Introduction: Navigating the Global Market for remove headlight

In today’s rapidly evolving automotive market, sourcing reliable solutions for removing headlights is a critical challenge for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. The process of effectively disassembling headlights not only requires specialized knowledge and tools but also poses significant risks of damage if not executed correctly. This guide offers a comprehensive exploration of the best practices and techniques for removing headlights, ensuring that buyers are equipped with the knowledge to make informed decisions.

Within this guide, you will find in-depth insights into various types of headlights, their applications in different vehicle models, and a detailed breakdown of the tools and techniques necessary for safe removal. Additionally, we address the importance of supplier vetting, helping you identify trustworthy partners who can deliver quality components and services. Cost considerations are also discussed, providing a clear understanding of the financial implications associated with sourcing these automotive parts.

By leveraging the information in this guide, international B2B buyers, particularly those in countries like Nigeria and Brazil, can navigate the complexities of the global market with confidence. Whether you are looking to enhance your service offerings or streamline your procurement processes, this resource empowers you to make strategic purchasing decisions that align with your business goals.

جدول المحتويات

- Top 3 Remove Headlight Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for remove headlight

- Understanding remove headlight Types and Variations

- Key Industrial Applications of remove headlight

- 3 Common User Pain Points for ‘remove headlight’ & Their Solutions

- Strategic Material Selection Guide for remove headlight

- In-depth Look: Manufacturing Processes and Quality Assurance for remove headlight

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘remove headlight’

- Comprehensive Cost and Pricing Analysis for remove headlight Sourcing

- Alternatives Analysis: Comparing remove headlight With Other Solutions

- Essential Technical Properties and Trade Terminology for remove headlight

- Navigating Market Dynamics and Sourcing Trends in the remove headlight Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of remove headlight

- Strategic Sourcing Conclusion and Outlook for remove headlight

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding remove headlight Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| مصابيح هالوجين أمامية هالوجين | Traditional bulb technology, affordable, easy to replace | ورش إصلاح السيارات، خدمات الأساطيل | Pros: Cost-effective, wide availability. Cons: Shorter lifespan, less energy-efficient. |

| مصابيح LED أمامية | Energy-efficient, longer lifespan, bright illumination | Luxury vehicle manufacturers, aftermarket upgrades | Pros: Longer lifespan, lower energy consumption. Cons: Higher initial cost, may require additional components. |

| Xenon (HID) Headlights | High-intensity discharge, produces a bright white light | High-performance vehicle markets, automotive racing | Pros: Superior visibility, stylish appearance. Cons: More complex installation, potential compatibility issues. |

| مصابيح أمامية متكيفة | Adjusts beam direction based on steering angle | Advanced automotive technology sectors | Pros: Enhanced safety, improved visibility. Cons: Higher cost, potential for more maintenance. |

| مصابيح الليزر الأمامية | Uses laser technology for high precision and distance | Premium automotive manufacturers | Pros: Exceptional range, energy-efficient. Cons: Very high cost, limited availability. |

What Are Halogen Headlights and Their B2B Relevance?

Halogen headlights are the most common type found in vehicles, utilizing a tungsten filament enclosed in a halogen gas-filled bulb. Their affordability and ease of replacement make them a staple in automotive repair shops and fleet services. B2B buyers appreciate their wide availability and cost-effectiveness; however, they have a shorter lifespan and are less energy-efficient compared to newer technologies. When considering bulk purchases, businesses should weigh the initial low cost against the potential for more frequent replacements.

How Do LED Headlights Stand Out for Businesses?

LED headlights represent a significant advancement in automotive lighting, offering energy efficiency and a longer lifespan than traditional halogen bulbs. These lights provide bright illumination, making them ideal for luxury vehicle manufacturers and aftermarket upgrades. While the initial investment is higher, the reduced energy consumption and longevity can lead to lower long-term costs. B2B buyers must consider compatibility with existing vehicle systems and the potential need for additional components during installation.

What Are the Benefits of Xenon (HID) Headlights for High-Performance Markets?

Xenon or High-Intensity Discharge (HID) headlights produce a bright white light that enhances visibility, making them popular in high-performance vehicles and automotive racing. Their stylish appearance and superior illumination are appealing to buyers in niche markets. However, the complexity of installation and potential compatibility issues can deter some businesses. B2B buyers should evaluate the specific needs of their clientele and the vehicles they service to ensure HID headlights are a suitable investment.

Why Choose Adaptive Headlights for Enhanced Safety?

Adaptive headlights are an innovative solution that adjusts the beam direction based on the vehicle’s steering angle, significantly improving nighttime visibility and safety. This technology is increasingly sought after in advanced automotive sectors, where safety and performance are paramount. While they offer substantial benefits, their higher cost and potential maintenance requirements can be a deterrent for some businesses. B2B buyers should assess the market demand for such advanced features before committing to a purchase.

What Makes Laser Headlights a Premium Option for Automotive Manufacturers?

Laser headlights are at the forefront of automotive lighting technology, providing exceptional range and precision. Their energy efficiency and ability to illuminate distant objects make them an attractive option for premium automotive manufacturers. However, the high cost and limited availability can pose challenges for B2B buyers. Businesses should carefully consider their target market and the potential return on investment when looking to incorporate laser headlights into their product offerings.

