Introduction: Navigating the Global Market for partes de un alternador

In today’s global marketplace, sourcing high-quality partes de un alternador (alternator parts) is a critical challenge for B2B buyers. With the automotive industry’s rapid evolution and increasing demand for reliable electrical systems, understanding the nuances of alternator components is essential. This guide delves into the various types of alternator parts, their specific applications, and the importance of thorough supplier vetting to ensure quality and compliance with international standards.

From the intricate workings of stators and rotors to the significance of regulators and rectifiers, each component plays a vital role in the overall performance of automotive electrical systems. For buyers in regions like Africa, South America, the Middle East, and Europe—including countries such as Nigeria and Germany—navigating this complex landscape can be daunting. This guide not only addresses the types and functions of alternator parts but also provides insights into cost considerations and best practices for procurement.

By equipping international B2B buyers with actionable knowledge, this resource empowers them to make informed purchasing decisions, fostering successful partnerships and enhancing operational efficiency. Whether you are looking to replace components or explore new suppliers, understanding the global market for alternator parts will be invaluable in securing the best products for your business needs.

جدول المحتويات

- Top 5 Partes De Un Alternador Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for partes de un alternador

- Understanding partes de un alternador Types and Variations

- Key Industrial Applications of partes de un alternador

- 3 Common User Pain Points for ‘partes de un alternador’ & Their Solutions

- Strategic Material Selection Guide for partes de un alternador

- In-depth Look: Manufacturing Processes and Quality Assurance for partes de un alternador

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘partes de un alternador’

- Comprehensive Cost and Pricing Analysis for partes de un alternador Sourcing

- Alternatives Analysis: Comparing partes de un alternador With Other Solutions

- Essential Technical Properties and Trade Terminology for partes de un alternador

- Navigating Market Dynamics and Sourcing Trends in the partes de un alternador Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of partes de un alternador

- Strategic Sourcing Conclusion and Outlook for partes de un alternador

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding partes de un alternador Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولدات التقليدية | Utilizes electromagnetic induction; typically includes rotor and stator. | Automotive, heavy machinery, generators | الإيجابيات: متوفر على نطاق واسع، فعال من حيث التكلفة. السلبيات: كفاءة محدودة عند عدد دورات منخفض في الدقيقة. |

| المولدات بدون فرش | No brushes; uses electronic components for excitation. | Renewable energy systems, aviation | الإيجابيات: Lower maintenance, higher efficiency. السلبيات: More expensive upfront. |

| مولدات كهربائية عالية الإنتاج | Designed to provide higher amperage output for demanding applications. | Performance vehicles, sound systems | الإيجابيات: يدعم الأحمال الكهربائية العالية. السلبيات: Requires careful installation and may be costly. |

| المولدات الذكية | Features advanced electronics for optimized performance and energy savings. | Hybrid vehicles, modern automotive | الإيجابيات: Enhanced fuel efficiency, adaptive charging. السلبيات: Complex systems may require specialized knowledge for repairs. |

| مولدات كهربائية بحرية | Built to withstand harsh marine environments; often waterproof. | Marine vessels, offshore equipment | الإيجابيات: Durable and corrosion-resistant. السلبيات: Higher price point due to specialized design. |

What are the Key Characteristics of Conventional Alternators?

