مقدمة: الإبحار في السوق العالمية للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

في المشهد المعقد لمكونات السيارات، يعد فهم الاختلافات بين الملف اللولبي لبدء التشغيل وبادئ التشغيل أمرًا ضروريًا للمشترين من الشركات الذين يتنقلون في السوق العالمية. يلعب هذان المكونان دورًا محوريًا في أنظمة إشعال السيارة، ومع ذلك يمكن أن تختلف وظائفهما ومتطلبات التوريد بشكل كبير. بالنسبة للمشترين الدوليين، لا سيما أولئك الموجودين في الأسواق الناشئة مثل نيجيريا والبرازيل، لا يكمن التحدي في تحديد المكونات المناسبة فحسب، بل أيضًا في ضمان الجودة والموثوقية في عمليات الشراء.

يتعمق هذا الدليل الشامل في الفروق الدقيقة للملفات اللولبية والمبتدئات، ويستكشف أنواعها وتطبيقاتها والعوامل الحاسمة التي يجب مراعاتها عند الحصول على هذه المكونات. سوف يكتسب المشترون رؤى حول الاختلافات التشغيلية بين هذه الأجهزة، مما يساعدهم على اتخاذ قرارات مستنيرة تتماشى مع احتياجاتهم الخاصة. بالإضافة إلى ذلك، سوف نغطي تقنيات فحص الموردين، واعتبارات التكلفة، وأفضل الممارسات للحفاظ على الأداء الأمثل في المناخات والظروف المتنوعة الموجودة في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

يهدف هذا الدليل إلى تبسيط عملية الشراء وتقليل المخاطر وتعزيز الكفاءة التشغيلية من خلال تمكين المشترين بين الشركات بالمعرفة والأدوات اللازمة للمشتريات الفعالة، وذلك من خلال تمكين المشترين بين الشركات بالمعرفة والأدوات اللازمة للمشتريات الفعالة. سواء أكنت موزعًا أو مدير أسطول أو مصنع سيارات، فإن فهم الفروق بين الملفات اللولبية لبادئ الحركة والمبتدئين سيمكنك من تأمين أفضل الحلول لاحتياجات عملك.

جدول المحتويات

- قائمة المصنعين والموردين لأفضل 4 ملفات لولبية بادئ تشغيل مقابل بادئ التشغيل

- مقدمة: الإبحار في السوق العالمية للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

- فهم الملف اللولبي لبادئ التشغيل مقابل أنواع بادئ التشغيل والاختلافات

- التطبيقات الصناعية الرئيسية للملف اللولبي البادئ مقابل البادئ اللولبي لبدء التشغيل

- 3 نقاط ألم شائعة لدى المستخدمين لـ ‘الملف اللولبي لبدء التشغيل مقابل بدء التشغيل’ وحلولها

- دليل اختيار المواد الاستراتيجية للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

- نظرة متعمقة: عمليات التصنيع وضمان الجودة للملف اللولبي البادئ مقابل البادئ

- دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘الملف اللولبي لبدء التشغيل مقابل بادئ التشغيل’

- تحليل شامل للتكلفة والتسعير للملف اللولبي لبادئ التشغيل مقابل مصدر بادئ التشغيل

- تحليل البدائل: مقارنة الملف اللولبي البادئ مقابل البادئ بالحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع الملف اللولبي لبادئ الحركة مقابل قطاع البادئ

- الأسئلة المتداولة (FAQs) لمشتري الملف اللولبي لبادئ الحركة مقابل بادئ الحركة

- استنتاج وتوقعات التوريد الاستراتيجي للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

- إخلاء مسؤولية هام وشروط الاستخدام

فهم الملف اللولبي لبادئ التشغيل مقابل أنواع بادئ التشغيل والاختلافات

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| الملف اللولبي الكهرومغناطيسي | يستخدم القوة الكهرومغناطيسية لتعشيق بادئ التشغيل؛ وغالباً ما يتم تركيبه على بادئ التشغيل نفسه. | تصنيع السيارات وإصلاحها | الإيجابيات: متانة عالية؛ فعالة في تطبيقات عزم الدوران العالي. السلبيات: يمكن أن يكون استبدالها أكثر تكلفة. |

| الملف اللولبي القائم على التتابع | يعمل كمفتاح يتم التحكم به بواسطة مرحل؛ ويوجد عادةً في صندوق الصمامات الكهربائية. | المركبات التجارية والآلات والمركبات التجارية | الإيجابيات: فعالة من حيث التكلفة؛ أسهل في الاستبدال من الملفات اللولبية. السلبيات: قد لا تتعامل مع تيار كبير مثل الملفات اللولبية. |

| الملف اللولبي لبدء التشغيل المدمج | يجمع بين بادئ التشغيل والملف اللولبي في وحدة واحدة؛ تصميم مدمج. | الآلات الثقيلة والمحركات الصناعية | الإيجابيات: موفرة للمساحة؛ تركيب مبسّط. السلبيات: في حالة تعطل أحد المكونات، يجب استبدال الوحدة بأكملها. |

| الملف اللولبي لبدء التشغيل عن بُعد | يسمح بتفعيل المشغّل عن بُعد؛ مفيد في التطبيقات المتخصصة. | السباقات والمركبات المتخصصة | الإيجابيات: تحكم محسّن وملاءمة محسّنة؛ مفيدة في الإنشاءات المخصصة. السلبيات: يمكن أن يؤدي التعقيد إلى زيادة الصيانة. |

| ملف لولبي عالي التيار | مصممة للتطبيقات التي تتطلب تياراً عالياً؛ وغالباً ما تكون أكبر حجماً وأكثر قوة. | التطبيقات الصناعية، المولدات الكهربائية | الإيجابيات: تتحمل الأحمال العالية بفعالية؛ موثوقة تحت الضغط. السلبيات: قد يحد التصميم الضخم من خيارات التركيب. |

ما هي خصائص الملفات اللولبية الكهرومغناطيسية؟

تُستخدم الملفات اللولبية الكهرومغناطيسية على نطاق واسع في تطبيقات السيارات بسبب كفاءتها ومتانتها. فهي تشغل محرك بدء التشغيل مباشرة عند تلقي إشارة الإشعال. تعد هذه الملفات اللولبية مناسبة بشكل خاص لمتطلبات عزم الدوران العالي، مما يجعلها مثالية للمركبات والآلات الثقيلة. عند الشراء، يجب على مشتري B2B مراعاة تصنيف الجهد الكهربائي للملف اللولبي وتوافقه مع النظام الكهربائي للمركبة لضمان الأداء الأمثل.

كيف تختلف الملفات اللولبية القائمة على التتابع؟

تعمل الملفات اللولبية القائمة على الترحيل كمفاتيح تتحكم في تنشيط محرك بدء التشغيل من خلال إشارة ترحيل. وهي توجد عادةً في المركبات التجارية والآلات حيث تكون فعالية التكلفة أمرًا بالغ الأهمية. يجب على مشتري B2B تقييم التصنيف الحالي للترحيل وسهولة الاستبدال، حيث يمكن أن تكون هذه الملفات اللولبية أقل تكلفة ولكنها قد تتطلب صيانة متكررة أكثر مقارنة بالملفات اللولبية الكهرومغناطيسية.

ما هي فوائد الملفات اللولبية المتكاملة لبدء التشغيل؟

تجمع الملفات اللولبية لبادئ التشغيل المدمجة كلاً من بادئ التشغيل والملف اللولبي في وحدة واحدة، وهو أمر مفيد للتطبيقات ذات المساحة المحدودة مثل الماكينات الثقيلة والمحركات الصناعية. يبسط هذا التصميم عملية التركيب ويقلل من عدد المكونات التي يمكن أن تتعطل. ومع ذلك، يجب على مشتري B2B أن يدركوا أنه في حالة فشل الملف اللولبي، ستحتاج وحدة البادئ بأكملها إلى الاستبدال، مما يؤدي إلى ارتفاع التكاليف.

ما السيناريوهات التي تستخدم فيها الملفات اللولبية لبدء التشغيل عن بُعد؟

تم تصميم الملفات اللولبية لبدء التشغيل عن بُعد للتطبيقات المتخصصة، مثل سيارات السباق أو السيارات المخصصة، حيث يكون التنشيط عن بُعد مفيداً. تعمل هذه الملفات اللولبية على تعزيز تحكم المستخدم وراحته، ولكنها قد تؤدي إلى تعقيدات في التركيب والصيانة. يجب على المشترين النظر في المتطلبات المحددة لاستخداماتهم والحاجة المحتملة إلى أسلاك أو عناصر تحكم إضافية عند اختيار هذا النوع.

ما الذي يجعل الملفات اللولبية عالية التيار مثالية للتطبيقات الصناعية؟

صُممت الملفات اللولبية عالية التيار للتطبيقات التي تتطلب معالجة طاقة كبيرة، مما يجعلها مثالية للإعدادات الصناعية مثل المولدات والآلات الثقيلة. يضمن تصميمها القوي الموثوقية في ظل ظروف الضغط العالي. يجب على مشتري B2B تقييم الأبعاد المادية وخيارات التركيب، حيث تميل هذه الملفات اللولبية إلى أن تكون أكبر حجمًا وقد لا تتناسب مع جميع التركيبات، مما يستلزم تخطيطًا دقيقًا.

التطبيقات الصناعية الرئيسية للملف اللولبي البادئ مقابل البادئ اللولبي لبدء التشغيل

| الصناعة/القطاع | التطبيق المحدد للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | التكامل في خطوط التجميع لإنتاج المركبات | يعزز الكفاءة في تشغيل المحركات أثناء التجميع | شهادات ضمان الجودة؛ التوافق مع أنواع المحركات المختلفة |

| معدات زراعية | أنظمة التشغيل في الجرارات والحصادات | تشغيل موثوق للمحرك من أجل عمليات زراعية متواصلة دون انقطاع | المتانة في مواجهة الظروف البيئية القاسية؛ توافر قطع الغيار |

| ماكينات البناء | تشغيل الآلات الثقيلة مثل الحفارات والرافعات | ضمان الجاهزية التشغيلية وتقليل وقت التعطل إلى الحد الأدنى | مقاومة الاهتزاز والصدمات؛ الامتثال لمعايير السلامة |

| الصناعة البحرية | أنظمة تشغيل القوارب والمحركات البحرية | تشغيل موثوق به في البيئات البحرية الصعبة | مقاومة التآكل؛ التوافق مع الأنظمة الكهربائية البحرية |

| الطاقة المتجددة | تستخدم في توربينات الرياح لآليات بدء التشغيل | يدعم توليد الطاقة من خلال ضمان موثوقية التوربينات | مواد عالية الجودة لطول العمر الافتراضي؛ الالتزام بلوائح الصناعة |

كيف يتم استخدام ‘الملف اللولبي المبدئ مقابل المبدئ’ في صناعة السيارات؟

في صناعة السيارات، تُعد الملفات اللولبية لبادئ التشغيل والمبتدئات من المكونات الهامة في خط تجميع السيارات. فهي تسهل التشغيل الموثوق للمحركات، وهو أمر ضروري لكفاءة عمليات الإنتاج. يمكن أن يؤدي خلل في بادئ التشغيل أو الملف اللولبي إلى تعطل كبير، مما يؤثر على الإنتاج الكلي. يجب على المشترين في هذا القطاع مراعاة شهادات ضمان الجودة وضمان التوافق مع أنواع المحركات المختلفة للحفاظ على معايير الإنتاج.

