مقدمة: الإبحار في السوق العالمية لـ para q sirve el alternador

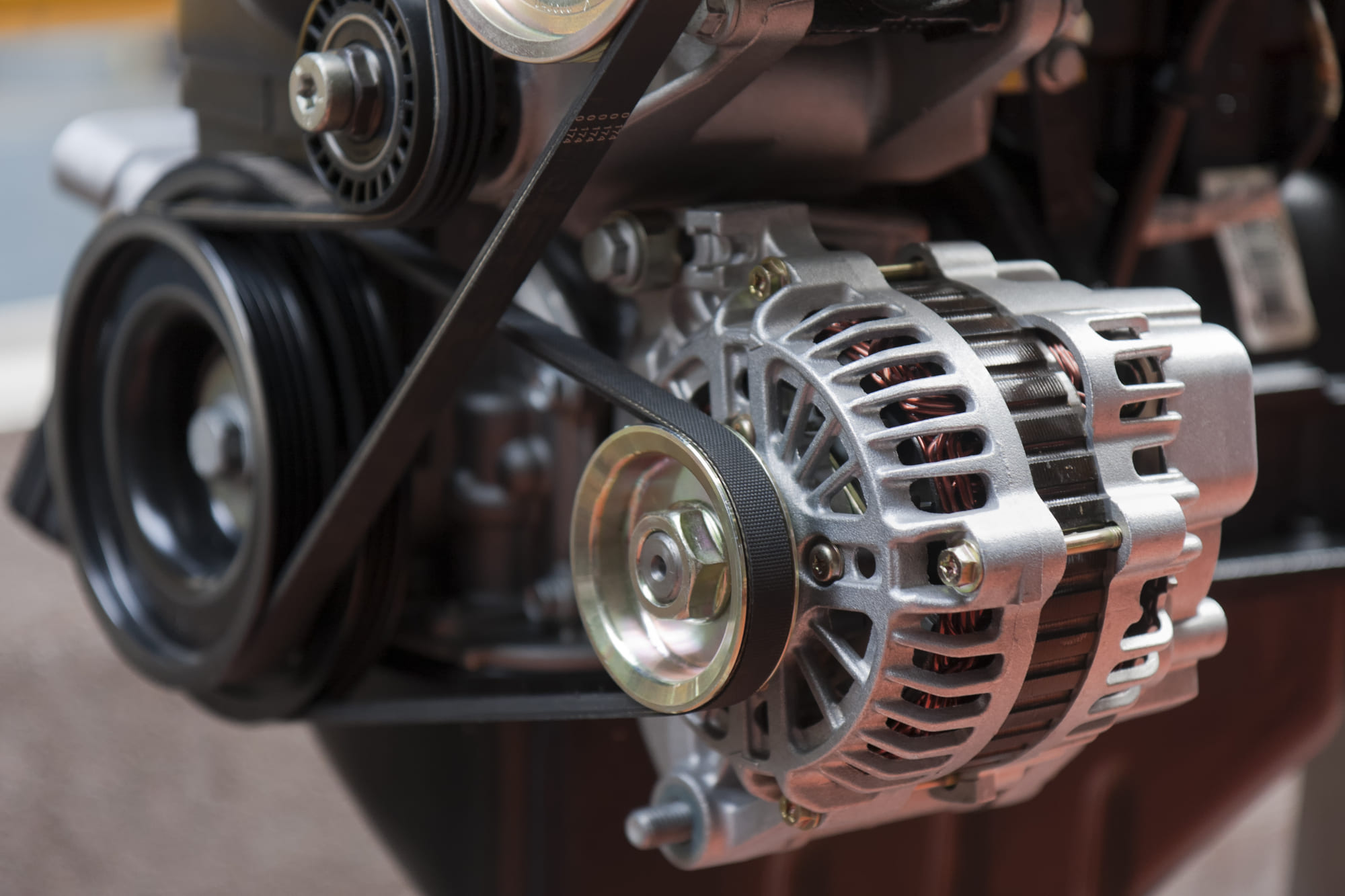

In today’s global market, understanding the role of the alternator is crucial for businesses involved in automotive supply and maintenance. The alternator serves as a vital component in vehicles, converting mechanical energy into electrical energy, which is essential for powering various systems while the engine runs. For B2B buyers, especially those sourcing automotive parts across regions such as Africa, South America, the Middle East, and Europe, navigating the complexities of alternator specifications, applications, and supplier reliability can be challenging.

This comprehensive guide will delve into the types of alternators available, their specific applications in diverse automotive settings, and the importance of vetting suppliers to ensure high-quality purchases. It will also explore the cost implications and market trends that affect the procurement of alternators, providing actionable insights that empower businesses to make informed decisions.

By equipping international B2B buyers with the necessary knowledge about the alternator’s functionality and market dynamics, this guide aims to streamline the purchasing process, minimize risks, and enhance operational efficiency. Whether you’re in the automotive repair industry or involved in vehicle manufacturing, understanding the intricacies of alternators will position your business for success in a competitive landscape.

جدول المحتويات

- Top 3 Para Q Sirve El Alternador Manufacturers & Suppliers List

- مقدمة: الإبحار في السوق العالمية لـ para q sirve el alternador

- فهم أنواع واختلافات بارا كيو سيرف إلدورادور

- التطبيقات الصناعية الرئيسية لـ para q sirve el alternador

- 3 نقاط ألم شائعة لدى المستخدمين ‘para q sirve el alternador’ وحلولها

- دليل اختيار المواد الاستراتيجية ل para q sirve el alternador

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لـ para q sirve el alternador

- دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘para q sirve el alternador’

- تحليل شامل للتكاليف والتسعير من أجل التكلفة والتسعير من أجل التوريد البديل

- تحليل البدائل: مقارنة بارا كيو سيرفي إيل البديل مع الحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية لـ para q sirve el alternador

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع التوريدات البديلة

- الأسئلة المتداولة (FAQs) للمشترين من para q sirve el alternador

- استنتاجات وتوقعات التوريد الاستراتيجي للمصادر الاستراتيجية ل para q sirve el alternador

- إخلاء مسؤولية هام وشروط الاستخدام

فهم أنواع واختلافات بارا كيو سيرف إلدورادور

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولد القياسي | Converts mechanical energy to electrical energy; common design. | تصنيع السيارات، وورش التصليح | الإيجابيات: متوفر على نطاق واسع، فعال من حيث التكلفة. السلبيات: Limited power for high-demand applications. |

| مولد كهربائي عالي الطاقة | Generates higher amperage for power-hungry vehicles. | مركبات عالية الأداء، آلات ثقيلة | الإيجابيات: Supports additional electrical components. السلبيات: تكلفة أعلى وقد تتطلب تعديلات. |

| المولد الذكي | Features advanced electronic control for optimized charging. | السيارات الكهربائية والأنظمة الهجينة | الإيجابيات: Increases battery life and efficiency. السلبيات: More complex and expensive to replace. |

| مولد كهربائي بحري | Designed for marine environments; corrosion-resistant materials. | Marine vessels, boats | الإيجابيات: متانة وموثوقية في الظروف القاسية. السلبيات: Specialized, often higher cost. |

| المولد الصناعي | Built for heavy-duty applications; capable of continuous operation. | Industrial machinery, generators | الإيجابيات: High reliability and power output. السلبيات: Bulkier and more expensive than standard models. |

ما هي خصائص المولدات القياسية؟

Standard alternators are the most commonly used type in vehicles, converting mechanical energy from the engine into electrical energy. They typically produce a moderate output suitable for everyday automotive needs, making them ideal for general use in passenger cars and light trucks. When considering a standard alternator, B2B buyers should evaluate compatibility with their fleet’s vehicles and the cost-effectiveness of replacement parts, as these units are generally less expensive and widely available.

