Introduction: Navigating the Global Market for parts of alternator

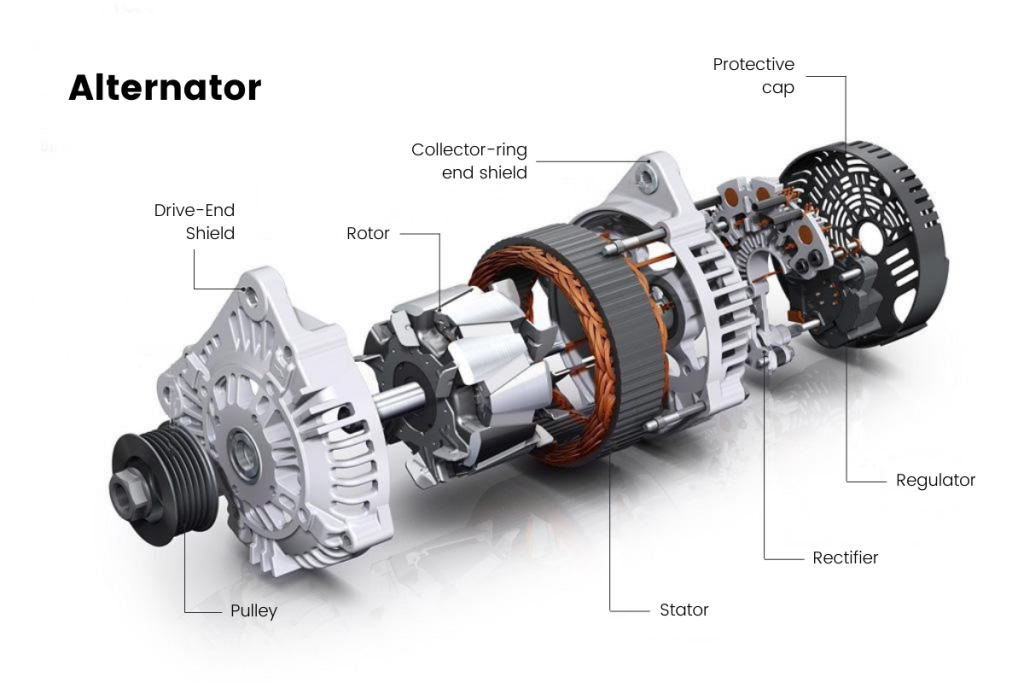

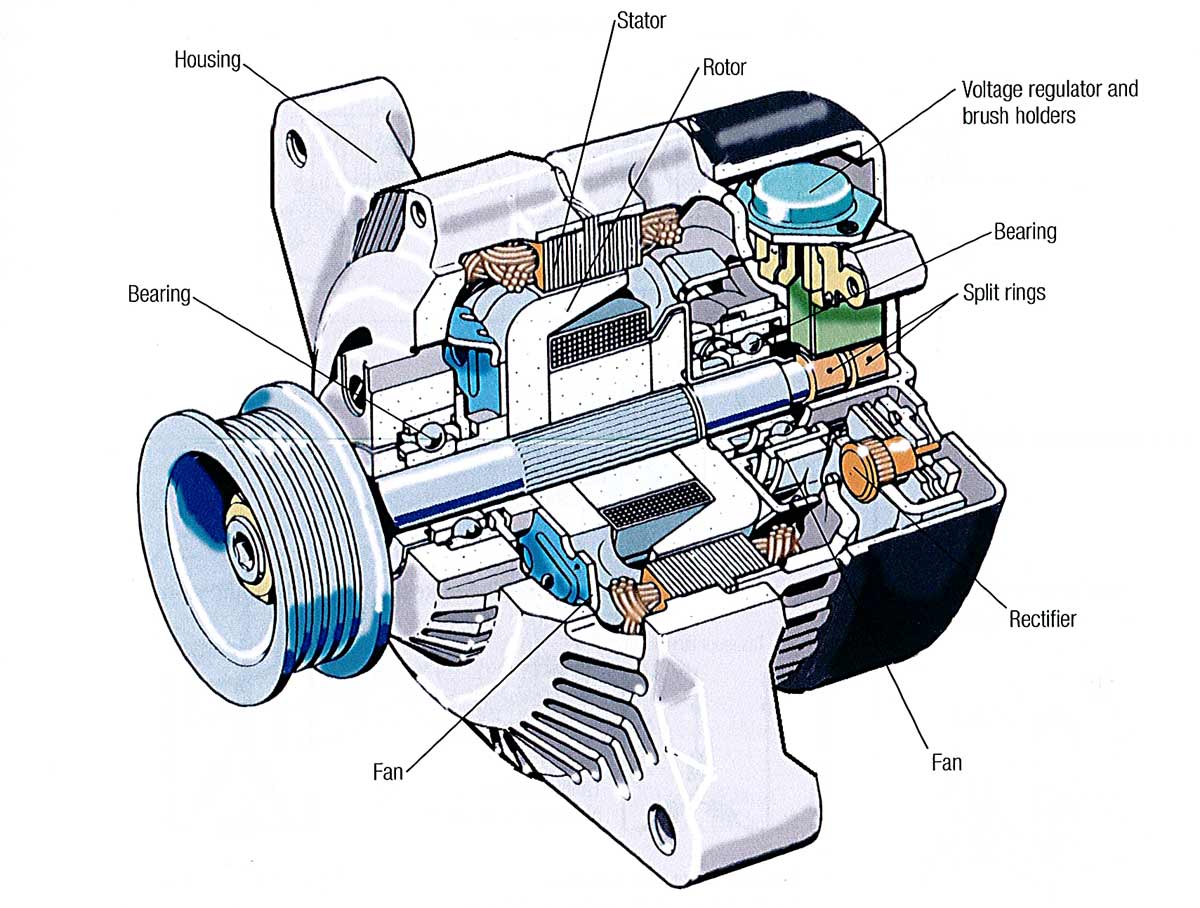

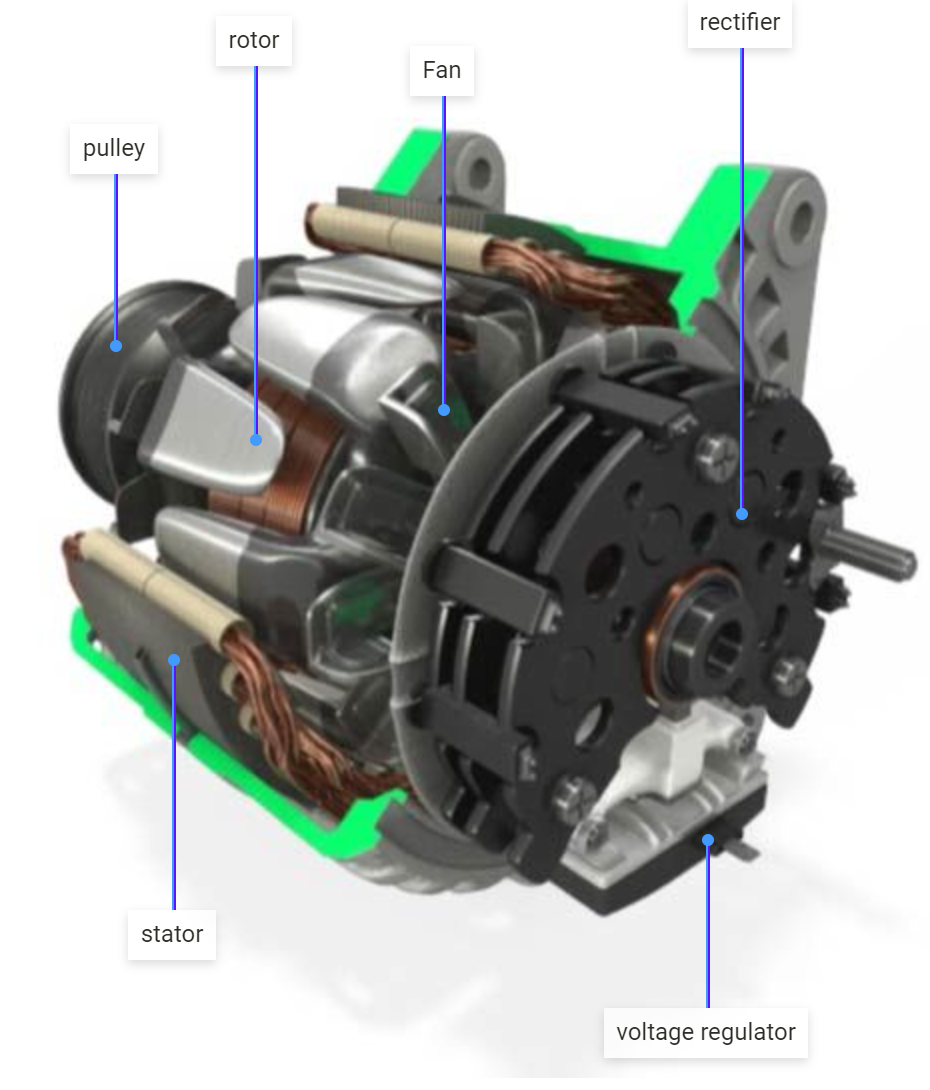

In the rapidly evolving automotive industry, sourcing reliable parts of alternators can present a significant challenge for international B2B buyers. Whether you are operating in Africa, South America, the Middle East, or Europe, understanding the intricate components of alternators and their functions is crucial for making informed purchasing decisions. This comprehensive guide delves into the essential parts of alternators, such as rotors, stators, rectifiers, and voltage regulators, highlighting their roles in the efficient operation of vehicles.

Beyond merely listing components, this guide explores various applications, from automotive to industrial uses, and provides insights into the latest trends impacting the alternator market. It also offers practical advice on vetting suppliers, ensuring quality assurance, and understanding the cost implications associated with different parts. With an emphasis on actionable strategies, this resource empowers B2B buyers to navigate the complexities of global sourcing effectively.

By arming yourself with this knowledge, you can enhance your procurement process, minimize risks, and ultimately secure high-quality alternator components that meet your operational needs. Whether you are a seasoned buyer or new to the market, this guide is designed to equip you with the tools necessary to thrive in the competitive landscape of alternator parts sourcing.

جدول المحتويات

- Top 5 Parts Of Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts of alternator

- Understanding parts of alternator Types and Variations

- Key Industrial Applications of parts of alternator

- 3 Common User Pain Points for ‘parts of alternator’ & Their Solutions

- Strategic Material Selection Guide for parts of alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for parts of alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of alternator’

- Comprehensive Cost and Pricing Analysis for parts of alternator Sourcing