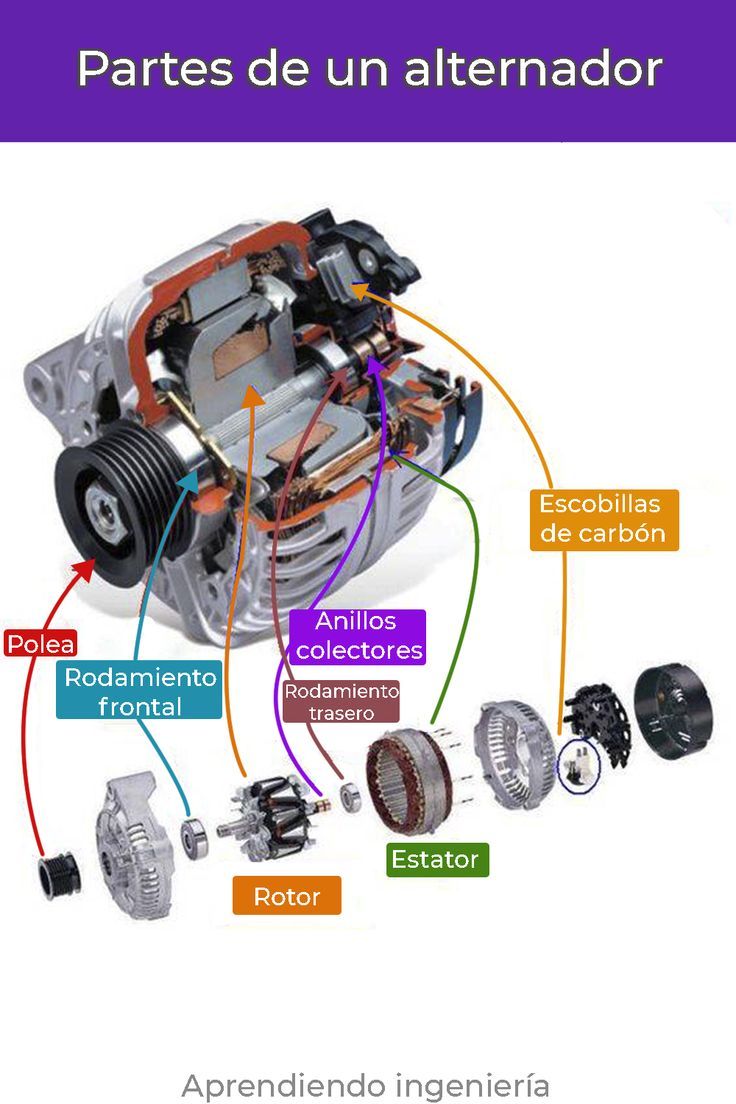

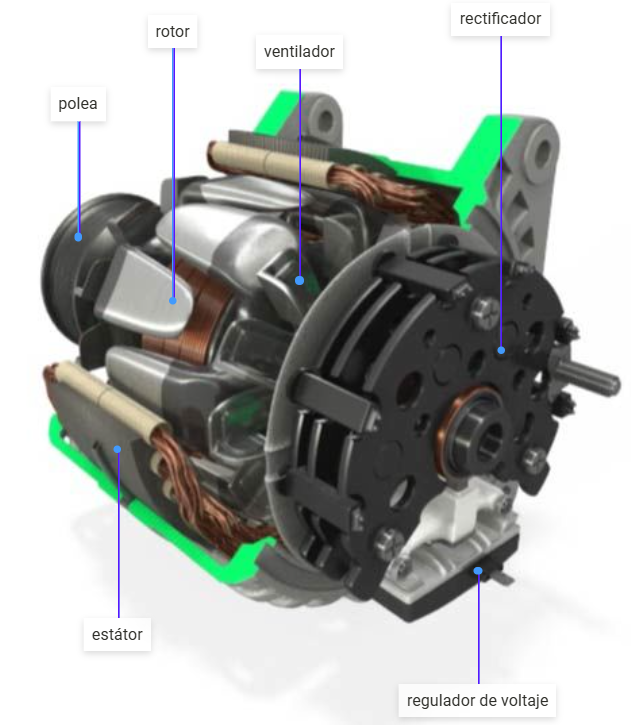

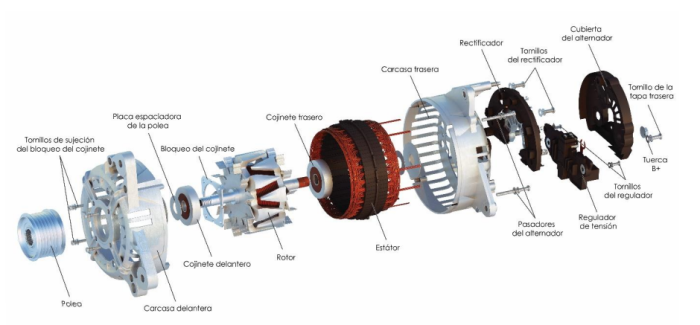

Conventional alternators are the most common type found in vehicles and machinery. They operate on the principle of electromagnetic induction, where a rotor spins within a stator to generate electricity. These alternators are usually easy to source and replace, making them a practical choice for many B2B applications. However, they may struggle to maintain efficiency at lower RPMs, which can be a consideration for industries requiring consistent power across varying speeds.

كيف تختلف المولدات بدون فرش عن الأنواع الأخرى؟

Brushless alternators eliminate the need for brushes by using electronic components for excitation. This design leads to reduced wear and tear, resulting in lower maintenance requirements. They are particularly suitable for renewable energy applications and aviation, where reliability is paramount. While the initial investment is higher, the long-term savings from reduced maintenance can make them an attractive option for businesses focused on operational efficiency.

What Are High-Output Alternators Best Suited For?

High-output alternators are engineered to deliver greater amperage, making them ideal for performance vehicles and applications with high electrical demands, such as advanced sound systems. They can support the additional load from aftermarket accessories, ensuring consistent power delivery. However, their installation may require specialized knowledge, and they typically come at a higher price point, which should be factored into purchasing decisions.

Why Consider Smart Alternators for Modern Applications?

Smart alternators integrate advanced electronics to optimize charging and enhance fuel efficiency in modern vehicles. They adjust their output based on the vehicle’s electrical needs, making them particularly useful in hybrid and electric vehicles. While they offer significant energy savings, the complexity of these systems may necessitate specialized training for maintenance and repairs, which could impact overall costs for businesses.

ما الذي يجعل المولدات البحرية فريدة من نوعها؟

Marine alternators are specifically designed to operate in harsh marine environments, featuring waterproof and corrosion-resistant designs. They are essential for powering equipment on boats and offshore platforms, where reliability is critical. Although they may have a higher upfront cost due to their specialized construction, the investment is justified by their durability and performance in demanding conditions.

Key Industrial Applications of partes de un alternador

| الصناعة/القطاع | Specific Application of partes de un alternador | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | إنتاج السيارات الكهربائية والهجينة | Enhances efficiency and sustainability of vehicle power systems | Quality certifications and compliance with international standards |

| الطاقة المتجددة | Power generation systems in solar and wind installations | Supports energy conversion, ensuring reliable electricity supply | Compatibility with existing systems and durability under harsh conditions |

| التعدين والمعدات الثقيلة | Alternators in heavy machinery for power generation | Ensures continuous operation and reduces downtime | Availability of replacement parts and robust performance under extreme conditions |

| البحرية والشحن | إمداد الطاقة للأنظمة الكهربائية على متن الطائرة | Critical for navigation, safety systems, and crew comfort | Corrosion resistance and compliance with maritime regulations |

| الاتصالات السلكية واللاسلكية | Power systems for communication towers | ضمان الخدمة المستمرة والموثوقية دون انقطاع | Sourcing from reliable suppliers with proven track records |

How Are ‘partes de un alternador’ Used in Automotive Manufacturing?

In the automotive manufacturing sector, ‘partes de un alternador’ play a crucial role in the production of electric and hybrid vehicles. These components, such as the rotor and stator, are essential for converting mechanical energy into electrical energy, powering vehicle systems efficiently. As the demand for sustainable transportation grows, manufacturers require high-quality alternator parts that comply with international standards to enhance vehicle performance and longevity. Buyers from regions like Germany and South America must ensure that sourced components meet rigorous quality certifications to maintain competitive advantage.

What Role Do ‘partes de un alternador’ Play in Renewable Energy?

In renewable energy applications, particularly in solar and wind installations, ‘partes de un alternador’ are integral to converting generated energy into usable electricity. The alternator’s efficiency directly impacts the overall energy conversion process, making its components critical for maintaining system reliability. International buyers, especially from Africa and the Middle East, should consider sourcing durable and compatible parts that can withstand environmental challenges, ensuring sustained operational efficiency in renewable energy systems.

