مقدمة: الإبحار في السوق العالمي ل que es el solenoide

In today’s fast-paced global market, understanding the role of a solenoid is crucial for B2B buyers aiming to optimize their operations. Sourcing effective solenoids can be a challenge, particularly for industries reliant on fluid control systems, such as automotive and hydraulics. This guide, “que es el solenoide,” offers a comprehensive examination of solenoid types, their applications across various sectors, and best practices for supplier vetting. By addressing critical factors such as cost analysis and performance standards, this resource empowers international B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—to make informed purchasing decisions.

Navigating the complexities of solenoid procurement requires more than just technical knowledge; it demands an understanding of market dynamics and supplier reliability. This guide equips readers with actionable insights to identify high-quality solenoid solutions tailored to specific operational needs. From exploring the fundamental principles of solenoids to evaluating the latest innovations, buyers will gain the confidence to select the right components that enhance efficiency and reliability in their systems. As we delve into the intricacies of solenoid technology and its applications, this guide serves as a vital tool for those aiming to stay ahead in a competitive landscape.

جدول المحتويات

- Top 4 Que Es El Solenoide Manufacturers & Suppliers List

- مقدمة: الإبحار في السوق العالمي ل que es el solenoide

- فهم que es que es el solenoide أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لمصطلح que es el solenoide

- 3 نقاط ألم شائعة لدى المستخدمين ‘que es el solenoide’ وحلولها

- دليل اختيار المواد الاستراتيجية ل que es el solenoide

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لمصنع que es el solenoide

- دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة ‘que es el solenoide’

- تحليل شامل للتكلفة والتسعير لمصادر que es el solenoide Sourcing

- تحليل البدائل: مقارنة que es el solenoide مع الحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية ل que es el solenoide

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع que es el solenoide

- الأسئلة المتداولة (FAQs) لمشتري B2B من que es el solenoide

- استنتاجات وتوقعات التوريد الاستراتيجي لـ que es el solenoide

- إخلاء مسؤولية هام وشروط الاستخدام

فهم que es que es el solenoide أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| الملف اللولبي الكهروميكانيكي | Converts electrical energy to mechanical motion. | Automotive, industrial automation, robotics. | الإيجابيات: Reliable, efficient. السلبيات: Size can limit application. |

| Válvula Solenoide | Controls fluid flow via electromagnetic actuation. | Water treatment, chemical processing, HVAC. | الإيجابيات: Precision control, quick response. السلبيات: Requires electrical supply. |

| الملف اللولبي المصغر | Compact design for space-constrained applications. | Medical devices, small machinery, consumer electronics. | الإيجابيات: موفرة للمساحة وخفيفة الوزن. السلبيات: خرج طاقة محدود. |

| ملف لولبي قابل للإغلاق | يحافظ على الوضع بدون طاقة مستمرة. | Security systems, door locks, automation. | الإيجابيات: Energy-efficient, holds position. السلبيات: More complex control circuitry. |

| Direct-Acting Solenoid | Directly moves the valve or actuator component. | Pneumatic systems, hydraulic machinery. | الإيجابيات: Immediate response, simple design. السلبيات: Can wear out faster under heavy use. |

What Are the Key Characteristics of Electromechanical Solenoids?

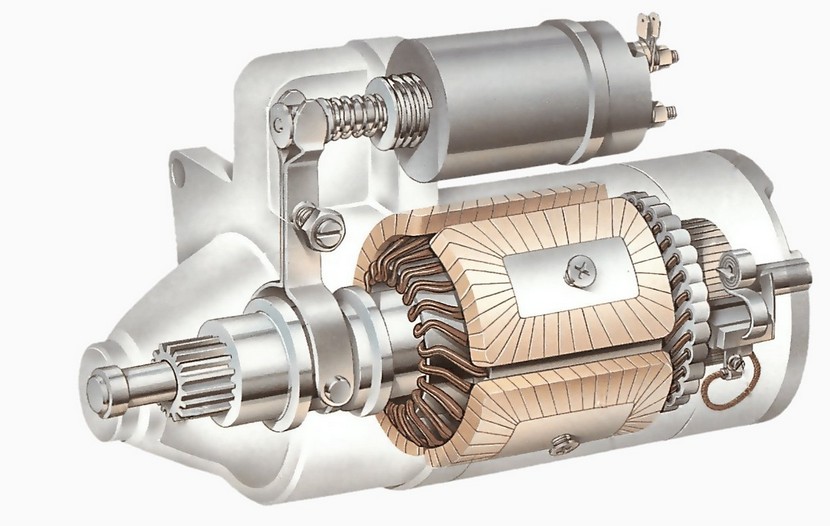

Electromechanical solenoids are primarily designed to convert electrical energy into mechanical energy. They consist of a coil of wire that generates a magnetic field when energized, moving a ferromagnetic plunger. These solenoids are widely used in automotive applications, industrial automation, and robotics, where reliable and efficient actuation is essential. B2B buyers should consider the size and mounting options, as these factors can influence integration into existing systems.

How Do Válvulas Solenoides Function in Fluid Control?

Válvulas solenoides serve as critical components in managing fluid flow across various industries, including water treatment and HVAC systems. They utilize electromagnetic forces to open or close valves, allowing for precise control over liquid or gas movement. Buyers should evaluate the valve’s compatibility with the fluids being managed and its response time, ensuring that it meets specific operational requirements.

