Introduction: Navigating the Global Market for signs that your car alternator is going bad

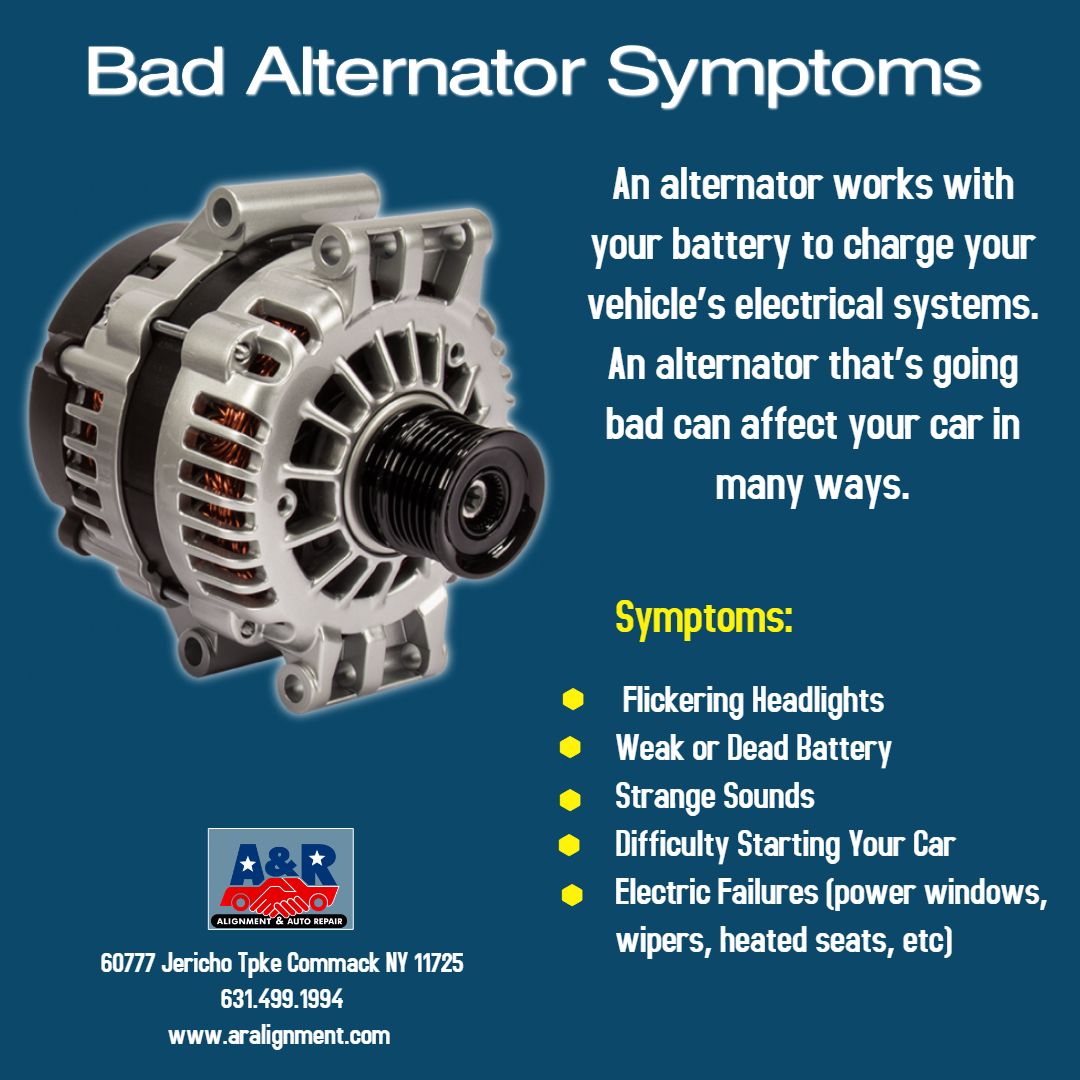

In the intricate landscape of automotive maintenance, recognizing the signs that your car alternator is going bad is crucial for ensuring operational efficiency and preventing unexpected breakdowns. For international B2B buyers, particularly those in emerging markets such as Africa, South America, the Middle East, and Europe, understanding these warning signs can significantly impact procurement decisions. Faulty alternators not only lead to vehicle performance issues but can also escalate repair costs and downtime, making it imperative to source quality components and services.

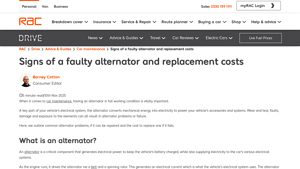

This comprehensive guide delves into the various symptoms of a failing alternator, including starting difficulties, electrical malfunctions, and warning lights. It will also explore the different types of alternators available, their applications across various vehicle models, and critical insights on supplier vetting processes to ensure high-quality parts. Additionally, we will provide an overview of cost considerations, helping you to budget effectively for both repairs and replacements.

By empowering B2B buyers with the knowledge to identify alternator issues early, this guide facilitates informed purchasing decisions that enhance fleet reliability and performance. Whether you’re operating in bustling urban centers or remote regions, understanding these essential aspects will enable you to maintain a competitive edge in the automotive sector.

جدول المحتويات

- Top 2 Signs That Your Car Alternator Is Going Bad Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for signs that your car alternator is going bad

- Understanding signs that your car alternator is going bad Types and Variations

- Key Industrial Applications of signs that your car alternator is going bad

- 3 Common User Pain Points for ‘signs that your car alternator is going bad’ & Their Solutions

- Strategic Material Selection Guide for signs that your car alternator is going bad

- In-depth Look: Manufacturing Processes and Quality Assurance for signs that your car alternator is going bad

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘signs that your car alternator is going bad’

- Comprehensive Cost and Pricing Analysis for signs that your car alternator is going bad Sourcing

- Alternatives Analysis: Comparing signs that your car alternator is going bad With Other Solutions

- Essential Technical Properties and Trade Terminology for signs that your car alternator is going bad

- Navigating Market Dynamics and Sourcing Trends in the signs that your car alternator is going bad Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of signs that your car alternator is going bad

- Strategic Sourcing Conclusion and Outlook for signs that your car alternator is going bad

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding signs that your car alternator is going bad Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| مشكلات البداية | Difficulty starting the vehicle; clicking sound upon ignition. | ورش تصليح السيارات، وإدارة أساطيل السيارات. | الإيجابيات: Early detection can prevent breakdowns. السلبيات: Requires immediate attention to avoid further damage. |

| Electrical System Warnings | Dashboard warning lights, fluctuating electrical components. | Vehicle diagnostics services, auto parts suppliers. | الإيجابيات: Alerts to systemic issues. السلبيات: May require comprehensive electrical system checks. |

| Headlight Irregularities | Dimming or flickering headlights; inconsistent brightness. | Automotive repair, fleet service providers. | الإيجابيات: Simple visual cue for potential alternator issues. السلبيات: Might be mistaken for other electrical problems. |

| ضوضاء غير عادية | Growling or whining sounds from the engine when starting. | Repair workshops, automotive parts distributors. | الإيجابيات: Indicates mechanical failure early. السلبيات: May be confused with other engine noises. |

| الرائحة الحارقة | Presence of burning rubber or electrical odors. | Maintenance services, fleet management. | الإيجابيات: Strong warning signal of overheating. السلبيات: Can indicate severe damage needing immediate intervention. |

What Are the Characteristics of Starting Issues in Alternators?

