Introduction: Navigating the Global Market for engine starter

In today’s competitive landscape, sourcing high-quality engine starters can pose significant challenges for international B2B buyers. Factors such as varying regional standards, diverse applications, and fluctuating costs necessitate a comprehensive understanding of the market. This guide aims to equip buyers from Africa, South America, the Middle East, and Europe—specifically countries like Saudi Arabia and Germany—with the insights needed to navigate the complexities of engine starter procurement.

Throughout this guide, we will explore the different types of engine starters available, their specific applications across various industries, and the critical factors to consider when vetting suppliers. We will also delve into cost analysis, helping you understand pricing structures and identify potential savings without compromising on quality. By providing a detailed overview of the engine starter market, this resource empowers you to make informed purchasing decisions that align with your operational needs.

Whether you are managing a fleet of vehicles or overseeing industrial machinery, understanding the intricacies of engine starter technology and supplier dynamics is crucial. This guide serves as a roadmap, enabling you to confidently source reliable engine starters that meet your performance and budgetary requirements, ultimately driving your business forward in an increasingly globalized market.

جدول المحتويات

- Top 4 Engine Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for engine starter

- Understanding engine starter Types and Variations

- Key Industrial Applications of engine starter

- 3 Common User Pain Points for ‘engine starter’ & Their Solutions

- Strategic Material Selection Guide for engine starter

- In-depth Look: Manufacturing Processes and Quality Assurance for engine starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘engine starter’

- Comprehensive Cost and Pricing Analysis for engine starter Sourcing

- Alternatives Analysis: Comparing engine starter With Other Solutions

- Essential Technical Properties and Trade Terminology for engine starter

- Navigating Market Dynamics and Sourcing Trends in the engine starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of engine starter

- Strategic Sourcing Conclusion and Outlook for engine starter

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding engine starter Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| محرك بدء تشغيل تقليدي | Uses a solenoid for engagement; high torque output. | السيارات والآلات الثقيلة | الإيجابيات: موثوق، متوفر على نطاق واسع. السلبيات: Can be heavy and less efficient. |

| محرك بدء التشغيل بتقليل التروس | Compact design; uses gears to increase torque. | Racing, Performance Vehicles | الإيجابيات: Lightweight, improved efficiency. السلبيات: تكلفة أولية أعلى. |

| محرك بدء مغناطيسي دائم | Utilizes permanent magnets for power; smaller size. | Electric Vehicles, Motorcycles | الإيجابيات: Compact, energy-efficient. السلبيات: Limited torque output compared to conventional types. |

| Bendix Starter Motor | Features a Bendix drive for automatic engagement. | السيارات، التطبيقات البحرية | الإيجابيات: Automatic disengagement, prevents damage. السلبيات: More complex, potential for failure in harsh environments. |

| Integrated Starter-Generator | Combines starter and generator functions; used in hybrids. | Mild Hybrids, Fuel-efficient Vehicles | الإيجابيات: Space-saving, enhances fuel efficiency. السلبيات: More expensive, specialized applications. |

ما هي الخصائص الرئيسية لمحركات التشغيل التقليدية؟

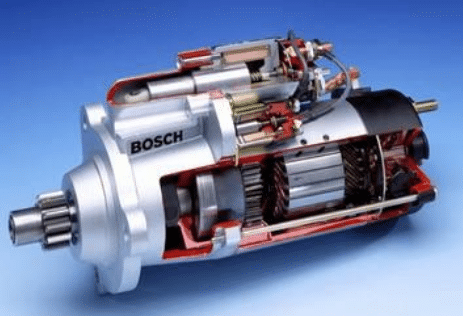

Conventional starter motors are the most common type used in vehicles, characterized by their reliance on a solenoid to engage the starter gear with the flywheel. This design allows for a high torque output necessary to crank the engine. They are suitable for a wide range of applications, particularly in the automotive and heavy machinery sectors. When purchasing, buyers should consider the availability of replacement parts and service, as well as the weight and efficiency of the motor, which may impact overall vehicle performance.

كيف تعمل محركات بدء التشغيل ذات التروس المخفضة على تحسين الأداء؟

Gear reduction starter motors incorporate a gear mechanism that increases torque while reducing the size of the motor itself. This makes them particularly popular in racing and performance vehicles, where every ounce of weight matters. Buyers should evaluate the balance between initial costs and the long-term benefits of improved efficiency and performance. The lightweight design also allows for easier installation in tight spaces, making them a versatile choice for performance applications.

What Benefits Do Permanent Magnet Starter Motors Offer?

Permanent magnet starter motors are distinguished by their use of permanent magnets instead of windings, resulting in a smaller and lighter design. These motors are increasingly found in electric vehicles and motorcycles, where space is at a premium. B2B buyers should consider the energy efficiency and compact size of these motors; however, they may have limitations in torque output compared to conventional starters. Applications demanding high torque may not find this type suitable.

Why Choose Bendix Starter Motors for Specific Applications?

Bendix starter motors are equipped with a Bendix drive mechanism, allowing for automatic engagement and disengagement of the starter gear from the flywheel. This feature minimizes wear and prevents damage to both the starter and engine, making it a reliable choice for automotive and marine applications. When purchasing, buyers should assess the complexity of the design and potential failure points, particularly in harsh operating environments.

What Are the Advantages of Integrated Starter-Generators?

