Introduction: Navigating the Global Market for parts to an alternator

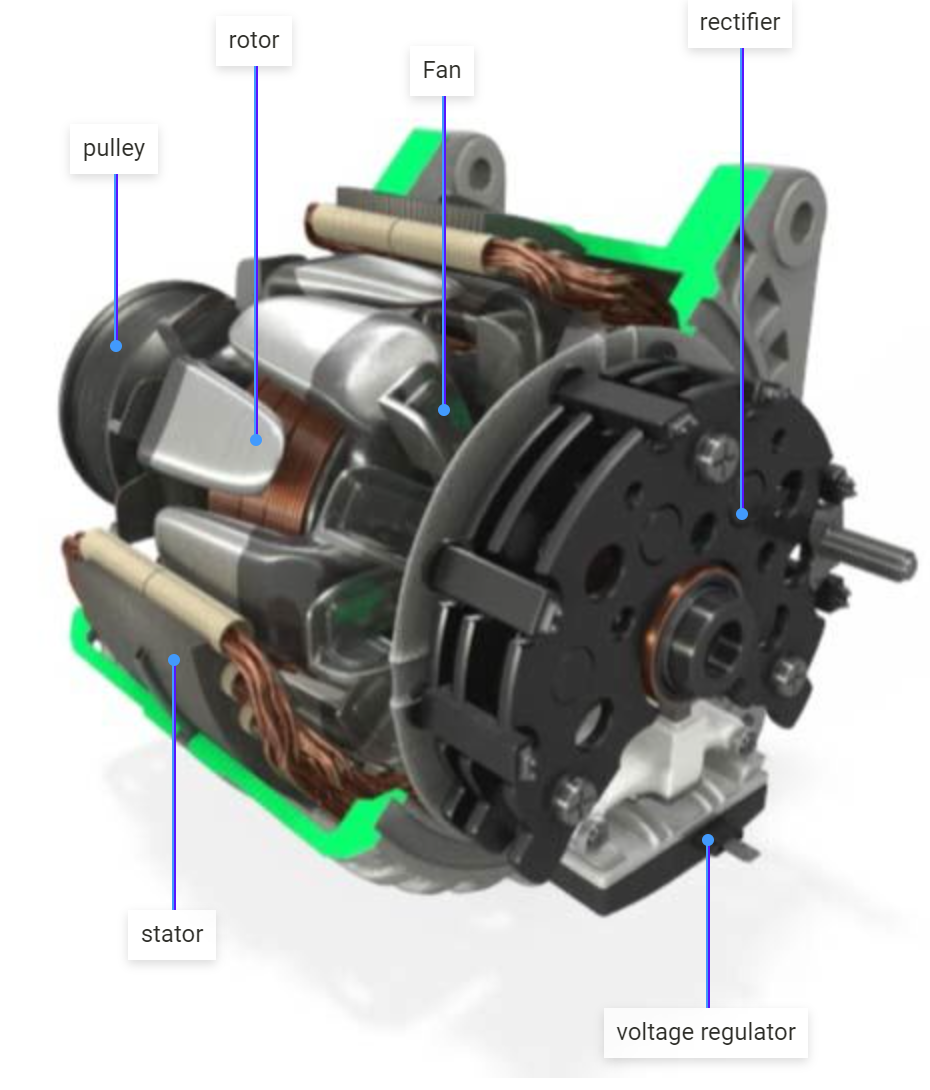

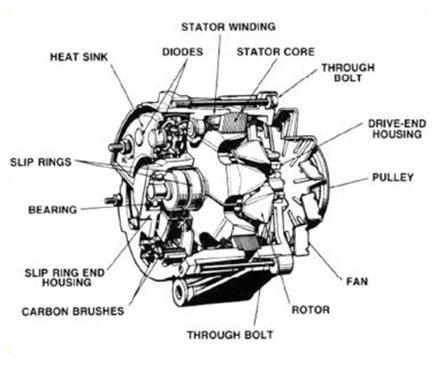

As international B2B buyers navigate the complex landscape of sourcing parts for an alternator, a critical challenge emerges: ensuring quality and compatibility while managing costs. Alternators are vital components in automotive and industrial applications, transforming mechanical energy into electrical power. This guide offers a comprehensive overview of the various parts that constitute an alternator, including rotors, stators, voltage regulators, and rectifiers, each playing a crucial role in its functionality.

In addition to detailing the types and applications of alternator parts, this resource delves into essential aspects such as supplier vetting strategies, cost considerations, and market trends. By understanding the intricacies of alternator components and their sourcing, B2B buyers from regions like Africa, South America, the Middle East, and Europe—including Brazil and Vietnam—can make informed purchasing decisions that align with their operational needs and budget constraints.

Empowered with actionable insights and best practices, this guide equips you to navigate the global market effectively, ensuring that you acquire high-quality alternator parts that enhance performance and reliability in your applications. Whether you’re looking to streamline procurement processes or establish long-term supplier relationships, this comprehensive resource serves as your go-to reference for all things related to alternator parts.

جدول المحتويات

- Top 4 Parts To An Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts to an alternator

- Understanding parts to an alternator Types and Variations

- Key Industrial Applications of parts to an alternator

- 3 Common User Pain Points for ‘parts to an alternator’ & Their Solutions

- Strategic Material Selection Guide for parts to an alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for parts to an alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts to an alternator’

- Comprehensive Cost and Pricing Analysis for parts to an alternator Sourcing

- Alternatives Analysis: Comparing parts to an alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for parts to an alternator

- Navigating Market Dynamics and Sourcing Trends in the parts to an alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts to an alternator

- Strategic Sourcing Conclusion and Outlook for parts to an alternator

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding parts to an alternator Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولد القياسي | Compact design, aluminum housing, includes rotor and stator | Automotive, light trucks | Pros: Cost-effective; Cons: Limited power output |

| مولد كهربائي عالي الطاقة | Enhanced power generation, larger stator and rotor size | مركبات عالية الأداء، آلات ثقيلة | Pros: Greater efficiency; Cons: Higher cost |

| مولد كهربائي بحري | مواد مقاومة للتآكل، مصممة للبيئات الرطبة | القوارب والمركبات البحرية | Pros: Durable; Cons: May require specialized knowledge |

| مولد يعمل بالسير | Operates via engine belt, standard in most vehicles | Automotive, commercial vehicles | Pros: Easy to replace; Cons: Dependent on engine operation |

| مولد كهربائي بدون فرش | No brushes or slip rings, reduced wear and tear | التطبيقات الصناعية، أنظمة الطاقة المتجددة | Pros: Longer lifespan; Cons: Higher initial investment |

ما هي الخصائص الرئيسية للمولدات القياسية؟

Standard alternators are the most common type found in passenger vehicles and light trucks. They typically feature an aluminum housing that effectively dissipates heat, ensuring efficiency during operation. These alternators convert mechanical energy from the engine into electrical energy, primarily for battery charging and powering electrical systems. B2B buyers should consider the compatibility with vehicle models and the cost-effectiveness of standard alternators, especially for fleet management.

