مقدمة: الإبحار في السوق العالمي لتكلفة إصلاح مشغل السيارة

في المشهد الديناميكي لصناعة السيارات، فإن فهم تكلفة إصلاح مشغل السيارة أمر بالغ الأهمية للمشترين بين الشركات الذين يتطلعون إلى تحسين استراتيجيات الشراء الخاصة بهم. تواجه العديد من الشركات الدولية تحدي الحصول على قطع غيار السيارات الموثوقة مع تحقيق التوازن بين الجودة والتكلفة. يُعد هذا الدليل بمثابة مورد شامل، حيث يتناول تعقيدات تكاليف إصلاح مشغلات السيارات في مختلف المناطق، بما في ذلك أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، مع التركيز بشكل خاص على أسواق مثل ألمانيا والبرازيل.

سنتطرق في هذا الدليل إلى الجوانب المختلفة لتكاليف إصلاح مشغلات السيارات، بما في ذلك أنواع المشغلات المتاحة وتطبيقاتها والعوامل الأساسية التي تؤثر على الأسعار. بالإضافة إلى ذلك، سنقدم رؤى حول عمليات التدقيق الفعالة للمورّدين لضمان الشراكة مع الشركات المصنعة ومقدمي الخدمات ذوي السمعة الطيبة. من خلال فحص تكاليف العمالة، وتأثير نوع السيارة، والتمييز بين بادئات التشغيل الجديدة والمعاد تصنيعها، يمكّن هذا الدليل المشترين الدوليين من الشركات من اتخاذ قرارات شراء مستنيرة.

قد يكون الإبحار في السوق العالمية لتكاليف إصلاح مشغلات السيارات أمراً شاقاً، ولكن مع المعلومات والاستراتيجيات الصحيحة، يمكن للشركات تبسيط عملياتها وتعزيز عروض خدماتها وتقليل التكاليف في نهاية المطاف. يهدف هذا الدليل إلى تزويدك بالمعرفة اللازمة للتنقل في هذه السوق المعقدة بثقة.

جدول المحتويات

- قائمة المصنعين والموردين لأفضل 6 شركات تصنيع وموردي تكاليف إصلاح مشغل السيارة

- مقدمة: الإبحار في السوق العالمي لتكلفة إصلاح مشغل السيارة

- فهم تكلفة إصلاح مشغّل السيارة أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لتكلفة إصلاح بادئ تشغيل السيارة

- 3 نقاط ألم شائعة لدى المستخدمين ‘تكلفة إصلاح مشغل السيارة’ وحلولها

- دليل اختيار المواد الاستراتيجية لتكلفة إصلاح بادئ تشغيل السيارة

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لتكلفة إصلاح بادئ تشغيل السيارة

- دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘تكلفة إصلاح مشغل السيارة’

- تحليل شامل للتكلفة والتسعير لتكلفة إصلاح بادئ تشغيل السيارة تحديد مصادر التكلفة

- تحليل البدائل: مقارنة تكلفة إصلاح بادئ تشغيل السيارة بالحلول الأخرى

- الخصائص الفنية والمصطلحات التجارية الأساسية لتكلفة إصلاح مشغل السيارة

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع تكاليف إصلاح مشغلات السيارات

- الأسئلة المتداولة (FAQs) لمشتري B2B لتكلفة إصلاح بادئ تشغيل السيارة

- استنتاجات وتوقعات المصادر الاستراتيجية لتكلفة إصلاح مشغل السيارة

- إخلاء مسؤولية هام وشروط الاستخدام

فهم تكلفة إصلاح مشغّل السيارة أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| محرك تشغيل جديد | مكونات جديدة تماماً ذات متانة أعلى | شركات تصنيع السيارات، خدمات الأساطيل | الإيجابيات: عمر أطول وأداء موثوق به. السلبيات: تكلفة أولية أعلى. |

| بادئ تشغيل معاد التصنيع | أعيد بناؤها باستخدام قطع مستعملة، بتكلفة أقل من المشغلات الجديدة | ورش التصليح والأساطيل ذات الميزانية المحدودة | الإيجابيات: حل فعال من حيث التكلفة. السلبيات: قد يكون عمرها الافتراضي أقصر من الجديد. |

| محرك بدء التشغيل في سوق قطع الغيار | قطع الغيار الخاصة بطرف ثالث، متفاوتة الجودة والأسعار | المرائب المستقلة والميكانيكيون المستقلون | الإيجابيات: خيارات متوفرة بأسعار معقولة. السلبيات: قد تختلف الجودة، مما يؤثر على الموثوقية. |

| بادئ تشغيل المعدات الأصلية | قطع الغيار المصنعة للمعدات الأصلية، المصممة لمركبات معينة | الوكلاء وخدمات التصليح المتطورة | الإيجابيات: توافق وجودة مضمونة. السلبيات: عادةً ما يكون الخيار الأغلى ثمناً. |

| خدمة تصليح البادئ | خدمات التشخيص والاستبدال التي يقدمها المتخصصون | ورش تصليح السيارات ومراكز الخدمة | الإيجابيات: خبير تركيب خبير، ضمان على الخدمة. السلبيات: يمكن أن تتراكم تكاليف العمالة. |

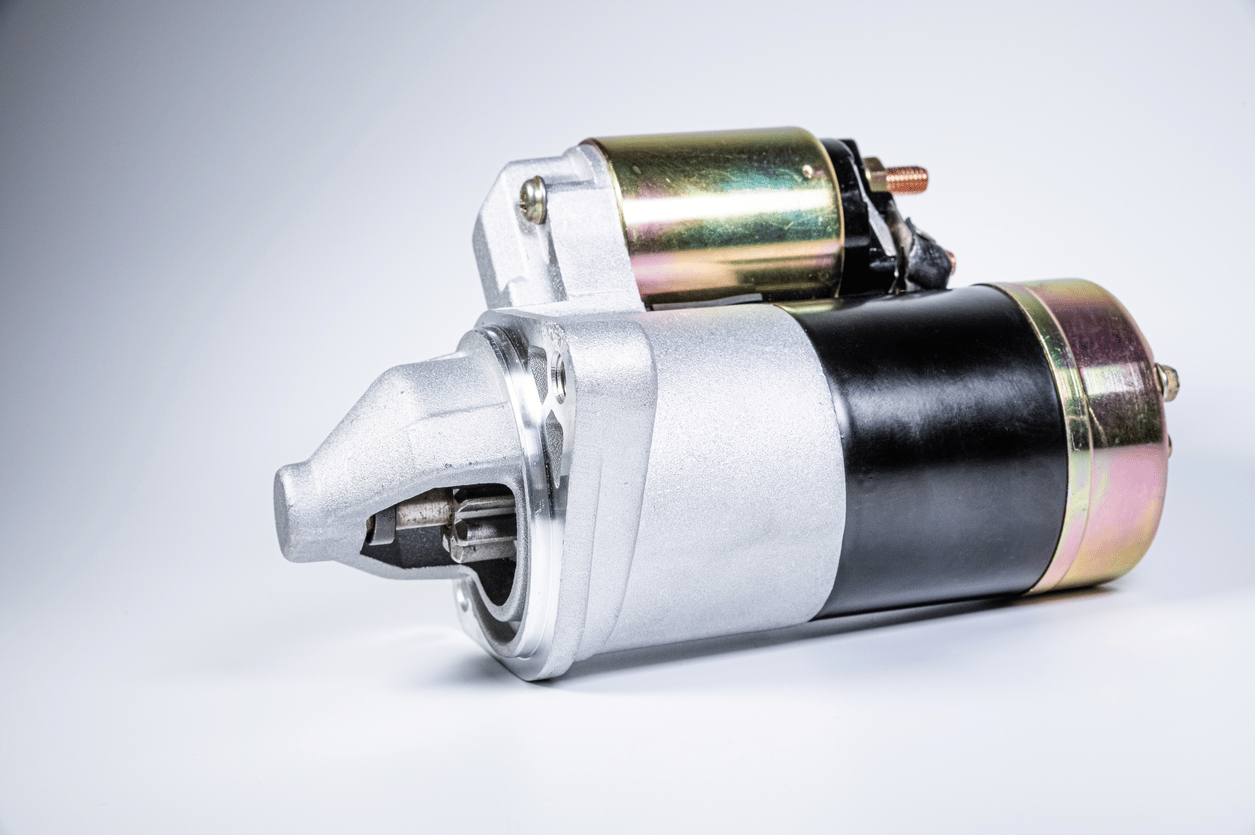

ما هي خصائص محرك بدء التشغيل الجديد؟

محرك بدء التشغيل الجديد هو مكون جديد تماماً مصمم لتوفير الأداء الأمثل وطول العمر. وعادةً ما تكون هذه المحركات أغلى ثمناً من نظيراتها المعاد تصنيعها ولكنها توفر عمراً أطول وموثوقية أعلى. وغالباً ما يفضل المشترون من الشركات وخاصة العاملين في مجال تصنيع السيارات وخدمات أساطيل السيارات، غالباً ما يفضلون المحركات الجديدة لمركباتهم لتقليل مخاطر الأعطال. عند الشراء، ضع في اعتبارك الضمان وسمعة الشركة المصنّعة، حيث يمكن أن تؤثر هذه العوامل بشكل كبير على القيمة على المدى الطويل.

كيف يختلف بادئ التشغيل المعاد تصنيعه؟

يتم إنشاء بادئات التشغيل المعاد تصنيعها عن طريق تجديد المكونات المستعملة لتلبية المواصفات الأصلية. غالبًا ما يكون هذا الخيار أكثر ملاءمة للميزانية، مما يجعله جذابًا لورش التصليح ومشغلي الأساطيل الذين يتطلعون إلى خفض التكاليف. في حين أنها يمكن أن تكون حلاً فعالاً من حيث التكلفة، يجب على المشترين بين الشركات تقييم عمليات ضمان الجودة للمورد، حيث قد لا يتطابق العمر الافتراضي مع عمر المبدئ الجديد. من المهم أيضاً فهم سياسات الضمان والإرجاع للتخفيف من المخاطر المرتبطة بالأعطال المحتملة.

