Introduction: Navigating the Global Market for alternator brands

In today’s fast-paced global market, sourcing reliable alternator brands can pose significant challenges for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. The alternator is a crucial component in various applications, from automotive to industrial machinery, providing the electrical power necessary for optimal performance. However, with numerous brands available, each offering varying specifications and quality levels, making informed purchasing decisions can be daunting.

This comprehensive guide serves as your roadmap to navigating the complexities of the alternator market. We delve into different types of alternators, their applications across industries, and essential factors to consider when selecting a supplier. From understanding the nuances of new versus remanufactured units to evaluating performance metrics and durability, this resource equips international buyers with the insights needed to make sound investments.

Moreover, we emphasize the importance of vetting suppliers to ensure quality and reliability, a critical step for businesses operating in regions where power supply stability is paramount. By leveraging the knowledge provided in this guide, buyers can confidently select alternator brands that not only meet their specific requirements but also enhance their operational efficiency and long-term sustainability.

جدول المحتويات

- Top 3 Alternator Brands Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alternator brands

- Understanding alternator brands Types and Variations

- Key Industrial Applications of alternator brands

- 3 Common User Pain Points for ‘alternator brands’ & Their Solutions

- Strategic Material Selection Guide for alternator brands

- In-depth Look: Manufacturing Processes and Quality Assurance for alternator brands

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator brands’

- Comprehensive Cost and Pricing Analysis for alternator brands Sourcing

- Alternatives Analysis: Comparing alternator brands With Other Solutions

- Essential Technical Properties and Trade Terminology for alternator brands

- Navigating Market Dynamics and Sourcing Trends in the alternator brands Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alternator brands

- Strategic Sourcing Conclusion and Outlook for alternator brands

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding alternator brands Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| مولدات كهربائية عالية الإنتاج | Generates up to 220 amps; designed for demanding electrical loads | Automotive, Heavy Machinery, Audio Systems | الإيجابيات: High performance; low maintenance. السلبيات: Higher cost; may require specific compatibility checks. |

| المولدات العادية | Standard carbon brush design; less durable under high loads | General Automotive, Light Commercial | الإيجابيات: فعالة من حيث التكلفة؛ متاحة على نطاق واسع. السلبيات: Shorter lifespan; less efficient at high speeds. |

| المولدات ذات المغناطيس الدائم | Uses permanent magnets for efficiency; compact design | Industrial Applications, Renewable Energy | الإيجابيات: Higher efficiency; lower weight. السلبيات: More expensive; limited power output. |

| المولدات المعاد تصنيعها | Rebuilt to meet OEM specifications; cost-effective option | Automotive Repair, Fleet Maintenance | الإيجابيات: Affordable; reliable performance. السلبيات: Potentially variable quality; limited warranty. |

| المولدات بدون فرش | No carbon brushes; longer life expectancy; low maintenance | High-End Automotive, Specialty Vehicles | الإيجابيات: Durable; efficient; quieter operation. السلبيات: Higher initial investment; requires specific installation knowledge. |

ما هي المولدات عالية الإنتاجية وتطبيقاتها؟

High-output alternators are designed to produce substantial electrical power, typically up to 220 amps, making them ideal for applications with high electrical demands, such as advanced audio systems and heavy machinery. Their brushless technology ensures low maintenance and increased durability. When purchasing, B2B buyers should consider compatibility with existing systems and the specific electrical load requirements of their applications.

How Do Regular Alternators Compare in the Market?

Regular alternators are the most common type, utilizing a carbon brush design that can lead to quicker wear and shorter lifespans. They are suitable for general automotive and light commercial applications, providing adequate power for standard vehicle electrical systems. While they are cost-effective and readily available, businesses should be cautious of their limitations under heavy loads and consider the total cost of ownership, including potential replacements.

What Are Permanent Magnet Alternators and Their Benefits?

Permanent magnet alternators leverage the use of permanent magnets for improved efficiency and a compact design. They are particularly effective in industrial applications and renewable energy sectors where space and efficiency are critical. While they offer benefits such as higher efficiency and lower weight, the initial investment can be higher, making it essential for buyers to evaluate their long-term operational needs against upfront costs.

Why Choose Remanufactured Alternators for Your Business?

Remanufactured alternators provide a cost-effective alternative to new units, rebuilt to meet original equipment manufacturer (OEM) specifications. They are commonly used in automotive repair and fleet maintenance due to their affordability and reliable performance. Buyers should ensure they source from reputable suppliers to mitigate quality variability and consider warranty options to safeguard their investments.

ما المزايا التي تقدمها المولدات بدون فرش؟

Brushless alternators are designed without carbon brushes, which enhances their durability and reduces maintenance needs. They are commonly used in high-end automotive and specialty vehicle applications. While they come with a higher price tag, their longevity and efficiency can lead to lower operational costs over time. B2B buyers should assess the installation requirements and long-term benefits to justify the initial expense.

Key Industrial Applications of alternator brands

| الصناعة/القطاع | Specific Application of alternator brands | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| الزراعة | Powering irrigation systems and farm machinery | Enhanced efficiency in operations and reduced downtime | Compatibility with various machinery and voltage requirements |

| البناء | Supporting heavy machinery and temporary power supply | Reliable power for continuous operations on-site | Durability under harsh conditions and service support availability |

| التصنيع | Providing power for assembly lines and production equipment | Increased productivity and minimized production delays | Energy efficiency and compatibility with existing systems |

| التعدين | Powering equipment in remote locations | Ensures operational continuity in challenging environments | Robustness against environmental factors and maintenance options |

| الاتصالات السلكية واللاسلكية | Supporting backup power for communication towers | ضمان عدم انقطاع الخدمة والموثوقية دون انقطاع | Compliance with local regulations and scalability options |

How Are Alternator Brands Used in Agriculture?