Integrated starter-generators combine the functions of a starter and a generator, primarily used in mild hybrid vehicles to enhance fuel efficiency. This innovative design allows for a more compact engine compartment while providing the dual functionality of starting the engine and generating power. B2B buyers should weigh the higher initial costs against the long-term benefits of improved fuel efficiency and reduced emissions, especially in markets with stringent environmental regulations.

Key Industrial Applications of engine starter

| الصناعة/القطاع | Specific Application of engine starter | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | Starting internal combustion engines in vehicles | Ensures reliable engine ignition, enhancing production efficiency | Look for starters with high torque ratings and durability to withstand high-cycle use. |

| المعدات الثقيلة | Powering large machinery engines (e.g., excavators, bulldozers) | Provides dependable engine start-up, crucial for operational uptime | Evaluate starters with robust construction for harsh environments and high performance in extreme conditions. |

| بحري | Initiating engines in boats and ships | Guarantees quick engine start, essential for safety and compliance | Consider starters that are resistant to corrosion and designed for marine applications. |

| الزراعة | Starting engines in tractors and harvesters | Enhances productivity by ensuring machinery is ready for use | Focus on starters that can handle varying voltage levels and are easy to maintain. |

| الطاقة المتجددة | Starting engines in hybrid systems (e.g., wind turbines) | Supports integration of traditional and renewable energy sources | Source starters that are compatible with hybrid technology and offer energy efficiency. |

How Is the Engine Starter Used in Automotive Manufacturing?

In the automotive manufacturing sector, engine starters are crucial for initiating internal combustion engines in vehicles. They provide the necessary torque to turn the engine over, ensuring reliable ignition. This reliability is vital for maintaining production efficiency, as any delays in starting engines can lead to significant downtime and increased costs. International buyers should prioritize starters with high torque ratings and durability, especially when sourcing from regions with varying climates and operational conditions.

What Role Does the Engine Starter Play in Heavy Equipment?

Heavy equipment, such as excavators and bulldozers, relies on powerful engine starters to ensure that large machinery can start quickly and reliably. This is particularly important in construction and mining operations, where uptime is critical to project timelines and profitability. Buyers in this sector must evaluate starters for their robust construction, as they need to withstand harsh environments and high-performance demands. Ensuring compatibility with heavy-duty machinery specifications is essential for effective sourcing.

Why Are Engine Starters Important in Marine Applications?

In marine applications, engine starters are essential for initiating engines in boats and ships. A reliable starting system is crucial not only for operational efficiency but also for safety, as it enables quick engine start-up in emergency situations. Buyers should consider starters that are specifically designed for marine environments, focusing on corrosion resistance and reliability under challenging conditions. This is particularly relevant for international buyers operating in coastal or humid regions.

How Do Engine Starters Enhance Agricultural Productivity?

Agricultural machinery, including tractors and harvesters, requires dependable engine starters to ensure that equipment is ready for use at critical times during planting and harvesting seasons. A reliable starting system can significantly enhance productivity by reducing downtime. When sourcing starters for agricultural equipment, buyers should focus on models that can handle varying voltage levels and offer ease of maintenance, as these factors can influence long-term operational efficiency.

What Is the Significance of Engine Starters in Renewable Energy Systems?

In the renewable energy sector, particularly in hybrid systems like wind turbines, engine starters play a key role in initiating engines that complement renewable energy sources. This integration is essential for optimizing energy production and ensuring reliability. Buyers should seek starters that are compatible with hybrid technologies and designed for energy efficiency, as this can lead to improved performance and reduced operational costs. International buyers must also consider local regulations and standards when sourcing these components.

3 Common User Pain Points for ‘engine starter’ & Their Solutions

السيناريو 1: صعوبة تحديد مشاكل محرك بدء التشغيل

المشكلة: B2B buyers often encounter significant challenges in diagnosing starter motor problems, especially in large fleets or industrial applications. When a vehicle fails to start, it can lead to costly downtime and operational inefficiencies. Buyers may find it difficult to determine whether the issue lies with the starter motor, battery, or other electrical components. This uncertainty can result in unnecessary replacements or repairs, increasing operational costs.

الحل: To effectively diagnose starter motor issues, establish a systematic troubleshooting process. Start by checking the battery’s charge and ensuring all connections are clean and secure. Utilize diagnostic tools like multimeters to test voltage drop across the starter circuit. If the starter motor is suspected, remove it for testing at an auto parts store that offers testing services. This can confirm if the starter is faulty without incurring additional costs from unnecessary replacements. Furthermore, consider investing in comprehensive training for your maintenance team on starter motor diagnostics. This proactive approach minimizes downtime and ensures that the correct components are replaced, improving overall fleet reliability.

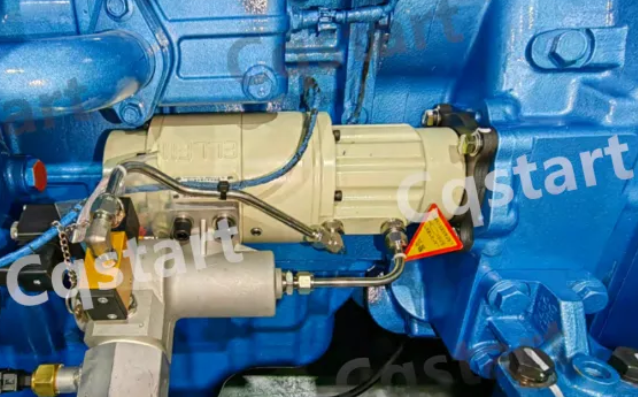

Illustrative image related to engine starter

Scenario 2: Sourcing Quality Starter Motors for Diverse Applications

المشكلة: International B2B buyers often face challenges in sourcing high-quality starter motors suitable for various applications, including commercial vehicles, agricultural machinery, or construction equipment. The vast range of specifications, brands, and types can lead to confusion. Poor quality or incompatible starter motors can cause operational failures, affecting project timelines and customer satisfaction.

