مقدمة: التنقل في السوق العالمية لقطع غيار المولدات الكهربائية

In today’s competitive landscape, sourcing high-quality alternator parts poses a significant challenge for international B2B buyers. The intricacies of global supply chains and varying standards across regions can lead to uncertainties, especially for businesses in Africa, South America, the Middle East, and Europe, including key markets like Brazil and Saudi Arabia. This guide is designed to help you navigate the complexities of the alternator parts market, offering insights into the types of components available, their applications across various industries, and the essential criteria for vetting suppliers.

From standard units to high-output alternatives, the scope of this guide encompasses a comprehensive range of products tailored to meet diverse needs. We delve into the factors influencing costs and highlight best practices for establishing reliable partnerships with manufacturers and distributors. By equipping you with actionable insights and market intelligence, this guide empowers you to make informed purchasing decisions that align with your operational requirements and budget constraints.

As you explore the various sections, you will find valuable information on alternative solutions, troubleshooting tips, and innovative technologies that can enhance your operational efficiency. Whether you are a procurement manager or a business owner, this resource is your roadmap to successfully sourcing alternator parts in the global marketplace, ensuring that you remain competitive and well-equipped to meet customer demands.

جدول المحتويات

- Top 4 Alternators Parts Manufacturers & Suppliers List

- مقدمة: التنقل في السوق العالمية لقطع غيار المولدات الكهربائية

- فهم أنواع أجزاء المولدات وأنواعها واختلافاتها

- التطبيقات الصناعية الرئيسية لقطع غيار المولدات الكهربائية

- 3 نقاط ألم شائعة لدى المستخدمين لـ ‘أجزاء المولدات’ وحلولها

- دليل اختيار المواد الاستراتيجية لأجزاء المولدات الكهربائية

- نظرة متعمقة: عمليات التصنيع وضمان جودة قطع غيار المولدات الكهربائية

- دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘قطع غيار المولدات’

- التحليل الشامل للتكلفة والتسعير الشامل لمصادر قطع غيار المولدات الكهربائية

- تحليل البدائل: مقارنة أجزاء المولدات بالحلول الأخرى

- الخواص الفنية الأساسية والمصطلحات التجارية لأجزاء المولدات الكهربائية

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع قطع غيار المولدات الكهربائية

- الأسئلة المتداولة (FAQs) لمشتري قطع غيار مولدات التيار المتردد B2B

- استنتاجات وتوقعات التوريد الاستراتيجي لقطع غيار المولدات الكهربائية

- إخلاء مسؤولية هام وشروط الاستخدام

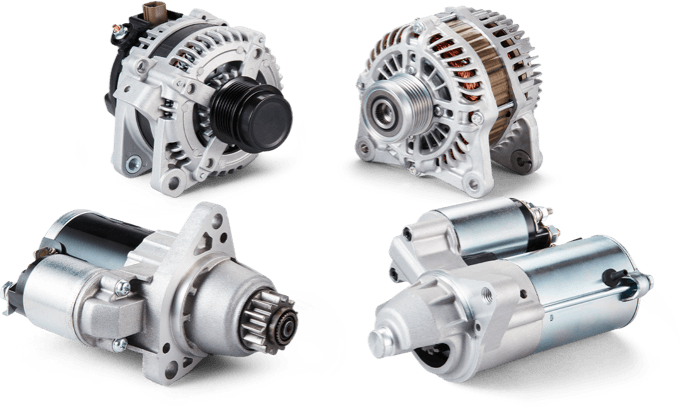

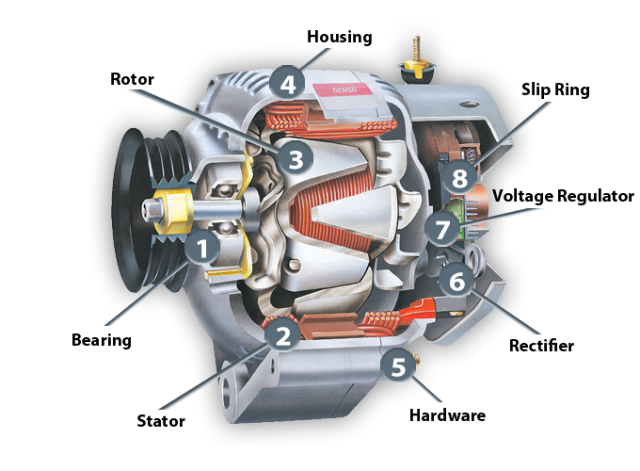

فهم أنواع أجزاء المولدات وأنواعها واختلافاتها

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولدات عالية الإنتاجية | Higher amperage ratings; robust design for heavy loads | المركبات الثقيلة والآلات الصناعية | الإيجابيات: Increased power output; reliability. السلبيات: Higher initial cost; may require specific installation. |

| المولدات القياسية | Standard amperage output; widely compatible | التطبيقات العامة للسيارات | الإيجابيات: Cost-effective; easy to source. السلبيات: Limited power for high-demand applications. |

| مولدات كهربائية بحرية | Corrosion-resistant materials; designed for marine use | Boats, yachts, and other watercraft | الإيجابيات: Durability in harsh environments; specialized design. السلبيات: Can be more expensive; limited to marine applications. |

| Dual Rectifier Alternators | Features two rectifiers for improved performance | High-performance vehicles, audio systems | الإيجابيات: Enhanced reliability; better performance under load. السلبيات: Complexity may require specialized knowledge for installation. |

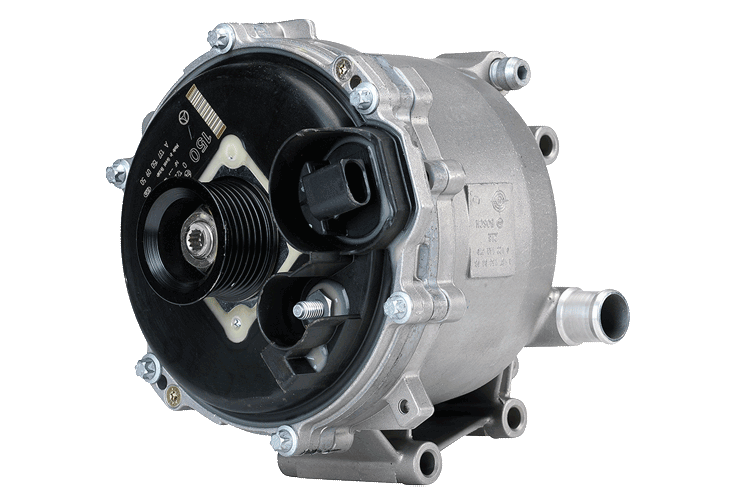

| المولدات ذات المغناطيس الدائم | Uses permanent magnets instead of electromagnets | Hybrid vehicles, small engines | الإيجابيات: Compact size; high efficiency. السلبيات: Limited power output; may not suit all applications. |

What Are High Output Alternators and Their B2B Relevance?

