مقدمة: التنقل في السوق العالمية لتكلفة استبدال محرك بدء التشغيل

في المشهد الديناميكي لصناعة السيارات، فإن فهم تكلفة استبدال محرك بدء التشغيل أمر بالغ الأهمية للمشترين الدوليين بين الشركات. يشكل الحصول على مكونات موثوقة بأسعار تنافسية تحديًا كبيرًا، خاصة في الأسواق المتنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. صُمم هذا الدليل لتمكين صانعي القرار من خلال تقديم نظرة عامة شاملة عن تكاليف استبدال محركات بدء التشغيل، بما في ذلك رؤى حول مختلف الأنواع والتطبيقات والعوامل المؤثرة في التسعير.

لا يقتصر التنقل بين تعقيدات شراء محرك البادئ على تقييم التكاليف فحسب، بل يشمل أيضاً التدقيق في الموردين لضمان الجودة والموثوقية. يتعمق هذا الدليل في أنواع محركات البادئ المختلفة المتاحة، وتطبيقاتها في مختلف طرازات السيارات، ومجموعة التكاليف المحتملة التي ينطوي عليها الأمر - بدءاً من الخيارات المناسبة للميزانية إلى البدائل الممتازة. علاوة على ذلك، يتناول الاعتبارات الرئيسية لاختيار الموردين، ويزود المشترين بالأدوات اللازمة لاتخاذ خيارات مستنيرة تتوافق مع احتياجاتهم التشغيلية.

من خلال تقديم رؤى قابلة للتنفيذ واتجاهات الصناعة، يهدف هذا المورد إلى تعزيز عملية الشراء للمشترين بين الشركات. سواء أكنت تقوم بتوريد قطع غيار لأسطول سيارات في نيجيريا أو تدير الخدمات اللوجستية لخدمات السيارات في المملكة العربية السعودية، فإن فهم تعقيدات تكاليف استبدال المحركات البادئة سيمكنك من تحسين استراتيجية الشراء الخاصة بك وتحقيق قيمة أكبر لمؤسستك.

جدول المحتويات

- قائمة المصنعين والموردين لأفضل 4 شركات تصنيع وموردي تكلفة استبدال محرك بدء التشغيل

- مقدمة: التنقل في السوق العالمية لتكلفة استبدال محرك بدء التشغيل

- فهم تكلفة استبدال محرك بدء التشغيل أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لتكلفة استبدال محرك بدء التشغيل

- 3 نقاط ألم شائعة لدى المستخدمين فيما يتعلق بـ ‘تكلفة استبدال محرك بدء التشغيل’ وحلولها

- دليل اختيار المواد الاستراتيجية لتكلفة استبدال محرك بدء التشغيل

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لتكلفة استبدال محرك بدء التشغيل

- دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘تكلفة استبدال محرك بدء التشغيل’

- تحليل شامل للتكلفة والتسعير لتكلفة استبدال المحرك البادئ تحديد مصادر التكلفة الشاملة

- تحليل البدائل: مقارنة تكلفة استبدال محرك بدء التشغيل بالحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية لتكلفة استبدال محرك بدء التشغيل

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع تكلفة استبدال المحركات البادئة

- الأسئلة المتداولة (FAQs) لمشتري B2B لتكلفة استبدال محرك بدء التشغيل

- استنتاج المصادر الاستراتيجية والتوقعات لتكلفة استبدال محرك بدء التشغيل

- إخلاء مسؤولية هام وشروط الاستخدام

فهم تكلفة استبدال محرك بدء التشغيل أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| محرك تشغيل جديد | مكونات جديدة تماماً، عادةً ما تكون أعلى تكلفة | وكلاء السيارات، خدمات أساطيل السيارات | الإيجابيات: الموثوقية وتغطية الضمان. السلبيات: استثمار أولي أعلى. |

| محرك بدء التشغيل المعاد بناؤه | قطع غيار مجددة، بتكلفة أقل من الجديدة | ورش تصليح السيارات، وتجار التجزئة لما بعد البيع بالتجزئة | الإيجابيات: فعالة من حيث التكلفة وجيدة النوعية. السلبيات: عمر افتراضي أقصر من الجديد. |

| محرك بدء التشغيل المستعمل | قطع غيار مستعملة، بسعر أقل بكثير | ساحات الخردة والميكانيكيون المهتمون بالميزانية | الإيجابيات: بأسعار معقولة جداً. السلبيات: موثوقية غير مؤكدة، لا يوجد ضمان. |

| محرك بدء التشغيل OEM | قطع غيار الشركة المصنعة للمعدات الأصلية، أسعار ممتازة | إصلاح السيارات الفاخرة، والأعمال التي تركز على مصنعي المعدات الأصلية | الإيجابيات: ملاءمة مثالية وجودة عالية. السلبيات: باهظة التكلفة، ومدة زمنية أطول. |

| محرك بدء التشغيل ما بعد البيع | قطع الغيار غير المصنعة محلياً، متفاوتة الجودة والسعر | ورش التصليح المستقلة، المشترون المستقلون الذين يراعون التكلفة | الإيجابيات: أسعار تنافسية وخيارات متنوعة. السلبيات: جودة متفاوتة ومشاكل محتملة في الملاءمة. |

ما هي خصائص محركات التشغيل الجديدة؟

يتم تصنيع محركات بدء التشغيل الجديدة من الصفر باستخدام مكونات جديدة تمامًا، مما يضمن الأداء الأمثل والموثوقية. وهي مثالية للشركات التي تحتاج إلى حل يمكن الاعتماد عليه، مثل وكلاء السيارات وخدمات الأساطيل. على الرغم من أن التكلفة الأولية أعلى مقارنة بالخيارات الأخرى، إلا أن المشترين يستفيدون من تغطية الضمان وراحة البال، مع العلم أنهم يستثمرون في منتج مصمم ليدوم طويلاً.

لماذا تختار محركات بدء التشغيل المعاد بناؤها لتحقيق كفاءة التكلفة؟

تعتبر محركات البادئ المعاد بناؤها خياراً اقتصادياً، حيث أنها تتكون من قطع مجددة تم إصلاحها أو استبدالها لاستعادة وظائفها. هذا الخيار شائع بين ورشات تصليح السيارات وتجار التجزئة لما بعد البيع بالتجزئة الذين يتطلعون إلى تقديم حلول فعالة من حيث التكلفة لعملائهم. وعلى الرغم من أن هذه البادئات توفر جودة جيدة بسعر أقل، إلا أنه يجب على المشترين أن يأخذوا بعين الاعتبار احتمال أن يكون عمرها الافتراضي أقصر مقارنة بالوحدات الجديدة، مما يجعل من الضروري تقييم شروط الضمان.

ما هي مزايا محركات التشغيل المستعملة؟

يتم الحصول على محركات البادئ المستعملة من ساحات الخردة وتوفر أسعاراً أقل بكثير، مما يجعلها جذابة للميكانيكيين والشركات المهتمة بالميزانية. ومع ذلك، فإن عدم اليقين المحيط بموثوقيتها يشكل خطراً، حيث قد لا تعمل هذه الأجزاء على النحو الأمثل أو قد تتعطل في وقت أقرب مما هو متوقع. يجب على المشترين توخي الحذر ومراعاة عدم وجود ضمان عند اختيار هذا الإجراء الموفر للتكلفة.

لماذا الاستثمار في محركات بادئ الحركة المصنعة للمعدات الأصلية؟

تم تصميم محركات البادئ OEM (الشركة المصنعة للمعدات الأصلية) خصيصاً لموديلات وطرازات معينة من السيارات، مما يضمن ملاءمة مثالية وجودة عالية. وهي مفضلة بشكل خاص في إصلاح السيارات الفاخرة ومن قبل الشركات التي تركز على قطع غيار OEM. في حين أن الاستثمار أعلى، فإن ضمان التوافق والأداء يجعل قطع غيار OEM خياراً موثوقاً للشركات التي تعطي الأولوية للجودة ورضا العملاء.

