مقدمة: الإبحار في السوق العالمية لتشغيل سيارة ذات بادئ تشغيل تالف

يمكن أن يمثل التعامل مع تعقيدات تشغيل سيارة مع بداية تشغيل معطلة تحديات كبيرة للمشترين الدوليين من الشركات الدولية، خاصة في الأسواق المتنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. يمكن أن يؤدي تعطل بادئ التشغيل إلى تعطل غير متوقع، مما يؤثر على الكفاءة التشغيلية ورضا العملاء. يهدف هذا الدليل إلى تزويد الشركات بالمعرفة اللازمة لتشخيص مشاكل البادئ بفعالية، واستكشاف الحلول المؤقتة المختلفة، وفهم متى يكون التدخل المهني ضرورياً.

نتعمق في أنواع مختلفة من محركات بدء التشغيل، وتطبيقاتها في مختلف طرازات السيارات، والدور الحاسم لفحص الموردين في ضمان شراء مكونات عالية الجودة. بالإضافة إلى ذلك، نغطي اعتبارات التكلفة، مما يمكّن المشترين من اتخاذ قرارات مالية مستنيرة تتماشى مع قيود ميزانيتهم.

من خلال توفير رؤى قابلة للتنفيذ ونصائح عملية، يمكّن هذا المورد الشامل المشترين من الشركات من التنقل في السوق العالمية بثقة. وسواء أكان الحصول على المكونات اللازمة لإدارة الأسطول أو تلبية احتياجات المركبات الفردية، فإن دليلنا بمثابة أداة قيّمة في التغلب على العقبات التي تمثلها مشاكل البداية، مما يضمن قدرة الشركات على الحفاظ على زخمها والوفاء بالتزاماتها.

جدول المحتويات

- أفضل 1 قائمة المصنعين والموردين لبدء تشغيل سيارة مع بداية سيئة

- مقدمة: الإبحار في السوق العالمية لتشغيل سيارة ذات بادئ تشغيل تالف

- فهم بدء تشغيل السيارة مع بادئ تشغيل معطل أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لبدء تشغيل السيارة مع بادئ تشغيل معطل

- 3 نقاط ألم شائعة لدى المستخدمين لـ ‘تشغيل السيارة مع بادئ تشغيل معطل’ وحلولها

- دليل اختيار المواد الاستراتيجية لتشغيل سيارة ذات بادئ تشغيل تالف

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لبدء تشغيل سيارة ذات بادئ تشغيل تالف

- دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘تشغيل سيارة ذات بادئ تشغيل تالف’

- تحليل شامل للتكلفة والتسعير لبدء تشغيل سيارة ذات بادئ تشغيل معطوب المصادر

- تحليل البدائل: مقارنة تشغيل سيارة ذات بادئ تشغيل تالف مع حلول أخرى

- الخصائص التقنية والمصطلحات التجارية الأساسية لتشغيل سيارة مع بادئ تشغيل معطّل

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع تشغيل السيارات ذات البادئ التالف

- الأسئلة المتداولة (FAQs) لمشتري B2B لبدء تشغيل السيارة مع بادئ تشغيل تالف

- استنتاج المصادر الاستراتيجية والتوقعات لبدء تشغيل سيارة ذات بادئ تشغيل معطل

- إخلاء مسؤولية هام وشروط الاستخدام

فهم بدء تشغيل السيارة مع بادئ تشغيل معطل أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| استكشاف الأعطال الكهربائية الأساسية وإصلاحها | ينطوي على فحص توصيلات البطارية والأطراف | ورش إصلاح السيارات، خدمات الأساطيل | الإيجابيات: منخفضة التكلفة وسريعة الإصلاح. السلبيات: قد تؤدي الحلول المؤقتة إلى تكرار المشكلات. |

| تشغيل يدوي بالضغط على زر تشغيل يدوي | يستخدم قوة الدفع لبدء تشغيل مركبة ذات ناقل حركة يدوي | خدمات استرداد المركبات | الإيجابيات: لا حاجة إلى أدوات، حل فوري. السلبيات: تقتصر على المركبات اليدوية ومخاطر السلامة. |

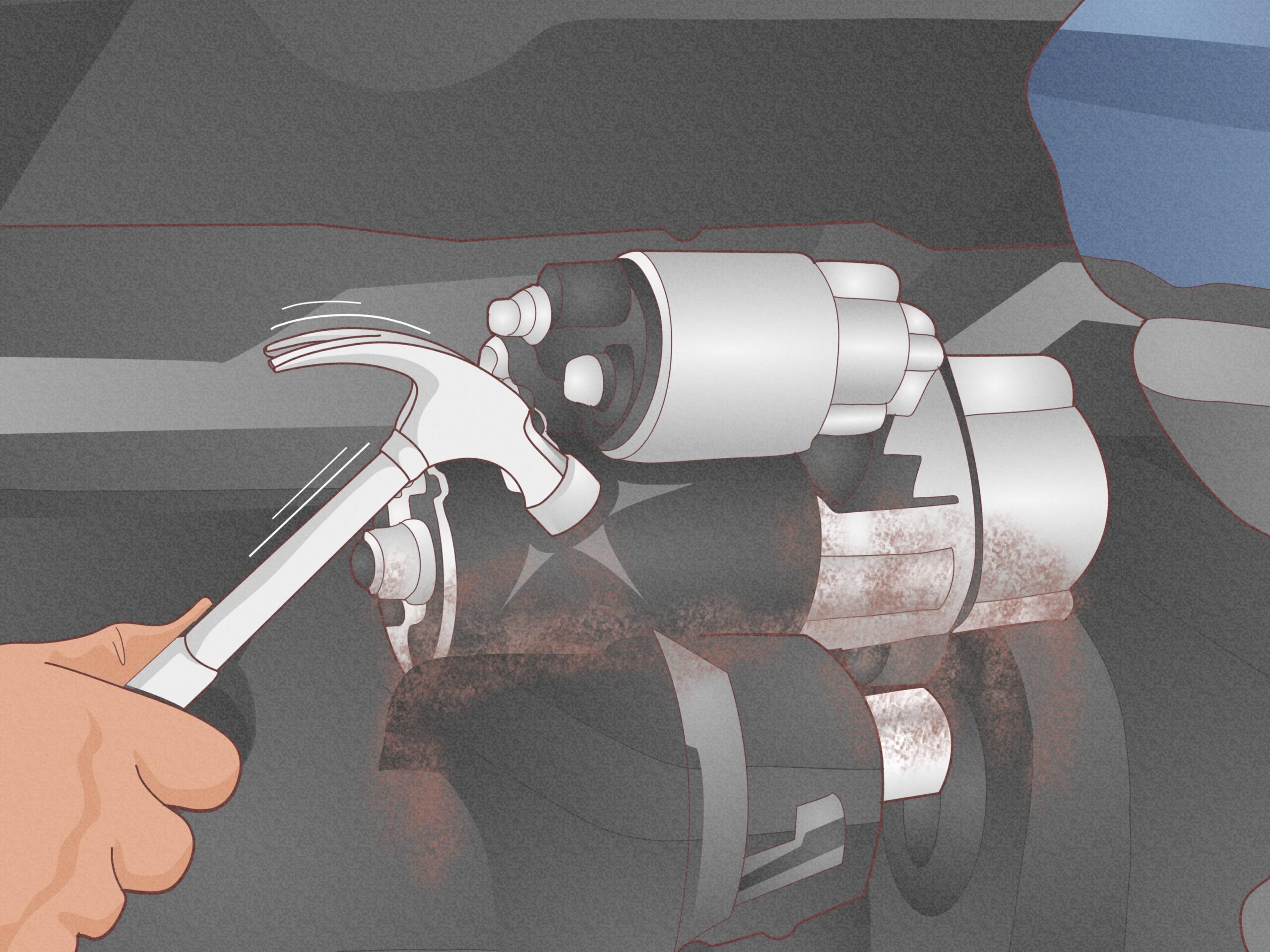

| النقر على البادئ | التدخل الميكانيكي بضرب المشغل برفق | الميكانيكيون المتنقلون والمساعدة على الطريق | الإيجابيات: تقنية بسيطة وفعالة في العديد من الحالات. السلبيات: خطر إتلاف المكونات إذا أسيء استخدامها. |

| فحوصات الملف اللولبي والترحيل | ينطوي على فحص توصيلات الملف اللولبي والصمامات | تشخيص السيارات، وورش التصليح | الإيجابيات: يحدد المشكلات الأساسية ويمنع حدوث إخفاقات مستقبلية. السلبيات: يتطلب معرفة وأدوات محددة. |

| القفز المؤقت للبطارية | تعزيز طاقة البطارية لتشغيل السيارة | إدارة الأسطول، وورش السيارات، وورش السيارات | الإيجابيات: سريعة وسهلة ومفيدة للبطاريات الضعيفة. السلبيات: ليس إصلاحاً لمشاكل البادئين، واحتمال حدوث أعطال متكررة. |

ما هي خصائص استكشاف الأخطاء وإصلاحها الكهربائية الأساسية؟

يركز استكشاف الأعطال الكهربائية الأساسية وإصلاحها على تشخيص وحل المشكلات المتعلقة بتوصيلات البطارية وأطرافها. هذه الطريقة ضرورية لورش تصليح السيارات وخدمات الأساطيل التي تواجه مشاكل في بدء التشغيل بشكل متكرر. من خلال ضمان التوصيلات النظيفة والآمنة، يمكن للشركات توفير حلول فورية للعملاء. ومع ذلك، على الرغم من أن هذا النهج فعال من حيث التكلفة، إلا أنه قد يكون بمثابة حل مؤقت فقط للمشاكل الأعمق، مما يستلزم إجراء المزيد من الإصلاحات في المستقبل.

