مقدمة: الإبحار في السوق العالمية من أجل cual es el alternador del carro

في مشهد السيارات سريع التطور، يعد فهم تعقيدات مكونات السيارة أمرًا بالغ الأهمية لمشتري B2B، خاصةً عندما يتعلق الأمر بالحصول على مولدات كهربائية موثوقة للسيارات. يلعب المولد دورًا محوريًا في توليد الكهرباء، مما يضمن ليس فقط عمل المحرك بكفاءة ولكن أيضًا تشغيل الأنظمة الكهربائية المختلفة داخل السيارة بسلاسة. ومع ذلك، قد يكون الإبحار في تعقيدات السوق العالمية لمولدات التيار المتردد أمرًا شاقًا، خاصة بالنسبة للمشترين الدوليين من مناطق متنوعة مثل إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، بما في ذلك ألمانيا والمملكة العربية السعودية.

يتعمق هذا الدليل الشامل في الأنواع المختلفة لمولدات التيار المتردد وتطبيقاتها عبر طرازات السيارات المختلفة والاعتبارات الأساسية لفحص الموردين. ويتناول أيضًا عوامل حاسمة مثل تحليل التكلفة وتغطية الضمان وعلامات الأعطال الشائعة، مما يمكّن المشترين من اتخاذ قرارات شراء مستنيرة. يهدف هذا الدليل، من خلال تزويد المشترين الدوليين بين الشركات بالمعرفة اللازمة لتقييم الموردين والمنتجات بفعالية، إلى التخفيف من المخاطر المرتبطة بتوريد مولدات الكهرباء، مما يؤدي في النهاية إلى تعزيز الكفاءة التشغيلية وتقليل تكاليف الإصلاح غير المتوقعة. سواء كنت تسعى للحصول على مولدات كهربائية عالية الأداء للأساطيل التجارية أو قطع غيار لسيارات الركاب، فإن فهم هذه المكونات ضروري للحفاظ على نجاح أعمالك في قطاع السيارات.

جدول المحتويات

- قائمة المصنعين والموردين أعلى 3 Cual Es El Alternador Del Carro

- مقدمة: الإبحار في السوق العالمية من أجل cual es el alternador del carro

- فهم cual es el alternador del carro الأنواع والاختلافات

- التطبيقات الصناعية الرئيسية ل cual es el alternador del carro

- 3 نقاط ألم شائعة لدى المستخدمين ‘cual es el alternador del carro’ وحلولها

- دليل اختيار المواد الاستراتيجية ل cual es el alternador del carro

- نظرة متعمقة: عمليات التصنيع وضمان الجودة ل cual es el alternador del carro

- دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة ‘cual es el alternador del carro’

- تحليل شامل للتكاليف والتسعير لـ cual es el alternador del carro Sourcing

- تحليل البدائل: مقارنة cual es el alternador del carro مع الحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية ل cual es el alternador del carro

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع السيارات

- الأسئلة المتداولة (FAQs) لمشتري B2B من cual es el alternador del carro

- استنتاج وتوقعات التوريد الاستراتيجي ل cual es el alternador del carro

- إخلاء مسؤولية هام وشروط الاستخدام

فهم cual es el alternador del carro الأنواع والاختلافات

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولد التقليدي | تستخدم الحث الكهرومغناطيسي لتوليد الكهرباء. | المركبات القياسية، وإدارة الأسطول. | الإيجابيات: فعالة من حيث التكلفة ومتوفرة على نطاق واسع. السلبيات: كفاءة محدودة عند سرعات الخمول. |

| مولد كهربائي عالي الطاقة | مصممة لمتطلبات كهربائية أعلى، وغالباً ما تكون بمكونات مطورة. | المركبات عالية الأداء والآلات الثقيلة. | الإيجابيات: يدعم ملحقات كهربائية إضافية. السلبيات: تكلفة أولية أعلى، قد تتطلب تعديلات. |

| المولد الذكي | يتضمن تقنية متقدمة لتحسين الأداء وكفاءة الطاقة. | السيارات الكهربائية والهجينة، والسيارات الفاخرة. | الإيجابيات: كفاءة محسّنة في استهلاك الوقود، وعمر أطول للبطارية. السلبيات: أكثر تعقيداً، ويحتمل أن تكون تكاليف الإصلاح أعلى. |

| مولد كهربائي بدون فرش | تفتقر إلى الفرش، مما يقلل من التآكل ومتطلبات الصيانة. | التطبيقات الصناعية والأساطيل التجارية. | الإيجابيات: متانة أعلى، وصيانة أقل. السلبيات: استثمار مقدم أعلى. |

| المولد المتجدد | تلتقط الطاقة أثناء الكبح لإعادة شحن البطارية. | السيارات الكهربائية، وأنظمة النقل العام. | الإيجابيات: يعزز كفاءة الطاقة ويقلل من الانبعاثات. السلبيات: تكامل معقد، تكاليف إصلاح أعلى. |

ما هي خصائص المولدات التقليدية؟

المولدات التقليدية هي النوع الأكثر شيوعًا الموجود في المركبات القياسية، حيث تستخدم الحث الكهرومغناطيسي لتحويل الطاقة الميكانيكية إلى طاقة كهربائية. وعادةً ما تكون فعالة من حيث التكلفة وسهلة التوريد، مما يجعلها مثالية لإدارة الأساطيل والتطبيقات العامة للسيارات. ومع ذلك، قد تواجه صعوبة في توفير الطاقة الكافية عند سرعات التباطؤ، وهو ما يمكن أن يكون أحد الاعتبارات بالنسبة لمشتري B2B الذين يركزون على الكفاءة.

ما الذي يميز المولدات عالية الإنتاجية عن غيرها؟

تم تصميم المولدات عالية الإنتاجية لتلبية متطلبات المركبات المزودة بملحقات كهربائية إضافية، مثل أنظمة الصوت أو الإضاءة ما بعد البيع. غالبًا ما تتميز هذه المولدات بمكونات مطورة للتعامل مع الأحمال المتزايدة، مما يجعلها مناسبة للمركبات عالية الأداء والآلات الثقيلة. وعلى الرغم من أنها توفر خرج طاقة فائق، يجب أن يكون المشترون على دراية بالتكاليف الأولية الأعلى والحاجة المحتملة لإجراء تعديلات على النظام الكهربائي للسيارة.

كيف تعمل المولدات الذكية على تحسين أداء السيارة؟

تستخدم المولدات الذكية تقنية متطورة لمراقبة الإنتاج الكهربائي وتحسينه، وتحسين كفاءة استهلاك الوقود وإطالة عمر البطارية. وهي توجد عادةً في السيارات الكهربائية والهجينة، بالإضافة إلى السيارات الفاخرة. بالنسبة إلى مشتري B2B، يمكن أن يؤدي الاستثمار في المولدات الذكية إلى تحقيق وفورات على المدى الطويل بسبب انخفاض استهلاك الوقود؛ ومع ذلك، قد يؤدي تعقيد هذه الأنظمة إلى ارتفاع تكاليف الإصلاح في حال ظهور مشاكل.

لماذا نفكر في المولدات بدون فرش للتطبيقات الصناعية؟

تم تصميم المولدات بدون فرش بدون فرش، مما يقلل بشكل كبير من احتياجات التآكل والصيانة. وهذا يجعلها مفيدة بشكل خاص للتطبيقات الصناعية والأساطيل التجارية، حيث يمكن أن يكون وقت التعطل مكلفاً. في حين أنها تأتي عادةً باستثمارات مقدمة أعلى، إلا أن المتانة طويلة الأجل ومتطلبات الصيانة المنخفضة يمكن أن توفر وفورات كبيرة للشركات.

ما المزايا التي تقدمها المولدات المتجددة؟

تُعدّ المولدات المتجددة عنصراً أساسياً في السيارات الكهربائية وأنظمة النقل العام، حيث تقوم بالتقاط الطاقة أثناء الكبح لإعادة شحن البطارية. وتعزز هذه القدرة كفاءة الطاقة وتقلل من الانبعاثات، مما يتماشى مع التركيز المتزايد على الاستدامة في صناعة السيارات. ومع ذلك، يمكن أن يؤدي تعقيد دمج الأنظمة المتجددة إلى ارتفاع تكاليف الإصلاح، مما يجعل من الضروري للمشترين الموازنة بين هذه العوامل والفوائد المحتملة على المدى الطويل.