In agriculture, alternator brands are crucial for powering irrigation systems and farm machinery. They ensure a reliable energy supply, enabling farmers to maintain optimal crop conditions and enhance productivity. With the increasing reliance on technology in farming, buyers must consider compatibility with various machinery and specific voltage requirements. This is particularly vital for international buyers in regions like Africa and South America, where power supply can be inconsistent.

What Role Do Alternators Play in Construction?

In the construction industry, alternators provide essential power for heavy machinery and temporary power setups. They facilitate continuous operations on-site, reducing downtime and enhancing project efficiency. Buyers should focus on the durability of alternators, as construction environments can be harsh. Additionally, reliable service support is critical for businesses operating in remote locations, especially in the Middle East and Africa.

How Do Manufacturing Industries Benefit from Alternators?

Manufacturing facilities utilize alternators to power assembly lines and production equipment, directly impacting productivity. A reliable power source minimizes production delays and ensures smooth operations. When sourcing alternators, businesses should prioritize energy efficiency and compatibility with existing systems to maximize return on investment. This is particularly important for international buyers in Europe, where energy costs can significantly affect operational budgets.

What Are the Applications of Alternators in Mining?

In the mining sector, alternators are vital for powering equipment in remote locations where electricity supply is scarce. They ensure operational continuity in challenging environments, allowing mining operations to proceed without interruptions. Buyers in this sector must look for robust alternators that can withstand extreme conditions and evaluate available maintenance options to ensure long-term reliability.

How Do Alternators Support Telecommunications?

Alternator brands are essential in telecommunications for providing backup power to communication towers. This ensures uninterrupted service, which is critical for maintaining connectivity in both urban and rural areas. Buyers should consider compliance with local regulations and the scalability of power solutions to adapt to future demands. This is particularly relevant for international buyers in regions like Africa and South America, where infrastructure development is ongoing.

3 Common User Pain Points for ‘alternator brands’ & Their Solutions

Scenario 1: Compatibility Confusion with Alternator Brands

المشكلة: B2B buyers often face significant challenges in ensuring that the alternators they procure are compatible with their existing generator or vehicle models. With a plethora of brands and specifications available, it can be overwhelming to identify which alternator will meet the operational demands and fit the mechanical requirements of their equipment. This confusion can lead to costly delays, increased downtime, and wasted resources if the wrong alternator is purchased.

الحل: To mitigate compatibility issues, B2B buyers should take a systematic approach when sourcing alternators. Begin by thoroughly documenting the specifications of your existing systems, including make, model, power requirements, and any specific electrical load considerations. Leverage online resources and manufacturer catalogs to cross-reference these specifications against available alternator brands. Engaging directly with manufacturers or authorized distributors can provide additional insights into compatibility and performance. Furthermore, consider investing in high-quality alternators from reputable brands known for their reliability and extensive product range, such as Leroy Somer or John Deere. This proactive approach ensures you make informed decisions, minimizing the risk of purchasing incompatible products.

Illustrative image related to alternator brands

Scenario 2: Quality vs. Cost Dilemma in Alternator Selection

المشكلة: When sourcing alternators, B2B buyers frequently grapple with the dilemma of balancing quality and cost. While lower-priced alternatives may seem attractive, they often lack the durability and performance required for demanding applications. Poor-quality alternators can lead to failures, increased maintenance costs, and ultimately, lost business due to downtime, especially in critical industries such as construction or agriculture.

الحل: To address the quality versus cost dilemma, buyers should prioritize long-term value over initial price. Conduct a comprehensive market analysis to identify leading alternator brands that offer a track record of reliability and performance, such as Stamford and Marelli. Request performance data, warranty terms, and customer reviews to assess the overall value proposition. When evaluating options, consider the total cost of ownership, which includes potential savings from reduced maintenance and downtime. Establishing a relationship with trusted suppliers who can provide insights into the best products for your specific applications can also lead to better purchasing decisions. Investing in quality alternators may have a higher upfront cost, but it will pay off in terms of efficiency and reliability.

Scenario 3: Insufficient Technical Support and Guidance

المشكلة: B2B buyers often encounter a lack of technical support and guidance from alternator manufacturers or suppliers. This can be particularly challenging when facing installation or operational issues. Without access to expert advice, buyers may struggle to troubleshoot problems effectively, leading to prolonged downtimes and frustration.

الحل: To ensure adequate technical support, B2B buyers should choose alternator brands that provide robust customer service and technical assistance. Prioritize manufacturers known for their comprehensive support, including installation guides, troubleshooting resources, and responsive customer service teams. Engage with the supplier’s technical representatives during the purchasing process to clarify installation procedures, maintenance schedules, and common issues. Additionally, consider investing in training for your technical staff to enhance their understanding of alternator technology and troubleshooting methods. Establishing a strong partnership with your alternator supplier can facilitate ongoing support, ensuring that your team has the resources necessary to address any challenges promptly. By prioritizing technical support, businesses can enhance operational efficiency and reduce the likelihood of costly downtimes.