How Are ‘partes de un alternador’ Applied in Mining and Heavy Equipment?

Within the mining and heavy equipment sector, ‘partes de un alternador’ are essential for the reliable power generation needed to operate machinery under extreme conditions. Components like the regulator and bearings must endure high levels of vibration and temperature, which are common in this industry. Buyers must prioritize sourcing robust and high-performance parts to minimize downtime and enhance the efficiency of their equipment, particularly in regions where operational reliability is paramount.

What Is the Importance of ‘partes de un alternador’ in Marine and Shipping Industries?

In the marine and shipping industries, ‘partes de un alternador’ are vital for the power supply of onboard electrical systems, which include navigation and safety equipment. The reliability of these components ensures that critical systems function without interruption, contributing to the safety and comfort of crew and passengers. Buyers in this sector should focus on sourcing corrosion-resistant parts that comply with maritime regulations, as the harsh marine environment can significantly impact component durability.

How Do ‘partes de un alternador’ Support Telecommunications Infrastructure?

For telecommunications, ‘partes de un alternador’ are fundamental in ensuring uninterrupted power supply to communication towers. These components help maintain reliable service, which is essential for connectivity in today’s digital age. Buyers must seek high-quality alternator parts that guarantee performance consistency, particularly in regions with unreliable power sources. Establishing relationships with trusted suppliers can ensure timely access to replacement parts, minimizing service disruptions.

3 Common User Pain Points for ‘partes de un alternador’ & Their Solutions

السيناريو 1: أعطال المولد المتكررة في مركبات الأسطول

المشكلة: B2B buyers managing fleets often face recurring issues with alternator failures, leading to unexpected downtime and increased maintenance costs. For example, a logistics company may experience consistent failures in alternators across multiple vehicles, disrupting operations and delaying deliveries. This not only affects customer satisfaction but also strains budgets due to the high costs associated with repairs and replacements.

الحل: To mitigate frequent alternator failures, it is crucial to analyze the root cause of the issues. This can often be traced back to subpar quality parts or incorrect installation. Buyers should prioritize sourcing high-quality components, such as those from reputable manufacturers like Valeo, which are designed to withstand harsh operating conditions. Establishing a preventive maintenance schedule that includes regular inspections of the alternator and its components—like the rotor and stator—can also help identify wear and tear before they lead to failures. Implementing training sessions for mechanics on proper installation techniques and maintenance can further reduce the likelihood of issues. Additionally, consider investing in diagnostic tools to monitor the health of alternators in real-time, allowing for proactive interventions.

Scenario 2: Difficulty Sourcing Compatible Alternator Parts

المشكلة: Many B2B buyers encounter challenges in finding compatible parts for alternators, particularly when dealing with vehicles from different manufacturers or older models. This difficulty can lead to prolonged downtime as teams search for the right components, ultimately affecting productivity and service delivery.

الحل: To streamline the sourcing process, buyers should develop a comprehensive parts catalog that includes detailed specifications for each vehicle type in their fleet. Collaborating with suppliers who have extensive inventories and can provide accurate compatibility information is vital. Utilizing online platforms that aggregate data from multiple suppliers can also enhance visibility into available parts. Moreover, establishing relationships with manufacturers who offer OEM and aftermarket parts ensures access to quality components tailored for specific applications. Additionally, leveraging technology such as inventory management systems can help track parts availability and expedite the ordering process, reducing lead times and improving overall efficiency.

Scenario 3: Understanding the Technical Specifications of Alternator Components

المشكلة: B2B buyers often struggle with understanding the technical specifications of alternator components, such as the role of the rectifier or the importance of the voltage regulator. This lack of knowledge can lead to incorrect part selection, resulting in poor performance and potential damage to the vehicle’s electrical system.

الحل: To empower buyers with the necessary knowledge, it is essential to provide comprehensive training and resources. This can include detailed product guides, technical workshops, and online webinars that explain the functions and specifications of each alternator component. Buyers should also invest in consulting with experts or engineers who can provide insights into the latest advancements in alternator technology and how they impact performance. Encouraging collaboration among teams—such as mechanics and procurement—can facilitate better decision-making when it comes to selecting parts. Furthermore, creating a centralized knowledge base where all team members can access information about alternator components and their specifications can enhance understanding and reduce errors in sourcing decisions.

Strategic Material Selection Guide for partes de un alternador

What are the Key Materials Used in Alternator Components?

When selecting materials for alternator parts, it is essential to consider their properties, advantages, and limitations in relation to performance, cost, and manufacturing complexity. Here, we analyze four common materials used in the manufacturing of alternator components: aluminum, copper, steel, and plastic.

How Does Aluminum Perform in Alternator Components?

Aluminum is widely used for various components of alternators, including the housing and some internal parts. Its key properties include lightweight, excellent corrosion resistance, and good thermal conductivity. These attributes make aluminum a preferred choice for applications where weight reduction and heat dissipation are critical.

الإيجابيات: The lightweight nature of aluminum contributes to overall vehicle efficiency, enhancing fuel economy. Its corrosion resistance extends the lifespan of components, reducing maintenance costs.

السلبيات: While aluminum is durable, it may not withstand high mechanical stresses as effectively as some other metals. Additionally, the manufacturing process can be more complex, leading to higher production costs.

التأثير على التطبيق: Aluminum is compatible with various media, including oils and coolants, making it suitable for automotive applications. However, it may require protective coatings in environments with extreme corrosion potential.

ما الدور الذي يلعبه النحاس في كفاءة المولد؟

Copper is primarily used in the windings of the stator and rotor due to its exceptional electrical conductivity. This property is crucial for efficient energy transfer within the alternator.

الإيجابيات: Copper’s high conductivity ensures minimal energy loss, improving the overall efficiency of the alternator. Its durability and resistance to thermal degradation enhance the longevity of electrical components.

