Introduction: Navigating the Global Market for starter motor price

In the dynamic landscape of global commerce, sourcing starter motors at competitive prices poses a significant challenge for international B2B buyers. The complexities of pricing, influenced by factors such as manufacturing origin, technological specifications, and market demand, can leave businesses in regions like Nigeria, Germany, and Brazil feeling overwhelmed. This guide delves into the multifaceted world of starter motor prices, providing a thorough exploration of various types, applications, and the critical factors influencing cost.

From understanding the differences between new and remanufactured units to evaluating essential features like kW ratings and voltage specifications, this guide equips buyers with the knowledge needed to make informed purchasing decisions. It also addresses the crucial aspect of supplier vetting, offering strategies to identify reliable manufacturers and distributors in diverse markets across Africa, South America, the Middle East, and Europe. By leveraging this comprehensive resource, businesses can navigate the complexities of the starter motor market with confidence, ultimately leading to better procurement practices and enhanced operational efficiency.

With actionable insights and expert analysis, this guide is designed to empower B2B buyers to not only understand starter motor pricing but also to optimize their sourcing strategies, ensuring they secure the best value for their investments in this critical automotive component.

جدول المحتويات

- Top 3 Starter Motor Price Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for starter motor price

- Understanding starter motor price Types and Variations

- Key Industrial Applications of starter motor price

- 3 Common User Pain Points for ‘starter motor price’ & Their Solutions

- Strategic Material Selection Guide for starter motor price

- In-depth Look: Manufacturing Processes and Quality Assurance for starter motor price

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor price’

- Comprehensive Cost and Pricing Analysis for starter motor price Sourcing

- Alternatives Analysis: Comparing starter motor price With Other Solutions

- Essential Technical Properties and Trade Terminology for starter motor price

- Navigating Market Dynamics and Sourcing Trends in the starter motor price Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of starter motor price

- Strategic Sourcing Conclusion and Outlook for starter motor price

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding starter motor price Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| New Starter Motors | Brand new components, often with warranties | تصنيع السيارات، خدمات أساطيل السيارات | الإيجابيات: High reliability, long lifespan. السلبيات: تكلفة أولية أعلى. |

| Remanufactured Motors | أعيد بناؤها من قطع مستعملة، وتم اختبارها للتأكد من جودتها | Repair shops, automotive aftermarket | الإيجابيات: Cost-effective, good quality assurance. السلبيات: عمر افتراضي أقصر من الجديد. |

| مشغلات تخفيض التروس | Enhanced torque output, compact design | Heavy machinery, performance vehicles | الإيجابيات: Efficient power use, smaller size. السلبيات: Can be more expensive. |

| المشغلات المغناطيسية الدائمة | Uses permanent magnets for lighter weight and size | Electric vehicles, compact engines | الإيجابيات: خفيفة الوزن وفعالة. السلبيات: Limited power for larger engines. |

| High Torque Starters | مصممة للتطبيقات عالية الأداء | السباق، المركبات الثقيلة | الإيجابيات: Exceptional starting power. السلبيات: Typically more costly and heavier. |

What are the Characteristics of New Starter Motors?

New starter motors are built from brand new components, ensuring maximum reliability and performance. They come with warranties, which can be a significant advantage for B2B buyers concerned about long-term investments. These motors are particularly suitable for automotive manufacturers and fleet services where reliability is paramount. However, the higher initial cost may deter some buyers, especially in markets sensitive to price.

How Do Remanufactured Motors Compare for B2B Buyers?

Remanufactured starter motors are an economical alternative to new units. They are rebuilt from used parts and undergo rigorous testing to meet quality standards. This type is ideal for repair shops and the automotive aftermarket, where cost-effectiveness is crucial. While they offer good quality assurance, buyers should be aware that their lifespan may not match that of new motors, which can lead to more frequent replacements.

Why Choose Gear Reduction Starters for Heavy Machinery?

Gear reduction starters are designed to provide enhanced torque output in a compact form factor. This makes them ideal for heavy machinery and performance vehicles that require efficient power delivery. B2B buyers in these sectors benefit from the efficiency and space-saving design, although the cost may be higher compared to standard options. The performance advantage often justifies the investment for businesses focused on productivity.

What are the Advantages of Permanent Magnet Starters?

Permanent magnet starters leverage lightweight materials and design, making them suitable for electric vehicles and compact engines. Their efficiency and reduced weight can lead to improved fuel economy and performance. However, they may not provide sufficient power for larger engines, which is a consideration for buyers in traditional automotive sectors. The trade-off between weight and power output is crucial in making a purchasing decision.

How Do High Torque Starters Benefit Racing and Heavy-Duty Applications?

High torque starters are engineered for high-performance applications, delivering exceptional starting power crucial in racing and heavy-duty vehicles. They are designed to handle the demands of engines that require quick and reliable starts under extreme conditions. While they offer significant advantages, their higher cost and weight may be a concern for some buyers. Understanding the specific needs of the application will help determine if the investment is justified.

Key Industrial Applications of starter motor price

| الصناعة/القطاع | Specific Application of starter motor price | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | إنتاج المركبات وخطوط التجميع | Reduces downtime and improves efficiency | Quality assurance, compatibility with various vehicle models, and bulk pricing options. |

| الزراعة | Tractors and heavy machinery | Ensures reliable start-up in remote locations | Weather-resistant components, local availability, and service support. |

| البناء | Heavy construction equipment | Enhances operational uptime on job sites | Durability under harsh conditions, warranty terms, and availability of parts for maintenance. |

| بحري | Boats and ships | Critical for starting engines in marine applications | Corrosion resistance, voltage specifications, and compliance with marine regulations. |

| التعدين | Equipment such as excavators and trucks | Vital for efficient operation in challenging terrains | Robustness, power ratings, and sourcing from reliable manufacturers to ensure performance. |

How is ‘starter motor price’ utilized in the automotive manufacturing sector?