ما هي مشغلات ما بعد البيع وتطبيقاتها؟

يتم إنتاج مشغلات ما بعد البيع من قبل جهات تصنيع خارجية وهي متوفرة بأسعار ومستويات جودة مختلفة. وهي تُستخدم على نطاق واسع من قبل الكراجات المستقلة والميكانيكيين الذين يعملون بأنفسهم نظراً لقدرتها على تحمل التكاليف. ومع ذلك، يجب أن يتوخى المشترون من الشركات الحذر، حيث يمكن أن تختلف الجودة بشكل كبير. عند اختيار خيارات ما بعد البيع، من الضروري البحث عن سمعة الشركة المصنّعة ومراجعات العملاء لضمان الموثوقية والأداء.

لماذا تختار مشغلات OEM للتطبيقات المتطورة؟

تم تصميم مشغلات OEM خصيصاً لموديلات وطرازات معينة من السيارات، مما يضمن ملاءمة مثالية وأداءً مثالياً. يتم استخدامها عادةً من قبل الوكلاء وخدمات الإصلاح المتطورة التي تعطي الأولوية للجودة والموثوقية. على الرغم من أنها تأتي بسعر مرتفع، إلا أن ضمان التوافق والأداء يجعلها الخيار المفضل للمشترين الذين يركزون على الحفاظ على سلامة السيارة. يجب على المشترين أيضاً مراعاة توافر قطع الغيار ودعم الخدمة عند اختيار منتجات OEM.

ما هي فوائد خدمات إصلاح البادئ الاحترافية؟

تشمل خدمات إصلاح البادئ الاحترافية التشخيص واستبدال قطع الغيار والتركيب على يد فنيين مدربين. يعد هذا الخيار حيوياً بالنسبة لورش إصلاح السيارات ومراكز الخدمة، حيث يوفر الخبرة التي تضمن الأداء الوظيفي السليم وطول عمر نظام البادئ. في حين أن تكاليف العمالة قد تكون مصدر قلق، إلا أن فوائد تغطية الضمان والضمان المهني غالباً ما تفوق النفقات الأولية. يجب على المشترين بين الشركات تقييم سمعة مزوّد الخدمة وخبرته لضمان خدمة عالية الجودة.

التطبيقات الصناعية الرئيسية لتكلفة إصلاح بادئ تشغيل السيارة

| الصناعة/القطاع | التطبيق المحدد لتكلفة إصلاح بادئ تشغيل السيارة | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | تقديم أسعار تنافسية لإصلاحات المبتدئين | جذب المزيد من العملاء وزيادة حجم الخدمة | جودة قطع الغيار وأسعار العمالة وخيارات الضمان |

| إدارة الأسطول | وضع ميزانية لبدائل بادئ التشغيل في مركبات الأسطول | تقليل وقت التوقف عن العمل وتحسين الكفاءة التشغيلية | خيارات الشراء بالجملة وشبكات الموردين الموثوقة |

| خدمات النقل والمواصلات | تقييم تكاليف إصلاح المركبات التجارية | تعزيز إدارة التكاليف وموثوقية الخدمة | تكاليف العمالة المحلية، وتوفر القطع، والجداول الزمنية للإصلاحات |

| بيع قطع غيار السيارات بالتجزئة | استراتيجيات التسعير لمبيعات المحركات البادئة | زيادة المبيعات من خلال التسعير التنافسي | علاقات الموردين وتحليل الطلب في السوق |

| تصنيع المركبات | تحليل تكلفة مكونات بدء التشغيل في الإنتاج | تحسين تسعير المنتجات والتحكم في الهامش | توريد المكونات عالية الجودة وفهم اتجاهات السوق |

في ورشة تصليح السيارات يعد فهم تكاليف إصلاح مشغلات السيارات أمرًا بالغ الأهمية لوضع استراتيجيات تسعير تنافسية. فمن خلال تقدير تكاليف الإصلاح بدقة، يمكن للمحلات التجارية جذب المزيد من العملاء وزيادة حجم الخدمة. ويتطلب ذلك تحقيق التوازن بين جودة قطع الغيار وتكاليف العمالة، إلى جانب تقديم ضمانات تطمئن العملاء بشأن موثوقية الإصلاحات.

بالنسبة لـ إدارة الأسطول, ، فإن معرفة التكاليف المرتبطة بإصلاحات بدء التشغيل أمر ضروري لوضع الميزانية وتقليل وقت تعطل المركبات إلى الحد الأدنى. يمكن لمشغلي الأساطيل إدارة نفقاتهم بشكل أفضل من خلال التخطيط للصيانة والإصلاحات المنتظمة، مما يضمن الكفاءة التشغيلية. يعد الحصول على موردين موثوق بهم يمكنهم توفير أسعار مجمعة لمحركات البادئ والقطع المرتبطة بها من الاعتبارات المهمة لهذه الشركات.

في خدمات النقل في هذا المجال، يساعد تقييم تكاليف إصلاح المركبات التجارية الشركات في الحفاظ على موثوقية الخدمة. يسمح فهم التكاليف المتضمنة بإدارة التكاليف بشكل أفضل والقدرة على تقديم أسعار شفافة للعملاء. يجب أن يراعي هذا القطاع أسعار العمالة المحلية وتوافر قطع الغيار لتقليل الجداول الزمنية للإصلاح وضمان عودة المركبات إلى الطريق بسرعة.

بائعو قطع غيار السيارات بالتجزئة الاستفادة من الفهم القوي لاستراتيجيات تسعير المحركات البادئة. من خلال تحليل تكاليف الإصلاح وطلب السوق، يمكن لتجار التجزئة تحديد أسعار تنافسية تجذب المستهلكين. إن بناء علاقات قوية مع الموردين لضمان التدفق المستمر لقطع الغيار عالية الجودة أمر ضروري للحفاظ على المخزون وتلبية احتياجات العملاء.

بالنسبة لـ الشركات المصنعة للمركبات, فإن تحليل تكاليف المكونات الأولية أمر حيوي لتحديد أسعار المنتجات والتحكم في هوامش الربح. ويتطلب ذلك فهماً شاملاً لاتجاهات السوق وتحديد مصادر المكونات عالية الجودة التي تلبي معايير الإنتاج. يجب على المصنّعين أيضًا مراعاة موثوقية الأجزاء التي يختارون دمجها في سياراتهم على المدى الطويل، مما يؤثر على رضا العملاء وسمعة العلامة التجارية.

3 نقاط ألم شائعة لدى المستخدمين ‘تكلفة إصلاح مشغل السيارة’ وحلولها

السيناريو 1: التكاليف غير المتوقعة من أعطال المبتدئين

المشكلة: غالبًا ما يواجه المشترون بين الشركات، مثل مديري أساطيل السيارات أو ورش تصليح السيارات، تكاليف غير متوقعة عند تعطل بادئ التشغيل في السيارة. قد يكون هذا الموقف صعباً بشكل خاص إذا واجهت عدة مركبات مشاكل في بادئ التشغيل في وقت واحد، مما يؤدي إلى زيادة وقت التعطل ونفقات الإصلاح. إن الافتقار إلى الشفافية في التسعير يمكن أن يجعل من الصعب على المشترين وضع ميزانية فعالة، حيث قد لا يأخذون في الحسبان النطاق الكامل للتكاليف المحتملة المرتبطة باستبدال البادئ بما في ذلك قطع الغيار والعمالة وأي إصلاحات إضافية مطلوبة.

الحل: وللتخفيف من مخاطر التكاليف غير المتوقعة، يجب على المشترين إنشاء فهم واضح للتسعير النموذجي لبدائل بادئ التشغيل عبر طرازات السيارات المختلفة. يمكن أن يساعد إنشاء مصفوفة تكلفة شاملة تحدد متوسط التكاليف للمبتدئين الاقتصاديين والمصنعين الأصليين والمبتدئين ذوي الأداء العالي في التنبؤ بالنفقات بشكل أكثر دقة. بالإضافة إلى ذلك، من المفيد بناء علاقات مع موردين موثوقين يمكنهم توفير أسعار ثابتة وقطع غيار عالية الجودة. من خلال تنفيذ جدول الصيانة الاستباقية، يمكن لمديري الأساطيل تحديد المشكلات المحتملة في بادئ التشغيل قبل أن تؤدي إلى أعطال، مما يقلل من احتمالية إجراء إصلاحات طارئة مكلفة.