الحل: Streamline your sourcing process by developing a clear set of specifications based on your equipment needs. Collaborate with reputable suppliers who offer a range of products, including OEM and aftermarket options. Make sure to assess suppliers on their quality assurance processes and after-sales support. Utilize platforms that provide detailed product information, including torque ratings and compatibility guides. Establish long-term relationships with manufacturers who can offer insights into the latest advancements in starter technology. This way, you can ensure that the starter motors you procure are not only reliable but also tailored to your operational requirements, enhancing performance and longevity.

Scenario 3: Managing Inventory and Replacement Cycles for Starter Motors

المشكلة: Efficient inventory management of starter motors is a significant pain point for B2B buyers, particularly those with extensive fleets or service centers. Over-ordering can lead to excessive holding costs, while under-ordering risks running out of essential components when needed. This balancing act is further complicated by fluctuating demand and varying lead times from suppliers.

Illustrative image related to engine starter

الحل: Implement a just-in-time (JIT) inventory management system to optimize your starter motor inventory. Analyze historical usage data to forecast demand accurately, enabling you to stock the right quantity of starter motors. Utilize inventory management software that integrates with your procurement system to track stock levels in real-time. Establish agreements with suppliers for expedited shipping or consignment stock arrangements to mitigate risks of stockouts. Regularly review and adjust your inventory policies based on market trends and seasonal demands. By adopting a proactive inventory strategy, you can significantly reduce costs associated with holding inventory while ensuring that you have the necessary starter motors available when required, thus maintaining operational efficiency.

Strategic Material Selection Guide for engine starter

What Are the Common Materials Used in Engine Starters?

When selecting materials for engine starters, several factors come into play, including performance, cost, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of engine starters: aluminum, steel, copper, and plastic composites.

How Does Aluminum Perform in Engine Starters?

Aluminum is a lightweight metal known for its excellent corrosion resistance and good thermal conductivity. In engine starters, aluminum is often used for housing and structural components.

الإيجابيات: Aluminum’s lightweight nature helps reduce the overall weight of the starter, improving fuel efficiency in vehicles. Its corrosion resistance ensures longevity, especially in humid or coastal environments.

السلبيات: While aluminum is durable, it is not as strong as steel and can be prone to deformation under high stress. Additionally, the cost of aluminum can be higher than that of some steel options.

التأثير على التطبيق: Aluminum is particularly suitable for applications where weight savings are crucial, such as in hybrid or electric vehicles. However, buyers must ensure that the aluminum used meets specific standards, such as ASTM B221 for extruded aluminum.

What Role Does Steel Play in Engine Starter Manufacturing?

Steel is a traditional choice for engine starters, particularly for components that require high strength and durability, such as the drive gear and casing.

الإيجابيات: Steel offers superior strength and resistance to wear and tear, making it ideal for high-torque applications. It is also relatively inexpensive compared to aluminum and other advanced materials.

السلبيات: The primary drawback of steel is its susceptibility to corrosion, which can lead to premature failure if not properly treated. Additionally, steel components can add significant weight to the starter.

التأثير على التطبيق: Steel is widely accepted in various markets, including Europe and the Middle East, where standards such as DIN EN 10025 apply. Buyers should consider corrosion-resistant coatings to enhance the longevity of steel components.

Illustrative image related to engine starter

Why Is Copper Important in Engine Starter Components?

Copper is primarily used in the electrical components of engine starters, including wiring and contacts, due to its excellent electrical conductivity.

الإيجابيات: Copper ensures efficient power transfer, which is critical for the high current demands of starter motors. Its thermal conductivity also aids in dissipating heat generated during operation.

السلبيات: The main limitation of copper is its cost, which can be significantly higher than alternatives like aluminum. Additionally, copper is prone to corrosion if not properly insulated.

التأثير على التطبيق: In regions with high humidity or salt exposure, such as coastal areas in South America or the Middle East, buyers should ensure that copper components are adequately treated to prevent corrosion. Compliance with standards like ASTM B170 for copper wire is essential.

Illustrative image related to engine starter

How Do Plastic Composites Enhance Engine Starters?

Plastic composites are increasingly being used in engine starters for non-structural components, such as housing and insulation.

الإيجابيات: These materials are lightweight, cost-effective, and can be molded into complex shapes, allowing for design flexibility. They also provide excellent electrical insulation and resistance to corrosion.

السلبيات: Plastic composites may not withstand high temperatures or mechanical stresses as well as metals, limiting their use in certain applications. They can also be less durable over time compared to metal counterparts.

التأثير على التطبيق: Buyers should consider the specific temperature and pressure ratings of plastic composites to ensure compatibility with engine environments. Compliance with international standards, such as ISO 9001 for quality management, is also critical.