Strategic Material Selection Guide for alternator brands

What Are the Key Materials Used in Alternator Manufacturing?

When selecting alternators for industrial applications, the choice of materials significantly influences performance, durability, and overall cost-effectiveness. Below are analyses of four common materials used in alternator manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. النحاس

الخصائص الرئيسية: Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can withstand high temperatures, making it suitable for alternator windings.

الإيجابيات والسلبيات: The primary advantage of copper is its superior conductivity, which enhances the efficiency of the alternator. However, copper is relatively expensive compared to other materials, which can increase manufacturing costs. Additionally, the weight of copper can be a concern for specific applications requiring lightweight components.

التأثير على التطبيق: Copper’s high conductivity ensures efficient power generation and distribution, making it ideal for high-performance alternators. Its corrosion resistance also extends the lifespan of the alternator in harsh environments.

اعتبارات للمشترين الدوليين: Compliance with international standards such as ASTM B170 for copper wire is crucial. Buyers in regions like Africa and South America should consider local sourcing to mitigate costs and ensure compliance with regional regulations.

2. الألومنيوم

الخصائص الرئيسية: Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity, although not as high as copper.

Illustrative image related to alternator brands

الإيجابيات والسلبيات: The main advantage of aluminum is its lightweight nature, which reduces overall alternator weight and improves fuel efficiency in vehicles. However, it has lower conductivity than copper, which may affect performance in high-load applications. Additionally, aluminum can be more susceptible to wear over time.

التأثير على التطبيق: Aluminum is commonly used in alternator housings and rotor components, where weight savings are critical. Its corrosion resistance makes it suitable for outdoor applications, particularly in humid or saline environments.

اعتبارات للمشترين الدوليين: Buyers should check for compliance with standards like ASTM B221 for aluminum extrusions. In regions like the Middle East, where humidity can be high, aluminum’s corrosion resistance is a significant advantage.

Illustrative image related to alternator brands

3. الفولاذ

الخصائص الرئيسية: Steel is known for its strength, durability, and ability to withstand high pressures and temperatures. It is often used in the structural components of alternators.

الإيجابيات والسلبيات: Steel’s primary advantage is its mechanical strength, which provides durability and resistance to physical damage. However, it is heavier than aluminum and copper, which can negatively impact performance in weight-sensitive applications. Steel is also prone to corrosion unless properly treated.

التأثير على التطبيق: Steel is typically used for the alternator frame and other structural components, ensuring robustness and longevity. Its ability to withstand high temperatures makes it suitable for heavy-duty applications.

اعتبارات للمشترين الدوليين: Compliance with international standards such as ASTM A36 for structural steel is essential. Buyers in Europe and South America should consider the availability of treated steel options to enhance corrosion resistance.

4. المواد المركبة

الخصائص الرئيسية: Composite materials, such as reinforced plastics, offer a combination of lightweight properties and resistance to corrosion and wear.

الإيجابيات والسلبيات: The key advantage of composites is their lightweight nature and resistance to environmental factors. They can be molded into complex shapes, allowing for innovative designs. However, composites can be more expensive to produce and may not provide the same mechanical strength as metals.

التأثير على التطبيق: Composites are often used in non-structural components of alternators, such as covers and insulators, where weight savings are beneficial. Their resistance to corrosion makes them ideal for applications in harsh environments.

اعتبارات للمشترين الدوليين: Buyers should ensure compliance with relevant standards for composites, such as ASTM D638 for tensile properties. In regions with extreme weather conditions, the durability of composite materials can be a significant selling point.

Illustrative image related to alternator brands

Summary Table of Material Selection for Alternator Brands

| المواد | Typical Use Case for alternator brands | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | الملفات والتوصيلات الكهربائية | موصلية كهربائية ممتازة | تكلفة ووزن أعلى | عالية |

| الألومنيوم | Housings and rotors | خفيف الوزن ومقاوم للتآكل | موصلية أقل من النحاس | متوسط |

| الصلب | المكونات الهيكلية | قوة ومتانة عالية | أثقل وزناً وعرضة للتآكل | متوسط |

| المواد المركبة | المكونات غير الهيكلية | Lightweight and resistant to corrosion | Potentially lower mechanical strength | متوسط |

This analysis provides valuable insights for B2B buyers looking to select the most suitable materials for alternators, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for alternator brands

ما هي المراحل الرئيسية في عملية تصنيع المولدات الكهربائية؟

Manufacturing alternators involves several critical stages that ensure the end product meets the required performance and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

How is Material Prepared for Alternators?

The first stage, material preparation, involves selecting high-quality raw materials such as copper for windings, steel for the frame, and various alloys for other components. Suppliers often undergo rigorous screening to ensure they meet international standards. Materials are then cut, shaped, and treated to enhance durability and conductivity. For instance, copper wires are often coated with a thin layer of insulation to prevent short circuits and ensure efficient electrical flow.

ما هي تقنيات التشكيل المستخدمة في تصنيع المولد؟

In the forming stage, the prepared materials are shaped into the necessary components. This process may involve techniques such as stamping for the rotor and stator, where sheets of metal are cut into precise shapes. Additionally, die casting may be employed for producing intricate parts that require high dimensional accuracy. Advanced technologies like CNC machining are also utilized for enhanced precision in creating components such as the housing and mounting brackets.

How Does the Assembly Process Work for Alternators?