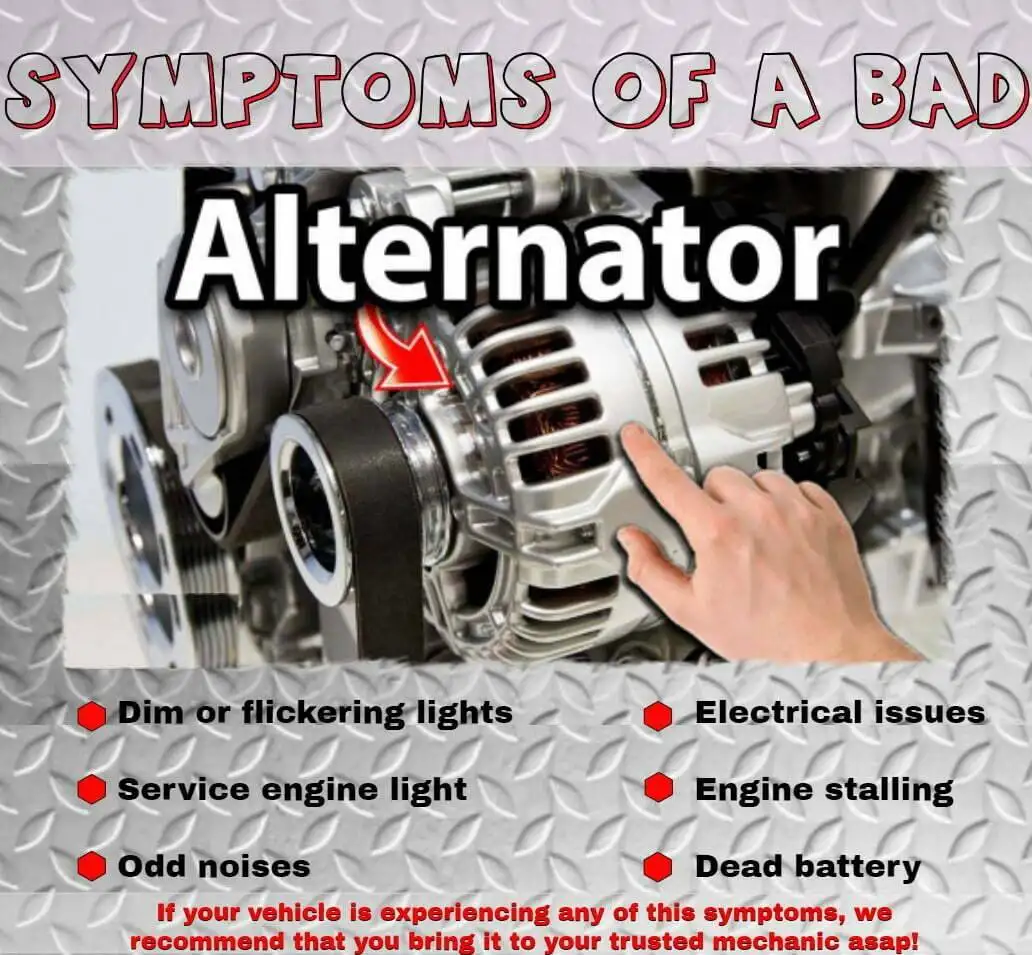

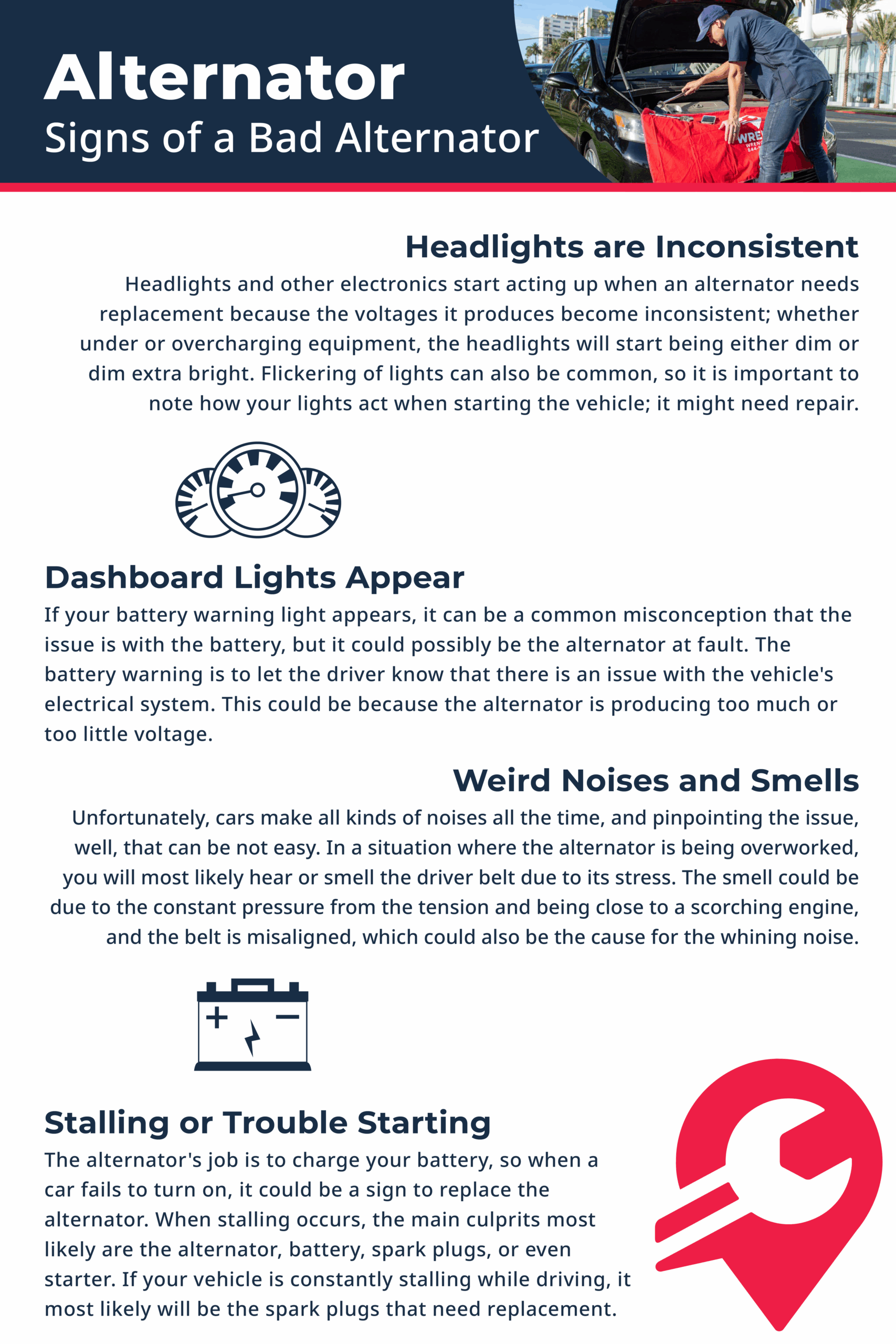

Starting issues are often the first and most apparent sign of a failing alternator. When a vehicle struggles to start or produces a clicking noise instead of the engine turning over, it indicates that the alternator may not be adequately charging the battery. For B2B buyers, particularly in automotive repair or fleet management, identifying this issue early can prevent more severe complications, such as complete battery failure or unexpected downtime. Regular inspections and proactive maintenance can significantly reduce repair costs and improve operational efficiency.