Key Industrial Applications of remove headlight

| الصناعة/القطاع | Specific Application of remove headlight | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| إصلاح السيارات | Headlight restoration and customization | Enhances vehicle aesthetics and functionality, increasing resale value | Quality of sealants and adhesives, availability of tools |

| تصنيع المركبات | Quality control during assembly | Ensures proper installation and functionality of headlights | Compliance with safety standards, supplier reliability |

| Aftermarket Accessories | Custom headlight modifications for performance enhancement | Differentiates product offerings and attracts niche markets | Compatibility with various vehicle models, design expertise |

| إدارة الأسطول | Regular maintenance and replacement of headlights | Reduces downtime and improves safety for commercial vehicles | Bulk purchasing options, warranty and service agreements |

| Automotive Training | Educational purposes in technical training programs | Prepares technicians for real-world applications and enhances skills | Access to training materials, practical tools and equipment |

How is ‘remove headlight’ used in the automotive repair industry?

In the automotive repair sector, the process of removing headlights is essential for restoration and customization projects. Technicians often disassemble headlights to clean, repair, or modify them for enhanced performance or aesthetic appeal. This process not only improves the functionality of vehicles but also increases their resale value. For international buyers, sourcing high-quality sealants and specialized tools is crucial to ensure effective repairs and maintain safety standards.

Illustrative image related to remove headlight

What role does ‘remove headlight’ play in vehicle manufacturing?

In vehicle manufacturing, the removal of headlights is a critical step in the assembly process. Quality control teams often need to access headlights to ensure they are installed correctly and function as intended. Proper installation is vital for vehicle safety and compliance with regulations. Buyers in this sector should consider suppliers that offer reliable components and adhere to international safety standards, particularly in regions like Africa and South America, where regulatory compliance may vary.

How is ‘remove headlight’ applied in aftermarket accessories?

The aftermarket accessories industry utilizes the removal of headlights for custom modifications aimed at performance enhancement. This application allows businesses to offer unique products that cater to specific consumer preferences, such as enhanced lighting or personalized designs. For B2B buyers, understanding compatibility with various vehicle models and ensuring that suppliers have the necessary design expertise is essential for success in this competitive market.

Why is ‘remove headlight’ important for fleet management?

Fleet management companies frequently engage in the removal and replacement of headlights to ensure the safety and reliability of their vehicles. Regular maintenance of headlights is crucial to minimize downtime and maintain operational efficiency. For international buyers, securing bulk purchasing agreements and warranties from suppliers can lead to significant cost savings and ensure consistent quality across their fleet.

How does ‘remove headlight’ benefit automotive training programs?

In automotive training programs, the process of removing headlights serves as an educational tool for aspiring technicians. It provides hands-on experience with real-world applications, helping students understand the intricacies of automotive repair. Access to comprehensive training materials and the right tools is vital for institutions looking to equip their students with practical skills that meet industry standards, particularly in diverse markets across Europe and the Middle East.

3 Common User Pain Points for ‘remove headlight’ & Their Solutions

Scenario 1: Difficulty in Accessing Headlight Assembly for Maintenance

المشكلة: B2B buyers in the automotive repair sector often encounter challenges when trying to access the headlight assembly of various vehicle models. This difficulty can stem from complex designs, where headlights are buried under multiple layers of body panels or bumper covers. For example, automotive technicians in workshops may find that specific models require disassembly of the front bumper or other components, leading to wasted time and increased labor costs. This can be especially frustrating in regions where technicians are already facing labor shortages and need to maximize efficiency.

الحل: To address this challenge, it is essential to invest in comprehensive vehicle-specific repair guides and databases that detail the exact procedures for headlight removal for various makes and models. Suppliers should provide easy access to OEM repair manuals or online resources that offer step-by-step instructions, including diagrams and necessary tools. Furthermore, workshops can enhance technician training by including hands-on workshops focused on headlight removal techniques. Utilizing a standard toolkit that includes specialized tools like socket wrenches and trim removal tools can significantly speed up the process. By equipping technicians with the right knowledge and tools, automotive repair businesses can improve turnaround times and customer satisfaction.

Scenario 2: Unforeseen Damage During Headlight Removal

المشكلة: Another common pain point for B2B buyers is the risk of damaging headlights or surrounding components during removal. This is particularly critical for dealerships or repair shops that handle high-value vehicles. A technician may accidentally crack the headlight lens or damage the mounting brackets, leading to costly replacements and extended downtime for the vehicle. Such mishaps not only affect the bottom line but can also harm the reputation of the service provider.

Illustrative image related to remove headlight

الحل: To mitigate the risk of damage, B2B buyers should implement a standardized removal procedure that emphasizes caution and precision. This includes using protective padding around the work area and ensuring that technicians are trained in the proper techniques for headlight removal. Workshops can also invest in quality replacement parts from trusted suppliers to ensure that any necessary replacements are readily available and fit perfectly, reducing the risk of further damage. Additionally, investing in tools specifically designed for headlight removal can minimize the chances of mishaps. Providing technicians with adequate time and a clear protocol can lead to safer, more efficient operations, ultimately saving costs and preserving client relationships.

Scenario 3: Inconsistent Quality of Aftermarket Headlight Products

المشكلة: B2B buyers often face challenges with the inconsistent quality of aftermarket headlight products. Variability in manufacturing standards can lead to poor fitting, inadequate lighting performance, and a higher likelihood of failure. This is particularly relevant for businesses in regions like Africa and South America, where the availability of reliable aftermarket parts may be limited. The consequences can be severe, affecting customer safety and leading to increased warranty claims or customer dissatisfaction.

