Introduction: Navigating the Global Market for cost for headlight replacement

Navigating the complex landscape of headlight replacement costs can be a daunting challenge for international B2B buyers, especially when sourcing components that ensure safety and compliance across diverse markets. With the prices of headlight assemblies and bulbs varying widely based on technology, vehicle make, and regional availability, understanding the intricacies of these costs is essential. This comprehensive guide delves into the various types of headlight technologies, including halogen, HID, and LED, alongside their applications in different vehicle models.

Moreover, it outlines the critical factors influencing pricing, such as OEM versus aftermarket options, installation fees, and additional features that may impact the overall expense. By providing insights into supplier vetting processes and highlighting key considerations for cost-effectiveness, this guide equips B2B buyers from Africa, South America, the Middle East, and Europe—including emerging markets like Brazil and Vietnam—with the knowledge to make informed purchasing decisions.

In an industry where quality and reliability are paramount, understanding the true cost of headlight replacement not only aids in budget planning but also enhances the safety and performance of the vehicles in your fleet. With this information at your fingertips, you can navigate the global market with confidence, ensuring that your investments yield maximum value.

جدول المحتويات

- Top 3 Cost For Headlight Replacement Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cost for headlight replacement

- Understanding cost for headlight replacement Types and Variations

- Key Industrial Applications of cost for headlight replacement

- 3 Common User Pain Points for ‘cost for headlight replacement’ & Their Solutions

- Strategic Material Selection Guide for cost for headlight replacement

- In-depth Look: Manufacturing Processes and Quality Assurance for cost for headlight replacement

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cost for headlight replacement’

- Comprehensive Cost and Pricing Analysis for cost for headlight replacement Sourcing

- Alternatives Analysis: Comparing cost for headlight replacement With Other Solutions

- Essential Technical Properties and Trade Terminology for cost for headlight replacement

- Navigating Market Dynamics and Sourcing Trends in the cost for headlight replacement Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cost for headlight replacement

- Strategic Sourcing Conclusion and Outlook for cost for headlight replacement

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding cost for headlight replacement Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| مصابيح هالوجين أمامية هالوجين | Simple technology, low cost, short lifespan (500-1,000 hours) | Standard vehicles, budget-conscious fleets | الإيجابيات: Affordable, easy to replace. سلبيات: Short lifespan, less energy-efficient. |

| HID (High-Intensity Discharge) Headlights | Brighter output, longer lifespan (2,000-10,000 hours) | Mid-range to high-end vehicles | الإيجابيات: Superior brightness, longer-lasting. سلبيات: Higher initial cost, complex installation. |

| LED (Light Emitting Diode) Headlights | Highly efficient, long lifespan (up to 40,000 hours) | Luxury and electric vehicles | الإيجابيات: Energy-efficient, longevity. سلبيات: Expensive, may require specialized installation. |

| مصابيح أمامية متكيفة | Adjusts beam direction based on vehicle speed and steering | Premium vehicles with advanced safety features | الإيجابيات: Enhanced visibility, safety. سلبيات: High replacement cost, complex technology. |

| Aftermarket Headlight Assemblies | Varying quality and price, often cheaper than OEM parts | Cost-sensitive buyers, DIY enthusiasts | الإيجابيات: Cost-effective, wide variety. سلبيات: Quality can be inconsistent, potential fit issues. |

What Are Halogen Headlights and Their B2B Relevance?

Halogen headlights are the most basic and cost-effective option available, making them suitable for standard vehicles and budget-conscious fleets. Their low initial cost appeals to businesses looking to minimize expenses. However, the relatively short lifespan of halogen bulbs means that companies may incur more frequent replacement costs. B2B buyers should consider the total cost of ownership when choosing halogen headlights, weighing initial savings against long-term maintenance.

Why Choose HID Headlights for Your Fleet?

HID headlights offer a significant upgrade in brightness and longevity compared to halogen options. With a lifespan of 2,000 to 10,000 hours, they are ideal for mid-range to high-end vehicles where visibility is crucial. B2B buyers in sectors such as transportation and logistics may find HID headlights beneficial for night-time operations. However, the higher upfront cost and potential installation complexity must be considered, as they may require professional installation to ensure proper functionality.