How Do Electrical System Warnings Indicate Alternator Problems?

Electrical system warnings, such as dashboard lights illuminating or fluctuations in electronic components, signify potential alternator failure. These symptoms are critical for businesses that rely on vehicle diagnostics services or auto parts suppliers. Understanding these warning signs allows for timely interventions and repairs, ultimately enhancing vehicle reliability. B2B buyers should prioritize training their teams to recognize these indicators and invest in diagnostic tools that can quickly assess electrical system health.

Why Are Headlight Irregularities Important for Maintenance?

Headlight irregularities, such as flickering or inconsistent brightness, serve as a visual cue that something may be wrong with the alternator. This symptom is particularly relevant for automotive repair shops and fleet service providers, as it can lead to safety concerns if left unaddressed. B2B buyers should consider implementing routine visual inspections as part of their maintenance protocols. By catching these signs early, they can save on potentially larger repairs and enhance customer satisfaction through reliable vehicle performance.

What Do Unusual Noises from the Engine Indicate?

Unusual noises, such as growling or whining sounds from the engine, can indicate mechanical failures related to the alternator. For repair workshops and automotive parts distributors, recognizing these sounds is crucial for diagnosing issues before they escalate. B2B buyers should ensure their technicians are trained to identify and address such symptoms promptly, as this can lead to improved service quality and reduced turnaround times for repairs.

How Does a Burning Smell Signal Alternator Failure?

The presence of a burning smell, often resembling rubber or electrical odors, is a strong indicator of a failing alternator. This symptom is particularly relevant for maintenance services and fleet management, as it suggests overheating components that could lead to significant damage if not addressed immediately. B2B buyers should invest in staff training to recognize these critical warning signs and develop maintenance schedules that include regular checks for odors or signs of overheating. Proactive measures can mitigate risks and enhance vehicle longevity.

Key Industrial Applications of signs that your car alternator is going bad

| الصناعة/القطاع | Specific Application of signs that your car alternator is going bad | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | Diagnostic tools for identifying alternator issues | Increases service efficiency and customer satisfaction | Quality of diagnostic equipment, training for technicians |

| إدارة الأسطول | Regular monitoring of vehicle alternators | يقلل من وقت التعطل وتكاليف الصيانة | Compatibility with fleet vehicles, scalability of solutions |

| لوجستيات النقل والمواصلات | Ensuring reliability of delivery vehicles | Minimizes delivery disruptions and enhances service reliability | Robustness of monitoring systems, support for international operations |

| موردو قطع غيار السيارات | Providing replacement parts for faulty alternators | Increases sales of high-demand parts | Sourcing high-quality parts, understanding market demand |

| تصنيع المركبات | Quality assurance in production lines | Enhances vehicle reliability and brand reputation | Supplier reliability, adherence to international standards |

How Can Automotive Repair Shops Benefit from Identifying Signs of a Failing Alternator?

Automotive repair shops can leverage diagnostic tools that identify signs of a failing alternator to enhance service efficiency. By quickly diagnosing alternator issues, these shops can reduce the time taken for repairs, leading to higher customer satisfaction. The key sourcing considerations include the quality of diagnostic equipment and ensuring technicians are adequately trained to interpret the results effectively.

What Advantages Does Fleet Management Gain from Monitoring Alternator Health?

For fleet management companies, regular monitoring of vehicle alternators is crucial. By identifying early signs of alternator failure, businesses can schedule timely maintenance, thereby reducing vehicle downtime and overall maintenance costs. Buyers in this sector should consider solutions that are compatible with a variety of fleet vehicles and can scale as the fleet grows.

How Does Transportation Logistics Improve Reliability Through Alternator Monitoring?

In the transportation logistics industry, ensuring the reliability of delivery vehicles is paramount. By monitoring alternator health, companies can prevent unexpected breakdowns that may disrupt delivery schedules. It’s essential for these businesses to invest in robust monitoring systems that support international operations, ensuring consistent performance across different regions.

Why Are Automotive Parts Suppliers Focused on Replacement Parts for Alternators?

Automotive parts suppliers recognize that providing replacement parts for faulty alternators is a lucrative market. By understanding the signs of a failing alternator, suppliers can better predict demand for specific components, thus increasing sales. Sourcing high-quality parts is critical, as is keeping an eye on market trends to meet customer needs effectively.

What Role Does Quality Assurance Play in Vehicle Manufacturing Related to Alternator Functionality?

In vehicle manufacturing, quality assurance regarding alternator functionality is vital for enhancing overall vehicle reliability. By integrating checks for alternator performance into production lines, manufacturers can improve their brand reputation and customer trust. Key considerations for sourcing in this context include ensuring supplier reliability and adherence to international manufacturing standards.

Illustrative image related to signs that your car alternator is going bad

3 Common User Pain Points for ‘signs that your car alternator is going bad’ & Their Solutions

Scenario 1: Frequent Vehicle Downtime Due to Alternator Issues

المشكلة: For fleet managers and automotive service providers, unexpected vehicle downtime can lead to significant operational inefficiencies and financial losses. When alternators begin to fail, vehicles may stall or fail to start, leaving businesses scrambling to manage logistics and customer commitments. This situation not only affects productivity but also impacts customer satisfaction as delays can tarnish a company’s reputation.

الحل: To mitigate the risk of downtime, it is crucial for B2B buyers to implement a proactive maintenance schedule that includes regular inspections of the alternator and its associated systems. Establish partnerships with reliable suppliers that offer high-quality alternators and components. Train your staff to recognize the early signs of alternator issues, such as dimming headlights or dashboard warning lights, so they can act swiftly. By leveraging diagnostic tools to monitor the health of the electrical system, businesses can address potential problems before they escalate, ensuring vehicles remain operational and minimizing costly disruptions.

Scenario 2: Increasing Repair Costs from Ignored Signs

المشكلة: Automotive repair shops often face the challenge of customers arriving with escalated issues that stem from neglected alternator problems. Many vehicle owners may overlook early warning signs, leading to more severe electrical system failures and costly repairs. This not only frustrates the shop owners due to the increased workload but also affects their profitability and customer retention rates when clients are unhappy with the unexpectedly high repair bills.