التطبيقات الصناعية الرئيسية ل cual es el alternador del carro

| الصناعة/القطاع | تطبيق محدد ل cual es el alternador del carro | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | إنتاج المركبات ومكونات السيارات | يضمن توليد طاقة موثوقة لوظائف السيارة | مراقبة الجودة، والامتثال للمعايير الدولية |

| إدارة الأسطول | صيانة أساطيل المركبات التجارية | تقليل وقت التوقف عن العمل وتكاليف الإصلاح من خلال الصيانة الاستباقية | موثوقية المورد، وشروط الضمان، ودعم الخدمة |

| الطاقة المتجددة | التكامل مع المركبات الهجينة والكهربائية | دعم مبادرات كفاءة الطاقة والاستدامة | التوافق مع الأنظمة الحالية والتطورات التكنولوجية والتقدم التكنولوجي |

| خدمات النقل والمواصلات | تشغيل الحافلات والمركبات اللوجستية | تعزيز الكفاءة التشغيلية وسلامة خدمات النقل | فعالية التكلفة وتوافر قطع الغيار |

| ورش تصليح السيارات | صيانة واستبدال مولدات التيار المتردد | تسهيل إرضاء العملاء من خلال الإصلاحات في الوقت المناسب | الوصول إلى قطع الغيار عالية الجودة، وتدريب الفنيين |

كيف يتم استخدام ‘cual es el alternador del carro’ في صناعة السيارات؟

في صناعة السيارات، يعتبر مولد التيار المتردد جزءًا لا يتجزأ من خطوط تجميع المركبات، حيث يوفر الطاقة الكهربائية اللازمة لتشغيل الأنظمة المختلفة أثناء الإنتاج. وهذا يضمن عمل جميع المكونات، بما في ذلك ميزات السلامة والأنظمة الإلكترونية، بشكل صحيح قبل اكتمال السيارة. بالنسبة للمشترين الدوليين، وخاصة من مناطق مثل أوروبا والشرق الأوسط، فإن الحصول على مولدات كهربائية عالية الجودة تلبي معايير الصناعة الصارمة أمر بالغ الأهمية. يمكن أن يؤثر الامتثال لشهادات الجودة الدولية بشكل كبير على كفاءة الإنتاج وسلامة السيارة.

ما الدور الذي يلعبه ‘cual es el alternador del carro’ في إدارة الأسطول؟

بالنسبة لإدارة الأسطول، يُعد مولد التيار المتردد أمرًا حيويًا للحفاظ على السلامة التشغيلية للمركبات التجارية. يضمن المولد الذي يعمل بشكل جيد استمرار تشغيل جميع الأنظمة الكهربائية، بما في ذلك أجهزة الملاحة والاتصالات، وبالتالي تقليل مخاطر الأعطال غير المتوقعة. وهذا الأمر مهم بشكل خاص للشركات العاملة في أفريقيا وأمريكا الجنوبية، حيث تُعد موثوقية السيارة ضرورية للخدمات اللوجستية. يجب على المشترين إعطاء الأولوية للموردين الذين يقدمون ضمانات وخدمات دعم قوية لضمان طول عمر الأسطول وتقليل تكاليف الصيانة.

كيف يدعم برنامج ‘cual es el alternador del carro’ مبادرات الطاقة المتجددة؟

في مجال الطاقة المتجددة، خاصةً مع ظهور السيارات الهجينة والكهربائية، تتطور وظيفة المولد. فهو ضروري لتحويل الطاقة الميكانيكية بكفاءة إلى طاقة كهربائية، وهو أمر ضروري لشحن البطاريات وتشغيل المحركات الكهربائية. يتماشى هذا التطبيق مع أهداف الاستدامة العالمية، مما يجذب الشركات التي تركز على الحد من بصمتها الكربونية. بالنسبة للمشترين الدوليين، يعد فهم التطورات التكنولوجية في تصميم المولدات وكفاءتها أمرًا أساسيًا لاتخاذ قرارات شراء مستنيرة.

ما هي أهمية ‘cual es el alternador del carro’ في خدمات النقل؟

في خدمات النقل، مثل الحافلات والمركبات اللوجستية، يلعب المولد دورًا حاسمًا في ضمان موثوقية الأنظمة الكهربائية التي تعزز السلامة والكفاءة. يمكن أن يؤدي تعطل مولد التيار المتردد إلى تأخيرات تشغيلية كبيرة، مما يؤثر على تقديم الخدمة. يجب أن يأخذ المشترون في هذا القطاع في الاعتبار التكلفة الإجمالية للملكية، بما في ذلك موثوقية المولدات وتوافر قطع الغيار، خاصة في المناطق التي تعاني من تحديات لوجستية في سلسلة التوريد.

ما مدى أهمية ‘cual es el alternador del carro’ لورش إصلاح السيارات؟

بالنسبة لورش إصلاح السيارات، يعتبر مولد التيار المتردد مكونًا شائعًا يتطلب الصيانة أو الاستبدال. يمكن أن يؤدي ضمان الحصول على مولدات عالية الجودة إلى زيادة رضا العملاء وتكرار العمل. يجب أن تركز محلات التصليح على التوريد من موردين ذوي سمعة طيبة يوفرون التدريب للفنيين على أحدث تقنيات وتقنيات إصلاح المولدات. يمكن أن يؤدي هذا التركيز على الجودة والخدمة إلى تمييز ورش الإصلاح في الأسواق التنافسية في جميع أنحاء أوروبا والشرق الأوسط.

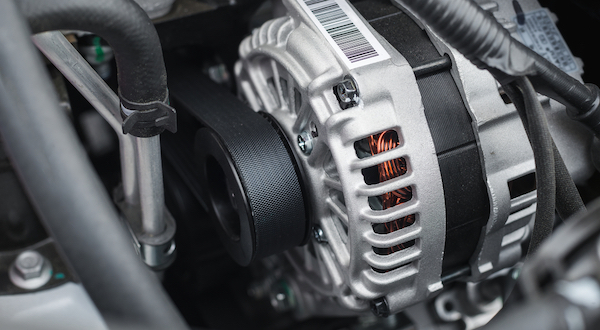

صورة توضيحية متعلقة ب cual es el alternador del carro

3 نقاط ألم شائعة لدى المستخدمين ‘cual es el alternador del carro’ وحلولها

السيناريو 1: فهم وظيفة المولد في مركبات الأسطول

المشكلة: غالبًا ما يواجه المشترون من الشركات الذين يديرون أساطيل المركبات تحديات في ضمان تشغيل جميع المركبات باستمرار. تنشأ مشكلة شائعة عندما يكون مديرو الأساطيل غير مدركين للدور الحاسم الذي تلعبه المولدات في وظائف المركبات. إذا تعطل أحد المولدات، فقد يؤدي ذلك إلى حدوث أعطال غير متوقعة، الأمر الذي لا يؤدي فقط إلى تعطيل العمليات بل يؤدي أيضًا إلى تكبد تكاليف إصلاح عالية وفقدان الإنتاجية. يجب أن يتأكد مديرو الأساطيل من أن المولدات تعمل بشكل صحيح لمنع هذه المشاكل، ولكن قد يؤدي نقص المعرفة حول صيانتها إلى حدوث سهو.

الحل: للتخفيف من حدة هذه المشكلة، يجب على مديري الأساطيل تنفيذ جدول صيانة روتيني يتضمن فحوصات منتظمة لمولدات التيار المتردد. يمكن أن يتضمن ذلك إجراء فحوصات بصرية واختبار الخرج الكهربائي للتأكد من مطابقته لمواصفات الشركة المصنعة. قد يكون من المفيد أيضاً الاستثمار في تدريب الميكانيكيين على كيفية تشخيص مشاكل المولدات في وقت مبكر. بالإضافة إلى ذلك، يضمن الحصول على مولدات عالية الجودة من موردين ذوي سمعة طيبة أن تكون البدائل متينة وموثوقة. يمكن أن يؤدي إنشاء علاقة مع موزع قطع غيار موثوق به إلى تبسيط عملية الشراء، مما يضمن توفر قطع الغيار بسهولة عند الحاجة. هذا النهج الاستباقي لا يعزز موثوقية الأسطول فحسب، بل يحسن أيضًا ميزانيات الصيانة من خلال منع الإصلاحات المكلفة.

السيناريو 2: تحديد علامات تعطل المولد في إصلاحات السيارات

المشكلة: غالبًا ما تواجه ورش تصليح السيارات صعوبات في تشخيص أعطال المولدات، مما قد يؤدي إلى التشخيص الخاطئ والإصلاحات غير الضرورية. قد يأتي العملاء بأعراض مثل تعتيم المصابيح الأمامية أو صعوبة في تشغيل السيارة، ولكن بدون فهم واضح لكيفية عمل المولدات، قد يقوم الفنيون باستبدال البطاريات أو المشغلات عن طريق الخطأ بدلاً من معالجة المشكلة الأساسية. قد يؤدي ذلك إلى عدم رضا العملاء وزيادة التكاليف التشغيلية لورش الإصلاح.

الحل: يجب أن تستثمر ورش التصليح في برامج تدريب الفنيين التي تركز بشكل خاص على الأنظمة الكهربائية، بما في ذلك مولد التيار المتردد. سيساعد تزويد الفنيين بأدوات التشخيص التي يمكنها اختبار خرج المولد وأدائه في استكشاف الأعطال وإصلاحها بدقة. يمكن للورش أيضًا تطوير قائمة مرجعية للمشاكل الشائعة المتعلقة بمولد التيار المتردد، بما في ذلك التحقق من وجود أضواء تحذيرية على لوحة العدادات أو أصوات غير عادية أو روائح احتراق. يمكن أن يؤدي تشجيع الفنيين على التواصل بشفافية مع العملاء بشأن التشخيصات إلى بناء الثقة وتعزيز رضا العملاء. بالإضافة إلى ذلك، فإن إقامة شراكات مع الشركات المصنعة لمولدات التيار المتردد للوصول المباشر إلى الدعم الفني يمكن أن يساعد الورش على البقاء على اطلاع دائم على أوضاع الأعطال الشائعة والحلول الشائعة، مما يؤدي في النهاية إلى تحسين جودة الخدمة.