- Alternatives Analysis: Comparing parts of alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for parts of alternator

- Navigating Market Dynamics and Sourcing Trends in the parts of alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts of alternator

- Strategic Sourcing Conclusion and Outlook for parts of alternator

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding parts of alternator Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولد القياسي | Basic design with rotor and stator; widely used in vehicles. | Automotive manufacturing and repair shops. | Pros: Cost-effective; Cons: Limited output for high-demand applications. |

| مولد كهربائي عالي الطاقة | Enhanced output capacity; often includes advanced cooling. | المركبات عالية الأداء والآلات الثقيلة. | Pros: Higher power output; Cons: More expensive, may require modifications. |

| مولد كهربائي بحري | Designed to resist corrosion; optimized for marine environments. | Boat manufacturing and repair. | Pros: Durability in harsh conditions; Cons: Higher cost due to specialized materials. |

| مولد كهربائي بدون فرش | Lacks brushes, reducing maintenance needs; uses electronic controls. | Industrial applications, renewable energy. | Pros: Longer lifespan, lower maintenance; Cons: Initial investment can be higher. |

| Automotive Alternator | Incorporates smart technology for voltage regulation and diagnostics. | Modern automotive sectors, electric vehicles. | Pros: Improved efficiency and diagnostics; Cons: Complexity may lead to higher repair costs. |

What Are the Characteristics of Standard Alternators and Their B2B Suitability?

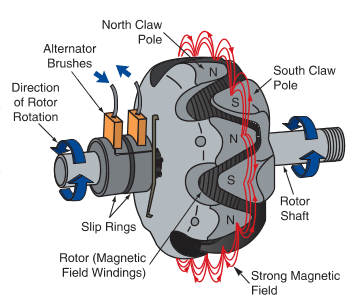

Standard alternators are the most common type found in passenger vehicles and light trucks. They consist of a rotor and stator, generating electrical energy through mechanical movement. These alternators are cost-effective and easily sourced, making them ideal for automotive manufacturers and repair shops looking for reliable parts at a lower price point. However, their output may not suffice for high-demand applications, which is a critical consideration for businesses looking to power advanced electrical systems.

How Do High-Output Alternators Differ and Who Should Consider Them?