كيف تختلف المولدات عالية الإنتاجية عن المولدات القياسية؟

High-output alternators are designed to deliver more electrical power than standard models, making them ideal for performance vehicles or heavy machinery that require additional electrical support. These alternators feature larger stators and rotors, which enhance power generation capabilities. B2B buyers looking for high-output options should assess their specific power requirements and the potential need for upgraded wiring and battery systems to accommodate increased load.

ما الذي يجعل المولدات البحرية فريدة من نوعها؟

Marine alternators are specifically designed to withstand harsh marine environments, often utilizing corrosion-resistant materials to ensure longevity. They provide reliable power for boats and other marine vehicles, where exposure to moisture and saltwater is prevalent. For B2B buyers in the marine industry, understanding the unique specifications and maintenance requirements of marine alternators is crucial for ensuring optimal performance and reliability.

Why Choose Belt-Driven Alternators?

Belt-driven alternators are the most prevalent type in automotive applications, relying on a belt connected to the engine to function. They are straightforward to replace and maintain, making them a practical choice for many businesses in the automotive sector. B2B buyers should consider the ease of installation and maintenance when selecting this type, as well as its dependency on the engine’s operational status.

ما المزايا التي تقدمها المولدات بدون فرش؟

Brushless alternators eliminate the need for brushes and slip rings, leading to reduced wear and tear and a longer operational lifespan. These are commonly used in industrial applications and renewable energy systems, where reliability is paramount. B2B buyers should weigh the higher initial investment against the long-term savings in maintenance and replacement costs when considering brushless options for their operations.

Key Industrial Applications of parts to an alternator

| الصناعة/القطاع | Specific Application of parts to an alternator | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | Production of alternators for vehicles | Ensures reliable power supply for vehicle electronics | Quality assurance and compliance with international standards |

| الطاقة المتجددة | Wind turbine generators using alternator parts | Converts mechanical energy to electrical, enhancing efficiency | Sourcing durable components to withstand environmental conditions |

| Marine & Shipping | تزويد الأنظمة الكهربائية على متن السفن بالطاقة | Reliable energy source for navigation and communication systems | Availability of marine-grade components resistant to corrosion |

| الآلات الثقيلة | المولدات في معدات البناء والمعدات الزراعية | Provides power for machinery operation, reducing downtime | Compatibility with various engine types and power requirements |

| عمليات التعدين | Electrical systems in mining equipment | Supports operations in remote locations with limited power access | Sourcing robust parts that can endure harsh operating environments |

How Are Parts to an Alternator Used in Automotive Manufacturing?

In automotive manufacturing, alternators are crucial for powering electrical systems within vehicles. The components, such as the rotor and stator, work together to convert mechanical energy from the engine into electrical energy. Reliable alternators ensure that vehicles can operate their electronic components, such as infotainment systems and safety features, without interruption. International buyers should prioritize sourcing parts that meet stringent quality standards to ensure durability and performance in various climates.

What Role Do Alternator Parts Play in Renewable Energy Applications?

In the renewable energy sector, particularly in wind turbines, alternator parts are essential for converting mechanical energy generated by turbine blades into electrical energy. The efficiency of this conversion directly impacts energy output and system reliability. Buyers in this field must consider sourcing high-quality components that can withstand harsh environmental conditions, such as extreme temperatures and moisture, to ensure long-term operational success.

How Are Alternator Parts Utilized in Marine and Shipping Industries?

Marine applications rely heavily on alternators to power onboard electrical systems, including navigation and communication equipment. The reliability of these systems is critical for safe operations at sea. Marine-grade alternator components must be sourced to ensure resistance to corrosion and the ability to function effectively in a salty environment. Buyers should focus on suppliers who can guarantee compliance with maritime safety standards.

Why Are Alternator Parts Important in Heavy Machinery?

In heavy machinery, such as construction and agricultural equipment, alternators are vital for providing electrical power to operate various functions, including hydraulic systems and lighting. The reliability of these components minimizes downtime and enhances productivity on job sites. Buyers should seek parts that are compatible with a range of engine types and can handle the high demands of heavy-duty applications, ensuring consistent performance.

How Do Mining Operations Benefit from Alternator Parts?

Mining operations often utilize alternators to supply power to equipment in remote locations where access to traditional power sources is limited. The robustness of alternator components is critical, as they must endure harsh working conditions, including dust and extreme temperatures. International buyers should prioritize sourcing durable parts that meet industry standards for performance and reliability, ensuring uninterrupted operations in challenging environments.

3 Common User Pain Points for ‘parts to an alternator’ & Their Solutions

السيناريو 1: صعوبة الحصول على قطع غيار المولدات عالية الجودة

المشكلة: Many B2B buyers struggle with the challenge of sourcing high-quality alternator parts that meet their specific needs. This is particularly prevalent in regions like Africa and South America, where local suppliers may not consistently offer reliable or durable components. Buyers often face issues with counterfeit parts, which can lead to premature failure of the alternator and increase overall maintenance costs. Additionally, the lack of standardized quality checks can result in inconsistent product performance.

الحل: To effectively source quality alternator parts, buyers should establish partnerships with reputable suppliers who have a proven track record of quality assurance. It’s crucial to verify the supplier’s certifications and quality control processes. Consider engaging with manufacturers that provide detailed specifications for their components, ensuring they meet international standards. Utilizing platforms that specialize in B2B transactions can also enhance access to verified suppliers. Furthermore, implementing a robust inspection process upon receipt of parts can help in identifying counterfeit items before they enter the supply chain.

Scenario 2: Incompatibility of Alternator Parts with Vehicle Models

المشكلة: A common issue faced by B2B buyers is the incompatibility of alternator parts with specific vehicle models. This often arises when buyers are unaware of the exact specifications required for different models or when they rely on generic parts that do not fit properly. Such mismatches can lead to installation challenges, increased labor costs, and longer vehicle downtime, ultimately affecting business operations.

الحل: To mitigate the risk of incompatibility, it is essential for buyers to conduct thorough research on the specific requirements for each vehicle model they service. This can involve consulting manufacturer specifications and utilizing parts catalogs that provide detailed compatibility information. Buyers should also consider working closely with manufacturers to obtain precise part numbers and compatibility charts. Training staff on the nuances of different vehicle systems can further enhance accuracy in parts selection. Implementing a systematic inventory management system that categorizes parts by vehicle type can also streamline the ordering process, ensuring that the correct parts are always available when needed.

Scenario 3: High Costs of Alternator Parts and Maintenance

المشكلة: The rising costs of alternator parts and associated maintenance can be a significant pain point for B2B buyers. This is especially true for businesses operating in regions with fluctuating currency exchange rates and import tariffs. High costs can erode profit margins, making it challenging to maintain competitive pricing while ensuring quality service.

الحل: To address the issue of high costs, buyers should explore bulk purchasing options to leverage economies of scale, potentially reducing unit prices. Building long-term relationships with suppliers can also lead to better pricing agreements and access to exclusive deals. Additionally, conducting a cost-benefit analysis on the total cost of ownership for different parts can help in identifying more cost-effective alternatives that do not compromise quality. Consider investing in training for maintenance staff to ensure proper installation and care, thereby extending the life of the alternator parts and reducing the frequency of replacements. Exploring local manufacturing options or suppliers that offer locally sourced components can also mitigate the impact of import costs and tariffs.

Strategic Material Selection Guide for parts to an alternator

What Are the Key Materials Used in Alternator Components?