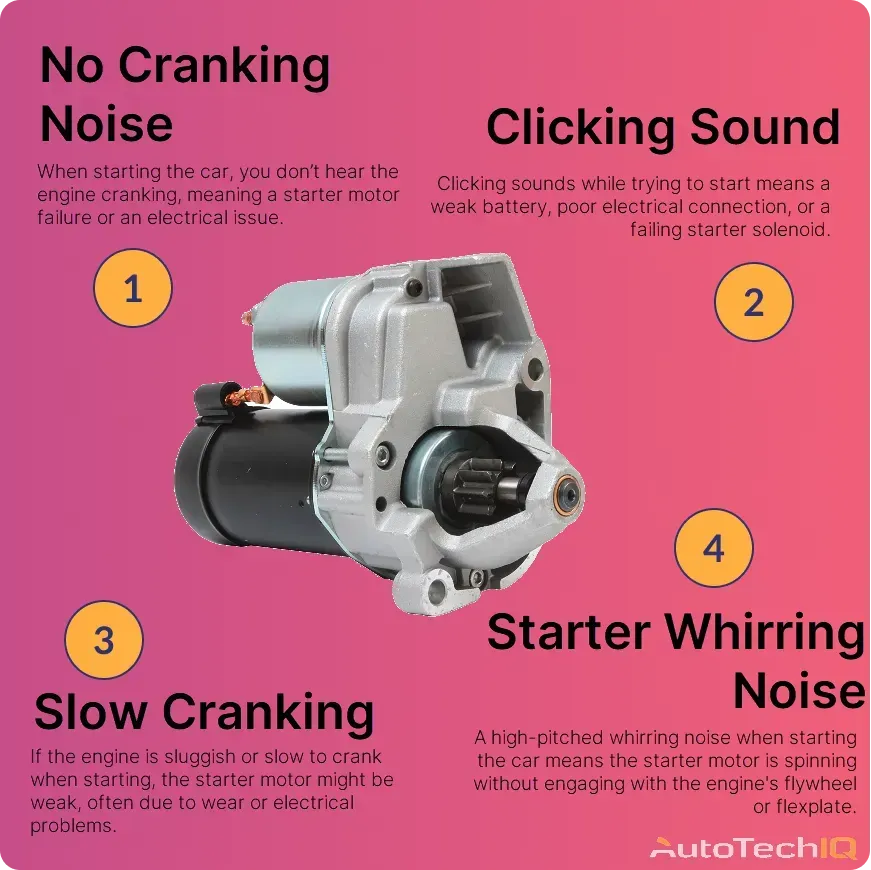

السيناريو 2: صعوبة في تقييم مشكلات البداية

المشكلة: بالنسبة للمشترين في B2B، قد يكون تشخيص مشاكل البادئ مهمة شاقة. قد تشير العديد من الأعراض المرتبطة بأعطال البادئ - مثل ضوضاء النقر أو ضعف تدوير المحرك - إلى وجود مشاكل في البطارية أو النظام الكهربائي. يمكن أن يؤدي هذا الغموض إلى إصلاحات غير ضرورية أو استبدال قطع الغيار، مما يؤدي إلى تضخيم التكاليف وإحباط العملاء الذين يتوقعون تشخيصاً دقيقاً.

الحل: ولتعزيز دقة التشخيص، يجب على المشترين من الشركات الاستثمار في تدريب الفنيين لديهم فيما يتعلق بالأعراض المحددة وعمليات التشخيص المتعلقة بمشاكل بدء التشغيل. سيؤدي استخدام أدوات التشخيص المتقدمة التي يمكنها تحديد السبب الجذري لمشاكل بدء التشغيل إلى تبسيط عملية الإصلاح وتقليل التشخيص الخاطئ. يمكن أن يؤدي وضع بروتوكول لاختبار البطارية والنظام الكهربائي بشكل منهجي قبل استنتاج أن المشكلة في المبدئ إلى توفير الوقت والموارد. بالإضافة إلى ذلك، يمكن أن يساعد الاحتفاظ بسجلات مفصّلة للإصلاحات السابقة لبداية التشغيل في تحديد الأنماط التي قد تشير إلى وجود مشاكل مزمنة في طرازات معينة من المركبات.

السيناريو 3: تحقيق التوازن بين الجودة والتكلفة في استبدال المبتدئين

المشكلة: غالبًا ما يواجه المشترون بين الشركات تحدي الموازنة بين الجودة والتكلفة عند اختيار بادئات التشغيل للاستبدال. على الرغم من أن مبتدئات ما بعد البيع الأرخص ثمناً قد تبدو جذابة لتوفير التكاليف، إلا أنها قد لا توفر نفس الموثوقية أو طول العمر مثل قطع غيار المعدات الأصلية. يمكن أن تؤدي هذه المعضلة إلى ارتفاع النفقات على المدى الطويل إذا تعطلت الأجزاء الأقل جودة قبل الأوان، مما يؤدي إلى تكرار الإصلاحات وعدم رضا العملاء.

الحل: وللتغلب على هذا التحدي بفعالية، يجب على المشترين بين الشركات إجراء بحث شامل لفهم نسبة التكلفة إلى الفائدة لخيارات المبتدئين المختلفة. يمكن أن تساعد إقامة شراكات مع المصنعين أو الموزعين ذوي السمعة الطيبة الذين يقدمون معلومات مفصلة عن أداء وكفالة بادئات التشغيل الخاصة بهم المشترين على اتخاذ قرارات مستنيرة. يمكن أن يؤدي تطبيق استراتيجية الشراء المتدرج - حيث يختار المشترون قطع غيار المعدات الأصلية للمركبات المهمة وخيارات ما بعد البيع للمركبات الأقل أهمية - إلى تحقيق التوازن بين الجودة والتكلفة. بالإضافة إلى ذلك، يمكن أن يؤدي التفكير في خيارات الشراء بالجملة أو التفاوض على عقود مع الموردين إلى تحقيق وفورات كبيرة دون المساومة على الجودة. كما أن المراجعة المنتظمة والمقارنة المنتظمة لأداء مختلف البادئات ستساعد في تحسين قرارات الشراء.

دليل اختيار المواد الاستراتيجية لتكلفة إصلاح بادئ تشغيل السيارة

ما هي المواد المستخدمة بشكل شائع في إصلاح مشغل السيارة وانعكاساتها على التكلفة؟

في مجال إصلاح بادئ تشغيل السيارة، يمكن أن يؤثر اختيار المواد بشكل كبير على كل من الأداء والتكلفة. فيما يلي تحليلات لأربع مواد شائعة مستخدمة في مكونات بادئ التشغيل، مع التركيز على خصائصها ومزاياها وعيوبها واعتباراتها بالنسبة للمشترين الدوليين من الشركات.

ما هي الخصائص الرئيسية للنحاس في مكونات بادئ تشغيل السيارة؟

يُستخدم النحاس على نطاق واسع في المكونات الكهربائية نظراً لخصائصه الممتازة في التوصيل والحرارة. ويتميز بدرجة حرارة عالية، تبلغ عادةً حوالي 200 درجة مئوية، ويوفر مقاومة جيدة للتآكل عند معالجته بشكل صحيح.

الإيجابيات والسلبيات:

تضمن الموصلية العالية للنحاس نقل الطاقة بكفاءة، وهو أمر ضروري لأداء المشغّل. ومع ذلك، فهو مكلف نسبيًا مقارنة ببدائل مثل الألومنيوم ويمكن أن يكون عرضة للتآكل إذا لم يتم طلاؤه أو معالجته بشكل مناسب. كما أن تعقيد التصنيع معتدل، حيث يتطلب عمليات متخصصة للتشكيل والتوصيل.

التأثير على التطبيق:

يتوافق النحاس مع مختلف الوسائط، بما في ذلك الأنظمة الكهربائية ووصلات البطاريات. إن موصلية النحاس العالية تجعله مثاليًا لمحركات بدء التشغيل، حيث يكون النقل السريع للطاقة ضروريًا.

اعتبارات للمشترين الدوليين:

بالنسبة للمشترين في مناطق مثل أفريقيا وأمريكا الجنوبية، حيث يمكن أن تؤدي الرطوبة والظروف البيئية إلى التآكل، يُنصح باختيار مكونات النحاس ذات الطلاءات الواقية. كما أن الامتثال لمعايير مثل ASTM B187 لسبائك النحاس ضروري أيضًا لضمان الجودة.

كيف يقارن الألومنيوم من حيث الأداء والتكلفة؟

يعد الألومنيوم خيارًا شائعًا آخر لمكونات بدء التشغيل، وهو معروف بطبيعته الخفيفة الوزن ومقاومته الجيدة للتآكل. ويمكنه تحمّل درجات حرارة تصل إلى 150 درجة مئوية، مما يجعله مناسباً لمختلف تطبيقات السيارات.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

الإيجابيات والسلبيات:

وتتمثل الميزة الأساسية للألومنيوم في انخفاض تكلفته وخصائصه خفيفة الوزن، مما قد يعزز كفاءة استهلاك الوقود في المركبات. ومع ذلك، فإن موصلية الألومنيوم أقل من النحاس، مما قد يؤثر على الأداء في التطبيقات عالية الطلب. يمكن أن تكون عمليات تصنيع الألومنيوم معقدة بسبب قابليته للطرق، مما يتطلب معالجة دقيقة أثناء الإنتاج.

التأثير على التطبيق:

وغالبًا ما يستخدم الألومنيوم في العلب والأغلفة للمبتدئين، حيث يكون تقليل الوزن مفيدًا. ومع ذلك، قد لا يكون الخيار الأفضل للمكونات التي تتطلب توصيلًا كهربائيًا عاليًا.

اعتبارات للمشترين الدوليين:

قد يفضل المشترون في أوروبا والشرق الأوسط الألومنيوم بسبب خصائصه خفيفة الوزن، بما يتماشى مع لوائح كفاءة استهلاك الوقود. ويُعد الامتثال لمعايير مثل DIN EN 573 لسبائك الألومنيوم أمرًا بالغ الأهمية لضمان جودة المنتج.

ما الدور الذي يلعبه الفولاذ في إصلاح مشغل السيارة؟

كثيرًا ما يستخدم الفولاذ، وخاصة الفولاذ المقاوم للصدأ، في إصلاح البادئ لقوته ومتانته. وتصل درجة حرارته إلى حوالي 300 درجة مئوية ومقاومة ممتازة للتآكل، خاصةً في أنواع الفولاذ المقاوم للصدأ.

الإيجابيات والسلبيات:

إن قوة الفولاذ تجعله مثالياً للمكونات الهيكلية، مما يوفر متانة ضد الإجهاد الميكانيكي. ومع ذلك، فهو أثقل من كل من النحاس والألومنيوم، وهو ما يمكن أن يكون عيباً في المركبات عالية الأداء. كما أن تكلفة الفولاذ المقاوم للصدأ أعلى من الفولاذ العادي ولكنه يوفر عمر افتراضي أفضل.

التأثير على التطبيق:

يشيع استخدام الفولاذ في تصنيع علب البادئ وأقواس التثبيت، حيث تكون القوة أمرًا بالغ الأهمية. كما أن توافقه مع مختلف الوسائط، بما في ذلك الزيت وسائل التبريد، يجعله متعدد الاستخدامات.