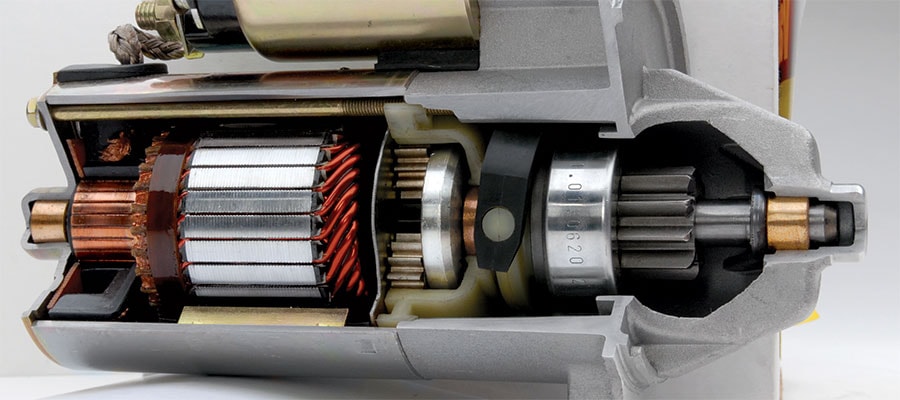

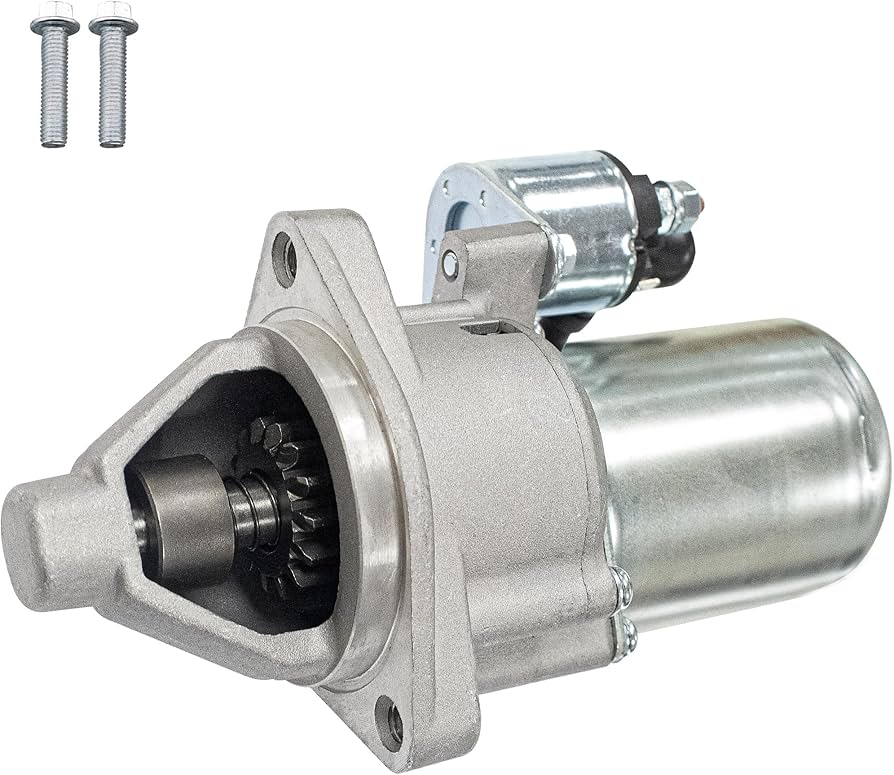

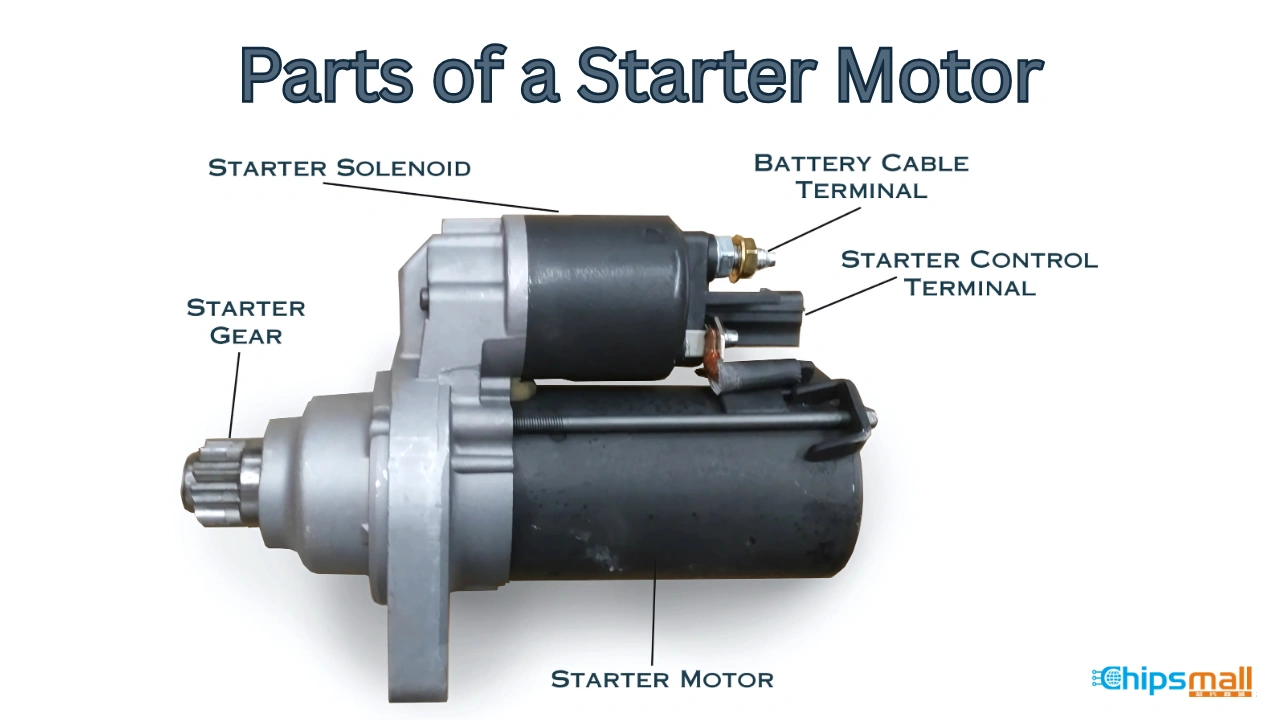

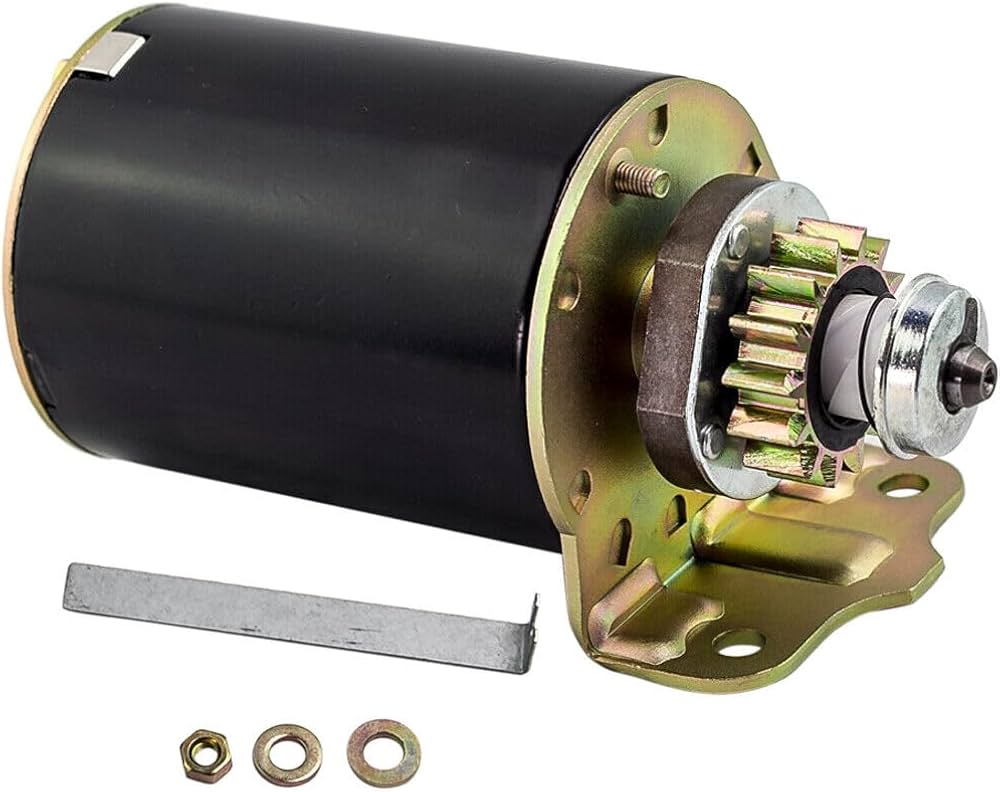

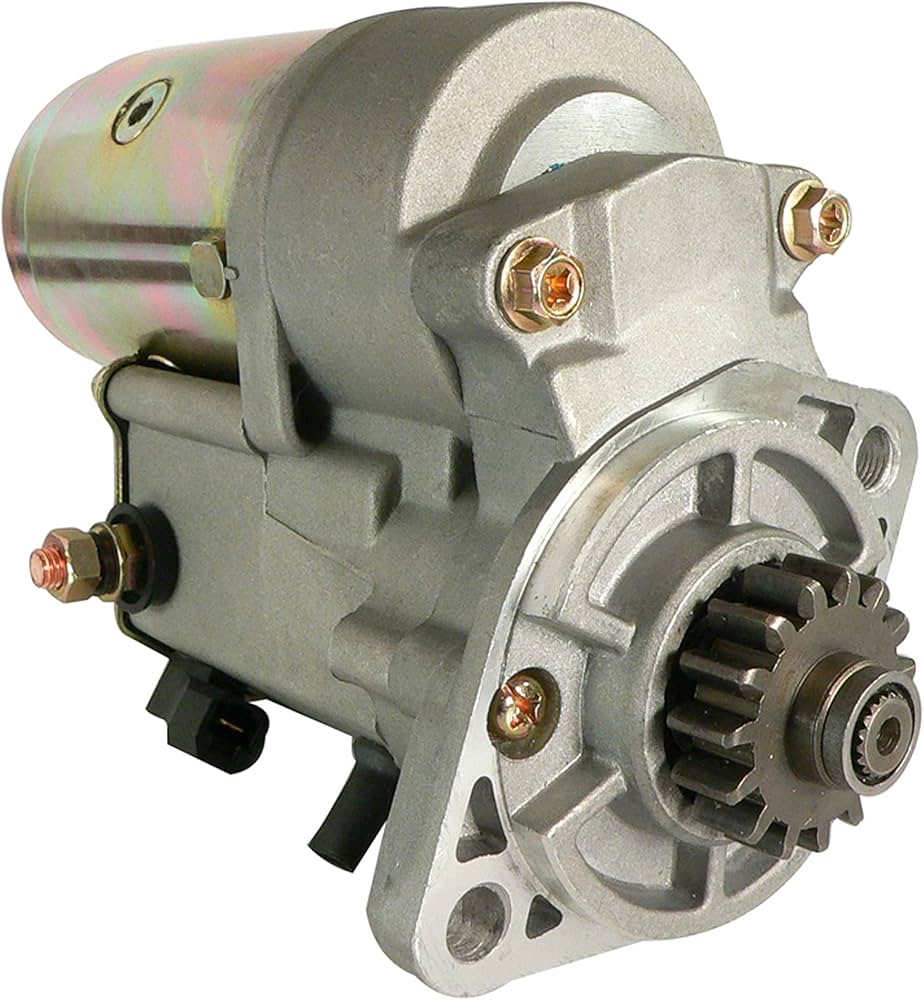

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

كيف تقارن محركات التشغيل ما بعد البيع؟

توفر محركات البادئ ما بعد البيع مجموعة واسعة من الخيارات بأسعار تنافسية، مما يجذب ورش التصليح المستقلة والمشترين الذين لديهم حساسية تجاه التكلفة. تم تصميم هذه الأجزاء لتناسب مختلف الماركات والموديلات، مما يوفر مرونة في التوريد. ومع ذلك، فإن التباين في الجودة يعني أنه يجب على المشترين إجراء بحث شامل للتأكد من اختيار مورد حسن السمعة، حيث يمكن أن تؤدي المكونات ذات الجودة الرديئة إلى مشاكل في الملاءمة وأعطال محتملة.