ما هو الدور الذي تلعبه أنظمة البادئ في المعدات الزراعية؟

تُعد الملفات اللولبية والمبتدئات ذات أهمية حيوية في المعدات الزراعية مثل الجرارات والحصادات. فهي توفر الطاقة اللازمة لتشغيل المحركات، مما يضمن تشغيل الآلات بكفاءة خلال فترات الزراعة الحرجة. يقلل نظام بدء التشغيل الموثوق به من مخاطر التأخير في التشغيل، مما قد يكون ضارًا في المهام الزراعية الحساسة للوقت. يجب على المشترين إعطاء الأولوية للمكونات التي تثبت متانتها ضد الظروف البيئية القاسية وضمان توافر قطع الغيار اللازمة للصيانة.

كيف يتم استخدام مكونات البادئ في ماكينات البناء؟

في صناعة الإنشاءات، تعتمد الآلات الثقيلة مثل الحفارات والرافعات على أنظمة تشغيل فعالة. يعمل الملف اللولبي وبداية التشغيل معًا لضمان جاهزية هذه الماكينات للتشغيل في أي وقت. يمكن أن يؤدي التأخير بسبب مشاكل في بدء التشغيل إلى تعطل مكلف وتأخير المشروع. يحتاج المشترون في هذا القطاع إلى التركيز على توفير مشغلات مقاومة للاهتزازات والصدمات، بالإضافة إلى أنها متوافقة مع معايير السلامة لحماية المشغلين.

ما أهمية أنظمة التشغيل في الصناعة البحرية؟

تستخدم الصناعة البحرية الملفات اللولبية لبدء التشغيل والمبتدئات في القوارب والمحركات البحرية لضمان التشغيل الموثوق به في البيئات الصعبة. يجب أن تتحمل هذه المكونات التآكل وتعمل بكفاءة في ظروف المياه المالحة. يعد نظام بدء التشغيل الذي يمكن الاعتماد عليه أمرًا بالغ الأهمية للسلامة والجاهزية التشغيلية. يجب على المشترين البحث عن المنتجات التي توفر مقاومة للتآكل والتوافق مع الأنظمة الكهربائية البحرية لتعزيز الموثوقية.

كيف يتم استخدام الملفات اللولبية البادئة في تطبيقات الطاقة المتجددة؟

في قطاع الطاقة المتجددة، وخاصة في توربينات الرياح، تعتبر الملفات اللولبية لبدء التشغيل جزءًا لا يتجزأ من آليات بدء التشغيل. فهي تضمن قدرة التوربينات على بدء التشغيل بسلاسة، وهو أمر ضروري لتعظيم توليد الطاقة. الموثوقية أمر بالغ الأهمية، حيث أن أي عطل يمكن أن يؤدي إلى فقدان إنتاج الطاقة. يجب على المشترين الحصول على مواد عالية الجودة تضمن طول العمر والالتزام بلوائح الصناعة، وبالتالي دعم مبادرات الطاقة المستدامة.

3 نقاط ألم شائعة لدى المستخدمين لـ ‘الملف اللولبي لبدء التشغيل مقابل بدء التشغيل’ وحلولها

السيناريو 1: صعوبة في تشخيص مشاكل البداية

المشكلة:

غالبًا ما يواجه المشترون من الشركات ولا سيما أولئك الذين يديرون الأساطيل أو مراكز خدمة السيارات تحديات في تشخيص ما إذا كانت مشكلة بدء التشغيل نابعة من الملف اللولبي لبادئ التشغيل أو من المبدئ نفسه. يمكن أن يؤدي التشخيص الخاطئ إلى استبدال قطع الغيار غير الضرورية وزيادة وقت التعطل وتكاليف العمالة الإضافية. على سبيل المثال، قد يتلقى مدير الأسطول تقريرًا عن مركبة تفشل في التشغيل بشكل متقطع، مما يؤدي إلى ارتباك حول ما إذا كان يجب استبدال المبدئ أو الملف اللولبي أو كليهما. لا تؤثر حالة عدم اليقين هذه على الجداول الزمنية للإصلاح فحسب، بل ترهق الميزانيات وتؤثر على كفاءة الأسطول بشكل عام.

الحل:

لتشخيص المشكلة بفعالية، قم بتنفيذ بروتوكول منهجي لاستكشاف الأخطاء وإصلاحها. ابدأ بفحص شامل للنظام الكهربائي، بما في ذلك البطارية والأسلاك. استخدم مقياس متعدد لفحص الجهد الكهربائي في الملف اللولبي لبادئ التشغيل عند تشغيل الإشعال. إذا كان هناك جهد كهربائي ولكن بادئ التشغيل لا يعمل، فمن المحتمل أن يكون الملف اللولبي هو السبب. وعلى العكس، إذا لم يكن هناك جهد، فقد تكون المشكلة في مفتاح الإشعال أو الأسلاك. بالإضافة إلى ذلك، ضع في اعتبارك الاستثمار في أدوات التشخيص التي يمكنها محاكاة ظروف بدء التشغيل وتوفير رؤى حول أداء الملف اللولبي وبادئ التشغيل. سيوفر إنشاء عملية تشخيص واضحة الوقت والموارد، مما يؤدي إلى اتخاذ قرارات شراء أكثر استنارة.

السيناريو 2: سوء فهم مواصفات المنتج

المشكلة:

غالبًا ما يكون العديد من المشترين بين الشركات غير واضحين بشأن المواصفات المطلوبة للملفات اللولبية والمبتدئات، مما يؤدي إلى عدم تطابق محتمل في مخزونهم. على سبيل المثال، قد يطلب المشتري في البرازيل ملفًا لولبيًا لا يتناسب مع طراز بادئ التشغيل الخاص به، مما يؤدي إلى تأخيرات وزيادة تكاليف الشحن بسبب المرتجعات أو إعادة الطلبات. وتبرز هذه المشكلة بشكل خاص في المناطق التي تتنوع فيها موديلات السيارات وتنوعها، كما هو الحال في أفريقيا والشرق الأوسط، حيث قد لا تتوافق احتياجات السوق المحلية مع المعايير العالمية.

الحل:

للتخفيف من عدم تطابق المواصفات، من الضروري تطوير قاعدة بيانات شاملة لمواصفات السيارة ومكونات البادئ المقابلة لها. يجب على المشترين الاستفادة من الرموز القياسية في الصناعة أو أرقام قطع غيار المعدات الأصلية عند الحصول على المنتجات. تعاون مع الموردين الذين يمكنهم توفير كتالوجات مفصلة وأدوات الإحالة المرجعية التي تطابق مواصفات الملف اللولبي وبادئ الحركة مع مختلف طرازات المركبات. علاوة على ذلك، ضع في اعتبارك تطبيق نظام قوي لإدارة المخزون يتتبع القطع بناءً على مواصفاتها وتاريخ استخدامها. سيؤدي هذا النهج الاستباقي إلى تعزيز دقة الطلبات وتبسيط عمليات الشراء.

السيناريو 3: التكاليف المرتفعة لاستبدال المكونات

المشكلة:

يواجه المشترون بين الشركات، وخاصة أولئك الذين يعملون في أسواق تنافسية، تحدي ارتفاع التكاليف المرتبطة باستبدال المشغلات والملفات اللولبية. في مناطق مثل نيجيريا أو البرازيل، حيث قد تكون الاقتصادات المحلية حساسة لتقلبات الأسعار، يمكن أن يؤدي العبء المالي لعمليات الاستبدال المتكررة إلى ضغوط تشغيلية كبيرة. قد يضطر المشترون إلى التنازل عن الجودة لإدارة التكاليف، مما قد يؤدي إلى انخفاض الأداء وارتفاع معدلات الفشل على المدى الطويل.

الحل:

الاستثمار في منتجات عالية الجودة ضروري لتقليل التكاليف على المدى الطويل. قم بإقامة علاقات مع الشركات المصنعة ذات السمعة الطيبة التي تقدم ضمانات أو كفالات على الملفات اللولبية والمبتدئين. بالإضافة إلى ذلك، ضع في اعتبارك اتفاقيات الشراء بالجملة لخفض تكاليف الوحدة مع ضمان مكونات عالية الجودة. قم بتثقيف فريق المشتريات الخاص بك حول قيمة المتانة والموثوقية على السعر الأولي، مع التركيز على التكلفة الإجمالية للملكية. يمكن أيضًا أن يؤدي التدريب المنتظم على الصيانة المناسبة واستكشاف الأخطاء وإصلاحها إلى إطالة عمر كل من المشغلات والملفات اللولبية، مما يقلل في النهاية من تكرار الاستبدال والتكاليف المرتبطة به. من خلال التركيز على الجودة والتوريد الاستراتيجي، يمكن للمشترين تعزيز كفاءتهم التشغيلية مع إدارة النفقات بفعالية.

دليل اختيار المواد الاستراتيجية للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

ما هي المواد الشائعة المستخدمة في الملفات اللولبية والمبتدئين؟

عند اختيار المواد اللازمة للملفات اللولبية وبادئ التشغيل، من الضروري مراعاة خصائص أدائها ومتانتها وتوافقها مع ظروف التشغيل المختلفة. فيما يلي، نحلل أربع مواد شائعة مستخدمة في هذه المكونات: النحاس والألومنيوم والصلب والمركبات البلاستيكية.

كيف يكون أداء النحاس في ملفات لولبية وبادئ التشغيل؟

يُستخدم النحاس على نطاق واسع في التوصيلات الكهربائية نظراً لخصائصه الممتازة في التوصيل والحرارة. ويتميز بدرجة حرارة عالية، مما يجعله مناسباً للبيئات التي يكون فيها توليد الحرارة كبيراً.

الإيجابيات: تضمن الموصلية الكهربائية العالية للنحاس نقل الطاقة بكفاءة، وهو أمر بالغ الأهمية للتنشيط السريع للمشغل. كما أنه يُظهر مقاومة جيدة للتآكل عند طلائه بشكل صحيح.