Summary Table of Material Selection for Engine Starters

| المواد | Typical Use Case for engine starter | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | المكونات السكنية والهيكلية | خفيف الوزن ومقاوم للتآكل | أقل قوة من الفولاذ | متوسط |

| الصلب | Drive gear and casing | قوة ومتانة عالية | عرضة للتآكل | منخفض |

| النحاس | الأسلاك الكهربائية والتوصيلات الكهربائية | موصلية كهربائية ممتازة | High cost and corrosion-prone | عالية |

| المركبات البلاستيكية | المكونات غير الهيكلية | خفة الوزن ومرونة التصميم | Limited heat and stress resistance | متوسط |

This strategic material selection guide provides insights that can help international B2B buyers make informed decisions when sourcing engine starters, ensuring compliance with local standards and optimizing performance for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for engine starter

What Are the Main Stages in the Manufacturing Process of Engine Starters?

The manufacturing of engine starters involves several critical stages, each designed to ensure the reliability and performance of the final product. Understanding these stages is essential for B2B buyers looking to source high-quality starters for their automotive needs.

How Is Material Prepared for Engine Starters?

The first step in the manufacturing process is material preparation. This includes selecting high-grade metals such as copper for windings, steel for the housing, and various alloys for gears. The materials undergo rigorous quality checks to ensure they meet the required specifications. Suppliers often use materials that comply with international standards, including ISO 9001, to guarantee durability and performance.

What Techniques Are Used for Forming Engine Starters?

Once the materials are ready, the next phase is forming. Key techniques include:

-

الختم والتصنيع الآلي: These processes are used to create the housing and internal components. Stamping involves cutting shapes from metal sheets, while machining refines these shapes to precise dimensions.

-

اللف: For the electric motor, copper wires are wound around the armature. This step is critical as the winding affects the motor’s efficiency and torque output.

-

الصب: Some components may be cast from molten metal to achieve complex shapes that are difficult to machine.

Each of these forming techniques must adhere to strict tolerances to ensure compatibility between parts and optimal performance of the starter motor.

Illustrative image related to engine starter

How Are Engine Starters Assembled?

After forming, the components move to the assembly stage. This process generally includes:

-

تجميع المكونات: Individual parts like the solenoid, motor, and pinion gear are assembled. Automated assembly lines are often employed to enhance efficiency and precision.

-

الاختبار أثناء التجميع: As components are assembled, initial testing occurs to ensure that parts fit correctly and function as intended. This includes electrical testing to verify the connections and functionality of the solenoid and motor.

What Finishing Processes Are Applied to Engine Starters?

The final stage involves finishing processes that enhance the starter’s durability and appearance. Common finishing techniques include:

-

الطلاء: Components may be coated with protective materials to prevent corrosion and wear. This is particularly important in harsh environments.

-

الفحص النهائي: A comprehensive inspection is conducted to ensure that the assembled starter meets all performance and aesthetic standards before packaging.

How Is Quality Assurance Integrated Into the Manufacturing Process?

Quality assurance (QA) is a critical component of the manufacturing process for engine starters. It encompasses several aspects, from initial material selection to final product testing.

What International Standards Guide Quality Assurance for Engine Starters?

B2B buyers should be aware of the international quality standards that govern the manufacturing of engine starters. The ISO 9001 standard focuses on quality management systems, ensuring that manufacturers consistently produce products that meet customer and regulatory requirements.

Additionally, industry-specific certifications such as CE marking in Europe and API standards in the oil and gas sector may be relevant, especially for starters used in specialized applications. These certifications indicate compliance with safety and performance criteria.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في التصنيع؟

Quality control (QC) checkpoints are crucial in the manufacturing process to identify defects and ensure product integrity. These checkpoints typically include:

-

مراقبة الجودة الواردة (IQC): This is the first line of defense, where raw materials and components are inspected upon arrival at the manufacturing facility. Only materials that pass this inspection are used in production.

-

مراقبة الجودة أثناء الإنتاج (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor the quality of components as they are formed and assembled. This helps catch any issues early on, reducing waste and rework.

-

مراقبة الجودة النهائية (FQC): After assembly, each starter undergoes a final inspection and testing phase. This includes performance tests to ensure that the starter operates within specified parameters.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

For B2B buyers, verifying a supplier’s quality control practices is essential to ensure they receive reliable products. Here are several strategies to achieve this:

What Are Effective Methods for Auditing Suppliers?

-

تدقيق الموردين: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can include reviewing their ISO certifications, manufacturing facilities, and QC protocols.

-

طلب تقارير الجودة: Suppliers should be able to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC inspections. These reports can help buyers assess the reliability of the manufacturing process.

-

عمليات التفتيش من قبل أطراف ثالثة: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality control practices. This is particularly useful for international buyers who may not have the resources to conduct on-site audits.

ما هي الفروق الدقيقة التي يجب على المشترين الدوليين بين الشركات أخذها في الاعتبار فيما يتعلق بمراقبة الجودة؟

When sourcing engine starters from international suppliers, B2B buyers must consider several nuances related to quality control:

-

الاختلافات الثقافية والتنظيمية: Different regions may have varying standards and practices. Buyers should familiarize themselves with local regulations and ensure that suppliers comply with both international and local quality standards.

-

الخدمات اللوجستية وإدارة سلسلة التوريد: The complexity of international logistics can impact product quality. Buyers should work closely with suppliers to establish clear communication channels and ensure that quality is maintained throughout the supply chain.