اعتبارات للمشترين الدوليين:

في المناطق التي تطبق معايير صارمة في مجال السيارات، مثل ألمانيا، يعد الامتثال لمعايير DIN للفولاذ أمراً ضرورياً. يجب على المشترين أيضاً مراعاة آثار الوزن على أداء السيارة، خاصة في الأسواق التي تركز على كفاءة استهلاك الوقود.

كيف تؤثر المواد المركبة في اختيار مكوّنات المبتدئين؟

يتم استخدام المواد المركبة، بما في ذلك البلاستيك المقوى، بشكل متزايد في مكونات البادئ نظراً لخصائصها الخفيفة الوزن والمقاومة للتآكل. ويمكنها تحمل درجات حرارة تصل إلى 120 درجة مئوية.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

الإيجابيات والسلبيات:

وتتمثل الميزة الأساسية للمركبات في انخفاض وزنها ومقاومتها للتآكل، مما يجعلها مناسبة لمختلف تطبيقات السيارات. ومع ذلك، قد لا تضاهي قوتها الميكانيكية قوة المعادن، مما قد يحد من استخدامها في البيئات عالية الإجهاد. كما يمكن أن يكون تعقيد التصنيع أعلى، مما يتطلب تقنيات متخصصة.

التأثير على التطبيق:

وغالباً ما تستخدم المركبات في المكونات غير الهيكلية، مثل الأغطية والعوازل، حيث يكون توفير الوزن أمراً بالغ الأهمية. ويعزز توافقها مع مختلف سوائل السيارات من نطاق استخدامها.

اعتبارات للمشترين الدوليين:

بالنسبة للمشترين في الأسواق الناشئة، يمكن أن توفر المواد المركبة وفورات في التكاليف ومزايا الأداء. ومع ذلك، فإن فهم اللوائح المحلية فيما يتعلق باستخدام المواد والامتثال للمعايير مثل ASTM D638 للمواد البلاستيكية أمر بالغ الأهمية.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

جدول تلخيصي لاختيار المواد اللازمة لإصلاح مشغل السيارة

| المواد | حالة الاستخدام النموذجية لتكلفة إصلاح بادئ تشغيل السيارة | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | التوصيلات الكهربائية في المبتدئين | موصلية ممتازة | التكلفة العالية واحتمالية التآكل | عالية |

| الألومنيوم | علب وأغلفة خفيفة الوزن | فعالة من حيث التكلفة وخفيفة الوزن | موصلية أقل من النحاس | متوسط |

| الصلب | المكونات الهيكلية مثل الأقواس | قوة ومتانة عالية | أثقل من البدائل | متوسطة إلى عالية |

| المركبات | المكونات غير الهيكلية مثل الأغطية | خفيف الوزن ومقاوم للتآكل | قوة ميكانيكية أقل | متوسط |

يوفر هذا الدليل الاستراتيجي لاختيار المواد رؤى قيّمة للمشترين من الشركات لمساعدتهم على اتخاذ قرارات مستنيرة بناءً على الأداء والتكلفة والاعتبارات الإقليمية.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لتكلفة إصلاح بادئ تشغيل السيارة

ما هي المراحل الرئيسية لتصنيع مشغلات السيارات؟

يُعد فهم عملية تصنيع بادئات تشغيل السيارات أمرًا بالغ الأهمية بالنسبة لمشتري الأعمال التجارية الذين يتطلعون إلى تحسين التكاليف وضمان الجودة. يتضمن إنتاج بادئات تشغيل السيارات عمومًا عدة مراحل رئيسية: إعداد المواد والتشكيل والتجميع والتشطيب.

كيف يتم تحضير المواد لبدّالات السيارات؟

الخطوة الأولى في تصنيع مشغلات السيارات هي إعداد المواد. يتم اختيار المواد عالية الجودة مثل الفولاذ والنحاس والسبائك المختلفة بناءً على متانتها وتوصيلها. وغالباً ما يقوم الموردون بإجراء تقييمات شاملة للتأكد من أن المواد تفي بمعايير الصناعة. قد تتضمن هذه المرحلة أيضاً التوريد من موردين محليين أو دوليين، مما قد يؤثر على التكلفة والمهل الزمنية.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

ما هي التقنيات المستخدمة في تشكيل مشغلات السيارات؟

تعتبر تقنيات التشكيل حيوية في تشكيل مكونات محرك بدء التشغيل. تشمل الطرق الشائعة الختم والتشكيل والصب بالقالب، والتي تشكل المكونات المعدنية في أشكال دقيقة. على سبيل المثال، غالبًا ما يُستخدم الصب بالقالب في الأشكال الهندسية المعقدة، بينما الختم مناسب للأجزاء المعدنية المسطحة. كل تقنية لها مزاياها، مما يؤثر على التكلفة الإجمالية وجودة محرك البادئ.

كيف يتم تجميع مشغلات السيارات؟

التجميع هو مرحلة حرجة حيث يتم تجميع المكونات المختلفة، مثل المحرك وملفات المجال والملف اللولبي معًا. تُستخدم خطوط التجميع الآلية بشكل شائع لتعزيز الكفاءة والدقة. قد يقوم العمال أيضًا بالتجميع اليدوي للأجزاء المعقدة، مما يضمن مراقبة الجودة طوال العملية. غالبًا ما تتضمن مرحلة التجميع اختبار المكونات للتأكد من توافقها وأدائها.

ما هي عمليات التشطيب التي يتم تطبيقها على مشغلات السيارات؟

تشمل مرحلة التشطيب المعالجات السطحية مثل الطلاء أو الطلاء أو الطلاء للحماية من التآكل والتآكل. وتعد هذه العمليات ضرورية لضمان طول عمر وموثوقية البادئ. قد تشمل فحوصات ضمان الجودة خلال هذه المرحلة الفحوصات البصرية والاختبارات الوظيفية للتحقق من أن المنتج يفي بالمواصفات قبل تعبئته للشحن.

ما هي معايير ضمان الجودة لتصنيع بادئ تشغيل السيارة؟

يعد ضمان الجودة أمرًا بالغ الأهمية في صناعة السيارات، لا سيما بالنسبة لمكونات مثل مشغلات السيارات التي تعتبر بالغة الأهمية لأداء السيارة. وتوفر المعايير الدولية مثل ISO 9001 إطار عمل لأنظمة إدارة الجودة، مما يضمن تلبية الشركات المصنعة لمتطلبات العملاء والمتطلبات التنظيمية باستمرار.

ما هي المعايير الدولية التي يجب على المشترين بين الشركات أخذها في الاعتبار؟

بالإضافة إلى شهادة الأيزو 9001، يجب أن يكون المشترون بين الشركات على دراية بالشهادات الخاصة بالصناعة مثل علامة CE للامتثال لمعايير الصحة والسلامة وحماية البيئة الأوروبية. في مناطق مثل أفريقيا وأمريكا الجنوبية، قد تنطبق المعايير المحلية أيضًا، لذا يجب على المشترين التحقق من التزام الموردين باللوائح ذات الصلة.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في عملية التصنيع؟

يتم وضع نقاط فحص مراقبة الجودة بشكل استراتيجي في جميع مراحل عملية التصنيع. تقوم مراقبة الجودة الواردة (IQC) بتقييم المواد الخام عند وصولها والتأكد من مطابقتها للمواصفات. تراقب مراقبة الجودة أثناء العملية (IPQC) عملية التصنيع، بينما تتحقق مراقبة الجودة النهائية (FQC) من أن المنتج النهائي يفي بجميع معايير الجودة قبل الشحن.

كيف يتم تنفيذ طرق الاختبار في ضمان جودة مشغلات السيارات؟

تلعب طرق الاختبار دورًا مهمًا في ضمان الجودة. وتشمل الطرق الشائعة الاختبارات الوظيفية، حيث يتم إخضاع المبتدئات لظروف تحاكي الاستخدام الفعلي. وتتحقق الاختبارات الكهربائية من وجود دوائر كهربائية قصيرة، بينما تقيّم الاختبارات البيئية الأداء في ظل ظروف قاسية مثل تغيرات درجات الحرارة.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

يمكن للمشترين بين الشركات اتخاذ عدة خطوات للتحقق من عمليات مراقبة الجودة للموردين المحتملين. ويُعد إجراء عمليات التدقيق نهجاً استباقياً يسمح للمشترين بتقييم ممارسات التصنيع وأنظمة الجودة بشكل مباشر. يمكن أن يوفر طلب تقارير وشهادات الجودة نظرة ثاقبة حول امتثال المورد للمعايير الدولية. بالإضافة إلى ذلك، يمكن لعمليات التفتيش من طرف ثالث التحقق من أن منتجات المورد تفي بمعايير الجودة المحددة.

ما هي الفروق الدقيقة في مراقبة الجودة والشهادات بالنسبة للمشترين الدوليين؟

يجب أن يكون المشترون الدوليون، لا سيما من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، على دراية بالفروق الدقيقة في الشهادات. قد يكون للأسواق المختلفة متطلبات مختلفة لضمان الجودة. على سبيل المثال، قد يعطي المشترون الأوروبيون الأولوية لشهادة CE، بينما قد يبحث المشترون في الشرق الأوسط عن الامتثال للمعايير المحلية. إن فهم هذه الفروق الدقيقة أمر بالغ الأهمية لتقليل المخاطر وضمان سلاسة عمليات الشراء.

كيف تؤثر الاختلافات الإقليمية على جودة بادئ تشغيل السيارة وتكاليفه؟

يمكن أن تؤثر الاختلافات الإقليمية بشكل كبير على كل من الجودة والتكاليف. على سبيل المثال، قد تلتزم الشركات المصنعة في أوروبا بلوائح بيئية أكثر صرامة، مما قد يؤدي إلى زيادة تكاليف الإنتاج. وعلى العكس من ذلك، قد يقدم الموردون في المناطق ذات تكاليف العمالة المنخفضة أسعارًا تنافسية ولكنهم قد لا يستوفون نفس معايير الجودة. يجب على المشترين بذل العناية الواجبة للتأكد من أنهم يقومون بالتوريد من موردين ذوي سمعة جيدة يمكنهم تقديم منتجات عالية الجودة باستمرار.