السلبيات: Copper is relatively expensive compared to other materials, which can increase the overall cost of alternator production. Additionally, it is prone to corrosion if not properly insulated or coated.

التأثير على التطبيق: Copper is highly compatible with electrical applications, making it ideal for high-performance alternators. International buyers should ensure compliance with electrical standards, such as ASTM and DIN, particularly regarding wire gauge and insulation.

Why is Steel Important for Structural Components in Alternators?

Steel is commonly used for structural components like the frame and supports of alternators. Its key properties include high tensile strength, durability, and resistance to deformation under load.

الإيجابيات: The strength of steel allows for robust construction, ensuring that alternators can withstand high levels of vibration and stress. This durability translates to a longer service life.

السلبيات: Steel is heavier than aluminum, which can negatively impact vehicle weight and fuel efficiency. Additionally, it is susceptible to corrosion, requiring protective coatings or treatments.

التأثير على التطبيق: Steel components are essential for maintaining structural integrity under demanding conditions. Buyers in regions with high humidity or saline environments should prioritize corrosion-resistant coatings to extend the lifespan of steel parts.

Illustrative image related to partes de un alternador

How Does Plastic Contribute to the Functionality of Alternators?

Plastic is often used for non-structural components such as covers and insulators. Its key properties include lightweight, good insulation, and resistance to chemical exposure.

الإيجابيات: The use of plastic helps reduce the overall weight of the alternator, contributing to improved vehicle efficiency. Its insulating properties prevent electrical shorts and enhance safety.

السلبيات: While plastic is resistant to many chemicals, it may not withstand high temperatures as effectively as metals. Additionally, certain plastics can become brittle over time, leading to potential failures.

التأثير على التطبيق: Plastic components must be carefully selected to ensure compatibility with oils and other automotive fluids. International buyers should consider material certifications to meet local standards and regulations.

جدول تلخيصي لاختيار المواد لأجزاء المولدات

| المواد | Typical Use Case for partes de un alternador | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | Housing, internal components | خفيف الوزن ومقاوم للتآكل | Less effective under high mechanical stress | متوسط |

| النحاس | Stator and rotor windings | موصلية كهربائية ممتازة | ارتفاع التكلفة واحتمالية التآكل | عالية |

| الصلب | المكونات الهيكلية | High tensile strength and durability | أثقل وزناً وعرضة للتآكل | متوسط |

| بلاستيك | الأغطية والعوازل | خفيف الوزن وعزل جيد | Limited temperature resistance and potential brittleness | منخفض |

This strategic material selection guide provides valuable insights for B2B buyers looking to source alternator components. By understanding the properties and applications of each material, companies can make informed decisions that align with their performance, cost, and compliance requirements.

Illustrative image related to partes de un alternador

In-depth Look: Manufacturing Processes and Quality Assurance for partes de un alternador

What Are the Main Stages in the Manufacturing Process of Alternator Parts?

The manufacturing process for alternator parts involves several key stages that ensure the quality and functionality of the final product. Understanding these stages is crucial for B2B buyers who are looking for reliable suppliers.

-

تحضير المواد: The first step involves sourcing high-quality raw materials such as copper for windings, aluminum for casings, and specialized steel for bearings. Suppliers often use techniques such as chemical analysis and mechanical testing to verify material properties, ensuring they meet the required specifications for durability and conductivity.

-

تشكيل: During this stage, raw materials are shaped into components using various techniques like die casting, stamping, and machining. For example, the rotor and stator cores are typically stamped from laminated sheets of electrical steel to minimize energy losses. Precision in this stage is critical, as any defects can lead to inefficiencies in performance.

-

الجمعية: Once the components are formed, they undergo assembly. This can involve manual labor or automated processes, depending on the scale of production. Key components like the rotor, stator, and rectifier are assembled with precision to ensure optimal alignment and functionality. The assembly process often incorporates the use of fixtures and jigs to maintain quality.

-

التشطيب: The final stage involves surface treatments, such as anodizing or coating, to enhance corrosion resistance and improve aesthetics. This is also the stage where components are subjected to electrical testing to ensure they meet performance standards. Proper finishing techniques help in extending the lifecycle of the alternator parts and reducing maintenance needs.

ما هي معايير ضمان الجودة التي يجب أن يأخذها مشترو B2B بعين الاعتبار؟

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding quality assurance standards is essential for making informed purchasing decisions. Here are the relevant standards and checkpoints:

-

المعايير الدولية: Adherence to ISO 9001 standards is a must for manufacturers. This certification demonstrates a commitment to quality management systems and continuous improvement. Additionally, certifications such as CE mark (for European markets) and API (for specific automotive applications) are indicators of compliance with industry regulations.

-

نقاط مراقبة الجودة: Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

– مراقبة الجودة الواردة (IQC): This step checks the quality of raw materials before they enter the production line. Suppliers typically perform visual inspections and material testing to ensure compliance with specifications.

– مراقبة الجودة أثناء الإنتاج (IPQC): During the manufacturing process, various tests are conducted to ensure that components are being produced according to the required standards. This can involve dimensional checks and functional tests.

– مراقبة الجودة النهائية (FQC): Once assembly is complete, final inspections are performed to verify that the assembled alternator parts meet all design and performance specifications. This may include testing electrical performance, mechanical strength, and visual inspections for defects.

What Testing Methods Are Commonly Used in the Manufacturing of Alternator Parts?

A variety of testing methods are employed to ensure the quality and performance of alternator parts. B2B buyers should be aware of these methods to better assess supplier capabilities:

-

الاختبارات الكهربائية: This includes testing for insulation resistance, voltage output, and current draw. These tests help ensure that the alternator will perform efficiently under load conditions.

-

الاختبارات الميكانيكية: Mechanical properties are evaluated through tensile tests, hardness tests, and fatigue testing. These assessments ensure that components can withstand operational stresses and vibrations.

-

اختبار البيئة: Components may undergo environmental testing to simulate conditions such as temperature extremes, humidity, and exposure to corrosive substances. This testing is vital for ensuring long-term reliability, especially for buyers in harsher climates.