كيف تختلف المولدات عالية الإنتاجية عن المولدات القياسية؟

High-output alternators are specifically designed to generate greater amperage, catering to vehicles that require additional electrical power for components such as sound systems, lighting, and performance upgrades. These alternators are commonly used in performance vehicles and heavy machinery where power demands exceed typical levels. Buyers should consider the specific electrical requirements of their applications and be prepared for potential installation modifications, as high-output units can be more expensive and complex to install.

What Makes Smart Alternators a Valuable Investment?

Smart alternators incorporate advanced electronic controls to optimize battery charging and energy management, particularly in electric and hybrid vehicles. These systems can adjust output based on real-time energy needs, improving efficiency and extending battery life. For B2B buyers, investing in smart alternators can lead to long-term savings on battery replacements and energy costs, although the initial purchase price and potential installation complexity may be higher compared to traditional models.

Why Are Marine Alternators Specialized?

Marine alternators are engineered to withstand harsh marine environments, utilizing corrosion-resistant materials and designs to ensure longevity and reliability. These units are crucial for powering onboard electrical systems in boats and other marine vessels. B2B buyers in the marine industry should prioritize durability and performance when selecting alternators, understanding that while they may come at a higher cost, their resilience in saltwater conditions can prevent costly failures.

What Are the Key Features of Industrial Alternators?

Industrial alternators are built for heavy-duty applications, capable of continuous operation in demanding environments. They are commonly used in industrial machinery and power generation, offering high reliability and power output. B2B buyers should assess the specific power requirements of their operations, as these alternators are typically bulkier and more expensive than standard models, but they provide essential reliability for critical industrial functions.

التطبيقات الصناعية الرئيسية لـ para q sirve el alternador

| الصناعة/القطاع | تطبيق محدد لـ para q sirve el alternador | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | تشغيل الأنظمة الكهربائية للمركبات | Ensures reliability of vehicles, improving customer satisfaction and reducing warranty claims | Quality standards, compatibility with various vehicle models, and supplier reliability |

| الطاقة المتجددة | التكامل في السيارات الهجينة والكهربائية | Supports the transition to sustainable transport solutions, enhancing brand image and marketability | Compliance with international standards, efficiency ratings, and environmental impact assessments |

| معدات البناء | Supplying power for heavy machinery | Increases operational efficiency and minimizes downtime due to electrical failures | Durability, resistance to harsh environments, and service support availability |

| الصناعة البحرية | تزويد الأنظمة الكهربائية على متن السفن بالطاقة | Enhances safety and functionality of marine operations, leading to better performance and compliance | Saltwater resistance, maintenance support, and energy efficiency |

| الزراعة | Powering irrigation systems and agricultural machinery | Improves productivity and reliability in farming operations, leading to better crop yields | Compatibility with existing systems, energy efficiency, and availability of spare parts |

How is para q sirve el alternador utilized in the automotive manufacturing sector?

In the automotive manufacturing sector, alternators are critical for powering the electrical systems of vehicles. They convert mechanical energy from the engine into electrical energy, ensuring that essential components such as lighting, infotainment, and safety systems function effectively. This reliability is paramount for manufacturers, as it directly influences customer satisfaction and reduces warranty claims. For international buyers, sourcing alternators that meet quality standards and are compatible with various vehicle models is crucial to maintain operational efficiency and brand reputation.

What role does para q sirve el alternador play in renewable energy applications?

In the renewable energy sector, particularly in hybrid and electric vehicles, alternators are integral for energy conversion and management. They help in efficiently recharging batteries and supplying power to electric motors, facilitating the transition to sustainable transportation. This capability not only enhances the performance of electric vehicles but also boosts the brand image of manufacturers committed to sustainability. Buyers in this sector should prioritize sourcing alternators that comply with international performance standards and evaluate their efficiency ratings to ensure optimal operation.

How does para q sirve el alternador contribute to the construction equipment industry?

In the construction equipment industry, alternators are essential for supplying power to heavy machinery. They convert the engine’s mechanical energy into electrical energy, which is vital for operating hydraulic systems, lighting, and other electrical components. This functionality increases operational efficiency and minimizes downtime, critical factors for construction projects. Buyers should consider the durability and resistance of alternators to harsh environments, along with the availability of service support to maintain machinery performance.

Why is para q sirve el alternador important in the marine industry?

In the marine industry, alternators are used to power onboard electrical systems in vessels. They provide the necessary electricity for navigation, communication, and safety equipment, enhancing the overall functionality and safety of marine operations. This reliability is crucial for compliance with maritime regulations and for ensuring the safety of crew and cargo. Buyers must focus on sourcing alternators that offer saltwater resistance, as well as robust maintenance support to guarantee long-term operational efficiency.

صورة توضيحية متعلقة ب para q sirve el alternador

How is para q sirve el alternador applied in agriculture?

In agriculture, alternators are utilized to power irrigation systems and agricultural machinery, facilitating efficient farming operations. They ensure that equipment operates reliably, which is essential for maximizing crop yields. International buyers in this sector should prioritize compatibility with existing systems and energy efficiency when sourcing alternators, as these factors directly impact productivity and operational costs. Additionally, the availability of spare parts is a key consideration to minimize downtime during critical farming periods.

3 نقاط ألم شائعة لدى المستخدمين ‘para q sirve el alternador’ وحلولها

Scenario 1: Inconsistent Power Supply in Commercial Fleets

المشكلة: B2B buyers managing commercial vehicle fleets often encounter issues with inconsistent power supply due to faulty alternators. This can lead to significant downtime as vehicles may fail to start or experience electrical malfunctions during operations. For companies reliant on transportation for logistics or services, this not only affects productivity but also increases operational costs due to unexpected repairs and service interruptions.

الحل: To mitigate this issue, fleet managers should prioritize regular maintenance checks of the alternators, especially in regions with extreme weather conditions that could affect performance. It’s advisable to establish a relationship with reliable suppliers who can provide high-quality alternators tailored for specific vehicle models. Additionally, implementing a predictive maintenance strategy using telematics can help monitor alternator performance in real-time, allowing for proactive replacements before failures occur. Ensure that your maintenance team is trained to recognize early signs of alternator issues, such as unusual noises or warning lights, to address problems before they escalate.

السيناريو 2: صعوبة في فهم مواصفات المولدات

المشكلة: B2B buyers often struggle with understanding the specific electrical requirements and compatibility of alternators for different vehicle models, leading to purchasing errors. This challenge is particularly acute in industries that require specialized vehicles, such as construction or emergency services, where reliable power supply is critical for equipment and tools.

الحل: To avoid compatibility issues, it’s essential to create a detailed specification guide that includes the electrical output requirements, mounting configurations, and any additional features needed for your vehicles. Engage with manufacturers or suppliers who provide comprehensive technical documentation for their alternators. This should include diagrams, installation instructions, and performance data. Participating in industry trade shows or workshops can also provide valuable insights into the latest advancements in alternator technology, helping buyers make informed decisions. Furthermore, establishing a clear line of communication with suppliers can facilitate better understanding and sourcing of alternators that meet specific operational needs.

Scenario 3: Rising Costs Due to Alternator Failures

المشكلة: Frequent alternator failures can lead to escalating costs for B2B buyers, not just in terms of repairs but also through lost revenue from vehicle downtime. This problem is exacerbated in regions with limited access to quality automotive parts, where businesses may resort to cheaper, lower-quality alternators that fail sooner.

الحل: To combat rising costs, businesses should focus on investing in high-quality alternators from reputable manufacturers, even if the initial costs are higher. Consider forming partnerships with manufacturers who offer warranties and service agreements, ensuring that you receive support in the event of a failure. Implementing a comprehensive training program for mechanics on the importance of selecting quality parts can also reduce reliance on inferior products. Additionally, conducting regular audits of your vehicle’s electrical systems and establishing a budget for preventative maintenance can help identify potential issues before they escalate into costly repairs. Leveraging technology, such as inventory management systems, can streamline the procurement process, ensuring that you always have access to quality alternators when needed, reducing downtime and costs in the long run.

دليل اختيار المواد الاستراتيجية ل para q sirve el alternador

What Materials Are Commonly Used in Alternators and Their Key Properties?