When selecting materials for alternator components, it is crucial to consider their properties, performance, and suitability for various applications. This guide analyzes four common materials used in alternators: aluminum, copper, steel, and plastic. Each material has distinct advantages and disadvantages that can significantly impact the performance and cost-effectiveness of the alternator.

كيف يفيد الألومنيوم تصميم المولد؟

Aluminum is widely used for the outer housing of alternators due to its lightweight nature and excellent heat dissipation properties. It has a high strength-to-weight ratio, making it ideal for automotive applications where reducing weight is essential for fuel efficiency. Aluminum does not magnetize, which is critical for the alternator’s functioning, as it avoids interference with the magnetic field generated by the rotor.

الإيجابيات: Aluminum is durable, corrosion-resistant, and relatively inexpensive. Its ease of manufacturing allows for complex shapes and designs, which can enhance the overall efficiency of the alternator.

السلبيات: While aluminum is strong, it is not as robust as steel, which may lead to issues in high-impact environments. Additionally, its thermal expansion properties require careful consideration in design to avoid thermal fatigue.

التأثير على التطبيق: Aluminum is suitable for environments with moderate temperature fluctuations but may not perform well in extreme heat without proper insulation.

اعتبارات للمشترين الدوليين: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Africa and South America should also consider local availability and recycling practices, as aluminum is highly recyclable.

Why Choose Copper for Electrical Components in Alternators?

Copper is the preferred material for electrical windings and connections within alternators due to its excellent electrical conductivity. This property ensures efficient power transfer, which is vital for the alternator’s performance in charging batteries and powering electrical systems.

الإيجابيات: Copper’s high conductivity translates to lower energy losses, improving overall efficiency. It is also relatively easy to work with, allowing for intricate winding designs.

السلبيات: Copper is heavier than aluminum, which may impact the overall weight of the alternator. It is also more expensive and can be prone to corrosion if not properly insulated.

التأثير على التطبيق: Copper is ideal for applications requiring high conductivity and reliability, especially in regions with fluctuating temperatures that could affect electrical performance.

اعتبارات للمشترين الدوليين: Buyers should ensure compliance with electrical standards specific to their regions, such as JIS in Japan and DIN in Europe. The fluctuating price of copper can also affect budgeting for manufacturers.

How Does Steel Contribute to Durability in Alternator Parts?

Steel is often used for components that require high strength and durability, such as the rotor shaft and internal brackets. Its mechanical properties make it suitable for withstanding the stresses encountered during operation.

الإيجابيات: Steel is incredibly strong and resistant to deformation, making it ideal for high-load applications. It is also cost-effective compared to other metals.

السلبيات: Steel is heavier than both aluminum and copper, which can negatively impact fuel efficiency in automotive applications. It is also susceptible to corrosion if not treated or coated.

التأثير على التطبيق: Steel is suitable for environments where mechanical strength is paramount, but its weight may limit its use in lightweight applications.