High-output alternators are engineered to provide enhanced electrical output, often featuring advanced cooling systems to handle increased demand. These alternators are particularly suitable for performance vehicles and heavy machinery that require more power for accessories and systems. B2B buyers in the automotive performance sector or heavy equipment manufacturing should consider these options for their ability to meet higher electrical needs. However, they come at a higher cost and may necessitate modifications to existing setups.

What Makes Marine Alternators Unique for Specific Applications?

Marine alternators are specifically designed to withstand the corrosive conditions of saltwater environments. They incorporate materials and coatings that enhance their durability and longevity. Businesses involved in boat manufacturing and repair should prioritize these alternators for their resilience and reliability in harsh marine conditions. The trade-off is that marine alternators tend to be more expensive due to their specialized construction.

Why Choose Brushless Alternators for Industrial Applications?

Brushless alternators are characterized by their lack of brushes, which significantly reduces maintenance needs and extends lifespan. They utilize electronic controls for efficient operation, making them ideal for industrial applications and renewable energy systems. B2B buyers should consider these alternators for their long-term cost savings and reliability. However, the initial investment may be higher, which could impact budget considerations.

What Advantages Do Automotive Alternators with Smart Technology Offer?

Automotive alternators equipped with smart technology provide enhanced voltage regulation and diagnostic capabilities. These features are particularly beneficial for modern automotive sectors, including electric vehicles that require precise power management. B2B buyers should evaluate these alternators for their efficiency and advanced functionalities, although the complexity may lead to higher repair costs in the event of a malfunction.

Key Industrial Applications of parts of alternator

| الصناعة/القطاع | Specific Application of parts of alternator | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | Use of rotors and stators in vehicle alternators | Ensures reliable power generation for vehicle systems | Quality certifications, compatibility with engine specifications |

| الطاقة المتجددة | Alternator components in wind turbines | Converts mechanical energy from wind into usable electrical power | Durability against environmental conditions, efficient design |

| Marine Engineering | Alternators in ship engines and auxiliary systems | Provides essential power for navigation and onboard systems | مقاومة التآكل، والامتثال للوائح البحرية |

| معدات البناء | Alternator parts in heavy machinery like excavators | Powers hydraulic systems and electrical components | Robustness, ease of maintenance, and global supply chain access |

| الآلات الزراعية | Alternators in tractors and harvesters | Supports electronic systems for precision farming | Adaptability to various fuel types, reliability under load |

How Are Parts of Alternators Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, rotors and stators are integral components of alternators that provide electrical energy to power vehicle systems such as lighting, ignition, and infotainment. Reliable power generation is crucial for vehicle performance and safety, making high-quality alternator parts essential. Buyers must focus on sourcing components that meet specific quality certifications and compatibility with diverse engine specifications to ensure seamless integration and operation in various vehicle models.

ما الدور الذي تلعبه مكونات المولد في تطبيقات الطاقة المتجددة؟

In renewable energy, particularly wind energy, alternator components like rotors and stators are vital for converting mechanical energy generated by wind turbines into electrical energy. This conversion is essential for generating clean, sustainable power. B2B buyers in this sector should prioritize sourcing parts that exhibit durability against harsh environmental conditions, as well as efficiency in design to maximize energy output. Understanding the specific technical requirements of wind turbine systems is key for optimal performance.

How Are Alternators Used in Marine Engineering?

In marine engineering, alternators are crucial for powering ship engines and auxiliary systems, ensuring reliable operation of navigation and onboard equipment. The harsh marine environment necessitates components that are resistant to corrosion and can withstand high levels of vibration. International buyers must consider compliance with maritime regulations and standards when sourcing alternator parts, ensuring that they can endure the demanding conditions of the marine industry.

What Is the Importance of Alternator Parts in Construction Equipment?

Construction equipment, such as excavators and bulldozers, relies on alternator parts to power hydraulic systems and electrical components. These machines often operate in rugged environments, making robustness and ease of maintenance essential features for alternator components. B2B buyers should focus on sourcing durable parts that can handle heavy loads and are readily available through a reliable global supply chain, ensuring minimal downtime and increased operational efficiency.

How Do Alternators Contribute to Agricultural Machinery Performance?

In the agricultural sector, alternators are found in tractors and harvesters, providing the electrical power necessary for precision farming technologies and other electronic systems. The reliability of alternator components directly impacts farming efficiency and productivity. Buyers should look for parts that can adapt to various fuel types and maintain reliability under heavy operational loads, ensuring that agricultural machinery performs optimally throughout the farming season.

3 Common User Pain Points for ‘parts of alternator’ & Their Solutions

Scenario 1: Ensuring Compatibility with Vehicle Specifications

المشكلة: One of the most significant challenges faced by B2B buyers in the automotive industry is ensuring that the alternator parts they procure are compatible with the specific vehicle models they service. In regions like Africa and South America, where vehicle models may vary widely and sometimes include older or less common makes, sourcing the right parts can lead to compatibility issues. This not only results in increased operational downtime but also impacts customer satisfaction as repairs are delayed.

الحل: To effectively mitigate compatibility issues, B2B buyers should invest in robust databases or software that allow for detailed cross-referencing of alternator parts with vehicle specifications. Partnering with suppliers who provide comprehensive catalogs that include OEM (Original Equipment Manufacturer) specifications and diagrams can also be beneficial. Additionally, establishing direct communication channels with manufacturers can facilitate access to technical support and advice, ensuring that the right part is sourced the first time. Regular training sessions for procurement teams on the latest industry trends and vehicle models can further enhance decision-making processes.

Scenario 2: Managing Quality Assurance for Alternator Parts

المشكلة: Quality assurance remains a persistent concern for B2B buyers, particularly when sourcing alternator parts from various suppliers. Poor quality components can lead to failures that not only damage the vehicle’s electrical system but also tarnish the reputation of the service provider. This is especially critical in regions like the Middle East, where extreme temperatures can exacerbate the failure rates of subpar components, leading to costly repairs and warranty claims.

الحل: To address quality assurance challenges, B2B buyers should implement a rigorous supplier evaluation process that includes quality control certifications, product testing, and customer feedback reviews. Establishing long-term relationships with trusted suppliers who have a proven track record of delivering high-quality alternator parts can significantly reduce risks. Additionally, investing in quality assurance training for staff involved in the procurement and installation processes will ensure that they can identify substandard components. Regular audits and inspections of incoming parts, alongside clear return policies for defective items, will further bolster quality control measures.