السيناريو 3: إدارة التكاليف المرتبطة باستبدال المولد

المشكلة: غالبًا ما يعاني المشترون من الشركات بين الشركات، وخاصة أولئك الذين يعملون في مناطق ذات ظروف سوق متقلبة، من التكاليف المرتبطة باستبدال المولدات. يمكن أن تختلف الأسعار بشكل كبير بناءً على المورد والموقع وطراز السيارة، مما قد يؤدي إلى تجاوز الميزانية إذا لم تتم إدارتها بشكل صحيح. بالإضافة إلى ذلك، يمكن أن تؤدي الأعطال غير المتوقعة إلى تعطيل التدفق النقدي، خاصة بالنسبة للشركات الصغيرة التي قد لا يكون لديها احتياطي كبير للنفقات المفاجئة.

الحل: لإدارة التكاليف بشكل فعال، يجب على الشركات إجراء بحث شامل في السوق لتحديد الموردين الموثوق بهم الذين يقدمون أسعارًا تنافسية على المولدات. كما قد يؤدي إبرام عقود طويلة الأجل مع الموردين إلى الحصول على خصومات وضمان إمدادات ثابتة من قطع الغيار عند الحاجة. بالإضافة إلى ذلك، يمكن أن يساعد تنفيذ برنامج الصيانة الوقائية في تقليل احتمالية حدوث أعطال مفاجئة، وبالتالي توزيع تكاليف الإصلاح على مدار الوقت. يمكن للشركات أيضًا أن تفكر في الاستثمار في مولدات ما بعد البيع عالية الجودة التي تقدم أداءً مماثلاً لقطع غيار المعدات الأصلية بتكلفة مخفضة. من خلال التخطيط الاستراتيجي لعمليات استبدال وإصلاح المولدات وإصلاحها، يمكن للشركات تخصيص ميزانياتها بشكل أفضل وتقليل الأثر المالي للأعطال غير المتوقعة للمركبات.

دليل اختيار المواد الاستراتيجية ل cual es el alternador del carro

ما هي المواد المستخدمة بشكل شائع في مولدات الكهرباء للمركبات؟

عند اختيار المواد اللازمة لبناء المولدات الكهربائية، من الضروري مراعاة خصائص مثل التوصيل الكهربائي والمقاومة الحرارية ومقاومة التآكل. يركز التحليل التالي على أربع مواد شائعة مستخدمة في تصنيع المولدات الكهربائية: الألومنيوم والنحاس والصلب والمركبات البلاستيكية. كل مادة لها مزايا وعيوب مميزة يمكن أن تؤثر على الأداء والتكلفة والملاءمة لمختلف التطبيقات.

الألومنيوم: خفيف الوزن ومقاوم للتآكل

الخصائص الرئيسية: يشتهر الألومنيوم بطبيعته خفيفة الوزن ومقاومته الممتازة للتآكل. يمكن أن يتحمل درجات حرارة تصل إلى 600 درجة مئوية، مما يجعله مناسبًا للتطبيقات عالية الحرارة.

الإيجابيات والسلبيات: الميزة الأساسية للألومنيوم هي انخفاض وزنه، مما يساهم في تحسين كفاءة استهلاك الوقود في المركبات. ومع ذلك، فهو أغلى من الفولاذ وقد لا يوفر نفس القوة الهيكلية، مما يجعله أقل ملاءمة للتطبيقات عالية الإجهاد.

التأثير على التطبيق: إن مقاومة الألومنيوم للتآكل تجعله مثاليًا للبيئات ذات الرطوبة العالية أو التعرض للمياه المالحة، وهو أمر شائع في المناطق الساحلية.

اعتبارات للمشترين الدوليين: في أوروبا، يعد الامتثال لمعايير مثل DIN EN 573 أمرًا بالغ الأهمية عند الحصول على مكونات الألومنيوم. يجب على المشترين من الشرق الأوسط مراعاة أداء المواد في ظروف الحرارة الشديدة.

النحاس: توصيل كهربائي فائق

الخصائص الرئيسية: يتميز النحاس بأعلى توصيلية كهربائية بين المعادن، مما يجعله خياراً ممتازاً للمكونات الكهربائية. ويمكن أن يعمل بفعالية في درجات حرارة تصل إلى 200 درجة مئوية.

الإيجابيات والسلبيات: وتتمثل الميزة الرئيسية للنحاس في كفاءته في توصيل الكهرباء، مما يعزز الأداء العام للمولد. ومع ذلك، فإن النحاس أثقل وأكثر تكلفة من الألومنيوم، مما قد يزيد من تكاليف الإنتاج.

صورة توضيحية متعلقة ب cual es el alternador del carro

التأثير على التطبيق: تُعد الموصلية العالية للنحاس ضرورية للتطبيقات التي تتطلب نقلًا سريعًا للطاقة، كما هو الحال في المركبات عالية الأداء.

اعتبارات للمشترين الدوليين: إن الامتثال لمعايير ASTM B170 ضروري للمكونات النحاسية. وفي مناطق مثل أمريكا الجنوبية، حيث يتوفر النحاس بكثرة، قد يكون التوريد من مصادر أكثر فعالية من حيث التكلفة.

الفولاذ: القوة والمتانة

الخصائص الرئيسية: يشتهر الفولاذ بقوته ومتانته العالية في الشد، حيث يتحمل درجات حرارة تصل إلى 300 درجة مئوية دون حدوث تشوه كبير.

الإيجابيات والسلبيات: الميزة الأساسية للفولاذ هي قوته، مما يجعله مناسبًا للمكونات الهيكلية للمولد. ومع ذلك، فهو أثقل وزناً وأكثر عرضة للتآكل ما لم تتم معالجته، مما قد يزيد من تكاليف الصيانة.

التأثير على التطبيق: يُعد الفولاذ مثالياً للاستخدامات الشاقة حيث تكون المتانة أمرًا بالغ الأهمية، كما هو الحال في المركبات التجارية.

اعتبارات للمشترين الدوليين: يجب على المشترين في أفريقيا أن يكونوا على دراية بالحاجة إلى الطلاءات المقاومة للتآكل، خاصة في المناخات الرطبة. كما يمكن أن يؤثر الامتثال لمعايير ISO 9001 لإدارة الجودة على قرارات التوريد.

المركبات البلاستيكية: خفيفة الوزن وفعالة من حيث التكلفة

الخصائص الرئيسية: المركبات البلاستيكية خفيفة الوزن ويمكنها تحمل درجات حرارة معتدلة تصل عادةً إلى 120 درجة مئوية. وهي توفر مقاومة جيدة للتآكل والتآكل.

الإيجابيات والسلبيات: الميزة الرئيسية لمركبات البلاستيك هي فعاليتها من حيث التكلفة وسهولة تصنيعها. ومع ذلك، قد لا تكون مناسبة للتطبيقات عالية الإجهاد بسبب انخفاض قوتها الميكانيكية مقارنة بالمعادن.

التأثير على التطبيق: غالبًا ما تستخدم المركبات البلاستيكية للمكونات غير الحاملة، مثل العلب أو العوازل في المولدات.

اعتبارات للمشترين الدوليين: يعد الامتثال للوائح REACH في أوروبا أمرًا بالغ الأهمية لتوريد المواد البلاستيكية. يجب على المشترين من الشرق الأوسط مراعاة أداء المواد في البيئات ذات درجات الحرارة العالية.

جدول ملخص لاختيار المواد للمولدات الكهربائية

| المواد | حالة الاستخدام النموذجية ل cual es el alternador del carro | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | المكونات السكنية والهيكلية | خفيف الوزن ومقاوم للتآكل | تكلفة أعلى وقوام أقل | متوسط |

| النحاس | الملفات الكهربائية والموصلات | موصلية كهربائية فائقة | ثقيلة وباهظة الثمن | عالية |

| الصلب | المكونات الهيكلية في مركبات الخدمة الشاقة | قوة ومتانة عالية | أثقل وزناً وعرضة للتآكل | متوسط |

| المركبات البلاستيكية | المكونات غير الحاملة مثل العلب مثل العلب | فعالة من حيث التكلفة وخفيفة الوزن | قوة ميكانيكية أقل | منخفض |

يوفر دليل اختيار المواد هذا رؤى قيّمة للمشترين الدوليين في مجال الأعمال بين الشركات، مما يساعدهم على اتخاذ قرارات مستنيرة بناءً على الأداء والتكلفة والامتثال للمعايير المحلية.

نظرة متعمقة: عمليات التصنيع وضمان الجودة ل cual es el alternador del carro

ما هي المراحل الرئيسية لتصنيع مولد السيارات؟

تنطوي عملية تصنيع مولد التيار المتردد للسيارات على عدة مراحل رئيسية، كل مرحلة منها حاسمة لضمان تلبية المنتج النهائي لمعايير الأداء وتوقعات العملاء. يمكن أن يساعد فهم هذه المراحل مشتري B2B على اتخاذ قرارات مستنيرة عند الحصول على مولدات التيار المتردد.