السلبيات: العيب الأساسي للنحاس هو تكلفته المرتفعة نسبيًا مقارنةً بالمواد الأخرى. بالإضافة إلى ذلك، يمكن أن يكون النحاس عرضة للأكسدة إذا تعرض للرطوبة، مما قد يؤدي إلى انخفاض التوصيلية بمرور الوقت.

التأثير على التطبيق: يعد النحاس مثاليًا للتطبيقات التي تتطلب أداءً كهربائيًا عاليًا، كما هو الحال في الملفات اللولبية لبدء التشغيل حيث يكون الاشتباك السريع ضروريًا. ومع ذلك، يجب على المشترين التأكد من أن المكونات النحاسية تتوافق مع المعايير الدولية مثل ASTM B187.

ما هو الدور الذي يلعبه الألومنيوم في مكونات البادئ؟

الألومنيوم هو خيار شائع آخر، خاصةً لخصائصه خفيفة الوزن ومقاومته للتآكل. وغالباً ما يستخدم في مبيت المبتدئين والملفات اللولبية.

الإيجابيات: تقلل طبيعة الألومنيوم خفيفة الوزن من الوزن الإجمالي للسيارة، مما يعزز كفاءة استهلاك الوقود. كما أنه يتمتع بموصلية حرارية جيدة ومقاومة جيدة للتآكل، مما يجعله مناسباً للبيئات القاسية.

السلبيات: وعلى الرغم من أن الألومنيوم أقل تكلفة من النحاس، إلا أنه يتميز بتوصيل كهربائي أقل، مما قد يؤثر على الأداء في التطبيقات عالية الطلب. بالإضافة إلى ذلك، يمكن أن يكون الألومنيوم أقل تحملاً للإجهاد الميكانيكي مقارنةً بالفولاذ.

التأثير على التطبيق: في المناطق ذات الرطوبة العالية، تكون مقاومة الألومنيوم للتآكل مفيدة في المناطق ذات الرطوبة العالية. ومع ذلك، يجب على المشترين الدوليين النظر في الخواص الميكانيكية للألومنيوم في ظل الظروف المحلية، مع ضمان الامتثال لمعايير مثل DIN 1725.

لماذا يعتبر الفولاذ مادة شائعة للمبتدئين؟

غالبًا ما يُستخدم الفولاذ، وخاصة الفولاذ عالي الكربون، في بناء علب وتروس البادئ نظرًا لقوته ومتانته.

الإيجابيات: يوفر الفولاذ قوة ميكانيكية ممتازة ومقاومة ممتازة للتآكل، مما يجعله مناسبًا للتطبيقات عالية العزم. كما أنه فعال من حيث التكلفة نسبياً مقارنة بالمعادن الأخرى.

السلبيات: الفولاذ أثقل من الألومنيوم والنحاس، مما قد يؤثر سلباً على وزن السيارة وكفاءة استهلاك الوقود. بالإضافة إلى ذلك، فهو عرضة للصدأ إذا لم يتم طلاؤه بشكل صحيح.

التأثير على التطبيق: تعتبر المكونات الفولاذية مثالية للتطبيقات الشاقة، خاصة في البيئات ذات الإجهاد الميكانيكي العالي. يجب أن يتأكد المشترون في مناطق مثل أفريقيا وأمريكا الجنوبية من أن مكونات الصلب تفي بمعايير مقاومة التآكل المحلية، مثل JIS G3101.

كيف تتلاءم المركبات البلاستيكية مع تكنولوجيا المبتدئين؟

يتم استخدام المركبات البلاستيكية بشكل متزايد في الملفات اللولبية لبدء التشغيل، خاصةً في مكونات العزل والمبيت.

الإيجابيات: هذه المواد خفيفة الوزن ومقاومة للتآكل ويمكن تشكيلها في أشكال معقدة، مما يتيح مرونة في التصميم. كما أنها تتمتع بخصائص عزل كهربائي جيدة.

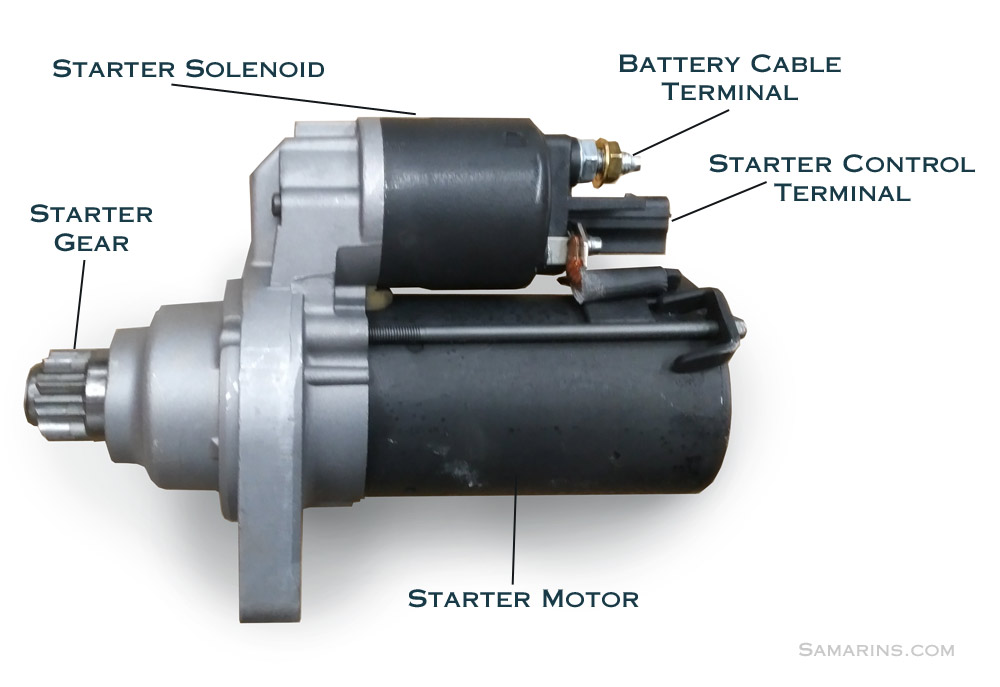

صورة توضيحية متعلقة بالملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

السلبيات: قد لا تتحمل مركبات البلاستيك درجات الحرارة العالية مثل المعادن، مما يحد من استخدامها في التطبيقات عالية الحرارة. كما أن قوتها الميكانيكية أقل بشكل عام من المعادن.

التأثير على التطبيق: في المناطق ذات درجات الحرارة القصوى، يجب تقييم الخواص الحرارية للمركبات البلاستيكية في المناطق ذات درجات الحرارة القصوى. يعد الامتثال للمعايير ذات الصلة، مثل ASTM D638 لخصائص الشد، أمرًا ضروريًا للمشترين الدوليين.

جدول ملخص لاختيار المواد اللازمة للملفات اللولبية والمبتدئين

| المواد | حالة الاستخدام النموذجية للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | التوصيلات الكهربائية في الملفات اللولبية | موصلية كهربائية عالية | باهظة الثمن وعرضة للأكسدة | عالية |

| الألومنيوم | مبيت للمشغلات والملفات اللولبية | خفيف الوزن ومقاوم للتآكل | موصلية أقل من النحاس | متوسط |

| الصلب | التروس والمكونات الهيكلية | قوة ميكانيكية ممتازة | أثقل وزناً وعرضة للصدأ | منخفض |

| المركبات البلاستيكية | مكونات العزل والإسكان | خفة الوزن ومرونة التصميم | أداء محدود في درجات الحرارة العالية | متوسط |

يزود هذا التحليل الشامل للمواد المستخدمة في الملفات اللولبية والمبتدئات للمشترين الدوليين من الشركات برؤى مهمة في اختيار المواد، مما يضمن اتخاذ قرارات مستنيرة تتماشى مع احتياجاتهم التشغيلية والمعايير الإقليمية.

نظرة متعمقة: عمليات التصنيع وضمان الجودة للملف اللولبي البادئ مقابل البادئ

ما هي عمليات التصنيع الرئيسية للملفات اللولبية والمبتدئين الرئيسية؟

يتضمن تصنيع ملفات لولبية وبادئات التشغيل عدة مراحل حاسمة، تساهم كل منها في الجودة والأداء العام للمنتج النهائي. ويمكن تصنيف العمليات على نطاق واسع إلى إعداد المواد والتشكيل والتجميع والتشطيب.

كيف يتم تحضير المواد اللازمة لتصنيع ملفات لولبية وبادئات التشغيل؟

الخطوة الأولى في عملية التصنيع هي إعداد المواد، حيث يتم اختيار المواد الخام عالية الجودة بناءً على خصائصها الكهربائية والميكانيكية. وتشمل المواد الشائعة النحاس للملفات نظرًا لتوصيلها الممتاز، والفولاذ للعلب والسبائك المختلفة للمكونات التي تتطلب المتانة ومقاومة التآكل.

قبل الإنتاج، تخضع المواد لاختبارات صارمة للتأكد من أنها تفي بمعايير الصناعة. على سبيل المثال، غالباً ما تخضع الأسلاك النحاسية لاختبارات التوصيل وقوة الشد. يعد هذا الفحص الأولي للجودة أمراً بالغ الأهمية، حيث يمكن أن تؤدي المواد دون المستوى المطلوب إلى فشل المنتج في وقت لاحق في عملية التصنيع.

ما تقنيات التشكيل الشائعة الاستخدام في تصنيع البادئات؟

التشكيل هو الخطوة التالية، حيث يتم تشكيل المواد الخام إلى مكونات. يتم استخدام تقنيات مختلفة اعتمادًا على الجزء الذي يتم إنتاجه:

-

الختم: يُستخدم الختم في المقام الأول للأجزاء المعدنية، ويتضمن الختم استخدام القوالب لقطع وتشكيل المواد في التكوينات المطلوبة. وهذا شائع بشكل خاص لمبيت الملف اللولبي والألواح الطرفية.

-

اللف: تعتبر عملية اللف أمرًا بالغ الأهمية بالنسبة للملفات اللولبية، حيث يتم لف الأسلاك النحاسية حول قلب الملف لإنشاء المجال الكهرومغناطيسي اللازم للتشغيل. الدقة هي المفتاح هنا، حيث أن عدد اللفات وضيق اللف يؤثران بشكل مباشر على أداء الملف اللولبي.

-

القولبة بالحقن: بالنسبة للمكونات المصنوعة من البلاستيك، مثل الأغطية أو العزل، غالبًا ما يتم استخدام القولبة بالحقن. تسمح هذه التقنية بأشكال معقدة وتشطيبات سطحية ممتازة.