الحل: Repair shops can combat this issue by offering educational resources to clients about the signs of a failing alternator. Create informative content, such as brochures or digital newsletters, that outline common symptoms like unusual noises, flickering lights, or starting difficulties. Implement a system for following up with customers after service appointments, encouraging them to report any anomalies they observe. Additionally, consider bundling alternator inspections with routine maintenance services to help clients stay aware of their vehicle’s condition, ultimately reducing the likelihood of severe issues and fostering trust in your services.

Illustrative image related to signs that your car alternator is going bad

Scenario 3: Difficulty in Sourcing Quality Replacement Parts

المشكلة: B2B buyers, especially those operating in regions with limited access to reliable automotive parts, often struggle to find quality replacement alternators. This challenge can lead to delays in repairs and increased operational costs, as sourcing from unreliable suppliers can result in subpar parts that fail prematurely. The risk of unsatisfactory replacements not only impacts the performance of the vehicles but also the long-term trust between businesses and their customers.

الحل: Establishing strong relationships with reputable parts distributors is essential for ensuring access to quality alternators. Conduct thorough research to identify suppliers with a proven track record for reliability and customer service. Leverage technology to compare prices, warranty offers, and customer reviews before making procurement decisions. Additionally, consider investing in a stock of high-demand alternators to streamline repairs and minimize wait times for clients. By prioritizing quality over cost, businesses can enhance their service reputation and ensure that vehicles operate reliably, ultimately leading to higher customer satisfaction and retention.

Strategic Material Selection Guide for signs that your car alternator is going bad

When it comes to identifying signs that a car alternator is failing, the choice of materials used in the manufacturing of diagnostic tools and components can significantly impact performance and reliability. Below are analyses of several common materials used in the automotive industry, particularly relevant for B2B buyers focused on the automotive sector.

What Are the Key Properties of Copper in Automotive Applications?

Copper is a highly conductive metal that is often used in wiring and electrical components, including those related to alternators. Its key properties include excellent electrical conductivity, corrosion resistance, and high thermal conductivity, which are essential for efficient energy transfer and heat dissipation.

إيجابيات النحاس وسلبياته:

– الإيجابيات: Copper’s high conductivity allows for minimal energy loss, making it ideal for electrical applications. It is also relatively easy to work with, allowing for complex designs and configurations.

– السلبيات: Copper is more expensive than other conductive materials, and it can corrode if not properly insulated or protected, especially in humid environments.

التأثير على التطبيق: Copper wiring is essential for ensuring that the alternator receives and distributes electrical energy efficiently. Its ability to handle high temperatures makes it suitable for automotive applications where heat generation is a concern.

اعتبارات للمشترين الدوليين من الشركات إلى الشركات: Buyers in regions like Africa and South America should consider the availability of copper and its price fluctuations. Compliance with international standards such as ASTM B170 for copper wire may also be necessary.

كيف يمكن مقارنة الألومنيوم كمادة لمكونات المولد؟

Aluminum is another commonly used material, especially for housing and structural components of alternators. It is lightweight and has good corrosion resistance, making it an attractive option in automotive applications.

إيجابيات وسلبيات الألومنيوم:

– الإيجابيات: Its lightweight nature contributes to overall vehicle efficiency, and its corrosion resistance extends the lifespan of components.

– السلبيات: Aluminum has lower electrical conductivity compared to copper, which may lead to increased resistance in electrical applications.

التأثير على التطبيق: The use of aluminum in alternator housings helps reduce the weight of the vehicle, improving fuel efficiency. However, its lower conductivity may necessitate thicker wiring or additional components to ensure adequate electrical performance.

اعتبارات للمشترين الدوليين من الشركات إلى الشركات: In regions with high humidity, aluminum’s corrosion resistance can be a significant advantage. Compliance with standards such as ASTM B221 for aluminum extrusions can facilitate smoother procurement processes.

What Role Does Plastic Play in Alternator Diagnostics?

Plastic materials, particularly high-grade thermoplastics, are often used for insulating components and housings in automotive applications. Key properties include lightweight, good electrical insulation, and resistance to various chemicals.

إيجابيات وسلبيات البلاستيك:

– الإيجابيات: Plastics are generally less expensive than metals and can be molded into complex shapes, making them suitable for various applications.

– السلبيات: Plastics may not withstand high temperatures as effectively as metals, which can be a concern in high-heat environments like an engine compartment.

التأثير على التطبيق: The use of plastic in alternator components helps reduce weight and costs, but care must be taken to ensure that the selected plastic can withstand the operational temperatures and environmental conditions.

اعتبارات للمشترين الدوليين من الشركات إلى الشركات: Buyers should be aware of the specific grades of plastic that meet automotive standards, such as ISO 9001 for quality management systems, to ensure compliance and reliability.

Illustrative image related to signs that your car alternator is going bad

How Do Composites Enhance Performance in Automotive Applications?

Composite materials, which combine two or more materials to create a product with enhanced properties, are increasingly used in automotive applications. Their key properties include high strength-to-weight ratios and excellent resistance to corrosion and wear.

إيجابيات وسلبيات المركبات:

– الإيجابيات: Composites can be tailored to meet specific performance requirements, offering versatility in design and application.

– السلبيات: They can be more expensive to manufacture and may require specialized processes for production and repair.

التأثير على التطبيق: Composites can be used in high-stress areas of the alternator, providing durability while minimizing weight. This can lead to improved overall vehicle performance.

اعتبارات للمشترين الدوليين من الشركات إلى الشركات: Understanding the specific composite materials that meet regional standards, such as DIN EN 12224 for composites, is crucial for ensuring product compatibility and performance.

Summary Table of Material Selection for Alternator Diagnostics

| المواد | Typical Use Case for signs that your car alternator is going bad | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | Wiring and electrical connections in alternators | موصلية كهربائية ممتازة | Higher cost and potential corrosion | عالية |

| الألومنيوم | Housing and structural components of alternators | خفيف الوزن ومقاوم للتآكل | Lower electrical conductivity than copper | متوسط |

| بلاستيك | مكونات العزل والأغطية العازلة | Cost-effective and moldable | أداء محدود في درجات الحرارة العالية | منخفض |

| المركبات | High-stress areas in alternator components | نسبة عالية من القوة إلى الوزن | More expensive and complex manufacturing | عالية |

This analysis provides a comprehensive overview of material selection relevant to the automotive sector, particularly for diagnosing alternator issues. Buyers should consider these factors carefully to ensure optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for signs that your car alternator is going bad