الحل: To overcome this issue, B2B buyers should establish strong relationships with reputable suppliers who provide high-quality aftermarket products. It’s crucial to conduct thorough research and seek out suppliers with a proven track record of quality and customer service. Implementing a robust quality assurance process, including regular audits of incoming parts, can help ensure that only the best products are used. Additionally, workshops can benefit from offering warranties on their services, thus enhancing customer trust and providing a safety net in case of product failure. By prioritizing quality and reliability, businesses can improve customer satisfaction and reduce the risk of future issues.

Strategic Material Selection Guide for remove headlight

What Are the Key Materials Used in Headlight Removal Tools?

When considering the materials for tools and components used in headlight removal, several options stand out due to their unique properties and performance characteristics. Understanding these materials can help international B2B buyers make informed decisions that align with their operational needs and regional standards.

Illustrative image related to remove headlight

What Are the Key Properties of Aluminum in Headlight Removal Tools?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. It typically withstands temperatures up to 400°F (204°C), making it suitable for applications involving heat exposure, such as when baking headlights open. Its non-magnetic properties also ensure that it does not interfere with electronic components.

الإيجابيات: Aluminum tools are durable, lightweight, and resistant to rust. They are relatively easy to manufacture and can be produced at a lower cost compared to some other metals.

السلبيات: While strong, aluminum can be prone to deformation under high stress or impact, which may limit its use in heavy-duty applications.

التأثير على التطبيق: Aluminum’s compatibility with various automotive environments makes it ideal for headlight removal tools, which may encounter moisture and heat.

اعتبارات للمشترين الدوليين: Compliance with standards like ASTM and DIN is crucial. Buyers from regions like Africa and South America should ensure that suppliers can meet these specifications to avoid issues with tool performance and safety.

How Does Steel Compare as a Material for Headlight Removal Tools?

Steel, particularly stainless steel, is another popular choice for manufacturing headlight removal tools. It offers high tensile strength and can endure significant wear and tear, making it suitable for heavy-duty applications.

الإيجابيات: Steel tools are highly durable and resistant to deformation. They can handle high temperatures and are less likely to break under stress compared to aluminum.

السلبيات: Steel is heavier than aluminum, which can make tools cumbersome to use. Additionally, if not properly treated, steel can corrode over time, especially in humid environments.

التأثير على التطبيق: Steel’s robustness makes it ideal for tools that require repeated use, ensuring longevity and reliability during headlight removal tasks.

اعتبارات للمشترين الدوليين: Buyers should check for compliance with corrosion-resistant standards, especially in humid regions like the Middle East. Understanding local manufacturing capabilities and sourcing options is also essential.

What Role Does Plastic Play in Headlight Removal Tools?

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is frequently used in the manufacturing of headlight removal tools. These materials are lightweight and can be designed to be flexible, which is beneficial for certain applications.

الإيجابيات: Plastic tools are resistant to corrosion and can withstand a range of chemicals, making them suitable for automotive applications. They are also cost-effective and can be produced in various shapes and sizes.

السلبيات: Plastic is generally less durable than metal, and extreme temperatures can lead to warping or melting.

Illustrative image related to remove headlight

التأثير على التطبيق: Plastic tools are ideal for less demanding tasks, such as prying open headlight assemblies without scratching or damaging the lens.

اعتبارات للمشترين الدوليين: Buyers should ensure that the plastic materials used meet safety standards relevant to their region, such as JIS in Japan or EN standards in Europe.

How Do Composites Enhance Headlight Removal Tool Performance?

Composite materials, often a combination of plastic and fiberglass, offer a unique blend of strength and lightweight properties. They can withstand higher temperatures than standard plastics and provide better durability.

الإيجابيات: Composites are resistant to corrosion and can be engineered for specific performance characteristics, making them versatile for various applications.

السلبيات: The manufacturing process for composites can be more complex and costly, which may affect the overall price of the tools.

التأثير على التطبيق: Composites are particularly useful in environments where both heat and moisture are present, as they maintain structural integrity under these conditions.

اعتبارات للمشترين الدوليين: It’s essential to assess the availability of composite materials and their compliance with local standards, especially in emerging markets where specific regulations may apply.

Summary Table of Material Selection for Headlight Removal Tools

| المواد | Typical Use Case for remove headlight | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | Lightweight tools for prying | نسبة قوة إلى الوزن ممتازة | Prone to deformation under stress | منخفض |

| الصلب | Heavy-duty tools for repeated use | Highly durable and strong | Heavier and can corrode | متوسط |

| بلاستيك | Non-damaging prying tools | فعالة من حيث التكلفة ومقاومة للتآكل | أقل متانة في الظروف القاسية | منخفض |

| المركبات | Specialized tools for high-performance | High strength and lightweight | More complex and costly to manufacture | عالية |

This analysis provides a comprehensive overview of the materials used in headlight removal tools, focusing on their properties, advantages, and considerations for international B2B buyers. Understanding these factors will aid in making informed purchasing decisions that align with specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for remove headlight

What Are the Main Stages in the Manufacturing Process of Headlight Assemblies?

The manufacturing of headlight assemblies involves several critical stages that ensure both functionality and aesthetic appeal. Each stage is integral to producing a reliable product that meets the standards required by automotive manufacturers worldwide.