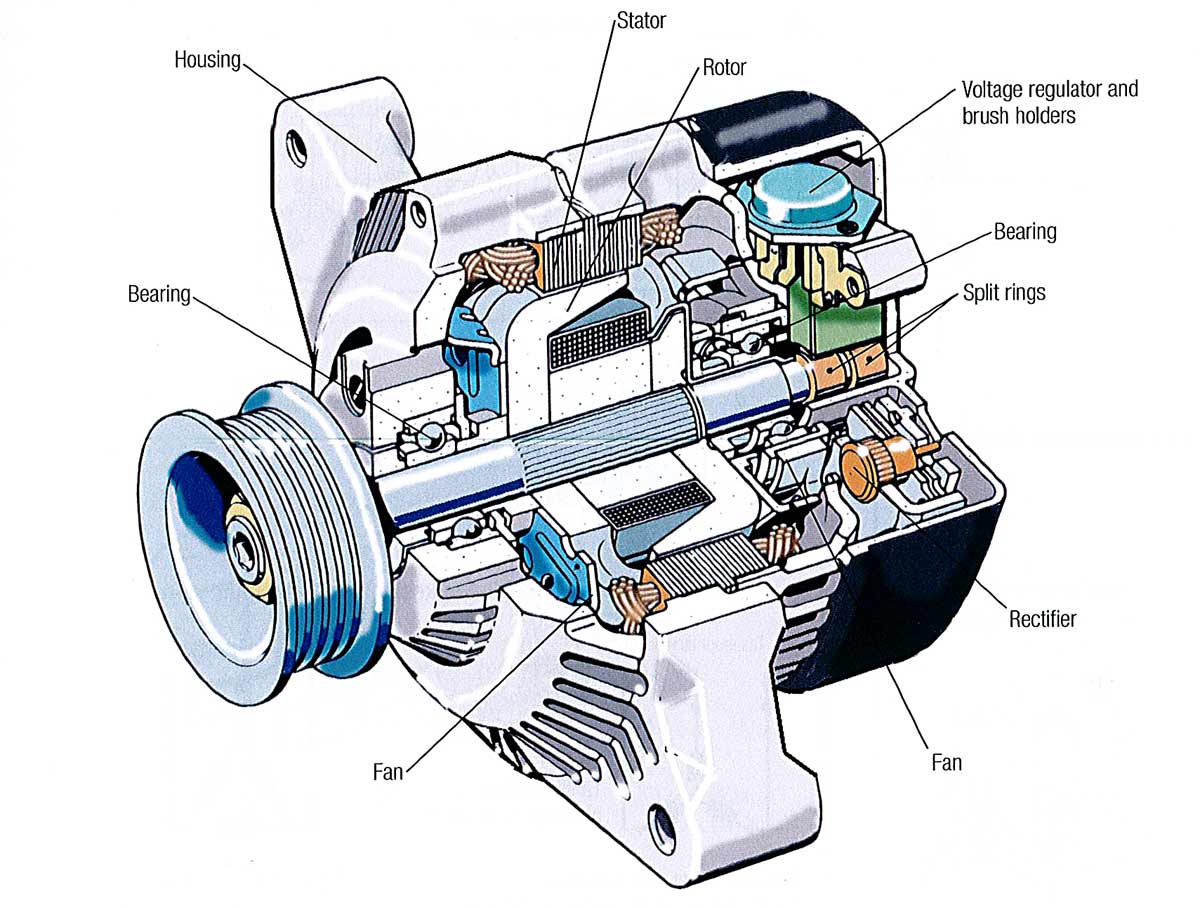

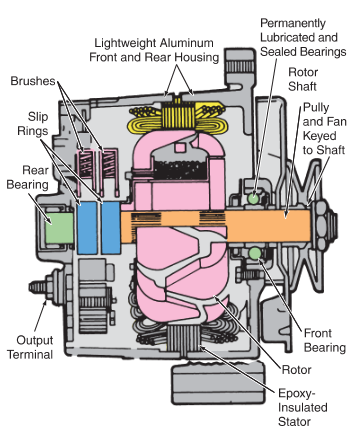

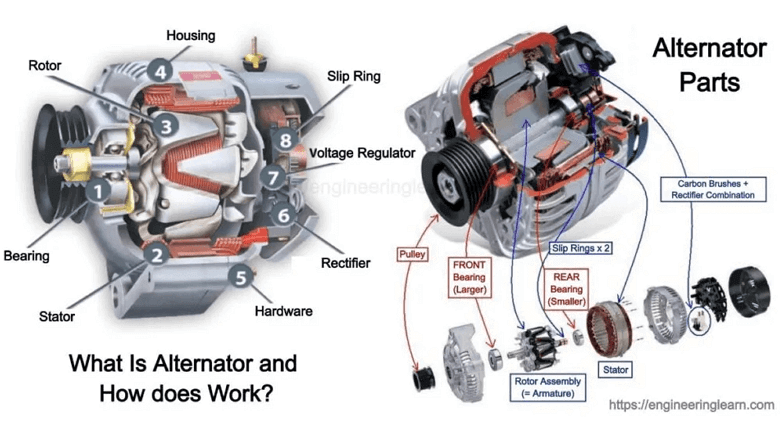

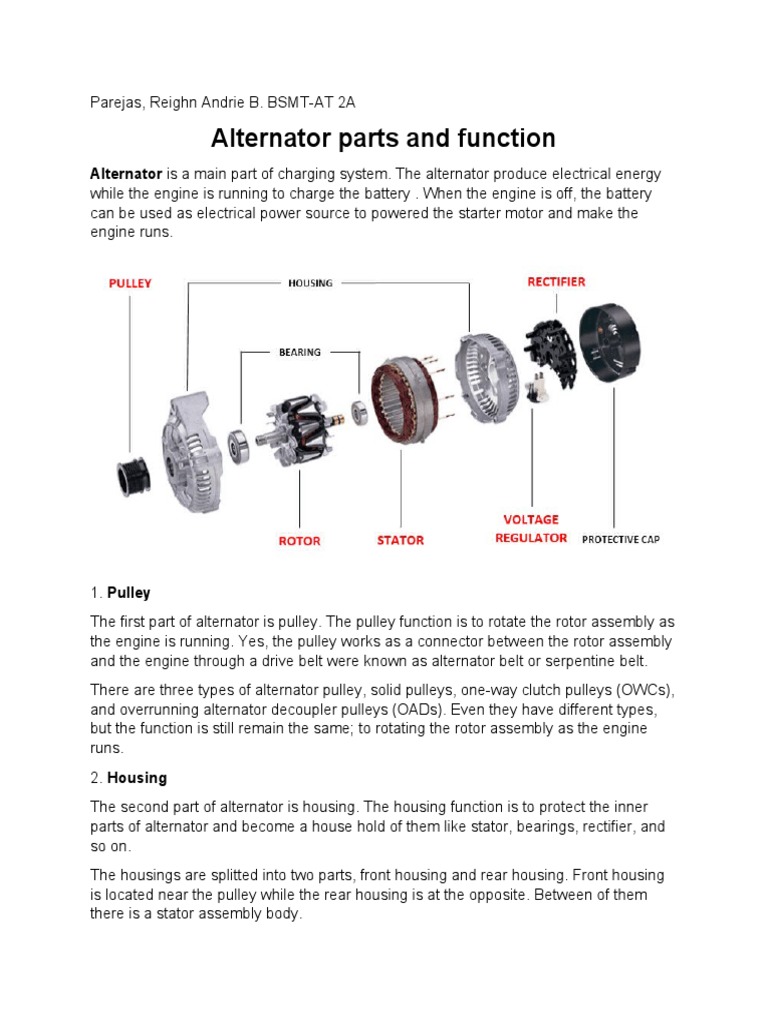

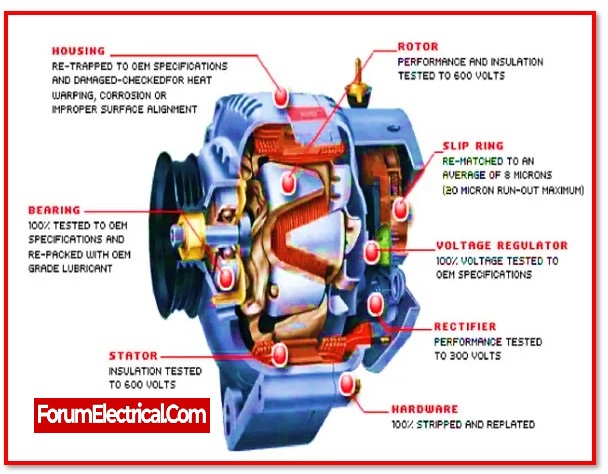

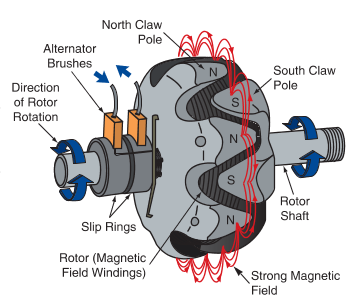

Illustrative image related to parts to an alternator

اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM for steel grades is crucial. Buyers should also consider the local environment’s impact on steel’s corrosion resistance, particularly in humid or coastal regions.

What Role Does Plastic Play in Alternator Components?

Plastic is commonly used for insulators and housing components in alternators. Its lightweight nature and resistance to electrical conductivity make it an excellent choice for specific applications.

الإيجابيات: Plastic is lightweight, cost-effective, and can be molded into complex shapes, allowing for efficient design and manufacturing. It also provides good insulation properties.

Illustrative image related to parts to an alternator

السلبيات: Plastic generally lacks the mechanical strength of metals, making it unsuitable for load-bearing components. It can also degrade over time when exposed to high temperatures or UV light.

التأثير على التطبيق: Plastic is ideal for non-load-bearing components and environments where weight savings are critical.

اعتبارات للمشترين الدوليين: Buyers should ensure that the plastics used comply with regional standards for thermal and electrical performance, especially in high-temperature environments.

Summary of Material Selection for Alternator Parts

| المواد | Typical Use Case for parts to an alternator | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | Outer housing, heat sinks | خفيف الوزن، تبديد جيد للحرارة | أقل متانة من الفولاذ | متوسط |

| النحاس | Electrical windings, connections | موصلية عالية | Heavier, more expensive | عالية |

| الصلب | Rotor shaft, internal brackets | قوة عالية وفعالة من حيث التكلفة | أثقل وزناً، وعرضة للتآكل | منخفض |

| بلاستيك | Insulators, non-load-bearing components | Lightweight, moldable | Low mechanical strength | منخفض |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and considerations for materials used in alternator components. Understanding these factors can lead to better decision-making and optimized performance in diverse applications across international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for parts to an alternator

What Are the Main Stages of Manufacturing Parts for an Alternator?

The manufacturing process for alternator components encompasses several critical stages, ensuring that each part meets stringent performance and quality standards. The key stages typically include material preparation, forming, assembly, and finishing.

Illustrative image related to parts to an alternator

How Is Material Prepared for Alternator Parts?

Material preparation is the foundation of high-quality alternator parts. The most commonly used materials include aluminum for housings due to its lightweight and non-magnetic properties, and copper for windings due to its excellent conductivity. Manufacturers typically source raw materials from certified suppliers who adhere to international standards.