-

التصنيع الآلي: يتم استخدام هذه العملية للمكونات الدقيقة، مثل تروس محرك بدء التشغيل، حيث يلزم وجود تفاوتات محددة لضمان الارتباط المناسب مع المحرك.

ما هي خطوات التجميع للمشغلات والملفات اللولبية؟

بمجرد تشكيل المكونات، تكون المرحلة التالية هي التجميع. هذه المرحلة حاسمة لأنها تتضمن دمج جميع الأجزاء في وحدة وظيفية. وتشمل الخطوات الرئيسية ما يلي:

-

فحص المكونات: يتم فحص كل جزء للتأكد من عدم وجود عيوب قبل التجميع. ويشمل ذلك الفحوصات البصرية والقياسات للتأكد من مطابقة المكونات للمواصفات.

-

تقنيات الانضمام: يتم استخدام طرق مختلفة لربط الأجزاء، مثل اللحام للمكونات المعدنية والمواد اللاصقة للأجزاء البلاستيكية. يعد ضمان التوصيل الآمن والموثوق به أمرًا حيويًا لمتانة المشغل أو الملف اللولبي.

-

التجميع النهائي: يتم تجميع جميع المكونات في بيئة نظيفة لمنع التلوث. وتتضمن هذه المرحلة أيضاً تركيب أي توصيلات كهربائية ضرورية واختبار الأداء الوظيفي قبل الانتقال إلى مرحلة التشطيب.

ما هي عمليات التشطيب المهمة للجودة؟

تعزز مرحلة التشطيب من متانة المنتج وجمالياته. وتشمل العمليات الشائعة ما يلي:

-

الطلاء: قد يتم طلاء المكونات بطبقات واقية لمقاومة التآكل، خاصةً تلك التي تتعرض لبيئات قاسية. ويعد الطلاء الكهربائي أو الطلاء بالمسحوق من التقنيات الشائعة.

-

تشطيب عالي الجودة: قد يتضمن ذلك تلميع أو طلاء الأجزاء المرئية من بادئ التشغيل أو الملف اللولبي لضمان مظهر احترافي.

-

الفحص النهائي: يتم إجراء فحص شامل للتحقق من تنفيذ جميع عمليات التجميع والتشطيب بشكل صحيح، والتحقق من المحاذاة والملاءمة والتشطيب.

كيف يتم تنفيذ ضمان الجودة في تصنيع البادئات والملفات اللولبية؟

يعد ضمان الجودة (QA) عنصرًا أساسيًا في عملية التصنيع، مما يضمن أن المنتجات تلبي المعايير الدولية وتوقعات العملاء.

ما هي المعايير الدولية ذات الصلة بضمان الجودة؟

يلتزم العديد من المصنعين بالمعايير الدولية مثل ISO 9001، التي تحدد مبادئ إدارة الجودة. يدل الامتثال لمعايير الأيزو على الالتزام بالجودة والتحسين المستمر. بالإضافة إلى ذلك، قد تكون الشهادات الخاصة بالصناعة، مثل علامة CE للمنتجات التي تباع في أوروبا أو معايير API لتطبيقات النفط والغاز، مطلوبة اعتمادًا على الاستخدام المقصود للمشغل أو الملف اللولبي.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في التصنيع؟

يتم دمج نقاط مراقبة الجودة (QC) في جميع مراحل عملية التصنيع:

-

مراقبة الجودة الواردة (IQC): يتم فحص المواد عند وصولها للتأكد من مطابقتها للمواصفات قبل دخولها خط الإنتاج.

-

مراقبة الجودة أثناء الإنتاج (IPQC): أثناء التصنيع، يتم إجراء فحوصات مستمرة في مراحل مختلفة لتحديد وتصحيح أي عيوب في وقت مبكر من العملية. وقد يشمل ذلك فحوصات الأبعاد والاختبارات الكهربائية والفحوصات البصرية.

-

مراقبة الجودة النهائية (FQC): بعد التجميع والتشطيب، يتم إجراء فحص شامل. ويشمل ذلك الاختبار الوظيفي للمشغل أو الملف اللولبي للتأكد من أنه يعمل بشكل صحيح في الظروف المتوقعة.

ما هي طرق الاختبار الشائعة الاستخدام للمشغلات والملفات اللولبية؟

يتم استخدام طرق اختبار مختلفة لضمان موثوقية المنتج:

-

الاختبارات الكهربائية: ويشمل ذلك فحوصات الاستمرارية والمقاومة واختبار الحمل للتأكد من أن الملف اللولبي يعمل بشكل صحيح وأن بادئ التشغيل يسحب التيار المناسب.

-

الاختبار الوظيفي: يتم اختبار المنتج المجمّع في ظروف تحاكي التشغيل في العالم الحقيقي لتقييم الأداء والموثوقية.

-

اختبار المتانة: قد تخضع المشغّلات لاختبارات إجهاد لمحاكاة البلى مع مرور الوقت، مما يضمن قدرتها على تحمل متطلبات التشغيل.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

بالنسبة للمشترين بين الشركات، لا سيما في الأسواق الدولية مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، فإن التحقق من مراقبة جودة الموردين أمر ضروري:

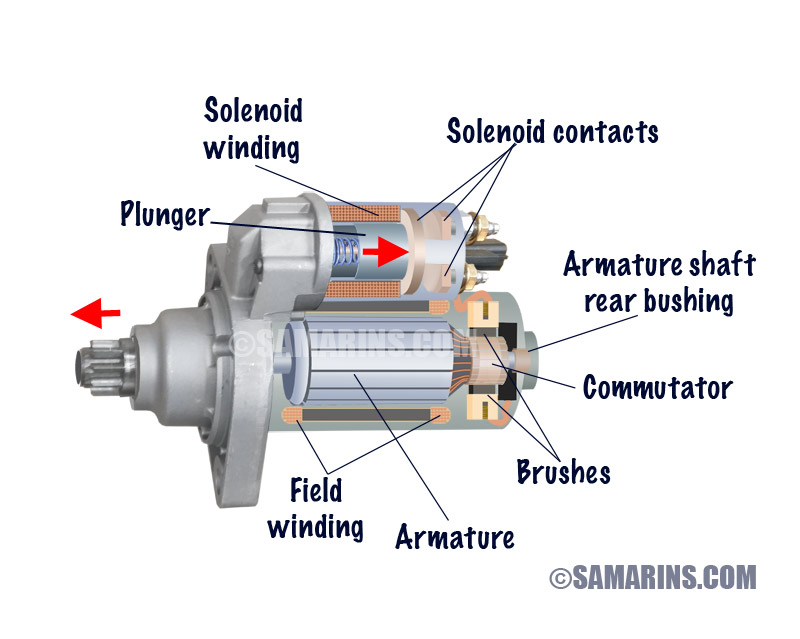

صورة توضيحية متعلقة بالملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

-

تدقيق الموردين: يمكن أن يوفر إجراء عمليات التدقيق في مرافق التصنيع نظرة ثاقبة على عمليات المورد والالتزام بمعايير الجودة. وقد يشمل ذلك مراجعة الوثائق، ومراقبة عمليات الإنتاج، وتقييم مدى الالتزام بالمعايير الدولية.

-

تقارير الجودة: يمكن أن يساعد طلب تقارير وشهادات الجودة التفصيلية في التحقق من استيفاء الموردين لمعايير الصناعة الضرورية.

-

عمليات التفتيش من قبل أطراف ثالثة: إن الاستعانة بخدمات التفتيش من طرف ثالث يمكن أن يوفر تقييماً غير متحيز لعمليات مراقبة الجودة وجودة المنتج لدى المورد. وهذا الأمر مفيد بشكل خاص للمشترين الدوليين الذين قد لا تتوفر لديهم موارد محلية لإجراء عمليات التفتيش.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

يجب أن يكون المشترون الدوليون على دراية بالفروق الدقيقة المختلفة في مراقبة الجودة:

-

الامتثال التنظيمي: لدى البلدان المختلفة أنظمة مختلفة فيما يتعلق بقطع غيار السيارات. ومن الضروري فهم هذه المتطلبات لضمان الامتثال وتجنب المشاكل القانونية المحتملة.

-

الاعتبارات الثقافية: يمكن أن يختلف التواصل والتوقعات حول الجودة باختلاف المنطقة. ويمكن أن يساعد وضع معايير وتوقعات واضحة في سد أي فجوات.

-

الشراكات المحلية: يمكن أن يؤدي تطوير العلاقات مع الشركاء المحليين إلى تسهيل المعاملات بشكل أكثر سلاسة وتعزيز عمليات ضمان الجودة.

من خلال فهم عمليات التصنيع ومقاييس ضمان الجودة للملفات اللولبية والمبتدئين، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة تضمن أداء المنتج الموثوق به والامتثال لمعايير الصناعة.

دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘الملف اللولبي لبدء التشغيل مقابل بادئ التشغيل’

يعد شراء ملفات لولبية وبادئ التشغيل مهمة بالغة الأهمية للشركات العاملة في مجال توريد قطع غيار السيارات أو خدمات الإصلاح. يوفر هذا الدليل قائمة مرجعية عملية مصممة لمساعدة المشترين بين الشركات في اتخاذ قرارات مستنيرة بشأن التوريد. من خلال اتباع هذه الخطوات، يمكنك التأكد من اختيار المكونات المناسبة التي تلبي احتياجاتك التشغيلية ومعايير الجودة.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

ابدأ بتحديد المتطلبات الفنية للملف اللولبي بادئ الحركة وبادئ الحركة الذي تحتاجه. يتضمن ذلك تصنيفات الجهد، والتوافق مع طرازات محددة من المركبات، ومعايير الأداء. يساعد فهم هذه المواصفات في تضييق نطاق الخيارات ويضمن لك شراء المكونات التي ستعمل بفعالية في تطبيقاتك.

- الجهد والأمبيرية: تحديد المتطلبات الكهربائية لضمان التوافق.

- توافق المركبة: تحديد الماركات والموديلات التي سيتم استخدام القطع فيها.

الخطوة 2: البحث في اتجاهات السوق والابتكارات

ابق على اطلاع على أحدث الاتجاهات في تقنية بادئ تشغيل السيارات. ويشمل ذلك التطورات في تصميمات الملف اللولبي والمواد المستخدمة وأي لوائح جديدة قد تؤثر على قرارات الشراء الخاصة بك. يمكن أن توفر معرفة اتجاهات السوق الحالية رؤى حول منتجات ذات جودة أفضل وأسعار أكثر تنافسية.

- التقنيات الناشئة: ابحث عن الابتكارات التي يمكن أن تعزز الأداء أو تخفض التكاليف.