-

الاختبارات غير المدمرة (NDT): Techniques such as ultrasonic testing, magnetic particle inspection, and dye penetrant testing are used to detect internal and surface defects without damaging the components. This is particularly important for critical components like rotors and stators.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

When sourcing alternator parts, B2B buyers should take proactive steps to verify the quality control processes of potential suppliers:

-

تدقيق الموردين: Conducting regular audits of suppliers can provide insight into their manufacturing processes and adherence to quality standards. This includes reviewing documentation, interviewing staff, and observing production practices.

-

طلب تقارير الجودة: Buyers should ask for quality assurance reports that outline testing results, certifications, and compliance with international standards. These reports can provide transparency and confidence in the supplier’s capabilities.

-

عمليات التفتيش من قبل أطراف ثالثة: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages of production, offering additional assurance of product quality.

-

Understanding Quality Control Nuances: Buyers should be aware that different regions may have varying quality standards and practices. For instance, European suppliers may emphasize compliance with CE marking, while suppliers in other regions may focus on different certifications. Understanding these nuances can aid in selecting the right supplier.

Conclusion: The Importance of Quality Assurance in the Alternator Parts Supply Chain

For B2B buyers sourcing alternator parts, a comprehensive understanding of manufacturing processes and quality assurance practices is essential. By focusing on material preparation, forming, assembly, and finishing stages, as well as adhering to international quality standards, buyers can ensure they select suppliers that meet their performance and reliability needs. Engaging in audits, requesting quality reports, and utilizing third-party inspections will further enhance the confidence in the quality of the alternator parts being procured.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘partes de un alternador’

In the competitive landscape of B2B procurement, sourcing quality components for alternators is essential for ensuring operational efficiency and reliability. This checklist serves as a practical guide for international buyers looking to procure ‘partes de un alternador’. By following these steps, you can streamline your sourcing process and secure high-quality products that meet your specific needs.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Before initiating the sourcing process, it’s crucial to clearly outline the technical requirements for the alternator parts you need. This includes understanding the specifications of each component, such as size, material, and compatibility with existing systems.

– Key Points to Consider:

– Identify the make and model of the alternator.

– Determine the performance standards required for your application.

الخطوة 2: إجراء أبحاث السوق

Investigate the market to identify potential suppliers and understand the pricing landscape. This research will help you gauge the average costs and quality standards in the industry.

– بنود العمل:

– Explore online platforms and trade shows relevant to automotive components.

– Analyze competitors’ sourcing strategies to identify best practices.

الخطوة 3: تقييم الموردين المحتملين

Thoroughly vet suppliers before making any commitments. Assess their capabilities, reputation, and product offerings to ensure they align with your technical needs.

– ما الذي يجب البحث عنه:

– Request company profiles, certifications, and references from other clients.

– Check for experience in supplying parts specific to your industry or region.

الخطوة 4: التحقق من شهادات الموردين

Ensure that the suppliers hold relevant certifications that demonstrate their compliance with international quality standards. This is vital for maintaining the integrity and safety of your products.

– Certification Examples:

– ISO 9001 for quality management systems.

– Specific automotive industry standards such as IATF 16949.

الخطوة 5: طلب عينات أو نماذج أولية

Before placing a large order, request samples or prototypes of the alternator parts. This allows you to assess the quality and compatibility with your applications firsthand.

– Importance of This Step:

– Testing samples can help identify any potential issues before full-scale procurement.

– It provides an opportunity to evaluate the supplier’s responsiveness and quality control processes.

الخطوة 6: Establish Clear Terms and Conditions

Once you have selected a supplier, it’s essential to negotiate clear terms and conditions regarding pricing, delivery schedules, and warranty policies. This minimizes misunderstandings and protects your interests.

– نقاط التفاوض:

– Discuss payment terms and potential discounts for bulk orders.

– Clarify return policies and support services offered.

الخطوة 7: مراقبة أداء الموردين

After procurement, continuously monitor the supplier’s performance and the quality of the parts delivered. Establishing a feedback loop can help you maintain a strong relationship and ensure future orders meet your expectations.

– أفضل الممارسات:

– Conduct regular quality assessments of received parts.

– Maintain open communication with the supplier to address any concerns promptly.

By following this step-by-step checklist, B2B buyers can enhance their procurement process for alternator parts, ensuring they secure high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for partes de un alternador Sourcing

What Are the Key Cost Components in Sourcing Alternator Parts?

When sourcing parts for alternators, understanding the cost structure is essential for effective budget management. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

المواد: The choice of materials significantly impacts the cost. High-performance metals and composites used in components like rotors and stators can elevate expenses, while cheaper alternatives may affect durability and efficiency.

-

العمل: Labor costs vary based on the region and the complexity of the manufacturing process. Skilled labor is often required for precision assembly, especially for components like the bridge rectifier and voltage regulator.

-

تكاليف التصنيع العامة: This includes costs related to the manufacturing facility, equipment maintenance, and utilities. Efficient operations can reduce overhead, but this often requires initial investment in technology and training.

-

الأدوات: Specialized tooling for manufacturing specific alternator parts can be a significant upfront cost. However, these costs can be amortized over larger production runs, making them more manageable for bulk orders.

-

مراقبة الجودة: Ensuring that alternator parts meet international standards requires investment in quality control processes and testing equipment. This is particularly important for B2B buyers who require certifications for compliance.

-

اللوجستيات: Shipping costs can vary widely based on the origin of the parts, destination, and chosen Incoterms. International shipping can introduce additional costs, such as tariffs and insurance.

-

الهامش: Finally, suppliers will include a profit margin in their pricing. This margin can vary based on supplier reputation, market demand, and the competitive landscape.

What Factors Influence Pricing for Alternator Parts?

Several factors influence pricing beyond the basic cost structure, particularly for international B2B buyers:

-

الحجم والحد الأدنى لكمية الطلب (MOQ): Larger orders typically benefit from economies of scale, reducing the per-unit price. Negotiating lower MOQs can also lead to better pricing.