كيف يعمل نظام التشغيل بالدفع اليدوي؟

إن التشغيل بالدفع اليدوي هو أسلوب يستخدم بشكل أساسي في السيارات المزودة بناقل حركة يدوي. وهي تعتمد على قوة دفع السيارة لتشغيل المحرك بينما يكون الإشعال في وضع التشغيل. هذه الطريقة مفيدة بشكل خاص لخدمات استعادة المركبات التي تحتاج إلى تشغيل السيارة بسرعة دون انتظار المساعدة الميكانيكية. وعلى الرغم من سهولة الوصول إلى هذه التقنية، إلا أنها تنطوي على مخاطر تتعلق بالسلامة وتقتصر على المركبات اليدوية، مما يجعلها أقل قابلية للتطبيق على الطرازات الأوتوماتيكية.

ما هي تقنية النقر على المبدئ؟

ينطوي النقر على مفتاح التشغيل على ضرب محرك التشغيل برفق لتحرير أي مكونات عالقة. يعد هذا التدخل الميكانيكي ممارسة شائعة بين الميكانيكيين المتنقلين وفرق المساعدة على الطريق. يمكن أن يكون فعالاً في تشغيل السيارة مؤقتاً. ومع ذلك، يجب توخي الحذر لتجنب القوة المفرطة التي قد تؤدي إلى تلف المحرك أو المكونات المحيطة به. بساطة هذه التقنية تجعلها جذابة لكنها ليست حلاً دائماً.

لماذا تعتبر فحوصات الملف اللولبي والترحيل مهمة؟

يعد فحص توصيلات الملف اللولبي والترحيل أمراً بالغ الأهمية لتشخيص المشاكل المتعلقة ببادئ التشغيل. وغالباً ما يتم استخدام هذه الطريقة من قبل المتخصصين في تشخيص السيارات وورش التصليح لتحديد المشاكل الكامنة التي قد تتسبب في تعطل المبدئ. من خلال التأكد من أن هذه المكونات تعمل بشكل صحيح، يمكن للشركات منع المشاكل المستقبلية وتعزيز رضا العملاء. ومع ذلك، يتطلب هذا النهج معرفة وأدوات متخصصة، مما قد يمثل تكلفة إضافية لبعض مزودي الخدمة.

ما هي فوائد القفز المؤقت للبطارية؟

يتضمن القفز المؤقت للبطارية استخدام سيارة أخرى أو معزز بطارية محمول لزيادة طاقة البطارية الضعيفة. هذه الطريقة قابلة للتطبيق على نطاق واسع في إدارة أساطيل السيارات وورش السيارات حيث تكون الحلول السريعة ضرورية. على الرغم من أنها يمكن أن توفر إغاثة فورية لمشاكل بدء التشغيل، إلا أنها لا تعالج المشاكل المتعلقة بالمشغل نفسه، مما يؤدي إلى أعطال متكررة محتملة. يجب على الشركات الموازنة بين فوائد الإشباع الفوري والحاجة إلى حلول طويلة الأجل.

التطبيقات الصناعية الرئيسية لبدء تشغيل السيارة مع بادئ تشغيل معطل

| الصناعة/القطاع | تطبيق محدد لبدء تشغيل السيارة مع بادئ تشغيل معطل | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | استخدام إصلاحات مؤقتة لسيارات العملاء ذات المشغلات التالفة | يزيد من رضا العملاء من خلال توفير حلول سريعة | توافر الأدوات وقطع الغيار اللازمة للإصلاحات؛ تدريب الموظفين |

| إدارة الأسطول | تنفيذ إجراءات الطوارئ لمركبات الأسطول التي تعاني من مشاكل في بدء التشغيل | تقليل وقت التعطل وضمان الكفاءة التشغيلية | الوصول إلى أدوات التشخيص الموثوقة وقطع غيار البادئ الموثوق بها |

| خدمات النقل والمواصلات | تقديم المساعدة على الطريق للمركبات التي لا تعمل على الطريق | تعزيز عروض الخدمات وثقة العملاء | معدات موثوقة للتشخيص؛ وفنيون مهرة للإصلاحات |

| معدات البناء | تشغيل الآلات الثقيلة ذات المشغلات المعطوبة في الميدان | الحد من التأخير في المشروع والانقطاعات التشغيلية | أدوات متينة مناسبة للبيئات القاسية؛ توافر قطع الغيار |

| الخدمات اللوجستية والشحن | إجراءات التشغيل في حالات الطوارئ لمركبات التوصيل التي تعاني من أعطال في بادئ التشغيل | ضمان التسليم في الوقت المناسب والمحافظة على التزامات الخدمة | التوريد الفعال لمكونات وأدوات بدء التشغيل للإصلاحات السريعة |

كيف يمكن لورش تصليح السيارات الاستفادة من تشغيل سيارة مع بادئ تشغيل تالف؟

يمكن لورش تصليح السيارات الاستفادة من المعرفة حول تشغيل السيارات ذات المشغلات المعطلة لتقديم المساعدة الفورية للعملاء. من خلال استخدام إصلاحات مؤقتة، مثل تنظيف الوصلات أو استخدام مطرقة لصعق المشغّل، يمكن لورش الإصلاح تعزيز رضا العملاء من خلال حلول سريعة. لا يساعد هذا النهج في الاحتفاظ بالعملاء فحسب، بل يرسخ سمعة المتجر كمزود خدمة موثوق به. يجب أن تتأكد الورش من تجهيزها بأدوات التشخيص وتدريب الموظفين على التعامل مع مثل هذه السيناريوهات بفعالية.

ما هو الدور الذي تلعبه إدارة الأسطول في معالجة مشاكل المبتدئين؟

يمكن لشركات إدارة الأسطول تنفيذ إجراءات طارئة للمركبات التي تظهر بها مشاكل في بدء التشغيل. من خلال تدريب السائقين وموظفي الصيانة على كيفية معالجة هذه المشاكل، يمكن للشركات تقليل وقت تعطل المركبات بشكل كبير، مما يضمن سير العمليات بسلاسة. يؤدي هذا النهج الاستباقي إلى إدارة أفضل للموارد ويمكن أن يوفر التكاليف المرتبطة بفقدان الإنتاجية. تشمل الاعتبارات الرئيسية توفير أدوات تشخيص موثوقة وضمان تدريب موظفي الصيانة بشكل كافٍ لإجراء تقييمات وإصلاحات سريعة في الموقع.

صورة توضيحية تتعلق ببدء تشغيل السيارة مع بادئ تشغيل معطل

كيف تقوم خدمات النقل بتعزيز عروضها من خلال حلول المبتدئين؟

يمكن لخدمات النقل تحسين عروض المساعدة على الطريق من خلال دمج تقنيات تشغيل السيارات ذات المشغلات المعطلة. وهذا لا يعزز ثقة العملاء فحسب، بل يميز خدمتهم عن المنافسين أيضاً. يمكن أن تؤدي الحلول السريعة والفعالة إلى زيادة ولاء العملاء وتكرار الأعمال. يجب على الشركات في هذا القطاع التركيز على المعدات الموثوقة للتشخيص والتأكد من تدريب الفنيين على التعامل مع مختلف أنواع المركبات ومشاكل بدء التشغيل.

لماذا من المهم لمشغلي معدات البناء معالجة مشاكل البادئ؟

بالنسبة لشركات الإنشاءات، تُعد القدرة على تشغيل الآلات الثقيلة ذات المشغلات المعطلة أمرًا بالغ الأهمية لتقليل التأخير في المشروع. يسمح تنفيذ إصلاحات مؤقتة للمشغلين بمواصلة تشغيل الآلات، وبالتالي تجنب التوقف المكلف. يجب على الشركات مراعاة متانة الآلات المستخدمة في الميدان والتأكد من أن لديها إمدادات جاهزة من قطع الغيار لمعالجة مشاكل البادئ بسرعة. يمكن لهذه القدرة أن تعزز بشكل كبير الكفاءة التشغيلية في مواقع العمل.

كيف يمكن لشركات الخدمات اللوجستية والشحن ضمان التسليم في الوقت المناسب مع حلول المبتدئين؟

يمكن لشركات الخدمات اللوجستية والشحن أن تحافظ على التزامها بالتسليم في الوقت المناسب من خلال وضع إجراءات طارئة للمركبات التي تفشل في العمل بسبب مشاكل في بدء التشغيل. إن فهم كيفية إدارة مثل هذه المشاكل يمكن أن يمنع التأخير الذي يؤثر على رضا العملاء. يعد التوريد الفعال لمكونات وأدوات بدء التشغيل أمرًا ضروريًا، وكذلك ضمان تدريب السائقين على التقنيات الأساسية لاستكشاف الأعطال وإصلاحها. هذا الاستعداد لا يعزز موثوقية الخدمة فحسب، بل يبني أيضاً سمعة قوية في سوق الخدمات اللوجستية التنافسية.