High output alternators are designed to provide significantly higher amperage ratings compared to standard units, making them ideal for heavy-duty vehicles and industrial machinery. Their robust construction ensures reliability under demanding conditions, which is critical for businesses that depend on uninterrupted power supply. When purchasing, buyers should consider the specific amperage needs of their application and whether the alternator requires specialized installation.

How Do Standard Alternators Fit into the Market?

Standard alternators are the most commonly used type, offering compatibility across a wide range of automotive applications. They provide sufficient power for everyday vehicles, making them a cost-effective choice for fleet operators and automotive repair shops. B2B buyers should evaluate their needs based on vehicle specifications and the electrical load requirements to ensure they select an appropriate unit.

Why Are Marine Alternators Essential for Watercraft?

Marine alternators are specifically engineered to withstand harsh marine environments, featuring corrosion-resistant materials and designs tailored for boats and yachts. This specialization is crucial for ensuring reliability and longevity in saltwater conditions. Buyers in the marine sector should prioritize quality and durability when selecting alternators, as failure can lead to significant operational disruptions.

What Benefits Do Dual Rectifier Alternators Offer?

Dual rectifier alternators utilize two rectifiers to enhance performance, particularly in high-demand applications such as audio systems and performance vehicles. Their design improves reliability under heavy loads, making them suitable for businesses that require consistent power delivery. However, the complexity of installation may necessitate professional assistance, which buyers should factor into their purchasing decisions.

How Do Permanent Magnet Alternators Differ from Traditional Models?

Permanent magnet alternators operate using permanent magnets rather than electromagnets, resulting in a compact and efficient design. They are commonly used in hybrid vehicles and small engines, appealing to B2B buyers focused on energy efficiency and space-saving solutions. However, their limited power output may restrict their applicability in larger systems, necessitating careful consideration of the specific requirements of the intended use.

التطبيقات الصناعية الرئيسية لقطع غيار المولدات الكهربائية

| الصناعة/القطاع | Specific Application of Alternators Parts | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | High-output alternators for performance vehicles | Enhanced power supply for advanced electrical systems | Quality assurance, compatibility with vehicle models, and reliability. |

| الزراعة | مولدات المولدات للآلات الزراعية | Increased efficiency and reliability in field operations | Durability in harsh environments and availability of replacement parts. |

| بحري | Marine alternators for boats and vessels | طاقة موثوقة للملاحة والأنظمة الموجودة على متن الطائرة | Corrosion resistance, compliance with marine standards, and service support. |

| البناء | Alternators for heavy equipment like generators and cranes | Continuous power supply, reducing downtime on-site | High output capacity, rugged design, and local support services. |

| الطاقة المتجددة | المولدات في أنظمة طاقة الرياح والطاقة الشمسية | Maximized energy conversion and storage capabilities | Customization options, efficiency ratings, and integration with existing systems. |

كيف تُستخدم قطع غيار المولدات في قطاع السيارات؟

In the automotive industry, high-output alternators are crucial for performance vehicles that require a reliable and robust electrical system. These alternators supply power to advanced components such as infotainment systems, lighting, and performance-enhancing accessories. International buyers must prioritize quality and compatibility with specific vehicle models to avoid electrical failures. Additionally, sourcing from reputable manufacturers ensures longevity and performance under demanding conditions.

What Is the Role of Alternators in Agriculture?

Agricultural machinery, including tractors and harvesters, relies heavily on alternators for efficient operation. These parts convert mechanical energy into electrical energy, powering essential systems like GPS and automated controls. For buyers in regions like South America and Africa, durability in extreme weather conditions is vital. Ensuring access to replacement parts and service support can significantly reduce downtime during critical harvest periods.

How Do Marine Applications Benefit from Alternators Parts?

In the marine sector, alternators provide essential power for navigation systems, lighting, and onboard appliances. Marine alternators must be corrosion-resistant due to exposure to saltwater and harsh environments. Buyers in the Middle East and Europe should ensure that sourced products meet marine safety standards and offer reliable performance. Additionally, having local service options can help in maintaining these systems effectively.

Why Are Alternators Important in Construction Equipment?

Heavy construction equipment, such as cranes and generators, requires robust alternators to ensure a continuous power supply. These alternators are integral for operating hydraulic systems and electronic controls, directly impacting productivity on job sites. For international buyers, particularly in developing regions, sourcing high-output and rugged alternators is critical to withstand the demanding conditions typical of construction environments. Reliable supplier support can also mitigate the risks associated with equipment failure.

How Do Alternators Support Renewable Energy Initiatives?

In the renewable energy sector, alternators are essential components in wind and solar energy systems, converting generated energy into usable electrical power. They enhance energy storage capabilities and improve overall system efficiency. Buyers focused on sustainability must consider customization options that align with their specific energy solutions. Additionally, understanding efficiency ratings and sourcing from manufacturers with a proven track record in renewable technologies is vital for maximizing investment returns.

3 نقاط ألم شائعة لدى المستخدمين لـ ‘أجزاء المولدات’ وحلولها

Scenario 1: Challenges in Sourcing Quality Alternator Parts

المشكلة:

International B2B buyers often struggle with sourcing high-quality alternator parts, particularly when dealing with different suppliers across various regions. This challenge is exacerbated by the inconsistency in product quality, leading to concerns about reliability and performance. Buyers may receive parts that do not meet the required specifications or fail prematurely, causing disruptions in operations and potential damage to equipment.

الحل:

To ensure the procurement of quality alternator parts, buyers should establish relationships with reputable suppliers known for their quality control measures. Conduct thorough research on manufacturers and suppliers, focusing on their track record and customer reviews. Utilize platforms that specialize in B2B transactions, ensuring that they have stringent quality assurance processes in place. It’s also advisable to request detailed specifications and certifications for the parts being purchased. Building a strong communication channel with suppliers can facilitate better understanding of product requirements, leading to more satisfactory outcomes.