Once sourced, materials undergo rigorous inspections to ensure they meet specified mechanical and chemical properties. This process might involve spectroscopic analysis for metal composition and tensile strength tests. In regions like Africa and South America, local sourcing can reduce costs but necessitates thorough supplier evaluations to ensure material quality.

What Techniques Are Used in Forming Alternator Parts?

The forming stage involves transforming raw materials into specific shapes and dimensions. Key techniques include:

- الصب: Commonly used for aluminum housings, this technique allows for complex shapes and reduces waste.

- التصنيع الآلي: Precision machining is critical for components like the rotor and stator, where tight tolerances are essential for performance.

- Stamping and Die-Cutting: Employed for creating flat components such as brackets and covers, this method offers high efficiency for mass production.

These techniques are often supported by CNC (Computer Numerical Control) technology, which enhances precision and repeatability, vital for maintaining quality across large production runs.

How Are Components Assembled in the Manufacturing Process?

The assembly process is where individual components come together to form the complete alternator. This stage includes integrating the rotor, stator, rectifier, and other electrical components.

Assembly typically follows a systematic workflow to ensure accuracy and efficiency. Key steps include:

- التجميع الفرعي: Smaller components, like the rotor and slip rings, are assembled independently before being integrated into the main unit.

- التوصيلات الكهربائية: Proper connections are critical for functionality. Automated systems may be employed to ensure consistent wiring and soldering.

- الاختبار أثناء التجميع: Throughout the assembly process, manufacturers often conduct preliminary tests on components to identify defects early.

This stage is crucial, as the quality of the assembly impacts the overall performance and longevity of the alternator.

Illustrative image related to parts to an alternator

What Finishing Processes Enhance Quality and Durability?

Finishing processes are essential to enhance both the aesthetic and functional qualities of alternator parts. Common finishing techniques include:

- معالجة السطح: Anodizing or powder coating aluminum housings can improve corrosion resistance and aesthetics.

- Balancing and Alignment: Rotors must be precisely balanced to minimize vibrations during operation, which can lead to premature wear.

- الفحص النهائي: Each finished alternator undergoes a final inspection, which may include functional testing to ensure it meets performance specifications.

These finishing steps are critical in ensuring that the alternator operates efficiently and has a long service life, thus meeting the expectations of B2B buyers.

What Quality Assurance Standards Are Relevant in Alternator Manufacturing?

Quality assurance (QA) is pivotal in the manufacturing of alternator parts. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain consistent quality management systems. This certification is recognized globally and signifies that a manufacturer has implemented effective quality controls throughout their processes.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for safety and performance in Europe, and API (American Petroleum Institute) standards for components used in automotive applications, are also critical. These certifications help B2B buyers verify that the parts are compliant with regulatory requirements in their respective markets.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في تصنيع المولدات؟

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to ensure that defects are identified and addressed promptly. Key QC checkpoints include:

Illustrative image related to parts to an alternator

- مراقبة الجودة الواردة (IQC): This initial stage inspects raw materials and components upon arrival to ensure they meet predefined specifications.

- مراقبة الجودة أثناء الإنتاج (IPQC): Throughout the manufacturing process, operators conduct checks to monitor compliance with quality standards, often using statistical process control (SPC) techniques.

- مراقبة الجودة النهائية (FQC): Before shipping, each alternator is subjected to comprehensive testing, including electrical performance tests, thermal performance, and noise level assessments.

These checkpoints are essential for maintaining the integrity of the production process and ensuring that only high-quality products reach the market.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps to ensure quality assurance:

- تدقيق الموردين: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality management systems, and adherence to international standards.

- طلب تقارير الجودة: Buyers should request documentation of quality control processes, including test results and certifications. This transparency is vital for building trust.

- إشراك مفتشي الطرف الثالث: Utilizing independent inspection services can provide an unbiased assessment of the supplier’s quality practices and product conformity.

By implementing these verification methods, B2B buyers can mitigate risks associated with poor-quality components and ensure reliable performance from the alternators they procure.

ما هي الفروق الدقيقة في مراقبة الجودة والاعتماد للمشترين الدوليين بين الشركات؟

Navigating the QC and certification landscape can be challenging for international buyers, particularly when dealing with suppliers from diverse regions. Understanding local regulations and industry standards is essential.

Illustrative image related to parts to an alternator

For example, in Europe, compliance with CE marking is mandatory, while in other regions, different standards may apply. Additionally, cultural differences in business practices and communication styles can impact the effectiveness of quality assurance processes.

Buyers should familiarize themselves with local industry standards and engage in open dialogue with suppliers to clarify any uncertainties regarding compliance and quality expectations. This proactive approach can foster better relationships and ensure that both parties are aligned in their commitment to quality.

By taking these factors into account, international B2B buyers can navigate the complexities of sourcing alternator parts with greater confidence and assurance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts to an alternator’

In the competitive landscape of B2B procurement, acquiring parts for an alternator demands careful consideration and strategic sourcing. This guide serves as a practical checklist to assist international buyers, particularly from Africa, South America, the Middle East, and Europe, in navigating the complexities of sourcing these essential components.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Before initiating the procurement process, it is essential to outline the specific technical requirements for the alternator parts you need. This includes identifying the type of alternator (e.g., AC or DC), compatibility with existing systems, and performance specifications. Clear specifications help in filtering potential suppliers and ensuring that you receive parts that meet your operational needs.

Illustrative image related to parts to an alternator

الخطوة 2: البحث عن الموردين المحتملين

Invest time in identifying suppliers who specialize in alternator components. Look for companies with a proven track record in the industry, particularly those with experience in your target market. Utilize online directories, industry forums, and trade shows to compile a list of potential suppliers.

- Check Reviews and Ratings: Online reviews and testimonials can provide insight into a supplier’s reliability and product quality.

- الخبرة في المجال: Prioritize suppliers with experience in your specific sector, as they are likely to understand your unique requirements better.

الخطوة 3: تقييم شهادات الموردين

Certifications can serve as a reliable indicator of quality and compliance with international standards. Verify if the suppliers hold relevant certifications such as ISO 9001 for quality management or ISO/TS 16949 for automotive parts.

- ضمان الجودة: Ensure the suppliers have robust quality control processes in place.

- Environmental Compliance: Check for certifications related to environmental standards, which can be crucial in global markets.

الخطوة 4: طلب عينات أو نماذج أولية

Before placing a large order, request samples or prototypes of the parts. This step allows you to evaluate the quality, compatibility, and performance of the components firsthand.

- إجراءات الاختبار: Conduct thorough testing to ensure the parts meet your specifications.

- Feedback Loop: Use this opportunity to provide feedback to the supplier, which can improve future orders.

الخطوة 5: التفاوض على الشروط والأحكام

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery timelines. Establishing clear terms helps prevent misunderstandings later in the procurement process.

Illustrative image related to parts to an alternator

- خصومات الحجم: Inquire about bulk purchase discounts to optimize costs.

- مرونة الدفع: Discuss payment terms that align with your cash flow needs.

الخطوة 6: Confirm Warranty and Support Options

Ensure that the supplier provides a warranty for the parts and outline the support options available. This is crucial for minimizing risks associated with defects or performance issues after procurement.

- مدة الضمان: Look for suppliers offering extended warranties as a sign of confidence in their products.

- After-Sales Support: Assess the level of technical support available, which can be vital in case of installation or operational challenges.