3 نقاط ألم شائعة لدى المستخدمين لـ ‘تشغيل السيارة مع بادئ تشغيل معطل’ وحلولها

السيناريو 1: صعوبة تشخيص السبب الجذري لمشكلات بدء التشغيل

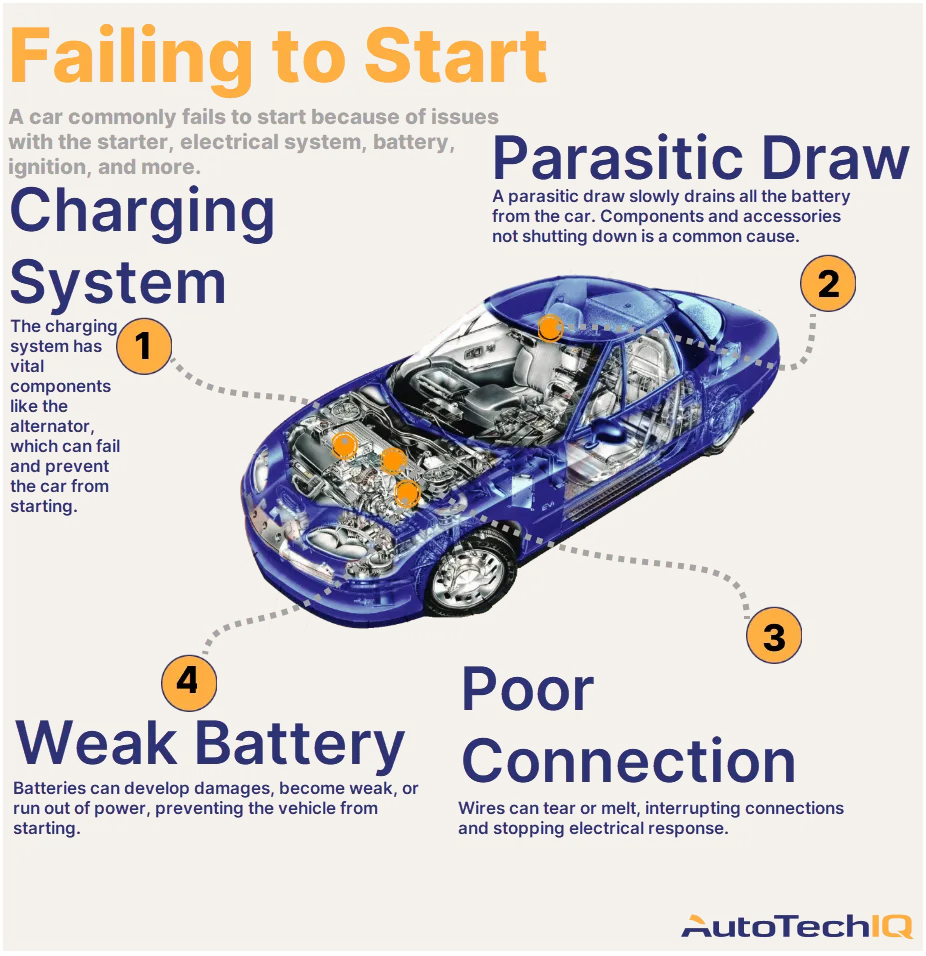

المشكلة: غالباً ما يصادف المشترون من الشركات ولا سيما أولئك الذين يديرون أساطيل أو شركات إصلاح السيارات، سيارات لا تعمل دون إشارة واضحة للمشكلة الأساسية. يمكن أن تنشأ هذه الحالة من عطل في بادئ التشغيل، لكن الأعراض يمكن أن تحاكي مشاكل في البطارية أو نظام الإشعال. يمكن أن يؤدي التشخيص الخاطئ للمشكلة إلى تكاليف غير ضرورية وإضاعة الوقت، مما يؤثر على الكفاءة التشغيلية ورضا العملاء.

صورة توضيحية تتعلق ببدء تشغيل السيارة مع بادئ تشغيل معطل

الحل: لتشخيص المشكلة بفعالية، من الضروري إجراء مقاربة منهجية. ابدأ باختبار جهد البطارية باستخدام مقياس الفولتميتر؛ تشير القراءة الأقل من 12.5 فولت إلى ضعف البطارية التي قد تحتاج إلى تشغيلها. إذا كانت البطارية تعمل بشكل صحيح، افحص أطراف البطارية بحثاً عن أي تآكل أو وصلات مفكوكة. غالباً ما يمكن أن يؤدي تنظيف الأطراف والتأكد من إحكام تركيبها إلى حل المشكلة. للحصول على تشخيص أكثر شمولاً، قم باختبار محرك بدء التشغيل مباشرةً عن طريق النقر عليه برفق بمطرقة، مما قد يؤدي أحياناً إلى إزاحة المكونات العالقة. يمكن أن يؤدي تزويد الفنيين بأدوات التشخيص وتدريبهم على طرق استكشاف الأعطال وإصلاحها إلى تحسين الدقة في تحديد المشاكل المتعلقة بمشغل المحرك بشكل كبير.

السيناريو 2: معرفة محدودة بالحلول المؤقتة للمبتدئين السيئين

المشكلة: قد يعاني العديد من المشترين في قطاع الأعمال بين الشركات، لا سيما في المناطق ذات الوصول المحدود إلى قطع غيار السيارات أو الأدوات، من مشكلة عدم قدرة السيارات على العمل بسبب عطل في بادئ التشغيل. في مثل هذه السيناريوهات، يمكن أن يؤدي عدم القدرة على إجراء إصلاحات سريعة إلى فترات تعطل طويلة، مما يؤثر على جداول التسليم أو خدمة العملاء. بدون فهم واضح للحلول البديلة المؤقتة، قد تواجه الشركات زيادة في التكاليف التشغيلية.

الحل: يمكن أن يساعد تنفيذ مجموعة من الحلول العملية والمؤقتة في التخفيف من تأثير بدء التشغيل السيئ. على سبيل المثال، إذا كانت السيارة مزودة بناقل حركة يدوي، يمكن أن يكون نظام التشغيل بالدفع حلاً فعالاً على المدى القصير. يجب أن يقوم المشترون بتدريب فرقهم على كيفية تشغيل السيارة بالدفع بأمان، مع التأكيد على أهمية العمل الجماعي وبروتوكولات السلامة. بالإضافة إلى ذلك، يمكن أن يؤدي الاحتفاظ بمجموعة من الأدوات الأساسية، بما في ذلك كابلات التوصيل ومطرقة لتشغيل المحرك، إلى تمكين الموظفين من التعامل مع المشاكل البسيطة بكفاءة. يمكن أن يؤدي توفير الموارد التعليمية أو ورش العمل حول هذه الإصلاحات المؤقتة إلى تعزيز مهارات القوى العاملة، مما يضمن تجهيزهم بشكل أفضل للتعامل مع مثل هذه التحديات.

السيناريو 3: توريد بدائل موثوقة لبدائل التشغيل في أسواق متنوعة

المشكلة: يمكن أن يكون الحصول على بادئات تشغيل بديلة عالية الجودة مهمة شاقة للمشترين بين الشركات، خاصةً في الأسواق الدولية ذات المعايير والتوافر المتفاوتة. في مناطق مثل أفريقيا وأمريكا الجنوبية، قد يواجه المشترون تحديات تتعلق بالمنتجات المقلدة وسلاسل التوريد غير المتسقة وتقلب الأسعار، مما قد يضر بموثوقية أساطيلهم.

الحل: وللتغلب على هذه التحديات، من الضروري إقامة علاقات مع موردين ذوي سمعة طيبة يلتزمون بمعايير الجودة العالمية. يمكن أن يساعد إجراء بحث شامل عن الموردين المحتملين، بما في ذلك المراجعات والشهادات، في ضمان الموثوقية. يجب على المشترين أيضاً النظر في إبرام اتفاقيات الشراء بالجملة لتأمين أسعار أفضل وضمان إمدادات ثابتة من المبتدئين ذوي الجودة العالية. بالإضافة إلى ذلك، فإن الاستفادة من الموزعين المحليين الذين يفهمون السوق الإقليمية يمكن أن يسهل المعاملات بشكل أكثر سلاسة ويقلل من مخاطر المنتجات المقلدة. إن تنفيذ عملية ضمان الجودة التي تشمل اختبار الأجزاء الواردة قبل توزيعها يمكن أن يزيد من الحماية من المشاكل التي قد تنشأ من المكونات دون المستوى المطلوب.

دليل اختيار المواد الاستراتيجية لتشغيل سيارة ذات بادئ تشغيل تالف

ما هي المواد الأفضل لتشغيل سيارة مع بادئ تشغيل سيارتك المتعطل؟

عند التفكير في المواد المستخدمة في تشغيل سيارة ذات بادئ تشغيل سيارة، من الضروري التركيز على مكونات مثل كابلات التوصيل وأطراف البطارية ومحركات بادئ التشغيل. تلعب كل مادة دوراً حاسماً في ضمان الأداء الموثوق به، خاصة في البيئات الصعبة مثل تلك الموجودة في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

ما هي الخصائص الرئيسية للنحاس في كابلات التوصيل؟

النحاس هو المادة الأكثر شيوعًا المستخدمة في كابلات التوصيل نظرًا لتوصيلها الكهربائي الممتاز. وهي تعمل عادةً بفعالية في نطاق درجة حرارة تتراوح بين -40 درجة مئوية و90 درجة مئوية وتتميز بمقاومة التآكل التي تعتبر حيوية للحفاظ على الأداء مع مرور الوقت.

الإيجابيات والسلبيات:

تتميز كابلات التوصيل النحاسية بمتانتها العالية، مما يسمح بالاستخدام المتكرر دون تآكل كبير. ومع ذلك، فإنها تميل إلى أن تكون أغلى من البدائل مثل الألومنيوم، كما أن تعقيد تصنيعها أعلى بسبب الحاجة إلى عزل أكثر سمكاً لمنع تراكم الحرارة.

التأثير على التطبيق:

إن توافق النحاس مع مختلف الأنظمة الكهربائية يجعله مناسباً لتشغيل السيارات من مختلف الماركات والموديلات.

اعتبارات للمشترين الدوليين:

يجب على مشتري B2B التأكد من أن النحاس المستخدم يفي بالمعايير الدولية مثل ASTM B3 للموصلات النحاسية العارية. في المناطق ذات الرطوبة العالية أو التعرض للملح، قد يكون من الضروري أيضًا استخدام الطلاء المقاوم للتآكل.

لماذا تختار الألومنيوم لأطراف البطارية؟

الألومنيوم هو مادة أخرى غالباً ما تُستخدم في أطراف البطاريات نظراً لطبيعته الخفيفة الوزن وتوصيله الجيد، وإن كان أقل من النحاس. يمكن لمكونات الألومنيوم عادةً أن تتحمل درجات حرارة تصل إلى 120 درجة مئوية وهي مقاومة للتآكل عند معالجتها بشكل صحيح.

الإيجابيات والسلبيات:

إن طبيعة الألومنيوم الخفيفة الوزن تجعله فعالاً من حيث التكلفة وأسهل في التعامل معه. ومع ذلك، فهو أقل متانة مقارنةً بالنحاس، ويمكن أن تكون موصلية الألومنيوم محدودة في التطبيقات عالية الأداء.