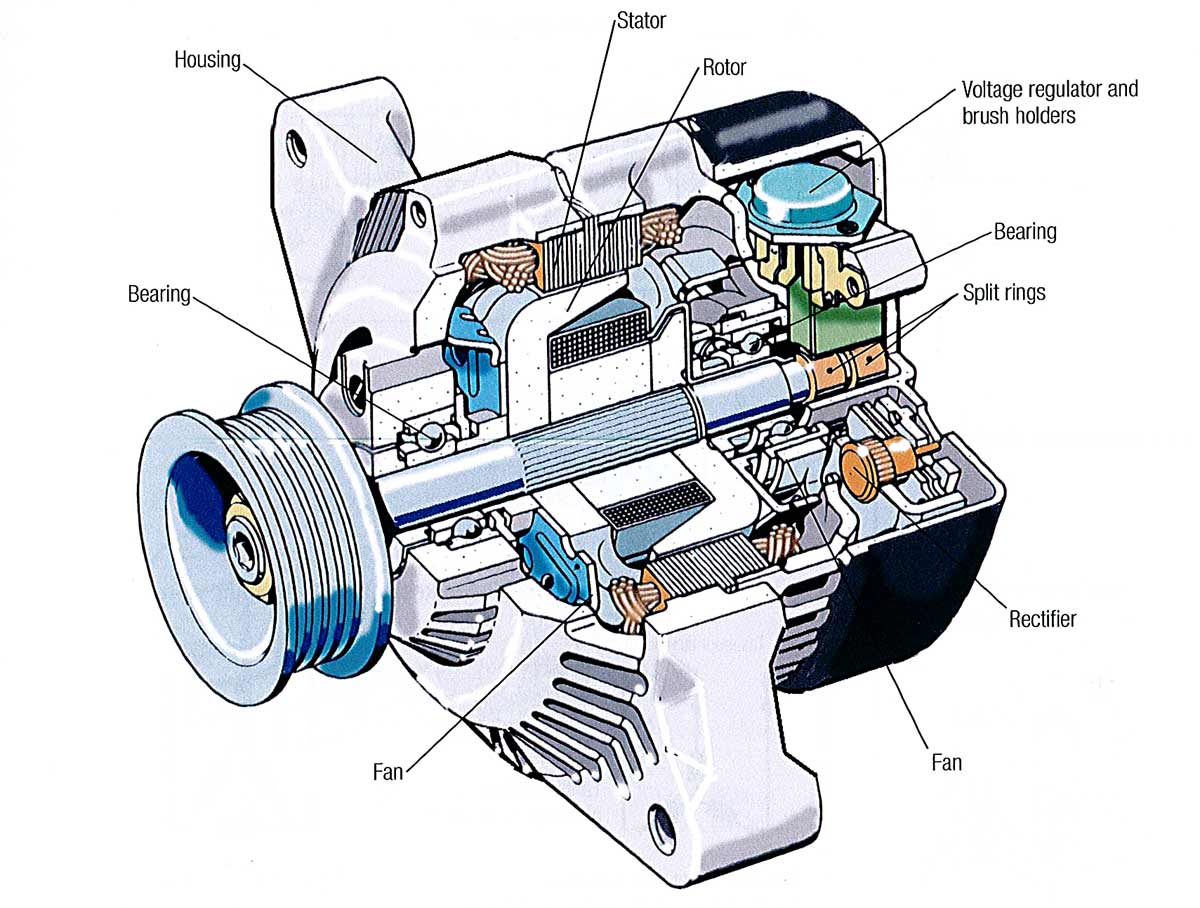

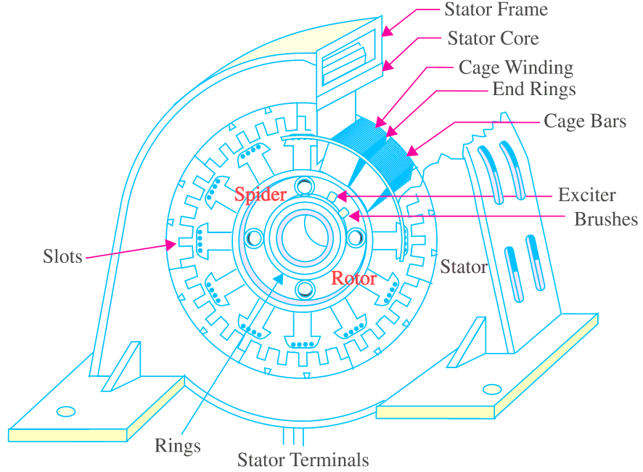

صورة توضيحية متعلقة بأجزاء المولدات

Scenario 2: Difficulty in Compatibility and Specifications

المشكلة:

Another common pain point for B2B buyers is the compatibility of alternator parts with existing machinery. Many buyers encounter situations where the parts they purchase do not fit or function as intended due to mismatched specifications. This issue can lead to costly downtime and the need for additional purchases or modifications, significantly impacting operational efficiency.

الحل:

Buyers should conduct a thorough compatibility analysis before making any purchases. This involves understanding the specifications of the existing alternators, including voltage ratings, amperage, and physical dimensions. Utilizing comprehensive catalogs or databases that provide detailed information about alternator parts can help in identifying suitable replacements. Additionally, engaging with technical support from suppliers can provide insights into whether specific parts will be compatible. Creating a checklist of required specifications based on the equipment will streamline the sourcing process and minimize compatibility issues.

Scenario 3: Managing Lead Times and Delivery Issues

المشكلة:

International logistics can introduce delays in the delivery of alternator parts, creating a significant pain point for B2B buyers. Extended lead times can lead to project delays and increased operational costs. This issue is particularly acute in regions where shipping logistics may be less reliable, causing uncertainty about when parts will arrive.

الحل:

To mitigate lead time issues, buyers should proactively engage with suppliers about their shipping capabilities and expected delivery timelines. Establishing clear agreements on delivery times and tracking processes can enhance transparency. Furthermore, maintaining a buffer stock of critical alternator parts can prevent operational disruptions during unforeseen delays. Buyers can also explore local suppliers or distributors that can provide quicker access to parts, reducing reliance on international shipping. Utilizing demand forecasting tools can help in planning inventory levels and ensuring that essential parts are available when needed.

دليل اختيار المواد الاستراتيجية لأجزاء المولدات الكهربائية

What Are the Key Materials Used in Alternator Parts?

When selecting materials for alternator parts, it’s crucial to consider properties that influence performance, durability, and cost. Below, we analyze four common materials used in the manufacturing of alternator components: aluminum, copper, steel, and plastic. Each material has distinct characteristics that can affect the overall performance of alternators, especially in diverse environments such as those found in Africa, South America, the Middle East, and Europe.

كيف يفيد الألومنيوم أجزاء المولد؟

Aluminum is a lightweight metal commonly used in alternator housings and components. Its key properties include excellent corrosion resistance and a good strength-to-weight ratio, making it ideal for automotive applications. Aluminum can withstand temperatures up to 150°C (302°F) and pressures typical in automotive environments.

الإيجابيات: Aluminum is durable and lightweight, which contributes to better fuel efficiency in vehicles. It is also relatively easy to machine and form, reducing manufacturing complexity.

السلبيات: While aluminum is cost-effective, it can be more expensive than some steel options. It may also be less durable under extreme conditions compared to heavier metals.

التأثير على التطبيق: Aluminum’s corrosion resistance makes it suitable for humid or coastal environments, which is beneficial for markets in South America and Africa.

اعتبارات للمشترين الدوليين: Buyers should ensure compliance with relevant standards, such as ASTM B211 for aluminum alloys, and consider local preferences for lightweight materials in automotive applications.

صورة توضيحية متعلقة بأجزاء المولدات

ما الدور الذي يلعبه النحاس في أداء المولد؟

Copper is primarily used in the windings of alternators due to its exceptional electrical conductivity. It can handle high temperatures (up to 200°C or 392°F) and has good resistance to corrosion, especially when coated.