الخطوة 7: وضع خطة التواصل

Effective communication is key to a successful procurement process. Establish a clear plan for ongoing communication with your supplier to address any issues that may arise during production or delivery.

- Regular Updates: Schedule regular check-ins to discuss order status and any potential concerns.

- Point of Contact: Designate a specific contact person on both sides to streamline communication.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for alternator parts, ensuring they secure high-quality components that meet their operational demands while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for parts to an alternator Sourcing

What Are the Key Cost Components in Sourcing Parts for an Alternator?

When sourcing parts for alternators, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

المواد: The quality and type of materials significantly impact costs. Common materials like aluminum for the housing, copper for windings, and steel for the rotor are frequently used. Prices fluctuate based on global supply and demand, as well as local availability.

-

العمل: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this can come at the expense of quality. Skilled labor is essential for precision components like slip rings and rectifiers.

-

تكاليف التصنيع العامة: This encompasses utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer better pricing.

-

الأدوات: Initial costs for specialized tooling can be significant, especially for custom parts. This is often amortized over the production volume, making it important to negotiate minimum order quantities (MOQs) that justify these expenses.

-

مراقبة الجودة (QC): Investing in robust QC processes ensures that parts meet specifications and standards. This can add to the cost but is essential for minimizing returns and ensuring reliability.

-

اللوجستيات: Transportation costs, including shipping and handling, play a crucial role in the total cost. Incoterms should be clearly defined to understand who bears these costs.

-

الهامش: Suppliers will include a profit margin in their pricing. Understanding market rates and competitor pricing can help buyers negotiate better terms.

How Do Price Influencers Impact the Sourcing of Alternator Parts?

Several factors influence the pricing of alternator parts, which B2B buyers should consider:

-

الحجم والحد الأدنى لكمية الطلب (MOQ): Higher volumes often lead to lower per-unit costs. Establishing long-term contracts can also secure better pricing.

-

المواصفات والتخصيص: Custom parts tailored to specific requirements typically incur higher costs. Buyers should weigh the benefits of customization against the potential cost increase.

-

جودة المواد والشهادات: Parts that meet higher quality standards or certifications (like ISO) can command higher prices. However, investing in quality can lead to lower failure rates and reduced total cost of ownership.

-

عوامل الموردين: Supplier reputation, reliability, and service quality can significantly affect pricing. Established suppliers may charge more but provide better service and reliability.

-

مصطلحات التجارة الدولية: The choice of Incoterms affects logistics costs and risks. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for accurate pricing.

What Tips Can Help B2B Buyers Optimize Costs When Sourcing Alternator Parts?

To maximize cost efficiency, buyers should consider the following strategies:

-

التفاوض على الشروط: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Strong negotiation can lead to significant savings.

-

تقييم التكلفة الإجمالية للملكية (TCO): Instead of focusing solely on purchase price, evaluate the overall costs associated with the parts, including installation, maintenance, and potential downtime.

-

الاستفادة من الموردين المحليين: For buyers in regions like Africa or South America, sourcing from local suppliers can reduce logistics costs and lead times. This is particularly relevant for industries with fast-paced demand cycles.

-

رصد اتجاهات السوق: Stay informed about material price fluctuations and global supply chain changes. This knowledge can help buyers make timely purchasing decisions.

-

Consider Strategic Partnerships: Building long-term relationships with suppliers can lead to better pricing and priority service during high-demand periods.

إخلاء المسؤولية بشأن الأسعار الإرشادية

Prices for alternator parts can vary widely based on the factors discussed. It is important for buyers to conduct thorough market research and obtain multiple quotes to ensure they are receiving competitive pricing. Always account for fluctuations in material costs and other variables that may affect final pricing.

Illustrative image related to parts to an alternator

Alternatives Analysis: Comparing parts to an alternator With Other Solutions

Exploring Alternatives to Parts for an Alternator

In the competitive landscape of automotive parts and energy generation, understanding viable alternatives to traditional alternator components can empower B2B buyers to make informed purchasing decisions. Various technologies and methodologies exist that can either complement or replace the conventional parts of an alternator, each presenting distinct advantages and challenges. This analysis will provide a comparative overview of these alternatives, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

جدول المقارنة

| جانب المقارنة | Parts To An Alternator | Alternative 1: Battery Management Systems (BMS) | Alternative 2: DC Generators |

|---|---|---|---|

| الأداء | كفاءة عالية في تحويل الطاقة الميكانيكية إلى طاقة كهربائية | Optimizes battery usage, prolonging life and performance | Reliable energy generation, especially for off-grid applications |

| التكلفة | Moderate initial investment, with variable ongoing costs for maintenance | High upfront cost but savings on battery replacements | Generally lower initial cost but can incur higher operational costs |

| سهولة التنفيذ | Simple integration into existing vehicle systems | Requires technical expertise for proper installation | Straightforward setup, but may require adaptation for specific uses |

| الصيانة | Regular checks needed for wear and tear | Minimal maintenance, mostly software updates | Routine maintenance is necessary to ensure reliability |

| أفضل حالة استخدام | Best for standard vehicles and machinery requiring consistent electrical supply | Ideal for electric vehicles and hybrid systems | Suitable for remote power generation and backup systems |

تفصيل البدائل

1. Battery Management Systems (BMS)

Battery Management Systems are increasingly popular in electric and hybrid vehicles. They enhance battery performance by monitoring charge levels, optimizing usage, and extending battery life. BMS can be costlier initially due to the advanced technology and expertise required for installation. However, they reduce long-term costs associated with battery replacements and improve overall vehicle efficiency. The primary downside is the complexity of implementation, which may deter some buyers.

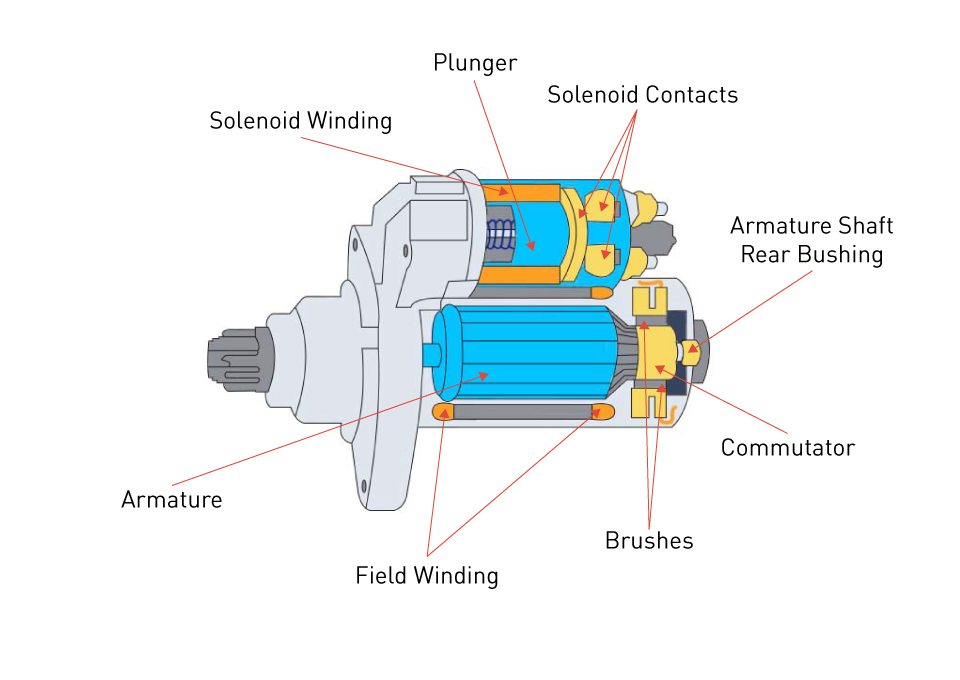

2. DC Generators

DC generators serve as an alternative to alternators by providing direct current power. They are particularly effective in applications where a stable, off-grid power supply is needed, such as in remote locations or backup systems. Their lower initial costs and simpler technology make them an attractive option for many users. However, they may have higher operational costs and maintenance requirements, as they are less efficient compared to modern alternators. Their best use cases include agricultural machinery, construction equipment, and emergency power supplies.