-

تحضير المواد

The process begins with the careful selection of materials. Common materials used include polycarbonate for the lens, aluminum or plastic for the housing, and various types of adhesives and sealants. These materials must adhere to specific international standards, such as ISO 9001, which ensures quality management systems are in place. Suppliers often conduct thorough material inspections to verify compliance with specifications before moving to the next stage. -

تشكيل

In this stage, the raw materials undergo various forming processes. For polycarbonate lenses, injection molding is the predominant method, allowing for high precision and uniformity. Housing components may be produced through injection molding or die casting. Advanced techniques such as computer numerical control (CNC) machining can also be employed for components requiring high accuracy. -

الجمعية

Once the individual components are prepared, they are assembled. This includes fitting the lens to the housing, securing bulbs, and connecting electrical components. Automated assembly lines are often utilized to enhance efficiency, but manual assembly is also common for more complex designs. Quality control checkpoints during assembly ensure that components fit correctly and function as intended. -

التشطيب

The finishing stage involves applying protective coatings, which may include anti-fog or UV-resistant layers. These coatings are essential for enhancing durability and performance. The final product undergoes a visual inspection to check for defects, scratches, or any other imperfections that could affect performance or aesthetic value.

كيف يتم تنفيذ ضمان الجودة في تصنيع المصابيح الأمامية؟

Quality assurance (QA) in headlight manufacturing is vital for ensuring that the final products meet both safety and performance standards. Several international and industry-specific standards guide this process.

Illustrative image related to remove headlight

-

المعايير الدولية

Compliance with ISO 9001 is crucial, as it outlines requirements for a quality management system. This standard helps manufacturers consistently provide products that meet customer and regulatory requirements. Other relevant standards include CE marking, which indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. -

المعايير الخاصة بالصناعة

Automotive parts, including headlights, may also be subject to specific standards such as the Automotive Parts Industry (API) specifications. These standards often include rigorous testing protocols to ensure reliability under various conditions, including temperature extremes and humidity. -

نقاط مراقبة الجودة

Quality control is integrated throughout the manufacturing process through several checkpoints:

– مراقبة الجودة الواردة (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

– مراقبة الجودة أثناء الإنتاج (IPQC): During manufacturing, regular checks are conducted to monitor processes and detect defects early.

– مراقبة الجودة النهائية (FQC): The finished products undergo comprehensive testing and inspection before shipment. This includes functionality tests, visual inspections, and durability assessments. -

طرق الاختبار الشائعة

Testing methods for headlights include photometric testing to measure light output and distribution, as well as environmental testing for temperature and humidity resistance. Water and dust ingress tests (IP rating tests) are also conducted to ensure that the headlights can withstand various environmental conditions.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are actionable steps:

-

تدقيق الموردين

Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. During the audit, buyers should assess compliance with international standards and review documentation related to quality management. -

مراجعة تقارير الجودة

Requesting quality assurance reports can help buyers understand the supplier’s commitment to quality. These reports should detail IQC, IPQC, and FQC processes and highlight any non-conformities and corrective actions taken. -

عمليات التفتيش من قبل أطراف ثالثة

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes. These services often conduct random checks on production runs and can verify adherence to international standards. -

الشهادات والاعتمادات

Buyers should ensure that suppliers possess relevant certifications, such as ISO 9001 and CE markings. This not only assures quality but also compliance with regulatory requirements in the buyer’s region.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين؟

International buyers face unique challenges when sourcing automotive components like headlights. Understanding these nuances can enhance procurement strategies:

-

الامتثال التنظيمي

Different regions have varying regulations regarding automotive parts. For example, headlights sold in the European market must comply with CE marking requirements, while those in the U.S. may need to meet Federal Motor Vehicle Safety Standards (FMVSS). Buyers must ensure that their suppliers are aware of and comply with these regulations. -

الاختلافات الثقافية

Communication and business practices can differ significantly across regions. Buyers should be prepared to navigate these cultural nuances when establishing quality expectations and conducting audits. -

اعتبارات سلسلة التوريد

Disruptions in the supply chain can impact the availability and quality of products. Establishing strong relationships with multiple suppliers can mitigate risks and ensure a steady supply of quality headlights. -

ممارسات الاستدامة

Increasingly, buyers are prioritizing suppliers that adopt sustainable manufacturing practices. Ensuring that suppliers adhere to environmental standards can enhance brand reputation and meet consumer demand for eco-friendly products.

By thoroughly understanding the manufacturing processes and quality assurance practices in headlight production, B2B buyers can make informed decisions that ensure they receive reliable, high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘remove headlight’

This guide is designed to assist B2B buyers in effectively sourcing components and services related to the removal of vehicle headlights. Whether you’re in the automotive repair industry or involved in vehicle manufacturing, understanding the procurement process is crucial for ensuring quality and efficiency in your operations.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Begin by clearly defining the specifications of the headlight removal tools and equipment you require. This includes understanding the types of vehicles you will be working on and the specific tools necessary for efficient headlight removal. Having precise specifications helps in narrowing down potential suppliers who can meet your needs accurately.

- Consider vehicle types: Different vehicles may require unique tools or methods for headlight removal.

- Identify tool features: Look for tools that offer durability, ease of use, and compatibility with various vehicle models.

الخطوة 2: إجراء أبحاث السوق

Investigate the market to identify potential suppliers and manufacturers of headlight removal tools. Look for companies with a proven track record in the automotive industry, particularly those that serve the regions you operate in.

- الاستفادة من تقارير الصناعة: These can provide insights into leading suppliers and emerging trends in automotive tools.

- Engage with local distributors: They often have valuable knowledge about market demands and can recommend reputable manufacturers.

الخطوة 3: تقييم الموردين المحتملين

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step ensures you are partnering with reliable suppliers who have demonstrated quality in their products.

- Review certifications: Ensure that suppliers comply with international quality standards relevant to automotive tools.