Scenario 3: Dealing with Supply Chain Disruptions

المشكلة: Supply chain disruptions pose a significant threat to B2B buyers in the alternator parts sector, particularly in light of recent global events that have affected logistics and material availability. Buyers in Europe and South America may experience delays in receiving critical components, leading to halted operations and dissatisfied customers who depend on timely vehicle repairs.

الحل: To combat supply chain disruptions, B2B buyers should develop a diversified supplier network that includes multiple sources for critical alternator parts. This not only mitigates the risk of dependency on a single supplier but also fosters competitive pricing and improved negotiation power. Additionally, implementing an inventory management system that tracks stock levels and predicts future demands based on historical data can help maintain a buffer stock of essential components. Establishing contingency plans, such as alternative shipping routes or local suppliers, can further enhance resilience against unexpected supply chain challenges. Engaging in proactive communication with suppliers about potential delays or shortages can also facilitate timely adjustments in procurement strategies.

Strategic Material Selection Guide for parts of alternator

What Are the Key Materials Used in Alternator Parts?

When selecting materials for alternator components, it is essential to consider factors such as performance, durability, cost, and regional compliance. The following analysis examines four common materials used in alternator parts: aluminum, copper, steel, and plastic. Each material has unique properties and implications for B2B buyers, particularly in diverse international markets.

كيف يعمل الألومنيوم في تطبيقات المولد؟

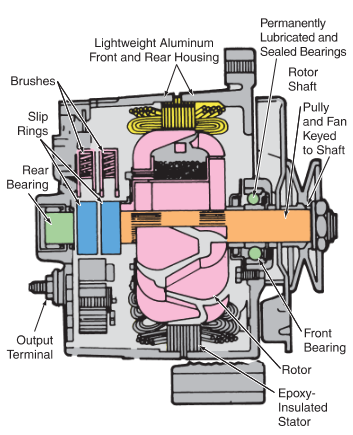

Aluminum is widely used for the outer housing of alternators due to its lightweight nature and excellent heat dissipation properties. It typically has a temperature rating of around 150°C and is resistant to corrosion, making it suitable for various environmental conditions.

الإيجابيات والسلبيات: The primary advantage of aluminum is its low weight, which contributes to the overall efficiency of the alternator. However, aluminum can be more expensive than other materials and may require specialized manufacturing processes, such as die-casting or extrusion.

التأثير على التطبيق: Aluminum’s corrosion resistance makes it ideal for automotive applications in humid or coastal regions. Buyers should ensure that the aluminum used meets international standards like ASTM B221 for structural applications.

Why Is Copper Preferred for Electrical Components?

Copper is commonly used in the windings and connectors of alternators due to its high electrical conductivity and thermal properties. It can handle temperatures up to 200°C and has excellent resistance to oxidation.

الإيجابيات والسلبيات: The key advantage of copper is its superior conductivity, which enhances the efficiency of the alternator. However, copper is relatively expensive, and its weight can be a disadvantage in applications where minimizing weight is critical.

التأثير على التطبيق: In regions with stringent electrical standards, such as Germany, copper components must comply with DIN EN 13601 for electrical conductors. Buyers should consider the long-term benefits of copper’s conductivity against its higher initial cost.

ما الدور الذي يلعبه الصلب في تصنيع المولد؟

Steel is often used in the rotor and stator components of alternators due to its strength and durability. It can withstand high pressures and temperatures, typically rated up to 250°C, making it suitable for demanding automotive environments.

الإيجابيات والسلبيات: The major advantage of steel is its robustness and low cost compared to aluminum and copper. However, steel is heavier, which can affect the overall efficiency of the alternator, and it is prone to corrosion unless properly treated.

التأثير على التطبيق: In markets like Saudi Arabia, where high temperatures and dust are prevalent, using corrosion-resistant steel or applying protective coatings can enhance the longevity of alternator components. Compliance with JIS G3101 standards for structural steel may also be necessary.

How Is Plastic Utilized in Alternator Components?

Plastic materials, such as thermoplastics, are increasingly used for non-structural components like covers and insulation. They can withstand temperatures up to 120°C and offer good electrical insulation properties.

الإيجابيات والسلبيات: The main advantage of plastic is its lightweight nature and cost-effectiveness. However, plastics may not provide the same level of durability as metals and can degrade under extreme heat or UV exposure.

التأثير على التطبيق: In regions with varying climates, such as South America, selecting high-quality plastics that meet ASTM D638 standards for tensile properties is crucial. Buyers should also consider the environmental impact of plastic disposal.

جدول تلخيصي لاختيار المواد لأجزاء المولدات

| المواد | Typical Use Case for parts of alternator | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | Outer housing | خفيفة الوزن وممتازة في تبديد الحرارة | ارتفاع التكلفة وتعقيد التصنيع | متوسط |

| النحاس | اللفات والموصلات | موصلية كهربائية فائقة | غالية الثمن وثقيلة الوزن | عالية |

| الصلب | Rotor and stator components | قوية ومتينة | أثقل وزناً وعرضة للتآكل | منخفض |

| بلاستيك | المكونات غير الهيكلية | خفيفة الوزن وفعالة من حيث التكلفة | أقل متانة في الظروف القاسية | منخفض |

By understanding the properties, advantages, and limitations of these materials, B2B buyers can make informed decisions that align with their operational needs and compliance requirements in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for parts of alternator

The manufacturing of alternator parts involves a series of meticulously planned processes, each contributing to the final product’s performance and reliability. Understanding these processes is crucial for international B2B buyers looking to source high-quality alternator components.

What Are the Main Stages in the Manufacturing Process of Alternator Parts?

The manufacturing process for alternator parts can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How is Material Prepared for Alternator Components?

The first step involves selecting appropriate materials, primarily aluminum for the housing due to its lightweight and heat-dissipating properties. Copper is used for windings, while steel may be employed for other components like the rotor and stator cores. Materials are often sourced from certified suppliers who meet international standards to ensure quality and consistency.

Once materials are selected, they undergo processes such as cutting, shaping, and treating to meet specific dimensions and mechanical properties. This may include heat treatment for enhancing hardness or corrosion resistance.

What Forming Techniques are Commonly Used?

The forming stage typically employs various techniques depending on the part being manufactured.

- الصب بالقالب: This is frequently used for producing the aluminum housing. It allows for complex shapes with high dimensional accuracy and smooth surfaces, minimizing the need for extensive machining.

- الختم: Commonly used for producing flat components like the stator and rotor plates. This process involves pressing sheets of metal into desired shapes.