- الامتثال التنظيمي: كن على دراية بأي معايير جديدة يمكن أن تؤثر على اختياراتك.

الخطوة 3: تقييم الموردين المحتملين

قبل الالتزام بأحد الموردين، قم بإجراء تقييمات شاملة. اطلب ملفات تعريف الشركة وكتالوجات المنتجات والمراجع من الشركات الأخرى التي اشترت منتجات مماثلة. هذه الخطوة ضرورية للتأكد من موثوقية وسمعة الموردين المحتملين.

- تاريخ الموردين: ابحث عن موردين لديهم سجل حافل في تقديم قطع غيار السيارات عالية الجودة.

- آراء العملاء: تحقق من المراجعات والشهادات من المشترين الآخرين من الشركات لقياس مدى الرضا.

الخطوة 4: تقييم تدابير مراقبة الجودة

يعد ضمان الجودة أمرًا حيويًا في صناعة السيارات، حيث يمكن أن يؤدي تعطل المكوّنات إلى اضطرابات تشغيلية كبيرة. استفسر عن عمليات مراقبة الجودة التي يستخدمها الموردون. تأكد من حصولهم على شهادات مثل معايير ISO أو غيرها من الشهادات الصناعية ذات الصلة.

- إجراءات الاختبار: اسأل عن أنواع الاختبارات التي يتم إجراؤها على الملفات اللولبية لبدء التشغيل والمبتدئين قبل التسليم.

- شهادات الجودة: تحقق مما إذا كان المورد يحمل شهادات جودة معترف بها.

الخطوة 5: طلب عينات للاختبار

قبل وضع اللمسات الأخيرة على طلبك، اطلب عينات من الملفات اللولبية والمبتدئين. يتيح لك اختبار العينات تقييم أداء المنتجات وتوافقها مع متطلباتك. يمكن لهذه الخطوة أن تمنع الأخطاء المكلفة المرتبطة بالطلبات بالجملة للقطع غير المناسبة.

- اختبار الأداء: التحقق من الكفاءة والمتانة في ظل ظروف التشغيل المحاكاة.

- توافق التثبيت: التأكد من أن العينات تتناسب بشكل جيد مع التطبيقات المقصودة.

الخطوة 6: التفاوض على الشروط والأحكام

بمجرد تحديد المورد المناسب، تفاوض على شروط الشراء. وهذا يشمل التسعير وشروط الدفع والمهل الزمنية وسياسات الإرجاع. تساعد الاتفاقات الواضحة على تجنب سوء الفهم وضمان سلاسة عملية الشراء.

- شروط الدفع: ناقش الخيارات التي تناسب التدفق النقدي ودورة المشتريات الخاصة بك.

- جداول التسليم: تأكيد المهل الزمنية لضمان توافر القطع في الوقت المناسب.

الخطوة 7: تأسيس علاقة طويلة الأمد

بعد عملية الشراء الأولية، اسعَ إلى بناء علاقة طويلة الأمد مع المورد الخاص بك. يمكن أن يؤدي التواصل المنتظم والتغذية الراجعة إلى تحسين الخدمة والتسعير وتوافر المنتج في المستقبل. يمكن أن تكون الشراكة القوية مفيدة لكلا الطرفين، خاصة في سوق السيارات التنافسي.

- التغذية الراجعة المستمرة: شارك تجاربك للمساعدة في تحسين عروض المنتجات.

- خصومات الحجم: استفسر عن الخصومات على الطلبات بالجملة أو تكرار الشراء.

من خلال اتباع قائمة المراجعة هذه، يمكن للمشترين بين الشركات تبسيط عملية توريد الملفات اللولبية والمبتدئات، مما يضمن اتخاذ قرارات مستنيرة تساهم في كفاءة أعمالهم وموثوقيتها.

تحليل شامل للتكلفة والتسعير للملف اللولبي لبادئ التشغيل مقابل مصدر بادئ التشغيل

ما هي مكونات التكلفة الرئيسية للملفات اللولبية والمبتدئين؟

عند تقييم هيكل التكلفة للملفات اللولبية والمبتدئين، تساهم العديد من المكونات بشكل كبير في التسعير النهائي. المواد تمثل جزءًا كبيرًا من التكاليف، حيث تتطلب الملفات اللولبية غالبًا معادن ومكونات كهربائية متخصصة، بينما تنطوي المشغلات على تعقيد إضافي بسبب أجزائها الميكانيكية.

تكاليف العمالة مهمة أيضًا؛ عادةً ما ينطوي تصنيع بادئات التشغيل عادةً على عمليات تجميع أكثر تعقيدًا، وبالتالي تكبد نفقات عمالة أعلى مقارنةً بالملفات اللولبية. وعلاوة على ذلك, النفقات العامة للتصنيع مثل المرافق وتكاليف المرافق وصيانة المعدات يجب تخصيصها وفقًا لذلك، مما يؤثر على التسعير الإجمالي.

بالإضافة إلى ذلك, تكاليف الأدوات يمكن أن تختلف القوالب والماكينات بناءً على مدى تعقيد المكونات التي يتم إنتاجها. مراقبة الجودة (QC) تعتبر العمليات ضرورية لكلا المنتجين ولكنها قد تختلف من حيث الكثافة، حيث تتطلب المواد المبتدئة عمومًا اختبارات أكثر صرامة بسبب متطلباتها التشغيلية. وأخيراً, التكاليف اللوجستية يجب أخذها في الاعتبار، خاصةً بالنسبة للشحنات الدولية، حيث يمكن أن تتقلب هذه الشحنات بناءً على الوجهة وطرق الشحن.

كيف تؤثر العوامل المؤثرة في التسعير على تكاليف الملف اللولبي وبداية التشغيل؟

هناك عدة عوامل تؤثر على تسعير البادئات والملفات اللولبية. الحجم والحد الأدنى لكمية الطلب (MOQ) مهمة، حيث يمكن أن تؤدي الطلبات الكبيرة إلى انخفاض تكاليف الوحدة بسبب وفورات الحجم. كما يمكن أن تؤثر المواصفات والميزات المخصصة على التسعير؛ فقد تتكبد تكاليف إضافية بسبب المواصفات والميزات المخصصة؛ فقد تتكبد ملفات لولبية أو مشغلات مخصصة مصممة لتطبيقات محددة.

اختيار المواد يلعب دورًا حاسمًا في تحديد السعر، حيث أن المواد عالية الجودة غالبًا ما تؤدي إلى زيادة المتانة ولكن أيضًا إلى ارتفاع التكاليف. الشهادات ومعايير الجودة يمكن أن تؤثر على السعر؛ فالمنتجات التي تفي بشهادات الجودة العالمية قد تحصل على علاوة سعرية، خاصة في الأسواق ذات متطلبات الامتثال الصارمة.

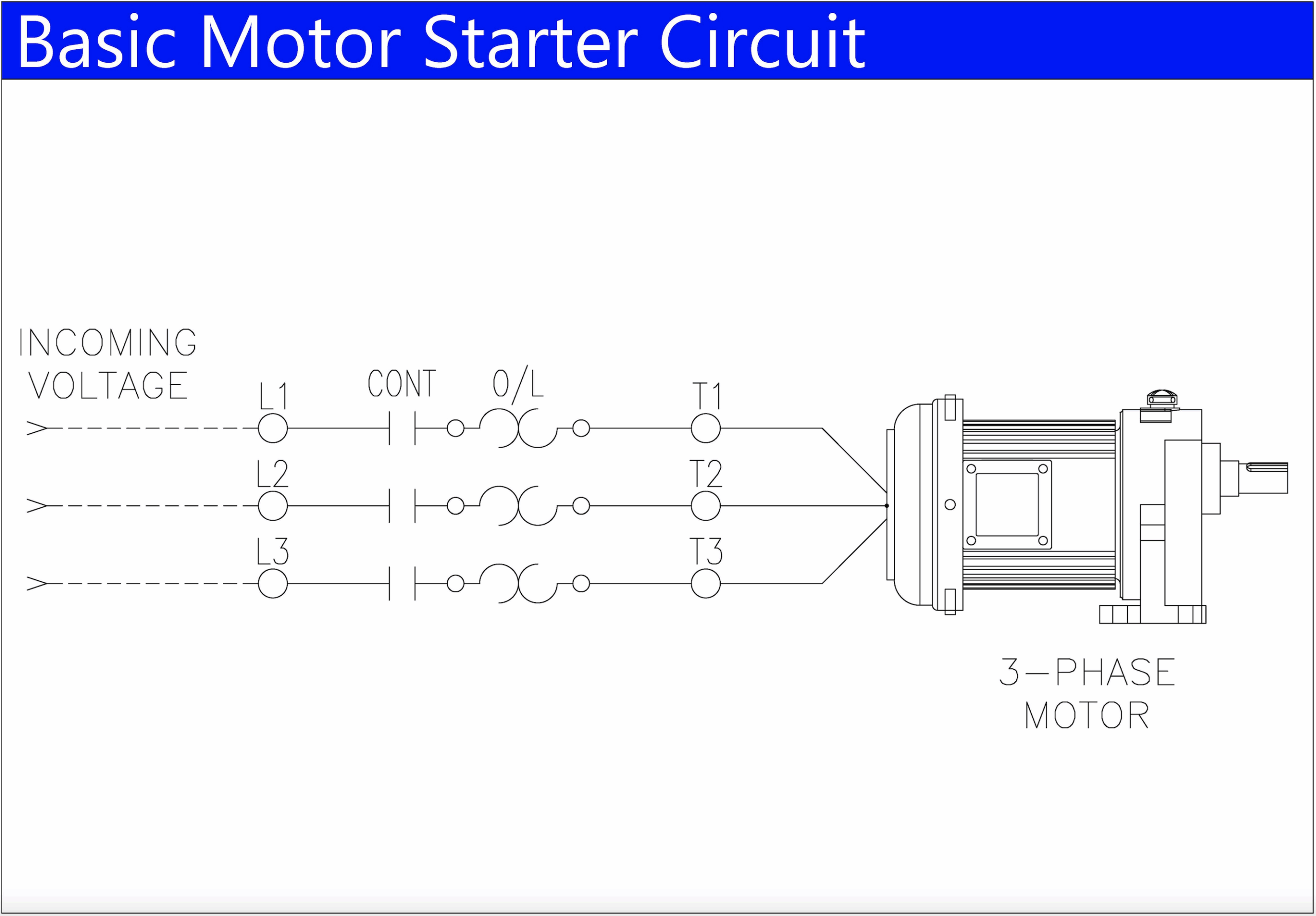

صورة توضيحية متعلقة بالملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

عوامل الموردين مثل السمعة والموقع وقدرات التصنيع تؤثر أيضًا على الأسعار. قد يتقاضى الموردون ذوو التكنولوجيا المتقدمة أو الخبرة المتخصصة أسعارًا أعلى ولكنهم يقدمون موثوقية وأداءً أفضل. وأخيراً، فهم مصطلحات التجارة الدولية أمر حيوي للمشترين الدوليين لتوضيح مسؤوليات وتكاليف الشحن، والتي يمكن أن تؤثر بشكل كبير على النفقات الإجمالية.