1. تحضير المواد

تتضمن المرحلة الأولى من تصنيع المولد اختيار المواد وإعدادها بعناية. وتُستخدم المعادن عالية الجودة مثل الألومنيوم والنحاس بشكل شائع لخصائصها الموصلة وخصائصها خفيفة الوزن. ويخضع المصنعون عادةً لعملية تقييم صارمة للموردين لضمان استيفاء المواد لمعايير جودة محددة.

وبمجرد اختيارها، يتم قطع المواد وتشكيلها في المكونات الضرورية، مثل الدوار والجزء الثابت والمبيت. وغالباً ما تتضمن هذه العملية تقنيات تصنيع متقدمة، بما في ذلك التصنيع باستخدام الحاسب الآلي (التحكم العددي الحاسوبي)، لتحقيق أبعاد وتفاوتات دقيقة.

2. تقنيات التشكيل في إنتاج المولدات الكهربائية

تعتبر تقنيات التشكيل حاسمة في تشكيل مكونات المولد. ويمكن أن يشمل ذلك عمليات مثل الصب بالقالب للمبيت والختم للوصلات الكهربائية. تسمح عملية الصب بالقالب بإنتاج أشكال معقدة ذات تشطيبات سطحية ممتازة، وهي ضرورية لأداء المولد.

وبالإضافة إلى طرق التشكيل التقليدية، قد يستخدم المصنعون تقنيات مثل القولبة بالحقن للمكونات البلاستيكية أو التشكيل للأجزاء المعدنية، اعتمادًا على متطلبات التصميم ومواصفات الأداء.

3. تجميع مكونات المولد

بمجرد تشكيل المكونات الفردية، تبدأ عملية التجميع. ويتم تنفيذ هذه المرحلة غالباً في بيئة غرفة نظيفة لمنع التلوث. يتم تجميع المكونات الرئيسية، مثل الدوار والجزء الثابت، باستخدام تقنيات محاذاة دقيقة لضمان الأداء الأمثل.

وتؤدي الأتمتة دورًا مهمًا في هذه المرحلة، حيث تساعد الأذرع الآلية وخطوط التجميع الآلية على تبسيط العملية. ولا يؤدي ذلك إلى تعزيز الكفاءة فحسب، بل يضمن أيضًا اتساق الجودة عبر الدفعات.

4. عمليات التشطيب لتحسين الجودة

تتضمن عملية التشطيب عدة خطوات مصممة لتعزيز متانة وأداء المولد. يتم تطبيق المعالجات السطحية، مثل الطلاء بأكسيد الألومنيوم أو الطلاء بالمسحوق، للحماية من التآكل والتآكل. وتساهم هذه المعالجات أيضًا في المظهر الجمالي للمولد.

بالإضافة إلى ذلك، يقوم المصنعون بإجراء العديد من فحوصات الجودة أثناء مرحلة التشطيب، بما في ذلك عمليات فحص الأبعاد وتقييم جودة السطح، لضمان استيفاء المولدات للمواصفات المطلوبة.

ما هي ممارسات ضمان الجودة الشائعة في تصنيع المولدات؟

يعد ضمان الجودة (QA) عنصرًا حاسمًا في عملية تصنيع مولدات السيارات، مما يضمن أن المنتجات التي يتم تسليمها إلى المشترين من الشركات موثوقة وتفي بالمعايير الدولية.

1. المعايير الدولية لمراقبة الجودة

غالبًا ما تلتزم الشركات المصنعة لمولدات السيارات بمعايير الجودة الدولية مثل ISO 9001، والتي توفر إطارًا لأنظمة إدارة الجودة. يشير الامتثال لهذا المعيار إلى أن الشركة المصنعة قد أنشأت عمليات لضمان جودة المنتج ورضا العملاء.

بالإضافة إلى معايير الأيزو، يمكن أن تكون الشهادات الخاصة بالصناعة مثل شهادة المطابقة الأوروبية (CE) للمنتجات التي تباع في أوروبا أو شهادات معهد البترول الأمريكي (API) لتطبيقات محددة للسيارات مؤشرات مهمة للجودة.

2. نقاط التحقق الرئيسية لمراقبة الجودة في عملية الإنتاج

يتم دمج نقاط التحقق من مراقبة الجودة في جميع مراحل عملية التصنيع لاكتشاف العيوب مبكرًا وضمان الحصول على مخرجات عالية الجودة. تشمل نقاط الفحص الشائعة ما يلي:

- مراقبة الجودة الواردة (IQC): يتضمن ذلك فحص المواد الخام عند وصولها للتأكد من استيفائها للمعايير المحددة قبل بدء الإنتاج.

- مراقبة الجودة أثناء الإنتاج (IPQC): أثناء عملية التصنيع، يتم اختبار عينات عشوائية في مراحل مختلفة لمراقبة الجودة وتحديد أي انحرافات عن المواصفات.

- مراقبة الجودة النهائية (FQC): بعد التجميع، يخضع كل مولد بعد التجميع لاختبارات صارمة للتأكد من استيفائه لمعايير الأداء، بما في ذلك الإخراج الكهربائي والسلامة الميكانيكية.

3. طرق الاختبار الشائعة للمولدات الكهربائية

يمكن أن تتنوع طرق اختبار مولدات السيارات، ولكن يتم استخدام العديد من التقنيات الشائعة لضمان الأداء الوظيفي والمتانة:

صورة توضيحية متعلقة ب cual es el alternador del carro

- الاختبارات الكهربائية: ويشمل ذلك قياس خرج الجهد وتدفق التيار والكفاءة في ظل ظروف تحميل مختلفة.

- الاختبار الميكانيكي: تساعد الاختبارات مثل تحليل الاهتزازات والدورة الحرارية في تقييم متانة المكونات في ظل ظروف العالم الحقيقي.

- اختبار البيئة: قد تخضع المولدات أيضًا للتعرض لدرجات حرارة ومستويات رطوبة قصوى لضمان قدرتها على العمل بشكل موثوق في مناخات متنوعة.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

عند الحصول على مولدات الكهرباء، يجب على المشترين بين الشركات التأكد من أن مورديهم يحافظون على معايير عالية الجودة. فيما يلي بعض الخطوات القابلة للتنفيذ للتحقق من عمليات مراقبة الجودة لدى المورد:

1. إجراء عمليات تدقيق الموردين

يمكن أن يوفر إجراء عمليات التدقيق في الموقع رؤى قيّمة حول عمليات التصنيع وممارسات ضمان الجودة لدى المورّد. وخلال عملية التدقيق، يجب على المشترين تقييم مدى امتثال المورد للمعايير الدولية، ومراجعة أنظمة إدارة الجودة الخاصة به، ومراقبة ممارسات التصنيع بشكل مباشر.

2. طلب تقارير ضمان الجودة

يجب أن يكون الموردون على استعداد لتقديم تقارير ضمان الجودة التفصيلية التي توضح منهجيات الاختبار والنتائج والالتزام بالمعايير ذات الصلة. يمكن أن تساعد هذه التقارير المشترين على فهم جودة المولدات التي يدرسونها.

3. استخدام خدمات التفتيش من طرف ثالث

يمكن أن يضيف إشراك خدمات الفحص من طرف ثالث طبقة إضافية من الضمان. يمكن لهذه الكيانات المستقلة إجراء فحوصات الجودة في مراحل مختلفة من عملية التصنيع، مما يوفر تقييمات غير متحيزة لجودة المولدات.

ما هي الفروق الدقيقة في مراقبة الجودة للمشترين الدوليين بين الشركات؟

يجب أن يكون المشترون الدوليون بين الشركات، ولا سيما من مناطق متنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، على دراية بالعديد من الفروق الدقيقة المتعلقة بمراقبة الجودة:

- الامتثال التنظيمي: قد يكون لدى المناطق المختلفة لوائح مختلفة فيما يتعلق بمكونات السيارات. يجب على المشترين التأكد من امتثال الموردين للوائح والمعايير المحلية، مثل تلك التي وضعها الاتحاد الأوروبي أو الاتحادات الإقليمية للسيارات.

- الاختلافات الثقافية في توقعات الجودة: قد يكون فهم السياق الثقافي لتوقعات الجودة أمراً بالغ الأهمية. على سبيل المثال، قد تعطي بعض المناطق الأولوية للسعر على الجودة، بينما قد يكون لدى مناطق أخرى متطلبات جودة صارمة.

- الاعتبارات اللوجستية: يمكن أن يؤثر الشحن والمناولة على جودة المنتج. يجب على المشترين مناقشة طرق التغليف والنقل مع الموردين لضمان وصول المولدات الكهربائية في أفضل حالة.

من خلال فهم عمليات التصنيع وممارسات ضمان الجودة الخاصة بمولدات السيارات، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة وإقامة شراكات قوية مع موردين موثوقين.

دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة ‘cual es el alternador del carro’

لمساعدة المشترين بين الشركات في شراء مولدات التيار المتردد للمركبات، يوفر هذا الدليل قائمة مراجعة منظمة مصممة لتبسيط عملية التوريد. يعد فهم الجوانب الهامة لمولدات التيار المتردد والموردين أمرًا ضروريًا لاتخاذ قرارات شراء مستنيرة.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

يعد وضع مواصفات فنية واضحة أمرًا أساسيًا عند تحديد مصادر مولدات الطاقة المتغيرة. ويشمل ذلك فهم طراز السيارة وطرازها، ومتطلبات خرج الطاقة، والتوافق مع الأنظمة الحالية. تساعد المواصفات الدقيقة في تصفية الموردين الذين يمكنهم تلبية احتياجاتك الدقيقة.

صورة توضيحية متعلقة ب cual es el alternador del carro

- الاعتبارات الرئيسية:

- معدلات الجهد والتيار الكهربائي.

- الأبعاد المادية وتكوينات التركيب.

الخطوة 2: البحث في اتجاهات السوق والتسعير

إن فهم اتجاهات السوق الحالية وأسعار المولدات الكهربائية سيزودك بالمعرفة اللازمة لاتخاذ قرارات شراء تنافسية. تحليل التقلبات في الأسعار بناءً على متغيرات سلسلة التوريد والطلب الإقليمي والتقدم التكنولوجي في تصنيع المولدات الكهربائية.

- بنود العمل:

- مراجعة تقارير وتوقعات الصناعة.

- قارن الأسعار بين عدة موردين لقياس متوسط التكاليف.

الخطوة 3: تحديد الموردين المحتملين وتقييمهم

فحص الموردين المحتملين بدقة للتأكد من قدرتهم على تقديم منتجات عالية الجودة. ابحث عن الموردين المعروفين الذين لديهم سجل حافل في قطاع قطع غيار السيارات. اطلب ملفات تعريف الشركة وكتالوجات المنتجات والمراجع من عملاء آخرين.

- معايير تقييم الموردين:

- سنوات في العمل والسمعة في هذا المجال.

- سرعة الاستجابة لخدمة العملاء وقدرات الدعم.

الخطوة 4: التحقق من الشهادات ومعايير الجودة

تأكد من حصول الموردين على الشهادات ذات الصلة، مثل ISO أو ما يعادلها، والتي تشير إلى الالتزام بمعايير إدارة الجودة. شهادات الجودة ضرورية لضمان استيفاء المولدات لمعايير السلامة والأداء.

- شهادات مهمة:

- ISO 9001 لإدارة الجودة.

- معايير محددة لصناعة السيارات (مثل IATF 16949).

الخطوة 5: طلب عينات للاختبار

قبل إجراء عملية شراء كبيرة، اطلب عينات من المولدات لاختبارها. تتيح لك هذه الخطوة تقييم أداء المنتج ومتانته وتوافقه مع مركباتك. يساعد اختبار العينات أيضًا في تحديد أي مشاكل محتملة في وقت مبكر من عملية الشراء.

- مجالات تركيز الاختبار:

- الخرج الكهربائي في ظروف الأحمال المختلفة.

- مستويات الضوضاء وسلاسة التشغيل.

الخطوة 6: التفاوض على الشروط والأحكام

بمجرد تحديد المورد المناسب، ادخل في مفاوضات بشأن الأسعار وشروط الدفع وجداول التسليم. يمكن أن يؤدي التفاوض الواضح إلى أسعار أفضل وشروط مواتية، وهو أمر بالغ الأهمية للحفاظ على قيود الميزانية.

- نقاط التفاوض الرئيسية:

- خصومات الشراء بالجملة.

- سياسات الضمان والإرجاع.

الخطوة 7: إقامة شراكة طويلة الأمد

يمكن أن يؤدي بناء علاقة طويلة الأجل مع المورد الذي اخترته إلى تحقيق فوائد مثل أولوية الخدمة، وأسعار أفضل للطلبات المستقبلية، ورؤى حول تطورات المنتجات الجديدة. ومن شأن التواصل المنتظم والتغذية الراجعة أن يعزز التعاون.

- استراتيجيات الشراكة:

- جدولة اجتماعات منتظمة لمناقشة الأداء والتوقعات.

- مشاركة توقعات الاحتياجات المستقبلية لمساعدة الموردين على التخطيط وفقًا لذلك.

من خلال اتباع قائمة المراجعة المنظمة هذه، يمكن للمشترين بين الشركات التعامل مع تعقيدات توريد مولدات الكهرباء بفعالية، مما يضمن اختيار المنتجات والموردين المناسبين لاحتياجاتهم الخاصة.

تحليل شامل للتكاليف والتسعير لـ cual es el alternador del carro Sourcing

ما هي مكونات التكلفة الرئيسية في توريد مولدات السيارات؟

عند التزود بمولدات السيارات، يجب على المشترين الدوليين بين الشركات النظر في مكونات التكلفة المختلفة التي تساهم في هيكل التسعير الكلي. وتشمل التكاليف الأساسية المواد، والعمالة، ونفقات التصنيع العامة، والأدوات، ومراقبة الجودة، والخدمات اللوجستية، وهوامش الربح.

صورة توضيحية متعلقة ب cual es el alternador del carro

-

المواد: تؤثر المواد المستخدمة في تصنيع المولدات، مثل النحاس للملفات والصلب للإطار والألومنيوم للمبيت تأثيرًا كبيرًا على الأسعار. ويمكن أن يؤدي تذبذب أسعار هذه المواد الخام إلى تفاوت في التكلفة.

-

العمل: تختلف تكاليف العمالة حسب المنطقة التي يتم فيها إنتاج المولدات الكهربائية. وقد تقدم البلدان ذات تكاليف العمالة المنخفضة أسعاراً تنافسية، ولكن ينبغي موازنة ذلك مع جودة ومهارات القوى العاملة.

-

تكاليف التصنيع العامة: يشمل ذلك النفقات المتعلقة بتشغيل المصنع، بما في ذلك المرافق وصيانة المعدات والتكاليف الإدارية. ويمكن أن يؤدي ارتفاع التكاليف العامة إلى ارتفاع الأسعار، لا سيما في المناطق ذات اللوائح الصارمة المتعلقة بالعمالة والبيئة.

-

الأدوات: يمكن أن تكون الأدوات المخصصة لتصميمات محددة لمولدات المولدات استثمارًا أوليًا كبيرًا. يجب على المشترين الاستفسار عن تكاليف الأدوات إذا كانوا يحتاجون إلى تصميمات مخصصة أو مواصفات محددة.

-

مراقبة الجودة (QC): إن ضمان استيفاء المولدات لمعايير الجودة أمر بالغ الأهمية. قد تؤدي عمليات مراقبة الجودة المحسّنة إلى زيادة التكاليف ولكنها يمكن أن تقلل من المرتجعات ومطالبات الضمان، مما يعود بالنفع على المشترين على المدى الطويل.

-

اللوجستيات: ينبغي أن تؤخذ تكاليف الشحن، بما في ذلك الشحن والتأمين، في الحسبان، لا سيما بالنسبة للمعاملات الدولية. ويمكن أن يؤثر اختيار شروط التجارة الدولية على من يتحمل هذه التكاليف ومتى يتم تكبدها.

-

الهامش: يضيف الموردون عادةً هامش ربح لتغطية تكاليفهم وكسب الربح. ويمكن أن يختلف هذا الهامش حسب طلب السوق والمنافسة.

كيف تؤثر العوامل المؤثرة في الأسعار على مصادر مولدات السيارات؟

تؤثر العديد من العوامل على أسعار مولدات التيار المتردد للسيارات، مما يجعل من الضروري للمشترين إجراء بحث شامل في السوق.

-

الحجم/الحد الأدنى لكمية الطلب: غالبًا ما تؤدي أحجام الطلبات المرتفعة إلى خصومات، مما يجعل من المفيد للمشترين الشراء بكميات كبيرة. كما أن إقامة علاقات طويلة الأجل مع الموردين يمكن أن يوفر أسعاراً أفضل.

-

المواصفات والتخصيص: يمكن أن تؤدي المواصفات المخصصة إلى زيادة التكاليف بسبب الأدوات والعمالة الإضافية. يجب على المشترين تحديد احتياجاتهم بوضوح لتجنب النفقات غير المتوقعة.

-

شهادات المواد والجودة: يمكن أن تؤثر جودة المواد المستخدمة بشكل كبير على السعر. وبالإضافة إلى ذلك، قد يكون التوريد من موردين حاصلين على شهادات جودة معترف بها (مثل المنظمة الدولية لتوحيد المقاييس) بسعر أعلى، ولكن يمكن أن يضمن الموثوقية والأداء.

-

عوامل الموردين: يمكن أن تؤثر سمعة الموردين وموثوقيتهم وموقعهم الجغرافي على الأسعار. فقد يقدم الموردون المحليون خدمة توصيل أسرع وتكاليف شحن أقل، بينما قد يوفر الموردون الدوليون مزايا من حيث التكلفة.

-

مصطلحات التجارة الدولية: إن فهم شروط التجارة الدولية أمر بالغ الأهمية للمعاملات الدولية. فالمصطلحات مثل فوب (FOB) (مجاناً على ظهر السفينة) وسيف (التكلفة والتأمين والشحن) تحدد كيفية توزيع التكاليف بين المشترين والبائعين.