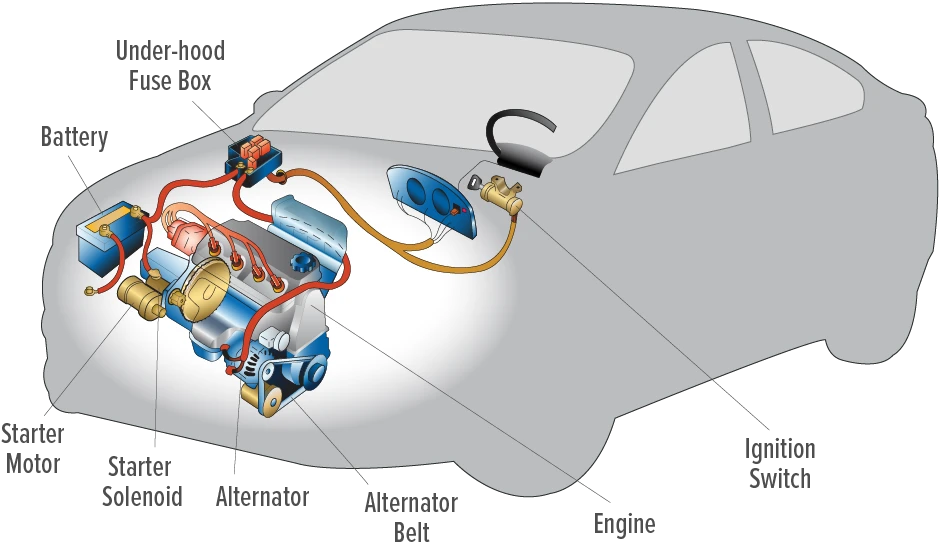

What Are the Key Stages in the Manufacturing Process of Car Alternators?

The manufacturing process of car alternators involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. Understanding these stages helps B2B buyers evaluate potential suppliers effectively.

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in the manufacturing process is the preparation of raw materials. Common materials used in alternator production include high-grade aluminum for the housing, copper for the windings, and various types of steel for the rotor. The selection of materials is crucial as it affects the durability and efficiency of the alternator.

Once the materials are sourced, they undergo a series of processes such as cutting, machining, and forming. For example, aluminum casings are often die-cast to form precise shapes that accommodate the alternator’s internal components. Copper wires are drawn to specific gauges to ensure optimal conductivity, which is vital for the alternator’s performance.

كيف يتم تشكيل المولدات وتجميعها؟

After material preparation, the next stage is the forming and assembly of the alternator. This involves several key techniques:

-

تجميع الجزء الثابت: The stator, which consists of copper windings, is assembled first. The windings are carefully placed into the stator core, and insulation is applied to prevent short circuits.

-

Rotor Fabrication: The rotor is typically assembled with permanent magnets or wound coils, depending on the alternator type. This component is crucial for generating the electromagnetic field necessary for electricity production.

-

التكامل: The stator and rotor are then integrated into the alternator housing. This requires precise alignment to ensure efficient operation. Any misalignment can lead to premature wear or failure.

-

التجميع النهائي: Other components, such as voltage regulators and rectifiers, are added during the final assembly phase. Quality control measures are implemented at each stage to ensure that all parts fit together seamlessly.

What Quality Control Standards Are Relevant for Car Alternator Manufacturing?

Quality assurance is a cornerstone of manufacturing high-performance car alternators. International standards such as ISO 9001 play a significant role in establishing quality management systems that ensure consistent product quality.

How Does ISO 9001 Impact Quality Assurance in Alternator Production?

ISO 9001 focuses on a process-oriented approach, emphasizing continuous improvement and customer satisfaction. Manufacturers adhering to this standard must establish documented procedures, conduct regular internal audits, and ensure that their processes meet predefined quality criteria. This certification not only assures B2B buyers of quality but also enhances the manufacturer’s credibility in the marketplace.

What Other Industry-Specific Standards Should B2B Buyers Consider?

In addition to ISO 9001, there are several industry-specific certifications that are particularly relevant to automotive components:

Illustrative image related to signs that your car alternator is going bad

- علامة CE: This certification is essential for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

- API Certification: For alternators used in heavy-duty applications, API standards can assure buyers of performance and reliability.

What Are the Key Quality Control Checkpoints During the Manufacturing Process?

Quality control checkpoints are integral to ensuring that alternators meet industry standards and customer expectations. The following checkpoints are commonly implemented:

-

مراقبة الجودة الواردة (IQC): This initial checkpoint involves the inspection of raw materials and components before they enter the production line. Suppliers must provide certification of material quality to pass this stage.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During manufacturing, regular inspections are conducted to monitor the assembly process. This includes verifying dimensions, electrical resistance, and other critical parameters to catch defects early.

-

مراقبة الجودة النهائية (FQC): At the end of the production line, the completed alternators undergo rigorous testing to ensure they meet performance specifications. This can include load testing, thermal cycling tests, and durability evaluations.

ما هي طرق الاختبار المستخدمة بشكل شائع في ضمان جودة المولد؟

Various testing methods are employed to ensure that alternators function correctly and efficiently. Common methods include:

- الاختبارات الكهربائية: This involves checking the output voltage and current under different loads to verify performance.

- الاختبار الحراري: Alternators are subjected to extreme temperatures to ensure they can operate effectively in various climates.

- اختبار الاهتزازات: This method assesses the alternator’s resilience to vibrations, which is crucial for automotive applications.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

For B2B buyers, understanding a supplier’s quality control processes is essential for making informed purchasing decisions. Here are several ways to verify supplier QC:

-

تدقيق الموردين: Conducting on-site audits allows buyers to assess the manufacturer’s quality management system firsthand. This includes reviewing documentation, inspecting processes, and evaluating the overall production environment.

-

طلب تقارير الجودة: Suppliers should provide detailed quality reports, including data from IQC, IPQC, and FQC checkpoints. These reports can offer insight into the manufacturer’s commitment to quality.

-

عمليات التفتيش من قبل أطراف ثالثة: Engaging independent inspection services can provide an unbiased assessment of the supplier’s quality practices. This is particularly important for international buyers who may not be able to visit the manufacturing facility.

ما هي الفروق الدقيقة في مراقبة الجودة للمشترين الدوليين بين الشركات؟

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, may encounter unique challenges in verifying quality control. Factors to consider include:

-

الامتثال التنظيمي: Different regions may have varying regulations regarding automotive components. Understanding local compliance requirements is essential to avoid penalties or product recalls.

-

الاختلافات الثقافية: Communication styles and business practices can vary significantly across cultures. Establishing clear expectations regarding quality standards and reporting can mitigate misunderstandings.

-

الخدمات اللوجستية وإدارة سلسلة التوريد: Global supply chains can introduce complexities that impact quality. Buyers should consider the entire supply chain when assessing a supplier’s quality assurance processes.

By understanding the manufacturing processes and quality assurance measures associated with car alternators, B2B buyers can make informed decisions and ensure they source high-quality products that meet their operational needs.

Illustrative image related to signs that your car alternator is going bad

Practical Sourcing Guide: A Step-by-Step Checklist for ‘signs that your car alternator is going bad’

مقدمة

Understanding the signs of a failing car alternator is critical for maintaining vehicle performance and avoiding unexpected breakdowns. This guide provides a practical checklist for B2B buyers focused on sourcing automotive parts or services related to alternator diagnostics and repairs. By following these steps, you can ensure that you are well-prepared to identify potential issues early, reducing downtime and repair costs.