الخلاصة: اتخاذ قرارات مستنيرة في شراء بادئ تشغيل السيارات

يعد التنقل بين تعقيدات عمليات التصنيع وضمان الجودة لبدالات تشغيل السيارات أمرًا ضروريًا للمشترين بين الشركات. من خلال فهم المراحل الرئيسية للإنتاج، ومعايير ضمان الجودة ذات الصلة، والفروق الدقيقة في الشهادات الدولية، يمكن للمشترين اتخاذ قرارات مستنيرة تتماشى مع احتياجاتهم التشغيلية وقيود ميزانيتهم. إن إعطاء الأولوية للموردين الذين لديهم تدابير قوية لمراقبة الجودة سيؤدي في النهاية إلى تحسين أداء المنتج ورضا العملاء.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘تكلفة إصلاح مشغل السيارة’

للتعامل بفعالية مع تعقيدات الحصول على خدمات إصلاح مشغلات السيارات، من الضروري اتباع نهج منظم. يُستخدم هذا الدليل كقائمة مرجعية لمساعدة المشترين من الشركات على اتخاذ قرارات مستنيرة، مما يضمن حصولهم على أفضل الخدمات ذات الجودة العالية بأسعار تنافسية.

الخطوة 1: تقييم احتياجات سيارتك

إن فهم المتطلبات المحددة لسيارتك أمر بالغ الأهمية. حدّد طراز السيارة وطرازها وسنتها، حيث إن السيارات المختلفة لها أنواع مختلفة من البادئات وتعقيدات التركيب. سيؤدي هذا التقييم الأولي إلى إثراء مناقشاتك مع الموردين والتأكد من أنك تبحث عن القطع والخدمات المناسبة.

الخطوة 2: البحث عن خيارات الموردين ومقارنتها

من الضروري إجراء تحليل شامل للسوق لتحديد الموردين المحتملين. ابحث عن الشركات المتخصصة في إصلاح بادئ تشغيل السيارات، وقم بتقييم عروض خدماتهم وسمعتهم ومراجعات العملاء. انتبه إلى الموردين الذين لديهم سجل حافل في منطقتك الجغرافية، فقد يكون لديهم معلومات عن احتياجات السيارات المحلية وتكاليف العمالة.

الخطوة 3: تقييم شهادات الموردين وخبراتهم

قبل التعامل مع أي مورّد، تحقق من أوراق اعتماده وخبرته في هذا المجال. تحقق من الشهادات التي تثبت الامتثال لمعايير السلامة والجودة، مثل شهادات ISO أو تراخيص إصلاح السيارات المحلية. من المرجح أن يقدم الموردون ذوو الخبرة خدمة موثوقة ويمكنهم تقديم رؤى قيمة في عملية الإصلاح.

الخطوة 4: طلب عروض أسعار مفصلة

بمجرد الانتهاء من وضع قائمة مختصرة بالموردين المحتملين، اطلب عروض أسعار مفصلة تفصّل التكاليف المرتبطة بالإصلاح. يجب أن يتضمن عرض الأسعار الجيد ما يلي:

– تكاليف قطع الغيار: التفريق بين القطع الجديدة والمعاد تصنيعها.

– تكاليف العمالة: فهم أسعار الساعة والساعات المقدرة للإصلاح.

– الرسوم الإضافية: استفسر عن أي رسوم إضافية محتملة للتشخيص أو الإصلاحات غير المتوقعة.

الخطوة 5: استفسر عن الضمان والدعم

يمكن أن تؤثر شروط الضمان بشكل كبير على رضاك وتكاليفك على المدى الطويل. اسأل الموردين المحتملين عن الضمانات التي يقدمونها على قطع الغيار والعمالة. فالضمان القوي لا يحمي استثمارك فحسب، بل يعكس أيضاً ثقة المورد في خدماته.

الخطوة 6: تقييم الخدمات اللوجستية ووقت الاستجابة

ضع في اعتبارك الخدمات اللوجستية التي تنطوي عليها عملية الإصلاح. استفسر عن الوقت المتوقع لعمليات الإصلاح، بالإضافة إلى قدرة المورد على التعامل مع الطلبات العاجلة. يمكن للخدمات اللوجستية الفعالة أن تقلل من وقت التعطل وتضمن عودة مركباتك إلى العمل في أسرع وقت ممكن.

الخطوة 7: إنشاء قنوات التواصل والدعم

التواصل الفعال ضروري لنجاح الشراكة. أنشئ خطوط اتصال واضحة مع المورد الذي اخترته وتأكد من استجابته للاستفسارات والتحديثات طوال عملية الإصلاح. سيسهل ذلك تجربة أكثر سلاسة ويساعد في معالجة أي مشاكل قد تنشأ أثناء عملية الإصلاح.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

من خلال اتباع هذه الخطوات، يمكن للمشترين بين الشركات التعامل بشكل استراتيجي مع مصادر خدمات إصلاح مشغلات السيارات، مما يضمن لهم تأمين إصلاحات عالية الجودة مع تحسين التكاليف وكفاءة الوقت.

تحليل شامل للتكلفة والتسعير لتكلفة إصلاح بادئ تشغيل السيارة تحديد مصادر التكلفة

ما هي مكونات التكلفة الرئيسية لإصلاح مشغل السيارة؟

عند البحث عن مصادر لإصلاح بادئ تشغيل السيارة، يجب مراعاة العديد من مكونات التكلفة لفهم هيكل التسعير العام. وتشمل المكونات الأساسية المواد، والعمالة، ونفقات التصنيع العامة، والأدوات، ومراقبة الجودة، والخدمات اللوجستية، وهوامش الربح.

-

المواد: تعتبر تكلفة محرك البادئ نفسه عاملاً مهماً. ويختلف ذلك اعتماداً على ما إذا كنت تختار بادئ تشغيل اقتصادي، أو جزء من صانع المعدات الأصلية، أو وحدة عالية الأداء. يمكن أن يكون النطاق السعري لهذه المكونات واسعًا، بدءًا من $75 للخيارات المناسبة للميزانية إلى أكثر من $1000 للمبتدئين ذوي الأداء العالي.

-

العمل: يمكن أن تتفاوت تكاليف العمالة بناءً على مدى تعقيد عملية التركيب. قد تتراوح تكلفة استبدال بادئ التشغيل الأساسي للمركبة بين $100 و$250، في حين يمكن أن تتكلف المركبات الفاخرة أو عالية الأداء تكاليف عمالة تتراوح بين $300 و$600 أو أكثر بسبب التعقيدات التي ينطوي عليها الأمر.

-

تكاليف التصنيع العامة: يشمل ذلك التكاليف غير المباشرة المرتبطة بالإنتاج، مثل المرافق والإيجار والمصروفات الإدارية. وعادةً ما تُؤخذ هذه التكاليف في الاعتبار في استراتيجية التسعير الإجمالية للمصنعين والموردين.

-

الأدوات ومراقبة الجودة: الأدوات المتخصصة المطلوبة للتركيب والاختبار تضمن موثوقية المشغلات. عمليات مراقبة الجودة ضرورية للحفاظ على معايير المنتج، مما قد يضيف إلى التكلفة الإجمالية.

-

اللوجستيات: يمكن أن تتفاوت تكاليف النقل تفاوتاً كبيراً تبعاً للموقع الجغرافي للموردين والمشترين. وبالنسبة للمعاملات الدولية، يمكن أن تتصاعد هذه التكاليف بسبب التعريفات والرسوم الجمركية ورسوم الشحن.

-

الهامش: يضيف الموردون عادةً هامش ربح لتغطية التكاليف والمخاطر التشغيلية. ويمكن أن يختلف هذا الهامش حسب المنافسة في السوق والطلب واستراتيجية التسعير الخاصة بالمورد.

ما الذي يؤثر على أسعار مكونات بادئ تشغيل السيارة؟

يمكن أن تؤثر عدة عوامل على أسعار مكونات بادئ تشغيل السيارات في سوق B2B:

-

الحجم والحد الأدنى لكمية الطلب (MOQ): قد تؤدي الطلبات الأكبر إلى تخفيضات بسبب وفورات الحجم. وينبغي للمشترين أن يتفاوضوا على طلبات الشراء التي تتماشى مع استراتيجية الشراء الخاصة بهم لتحسين كفاءة التكلفة.

-

المواصفات والتخصيص: قد تتكبد المكونات المخصصة التي تلبي طرازات معينة من السيارات أو متطلبات الأداء تكاليف أعلى. من الضروري أن يحدد المشترون مواصفاتهم بوضوح لتجنب النفقات غير المتوقعة.

-

جودة المواد والشهادات: يمكن أن تؤثر المواد والشهادات ذات الجودة العالية على الأسعار. يجب على المشترين النظر في الفوائد طويلة الأجل للاستثمار في القطع المعتمدة مقابل البدائل الأرخص التي قد لا توفر نفس الموثوقية.

-

عوامل الموردين: يمكن أن يؤثر اختيار المورد تأثيراً كبيراً على التسعير. فقد يفرض الموردون الراسخون ذوو السمعة القوية أسعاراً أعلى بسبب الجودة والموثوقية المتصورة، في حين أن الموردين الجدد أو الأقل شهرة قد يعرضون أسعاراً أقل لكسب حصة في السوق.

-

مصطلحات التجارة الدولية: يعد فهم شروط التجارة الدولية أمرًا بالغ الأهمية للمشترين الدوليين لأنها تحدد مسؤوليات المشترين والبائعين في الشحن. ويمكن أن يؤثر ذلك على التكلفة الإجمالية، بما في ذلك التأمين والشحن والرسوم الجمركية.