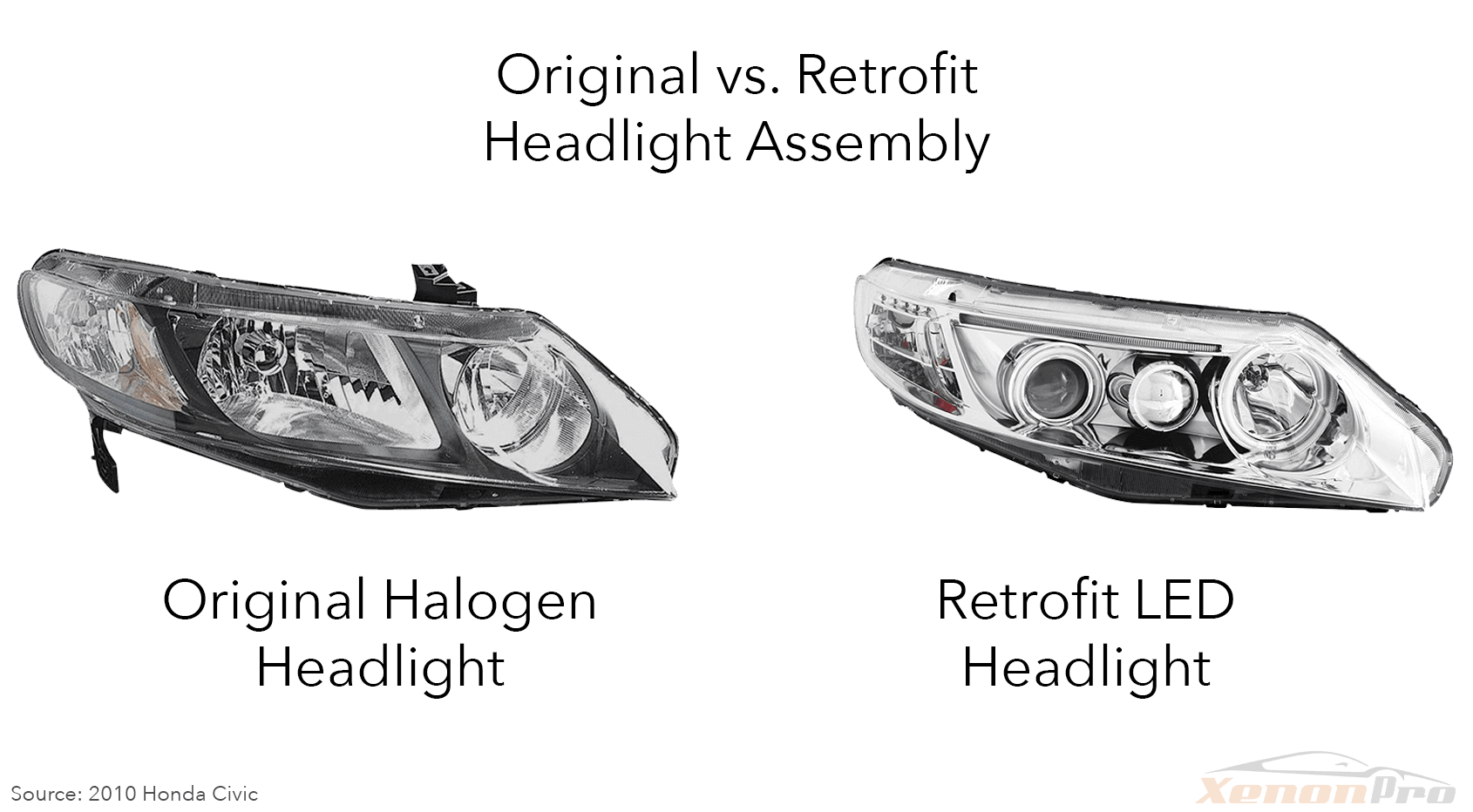

Illustrative image related to cost for headlight replacement

What Advantages Do LED Headlights Provide for Luxury Vehicles?

LED headlights are increasingly popular in luxury and electric vehicles due to their energy efficiency and long lifespan of up to 40,000 hours. For B2B buyers in high-end automotive sectors, investing in LED technology can lead to lower energy costs and reduced maintenance frequency. While the initial investment is higher, the long-term savings and superior performance make LED headlights a compelling option for businesses prioritizing quality and sustainability.

How Do Adaptive Headlights Enhance Safety for Businesses?

Adaptive headlights represent the forefront of automotive lighting technology, adjusting their beam direction based on vehicle speed and steering angle. This feature enhances visibility during nighttime driving and is particularly valuable for premium vehicles equipped with advanced safety systems. B2B buyers in the automotive sector should consider adaptive headlights for their fleets, as they can improve safety ratings and reduce accident risks. However, the complexity and high replacement costs may deter cost-sensitive buyers.

Why Consider Aftermarket Headlight Assemblies for Cost Savings?

Aftermarket headlight assemblies provide a budget-friendly alternative to OEM parts, appealing to cost-sensitive businesses and DIY enthusiasts. With a wide variety of options available, B2B buyers can select assemblies that fit their specific needs. However, the variability in quality and potential fit issues can pose risks, so it is essential for buyers to conduct thorough research and choose reputable suppliers. Balancing initial costs with quality assurance is key in making informed purchasing decisions.

Key Industrial Applications of cost for headlight replacement

| الصناعة/القطاع | Specific Application of Cost for Headlight Replacement | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | Providing cost estimates for headlight replacements to customers | Enhances customer trust and satisfaction by offering transparent pricing | Availability of quality parts, labor costs, and local demand for services |

| إدارة الأسطول | Budgeting for headlight replacements across a fleet of vehicles | Reduces downtime and ensures compliance with safety regulations | Bulk purchasing options, supplier reliability, and warranty terms |

| خدمات النقل والمواصلات | Assessing costs for headlight replacements in commercial vehicles | Ensures operational efficiency and safety for drivers and passengers | Quality of parts, installation expertise, and turnaround time |

| بائعو قطع غيار السيارات بالتجزئة | Sourcing and selling headlight replacement parts | Increases revenue through a diverse product range | Supplier relationships, pricing strategies, and market trends |

| Vehicle Manufacturers | Integrating headlight replacement costs into warranty programs | Enhances customer loyalty and reduces service costs | Compliance with international standards, part compatibility, and pricing models |

How Do Automotive Repair Shops Benefit from Understanding Headlight Replacement Costs?

Automotive repair shops often face the challenge of providing accurate cost estimates for headlight replacements. By understanding the cost structure, including parts and labor, they can build customer trust and enhance satisfaction. This transparency is crucial, particularly in competitive markets in regions like Africa and South America, where customers may be price-sensitive. Shops need to source quality parts while managing labor costs effectively to remain profitable.

Illustrative image related to cost for headlight replacement

Why Is Cost Management Critical for Fleet Management?

Fleet management companies must budget for regular maintenance, including headlight replacements, to ensure vehicle safety and compliance with regulations. Understanding the total cost, including parts and labor, allows fleet managers to minimize downtime and maximize operational efficiency. In regions like the Middle East, where harsh driving conditions can lead to frequent replacements, sourcing reliable suppliers who can offer bulk purchasing options becomes essential.

How Do Transportation Services Assess Headlight Replacement Costs?

Transportation services, such as ride-sharing and logistics companies, must regularly assess the costs associated with headlight replacements to maintain safety and efficiency. This includes evaluating the total cost of ownership, including potential downtime and safety risks for drivers and passengers. In Europe and Brazil, where regulatory compliance is stringent, understanding the cost implications of headlight replacements is vital for avoiding penalties and ensuring passenger safety.

What Role Do Automotive Parts Retailers Play in Headlight Replacement Costs?