-

دعم ما بعد البيع والضمان: A robust after-sales support system can be indicative of a supplier’s commitment to quality. Buyers should inquire about warranty policies and support services to ensure they are protected in case of defects.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for engine starters is crucial for B2B buyers. By focusing on key stages of manufacturing and quality control, buyers can make informed decisions that ensure they source reliable, high-quality products for their automotive needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘engine starter’

In the competitive landscape of engine starter procurement, making informed decisions is crucial for B2B buyers. This step-by-step checklist will guide you through the essential actions needed to source engine starters effectively, ensuring reliability, compatibility, and value for your investment.

الخطوة 1: تحديد المواصفات الفنية الخاصة بك

Identify the requirements specific to your application. Start by determining the type of vehicle or machinery the starter will be used in, including engine size, voltage, and power output (kW rating). Knowing these specifications helps narrow down options and ensures compatibility with existing systems.

- Voltage Compatibility: Ensure the starter matches the electrical system (e.g., 12V or 24V).

- Power Output Needs: Assess the required torque and performance to avoid underperformance or failure.

Step 2: Research Supplier Options

Compile a list of potential suppliers. Look for manufacturers and distributors specializing in automotive parts, particularly those with a strong reputation for quality and reliability. Online platforms, industry directories, and trade shows can be excellent resources for finding reputable suppliers.

Illustrative image related to engine starter

- Regional Focus: Consider suppliers with experience in your target market regions (Africa, South America, the Middle East, and Europe).

- نطاق المنتج: Ensure suppliers offer a variety of engine starters to meet diverse technical needs.

الخطوة 3: التحقق من شهادات الموردين

Assess the legitimacy and quality assurance of potential suppliers. Verify that suppliers hold relevant certifications, such as ISO 9001, which indicates a commitment to quality management. This step helps mitigate risks associated with substandard products.

- Quality Control Processes: Inquire about their manufacturing and quality assurance processes.

- Industry Compliance: Ensure compliance with local regulations and standards applicable to your region.

Step 4: Evaluate Potential Suppliers

Conduct thorough evaluations of shortlisted suppliers. Request company profiles, product samples, and references from previous clients in similar industries. This will help ascertain their reliability and customer service track record.

- Case Studies: Look for documented success stories that showcase their expertise.

- Client Feedback: Seek testimonials or reviews to gauge customer satisfaction.

Step 5: Request and Compare Quotes

Gather detailed quotes from your shortlisted suppliers. Ensure that each quote includes pricing, delivery timelines, warranty information, and terms of payment. This transparency will enable you to make an informed decision based on both cost and value.

Illustrative image related to engine starter

- Consider Total Cost of Ownership: Evaluate not just the initial cost but also potential maintenance and replacement expenses.

- التفاوض على الشروط: Be open to negotiating terms to secure the best deal for your organization.

Step 6: Test and Validate Product Performance

Before finalizing your order, test the engine starter. If possible, conduct performance tests to ensure that the starter meets your technical specifications and operational needs. This step is vital to avoid future operational disruptions.

- Field Testing: Install starters in actual operational settings to assess performance.

- حلقة التغذية الراجعة: Gather input from technicians or operators on usability and reliability.

Step 7: Establish a Long-term Relationship

Aim to build a strategic partnership with your chosen supplier. A reliable supplier can provide ongoing support, updates on new technologies, and insights into product improvements, which can be valuable for your operations.

- Communication Channels: Maintain open lines of communication for future needs and concerns.

- آلية التغذية الراجعة: Provide feedback on products and services to enhance the supplier’s offerings and your procurement process.

By following this comprehensive checklist, B2B buyers can navigate the complexities of sourcing engine starters, ensuring that they procure high-quality products that meet their specific operational requirements.

Comprehensive Cost and Pricing Analysis for engine starter Sourcing

What Are the Key Cost Components in Engine Starter Sourcing?

When sourcing engine starters, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

المواد: The raw materials used in the production of engine starters, such as steel, copper, and plastic components, significantly influence costs. The prices of these materials fluctuate based on global market trends, impacting overall pricing.

-

العمل: Labor costs encompass wages for workers involved in assembly, quality control, and packaging. Regions with lower labor costs may offer more competitive pricing, making geographical considerations important for international buyers.

-

تكاليف التصنيع العامة: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead, affecting the final price.

-

الأدوات: Investment in specialized tools and machinery for production can lead to higher initial costs. However, these costs may be amortized over time, especially for high-volume orders, making them less significant on a per-unit basis.

-

مراقبة الجودة (QC): Implementing rigorous QC processes ensures that the starters meet performance and safety standards. While this may increase upfront costs, it minimizes the risk of failures and returns, which can be more costly in the long run.

-

اللوجستيات: Transportation and warehousing costs are essential in the supply chain. International buyers should consider the implications of shipping methods, distances, and local logistics infrastructure on overall costs.

-

الهامش: Suppliers typically include a profit margin in their pricing, which can vary based on competition, brand reputation, and market demand.

How Do Price Influencers Affect Engine Starter Costs?

Several factors can influence the pricing of engine starters, particularly for B2B buyers:

-

الحجم/الحد الأدنى لكمية الطلب: Larger orders often result in lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

المواصفات والتخصيص: Custom-engineered starters or those with specific features (like higher torque ratings or specialized materials) can lead to increased costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

جودة المواد والشهادات: Higher quality materials and compliance with industry certifications (such as ISO standards) typically result in higher prices. However, investing in quality can yield long-term savings through improved reliability and reduced maintenance needs.

-

عوامل الموردين: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers with a track record of quality may command higher prices, while lesser-known suppliers might offer lower prices but come with increased risk.