ما هي بعض النصائح للتفاوض وضمان كفاءة التكلفة؟

-

التفاوض الفعال: عند إشراك الموردين، استفد من قوتك الشرائية. سلط الضوء على العلاقات المحتملة طويلة الأجل أو التزامات الطلبات بالجملة للتفاوض على أسعار وشروط أفضل.

-

التركيز على التكلفة الإجمالية للملكية: ضع في اعتبارك ليس فقط التكاليف الأولية ولكن أيضًا الآثار المترتبة على مشترياتك على المدى الطويل. فالاستثمار في مشغلات ذات جودة أعلى قد يؤدي إلى استبدال أقل وتكاليف صيانة أقل بمرور الوقت.

-

فهم الفروق الدقيقة في التسعير للمشترين الدوليين: يجب على المشترين من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا أن يكونوا على دراية بظروف السوق المحلية وتقلبات العملة ولوائح الاستيراد التي يمكن أن تؤثر على الأسعار. يمكن أن يساعد بناء العلاقات مع الموزعين المحليين أيضًا في التغلب على هذه التعقيدات.

إخلاء المسؤولية بشأن الأسعار الإرشادية

الأسعار المذكورة في هذا التحليل إرشادية ويمكن أن تختلف بشكل كبير بناءً على ظروف السوق وعلاقات الموردين ومتطلبات المشتري المحددة. يُنصح المشترون بإجراء بحث شامل للسوق والحصول على عروض أسعار متعددة لضمان أسعار تنافسية تناسب احتياجاتهم.

تحليل البدائل: مقارنة تكلفة إصلاح بادئ تشغيل السيارة بالحلول الأخرى

استكشاف بدائل لتكاليف إصلاح مشغّل السيارة

في قطاع السيارات، يعتبر التحدي المتمثل في إدارة تكاليف صيانة السيارات كبيراً، خاصةً بالنسبة للمشترين من الشركات الذين يعتمدون على الأساطيل. ومن أكثر الإصلاحات شيوعاً استبدال مشغل السيارة، والذي قد يكون مكلفاً. ومع ذلك، توجد بدائل قد توفر فوائد وتكاليف مختلفة. يقارن هذا التحليل تكاليف إصلاح بادئ تشغيل السيارة مع بديلين قابلين للتطبيق: استبدال البطارية واستخدام أجهزة بدء التشغيل المحمولة.

| جانب المقارنة | تكلفة إصلاح مشغّل السيارة | استبدال البطارية | بادئ الحركة المحمول |

|---|---|---|---|

| الأداء | استعادة الوظيفة الكاملة؛ ضروري لبدء التشغيل | يحسن كفاءة التشغيل إذا كانت البطارية ضعيفة | يوفر تعزيزاً فورياً للطاقة لبدء التشغيل |

| التكلفة | $250 - $1,000+ | $100 - $300 | $50 - $150 |

| سهولة التنفيذ | تتطلب خدمة احترافية؛ معقدة بالنسبة للأعمال اليدوية | سهل بشكل عام؛ يمكن القيام به بنفسك بنفسك | سهل للغاية؛ التوصيل والتشغيل |

| الصيانة | صيانة منخفضة بعد الإصلاح | معتدلة؛ يختلف عمر البطارية | منخفضة؛ تتطلب الشحن |

| أفضل حالة استخدام | مشاكل مستمرة في بدء التشغيل؛ فشل كامل في بدء التشغيل | أعراض ضعف البطارية؛ بدء التشغيل المتقطع | بدء التشغيل في حالات الطوارئ؛ حل مؤقت |

تحليل متعمق للبدائل

استبدال البطارية: هل هو خيار قابل للتطبيق؟

غالباً ما يكون استبدال البطارية الضعيفة أو المعطوبة حلاً أكثر وضوحاً من إصلاح البادئ. تتراوح تكلفة البطاريات عادةً ما بين $100 و$300، اعتماداً على العلامة التجارية والمواصفات. إن سهولة الاستبدال تجعل هذا الخيار جذاباً؛ حيث يمكن للعديد من الشركات القيام بهذه المهمة داخل الشركة، مما يقلل من تكاليف العمالة. ومع ذلك، إذا كان البادئ معيباً بالفعل، فإن مجرد استبدال البطارية قد لا يحل المشكلة الأساسية، مما يؤدي إلى مزيد من النفقات في المستقبل.

بادئ التشغيل السريع المحمول: حل سريع لمشاكل بدء التشغيل

اكتسبت أجهزة بدء التشغيل المحمولة شعبية كبيرة كحل سريع للمركبات التي تتعطل عن العمل. وتوفر هذه الأجهزة التي يتراوح سعرها بين $50 و$150، دفعة طاقة فورية، مما يسمح بتشغيل المحرك دون الحاجة إلى خدمة احترافية. إن سهولة استخدامها تجعلها خياراً جذاباً للشركات التي ترغب في تقليل وقت التوقف عن العمل. ومع ذلك، في حين أنها يمكن أن تعالج مؤقتًا مشاكل بدء التشغيل، إلا أنها لا تصلح المشاكل الكامنة في بادئ التشغيل أو البطارية وقد تؤدي إلى مشاكل متكررة إذا لم يتم تشخيصها بشكل صحيح.

الخلاصة: كيفية اختيار الحل المناسب لاحتياجاتك

عند تقييم الخيارات المتاحة لمعالجة مشاكل بدء التشغيل في المركبات، يجب على مشتري B2B مراعاة الظروف الخاصة المحيطة بأداء كل مركبة. إذا كانت مشاكل بدء التشغيل متكررة ومستمرة، فقد يكون الاستثمار في إصلاح البادئ ضرورياً لضمان الموثوقية على المدى الطويل. وعلى العكس من ذلك، إذا كانت المشاكل متقطعة، فقد يكون استبدال البطارية أو مشغّل كهربائي محمول كافياً. إن تحليل التكلفة الإجمالية للملكية، بما في ذلك الإصلاحات المستقبلية المحتملة ووقت التعطل، سيساعد المشترين على اتخاذ قرارات مستنيرة تناسب الاحتياجات التشغيلية لأسطولهم على أفضل وجه.

الخصائص الفنية والمصطلحات التجارية الأساسية لتكلفة إصلاح مشغل السيارة

ما هي الخصائص التقنية الرئيسية لبدّالات السيارات وأهميتها في تكاليف الإصلاح؟

عندما يتعلق الأمر بفهم التكاليف المرتبطة بإصلاح واستبدال بادئ تشغيل السيارة، فإن العديد من الخصائص التقنية تلعب دوراً حاسماً. فيما يلي بعض المواصفات الأساسية التي يجب على المشترين أخذها بعين الاعتبار:

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

1. درجة جودة المواد

تؤثر درجة المواد المستخدمة في محرك بدء التشغيل بشكل كبير على متانته وأدائه. وتشمل المواد الشائعة الفولاذ عالي الجودة وسبائك الألومنيوم. تعمل المواد عالية الجودة على تعزيز مقاومة البادئ للتآكل والحرارة، مما قد يؤدي إلى إطالة عمر الخدمة. في سياق B2B، قد يؤدي الاستثمار في المواد عالية الجودة إلى انخفاض التكاليف على المدى الطويل بسبب انخفاض وتيرة الاستبدال.

2. المقاومة الكهربائية

المقاومة الكهربائية هي خاصية مهمة تؤثر على كفاءة محرك بدء التشغيل. تؤدي المقاومة المنخفضة بشكل عام إلى توصيل وأداء أفضل، مما يسمح بتحريك المحرك بشكل أسرع. في التطبيقات التجارية، يمكن للمقاومة الكهربائية المنخفضة أن تساهم في تحسين كفاءة استهلاك الوقود وتقليل الضغط على البطارية، مما يجعلها من الاعتبارات الرئيسية لمشغلي الأساطيل.

3. تصنيف عزم الدوران

يشير تصنيف العزم إلى قوة الدوران التي يمكن أن ينتجها محرك بدء التشغيل. وهو يختلف بناءً على نوع المركبة وحجم المحرك. يعد فهم متطلبات عزم الدوران أمرًا حيويًا لضمان قدرة البادئ المختار على تدوير المحرك بشكل مناسب، خاصة في المركبات الكبيرة أو تلك التي تحتوي على محركات عالية الأداء. بالنسبة لمشتري B2B، هذا يعني مطابقة مواصفات البادئ مع مواصفات السيارة المحددة لتجنب الأخطاء المكلفة.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

4. الجهد التشغيلي

تعمل معظم بادئات التشغيل في السيارات بجهد 12 فولت، ولكن توجد اختلافات في مركبات الخدمة الشاقة. يعد التأكد من مطابقة بادئ التشغيل للجهد التشغيلي للمركبة أمرًا بالغ الأهمية للأداء والسلامة. في معاملات B2B، يمكن أن يساعد التأكد من الجهد التشغيلي في منع الأخطاء المكلفة في المشتريات، مما يضمن التوافق مع الأسطول أو المخزون.

5. مستويات التحمل

تشير مستويات التفاوت المسموح به إلى الاختلافات المسموح بها في أبعاد البادئ ومواصفات الأداء. تعتبر مستويات التفاوت المسموح بها ضرورية لضمان ملاءمة البادئ بشكل صحيح وعمله بفعالية داخل النظام الكهربائي للسيارة. بالنسبة لمشتري B2B، يمكن أن يساعد فهم مستويات التفاوت المسموح بها في اختيار القطع التي تقلل من مشاكل التركيب وتعزز الكفاءة التشغيلية.

ما هي المصطلحات التجارية الشائعة المتعلقة بتكاليف إصلاح مشغل السيارة؟

في صناعة إصلاح السيارات، يتم استخدام بعض المصطلحات والمصطلحات التجارية بشكل متكرر. يمكن أن يساعد الإلمام بهذه المصطلحات المشترين من الشركات في اتخاذ قرارات مستنيرة.