When selecting materials for alternators, it’s crucial to consider their properties and how they impact performance. The most common materials include aluminum, copper, steel, and plastic. Each material has unique advantages and disadvantages that can affect the durability, efficiency, and overall functionality of the alternator.

كيف يفيد الألومنيوم في تصنيع المولدات؟

Aluminum is widely used in alternator housings and components due to its lightweight nature and excellent corrosion resistance. With a temperature rating up to 150°C, aluminum can withstand the heat generated during operation. Its low density contributes to reduced overall weight, enhancing fuel efficiency in vehicles.

الإيجابيات: Aluminum is cost-effective and easy to manufacture, allowing for complex shapes and designs. Its corrosion resistance makes it suitable for various environments, particularly in regions with high humidity or salt exposure.

السلبيات: While aluminum is durable, it may not withstand high-stress applications as well as other metals. Additionally, its thermal conductivity can lead to heat dissipation issues if not managed correctly.

التأثير على التطبيق: Aluminum’s compatibility with various media makes it suitable for automotive applications, but buyers should ensure it meets local standards for automotive parts.

Why is Copper Essential for Electrical Conductivity in Alternators?

Copper is a critical material for the windings and electrical connections in alternators due to its superior electrical conductivity. It can handle high currents and has a temperature rating of approximately 200°C, making it ideal for the electrical demands of modern vehicles.

الإيجابيات: Copper’s excellent conductivity ensures efficient energy transfer, reducing losses and improving overall performance. It is also highly durable and resistant to corrosion when properly coated.

السلبيات: The primary disadvantage is its cost, which is higher than aluminum. Additionally, copper can be susceptible to oxidation if not adequately protected, potentially leading to electrical failures.

التأثير على التطبيق: Given its essential role in electrical systems, international buyers must consider copper’s compliance with electrical standards, such as ASTM and IEC, to ensure reliability.

صورة توضيحية متعلقة ب para q sirve el alternador

ما الدور الذي يلعبه الفولاذ في بناء المولد؟

Steel is often used for the structural components of alternators, including the rotor and stator cores. It offers high strength and durability, with a temperature rating of up to 300°C, making it suitable for high-performance applications.

الإيجابيات: Steel is robust and can withstand significant mechanical stress, making it ideal for heavy-duty applications. It is also relatively inexpensive compared to other metals.

السلبيات: However, steel is heavier than aluminum and can be prone to rust if not coated or treated properly. This can be a concern in humid or corrosive environments.

التأثير على التطبيق: Buyers in regions with high humidity or exposure to saltwater should prioritize corrosion-resistant coatings for steel components to enhance longevity.

صورة توضيحية متعلقة ب para q sirve el alternador

How Does Plastic Contribute to Alternator Efficiency?

Plastic materials are increasingly used for non-structural components in alternators, such as housings and insulators. They can withstand temperatures up to 120°C and provide excellent electrical insulation.

الإيجابيات: Plastics are lightweight, which can contribute to overall vehicle efficiency. They are also resistant to corrosion and can be molded into complex shapes, making them versatile for various applications.

السلبيات: The main limitation of plastics is their lower thermal stability compared to metals, which may lead to degradation under high temperatures. Additionally, they may not provide the same structural integrity as metal components.

التأثير على التطبيق: International buyers should ensure that the plastics used comply with automotive standards for safety and performance, particularly in regions with extreme temperatures.

جدول ملخص لاختيار المواد للمولدات الكهربائية

| المواد | حالة الاستخدام النموذجي لـ para q sirve el alternador | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | المساكن والمكونات الهيكلية | خفيف الوزن ومقاوم للتآكل | Less stress resistance than metals | متوسط |

| النحاس | الملفات والتوصيلات الكهربائية | موصلية كهربائية ممتازة | ارتفاع التكلفة ومخاطر الأكسدة | عالية |

| الصلب | أنوية الدوار والجزء الثابت | قوة ومتانة عالية | أثقل وزناً وعرضة للصدأ | منخفض |

| بلاستيك | Non-structural components like insulators | خفيف الوزن ومقاوم للتآكل | Lower thermal stability | متوسط |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for alternators, ensuring they make informed decisions that align with their operational needs and regional standards.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لـ para q sirve el alternador

ما هي المراحل الرئيسية في عملية تصنيع المولدات الكهربائية؟

The manufacturing process of alternators is a multi-step operation that requires precision and adherence to quality standards. Understanding these stages can help B2B buyers assess the capabilities of suppliers and ensure they are acquiring high-quality components.

كيف يتم تحضير المواد لتصنيع المولد؟

The manufacturing process begins with material preparation, which typically involves sourcing high-grade raw materials such as copper, aluminum, and high-strength steel. These materials are selected for their electrical conductivity, durability, and resistance to wear. Suppliers often perform chemical and physical tests on materials to ensure they meet specific standards before they proceed to the next stage.

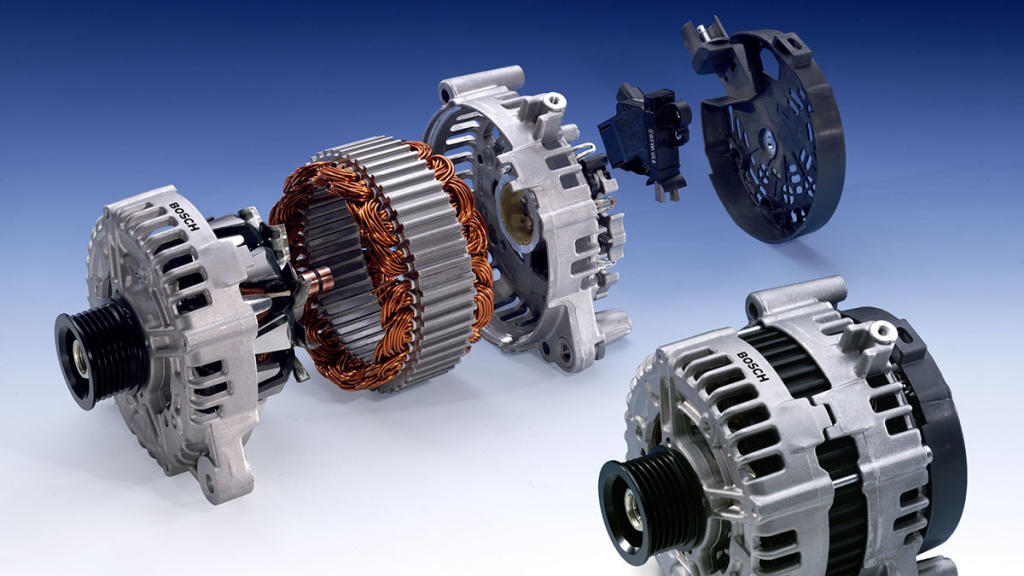

صورة توضيحية متعلقة ب para q sirve el alternador

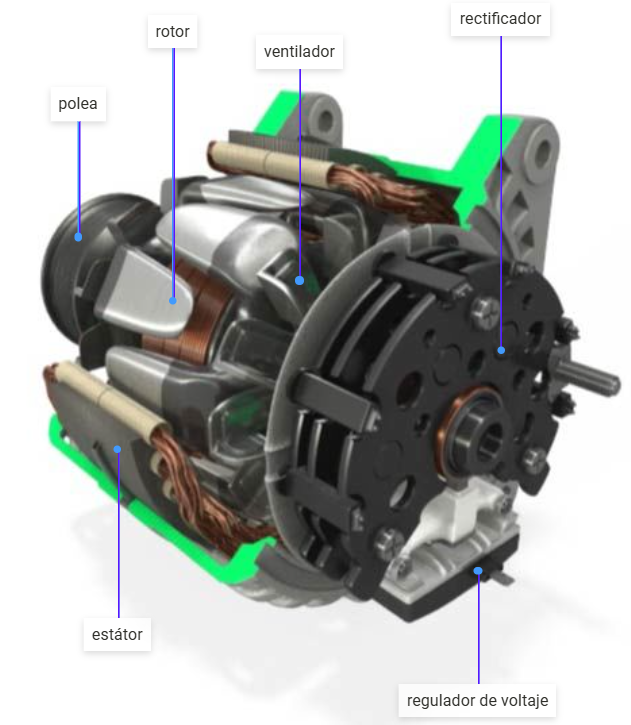

Once the materials are sourced, they undergo cutting and machining processes to create the necessary components, such as the rotor, stator, and housing. Advanced CNC (Computer Numerical Control) machines are commonly used to achieve precise dimensions and tolerances, which are critical for the efficient functioning of the alternator.