- التصنيع الآلي: Precision machining is often necessary for components like slip rings and bearings. CNC (Computer Numerical Control) machines are utilized to achieve high tolerances and finishes.

كيف يتم تجميع أجزاء المولد؟

Assembly involves combining the various manufactured components into a complete alternator unit. This stage requires precision to ensure that each part fits correctly, as misalignment can lead to operational failures.

- خطوط التجميع الآلي: Many manufacturers use automated systems for consistent assembly, reducing human error and increasing efficiency.

- التجميع اليدوي: In some cases, especially for high-end or specialized alternators, skilled workers may perform manual assembly to ensure quality and attention to detail.

What Finishing Processes Are Applied to Enhance Quality?

Finishing processes are critical for enhancing the durability and aesthetic appeal of alternator parts. Common finishing techniques include:

Illustrative image related to parts of alternator

- الطلاء بأكسيد الألومنيوم: Often applied to aluminum components to increase corrosion resistance and improve surface hardness.

- Painting: Some manufacturers apply protective coatings to enhance durability and provide a finished look.

- Surface Treatments: Processes such as shot peening or polishing may be used to improve the surface characteristics of critical components.

What Quality Control (QC) Measures Are Essential in Alternator Manufacturing?

Quality control is integral to ensuring that alternator parts meet specified standards and perform reliably in the field.

Which International Standards Should Be Considered?

B2B buyers should ensure that their suppliers adhere to relevant international quality standards, such as:

- آيزو 9001: This standard emphasizes a quality management system that ensures consistent product quality and customer satisfaction.

- علامة CE: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- معايير API: If applicable, particularly in the automotive sector, suppliers may also need to comply with standards set by the American Petroleum Institute.

What Are the Key QC Checkpoints?

The QC process typically includes several checkpoints:

- مراقبة الجودة الواردة (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers should provide certificates of compliance for materials to ensure they meet specified standards.

- مراقبة الجودة أثناء الإنتاج (IPQC): During the manufacturing process, regular inspections are conducted to monitor operations and ensure that components are being produced according to specifications.

- مراقبة الجودة النهائية (FQC): Once assembly is complete, final inspections are performed to verify that the finished alternator parts meet all quality and performance standards before they are shipped.

ما هي طرق الاختبار الشائعة المستخدمة لضمان الجودة؟

To verify the performance and reliability of alternator parts, manufacturers employ various testing methods, including:

- الاختبارات الكهربائية: This ensures that components like rectifiers and voltage regulators function correctly under load conditions.

- الاختبارات الميكانيكية: Components may be subjected to stress tests to evaluate their durability and performance under extreme conditions.

- الاختبار الحراري: Assessing heat dissipation capabilities is crucial for components that generate significant heat during operation.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

B2B buyers should take proactive steps to verify the quality control practices of their suppliers, especially when sourcing from international markets.

- تدقيق الموردين: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall facility conditions.

- تقارير الجودة: Requesting detailed quality reports can provide insights into the supplier’s QC processes and compliance with international standards.

- عمليات التفتيش من قبل أطراف ثالثة: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures and product reliability.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

International buyers must be aware of specific nuances that may affect quality control:

- الامتثال التنظيمي: Different regions may have varying regulations that impact the manufacturing and certification of alternator parts. Understanding these requirements is crucial for compliance.

- الاختلافات الثقافية: Approaches to quality assurance may vary based on regional practices. Building strong relationships with suppliers can facilitate better communication and understanding of quality expectations.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for alternator parts is essential for international B2B buyers. By focusing on these aspects, buyers can make informed decisions and ensure they source high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of alternator’

To effectively procure parts of an alternator for your business, a structured approach can ensure you acquire quality components that meet your operational needs. This checklist serves as a practical guide to streamline your sourcing process.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Before engaging with suppliers, clearly outline the technical requirements for the alternator parts you need. This includes specifications such as size, materials, electrical ratings, and compatibility with existing systems.

– Key Considerations: Ensure that you understand the specific applications of the alternator parts in your machinery or vehicles to avoid costly mismatches.

Illustrative image related to parts of alternator

الخطوة 2: البحث عن الموردين المحتملين

Conduct thorough research to identify potential suppliers who specialize in alternator parts. Utilize industry directories, trade shows, and online platforms to gather a list of candidates.

– What to Look For: Focus on suppliers with a strong reputation in your target regions, such as Africa, South America, the Middle East, and Europe. Pay attention to their experience with the specific alternator parts you require.

الخطوة 3: تقييم شهادات الموردين

Verifying that suppliers hold relevant certifications is crucial for ensuring quality and compliance with industry standards.

– Important Certifications: Look for ISO certifications or other relevant quality management system certifications. This not only reflects the quality of their manufacturing processes but also their commitment to safety and reliability.

الخطوة 4: طلب العينات والوثائق الفنية

Before making a bulk purchase, request samples of the alternator parts along with technical documentation. This allows you to assess the quality and compatibility of the components.

– Documentation to Review: Specifications sheets, installation guides, and maintenance manuals are essential to evaluate if the parts meet your operational requirements.

الخطوة 5: تحقق من المراجع وملاحظات العملاء

Ask for references from previous clients or case studies that demonstrate the supplier’s ability to deliver quality parts on time.

– Why This Matters: Feedback from other businesses in similar industries can provide insights into the supplier’s reliability, customer service, and after-sales support.

الخطوة 6: التفاوض على الأسعار والشروط

Once you have shortlisted potential suppliers, initiate negotiations to secure favorable pricing and terms.

– Negotiation Points: Consider factors like bulk order discounts, payment terms, and delivery schedules. Ensure that all agreements are documented to avoid misunderstandings.

الخطوة 7: Establish a Quality Control Process

Implement a quality control process to inspect the parts upon arrival. This helps to ensure that the components meet your specifications and are free from defects.

– Quality Assurance Steps: Develop a checklist for receiving inspections and consider periodic audits of the supplier’s production processes to maintain quality over time.

By following this structured sourcing checklist, you can effectively navigate the complexities of procuring alternator parts, ensuring that your business operates smoothly and efficiently.

Comprehensive Cost and Pricing Analysis for parts of alternator Sourcing

What Are the Key Cost Components in Sourcing Alternator Parts?

When sourcing parts for alternators, understanding the cost structure is crucial for effective budget management and procurement strategies. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

المواد: The choice of materials significantly impacts the overall cost. Common materials for alternator components include aluminum for housings due to its lightweight and non-magnetic properties, copper for windings, and various alloys for internal components. Sourcing high-quality materials can lead to higher upfront costs but can enhance longevity and performance, ultimately reducing Total Cost of Ownership (TCO).