1. OEM (الشركة المصنعة للمعدات الأصلية)

يتم تصنيع قطع الغيار الأصلية من قبل الشركة نفسها التي أنتجت القطع الأصلية المستخدمة في السيارة. وهي توفر عادةً مستوى أعلى من الموثوقية والتوافق مقارنةً بخيارات ما بعد البيع. بالنسبة للشركات، يمكن أن يؤدي اختيار قطع الغيار الأصلية إلى تقليل مشاكل الضمان وضمان الأداء الأمثل، وإن كان ذلك بتكلفة أعلى.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

2. MOQ (الحد الأدنى لكمية الطلب)

يشير مصطلح "موك" إلى أصغر كمية من المنتج الذي يرغب المورد في بيعه. يعد فهم موك أمرًا ضروريًا للمشترين بين الشركات لأنه يؤثر على إدارة المخزون واستراتيجيات الشراء. قد يؤدي ارتفاع موك إلى خصومات على الشراء بالجملة، ولكنه قد يؤدي أيضًا إلى تقييد رأس المال.

3. طلب عرض أسعار (RFQ)

طلب عرض الأسعار هو مستند يتم إرساله إلى الموردين لطلب معلومات التسعير لمنتجات أو خدمات محددة. بالنسبة للشركات التي تتطلع إلى شراء مبتدئين أو مكونات ذات صلة، فإن إصدار طلب عرض أسعار يمكن أن يسهل عملية تقديم العطاءات التنافسية ويضمن تسعيراً أفضل.

4. شروط التجارة الدولية (Incoterms)

تحدد شروط التجارة الدولية مسؤوليات المشترين والبائعين في الشحن الدولي. ويُعد فهم هذه الشروط أمرًا بالغ الأهمية لمعاملات B2B، خاصةً عند توريد قطع الغيار من بلدان مختلفة. فهي توضح من هو المسؤول عن الشحن والتأمين والتعريفات الجمركية، وبالتالي تقليل النزاعات المحتملة.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

5. تغطية الضمان

تشير تغطية الضمان إلى الضمان الذي توفره الشركة المصنعة فيما يتعلق بأداء وطول عمر البادئ. في المعاملات بين الشركات (B2B)، يعد فهم شروط الضمان أمرًا بالغ الأهمية لإدارة المخاطر، مما يضمن حماية الشركات من الأجزاء المعيبة ويمكنها التخطيط لعمليات الاستبدال المحتملة.

من خلال الإلمام بهذه الخصائص التقنية والشروط التجارية، يمكن للمشترين بين الشركات التعامل مع تعقيدات تكاليف إصلاح مشغلات السيارات بشكل أكثر فعالية، مما يضمن اتخاذ قرارات تتماشى مع احتياجاتهم التشغيلية وقيود ميزانيتهم.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع تكاليف إصلاح مشغلات السيارات

ما هي المحركات العالمية التي تؤثر على سوق تكلفة إصلاح مشغل السيارة؟

يشهد قطاع تكاليف إصلاح بادئ تشغيل السيارات تحولات كبيرة مدفوعة بالتطورات التكنولوجية وتطور تفضيلات المستهلكين. على الصعيد الدولي، هناك طلب متزايد على السيارات الكهربائية والهجينة، وهو ما يؤثر بدوره على أنظمة بدء التشغيل المستخدمة في هذه السيارات. ويكتسب هذا الاتجاه أهمية خاصة بالنسبة للمشترين من الشركات في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، حيث يتزايد اعتماد السيارات الكهربائية (EV). تتصدر دول مثل ألمانيا المشهد في مجال البنية التحتية للسيارات الكهربائية، بينما تكثف البرازيل وجنوب أفريقيا دعمها لتقنيات السيارات المستدامة.

بالإضافة إلى ذلك، يستلزم التعقيد المتزايد لإلكترونيات السيارات معرفة وأدوات متخصصة لإصلاح البادئات، مما يؤثر على تكاليف العمالة. يجب على المشترين من الشركات أيضًا مراعاة تقلب أسعار المواد الخام، مدفوعة باضطرابات سلسلة التوريد العالمية، والتي يمكن أن تؤثر على أسعار مكونات البادئ. يبرز الاتجاه نحو قطع الغيار المعاد تصنيعها كحل فعال من حيث التكلفة، مما يوفر للمشترين بديلاً عمليًا لبدايات التشغيل الجديدة، خاصة في الأسواق ذات الميزانية المحدودة.

ما هي الاتجاهات الحالية والناشئة في مجال تكنولوجيا B2B/التوريد بين الشركات؟

في قطاع تكاليف إصلاح مشغلات السيارات، يعمل التحول الرقمي على إعادة تشكيل كيفية حصول الشركات على المكونات والخدمات. ويستفيد المشترون بين الشركات بشكل متزايد من المنصات الإلكترونية للمشتريات عبر الإنترنت، مما يمكنهم من مقارنة الأسعار والجودة من مختلف الموردين بسهولة. وتكتسب حلول التجارة الإلكترونية المصممة خصيصًا لقطع غيار السيارات زخمًا متزايدًا، مما يؤدي إلى تبسيط عملية الشراء وتعزيز كفاءة سلسلة التوريد.

هناك اتجاه ملحوظ آخر يتمثل في دمج تحليلات البيانات في إدارة المخزون، مما يسمح للشركات بالتنبؤ بالطلب بشكل أكثر دقة وتقليل المخزون الزائد. ويُعد هذا النهج التحليلي مفيدًا بشكل خاص في المناطق التي تشهد تقلبات في ظروف السوق، مثل الشرق الأوسط وأمريكا الجنوبية. علاوة على ذلك، فإن ظهور تكنولوجيا سلسلة الكتل يعزز الشفافية في سلسلة التوريد، مما يضمن قدرة المشترين على تتبع منشأ المكونات والتحقق من صحتها.

كيف تؤثر الاستدامة والمصادر الأخلاقية على قطاع تكلفة إصلاح مشغلات السيارات؟

تُعد الاستدامة والتوريد الأخلاقي من الاعتبارات الحيوية بشكل متزايد للمشترين بين الشركات في قطاع السيارات. ويدفع التأثير البيئي لتصنيع المكونات الأولية للشركات إلى البحث عن موردين يلتزمون بالممارسات المستدامة. ولا يتماشى هذا التحول مع الأهداف البيئية العالمية فحسب، بل يتوافق أيضًا مع المستهلكين الذين يعطون الأولوية للمنتجات الصديقة للبيئة.

يتم تشجيع المشترين على البحث عن الموردين الذين يقدمون شهادات ‘خضراء’، مثل ISO 14001، والتي تشير إلى الامتثال لمعايير الإدارة البيئية. وبالإضافة إلى ذلك، أصبح استخدام المواد المعاد تدويرها في تصنيع المبتدئين أكثر انتشارًا، مما يوفر فرصة للشركات لتقليل بصمتها الكربونية مع احتمال خفض التكاليف.

من خلال إعطاء الأولوية لسلاسل التوريد الأخلاقية، يمكن للشركات التخفيف من المخاطر المرتبطة بممارسات العمل والانتهاكات البيئية. هذا التركيز على الاستدامة لا يعزز سمعة العلامة التجارية فحسب، بل يلبي أيضاً احتياجات شريحة متزايدة من المستهلكين الواعين بيئياً.

ما هو تطور قطاع تكلفة إصلاح مشغل السيارة؟

يعكس تطور قطاع تكاليف إصلاح بادئ تشغيل السيارات التغيرات الأوسع نطاقاً في صناعة السيارات. في البداية، كانت محركات بدء التشغيل عبارة عن أجهزة ميكانيكية بسيطة، لكن التطورات في التكنولوجيا أدت إلى أنظمة أكثر تعقيداً وكفاءة. وقد أدى إدخال المحركات المبتدئة عالية الأداء لسيارات السباق والسيارات الفاخرة، بالإضافة إلى التحول نحو السيارات الكهربائية، إلى تغيير مشهد السوق.

مع استمرار قطاع صناعة السيارات في الابتكار، يجب أن يتكيف قطاع إصلاح البادئات مع التقنيات الجديدة وتوقعات المستهلكين. ويمثل هذا التطور تحديات وفرصاً للمشترين من الشركات الذين يجب عليهم التعامل مع مشهد يتسم بالتغير السريع مع البحث عن حلول فعالة من حيث التكلفة لتلبية احتياجاتهم التشغيلية. من خلال البقاء على اطلاع على اتجاهات الصناعة والتطورات التكنولوجية، يمكن للشركات اتخاذ قرارات استراتيجية للتوريد تتماشى مع أهدافها طويلة الأجل.

