لقطع غيار المولدات ليس مجرد مهمة شراء؛ بل هو عنصر حيوي للتميز التشغيلي. وبالاستفادة من الأفكار التي تمت مشاركتها في هذا الدليل، يتم تشجيع المشترين الدوليين على اتخاذ خطوات استباقية في تحسين استراتيجيات التوريد الخاصة بهم، مما يؤدي في النهاية إلى زيادة الكفاءة والنمو في أسواقهم.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.