الإيجابيات: The high conductivity of copper enhances the efficiency of alternators, leading to better performance and lower energy losses.

السلبيات: Copper is more expensive than aluminum and can be heavier, which may not align with the push for lightweight components in modern vehicles.

التأثير على التطبيق: Copper’s thermal properties make it suitable for high-performance applications, such as in racing or heavy-duty vehicles.

صورة توضيحية متعلقة بأجزاء المولدات

اعتبارات للمشترين الدوليين: Buyers should be aware of copper’s price volatility and ensure compliance with international standards like ASTM B170 for copper wire.

لماذا يستخدم الفولاذ في مكونات المولد؟

Steel is often used for structural components of alternators, such as brackets and housings. It offers high strength and durability, with temperature ratings that can exceed 300°C (572°F) depending on the alloy.

الإيجابيات: Steel is robust and provides excellent mechanical strength, making it suitable for heavy-duty applications.

صورة توضيحية متعلقة بأجزاء المولدات

السلبيات: Steel is heavier than aluminum and can be prone to corrosion unless treated or coated, which can increase manufacturing complexity.

التأثير على التطبيق: Steel’s durability makes it ideal for applications that require resilience, such as in industrial or agricultural machinery.

اعتبارات للمشترين الدوليين: Buyers should consider local regulations regarding the use of steel and ensure compliance with standards like ASTM A36 for structural steel.

صورة توضيحية متعلقة بأجزاء المولدات

How Is Plastic Utilized in Alternator Parts?

Plastic is often used in non-structural components, such as insulators and housings for voltage regulators. Its key properties include lightweight, good insulation, and resistance to corrosion.

الإيجابيات: Plastic is cost-effective and can be molded into complex shapes, reducing manufacturing costs.

السلبيات: While plastic is lightweight, it may not withstand high temperatures or mechanical stress as well as metals.

التأثير على التطبيق: Plastic components are suitable for applications where weight savings are critical, but they may not be ideal for high-stress environments.

صورة توضيحية متعلقة بأجزاء المولدات

اعتبارات للمشترين الدوليين: Buyers should ensure that plastics meet relevant standards for automotive applications, such as ISO 9001 for quality management.

جدول تلخيصي لاختيار المواد لأجزاء المولدات

| المواد | حالة الاستخدام النموذجية لقطع غيار المولدات | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | العلب، الأقواس | خفيف الوزن ومقاوم للتآكل | أقل متانة في الظروف القاسية | متوسط |

| النحاس | Windings | موصلية كهربائية عالية | Expensive, heavier than aluminum | عالية |

| الصلب | المكونات الهيكلية | قوة ومتانة عالية | Heavy, prone to corrosion | متوسط |

| بلاستيك | Insulators, non-structural parts | فعالة من حيث التكلفة وخفيفة الوزن | مقاومة محدودة لدرجات الحرارة | منخفض |

In conclusion, selecting the right material for alternator parts is essential for optimizing performance and durability. Understanding the properties, advantages, and limitations of each material can aid international B2B buyers in making informed decisions tailored to their specific market needs.

نظرة متعمقة: عمليات التصنيع وضمان جودة قطع غيار المولدات الكهربائية

ما هي المراحل الرئيسية في عملية تصنيع أجزاء المولد؟

The manufacturing process of alternator parts typically consists of several essential stages: material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the functionality, reliability, and durability of the end product.

صورة توضيحية متعلقة بأجزاء المولدات

How Does Material Preparation Impact the Quality of Alternator Parts?

Material preparation is the first and one of the most critical steps in the manufacturing process. This involves selecting high-quality raw materials, such as copper for windings, aluminum for housings, and steel for brackets. The materials must be thoroughly inspected for defects and conform to industry standards to ensure they can withstand operational stresses.

Advanced techniques such as computer-aided design (CAD) are often used to optimize material usage and minimize waste. Additionally, suppliers may conduct chemical analysis and mechanical testing on raw materials to verify their suitability for manufacturing alternator parts.

What Forming Techniques Are Commonly Used in Alternator Parts Manufacturing?

The forming stage encompasses various techniques such as stamping, forging, and machining. Stamping is commonly used for creating the metal casing and internal components, which allows for precise shapes and dimensions. Forging may be used for parts that require high strength, such as brackets and mounts.

Machining is utilized to achieve fine tolerances and surface finishes on critical components like rotors and stators. The choice of forming technique depends on the component’s design and the required physical properties, impacting both performance and cost.

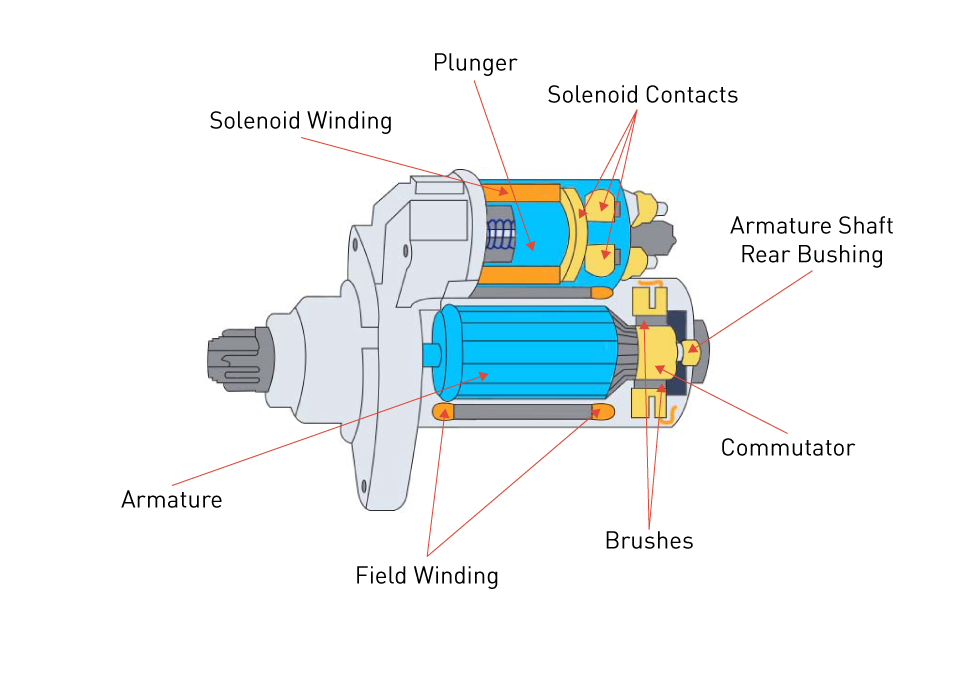

How Is the Assembly Process Conducted for Alternator Parts?