- Check customer reviews: Feedback from previous clients can provide insights into the supplier’s reliability and product performance.

الخطوة 4: طلب عينات أو عروض توضيحية

Once you’ve shortlisted potential suppliers, request samples of the headlight removal tools or arrange for a demonstration. This hands-on approach allows you to assess the quality and effectiveness of the tools before committing to a larger purchase.

- Inspect tool ergonomics: Evaluate how comfortable and user-friendly the tools are for technicians.

- Test durability: Ensure that the materials used can withstand regular use without compromising performance.

الخطوة 5: التفاوض على الأسعار والشروط

Engage in discussions with your chosen suppliers regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing structures or favorable terms that can enhance your overall procurement strategy.

- Understand bulk pricing: Inquire about discounts for larger orders, which can significantly reduce costs.

- Clarify shipping details: Ensure that delivery timelines align with your operational needs to avoid disruptions.

الخطوة 6: Verify After-Sales Support and Warranty

Inquire about the after-sales support provided by the supplier, including warranty terms and service options. Reliable after-sales support can be critical in maintaining operational efficiency and addressing any issues that may arise with the tools.

- Assess warranty coverage: A robust warranty can protect your investment in case of defects or issues.

- Evaluate customer service availability: Quick access to support can minimize downtime in your operations.

الخطوة 7: Finalize Your Supplier Agreement

After all evaluations and negotiations, finalize your agreement with the chosen supplier. Ensure that all terms are clearly documented, including delivery schedules, payment terms, and warranty details.

- Include performance clauses: Consider adding clauses that hold suppliers accountable for meeting quality and delivery standards.

- Regularly review supplier performance: Maintain an ongoing assessment of supplier performance to ensure they continue to meet your needs over time.

By following this structured approach, B2B buyers can effectively source the necessary tools and services for headlight removal, ensuring quality and efficiency in their operations.

Comprehensive Cost and Pricing Analysis for remove headlight Sourcing

What Are the Key Cost Components for Sourcing ‘Remove Headlight’ Services?

When analyzing the cost structure for sourcing services related to removing headlights, several key components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

المواد: The primary materials involved are the headlights themselves, which can vary significantly in price based on the type (halogen, LED, etc.) and brand. The adhesive sealants used to close the headlights after servicing also contribute to material costs.

-

العمل: Labor costs are influenced by the skill level required for the task. Skilled technicians may command higher wages, but their efficiency can lead to lower overall labor costs in the long run.

-

تكاليف التصنيع العامة: This includes costs associated with the facility, equipment depreciation, utilities, and administrative expenses. These overhead costs are typically calculated as a percentage of direct labor and materials.

-

الأدوات: Special tools may be required for disassembling and reassembling headlights, particularly for custom or high-end models. The initial investment in tooling can be significant, but it is amortized over time based on usage.

-

مراقبة الجودة (QC): Ensuring the headlights are properly sealed after removal is critical to prevent moisture damage. QC processes can add to the overall cost but are essential for maintaining product integrity.

-

اللوجستيات: Shipping and handling costs can vary based on the distance and the mode of transport. For international buyers, understanding the logistics involved in transporting headlights is crucial.

-

الهامش: Suppliers will include a profit margin that reflects their operational costs and market position. This margin can be influenced by competition and perceived value.

How Do Pricing Influencers Affect ‘Remove Headlight’ Costs?

Several factors can influence pricing for removing headlights, including volume or minimum order quantity (MOQ), specifications and customization, materials used, quality certifications, supplier reliability, and Incoterms.

-

الحجم/الحد الأدنى للطلب: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should inquire about volume discounts and establish clear expectations regarding minimum order quantities.

-

المواصفات/التخصيص: Custom requests can lead to higher costs due to the need for specialized materials or additional labor. Clear communication about specifications can help avoid unexpected costs.

-

المواد: The choice of materials directly impacts pricing. Premium materials or advanced lighting technology will typically come at a higher price point.

-

الجودة/الشهادات: Products that meet specific quality standards or certifications may command higher prices. Buyers should consider whether these certifications are necessary for their market.

-

عوامل الموردين: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more but often provide better quality assurance.

-

مصطلحات التجارة الدولية: Understanding the terms of trade, including who is responsible for shipping and handling, can significantly affect the total cost. Buyers should negotiate terms that minimize their risk and costs.

What Are the Best Buyer Tips for Cost-Efficiency in ‘Remove Headlight’ Procurement?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency in sourcing ‘remove headlight’ services:

-

التفاوض مع الموردين: Establishing strong relationships with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate based on volume or long-term contracts.

-

النظر في التكلفة الإجمالية للملكية (TCO): When evaluating suppliers, consider not just the purchase price but also the costs associated with logistics, installation, and potential maintenance.

-

فهم الفروق الدقيقة في الأسعار: Each region may have different pricing structures based on local demand, labor costs, and material availability. Be aware of these differences when sourcing internationally.

-

Leverage Technology: Utilize online platforms and marketplaces to compare prices and suppliers. This can also help in finding suppliers that are experienced in exporting to your region.

-

ابق على اطلاع: Keep abreast of market trends, material costs, and supply chain disruptions that could impact pricing. Being informed can help you make better purchasing decisions.