الخطوة 1: Identify Common Symptoms of Alternator Failure

Begin by familiarizing yourself with the typical signs of a failing alternator. This knowledge is essential for accurate diagnosis and timely intervention. Key symptoms to note include:

– Difficulty starting the vehicle: A clicking sound when turning the key can indicate insufficient power.

– Dimming or flickering headlights: Inconsistent electrical supply often manifests in your vehicle’s lighting.

الخطوة 2: حدد المواصفات الفنية الخاصة بك

Clearly outline the specific requirements for the alternator or diagnostic equipment you need. Knowing your vehicle’s make, model, and electrical specifications will help in sourcing the right products. Consider:

– Voltage ratings: Ensure compatibility with your vehicle’s electrical system.

– Physical dimensions: Confirm that the part will fit within the designated space in the engine bay.

الخطوة 3: البحث عن الموردين المحتملين

Conduct thorough research on suppliers that specialize in automotive electrical components. Assess their reputation in the industry to ensure reliability. Important factors include:

– Experience and expertise: Look for suppliers with a proven track record in alternator parts.

– Customer reviews and testimonials: These can provide insights into product quality and customer service.

الخطوة 4: تقييم جودة المنتج والضمان

Prioritize suppliers that offer high-quality products backed by robust warranties. This is crucial for minimizing long-term costs and ensuring reliability. Pay attention to:

– Material quality: Durable materials can enhance performance and lifespan.

– شروط الضمان: A longer warranty can indicate confidence in product durability.

Illustrative image related to signs that your car alternator is going bad

الخطوة 5: Verify Compliance with Industry Standards

Ensure that the alternator or diagnostic tools meet relevant industry standards and certifications. Compliance is vital for safety and performance. Check for:

– شهادات الأيزو: These indicate adherence to international quality standards.

– Local regulations: Familiarize yourself with any specific requirements in your region.

الخطوة 6: Consider After-Sales Support and Service

A strong after-sales support system can be a game-changer in the sourcing process. Evaluate suppliers based on their ability to provide ongoing support. Look for:

– Technical assistance: Access to knowledgeable staff who can assist with installation and troubleshooting.

– Return policies: Clear policies can mitigate risks associated with defective parts.

الخطوة 7: Conduct a Cost-Benefit Analysis

Finally, perform a comprehensive cost-benefit analysis to assess the overall value of the products or services being sourced. This step will help you determine the best financial decision for your business. Consider:

– Total cost of ownership: Factor in purchase price, installation costs, and potential long-term savings.

– Impact on operational efficiency: Evaluate how sourcing high-quality parts can reduce downtime and improve vehicle reliability.

By following this checklist, you can ensure a more informed and efficient procurement process for identifying and addressing alternator issues in your fleet or automotive business.

Comprehensive Cost and Pricing Analysis for signs that your car alternator is going bad Sourcing

When sourcing components related to the signs of a failing car alternator, it’s essential to understand the various cost components and price influencers that affect the overall pricing structure. This analysis aims to provide actionable insights for international B2B buyers, particularly those from diverse markets such as Africa, South America, the Middle East, and Europe.

ما هي المكونات الرئيسية لتكلفة شراء المولدات الكهربائية؟

المواد: The primary materials involved in alternator production include copper for windings, aluminum for housing, and steel for components like bearings. The cost of these raw materials fluctuates based on global market trends, which can significantly impact the overall pricing.

العمل: Labor costs vary widely depending on the region. For instance, manufacturers in regions with lower labor costs may offer competitive pricing, but this could also affect quality. Understanding the skill level and labor market in specific countries can help buyers evaluate potential suppliers.

Illustrative image related to signs that your car alternator is going bad

تكاليف التصنيع العامة: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production processes can minimize overhead costs, enabling suppliers to offer better pricing.

الأدوات: Custom tooling can be a significant upfront cost for manufacturers, especially if bespoke components are required. Buyers should consider whether they need standard parts or if customization is necessary, as this will influence pricing.

مراقبة الجودة (QC): Implementing stringent QC measures ensures product reliability but can also add to the overall cost. Buyers should look for suppliers who balance quality assurance with cost-effectiveness.

اللوجستيات: Shipping and handling costs are crucial, particularly for international buyers. Factors such as shipping distance, freight methods, and tariffs can drastically alter the final price. Buyers should consider the total logistics expenses when evaluating suppliers.

الهامش: Supplier margins vary based on market competition and perceived value. Understanding the typical margins in the industry can help buyers negotiate better terms.

How Do Price Influencers Affect Alternator Component Costs?

الحجم والحد الأدنى لكمية الطلب (MOQ): Bulk purchasing often results in lower per-unit costs. Buyers should assess their needs and negotiate MOQs that align with their production schedules to maximize cost efficiency.

المواصفات والتخصيص: Unique specifications can lead to increased costs due to the need for custom tooling and specialized materials. Buyers should clearly define their requirements to avoid unexpected expenses.

جودة المواد والشهادات: Higher quality materials often come at a premium. Certifications (e.g., ISO, CE) can also affect pricing, as suppliers may pass on the costs of achieving and maintaining these standards.

Illustrative image related to signs that your car alternator is going bad

عوامل الموردين: The reputation and reliability of the supplier play significant roles in pricing. Established suppliers may charge more due to their track record, while emerging suppliers may offer lower prices to gain market share.

مصطلحات التجارة الدولية: Understanding the Incoterms applied in your agreements can significantly influence total costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping and insurance costs, impacting overall pricing.

What Buyer Tips Can Help Maximize Cost-Efficiency?

التفاوض: Engaging in discussions with suppliers can yield better pricing, especially when leveraging volume commitments or long-term contracts. Establishing a relationship can also facilitate better terms.

التكلفة الإجمالية للملكية (TCO): Buyers should look beyond initial costs and consider long-term expenses, including maintenance, reliability, and potential downtime costs associated with alternator failures.

Illustrative image related to signs that your car alternator is going bad

الفروق الدقيقة في الأسعار للمشترين الدوليين: Different regions may have varying norms regarding pricing, lead times, and payment terms. Understanding local market dynamics is crucial for effective negotiation.

إخلاء المسؤولية بشأن الأسعار الإرشادية: Prices can fluctuate based on market conditions, currency exchange rates, and geopolitical factors. Buyers should seek updated quotations and be aware of the potential for price changes throughout the sourcing process.

By taking these considerations into account, B2B buyers can better navigate the complexities of sourcing alternator components, ensuring they make informed purchasing decisions that align with their operational needs.