The assembly stage is crucial for ensuring that all components fit together correctly and function as intended. Skilled technicians or automated systems assemble parts like the rotor, stator, voltage regulator, and rectifier in a clean environment to prevent contamination. During this stage, careful attention is paid to torque specifications and alignment to avoid operational issues.

What Finishing Processes Are Involved in Alternator Production?

Finishing processes include surface treatment, painting, and quality checks. Surface treatments such as anodizing or powder coating protect components from corrosion and wear. Aesthetic finishes may also be applied for branding purposes. Final inspections ensure that the alternators meet visual and functional standards before they are packaged for shipment.

What Quality Assurance Standards Are Relevant for Alternator Manufacturers?

Quality assurance is an integral part of the manufacturing process for alternators. Reputable manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with other industry-specific certifications like CE and API is also common, particularly for alternators used in critical applications like automotive and industrial sectors.

How Are Quality Control Checkpoints Established in Alternator Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These checkpoints typically include:

Illustrative image related to alternator brands

- مراقبة الجودة الواردة (IQC): This initial stage involves inspecting raw materials for defects and compliance with specifications.

- مراقبة الجودة أثناء الإنتاج (IPQC): Continuous monitoring during production ensures that any deviations are promptly addressed. Techniques such as statistical process control (SPC) are often utilized.

- مراقبة الجودة النهائية (FQC): The final products undergo rigorous testing for performance, electrical output, and safety before being cleared for shipment.

ما هي طرق الاختبار الشائعة المستخدمة لضمان جودة المولد؟

Common testing methods for alternators include:

- الاختبارات الكهربائية: This assesses the output voltage, current capacity, and overall functionality under various load conditions.

- الاختبار الحراري: Evaluates the alternator’s ability to operate under high temperatures, simulating real-world conditions.

- اختبار الاهتزاز والضوضاء: Ensures that the alternator operates smoothly without excessive noise or vibration, which could indicate mechanical issues.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital. Here are a few actionable steps:

- طلب التوثيق: Suppliers should provide relevant certifications and quality assurance documents, including ISO certificates and test reports.

- إجراء عمليات التدقيق: Regular audits can help assess compliance with quality standards. Buyers can either conduct these themselves or hire third-party services.

- عمليات التفتيش من طرف ثالث: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing processes and product quality.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

International buyers must be aware of specific nuances when dealing with quality control. Different regions may have varying standards and regulations that affect product compliance. For instance, alternators intended for the European market must comply with CE marking requirements, while products destined for markets in Africa may need to meet local regulations. Understanding these requirements is essential to avoid delays and ensure market acceptance.

How Do Quality Issues Impact B2B Relationships?

Quality issues can severely impact the relationship between buyers and suppliers. Subpar products can lead to operational failures, increased costs, and damage to reputation. Establishing clear quality expectations and maintaining open communication channels can help mitigate these risks.

Conclusion: The Importance of Quality in Alternator Manufacturing

In conclusion, the manufacturing processes and quality assurance protocols in alternator production are crucial for ensuring that products meet the necessary performance and reliability standards. B2B buyers must conduct thorough due diligence to verify the quality control measures of their suppliers. By understanding the manufacturing process and maintaining a focus on quality assurance, buyers can make informed decisions that ultimately lead to successful partnerships and improved operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alternator brands’

To support B2B buyers in sourcing alternator brands effectively, this practical checklist outlines essential steps to ensure a successful procurement process. By following this guide, you can make informed decisions that align with your operational needs and budget constraints.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Establishing clear technical specifications is crucial for identifying the right alternator for your application. Consider factors such as voltage output, amperage, size, and compatibility with existing systems. This clarity will help you narrow down your options and avoid costly mismatches later in the procurement process.

الخطوة 2: Research Reputable Alternator Brands

Invest time in researching well-established alternator brands known for quality and reliability. Look for brands like Leroy Somer, John Deere, Marelli, and Stamford, which have proven track records in various industries. Prioritize those with certifications and industry recognition, as these indicators often reflect superior manufacturing standards.

الخطوة 3: تقييم شهادات الموردين

Before engaging with suppliers, verify their certifications and compliance with international standards. Certifications such as ISO 9001 or other relevant quality management standards ensure that the manufacturer maintains high-quality processes. This step helps mitigate risks associated with product failures and enhances your overall supply chain reliability.

الخطوة 4: طلب معلومات مفصلة عن المنتج

Engage potential suppliers by requesting detailed product information, including datasheets, warranty terms, and installation guides. This documentation should provide insights into the alternator’s performance characteristics and expected lifespan. Understanding these details can assist in comparing different offerings and making informed decisions.

الخطوة 5: Assess Supply Chain Capabilities

Evaluate the supplier’s ability to meet your logistical requirements. Consider their production capacity, lead times, and shipping options, especially if you are sourcing from international markets. Ensure that they can provide timely deliveries to avoid disruptions in your operations.

الخطوة 6: Seek Customer Reviews and References

Customer feedback can offer invaluable insights into a supplier’s reliability and product quality. Look for testimonials and case studies from companies in similar sectors or regions. This step not only builds confidence in your choice but also highlights potential issues you might face.

الخطوة 7: التفاوض على الشروط والأحكام

Once you have identified a preferred supplier, engage in negotiations regarding pricing, payment terms, and warranty conditions. Ensure that you have a clear understanding of return policies and service agreements. A well-negotiated contract protects your interests and establishes a solid foundation for your business relationship.