What Advantages Do Miniature Solenoids Offer for Compact Applications?

Miniature solenoids are designed for applications with limited space, such as medical devices and consumer electronics. Their compact size and lightweight nature make them suitable for integration into small machinery without compromising performance. When purchasing, B2B buyers should assess the solenoid’s power output and operational voltage, as these can affect functionality in tight spaces.

How Do Latching Solenoids Enhance Energy Efficiency?

Latching solenoids are unique in that they maintain their position without requiring continuous power, making them ideal for security systems and automation where energy conservation is crucial. These solenoids use a magnetic field to hold the actuator in place, reducing energy consumption significantly. Buyers should consider the complexity of control circuitry, as this can impact installation and maintenance requirements.

What Are the Features of Direct-Acting Solenoids in Pneumatic Systems?

Direct-acting solenoids are commonly used in pneumatic and hydraulic systems, where they provide immediate response by directly moving the actuator. Their straightforward design allows for easy integration into various machinery. B2B buyers should be aware of the solenoid’s durability and operational limits, as heavy usage can lead to quicker wear and tear, influencing long-term reliability.

التطبيقات الصناعية الرئيسية لمصطلح que es el solenoide

| الصناعة/القطاع | تطبيق محدد ل que es el solenoide | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | Control of fuel injection systems | Enhances engine efficiency and performance, leading to better fuel economy | Need for high reliability and temperature resistance in solenoids |

| المكونات الهيدروليكية | Actuation of hydraulic valves | Improves control of fluid flow in machinery, enhancing operational efficiency | Compatibility with various hydraulic fluids and pressure ratings |

| الزراعة | Automation of irrigation systems | Increases crop yield through precise water management | Durability in harsh environmental conditions and resistance to corrosion |

| أنظمة التدفئة والتهوية وتكييف الهواء | تنظيم تدفق غاز التبريد في وحدات تكييف الهواء | Improves energy efficiency and reduces operational costs | Compliance with international safety standards and energy ratings |

| الأتمتة الصناعية | Actuation in robotic systems for manufacturing processes | Increases production speed and precision, reducing labor costs | Availability of custom solenoids for specific automation needs |

How is que es el solenoide Used in the Automotive Industry?

In the automotive sector, solenoids are integral to fuel injection systems, where they control the precise timing and amount of fuel delivered to the engine. This not only enhances engine performance but also optimizes fuel efficiency, which is crucial in competitive markets. International buyers should ensure that the solenoids meet high reliability standards, as any failure can lead to significant downtime and repair costs. Additionally, solenoids must be able to withstand high temperatures and vibrations typical in automotive applications.

What Role Do Solenoids Play in Hydraulic Systems?

In hydraulic systems, solenoids are used to actuate valves that control the flow of hydraulic fluids. This application is vital in machinery such as excavators and forklifts, where precise fluid control is essential for operational efficiency. By automating the flow control, businesses can minimize manual interventions and enhance productivity. Buyers should focus on sourcing solenoids that are compatible with various hydraulic fluids and can operate under high pressure, ensuring durability and performance in demanding environments.

How are Solenoids Beneficial in Agriculture?

Solenoids find significant applications in agricultural automation, particularly in irrigation systems. They enable precise control over water distribution, which is crucial for optimizing crop yield and resource management. With increasing pressure on water resources, efficient irrigation directly translates into cost savings and enhanced agricultural productivity. Buyers in this sector should prioritize solenoids that demonstrate durability against environmental factors and corrosion, ensuring long-term reliability in various climates.

Why are Solenoids Important for HVAC Systems?

In HVAC systems, solenoids regulate the flow of refrigerants, playing a key role in maintaining optimal temperatures within buildings. Efficient refrigerant flow directly impacts energy consumption and overall system performance, making solenoids a critical component for energy management. Businesses should consider sourcing solenoids that comply with international safety standards and energy ratings, as this not only ensures legal compliance but also contributes to sustainability goals.

How Do Solenoids Enhance Industrial Automation?

In industrial automation, solenoids are utilized to actuate robotic systems, allowing for precise movements and control in manufacturing processes. This leads to increased production speeds and reduced labor costs, making operations more efficient. For B2B buyers, it is essential to source custom solenoids tailored to specific automation needs, ensuring compatibility with existing systems and enhancing overall operational effectiveness.

3 نقاط ألم شائعة لدى المستخدمين ‘que es el solenoide’ وحلولها

Scenario 1: Understanding Solenoid Functionality in Fluid Control Systems

المشكلة: A B2B buyer in the automotive industry is faced with the challenge of integrating solenoids into fluid control systems. They struggle to understand how solenoids operate within their specific applications, leading to inefficiencies and potential failures in their products. This lack of clarity can result in improper installation, leading to increased downtime, wasted resources, and potential safety hazards.

الحل: To overcome this issue, buyers should invest time in understanding the core principles of solenoid functionality. This includes recognizing how the solenoid generates a magnetic field to actuate valves. A practical first step is to consult technical documentation and product datasheets provided by manufacturers, which often include diagrams and specifications on how solenoids interact with fluid dynamics. Furthermore, reaching out for technical support from suppliers can provide tailored guidance based on specific applications. Participating in training sessions or webinars offered by experts can also enhance understanding, enabling better integration of solenoids into systems, thus improving reliability and performance.