-

مصطلحات التجارة الدولية: The terms of shipping (Incoterms) can significantly affect pricing. Buyers should understand who bears the cost of transportation, insurance, and duties to accurately calculate total expenses.

What Are Effective Buyer Tips for Negotiating Engine Starter Prices?

Navigating the complexities of engine starter sourcing requires strategic negotiation and a focus on cost-efficiency:

-

إجراء بحث شامل للسوق: Understanding the market landscape and competitor pricing can provide leverage during negotiations. This knowledge allows buyers to make informed offers and counteroffers.

-

تقييم التكلفة الإجمالية للملكية (TCO): When assessing pricing, consider not just the purchase price but also factors like installation, maintenance, and potential downtime costs. A lower upfront cost might not be the most economical choice in the long run.

-

الاستفادة من علاقات الموردين: Building strong relationships with suppliers can lead to better pricing, more favorable terms, and priority service. Regular communication and collaboration can enhance trust and lead to mutually beneficial agreements.

-

التفاوض على شروط الدفع: Flexible payment terms can enhance cash flow and reduce financial pressure. Consider negotiating extended payment terms or discounts for early payment to optimize financial management.

-

Be Aware of Pricing Nuances for International Buyers: Different regions may have unique pricing structures influenced by local economic conditions, tariffs, and trade agreements. Buyers from Africa, South America, the Middle East, and Europe should be mindful of these factors to ensure they secure the best deals.

إخلاء المسؤولية بشأن الأسعار الإرشادية

The prices for engine starters can vary widely based on the factors mentioned above. Buyers should seek multiple quotes and conduct due diligence to ascertain the most accurate pricing for their specific needs. Always consider the total cost of ownership when evaluating options to ensure a financially sound decision.

Alternatives Analysis: Comparing engine starter With Other Solutions

Understanding Alternatives to Engine Starters

In the realm of automotive and machinery applications, engine starters are crucial for initiating the operation of internal combustion engines. However, as technology evolves, alternative solutions have emerged that offer varying benefits and drawbacks. This analysis compares traditional engine starters with two alternatives: مولد بدء التشغيل المدمج (ISG) systems and Air Starter systems. Each solution has unique attributes that may appeal to different B2B buyers based on performance needs, cost constraints, and operational environments.

جدول المقارنة

| جانب المقارنة | Engine Starter | مولد بدء التشغيل المدمج (ISG) | Air Starter |

|---|---|---|---|

| الأداء | High torque for brief intervals | Smooth operation, higher efficiency | Instant engagement, high reliability |

| التكلفة | استثمار أولي معتدل | Higher upfront costs | Variable costs based on air supply |

| سهولة التنفيذ | إجراءات التثبيت القياسية | Requires modifications to engine | Complex installation, needs air supply infrastructure |

| الصيانة | Moderate; can fail over time | Low; fewer moving parts | High; air compressor maintenance needed |

| أفضل حالة استخدام | Conventional vehicles, machinery | Mild hybrids, electric vehicles | Heavy-duty applications, industrial settings |

In-depth Analysis of Alternatives

مولد بدء التشغيل المدمج (ISG)

The ISG combines the functions of an electric starter and an alternator into a single unit, making it an attractive option for modern vehicles, particularly mild hybrids. The primary advantage of ISG systems lies in their ability to enhance fuel efficiency and reduce emissions due to their regenerative capabilities. However, the initial investment is typically higher than traditional starters, and their installation may require significant modifications to existing engine designs. ISG systems are ideal for companies looking to modernize their fleets with eco-friendly solutions, but they may not be suitable for all existing vehicle platforms.

Air Starter

Air starters utilize compressed air to initiate engine operation, making them particularly effective in heavy-duty applications such as trucks, construction equipment, and marine vessels. The main advantage of air starters is their reliability in extreme conditions, as they do not rely on electrical components, which can fail in harsh environments. However, these systems require a constant supply of compressed air, leading to additional infrastructure and maintenance costs. Air starters are best suited for industries where durability and performance in challenging conditions are paramount, but the complexity of installation and ongoing air supply management may deter some buyers.

الخلاصة: كيفية اختيار الحل المناسب لاحتياجاتك

When selecting an engine starting solution, B2B buyers should consider their specific operational requirements, including performance expectations, budget constraints, and maintenance capabilities. For traditional applications, engine starters remain a reliable choice, while ISG systems provide a modern, efficient alternative for newer vehicle technologies. Conversely, air starters offer robustness for heavy-duty environments but come with higher complexity and maintenance needs. By thoroughly assessing these factors, buyers can make informed decisions that align with their operational goals and financial realities.

Illustrative image related to engine starter

Essential Technical Properties and Trade Terminology for engine starter

What Are the Key Technical Properties of Engine Starters?

When evaluating engine starters for procurement, understanding their technical properties is crucial for ensuring compatibility, reliability, and efficiency. Here are several critical specifications that buyers should consider:

1. Power Rating (kW)

The power rating of an engine starter, typically measured in kilowatts (kW), indicates its capability to generate torque to crank the engine. Common ratings range from 0.4 kW to over 1.2 kW. A higher power rating is essential for larger engines or those with higher compression ratios. For B2B buyers, selecting the appropriate power rating ensures that the starter can reliably start the engine, reducing the risk of failures and downtime.