الخلاصة: كيفية اختيار الحل المناسب لاحتياجاتك

When considering alternatives to parts for an alternator, B2B buyers should evaluate their specific requirements, including operational context, budget constraints, and long-term maintenance capabilities. For businesses focused on electric or hybrid vehicle applications, investing in a Battery Management System may yield significant returns through enhanced battery life and efficiency. Conversely, those needing reliable power in remote locations may find DC generators to be a cost-effective solution. Ultimately, a thorough analysis of the operational demands and financial implications will guide buyers toward the most suitable alternative for their unique situations.

Essential Technical Properties and Trade Terminology for parts to an alternator

ما هي الخصائص التقنية الرئيسية لأجزاء المولد؟

Understanding the technical properties of alternator components is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Here are some essential specifications to consider:

1. درجة المواد

Alternators are primarily constructed from aluminum and copper. Aluminum is chosen for its lightweight properties and resistance to corrosion, while copper is used for windings due to its excellent electrical conductivity. B2B buyers should ensure that the materials meet industry standards, as this affects the durability and efficiency of the alternator.

2. التسامح

Tolerance refers to the permissible limit of variation in a physical dimension. For alternators, precise tolerances are critical for components like the rotor and stator, which need to fit closely without friction. Insufficient tolerance can lead to mechanical failure or reduced efficiency. Buyers must specify tolerances that align with their operational requirements to ensure compatibility with existing systems.

Illustrative image related to parts to an alternator

3. تصنيف الجهد الكهربائي

Voltage rating indicates the maximum voltage an alternator can handle without risk of failure. This is particularly important for ensuring that the alternator can meet the electrical demands of various vehicles or applications. Buyers should verify that the voltage rating matches their electrical system requirements to avoid operational failures.

4. كفاءة التبريد

Heat dissipation is vital for alternator performance. Components like internal cooling fans or venting systems must be designed to manage heat effectively. Buyers should assess the cooling efficiency specifications to ensure that the alternator can operate under the expected load without overheating, which can lead to premature failure.

5. Bearings Type

Alternators typically utilize ball or roller bearings to support the rotor shaft. The type and quality of bearings affect the operational lifespan and noise levels of the alternator. Buyers should inquire about the bearing specifications, as high-quality bearings can significantly enhance reliability and reduce maintenance needs.

Illustrative image related to parts to an alternator

6. الوزن

The weight of an alternator can impact installation and overall vehicle dynamics. Lighter alternators can improve fuel efficiency and reduce wear on engine components. Buyers should consider the weight specifications to ensure that the alternator meets their performance and installation criteria.

What Are Common Trade Terms in the Alternator Parts Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several common terms:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to companies that produce parts that are used in the manufacturing of a vehicle. In the alternator market, OEM parts are often preferred for their guaranteed compatibility and reliability. Buyers should specify whether they are looking for OEM parts to ensure quality.

Illustrative image related to parts to an alternator

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding the MOQ is essential for buyers to manage their inventory and ensure cost-effectiveness. Buyers should negotiate MOQs that align with their purchasing capabilities and market demand.

3. طلب عرض أسعار (RFQ)

An RFQ is a formal request for pricing information from suppliers. It typically includes specifications, quantities, and delivery timelines. Buyers should prepare detailed RFQs to receive accurate and competitive quotes from potential suppliers.

4. شروط التجارة الدولية (Incoterms)

Incoterms define the responsibilities of buyers and sellers in international shipping. They specify who is responsible for shipping costs, insurance, and liability during transit. Understanding Incoterms is crucial for buyers to mitigate risks and ensure smooth international transactions.

5. المهلة الزمنية

Lead time refers to the time it takes from placing an order to receiving the goods. In the alternator parts industry, lead times can vary significantly based on manufacturing capabilities and supply chain logistics. Buyers should consider lead times when planning their inventory and production schedules.

6. قطع غيار ما بعد البيع

Aftermarket parts are components made by companies other than the original manufacturer. While often more affordable, the quality can vary. Buyers should evaluate the specifications and reliability of aftermarket parts to ensure they meet performance standards.

Illustrative image related to parts to an alternator

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing alternator parts, ensuring compatibility, efficiency, and reliability in their applications.

Navigating Market Dynamics and Sourcing Trends in the parts to an alternator Sector

What Are the Key Market Drivers and Trends in the Parts to an Alternator Sector?

The global market for alternator parts is experiencing notable growth driven by several factors. Increasing vehicle production and sales, particularly in emerging markets like Africa and South America, are boosting the demand for alternators. Additionally, the shift toward electric and hybrid vehicles is reshaping the landscape, requiring innovative components that enhance energy efficiency. B2B buyers are increasingly seeking suppliers who can provide high-quality, durable parts that meet stringent automotive standards.

Emerging technologies such as IoT and AI are influencing sourcing trends within the sector. These technologies enable real-time monitoring and predictive maintenance, allowing manufacturers to optimize their inventory and reduce downtime. International B2B buyers are also leveraging e-commerce platforms for streamlined procurement processes, making it easier to compare suppliers and negotiate prices. Moreover, transparency in the supply chain is becoming a critical factor, with buyers prioritizing suppliers who can provide detailed sourcing information and certifications.

Illustrative image related to parts to an alternator

In regions like Europe and the Middle East, regulatory frameworks focused on emissions control and sustainability are prompting a demand for more efficient alternator components. This trend is pushing manufacturers to innovate, leading to the development of lightweight materials and advanced cooling systems that enhance performance and reduce environmental impact.

How Is Sustainability Shaping Sourcing Decisions for Alternator Parts?

Sustainability is increasingly becoming a cornerstone of sourcing strategies in the parts to an alternator sector. The environmental impact of automotive manufacturing and the urgency to combat climate change are driving buyers to seek out suppliers committed to ethical practices. Sustainable sourcing not only addresses regulatory requirements but also enhances brand reputation and customer loyalty.

Buyers are prioritizing suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 and adherence to green materials. This includes the use of recyclable materials in the production of alternator parts, such as aluminum and copper, which can significantly reduce waste and energy consumption. Furthermore, companies are focusing on the life cycle assessment of parts to ensure that environmental considerations are integrated at every stage of production.