ما هي بعض النصائح للمشتري لتحقيق الكفاءة من حيث التكلفة في توريد المولدات؟

بالنسبة للمشترين الدوليين، لا سيما في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، إليك بعض النصائح العملية لتعزيز كفاءة التكلفة:

-

التفاوض بفعالية: إشراك الموردين في المفاوضات لتأمين أفضل الأسعار الممكنة. الاستفادة من التزامات الحجم أو العقود طويلة الأجل للحصول على شروط مواتية.

-

النظر في التكلفة الإجمالية للملكية (TCO): تقييم ليس فقط سعر الشراء ولكن التكلفة الإجمالية للملكية، بما في ذلك الصيانة ومطالبات الضمان والكفاءة التشغيلية. وقد تؤدي البدائل الأرخص إلى تكاليف أعلى على المدى الطويل.

-

تقييم الفروق الدقيقة في التسعير: انتبه إلى اختلافات الأسعار الإقليمية. على سبيل المثال، قد يكون لمولدات التيار المتردد التي يتم الحصول عليها من أوروبا تكاليف أولية أعلى ولكنها تأتي بجودة أعلى ومعدلات أعطال أقل، مما قد يقلل من التكاليف الإجمالية.

-

إجراء عمليات تدقيق الموردين: قبل وضع اللمسات الأخيرة على المورّد، قم بإجراء عمليات تدقيق أو اطلب مراجع للتأكد من استيفائه لمعايير الجودة وقدرته على التسليم باستمرار.

-

ابق على اطلاع على اتجاهات السوق: مواكبة التغييرات في أسعار المواد الخام وديناميكيات سلسلة التوريد العالمية، حيث يمكن أن تؤثر هذه التغييرات بشكل مباشر على أسعار المولدات.

من خلال فهم مكونات التكلفة والمؤثرات السعرية هذه، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة عند الحصول على مولدات التيار المتردد للسيارات، مما يضمن الجودة والفعالية من حيث التكلفة في استراتيجيات الشراء الخاصة بهم.

تحليل البدائل: مقارنة cual es el alternador del carro مع الحلول الأخرى

فهم بدائل الأنظمة الكهربائية للمركبات

في صناعة السيارات، يعد فهم بدائل المكونات التقليدية مثل مولد التيار المتردد أمرًا ضروريًا لمشتري B2B. يلعب المولد دورًا حاسمًا في تحويل الطاقة الميكانيكية إلى طاقة كهربائية، مما يضمن عمل بطارية السيارة والأنظمة الكهربائية بشكل صحيح. ومع ذلك، يمكن للعديد من الحلول البديلة تحقيق أهداف مماثلة، ولكل منها مزايا وعيوب فريدة.

| جانب المقارنة | كوال إس إل ألتيرادور ديل كارو | نظام إدارة البطارية | نظام الطاقة الهجين |

|---|---|---|---|

| الأداء | موثوقة وفعالة في الظروف العادية | يمكن تحسين عمر البطارية واستخدام الطاقة | يوفر كفاءة أعلى وانبعاثات أقل |

| التكلفة | تكلفة أولية معتدلة؛ قد يكون الاستبدال مكلفاً | تكلفة أولية أقل؛ إمكانية تحقيق وفورات أكبر على المدى الطويل | استثمار أعلى مقدمًا؛ قد يوفر التكاليف مع مرور الوقت |

| سهولة التنفيذ | تركيب قياسي في معظم السيارات | تركيب بسيط نسبياً؛ يعتمد على تصميم المركبة | تركيب معقد؛ يتطلب معرفة متخصصة |

| الصيانة | يلزم إجراء فحوصات منتظمة؛ يمكن أن تكون مكلفة في حالة تعطلها | الحد الأدنى من الصيانة؛ قد يلزم استبدال البطارية | يتطلب صيانة منتظمة؛ يمكن أن يؤدي التعقيد إلى زيادة تكاليف الصيانة |

| أفضل حالة استخدام | معظم المركبات التقليدية | السيارات الكهربائية والهجينة للاستخدام الأمثل للبطاريات | مركبات تركز على كفاءة استهلاك الوقود وتقليل الانبعاثات |

تفصيل البدائل

نظام إدارة البطارية (BMS)

صُمم نظام إدارة البطارية لمراقبة أداء البطارية وإدارتها، مما يضمن دورات شحن وتفريغ مثالية. يمكن لنظام إدارة البطارية أن يعزز طول عمر البطارية وكفاءتها، مما يجعله مفيداً بشكل خاص للسيارات الكهربائية. وتتمثل الميزة الرئيسية لنظام إدارة البطاريات في انخفاض تكلفته الأولية والحد الأدنى من متطلبات الصيانة مقارنةً بمولدات التيار المتردد التقليدية. ومع ذلك، قد لا توفر نفس المستوى من الموثوقية في السيارات التقليدية، حيث إنها مصممة خصيصاً للأنظمة التي تعمل بالبطاريات.

نظام الطاقة الهجين

تجمع أنظمة الطاقة الهجينة بين محركات الاحتراق الداخلي التقليدية والدفع الكهربائي، مما يوفر كفاءة أعلى وانبعاثات أقل. يمكن لهذا النظام أن يعزز أداء السيارة بشكل كبير ويقلل من استهلاك الوقود. أما الجانب السلبي فيتمثل في الاستثمار المقدم المرتفع اللازم للتركيب والتعقيد الذي ينطوي عليه الأمر، والذي يتطلب معرفة متخصصة للصيانة. هذا الحل هو الأنسب للشركات التي تتطلع إلى الاستثمار في التكنولوجيا المتطورة لتحسين الاستدامة.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

عند اختيار الحل المناسب للأنظمة الكهربائية للمركبات، يجب على المشترين من الشركات مراعاة احتياجاتهم التشغيلية المحددة وقيود الميزانية والاستخدام المقصود لسياراتهم. بينما يظل المولد التقليدي خيارًا موثوقًا به لمعظم المركبات، فإن البدائل مثل أنظمة إدارة البطاريات وأنظمة الطاقة الهجينة تقدم مزايا فريدة قد تتوافق بشكل أفضل مع احتياجات السيارات المتقدمة. سيؤدي تقييم الأداء والتكلفة والصيانة وسهولة التنفيذ إلى توجيه المشترين في اتخاذ قرارات مستنيرة تعزز كفاءة أسطولهم واستدامته.

الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية ل cual es el alternador del carro

ما هي الخصائص التقنية الرئيسية لمولد السيارات؟

يعد فهم الخصائص التقنية الأساسية لمولد السيارات أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات، وخاصة أولئك الذين يشاركون في شراء قطع غيار السيارات. فيما يلي بعض المواصفات الهامة التي يجب مراعاتها:

-

جهد الخرج

يولّد المولد عادةً جهد خرج يتراوح بين 12 و14.5 فولت، وهو أمر ضروري لشحن البطارية وتشغيل الأنظمة الكهربائية. يعد ضمان خرج الجهد الصحيح أمرًا حيويًا لطول عمر المكونات الكهربائية للسيارة وعمر البطارية. يجب على مشتري B2B التحقق من أن المولدات التي يحصلون عليها تفي بمتطلبات الجهد المحدد لطرازات سياراتهم المستهدفة. -

تصنيف الأمبيرية

تأتي المولدات بتصنيفات متفاوتة للتيار الكهربائي، تتراوح عادةً من 60 إلى أكثر من 200 أمبير. يشير هذا التصنيف إلى مقدار التيار الكهربائي الذي يمكن أن يوفره المولد. يعد التصنيف الأعلى للتيار الكهربائي ضرورياً للمركبات المزودة بملحقات كهربائية متعددة، مثل أنظمة المعلومات والترفيه المتقدمة أو الإضاءة الإضافية. يجب على المشترين تقييم الاحتياجات الكهربائية لمركباتهم المستهدفة لاختيار مولدات ذات أمبيرية كافية. -

تركيب المواد

تؤثر المواد المستخدمة في المولدات، مثل الألومنيوم عالي الجودة والنحاس، على المتانة والكفاءة. تضمن المواد عالية الجودة إدارة حرارية أفضل ومقاومة للتآكل، وهو أمر مهم بشكل خاص في المناخات المتنوعة الموجودة في مناطق مثل أفريقيا والشرق الأوسط. يجب على مشتري B2B إعطاء الأولوية لمشتري B2B للحصول على مولدات التيار المتردد المصنوعة من مواد موثوقة لتقليل معدلات الأعطال. -

نوع المحمل

قد تستخدم المولدات إما محامل كروية أو أسطوانية، مما يؤثر على عمرها التشغيلي وكفاءتها. توفر المحامل الكروية بشكل عام أداءً أفضل في التطبيقات عالية السرعة، بينما يمكن للمحامل الدوارة أن توفر قدرة تحميل محسنة. يعد فهم نوع المحمل أمرًا بالغ الأهمية للمشترين الذين يبحثون عن الموثوقية وتقليل تكاليف الصيانة في عروض السيارات الخاصة بهم. -

نوع المنظم

يمكن أن تحتوي المولدات على منظمات جهد داخلية أو خارجية. المنظمون الداخليون أكثر شيوعاً وأسهل في التركيب، بينما يمكن للمنظمين الخارجيين توفير أداء أفضل في التطبيقات المتخصصة. يجب على المشترين تقييم نوع المنظم الذي يتوافق مع عروض خدماتهم أو المركبات التي يدعمونها. -

تكوين التثبيت

يختلف تكوين تركيب المولد حسب طراز السيارة وطرازها. تتضمن التكوينات الشائعة حوامل جانبية أو علوية، مما يؤثر على التوافق مع تصميمات المحرك المختلفة. يجب على مشتري B2B التأكد من إمكانية دمج المولدات التي يحصلون عليها بسهولة في المركبات التي يستهدفونها لتجنب مشاكل التوافق.