العمل: Labor costs can vary depending on the region and the skill level required for assembly and testing. In regions with higher labor costs, such as parts of Europe, manufacturers may pass these expenses onto buyers. Conversely, sourcing from regions with lower labor costs may offer savings but could compromise on quality or service levels.

تكاليف التصنيع العامة: This includes costs associated with utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes and economies of scale can lower overhead costs, allowing suppliers to offer competitive pricing.

الأدوات: The initial investment in tooling can be significant, especially for custom components. Buyers should consider whether the supplier has the capability to produce the required parts with existing tooling or if new investments will be necessary.

Illustrative image related to parts of alternator

مراقبة الجودة: Quality assurance processes are vital for ensuring that alternator parts meet industry standards. While rigorous QC can increase costs, it is essential for preventing defects that could lead to costly recalls or repairs.

اللوجستيات: Transportation and shipping costs can vary based on the distance from the supplier to the buyer and the chosen shipping method. International shipping may involve additional fees such as tariffs and insurance, which should be factored into the overall cost.

الهامش: Suppliers will include a profit margin on their pricing, which can vary based on their market position, brand reputation, and the competitive landscape.

How Do Pricing Influencers Affect Alternator Part Sourcing?

Several factors can influence pricing when sourcing alternator parts, particularly for international B2B buyers.

الحجم والحد الأدنى لكمية الطلب (MOQ): Larger order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to ensure they are not overcommitting to inventory they cannot sell.

المواصفات والتخصيص: Custom parts designed to meet specific requirements can significantly increase costs. Buyers should evaluate whether customization is necessary or if standard components will suffice.

شهادات المواد والجودة: The quality of materials and any certifications (e.g., ISO, TS16949) can influence pricing. Buyers should prioritize suppliers who can provide documentation of quality standards to ensure reliability.

عوامل الموردين: The supplier’s reputation, financial stability, and production capacity can impact pricing. Established suppliers may charge a premium, but they often offer better reliability and service.

Illustrative image related to parts of alternator

مصطلحات التجارة الدولية: Understanding the terms of sale (Incoterms) is vital for managing logistics costs and responsibilities. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the final price and should be clearly defined in contracts.

What Are Effective Buyer Tips for Sourcing Alternator Parts Internationally?

For international buyers, especially from Africa, South America, the Middle East, and Europe, several strategies can enhance sourcing efficiency:

-

تفاوض بذكاء: Leverage your position as a bulk buyer to negotiate better terms. Be prepared to walk away if the pricing does not meet your TCO expectations.

-

التركيز على كفاءة التكلفة: Look beyond the initial purchase price. Consider logistics, potential tariffs, and the lifecycle of the product. A lower upfront cost may lead to higher maintenance costs down the line.

-

فهم الفروق الدقيقة في الأسعار: Pricing can fluctuate based on geopolitical factors, supply chain disruptions, and currency exchange rates. Staying informed about these factors can help you make timely purchasing decisions.

-

بناء علاقات مع الموردين: Establishing strong relationships with suppliers can lead to better pricing, priority service, and insights into upcoming changes in pricing or supply chain dynamics.

-

إجراء بحث شامل: Before committing, conduct due diligence on potential suppliers, including reviews of their past performance, quality of products, and adherence to delivery schedules.

By applying these insights and strategies, international B2B buyers can navigate the complexities of sourcing alternator parts more effectively, ensuring they receive quality components at competitive prices.

Alternatives Analysis: Comparing parts of alternator With Other Solutions

Understanding Alternatives in Alternator Technology

As businesses seek efficient energy solutions for their vehicles and machinery, understanding the alternatives to traditional alternator components becomes crucial. The parts of an alternator, such as the rotor, stator, and voltage regulator, serve to convert mechanical energy into electrical energy. However, there are several alternative technologies that can achieve similar objectives. This analysis will provide a comparative overview of traditional alternator parts against other viable solutions, including DC generators and energy storage systems.

Illustrative image related to parts of alternator

جدول المقارنة

| جانب المقارنة | Parts of Alternator | مولدات التيار المستمر | Energy Storage Systems |

|---|---|---|---|

| الأداء | High efficiency in converting mechanical energy to electrical | Moderate, suitable for low-speed applications | High, provides instant power when needed |

| التكلفة | Moderate initial cost with long-term savings | Lower initial cost but higher operational costs | High initial investment, but cost-effective in the long run |

| سهولة التنفيذ | Relatively straightforward installation in vehicles | Simple installation but limited to specific applications | Complex setup requiring integration with existing systems |

| الصيانة | Moderate; requires periodic checks on brushes and diodes | منخفضة؛ تحتاج إلى الحد الأدنى من الصيانة | High; requires regular monitoring and management of battery health |

| أفضل حالة استخدام | Automotive applications and heavy machinery | Small-scale power generation | Renewable energy systems, backup power solutions |

تحليل متعمق للبدائل

ما هي مولدات التيار المستمر وكيف يمكن المقارنة بينها؟

DC generators convert mechanical energy directly into direct current (DC) electricity. They are effective for low-speed applications, such as small-scale power generation. One of their primary advantages is the lower initial cost compared to alternators. However, they tend to have moderate performance levels, making them less suitable for high-demand automotive applications where efficiency is crucial. Additionally, while maintenance is minimal, the operational costs can accumulate over time due to their lower efficiency.

How Do Energy Storage Systems Serve as Alternatives?

Energy storage systems, such as batteries and supercapacitors, offer a modern solution to energy needs. These systems provide instant power on demand, making them highly effective for backup power applications or renewable energy integration. Their performance is superior in terms of instant availability, but they come with a high initial investment and require complex setup and management. Maintenance can also be demanding, as regular monitoring of battery health is essential to ensure optimal performance and longevity.

اتخاذ الخيار الصحيح لاحتياجات عملك

When evaluating which solution best meets your business requirements, consider the specific application, budget constraints, and long-term operational goals. Traditional alternators are well-suited for automotive and heavy machinery applications, where high efficiency and reliability are essential. In contrast, DC generators may be more appropriate for simpler, low-power applications, while energy storage systems excel in scenarios where immediate power availability is critical. By thoroughly assessing these factors, B2B buyers can make informed decisions that align with their operational needs and financial objectives.