Automotive parts retailers need to stay informed about headlight replacement costs to maintain competitive pricing and stock a diverse range of products. By sourcing quality parts at reasonable prices, they can increase revenue while meeting customer demand. In international markets, understanding local pricing strategies and market trends is crucial for establishing successful supplier relationships.

How Do Vehicle Manufacturers Integrate Replacement Costs into Warranty Programs?

Vehicle manufacturers often incorporate headlight replacement costs into their warranty programs to enhance customer loyalty and reduce service costs. By providing clear information on replacement costs and ensuring compatibility with their vehicles, they can improve customer satisfaction. For international buyers, compliance with local standards and effective pricing models are essential for maintaining brand reputation and customer trust.

3 Common User Pain Points for ‘cost for headlight replacement’ & Their Solutions

Scenario 1: Unpredictable Costs of Headlight Replacement

المشكلة: B2B buyers often encounter unpredictability regarding the costs associated with headlight replacement, especially when managing a fleet of vehicles. The wide price range for parts—ranging from basic halogen bulbs to advanced HID or LED systems—can make budgeting a challenge. Additionally, costs can escalate due to unexpected labor fees or the need for specialized tools for installation, leaving buyers feeling uncertain about their overall maintenance expenses.

Illustrative image related to cost for headlight replacement

الحل: To manage these unpredictable costs effectively, buyers should implement a structured procurement process that includes a thorough analysis of their vehicle fleet. Begin by cataloging the types of headlights used across all vehicles, noting whether they are halogen, HID, or LED. This will provide a clearer picture of potential replacement costs. Next, establish relationships with multiple suppliers to compare prices and negotiate bulk purchasing agreements. Consider investing in training for in-house maintenance teams to perform simpler replacements, thus reducing labor costs. Additionally, setting aside a maintenance budget that factors in both the cheapest and most expensive scenarios can ensure financial preparedness for any situation.

Scenario 2: Quality vs. Cost Dilemma in Headlight Assembly

المشكلة: B2B buyers often grapple with the dilemma of choosing between OEM (Original Equipment Manufacturer) parts and aftermarket alternatives. While OEM parts guarantee quality and compatibility, they can significantly increase the overall cost of headlight assembly replacement. On the other hand, aftermarket options may be cheaper but often come with uncertainties regarding their longevity and reliability, leading to potential future costs if they fail prematurely.

الحل: To navigate this quality versus cost dilemma, buyers should conduct a cost-benefit analysis that factors in not only the initial purchase price but also the long-term implications of each option. Evaluate the performance reviews and warranty terms for aftermarket products to gauge their reliability. Engage with fellow fleet managers or industry forums to gather insights on their experiences with various suppliers. A hybrid approach can also be effective—using OEM parts for critical vehicles while opting for aftermarket options for less critical ones. This balanced strategy allows for cost savings without compromising safety and operational efficiency.

Scenario 3: Labor Costs and Installation Complexity in Headlight Replacement

المشكلة: Many B2B buyers are unaware of the significant labor costs associated with headlight replacement until they receive repair estimates. The installation complexity varies widely depending on the vehicle model, which can lead to labor charges that range from a few minutes to several hours. This variability can disrupt maintenance budgets and timelines, especially for businesses that rely heavily on their vehicles for operations.

الحل: To mitigate unexpected labor costs, buyers should invest in training for their in-house mechanics or maintenance personnel. Conducting a workshop or partnering with suppliers to provide hands-on training can empower staff to handle headlight replacements confidently. Additionally, investing in a comprehensive service manual for each vehicle model can help ensure that the team is well-prepared to tackle replacements efficiently. Create a partnership with a local repair shop that offers competitive rates for more complex installations; this way, you can control costs while ensuring that more complicated replacements are handled by professionals. Regularly assessing the fleet for headlight condition can also prevent last-minute replacements, allowing for planned maintenance and budgeting.

Strategic Material Selection Guide for cost for headlight replacement

What Are the Key Materials Used in Headlight Replacement?

When considering headlight replacement, the choice of materials is critical for ensuring performance, durability, and cost-effectiveness. Below, we analyze four common materials used in headlight assemblies and bulbs, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Polycarbonate Impact Headlight Replacement Costs?

Polycarbonate is a popular choice for headlight lenses due to its lightweight and high impact resistance. It can withstand significant temperature variations and is less prone to shattering compared to glass. This material is particularly advantageous in regions with extreme weather conditions.

الإيجابيات: Polycarbonate is durable and offers excellent clarity, which is essential for effective illumination. It is also relatively inexpensive, making it a cost-effective option for manufacturers.

Illustrative image related to cost for headlight replacement

السلبيات: However, polycarbonate can be prone to scratching and may degrade over time due to UV exposure, necessitating periodic replacements or treatments to maintain clarity.

التأثير على التطبيق: Polycarbonate is compatible with various automotive applications, but its susceptibility to environmental factors means it may require additional coatings for UV protection.

اعتبارات للمشترين الدوليين: Buyers from regions like Africa and South America should ensure compliance with local automotive standards, as polycarbonate may not meet certain durability requirements in harsh climates.

Illustrative image related to cost for headlight replacement

What Role Does Glass Play in Headlight Assemblies?

Glass is traditionally used in headlight assemblies, particularly for halogen bulbs. It offers excellent optical clarity and is resistant to scratching, ensuring long-term performance.

الإيجابيات: Glass is chemically inert and provides superior protection against UV rays, which helps maintain the integrity of the headlight over time.

السلبيات: The primary drawback is its weight and fragility, making it more susceptible to breakage during shipping or installation. Additionally, glass headlights can be more expensive to produce.

Illustrative image related to cost for headlight replacement

التأثير على التطبيق: Glass is suitable for standard halogen applications but may not be ideal for advanced lighting systems that require more complex shapes and designs.

اعتبارات للمشترين الدوليين: Compliance with safety standards is crucial, especially in regions with stringent regulations. Buyers should verify that glass components meet local automotive safety and performance standards.

How Do LED Materials Affect Headlight Replacement Costs?

LED (Light Emitting Diode) technology is becoming increasingly popular in headlight assemblies due to its energy efficiency and longevity. The materials used in LED systems often include specialized plastics and metals for heat dissipation.