Alternatives Analysis: Comparing signs that your car alternator is going bad With Other Solutions

Exploring Alternatives to Recognizing Signs of a Failing Car Alternator

In the automotive industry, understanding when a car alternator is failing is crucial for maintenance and repair decisions. While identifying signs of a bad alternator is essential, exploring alternative methods and technologies can also enhance vehicle reliability and performance. Below, we compare the traditional signs of alternator failure against two alternative solutions: onboard diagnostic systems and battery management systems.

| جانب المقارنة | Signs That Your Car Alternator Is Going Bad | Onboard Diagnostic Systems (OBD-II) | أنظمة إدارة البطاريات (BMS) |

|---|---|---|---|

| الأداء | Relies on physical symptoms; may miss subtle issues | Provides real-time data and error codes for precise diagnostics | Monitors battery health and charging efficiency |

| التكلفة | No direct costs but may incur repair expenses | Moderate cost for OBD-II scanners and installation | Higher initial investment but can prevent costly failures |

| سهولة التنفيذ | Requires knowledge of symptoms and manual checks | User-friendly; requires minimal training to use | Requires installation and configuration but automates monitoring |

| الصيانة | Low maintenance; requires regular observation | Low maintenance; updates may be needed for software | Requires periodic checks of sensors and calibration |

| أفضل حالة استخدام | Useful for drivers familiar with vehicle maintenance | Ideal for fleet management and professional mechanics | Best for electric and hybrid vehicles with complex battery systems |

تحليل متعمق للبدائل

Onboard Diagnostic Systems (OBD-II)

Onboard Diagnostic Systems provide a comprehensive solution for vehicle diagnostics. They can detect and report issues in real-time, including those related to the alternator. The primary advantage of OBD-II systems is their ability to generate error codes, which can help technicians pinpoint problems quickly. However, these systems can require an initial investment in both the diagnostic tool and potential installation, making them less accessible for casual users. For businesses operating fleets, the investment can lead to significant long-term savings by preventing unexpected breakdowns.

أنظمة إدارة البطاريات (BMS)

Battery Management Systems monitor the health and performance of a vehicle’s battery and charging systems. They are particularly beneficial for electric and hybrid vehicles, ensuring optimal battery life and efficiency. By providing detailed analytics on battery performance, BMS can alert users to potential issues before they become critical, thus minimizing downtime. The downside is the higher initial investment compared to simply observing alternator signs. However, the preventative capabilities of a BMS can lead to reduced maintenance costs and increased vehicle reliability.

الخلاصة: كيفية اختيار الحل المناسب لاحتياجاتك

When deciding on the best approach to monitor and maintain your vehicle’s electrical system, consider your specific operational needs and budget constraints. For businesses relying on traditional vehicles, understanding the signs of alternator failure may suffice. However, for those managing fleets or operating electric vehicles, investing in OBD-II or BMS technologies may provide greater long-term value and reliability. Ultimately, the right solution will depend on the complexity of the vehicle systems you manage and your commitment to proactive maintenance strategies.

Essential Technical Properties and Trade Terminology for signs that your car alternator is going bad

What Key Technical Properties Should You Know About Car Alternators?

Understanding the technical specifications of car alternators is crucial for B2B buyers involved in automotive parts procurement. Here are some essential properties to consider:

1. ناتج الجهد

The voltage output of an alternator typically ranges between 12V to 14.5V. This specification is critical because it indicates the alternator’s ability to charge the battery and power the vehicle’s electrical systems. A faulty alternator may not provide adequate voltage, leading to battery drain and potential vehicle stalling.

2. Amp Rating

The amp rating refers to the maximum current the alternator can produce, usually measured in amperes (A). This rating is vital for understanding how well the alternator can support various electrical components, especially in vehicles with extensive electronic systems. A higher amp rating is essential for vehicles with added accessories like advanced audio systems or off-road lighting.

3. Bearing Type

Alternators can have different types of bearings, such as ball bearings or sleeve bearings. The bearing type affects the durability and performance of the alternator. Ball bearings generally offer higher load capacity and longer life, making them preferable for high-performance applications. Understanding bearing specifications helps in selecting an alternator that meets specific operational demands.

Illustrative image related to signs that your car alternator is going bad

4. Case Material

The casing of the alternator is typically made from aluminum or composite materials. Aluminum casings are lightweight and dissipate heat effectively, which is crucial for preventing overheating during prolonged use. The choice of material can influence the alternator’s weight, performance, and longevity, impacting overall vehicle efficiency.

5. Rotor Type

Alternators may feature either a wound rotor or a permanent magnet rotor. Wound rotors are more common in larger vehicles and provide better performance at high speeds, while permanent magnet rotors are lightweight and can be found in smaller vehicles. Understanding rotor types aids in selecting the right alternator for specific vehicle applications.

What Trade Terminology is Important for Purchasing Alternators?

Navigating the automotive parts market requires familiarity with specific trade terms. Here are some essential jargon terms relevant to alternators:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the original manufacturer of the vehicle. Purchasing OEM alternators ensures compatibility and reliability, as they meet the manufacturer’s specifications. B2B buyers often prefer OEM parts for fleet maintenance to minimize the risk of failures.

Illustrative image related to signs that your car alternator is going bad

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers as it affects inventory management and cost efficiency. For alternators, knowing the MOQ helps in planning procurement strategies, especially for bulk orders.

3. طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers requesting price and delivery information for specific products. For B2B buyers, issuing an RFQ for alternators allows for competitive pricing and helps in assessing supplier capabilities. This process is essential for making informed purchasing decisions.

4. شروط التجارة الدولية (Incoterms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is vital for B2B transactions involving alternators, as they clarify shipping responsibilities, risks, and costs, ensuring smooth logistics.

5. ما بعد البيع

The aftermarket refers to the secondary market for vehicle parts, including alternators. These parts are not made by the original manufacturer but can offer cost-effective alternatives. Understanding the aftermarket landscape is important for B2B buyers looking for competitive pricing or specific features that OEM parts may not provide.

In summary, comprehending the technical properties and trade terminology associated with car alternators not only facilitates better purchasing decisions but also enhances overall supply chain efficiency in the automotive sector.

Navigating Market Dynamics and Sourcing Trends in the signs that your car alternator is going bad Sector

Market Overview & Key Trends: What Are the Current Dynamics in the Alternator Sector?

The automotive sector is undergoing significant transformations, driven by technological advancements and shifting consumer preferences. One of the primary global drivers for the alternator market is the increasing demand for electric vehicles (EVs) and hybrid vehicles, which require advanced alternator systems to efficiently manage energy. As countries across Africa, South America, the Middle East, and Europe implement stricter emissions regulations, there is a growing emphasis on high-efficiency alternators that can support the burgeoning electrification of vehicles.

Illustrative image related to signs that your car alternator is going bad

Emerging B2B tech trends include the integration of smart technologies in alternators, such as IoT-enabled devices that provide real-time diagnostics and predictive maintenance capabilities. This trend is particularly relevant for international buyers looking to enhance their service offerings and reduce long-term operational costs. Additionally, the rise of e-commerce platforms is reshaping sourcing strategies, allowing businesses to procure alternators and related components directly from manufacturers, minimizing intermediaries and reducing costs.

Market dynamics are also influenced by the varying quality standards across regions. Buyers from Europe may prioritize premium components with stringent quality certifications, while those in emerging markets like Vietnam and Brazil may focus on cost-effective solutions without compromising on essential performance metrics. Understanding these regional nuances is critical for B2B buyers aiming to optimize their supply chain and meet the diverse demands of their customer base.