إخلاء المسؤولية عن الأسعار الإرشادية

Prices for sourcing ‘remove headlight’ services can vary widely based on the factors discussed above. Buyers should consider this information as indicative and conduct thorough market research to obtain precise quotes tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing remove headlight With Other Solutions

Understanding Alternatives to ‘Remove Headlight’ Solutions

In the automotive sector, particularly for businesses involved in vehicle maintenance and repair, understanding various methods to access headlight assemblies is crucial. While the traditional approach of removing headlights is widely known, there are alternative solutions that may offer different advantages depending on the specific needs of a business. This section compares the traditional method of removing headlights with two viable alternatives: using heat guns and employing specialized headlight repair kits.

جدول المقارنة

| جانب المقارنة | Remove Headlight | Heat Gun Method | Headlight Repair Kits |

|---|---|---|---|

| الأداء | Effective for thorough access | Good for quick access | Limited to minor repairs |

| التكلفة | Moderate (tools + labor) | Low (heat gun purchase) | Moderate to high (kit cost) |

| سهولة التنفيذ | Moderate (requires technical skill) | Easy (requires minimal skill) | Easy (user-friendly instructions) |

| الصيانة | Requires re-sealing after removal | Minimal, just the heat gun upkeep | None, disposable after use |

| أفضل حالة استخدام | Complete headlight assembly repairs | Quick fixes or bulb changes | Minor cosmetic repairs or fixes |

تفصيل البدائل

Heat Gun Method

Using a heat gun to soften the adhesive sealant of headlights can be a practical alternative to the traditional removal method. This approach is particularly effective for quick access to the headlight without needing to disassemble the entire assembly. The heat gun method requires less technical skill and is generally more straightforward, allowing technicians to replace bulbs or perform minor adjustments quickly. However, it may not be suitable for extensive repairs, as it doesn’t provide full access to the assembly like removing the headlight does. Additionally, improper use can lead to damage to the headlight, necessitating careful handling.

Illustrative image related to remove headlight

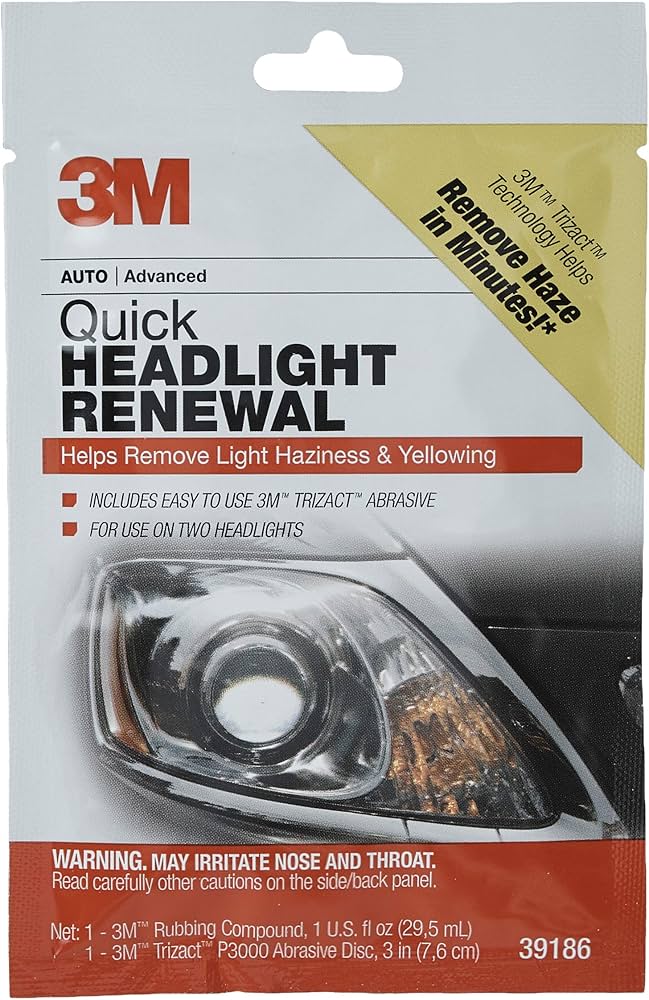

Headlight Repair Kits

Specialized headlight repair kits offer a convenient solution for businesses focused on cosmetic fixes or minor repairs. These kits often include materials for polishing, sealing, and restoring headlights without the need for complete disassembly. They are user-friendly and designed for quick application, making them ideal for businesses looking to enhance customer satisfaction with minimal downtime. However, their limitations become apparent when dealing with significant issues or when full access to the headlight internals is necessary. The effectiveness of these kits can vary, and they may not be a long-term solution for all headlight problems.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

When selecting the appropriate method for accessing headlights, B2B buyers must consider their specific requirements, including the nature of repairs, cost constraints, and the skill level of their technicians. While removing the headlight provides comprehensive access for thorough repairs, alternatives like the heat gun method and headlight repair kits offer valuable options for quick fixes and cosmetic enhancements. Ultimately, the choice should align with the business’s operational goals, customer expectations, and the specific challenges presented by each vehicle type.

Essential Technical Properties and Trade Terminology for remove headlight

What Are the Key Technical Properties to Consider for Removing Headlights?

When dealing with the removal of headlights, several technical properties are critical to ensure successful execution and compatibility with various vehicle models. Understanding these properties can enhance decision-making and lead to better procurement strategies.