التأثير على التطبيق:

تُستخدم أطراف البطاريات المصنوعة من الألومنيوم على نطاق واسع في السيارات الاقتصادية ويمكن أن تكون مناسبة لمختلف تطبيقات السيارات، شريطة أن تتم صيانتها بشكل مناسب.

اعتبارات للمشترين الدوليين:

يجب على المشترين البحث عن الامتثال لمعايير مثل JIS C 3101 في اليابان أو DIN 17615 في أوروبا لضمان الجودة والتوافق مع اللوائح المحلية.

ما هي فوائد الصلب لمحركات بدء التشغيل؟

يشيع استخدام الفولاذ في علب محرك البادئ نظراً لقوته ومتانته. ويمكنه تحمل درجات الحرارة والضغوط العالية، مما يجعله مناسباً للبيئة الصعبة في حجرة المحرك.

الإيجابيات والسلبيات:

تُعد متانة الفولاذ ميزة كبيرة، حيث يوفر موثوقية طويلة الأجل. ومع ذلك، فهو أثقل من الألومنيوم ويمكن أن يكون عرضة للصدأ إذا لم تتم معالجته بشكل صحيح، مما قد يؤثر على الأداء بمرور الوقت.

التأثير على التطبيق:

تُعد محركات بدء التشغيل الفولاذية مثالية للاستخدامات الشاقة ويمكنها التعامل مع ضغوط الاستخدام المتكرر، خاصة في المركبات التجارية.

اعتبارات للمشترين الدوليين:

بالنسبة لمشتري B2B، فإن ضمان استيفاء مكونات الصلب لمعايير مثل ASTM A36 أو EN 10025 أمر بالغ الأهمية لضمان الجودة والامتثال للوائح المحلية.

كيف يدخل البلاستيك في العزل الكهربائي؟

غالبًا ما تُستخدم المواد البلاستيكية للعزل في المكونات الكهربائية، بما في ذلك محركات بدء التشغيل وأطراف البطاريات. وهي توفر خصائص عزل كهربائية ممتازة ويمكن أن تعمل بفعالية في نطاق واسع من درجات الحرارة.

الإيجابيات والسلبيات:

البلاستيك خفيف الوزن وفعال من حيث التكلفة، مما يجعله خيارًا جذابًا للمصنعين. ومع ذلك، قد لا يكون متينًا مثل المعادن في التطبيقات عالية الحرارة ويمكن أن يتحلل بمرور الوقت إذا تعرض للأشعة فوق البنفسجية.

التأثير على التطبيق:

يعد العزل البلاستيكي أمرًا بالغ الأهمية لمنع حدوث ماس كهربائي وضمان التشغيل الآمن في تطبيقات السيارات.

اعتبارات للمشترين الدوليين:

يجب على مشتري B2B التأكد من أن المواد البلاستيكية المستخدمة تتوافق مع معايير مثل ISO 9001 لإدارة الجودة و ASTM D638 لخصائص الشد.

جدول ملخص اختيار المواد

| المواد | حالة استخدام نموذجية لتشغيل سيارة مع بادئ تشغيل معطل | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | كابلات التوصيل لبدء تشغيل المركبات | موصلية كهربائية ممتازة | تكلفة عالية مقارنة بالبدائل | عالية |

| الألومنيوم | أطراف البطارية للتوصيلات الكهربائية | خفيفة الوزن وفعالة من حيث التكلفة | انخفاض الموصلية والمتانة | متوسط |

| الصلب | علب محرك التشغيل من أجل المتانة | قوة عالية وموثوقية طويلة الأمد | أثقل وزناً وعرضة للصدأ | متوسط |

| بلاستيك | العزل للمكونات الكهربائية | خفيف الوزن وعزل ممتاز | أقل متانة في التطبيقات ذات الحرارة العالية | منخفض |

يقدم دليل اختيار المواد الاستراتيجية هذا نظرة ثاقبة حول المواد الأنسب لبدء تشغيل السيارة مع بادئ تشغيل سيئ، وهو مصمم خصيصًا للمشترين الدوليين من الشركات. ويمكن أن يؤدي فهم هذه الخصائص والاعتبارات إلى اتخاذ قرارات شراء أفضل وتحسين أداء المنتج في مختلف الأسواق.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لبدء تشغيل سيارة ذات بادئ تشغيل تالف

ما هي المراحل الرئيسية لتصنيع محرك التشغيل؟

ينطوي تصنيع محرك بدء التشغيل، وهو مكون مهم لبدء تشغيل السيارة، على عدة مراحل محددة جيدًا، كل منها ضروري لضمان أداء المنتج النهائي وموثوقيته. وتشمل المراحل الأساسية إعداد المواد والتشكيل والتجميع والتشطيب.

-

تحضير المواد

الخطوة الأولى في عملية التصنيع هي اختيار مواد عالية الجودة. وعادةً ما تُصنع المحركات البادئة من مزيج من المعادن، بما في ذلك الفولاذ للمبيت والنحاس للملفات. وتتضمن مرحلة التحضير الحصول على هذه المواد من موردين معتمدين يستوفون معايير الجودة العالمية. وتشمل هذه المرحلة أيضًا قطع المواد ومعالجتها لتعزيز المتانة والأداء. -

تشكيل

تشمل مرحلة التشكيل عمليات مثل الختم والتشغيل الآلي والصب. يُستخدم الختم لإنشاء مبيت المحرك، بينما تضمن المعالجة الآلية تصنيع مكونات مثل المحرك والأعمدة وفقًا لمواصفات دقيقة. وغالبًا ما يتم استخدام تقنيات متقدمة، مثل التصنيع باستخدام الحاسب الآلي، لتحقيق دقة عالية. هذه المرحلة ضرورية لضمان توافق المكونات مع بعضها البعض بسلاسة، وهو أمر حيوي لتحقيق الأداء الأمثل. -

الجمعية

أثناء التجميع، يتم تجميع المكونات المختلفة معاً. ويشمل ذلك الدوار والجزء الثابت والفرش والملف اللولبي. غالبًا ما تستخدم عملية التجميع آلات آلية لتعزيز السرعة والدقة. يجب تركيب كل مكون بترتيب واتجاه محددين لضمان عمل المحرك البادئ بشكل صحيح. قد تتضمن هذه المرحلة أيضًا لحام أو تجعيد التوصيلات الكهربائية لضمان التوصيل الموثوق به. -

التشطيب

المرحلة الأخيرة في عملية التصنيع هي التشطيب. ويشمل ذلك الطلاء أو الطلاء أو الطلاء للحماية من التآكل وتحسين المظهر الجمالي. يتم إجراء فحوصات الجودة خلال هذه المرحلة للتأكد من أن كل محرك بادئ تشغيل يفي بالمواصفات المطلوبة. وتشمل اللمسات النهائية أيضًا التغليف، مما يضمن حماية المنتج أثناء النقل وجاهزيته للتوزيع.

ما هي ممارسات ضمان الجودة الضرورية لمحركات التشغيل؟

يعد ضمان الجودة (QA) أمرًا حيويًا في تصنيع محركات بدء التشغيل، مما يضمن موثوقية المنتجات النهائية ومطابقتها لمعايير الصناعة. وتشمل الممارسات الرئيسية الالتزام بالمعايير الدولية، وإجراء عمليات تفتيش شاملة، وتنفيذ عمليات التحسين المستمر.

-

الالتزام بالمعايير الدولية

يعد الامتثال لمعايير الجودة الدولية، مثل ISO 9001، أمرًا بالغ الأهمية للمصنعين. وتوضح هذه الشهادة أن الشركة لديها نظام قوي لإدارة الجودة. بالنسبة لمكونات السيارات، قد تنطبق معايير إضافية خاصة بالصناعة مثل علامة CE أو شهادة API، اعتمادًا على السوق والمتطلبات التنظيمية. -

نقاط مراقبة الجودة

يتم دمج نقاط التحقق من مراقبة الجودة (QC) في جميع مراحل عملية التصنيع لاكتشاف العيوب في وقت مبكر. وتشمل نقاط الفحص هذه عادةً ما يلي:

– مراقبة الجودة الواردة (IQC): فحص المواد الخام عند وصولها للتأكد من مطابقتها للمعايير المحددة.

– مراقبة الجودة أثناء الإنتاج (IPQC): فحوصات مستمرة أثناء الإنتاج لمراقبة الالتزام بالمواصفات واكتشاف المشكلات مبكرًا.

– مراقبة الجودة النهائية (FQC): اختبار شامل للمنتج النهائي للتحقق من الأداء الوظيفي والسلامة قبل الشحن. -

طرق الاختبار الشائعة لمحركات التشغيل

يتم استخدام طرق اختبار مختلفة لضمان جودة وموثوقية محركات بدء التشغيل. وقد تشمل هذه الطرق ما يلي:

– الاختبارات الكهربائية: التحقق من الجهد، والتيار، والمقاومة للتأكد من الأداء السليم.

– اختبار المتانة: تعريض محرك بدء التشغيل لظروف قاسية لتقييم الأداء تحت الضغط.

– اختبار الاهتزازات: التأكد من قدرة المحرك على تحمل الاهتزازات التي تواجهها أثناء تشغيل السيارة.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

بالنسبة للمشترين الدوليين بين الشركات، خاصةً أولئك القادمين من مناطق متنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، فإن التحقق من مراقبة جودة الموردين أمر بالغ الأهمية لضمان موثوقية المنتج.