Scenario 2: Sourcing Quality Solenoids for Diverse Applications

المشكلة: A procurement manager at a manufacturing firm faces difficulty sourcing high-quality solenoids that meet varying operational requirements across different machinery. The challenge lies in distinguishing between reliable products and subpar alternatives, which can lead to increased operational costs and maintenance issues down the line.

الحل: To effectively source quality solenoids, buyers should establish a clear set of criteria that includes specifications such as material compatibility, electrical ratings, and environmental resistance. Engaging with multiple suppliers and requesting samples can facilitate comparative analysis. Additionally, leveraging industry-specific forums and trade shows can provide insights into reputable manufacturers known for their quality standards. Buyers should also consider certifications and compliance with international standards, as these can be indicative of a product’s reliability. Building long-term relationships with suppliers who demonstrate transparency and responsiveness can further enhance sourcing strategies, ensuring access to quality products tailored to diverse applications.

Scenario 3: Troubleshooting Solenoid Issues in Automation Systems

المشكلة: An engineer responsible for an automated production line encounters frequent failures with solenoid valves, leading to production delays and increased operational costs. The engineer is unsure whether the issues stem from electrical malfunctions, environmental factors, or improper installation, creating frustration and impacting overall productivity.

الحل: To troubleshoot solenoid issues effectively, a systematic approach should be adopted. First, the engineer should conduct a thorough inspection of the electrical connections and the solenoid’s operational environment. Checking for signs of wear, corrosion, or contamination can identify environmental factors affecting performance. Implementing regular maintenance schedules that include testing solenoid functionality can preempt failures. Utilizing diagnostic tools to measure voltage and resistance can help pinpoint electrical issues. Additionally, collaborating with solenoid manufacturers for advanced troubleshooting support can provide insights into common failure modes and solutions. Documenting all findings and establishing a feedback loop for continuous improvement can also enhance reliability and efficiency in the long term.

دليل اختيار المواد الاستراتيجية ل que es el solenoide

ما هي المواد المستخدمة عادة في تصنيع الملف اللولبي؟

When selecting materials for solenoids, it is crucial to consider their properties and how they align with the specific requirements of various applications. Below, we analyze four common materials used in solenoid construction, focusing on their key properties, advantages and disadvantages, and implications for international buyers.

Copper: The Preferred Conductor

الخصائص الرئيسية: Copper is known for its excellent electrical conductivity, high thermal conductivity, and good corrosion resistance. It typically operates effectively in a temperature range of -200°C to 200°C, making it suitable for various environments.

إيجابيات وسلبيات: The primary advantage of copper is its superior conductivity, which allows for efficient energy transfer and minimal heat loss. However, it is susceptible to corrosion in certain environments, particularly in saline or acidic conditions. Additionally, copper can be more expensive than other conductive materials, which may affect overall production costs.

التأثير على التطبيق: Copper solenoids are ideal for applications where high efficiency is required, such as in automotive and industrial automation. However, buyers must ensure that the solenoid will not be exposed to corrosive media.

اعتبارات للمشترين الدوليين: Buyers in regions like Europe and South America should consider compliance with standards such as ASTM B170 for copper wire. Additionally, the availability of copper may vary by region, impacting lead times and costs.

Stainless Steel: The Durable Choice

الخصائص الرئيسية: Stainless steel offers excellent corrosion resistance, high strength, and durability. It can withstand temperatures ranging from -200°C to 800°C, making it versatile for various applications.

إيجابيات وسلبيات: The key advantage of stainless steel is its resistance to rust and corrosion, which extends the lifespan of solenoids used in harsh environments. However, it is heavier and more expensive than other materials, which can increase manufacturing complexity and costs.

التأثير على التطبيق: Stainless steel solenoids are particularly suitable for applications in the food and beverage industry, as well as in chemical processing, where exposure to aggressive media is common.

اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM A276 for stainless steel is essential for international buyers. Additionally, buyers from the Middle East and Africa should consider local sourcing options to mitigate costs.

Aluminum: The Lightweight Alternative

الخصائص الرئيسية: Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. It typically operates effectively within a temperature range of -50°C to 150°C.

إيجابيات وسلبيات: The primary advantage of aluminum is its lightweight nature, which can reduce the overall weight of the solenoid assembly. However, its lower strength compared to steel and copper can be a limitation in high-stress applications.

التأثير على التطبيق: Aluminum solenoids are well-suited for applications where weight is a critical factor, such as in aerospace or portable devices. However, they may not be suitable for high-pressure environments.

اعتبارات للمشترين الدوليين: Buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions. In regions like Brazil, where manufacturing capabilities may vary, sourcing high-quality aluminum can be a challenge.

Ferrite: The Magnetic Core Component

الخصائص الرئيسية: Ferrite materials are characterized by their magnetic properties, high resistance to electrical conductivity, and ability to operate effectively at high frequencies. They typically withstand temperatures up to 200°C.

إيجابيات وسلبيات: Ferrite is advantageous for its magnetic properties, which enhance the efficiency of solenoids. However, it is brittle and can be prone to cracking under stress, limiting its applications.

التأثير على التطبيق: Ferrite is primarily used in solenoid cores to improve magnetic performance, making it ideal for applications in electronics and telecommunications.

اعتبارات للمشترين الدوليين: Buyers should look for compliance with standards such as JIS C 2502 for ferrite materials. In Europe, ensuring that ferrite components meet RoHS compliance is essential for market acceptance.