التطبيقات الصناعية الرئيسية لتكلفة استبدال محرك بدء التشغيل

| الصناعة/القطاع | التطبيق المحدد لتكلفة استبدال محرك بدء التشغيل | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | تقدير تكاليف استبدال محرك بدء التشغيل | يساعد في تقديم عروض أسعار دقيقة للعملاء، مما يعزز ثقة العملاء ورضاهم. | توفر قطع الغيار الأصلية مقابل قطع ما بعد البيع، وشروط الضمان، وأوقات الشحن. |

| النقل والخدمات اللوجستية | صيانة أسطول المركبات التجارية | يقلل من وقت التعطل ويضمن تشغيل السيارة بشكل موثوق، وهو أمر ضروري للحفاظ على جداول الخدمة. | خيارات الشراء بالجملة، والتوافق مع مختلف طرازات السيارات، وموثوقية المورد المحلي. |

| التعدين والمعدات الثقيلة | صيانة مشغلات الآلات الثقيلة | يقلل من الاضطرابات التشغيلية ويعزز موثوقية المعدات في العمليات الحرجة. | جودة القطع، ودعم الخدمة، والقدرة على توفير مشغلات متخصصة للمعدات الفريدة من نوعها. |

| الزراعة | استبدال المشغلات في الآلات الزراعية | يضمن الزراعة والحصاد في الوقت المناسب، وهو أمر بالغ الأهمية لزيادة المحصول والربحية. | الوصول إلى الموردين المحليين للاستبدال السريع، وفهم متطلبات الماكينات المحددة. |

| البناء | بدائل محرك بدء التشغيل لمركبات الإنشاءات | يحافظ على الجداول الزمنية للمشروع ويقلل من وقت تعطل الآلات، مما قد يؤثر على تكاليف المشروع. | تقييم توافق القطع، وتوافر الدعم الفني، والجداول الزمنية للتسليم. |

كيف تستفيد محلات تصليح السيارات من فهم تكاليف استبدال محرك البادئ؟

كثيراً ما تتعامل ورش تصليح السيارات مع مشاكل محرك البادئ في كثير من الأحيان، مما يجعل من الضروري تقدير تكاليف الاستبدال بدقة. من خلال فهم هذه التكاليف، يمكن للمحلات التجارية تقديم عروض أسعار دقيقة للعملاء، مما يعزز الثقة ويعزز رضا العملاء. تساعد هذه المعرفة أيضًا في إدارة المخزون بفعالية، مما يضمن توفر القطع المناسبة عند الحاجة إليها. بالنسبة للمشترين الدوليين، خاصةً في مناطق مثل أفريقيا أو أمريكا الجنوبية، فإن الحصول على موردين موثوقين يقدمون خيارات تصنيع المعدات الأصلية وما بعد البيع أمر بالغ الأهمية للحفاظ على الأسعار والجودة التنافسية.

لماذا يعد فهم تكاليف استبدال المحرك البادئ أمرًا بالغ الأهمية للنقل والخدمات اللوجستية؟

في قطاع النقل والخدمات اللوجستية، تُعد صيانة الأسطول أمرًا حيويًا لتحقيق الكفاءة التشغيلية. تتيح معرفة تكاليف استبدال المحركات البادئة لمديري الأساطيل وضع ميزانية فعالة وتقليل وقت تعطل المركبات إلى الحد الأدنى. هذا الأمر مهم بشكل خاص في مناطق مثل الشرق الأوسط، حيث يمكن أن تؤدي الظروف البيئية القاسية إلى تسريع التآكل والتلف. يجب على الشركات النظر في اتفاقيات الشراء بالجملة لتقليل التكاليف، مما يضمن الوصول السريع إلى قطع الغيار التي تناسب مختلف طرازات المركبات.

ما هو الدور الذي تلعبه تكلفة استبدال محرك البادئ في التعدين وصيانة المعدات الثقيلة؟

بالنسبة للصناعات التي تعتمد على الآلات الثقيلة، مثل التعدين، فإن فهم تكاليف استبدال المحرك البادئ أمر بالغ الأهمية للحفاظ على وقت تشغيل المعدات. يمكن أن يؤدي تعطل المحرك إلى اضطرابات تشغيلية كبيرة، مما يؤثر على الإنتاجية والربحية. يجب على المشترين في هذا القطاع إعطاء الأولوية لتوريد قطع غيار عالية الجودة توفر المتانة والموثوقية، وغالبًا ما تتطلب بادئات تشغيل متخصصة. إن إقامة علاقات مع الموردين الذين يمكنهم توفير دعم الخدمة والتسليم السريع أمر ضروري لتقليل وقت التوقف عن العمل.

كيف يمكن للزراعة الاستفادة من معرفة تكاليف استبدال المحرك البادئ؟

في مجال الزراعة، تُعد موثوقية الآلات أمرًا بالغ الأهمية للزراعة والحصاد في الوقت المناسب. إن فهم التكاليف المرتبطة باستبدال محركات بدء التشغيل يساعد المزارعين والشركات الزراعية على ضمان تشغيل معداتهم دائمًا. تسمح هذه المعرفة بتخطيط مالي أفضل وتقلل من مخاطر تعطل المعدات خلال الفترات الحرجة. يجب على المشترين التركيز على الموردين المحليين للوصول السريع إلى قطع الغيار والنظر في متطلبات الآلات المحددة لتجنب مشاكل التوافق.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

لماذا من المهم لشركات الإنشاءات مراقبة تكاليف استبدال محرك البادئ؟

تعتمد شركات المقاولات بشكل كبير على ماكيناتها للوفاء بالمواعيد النهائية للمشروع. ولذلك، فإن فهم تكاليف استبدال محرك البادئ أمر ضروري للحفاظ على وظائف الماكينات وتقليل وقت الخمول. يمكن أن تؤدي التأخيرات الناجمة عن أعطال المعدات إلى زيادة تكاليف المشروع وانخفاض الربحية. يجب على المشترين تقييم مدى توافق قطع الغيار وموثوقية الموردين، مما يضمن قدرتهم على الحصول على المكونات الضرورية بسرعة لإبقاء المشاريع على المسار الصحيح.

3 نقاط ألم شائعة لدى المستخدمين فيما يتعلق بـ ‘تكلفة استبدال محرك بدء التشغيل’ وحلولها

السيناريو 1: تباين التكلفة غير المتوقع في استبدال محرك بدء التشغيل

المشكلة: غالبًا ما يواجه المشترون من الشركات تحديات مع التكاليف غير المتوقعة المرتبطة باستبدال محرك بدء التشغيل. يمكن أن ينبع التباين في تكاليف الاستبدال من عوامل عديدة بما في ذلك نوع السيارة وطرازها، والموقع الجغرافي، وما إذا كان الاستبدال يتم بواسطة وكيل أو ميكانيكي مستقل. بالنسبة لمديري أساطيل السيارات، يؤدي عدم القدرة على التنبؤ إلى تعقيد عملية وضع الميزانية والتنبؤ، مما يؤدي إلى مشاكل محتملة في التدفق النقدي. علاوة على ذلك، يمكن أن يؤدي ارتفاع التكاليف غير المتوقعة إلى تعطيل الكفاءة التشغيلية، خاصة في المناطق التي يكون فيها توافر قطع الغيار محدوداً.

الحل: للتخفيف من التباين في التكلفة، يجب على المشترين المشاركة في أبحاث السوق الاستباقية لفهم نطاقات الأسعار النموذجية لبدائل محركات بدء التشغيل الخاصة بمركبات أسطولهم. إنشاء علاقات مع موردين متعددين، بما في ذلك الموزعين المحليين والدوليين لمقارنة الأسعار والتوافر. يمكن أن يساعد استخدام المنصات الإلكترونية التي تجمع أسعار قطع الغيار عبر الإنترنت في تحديد العروض التنافسية. بالإضافة إلى ذلك، فكر في التفاوض على اتفاقيات الشراء بالجملة مع الموردين لتأمين أسعار أفضل وضمان توافر قطع الغيار. يمكن أن يؤدي تنفيذ جدول زمني للصيانة الوقائية إلى تقليل احتمالية الاستبدال غير المتوقع، مما يسمح بتخطيط مالي أفضل.

السيناريو 2: صعوبة في تشخيص مشاكل محرك البادئ بدقة

المشكلة: في كثير من الحالات، يواجه مشترو B2B صعوبات في التشخيص الدقيق لما إذا كانت مشكلة بدء التشغيل نابعة من محرك التشغيل نفسه أو من المكونات المرتبطة به، مثل البطارية أو نظام الإشعال. يمكن أن يؤدي عدم اليقين هذا إلى عمليات استبدال غير ضرورية، مما يؤدي إلى تضخيم تكاليف الإصلاح وإطالة فترة تعطل السيارة. بالنسبة للشركات التي تعتمد على النقل في عملياتها، يمكن أن يؤدي ذلك إلى خسارة الإيرادات وانخفاض الإنتاجية.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

الحل: ولمواجهة هذا التحدي، يجب على المشترين من الشركات الاستثمار في أدوات التشخيص والتدريب لفرق الصيانة لديهم. يمكن أن يساعد تنفيذ بروتوكول منهجي لاستكشاف الأعطال وإصلاحها الفنيين على تشخيص المشاكل بدقة قبل الشروع في الاستبدال. على سبيل المثال، يمكن أن يؤدي استخدام مقياس متعدد لفحص جهد البطارية والتوصيلات إلى استبعاد المشاكل المتعلقة بالبطارية. كما أن تشجيع التعاون مع الميكانيكيين ذوي الخبرة يمكن أن يوفر أيضاً رؤى حول المشاكل الشائعة الخاصة بأنواع معينة من المركبات. وأخيراً، يمكن أن يساعد وضع برنامج صيانة منتظم يتضمن عمليات فحص نظام التشغيل في تحديد المشاكل المحتملة قبل تفاقمها، مما يؤدي إلى اتخاذ قرارات أكثر استنارة فيما يتعلق باستبدال البادئ.

السيناريو 3: تحدي توفير محركات بدء التشغيل عالية الجودة

المشكلة: نقطة أخرى مهمة بالنسبة للمشترين من الشركات هي الحصول على محركات بدء التشغيل عالية الجودة التي توفر الموثوقية وطول العمر. فمع انتشار قطع غيار ما بعد البيع، قد يكون التمييز بين المكونات منخفضة الجودة والمكونات عالية الجودة أمرًا شاقًا. يمكن أن يؤدي اختيار القطع الأرخص وغير الموثوقة إلى أعطال متكررة، وزيادة تكاليف العمالة، وفي نهاية المطاف، تأثير سلبي على الكفاءة التشغيلية.