2. عزم الدوران الناتج

Torque output is the measure of the rotational force the starter can exert. It is critical for overcoming engine inertia during cranking. Higher torque ratings are particularly important for diesel engines or performance vehicles. For decision-makers, understanding torque specifications helps in matching starters with specific engine requirements, thus avoiding underperformance or potential damage.

3. تركيب المواد

The materials used in the construction of the starter, such as copper for windings and durable alloys for housing, impact durability and efficiency. High-grade materials can withstand the thermal and mechanical stresses of repeated use. B2B buyers should prioritize starters made from high-quality materials to ensure longevity and reduce maintenance costs.

4. Compatibility with Vehicle Models

Engine starters are often designed for specific vehicle makes and models. OEM (Original Equipment Manufacturer) starters are tailored to fit exactly and function correctly within designated vehicles. Buyers must verify compatibility to avoid issues during installation and operation, ensuring seamless integration into existing systems.

5. المقاومة الكهربائية

Electrical resistance, measured in ohms, affects the efficiency and performance of the starter. Low resistance is preferred as it allows for better electrical flow and reduces energy loss. For B2B buyers, understanding resistance can help in selecting starters that minimize energy consumption and enhance vehicle efficiency.

What Are Common Trade Terms Related to Engine Starters?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions involving engine starters. Here are several key terms:

Illustrative image related to engine starter

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the manufacturer of the original vehicle. These parts are typically more reliable and compatible than aftermarket alternatives. For buyers, choosing OEM starters can ensure compliance with warranty requirements and maintain vehicle performance.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for buyers to plan their inventory and budget effectively. Suppliers may set MOQs to ensure profitability, so negotiating favorable terms can lead to cost savings for bulk orders.

3. طلب عرض أسعار (RFQ)

An RFQ is a document issued by a buyer to solicit price offers from suppliers for specific products or services. It is an essential part of the procurement process, allowing buyers to compare prices and terms. Properly crafted RFQs can lead to better deals and streamlined purchasing decisions.

Illustrative image related to engine starter

4. مصطلحات التجارة الدولية

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is crucial for international transactions, helping buyers understand their liabilities and ensuring smooth logistics.

5. قطع الغيار المعاد تصنيعها

Remanufactured parts are previously used components that have been restored to like-new condition. These can be a cost-effective alternative to new parts while maintaining quality standards. For buyers looking to optimize costs, considering remanufactured starters can provide significant savings without compromising performance.

Understanding these technical properties and trade terminology is essential for B2B buyers in the engine starter market. This knowledge can facilitate better purchasing decisions, enhance supplier negotiations, and ultimately contribute to operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the engine starter Sector

What Are the Key Market Drivers for Engine Starters in B2B Sourcing?

The engine starter sector is experiencing significant transformation, driven by several global trends. The rise of electric vehicles (EVs) is reshaping the market, with manufacturers focusing on high-efficiency starter motors that can seamlessly integrate with hybrid and fully electric systems. This shift is particularly relevant for B2B buyers in regions like Europe, where stringent emissions regulations are propelling the adoption of greener technologies. Additionally, the demand for high-performance components is increasing, leading to innovations in starter motor design and materials, enhancing durability and reducing weight.

Emerging markets in Africa and South America are also witnessing growth in the automotive sector, driven by rising disposable incomes and urbanization. B2B buyers from these regions should consider local supply chains that can offer competitive pricing and flexibility. Furthermore, advancements in digital technologies, such as IoT and AI, are influencing sourcing strategies, enabling buyers to optimize inventory management and predict maintenance needs through data analytics.

How Is Sustainability Reshaping Sourcing Trends for Engine Starters?

As environmental concerns gain prominence, sustainability is becoming a critical factor in sourcing decisions for engine starters. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to minimizing their environmental impact. This involves evaluating the lifecycle of starter motors, from raw material extraction to end-of-life disposal.

Ethical sourcing practices are essential, with businesses seeking suppliers who adhere to fair labor standards and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and materials that are recyclable or made from recycled content can enhance a supplier’s appeal. Companies that invest in sustainable practices not only contribute to environmental preservation but also align with the values of their customers, fostering brand loyalty and improving market positioning.

Illustrative image related to engine starter

What Is the Historical Context of Engine Starters Relevant to Today’s B2B Buyers?

The evolution of the engine starter can be traced back to its invention in 1911 by Charles Kettering, which revolutionized automotive technology by eliminating the need for hand cranking. This innovation laid the foundation for modern automotive systems and paved the way for advancements in starter design, including improvements in efficiency and reliability.

Over the decades, the introduction of components like solenoids and gear drives has enhanced the functionality of starter motors, making them essential for both traditional internal combustion engines and modern hybrid vehicles. Understanding this historical context can provide B2B buyers with insights into the reliability and performance characteristics of various starter models, guiding them in making informed sourcing decisions. As the market continues to evolve, recognizing the legacy of these components can help businesses appreciate the innovations driving the next generation of engine starters.

الخلاصة

The engine starter sector is poised for significant changes influenced by technological advancements, sustainability initiatives, and evolving market dynamics. B2B buyers, particularly those from emerging markets and regions with strict environmental regulations, must stay informed about these trends to make strategic sourcing decisions. By prioritizing sustainability and understanding the historical context of engine starters, businesses can navigate the complexities of this sector and secure reliable, efficient products that meet their operational needs.

Illustrative image related to engine starter

Frequently Asked Questions (FAQs) for B2B Buyers of engine starter

-

How do I solve starter motor failure in my fleet vehicles?