-

إجراء عمليات تدقيق الموردين

يمكن أن توفر عمليات التدقيق المنتظمة للموردين المحتملين نظرة ثاقبة على عمليات التصنيع وممارسات ضمان الجودة لديهم. تتيح المراجعة في الموقع للمشترين تقييم بيئة الإنتاج ومراجعة وثائق الجودة وتقييم الالتزام بالمعايير الدولية. -

طلب تقارير الجودة

يجب على المشترين طلب تقارير جودة مفصلة توضح عمليات مراقبة الجودة ونتائجها. وينبغي أن تتضمن هذه التقارير بيانات من مراحل مراقبة الجودة المتكاملة ومراقبة الجودة المتكاملة ومراقبة الجودة الكاملة، مما يوفر الشفافية بشأن كيفية الحفاظ على الجودة في جميع مراحل الإنتاج. -

إشراك خدمات التفتيش من طرف ثالث

يمكن أن يضيف استخدام خدمات التفتيش من طرف ثالث طبقة إضافية من الضمان. يمكن لهذه المنظمات المستقلة إجراء عمليات التفتيش في مراحل الإنتاج المختلفة، مما يوفر تقييمات غير متحيزة للجودة والامتثال للمعايير.

ما هي الفروق الدقيقة في مراقبة الجودة والاعتماد التي يجب على المشترين الدوليين مراعاتها؟

عند التعامل مع الموردين في مختلف المناطق، يجب على المشترين بين الشركات التعامل مع مختلف الفروق الدقيقة في مراقبة الجودة والاعتماد.

صورة توضيحية تتعلق ببدء تشغيل السيارة مع بادئ تشغيل معطل

-

المعايير واللوائح الإقليمية

قد يكون للمناطق المختلفة لوائح محددة تحكم مكونات السيارات. على سبيل المثال، قد يطلب المشترون الأوروبيون علامة CE للامتثال لتوجيهات الاتحاد الأوروبي، بينما قد يركز المشترون في الشرق الأوسط على الشهادات المحلية. إن فهم هذه المتطلبات الإقليمية أمر بالغ الأهمية لتجنب مشاكل الامتثال. -

الاختلافات الثقافية والتشغيلية

يمكن أن تؤثر الاختلافات الثقافية على ممارسات التصنيع وعمليات ضمان الجودة. وينبغي على المشترين مراعاة هذه العوامل عند إقامة الشراكات، حيث يمكن أن تؤثر على التواصل والتوقعات المتعلقة بالجودة. -

العلاقات طويلة الأمد والتحسين المستمر

يمكن أن يؤدي بناء علاقات طويلة الأجل مع الموردين إلى تعزيز ثقافة التحسين المستمر. وينبغي للمشترين تشجيع الموردين على اعتماد أفضل الممارسات والاستثمار في تحسينات الجودة، بما يضمن تلبية المنتجات للمعايير والتوقعات المتطورة.

الخلاصة

وخلاصة القول، إن فهم عمليات التصنيع وممارسات ضمان الجودة للمحركات البادئة أمر ضروري للمشترين بين الشركات. فمن خلال التركيز على مراقبة الجودة، والتحقق من ممارسات الموردين، والتحقق من ممارسات الموردين، والتحقق من المعايير الدولية، يمكن للشركات ضمان حصولها على منتجات موثوقة تلبي احتياجاتها التشغيلية. لا يعزز هذا النهج أداء المنتج فحسب، بل يعزز أيضًا الشراكات داخل سلسلة توريد السيارات العالمية.

دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘تشغيل سيارة ذات بادئ تشغيل تالف’

في صناعة السيارات، يمكن أن تكون معرفة كيفية تشغيل سيارة ذات بادئ تشغيل معطل أمرًا ضروريًا لتقليل وقت التعطل وضمان الكفاءة التشغيلية. يقدّم هذا الدليل قائمة مرجعية عملية لمشتري السيارات، لا سيما في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، لمعالجة المشاكل المتعلقة ببداية التشغيل في السيارات بفعالية.

الخطوة 1: التعرف على الأعراض الشائعة للمبتدئين السيئين

يعد فهم علامات وجود عطل في بادئ التشغيل أمراً بالغ الأهمية لاستكشاف الأعطال وإصلاحها بفعالية. يمكن أن تشمل الأعراض صوت طقطقة عند تشغيل الإشعال أو عدم وجود صوت على الإطلاق. يمكن أن يؤدي التعرف على هذه المؤشرات في وقت مبكر إلى توفير الوقت والموارد من خلال مساعدتك في التفريق بين مشاكل البادئ والمشاكل المحتملة الأخرى مثل تعطل البطارية أو أعطال نظام الإشعال.

الخطوة 2: جمع الأدوات الأساسية للتشخيص

قبل محاولة إجراء أي إصلاحات، تأكد من توفر الأدوات اللازمة في متناول يدك. تشمل العناصر الرئيسية ما يلي:

– كابلات التوصيل: مفيد لاختبار حالة البطارية.

– الفولتميتر: لقياس جهد البطارية والتأكد مما إذا كانت المشكلة في البطارية وليس في بادئ التشغيل.

– طقم مفك البراغي والمقابس: لفصل أطراف البطارية وتنظيفها بأمان.

إن توفر هذه الأدوات بسهولة يسمح بإجراء عملية استكشاف الأعطال وإصلاحها بكفاءة أكبر، مما يقلل من التأخير في الإصلاحات.

الخطوة 3: تقييم توصيلات البطارية والجهد الكهربائي

ابدأ بفحص أطراف البطارية للتأكد من عدم وجود تآكل وتوصيلات مفكوكة. قم بتنظيف أي تراكمات بفرشاة سلكية وتأكد من إحكام تركيبها. يجب أن تقرأ البطارية السليمة 12.5 فولت على الأقل؛ أي شيء أقل من ذلك قد يشير إلى الحاجة إلى إعادة التشغيل أو الاستبدال. هذه الخطوة ضرورية لأن العديد من مشاكل البادئ تنبع من عدم كفاية إمدادات الطاقة بدلاً من البادئ نفسه.

الخطوة 4: افحص بادئ التشغيل والملف اللولبي

بمجرد استبعاد مشاكل البطارية، ركز على محرك بدء التشغيل والملف اللولبي. ابحث عن علامات التآكل أو التلف، وتأكد من أن جميع توصيلات الأسلاك آمنة. إذا كانت سيارتك تحتوي على ملف لولبي خارجي، افحصه بحثاً عن أسلاك مفكوكة أو تآكل. يعد نظام بدء التشغيل الذي تتم صيانته جيداً أمراً بالغ الأهمية لتشغيل السيارة بشكل موثوق، مما يجعل هذه الخطوة أولوية.

الخطوة 5: النظر في الإصلاحات المؤقتة للاحتياجات الفورية

إذا تم التأكد من وجود عطل في بادئ التشغيل ولكن الإصلاح الفوري غير ممكن، فكر في الحلول المؤقتة. يمكن أن يؤدي النقر على المشغّل برفق باستخدام مطرقة في بعض الأحيان إلى تحرير المكونات العالقة، ويمكن أن يؤدي تشغيل السيارات ذات ناقل الحركة اليدوي بالدفع إلى تجاوز مشاكل المشغّل مؤقتاً. يمكن أن تكون هذه الطرق عملية للشركات التي تحتاج إلى إبقاء المركبات قيد التشغيل أثناء انتظار قطع الغيار أو الإصلاحات.

الخطوة 6: جدولة إصلاحات احترافية

بعد تنفيذ الإصلاحات المؤقتة، خطط لإجراء تشخيصات وإصلاحات احترافية. قم بتوثيق الأعراض وأي تدابير مؤقتة تم اتخاذها، حيث يمكن أن تكون هذه المعلومات ذات قيمة لفنيي السيارات. يمكن لفحوصات الصيانة الدورية أن تمنع حدوث مشاكل في بداية التشغيل في المستقبل، مما يضمن بقاء أسطولك موثوقاً وفعالاً.

صورة توضيحية تتعلق ببدء تشغيل السيارة مع بادئ تشغيل معطل

الخطوة 7: تقييم خيارات الموردين لقطع الغيار البديلة

عند الحصول على بادئات تشغيل أو مكونات بديلة، قم بتقييم الموردين المحتملين بناءً على موثوقيتهم وجودة القطع. اطلب مواصفات المنتج والضمانات ومراجعات العملاء للتأكد من أنك تشتري من موردين ذوي سمعة طيبة. يعد اختيار المورد المناسب أمرًا بالغ الأهمية للحفاظ على السلامة التشغيلية لمركباتك وتقليل وقت التعطل في المستقبل.

باتباع قائمة التحقق هذه، يمكن للمشترين من الشركات التأكد من استعدادهم الجيد لمعالجة مشكلات بدء التشغيل بفعالية، مما يعزز كفاءتهم التشغيلية ويقلل من وقت تعطل المركبات.

تحليل شامل للتكلفة والتسعير لبدء تشغيل سيارة ذات بادئ تشغيل معطوب المصادر

ما هي مكونات التكلفة الرئيسية لتشغيل سيارة مع بادئ تشغيل معطل؟

عند تحليل التكاليف المرتبطة بتشغيل سيارة مع بادئ تشغيل تالف، يجب مراعاة عدة مكونات. وتشمل هذه العناصر المواد، والعمالة، ونفقات التصنيع العامة، والأدوات، ومراقبة الجودة، والخدمات اللوجستية، وهامش الربح.

-

المواد: المواد الأساسية المستخدمة هي المكونات اللازمة للإصلاحات المؤقتة، مثل كابلات التوصيل ومفاتيح الربط ومفاتيح الربط ومقاييس الفولتية والمطارق. يمكن أن تختلف جودة هذه المواد بشكل كبير، مما يؤثر على كل من الأداء والتسعير. على سبيل المثال، قد تأتي الأدوات عالية الجودة بسعر أعلى ولكنها توفر عمرًا أطول وموثوقية أفضل.

-

العمل: تعتمد تكاليف العمالة على مدى تعقيد عملية الإصلاح وأسعار السوق المحلية لفنيي السيارات. ففي المناطق ذات تكاليف العمالة المرتفعة، مثل أوروبا، قد ترتفع التكلفة الإجمالية للإصلاحات. وعلى العكس من ذلك، في مناطق مثل أفريقيا وأمريكا الجنوبية، قد تكون أسعار العمالة أكثر تنافسية في مناطق مثل أفريقيا وأمريكا الجنوبية.