The assembly process involves integrating various components into a complete alternator. This step typically follows a systematic approach to ensure each part fits perfectly. Technicians often use specialized tools and fixtures to facilitate accurate assembly, which can include the installation of bearings, brushes, and rectifiers.

During assembly, manufacturers must adhere to strict guidelines to ensure that torque specifications and alignment are maintained. This precision is vital for the alternator’s performance and longevity.

What Finishing Processes Are Important for Alternator Parts?

Finishing processes enhance the aesthetic and functional properties of alternator parts. Common techniques include anodizing, painting, and surface treatment to improve corrosion resistance and wear properties.

A thorough finishing process also includes quality checks to ensure that surfaces are free from defects and meet the required specifications. For example, anodizing not only provides a protective layer but can also improve electrical insulation properties, which is essential for high-performance alternators.

What Quality Assurance Standards Are Relevant to Alternator Parts?

Quality assurance (QA) is critical in the manufacturing of alternator parts to ensure that products meet both international and industry-specific standards. ISO 9001 is one of the most recognized standards that provides a framework for a quality management system. Compliance with ISO 9001 indicates that a manufacturer consistently meets customer and regulatory requirements.

صورة توضيحية متعلقة بأجزاء المولدات

In addition to ISO standards, certifications such as CE mark (for European markets) and API (American Petroleum Institute) standards may be relevant depending on the application of the alternators. These certifications serve as a guarantee of safety, reliability, and performance.

How Are Quality Control Checkpoints Established in Manufacturing?

Quality control (QC) checkpoints are essential to monitor the manufacturing process at various stages. Common checkpoints include:

-

مراقبة الجودة الواردة (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards before they enter the production process.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During production, random sampling and inspections are conducted to detect defects early. This step helps in addressing any issues before they escalate.

-

مراقبة الجودة النهائية (FQC): After assembly, every alternator undergoes rigorous testing to confirm that it meets design specifications. This may include electrical testing, load testing, and performance assessments.

What Testing Methods Are Commonly Used for Alternator Parts?

Testing methods are crucial for validating the performance and safety of alternator parts. Common testing techniques include:

-

الاختبارات الكهربائية: This checks the output voltage and current to ensure the alternator functions as intended.

-

الاختبار الحراري: This assesses how well components withstand heat generated during operation.

-

اختبار الاهتزازات: This evaluates the durability of parts against operational stresses and ensures that they can handle vibrations without failure.

-

Lifecycle Testing: Simulating operational conditions over extended periods helps predict the longevity and reliability of alternators.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Here are several actionable strategies:

-

إجراء عمليات تدقيق للموردين: Regular audits can help assess the supplier’s adherence to quality management systems and manufacturing processes.

-

طلب تقارير الجودة: Ask suppliers for documentation that outlines their quality control measures, including inspection reports and compliance certifications.

-

Engage Third-Party Inspections: Utilizing independent inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality assurance processes.

-

Check References and Reviews: Researching customer feedback and industry reputation can offer insights into a supplier’s reliability and commitment to quality.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

International buyers must navigate additional complexities in quality control when sourcing alternator parts. This includes understanding regional compliance requirements, cultural differences in manufacturing practices, and variations in quality standards.

For example, buyers from Africa and South America may encounter different regulatory landscapes compared to those in Europe or the Middle East. It’s essential to engage with suppliers familiar with local regulations and who can provide documentation and certifications that comply with both international and regional standards.

In conclusion, understanding the intricacies of manufacturing processes and quality assurance for alternator parts is essential for B2B buyers seeking reliable and high-performance products. By focusing on these areas, buyers can make informed decisions that align with their operational needs and quality expectations.

دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘قطع غيار المولدات’

مقدمة

Sourcing alternator parts for your business can be a complex process, particularly when operating in diverse international markets. This guide provides a practical checklist to ensure that you navigate the procurement landscape effectively, mitigating risks and securing quality components that meet your specifications.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Before reaching out to suppliers, it’s essential to clearly outline your technical requirements. Consider factors such as voltage ratings, amperage, and specific compatibility with existing systems. Defining these parameters upfront helps prevent costly errors and ensures that suppliers can meet your unique needs.

- Key Specifications: Voltage (e.g., 12V, 24V), Amperage (e.g., high-output vs. standard), and type of vehicle or equipment.

- Industry Standards: Be aware of any relevant standards (e.g., ISO, SAE) that may apply to the alternator parts you require.

الخطوة 2: البحث عن الموردين المحتملين

Conduct thorough research to identify potential suppliers who specialize in alternator parts. Utilize online directories, trade shows, and industry forums to gather a list of candidates. This step is crucial as it sets the foundation for your procurement process.

صورة توضيحية متعلقة بأجزاء المولدات

- Consider Reputation: Look for suppliers with a strong reputation in the industry and positive reviews from previous customers.

- Local vs. International: Assess whether you prefer local suppliers for easier communication and logistics or international suppliers for potentially better pricing.

الخطوة 3: تقييم شهادات الموردين

Before engaging with suppliers, verify their certifications and quality assurance processes. Certifications such as ISO 9001 indicate adherence to quality management standards, which is critical for ensuring the reliability of the parts you purchase.

- طلب التوثيق: Ask for copies of relevant certifications and quality control procedures.

- الامتثال للوائح: Ensure that the supplier complies with any local regulations in your target markets, particularly in regions like Africa and the Middle East.

الخطوة 4: طلب عينات

Once you have shortlisted potential suppliers, request samples of the alternator parts you are interested in. This step allows you to assess the quality and compatibility of the products firsthand.

- إجراءات الاختبار: Establish criteria for testing samples, including performance under load and durability.

- فحوصات التوافق: Ensure that the samples are compatible with your existing systems to avoid future issues.

الخطوة 5: التفاوض على الشروط والأسعار

Engage in discussions with your selected suppliers to negotiate terms, pricing, and delivery schedules. This step is vital for ensuring that you achieve a favorable deal while securing the necessary parts for your operations.

- Consider Total Cost of Ownership: Look beyond initial pricing and consider factors like shipping costs, duties, and potential customs delays.

- شروط الدفع: Discuss payment options that protect your business, such as letters of credit or escrow services for larger orders.

الخطوة 6: وضع خطة التواصل

Once you finalize your supplier, establish a clear communication plan to facilitate ongoing collaboration. Effective communication is key to addressing any issues that may arise during production or delivery.

صورة توضيحية متعلقة بأجزاء المولدات

- تحديثات منتظمة: Schedule regular check-ins to discuss order status and any changes in requirements.

- Point of Contact: Designate a point of contact on both sides to streamline communication and ensure accountability.

الخطوة 7: Monitor Performance and Provide Feedback

After procuring alternator parts, monitor the supplier’s performance and provide constructive feedback. Continuous assessment helps maintain quality and fosters a strong supplier relationship.

- مقاييس الأداء: Track delivery times, product quality, and responsiveness to inquiries.

- Long-term Partnerships: Consider establishing long-term partnerships with reliable suppliers for future needs, which can lead to better pricing and service.