What Techniques Are Used in the Forming Process of Alternators?

The forming stage of alternator manufacturing is crucial as it shapes the individual components. Techniques such as stamping, forging, and casting are employed, depending on the part being produced.

-

الختم: This method is primarily used for creating the stator and rotor laminations. Stamping machines apply high pressure to sheets of metal, cutting them into the required shapes.

-

تزوير: Used for parts requiring high strength, such as the rotor shaft. This process involves shaping heated metal using compressive forces.

-

الصب: Often utilized for the alternator housing, casting allows for complex shapes and designs that would be difficult to achieve with other methods.

Each of these techniques must be closely monitored to ensure that the dimensions and mechanical properties of the components meet the required specifications.

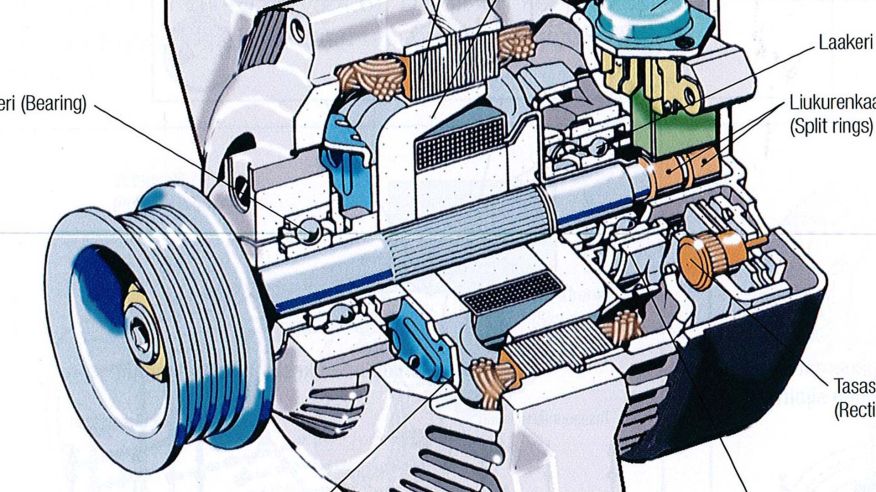

What Are the Assembly Processes for Alternators?

After the individual components are formed, they move to the assembly stage. This process involves several key steps:

-

تكامل المكونات: The rotor and stator are assembled together with precise alignment to ensure efficient magnetic coupling.

-

التوصيلات الكهربائية: Wiring is integrated, including the rectifier and voltage regulator, which converts AC to DC and maintains the appropriate voltage output.

-

التجميع النهائي: The entire unit is housed in a protective casing, and any additional components, such as fans for cooling, are attached.

Robotic automation is increasingly used in assembly processes to enhance precision and reduce labor costs, which can be particularly beneficial for international B2B buyers looking for cost-effective solutions.

What Finishing Processes Are Important for Alternators?

Finishing processes are essential to ensure the durability and aesthetic quality of the alternators. Typical finishing steps include:

-

معالجة السطح: Components often undergo surface treatments such as anodizing or powder coating to improve corrosion resistance and enhance appearance.

-

Balancing: The assembled alternator must be balanced to reduce vibrations during operation. This is crucial for maintaining performance and longevity.

-

فحوصات الجودة: After finishing, each unit is subjected to rigorous quality checks to ensure it meets all operational specifications.

What Quality Assurance Standards Are Relevant for Alternator Manufacturing?

Quality assurance is a critical aspect of alternator manufacturing, especially for international B2B buyers. Compliance with international standards such as ISO 9001 is often a prerequisite. This standard focuses on maintaining a robust quality management system (QMS) that ensures consistent product quality and enhances customer satisfaction.

كيف يتم دمج نقاط التحقق من مراقبة الجودة في عملية التصنيع؟

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process. Common checkpoints include:

-

مراقبة الجودة الواردة (IQC): Materials are inspected upon arrival to ensure they meet specified criteria before they are used in production.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During the manufacturing stages, random samples are taken to verify that processes are being followed correctly and that products meet quality standards.

-

مراقبة الجودة النهائية (FQC): Before shipment, each alternator undergoes comprehensive testing, including electrical performance tests, thermal tests, and vibration tests to ensure it operates within specified parameters.

ما هي طرق الاختبار الشائعة المستخدمة للمولدات؟

Various testing methods are employed to validate the performance and reliability of alternators:

-

الاختبارات الكهربائية: This includes load testing to ensure the alternator can handle specified electrical loads without overheating or failing.

-

الاختبار الحراري: Units are subjected to high temperatures to verify that they can operate efficiently under extreme conditions.

-

Vibration Analysis: This assesses the mechanical stability of the alternator during operation.

B2B buyers should request detailed testing reports from suppliers to verify that these tests have been conducted and that the products meet the required standards.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

To ensure they are partnering with reliable suppliers, B2B buyers should consider the following verification strategies:

-

تدقيق الموردين: Conducting on-site audits allows buyers to evaluate the manufacturing processes, equipment, and quality control systems in place. This can help identify any potential risks in the supply chain.

-

تقارير الجودة: Requesting access to quality assurance documentation, including testing results and compliance certifications, provides transparency and builds trust.

-

عمليات التفتيش من قبل أطراف ثالثة: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product reliability.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

International B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances:

-

الامتثال التنظيمي: Different regions may have varying regulations and standards. Buyers should ensure that suppliers are compliant with local laws and international standards.

-

الاعتبارات الثقافية: Understanding the cultural context of suppliers can aid in building strong relationships and navigating any potential communication barriers.

-

التحديات اللوجستية: Consideration must be given to shipping, customs, and potential delays that could affect the quality and delivery of alternators.

By being proactive and informed about the manufacturing processes and quality assurance practices in the alternator supply chain, B2B buyers can make well-informed decisions that contribute to their operational success.

دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘para q sirve el alternador’

مقدمة

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring alternators. Understanding the essential functions and specifications of alternators is crucial for selecting high-quality components that meet your operational needs. This guide provides actionable steps to ensure you make informed decisions throughout the procurement process.

الخطوة 1: تحديد المواصفات الفنية الخاصة بك

Start by clearly outlining the technical requirements for the alternators you need. This includes understanding the voltage, amperage, and type of vehicle or machinery they will be used in. By defining these specifications, you ensure compatibility and performance, reducing the risk of purchasing unsuitable products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in alternators. Look for companies with a solid reputation in the automotive or industrial sectors. Utilize online resources, industry publications, and trade shows to gather a list of reputable suppliers who meet your criteria.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that your potential suppliers hold the necessary certifications and quality standards. Certifications such as ISO 9001 or specific automotive standards indicate that a supplier adheres to recognized quality management practices. This step is vital to ensure product reliability and compliance with international standards.

Step 4: Assess Product Range and Availability

Review the supplier’s product range to ensure they offer the specific types of alternators you require. Check for availability of various models that cater to different applications. A supplier with a diverse inventory can provide flexibility in your procurement process and help you avoid delays.

Step 5: Request Samples and Technical Data

Before finalizing a supplier, request samples or technical data sheets for the alternators you are considering. This will allow you to assess the quality of their products firsthand. Pay attention to details such as durability, performance ratings, and any warranties provided, as these factors can significantly influence your purchasing decision.