الإيجابيات: LEDs have a lifespan that can exceed 40,000 hours, significantly reducing the frequency of replacements. They also consume less energy, which can be a selling point in markets focused on sustainability.

Illustrative image related to cost for headlight replacement

السلبيات: The initial cost of LED headlight assemblies is generally higher than traditional options, and they can require more complex manufacturing processes, which may increase overall costs.

التأثير على التطبيق: LED headlights are compatible with various vehicle types, including luxury and electric vehicles, but they require specific electrical systems for optimal performance.

اعتبارات للمشترين الدوليين: Buyers should be aware of the different voltage and compatibility standards in their regions, especially in emerging markets like Vietnam and Brazil, where electrical systems may vary.

Illustrative image related to cost for headlight replacement

What About HID Materials in Headlight Assemblies?

High-Intensity Discharge (HID) headlights use a gas-filled bulb and require a ballast to operate. The materials involved include quartz glass and various metals for the electrodes.

الإيجابيات: HID lights produce a bright, white light that enhances visibility, making them popular in premium vehicles. They also have a longer lifespan than halogen bulbs.

السلبيات: The complexity of HID systems can lead to higher replacement costs, and they may require professional installation, adding to labor expenses.

التأثير على التطبيق: HID systems are ideal for high-performance vehicles but may not be suitable for all applications due to their specific electrical requirements.

اعتبارات للمشترين الدوليين: Compliance with international standards for HID systems is essential, particularly in regions with specific regulations regarding emissions and energy consumption.

Illustrative image related to cost for headlight replacement

جدول ملخص لاختيار المواد اللازمة لاستبدال المصابيح الأمامية

| المواد | Typical Use Case for cost for headlight replacement | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| بولي كربونات | Headlight lenses for standard vehicles | خفيفة الوزن ومقاومة للصدمات | عرضة للخدش والتدهور بسبب الأشعة فوق البنفسجية | منخفض |

| زجاج | Halogen headlight assemblies | وضوح بصري ممتاز | Heavy and fragile | متوسط |

| الصمام الثنائي الباعث للضوء | Advanced headlight systems for luxury vehicles | عمر افتراضي طويل وموفر للطاقة | تكلفة أولية أعلى | عالية |

| HID | High-performance vehicle headlights | Bright light output | Complexity and higher replacement cost | عالية |

This analysis provides a comprehensive overview of the materials used in headlight replacement, enabling B2B buyers to make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cost for headlight replacement

ما هي المراحل الرئيسية لتصنيع مكونات المصابيح الأمامية؟

The manufacturing of headlight components involves a series of intricate stages that ensure the final product meets both quality and performance standards. The typical process includes material preparation, forming, assembly, and finishing.

كيف يتم تحضير المواد لإنتاج المصابيح الأمامية؟

The first step in the manufacturing process is material preparation. Common materials used in headlight assemblies include polycarbonate for lenses, aluminum or plastic for housing, and various types of glass or plastic for bulbs. These materials must be sourced from reputable suppliers to ensure durability and compliance with safety standards.

Before production, materials undergo rigorous testing for quality and consistency. This may include checking for defects, verifying material properties, and ensuring they meet specific industry standards. Documentation of material certifications is essential, especially for international B2B buyers, to validate the origin and quality of the materials used.

What Forming Techniques Are Used in Headlight Manufacturing?

The forming stage involves shaping the prepared materials into the desired components. Common techniques include injection molding for plastic parts and stamping or machining for metal components. Injection molding is widely used for producing complex shapes and is crucial for creating lenses and housings.

Illustrative image related to cost for headlight replacement

Advanced technologies, such as 3D printing, are increasingly being adopted for prototyping and custom parts. This allows manufacturers to produce more intricate designs that can enhance the headlight’s functionality and aesthetics. These techniques not only improve production efficiency but also help in minimizing waste, which is a significant consideration for environmentally conscious buyers.

How Are Headlight Assemblies Assembled and Finished?

Once the individual components are formed, the assembly stage begins. This involves combining the lens, housing, and bulbs into a complete headlight unit. Automated assembly lines are often utilized to enhance precision and speed. However, quality control is paramount, and skilled technicians may perform final assembly tasks to ensure that every unit meets the required specifications.

The finishing stage includes surface treatments, such as UV coating for lenses to improve durability and resistance to yellowing, as well as final inspections to check for aesthetic flaws. Proper finishing not only enhances the product’s appearance but also extends its lifespan, making it a critical component of the manufacturing process.

ما هي معايير ضمان الجودة التي يجب أن يأخذها مشترو B2B بعين الاعتبار؟

Quality assurance (QA) is vital in the manufacturing of headlight assemblies, especially when catering to international markets. Buyers should be aware of relevant international standards, such as ISO 9001, which focuses on quality management systems, ensuring consistent quality and continuous improvement in production processes.

In addition to ISO certifications, industry-specific standards such as CE marking in Europe and compliance with automotive safety regulations are crucial for ensuring that products meet safety and performance benchmarks. These certifications indicate that the manufacturer has met rigorous testing and quality assurance processes.

Which QC Checkpoints Are Critical in Headlight Manufacturing?

Quality control involves several checkpoints throughout the manufacturing process to ensure that the final product adheres to established standards. Key checkpoints include:

-

مراقبة الجودة الواردة (IQC): This is the first line of defense where raw materials are inspected upon arrival. Materials that do not meet specifications are rejected, preventing defects from entering the production line.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During production, various checks are performed to monitor the manufacturing process. This includes verifying that machines are functioning correctly and that components are being produced within tolerances.

-

مراقبة الجودة النهائية (FQC): Once assembly is complete, final inspections are conducted to ensure that the headlight units meet all specifications. This may involve functional testing, such as checking light output and alignment.

What Testing Methods Are Commonly Used in Headlight Quality Control?

Several testing methods are utilized to assess the quality and performance of headlight assemblies:

-

Photometric Testing: This measures the light output and distribution patterns to ensure compliance with regulations.