الأسئلة المتداولة (FAQs) لمشتري B2B لتكلفة إصلاح بادئ تشغيل السيارة

-

كيف يمكنني تحديد تكلفة إصلاح مشغل السيارة لأسطول سياراتي؟

لتقدير تكلفة إصلاح بادئ تشغيل السيارة لأسطول سيارتك، ضع في اعتبارك عدة عوامل بما في ذلك نوع السيارة وطرازها ونوع البادئ (OEM مقابل ما بعد البيع) وأسعار العمالة المحلية. يُنصح بالحصول على عروض أسعار من عدة موردين أو ورش تصليح للحصول على رؤية شاملة للتكاليف المحتملة. بالإضافة إلى ذلك، قم بتقييم حالة البادئ الحالي وأي مكونات ذات صلة قد تحتاج إلى عناية، حيث يمكن أن يؤثر ذلك على نفقات الإصلاح الإجمالية. -

ما هو أفضل نهج لتوريد قطع الغيار على المستوى الدولي؟

عند توريد قطع الغيار على المستوى الدولي، أعط الأولوية للموردين الذين لديهم سجل حافل في منطقتك. قم بتقييم شهاداتهم ومراجعات العملاء وقدراتهم الإنتاجية. تأكد من أنهم يوفرون قطع الغيار الأصلية أو قطع ما بعد البيع عالية الجودة التي تلبي مواصفاتك. ضع اتصالات واضحة فيما يتعلق بالمهل الزمنية ولوجستيات الشحن واللوائح الجمركية لتقليل التأخير وضمان الامتثال للقوانين المحلية. -

كيف يمكنني التحقق من مورّدي قطع غيار السيارات؟

للتدقيق في موردي قطع غيار السيارات، قم بإجراء فحوصات شاملة على خلفية الموردين بما في ذلك تاريخ أعمالهم وقدراتهم الإنتاجية وعمليات ضمان الجودة. اطلب عيّنات لتقييم جودة منتجاتهم والتحقق من مطابقتها للمعايير الدولية. بالإضافة إلى ذلك، ضع في اعتبارك زيارة منشآتهم إن أمكن، أو الاستعانة بخدمات الفحص من طرف ثالث للتحقق من عملياتهم قبل تقديم طلبات كبيرة. -

ما هي شروط الدفع الشائعة لمعاملات B2B الدولية؟

يمكن أن تختلف شروط الدفع للمعاملات الدولية بين الشركات اختلافًا كبيرًا ولكنها عادةً ما تتضمن خيارات مثل خطابات الاعتماد أو الدفعات المسبقة أو الشروط الصافية (على سبيل المثال، صافي 30 أو صافي 60). من الضروري التفاوض على الشروط التي توفر الأمان لكلا الطرفين. تأكد من الوضوح بشأن أسعار صرف العملات ورسوم المعاملات وطرق الدفع لتجنب أي سوء فهم قد يؤثر على التدفق النقدي. -

ما الحد الأدنى لكميات الطلب (موك) التي يجب أن أتوقعها من الموردين؟

يمكن أن يختلف الحد الأدنى لكميات الطلبات (MOQ) لقطع غيار السيارات البادئة بناءً على قدرات المورد الإنتاجية ومستويات المخزون. وتتراوح الكميات الشائعة للطلب الموك من 50 إلى 500 وحدة، اعتمادًا على الطلب على القطعة وتكاليف التصنيع. عند التفاوض، عبّر عن احتياجاتك بوضوح واستفسر عن المرونة في موكس، خاصةً إذا كنت تختبر خط إنتاج جديد أو تدخل سوقاً جديدة. -

كيف يمكنني التأكد من ضمان الجودة في قطع غيار السيارات؟

يمكن ضمان ضمان الجودة من خلال الاختيار الدقيق للموردين ووضع معايير ومواصفات جودة واضحة. طلب وثائق مفصلة مثل شهادات الأيزو وإجراءات الاختبار ومعلومات الضمان. تنفيذ فحوصات جودة منتظمة أثناء الإنتاج وعند استلام البضائع لتحديد أي اختلافات في وقت مبكر. يمكن أن يؤدي بناء علاقة قوية مع مورديك إلى تسهيل التواصل بشكل أفضل فيما يتعلق بتوقعات الجودة. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في الحسبان عند الشحن الدولي لقطع الغيار المبتدئة؟

عند التخطيط للخدمات اللوجستية للشحن الدولي لقطع الغيار المبتدئة، ضع في اعتبارك عوامل مثل طرق الشحن واللوائح الجمركية والجداول الزمنية للتسليم. تعامل مع مزودي الخدمات اللوجستية ذوي الخبرة في التعامل مع قطع غيار السيارات للتغلب على التحديات المحتملة. تأكد من إعداد الوثائق المناسبة لتسريع عملية التخليص الجمركي وتقليل مخاطر التأخير. بالإضافة إلى ذلك، قم بتقييم خيارات تأمين الشحن للحماية من الفقد أو التلف أثناء النقل. -

هل يمكنني تخصيص أجزاء بادئ التشغيل لتلبية متطلبات محددة للسيارة؟

نعم، يقدم العديد من الموردين خيارات تخصيص لقطع التشغيل لتلبية متطلبات محددة للمركبة. وقد يشمل ذلك تعديلات لتناسب الطرازات المختلفة أو مواصفات الأداء. عند مناقشة التخصيص، قدم المواصفات الفنية التفصيلية وأبلغ عن أي احتياجات فريدة بوضوح. كن على دراية بأن الطلبات المخصصة قد تستغرق مهل زمنية أطول وربما تكون تكاليفها أعلى، لذا ضع ذلك في الحسبان عند التخطيط ووضع الميزانية.

قائمة المصنعين والموردين لأفضل 6 شركات تصنيع وموردي تكاليف إصلاح مشغل السيارة

1. استبدال البادئ - رؤى حول التكلفة

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: تختلف أسعار استبدال البادئ بشكل كبير؛ يقترح بعض المستخدمين شراء البادئ واستبداله بنفسك لتوفير التكاليف. يمكن أن تتراوح رسوم العمالة من $180 إلى $220 في الساعة، مع إضافة التشخيصات إلى الإجمالي. قد يكلف الجزء نفسه حوالي $220، مما يؤدي إلى مخاوف بشأن الترميز. يمكن أن تعتمد صعوبة استبدال بادئ التشغيل على طراز السيارة وموديلها.

2. فيسبوك - تكلفة استبدال البادئ

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: تكلفة نقل السيارة إلى الورشة واستبدال المُشغّل

3. الفرصة الأخيرة لإصلاح السيارات - دليل تكلفة استبدال البادئ

المجال: lastchanceautorepairs.com

تاريخ التسجيل: 2009 (16 عامًا)

مقدمة: تكلفة استبدال البادئ: البادئات الاقتصادية: $75 - $200، بادئات التشغيل الأصلية: $150 - $400، بادئات تشغيل عالية الأداء: $300 - $1000+. تكاليف العمالة: استبدال بادئ التشغيل الأساسي للمركبة: $100 - $250، التركيبات المعقدة: $300 - $600+. يتراوح متوسط التكلفة الإجمالية بين $250 - $1,000+. تشمل العوامل التي تؤثر على التكلفة نوع المركبة، والمبتدئين الجدد مقابل المبتدئين المعاد تصنيعهم، والإصلاحات الإضافية. تكاليف الاستبدال الذاتي: قطع الغيار ...

4. كارفاكس - تكلفة استبدال محرك بدء التشغيل

المجال: carfax.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: هذه الشركة، كارفاكس - تكلفة استبدال محرك بدء التشغيل، هي كيان بارز في السوق. للحصول على تفاصيل محددة عن المنتج، يوصى بزيارة موقعهم الإلكتروني مباشرة.

5. AAA - تكاليف استبدال بادئ تشغيل السيارة

المجال: aaa.com

تاريخ التسجيل: 1990 (35 عامًا)

مقدمة: يتراوح متوسط تكلفة استبدال بادئ تشغيل السيارة من $700 إلى $1200، اعتماداً على طراز السيارة وطرازها وساعات العمل المطلوبة. يتراوح سعر القائمة لجزء بدء التشغيل نفسه من أقل من $100 إلى أكثر من $400. وتتراوح أسعار العمالة ضمن شبكة AAA المعتمدة لإصلاح السيارات من $100 إلى $250 في الساعة. تشمل العوامل التي تؤثر على التكلفة طراز السيارة وموديلها، ونوع البادئ (نوع المحرك).

6. CarTalk - دليل استبدال بادئ التشغيل

المجال: cartalk.com

تاريخ التسجيل: 1995 (30 عامًا)

مقدمة: تكلفة استبدال بادئ التشغيل: من $600 إلى $900 للمركبات العادية؛ ومن $900 إلى 1T4T1400 للموديلات الفاخرة. تتضمن أعراض تعطّل بادئ التشغيل أصوات نقر، وضوضاء صرير، ووظائف متقطعة. غالباً ما لا يكون إصلاح البادئ غير فعال من حيث التكلفة؛ وعادة ما يوصى بالاستبدال. يتم إعادة تصنيع معظم بادئات التشغيل بدلاً من الجديدة. السيارات الحديثة المزودة بأنظمة إيقاف التشغيل مزودة بمشغلات مصممة...

استنتاجات وتوقعات المصادر الاستراتيجية لتكلفة إصلاح مشغل السيارة

في الختام، يعد فهم تعقيدات تكاليف إصلاح بادئ تشغيل السيارة أمرًا ضروريًا للمشترين الدوليين من الشركات بين الشركات، خاصةً أولئك الذين يعملون في أسواق متنوعة في جميع أنحاء إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. تشمل العوامل الأساسية التي تؤثر على هذه التكاليف نوع السيارة، وأسعار العمالة، والاختيار بين بادئات التشغيل الجديدة والمعاد تصنيعها. من خلال التوريد الاستراتيجي للمكونات عالية الجودة والخدمات الاحترافية، يمكن للشركات تحسين كفاءتها التشغيلية وتقليل مخاطر نفقات الإصلاح غير المتوقعة.

لا يضمن الاستثمار في الموردين الموثوق بهم توافر قطع الغيار عالية الجودة فحسب، بل يعزز أيضًا رضا العملاء من خلال الإصلاحات الفعالة في الوقت المناسب. مع استمرار تطور صناعة السيارات، فإن البقاء على اطلاع على اتجاهات السوق وهياكل التكلفة سيمكن الشركات من اتخاذ قرارات قائمة على البيانات تتماشى مع أهدافها المالية.

صورة توضيحية متعلقة بتكلفة إصلاح بادئ تشغيل السيارة

للمضي قدمًا، نشجع المشترين من الشركات على الاستفادة من الرؤى المكتسبة من هذا الدليل لتحسين استراتيجيات التوريد الخاصة بهم. فمن خلال إعطاء الأولوية للجودة والموثوقية، يمكن للشركات أن تحقق النجاح في بيئة تزداد فيها المنافسة. تواصل مع موردين موثوق بهم واستكشف حلولاً مبتكرة لتبسيط عملياتك وتحسين عروض الخدمات التي تقدمها.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.