In the automotive manufacturing sector, starter motors are essential for vehicle assembly lines, where they play a critical role in ensuring that engines start reliably and efficiently. The price of starter motors can significantly impact production costs, making it crucial for manufacturers to source competitively priced components without compromising quality. Buyers in this sector often look for suppliers that can provide bulk pricing, consistent supply, and compatibility with various vehicle models to minimize downtime and maintain production efficiency.

What role does ‘starter motor price’ play in agriculture?

In agriculture, starter motors are used in tractors and heavy machinery to ensure reliable operation, particularly in remote locations where conditions can be challenging. The price of starter motors is a key consideration for farmers and agricultural businesses, as it directly affects their operational costs. Buyers in this sector need to focus on sourcing weather-resistant components that can withstand harsh environments, as well as ensuring that service support is readily available for maintenance and repairs.

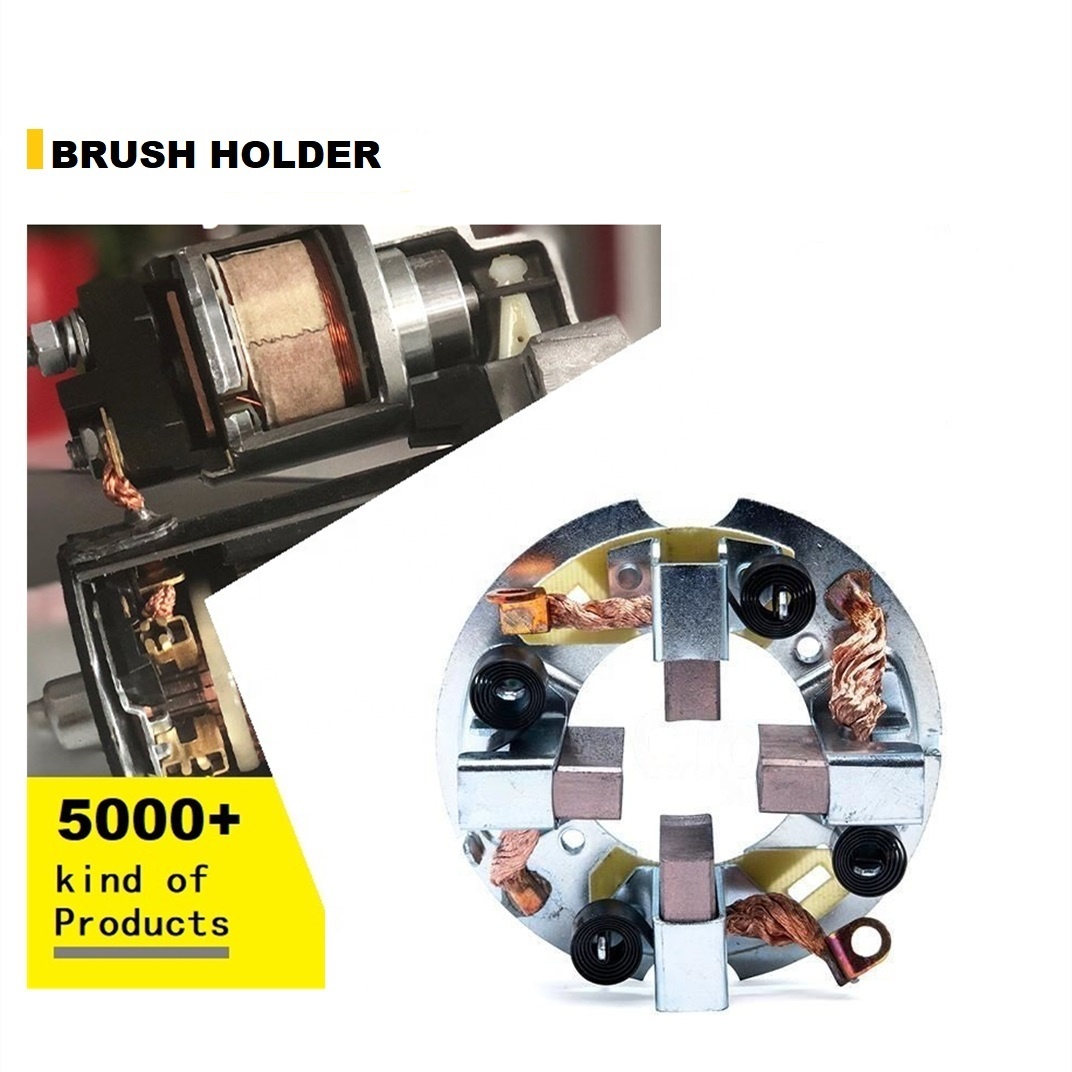

Illustrative image related to starter motor price

Why is ‘starter motor price’ important for construction equipment?

Starter motors are vital for heavy construction equipment, where reliable performance is essential for maintaining operational uptime on job sites. The price of starter motors can influence the overall cost of machinery, making it important for construction companies to evaluate sourcing options carefully. Durability under harsh conditions and favorable warranty terms are key considerations for buyers, as equipment failure can lead to costly delays and project overruns.

How does ‘starter motor price’ impact marine applications?

In the marine industry, starter motors are crucial for the reliable starting of engines in boats and ships. The price of starter motors is particularly significant due to the specialized requirements for marine applications, such as corrosion resistance and compliance with maritime regulations. Buyers in this sector must ensure that they source starter motors that meet specific voltage specifications and are capable of performing in challenging marine environments.