By following these steps, you can systematically approach the procurement of alternator brands, ensuring that you select a supplier that meets your technical, financial, and logistical needs. This thorough process will ultimately contribute to the long-term success and efficiency of your operations.

Comprehensive Cost and Pricing Analysis for alternator brands Sourcing

What Are the Key Cost Components in Sourcing Alternator Brands?

When evaluating the costs associated with sourcing alternators, several key components must be considered. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

المواد: The quality of raw materials significantly impacts the cost. High-grade materials such as copper for windings and durable casing materials can elevate prices but result in longer-lasting products. Sourcing these materials locally can reduce costs, while imported high-quality materials may incur additional tariffs and shipping fees.

-

العمل: Labor costs vary by region. Countries with lower labor costs, such as some in Asia, may offer more competitive pricing. However, the expertise required for skilled labor in manufacturing high-performance alternators can also affect costs.

-

تكاليف التصنيع العامة: This encompasses fixed costs associated with running manufacturing facilities, including utilities, rent, and equipment maintenance. Efficient production processes can help minimize these overhead costs, leading to more competitive pricing.

-

الأدوات: Initial investments in tooling and machinery can be substantial, particularly for customized alternators. However, these costs are amortized over the production run, making higher volumes more cost-effective.

-

مراقبة الجودة (QC): Implementing robust QC measures ensures product reliability and compliance with industry standards, which can increase costs. However, this can also lead to reduced warranty claims and higher customer satisfaction, justifying the investment.

-

اللوجستيات: Shipping and handling costs can vary widely based on the distance from the supplier, the mode of transport, and the weight of the products. Effective logistics management is crucial for minimizing these costs, especially for international shipments.

-

الهامش: Suppliers will add a profit margin to cover their costs and ensure sustainability. The margin can vary based on brand reputation, quality, and market demand.

What Influences the Pricing of Alternator Brands?

Several factors influence the pricing of alternators, particularly in the B2B landscape:

-

الحجم/الحد الأدنى لكمية الطلب: Larger orders typically benefit from volume discounts. Negotiating favorable terms based on projected usage can significantly impact overall costs.

-

المواصفات والتخصيص: Custom alternators designed for specific applications may incur additional costs. Buyers should clearly outline their requirements to avoid unexpected expenses later in the process.

-

شهادات المواد والجودة: Brands that offer certifications such as ISO or other industry standards often command higher prices due to perceived reliability and performance. Investing in reputable brands can yield long-term savings through durability.

-

عوامل الموردين: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more but provide assurances in quality and service.

-

مصطلحات التجارة الدولية: The agreed-upon Incoterms (International Commercial Terms) can affect pricing by defining responsibilities for shipping, insurance, and duties. Buyers should understand these terms to assess total costs accurately.

What Are the Best Practices for International B2B Buyers in Alternator Sourcing?

-

استراتيجيات التفاوض: Leverage your purchasing power by negotiating prices and terms based on your business volume and long-term potential. Building relationships with suppliers can also lead to better deals.

-

Understanding Total Cost of Ownership (TCO): TCO includes not just the purchase price but also maintenance, operational efficiency, and replacement costs. Investing in higher-quality alternators may lead to lower TCO over time.

-

Pricing Nuances for Global Markets: Different regions may have varying pricing structures due to economic conditions, tariffs, and competition. For instance, buyers in Brazil or Nigeria may find different cost implications based on local regulations and market dynamics.

-

Conducting Market Research: Stay informed about market trends, competitor pricing, and technological advancements. This knowledge can empower you to make informed purchasing decisions and negotiate better prices.

-

إخلاء المسؤولية بشأن الأسعار الإرشادية: Prices can fluctuate based on market conditions, demand, and supplier changes. It’s essential to seek quotes directly from suppliers for accurate and current pricing.

By understanding these cost components and pricing influencers, B2B buyers can make more informed decisions when sourcing alternators, ultimately leading to better financial outcomes for their businesses.

Alternatives Analysis: Comparing alternator brands With Other Solutions

فهم البدائل في حلول المولدات

In the realm of power generation and automotive applications, understanding the various options available is crucial for B2B buyers. While high-quality alternator brands such as Leroy Somer, John Deere, and Stamford offer robust solutions, there are alternative technologies that can also fulfill similar needs. This section compares established alternator brands against two viable alternatives: generators و battery storage systems. Each option has its own set of advantages and drawbacks, which are important to consider when making purchasing decisions.

Illustrative image related to alternator brands

| جانب المقارنة | Alternator Brands | Generator Solutions | Battery Storage Systems |

|---|---|---|---|

| الأداء | High efficiency, reliable output | Versatile power supply, can handle high loads | Excellent for peak load management, fast response |

| التكلفة | Higher initial investment, but durable | Variable cost depending on size and type, maintenance costs | Moderate initial cost with potential savings on energy bills |

| سهولة التنفيذ | Requires specific mounting and compatibility | Can be installed in various configurations, but requires space | Generally easier to install, especially in existing setups |

| الصيانة | Low maintenance, high durability | Regular maintenance needed, fuel management required | Minimal maintenance, long lifespan with proper care |

| أفضل حالة استخدام | Ideal for stable power needs in industrial applications | Suitable for emergency power and high-demand scenarios | Best for energy storage and load balancing in renewable setups |

Analyzing Generator Solutions as an Alternative

Generators serve as a robust alternative to alternators, particularly in scenarios where backup power is critical. They can provide a versatile power supply capable of handling high loads, making them suitable for construction sites and events. However, the initial investment can vary significantly based on the generator’s capacity and type (diesel, gas, etc.), and ongoing maintenance is essential to ensure reliability. While generators offer flexibility, they are often less efficient than high-quality alternators, especially for continuous power needs.