جدول ملخص لاختيار المواد للملفات اللولبية

| المواد | حالة الاستخدام النموذجية ل que es el solenoide | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | Automotive, industrial automation | موصلية كهربائية ممتازة | عرضة للتآكل | عالية |

| الفولاذ المقاوم للصدأ | Food processing, chemical industries | High corrosion resistance | أثقل وأكثر تكلفة | عالية |

| الألومنيوم | Aerospace, portable devices | خفيف الوزن | قوة أقل مقارنة بالفولاذ | متوسط |

| Ferrite | Electronics, telecommunications | Enhanced magnetic performance | Brittle and prone to cracking | متوسط |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding solenoid materials, taking into account their specific applications and regional considerations.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لمصنع que es el solenoide

What Are the Typical Manufacturing Processes for Solenoids?

The manufacturing process for solenoids involves several critical stages, each essential for ensuring the final product meets the specific requirements of B2B buyers. Understanding these stages can help buyers assess the quality and reliability of potential suppliers.

How Is Material Prepared for Solenoid Manufacturing?

The first stage in solenoid production involves material preparation. The primary materials used are copper wire for the coil, ferromagnetic materials for the core, and various plastics or metals for the housing.

- Wire Preparation: Copper wire is typically drawn to the required diameter before being insulated. The insulation is crucial as it prevents short circuits when the wire is wound into a coil.

- Core Material Selection: The core material is selected based on the magnetic properties required for the solenoid’s application. High-quality ferromagnetic materials enhance the solenoid’s efficiency and performance.

What Techniques Are Used for Forming Solenoids?

Once materials are prepared, the forming stage begins. This stage primarily involves winding the copper wire into a coil around the ferromagnetic core.

- Coiling: Automated machines are often employed to wind the copper wire uniformly around the core. The number of turns can vary based on design specifications; more turns typically result in a stronger magnetic field.

- Core Insertion: After coiling, the ferromagnetic core is inserted into the coil, ensuring a snug fit to maximize magnetic efficiency.

How Are Solenoids Assembled?

The assembly stage combines all components into a functional solenoid. This stage is crucial as it directly affects the solenoid’s operational reliability.

- تجميع المكونات: The coiled wire and core are placed within the housing, which may be made of plastic or metal, depending on the application.

- التوصيلات الكهربائية: Leads are attached to the ends of the coil to facilitate electrical connections. Soldering techniques are commonly used for secure connections.

What Finishing Processes Are Necessary for Solenoids?

The finishing stage involves several steps aimed at enhancing the solenoid’s durability and performance.

- Insulation: Additional insulation may be applied to prevent electrical leakage and protect the coil from environmental factors.

- الطلاء: Solenoids may undergo a coating process to prevent corrosion, especially if they will be used in harsh environments.

- فحوصات الجودة: Before packaging, each solenoid is subjected to various quality control checks to ensure compliance with industry standards.

What Are the Quality Assurance Standards for Solenoids?

Quality assurance is vital in the manufacturing of solenoids, as it ensures reliability and safety in their applications. International standards play a significant role in this process.

Which International Standards Are Relevant for Solenoid Manufacturing?

- آيزو 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- علامة CE: In Europe, solenoids must comply with CE marking regulations, indicating that they meet EU safety, health, and environmental protection standards.

- معايير API: For solenoids used in the oil and gas sector, adherence to American Petroleum Institute (API) standards is crucial to ensure safety and performance.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة أثناء الإنتاج؟

Quality control (QC) checkpoints are integrated into various stages of the manufacturing process:

- مراقبة الجودة الواردة (IQC): This involves checking raw materials for defects before they enter the production process.

- مراقبة الجودة أثناء الإنتاج (IPQC): Regular inspections during manufacturing help identify issues early, ensuring that defects are caught before they escalate.

- مراقبة الجودة النهائية (FQC): After assembly, each solenoid undergoes rigorous testing to confirm that it meets all specifications and standards.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

B2B buyers must ensure that their suppliers maintain high-quality standards. Here are some strategies for verification:

- تدقيق الموردين: Conducting on-site audits can provide insights into the manufacturing processes, quality control measures, and adherence to standards.

- تقارير الجودة: Requesting detailed quality reports from suppliers can help buyers understand the QC processes and results.

- عمليات التفتيش من قبل أطراف ثالثة: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality practices.

What Testing Methods Are Commonly Used for Solenoids?

Several testing methods are crucial for verifying the performance and reliability of solenoids:

- الاختبار الوظيفي: Ensures that the solenoid activates and deactivates correctly in response to electrical inputs.

- Leak Testing: For solenoids used in fluid control, leak testing is essential to ensure no fluids escape during operation.

- اختبار المتانة: This involves simulating operational conditions to test the solenoid’s performance over time, identifying potential failure points.

What Are the QC Nuances for International B2B Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, must consider several nuances in quality control:

- Compliance with Local Standards: Buyers should ensure that suppliers comply with both international and local regulations, which may vary significantly.

- Cultural Differences in Manufacturing Practices: Understanding regional manufacturing practices can help buyers anticipate potential quality issues.

- اعتبارات اللوجستيات وسلسلة التوريد: Ensuring that quality is maintained throughout the supply chain, from manufacturing to delivery, is critical for international transactions.