What are the sourcing considerations for ‘starter motor price’ in mining?

In the mining sector, starter motors are used in equipment like excavators and trucks, where their reliability is vital for efficient operation in challenging terrains. The price of starter motors can impact the overall operational budget for mining companies. Key sourcing considerations include the robustness of the motors, appropriate power ratings for heavy machinery, and establishing relationships with reliable manufacturers to ensure performance and availability of replacement parts.

3 Common User Pain Points for ‘starter motor price’ & Their Solutions

Scenario 1: Navigating Price Fluctuations in Starter Motors

المشكلة: B2B buyers often face the challenge of fluctuating prices for starter motors, which can significantly impact budgeting and forecasting. In regions such as Africa and South America, economic instability can lead to unpredictable pricing, making it difficult for companies to plan their procurement strategies. Buyers may find themselves caught off guard by sudden price increases, which can strain cash flow and disrupt supply chain operations.

Illustrative image related to starter motor price

الحل: To effectively navigate price fluctuations, B2B buyers should establish long-term relationships with multiple suppliers to gain insights into market trends and pricing forecasts. Regular communication with these suppliers can help buyers secure fixed pricing agreements or bulk purchase discounts, providing more predictable costs. Additionally, utilizing price monitoring tools can alert buyers to significant changes in starter motor prices, allowing them to act quickly to lock in lower rates. It’s also beneficial to conduct a market analysis to understand the factors influencing prices in specific regions, enabling more strategic purchasing decisions.

Scenario 2: Understanding Quality vs. Price Trade-offs

المشكلة: Another common issue for B2B buyers is the difficulty in balancing quality with price when sourcing starter motors. Lower-priced options might seem appealing, especially for cost-conscious buyers, but they may compromise on quality and durability, leading to higher long-term costs due to frequent replacements. Buyers in competitive markets, such as Europe, often struggle to justify the costs of higher-quality motors against the immediate savings of cheaper alternatives.

الحل: To address this dilemma, buyers should adopt a total cost of ownership (TCO) approach when evaluating starter motors. This involves considering not just the initial purchase price but also factors such as warranty duration, expected lifespan, and maintenance costs. Conducting a thorough supplier assessment that includes reviews of product reliability and performance can help buyers make informed decisions. Additionally, requesting samples or conducting pilot tests can provide firsthand experience with the product quality before committing to larger orders. Engaging in discussions with industry peers or attending trade shows can also provide valuable insights into the best-performing brands.

Scenario 3: Lack of Transparency in Pricing Structures

المشكلة: Many B2B buyers encounter a lack of transparency in the pricing structures of starter motors, leading to confusion and mistrust. This issue is particularly pronounced in regions with less regulated markets, where buyers may not fully understand what factors contribute to the final price. Unclear pricing can result in unexpected costs, making it challenging for businesses to stick to their budgets and undermining supplier relationships.

الحل: To combat this issue, buyers should seek suppliers who provide clear and comprehensive pricing breakdowns. This transparency can include details on base price, shipping costs, taxes, and any additional fees. When negotiating contracts, buyers should request itemized quotations and ensure that all terms are documented. Leveraging technology, such as procurement platforms that offer price comparisons across different suppliers, can also facilitate more informed purchasing decisions. Furthermore, fostering open communication with suppliers about pricing concerns can lead to better understanding and trust, ultimately benefiting the buyer-supplier relationship.

Strategic Material Selection Guide for starter motor price

What are the Key Materials Used in Starter Motor Manufacturing?

When selecting materials for starter motors, it’s essential to understand how these materials impact performance, durability, and overall cost. The most common materials used in starter motor construction include steel, aluminum, copper, and plastic. Each material has unique properties that can influence the final product’s price and suitability for specific applications.

How Does Steel Influence Starter Motor Performance and Cost?

Steel is a primary material used in the manufacturing of starter motor housings and components. It offers excellent strength and durability, making it capable of withstanding high temperatures and pressures. Additionally, steel has good corrosion resistance when properly treated, which is crucial for longevity in harsh environments.

الإيجابيات والسلبيات: The main advantage of steel is its robustness, which contributes to the overall durability of the starter motor. However, steel can be heavier than alternative materials, potentially impacting fuel efficiency in automotive applications. The manufacturing complexity can also be higher due to the need for additional processes like galvanization or coating to enhance corrosion resistance.

التأثير على التطبيق: Steel’s compatibility with various automotive fluids and its ability to handle high torque make it suitable for heavy-duty applications.

Illustrative image related to starter motor price

اعتبارات للمشترين الدوليين: Buyers from regions like Africa and the Middle East should ensure that the steel used meets local standards for corrosion resistance, particularly in humid or coastal environments. Compliance with ASTM standards is often preferred in these markets.

ما هو الدور الذي يلعبه الألومنيوم في تصميم محرك البادئ؟

Aluminum is increasingly used in starter motors due to its lightweight nature and good thermal conductivity. This material is particularly beneficial in applications where reducing weight is crucial, such as in electric vehicles.

الإيجابيات والسلبيات: The primary advantage of aluminum is its lightweight, which can enhance vehicle performance and efficiency. However, it is generally less durable than steel, making it more susceptible to wear and tear over time. The manufacturing process for aluminum can also be more complex and costly, impacting the overall price of the starter motor.

التأثير على التطبيق: Aluminum’s excellent heat dissipation properties make it ideal for applications that require efficient thermal management.