-

اختبار المتانة: Components undergo tests simulating extreme conditions, such as temperature variations and exposure to UV light, to assess their longevity.

-

Water Ingress Testing: This ensures that the headlight assembly can withstand moisture and prevent fogging or electrical failures.

Each of these testing methods plays a crucial role in ensuring that the final product is safe, reliable, and meets customer expectations.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability and safety. Here are several strategies:

-

عمليات التدقيق: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes and quality control measures firsthand. It also helps in assessing compliance with international standards.

-

تقارير الجودة: Requesting detailed quality reports can provide insights into the supplier’s QC processes, including defect rates, test results, and corrective actions taken for any non-conformance.

-

عمليات التفتيش من طرف ثالث: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These services can conduct inspections at various stages of production, ensuring that standards are met consistently.

What QC and Certification Nuances Should International Buyers Keep in Mind?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification. Differences in regulatory requirements can affect product acceptance in various markets.

Illustrative image related to cost for headlight replacement

For example, while CE marking is essential for products sold in Europe, other regions may have different compliance criteria. Understanding these differences is crucial for avoiding potential delays or additional costs related to non-compliance.

Additionally, it is advisable to establish clear communication channels with suppliers regarding quality expectations and to foster relationships that emphasize transparency in quality control practices. This proactive approach can lead to better collaboration and more reliable supply chains.

By understanding the manufacturing processes and quality assurance practices involved in headlight replacement, B2B buyers can make informed decisions that ensure they receive high-quality products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cost for headlight replacement’

مقدمة

Navigating the costs associated with headlight replacement can be complex, especially for B2B buyers in diverse markets. This guide provides a structured checklist to help you efficiently assess your procurement process, ensuring you make informed decisions that align with your business needs. From understanding your requirements to evaluating suppliers, each step is critical in ensuring cost-effectiveness and quality.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Clearly outline the type of headlight technology your vehicles require. This includes determining whether you need halogen, HID, or LED options, as each has different price points and installation complexities. Additionally, consider the make and model of the vehicles to ensure compatibility.

- نصيحة: Refer to manufacturer specifications to avoid mismatches that can lead to additional costs.

الخطوة 2: إجراء أبحاث السوق

Investigate current market prices and trends for headlight replacement components. Understanding the typical cost ranges will empower you to negotiate better deals and avoid overpaying.

- نصيحة: Utilize online platforms and industry reports that provide insights into pricing variations based on geographic location, which is particularly relevant for international buyers.

الخطوة 3: تقييم الموردين المحتملين

Before committing to a supplier, conduct thorough evaluations. Request company profiles, certifications, and references from existing clients in your industry or region. This ensures that the supplier has a proven track record and understands your specific needs.

Illustrative image related to cost for headlight replacement

- نصيحة: Look for suppliers that specialize in your vehicle types to ensure better service and support.

الخطوة 4: Compare OEM vs. Aftermarket Options

Determine whether to opt for Original Equipment Manufacturer (OEM) parts or aftermarket alternatives. OEM parts guarantee compatibility and quality but often come at a higher price. In contrast, aftermarket parts can be cost-effective but may vary in quality.

- نصيحة: Consider the long-term implications of each option, such as warranty coverage and the potential for additional replacements.

الخطوة 5: Assess Labor Costs and Installation Complexity

Understand the labor costs involved in the replacement process. If your team has the capability to perform installations, you can save significantly. However, if professional installation is necessary, factor in these costs during your budgeting phase.

- نصيحة: Inquire about bulk installation discounts if replacing headlights across multiple vehicles.

الخطوة 6: طلب عينات وإجراء فحوصات الجودة

Before finalizing your order, request samples of the headlight assemblies or bulbs. This allows you to evaluate the quality and performance of the products firsthand.

- نصيحة: Test samples in real-world conditions to ensure they meet safety and performance standards.

الخطوة 7: Establish a Clear Return Policy and Warranty Terms

Confirm that your supplier provides a clear return policy and warranty terms. This step is vital for protecting your investment, especially if you are dealing with complex lighting systems that may require adjustments or replacements.

Illustrative image related to cost for headlight replacement

- نصيحة: Ensure that warranty terms cover both parts and labor to minimize potential future costs.

By following this checklist, B2B buyers can streamline their procurement process for headlight replacements, ultimately leading to informed decisions and cost savings.

Comprehensive Cost and Pricing Analysis for cost for headlight replacement Sourcing

ما هي مكونات التكلفة الرئيسية لاستبدال المصابيح الأمامية؟

Understanding the cost structure for headlight replacement is crucial for B2B buyers, particularly those sourcing parts from diverse markets like Africa, South America, the Middle East, and Europe. The overall cost can be broken down into several key components:

-

المواد: The primary materials include the headlight bulbs (halogen, HID, or LED) and the headlight assembly. Bulb prices can range from $10 for basic halogen types to over $100 for advanced LED or HID systems. The assembly costs can vary significantly, with basic models starting around $30 and luxury or adaptive assemblies exceeding $4,000.

-

العمل: If installation is required, labor costs can add substantially to the total. Professional installation typically ranges from $100 to $400, depending on the complexity of the job. For businesses, considering the option for in-house installation can lead to significant savings.

-

تكاليف التصنيع العامة: This includes costs related to production facilities, machinery, and workforce expenses. Overhead can vary widely between manufacturers, affecting the final pricing.

-

الأدوات: Depending on the specific requirements for headlight design and production, tooling costs may be incurred. Custom tooling for unique vehicle models can increase initial costs but may lead to better price stability in the long run.

-

مراقبة الجودة (QC): Ensuring product quality through rigorous QC processes can add to the cost but is essential for maintaining safety and compliance with international standards.

-

اللوجستيات: Shipping and handling costs can vary based on the supplier’s location, shipping method, and the destination. Understanding Incoterms is vital for assessing who bears these costs.

-

الهامش: Suppliers will typically include a margin that reflects their operational costs and profit expectations. This margin can vary significantly based on competition, market demand, and product differentiation.