-

تركيب المواد

Headlight assemblies are typically made from polycarbonate or acrylic materials. Polycarbonate is favored for its high impact resistance and optical clarity, making it suitable for automotive applications. B2B buyers should ensure that the material used meets industry standards for durability and UV resistance, which affects the lifespan and performance of the headlight. -

Sealing Adhesive Quality

The adhesive used to seal headlight assemblies is crucial for preventing moisture ingress. High-quality sealants provide a strong bond and are resistant to temperature fluctuations. Understanding the specifications of these adhesives can help buyers select products that minimize the risk of failure due to environmental conditions, ultimately reducing warranty claims and enhancing customer satisfaction. -

Headlight Assembly Design Tolerance

Tolerance levels refer to the permissible limits of variation in the manufacturing process. For headlight assemblies, precise tolerances ensure a proper fit within the vehicle’s housing. Buyers should consider products that adhere to OEM specifications, as this ensures compatibility and ease of installation, reducing labor costs and time during the replacement process. -

Thermal Resistance Rating

Headlights generate heat during operation, and the materials used must withstand high temperatures without warping or degrading. A thermal resistance rating provides insight into how well the assembly can perform under such conditions. For B2B buyers, ensuring that headlights meet the necessary thermal specifications can prevent premature failures and enhance overall vehicle safety. -

Optical Performance Standards

The optical performance of headlights is evaluated based on light output and beam pattern. Adhering to industry standards such as SAE or ECE ensures that headlights provide adequate illumination for safe driving. Buyers should prioritize suppliers that comply with these standards to ensure that their products meet regulatory requirements and enhance vehicle safety.

What Are Common Trade Terms Related to Removing Headlights?

Familiarity with industry jargon is essential for effective communication and negotiation in the automotive parts market. Below are several key terms that B2B buyers should understand.

-

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the vehicle’s original manufacturer. These components are designed to match the specifications of the original headlights. Purchasing OEM parts can ensure compatibility and quality, making it a preferred choice for many automotive businesses. -

MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory costs effectively. Buyers should negotiate MOQs that align with their sales forecasts to avoid overstocking or stockouts. -

طلب عرض أسعار (RFQ)

An RFQ is a standard business process wherein buyers request pricing and terms from suppliers. Crafting a well-defined RFQ can help buyers obtain competitive quotes and streamline the procurement process. Including specifications for headlights in the RFQ will ensure accurate and relevant responses. -

شروط التجارة الدولية (Incoterms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help B2B buyers understand shipping costs, risk management, and liability during transit. -

قطع غيار ما بعد البيع

Aftermarket parts are components made by manufacturers other than the OEM. These parts can often be less expensive and may offer improved performance. However, buyers should assess the quality and compatibility of aftermarket headlights to avoid potential issues with installation and safety.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their procurement processes and ensure the reliability of automotive lighting solutions.

Illustrative image related to remove headlight

Navigating Market Dynamics and Sourcing Trends in the remove headlight Sector

What Are the Current Market Dynamics and Key Trends in the Remove Headlight Sector?

The remove headlight sector is experiencing a significant transformation driven by global automotive trends, technological advancements, and evolving consumer preferences. One of the primary market drivers is the increasing demand for customized and enhanced vehicle aesthetics, particularly in regions such as Africa, South America, the Middle East, and Europe. B2B buyers are increasingly looking for innovative solutions that allow for headlight modifications, such as retrofitting with LED or xenon lights, which offer better visibility and energy efficiency.

Emerging technologies like 3D printing are reshaping sourcing strategies within the sector, enabling manufacturers to produce bespoke headlight components more efficiently and cost-effectively. This trend is particularly appealing to international B2B buyers who seek to reduce lead times and lower inventory costs. Furthermore, the rise of online platforms for automotive parts sourcing is facilitating easier access to a broader range of suppliers and products, enhancing competitive pricing and product availability.

Market dynamics are also influenced by regulatory changes aimed at improving road safety and reducing environmental impact. Compliance with stringent regulations regarding lighting standards is essential for B2B buyers to ensure that the products they source meet international safety benchmarks. As a result, suppliers that prioritize quality assurance and regulatory compliance are likely to gain a competitive edge in this evolving market landscape.

How Can Sustainability and Ethical Sourcing Be Integrated into the Remove Headlight Supply Chain?

Sustainability and ethical sourcing are becoming increasingly important in the remove headlight sector, reflecting a broader industry shift toward environmental responsibility. The production and disposal of automotive parts, including headlights, can contribute significantly to environmental degradation. B2B buyers are now more focused on sourcing components from suppliers that implement sustainable practices, such as using recyclable materials and reducing energy consumption during manufacturing processes.

The importance of ethical supply chains cannot be overstated, particularly as consumers demand transparency regarding the origins of the products they purchase. Buyers should seek suppliers with certifications like ISO 14001 for environmental management and ISO 45001 for occupational health and safety. These certifications demonstrate a commitment to sustainable practices and can significantly enhance a supplier’s credibility in the eyes of B2B buyers.

Additionally, the integration of ‘green’ materials in headlight manufacturing, such as eco-friendly adhesives and plastics, is gaining traction. This not only reduces the environmental impact but also appeals to a growing segment of eco-conscious consumers and businesses. By prioritizing sustainability and ethical sourcing, B2B buyers in the remove headlight sector can contribute to a more sustainable future while enhancing their brand reputation.

What Is the Evolution of the Remove Headlight Sector and Its Relevance to B2B Buyers?

The remove headlight sector has evolved significantly over the past few decades, shifting from basic halogen bulbs to advanced lighting technologies like LED and adaptive headlights. This evolution has been fueled by technological innovations and increased consumer expectations for performance, safety, and aesthetic appeal. For B2B buyers, understanding this historical context is crucial for making informed sourcing decisions.