صورة توضيحية متعلقة ب para q sirve el alternador

Step 6: Analyze Pricing and Payment Terms

Compare pricing structures among different suppliers to ensure you are getting competitive rates. Additionally, review their payment terms to understand the financial implications of your purchase. Look for suppliers who offer flexible payment options, as this can assist with cash flow management in your business.

Step 7: Establish Clear Communication Channels

Finally, establish effective communication channels with your chosen supplier. Clear communication is essential for addressing any concerns, tracking orders, and resolving issues that may arise during the procurement process. Ensure you have a dedicated point of contact for efficient support and responsiveness.

By following these steps, B2B buyers can navigate the procurement of alternators effectively, ensuring they select high-quality products that meet their operational needs while fostering strong supplier relationships.

تحليل شامل للتكاليف والتسعير من أجل التكلفة والتسعير من أجل التوريد البديل

ما هي مكونات التكلفة الرئيسية في توريد المولدات الكهربائية؟

When sourcing alternators, several cost components play a crucial role in the overall pricing structure. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

المواد: The materials used in alternator production, such as copper wiring for the rotor and stator, iron for the core, and various electronic components, significantly impact the cost. Prices for these materials can fluctuate based on global supply and demand, affecting the final price of the alternator.

-

العمل: Labor costs vary by region and influence the overall production expenses. In countries with higher labor costs, such as those in Europe, the total cost will be elevated compared to regions with lower labor costs, such as parts of Africa or South America.

-

تكاليف التصنيع العامة: This includes expenses related to the factory, equipment maintenance, and utilities. High overhead costs can arise from advanced manufacturing technologies or stringent safety regulations, which may be more pronounced in developed markets.

-

الأدوات: The initial investment in tooling for the production of alternators can be substantial, especially for custom or specialized designs. Tooling costs are typically amortized over large production runs, thus affecting the unit price for smaller orders.

-

مراقبة الجودة (QC): Ensuring that alternators meet specific standards requires investment in quality control processes. This is particularly important for B2B buyers who may require certifications that guarantee the product meets international safety and performance standards.

-

اللوجستيات: Shipping and handling costs can vary significantly based on the destination, shipping method, and volume. Buyers should consider logistics as a critical component of total cost, especially when sourcing from overseas suppliers.

-

الهامش: Supplier margins can differ based on competition, demand, and market positioning. Understanding the margin expectations of suppliers can help buyers negotiate better pricing.

What Factors Influence Pricing for Alternators?

Several factors can influence the pricing of alternators, including volume and minimum order quantities (MOQs), specifications and customization, material quality, certifications, supplier reliability, and Incoterms.

صورة توضيحية متعلقة ب para q sirve el alternador

-

الحجم/الحد الأدنى للطلب: Purchasing in bulk often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, making it essential for buyers to assess their needs accurately.

-

المواصفات والتخصيص: Custom alternators designed for specific applications or vehicles may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

المواد والجودة: The choice of materials directly affects the durability and performance of the alternator. Higher-quality materials may lead to increased costs but can also reduce the total cost of ownership over time.

-

عوامل الموردين: The reliability and reputation of the supplier can influence pricing. Established suppliers with a track record of quality may charge a premium but can provide peace of mind regarding product performance.

-

مصطلحات التجارة الدولية: Understanding the shipping terms is vital. Different Incoterms can change the responsibility for shipping costs, risk, and insurance, which can significantly affect the overall cost.

What Negotiation Tips Can Help B2B Buyers Secure Better Prices?

When negotiating prices for alternators, international B2B buyers should consider the following strategies:

-

البحث والمقارنة المعيارية: Understanding market prices and competitor offerings will empower buyers during negotiations. Collecting quotes from multiple suppliers can provide leverage.

-

الاستفادة من العلاقات طويلة الأمد: Building strong relationships with suppliers can lead to better pricing and terms. Suppliers are often more willing to negotiate with buyers who demonstrate commitment.

-

التركيز على التكلفة الإجمالية للملكية (TCO): Highlighting the long-term savings from higher-quality alternators can justify a higher upfront cost, encouraging suppliers to offer discounts on premium products.

-

كن مرنًا مع الشروط: Being open to negotiating payment terms, lead times, and delivery schedules can create a win-win situation. Suppliers may be more inclined to reduce prices if they can adjust other terms.

-

ضع في اعتبارك التوريد المحلي: For buyers in regions such as Africa or South America, exploring local suppliers can reduce shipping costs and lead times, potentially resulting in better pricing.

الخلاصة

Understanding the comprehensive cost structure and pricing influences for alternators is essential for B2B buyers. By analyzing the cost components, recognizing the price influencers, and employing effective negotiation strategies, buyers can make informed decisions that optimize their sourcing processes. While prices can vary widely based on multiple factors, careful planning and market awareness can lead to significant savings and better supplier relationships.

تحليل البدائل: مقارنة بارا كيو سيرفي إيل البديل مع الحلول الأخرى

Exploring Alternative Solutions to the Alternator’s Role in Vehicle Power Management

When considering the critical functions served by the alternator in vehicles, it is essential to evaluate alternative solutions that can fulfill similar roles. The alternator is primarily responsible for converting mechanical energy into electrical energy, thereby powering various electrical components and recharging the battery while the engine runs. However, with advancements in technology, several alternatives have emerged, each with unique advantages and potential drawbacks.

| جانب المقارنة | Para Q Sirve El Alternador | Alternative 1: Starter Generator | Alternative 2: Battery Management Systems (BMS) |

|---|---|---|---|

| الأداء | High efficiency in energy conversion; reliable for continuous operation | Moderate efficiency; works during engine start-up and may not sustain long-term power needs | Highly efficient in energy management; optimizes battery life and performance |

| التكلفة | Generally cost-effective but can vary based on vehicle type | Higher initial cost due to complexity and integration | Variable costs depending on technology; can be cost-effective long-term |

| سهولة التنفيذ | Standard installation in most vehicles; requires minimal adjustments | More complex installation; may require significant vehicle modification | Integration can be complex; often requires software configuration |

| الصيانة | Low maintenance; periodic checks necessary | Higher maintenance due to mechanical wear | Low maintenance; software updates may be needed |

| أفضل حالة استخدام | Conventional vehicles with standard electrical demands | Hybrid and electric vehicles requiring dual functionality | Vehicles with advanced battery systems needing optimized management |

تفصيل البدائل

Alternative 1: Starter Generator

The starter generator combines the functions of a traditional starter motor and alternator into one unit. This technology is particularly useful in hybrid vehicles, where it facilitates energy recovery during braking and provides additional power during acceleration. Its performance can be robust, but it tends to have a higher initial cost and complexity in installation. Moreover, while it excels at providing power during start-up, it may not be as effective in sustaining long-term electrical needs when compared to a dedicated alternator.

صورة توضيحية متعلقة ب para q sirve el alternador

Alternative 2: Battery Management Systems (BMS)

Battery Management Systems are designed to monitor and manage battery health, ensuring optimal performance and longevity. BMS technology excels in managing power distribution, particularly in electric and hybrid vehicles. They can efficiently maximize battery usage and lifespan, making them highly effective in modern automotive applications. However, the complexity of integrating a BMS can be a challenge, often requiring software configuration and adjustments to existing electrical systems. Despite these complexities, the long-term cost savings and enhanced battery performance can outweigh initial hurdles.

Conclusion: Choosing the Right Power Management Solution

For B2B buyers evaluating the best power management solution for their vehicles, it is crucial to consider the specific operational needs and vehicle types. The alternator remains a reliable choice for conventional vehicles due to its efficiency and low maintenance. However, for businesses investing in hybrid or electric vehicles, exploring alternatives like starter generators or battery management systems may provide enhanced performance and efficiency. Assessing factors such as cost, ease of implementation, and maintenance will guide buyers toward the most suitable solution for their fleet’s unique requirements.

الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية لـ para q sirve el alternador

ما هي الخصائص التقنية الرئيسية للمولد الكهربائي؟

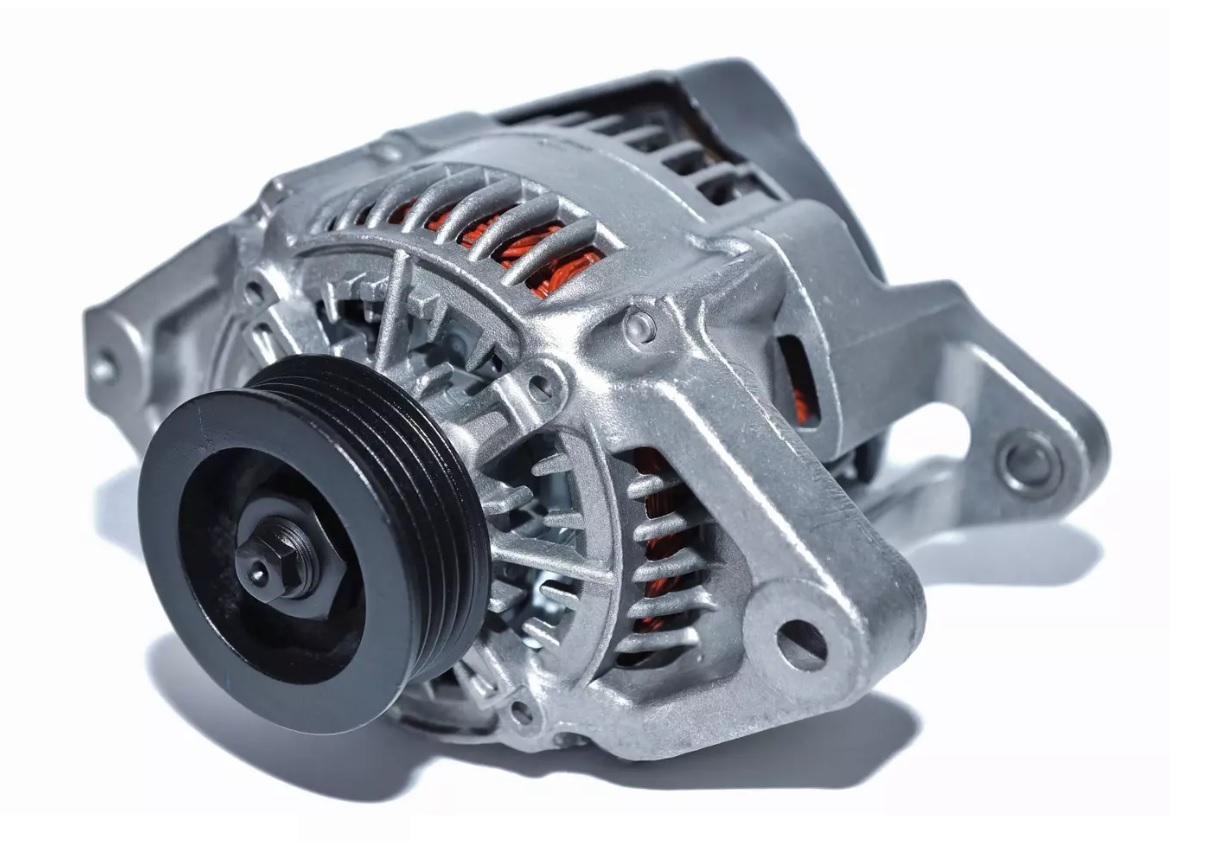

Understanding the essential technical properties of an alternator is crucial for B2B buyers in the automotive sector. Here are some of the key specifications that you should consider:

صورة توضيحية متعلقة ب para q sirve el alternador

1. درجة المواد

The materials used in alternators, typically aluminum or high-grade steel, influence durability and performance. High-grade materials provide resistance to corrosion and heat, extending the lifespan of the alternator. In B2B transactions, specifying material grades can ensure that manufacturers meet quality standards and reduce the frequency of replacements.

2. جهد الخرج

Alternators are designed to produce a specific voltage, commonly 12V for standard automotive applications. The output voltage must align with the vehicle’s electrical system to ensure efficient operation. For buyers, understanding output voltage specifications is vital for compatibility with various vehicle models, especially when dealing with OEM (Original Equipment Manufacturer) parts.

3. Power Rating (Amperage)

The power rating, measured in amps, indicates how much electrical current the alternator can provide. A typical automotive alternator may range from 40 to 150 amps. This specification is critical for ensuring that all electronic components in the vehicle, such as lights and infotainment systems, function properly. In procurement, knowing the required amperage helps in selecting the right alternator for different vehicle types.

4. تصنيف الكفاءة

Efficiency ratings of alternators indicate how well they convert mechanical energy into electrical energy. Higher efficiency means less energy loss as heat, leading to better fuel economy and improved performance. For B2B buyers, focusing on efficiency ratings can lead to cost savings over time, as more efficient alternators may reduce the load on the vehicle’s engine.

5. آلية التبريد

Alternators often include built-in cooling systems, such as fans or heat sinks, to dissipate heat generated during operation. A well-designed cooling mechanism is essential for maintaining performance and preventing premature failure. Buyers should consider cooling specifications to ensure reliability in varying environmental conditions, especially in regions with extreme temperatures.

6. نوع المنظم

Alternators feature either internal or external voltage regulators that control output voltage. Internal regulators are more common in modern vehicles due to their compact design and ease of installation. Understanding the type of regulator is essential for B2B buyers looking to replace or upgrade alternators, as compatibility with existing systems must be ensured.

ما هي المصطلحات التجارية الشائعة المتعلقة بالمولدات الكهربائية؟

Familiarity with trade terminology is essential for effective communication and negotiation in the automotive parts market. Here are some common terms associated with alternators:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the original manufacturer of the vehicle. Using OEM alternators ensures compatibility and quality, which is crucial for maintenance and repairs. B2B buyers often prefer OEM parts to maintain warranty coverage and vehicle integrity.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is vital for B2B transactions, as it can affect inventory management and cost efficiency. Buyers should negotiate MOQs that align with their purchasing capabilities to optimize stock levels.

3. طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the context of alternators, issuing an RFQ helps buyers gather competitive pricing and understand the supplier’s capabilities. It is a crucial step in the procurement process for B2B buyers.

4. مصطلحات التجارة الدولية

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping. They clarify who is responsible for shipping costs, insurance, and risks. For B2B buyers, understanding Incoterms is essential to avoid unexpected costs and ensure smooth logistics when sourcing alternators from international suppliers.

5. المهلة الزمنية

Lead time refers to the period between placing an order and receiving the product. Knowing lead times for alternators is critical for inventory planning and ensuring timely vehicle repairs. B2B buyers should consider lead times when negotiating with suppliers to align with their operational needs.

صورة توضيحية متعلقة ب para q sirve el alternador

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternators, ultimately ensuring the reliability and efficiency of their automotive applications.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع التوريدات البديلة