Following this checklist will empower you to make informed decisions while sourcing alternator parts, ensuring that your procurement process is efficient and effective.

التحليل الشامل للتكلفة والتسعير الشامل لمصادر قطع غيار المولدات الكهربائية

What Are the Key Cost Components in Alternator Parts Sourcing?

Understanding the cost structure for alternator parts is crucial for B2B buyers to make informed purchasing decisions. The primary components that contribute to the overall cost include:

-

المواد: Raw materials such as copper, aluminum, and steel are essential in manufacturing alternators. Prices for these materials can fluctuate based on global market trends, affecting overall costs. Buyers should consider sourcing materials from reliable suppliers to mitigate sudden price changes.

-

العمل: The cost of labor varies by region and can significantly impact manufacturing costs. In countries with higher wage standards, the cost of labor will be higher, which may reflect in the pricing of alternator parts. It is essential to assess the skill level and productivity of the workforce in the supplier’s location.

-

تكاليف التصنيع العامة: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, allowing suppliers to offer competitive pricing.

-

الأدوات: The initial setup for production, including molds and machinery, represents a significant upfront investment. Buyers may face higher prices for custom or specialized alternator parts due to these tooling costs.

-

مراقبة الجودة (QC): Ensuring that products meet specific standards can add to costs. Suppliers that implement rigorous QC processes may charge a premium, but this can lead to reduced failure rates and lower Total Cost of Ownership (TCO) for buyers.

-

اللوجستيات: Transportation and warehousing costs are critical in determining the final price. Buyers should account for shipping methods and distances, which can vary significantly across different regions, especially for international orders.

-

الهامش: Suppliers will typically add a margin to cover their business risks and ensure profitability. This margin can vary based on market competition, supplier reputation, and the complexity of the alternator parts.

What Influences Pricing for Alternator Parts?

Several factors can influence the pricing of alternator parts, making it essential for buyers to navigate these considerations effectively:

-

الحجم والحد الأدنى لكمية الطلب (MOQ): Bulk purchases often lead to discounts. Understanding the MOQ set by suppliers can help buyers optimize their orders for better pricing.

-

المواصفات والتخصيص: Custom parts or specific configurations will generally cost more due to the additional design and manufacturing processes involved. Buyers should weigh the benefits of customization against the higher costs.

-

شهادات المواد والجودة: Higher-quality materials or components that meet international standards (such as ISO certifications) can drive up prices. Buyers should evaluate whether the benefits of higher quality justify the additional costs.

-

عوامل الموردين: The reputation and reliability of suppliers can significantly influence pricing. Established suppliers may charge more due to their proven track record, while newer or less reputable suppliers might offer lower prices but come with higher risks.

-

مصطلحات التجارة الدولية: The choice of Incoterms can impact costs associated with shipping and insurance. Familiarity with these terms can help buyers negotiate better shipping arrangements and manage their overall expenditure.

How Can Buyers Negotiate Better Prices for Alternator Parts?

To achieve cost-efficient sourcing of alternator parts, buyers should consider the following strategies:

صورة توضيحية متعلقة بأجزاء المولدات

-

الاستفادة من العلاقات: Building long-term relationships with suppliers can lead to favorable pricing and terms. Regular communication and trust can open doors to better deals.

-

إجراء أبحاث السوق: Understanding market trends and competitor pricing can empower buyers during negotiations. Awareness of industry benchmarks allows buyers to advocate for fair pricing.

-

تقييم التكلفة الإجمالية للملكية (TCO): Instead of solely focusing on initial costs, buyers should assess the TCO, which includes maintenance, operational efficiency, and potential downtime. This broader perspective can justify higher upfront costs if they lead to better long-term savings.

-

اطلب عروض أسعار متعددة: Obtaining quotes from several suppliers can provide leverage in negotiations. It also offers insights into market pricing, helping buyers make informed decisions.

-

Be Culturally Aware: When dealing with international suppliers, understanding cultural nuances and negotiation styles can enhance communication and lead to more favorable outcomes.

الخلاصة

While pricing for alternator parts can be influenced by various factors, B2B buyers must adopt a comprehensive approach to sourcing. By understanding cost components, recognizing pricing influencers, and employing effective negotiation strategies, buyers can optimize their purchasing decisions and secure the best value for their investments. Always remember that indicative prices can vary, and thorough due diligence is essential for successful sourcing.

تحليل البدائل: مقارنة أجزاء المولدات بالحلول الأخرى

Understanding Alternatives in Alternator Parts

In the competitive landscape of automotive and industrial solutions, businesses often seek alternatives to traditional products. For alternator parts, understanding viable alternatives can lead to better performance, cost savings, and enhanced operational efficiency. This section explores how alternator parts compare to other solutions, providing B2B buyers with insights that can inform their purchasing decisions.

جدول المقارنة

| جانب المقارنة | قطع غيار المولدات | Alternative 1: Battery Systems | Alternative 2: Generators |

|---|---|---|---|

| الأداء | High efficiency; converts mechanical energy to electrical effectively | Limited by battery capacity; may require frequent recharging | High output; can power multiple devices simultaneously |

| التكلفة | Moderate initial investment; long-term savings through durability | Lower initial costs; ongoing battery replacement can increase total cost | Higher upfront costs; fuel and maintenance expenses add to overall cost |

| سهولة التنفيذ | Straightforward installation and compatibility with various vehicles | Simple to install; requires knowledge of battery management | Complex setup may require professional installation |

| الصيانة | Regular checks; parts may need replacement over time | Requires regular monitoring and maintenance; battery life varies | Regular maintenance required for fuel and mechanical parts |

| أفضل حالة استخدام | Ideal for automotive applications needing reliable power | Suitable for smaller applications or as a supplementary power source | Best for heavy-duty applications or off-grid power needs |

تفصيل البدائل

1. Battery Systems

Battery systems serve as an alternative to alternators by storing electrical energy for later use. They are often used in applications where intermittent power is needed. The primary advantage of battery systems is their lower initial cost and ease of installation. However, they have limitations in terms of capacity and lifespan, requiring frequent recharges and eventual replacements. For businesses focused on short-term power solutions, battery systems can be effective, but they may not provide the reliability needed for continuous operations.

صورة توضيحية متعلقة بأجزاء المولدات

2. Generators

Generators are another alternative, offering the ability to produce electrical power on demand. They are typically used in situations requiring large amounts of power, such as construction sites or events. The performance of generators is impressive, as they can supply consistent power over extended periods. However, they come with higher upfront costs and ongoing fuel and maintenance expenses. While they are suitable for heavy-duty applications, they may not be practical for smaller operations or vehicles where space and weight are concerns.