ما هي المصطلحات التجارية الشائعة المتعلقة بمولدات السيارات؟

الإلمام بالمصطلحات التجارية أمر ضروري للتواصل والتفاوض الفعال في صناعة قطع غيار السيارات. وفيما يلي بعض المصطلحات المهمة:

صورة توضيحية متعلقة ب cual es el alternador del carro

-

OEM (الشركة المصنعة للمعدات الأصلية)

يشير هذا المصطلح إلى الشركات المصنعة التي تنتج القطع المستخدمة في التجميع الأصلي للمركبات. وغالباً ما يتم تفضيل قطع الغيار الأصلية نظراً لتوافقها المضمون وجودتها. يجب على المشترين بين الشركات أن يأخذوا بعين الاعتبار قطع الغيار الأصلية لعملائهم الذين يبحثون عن الموثوقية. -

MOQ (الحد الأدنى لكمية الطلب)

يحدد موك أصغر كمية من المنتجات التي يرغب المورد في بيعها. يعد فهم موك أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات لإدارة المخزون وضمان فعالية التكلفة في طلبياتهم، خاصة عند الحصول على مولدات الكهرباء بكميات كبيرة. -

طلب عرض أسعار (RFQ)

طلب عرض الأسعار هو مستند رسمي يتم إرساله إلى الموردين لطلب تسعير وشروط لمنتجات محددة. ويمكن أن يؤدي استخدام طلبات عروض الأسعار إلى تبسيط عملية الشراء وضمان حصول المشترين على أسعار تنافسية لمولدات الكهرباء والمكونات الأخرى. -

شروط التجارة الدولية (Incoterms)

وهي قواعد معترف بها دوليًا تحدد مسؤوليات المشترين والبائعين فيما يتعلق بالشحن والتسليم. ويُعد الإلمام بشروط التجارة الدولية (Incoterms) أمرًا ضروريًا لمعاملات الأعمال بين الشركات التي تنطوي على توريد المولدات عبر الحدود، مما يساعد المشترين على فهم التزاماتهم وتكاليفهم. -

المهلة الزمنية

تشير المهلة الزمنية إلى الوقت بين تقديم الطلب واستلام المنتج. ويُعد فهم المهلة الزمنية أمرًا حيويًا للمشترين بين الشركات لإدارة سلاسل التوريد بفعالية وضمان توافر المولدات في الوقت المناسب لعملائهم. -

فترة الضمان

يشير هذا المصطلح إلى المدة التي تضمن فيها الشركة المصنعة المولد ضد العيوب. يمكن لفترة الضمان الأطول أن تعزز ثقة المشتري في جودة المنتج. يجب على المشترين بين الشركات النظر في شروط الضمان عند تقييم الموردين للتأكد من أنهم يقدمون منتجات موثوقة لعملائهم.

من خلال فهم هذه الخصائص التقنية والمصطلحات التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة، مما يضمن لهم شراء المولدات المناسبة التي تلبي متطلبات الأداء والسوق.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع السيارات

ما هي ديناميكيات السوق الحالية التي تؤثر على قطاع المولدات الكهربائية؟

يشهد السوق العالمي لمولدات الطاقة الكهربائية للسيارات نموًا قويًا في الوقت الحالي مدفوعًا بزيادة إنتاج السيارات والطلب المتزايد على السيارات الكهربائية (EVs). ومع توجه الدول في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا نحو حلول النقل المستدامة، تصبح الحاجة إلى أنظمة إدارة الطاقة الفعالة، مثل مولدات الطاقة الكهربائية، أمرًا بالغ الأهمية. تعمل التقنيات الناشئة، بما في ذلك التطورات في تصميم المولدات وعمليات التصنيع، على تغيير طرق التوريد التقليدية. يجب على المشترين بين الشركات أن يلاحظوا أن الموردين يستفيدون بشكل متزايد من الأتمتة وتقنيات التصنيع الذكية، والتي تعزز جودة المنتج مع تقليل المهل الزمنية.

علاوة على ذلك، فإن اتجاه السيارات الكهربائية يعيد تشكيل سوق المولدات الكهربائية. فمع اكتساب السيارات الهجينة والطرازات الكهربائية بالكامل، يتم استبدال المولدات التقليدية أو تعزيزها بأنظمة إدارة الطاقة الأكثر تطورًا. يجب على المشترين البقاء على اطلاع على هذه التحولات التكنولوجية، لأنها ستؤثر على المواصفات واستراتيجيات التوريد لقطع غيار السيارات. في مناطق مثل المملكة العربية السعودية وألمانيا، حيث تفضل السياسات الحكومية التقنيات الأكثر مراعاة للبيئة، يجب على الشركات مواءمة ممارسات التوريد الخاصة بها مع هذه اللوائح لتظل قادرة على المنافسة.

صورة توضيحية متعلقة ب cual es el alternador del carro

كيف تشكل الاستدامة والتوريد الأخلاقي سوق المولدات الكهربائية؟

أصبحت الاستدامة عاملاً رئيسيًا في صناعة السيارات، وقطاع المولدات الكهربائية ليس استثناءً. يخضع التأثير البيئي لعمليات الإنتاج، بما في ذلك الانبعاثات وتوليد النفايات، للتدقيق. ويعطي المشترون بين الشركات الأولوية بشكل متزايد للموردين الذين يظهرون التزامًا بالممارسات المستدامة. ويشمل ذلك استخدام المواد المعاد تدويرها وتقنيات التصنيع الموفرة للطاقة والالتزام باللوائح البيئية.

علاوة على ذلك، فإن التوريد الأخلاقي أمر حيوي للحفاظ على نزاهة العلامة التجارية وثقة المستهلك. ومن المرجح أن يجذب الموردون الذين يمكنهم تقديم ممارسات وشهادات شفافة لسلسلة التوريد مثل ISO 14001 أو غيرها من الشهادات الخضراء المشترين الدوليين. ويكتسب هذا الاتجاه أهمية خاصة في أوروبا، حيث يدافع المستهلكون والشركات على حد سواء عن المنتجات الصديقة للبيئة. كما يجب على الشركات في أفريقيا وأمريكا الجنوبية أن تأخذ بعين الاعتبار الآثار المترتبة على الاستدامة في استراتيجيات التوريد الخاصة بها، حيث يميل المشترون العالميون أكثر إلى التعاون مع الشركاء الذين يتشاركون قيمًا مماثلة فيما يتعلق بالمسؤولية البيئية.

ما هو التطور الموجز لمولدات السيارات؟

لقد كان تطور مولدات التيار المتردد في السيارات مهمًا منذ نشأتها في أوائل القرن العشرين. في الأصل، اعتمدت السيارات على المولدات لإنتاج الكهرباء، ولكن مع تقدم التكنولوجيا، أصبح المولد المولد المولد الخيار المفضل بسبب كفاءته وموثوقيته. وبحلول منتصف القرن العشرين، حلت المولدات إلى حد كبير محل المولدات في معظم السيارات، مما يمثل تحولاً محورياً في تكنولوجيا السيارات.

مع ظهور الأنظمة الإلكترونية في السيارات، تطورت المولدات لدعم المتطلبات الكهربائية المعقدة، بما في ذلك أنظمة المعلومات والترفيه وأنظمة مساعدة السائق المتقدمة (ADAS) ومكونات السيارات الكهربائية. وتركز الابتكارات الحديثة على تحسين الكفاءة وتقليل الوزن، وهو أمر ضروري مع تحرك صناعة السيارات نحو التحول إلى السيارات الكهربائية. بالنسبة للمشترين بين الشركات، يعد فهم هذا التطور أمرًا بالغ الأهمية، لأنه يسلط الضوء على أهمية اختيار الموردين الذين لا يقتصرون على المعرفة بالتقنيات الحالية فحسب، بل يتسمون أيضًا بالتفكير المستقبلي في نهجهم لتطوير المنتجات.

صورة توضيحية متعلقة ب cual es el alternador del carro

من خلال البقاء على اطلاع على ديناميكيات السوق هذه، وممارسات الاستدامة، والسياق التاريخي لمولدات الطاقة المترددة، يمكن للمشترين الدوليين بين الشركات اتخاذ قرارات استراتيجية للتوريد تتماشى مع اتجاهات الصناعة وتوقعات المستهلكين.