-

تكاليف التصنيع العامة: ويشمل ذلك التكاليف المتعلقة بالمرافق والمرافق وصيانة المعدات المرتبطة بإنتاج الأدوات المتعلقة ببدء التشغيل. ويمكن أن تختلف النفقات العامة اختلافاً كبيراً حسب الموقع الجغرافي والكفاءة التشغيلية للمورد.

-

الأدوات: إذا كانت هناك حاجة إلى أدوات متخصصة للإصلاح، فقد يضيف ذلك إلى الاستثمار الأولي. على سبيل المثال، قد تكون هناك حاجة إلى رافعات وحوامل للوصول إلى محركات تشغيل بعض المركبات. يجب أن تؤخذ هذه التكاليف في الحسبان في تحليل السعر الإجمالي.

-

مراقبة الجودة (QC): يمكن أن يؤدي تنفيذ عملية قوية لمراقبة الجودة إلى تكبد تكاليف إضافية ولكنه ضروري لضمان استيفاء جميع المكونات لمعايير السلامة والأداء. وقد يهتم المشترون الدوليون بشكل خاص بالشهادات وضمان الجودة.

-

اللوجستيات: يمكن لتكاليف الشحن والمناولة أن تؤثر بشكل كبير على التسعير الإجمالي، خاصة بالنسبة للمعاملات الدولية. وتؤدي شروط التجارة الدولية دوراً حاسماً في تحديد المسؤوليات المتعلقة بالشحن والتأمين والتعريفات، والتي يمكن أن تختلف باختلاف المناطق.

-

الهامش: يجب على الموردين تحديد هامش ربح يعكس المخاطر والاستثمار المرتبط بمنتجاتهم. ويمكن أن تختلف توقعات الهامش حسب المنافسة في السوق وعلاقات المشترين.

كيف تؤثر العوامل المؤثرة في السعر على تكلفة تشغيل سيارة ذات بادئ تشغيل سيء؟

يمكن أن تؤثر عدة عوامل على الأسعار عند الحصول على مكونات أو خدمات لتشغيل سيارة ذات بادئ تشغيل معطل:

-

الحجم/الحد الأدنى للطلب: غالبًا ما يقدم الموردون أسعارًا أفضل للمشتريات بالجملة. ويمكن أن يؤدي فهم الحد الأدنى لكميات الطلبات (MOQ) إلى تحقيق وفورات كبيرة للشركات التي تتطلب كميات أكبر.

-

المواصفات والتخصيص: قد تترتب تكاليف أعلى على الأدوات أو المعدات المخصصة المصممة لطرازات معينة من المركبات. يجب على المشترين تقييم ما إذا كان التخصيص ضرورياً أو ما إذا كانت الخيارات القياسية كافية.

-

شهادات المواد والجودة: يؤثر اختيار المواد بشكل كبير على التكلفة. وغالبًا ما تؤدي المواد عالية الجودة إلى تعزيز المتانة والأداء، مما يبرر ارتفاع السعر. بالإضافة إلى ذلك، قد تكون شهادات السلامة والجودة مطلوبة للامتثال الدولي.

-

عوامل الموردين: يمكن أن تؤثر سمعة المورد وموثوقيته على الأسعار. فقد يتقاضى الموردون الراسخون ذوو السجل الحافل أسعاراً أعلى، في حين أن الموردين الجدد أو الأقل سمعة قد يعرضون أسعاراً أقل ولكنهم يشكلون مخاطر أعلى.

-

مصطلحات التجارة الدولية: فهم شروط الشحن أمر ضروري للتسعير. ويمكن أن تؤثر المصطلحات الدولية المختلفة على الجهة المسؤولة عن تكاليف النقل والتأمين والتعريفات الجمركية، مما يؤثر على هيكل التكلفة الإجمالي.

ما هي أفضل النصائح للمشتري لتحقيق الكفاءة من حيث التكلفة في توريد حلول المبتدئين؟

لزيادة كفاءة التكلفة إلى أقصى حد عند الحصول على مكونات لتشغيل سيارة ذات بادئ تشغيل تالف، ضع في اعتبارك الاستراتيجيات التالية:

-

التفاوض: تعامل دائمًا مع الموردين بعقلية تفاوضية. افهم أسعار السوق وكن مستعدًا لمناقشة الأسعار بناءً على احتياجاتك وحجم الطلب.

-

التكلفة الإجمالية للملكية (TCO): التركيز ليس فقط على التكاليف الأولية ولكن أيضًا على الآثار المترتبة على المدى الطويل. قم بتقييم كيفية تأثير الجودة على المتانة والصيانة وتكاليف الاستبدال بمرور الوقت.

-

الفروق الدقيقة في الأسعار للمشترين الدوليين: عند التعامل مع الموردين الدوليين، يجب أن تكون على دراية بتقلبات أسعار العملات ورسوم الاستيراد واللوائح المحلية التي يمكن أن تؤثر على الأسعار. ومن شأن إقامة تواصل واضح بشأن التوقعات والمتطلبات أن يساعد في الحد من سوء الفهم.

-

علاقات الموردين: يمكن أن يؤدي بناء علاقات قوية مع الموردين إلى أسعار وشروط أفضل بمرور الوقت. وقد يحصل العملاء الأوفياء على خصومات أو أولوية في الخدمة.

إخلاء المسؤولية بشأن الأسعار الإرشادية

يمكن أن تختلف أسعار الأدوات والخدمات المتعلقة بتشغيل سيارة ذات بادئ تشغيل معطوب اختلافاً كبيراً بناءً على الموقع والمورّد وظروف السوق. يُنصح بالحصول على عروض أسعار متعددة وإجراء بحث شامل للتأكد من حصولك على أفضل قيمة لاستثمارك.

تحليل البدائل: مقارنة تشغيل سيارة ذات بادئ تشغيل تالف مع حلول أخرى

استكشاف بدائل لتشغيل سيارة ذات بادئ تشغيل تالف

عند مواجهة تحدي تشغيل السيارة مع وجود عطل في المحرك، من الضروري استكشاف البدائل القابلة للتطبيق التي يمكن أن تحقق نفس الهدف. توجد طرق مختلفة، لكل منها مجموعة من المزايا والعيوب الخاصة بها. سيقارن هذا التحليل “تشغيل السيارة مع بادئ تشغيل معطل” مع بديلين عمليين: استخدام بادئ تشغيل كهربائي واستخدام تقنية التشغيل بالدفع للمركبات ذات ناقل الحركة اليدوي.

| جانب المقارنة | تشغيل سيارة مع بداية تشغيل معطلة | بادئ التشغيل السريع | تقنية الدفع-البداية |

|---|---|---|---|

| الأداء | محدودة؛ قد تعمل بشكل مؤقت فقط | عالية؛ موثوقة وفعالة | معتدلة؛ فقط للمركبات اليدوية |

| التكلفة | منخفضة؛ الحد الأدنى من الأدوات المطلوبة | معتدلة؛ تكاليف شراء الجهاز | منخفضة؛ لا تتطلب أدوات إضافية |

| سهولة التنفيذ | متوسط؛ يتطلب بعض الفهم الميكانيكي | سهل؛ تصميم سهل الاستخدام | معتدل؛ يحتاج إلى مساعدة |

| الصيانة | لا يوجد؛ وعادةً ما يكون إصلاح مؤقت | منخفضة؛ تتطلب الشحن | لا يوجد؛ استخدام لمرة واحدة |

| أفضل حالة استخدام | حل قصير الأجل في حالات الطوارئ | الاستخدام المنتظم لمشاكل البطارية | إصلاح سريع للمركبات اليدوية |

ما هي مزايا وعيوب كل بديل؟

بادئ التشغيل السريع

توفر أجهزة بدء التشغيل السريع طريقة موثوقة وفعالة لتشغيل سيارة ببطارية فارغة، والتي قد يتم الخلط بينها وبين مشاكل في بدء التشغيل. وهي عبارة عن أجهزة محمولة يمكنها تزويد البطارية بطاقة كبيرة معززة للبطارية، مما يسمح بتشغيل السيارة دون الحاجة إلى سيارة أخرى. وتتمثل الميزة الأساسية في سهولة استخدامها وفعاليتها؛ حيث يمكن استخدامها من قبل أي شخص ليس لديه معرفة ميكانيكية. ومع ذلك، فهي تتطلب استثماراً مالياً، وتتضاءل فعاليتها في حال تعطّل المشغّل نفسه.

تقنية الدفع-البداية

تعتبر طريقة الدفع والتشغيل بالدفع حلاً عملياً للمركبات ذات ناقل الحركة اليدوي، حيث تسمح للسائق بتجاوز مشكلة بدء التشغيل من خلال تدوير السيارة لاكتساب قوة دفع. يمكن تنفيذ هذه التقنية باستخدام الحد الأدنى من الأدوات وهي فعالة من حيث التكلفة. ومع ذلك، فهي تتطلب مساعدة جسدية من الآخرين وهي مناسبة فقط للمركبات اليدوية، مما يحد من إمكانية تطبيقها. وعلاوة على ذلك، قد لا تكون هذه التقنية مجدية في حركة المرور أو على المنحدرات، مما يجعلها أقل موثوقية في المناطق الحضرية.

كيف ينبغي للمشترين بين الشركات اختيار الحل المناسب؟

عند اختيار الحل المناسب لبدء تشغيل سيارة ذات بادئ تشغيل معطل، يجب على مشتري B2B مراعاة عوامل مثل نوع السيارة وسيناريوهات الاستخدام الشائعة وقيود الميزانية. بالنسبة للشركات التي تشغّل أساطيل السيارات، قد يوفر الاستثمار في مشغّلات القفز حلاً طويل الأمد لمشاكل البطارية، في حين يمكن أن تكون البادئات التي تعمل بالدفع حلاً سريعاً لمركبات محددة في الأسطول. يمكن أن يؤدي فهم التحديات الفريدة والبيئات التشغيلية إلى توجيه المشترين نحو الخيار الأكثر فعالية وكفاءة لاحتياجاتهم.