Essential Technical Properties and Trade Terminology for parts of alternator

ما هي الخصائص التقنية الرئيسية لأجزاء المولد؟

Understanding the essential technical properties of alternator components is crucial for international B2B buyers, especially when sourcing parts for automotive applications. Here are some critical specifications that should be considered:

1. درجة جودة المواد

The materials used in alternator construction, primarily aluminum for the housing and copper for the windings, are vital for performance. Aluminum is lightweight, corrosion-resistant, and effective for heat dissipation, which is essential for an alternator’s efficiency. Copper, on the other hand, offers excellent electrical conductivity. For B2B buyers, specifying material grades can ensure durability and optimal performance in various climatic conditions, especially in regions like Africa and the Middle East where extreme temperatures are common.

Illustrative image related to parts of alternator

2. مستويات التحمل

Tolerance refers to the allowable deviation in dimensions during manufacturing. For alternator parts, such as the rotor and stator, maintaining tight tolerances is crucial for ensuring that components fit and function correctly, minimizing vibration and wear. B2B buyers should prioritize suppliers who adhere to stringent tolerance specifications, as this can directly impact the longevity and reliability of the alternator.

3. Electrical Output Specifications

Alternators are rated based on their electrical output, typically measured in amperes (A). Knowing the required output is essential for compatibility with vehicle systems. Buyers should assess the output ratings to ensure that the alternators will meet the demands of the vehicle’s electrical systems, particularly in commercial applications where multiple accessories may be in use simultaneously.

4. Heat Dissipation Capacity

Effective heat dissipation is crucial for the longevity of alternators. Components such as internal cooling fans and heat sinks play a significant role in managing temperatures. B2B buyers should inquire about the heat dissipation capabilities of alternators, especially when sourcing for vehicles operating in high-temperature environments.

5. Lifecycle and Warranty

Understanding the expected lifecycle of alternator components and the warranty offered by manufacturers can guide purchasing decisions. A longer lifecycle reduces the frequency of replacements, which is economically advantageous. Buyers should evaluate warranty terms as a measure of quality assurance.

What Are Common Trade Terms in the Alternator Parts Industry?

Familiarity with industry jargon is essential for smooth transactions and negotiations. Here are some common trade terms that B2B buyers should understand:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to companies that produce parts that are used in the manufacturing of vehicles. When sourcing alternator parts, purchasing from OEM suppliers often ensures compatibility and reliability, as these parts meet the original specifications set by vehicle manufacturers.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and cost efficiency. Buyers should negotiate MOQs to align with their purchasing needs without overcommitting resources.

3. طلب عرض أسعار (RFQ)

An RFQ is a formal document sent to suppliers requesting pricing information for specific products. For alternator parts, issuing an RFQ allows buyers to compare prices, terms, and conditions effectively, facilitating informed purchasing decisions.

4. شروط التجارة الدولية (Incoterms)

Incoterms define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), is crucial for B2B transactions to ensure clarity in shipping costs and liability.

5. ما بعد البيع

The aftermarket refers to the market for parts and accessories that are not sourced from the original manufacturer. For alternator components, buyers may explore both OEM and aftermarket options, weighing factors such as price, quality, and availability.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing alternator parts, ensuring compatibility, reliability, and cost-effectiveness in their procurement processes.

Illustrative image related to parts of alternator

Navigating Market Dynamics and Sourcing Trends in the parts of alternator Sector

What Are the Key Trends Shaping the Parts of Alternator Market?

The global alternator parts market is witnessing a transformative phase driven by technological advancements and changing consumer demands. A significant driver is the increasing adoption of electric and hybrid vehicles, particularly in Europe and parts of the Middle East. As manufacturers pivot towards producing more efficient alternators, components such as rectifiers, voltage regulators, and slip rings are being optimized for higher performance and reduced energy consumption.

Emerging technologies such as predictive maintenance tools are gaining traction, enabling B2B buyers to leverage data analytics for more informed sourcing decisions. This shift towards data-driven procurement is particularly relevant for international buyers from Africa and South America, where traditional supply chains are evolving. Furthermore, advancements in manufacturing processes, including 3D printing and automation, are enhancing production efficiencies and reducing lead times for parts sourcing.

Market dynamics also reflect a growing emphasis on local sourcing due to geopolitical uncertainties and supply chain disruptions witnessed during the COVID-19 pandemic. International buyers are increasingly seeking suppliers that can offer flexibility and responsiveness, thus ensuring continuity in operations. Additionally, as the automotive sector grapples with environmental regulations, there is a marked shift towards sourcing eco-friendly and compliant components, underscoring the need for due diligence in supplier selection.

How Is Sustainability Influencing Sourcing Practices in the Parts of Alternator Sector?

Sustainability has become a central theme in the sourcing of alternator parts, reflecting a broader commitment to environmental stewardship across industries. The production and disposal of automotive components, including alternators, can have significant environmental impacts, prompting B2B buyers to prioritize suppliers with sustainable practices.

Ethical sourcing is increasingly important, with buyers scrutinizing supply chains for transparency and adherence to environmental standards. Certifications such as ISO 14001 for environmental management and the Global Recycled Standard are becoming critical benchmarks for suppliers. Buyers are encouraged to seek materials that are recyclable or derived from sustainable sources, such as aluminum housing, which not only reduces the carbon footprint but also enhances the recyclability of the alternator parts.

Moreover, as regulatory frameworks tighten globally, international buyers must ensure compliance with environmental regulations specific to their regions, including the European Union’s stringent rules on waste and emissions. By focusing on sustainable sourcing practices, companies can not only mitigate risks associated with regulatory penalties but also enhance their brand reputation in increasingly eco-conscious markets.

What Is the Historical Context of the Alternator Parts Market?

The alternator has undergone significant evolution since its inception in the early 20th century, transitioning from basic designs to sophisticated components crucial for modern automotive applications. Initially, alternators were primarily used in larger vehicles, but advancements in technology allowed for their incorporation into smaller passenger cars by the 1960s.

The shift from direct current (DC) generators to alternating current (AC) alternators marked a pivotal moment, enhancing efficiency and power output. As automotive technology progressed, the introduction of electronic voltage regulators in the 1980s further optimized performance and reliability, leading to the advanced components we see today, such as digital rectifiers and smart voltage regulators.

This historical context is crucial for B2B buyers as it highlights the rapid advancements in technology that have continually reshaped the parts of alternators. Understanding this evolution can inform sourcing strategies, enabling buyers to select components that not only meet current performance standards but are also future-proofed against the ongoing technological shifts in the automotive industry.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of alternator

-

How do I solve quality issues when sourcing alternator parts?