الأسئلة المتداولة (FAQs) لمشتري B2B من cual es el alternador del carro

-

كيف يمكنني تحديد مولد التيار المتردد المعيب في السيارة؟

لتحديد المولد المعيب، راقب العديد من العلامات التحذيرية: ضوء تحذير البطارية على لوحة العدادات، ومصابيح أمامية خافتة أو خافتة أو وميضية، وصعوبة في تشغيل السيارة. بالإضافة إلى ذلك، إذا سمعت ضوضاء غير معتادة من المولد أو شممت رائحة مطاط محترق، فقد يشير ذلك إلى وجود عطل. يمكن أن يساعدك فحص خرج الجهد بانتظام باستخدام مقياس متعدد في التأكد مما إذا كان المولد يعمل بشكل صحيح؛ يجب أن ينتج المولد السليم حوالي 13.8 إلى 14.2 فولت عند تشغيل المحرك. -

ما هو أفضل مولد كهربائي للمركبات التجارية؟

عادةً ما يجمع أفضل مولد للمركبات التجارية بين الإنتاجية العالية والمتانة. ضع في اعتبارك علامات تجارية مثل Bosch أو Denso، المعروفة بموثوقيتها وأدائها في الظروف الصعبة. تأكد من أن المولد يلبي الاحتياجات الكهربائية المحددة لمركبتك، بما في ذلك متطلبات الحمل للأنظمة المساعدة. يمكن أن يوفر التعاون مع الموردين المتخصصين في مكونات الخدمة الشاقة أيضًا رؤى حول أفضل الخيارات المتاحة بناءً على التطبيقات الخاصة بمنطقتك. -

ما الذي يجب أن آخذه في الاعتبار عند شراء المولدات الكهربائية من الموردين الدوليين؟

عند الاستعانة بمصادر دولية لمولدات الكهرباء، قم بتقييم سمعة المورد، وشهادات الجودة، والامتثال للمعايير الدولية. من المهم فهم عمليات التصنيع الخاصة بالمورّد وما إذا كان يجري اختبارات صارمة لضمان الجودة. بالإضافة إلى ذلك، استفسر عن خبرتهم في الشحن إلى منطقتك، حيث يمكن أن تؤثر الخدمات اللوجستية بشكل كبير على المهل الزمنية والتكاليف. كما أن إنشاء تواصل واضح وتوقعات واضحة فيما يتعلق بمواصفات المنتج سيسهل أيضاً إجراء معاملة أكثر سلاسة. -

ما هو الحد الأدنى لكميات الطلب (MOQ) لمولدات التيار المتردد؟

يمكن أن يختلف الحد الأدنى لكميات الطلبات (MOQ) لمولدات التيار المتردد اختلافًا كبيرًا بناءً على المورد ونوع المولد. عادةً ما يتراوح الحد الأدنى للكميات المطلوبة من 10 إلى 100 وحدة للمنتجات القياسية. ومع ذلك، بالنسبة لمولدات المولدات المخصصة أو المتخصصة، قد يطلب الموردون كميات أعلى من موك. من المفيد التفاوض على موك مقدما للتوافق مع احتياجات المخزون الخاص بك، خاصة إذا كنت تدير ميزانية محدودة أو سعة تخزين محدودة. -

ما هي شروط السداد الشائعة عند شراء مولدات التيار المتردد دولياً؟

تشمل شروط الدفع الشائعة للمشتريات الدولية لمولدات الكهرباء خطابات الاعتماد، والدفعات المقدمة، والدفع عند التسليم. قد يقدم بعض الموردين شروطًا مرنة مثل صافي 30 أو صافي 60 يومًا، ويتوقف ذلك على الثقة الراسخة. قم دائمًا بتوضيح شروط الدفع قبل إنهاء العقد لتجنب سوء الفهم. يُنصح باستخدام طرق دفع آمنة لحماية استثمارك، خاصةً عند التعامل مع موردين جدد. -

كيف يمكنني التأكد من جودة المولدات التي يتم توريدها من الخارج؟

للتأكد من جودة المولدات التي يتم توريدها من الخارج، اطلب عينات قبل تقديم طلب بالجملة. وضع بروتوكولات ضمان الجودة، بما في ذلك عمليات التفتيش من طرف ثالث في موقع التصنيع. بالإضافة إلى ذلك، تحقق من شهادات المورد، مثل معايير ISO، التي تشير إلى الالتزام بأنظمة إدارة الجودة. كما أن التعامل مع الموردين الذين يقدمون ضمانات أو كفالات على منتجاتهم يمكن أن يوفر أيضًا مزيدًا من راحة البال فيما يتعلق بجودة المولدات. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد المولدات الكهربائية؟

عند استيراد مولدات الكهرباء، ضع في اعتبارك طرق الشحن واللوائح الجمركية والمهل الزمنية المرتبطة بمناطقك المحددة. تعامل مع شركاء الخدمات اللوجستية الذين لديهم خبرة في التعامل مع مكونات السيارات لضمان الامتثال لجميع لوائح الشحن والاستيراد. بالإضافة إلى ذلك، ضع في الحسبان التأخيرات المحتملة بسبب التخليص الجمركي وخطط لمخزونك وفقًا لذلك لتجنب نفاد المخزون. كما أن التغطية التأمينية أثناء النقل ضرورية أيضاً للتخفيف من المخاطر المرتبطة بالتلف أو الفقدان. -

كيف يمكنني تخصيص المولدات لتلبية احتياجات عملي الخاصة؟

يمكن تحقيق تخصيص المولدات الكهربائية من خلال التعاون الوثيق مع المصنعين الذين يقدمون حلولاً مخصصة. ناقش متطلباتك المحددة، مثل خرج الجهد والحجم وتكوينات التركيب مع الموردين المحتملين. يمكن للعديد من المصنعين استيعاب التصميمات المخصصة، ولكن كن مستعدًا لمهل زمنية أطول وتكاليف أعلى محتملة. تأكد من أن أي تعديلات تفي بمعايير الصناعة وتم التحقق من صحتها من خلال الاختبار لضمان الموثوقية في تطبيقاتك.

قائمة المصنعين والموردين أعلى 3 Cual Es El Alternador Del Carro

1. Facebook - Alternador de Auto

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: يعمل مولد التيار المتردد في السيارة على توليد الطاقة الكهربائية وتشغيل البطارية في السيارة. يعمل على تحويل طاقة المحرك إلى طاقة كهربائية من خلال عملية تحفيز كهرومغناطيسي.

2. السباق - ألتيرادور دي كوتشي

المجال: سباق.es

مقدمة: المولد البديل هو أحد مكونات السيارة التي تنتج الكهرباء وتجمعها في البطارية. يعمل من خلال الدوران الدوراني للمحرك، حيث يولد الكهرباء البديلة التي يتم توليدها بشكل متواصل بجهد 12 فولت من خلال لوحة ثنائية. يولد جهداً بين 13,5 فولت و14,5 فولت، منظم بواسطة منظم. في المحركات القديمة، كان المولد البديل عبارة عن قطعة مستقلة، بينما في المحركات القديمة كان المولد البديل عبارة عن...

3. Infinity Auto - Alternadores

المجال: infinityauto.com

تاريخ التسجيل: 2002 (23 عامًا)

مقدمة: المولد البديل هو مولد كهربائي يقوم بتوزيع الطاقة الكهربائية على السيارة واستعادة البطارية. Funciona convirtiendo convirtiendo energía mecánica energía eléctrica، مدفوعاً من خلال سيجارة المحرك عبر محور واحد. تشتمل مكوناته على: 1. الدوّار: قطعة دوّارة: قطعة سيليكونية ذات قضبان من الإيمانيات، تدور في داخل المحرك. 2. المُسْتدير: مجموعة كابلات من الكابلات من الكوبري التي تعمل مع الدوار لإنشاء...

استنتاج وتوقعات التوريد الاستراتيجي ل cual es el alternador del carro

باختصار، يعد فهم دور مولد التيار المتردد ووظائفه أمرًا ضروريًا للمشترين الدوليين في قطاع السيارات. لا يقوم المولد بتشغيل أنظمة السيارة الأساسية فحسب، بل يضمن أيضًا طول عمر البطارية والأداء العام للسيارة. يتيح التعرف على العلامات الشائعة لفشل المولد مثل تعتيم الأضواء أو صعوبة بدء التشغيل، للشركات معالجة احتياجات الصيانة بشكل استباقي، مما يوفر الوقت والتكاليف في نهاية المطاف.

يلعب التوريد الاستراتيجي دورًا محوريًا في شراء مولدات التيار المتردد عالية الجودة والمكونات ذات الصلة، مما يضمن الموثوقية والكفاءة في سلاسل التوريد. من خلال الشراكة مع موردين مرموقين، يمكن للشركات تعزيز قدراتها التشغيلية وتلبية متطلبات أسواقها في جميع أنحاء أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

مع استمرار تطور صناعة السيارات، سيكون الاستثمار في قطع الغيار عالية الجودة واستراتيجيات التوريد الموثوقة أمراً بالغ الأهمية. نحن نشجع المشترين بين الشركات على استكشاف الشراكات التي تعطي الأولوية للجودة والخدمة، مما يضمن الحفاظ على قدرتهم التنافسية في مشهد سريع التغير. اغتنم الفرصة لتعزيز سلسلة التوريد الخاصة بك وتأمين مستقبل أعمالك من خلال التركيز على التوريد الاستراتيجي لمكونات السيارات اليوم.

صورة توضيحية متعلقة ب cual es el alternador del carro

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.