صورة توضيحية تتعلق ببدء تشغيل السيارة مع بادئ تشغيل معطل

في نهاية المطاف، يتوقف الاختيار في النهاية على الموازنة بين التكلفة والأداء وسهولة التنفيذ، مما يضمن توافق الحل مع الأهداف التشغيلية الفورية وطويلة الأجل.

الخصائص التقنية والمصطلحات التجارية الأساسية لتشغيل سيارة مع بادئ تشغيل معطّل

ما هي الخصائص التقنية الرئيسية لتشغيل سيارة مع بادئ تشغيل معطل؟

عند معالجة التحديات المرتبطة ببدء تشغيل السيارة مع وجود عطل في بادئ تشغيل السيارة، تصبح العديد من الخصائص التقنية ضرورية للتشخيص الفعال والحلول المؤقتة. يمكن لفهم هذه الخصائص أن يساعد المشترين من الشركات B2B، لا سيما في قطاع قطع غيار وخدمات السيارات، على اتخاذ قرارات مستنيرة.

1. تصنيف الجهد الكهربائي

يعتبر تصنيف الجهد الكهربائي لنظام بدء التشغيل أمراً بالغ الأهمية، وعادةً ما يكون حوالي 12 فولت لمعظم السيارات. يشير هذا التصنيف إلى الجهد الكهربائي اللازم لتشغيل محرك البادئ. بالنسبة للشركات التي تبحث عن مصادر للمبتدئين أو المكونات، فإن ضمان التوافق مع نظام جهد السيارة أمر حيوي لتجنب مشاكل الأداء.

صورة توضيحية تتعلق ببدء تشغيل السيارة مع بادئ تشغيل معطل

2. التيار المستهلك

السحب الحالي، الذي يقاس بالأمبير (A)، هو مقدار التيار الكهربائي الذي يستهلكه محرك بدء التشغيل أثناء التشغيل. قد يسحب محرك البادئ النموذجي من 100 إلى 200 أمبير. بالنسبة لمشتري B2B، فإن فهم السحب الحالي ضروري لاختيار الأسلاك وأنظمة البطارية المناسبة التي يمكن أن تدعم بادئ التشغيل دون تحميل زائد.

3. تركيب المواد

تؤثر التركيبة المادية لمكونات بادئ التشغيل، خاصةً المبيت والمكونات الداخلية، على المتانة والأداء. وتشمل المواد الشائعة الألومنيوم والفولاذ عالي الجودة، والتي توفر توازناً بين الوزن والقوة. يجب على المشترين إعطاء الأولوية للأجزاء المصنوعة من مواد عالية الجودة لضمان طول العمر والموثوقية، خاصة في المناطق ذات الظروف الجوية القاسية.

4. نوع المحرك البادئ

يوجد نوعان أساسيان من محركات بدء التشغيل: محركات تخفيض التروس ومحركات الدفع المباشر. تتميز محركات بدء التشغيل المخفضة للتروس بأنها أخف وزنًا وتوفر عزم دوران أكبر، مما يجعلها مناسبة للتطبيقات عالية الأداء. يعد فهم نوع محرك البادئ أمرًا بالغ الأهمية لمشتري B2B عند البحث عن بدائل، حيث إنه يؤثر على التركيب والأداء.

5. نطاق درجة حرارة التشغيل

يحدد نطاق درجة حرارة التشغيل درجات الحرارة المحيطة التي يمكن أن يعمل فيها المبدئ بفعالية. تعمل معظم بادئات التشغيل بشكل جيد في حدود -40 درجة مئوية إلى +85 درجة مئوية. بالنسبة للمشترين الدوليين، خاصة في المناطق ذات المناخ القاسي، فإن اختيار بادئات التشغيل التي يمكنها تحمل درجات الحرارة المحلية أمر بالغ الأهمية لموثوقية التشغيل.

صورة توضيحية تتعلق ببدء تشغيل السيارة مع بادئ تشغيل معطل

ما هي المصطلحات التجارية الشائعة المتعلقة ببدء تشغيل السيارة مع بادئ تشغيل معطل؟

الإلمام بمصطلحات الصناعة يمكن أن يسهل المعاملات بشكل أكثر سلاسة ويعزز التواصل بين المشترين والموردين. فيما يلي بعض المصطلحات الشائعة ذات الصلة بقطاع السيارات:

1. OEM (الشركة المصنعة للمعدات الأصلية)

يشير مصطلح OEM إلى القطع المصنوعة من قبل الشركة المصنعة للسيارة. يضمن استخدام قطع غيار OEM التوافق وضمان الجودة، وهو أمر بالغ الأهمية بالنسبة للمشترين من الشركات الذين يبحثون عن مكونات موثوقة تفي بمواصفات المصنع.

2. MOQ (الحد الأدنى لكمية الطلب)

يشير موك إلى أصغر كمية من المنتج الذي يرغب المورد في بيعه. إن فهم موك ضروري للمشترين بين الشركات لإدارة تكاليف المخزون بفعالية وضمان تلبية متطلبات المورد دون الإفراط في التخزين.

3. طلب عرض أسعار (RFQ)

طلب عرض الأسعار هو مستند يستخدمه المشترون لطلب التسعير من الموردين. تسمح هذه العملية للشركات بمقارنة العروض واختيار أكثر الأسعار تنافسية، مما يضمن حصولها على قيمة لاحتياجاتها من المشتريات.

4. شروط التجارة الدولية (Incoterms)

إن شروط التجارة الدولية هي شروط تجارية دولية محددة مسبقًا توضح مسؤوليات المشترين والبائعين. وهي تحدد من المسؤول عن الشحن والتأمين والتعريفات الجمركية. بالنسبة للمشترين بين الشركات، يعد فهم شروط التجارة الدولية أمرًا بالغ الأهمية لإدارة الخدمات اللوجستية والتكاليف بفعالية.

5. سوق ما بعد البيع

يشير سوق ما بعد البيع إلى سوق قطع الغيار والإكسسوارات التي لا يتم الحصول عليها من الشركة المصنعة الأصلية للسيارة. يمكن أن يوفر هذا القطاع بدائل فعالة من حيث التكلفة للمشترين من الشركات الذين يتطلعون إلى صيانة أو إصلاح المركبات.

من خلال فهم هذه الخصائص التقنية والمصطلحات التجارية، يمكن للمشترين بين الشركات التعامل مع تعقيدات توريد وإدارة مكونات بادئ تشغيل السيارات بثقة وكفاءة.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع تشغيل السيارات ذات البادئ التالف

نظرة عامة على السوق والاتجاهات الرئيسية في تشغيل سيارة ذات بادئ تشغيل معطل

يشهد سوق الحلول التي تعالج مشاكل محركات بدء التشغيل تطوراً سريعاً مدفوعاً بعدة عوامل عالمية. أدت زيادة ملكية السيارات، لا سيما في الأسواق الناشئة في أفريقيا وأمريكا الجنوبية، إلى زيادة الطلب على حلول إصلاح السيارات الفعالة من حيث التكلفة. ونظرًا لأن هذه المناطق تشهد نموًا اقتصاديًا، فإن الحاجة إلى مكونات السيارات الموثوقة أمر بالغ الأهمية، مما يؤدي إلى زيادة أنشطة التوريد. بالإضافة إلى ذلك، فإن التطورات في التكنولوجيا تسهّل على المشترين من الشركات الوصول إلى أدوات التشخيص ومجموعات الإصلاح التي تمكّن المستخدمين من استكشاف مشاكل بدء التشغيل وإصلاحها بشكل أكثر فعالية.

وتكتسب الاتجاهات الناشئة مثل اعتماد تطبيقات الأجهزة المحمولة لتشخيص السيارات زخماً متزايداً. تمكّن هذه التطبيقات المستخدمين من تحديد مشاكل محرك بدء التشغيل واقتراح حلول مؤقتة لها، مما يسهل عملية الإصلاح. في أوروبا، لا سيما في ألمانيا، يتزايد التركيز على صيانة السيارات بنفسك، مما يعكس تحولاً ثقافياً نحو الاكتفاء الذاتي بين مالكي السيارات. ويكتمل هذا الاتجاه بظهور منصات التجارة الإلكترونية، التي تسهل الوصول إلى قطع غيار السيارات وأدواتها، مما يعزز ديناميكيات السوق للمشترين بين الشركات.

علاوة على ذلك، مع تحول صناعة السيارات نحو السيارات الكهربائية (EVs)، يشهد سوق محركات التشغيل التقليدية تحولات في استراتيجيات التوريد. حيث يقوم الموردون بتنويع خطوط إنتاجهم بشكل متزايد لتلبية احتياجات أسواق السيارات الهجينة والكهربائية، مما يضمن بقاءهم على صلة بالمشهد سريع التغير.

كيف يمكن أن تؤثر الاستدامة والمصادر الأخلاقية على سوق تشغيل السيارات ذات البادئ السيئ؟

أصبحت الاستدامة والمصادر الأخلاقية ذات أهمية قصوى في قطاع السيارات، مما يؤثر على قرارات الشراء بين المشترين من الشركات. ويخضع التأثير البيئي لقطع غيار السيارات، بما في ذلك محركات بدء التشغيل، للتدقيق حيث تهدف الشركات إلى تقليل آثار الكربون. ويعطي المشترون الأولوية بشكل متزايد للموردين الذين يظهرون التزامًا بالممارسات المستدامة، مثل استخدام المواد المعاد تدويرها أو تقديم منتجات ذات تأثير بيئي أقل.

لا يمكن المبالغة في أهمية سلاسل التوريد الأخلاقية. إن التوريد من الموردين الذين يلتزمون بممارسات العمل العادلة واللوائح البيئية أمر ضروري للشركات التي تتطلع إلى تعزيز سمعة علامتها التجارية والتوافق مع توقعات المستهلكين. يمكن أن تكون شهادات مثل ISO 14001 لأنظمة الإدارة البيئية أو شهادات التجارة العادلة بمثابة مؤشرات على التزام المورد بالاستدامة.