كيف يمكن أن تؤثر الاستدامة والتوريد الأخلاقي على سلسلة توريد المولدات الكهربائية؟

In today’s environmentally conscious market, sustainability and ethical sourcing are paramount. The production of alternators can have significant environmental impacts, from resource extraction to manufacturing processes. B2B buyers must consider suppliers that prioritize sustainable practices, such as using recycled materials and minimizing waste during production. This commitment not only reduces the environmental footprint but also aligns with the growing consumer demand for eco-friendly products.

Ethical supply chains are increasingly critical, especially in regions where labor practices may vary significantly. Buyers should seek out manufacturers that adhere to fair labor standards and are transparent about their sourcing practices. Certifications such as ISO 14001 for environmental management and ethical certifications can serve as benchmarks for evaluating suppliers.

Furthermore, the trend towards ‘green’ certifications is gaining traction in the alternator sector. Products that are certified to meet environmental standards can enhance a brand’s reputation and appeal to a broader customer base. By integrating sustainability into their sourcing strategies, B2B buyers can not only comply with regulations but also differentiate themselves in a competitive market.

What Is the Evolution of the Alternator Industry Relevant to B2B Buyers?

The alternator has evolved significantly since its inception in the early 20th century, transitioning from simple generators to sophisticated electronic devices that play a critical role in vehicle performance. Originally, alternators were primarily mechanical devices, but advancements in technology have led to the development of electronic alternators that offer improved efficiency and reliability.

In recent years, the industry has seen a shift towards compact designs that integrate seamlessly with modern vehicle architectures. This evolution is particularly relevant for B2B buyers, as it indicates a trend towards lighter and more efficient components that can enhance overall vehicle performance. Furthermore, the integration of digital technology into alternators allows for better diagnostics and maintenance, which is crucial for fleet operators and service providers aiming to reduce downtime and improve operational efficiency.

Understanding this historical context can provide valuable insights for B2B buyers looking to make informed sourcing decisions in a rapidly changing market. As the automotive landscape continues to evolve, staying abreast of these developments will be essential for maintaining a competitive edge.

Frequently Asked Questions (FAQs) for B2B Buyers of signs that your car alternator is going bad

-

How can I identify the signs of a failing alternator in vehicles?

To identify a failing alternator, look for several key indicators: difficulty starting the engine, dim or flickering headlights, dashboard warning lights, and unusual noises such as growling or whining. Additionally, if electronic features like power windows or the radio malfunction intermittently, it could signal alternator issues. Regular inspections and monitoring of battery performance can help catch these signs early, preventing further damage to the vehicle’s electrical system. -

What is the best way to source high-quality alternators for resale?

When sourcing alternators, prioritize suppliers with a proven track record in quality and reliability. Look for manufacturers that adhere to international quality standards and offer warranties on their products. Engage in thorough supplier vetting, including checking references, certifications, and customer reviews. Additionally, consider suppliers who provide customization options to meet specific market needs, enhancing your product offering. -

ما هو الحد الأدنى المعتاد لكميات الطلبات (MOQs) لمولدات التيار المتردد؟

Minimum order quantities for alternators can vary significantly based on the supplier and product type. Generally, MOQs may range from 50 to 500 units for bulk orders. It’s essential to communicate your purchasing needs with potential suppliers to negotiate MOQs that align with your business model. Some suppliers may offer flexibility for first-time buyers or smaller businesses looking to test market demand. -

What payment terms should I expect when importing alternators?

Payment terms for importing alternators typically include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit upfront, often around 30%, with the balance due upon shipment or delivery. It’s advisable to establish clear payment terms before finalizing contracts to ensure mutual agreement and to mitigate risks associated with international transactions. -

How do I ensure quality assurance (QA) for imported alternators?

To ensure quality assurance for imported alternators, establish clear specifications and standards with your supplier before production begins. Request samples for inspection and conduct thorough quality checks upon arrival. Consider partnering with third-party inspection services that specialize in automotive parts to perform on-site evaluations. Regular communication with suppliers throughout the manufacturing process can also help maintain quality standards. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد المولدات الكهربائية؟

When importing alternators, consider factors such as shipping methods, customs regulations, and delivery times. Choose a reliable freight forwarder experienced in handling automotive parts to streamline logistics. Be aware of potential tariffs and duties that may apply to your shipments and ensure all documentation is in order to avoid delays at customs. Timely communication with your supplier about shipping schedules is also crucial for inventory management. -

How can I customize alternators to meet specific market demands?

Customizing alternators involves discussing specific requirements with your manufacturer, such as voltage ratings, size, or design features. Some suppliers may offer customization services, allowing you to tailor products to meet regional demands or preferences. It’s essential to provide detailed specifications and collaborate closely with the manufacturer during the design and production phases to ensure that the final product aligns with your market needs. -

What are the common causes of alternator failure that I should communicate to my customers?

Common causes of alternator failure include overheating due to electrical overload, wear and tear from age, and improper installation of aftermarket electronics. Additionally, issues like belt wear, corrosion at connection points, and fluid leaks can contribute to alternator failure. Educating your customers about these factors can help them take preventive measures and understand the importance of regular maintenance to prolong alternator lifespan.

Top 2 Signs That Your Car Alternator Is Going Bad Manufacturers & Suppliers List

1. Reddit – Automotive Power Solutions

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: The battery provides power to all electronics, including the starter. The alternator charges the battery when the engine is running. The starter uses power from the battery to turn over the engine. Symptoms of a dead battery include no power at all, while a failing alternator may show a battery light on the dash when the engine is running.

2. استبدال المولد - تحليل التكلفة

المجال: rac.co.uk

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: Alternator replacement cost in the UK ranges from £250 to £800, with an average price of £535.05 for parts and labour. Specific average replacement costs by manufacturer include: Audi £628.59, BMW £603.37, Citroen £629.99, Ford £494.90, Mercedes £614.57, MINI £549.36, Nissan £482.06, Peugeot £663.06, Renault £587.78, Toyota £477.93, Vauxhall £477.93, Volkswagen £507.07, Volvo £539.62.

Strategic Sourcing Conclusion and Outlook for signs that your car alternator is going bad

In conclusion, recognizing the signs of a failing alternator is essential for maintaining vehicle performance and ensuring safety on the road. Key indicators include starting difficulties, fluctuating headlights, dashboard warning lights, and unusual noises from the engine. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding these signs not only aids in timely repairs but also fosters strategic sourcing decisions for high-quality alternators and related components.

Investing in reliable parts can significantly reduce downtime and repair costs, enhancing overall operational efficiency. Establishing relationships with trusted suppliers ensures access to quality products that meet the unique demands of diverse markets.

As we look to the future, the automotive industry is poised for innovation, with advancements in alternator technology promising improved performance and durability. International buyers should stay informed about emerging trends and supplier capabilities to capitalize on these developments. Take proactive steps today by assessing your sourcing strategies and aligning with suppliers who prioritize quality and service excellence. Your commitment to strategic sourcing will drive your business forward, ensuring you remain competitive in a rapidly evolving market.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.