الخلاصة

For B2B buyers sourcing solenoids, understanding the manufacturing processes and quality assurance measures is essential for making informed purchasing decisions. By focusing on the key stages of production, relevant quality standards, and verification methods, buyers can ensure they partner with reliable suppliers that meet their specific needs.

دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة ‘que es el solenoide’

To assist B2B buyers in sourcing solenoids effectively, this guide outlines a practical checklist that ensures informed decision-making. Whether you’re in the automotive, hydraulic, or any other industry requiring solenoids, following these steps will help you procure the right components for your needs.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Clearly outline the technical requirements for the solenoids you need. This includes voltage ratings, coil resistance, and physical dimensions. Knowing your specifications will help you narrow down your options and ensure compatibility with existing systems.

- تصنيف الجهد الكهربائي: Determine if you need low voltage (e.g., 12V) or high voltage (e.g., 240V) solenoids based on your application.

- مقاومة اللفائف: Assess the resistance levels required to ensure efficiency and safety in operation.

الخطوة 2: Identify Application Requirements

Different applications may require specific types of solenoids, such as normally open or normally closed configurations. Understand the role the solenoid will play in your system to make an informed choice.

صورة توضيحية متعلقة ب que es el solenoide

- Fluid Type: Identify whether the solenoid will control gases or liquids, as this impacts the material and design needed.

- وقت الاستجابة: Consider how quickly the solenoid must actuate to meet the demands of your application.

الخطوة 3: تقييم الموردين المحتملين

Before committing to a purchase, thoroughly vet potential suppliers. This involves reviewing their credibility, product offerings, and customer service reputation.

- Company Profiles: Request detailed profiles that include their manufacturing capabilities and experience in the industry.

- References: Seek testimonials or case studies from other buyers, especially those in similar markets or sectors.

الخطوة 4: التحقق من الشهادات والامتثال

Ensure that the solenoids meet relevant international standards and certifications. Compliance with regulations can affect safety and performance.

- شهادات الأيزو: Look for suppliers with ISO certifications, which indicate adherence to quality management standards.

- Industry-Specific Compliance: Check for any additional certifications required in your sector, such as ATEX for explosive environments.

الخطوة 5: طلب عينات أو نماذج أولية

Before placing a bulk order, request samples or prototypes of the solenoids. This allows you to assess quality and compatibility firsthand.

- الاختبار: Conduct performance tests to ensure the solenoid meets your specifications and operational requirements.

- Fit and Function: Verify that the solenoid integrates seamlessly with your existing systems.

الخطوة 6: التفاوض على الشروط والأسعار

Once you’ve selected a supplier, negotiate terms that align with your budget and delivery timelines. Clear communication can lead to better pricing and service agreements.

- خصومات الحجم: Inquire about discounts for bulk purchases, which can significantly reduce costs.

- Lead Times: Discuss expected lead times for delivery to avoid project delays.

الخطوة 7: تأسيس علاقة طويلة الأمد

Building a strong relationship with your supplier can lead to better service and future collaboration. Share feedback and discuss future projects to foster a partnership.

- Ongoing Support: Ensure the supplier offers after-sales support and is willing to assist with any issues that arise post-purchase.

- Future Needs: Keep the lines of communication open regarding upcoming projects or changes in your requirements.

By following these steps, B2B buyers can confidently source solenoids that meet their specific needs, ensuring optimal performance and reliability in their applications.

تحليل شامل للتكلفة والتسعير لمصادر que es el solenoide Sourcing

What Are the Key Cost Components for Sourcing ‘que es el solenoide’?

When sourcing solenoids, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

المواد: The choice of materials significantly impacts the overall cost. Common materials for solenoids include copper wire for the coil, ferromagnetic materials for the core, and various plastics for housing. Higher-quality materials can increase durability and efficiency but also raise costs.

-

العمل: Labor costs vary based on the region and the complexity of the solenoid’s design. Skilled labor is often required for assembly and quality control, particularly for custom or high-specification solenoids.

-

تكاليف التصنيع العامة: This includes expenses related to factory operations, such as utilities, equipment maintenance, and factory management salaries. Efficient manufacturing processes can lower overhead costs.

-

الأدوات: Initial tooling costs can be substantial, especially for custom solenoid designs. These costs are amortized over the production volume, making them a critical factor for buyers considering larger orders.

-

مراقبة الجودة (QC): Ensuring that solenoids meet industry standards involves rigorous testing and inspection processes. This can add to the overall cost but is essential for maintaining product reliability.

-

اللوجستيات: Shipping costs can vary widely depending on the origin and destination, as well as the chosen Incoterms. For international buyers, understanding freight costs and potential customs duties is vital.

-

الهامش: Suppliers typically add a profit margin to the cost of production. This margin can be influenced by the supplier’s market position, brand reputation, and the complexity of the solenoid.

What Factors Influence Pricing for Solenoids?

Several factors can affect the pricing of solenoids in the B2B market:

-

الحجم/الحد الأدنى لكمية الطلب: Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate volume discounts when possible.

-

المواصفات والتخصيص: Custom-designed solenoids or those with specific technical specifications often come at a premium. Buyers need to balance their requirements with budget constraints.

-

جودة المواد والشهادات: High-quality materials and products with industry certifications (e.g., ISO standards) can command higher prices. However, they may offer better performance and longevity.