اعتبارات للمشترين الدوليين: Buyers in Europe, such as those in Germany, may prefer aluminum components due to stringent regulations on vehicle weight and emissions. Compliance with DIN standards is essential for ensuring quality and performance.

How Does Copper Contribute to Electrical Efficiency in Starter Motors?

Copper is a critical material for electrical components within starter motors, such as windings and connectors. Its high electrical conductivity ensures efficient power transfer, which is vital for the motor’s performance.

الإيجابيات والسلبيات: The key advantage of copper is its superior conductivity, which enhances the starter motor’s efficiency. However, copper is more expensive than alternatives like aluminum, which can significantly affect the starter motor’s overall price. Additionally, copper is prone to corrosion, necessitating protective coatings.

التأثير على التطبيق: Copper’s compatibility with high-current applications makes it ideal for starter motors, particularly in heavy-duty vehicles.

اعتبارات للمشترين الدوليين: Buyers from South America and Africa should consider the availability and cost of copper, as fluctuations in global markets can impact pricing. Compliance with local electrical standards is also crucial.

What is the Role of Plastic in Starter Motor Components?

Plastic is often used in non-structural components of starter motors, such as housings and insulation materials. It provides excellent resistance to corrosion and can be molded into complex shapes.

الإيجابيات والسلبيات: The main advantage of plastic is its lightweight nature and resistance to corrosion, which can enhance the overall lifespan of the starter motor. However, plastic is generally less durable than metals and may not withstand high temperatures as effectively.

التأثير على التطبيق: Plastic is suitable for applications where weight reduction and corrosion resistance are priorities.

اعتبارات للمشترين الدوليين: Buyers in regions with high humidity or extreme temperatures should ensure that the plastic used can withstand local environmental conditions. Compliance with JIS standards may be relevant for certain markets.

جدول ملخص لاختيار المواد لمحركات التشغيل

| المواد | Typical Use Case for starter motor price | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الصلب | المساكن والمكونات الهيكلية | قوة ومتانة عالية | أثقل من البدائل | متوسط |

| الألومنيوم | Lightweight applications, electric vehicles | Lightweight and good thermal conductivity | أقل متانة من الفولاذ | عالية |

| النحاس | الملفات الكهربائية والموصلات | موصلية كهربائية فائقة | Higher cost and prone to corrosion | عالية |

| بلاستيك | Non-structural components, insulation | مقاومة التآكل وخفة الوزن | أقل متانة من المعادن | منخفض |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions based on performance, cost, and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for starter motor price

What Are the Main Stages of Starter Motor Manufacturing Processes?

The manufacturing of starter motors involves several critical stages, each designed to ensure quality and performance. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Starter Motors?

Material preparation is the foundation of the manufacturing process. High-quality materials such as steel, copper, and specialized alloys are selected based on their mechanical properties and electrical conductivity. These materials are sourced from reputable suppliers who meet international standards to ensure reliability. The materials undergo rigorous testing to verify their composition and integrity before proceeding to the next stage.

ما هي التقنيات المستخدمة في مرحلة تشكيل محركات التشغيل؟

During the forming stage, various techniques such as forging, machining, and stamping are employed. Forging is often used for critical components like the housing and rotor, as it enhances strength through grain structure manipulation. Precision machining is applied to ensure that parts fit together seamlessly, particularly for the pinion and gear mechanisms. Stamping is utilized for producing smaller components, ensuring high precision and repeatability. The choice of technique directly impacts the durability and performance of the starter motor.

Illustrative image related to starter motor price

كيف يتم إجراء عملية التجميع لمحركات التشغيل؟

The assembly process is where individual components come together to form the complete starter motor. This stage typically occurs in a cleanroom environment to minimize contamination. Skilled technicians or automated systems assemble the components, following strict protocols to ensure alignment and fit. Key elements, such as the solenoid and brushes, are carefully installed to ensure optimal performance. Each assembly line may incorporate robotics for repetitive tasks, enhancing efficiency and reducing human error.

ما هي عمليات التشطيب المطبقة على محركات التشغيل؟

Finishing processes include painting, coating, and quality checks. A protective coating is often applied to prevent corrosion and enhance durability. Additionally, final inspections are performed to ensure that all components are functioning correctly and that the starter motor meets specified performance standards. This stage is crucial for ensuring that the product is ready for the market and can withstand various operational conditions.

What Quality Assurance Standards Are Relevant for Starter Motor Manufacturing?

Quality assurance (QA) is vital in the manufacturing of starter motors, ensuring that products meet both safety and performance standards. Compliance with international standards, such as ISO 9001, is essential. This certification indicates that the manufacturer adheres to quality management principles, including a strong customer focus, involvement of top management, and a process approach.

What Industry-Specific Standards Should B2B Buyers Consider?

In addition to ISO certifications, industry-specific standards such as CE marking in Europe and API standards for automotive components are critical. These certifications ensure that the starter motors comply with safety regulations and performance benchmarks relevant to their intended markets. B2B buyers should verify that their suppliers have these certifications, as they can indicate a commitment to quality and safety.

What Are the Key Quality Control Checkpoints in Starter Motor Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each product meets the required standards. Key checkpoints include:

-

مراقبة الجودة الواردة (IQC): This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Any non-compliant materials are rejected or reworked.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During the manufacturing stages, continuous monitoring is conducted to identify any deviations from quality standards. This may involve measuring tolerances and conducting functional tests on components as they are assembled.

-

مراقبة الجودة النهائية (FQC): Before shipping, the finished starter motors undergo rigorous testing to assess their performance under various conditions. This may include electrical testing, load testing, and durability assessments.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

B2B buyers can take several steps to verify the quality control practices of their suppliers. Conducting audits is one of the most effective methods. An audit allows buyers to assess the manufacturing processes, QC protocols, and overall compliance with industry standards.