الحل: لضمان شراء محركات بدء التشغيل عالية الجودة، يجب على المشترين إعطاء الأولوية للموردين الذين يقدمون ضمانات ولديهم سمعة راسخة فيما يتعلق بالموثوقية. من الضروري إجراء بحث شامل عن المصنعين والموردين - ابحث عن المراجعات وشهادات الصناعة والامتثال للمعايير الدولية. يمكن أن يوفر تكوين الشراكات مع الموزعين ذوي السمعة الطيبة إمكانية الوصول إلى قطع الغيار المعتمدة والدعم الفني. بالإضافة إلى ذلك، ضع في اعتبارك تنفيذ عملية ضمان الجودة عند استلام القطع، مثل الفحص بحثاً عن العيوب أو التأكد من التوافق مع طراز السيارة المحدد. قد تكون تكلفة الاستثمار في قطع الغيار عالية الجودة أعلى مقدمًا ولكن يمكن أن يؤدي إلى توفير طويل الأجل من خلال تقليل وقت التعطل وتكاليف الصيانة.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

دليل اختيار المواد الاستراتيجية لتكلفة استبدال محرك بدء التشغيل

ما هي المواد الأساسية المستخدمة في استبدال محرك البادئ؟

عند التفكير في بدائل محركات بدء التشغيل، يؤثر اختيار المواد بشكل كبير على الأداء والمتانة والتكلفة. فيما يلي، نحلل أربع مواد شائعة مستخدمة في محركات بدء التشغيل، مع التركيز على خصائصها ومزاياها وعيوبها وآثارها على المشترين الدوليين من الشركات بين الشركات (B2B)، خاصة في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

كيف يؤثر النحاس على أداء محرك البادئ؟

الخصائص الرئيسية: يشتهر النحاس بتوصيله الكهربائي الممتاز وتوصيله الحراري ومقاومته للتآكل. ويمكنه تحمل درجات الحرارة العالية، مما يجعله مثاليًا للمكونات التي تتطلب نقل الطاقة بكفاءة.

الإيجابيات والسلبيات: الميزة الأساسية للنحاس هي موصلية النحاس الفائقة، مما يعزز كفاءة المحرك البادئ. ومع ذلك، فإن النحاس مكلف نسبياً ويمكن أن يكون عرضة للأكسدة إذا لم تتم معالجته بشكل صحيح. يمكن أن يكون تصنيع النحاس معقدًا أيضًا، مما يتطلب عمليات متخصصة للحفاظ على خصائصه الموصلة في البيئات عالية الضغط.

التأثير على التطبيق: إن توافق النحاس مع مختلف الأنظمة الكهربائية يجعله مناسبًا لمحركات بدء التشغيل في مختلف أنواع المركبات. ومع ذلك، فإن تكلفته العالية قد تحد من استخدامه في الأسواق ذات الميزانية المحدودة.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

اعتبارات للمشترين الدوليين: يجب على المشترين التأكد من امتثال المشترين للمعايير الدولية مثل ASTM B170 للمنتجات النحاسية. في المناطق ذات الرطوبة العالية أو البيئات المسببة للتآكل، قد يكون من الضروري استخدام طلاءات إضافية لتعزيز المتانة.

ما هو دور الفولاذ في تصنيع محرك التشغيل؟

الخصائص الرئيسية: يوفر الفولاذ قوة شد عالية ومتانة عالية، مما يجعله خيارًا شائعًا للمكونات الهيكلية في محركات بدء التشغيل. ويمكنه تحمل الضغط الميكانيكي الكبير وغالبًا ما تتم معالجته لمقاومة التآكل.

الإيجابيات والسلبيات: الميزة الرئيسية للفولاذ هي قوته وفعاليته من حيث التكلفة مقارنة بالمواد الأخرى. ومع ذلك، فهو أثقل من البدائل الأخرى مثل الألومنيوم، مما قد يؤثر على الوزن الإجمالي لمحرك بدء التشغيل. بالإضافة إلى ذلك، قد يتطلب الفولاذ طلاءات لمنع الصدأ، خاصة في المناخات الرطبة.

التأثير على التطبيق: يعتبر الفولاذ مناسباً للمكونات التي تتعرض لأحمال ميكانيكية عالية، مثل المبيت وأقواس التثبيت لمحركات بدء التشغيل. قد يكون وزنه في الاعتبار بالنسبة للمركبات عالية الأداء حيث يكون كل غرام مهم.

اعتبارات للمشترين الدوليين: يجب أن يكون المشترون على دراية بمعايير مثل ASTM A36 للفولاذ الإنشائي. في المناطق ذات اللوائح البيئية الصارمة، يمكن أن يؤدي اختيار الفولاذ المجلفن أو المطلي إلى تخفيف مشاكل التآكل.

كيف يعزز الألومنيوم كفاءة محرك البادئ؟

الخصائص الرئيسية: يتميز الألومنيوم بخفة وزنه ومقاومته للتآكل، كما يتميز بتوصيل حراري جيد. ويمكنه تحمل درجات حرارة معتدلة وغالبًا ما يستخدم في التطبيقات التي يكون فيها تقليل الوزن أمرًا بالغ الأهمية.

الإيجابيات والسلبيات: تتمثل الميزة الأساسية للألومنيوم في طبيعته خفيفة الوزن، والتي يمكن أن تحسن من كفاءة استهلاك الوقود في المركبات. ومع ذلك، فهو أقل متانة من الفولاذ وقد لا يتحمل الإجهاد الميكانيكي العالي بنفس الفعالية. كما يمكن أن تكون عملية التصنيع أكثر تعقيداً، مما قد يؤدي إلى زيادة التكاليف.

التأثير على التطبيق: يُعد الألومنيوم مثاليًا لأغطية ومكونات محرك بدء التشغيل حيث يكون توفير الوزن ضروريًا. كما أن مقاومته للتآكل تجعله مناسباً للمركبات التي تعمل في البيئات الساحلية أو الرطبة.

اعتبارات للمشترين الدوليين: يُعد الامتثال لمعايير مثل ASTM B221 لبثق الألومنيوم أمرًا بالغ الأهمية. وفي مناطق مثل أفريقيا وأمريكا الجنوبية، حيث تنتشر التضاريس الوعرة، يجب على المشترين تقييم الخواص الميكانيكية للألومنيوم لضمان تلبيته لاحتياجاتهم من المتانة.

ما هي الفوائد التي يقدمها البلاستيك في مكونات محرك البادئ؟

الخصائص الرئيسية: توفر اللدائن، ولا سيما اللدائن الحرارية المصممة هندسياً، عزلاً كهربائياً ممتازاً ومقاومة للتآكل. ويمكنها العمل بفعالية تحت مجموعة من درجات الحرارة والضغوط.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

الإيجابيات والسلبيات: تشمل مزايا استخدام البلاستيك طبيعته خفيفة الوزن وفعاليته من حيث التكلفة. ومع ذلك، قد لا تتحمل المواد البلاستيكية الأحمال الميكانيكية العالية مثل المعادن ويمكن أن تتحلل تحت الحرارة الشديدة أو التعرض للأشعة فوق البنفسجية.

التأثير على التطبيق: وغالبًا ما تستخدم المكونات البلاستيكية في التطبيقات غير الحاملة، مثل الأغطية أو العوازل في المحركات البادئة. خصائصها العازلة مفيدة لمنع التقصير الكهربائي.

اعتبارات للمشترين الدوليين: يجب أن يتأكد المشترون من أن المواد البلاستيكية المستخدمة تتوافق مع المعايير ذات الصلة، مثل ISO 9001 لإدارة الجودة. في المناطق ذات درجات الحرارة المرتفعة، من الضروري اختيار مواد بلاستيكية مقاومة للحرارة.

جدول ملخص لاختيار المواد اللازمة لاستبدال محرك البادئ

| المواد | حالة الاستخدام النموذجية لتكلفة استبدال محرك بدء التشغيل | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | المكونات الكهربائية والأسلاك | موصلية ممتازة | ارتفاع التكلفة ومخاطر الأكسدة | عالية |

| الصلب | المكونات الهيكلية والأغلفة | قوة ومتانة عالية | أثقل وقد تحتاج إلى طلاءات | متوسط |

| الألومنيوم | العلب والمكونات غير الحاملة | خفيف الوزن ومقاوم للتآكل | أقل متانة من الفولاذ | متوسط |

| بلاستيك | العوازل والأغطية | خفيفة الوزن وفعالة من حيث التكلفة | قوة ميكانيكية محدودة | منخفض |

يوفر هذا الدليل الاستراتيجي لاختيار المواد للمشترين بين الشركات رؤى أساسية حول المواد المستخدمة في بدائل محركات بدء التشغيل، مما يساعدهم على اتخاذ قرارات مستنيرة مصممة خصيصًا لتلبية احتياجاتهم الإقليمية المحددة ومتطلبات الامتثال.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لتكلفة استبدال محرك بدء التشغيل

ما هي عمليات التصنيع الرئيسية للمحركات البادئة؟

تعتبر عملية تصنيع محركات بدء التشغيل أمرًا بالغ الأهمية لضمان موثوقيتها وأدائها. تتضمن هذه العملية عادةً عدة مراحل: إعداد المواد والتشكيل والتجميع والتشطيب. إن فهم هذه المراحل يمكن أن يساعد مشتري B2B على تقدير التعقيدات التي ينطوي عليها إنتاج محركات بادئ الحركة عالية الجودة.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

كيف يتم تحضير المواد لإنتاج محرك بدء التشغيل؟

إعداد المواد هو المرحلة الأولى في عملية التصنيع. يتم الحصول على المواد الخام عالية الجودة، مثل الفولاذ للمبيت والنحاس للملفات، من موردين ذوي سمعة طيبة. إن اختيار المواد أمر بالغ الأهمية، لأنه يؤثر بشكل مباشر على متانة وكفاءة المحرك البادئ.

وبمجرد الحصول على المواد، تخضع لمختلف المعالجات لتعزيز خصائصها. على سبيل المثال، قد تتم معالجة المكونات الفولاذية بالحرارة لزيادة قوتها ومقاومتها للتآكل. وغالباً ما يتم عزل اللفات النحاسية لمنع حدوث دوائر قصيرة. تضمن هذه المرحلة استيفاء جميع المواد للمواصفات المطلوبة لمحركات بدء التشغيل عالية الأداء.

ما هي تقنيات التشكيل المستخدمة في تصنيع المحركات البادئة؟

تنطوي مرحلة التشكيل على تشكيل المواد الخام في المكونات التي ستشكل محرك بدء التشغيل. وتشمل التقنيات الرئيسية ما يلي:

-

الختم: تُستخدم هذه العملية لصنع العلب والأغطية المعدنية. تقوم ماكينات الختم بالضغط على الصفائح المعدنية وتشكيلها في الأشكال المطلوبة.

-

التصنيع الآلي: يتم استخدام عمليات التصنيع الآلي الدقيقة، مثل الخراطة والطحن، لإنشاء مكونات مثل المحرك والمبدل. يجب أن تتوافق هذه المكونات مع التفاوتات الدقيقة لضمان الملاءمة والوظيفة المناسبة.