Initially, headlights were primarily functional, designed to illuminate the road ahead. However, as vehicle design became more sophisticated, headlights began to play a significant role in the overall aesthetic and branding of vehicles. This transition has led to a surge in demand for customizable headlights, creating new opportunities for suppliers and manufacturers.

Today, B2B buyers must navigate a complex landscape characterized by rapid technological advancements, changing regulations, and heightened consumer awareness of sustainability. This evolution underscores the importance of staying informed about market trends and aligning sourcing strategies with both current technologies and future developments. As the sector continues to evolve, the ability to adapt to these changes will be paramount for success in the competitive B2B marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of remove headlight

-

How do I safely remove a headlight without damaging it?

To safely remove a headlight, first consult your vehicle’s manual for specific instructions. Generally, you need to open the vehicle’s hood, remove any obstructing parts like the bumper cover, and unscrew the bolts holding the headlight assembly. Disconnect the wiring harness carefully to avoid damaging the connectors. It’s advisable to wear gloves to protect your hands from any sharp edges and to handle the headlight gently to prevent cracks. -

What tools do I need to remove a headlight?

The essential tools for removing a headlight include a socket wrench set, a screwdriver, and possibly pliers. Depending on your vehicle, you might also need a flathead screwdriver to pry off any clips or covers. Having a soft cloth or towel to place the headlight on can help prevent scratches while you work. Always ensure that you have the right tools to minimize the risk of damage during the process. -

What are the best practices for sourcing headlights for resale?

When sourcing headlights for resale, prioritize suppliers that offer quality certifications and have a solid reputation in the market. Look for manufacturers that provide clear product specifications and warranty options. It’s beneficial to establish relationships with suppliers who can offer competitive pricing and flexible payment terms. Additionally, consider suppliers who can accommodate custom orders to meet specific market demands. -

What minimum order quantities (MOQ) should I expect when sourcing headlights?

Minimum order quantities for headlights can vary significantly between suppliers. Typically, MOQs range from 50 to 500 units, depending on the manufacturer and the type of headlights. For smaller businesses or new entrants, it’s advisable to negotiate MOQs to align with your initial budget and inventory management strategy. Establishing a good rapport with suppliers can lead to more favorable terms. -

How do I verify the quality of headlights before making a bulk purchase?

To verify the quality of headlights, request samples before placing a bulk order. Evaluate the materials used, the clarity of the lens, and the integrity of the seals. Certifications like ISO or compliance with local automotive regulations can also serve as quality indicators. Additionally, consider seeking reviews or testimonials from other businesses that have sourced from the supplier to gauge their reliability. -

What payment terms are common for international suppliers?

Common payment terms for international suppliers include upfront payments, letters of credit, and payment upon delivery. Some suppliers may offer net 30 or net 60 terms, allowing you to pay after receiving the goods. Ensure to clarify payment terms before finalizing agreements to avoid any misunderstandings. Using secure payment platforms can also protect against fraud and facilitate smoother transactions. -

What logistics considerations should I keep in mind when importing headlights?

When importing headlights, consider shipping methods, customs regulations, and potential tariffs. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but takes longer. Ensure compliance with local customs regulations to avoid delays. Partnering with a reliable logistics provider can streamline the process and help navigate complex international shipping challenges. -

How can I customize headlights for my market needs?

Customization options for headlights can include variations in design, color, and functionality, such as LED or xenon options. Collaborate with your supplier to understand available customization services and any associated costs. Providing clear specifications and examples of desired features can facilitate the design process. Additionally, consider market trends and consumer preferences in your region to ensure that your customized headlights meet local demands.

Top 3 Remove Headlight Manufacturers & Suppliers List

1. Donut Media – Video Creator

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: This company, Donut Media – Video Creator, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. WikiHow – Car Headlight Replacement Guide

المجال: wikihow.com

تاريخ التسجيل: 2004 (21 عامًا)

مقدمة: This article provides a step-by-step guide on how to open a car headlight, including removing the headlight assembly, unscrewing bolts, unplugging connectors, and baking the headlight to break the seal. It emphasizes the need for tools like a socket wrench and screwdriver, and suggests wearing gloves and old clothes due to the sticky sealant. The article is co-authored by automotive repair special…

3. Chevy Tahoe – Headlight Assembly Removal Guide

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: Easiest method for removing a headlight assembly on a Chevy Tahoe includes pulling the bumper cover and grille, accessing a bolt by removing the inner wheel well cover, and accessing the rest from the top. Some users noted that changing headlights can be done without removing the bumper or wheel well.

Strategic Sourcing Conclusion and Outlook for remove headlight

In conclusion, the process of removing headlights can serve as a pivotal aspect of automotive maintenance and customization, especially for international B2B buyers in regions like Africa, South America, the Middle East, and Europe. Understanding the detailed steps—such as safely detaching the headlight assembly and using heat techniques for sealant removal—underscores the importance of strategic sourcing. By partnering with reliable suppliers, businesses can ensure access to high-quality automotive parts and tools, ultimately enhancing service offerings and customer satisfaction.

Investing in strategic sourcing not only streamlines operations but also fosters innovation in product offerings, allowing companies to adapt to market demands efficiently. As the automotive industry continues to evolve, staying ahead of trends, such as headlight technology and customization options, will be crucial for maintaining competitive advantage.

We encourage B2B buyers to leverage these insights and consider the long-term benefits of establishing strong supplier relationships. By doing so, businesses can not only enhance their operational capabilities but also unlock new opportunities in the ever-competitive automotive market. Embrace the future of automotive maintenance with confidence and strategic foresight.

Illustrative image related to remove headlight

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.