What Influences Pricing for Headlight Replacement Parts?

Several factors can influence the pricing of headlight replacements, making it essential for buyers to be informed:

-

الحجم والحد الأدنى لكمية الطلب (MOQ): Bulk purchases often lead to lower per-unit costs. Negotiating MOQs can help achieve better pricing, especially for businesses with high turnover rates.

-

المواصفات والتخصيص: Custom-designed headlights or those that meet specific certifications can incur higher costs. Buyers should evaluate whether the additional features justify the price increase.

-

جودة المواد والشهادات: Higher-quality materials and certifications (such as ISO or safety ratings) may lead to increased costs but can enhance product reliability and safety.

-

عوامل الموردين: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their products based on their market position and quality assurance.

-

مصطلحات التجارة الدولية: Understanding the implications of different Incoterms can affect overall cost calculations. For instance, choosing DDP (Delivered Duty Paid) might simplify logistics but may be more expensive than FOB (Free on Board) options.

What Are Some Negotiation and Cost-Efficiency Tips for Buyers?

B2B buyers can adopt several strategies to enhance cost efficiency and negotiation outcomes:

-

الاستفادة من خصومات الحجم الكبير: Always inquire about discounts for larger orders. Suppliers often have tiered pricing that can be beneficial for businesses with substantial demand.

-

النظر في التكلفة الإجمالية للملكية (TCO): While upfront costs are essential, evaluating the TCO can provide insights into long-term savings. For example, investing in higher-quality LED lights may reduce replacement frequency and energy costs.

-

استكشاف الموردين المتعددين: Comparing quotes from various suppliers can reveal market rates and provide leverage during negotiations. This is particularly relevant for international buyers who might encounter varying price structures.

-

فهم الفروق الدقيقة في التسعير الإقليمي: Different regions may have unique pricing dynamics based on local demand, import tariffs, and currency fluctuations. Staying informed about these factors can aid in making better purchasing decisions.

-

بناء علاقات مع الموردين: Establishing long-term relationships can lead to better pricing, exclusive deals, and prioritized service, which can be advantageous in competitive markets.

الخلاصة

Navigating the complexities of headlight replacement sourcing requires an understanding of various cost components and pricing influencers. By leveraging negotiation strategies and considering the total cost of ownership, B2B buyers can optimize their sourcing decisions, ensuring they receive quality products at competitive prices. Always remember to seek indicative prices, as costs can fluctuate based on market conditions and supplier capabilities.

Alternatives Analysis: Comparing cost for headlight replacement With Other Solutions

Exploring Alternatives for Headlight Replacement Costs

When considering headlight replacement, B2B buyers often seek alternatives that may provide similar functionality at varying costs and efficiencies. Understanding these alternatives can help organizations make informed decisions that align with their operational needs and budget constraints. This analysis compares the traditional headlight replacement with two viable alternatives: headlight restoration and upgraded lighting technologies (such as LED or HID systems).

جدول المقارنة

| جانب المقارنة | Cost For Headlight Replacement | ترميم المصابيح الأمامية | Upgraded Lighting Technologies |

|---|---|---|---|

| الأداء | Standard illumination | Restores clarity, may not improve brightness | Enhanced brightness and visibility |

| التكلفة | $30 – $4,000+ | $20 – $50 | $50 – $300+ per unit |

| سهولة التنفيذ | Varies (DIY or professional) | DIY-friendly | Often requires professional installation |

| الصيانة | Periodic replacements | Infrequent, depends on usage | Long-lasting, but may require periodic checks |

| أفضل حالة استخدام | Vehicle maintenance | Older vehicles or foggy lenses | Newer vehicles or high-performance needs |

تفصيل البدائل

1. Headlight Restoration

Headlight restoration is a cost-effective method to restore the clarity and functionality of existing headlights. This process typically involves cleaning and polishing the headlight lenses, which can remove oxidation and yellowing. The primary advantage is its affordability, usually ranging from $20 to $50, making it an attractive option for companies with budget constraints. However, restoration does not replace the bulb and may not improve overall brightness. It’s best suited for older vehicles or those with foggy lenses rather than for enhancing performance.

Illustrative image related to cost for headlight replacement

2. Upgraded Lighting Technologies

Upgrading to advanced lighting technologies such as LED or HID systems offers significant benefits in terms of performance. These systems are designed to provide superior illumination and energy efficiency, with costs ranging from $50 to $300+ per unit. While the initial investment is higher compared to standard replacements, the long-term savings on energy consumption and reduced frequency of replacements can justify the expense. However, installation can be complex and often requires professional assistance, making it less ideal for organizations looking for quick fixes.

الخلاصة: كيفية اختيار الحل المناسب لاحتياجاتك

For B2B buyers evaluating headlight replacement options, the choice between traditional replacement, restoration, or upgrading lighting technologies should be guided by specific organizational needs. If budget constraints are a primary concern, headlight restoration can be an effective short-term solution. However, for organizations looking to enhance safety and visibility in their fleet, investing in upgraded lighting technologies may yield better long-term benefits. Ultimately, a thorough assessment of vehicle types, usage patterns, and budget will help determine the most suitable approach for maintaining optimal vehicle performance and safety.

Essential Technical Properties and Trade Terminology for cost for headlight replacement

What Are the Key Technical Properties Influencing Headlight Replacement Costs?

When considering the costs associated with headlight replacement, several technical specifications are crucial for B2B buyers to understand. These properties not only influence the pricing but also affect performance, durability, and compatibility with various vehicle models.

1. درجة المواد

The material used in headlight assemblies significantly impacts durability and performance. Common materials include polycarbonate and glass. Polycarbonate is lightweight and resistant to shattering, making it suitable for modern vehicles, whereas glass offers superior clarity but is heavier and more prone to breakage. For B2B buyers, understanding material grades is essential to ensure that the chosen product meets specific safety and longevity requirements.