How to Choose the Right Solution for Your Needs

Selecting the right solution between alternator parts, battery systems, and generators ultimately depends on your specific operational requirements. Consider factors such as the scale of your operations, budget constraints, and the environment in which the equipment will be used. For businesses in automotive sectors needing reliable, high-efficiency power, investing in quality alternator parts may be the best choice. Conversely, for applications with fluctuating power demands or limited budgets, battery systems could suffice. Finally, for heavy-duty or off-grid scenarios, generators provide a robust solution despite their higher costs. By evaluating these alternatives against your operational needs, you can make informed decisions that enhance your business’s efficiency and productivity.

الخواص الفنية الأساسية والمصطلحات التجارية لأجزاء المولدات الكهربائية

ما هي الخصائص التقنية الرئيسية لأجزاء المولد؟

When sourcing alternator parts, understanding the essential technical properties can significantly impact performance and compatibility. Here are some critical specifications to consider:

-

درجة المواد

– The material used in alternator components, such as copper for windings and aluminum or steel for housings, affects durability and conductivity. High-grade materials ensure longer life and better performance under demanding conditions. B2B buyers must prioritize suppliers who guarantee high-quality materials to minimize failure rates and enhance operational efficiency. -

تصنيف الأمبيرية

– This specification indicates the maximum electrical current an alternator can produce. Alternators are available in various amperage ratings, such as standard or high-output models. Selecting the correct amperage is crucial for compatibility with the electrical demands of vehicles or machinery. An inadequate rating may lead to insufficient power supply, affecting performance and reliability. -

ناتج الجهد

– Alternators typically operate at either 12V or 24V systems, with variations for specific applications. Understanding the required voltage output ensures that the alternator can adequately power electrical systems without causing damage. B2B buyers should verify voltage compatibility to avoid potential operational issues. -

مستويات التسامح

– Tolerance refers to the permissible limit of variation in a part’s dimension or performance. For alternators, this includes rotor and stator gaps, which directly affect efficiency and energy conversion. Tight tolerances are essential for high-performance applications, ensuring that parts fit precisely and operate effectively under load. -

آلية التبريد

– Many alternators incorporate cooling systems, such as external fans or heat sinks, to dissipate heat generated during operation. Efficient cooling extends the lifespan of alternator components and maintains performance. Buyers should assess whether the cooling mechanism is adequate for their specific use case, especially in high-demand environments.

What Are Common Trade Terms in the Alternator Parts Industry?

Navigating the alternator parts market requires familiarity with industry jargon. Here are key terms that B2B buyers should know:

-

OEM (الشركة المصنعة للمعدات الأصلية)

– OEM parts are produced by the original manufacturer of the vehicle or machinery. These components typically guarantee compatibility and quality. When sourcing alternator parts, opting for OEM can provide assurance of performance and reliability, which is especially important for businesses that prioritize quality. -

MOQ (الحد الأدنى لكمية الطلب)

– MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management. B2B buyers should negotiate MOQs that align with their operational needs to avoid excess stock or supply shortages. -

طلب عرض أسعار (RFQ)

– An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This document typically outlines quantities, specifications, and delivery timelines. Using RFQs helps buyers compare costs and terms effectively, ensuring they get the best value for their purchases. -

شروط التجارة الدولية (Incoterms)

– Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their liabilities and the logistics involved in importing alternator parts. Clear communication regarding Incoterms can prevent misunderstandings and ensure smooth transactions. -

قطع غيار ما بعد البيع

– Aftermarket parts are components made by manufacturers other than the original equipment manufacturer. They can offer cost-effective alternatives but may vary in quality and compatibility. Buyers should assess the reputation of aftermarket suppliers to ensure reliability and performance.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure the right alternator parts for their specific applications while navigating the complexities of international trade effectively.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع قطع غيار المولدات الكهربائية

What Are the Current Market Dynamics and Key Trends in the Alternators Parts Sector?

The alternators parts sector is experiencing a transformative phase driven by several global trends. A significant factor is the increasing demand for high-output and specialty alternators as industries seek reliable power solutions for vehicles, machinery, and renewable energy applications. This demand is particularly pronounced in emerging markets across Africa, South America, the Middle East, and Europe, where economic growth is spurring investments in infrastructure and automotive sectors.

One notable trend is the shift towards digitalization and the use of advanced manufacturing technologies. Technologies such as 3D printing and IoT-enabled devices are enhancing the customization and efficiency of alternator parts production, allowing suppliers to respond swiftly to changing market needs. Additionally, the rise of e-commerce platforms is facilitating easier access for international B2B buyers to source parts from global suppliers, streamlining procurement processes and reducing lead times.

Another dynamic is the emphasis on quality and performance over cost alone. Buyers are increasingly prioritizing suppliers who can provide durable and high-performance alternators, understanding that initial savings may lead to higher long-term costs due to frequent replacements or maintenance. This focus on quality is further influenced by stringent regulations and standards in various regions, compelling manufacturers to adopt best practices in production.

How Are Sustainability and Ethical Sourcing Impacting the Alternators Parts Sector?

Sustainability and ethical sourcing have become essential considerations in the alternators parts sector. As global awareness of environmental issues increases, B2B buyers are seeking suppliers who demonstrate a commitment to sustainable practices. This includes sourcing materials responsibly, minimizing waste during production, and implementing energy-efficient processes.

The environmental impact of alternators—particularly in terms of raw material extraction and manufacturing emissions—has prompted many companies to pursue certifications that highlight their commitment to sustainability. Certifications such as ISO 14001 (Environmental Management) and adherence to REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations are becoming prerequisites for many buyers. These certifications assure buyers that suppliers are actively managing their environmental impact and complying with international standards.

Moreover, the use of ‘green’ materials, such as recycled metals or biodegradable components, is gaining traction. Suppliers that invest in eco-friendly technologies and materials can not only reduce their carbon footprint but also appeal to a growing segment of environmentally-conscious buyers. This trend towards sustainability is not just a compliance issue; it represents a strategic advantage in a competitive market, as companies that prioritize ethical sourcing are often viewed more favorably by consumers and businesses alike.

What Is the Historical Context of the Alternators Parts Sector for B2B Buyers?

The alternators parts sector has evolved significantly since its inception in the early 20th century. Originally designed to provide electrical power for vehicles, advancements in technology have transformed alternators into sophisticated components capable of meeting the demands of modern automotive and industrial applications. The introduction of high-output alternators in the late 20th century marked a pivotal shift, enabling vehicles to support increased electrical loads from advanced systems such as infotainment and navigation.

The globalization of manufacturing has also played a crucial role in this evolution. As production capabilities expanded internationally, suppliers could leverage economies of scale, driving down costs and increasing the variety of alternators available to B2B buyers. This globalized supply chain has made it easier for buyers in regions like Africa, South America, and the Middle East to source high-quality alternator parts from established manufacturers, further enhancing their operational efficiency and product offerings.

Today, the sector is characterized by a blend of traditional manufacturing practices and cutting-edge technology, reflecting a commitment to innovation that meets the evolving needs of international B2B buyers.