-

عوامل الموردين: The supplier’s location, reputation, and production capabilities can influence pricing. Established suppliers with a track record of quality may charge more, but they can also reduce risks associated with product failure.

-

مصطلحات التجارة الدولية: The chosen Incoterms can affect the overall landed cost of solenoids. Understanding these terms helps buyers anticipate additional charges related to shipping, insurance, and duties.

What Are the Best Negotiation Tips for International Buyers of Solenoides?

When negotiating prices for solenoids, particularly in regions like Africa, South America, the Middle East, and Europe, consider these tips:

-

التأكيد على التكلفة الإجمالية للملكية (TCO): Rather than focusing solely on the upfront price, consider the long-term costs associated with maintenance, reliability, and energy efficiency. A higher initial investment may lead to lower operating costs.

-

الاستفادة من أبحاث السوق: Conduct thorough research on market prices and competitor offerings. This knowledge can empower buyers during negotiations and help identify competitive suppliers.

-

طلب عروض أسعار متعددة: Gathering quotes from several suppliers provides leverage in negotiations. It can also reveal price discrepancies and help identify the best value.

-

Be Open to Alternative Solutions: If a supplier cannot meet budget constraints, explore alternative options such as slightly different specifications or materials that may reduce costs.

-

Consider Long-term Partnerships: Building a long-term relationship with a supplier can lead to better pricing and terms over time. Loyalty can be rewarded with discounts and priority service.

الخلاصة

Understanding the intricate cost structure and pricing influences for sourcing solenoids is essential for international B2B buyers. By considering the key cost components, being aware of pricing influencers, and employing effective negotiation strategies, buyers can optimize their sourcing decisions, ensuring they receive high-quality products at competitive prices. Remember, these insights serve as guidelines and actual prices may vary based on specific circumstances and market conditions.

تحليل البدائل: مقارنة que es el solenoide مع الحلول الأخرى

Introduction to Alternative Solutions for Solenoids

In the realm of fluid control systems, solenoids are widely recognized for their efficiency in managing the flow of liquids and gases through valves. However, there are alternative technologies that also serve similar purposes. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific operational needs, budget constraints, and application requirements.

جدول المقارنة

| جانب المقارنة | Que Es El Solenoide | Pneumatic Actuators | Mechanical Actuators |

|---|---|---|---|

| الأداء | High precision in flow control | Fast actuation, high force | Reliable for high-load applications |

| التكلفة | استثمار أولي معتدل | Generally lower than solenoids | Higher due to complexity |

| سهولة التنفيذ | Requires electrical setup | Easier with compressed air | Mechanical setup, requires more space |

| الصيانة | Low, but dependent on electrical components | Moderate, air leaks possible | Low, but wear and tear on moving parts |

| أفضل حالة استخدام | Automated fluid handling | Quick-response applications | تطبيقات الخدمة الشاقة |

تفصيل البدائل

Pneumatic Actuators

Pneumatic actuators utilize compressed air to produce motion, making them an excellent alternative to solenoids in applications requiring rapid actuation. These devices are known for their high speed and ability to generate significant force, making them suitable for industries such as packaging and assembly. However, they may require a constant supply of compressed air, which can lead to additional operational costs. While they are generally easier to implement than solenoids, potential issues such as air leaks can complicate maintenance.

Mechanical Actuators

Mechanical actuators function through direct mechanical movement, often using gears or levers to achieve the desired motion. They are particularly effective in high-load environments, providing reliable performance without the need for electrical or pneumatic systems. However, they tend to be bulkier and require more space, which can be a drawback in compact setups. Mechanical actuators also face wear and tear over time, necessitating periodic maintenance. Despite these considerations, their robustness makes them ideal for applications in industries like manufacturing and heavy machinery.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

When selecting a fluid control solution, B2B buyers must consider the specific requirements of their operations, including performance needs, budget, and maintenance capabilities. Solenoids offer precise control and low maintenance, while pneumatic actuators provide speed and responsiveness, and mechanical actuators deliver strength and reliability. By evaluating these factors against the alternatives, businesses can make strategic decisions that enhance operational efficiency and cost-effectiveness in their respective industries.

الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية ل que es el solenoide

What Are the Key Technical Properties of Solenoids?

Understanding the technical properties of solenoids is essential for B2B buyers involved in industries such as automotive, hydraulic systems, and fluid control. Here are some critical specifications to consider:

1. درجة جودة المواد

The material used in the construction of solenoids significantly affects their performance and durability. Common materials include copper for the wire and various ferromagnetic materials for the core. Selecting high-grade materials ensures better conductivity and magnetic properties, leading to more efficient operation. Buyers should prioritize suppliers who offer solenoids made from durable materials that meet international standards.

2. Coil Resistance

The resistance of the coil is a vital specification that influences the power consumption and heat generation of a solenoid. Lower resistance values typically indicate higher efficiency, which is crucial for energy conservation in large-scale operations. B2B buyers must evaluate coil resistance to ensure compatibility with their electrical systems and to minimize operational costs.

3. Stroke Length

The stroke length refers to the distance the armature moves when the solenoid is activated. This specification is critical for applications requiring precise control of fluid flow or mechanical movement. Buyers should assess the stroke length to ensure it aligns with their application requirements, as it directly affects the solenoid’s effectiveness in operation.