-

اللف: يعد لف الأسلاك النحاسية حول المحرك خطوة حاسمة. وتستخدم آلات اللف الآلية لضمان اتساق الشد والدقة، وهما أمران حيويان لكفاءة المحرك.

-

القولبة: بالنسبة للمكونات البلاستيكية، غالبًا ما يتم استخدام تقنيات القولبة بالحقن. وهذا يسمح بإنشاء أشكال معقدة خفيفة الوزن وقوية في نفس الوقت.

تُعد تقنيات التشكيل هذه ضرورية لإنتاج محركات بدء التشغيل التي يمكنها تحمل الظروف القاسية التي تعمل فيها غالبًا.

كيف يتم تجميع وتشطيب محركات بدء التشغيل؟

تتضمن مرحلة التجميع تجميع جميع المكونات المصنعة معًا. وتشمل هذه العملية عادةً ما يلي:

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

-

تجميع المكونات: يقوم الفنيون المهرة أو الأنظمة الآلية بتجميع الأجزاء المختلفة، بما في ذلك الملف اللولبي والحديد والمبيت. ويجب تركيب كل مكون بدقة لضمان الأداء الأمثل.

-

التوصيلات الكهربائية: يتم إجراء التوصيلات الكهربائية المناسبة لضمان عمل محرك بدء التشغيل بشكل صحيح. قد تنطوي هذه الخطوة على لحام أو تجعيد الأسلاك بالأطراف.

-

الاختبار ومراقبة الجودة: بعد التجميع، يخضع كل محرك بادئ تشغيل لسلسلة من الاختبارات للتحقق من الأداء الوظيفي والأداء. ويمكن أن يشمل ذلك اختبار المنصة حيث يتم تشغيل المحرك تحت ظروف التحميل.

قد تشمل عمليات التشطيب أيضًا معالجات السطح لتحسين مقاومة التآكل، مثل الجلفنة أو طلاء المسحوق. لا تعمل هذه المعالجات على تحسين مظهر المحرك البادئ فحسب، بل تطيل عمره الافتراضي أيضًا.

ما هي إجراءات ضمان الجودة الضرورية لمحركات التشغيل؟

يعد ضمان الجودة (QA) جانبًا مهمًا من جوانب عملية التصنيع، مما يضمن أن محركات بدء التشغيل تلبي معايير الصناعة وتوقعات العملاء. بالنسبة للمشترين بين الشركات (B2B)، يمكن أن يساعد فهم تدابير ضمان الجودة المعمول بها في التخفيف من المخاطر المرتبطة بتوريد المكونات من الموردين الدوليين.

ما هي المعايير الدولية ذات الصلة بتصنيع المحركات البادئة؟

تلعب المعايير الدولية دوراً هاماً في ضمان جودة محركات بدء التشغيل. وتشمل المعايير الرئيسية ما يلي:

-

آيزو 9001: يركز هذا المعيار على نظم إدارة الجودة وينطبق على جميع عمليات التصنيع. ويشير الامتثال لمعيار الأيزو 9001 إلى أن الشركة المصنعة قد وضعت ممارسات فعالة لإدارة الجودة.

-

علامة CE: في أوروبا، تعتبر علامة CE ضرورية للإشارة إلى أن المنتج يفي بمتطلبات السلامة وحماية البيئة. وهي ذات أهمية خاصة للمكونات الكهربائية مثل محركات بدء التشغيل.

-

معايير API: بالنسبة لتطبيقات محددة، لا سيما في صناعة السيارات، يمكن أن يكون الالتزام بمعايير واجهة برمجة التطبيقات (API) أمرًا بالغ الأهمية. وتضمن هذه المعايير استيفاء المنتجات لمعايير الأداء والموثوقية.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في تصنيع المحركات البادئة؟

يتم دمج نقاط التحقق من مراقبة الجودة في جميع مراحل عملية التصنيع لتحديد العيوب وتصحيحها في وقت مبكر. وتشمل نقاط الفحص الشائعة ما يلي:

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

-

مراقبة الجودة الواردة (IQC): يتم فحص المواد الخام والمكونات عند وصولها إلى منشأة التصنيع. تضمن هذه الخطوة استخدام المواد التي تفي بالمعايير المحددة فقط في الإنتاج.

-

مراقبة الجودة أثناء الإنتاج (IPQC): أثناء عملية التصنيع، يتم إجراء عمليات تفتيش منتظمة لمراقبة جودة المكونات أثناء تشكيلها وتجميعها. وهذا يساعد على اكتشاف أي انحرافات عن معايير الجودة في وقت مبكر.

-

مراقبة الجودة النهائية (FQC): بعد التجميع، تخضع محركات البادئ لاختبارات شاملة للتحقق من وظائفها وأدائها. ويمكن أن يشمل ذلك الاختبار الكهربائي واختبار الحمل والفحص البصري.

تضمن نقاط الفحص هذه أن كل محرك بادئ تشغيل يتم إنتاجه يفي بالمواصفات ومعايير الجودة المطلوبة.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

بالنسبة للمشترين الدوليين بين الشركات، وخاصةً من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، فإن التحقق من ممارسات مراقبة الجودة لدى الموردين أمر حيوي. إليك بعض الخطوات القابلة للتنفيذ:

-

تدقيق الموردين: يمكن أن يوفر إجراء عمليات التدقيق الموقعي نظرة ثاقبة لعمليات التصنيع وإجراءات مراقبة الجودة الخاصة بالمورد. ويتيح ذلك للمشترين تقييم مدى الامتثال للمعايير الدولية بشكل مباشر.

-

طلب تقارير الجودة: يجب على المشترين طلب تقارير مراقبة الجودة التي تفصّل نتائج عمليات مراقبة الجودة المتكاملة ومراقبة الجودة الشاملة ومراقبة الجودة المالية. ويمكن أن توفر هذه التقارير الشفافية بشأن التزام المورد بالجودة.

-

عمليات التفتيش من قبل أطراف ثالثة: يمكن أن يوفر إشراك خدمات التفتيش من طرف ثالث تقييمًا غير متحيز لممارسات مراقبة الجودة لدى المورد. ويمكن لهذه الخدمات إجراء عمليات التفتيش في مختلف مراحل الإنتاج.

-

الشهادات والاعتمادات: يجب على المشترين التحقق من أن الموردين حاصلون على الشهادات ذات الصلة، مثل شهادة الأيزو 9001 أو علامة CE. ويمكن أن يشير ذلك إلى الالتزام بالحفاظ على معايير عالية الجودة.

يتيح فهم تدابير ضمان الجودة هذه للمشترين بين الشركات اتخاذ قرارات مستنيرة عند اختيار الموردين لمحركات بدء التشغيل، مما يضمن في النهاية موثوقية وأداء المنتجات التي يحصلون عليها.

دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘تكلفة استبدال محرك بدء التشغيل’

مقدمة

يعمل دليل التوريد العملي هذا كقائمة مرجعية خطوة بخطوة للمشترين بين الشركات الذين يتطلعون إلى إدارة التكاليف المرتبطة باستبدال محركات بدء التشغيل بفعالية. إن فهم تعقيدات التوريد، وتقييم الموردين، وتحديد التكاليف الإجمالية المترتبة على ذلك سيمكن الشركات من اتخاذ قرارات شراء مستنيرة، خاصة في الأسواق المتنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

قبل البدء في عملية الشراء، من الضروري تحديد المواصفات الفنية المطلوبة لمحركات بدء التشغيل بوضوح. ويشمل ذلك فهم طراز المركبات المعنية وطرازها وسنتها، بالإضافة إلى أي معايير أداء محددة يجب استيفاؤها.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

- الاعتبارات الرئيسية:

- ما نوع محركات بدء التشغيل المناسبة لأسطولك؟

- هل هناك أي متطلبات فريدة بناءً على طرازات المركبات الإقليمية؟

الخطوة 2: إجراء تحليل السوق

سيساعدك تحليل السوق على قياس متوسط التكاليف وتحديد الموردين المحتملين. ابحث عن نطاقات أسعار المحركات البادئة في منطقتك وقارنها بالمعايير الدولية لضمان التنافسية.

- الاعتبارات الرئيسية:

- ما هي النقاط السعرية المعتادة للمبتدئين الجدد مقابل المبتدئين المعاد بناؤهم؟

- كيف يمكن المقارنة بين الموردين المحليين والدوليين من حيث التكلفة والتوافر؟

الخطوة 3: تقييم الموردين المحتملين

قم بفحص الموردين المحتملين بدقة للتأكد من قدرتهم على تلبية احتياجاتك الفنية والميزانية. ابحث عن الموردين الراسخين الذين يتمتعون بسمعة طيبة في هذا المجال، واطلب ملفات تعريفية عن الشركة ودراسات حالة ومراجع.

- الاعتبارات الرئيسية:

- ما هو سجل المورد مع الشركات المماثلة؟

- هل لديهم القدرة على التعامل مع حجم طلبك والجداول الزمنية للتسليم؟

الخطوة 4: طلب عروض أسعار مفصلة

بمجرد الانتهاء من وضع قائمة مختصرة بالموردين، اطلب عروض أسعار مفصلة تفصّل التكاليف المترتبة على استبدال محرك بدء التشغيل. يجب أن يشمل ذلك قطع الغيار والعمالة والشحن وأي رسوم إضافية.

- الاعتبارات الرئيسية:

- هل هناك أي تكاليف خفية أو رسوم إضافية غير مدرجة في عرض الأسعار الأولي؟

- كيف يختلف هيكل التسعير بالنسبة للمشتريات بالجملة عن الوحدات الفردية؟

الخطوة 5: تقييم سياسات الضمان والإرجاع

إن فهم سياسات الضمان والإرجاع أمر بالغ الأهمية لتخفيف المخاطر المرتبطة بالمكونات المعيبة. تأكد من أن الموردين يقدمون ضمانات قوية تغطي قطع الغيار والعمالة، بالإضافة إلى إجراءات واضحة للإرجاع أو الاستبدال.

- الاعتبارات الرئيسية:

- ما هي مدة وتغطية الضمان؟

- كيف تعمل سياسة الإرجاع في حالة المنتجات المعيبة؟

الخطوة 6: التحقق من الامتثال والشهادات

التحقق من امتثال الموردين المحتملين لمعايير الجودة الدولية وحصولهم على الشهادات ذات الصلة. وهذا مهم بشكل خاص في الأسواق التي قد تختلف فيها اللوائح بشكل كبير.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

- الاعتبارات الرئيسية:

- ما هي الشهادات التي يحملها الموردون (على سبيل المثال، ISO، CE)؟

- هل منتجاتهم متوافقة مع اللوائح المحلية في السوق الذي تعمل فيه؟

الخطوة 7: وضع اللمسات الأخيرة على العقد

بمجرد الانتهاء من تقييم جميع الجوانب، قم بوضع اللمسات الأخيرة على العقد مع المورد الذي تم اختياره. تأكد من أن جميع الشروط المتفق عليها، بما في ذلك التسعير وجداول التسليم وشروط الدفع، موثقة بوضوح.