الأسئلة المتداولة (FAQs) لمشتري قطع غيار مولدات التيار المتردد B2B

-

How do I solve issues with alternator performance?

To address alternator performance issues, first, check the battery connections and ensure they are clean and tight. Next, inspect the alternator belt for wear and tension; a loose or damaged belt can impede functionality. If problems persist, use a multimeter to measure voltage output; it should typically be between 13.8 to 14.5 volts when the engine is running. If the alternator fails to deliver this voltage, it may require replacement or repair. Partnering with a reliable supplier can provide access to quality parts and technical support for troubleshooting. -

ما هو نوع المولد الأفضل للمركبات التجارية؟

For commercial vehicles, high-output alternators are often the best choice due to their ability to support heavy electrical loads from auxiliary systems like lights, radios, and refrigeration units. Look for alternators that offer at least 150 amps or more, which can sustain additional equipment without straining the electrical system. Brands known for durability and efficiency, such as Bosch or Denso, are recommended. Always verify compatibility with your vehicle’s specifications to ensure optimal performance. -

What should I consider when vetting suppliers for alternator parts?

When vetting suppliers, consider their reputation in the market, years of experience, and certifications related to quality standards (like ISO). Request references from other B2B buyers and check online reviews. Additionally, evaluate their product range to ensure they offer a variety of alternator parts that meet your needs. Assess their customer service responsiveness and technical support availability, as these can be crucial in resolving issues quickly. -

What is the typical minimum order quantity (MOQ) for alternator parts?

The minimum order quantity (MOQ) for alternator parts can vary significantly between suppliers, ranging from 50 to several hundred units. Some manufacturers may offer lower MOQs for specific parts or during promotional periods. It’s essential to communicate your needs clearly with potential suppliers and negotiate terms that align with your purchasing capacity. Be sure to assess how the MOQ impacts shipping costs and inventory management. -

What payment terms are commonly offered by suppliers?

Payment terms can differ based on the supplier’s policies and your relationship with them. Common terms include net 30, net 60, or upfront payment for first-time orders. Some suppliers may offer discounts for early payments or bulk purchases. It’s beneficial to establish clear payment expectations before placing an order, especially for international transactions, to avoid currency conversion issues and additional banking fees. -

How do I ensure quality assurance for alternator parts?

To ensure quality assurance, request detailed product specifications and certifications from suppliers. Conduct thorough inspections upon receiving the parts, checking for defects or inconsistencies. Many suppliers provide warranties or guarantees for their products; understanding these terms can protect your investment. Establishing a quality control process, including regular audits and feedback loops, helps maintain high standards over time. -

What logistics considerations should I keep in mind when sourcing alternator parts internationally?

When sourcing alternator parts internationally, consider shipping methods, costs, and delivery times. Understand the customs regulations and import duties that may apply to your country, as these can significantly affect overall costs. Collaborate with suppliers who have experience in international shipping to ensure compliance and smooth logistics. Additionally, factor in the supplier’s location and their ability to provide timely updates throughout the shipping process. -

Can I customize alternator parts for my specific needs?

Many suppliers offer customization options for alternator parts, allowing you to tailor specifications such as amperage, voltage output, or physical dimensions. When discussing customization, provide detailed requirements and any specific applications to ensure the supplier can meet your needs effectively. Be prepared for potential minimum order quantities and longer lead times associated with custom parts. Establish clear communication to avoid misunderstandings throughout the customization process.

Top 4 Alternators Parts Manufacturers & Suppliers List

1. DB Electrical – High Quality Alternators

المجال: dbelectrical.com

مسجل: 2000 (25 سنة)

مقدمة: High quality alternators at low prices; Free same day shipping over $50 (USA/48 only); Alternators generate voltage to keep battery charged and power electrical components; Features include high-temperature epoxy, heavy duty rectifiers, high quality regulators, well-engineered bearings, and high-temperature grease; Meets OEM standards for quality and fitment; Rigorous multipoint testing program fo…

2. Alternator Parts – High Output Alternators

المجال: Alternatorparts.com

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: USA Built High Output Alternators, Stock Amperage, Starters, and more. Over 40 years of auto electric experience in the USA. Featured products include: Dodge, Chrysler, Jeep, Plymouth, VW Van ECU Voltage Regulator Bypass, GM Dual Rectifier CS144 Alternators, Quicktifier External Rectifiers, GM Heavy Duty AD244 Alternators, Ford Large Case 6G Power Stroke Alternators, and Super Cool Finned External…

3. BNR PARTS – Alternators and Starters

المجال: ebay.com

تاريخ التسجيل: 1995 (30 عامًا)

مقدمة: BNR PARTS ALTERNATORS AND STARTERS offers a wide range of automotive parts including alternators and starters for various vehicle makes and models. The store features products for brands such as Acura, Alfa Romeo, Audi, BMW, Cadillac, Chevrolet, Dodge, Ferrari, Ford, Honda, Jaguar, Mercedes, Nissan, Porsche, Toyota, and many others. The store has sold 89K items and has 5.5K followers, boasting a 1…

4. Chevrolet Performa – Alternator

المجال: proformparts.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: {“الفئة”: ”المولدات والملحقات”، ”أنواع المنتجات”: [“المولد”، ”حامل المولد”، ”طقم تركيب المولد”، ”مباعد تركيب المولد”، ”بكرة المولد”]، ”مخرجات_مولدات_أمبيراج”:[“160 أمبير أمبير”، ”140 أمبير”، ”120 أمبير”، ”110 أمبير”، ”100 أمبير”، ”80 أمبير”، ”70 أمبير”، ”60 أمبير”، ”50 أمبير”]، ”العلامات التجارية”: [“شفروليه بيرفورمانس”، ”موبار”، ”موبار”، ”بروفورم المحرك”، ”كرايسلر بيغ بلوك”، ”كرايسلر سمول بلوك”، "شفروليه SB الجيل 1″، "شفروليه SB...

استنتاجات وتوقعات التوريد الاستراتيجي لقطع غيار المولدات الكهربائية

In today’s competitive landscape, the strategic sourcing of alternator parts is paramount for international B2B buyers. By prioritizing quality and reliability over cost, businesses can ensure optimal performance and longevity of their equipment. Key takeaways from this guide emphasize the importance of understanding the diverse range of products available, from high-output alternators to specialized components like voltage regulators and rectifiers. Engaging with trusted suppliers who value innovation and customer support can significantly enhance your sourcing strategy.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, there is a growing opportunity for businesses to leverage advanced technologies and efficient supply chains. Buyers are encouraged to conduct thorough research and establish partnerships with manufacturers that offer comprehensive solutions tailored to their specific needs.

Looking ahead, the demand for high-quality alternator parts will only increase. Embrace this opportunity to invest in reliable sources that will drive your business forward. By doing so, you will not only enhance operational efficiency but also position your company as a leader in your sector. Take action today to secure your competitive edge in the global market.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.