Illustrative image related to starter motor price

What Documentation Should Buyers Request from Suppliers?

Buyers should request comprehensive documentation, including:

- Quality Management System (QMS) documentation that outlines the supplier’s quality assurance processes.

- Test reports and certifications that validate the performance and safety of the starter motors.

- Traceability records that provide insights into the materials used and the production processes followed.

What Are the Common Testing Methods Used in Starter Motor Quality Assurance?

Various testing methods are employed to ensure the reliability of starter motors. Common methods include:

- الاختبارات الكهربائية: This assesses the electrical performance, ensuring that the motor operates efficiently under load conditions.

- اختبار المتانة: Starter motors are subjected to repeated cycles to simulate real-world use and assess their longevity.

- اختبار البيئة: This includes subjecting the motors to extreme temperatures and humidity levels to evaluate their performance in different climates.

What Nuances Should International B2B Buyers Be Aware of Regarding Quality Control?

International buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should consider several nuances regarding quality control:

- الاختلافات التنظيمية: Different regions may have varying regulations and standards. Buyers should familiarize themselves with local requirements to ensure compliance.

- الحواجز الثقافية واللغوية: Effective communication is vital. Buyers should ensure that they clearly articulate their quality expectations and understand the supplier’s capabilities.

- عمليات التفتيش من طرف ثالث: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing starter motors, ensuring they partner with reputable suppliers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘starter motor price’

مقدمة

Sourcing starter motors for your business requires a strategic approach to ensure that you get the best price without compromising on quality. This guide provides a step-by-step checklist to streamline your purchasing process, helping you navigate the complexities of international procurement, especially for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Clearly outline the technical requirements for the starter motors you need. This includes specifications such as voltage (e.g., 12V, 24V), kW rating, rotation direction, and design type (gear reduction or direct drive). Having precise specifications helps prevent miscommunications with suppliers and ensures that you receive products that meet your operational needs.

الخطوة 2: أسعار سوق الأبحاث

Conduct thorough market research to understand the typical price range for the starter motors you are interested in. Check various suppliers and platforms to compare prices, factoring in shipping costs and import duties. This knowledge will empower you to negotiate better deals and avoid overpaying.

الخطوة 3: تقييم الموردين المحتملين

Before making a commitment, it’s crucial to vet suppliers thoroughly. Look for established companies with a solid reputation in the industry. Request company profiles, case studies, and references from other businesses that have purchased similar products. This step helps ensure reliability and quality in your sourcing decisions.

الخطوة 4: التحقق من الشهادات والامتثال

Ensure that potential suppliers adhere to international quality standards and regulations. Check for certifications such as ISO, CE, or specific automotive standards relevant to your region. Compliance with these standards not only guarantees product quality but also ensures safety and reliability in your supply chain.

الخطوة 5: طلب عينات للاختبار

Before finalizing a bulk order, request samples of the starter motors. Testing samples allows you to assess quality, performance, and compatibility with your equipment. This step is particularly important when sourcing from international suppliers, as it minimizes the risk of receiving subpar products.

الخطوة 6: التفاوض على الشروط والأحكام

Once you have identified a suitable supplier, engage in negotiations regarding price, payment terms, and delivery schedules. Be clear about your expectations and any potential penalties for late deliveries. A well-negotiated contract protects your interests and establishes a framework for a successful business relationship.

Illustrative image related to starter motor price

الخطوة 7: Establish a Continuous Relationship

After the initial purchase, work on building a long-term relationship with your supplier. Regular communication can lead to better pricing, priority service, and insights into new products. Establishing trust and collaboration can significantly enhance your sourcing strategy and ensure consistent supply.

By following this checklist, B2B buyers can effectively navigate the complexities of procuring starter motors, ensuring that they secure favorable pricing while maintaining high standards of quality.

Comprehensive Cost and Pricing Analysis for starter motor price Sourcing

What Are the Key Cost Components Influencing Starter Motor Pricing?

Understanding the cost structure of starter motors is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

المواد: The choice of materials significantly impacts pricing. High-quality metals and components, such as copper windings and durable casing materials, may increase costs but enhance performance and longevity.

-

العمل: Labor costs vary by region and the complexity of assembly. For instance, countries with higher labor costs will naturally reflect this in the pricing of starter motors.

-

تكاليف التصنيع العامة: This encompasses indirect costs such as utilities, rent, and administrative expenses associated with the manufacturing facility. Efficient operations can minimize these costs.

-

الأدوات: Initial tooling costs can be substantial for custom orders. The more complex the design, the higher the tooling costs, which can affect pricing significantly for low-volume orders.

-

مراقبة الجودة: Investing in rigorous QC processes ensures product reliability but can add to the overall cost. Certifications (like ISO) may also influence pricing due to the additional compliance costs involved.

-

اللوجستيات: Shipping and handling costs vary based on the destination, chosen Incoterms, and the volume of the order. These can become a major factor, especially for international buyers.

-

الهامش: Suppliers typically mark up prices to ensure profitability. Understanding the competitive landscape can help buyers negotiate better deals.

كيف تؤثر العوامل المؤثرة في الأسعار على تكاليف المحرك البادئ؟

هناك عدة عوامل تؤثر على تسعير محركات بدء التشغيل بخلاف مكونات التكلفة الأساسية:

-

الحجم/الحد الأدنى للطلب: Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQs) to optimize pricing.

-

المواصفات/التخصيص: Custom features or specifications can significantly affect pricing. While tailored products may serve specific needs better, they generally come at a premium.