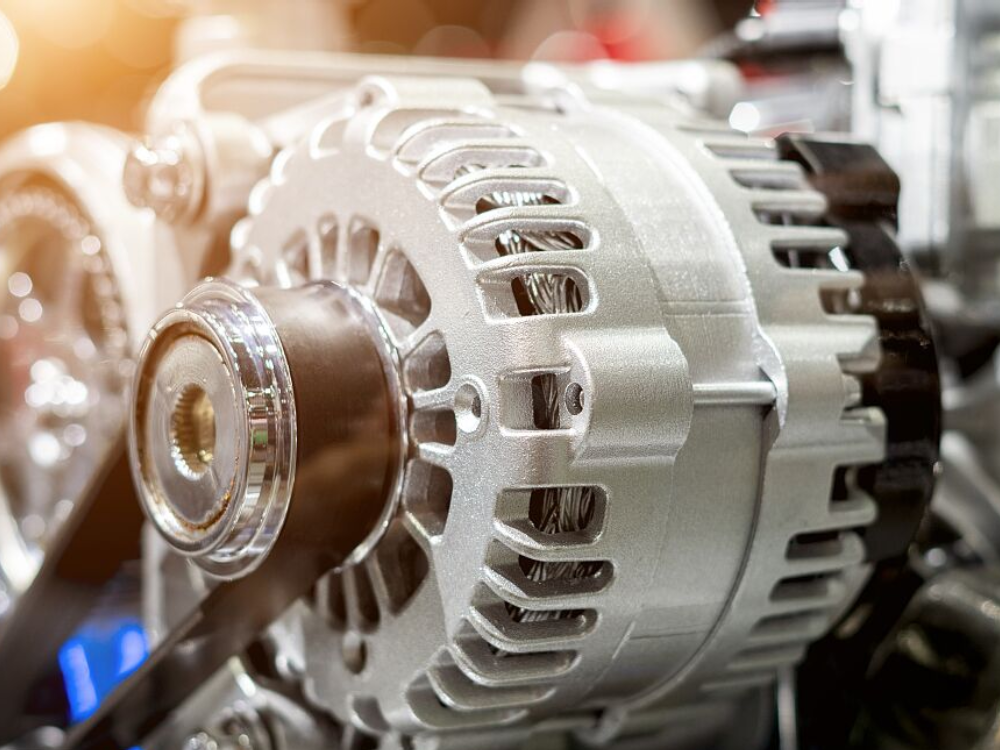

What Are the Current Market Dynamics in the Alternator Sector?

The global alternator market is experiencing significant growth, driven by the increasing demand for automotive components and the rise in electric vehicle (EV) adoption. Regions such as Africa, South America, the Middle East, and Europe are pivotal, given their expanding automotive industries and the push for modernized transportation systems. Key trends include a shift towards lightweight and high-efficiency alternators to enhance vehicle performance and fuel efficiency. Additionally, the integration of advanced technologies like IoT and AI in manufacturing processes is reshaping sourcing strategies, enabling companies to optimize production and reduce costs.

International B2B buyers are increasingly focused on long-term partnerships with suppliers that offer robust technical support and innovative solutions. The emergence of digital platforms for sourcing components has made it easier for companies to compare products and prices, fostering competitive pricing and improved transparency in supply chains. Furthermore, the ongoing emphasis on quality and reliability is prompting buyers to seek certifications and standards compliance, ensuring that their suppliers meet rigorous performance benchmarks.

How Are Sustainability and Ethical Sourcing Impacting the Alternator Industry?

As global awareness of environmental issues rises, the alternator sector is under pressure to adopt sustainable practices. The environmental impact of manufacturing processes, including resource depletion and emissions, is being scrutinized by both consumers and regulatory bodies. For B2B buyers, this translates into a growing importance placed on ethical sourcing and supply chain transparency. Companies are increasingly seeking suppliers that utilize environmentally friendly materials and processes.

Green certifications are becoming a key consideration in the purchasing process. Buyers are looking for partners that have obtained certifications such as ISO 14001, which demonstrates effective environmental management systems. Utilizing recycled materials in the production of alternators can also significantly reduce the carbon footprint associated with manufacturing. By prioritizing sustainability, B2B buyers not only enhance their corporate social responsibility profiles but also position themselves competitively in a market that increasingly values eco-friendly practices.

What Is the Historical Context of Alternators Relevant to B2B Buyers?

The evolution of alternators dates back to the early 20th century when they were first introduced as a solution to the limitations of direct current (DC) generators. Over the decades, advancements in technology have led to significant improvements in alternator design, efficiency, and reliability. The transition from DC to alternating current (AC) systems allowed for more efficient energy generation and distribution within vehicles.

This historical context is critical for B2B buyers, as understanding the technological advancements can inform their purchasing decisions. The shift towards higher output alternators that support modern electrical demands—such as infotainment systems, advanced safety features, and electric drivetrains—highlights the necessity for buyers to align with suppliers that stay ahead of technological trends. This alignment not only ensures compatibility with contemporary vehicle architectures but also positions businesses to leverage the latest innovations in automotive technology.

الأسئلة المتداولة (FAQs) للمشترين من para q sirve el alternador

-

What is the primary function of an alternator in a vehicle?

The alternator is a crucial component of a vehicle’s electrical system. Its primary function is to convert mechanical energy from the engine into electrical energy, which powers all electrical components while the engine is running. This includes recharging the battery and supplying electricity to systems such as lighting, infotainment, and climate control. Understanding this function is essential for B2B buyers looking to source reliable alternators for automotive applications. -

How can I identify a faulty alternator?

Signs of a malfunctioning alternator include difficulty starting the vehicle, dimming lights, or the battery warning light illuminating on the dashboard. Other indicators may include unusual noises, such as grinding or whining, and electrical issues with components that fluctuate in intensity. For B2B buyers, ensuring quality and reliability in alternators can minimize these risks and enhance customer satisfaction. -

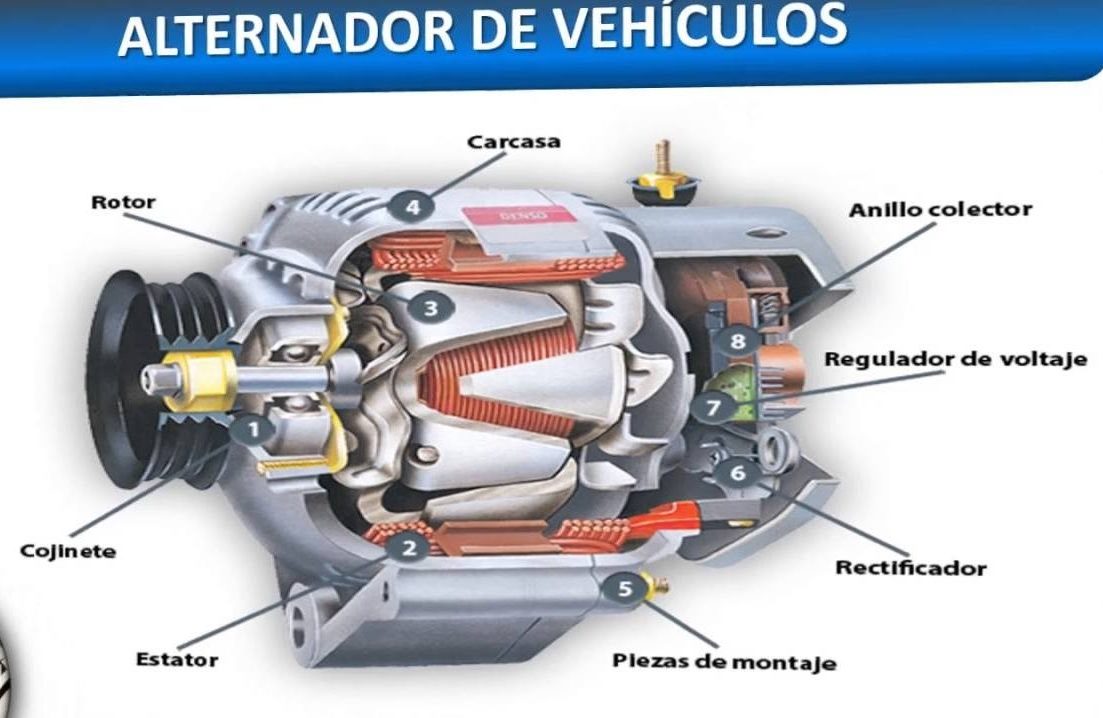

What are the key components to consider when sourcing an alternator?