To address starter motor failure, first conduct a thorough diagnostic to identify if the issue lies with the starter itself, the battery, or wiring. Common causes include worn bearings, insulation breakdown, or faulty solenoid connections. If the starter is removed, most auto parts stores can perform a bench test to confirm its condition. Regular maintenance and inspections can help prevent unexpected failures, ensuring that your fleet remains operational and minimizing downtime. -

What is the best starter motor brand for heavy-duty applications?

For heavy-duty applications, brands like Bosch, ACDelco, and Powermaster Performance are widely recognized for their durability and reliability. These brands offer starters designed to withstand high torque requirements and harsh operating conditions often found in commercial vehicles. When selecting a starter, consider the specific power requirements and compatibility with your engine to ensure optimal performance and longevity. -

ما هي العوامل التي يجب أن آخذها في الاعتبار عند شراء محركات بدء التشغيل من الخارج؟

When sourcing starter motors internationally, consider factors such as the supplier’s reputation, quality certifications, and compliance with international standards. Evaluate the supplier’s ability to provide necessary documentation, including safety and performance testing results. Additionally, assess their manufacturing capabilities and lead times, as well as their experience in exporting to your region, to ensure a smooth procurement process. -

كيف يمكنني فحص الموردين لمحركات التشغيل بفعالية؟

Effective supplier vetting involves several steps: check for industry certifications like ISO 9001, review customer testimonials, and request samples of their products. Conduct background checks to assess their financial stability and operational history. Establish communication to gauge their responsiveness and willingness to address your specific needs. Participating in trade shows or industry expos can also provide insights into potential suppliers and facilitate direct engagement. -

ما هو الحد الأدنى المعتاد لكميات الطلبات (MOQs) لمحركات بدء التشغيل؟

Minimum order quantities for starter motors can vary significantly depending on the manufacturer and the type of starter. Generally, MOQs can range from 50 to 500 units. However, many suppliers may be flexible, especially for new business relationships or bulk orders. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms that align with your inventory management strategy. -

ما هي شروط الدفع التي يجب أن أتوقعها عند شراء محركات بدء التشغيل دولياً؟

Payment terms for international purchases often include options such as letter of credit, advance payment, or payment upon delivery. Common terms can range from 30 to 90 days after delivery, depending on the supplier’s policies and your negotiation. Ensure that payment terms are clearly defined in the contract to avoid any misunderstandings. Additionally, consider using secure payment methods to protect your financial interests. -

How can I ensure quality assurance (QA) when sourcing starter motors?

To ensure quality assurance when sourcing starter motors, establish clear specifications and standards that the product must meet. Request documentation of quality control processes from the supplier, including inspection reports and testing results. Consider setting up regular audits or inspections during the manufacturing process. Additionally, utilizing third-party inspection services can provide an unbiased assessment of product quality before shipment. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد محركات بدء التشغيل؟

Logistics considerations for importing starter motors include selecting a reliable freight forwarder experienced in handling automotive parts. Ensure that you understand the shipping regulations and customs duties applicable in your region. Prepare all necessary documentation, including commercial invoices and packing lists, to facilitate smooth customs clearance. Additionally, consider the shipping method that balances cost and delivery time, ensuring timely receipt of your orders.

Top 4 Engine Starter Manufacturers & Suppliers List

1. Diesel Products – Mechanical Spring Starters

المجال: dieselproducts.com

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: Mechanical Spring Starters are mechanical starters that utilize energy stored in a high-tech spring pack, manually wound for instant release to start an engine. They have been in use for over 30 years, with over 30,000 units in service worldwide. A Spring Starter is equivalent to a 5 hp electric starter and eliminates the need for batteries, alternators, regulators, and wiring, as it does not requ…

2. Haynes – Ignition System Insights

المجال: us.haynes.com

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: This company, Haynes – Ignition System Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reddit – Combustion Engine Insights

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: This company, Reddit – Combustion Engine Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. 1A Auto – Starters

المجال: 1aauto.com

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: Starters are small electric motors that engage with the engine’s flywheel to crank the engine and start the combustion cycle. There are different types of starters: inertia starters, pre-engaged starters, and gear reduction starters. Inertia starters engage the ring gear as the pinion threads out, while pre-engaged starters use a solenoid to push the pinion out before starting the motor. Gear redu…

Strategic Sourcing Conclusion and Outlook for engine starter

In conclusion, strategic sourcing of engine starters is essential for optimizing procurement processes and ensuring the reliability of automotive operations. By understanding the critical role that starter motors play in vehicle performance, international B2B buyers can make informed decisions about the quality and specifications of the components they source. Emphasizing partnerships with reputable manufacturers and suppliers is crucial, particularly in regions such as Africa, South America, the Middle East, and Europe, where market dynamics can vary significantly.

Investing in high-quality starter motors not only enhances vehicle performance but also reduces long-term maintenance costs and downtime. As the automotive industry increasingly moves towards advanced technologies, including hybrid systems, staying ahead of trends in starter motor design and functionality will be key for competitive advantage.

Looking forward, it is imperative for B2B buyers to engage in continuous dialogue with suppliers to anticipate future needs and innovations in engine starters. Now is the time to reassess your sourcing strategies, foster strong supplier relationships, and ensure that your procurement aligns with the evolving automotive landscape. Take proactive steps today to secure the best engine starters for your fleet and position your business for success in the global market.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.