بالإضافة إلى ذلك، مع تطور سوق إصلاح السيارات، يتزايد التركيز على المنتجات التي تقلل من النفايات. على سبيل المثال، يقدم الموردون مجموعات إصلاح تسمح للمستخدمين بإصلاح محركات بدء التشغيل بدلاً من استبدالها بالكامل، مما يقلل من كمية النفايات الإلكترونية المتولدة. وقد أصبح هذا التحول نحو مبادئ الاقتصاد الدائري عامل تمييز تنافسي في سوق الأعمال بين الشركات.

تطور موجز لسوق المحركات البادئة

شهد سوق محركات بدء التشغيل تغيرات كبيرة منذ نشأته في أوائل القرن العشرين. في البداية، هيمنت المحركات ذات التدوير اليدوي، ولكن إدخال المحركات الكهربائية أحدث ثورة في تشغيل السيارات، مما جعل السيارات في متناول الجماهير. وعلى مر العقود، أدى التقدم في التكنولوجيا إلى تطوير محركات بادئ تشغيل أكثر إحكاماً وكفاءة، مما عزز الأداء والموثوقية.

في السنوات الأخيرة، شهد السوق في السنوات الأخيرة تحولاً نحو دمج التكنولوجيا الذكية في أنظمة بادئ التشغيل، مما يسمح بتحسين التشخيص والصيانة التنبؤية. ومع انتشار السيارات الكهربائية والهجينة بشكل أكبر، تتطور محركات البادئ التقليدية لتلبية المتطلبات الجديدة، بما في ذلك التصاميم خفيفة الوزن والحلول الموفرة للطاقة. ويعكس هذا التطور الاتجاهات الأوسع نطاقاً في صناعة السيارات نحو الاستدامة والابتكار، مما يضع سوق المحركات البادئ في وضع يسمح باستمرار النمو والتحول.

الأسئلة المتداولة (FAQs) لمشتري B2B لبدء تشغيل السيارة مع بادئ تشغيل تالف

-

كيف يمكنني تشغيل سيارة مع بادئ تشغيل معطل؟

لتشغيل سيارة ذات بادئ تشغيل معطل، تأكد أولاً من أن البطارية مشحونة بالكامل وأن التوصيلات نظيفة. إذا كانت البطارية تعمل، حاول النقر على بادئ التشغيل برفق باستخدام مطرقة أو قطعة من الخشب، حيث يمكن أن يؤدي ذلك أحياناً إلى تحرير المكونات العالقة. في حال فشلت هذه الطرق، فكّر في استخدام كابلات التوصيل لتشغيل السيارة، لكن انتبه إلى أنه إذا كان المشغّل نفسه معطوباً، فقد لا يحل ذلك المشكلة. اتبع دائماً بروتوكولات السلامة واستشر متخصصاً إذا لزم الأمر. -

ما هي الأدوات الضرورية لتشغيل سيارة ذات بادئ تشغيل معطل؟

تشمل الأدوات الرئيسية كابلات توصيل لاختبار طاقة البطارية ومطرقة أو مطرقة للنقر برفق على مفتاح التشغيل ومفتاح ربط لفصل أطراف البطارية ومقياس الفولتميتر لفحص جهد البطارية. بالإضافة إلى ذلك، يمكن لمصباح يدوي أن يساعد في إضاءة المناطق تحت غطاء المحرك، بينما تضمن معدات الحماية، مثل القفازات والنظارات الواقية، السلامة أثناء استكشاف الأخطاء وإصلاحها. قد يكون وجود رافعة وحوامل ضرورية أيضاً إذا كان الوصول إلى مفتاح التشغيل يتطلب رفع السيارة. -

ما هي علامات البداية السيئة؟

تشمل العلامات الشائعة لخلل في بادئ التشغيل وجود طقطقة واحدة أو عدم وجود صوت عند تدوير المفتاح، أو أصوات طقطقة سريعة، أو مشاكل متقطعة في بدء التشغيل. إذا كان المحرك يدور ولكن لا يعمل، فقد تكمن المشكلة في مكان آخر، مثل نظام الإشعال أو الوقود. يمكن أن يساعد الفحص المنتظم لوصلات البادئ والبطارية في تحديد المشاكل في وقت مبكر، مما يمنع حدوث أعطال مستقبلية. -

ما هي أفضل طريقة للحصول على قطع غيار للمشغل التالف؟

عند البحث عن قطع الغيار، من الضروري التعاون مع موردين ذوي سمعة جيدة متخصصين في مكونات السيارات. ابحث عن الموردين الذين يتمتعون بتقييمات ومراجعات قوية، وفكر في أولئك الذين يقدمون قطع غيار ما بعد البيع عالية الجودة. قد يتطلب الانخراط في التجارة الدولية فهم اللوائح المحلية والتعريفات الجمركية والامتثال، خاصةً إذا كان التوريد من مناطق مثل أوروبا أو آسيا. -

كيف يمكنني فحص الموردين لمكونات السيارات؟

للتحقق من الموردين، ابدأ بالتحقق من شهاداتهم وسمعتهم في المجال. اطلب مراجع وعينات لتقييم جودة المنتج. بالإضافة إلى ذلك، استفسر عن خبراتهم في مجال الشحن الدولي والمهل الزمنية والقدرة على التعامل مع المتطلبات الجمركية. يمكن أن يوفر حضور المعارض التجارية أو الفعاليات الصناعية أيضاً فرصاً لمقابلة الموردين شخصياً ومناقشة عروضهم. -

ما هي خيارات التخصيص التي يجب أن أضعها في الاعتبار لمكونات البداية؟

قد تتضمن خيارات التخصيص تصنيفات محددة للجهد الكهربائي أو أنواع الموصلات أو حتى وضع العلامات التجارية على المكونات. يمكن أن تؤدي مناقشة متطلباتك مع الموردين إلى حلول مصممة خصيصاً لتلبية احتياجاتك التشغيلية. كن واضحاً بشأن توقعاتك فيما يتعلق بالأداء والمتانة، خاصةً إذا كانت مركباتك تعمل في بيئات صعبة شائعة في مناطق مثل أفريقيا أو أمريكا الجنوبية. -

ما هي شروط الدفع المعتادة عند توريد قطع غيار السيارات دولياً؟

يمكن أن تختلف شروط الدفع اختلافًا كبيرًا بين الموردين، ولكن الممارسات الشائعة تشمل إيداعات مقدمة (عادةً 30-50%) مع استحقاق الرصيد عند التسليم أو بعد المعاينة. فكر في استخدام طرق دفع آمنة، مثل خطابات الاعتماد أو خدمات الضمان، لحماية استثمارك. قم دائمًا بتوضيح الشروط قبل وضع اللمسات الأخيرة على الطلبات لتجنب النزاعات لاحقًا. -

كيف تؤثر الخدمات اللوجستية والشحن على توريد قطع غيار السيارات؟

تلعب الخدمات اللوجستية دورًا حاسمًا في تسليم قطع غيار السيارات في الوقت المناسب. يمكن لعوامل مثل طرق الشحن والتخليص الجمركي والنقل المحلي أن تؤثر على المهل الزمنية والتكاليف. اعمل مع الموردين الذين لديهم شبكات لوجستية راسخة ويمكنهم توفير معلومات تتبع شفافة. يمكن أن يساعدك فهم المشهد اللوجستي في منطقتك في الحد من التأخير وضمان حصولك على القطع عند الحاجة.

أفضل 1 قائمة المصنعين والموردين لبدء تشغيل سيارة مع بداية سيئة

1. ويكي هاو - استكشاف مشاكل تشغيل السيارة وإصلاحها

المجال: wikihow.com

تاريخ التسجيل: 2004 (21 عامًا)

مقدمة: هذه الشركة، ويكي هاو - استكشاف مشاكل تشغيل السيارة وإصلاحها، هي كيان بارز في السوق. للحصول على تفاصيل محددة عن المنتج، يُنصح بزيارة موقعهم الإلكتروني مباشرةً.

استنتاج المصادر الاستراتيجية والتوقعات لبدء تشغيل سيارة ذات بادئ تشغيل معطل

باختصار، تتطلب معالجة تحديات تشغيل السيارة مع وجود عطل في بادئ التشغيل اتباع نهج متعدد الأوجه يعطي الأولوية للتشخيص السليم والحلول المؤقتة. بالنسبة للمشترين بين الشركات في قطاع السيارات، يمكن أن يؤدي فهم أهمية التوريد الاستراتيجي الفعال إلى تعزيز الكفاءة التشغيلية. من خلال شراء مكونات وأدوات عالية الجودة، مثل محركات بدء التشغيل الموثوقة وكابلات التوصيل ومعدات الصيانة، يمكن للشركات تقليل وقت التعطل وتحسين رضا العملاء.

وعلاوة على ذلك، فإن الاستفادة من الشراكات مع الموردين الموثوق بهم لا يضمن فقط الحصول على منتجات عالية الجودة، بل يعزز أيضًا الابتكار وسرعة الاستجابة في تقديم الخدمات. ومع تطور الأسواق، لا سيما في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، سيستمر الطلب على حلول السيارات الفعالة في الارتفاع.

يجب أن يركز المشترون الدوليون على بناء سلاسل توريد مرنة قادرة على التكيف مع ديناميكيات السوق المتغيرة والتقدم التكنولوجي. من خلال إعطاء الأولوية للتوريد الاستراتيجي، يمكن للشركات أن تضع نفسها في وضع أفضل لمواجهة هذه التحديات بشكل مباشر. نحن نشجعك على استكشاف شراكات جديدة والاستثمار في موارد عالية الجودة تمكّنك من التعامل مع تعقيدات إصلاح السيارات وتعزيز عروض الخدمات التي تقدمها. تبنَّ مستقبل حلول السيارات بثقة.

صورة توضيحية تتعلق ببدء تشغيل السيارة مع بادئ تشغيل معطل

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.