-

المواد: The choice between standard and premium materials will affect both the initial cost and the performance of the starter motor.

-

الجودة والشهادات: Motors that meet specific industry standards or come with certifications may carry higher prices but often provide added reliability and warranty benefits.

-

عوامل الموردين: The supplier’s reputation, location, and financial stability can influence pricing. Suppliers with established market positions may charge more due to perceived reliability.

-

مصطلحات التجارة الدولية: The chosen Incoterms dictate who bears the shipping costs and risks, impacting the total landed cost of the starter motor. Buyers should clarify these terms upfront to avoid unexpected expenses.

ما هي نصائح المشترين التي يجب أخذها بعين الاعتبار عند الشراء لتحقيق الكفاءة من حيث التكلفة؟

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, navigating the complexities of starter motor pricing requires strategic approaches:

-

التفاوض: Always engage in negotiations. Suppliers may have flexibility in pricing, especially if they see potential for long-term partnerships.

-

التكلفة الإجمالية للملكية (TCO): Evaluate the long-term costs associated with the starter motors, including installation, maintenance, and potential downtime. A cheaper upfront price may lead to higher TCO if the product is less reliable.

-

الفروق الدقيقة في الأسعار للمشترين الدوليين: Be aware of currency fluctuations, tariffs, and import duties that can impact pricing. Understanding the local market dynamics can also provide leverage in negotiations.

-

البحث والمقارنة: Conduct thorough market research to compare prices and quality across multiple suppliers. This not only aids in making informed decisions but can also enhance negotiation leverage.

-

علاقات الموردين: Cultivating strong relationships with suppliers can lead to better pricing and service. Regular communication and feedback can foster loyalty and favorable terms.

إخلاء المسؤولية

The prices indicated in this analysis are for illustrative purposes only and may vary based on the specific circumstances of each transaction, including the supplier’s location, the buyer’s negotiation skills, and market conditions at the time of purchase. Always consult with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing starter motor price With Other Solutions

Exploring Alternatives to Starter Motor Price: A Comparative Analysis

When considering the procurement of starter motors, it is essential to evaluate not only their prices but also the various alternative solutions available in the market. These alternatives can include different technologies or methods that achieve similar objectives. This analysis will help B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, make informed decisions based on performance, cost, and maintenance requirements.

| جانب المقارنة | Starter Motor Price | Alternative 1: Battery Start Systems | Alternative 2: Hybrid Start Solutions |

|---|---|---|---|

| الأداء | High reliability and quick engagement | Dependable but slower engagement | Efficient but can be complex |

| التكلفة | Moderate to high | Lower initial costs, but potential long-term battery replacement costs | استثمار أعلى مقدمًا |

| سهولة التنفيذ | Standard installation processes | Relatively easy installation | Requires specific infrastructure |

| الصيانة | احتياجات صيانة معتدلة | Low maintenance but battery lifespan limits | الصيانة الدورية المطلوبة |

| أفضل حالة استخدام | Conventional engines in various vehicles | Small vehicles or machinery | Large vehicles with dual systems |

نظرة متعمقة على البدائل

Alternative 1: Battery Start Systems

Battery start systems utilize a powerful battery to start the engine. These systems are particularly effective for smaller vehicles or machinery, where space and weight are considerations. The initial cost of battery systems is generally lower than traditional starter motors, making them appealing for budget-conscious buyers. However, it is crucial to account for the long-term costs associated with battery replacements, which can add up over time. Additionally, while battery systems are easier to install, they may not provide the same reliability as a dedicated starter motor, especially in colder climates.

Alternative 2: Hybrid Start Solutions

Hybrid start solutions combine traditional starter motors with advanced technologies, such as electric motors or battery systems. This method enhances efficiency and reduces fuel consumption, making it an attractive option for larger vehicles that require higher performance. However, hybrid systems tend to have a higher upfront investment and may require specific infrastructure for installation and maintenance. While they can offer significant long-term savings on fuel and emissions, the complexity of hybrid systems can pose challenges for maintenance, requiring specialized knowledge and tools.

الخلاصة: كيفية اختيار الحل المناسب لاحتياجاتك

When selecting between starter motors and alternative solutions, B2B buyers should assess their specific operational requirements, budget constraints, and long-term maintenance capabilities. Understanding the performance and cost implications of each option is essential in making an informed choice. By evaluating the best use cases for starter motors, battery start systems, and hybrid solutions, businesses can optimize their vehicle performance while also considering economic factors and maintenance needs.

Essential Technical Properties and Trade Terminology for starter motor price

What Are the Key Technical Properties to Consider for Starter Motor Pricing?

When evaluating starter motor prices, understanding specific technical properties is crucial for making informed purchasing decisions. Here are several key specifications that B2B buyers should consider:

-

Power Rating (kW)

The power rating, typically measured in kilowatts (kW), indicates the electrical power output of the starter motor. This specification is critical because it determines the motor’s capability to start various engine sizes and types. A higher kW rating often correlates with a higher price, reflecting increased performance and reliability. For international buyers, selecting the appropriate power rating ensures compatibility with local vehicle models and minimizes the risk of failures. -

Voltage Rating (V)

Starter motors are available in different voltage ratings, such as 6V, 12V, and 24V. The voltage must match the vehicle’s electrical system to ensure optimal performance. For instance, 12V systems are common in passenger vehicles, while heavy-duty trucks may utilize 24V systems. Misalignment in voltage can lead to inefficiencies and increased wear, making it essential for buyers to verify this specification before purchasing. -

اتجاه الدوران

Starter motors can rotate clockwise or counter-clockwise, depending on the engine design. This specification is vital for ensuring proper installation and operation. Incorrect rotation can lead to mechanical failures or damage to the engine. Understanding the rotation direction helps buyers avoid costly errors and ensure compatibility with their engine models. -

Design Type (Direct Drive vs. Gear Reduction)

The design of the starter motor significantly impacts its performance and durability. Direct drive motors typically provide a straightforward installation and are lighter, while gear reduction designs offer higher torque and are suited for larger engines. Buyers should evaluate their specific application needs to choose the appropriate design type, which can also influence pricing. -

الجديد مقابل المعاد تصنيعه

Starter motors come in two primary categories: new and remanufactured. New motors tend to have a higher price point due to their quality and warranty offerings. In contrast, remanufactured options can provide a cost-effective solution but may come with varying levels of reliability. Understanding the differences helps buyers weigh cost against performance and warranty considerations.