Exploring Battery Storage Systems as a Competitive Option

Battery storage systems are becoming increasingly popular, especially with the rise of renewable energy sources. They excel in managing peak load demands and can provide immediate power during outages or high-demand periods. The initial investment is typically moderate, and while they require less frequent maintenance, their efficiency can be influenced by environmental factors. Battery systems are particularly advantageous for businesses looking to optimize energy costs and integrate renewable sources, such as solar power, into their operations.

Conclusion: Making an Informed Choice for Your Power Needs

When selecting between alternator brands and alternative solutions like generators or battery storage systems, B2B buyers should assess their specific operational requirements. Consider factors such as performance needs, budget constraints, implementation ease, and maintenance capabilities. Each solution offers unique benefits; therefore, aligning the choice with the business’s operational goals and energy strategy is essential for maximizing efficiency and cost-effectiveness. Ultimately, the right solution will depend on the specific context of use, making informed research and consultation with experts critical in the decision-making process.

Essential Technical Properties and Trade Terminology for alternator brands

What Are the Key Technical Properties of Alternator Brands?

When evaluating alternators for B2B procurement, understanding essential technical properties is crucial. Here are several key specifications that influence performance, compatibility, and durability:

-

Power Output Rating (KW/Amps)

Power output is a primary specification that determines an alternator’s capability to supply electrical power. Measured in kilowatts (KW) or amps, this rating affects the alternator’s ability to support various electrical loads. For businesses, selecting an alternator with an appropriate power output ensures that the equipment can handle operational demands without risking overload or failure. -

تصنيف الكفاءة

Efficiency indicates how well an alternator converts mechanical energy from the engine into electrical energy. Higher efficiency ratings reduce energy waste, which translates into lower operational costs and improved performance. For B2B buyers, investing in high-efficiency alternators can lead to significant savings over time, particularly in energy-intensive applications. -

Cooling System Type

Alternators can incorporate different cooling mechanisms, such as air-cooled or liquid-cooled systems. The choice of cooling system impacts the alternator’s longevity and reliability, especially under heavy load conditions. For businesses operating in extreme environments, selecting an alternator with an effective cooling system can minimize downtime and maintenance costs. -

تركيب المواد

The materials used in alternator construction—such as copper windings, aluminum housings, or composite components—affect durability, weight, and heat dissipation. High-quality materials enhance performance and lifespan, making them a significant consideration for B2B buyers seeking reliable long-term solutions. -

نوع التركيب والأبعاد

Alternators come in various sizes and mounting configurations. Compatibility with existing machinery is vital, as improper fitting can lead to installation issues and operational inefficiencies. B2B buyers should ensure that the alternator’s specifications align with their equipment to avoid costly modifications.

What Common Trade Terms Should B2B Buyers Know When Dealing with Alternator Brands?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation in the alternator market. Here are several important terms:

Illustrative image related to alternator brands

-

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to products made by the original manufacturer of the equipment. In the alternator market, purchasing OEM parts often guarantees compatibility and reliability, which is crucial for businesses that prioritize performance. -

MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest number of units a supplier is willing to sell in a single order. Understanding MOQ helps businesses manage inventory and cost-effectiveness. For international buyers, negotiating MOQs can lead to better pricing structures and supply chain efficiencies. -

طلب عرض أسعار (RFQ)

An RFQ is a formal process where buyers request pricing information from suppliers for specific products. This term is vital for B2B transactions, enabling buyers to compare prices and terms from different vendors, ensuring they receive the best value. -

شروط التجارة الدولية (Incoterms)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. Understanding these terms helps businesses mitigate risks related to delivery, insurance, and tariffs, making them essential for global procurement strategies. -

المهلة الزمنية

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time for alternators is crucial for planning operations and managing project timelines, especially in industries where equipment availability is critical.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions when sourcing alternators, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the alternator brands Sector

What Are the Key Market Dynamics Impacting Alternator Brands?

The global alternator market is witnessing significant growth driven by increasing demand for automotive and industrial applications. Key trends shaping this landscape include the rise of electric vehicles (EVs) and the need for robust power generation systems in emerging markets. In regions such as Africa, South America, and the Middle East, rapid urbanization and infrastructure development are pushing the demand for reliable power sources, thereby elevating the need for high-quality alternators. Additionally, advancements in technology are influencing sourcing strategies, with a growing preference for high-output and brushless alternators that provide superior performance and durability.

International B2B buyers are increasingly focusing on supplier reliability and product certifications. The sourcing landscape is evolving as buyers prioritize manufacturers with strong reputations, proven track records, and comprehensive warranties. Moreover, the trend towards digitalization is reshaping procurement processes, enabling buyers to utilize online platforms for price comparisons, product reviews, and supplier evaluations, which enhances decision-making efficiency.

How Is Sustainability and Ethical Sourcing Reshaping the Alternator Brands Market?