ما هي النصائح التي يمكن للمشترين استخدامها للتفاوض على أسعار أفضل للمشغلات والملفات اللولبية؟

بالنسبة للمشترين بين الشركات، لا سيما من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، يمكن أن يؤدي التفاوض بفعالية إلى تحقيق وفورات كبيرة. تتمثل إحدى الاستراتيجيات في الاستفادة من التكلفة الإجمالية للملكية (TCO) التحليل، الذي يتجاوز أسعار الشراء الأولية ليأخذ في الاعتبار التكاليف طويلة الأجل مثل الصيانة والضمان ووقت التعطل المحتمل.

يجب أن يكون المشترون مستعدين أيضاً لمناقشة خصومات على الحجم. إن إبرام اتفاقية شراء طويلة الأجل يمكن أن يؤدي إلى هياكل تسعير أفضل. بالإضافة إلى ذلك، يمكن أن يؤدي فهم مشهد السوق وأسعار المنافسين إلى تمكين المشترين أثناء المفاوضات.

صورة توضيحية متعلقة بالملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

النظر في المصادر المحلية يمكن أن يؤدي أيضًا إلى كفاءة التكاليف، حيث يمكن أن يقلل من النفقات اللوجستية والمهل الزمنية. وعند التعامل مع الموردين الدوليين، فإن الإلمام الجيد بما يلي شروط وأحكام الشحن يمكن أن يمنع التكاليف والتأخيرات غير المتوقعة.

أخيرًا، يجب أن يظل المشترون على دراية بـ الفروق الدقيقة في التسعير في مناطقهم الخاصة. يمكن للظروف الاقتصادية وتقلبات العملة وديناميكيات سلسلة التوريد المحلية أن تؤثر جميعها على استراتيجيات التسعير، مما يجعل من الضروري البقاء على اطلاع على ظروف السوق.

الخلاصة

بينما يمكن أن تختلف التكاليف المرتبطة بالملفات اللولبية والمبتدئين اختلافًا كبيرًا بناءً على العديد من العوامل، فإن فهم المكونات الأساسية لهذه التكاليف والعوامل المؤثرة في التسعير واستراتيجيات التفاوض الفعالة يمكن أن يمكّن المشترين من الشركات من اتخاذ قرارات شراء مستنيرة. يُنصح بالمشاركة في أبحاث السوق الشاملة والحفاظ على علاقات قوية مع الموردين للتنقل في هذا المشهد المعقد بفعالية.

تحليل البدائل: مقارنة الملف اللولبي البادئ مقابل البادئ بالحلول الأخرى

استكشاف الحلول البديلة للملف اللولبي لبدء التشغيل وأنظمة بدء التشغيل

في صناعة السيارات، يعد اختيار آلية التشغيل المناسبة أمرًا بالغ الأهمية لتحقيق الكفاءة والموثوقية. في حين أن الملف اللولبي لبدء التشغيل ونظام بدء التشغيل هما خياران شائعان، إلا أن هناك حلولاً بديلة قد تقدم مزايا فريدة اعتمادًا على الاحتياجات التشغيلية المحددة. يقارن هذا التحليل بين هذه الخيارات لمساعدة مشتري B2B على اتخاذ قرارات مستنيرة.

صورة توضيحية متعلقة بالملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

جدول المقارنة

| جانب المقارنة | الملف اللولبي لبدء التشغيل مقابل بادئ التشغيل | البديل 1: بادئ التشغيل المدمج بالترحيل | البديل 2: نظام التشغيل المباشر |

|---|---|---|---|

| الأداء | عزم دوران عالي، بدء تشغيل موثوق | أداء معتدل، يعتمد على جودة الترحيل | كفاءة عالية، تشغيل سريع للمحرك |

| التكلفة | استثمار أولي معتدل | تكلفة أقل بسبب قلة المكونات | استثمار أولي أعلى ولكن مدخرات طويلة الأجل |

| سهولة التنفيذ | التركيب القياسي | تكامل بسيط مع الأنظمة الحالية | يتطلب التركيب والمعرفة المتخصصة |

| الصيانة | معتدل؛ قد يتعطل الملف اللولبي | منخفضة؛ صيانة عدد أقل من المكونات | منخفضة؛ أجزاء متحركة أقل وأقل تآكلاً |

| أفضل حالة استخدام | المركبات القياسية، تطبيقات الخدمة الشاقة | السيارات القديمة أو التطبيقات ذات الميزانية المحدودة | السيارات عالية الأداء والسباقات |

ما هي مزايا وعيوب بادئ التشغيل المدمج في المرحل؟

يجمع نظام بدء التشغيل المدمج بالتتابع بين محرك بدء التشغيل والتتابع لتبسيط عملية بدء التشغيل. هذا النظام مفيد بشكل خاص للمركبات القديمة التي قد لا تتطلب حلولاً عالية العزم. إن فعالية هذا البديل من حيث التكلفة تجعله جذاباً للمشترين المهتمين بالميزانية. ومع ذلك، فإن الأداء يعتمد على جودة المرحّل، مما قد يؤدي إلى بدء تشغيل غير متناسق في حال فشل المرحّل. بالإضافة إلى ذلك، على الرغم من سهولة التركيب، إلا أنه قد لا يوفر نفس مستوى الموثوقية الذي توفره أنظمة الملف اللولبي لبدء التشغيل المخصصة.

كيف يمكن مقارنة نظام التشغيل المباشر بالحلول التقليدية؟

تلغي أنظمة التشغيل المباشر الحاجة إلى ملف لولبي أو مرحل باستخدام تقنية متقدمة تسمح بالإشعال الفوري. هذا النظام مثالي للمركبات عالية الأداء ومركبات السباق حيث تكون السرعة والكفاءة أمرًا بالغ الأهمية. وتتمثل الميزة الأساسية في قدرته على التشغيل السريع للمحرك، مما يقلل من الوقت الذي يستغرقه المحرك في الدوران. ومع ذلك، فإن الاستثمار المبدئي أعلى بكثير، ويتطلب التركيب معرفة متخصصة، مما يجعله أقل سهولة في المركبات القياسية. وعلى الرغم من هذه العيوب، فإن الوفورات طويلة الأجل الناتجة عن تقليل التآكل والتلف في المكونات يمكن أن تكون كبيرة.

كيف يمكن للمشترين B2B اختيار الحل المناسب لاحتياجاتهم؟

عند الاختيار بين الملف اللولبي لبادئ الحركة وأنظمة بادئ الحركة مقابل الحلول البديلة، يجب على مشتري B2B مراعاة متطلباتهم التشغيلية المحددة وقيود الميزانية وأنواع المركبات. إذا كانت الموثوقية وعزم الدوران أمرًا بالغ الأهمية، فقد تكون الملفات اللولبية التقليدية لبادئ التشغيل هي الأنسب. وعلى العكس من ذلك، بالنسبة للمؤسسات التي تدير أساطيل قديمة أو تلك التي تتطلع إلى تقليل التكاليف، قد يكون بادئ التشغيل المدمج في المرحل أكثر ملاءمة. بالنسبة للتطبيقات عالية الأداء، قد يؤدي الاستثمار في نظام التشغيل المباشر إلى نتائج أفضل على المدى الطويل على الرغم من ارتفاع تكاليفه الأولية. في نهاية المطاف، فإن التقييم الشامل لاحتياجات الأداء وقدرات الصيانة سيوجه المشترين نحو الحل الأفضل لعملياتهم.

صورة توضيحية متعلقة بالملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

الخصائص التقنية الأساسية والمصطلحات التجارية للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

ما هي الخصائص التقنية الرئيسية للملفات اللولبية والمبتدئين؟

في قطاع B2B للسيارات، يعد فهم المواصفات المهمة للملفات اللولبية والمبتدئين في قطاع السيارات، أمرًا ضروريًا لاتخاذ قرارات شراء مستنيرة. فيما يلي العديد من الخصائص الرئيسية التي يجب مراعاتها:

-

درجة المواد

تؤثر المواد المستخدمة في تصنيع الملفات اللولبية وبادئ التشغيل تأثيراً مباشراً على متانتها وأدائها. وتشمل المواد الشائعة الفولاذ عالي الجودة والنحاس. يوفر الفولاذ عالي الجودة القوة ومقاومة التآكل، بينما يضمن النحاس كفاءة التوصيل الكهربائي. بالنسبة لمشتري B2B، فإن اختيار المكونات المصنوعة من مواد فائقة الجودة يمكن أن يقلل من معدلات الأعطال ويقلل من تكاليف الصيانة. -

التصنيف الحالي

يشير التصنيف الحالي لملف لولبي بادئ الحركة إلى الحد الأقصى للتيار الكهربائي الذي يمكنه التعامل معه دون ارتفاع درجة الحرارة أو تعطله. وعادةً ما يتم التعبير عن هذه المواصفات بالأمبير (A)، وهذه المواصفات ضرورية لضمان التوافق مع النظام الكهربائي للسيارة. يجب على المشترين مطابقة التصنيف الحالي مع متطلبات سيارتهم لتجنب تعطل الملف اللولبي أو بادئ التشغيل قبل الأوان. -

جهد التشغيل

تعمل معظم بادئات التشغيل والملفات اللولبية للسيارات إما بجهد 12 فولت أو 24 فولت. يعد فهم جهد التشغيل أمرًا حيويًا عند الحصول على المكونات، حيث يمكن أن يؤدي عدم تطابق الجهد الكهربائي إلى أداء غير ملائم أو فشل كامل. يجب على مشتري B2B التحقق من مواصفات الجهد لضمان الأداء الوظيفي الأمثل في تطبيقاتهم. -

مستويات التسامح

يشير التفاوت المسموح به إلى الانحراف المسموح به عن الأبعاد المحددة في تصنيع الملفات اللولبية لبادئ الحركة والمبتدئين. تضمن مستويات التحمل العالية ملاءمة المكونات بشكل مثالي وتشغيلها بسلاسة داخل نظام السيارة. في سياق B2B، يمكن لمستويات التسامح العالية أن تعزز موثوقية المنتج وتقلل من احتمالية حدوث أعطال ميكانيكية. -

المقاومة الحرارية

المقاومة الحرارية هي قدرة الملف اللولبي لبدء التشغيل على تحمل درجات الحرارة العالية المتولدة أثناء التشغيل. يمكن للمكونات ذات المقاومة الحرارية الأعلى أن تعمل بكفاءة دون ارتفاع درجة الحرارة، وهو أمر بالغ الأهمية في التطبيقات عالية الأداء أو التطبيقات الشاقة. بالنسبة لمشتري B2B، يمكن أن يؤدي اختيار الأجزاء ذات المقاومة الحرارية المناسبة إلى إطالة عمر الخدمة وتقليل مخاطر الأعطال.