When sourcing alternators, key components to evaluate include the rotor, stator, rectifier, and various electrical connections. Each of these parts plays a vital role in the alternator’s functionality and efficiency. Additionally, consider the quality of materials used, such as copper wiring and durable casings, to ensure longevity and performance. This attention to detail will help buyers choose reliable suppliers. -

ما هي خيارات التخصيص المتاحة للمولدات؟

Many manufacturers offer customization options for alternators, including variations in output voltage, size, and specific connector types to match particular vehicle models. Buyers should inquire about these options to ensure compatibility with their target applications. Customization can enhance performance and meet unique market demands, providing a competitive edge in the automotive sector. -

ما هو الحد الأدنى المعتاد لكميات الطلبات (MOQs) لمولدات التيار المتردد؟

Minimum order quantities (MOQs) for alternators can vary widely depending on the manufacturer and specific product line. Generally, MOQs may range from 50 to 500 units. Buyers should confirm MOQs with potential suppliers to ensure they align with their purchasing needs and market demand. Understanding MOQs can help businesses manage inventory effectively and reduce overhead costs. -

What payment terms are usually offered by alternator suppliers?

Payment terms for alternator suppliers can vary, but common options include net 30, net 60, or net 90 days. Some suppliers may offer discounts for upfront payments or larger orders. It is essential for buyers to negotiate favorable terms that align with their cash flow and budget strategies. Clear communication about payment expectations can foster strong supplier relationships. -

كيف يمكنني ضمان جودة المولدات الكهربائية؟

To ensure quality assurance for alternators, buyers should request certifications and quality control processes from suppliers. This may include ISO certifications, compliance with automotive industry standards, and detailed inspection reports. Establishing a thorough QA process not only guarantees product reliability but also builds trust and confidence with end customers. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد المولدات الكهربائية؟

When importing alternators, buyers should consider factors such as shipping methods, customs regulations, and lead times. It’s crucial to work with logistics partners familiar with international trade and automotive parts to ensure compliance and timely delivery. Additionally, understanding the total landed cost, including tariffs and taxes, will help in making informed purchasing decisions and maintaining profitability.

Top 3 Para Q Sirve El Alternador Manufacturers & Suppliers List

1. كيا - ألتيرادور

المجال: kia.com

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: Un alternador es un componente esencial en vehículos con motor de combustión, encargado de convertir energía química en energía eléctrica para cargar la batería y alimentar los componentes eléctricos del automóvil. Funciona en conjunto con la batería y el regulador de voltaje, generando corriente alterna que se transforma en corriente continua para cargar la batería. Los alternadores suelen durar …

2. Race – Alternadores de Coche

المجال: سباق.es

مقدمة: El alternador es un componente del coche que produce electricidad y la acumula en la batería, permitiendo el funcionamiento del motor y los sistemas de ayuda a la conducción. Genera electricidad alterna que se convierte en continua de 12 voltios mediante una placa de diodos. El voltaje generado debe estar entre 13,5 V y 14,5 V. En coches antiguos, el alternador funcionaba de manera independiente, …

3. Infinity Auto – Alternador

المجال: infinityauto.com

تاريخ التسجيل: 2002 (23 عامًا)

مقدمة: El alternador es un generador que distribuye electricidad al auto y recarga la batería. Funciona convirtiendo energía mecánica en energía eléctrica, impulsado por el cigüeñal del motor a través de una correa serpentina. Sus componentes principales incluyen: 1. Rotor: pieza cilíndrica rodeada de imanes que gira dentro del estator. 2. Estator: parte fija que contiene cables de cobre y trabaja junto …

استنتاجات وتوقعات التوريد الاستراتيجي للمصادر الاستراتيجية ل para q sirve el alternador

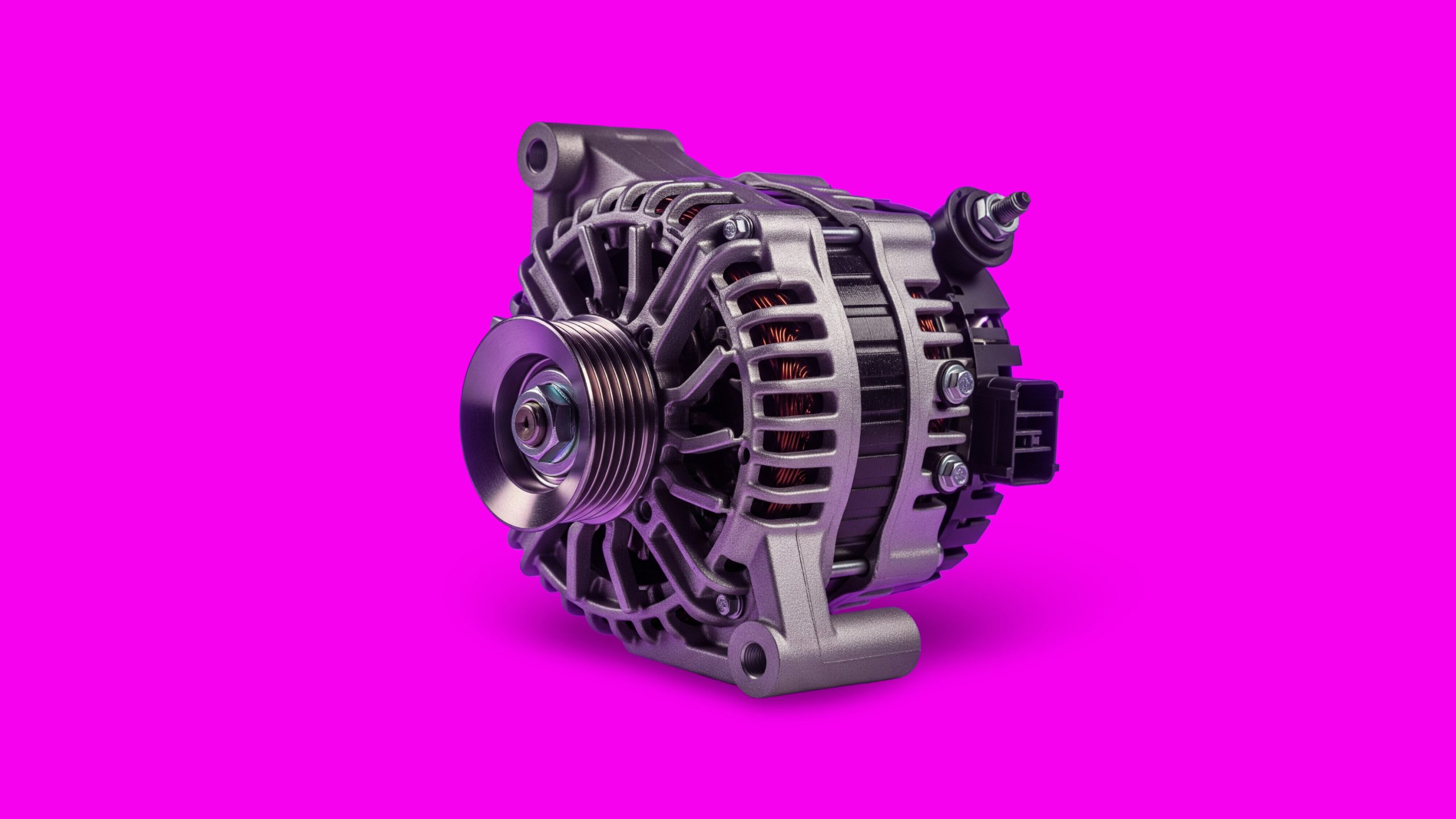

In summary, understanding the critical role of the alternator in automotive systems is paramount for international B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe. The alternator not only converts mechanical energy into electrical energy but also ensures the efficient operation of essential vehicle components, thereby enhancing overall vehicle performance and reliability.

Strategic sourcing of high-quality alternators can lead to reduced downtime, increased operational efficiency, and improved customer satisfaction. Buyers should prioritize partnerships with reputable manufacturers and suppliers who can guarantee the durability and performance of these vital components.

صورة توضيحية متعلقة ب para q sirve el alternador

As the automotive industry continues to evolve, driven by technological advancements and sustainability initiatives, staying ahead of trends will be crucial. International buyers are encouraged to leverage strategic sourcing to not only meet current demands but also to prepare for future innovations in vehicle technology. Engage with trusted suppliers, explore diverse product offerings, and invest in quality to enhance your competitive edge in the market.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.