Ethical supply chains are also under scrutiny, as buyers demand transparency regarding labor practices and sourcing methods. Adopting ethical sourcing practices can mitigate risks associated with supply chain disruptions and negative publicity. By aligning with suppliers who prioritize sustainability, B2B buyers can contribute to a more responsible automotive industry while ensuring compliance with global standards.

What Is the Historical Context of Alternator Parts for B2B Buyers?

The evolution of alternator parts can be traced back to the early 20th century when the first automotive electrical systems began to emerge. Initially, generators were used to power vehicles, but as electrical demands grew, the need for more efficient systems led to the development of the alternator in the 1960s. This transition marked a significant advancement in automotive technology, allowing for greater energy output and reduced reliance on mechanical components.

Over the decades, alternators have undergone significant improvements in design and functionality. The introduction of electronic voltage regulators and the use of advanced materials have enhanced their efficiency and durability. As vehicles have become more technologically advanced, so too have the components that power them, with modern alternators incorporating features such as integrated cooling systems and lightweight materials to improve performance.

For B2B buyers today, understanding the historical context of alternator parts is essential for navigating current market dynamics. Awareness of past innovations can inform sourcing decisions and help buyers identify suppliers who are at the forefront of technological advancements, ensuring they remain competitive in an evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of parts to an alternator

-

1. How do I solve issues with alternator part compatibility?

To resolve compatibility issues with alternator parts, first, ensure you have the correct specifications for your vehicle or equipment. Cross-reference the part numbers and dimensions with your existing components. Collaborate with your supplier to verify compatibility, as they often have extensive databases or catalogs. Consider using OEM (Original Equipment Manufacturer) parts for guaranteed fitment. If customizing parts, provide precise measurements and any specific requirements to your manufacturer to avoid further complications. -

2. What is the best way to identify quality alternator parts for international sourcing?

The best way to identify quality alternator parts is to source from reputable suppliers with a proven track record. Look for manufacturers that adhere to international quality standards, such as ISO certifications. Request samples to assess material quality and craftsmanship. Additionally, check customer reviews and testimonials to gauge satisfaction levels. Establish communication with suppliers to discuss their quality assurance processes and warranty offerings, which can also indicate reliability. -

3. What are the minimum order quantities (MOQs) for alternator parts?

Minimum order quantities (MOQs) for alternator parts can vary significantly by supplier and part type. Generally, MOQs can range from as low as 50 to several hundred units. When negotiating with suppliers, inquire if they offer flexible MOQs for first-time orders or if they can accommodate smaller batches for testing purposes. This flexibility can be crucial for new businesses or those looking to test market demand before committing to larger purchases. -

4. How can I ensure timely delivery of alternator parts in international trade?

To ensure timely delivery of alternator parts, establish clear timelines and deadlines with your supplier before placing an order. Utilize reliable logistics partners who specialize in international shipping and understand customs regulations in your target markets. Request regular updates on shipment status and consider using tracking services for transparency. Planning for potential delays, such as customs clearance, can also help mitigate risks associated with delivery timelines. -

5. What payment terms are common in international transactions for alternator parts?

Common payment terms in international transactions include options such as Letters of Credit (LC), advance payments, and net 30 or 60 days. It’s essential to discuss payment methods with your supplier upfront. Using escrow services can provide added security for both parties. Additionally, consider currency exchange rates and transaction fees associated with different payment methods, as these can impact overall costs. -

6. How do I vet suppliers for alternator parts effectively?

To effectively vet suppliers for alternator parts, conduct thorough research on their reputation and reliability. Check their business licenses, certifications, and industry affiliations. Request references from previous clients and follow up on their experiences. Visiting the supplier’s facility, if possible, can provide insights into their manufacturing processes. Additionally, assess their communication responsiveness and willingness to address your inquiries, as these factors often reflect their overall service quality. -

7. What customization options are available for alternator parts?

Customization options for alternator parts can include adjustments to dimensions, materials, and performance specifications. Many manufacturers offer tailored solutions to meet specific requirements, such as unique electrical outputs or enhanced durability. Discuss your needs with potential suppliers early in the sourcing process to understand their capabilities. Be prepared to provide detailed specifications and possibly prototype testing to ensure that the customized parts perform as intended. -

8. How can I implement quality assurance processes for alternator parts?

Implementing quality assurance processes for alternator parts involves setting clear quality criteria and inspection methods. Collaborate with your supplier to establish quality control measures, such as pre-production samples and in-process inspections. Utilize third-party inspection services to verify compliance with specifications before shipment. Regularly review and analyze defect rates and feedback from end-users to continually improve quality standards and supplier performance.

Top 4 Parts To An Alternator Manufacturers & Suppliers List

1. HowStuffWorks – Alternators Explained

المجال: auto.howstuffuffworks.com

مسجل: 1998 (27 سنة)

مقدمة: Alternators are small and lightweight, roughly the size of a coconut, constructed with an aluminum outer housing for heat dissipation and non-magnetization. Key components include: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L terminal (closes circuit to warning lamp), B terminal (main output to battery), and F terminal (full-field bypass for regulator…

2. Electude – Alternator Essentials

المجال: electude.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: المولد هو مكوّن أساسي في السيارات يقوم بتحويل الطاقة الميكانيكية إلى طاقة كهربائية، مما يولد الطاقة لوحدات الاستهلاك الكهربائية والبطارية في السيارة. وتشمل المكونات الرئيسية ما يلي:

1. Pulley: Transfers mechanical energy from the engine.

2. Rotor: Creates the magnetic field for generating alternating current.

3. Stator: The static part where voltage is generated.

4. Rectifier:…

3. Facebook – Key Components of an Alternator

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: This company, Facebook – Key Components of an Alternator, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. General Power – Alternator Parts

المجال: genpowerusa.com

تاريخ التسجيل: 2001 (24 عامًا)

مقدمة: Alternator Parts for Generators from General Power. Includes parts from various manufacturers such as STAMFORD, LEROY SOMER, and MARELLI. Key components include Alternator Stators, Bearing Kits, Diodes and Varistors, Droop Kits, Isolation Transformers, PMG, Rectifier Assembly Kits, Space Heaters, and Voltage Regulators. Voltage Regulators available for brands like Leroy Somer, Stamford, Marathon, …

Strategic Sourcing Conclusion and Outlook for parts to an alternator

In the dynamic landscape of alternator parts procurement, strategic sourcing emerges as a pivotal approach for international buyers. By understanding the intricate components—such as the rotor, stator, rectifier, and voltage regulator—businesses can make informed decisions that enhance operational efficiency and product reliability. Leveraging strategic sourcing not only ensures access to high-quality parts but also fosters relationships with suppliers that can lead to cost savings and innovative solutions.

For buyers in Africa, South America, the Middle East, and Europe, the importance of collaborating with reliable suppliers cannot be overstated. Investing time in researching and establishing partnerships with manufacturers who prioritize quality and compliance can significantly impact the longevity and performance of alternators in various applications.

Looking ahead, the global market for alternator parts will continue to evolve, driven by technological advancements and changing consumer demands. It is crucial for international B2B buyers to stay agile, adapt to market trends, and leverage strategic sourcing to ensure a competitive edge. Engage with trusted suppliers today to secure the best parts for your business needs and drive your operations forward.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.