ما هي المصطلحات التجارية الشائعة في سوق الملف اللولبي لبادئ الحركة والمبتدئ؟

يتضمن التنقل في سوق B2B لمكونات السيارات فهم المصطلحات الخاصة بالصناعة. فيما يلي بعض المصطلحات الشائعة التي يجب أن يكون المشترون على دراية بها:

-

OEM (الشركة المصنعة للمعدات الأصلية)

قطع غيار OEM هي مكونات مصنوعة من نفس الشركة المصنعة التي أنتجت القطع الأصلية في السيارة. وغالباً ما تضمن هذه القطع التوافق والجودة، مما يجعلها مرغوبة بشدة في سوق B2B. يجب على المشترين الذين يبحثون عن الموثوقية والأداء أن يأخذوا بعين الاعتبار مكونات OEM. -

MOQ (الحد الأدنى لكمية الطلب)

يشير مصطلح "موك" إلى الحد الأدنى لعدد الوحدات التي يرغب المورد في بيعها في طلب واحد. ويُعد فهم موك أمرًا حيويًا للمشترين بين الشركات لتخطيط مخزونهم وميزانيتهم بفعالية. قد يوفر الموردون الذين لديهم موك مرن في موك المزيد من الفرص للشركات الصغيرة لدخول السوق. -

طلب عرض أسعار (RFQ)

طلب عروض الأسعار هو عملية رسمية يطلب فيها المشترون عروض أسعار من الموردين لمنتجات أو خدمات محددة. وهذا المصطلح ضروري للمفاوضات بين الشركات، حيث يسمح للمشترين بمقارنة الأسعار والشروط من موردين مختلفين، مما يضمن حصولهم على أفضل صفقة. -

شروط التجارة الدولية (Incoterms)

إنكوترمز هي مجموعة من الشروط التجارية المحددة مسبقاً التي تنشرها غرفة التجارة الدولية. وهي توضح مسؤوليات المشترين والبائعين في المعاملات الدولية، بما في ذلك الشحن والتأمين والتعريفات. ويُعد فهم الشروط التجارية الدولية أمرًا بالغ الأهمية للمشترين بين الشركات المنخرطين في التجارة عبر الحدود، حيث إنها تساعد على تخفيف المخاطر وسوء الفهم. -

المهلة الزمنية

تشير المهلة الزمنية إلى مقدار الوقت المستغرق من تقديم الطلب إلى استلام البضائع. بالنسبة للمشترين بين الشركات (B2B)، يعد فهم المهل الزمنية أمرًا ضروريًا لإدارة المخزون والتخطيط الفعال. يمكن للموردين الذين لديهم مهل زمنية أقصر أن يساعدوا الشركات على الاستجابة بسرعة لمتطلبات السوق. -

فترة الضمان

تحدد فترة الضمان المدة التي تضمن فيها الشركة المصنعة أداء المنتج. في صناعة السيارات، يمكن أن تشير فترة الضمان الأطول إلى ثقة أكبر في موثوقية المنتج. يجب على المشترين بين الشركات النظر في شروط الضمان كجزء من استراتيجية الشراء الخاصة بهم لضمان حمايتهم من العيوب المحتملة.

من خلال الإلمام بهذه الخصائص التقنية والمصطلحات التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة تعزز كفاءتهم التشغيلية وموثوقية منتجاتهم في قطاع السيارات.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع الملف اللولبي لبادئ الحركة مقابل قطاع البادئ

ما هي العوامل الرئيسية المحركة للسوق التي تؤثر على قطاع الملف اللولبي لبدء التشغيل مقابل قطاع البادئ؟

يشهد سوق السيارات العالمي حاليًا تحولاً كبيرًا متأثرًا بالعديد من العوامل المحفزة. أحد العوامل المحفزة الرئيسية هو الطلب المتزايد على السيارات الكهربائية (EVs)، مما أدى إلى زيادة التركيز على أنظمة بدء التشغيل الفعالة، بما في ذلك الملفات اللولبية لبدء التشغيل والمبتدئين. ويتجلى هذا التحول بشكل خاص في مناطق مثل أوروبا وأجزاء من أمريكا الجنوبية، حيث تدعو الحكومات إلى استخدام تقنيات أكثر مراعاة للبيئة. بالإضافة إلى ذلك، تؤدي الزيادة الكبيرة في ملكية السيارات في الأسواق الناشئة مثل نيجيريا والبرازيل إلى زيادة الطلب على مكونات بادئ التشغيل الموثوقة.

هناك اتجاه ملحوظ آخر هو التقدم في تكنولوجيا السيارات. فالسيارات الحديثة مجهزة بشكل متزايد بأنظمة إلكترونية متطورة تعزز وظائف الملفات اللولبية لبادئ الحركة والمبتدئين. وقد دفع ذلك الشركات المصنعة إلى الابتكار وتحسين عروضها، مما أدى إلى مشهد تنافسي يتميز بتحسين أداء المنتج وكفاءته. وعلاوة على ذلك، فإن دمج التقنيات الذكية، مثل التشخيصات التي تدعم إنترنت الأشياء، يسمح بمراقبة أنظمة بادئ الحركة في الوقت الفعلي، وبالتالي تقليل وقت التعطل وتكاليف الصيانة لمشغلي أساطيل السيارات.

كما يجب على المشترين الدوليين بين الشركات أن يكونوا على دراية بديناميكيات سلسلة التوريد المتطورة. تتحول استراتيجيات التوريد نحو أنظمة المخزون في الوقت المناسب والموردين المحليين للتخفيف من المخاطر المرتبطة بالاضطرابات العالمية. وبينما يسعى المشترون من مناطق متنوعة إلى تحسين التكاليف مع ضمان الجودة، يجب عليهم تقييم الموردين بناءً على قدرتهم على التكيف مع هذه الديناميكيات المتغيرة.

كيف تؤثر الاستدامة على ممارسات التوريد لمكونات المبتدئين؟

لقد برزت الاستدامة كعامل حاسم في توريد مكونات السيارات، بما في ذلك الملفات اللولبية لبدء التشغيل والمبتدئين. ويخضع التأثير البيئي لعمليات التصنيع والمواد للتدقيق، مما يدفع الشركات إلى البحث عن موردين يعطون الأولوية للممارسات الصديقة للبيئة. بالنسبة للمشترين بين الشركات، يعد فهم مؤهلات الاستدامة لدى مورديهم أمرًا ضروريًا، حيث يطالب المستهلكون بشكل متزايد بالشفافية والمسؤولية في المنتجات التي يشترونها.

تكتسب مصادر التوريد الأخلاقية زخمًا متزايدًا، لا سيما في المناطق التي يتم فيها تشديد اللوائح التنظيمية حول ممارسات العمل والإشراف البيئي. يجب على المشترين البحث عن موردين معتمدين بشهادات اعتماد ‘خضراء’ معترف بها، مثل ISO 14001 للإدارة البيئية أو شهادات من المنظمات التي تروج لممارسات العمل الأخلاقية. كما يمكن أن يؤدي استخدام المواد المعاد تدويرها أو عمليات التصنيع المستدامة إلى تعزيز جاذبية المورد، خاصة في الأسواق التي يكون فيها المستهلكون واعين بيئيًا.

علاوة على ذلك، فإن التحول نحو السيارات الكهربائية قد خلق فرصًا للمصنعين لتطوير حلول مستدامة لبدء التشغيل تتماشى مع الاتجاه الأوسع للصناعة. يجب على المشترين النظر في كيفية تعامل الموردين المحتملين مع الاستدامة ضمن خطوط منتجاتهم، حيث إن ذلك لن يفيد البيئة فحسب، بل يمكن أن يعزز سمعة العلامة التجارية والقدرة التنافسية في السوق.

ما هو السياق التاريخي للملفات اللولبية والمبتدئين في صناعة السيارات؟

يعود تاريخ تطور الملفات اللولبية وبادئ التشغيل إلى أوائل القرن العشرين، عندما أحدث إدخال محرك بادئ التشغيل الكهربائي ثورة في أنظمة إشعال المركبات. قبل هذا الابتكار، كانت السيارات تعتمد على السواعد اليدوية، والتي كانت تتطلب عمالة كثيفة وغير آمنة في كثير من الأحيان. كانت المشغلات الكهربائية الأولى بدائية، لكنها وضعت الأساس للأنظمة المتطورة التي نراها اليوم.

على مر العقود، أدت التطورات في المواد والهندسة إلى تحسين كفاءة وموثوقية أنظمة بدء التشغيل بشكل كبير. وقد سمح دمج الملفات اللولبية كمفاتيح كهرومغناطيسية بإدارة الطاقة بشكل أكثر فعالية، مما مكّن المركبات من بدء التشغيل بأقل جهد ممكن. وقد كان هذا التطور حاسمًا في دعم صناعة السيارات المزدهرة، حيث أصبحت الملفات اللولبية وبادئات التشغيل مكونات أساسية في مجموعة كبيرة من المركبات، بدءًا من محركات الاحتراق التقليدية إلى الطرازات الكهربائية والهجينة الحديثة.

مع استمرار تطور مشهد السيارات، يوفر فهم السياق التاريخي لهذه المكونات رؤى قيمة حول ديناميكيات السوق الحالية والاتجاهات المستقبلية. يمكن للمشترين بين الشركات الاستفادة من هذه المعرفة لاتخاذ قرارات مستنيرة عند الحصول على الملفات اللولبية والمبتدئات، مما يضمن توافقها مع كل من التطورات التكنولوجية ومتطلبات السوق.