-

المواصفات والتخصيص: Custom parts or those with specific specifications usually come at a premium. Buyers should weigh the necessity of customization against potential cost savings of standard parts.

-

جودة المواد والشهادات: Higher quality materials and certifications (like ISO or TS standards) can increase costs but also ensure reliability and longevity, impacting the Total Cost of Ownership (TCO).

-

عوامل الموردين: The supplier’s reputation, reliability, and geographic location can affect pricing. Established suppliers may charge more but offer greater assurance in quality and delivery timelines.

-

مصطلحات التجارة الدولية: The choice of Incoterms can significantly impact the final cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, influencing overall pricing.

How Can Buyers Negotiate for Better Prices on Alternator Parts?

Negotiation is a critical skill for B2B buyers looking to optimize costs. Here are some effective strategies:

-

إجراء أبحاث السوق: Understanding market prices and competitor offerings can provide leverage in negotiations. Buyers should also be aware of current trends that may affect pricing.

-

بناء العلاقات: Establishing a strong relationship with suppliers can lead to better terms, including discounts or favorable payment conditions.

-

تقييم التكلفة الإجمالية للملكية (TCO): Consider not just the purchase price but also the TCO, which includes maintenance, operational efficiency, and the lifespan of the parts. A higher initial cost may be justified if it leads to lower long-term expenses.

-

Leverage Volume Purchases: If possible, consolidate orders across multiple projects to meet higher volume thresholds, which can lead to significant discounts.

-

Be Open to Alternatives: Be willing to explore different suppliers or materials that may offer similar performance at a lower cost.

ما هي الفروق الدقيقة في الأسعار بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

International buyers, particularly from Africa, South America, the Middle East, and Europe, face unique pricing challenges. Currency fluctuations, varying tariffs, and local market conditions can all influence costs. It’s crucial to account for these factors in negotiations and when planning budgets. Additionally, understanding local regulations regarding imports can help avoid unexpected expenses.

إخلاء المسؤولية: Prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate pricing tailored to your needs.

Alternatives Analysis: Comparing partes de un alternador With Other Solutions

Introduction to Alternatives in Alternator Components

In the automotive and industrial sectors, the efficiency and reliability of power generation systems are critical. While the traditional alternator, composed of various integral parts, has been the standard solution for converting mechanical energy into electrical energy, alternative technologies are emerging. This section explores viable alternatives to ‘partes de un alternador’, providing B2B buyers with insights to make informed decisions based on performance, cost, and application.

Comparison Table of Alternator Parts and Alternatives

| جانب المقارنة | Partes De Un Alternador | Alternative 1: Starter-Generator Systems | Alternative 2: Flywheel Energy Storage |

|---|---|---|---|

| الأداء | High efficiency, reliable power output | Moderate efficiency; dual function | High peak power, rapid response |

| التكلفة | Moderate initial cost, variable maintenance costs | استثمار أولي أعلى | High upfront cost, low operational costs |

| سهولة التنفيذ | Widely available and easy to install | More complex installation process | يتطلب تركيبًا متخصصًا |

| الصيانة | Regular maintenance needed for longevity | صيانة أقل بسبب قلة الأجزاء المتحركة | الحد الأدنى من الصيانة المطلوبة |

| أفضل حالة استخدام | تطبيقات السيارات القياسية | Hybrid vehicles and advanced start-stop systems | High-performance applications, energy recovery systems |

تفصيل البدائل

Alternative 1: Starter-Generator Systems

Starter-generator systems combine the functions of a starter motor and an alternator into one unit. They provide a dual function, allowing for both engine starting and power generation during operation. This system is particularly beneficial in hybrid vehicles where efficiency is paramount. However, while they offer moderate efficiency, the complexity of installation and higher initial costs may deter some buyers. They are best suited for applications requiring compactness and integrated functionality.

Alternative 2: Flywheel Energy Storage

Flywheel energy storage systems utilize kinetic energy stored in a rotating mass to provide power. These systems can deliver high peak power and respond rapidly to demand changes, making them ideal for high-performance applications or energy recovery systems. While they incur high upfront costs, they have low operational costs and minimal maintenance requirements. However, the need for specialized installation and potential space constraints can limit their use in standard automotive applications.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

When selecting between ‘partes de un alternador’ and its alternatives, B2B buyers should carefully assess their specific needs, including performance requirements, budget constraints, and maintenance capabilities. For traditional automotive applications, the reliable and established parts of an alternator may suffice. Conversely, for innovative projects like hybrid systems or high-performance applications, exploring starter-generator systems or flywheel energy storage could yield significant benefits. Ultimately, aligning the choice with operational goals and technical requirements will ensure a smart investment in power generation technology.

Essential Technical Properties and Trade Terminology for partes de un alternador

What Are the Key Technical Properties of Alternator Parts That B2B Buyers Should Know?

Understanding the technical specifications of alternator components is crucial for B2B buyers seeking quality and reliability. Here are several essential properties to consider:

-

درجة المواد: The materials used in alternator parts, such as aluminum for housings and copper for windings, significantly affect durability and performance. Higher-grade materials can withstand extreme temperatures and vibrations, reducing the risk of failure. For buyers, selecting parts with verified material specifications ensures longevity and efficiency in automotive applications.

-

مستويات التسامح: Tolerance refers to the allowable variation in dimensions during manufacturing. Tight tolerances are critical for components like the rotor and stator, where precise fit and alignment are necessary for optimal electrical performance. B2B buyers should prioritize suppliers who adhere to strict tolerance levels to avoid premature wear or malfunction.

-

تصنيف الأمبيرية: This specification indicates the maximum current an alternator can produce. It is essential for ensuring that the electrical system of the vehicle operates correctly. B2B buyers need to match the amperage rating of alternators with the requirements of the vehicles they service to prevent underperformance or damage to electrical components.