- الاعتبارات الرئيسية:

- هل قمت بتضمين بنود لمراجعات الأداء وعقوبات التأخير؟

- هل هناك فهم واضح لهيكل الدفع والجداول الزمنية؟

من خلال اتباع قائمة المراجعة هذه، يمكن للمشترين بين الشركات تبسيط عملية التوريد لاستبدال المحركات البادئة وضمان اتخاذ قرارات مستنيرة تتماشى مع احتياجاتهم التشغيلية وقيود الميزانية.

تحليل شامل للتكلفة والتسعير لتكلفة استبدال المحرك البادئ تحديد مصادر التكلفة الشاملة

ما هي مكونات التكلفة الرئيسية لاستبدال محرك بدء التشغيل؟

عند تحليل هيكل تكلفة استبدال محرك بدء التشغيل، تلعب عدة مكونات دورًا حاسمًا. وتشمل هذه المكونات ما يلي:

-

المواد: يمكن أن تتراوح تكلفة المواد بشكل كبير بناءً على جودة ونوع محرك البادئ. قد يتكلف محرك البادئ القياسي ما بين $80 إلى $350، في حين أن الوحدات المتخصصة أو عالية الأداء يمكن أن تتجاوز هذا النطاق. وتساهم المكونات مثل الملفات الكهرومغناطيسية والملفات اللولبية والأذرع في التكلفة الإجمالية للمواد.

-

العمل: يمكن أن تختلف تكاليف العمالة بشكل كبير اعتماداً على مدى تعقيد التركيب. قد يستغرق الاستبدال البسيط أقل من ساعة، بينما قد تتطلب المركبات الأكثر تعقيدًا عدة ساعات من العمل. في مناطق مثل أوروبا أو أمريكا الشمالية، يمكن أن تتراوح أسعار العمالة في مناطق مثل أوروبا أو أمريكا الشمالية من $75 إلى $150 في الساعة، بينما في بلدان مثل نيجيريا أو المملكة العربية السعودية، قد تكون الأسعار أقل، مما يؤثر على التكاليف الإجمالية.

-

تكاليف التصنيع العامة: ويشمل ذلك التكاليف المرتبطة بمرافق الإنتاج وصيانة المعدات والمرافق. ويمكن أن تؤدي عمليات التصنيع الفعالة إلى خفض التكاليف العامة، مما يعود بالنفع على المشترين.

-

الأدوات: يمكن للأدوات المتخصصة المطلوبة للتركيب أو الصيانة أن تضيف إلى التكاليف الأولية، خاصة بالنسبة لمحركات التشغيل المعقدة الموجودة في السيارات الفاخرة. يجب على المشترين النظر في إمكانية استئجار هذه الأدوات أو شرائها لتقليل النفقات.

-

مراقبة الجودة (QC): تضمن عمليات ضمان الجودة استيفاء محركات بدء التشغيل لمعايير السلامة والأداء. يمكن أن تؤدي مراقبة الجودة الشاملة إلى زيادة التكاليف الأولية ولكنها قد تؤدي إلى تقليل الأعطال والاستبدال في المستقبل.

-

اللوجستيات: يمكن أن تختلف تكاليف الشحن بناءً على المسافة من المورد ووسيلة النقل. يجب على المشترين الدوليين أن يأخذوا في الاعتبار رسوم الاستيراد والتعريفات الجمركية التي يمكن أن تؤثر بشكل كبير على الأسعار الإجمالية.

-

الهامش: يضيف الموردون عادةً هامشًا لتغطية التكاليف التشغيلية والأرباح. ويمكن أن يتقلب هذا الهامش حسب المنافسة في السوق والطلب.

كيف تؤثر العوامل المؤثرة في الأسعار على تكاليف استبدال محرك البادئ؟

تؤثر عدة عوامل على أسعار استبدال محرك بدء التشغيل:

-

الحجم/الحد الأدنى للطلب: يمكن أن يؤدي الشراء بالجملة إلى خصومات كبيرة. وغالباً ما يوفر الموردون هياكل تسعير أفضل للطلبيات الكبيرة، وهو أمر بالغ الأهمية للشركات التي تتطلع إلى الحفاظ على أسطولها.

-

المواصفات/التخصيص: يمكن أن تؤدي المواصفات المخصصة إلى زيادة التكاليف. وينبغي أن يكون المشترون واضحين بشأن متطلباتهم وأن يأخذوا في الاعتبار الحلول الجاهزة عندما يكون ذلك ممكناً لتقليل النفقات.

-

المواد: يمكن أن يؤثر الاختيار بين قطع OEM (الشركة المصنعة للمعدات الأصلية) مقابل بدائل ما بعد البيع على الأسعار. تميل قطع OEM إلى أن تكون أغلى ثمناً بسبب سمعة العلامة التجارية والتوافق المضمون.

-

الجودة/الشهادات: قد تكلف القطع ذات الجودة العالية والحاصلة على شهادات اعتماد أعلى في البداية، ولكنها يمكن أن توفر طول عمر وموثوقية أفضل، مما يقلل من التكلفة الإجمالية للملكية.

-

عوامل الموردين: يمكن أن تؤثر سمعة الموردين وموثوقيتهم على الأسعار. فقد يتقاضى الموردون الراسخون أسعاراً أعلى ولكنهم يقدمون ضمانات وخدمة عملاء أفضل.

-

مصطلحات التجارة الدولية: إن فهم شروط التجارة الدولية أمر حيوي للمشترين الدوليين. فهي تحدد مسؤوليات المشترين والبائعين فيما يتعلق بالشحن والتأمين والتعريفات الجمركية، والتي يمكن أن تؤثر على التكاليف الإجمالية.

ما هي النصائح التي يمكن أن تساعد المشتري في التفاوض على تكاليف محرك بدء التشغيل؟

يمكن للمشترين بين الشركات استخدام العديد من الاستراتيجيات لتأمين أسعار أفضل لبدائل محرك بدء التشغيل:

-

التفاوض: تفاوض دائماً على الأسعار، خاصة عند تقديم طلبات كبيرة. قد يقدم الموردون خصومات على الدفعات المقدمة أو العقود طويلة الأجل.

-

الفعالية من حيث التكلفة: قم بتقييم التكلفة الإجمالية للملكية بدلاً من السعر المقدم فقط. ضع في اعتبارك عوامل مثل تكاليف التركيب والعمر المتوقع وشروط الضمان.

-

الفروق الدقيقة في الأسعار للمشترين الدوليين: يجب على المشترين من مناطق مثل أفريقيا وأمريكا الجنوبية أن يكونوا على دراية بتقلبات أسعار العملات وظروف السوق المحلية التي يمكن أن تؤثر على الأسعار. وقد تسفر إقامة علاقات مع الموردين المحليين عن صفقات أفضل.

-

البحث والمقارنة: إجراء بحث شامل للسوق لمقارنة الأسعار والجودة بين مختلف الموردين. ويمكن أن يوفر ذلك نفوذاً أثناء المفاوضات.

-

فهم شروط الضمان: يمكن أن يوفر الضمان القوي التكاليف على المدى الطويل. تأكد من أن شروط الضمان واضحة وشاملة قبل إتمام عملية الشراء.

إخلاء المسؤولية

الأسعار المذكورة هي أسعار استرشادية ويمكن أن تختلف بناءً على الموقع وظروف السوق ومتطلبات السيارة المحددة. استشر دائماً الموردين للحصول على أدق وأحدث المعلومات عن الأسعار.

تحليل البدائل: مقارنة تكلفة استبدال محرك بدء التشغيل بالحلول الأخرى

في صناعة السيارات، وخاصةً بالنسبة للشركات التي تعتمد على أساطيل المركبات، فإن فهم التكاليف المرتبطة باستبدال محرك بدء التشغيل أمر بالغ الأهمية. ومع ذلك، توجد العديد من البدائل التي يمكن أن تخفف من الحاجة إلى الاستبدال أو تقدم حلولاً مختلفة لمشاكل بدء التشغيل. يستكشف هذا القسم تكاليف وفوائد استبدال محركات البادئ مقارنةً بالطرق البديلة، مما يساعد المشترين من الشركات على اتخاذ قرارات مستنيرة.

| جانب المقارنة | تكلفة استبدال محرك بدء التشغيل | استبدال البطارية | البدء السريع |

|---|---|---|---|

| الأداء | يستعيد قدرة تشغيل المحرك بالكامل | يحسن عمر البطارية وموثوقية التشغيل | توفر طاقة بدء تشغيل مؤقتة |

| التكلفة | $150 - $1,100 (قطع الغيار + العمالة) | $50 - $300 (قطع الغيار + العمالة) | الحد الأدنى (تكلفة كابلات قفزة البطارية $20 - $50) |

| سهولة التنفيذ | يتطلب تركيب احترافي أو خبرة في التركيب اليدوي | يمكن إجراؤها بواسطة ميكانيكي أو كمشروع ذاتي | بسيطة وسريعة مع كابلات القفز البسيطة والسريعة |

| الصيانة | صيانة منخفضة بعد التركيب | يلزم إجراء فحوصات منتظمة؛ قد تحتاج البطاريات إلى الاستبدال كل 3-5 سنوات | الحد الأدنى؛ افحص الكابلات وحالة البطارية |

| أفضل حالة استخدام | حل طويل الأجل لمشكلات البدء على المدى الطويل | عند انخفاض أداء البطارية أو فشلها | لاحتياجات البدء الفوري والقصير الأجل |

ما هي إيجابيات وسلبيات استبدال البطارية كبديل؟

يعد استبدال البطارية حلاً أكثر فعالية من حيث التكلفة للشركات التي تواجه مشكلات في بدء التشغيل. يتراوح سعر البطارية الجديدة عادةً من $50 إلى $300، ويمكن استبدالها في الغالب بأقل قدر من الخبرة الفنية. ومع ذلك، لا يكون هذا الحل قابلاً للتطبيق إلا إذا كانت البطارية هي بالفعل السبب الجذري لمشكلة بدء التشغيل. الجانب السلبي هو أنه إذا كان محرك بدء التشغيل نفسه معيباً، فإن استبدال البطارية لن يحل المشكلة، مما قد يؤدي إلى مزيد من التعطل.