Which Common Trade Terms Should B2B Buyers Know When Purchasing Starter Motors?

Familiarity with industry terminology enhances communication and negotiation during the purchasing process. Here are several essential trade terms relevant to starter motor procurement:

-

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to components made by the same company that manufactured the original part in a vehicle. Buyers often prefer OEM parts for their guaranteed compatibility and reliability, which can justify higher prices compared to aftermarket options. Understanding OEM specifications is crucial for maintaining warranty compliance and ensuring quality. -

MOQ (الحد الأدنى لكمية الطلب)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is critical for B2B buyers as it can affect inventory management and cash flow. Buyers should negotiate MOQs that align with their operational needs to avoid overstock or stockouts. -

طلب عرض أسعار (RFQ)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products, including starter motors. This process allows buyers to compare options based on pricing, delivery times, and terms. A well-structured RFQ can lead to better deals and supplier relationships. -

شروط التجارة الدولية (Incoterms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify shipping responsibilities, risk transfer, and cost allocation, which is especially important for international buyers dealing with diverse logistics and regulations. -

شروط الضمان

Warranty terms outline the conditions under which a buyer can claim repairs or replacements for defective products. Understanding these terms is vital for assessing the long-term value of the purchase and mitigating risk. Buyers should ensure that warranty conditions align with their operational needs and expectations.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of starter motor pricing with greater confidence, ensuring they make informed purchasing decisions that align with their business objectives.

Illustrative image related to starter motor price

Navigating Market Dynamics and Sourcing Trends in the starter motor price Sector

What Are the Key Trends Shaping the Starter Motor Price Market?

The global starter motor market is witnessing significant shifts driven by various factors, including technological advancements and changing consumer preferences. One of the primary drivers is the increasing demand for electric vehicles (EVs), which has led to innovations in starter motor design and functionality. As countries like Germany push for sustainable transportation, the need for high-efficiency starter motors is becoming critical. Furthermore, the rise of digital platforms for procurement is transforming how international B2B buyers source starter motors, allowing for greater transparency and efficiency in pricing and delivery.

Emerging technologies such as IoT and automation are also influencing sourcing trends. Suppliers are increasingly leveraging data analytics to optimize inventory management and enhance customer service, ensuring that buyers receive timely updates on pricing and availability. Additionally, the trend towards remanufactured starter motors is gaining traction as businesses seek cost-effective solutions without compromising on quality. This trend is particularly relevant in regions like Africa and South America, where budget constraints are a significant consideration for many buyers.

In summary, international B2B buyers must stay informed about these dynamics to capitalize on opportunities and navigate challenges in the starter motor market effectively.

How Is Sustainability Influencing Starter Motor Pricing and Sourcing?

Sustainability has emerged as a crucial factor in the sourcing of starter motors, with environmental impact considerations increasingly shaping buyer decisions. The manufacturing of starter motors often involves materials and processes that can have significant environmental footprints. As a result, B2B buyers are prioritizing suppliers that demonstrate commitment to sustainable practices, including the use of recycled materials and eco-friendly manufacturing processes.

Ethical sourcing is becoming a focal point, with businesses seeking to ensure that their supply chains adhere to responsible labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management) are gaining importance among suppliers, providing buyers with assurance regarding the sustainability of their sourcing decisions. Moreover, the growing consumer demand for “green” products is prompting manufacturers to innovate, leading to the development of starter motors that are not only efficient but also environmentally friendly.

By embracing sustainable sourcing practices, B2B buyers can enhance their brand reputation, align with global sustainability goals, and ultimately influence the pricing dynamics within the starter motor market.

What Is the Historical Context of Starter Motor Pricing?

The evolution of starter motors dates back to the early 20th century when the introduction of electric starters revolutionized the automotive industry. Initially, starter motors were rudimentary, often requiring manual operation. However, advancements in technology and engineering led to the development of more efficient and reliable starter motors, which became standard in vehicles by the 1930s.

Over the decades, the starter motor market has expanded alongside the automotive industry, responding to the increasing complexity of vehicle electrical systems. The introduction of remanufactured starter motors in the late 20th century provided a cost-effective alternative for buyers, reflecting a shift towards sustainability and resource efficiency.

Illustrative image related to starter motor price

Today, the starter motor market is characterized by a diverse range of products catering to various vehicle types and specifications. As international B2B buyers navigate this landscape, understanding the historical context can provide valuable insights into current pricing trends and sourcing strategies, enabling them to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of starter motor price

-

How do I determine the right starter motor for my application?

To select the appropriate starter motor, first identify the specifications required for your equipment, including voltage (e.g., 12V or 24V), power rating (kW), and rotation direction (clockwise or counter-clockwise). Assess the compatibility with your existing systems, considering factors like mounting type and pinion teeth count. It’s advisable to consult with suppliers who can provide technical support and ensure the starter motor meets your operational needs and environmental conditions, especially if you’re working in diverse climates across Africa, South America, the Middle East, or Europe. -

What factors influence the price of starter motors in international markets?