-

المقاومة الحرارية: Given the high temperatures that alternators can experience, thermal resistance is a key property. Components designed with thermal insulation or coatings can better handle heat, prolonging their lifespan. Buyers should seek parts that provide details on thermal resistance to ensure they can operate efficiently in varied climates.

-

Vibration Resistance: Alternators are subject to vibrations from the engine. Parts such as bearings and mounts need to be designed to withstand these forces to prevent failure. B2B buyers should inquire about vibration testing and certifications to ensure the reliability of the components they purchase.

What Are Common Trade Terms Used in the Alternator Parts Industry?

Familiarity with industry jargon helps B2B buyers navigate the procurement process more effectively. Here are some key terms:

Illustrative image related to partes de un alternador

-

OEM (الشركة المصنعة للمعدات الأصلية): This term refers to parts made by the original manufacturer of the vehicle. OEM parts are typically synonymous with quality and reliability. B2B buyers often prefer OEM components to maintain vehicle performance and warranty coverage.

-

MOQ (الحد الأدنى لكمية الطلب): MOQ indicates the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ is essential for budgeting and inventory management. Buyers should negotiate MOQs to align with their purchasing capabilities and market demands.

-

طلب عرض أسعار (RFQ): An RFQ is a document sent to suppliers to obtain pricing and terms for specific parts. This process helps buyers compare costs and terms from multiple vendors, ensuring they receive the best value for their purchases.

-

شروط التجارة الدولية (Incoterms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and delivery responsibilities, facilitating smoother international procurement.

-

سوق ما بعد البيع: This term refers to parts and accessories not made by the OEM but compatible with their vehicles. The aftermarket can offer cost-effective alternatives, and understanding this segment is crucial for buyers looking to expand their product offerings or reduce costs.

-

فترة الضمان: This specifies the duration during which a part is guaranteed against defects. A longer warranty period often indicates greater confidence in product quality. B2B buyers should consider warranty terms as part of their purchasing decision to safeguard their investments.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternator parts, ensuring they choose high-quality components that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the partes de un alternador Sector

Market Overview & Key Trends in the partes de un alternador Sector

The global alternator parts market is currently driven by the increasing demand for automotive components, particularly in regions like Africa, South America, the Middle East, and Europe. As countries in these areas experience economic growth and urbanization, the number of vehicles on the road continues to rise, leading to a higher demand for reliable and efficient alternator parts. In Nigeria, for example, the automotive sector is witnessing rapid expansion, thus creating opportunities for B2B buyers to source high-quality components.

Emerging trends in B2B sourcing for alternator parts include the adoption of advanced technologies such as predictive analytics and artificial intelligence. These tools help suppliers optimize inventory management and streamline logistics, ensuring timely delivery and reducing costs for buyers. Furthermore, there is a growing emphasis on digital platforms for sourcing, with many suppliers enhancing their online presence to facilitate easier access to product information and availability.

Illustrative image related to partes de un alternador

Market dynamics are also influenced by the shift towards electric and hybrid vehicles. As automakers transition to these technologies, the demand for specialized alternator parts, such as those designed for high-performance electric alternators, is likely to grow. B2B buyers should stay informed about the latest technological advancements in the sector to ensure they are sourcing parts that meet the evolving needs of the automotive market.

What is the Importance of Sustainability & Ethical Sourcing in B2B for partes de un alternador?

Sustainability has become a critical focus in the automotive industry, affecting sourcing practices for alternator parts. The environmental impact of manufacturing processes, including resource extraction and waste generation, is prompting B2B buyers to prioritize suppliers that demonstrate a commitment to sustainable practices. This includes sourcing materials that are recyclable or made from renewable resources, which not only reduces the ecological footprint but also appeals to environmentally conscious consumers.

Ethical sourcing is equally important, as buyers increasingly seek to ensure that their supply chains are free from human rights abuses and environmental degradation. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers looking to gain a competitive edge. B2B buyers should inquire about these certifications when evaluating potential partners to ensure they align with their values and compliance requirements.

Incorporating sustainability and ethical considerations into sourcing strategies not only enhances brand reputation but can also lead to long-term cost savings through improved efficiency and waste reduction. As the global market evolves, prioritizing these aspects will be key for B2B buyers in the partes de un alternador sector.

How Has the partes de un alternador Sector Evolved Over Time?

The evolution of the alternator parts sector reflects broader changes in automotive technology and consumer demands. Initially, alternators were primarily mechanical devices, but advancements in electronics have transformed them into sophisticated components capable of efficiently managing vehicle electrical systems. This shift has necessitated the development of more advanced parts, such as high-performance rotors and durable regulators, to accommodate the increasing electrical demands of modern vehicles.

Furthermore, globalization has played a significant role in shaping the market, enabling suppliers from various regions to compete on a larger scale. B2B buyers now have access to a diverse range of products, allowing them to source high-quality parts from different manufacturers worldwide. This evolution presents both opportunities and challenges, as buyers must navigate a complex landscape of suppliers while ensuring quality and compliance with international standards.

In summary, the partes de un alternador sector has undergone significant transformation driven by technological advancements, market demands, and a heightened focus on sustainability. For B2B buyers, understanding these trends is essential for making informed sourcing decisions that align with their business objectives and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of partes de un alternador

-

How do I solve issues with the alternator components?

To address problems with alternator parts, first diagnose the specific component. Common issues include worn-out bearings, damaged stators, or faulty regulators. Inspect the alternator for signs of overheating, unusual noises, or electrical failures. It’s advisable to consult with a certified technician or refer to the manufacturer’s guidelines for troubleshooting. Additionally, sourcing high-quality replacement parts from reputable suppliers can help prevent recurrent issues and ensure optimal performance. -

What is the best material for alternator parts in harsh environments?

For alternator components exposed to harsh conditions, such as high humidity or extreme temperatures, materials like zinc-nickel or cataforesis-coated metals are recommended. These materials provide enhanced corrosion resistance and durability, reducing wear and tear. When sourcing parts, ensure that the supplier offers products specifically designed for your operating environment, as this can significantly extend the lifespan of the alternator and reduce maintenance costs. -

How can I verify the quality of alternator parts before purchasing?