كيف يمكن مقارنة بدء التشغيل السريع باستبدال محرك بدء التشغيل؟

يُعدّ بدء التشغيل السريع حلاً فورياً ومنخفض التكلفة، وهو مفيد بشكل خاص في حالات الطوارئ. وهو ينطوي على توصيل بطارية السيارة ببطارية مشحونة باستخدام كابلات التوصيل، مما يسمح بتشغيل المحرك مؤقتاً. تُعدّ تكلفة توصيل البطارية بالبطارية قليلة جداً، وتتضمن في المقام الأول شراء الكابلات. ومع ذلك، فإن هذا ليس حلاً دائماً وقد يشير إلى وجود مشاكل كامنة في البطارية أو محرك التشغيل. بالإضافة إلى ذلك، قد يكون الاعتماد على هذه الطريقة بشكل متكرر غير عملي وقد يؤدي إلى مشاكل أكثر أهمية في المستقبل.

الخاتمة: كيف يمكن لمشتري B2B اختيار الحل المناسب؟

عند تحديد أفضل طريقة للتعامل مع مشاكل محرك البادئ يجب على مشتري B2B تقييم احتياجاتهم التشغيلية الخاصة وظروف السيارة. إذا كانت الموثوقية والأداء الوظيفي على المدى الطويل من الأولويات، فمن المستحسن الاستثمار في استبدال محرك بدء التشغيل على الرغم من ارتفاع تكلفته. وعلى العكس من ذلك، إذا كانت هناك قيود في الميزانية أو إذا كانت المشكلة ناتجة على الأرجح عن بطارية معطلة، فقد يكون استبدال البطارية أو تشغيل المحرك السريع بديلين مناسبين. يجب على المشترين النظر في المفاضلة بين التكاليف الأولية والموثوقية على المدى الطويل لاتخاذ قرار مستنير يتماشى مع أهدافهم التشغيلية.

الخصائص التقنية الأساسية والمصطلحات التجارية لتكلفة استبدال محرك بدء التشغيل

يعد فهم تعقيدات تكاليف استبدال المحرك البادئ أمرًا ضروريًا للمشترين بين الشركات في قطاع السيارات. سنقوم هنا بتفصيل الخصائص التقنية الرئيسية والمصطلحات الصناعية التي ستساعد في اتخاذ القرار وتعزيز استراتيجيات الشراء.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

ما هي المواصفات الفنية الرئيسية لمحركات بدء التشغيل؟

-

درجة المواد

تشير درجة مادة المحرك البادئ عادةً إلى جودة المواد المستخدمة وتكوينها، مثل الفولاذ والنحاس. تضمن المواد عالية الجودة المتانة والكفاءة، وهو أمر بالغ الأهمية للأداء في ظروف التشغيل المتنوعة. بالنسبة لمشتري B2B، يمكن أن يؤدي اختيار المحركات المصنوعة من مواد فائقة الجودة إلى إطالة عمر الخدمة وتقليل تكاليف الصيانة. -

أمبير التدوير (CA)

أمبيرية التحريك هي الحد الأقصى للتيار الذي يسحبه محرك البادئ أثناء محاولة تشغيل المحرك. تعتبر هذه المواصفات حيوية لأنها تؤثر بشكل مباشر على قدرة البادئ على العمل في المناخات المختلفة، خاصة في المناطق الباردة حيث غالباً ما تكون هناك حاجة إلى تيار كهربائي أعلى. يجب على المشترين تقييم هذه القيمة لضمان التوافق مع بطارية السيارة ومتطلبات المحرك. -

تصنيف عزم الدوران

يقيس تصنيف عزم الدوران قوة الدوران التي يمكن أن يبذلها محرك بدء التشغيل لقلب المحرك. غالبًا ما تكون هناك حاجة إلى تصنيف عزم دوران أعلى للمحركات الأكبر حجمًا أو تلك ذات نسب الضغط العالية. إن فهم متطلبات عزم الدوران يساعد مشتري B2B على اختيار بادئات التشغيل المناسبة التي يمكن أن تعمل بكفاءة مع طرازات معينة من المركبات، مما يقلل من مخاطر الأعطال المبكرة. -

نسبة تخفيض التروس

تشير هذه النسبة إلى العلاقة بين سرعة المحرك وسرعة خرج ترس البادئ. يمكن أن يؤدي ارتفاع نسبة تخفيض التروس إلى تعزيز كفاءة وقوة محرك البادئ. يجب أن يأخذ المشترون هذه المواصفات بعين الاعتبار لضمان الأداء الأمثل، خاصة بالنسبة للمركبات التي تتطلب تشغيل المحرك بسرعة في ظل ظروف صعبة. -

نطاق درجة حرارة التشغيل

يحدد نطاق درجة حرارة التشغيل الظروف البيئية التي يمكن أن يعمل فيها محرك بدء التشغيل بفعالية. هذه المواصفات ضرورية للمركبات التي تعمل في المناخات القاسية. يجب على المشترين تقييم هذا النطاق لضمان قدرة المحرك البادئ المختار على تحمل الظروف المحددة للأسواق المستهدفة.

ما هي المصطلحات التجارية الشائعة التي يجب أن يفهمها المشترون بين الشركات؟

-

OEM (الشركة المصنعة للمعدات الأصلية)

يشير مصطلح OEM إلى القطع المصنوعة من قبل الشركة المصنعة التي صنعت السيارة في الأصل. وغالباً ما يتم تفضيل هذه القطع لجودتها وتوافقها. يجب على مشتري B2B أن يأخذوا بعين الاعتبار مشغلات OEM لضمان الموثوقية والأداء، خاصة بالنسبة للمركبات المتطورة أو المتخصصة. -

MOQ (الحد الأدنى لكمية الطلب)

موك هو الحد الأدنى لعدد الوحدات التي يطلبها المورد للطلب الواحد. يعد فهم موك أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات لإدارة مستويات المخزون والتدفق النقدي بفعالية. ويساعد هذا المصطلح في التفاوض على المشتريات بالجملة، مما قد يؤدي إلى توفير في التكاليف. -

طلب عرض أسعار (RFQ)

طلب عروض الأسعار هو مستند يتم إرساله إلى الموردين لطلب تسعير وشروط لمنتجات محددة. بالنسبة للمشترين بين الشركات، يمكن أن يسهّل تقديم طلبات عروض الأسعار التنافسية وتحسين العلاقات مع الموردين. إنها أداة أساسية لعمليات التوريد والمشتريات. -

شروط التجارة الدولية (Incoterms)

تحدد إنكوترمز Incoterms مسؤوليات المشترين والبائعين في المعاملات الدولية، بما في ذلك الشحن والتأمين والتعريفات. ويُعد الإلمام بهذه الشروط أمرًا حيويًا للمشترين بين الشركات المشاركين في التجارة عبر الحدود، حيث إنها تحدد مسؤوليات المخاطر والتكاليف المرتبطة بمحركات الشحن البادئة. -

المهلة الزمنية

المهلة الزمنية هي الفترة الزمنية التي تستغرقها من تقديم الطلب إلى استلام البضائع. إن فهم المهل الزمنية أمر بالغ الأهمية لإدارة المخزون والتخطيط. يجب على المشترين بين الشركات أن يأخذوا في الحسبان المهل الزمنية عند التفاوض مع الموردين لضمان التسليم في الوقت المناسب وتجنب حدوث اضطرابات في عملياتهم.

من خلال فهم هذه الخصائص التقنية والمصطلحات الصناعية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة فيما يتعلق بتكاليف استبدال المحركات البادئة مما يعزز في نهاية المطاف كفاءة المشتريات والفعالية التشغيلية.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع تكلفة استبدال المحركات البادئة

ما هي الاتجاهات الرئيسية التي تؤثر على سوق تكلفة استبدال محرك بدء التشغيل؟

يشهد قطاع استبدال محركات بدء التشغيل حاليًا تحولاً كبيرًا مدفوعًا بعوامل عالمية مختلفة. ويتمثل أحد المحركات الرئيسية في الطلب المتزايد على موثوقية السيارة وأدائها، لا سيما في مناطق مثل أفريقيا والشرق الأوسط، حيث يمكن أن تؤدي ظروف القيادة القاسية إلى تفاقم أعطال البادئ. بالإضافة إلى ذلك، يؤدي التحول نحو السيارات الكهربائية والهجينة إلى إعادة تشكيل السوق، حيث يحتاج المشترون من الشركات إلى التكيف مع التقنيات الجديدة واستراتيجيات التوريد التي تلبي احتياجات هذه الأنواع المتطورة من السيارات.

أصبحت التكنولوجيات الناشئة، مثل المنصات الرقمية لشراء قطع الغيار، سائدة. تسهّل هذه المنصات إجراء مقارنات أسهل للأسعار وتحديد مصادر المكونات، مما يسمح للمشترين الدوليين بالوصول إلى مجموعة أوسع من المنتجات، بدءاً من الخيارات المناسبة للميزانية إلى قطع الغيار عالية الأداء. وعلاوة على ذلك، يؤدي ظهور التجارة الإلكترونية في مجال قطع غيار السيارات إلى تغيير كيفية تفاعل الشركات مع الموردين، مما يدفع إلى المزيد من الخدمات اللوجستية المبسطة وأوقات التسليم الأسرع.

وتتأثر اتجاهات التوريد أيضًا بالعوامل الجيوسياسية، مثل الاتفاقيات التجارية والتعريفات الجمركية، التي تؤثر على تكلفة الأجزاء المستوردة من مناطق مختلفة. يجب أن يظل المشترون في أفريقيا وأمريكا الجنوبية على علم بهذه الديناميكيات لاتخاذ قرارات فعالة من حيث التكلفة. بالإضافة إلى ذلك، فإن الاتجاه المتزايد للتصنيع الإقليمي يسمح للموردين المحليين بالمنافسة بفعالية أكبر، مما يقلل من المهل الزمنية وتكاليف النقل.

صورة توضيحية تتعلق بتكلفة استبدال محرك بدء التشغيل

كيف تؤثر الاستدامة والتوريد الأخلاقي على قطاع استبدال المحركات المبتدئة؟

لقد برزت الاستدامة كعامل حاسم في صناعة قطع غيار السيارات، بما في ذلك محركات بدء التشغيل. ويخضع التأثير البيئي لعمليات التصنيع ودورة حياة مكونات السيارات لتدقيق متزايد. ويعطي المشترون من الشركات الأولوية الآن للموردين الذين يظهرون التزامًا بالاستدامة، مثل استخدام المواد المعاد تدويرها أو تطبيق ممارسات التصنيع الموفرة للطاقة.