The price of starter motors can vary significantly based on several factors, including the brand, specifications (like power rating and voltage), new vs. remanufactured status, and supplier pricing strategies. Additionally, logistics costs, import tariffs, and regional demand can impact overall pricing. When sourcing internationally, consider fluctuations in currency exchange rates and shipping costs, which may also affect your final purchase price. Engaging with multiple suppliers can provide a range of prices for better comparison. -

كيف يمكنني ضمان جودة محركات التشغيل التي أشتريها؟

To guarantee quality, establish a clear set of specifications and standards before sourcing. Vet suppliers thoroughly by checking certifications, quality assurance processes, and product reviews. Request samples or conduct quality checks on bulk orders to ensure they meet your standards. Additionally, inquire about warranties and return policies, which can provide insight into the supplier’s confidence in their products. Engaging with suppliers who have a track record of servicing similar markets can also enhance your assurance of quality. -

ما هو الحد الأدنى لكمية الطلب (MOQ) لمحركات التشغيل؟

Minimum order quantities (MOQs) can vary widely among manufacturers and suppliers. Typically, MOQs are influenced by production capabilities and shipping logistics. For small to medium-sized businesses, it’s advisable to discuss your needs directly with suppliers to negotiate favorable terms. Some suppliers may offer flexibility with lower MOQs, especially for new partnerships or bulk orders. Additionally, consider the potential for cost savings with larger orders, balancing your immediate needs against long-term supply strategies. -

ما هي شروط الدفع التي يجب أن أتوقعها عند شراء محركات بدء التشغيل دولياً؟

Payment terms can differ significantly between suppliers and regions. Common arrangements include upfront payments, partial payments before shipment, and payment upon delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Discussing payment terms upfront helps establish trust and transparency in the business relationship. Additionally, ensure that all terms are documented in the purchase agreement to avoid misunderstandings later. -

How can I find reliable suppliers for starter motors in my region?

Finding reliable suppliers involves conducting thorough market research and utilizing platforms that connect B2B buyers with manufacturers. Attend trade shows or industry exhibitions to meet potential suppliers and assess their offerings firsthand. Online directories and B2B marketplaces can also be effective. Look for suppliers with positive reviews and established reputations in your industry. Networking with other businesses in your region can provide valuable recommendations and insights into trustworthy suppliers. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد محركات بدء التشغيل؟

Logistics play a crucial role in the successful importation of starter motors. Consider shipping methods, costs, and transit times when planning your order. Ensure that the supplier can provide the necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. Familiarize yourself with local regulations regarding imports, including tariffs and restrictions. Collaborating with a freight forwarder can streamline the process and mitigate potential delays or issues during transit. -

Can starter motors be customized to fit specific equipment needs?

Yes, many manufacturers offer customization options for starter motors. Customizations can include adjustments to voltage, power ratings, pinion teeth configurations, and mounting designs to ensure compatibility with specific equipment. When seeking customized solutions, communicate your precise requirements to the supplier early in the negotiation process. Be prepared for potential lead time increases and additional costs associated with custom manufacturing. A good supplier will work closely with you to ensure that the final product meets your specific operational needs.

Top 3 Starter Motor Price Manufacturers & Suppliers List

1. كارفاكس - تقارير تاريخ السيارة

المجال: carfax.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: CARFAX provides access to the largest global database of Vehicle History information, including details on known accidents, damages, theft reports, maintenance and inspections, mileage manipulations, import information, change of ownership, and open recalls. The service is available for vehicles from over 20 countries, including the USA and Canada, and aims to help users check sales data, avoid ex…

2. Pull Apart – Used Starters

المجال: pullapart.com

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: Used starters are affordable car starting systems that initiate the ignition of the engine, allowing it to operate on its own power. Starters, also known as starter motors or cranking motors, typically measure 6 to 8 inches in length and weigh 2 to 5 pounds. They are usually located in the steering column or behind the dashboard on the driver’s side. When purchasing a used starter, check for an in…

3. Advance Auto Parts – Starter

المجال: shop.advanceautoparts.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: Starter is an electric motor that rotates the engine to initiate the combustion process. Activated by turning the ignition key or pressing a button, it provides the cranking force needed to start the engine. Starters need replacement when they show signs of wear or fail to turn the engine over. Advance Auto Parts offers affordable starters for all vehicle makes and models from brands like Carquest…

Strategic Sourcing Conclusion and Outlook for starter motor price

In navigating the complexities of starter motor pricing, strategic sourcing emerges as a pivotal approach for international B2B buyers. By understanding market dynamics, including factors such as brand reputation, kW ratings, and the choice between new and remanufactured options, buyers can make informed decisions that align with their operational needs and budget constraints. Leveraging relationships with trusted suppliers, especially in regions like Africa, South America, the Middle East, and Europe, enhances negotiation power and fosters long-term partnerships that can lead to better pricing and terms.

As the global demand for automotive parts evolves, it is essential for buyers to stay ahead of market trends and technological advancements that influence starter motor performance and pricing. The future points toward increased competition and innovation, providing opportunities for cost savings and improved product offerings.

International buyers are encouraged to adopt a proactive sourcing strategy that not only focuses on cost but also emphasizes quality and reliability. By doing so, they can ensure their operations remain efficient and competitive in an ever-changing landscape. Embrace the potential of strategic sourcing to optimize your procurement processes and secure the best value for your business.

Illustrative image related to starter motor price

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.