To ensure the quality of alternator parts, request certifications and test reports from suppliers. Look for parts that meet international quality standards, such as ISO certifications. Additionally, consider suppliers who offer warranties or guarantees on their products, as this demonstrates confidence in their quality. Reading customer reviews and testimonials can also provide insight into the reliability and performance of the parts. -

What are the minimum order quantities (MOQs) for alternator parts?

Minimum order quantities for alternator parts can vary significantly among suppliers. Some manufacturers may offer flexible MOQs for smaller businesses, while others may require bulk orders to maintain competitive pricing. It’s advisable to discuss your specific needs with potential suppliers and negotiate MOQs based on your purchasing capacity and market demand. This flexibility can facilitate better cash flow management for your business. -

ما هي شروط الدفع التي يجب أن أتوقعها عند الحصول على قطع غيار المولدات على المستوى الدولي؟

Payment terms for international purchases of alternator parts typically include options such as letters of credit, wire transfers, or payment upon delivery. It’s crucial to clarify these terms upfront with your supplier to avoid any misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees. Establishing a reliable payment method that protects both parties can enhance trust and streamline the purchasing process. -

How can I ensure timely delivery of alternator parts from international suppliers?

To ensure timely delivery, select suppliers with a proven track record in logistics and distribution. Discuss shipping options and timelines upfront, and consider using freight forwarders who specialize in international shipping. Tracking shipments and setting clear expectations regarding delivery dates can mitigate delays. Additionally, building a strong relationship with your supplier can facilitate smoother communication and quicker resolution of any shipping issues that may arise. -

What customization options are available for alternator parts?

Many suppliers offer customization options for alternator parts to meet specific requirements. This can include modifications in size, material, or electrical specifications. When discussing customization, be clear about your needs and any industry standards that must be met. Custom parts may have different lead times and costs, so factor these into your planning. Engaging in early discussions with suppliers can help streamline the customization process. -

How do I evaluate potential suppliers of alternator parts?

Evaluating suppliers involves assessing their manufacturing capabilities, quality control processes, and reputation in the market. Request samples of their products to inspect quality firsthand. It’s also beneficial to check their compliance with industry standards and certifications. Additionally, consider their responsiveness to inquiries and willingness to collaborate on specific needs. Building a relationship with a reliable supplier can lead to better service and preferential terms in the long run.

Top 5 Partes De Un Alternador Manufacturers & Suppliers List

1. Valeo – Componentes del Alternador

المجال: valeoservice.com.br

مسجل: 2000 (25 سنة)

مقدمة: Componentes del Alternador de Valeo: 1. Polea: Conecta el alternador al motor a través de la correa, transmite el movimiento. 2. Cojinete Frontal: Soporte para el rotor y estator, asegura la fijación mecánica. 3. Estator: Genera corriente, contiene tres bobinas sujetas al campo magnético del rotor. 4. Rotor: Genera un campo electromagnético que induce corriente alterna en el estator. 5. Puente Rec…

2. Electude – Alternador Essentials

المجال: electude.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: Un alternador es un componente crucial en los sistemas automotrices que convierte energía mecánica en energía eléctrica. Sus componentes principales incluyen: 1. Polea: Transfiere energía mecánica del motor al alternador. 2. Rotor: Crea el campo magnético para generar corriente alterna. 3. Estator: Parte estática donde se genera la tensión. 4. Rectificador: Convierte corriente alterna en corriente…

3. Facebook – Componentes del Alternador

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: Componentes principales del alternador: Polea, Rotor, Estator o inducido, Rectificador de diodos, Regulador de voltaje, Rodamientos, Carcasa y carcasa exterior. Dato técnico: Un fallo en el regulador o en el rectificador puede causar sobretensión, dañando la ECU y otros componentes electrónicos.

4. Autoavance – Alternador Esencial

المجال: autoavance.co

مسجل: 2011 (14 سنة)

مقدمة: El alternador es un componente clave en vehículos, encargado de generar energía eléctrica para recargar la batería y alimentar sistemas eléctricos mientras el motor está en funcionamiento. Regula la tensión de salida entre 13.5 y 14.5 V. Sus partes principales incluyen: 1. Rotor: actúa como electroimán móvil, conectado al cigüeñal. 2. Estator: conjunto de bobinas fijas que inducen corriente altern…

5. Servicios Globales – Alternador Components

المجال: serviciosglobales.es

مقدمة: Partes del Alternador: 1. Rotor: Parte giratoria con bobinas y núcleos magnéticos. 2. Estator: Parte fija con bobinas que genera corriente eléctrica. 3. Puente Rectificador: Convierte corriente alterna (CA) a corriente continua (CC) mediante diodos. 4. Regulador de Voltaje: Controla la energía generada y mantiene voltaje constante. 5. Polea: Conectada al eje del rotor, impulsada por la correa del …

Strategic Sourcing Conclusion and Outlook for partes de un alternador

As we conclude our exploration of ‘partes de un alternador,’ it is essential to highlight the strategic importance of sourcing these components efficiently. Understanding the roles of each part—from the rotor and stator to the regulator—enables businesses to make informed purchasing decisions. Prioritizing quality and compatibility can significantly enhance the performance and durability of alternators, ultimately leading to reduced maintenance costs and improved customer satisfaction.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, strategic sourcing is not merely a process; it is a competitive advantage. By fostering relationships with reliable suppliers and leveraging regional manufacturing capabilities, businesses can ensure a consistent supply of high-quality parts while optimizing costs.

Looking ahead, the automotive industry is increasingly moving towards sustainability and innovation. Engage with suppliers who are committed to eco-friendly practices and cutting-edge technologies. This proactive approach will not only enhance your product offerings but also position your business favorably in a rapidly evolving market. Take the next step in your sourcing strategy—connect with industry leaders and explore opportunities for collaboration that can drive mutual growth and success.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.