صورة توضيحية متعلقة ب que es el solenoide

4. جهد التشغيل

Solenoids are designed to operate at specific voltage levels, which can range from low voltage (like 12V) to high voltage (like 240V). Understanding the operating voltage is crucial for ensuring that the solenoid functions correctly within a system without risk of damage. B2B buyers should confirm that the solenoid’s voltage specifications match their equipment to avoid compatibility issues.

5. Duty Cycle

The duty cycle indicates the percentage of time a solenoid can operate without overheating. For instance, a solenoid with a 50% duty cycle can operate for 30 seconds on and 30 seconds off. This is particularly important for applications that require prolonged use. Buyers should assess the duty cycle to ensure the solenoid can handle the demands of their operations without failure.

ما هي المصطلحات التجارية الشائعة المتعلقة بالملفات اللولبية؟

Familiarity with industry jargon is vital for effective communication in B2B transactions. Here are some essential terms related to solenoids:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of solenoids, buyers often seek OEM parts to ensure compatibility and reliability in their systems. Understanding OEM offerings helps buyers make informed decisions about sourcing components.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand as it can affect inventory costs and procurement strategies. Buyers should negotiate MOQs that align with their operational needs while maintaining cost-effectiveness.

صورة توضيحية متعلقة ب que es el solenoide

3. طلب عرض أسعار (RFQ)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. In the solenoid market, an RFQ helps buyers gather competitive pricing and terms from multiple vendors. This process is essential for making informed purchasing decisions.

4. شروط التجارة الدولية (Incoterms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, risk, and insurance. Familiarity with these terms is vital for B2B buyers involved in cross-border procurement of solenoids, as they dictate the logistics of delivery and cost implications.

5. CE Marking

CE marking indicates that a product complies with European health, safety, and environmental protection standards. For solenoid buyers in Europe, CE marking is crucial as it ensures that products meet regulatory requirements. Understanding CE marking helps buyers ensure compliance and avoid legal issues.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions regarding solenoid procurement, ultimately enhancing their operational efficiency and product reliability.

صورة توضيحية متعلقة ب que es el solenoide

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع que es el solenoide

What Are the Key Drivers and Trends in the Solenoid Market?

The global solenoid market is witnessing substantial growth, driven by advancements in automation and the increasing demand for efficient fluid control systems across various industries. Key drivers include the automotive sector, where solenoids are essential for controlling fuel injection and transmission systems, and the hydraulic and pneumatic industries, which rely heavily on solenoids for fluid management. In regions like Africa and South America, the rising industrialization and infrastructure development are propelling the demand for solenoid valves and actuators, while Europe and the Middle East are focusing on integrating smart technologies and IoT solutions to enhance system efficiency.

Emerging trends highlight the shift towards electric solenoids and electromagnetic actuators, which offer improved reliability and energy efficiency. Additionally, the incorporation of smart technologies such as sensors and control systems in solenoids is gaining traction, enabling better process automation and real-time monitoring. International B2B buyers should focus on suppliers that not only provide high-quality products but also innovate with these technologies to stay competitive in their markets.

How Is Sustainability Influencing the Sourcing of Solenoids?

Sustainability is becoming a critical factor in B2B sourcing decisions within the solenoid sector. The environmental impact of manufacturing processes and the lifecycle of products are under scrutiny, pushing companies to adopt greener practices. This includes sourcing materials from suppliers that prioritize sustainable production methods and reducing waste in manufacturing.

Ethical sourcing has gained prominence, with buyers increasingly favoring suppliers who can demonstrate compliance with environmental regulations and social responsibility. Certifications such as ISO 14001 for environmental management systems and adherence to RoHS (Restriction of Hazardous Substances) standards are becoming essential criteria for procurement decisions. For solenoids, utilizing recyclable materials and reducing energy consumption during production can significantly enhance a company’s sustainability profile. B2B buyers are encouraged to engage with manufacturers who not only meet performance requirements but also align with their sustainability goals.

What Is the Historical Context of Solenoids in the B2B Sector?

The history of solenoids dates back to the early 19th century when Hans Christian Ørsted discovered the relationship between electricity and magnetism. This led to the development of the first electromagnetic devices, including solenoids. Over the decades, the technology has evolved significantly, transitioning from simple mechanical applications to advanced systems used in various industries.

In the B2B context, the evolution of solenoids has paralleled advancements in manufacturing technologies and automation. Today, solenoids play a vital role in modern industrial processes, contributing to enhanced efficiency and control. As industries continue to innovate, the solenoid’s design and functionality will likely adapt, presenting ongoing opportunities for international buyers to source cutting-edge solutions that meet their specific operational needs.

الأسئلة المتداولة (FAQs) لمشتري B2B من que es el solenoide

-

How do I select the right solenoid for my application?

Selecting the appropriate solenoid involves understanding the specific requirements of your application, such as voltage, current, and the type of fluid or gas being controlled. Consider the operating environment, including temperature and pressure conditions. Additionally, assess the solenoid’s size, response time, and duty cycle. Collaborating with suppliers who offer customization options can also ensure you receive a solenoid tailored to your unique needs, enhancing efficiency and reliability in your operations. -

What industries commonly use solenoids?

Solenoids are widely utilized across various industries, including automotive, manufacturing, HVAC, and irrigation systems. In automotive applications, they control fuel and air flow, while in manufacturing, they manage fluid movement in hydraulic and pneumatic systems. HVAC systems use solenoids for controlling valve operations, and agricultural systems employ them for automated irrigation. Understanding the specific application within your industry will help in sourcing the right solenoid solution. -

What are the typical minimum order quantities (MOQs) for solenoids?