2. Light Output (Lumen Rating)

Light output, measured in lumens, determines how bright the headlights will be. Halogen bulbs typically produce around 1,000 to 1,500 lumens, while LED and HID systems can exceed 3,000 lumens. A higher lumen rating translates to better visibility, which is critical for safety. B2B buyers should assess light output specifications to ensure compliance with local regulations and customer safety standards.

3. Color Temperature (Kelvin Rating)

Color temperature affects the appearance of light emitted by the headlight. Measured in Kelvin (K), lower temperatures (around 3000K) produce a yellow light, while higher temperatures (up to 6000K) emit a white or blueish light. This specification can influence customer preference and is particularly important for markets with strict aesthetic or functional standards.

Illustrative image related to cost for headlight replacement

4. التوافق والملاءمة

Compatibility refers to whether a headlight assembly fits a specific vehicle model. This includes considerations of the assembly’s dimensions and mounting points. B2B buyers must ensure that the products they source meet the fitment specifications for different vehicle makes and models to avoid returns and dissatisfaction.

5. Service Life (Hours)

The expected service life of headlight bulbs varies significantly by type. Halogen bulbs typically last 500 to 1,000 hours, while HID systems can last between 2,000 to 10,000 hours, and LEDs can reach up to 40,000 hours. Understanding service life is essential for buyers as it influences replacement frequency and total cost of ownership.

6. Features and Technology

Modern headlight assemblies often include additional features such as adaptive lighting, automatic leveling, and daytime running lights (DRLs). These advanced technologies can increase both the cost and complexity of the assembly. B2B buyers should evaluate whether these features align with their market needs and customer expectations.

Which Trade Terms Are Essential for Understanding Headlight Replacement Costs?

Familiarity with trade terminology is crucial for B2B buyers in the automotive parts sector. Here are key terms that can aid in navigating the headlight replacement market effectively.

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM parts are manufactured by the vehicle’s original manufacturer. These parts guarantee compatibility and quality, often at a higher price point. B2B buyers should weigh the benefits of OEM against aftermarket options, considering factors like warranty and resale value.

Illustrative image related to cost for headlight replacement

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ refers to the minimum number of units that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory effectively and ensure they meet demand without overcommitting resources.

3. طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process is essential for B2B buyers to compare costs and negotiate favorable terms, ensuring they secure the best deals for headlight replacements.

4. شروط التجارة الدولية (Incoterms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost of headlight replacement for international buyers.

5. الضمان

A warranty is a guarantee provided by the manufacturer or supplier regarding the performance and durability of a product. Understanding warranty terms is essential for B2B buyers to assess risk and ensure that they are covered in case of product failure.

6. سوق ما بعد البيع

Aftermarket parts are produced by companies other than the original manufacturer. While often less expensive, they can vary in quality. Buyers should evaluate the risks and benefits of aftermarket options, especially concerning compatibility and longevity.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and customer expectations in the headlight replacement market.

Illustrative image related to cost for headlight replacement

Navigating Market Dynamics and Sourcing Trends in the cost for headlight replacement Sector

What are the Key Trends Influencing the Cost for Headlight Replacement in Global Markets?

The headlight replacement sector is undergoing significant transformations influenced by various global drivers. As vehicle technology continues to evolve, the demand for advanced lighting systems, including LED and HID headlights, is surging. These systems, while offering improved visibility and energy efficiency, come with higher replacement costs, ranging from $100 to $4,000 for assemblies in luxury vehicles. Additionally, the rise of electric vehicles (EVs) is reshaping market dynamics, as manufacturers focus on integrating cutting-edge lighting technologies that align with sustainability goals.

In terms of sourcing trends, international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking cost-effective yet high-quality aftermarket parts. The preference for aftermarket components is growing due to their affordability and availability, particularly in markets where OEM parts are prohibitively expensive. Furthermore, digital platforms are transforming procurement processes, enabling buyers to compare prices, access product reviews, and make informed purchasing decisions with greater ease.

The supply chain landscape is also shifting, driven by geopolitical factors and trade policies. Buyers must navigate tariffs and import regulations that can affect pricing and availability. Understanding local market conditions and establishing reliable relationships with suppliers can mitigate these challenges and ensure a steady flow of necessary components.

How is Sustainability Impacting Sourcing Practices for Headlight Replacement?

Sustainability is increasingly becoming a crucial consideration in the headlight replacement sector. The environmental impact of automotive lighting systems is significant, with traditional materials and manufacturing processes contributing to pollution and resource depletion. B2B buyers are now prioritizing suppliers that adhere to sustainable practices, including the use of eco-friendly materials and energy-efficient production methods.

Illustrative image related to cost for headlight replacement

Ethical sourcing has gained prominence, with a focus on ensuring that supply chains are free from exploitation and environmental harm. Certifications such as ISO 14001 for environmental management and various green certifications for materials signal a commitment to sustainability. Buyers are encouraged to partner with manufacturers who demonstrate transparency in their supply chains and actively engage in reducing their carbon footprints.

Moreover, the trend towards circular economy practices is influencing how headlight components are designed and produced. Buyers should look for suppliers that offer recyclable or biodegradable options, further minimizing the environmental impact. By aligning procurement strategies with sustainability goals, businesses can enhance their brand reputation and meet the growing consumer demand for environmentally responsible products.

How Has the Headlight Replacement Sector Evolved Over Time?

The evolution of the headlight replacement sector is marked by significant advancements in technology and shifting consumer preferences. Historically, halogen bulbs dominated the market due to their affordability and widespread availability. However, as concerns over energy efficiency and longevity grew, manufacturers began to innovate, leading to the introduction of HID and LED headlights. These advanced technologies offer not only better performance but also longer service lives, which can range from 2,000 to 40,000 hours, depending on the type.

The development of smart lighting systems has further transformed the landscape, incorporating adaptive features that enhance safety and functionality. As vehicles become more technologically sophisticated, the complexity of headlight systems increases, driving up replacement costs. This evolution necessitates that B2B buyers stay informed about emerging technologies and trends to make strategic sourcing decisions that balance cost, quality, and performance. Understanding the historical context of headlight technology will empower buyers to navigate current market dynamics effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of cost for headlight replacement

-

How do I determine the cost of headlight replacement for my vehicle?