الأسئلة المتداولة (FAQs) لمشتري الملف اللولبي لبادئ الحركة مقابل بادئ الحركة

-

كيف يمكنني تحديد ما إذا كنت بحاجة إلى استبدال الملف اللولبي لبدء التشغيل أو بادئ التشغيل؟

لتقييم ما إذا كان الملف اللولبي لبادئ التشغيل أو بادئ التشغيل نفسه معطوباً، استمع إلى أصوات معينة عند محاولة تشغيل المحرك. عادة ما تشير نقرة واحدة إلى وجود مشكلة في الملف اللولبي، بينما قد تشير سلسلة من النقرات إلى أن البطارية فارغة. إذا كان المحرك يدور بشكل متقطع، فقد تكون المشكلة في الملف اللولبي. ومع ذلك، إذا تم تعشيق بادئ التشغيل ولكنه فشل في فك الارتباط، فمن المحتمل أن يكون الملف اللولبي هو المشكلة. قم دائماً بإجراء فحص شامل، بما في ذلك التحقق من وجود أسلاك متآكلة أو صمامات محترقة قبل اتخاذ قرار الاستبدال. -

ما هي العوامل التي يجب مراعاتها عند اختيار الملف اللولبي أو مورد بادئ التشغيل؟

عند اختيار مورد لملفات لولبية أو مشغلات بادئ التشغيل، ضع في اعتبارك سمعة المورد وجودة المنتج والخبرة في المجال. ابحث عن الموردين الحاصلين على شهادات وعمليات ضمان الجودة. قم بتقييم قدرتهم على توفير حلول مخصصة وما إذا كانوا يقدمون ضمانات شاملة للمنتج. بالإضافة إلى ذلك، قم بتقييم قدراتهم اللوجستية، بما في ذلك خيارات الشحن والمهل الزمنية للشحن، خاصةً إذا كنت تقوم بالتوريد دوليًا من مناطق مثل أفريقيا أو أمريكا الجنوبية. -

ما هي خيارات التخصيص المتوفرة لملفات لولبية وبادئ التشغيل؟

تقدم العديد من الشركات المصنعة خيارات تخصيص لملفات لولبية وبادئ التشغيل لتلبية متطلبات محددة للمركبة. قد تتضمن التخصيصات معدلات جهد وأحجام وتكوينات تركيب مختلفة. ناقش مواصفاتك الفريدة مع الموردين المحتملين للتأكد من قدرتهم على تلبية احتياجاتك. يمكن للحلول المخصصة أن تعزز التوافق والأداء في التطبيقات المتنوعة، خاصةً في الأسواق الدولية حيث قد تختلف أنواع المركبات بشكل كبير. -

ما هو الحد الأدنى لكميات الطلبات (MOQs) للملفات اللولبية لبدء التشغيل والمبدلات؟

يمكن أن يختلف الحد الأدنى لكميات الطلبات اختلافًا كبيرًا بين الموردين، وغالبًا ما يعتمد ذلك على نوع المنتج وقدرات التصنيع. بشكل عام، قد يتراوح الحد الأدنى للكميات المطلوبة للملفات اللولبية والمبتدئين من بضع وحدات إلى عدة مئات. من الضروري تأكيد هذه التفاصيل مع المورد الخاص بك مقدمًا، خاصةً عند التخطيط للشحن الدولي وإدارة المخزون. يمكن أن يؤدي التفاوض على موك في بعض الأحيان إلى شروط مواتية، خاصةً للطلبات الكبيرة أو الشراكات طويلة الأجل. -

ما هي شروط الدفع التي يجب أن أتوقعها عند الحصول على ملفات لولبية وبادئ الحركة على المستوى الدولي؟

غالبًا ما تتضمن شروط الدفع للمشتريات الدولية خيارات مثل الدفع مقدمًا أو خطابات الاعتماد أو الدفع عند التسليم. تتضمن الممارسات الشائعة إيداع (على سبيل المثال، 30% مقدمًا) مع استحقاق الباقي قبل الشحن. تأكد من وضوح طرق الدفع التي يقبلها المورد الخاص بك وتأكيد أي رسوم إضافية مرتبطة بتحويل العملات أو المعاملات الدولية. يمكن أن يؤدي وضع شروط دفع آمنة ومرنة إلى تسهيل المعاملات بسلاسة أكبر وتعزيز الثقة بين الأطراف. -

كيف يمكنني التأكد من ضمان الجودة عند الحصول على ملفات لولبية ومشغلات بادئ الحركة؟

لضمان ضمان الجودة، اطلب مواصفات المنتج التفصيلية وشهادات الاعتماد من المورد الخاص بك. تلتزم العديد من الشركات المصنعة ذات السمعة الطيبة بالمعايير الدولية مثل ISO 9001. ضع في اعتبارك تنفيذ عملية مراقبة الجودة التي تتضمن عمليات فحص ما قبل الشحن أو اختبار طرف ثالث. وبالإضافة إلى ذلك، ابحث عن مراجع أو مراجعات من مشترين آخرين من الشركات لقياس موثوقية المورد وأداء المنتجات، خاصة في مناطق مثل الشرق الأوسط وأوروبا حيث قد تختلف توقعات الجودة. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في الحسبان عند الحصول على الملفات اللولبية لبدء التشغيل والمبتدئين؟

تلعب الخدمات اللوجستية دوراً حاسماً في التوريد الدولي. قم بتقييم خيارات الشحن الخاصة بالمورد، بما في ذلك المهل الزمنية وتكاليف الشحن والرسوم الجمركية المحتملة. تأكد من قدرتهم على توفير تتبع وتحديثات موثوقة طوال عملية الشحن. من المفيد أيضًا تقييم خبرتهم في التعامل مع الشحنات إلى منطقتك المحددة، حيث يمكن أن يؤثر ذلك على أوقات التسليم والرضا العام. يمكن أن تساعد مناقشة الخدمات اللوجستية مقدمًا في الحد من التأخيرات المحتملة وضمان توافر المنتج في الوقت المناسب. -

ما هي العلامات الشائعة لفشل الملف اللولبي أو بادئ التشغيل التي يجب أن أكون على دراية بها؟

تتضمن العلامات الشائعة لفشل الملف اللولبي لبدء التشغيل فشل المحرك في بدء التشغيل، أو صوت نقرة واحدة عند تدوير مفتاح التشغيل أو مشاكل متقطعة في بدء التشغيل. في بعض الحالات، قد يتسبب الملف اللولبي المعيب في بعض الحالات في تشغيل المحرك دون تدوير المفتاح أو الفشل في فك الارتباط بعد بدء التشغيل. بالنسبة للمبتدئين، ابحث عن أعراض مثل أصوات الطحن أو التأخير الكبير في بدء التشغيل. إن إدراك هذه العلامات يمكن أن يساعد في التشخيص في الوقت المناسب ويمنع حدوث المزيد من الأضرار في السيارة.

قائمة المصنعين والموردين لأفضل 4 ملفات لولبية بادئ تشغيل مقابل بادئ التشغيل

1. ريديت - مكونات محرك بدء التشغيل

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: يعد محرك بدء التشغيل والملف اللولبي لبدء التشغيل من مكونات نظام بدء تشغيل السيارة. يتم توصيل الملف اللولبي بمحرك البادئ وهو مسؤول عن تعشيق المحرك عند تشغيل مفتاح الإشعال. يقوم معظم الأشخاص عادةً باستبدال مجموعة محرك بدء التشغيل بالكامل بدلاً من الملف اللولبي فقط.

2. فورد - مرحل البادئ والملف اللولبي

المجال: ford-trucks.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: مرحل البادئ: يُستخدم في نظام 56 F1 بجهد 12 فولت؛ يوصل التيار العالي الذي يتطلبه بادئ التشغيل؛ يتم تركيبه عادةً على جدار الحماية/الرفرف الداخلي. ملف لولبي بادئ الحركة: يستخدم في نظام فورد 65 فورد 12 فولت؛ عادةً ما يتم تركيبه أعلى بادئ التشغيل؛ ينشط محرك البادئ؛ يوفر مصدر جهد عالي التيار للمشغل.

3. MasterCraft - ProStar 205V

المجال: teamtalk.mastercraft.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: 2001 ProStar 205V ProStar 205V، محرك بقوة 310 حصان، 278 ساعة عمل للمحرك، تشمل الأعراض صوت طقطقة عند بدء التشغيل، وفقدان الطاقة في لوحة العدادات والملحقات، ومشاكل محتملة في محرك التشغيل أو الملف اللولبي المتكامل، عمره 18 سنة، مشاكل متعلقة بالحرارة، يوصى بتشحيم تروس بنديكس سنوياً.

4. جاغوار-لوفرز - ملفات لولبية لبدء التشغيل

المجال: forums.jag-lovers.com

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: 1. أنواع الملفات اللولبية لبدء التشغيل:

- بادئ تشغيل بدون زر ضغط

- بادئ تشغيل مع زر ضغط

2. ميزات زر التشغيل بالضغط على الزر:

- النمط الأصلي المستخدم منذ عقود

- عادةً ما تكون أكثر تكلفة

- الجاذبية الجمالية في السيارات الكلاسيكية

- يسمح بالتشغيل اليدوي للصيانة أو الضبط

3. التوافق:

- أي من النوعين مناسب للاستخدام

4. ملاحظات إضافية:

- الاستيراد...

استنتاج وتوقعات التوريد الاستراتيجي للملف اللولبي لبادئ التشغيل مقابل بادئ التشغيل

مع استمرار سوق السيارات في التطور، فإن فهم الفروق بين الملفات اللولبية لبادئ التشغيل والمبتدئين أمر ضروري لاتخاذ قرارات استراتيجية بشأن التوريد. تؤكد النقاط الرئيسية على أنه في حين أن كلا المكونين يلعبان دورًا حاسمًا في أنظمة إشعال المركبات، فإن وظائفهما ونقاط الفشل المحتملة تختلف بشكل كبير. يجب على المشترين الدوليين بين الشركات إعطاء الأولوية لتوريد الملفات اللولبية والمبتدئات عالية الجودة للتخفيف من المخاطر المرتبطة بتعطل السيارة وتكاليف الصيانة.

يتيح التوريد الاستراتيجي للشركات تبسيط العمليات وتقليل النفقات العامة وتعزيز مرونة سلسلة التوريد. من خلال الشراكة مع موردين موثوقين، يمكن للمشترين ضمان الوصول إلى أحدث التقنيات والابتكارات، وهو أمر حيوي بشكل خاص في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، حيث تتطور أسواق السيارات بسرعة.

بالنظر إلى المستقبل، يجب أن تظل الشركات استباقية في التكيف مع تغيرات السوق، بما في ذلك التحولات نحو السيارات الكهربائية والهجينة. تعامل مع الموردين الذين يقدمون حلولاً شاملة مصممة خصيصاً لتلبية احتياجاتك الخاصة، واستفد من الرؤى المستندة إلى البيانات لاتخاذ قرارات شراء مستنيرة. لنمضِ معاً قدماً نحو مستقبل تكون فيه الكفاءة التشغيلية وموثوقية المنتج في طليعة استراتيجية التوريد الخاصة بك.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.