Sustainability is becoming a critical factor for B2B buyers in the alternator market. The environmental impact of manufacturing processes, especially in resource-intensive sectors, is under scrutiny. Buyers are increasingly seeking alternator brands that prioritize ethical sourcing and sustainable production methods. Companies that adopt practices such as reducing carbon footprints, utilizing recyclable materials, and ensuring energy-efficient manufacturing processes are gaining a competitive edge.

Furthermore, certifications such as ISO 14001 for environmental management and adherence to the REACH regulations for chemical safety are becoming essential criteria for supplier selection. These certifications not only demonstrate compliance but also reflect a commitment to sustainability that resonates with environmentally conscious buyers. In an era where corporate social responsibility is paramount, buyers are motivated to align their procurement strategies with suppliers that uphold ethical standards and sustainability practices, enhancing their brand reputation and consumer trust.

كيف تطور سوق المولدات بمرور الوقت؟

The alternator market has undergone significant transformations over the decades, evolving from basic mechanical devices to advanced electrical systems. Initially, alternators were primarily designed for automotive applications, but as technology progressed, their functionality expanded to include industrial and commercial uses. The introduction of high-output and brushless alternators has revolutionized the sector, catering to the increasing electrical demands of modern vehicles and industrial machinery.

In recent years, the shift towards renewable energy sources and electric vehicles has further propelled innovation within the alternator industry. Manufacturers are now focusing on producing lightweight, efficient, and environmentally friendly alternators that meet the needs of a rapidly changing market landscape. This evolution not only reflects technological advancements but also highlights the growing importance of sustainability and efficiency in the B2B procurement process.

In conclusion, the alternator brands sector is poised for continued growth driven by technological advancements, sustainability initiatives, and evolving buyer preferences. International B2B buyers must navigate these market dynamics strategically to align their sourcing decisions with current trends and future demands.

Frequently Asked Questions (FAQs) for B2B Buyers of alternator brands

-

How do I choose the right alternator brand for my business needs?

Choosing the right alternator brand involves assessing several factors, including the specific application, power requirements, and environmental conditions. Research reputable brands known for quality, such as Leroy Somer, John Deere, Marelli, and Stamford, and consider their track records in your industry. Additionally, evaluate customer reviews and technical specifications to ensure compatibility with your equipment. Engaging with suppliers for product samples or demonstrations can also provide insight into performance and reliability. -

What are the key specifications to consider when sourcing alternators?

When sourcing alternators, focus on specifications such as power output (measured in kilowatts or amps), efficiency ratings, and physical dimensions for compatibility with your generator. Additionally, consider the type of alternator (e.g., high-output vs. standard) based on your operational demands. Quality certifications and warranties from manufacturers are also crucial, as they indicate reliability and support. Lastly, ensure that the alternators meet industry standards relevant to your region. -

What is the typical lead time for ordering alternators from international suppliers?

Lead times for ordering alternators can vary significantly based on the supplier’s location, manufacturing capacity, and current demand. Typically, expect lead times of 4 to 12 weeks for custom orders, while standard products may ship within 2 to 6 weeks. It is crucial to communicate with suppliers early in the procurement process to establish realistic timelines and to factor in potential delays due to customs clearance or logistics challenges, especially in regions like Africa and South America. -

How can I vet alternator suppliers for quality and reliability?

To vet alternator suppliers, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients. Request certifications that demonstrate compliance with international quality standards, such as ISO 9001. Additionally, assess their customer service responsiveness and willingness to provide technical support. Conducting site visits or audits, if feasible, can further enhance your confidence in their manufacturing processes and capabilities. -

What are the minimum order quantities (MOQs) for alternators from manufacturers?

Minimum order quantities (MOQs) for alternators can vary widely among manufacturers, often ranging from 10 to 100 units, depending on the brand and specific model. Custom orders may have higher MOQs due to the production setup required. It is advisable to discuss MOQs with potential suppliers during initial negotiations and explore whether they offer flexibility for smaller orders, especially for new businesses or those testing market demand. -

ما هي شروط الدفع التي يجب أن أتوقعها عند توريد مولدات الكهرباء على المستوى الدولي؟

Payment terms for international orders can vary by supplier but typically include options such as advance payment, letters of credit, or payment upon delivery. Common terms may require a deposit of 30% to 50% upfront, with the balance due before shipment or upon receipt. Discuss and negotiate payment terms that align with your cash flow and risk management strategies. Additionally, consider using secure payment methods to protect against fraud and ensure transaction transparency. -

How do I ensure quality assurance (QA) for alternators purchased from overseas?

To ensure quality assurance for overseas purchases, request detailed quality control processes from your supplier, including inspection protocols before shipment. Establish clear specifications and standards that the alternators must meet and consider third-party inspection services to validate product quality before shipment. Additionally, negotiate warranties and after-sales support to address any potential issues with the alternators once they are in operation. -

ما هي الاعتبارات اللوجستية التي يجب أن أكون على دراية بها عند استيراد مولدات التيار المتردد؟

Logistics considerations for importing alternators include understanding shipping methods (air vs. sea), estimated transit times, and associated costs. Familiarize yourself with customs regulations in your country, including tariffs and documentation requirements, to avoid delays. Work with a reliable freight forwarder who can navigate international shipping complexities and offer guidance on best practices for packaging and handling to minimize damage during transit.

Top 3 Alternator Brands Manufacturers & Suppliers List

1. دينسو - جودة التصنيع

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: هذه الشركة، دينسو - كواليتي للتصنيع، هي كيان بارز في السوق. للحصول على تفاصيل محددة عن المنتجات، يُنصح بزيارة موقعها الإلكتروني مباشرةً.