To address quality issues, start by defining clear specifications and standards for the alternator parts you require. Conduct thorough research on potential suppliers, focusing on their certifications, reputation, and previous customer reviews. Request samples to evaluate the quality firsthand before placing a bulk order. Implement a quality assurance process, including inspections during production and upon receipt of goods, to ensure compliance with your standards. Building strong relationships with suppliers can also facilitate better quality control measures. -

What is the best way to evaluate suppliers of alternator parts?

Evaluating suppliers involves several key steps. First, assess their experience in the industry and their track record with similar products. Check for relevant certifications, such as ISO, that indicate adherence to quality management standards. Additionally, consider their production capacity, lead times, and flexibility in meeting your demands. Engage in direct communication to gauge their responsiveness and willingness to collaborate. Lastly, visiting their facilities, if feasible, can provide valuable insights into their operational capabilities. -

What customization options are available for alternator parts?

Customization options for alternator parts can vary widely among suppliers. Many manufacturers offer tailored solutions based on specific requirements, such as size, material, and design features. It is crucial to communicate your exact needs clearly and inquire about the minimum order quantities (MOQ) for custom parts. Some suppliers may provide prototypes for evaluation before final production. Additionally, ensure that the supplier has the technical expertise to accommodate your customization requests without compromising quality. -

What are the typical minimum order quantities (MOQ) for alternator parts?

Minimum order quantities for alternator parts can differ based on the supplier, part type, and customization requirements. Generally, MOQs can range from a few dozen to several hundred units. It is advisable to discuss your specific needs with potential suppliers to understand their MOQ policies. Some suppliers may offer flexibility in MOQs for first-time buyers or bulk orders. Always consider the potential impact of MOQs on your inventory management and cash flow. -

ما هي شروط الدفع التي يجب أن أتوقعها عند الحصول على قطع غيار المولدات على المستوى الدولي؟

Payment terms for international sourcing of alternator parts can vary widely. Common terms include advance payments, letters of credit, or a combination of upfront and net payment options. It’s essential to negotiate terms that align with your financial capabilities and risk tolerance. Consider using secure payment methods that offer buyer protection. Always clarify the currency used for transactions and any additional fees that may apply, such as banking charges or currency conversion fees. -

How can I ensure timely delivery of alternator parts?

To ensure timely delivery, begin by establishing clear timelines with your suppliers, including production and shipping durations. Choose suppliers with proven track records of meeting deadlines and who offer reliable shipping options. Utilize logistics partners experienced in international shipping to navigate potential customs delays. Regularly communicate with your supplier throughout the process to monitor progress and address any issues that may arise promptly. -

What quality assurance practices should I implement when sourcing alternator parts?

Implementing robust quality assurance practices is crucial when sourcing alternator parts. Begin by setting clear quality standards and specifications for the products. Conduct inspections at various stages, including pre-production, during manufacturing, and upon receipt of goods. Consider third-party quality control services to provide an objective assessment. Additionally, maintain open communication with suppliers to address any quality concerns quickly and collaboratively. -

What are the key logistics considerations when importing alternator parts?

When importing alternator parts, consider several logistics factors. First, evaluate shipping options, including air freight for speed or sea freight for cost-effectiveness. Understand customs regulations and duties in your country to avoid unexpected costs or delays. Collaborate with a logistics partner familiar with international trade to streamline the process. Finally, ensure adequate insurance coverage for your shipments to mitigate risks associated with loss or damage during transit.

Top 5 Parts Of Alternator Manufacturers & Suppliers List

1. HowStuffWorks - المولدات

المجال: auto.howstuffuffworks.com

مسجل: 1998 (27 سنة)

مقدمة: Alternators are small and lightweight, roughly the size of a coconut, constructed with an aluminum outer housing for heat dissipation. Key components include: 1. Drive pulley attached to the rotor shaft, converting mechanical energy to electrical power. 2. Terminals: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L terminal (closes circuit to warning lamp…

2. Autoelectro – Alternators

المجال: autoelectro.co.uk

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: Alternators generate energy to power a vehicle’s electrical system and charge the battery. They convert alternating current (AC) to direct current (DC) through a rectifier. Key components include:

- منظم: يتحكم في توزيع الطاقة على البطارية.

- المقوم: يحوّل التيار المتردد إلى تيار مستمر.

- دوّار: يعمل كمغناطيس كهربائي دوّار.

- حلقات الانزلاق: توفر تياراً مباشراً للدوار.

– Stator: Conta…

3. Facebook – Parts of Alternator

4. Electude – Alternator

المجال: electude.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: المولد هو مكوّن أساسي في السيارات يقوم بتحويل الطاقة الميكانيكية إلى طاقة كهربائية، مما يولد الطاقة لوحدات الاستهلاك الكهربائية والبطارية في السيارة. وتشمل المكونات الرئيسية ما يلي:

- بكرة: تنقل الطاقة الميكانيكية من المحرك.

– Rotor: Creates the magnetic field for generating alternating current.

- الجزء الثابت: الجزء الثابت حيث يتم توليد الجهد الكهربائي.

- المقوم: ...

5. Bermantec – Alternator Components

المجال: bermantec.com

مسجل: 2018 (7 سنوات)

مقدمة: Parts of the alternator include: 1. Rotor – a rotating magnetic field that spins and creates electromagnetic flow. 2. Stator – the static part consisting of an outer frame, stator core, and stator winding, which generates alternating current. 3. Rectifier – converts AC to DC using diodes, available in variants with 3, 6, or 8 diodes. 4. Voltage Regulator – maintains output voltage between 13.5 and…

Strategic Sourcing Conclusion and Outlook for parts of alternator

In conclusion, the strategic sourcing of alternator parts is crucial for maintaining operational efficiency and ensuring the reliability of automotive electrical systems. Understanding the intricate components such as the rotor, stator, rectifier, and voltage regulator allows international B2B buyers to make informed decisions that enhance product performance and longevity. By leveraging strategic sourcing practices, companies can not only reduce costs but also ensure quality and compliance with regional standards, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

As the automotive industry continues to evolve with advancements in technology and sustainability, the demand for high-quality alternator parts will only increase. It is imperative for businesses to establish strong supplier relationships and invest in innovative sourcing strategies that align with market trends.

We encourage international buyers to explore new partnerships and invest in quality components that drive performance and efficiency. By doing so, you position your business for growth and success in an increasingly competitive landscape. Embrace the future of automotive sourcing and ensure your supply chain is robust, resilient, and ready to meet the demands of tomorrow.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.