To determine the cost of headlight replacement, start by identifying your vehicle’s make and model, as this influences the price significantly. Next, assess whether you need a simple bulb replacement or a complete headlight assembly. Basic halogen bulbs are generally less expensive, ranging from $10 to $100, while HID or LED options can cost from $100 to over $400. Finally, consider labor costs if you opt for professional installation, which can add between $100 and $400 depending on the complexity. -

What factors influence the cost of headlight assembly replacement?

Several factors affect the cost of headlight assembly replacement, including the type of headlight technology (halogen, HID, LED), the make and model of the vehicle, and whether you choose OEM or aftermarket parts. Labor costs also vary based on the complexity of the installation. Additional features such as adaptive beams or built-in sensors can further increase the price, so it’s essential to account for these elements when budgeting for replacement. -

What are the advantages of OEM vs. aftermarket headlight assemblies?

OEM (Original Equipment Manufacturer) headlight assemblies ensure compatibility and quality, as they are designed specifically for your vehicle. However, they tend to be more expensive. Aftermarket assemblies can offer cost savings and a wider variety of options, but their quality can vary significantly. For B2B buyers, it’s crucial to assess the reliability of aftermarket suppliers to ensure that the products meet safety and performance standards. -

How can I effectively vet suppliers for headlight replacement parts?

To vet suppliers, conduct thorough research including checking their certifications, customer reviews, and industry reputation. Request samples to evaluate product quality and compatibility with your vehicle models. Additionally, consider their track record for timely delivery and responsive customer service. Establishing relationships with suppliers who demonstrate transparency and reliability can help ensure a smooth procurement process. -

What are typical minimum order quantities (MOQs) for headlight replacement parts?

Minimum order quantities (MOQs) for headlight replacement parts can vary widely based on the supplier and the type of product. Some suppliers may allow orders as low as 10 units, while others may require orders of 50 or more for bulk pricing. It’s essential to communicate your needs clearly with potential suppliers to negotiate MOQs that align with your purchasing strategy and inventory management. -

What payment terms should I expect when sourcing headlight replacement parts internationally?

Payment terms for international sourcing can differ significantly based on the supplier and your negotiating power. Common options include upfront payment, partial payment upon order confirmation, or payment upon delivery. It’s advisable to explore payment methods that offer buyer protection, such as letters of credit or escrow services, to mitigate risks associated with international transactions. -

What quality assurance (QA) measures should I look for in headlight replacement suppliers?

When sourcing headlight replacement parts, ensure that suppliers have robust quality assurance processes in place. Look for certifications such as ISO 9001, which indicate adherence to international quality standards. Additionally, inquire about their testing procedures, warranty policies, and return processes. A supplier with a commitment to quality will provide documentation and support to ensure that their products meet your specifications. -

How can I manage logistics for importing headlight replacement parts?

Effective logistics management for importing headlight replacement parts involves selecting reliable shipping partners and understanding customs regulations in your country. Collaborate with freight forwarders to streamline shipping processes and ensure compliance with import duties and taxes. Additionally, consider using a just-in-time inventory strategy to minimize storage costs and ensure that you have the necessary parts available when needed.

Top 3 Cost For Headlight Replacement Manufacturers & Suppliers List

1. Honda Clarity – Headlight Replacement Solutions

المجال: Insideevsforum.com

مسجل: 2017 (8 سنوات)

مقدمة: The headlight replacement for a Honda Clarity costs $1500 per headlight, totaling $3000 for both front headlights. The headlights are described as a sealed assembly, meaning the bulbs cannot be replaced individually. There are mentions of alternative solutions such as polishing hazy lenses or searching for cheaper online options, with some listings on eBay for around $1300 for a pair. The original…

2. Toyota – Low Beam Bulb Replacement

المجال: community.cartalk.com

تاريخ التسجيل: 1995 (30 عامًا)

مقدمة: 2016 Toyota Camry SE, 2.5L 4-cylinder, Low Beam Bulb Replacement, Dealer Quote: $445 for two Halogen Low Beam Bulbs, Bulb Cost: $35 each, Labor Cost: approximately $375.

3. زينون برو - دليل تكاليف استبدال المصابيح الأمامية

المجال: xenonpro.com

مسجل: 2013 (12 سنة)

مقدمة: Headlight Replacement Cost Guide:

– Halogen Bulbs: $30 – $50 per pair, lifespan 1,000+ hours.

– Xenon HID Bulbs: $50 – $150 per pair, lifespan 10,000+ hours.

– LED Bulbs: N/A (entire assembly must be replaced), lifespan 30,000+ hours.

– LED Conversion Kit: $60 – $200, lifespan 5,000+ hours.

– HID Conversion Kit: $50 – $200, lifespan 5,000+ hours.

– Factory LED bulbs cannot be replaced indivi…

Strategic Sourcing Conclusion and Outlook for cost for headlight replacement

In the realm of headlight replacement, understanding the multifaceted cost dynamics is crucial for international B2B buyers. Key factors such as headlight technology, vehicle make and model, and the choice between OEM and aftermarket parts significantly influence overall expenses. Recognizing that basic halogen assemblies can range from $150 to $300, while advanced systems may soar to $4,000 or more, allows for more informed budgeting and procurement strategies.

Strategic sourcing emerges as an invaluable approach to mitigate costs and enhance supply chain efficiency. By establishing strong relationships with suppliers and leveraging bulk purchasing, businesses can achieve significant savings while ensuring quality. Moreover, exploring DIY options for simpler replacements can further optimize expenditures, empowering companies to maintain their fleets without incurring excessive labor costs.

As the automotive landscape continues to evolve, particularly with advancements in headlight technology, staying abreast of market trends and supplier capabilities will be essential. B2B buyers from regions like Africa, South America, the Middle East, and Europe should proactively engage with suppliers, seeking innovative solutions that align with their specific needs. Embrace strategic sourcing today to enhance your operational efficiency and drive long-term success in your headlight replacement initiatives.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.