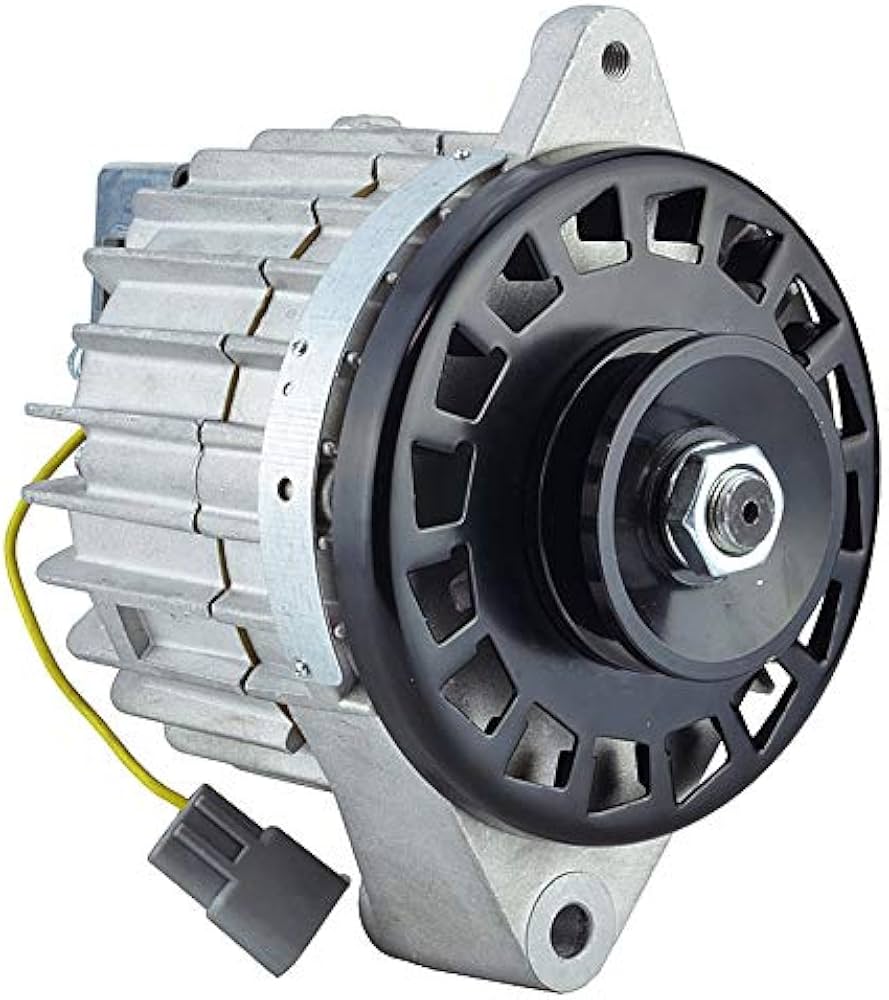

2. GenPower USA – Alternators by Leading Manufacturers

المجال: genpowerusa.com

تاريخ التسجيل: 2001 (24 عامًا)

مقدمة: Alternators by Manufacturer: LEROY SOMER, STAMFORD, CUMMINS, MARATHON, KOHLER, MAGNAPLUS, MARELLI, MECC ALTE, NEWAGE, SDMO. Alternators by Power Rating: 10 KW to 40 KW, 45 KW to 95 KW, 100 KW to 175 KW, 200 KW to 350 KW, 400 KW to 600 KW, 650 KW to 2000 KW, 10 KVA to 40 KVA, 45 KVA to 100 KVA, 110 KVA to 200 KVA, 250 KVA to 400 KVA, 440 KVA to 750 KVA, 800 KVA to 2500 KVA. Alternators by Frequency…

3. Mechman – High Output Alternators

المجال: mechman.com

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: Mechman Alternators are U.S.A made high output alternators with options for 1-year, 2-year, and lifetime extended warranties. They offer a range of products including 24 Volt and 48 Volt alternators, engine stands, bracket kits, pulleys, plugs and harnesses, voltage control, and cable accessories. The alternators have outputs ranging from 150a to 370a and are designed for various applications. Not…

Strategic Sourcing Conclusion and Outlook for alternator brands

As international B2B buyers navigate the competitive landscape of alternator sourcing, strategic procurement becomes paramount. Key takeaways emphasize the importance of selecting reputable brands such as Leroy Somer, John Deere, Marelli, and Stamford, known for their reliability and performance. Investing in high-quality alternators not only enhances generator longevity but also minimizes operational disruptions, a critical consideration in regions like Africa and South America where reliable power supply can significantly impact productivity.

Illustrative image related to alternator brands

Buyers should prioritize compatibility, power ratings, and manufacturer certifications when evaluating alternators. This strategic approach ensures that businesses can meet their unique energy demands while optimizing cost-efficiency. Furthermore, leveraging remanufactured options can provide an economically viable alternative without compromising quality.

Looking ahead, the demand for advanced electrical solutions will continue to rise, driven by technological advancements and increasing energy needs across various sectors. Now is the opportune moment for businesses to align their sourcing strategies with trusted suppliers to secure a sustainable and efficient power supply. By making informed decisions today, buyers can position themselves for success in an evolving market landscape. Embrace the future of power solutions—partner with leading alternator brands to empower your operations.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.