Minimum order quantities (MOQs) for solenoids can vary significantly depending on the supplier and the specific model. Generally, MOQs can range from as low as 10 units for standard models to several hundred for custom designs. It’s advisable to communicate your needs directly with suppliers to negotiate terms that suit your purchasing strategy, especially if you are looking to test a new application or technology. -

How can I vet suppliers of solenoids effectively?

Vetting suppliers is crucial for ensuring quality and reliability. Start by checking the supplier’s certifications and compliance with international standards such as ISO. Evaluate their experience in your specific industry and request references or case studies. Additionally, assess their production capabilities, lead times, and after-sales support. A site visit can also provide valuable insights into their operational standards and quality control processes. -

ما هي شروط الدفع الشائعة عند توريد الملفات اللولبية دولياً؟

Payment terms can vary widely based on the supplier and region. Common terms include 30% upfront payment with the balance due upon delivery, or net 30/60 days after receipt of goods. It’s essential to clarify terms early in negotiations to avoid misunderstandings. Consider using secure payment methods like letters of credit for larger transactions to mitigate risks associated with international trade. -

How do I ensure quality assurance (QA) when sourcing solenoids?

To ensure quality assurance, request detailed product specifications and quality control processes from your supplier. Consider implementing a third-party inspection service to evaluate the solenoids before shipment. Establishing clear QA metrics, such as performance tests and material certifications, can help verify that the products meet your standards. Regular communication with your supplier throughout the production process is also key to addressing any potential quality issues promptly. -

ما هي الاعتبارات اللوجستية التي يجب مراعاتها عند استيراد الملفات اللولبية؟

When importing solenoids, consider shipping methods, customs regulations, and potential tariffs in your country. Air freight is faster but more expensive than sea freight, which may be more cost-effective for larger orders. Ensure that all documentation, such as invoices and packing lists, is accurate to avoid customs delays. Working with a logistics partner experienced in international shipping can streamline the process and help navigate complex regulations. -

Can solenoids be customized for specific applications?

Yes, solenoids can often be customized to meet specific application requirements, including size, voltage, and materials used. Many manufacturers offer customization options that allow you to tailor the solenoid’s design to better suit your operational needs. Engaging with suppliers who specialize in custom solutions can enhance performance and ensure compatibility with your existing systems, leading to improved efficiency and reliability.

Top 4 Que Es El Solenoide Manufacturers & Suppliers List

1. Tameson – Solenoides y Válvulas Solenoides

المجال: تامسون

مقدمة: Un solenoide es una bobina de alambre que genera un campo magnético al ser energizada, moviendo una armadura ferrosa para controlar el flujo a través de una válvula solenoide. Componentes del solenoide incluyen: Bobina (A) – alambre de cobre enrollado; Núcleo estacionario (B) – cilindro ferromagnético; Anillo de sombreado (C) – reduce ruido y vibración; Resorte (D) – devuelve la armadura a su posi…

2. HelloAuto – Solenoide de Arranque

المجال: helloauto.com

مسجل: 2006 (19 سنة)

مقدمة: Un solenoide o bobina es un hilo metálico cubierto y enrollado sobre un cilindro. Genera un campo electromagnético al pasar corriente eléctrica. Se utiliza en piezas esenciales de automóviles, especialmente en el solenoide de arranque, que es crucial para poner en marcha el motor. Al girar la llave de contacto, la corriente eléctrica activa el solenoide, generando un campo magnético que hace funci…

3. Autodoc – Bobina de Alambre y Émbolo Móvil

المجال: autodoc.es

مقدمة: This company, Autodoc – Bobina de Alambre y Émbolo Móvil, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Serté Criégo – Solenoides de Riego

المجال: sertecriego.com

Registered: 2014 (11 years)

مقدمة: Un solenoide de riego es un componente electromagnético utilizado en sistemas de riego automático para controlar el flujo de agua a través de válvulas de riego. Funciona mediante una bobina de alambre conductor que, al recibir corriente eléctrica, genera un campo magnético que mueve un émbolo o pistón. Existen varios tipos de solenoides:

1. Solenoides de acción directa (Normally Open/Normally Clo…

استنتاجات وتوقعات التوريد الاستراتيجي لـ que es el solenoide

In summary, understanding the function and applications of solenoids is critical for international B2B buyers engaged in sectors such as automotive, hydraulic, and fluid management. Solenoids serve as essential components that convert electrical energy into mechanical motion, facilitating efficient control of fluid dynamics across various systems. As the demand for automation and precision in industrial operations grows, strategic sourcing of high-quality solenoids becomes paramount.

By collaborating with reputable manufacturers and suppliers, businesses can ensure reliability and performance in their operations. Key factors to consider include the specifications of solenoids, their adaptability to specific applications, and the potential for customization to meet unique operational needs.

Looking ahead, the landscape for solenoid applications is set to expand, driven by technological advancements and the increasing push for automation across industries. International buyers from Africa, South America, the Middle East, and Europe should seize this opportunity to enhance their supply chains. Engaging with leading solenoid manufacturers can yield significant competitive advantages. Take action now to explore strategic partnerships that align with your business goals and technical requirements, ensuring you stay ahead in the evolving marketplace.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.