لا يمكن المبالغة في أهمية المصادر الأخلاقية. حيث يتزايد اهتمام المشترين بمصادر المواد المستخدمة في المحركات المبتدئة، مع التركيز على تجنب المعادن المتعارضة وضمان ممارسات العمل العادلة في جميع مراحل سلسلة التوريد. أصبحت شهادات مثل ISO 14001 للإدارة البيئية وشهادات التجارة العادلة معايير أساسية في اختيار الموردين.

وعلاوة على ذلك، تستكشف الشركات البدائل ‘الخضراء’، بما في ذلك التغليف الصديق للبيئة والمكونات القابلة للتحلل الحيوي. من خلال التوافق مع الموردين الذين يعطون الأولوية لهذه القيم، يمكن للشركات تعزيز سمعة علامتها التجارية وجذب قاعدة عملاء واعية بيئياً. لا يساعد هذا التحول في تخفيف الأثر البيئي فحسب، بل يمكن أن يؤدي أيضًا إلى توفير التكاليف على المدى الطويل من خلال تحسين الكفاءة وتقليل النفايات.

كيف تطور سوق تكلفة استبدال محرك بدء التشغيل بمرور الوقت؟

لقد تطور سوق استبدال محركات بدء التشغيل بشكل كبير على مر العقود، متأثرًا بالتطورات في تكنولوجيا السيارات والتغيرات في سلوك المستهلك. تاريخيًا، كانت محركات بدء التشغيل أجهزة بسيطة نسبيًا، ولكن مع ازدياد تعقيد السيارات مع ظهور أنظمة الإشعال الإلكترونية والإدارة المتقدمة للوقود، تطور تصميم ووظائف محركات بدء التشغيل لتلبية هذه المتطلبات.

في الأيام الأولى لتصنيع السيارات، كان توريد محركات بدء التشغيل في المقام الأول شأنًا محليًا في المقام الأول، حيث كانت قطع الغيار تُنتج وتباع في الأسواق الإقليمية. ومع ذلك، فقد غيرت العولمة هذا المشهد، مما مكن المشترين الدوليين من الوصول إلى مجموعة متنوعة من المنتجات من مختلف المصنعين في جميع أنحاء العالم. وقد أدى هذا التطور إلى زيادة المنافسة، وبالتالي إلى نطاق سعري أوسع لمحركات بدء التشغيل.

نظرًا لأن السيارات أصبحت أكثر تطورًا، فقد تذبذبت تكلفة الاستبدال أيضًا، مدفوعة بعوامل مثل نوع السيارة وطرازها ومدى تعقيد عملية التركيب. واليوم، يجب على المشترين بين الشركات التنقل في مشهد أكثر تعقيداً في السوق، والموازنة بين اعتبارات التكلفة والحاجة إلى الجودة والموثوقية في قراراتهم المتعلقة بالتوريد.

الأسئلة المتداولة (FAQs) لمشتري B2B لتكلفة استبدال محرك بدء التشغيل

-

كيف يمكنني تحديد تكلفة استبدال محرك بدء التشغيل لسيارتي؟

لتقييم تكلفة استبدال محرك البادئ بدقة، ضع في اعتبارك عدة عوامل بما في ذلك طراز سيارتك وطرازها وسنة صنعها. عادةً ما تتكبد سيارات السيدان الشائعة تكاليف أقل بسبب توفر قطع الغيار بسهولة وسهولة وصول الميكانيكيين إليها. في المقابل، قد تتطلب السيارات الأكبر حجماً أو الموديلات الفاخرة قطع غيار متخصصة أو عمالة مكثفة، مما يزيد من التكاليف. يُنصح بالحصول على عروض أسعار من عدة موردين أو ميكانيكيين لمقارنة الأسعار والتأكد من حصولك على صفقة عادلة بناءً على متطلبات سيارتك المحددة. -

ما هي العوامل الرئيسية التي تؤثر على تكاليف استبدال محرك بدء التشغيل؟

هناك عدة عوامل يمكن أن تؤثر بشكل كبير على تكلفة استبدال محرك البادئ. وتشمل هذه العوامل نوع السيارة، ومدى تعقيد تركيب البادئ، وتكاليف العمالة في منطقتك، وما إذا كنت تختار بادئ تشغيل جديد أو معاد بناؤه. بالإضافة إلى ذلك، إذا كانت سيارتك تعاني من مشاكل كهربائية أساسية أخرى، فقد يؤدي ذلك أيضاً إلى زيادة التكلفة الإجمالية. قم دائماً بإجراء فحص شامل قبل الشروع في الاستبدال لتجنب النفقات غير المتوقعة. -

ما الذي يجب أن أبحث عنه عند الحصول على محركات بدء التشغيل من الموردين الدوليين؟

عند الحصول على محركات بدء التشغيل من موردين دوليين، تأكد من أن لديهم سجل حافل من الموثوقية والجودة. تحقق من شهاداتهم وامتثالهم للمعايير الدولية. بالإضافة إلى ذلك، ضع في اعتبارك قدرة المورد على توفير خيارات التخصيص، والحد الأدنى لكميات الطلبات (MOQ)، وشروط الدفع. يمكن أن يساعد تقييم آراء العملاء وطلب العينات أيضًا في اتخاذ قرارات مستنيرة بشأن مصداقية المورد وجودة المنتج. -

ما هو الحد الأدنى المعتاد لكميات الطلبات (MOQ) لمحركات بدء التشغيل؟

يمكن أن يختلف الحد الأدنى لكميات الطلبات (MOQ) لمحركات بدء التشغيل اختلافًا كبيرًا بين الموردين، حيث يتراوح عادةً بين 50 إلى 500 وحدة. قد يقدم الموردون الأصغر حجمًا كميات أقل من موك أقل، بينما قد يكون لدى المصنعين الأكبر حجمًا متطلبات أعلى. من المهم توضيح موك قبل التعامل مع المورد للتأكد من توافقه مع احتياجات مخزونك. بالإضافة إلى ذلك، فكر في التفاوض على الشروط التي قد تسمح بالمرونة في أحجام الطلبات، خاصةً إذا كنت تختبر السوق أو تقوم بتوسيع خط إنتاجك. -

ما هي شروط الدفع الشائعة عند شراء محركات بدء التشغيل دولياً؟

يمكن أن تختلف شروط الدفع للمشتريات الدولية لمحركات بدء التشغيل بناءً على سياسات المورد والجدارة الائتمانية للمشتري. تشمل الشروط الشائعة الدفع مقدماً أو خطاب اعتماد أو الدفع عند التسليم. من الضروري التفاوض على الشروط التي تحمي مصالحك مع ضمان ارتياح المورد لهذا الترتيب. بالإضافة إلى ذلك، ضع في اعتبارك العملة التي ستتم بها المعاملة، حيث يمكن أن تؤثر التقلبات على التكاليف الإجمالية. -

كيف يمكنني ضمان جودة محركات التشغيل التي يتم توريدها من الخارج؟

لضمان الجودة عند الحصول على محركات بدء التشغيل من الخارج، قم بإجراء العناية الواجبة على المورد. اطلب الشهادات التي تشير إلى الامتثال لمعايير الجودة، مثل ISO 9001. تنفيذ عملية ضمان الجودة التي تشمل عمليات فحص ما قبل الشحن واختبار العينات قبل الطلبات بالجملة. يمكن أيضًا أن يؤدي إنشاء علاقة قوية مع الموردين إلى تسهيل التواصل بشكل أفضل فيما يتعلق بتوقعات الجودة وأي مشكلات محتملة تنشأ أثناء الإنتاج. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد محركات بدء التشغيل؟

عند استيراد محركات بدء التشغيل، ضع في اعتبارك الجوانب اللوجستية مثل طرق الشحن واللوائح الجمركية والمهل الزمنية. اختر وكيل شحن موثوقًا به على دراية بقطع غيار السيارات للتغلب على أي تعقيدات ينطوي عليها الشحن الدولي. ضع في اعتبارك أيضاً الرسوم الجمركية والضرائب المحتملة التي قد تنطبق عند الاستيراد، حيث يمكن أن تؤثر بشكل كبير على التكاليف الإجمالية. يمكن أن يساعد التخطيط السليم والتواصل مع شريكك اللوجستي في ضمان التسليم في الوقت المناسب وتقليل الاضطرابات. -

كيف يمكنني استكشاف مشاكل محركات التشغيل وإصلاحها قبل اتخاذ قرار استبدالها؟

قبل استبدال محرك بادئ التشغيل، قم باستكشاف الأعطال المحتملة عن طريق فحص البطارية وتوصيلاتها وفحص الصمامات المتعلقة ببادئ التشغيل، والاستماع إلى الأصوات غير المعتادة عند محاولة تشغيل السيارة. يمكن للمقياس المتعدد أن يساعد في اختبار جهد البطارية، ويمكن أن يساعد فحص مرحل البادئ أيضاً في تحديد الأعطال. يمكن أن يؤدي إجراء هذه الفحوصات الأولية إلى توفير الوقت والتكاليف من خلال تحديد المشكلة الفعلية، والتي قد لا تتطلب بالضرورة استبدال محرك بادئ التشغيل بالكامل.

قائمة المصنعين والموردين لأفضل 4 شركات تصنيع وموردي تكلفة استبدال محرك بدء التشغيل

1. آخر فرصة لإصلاح السيارات – تكاليف استبدال المُشغّل

المجال: lastchanceautorepairs.com

تاريخ التسجيل: 2009 (16 عامًا)

مقدمة: تكلفة استبدال البادئ: البادئات الاقتصادية: $75 - $200، بادئات التشغيل الأصلية: $150 - $400، بادئات تشغيل عالية الأداء: $300 - $1000+. تكاليف العمالة: استبدال بادئ التشغيل الأساسي للمركبة: $100 - $250، التركيبات المعقدة: $300 - $600+. العوامل المؤثرة على التكلفة: نوع المركبة وطرازها، المبتدئين الجدد مقابل المبتدئين المعاد تصنيعهم، الإصلاحات الإضافية. تكاليف الأعمال اليدوية: قطع الغيار فقط: $100 - $400، استثمار الوقت: 2-6 ساعات. محترف ب...

2. كارفاكس - نظرة عامة على تكلفة محرك بدء التشغيل

المجال: carfax.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: يتراوح متوسط تكلفة محرك بدء تشغيل السيارة من $100 إلى $400، بما في ذلك قطع الغيار والعمالة. يمكن أن يختلف السعر بناءً على نوع السيارة وطرازها، بالإضافة إلى موقع ونوع ورشة الإصلاح. تمثل تكاليف العمالة عادةً $50 إلى $150 من التكلفة الإجمالية. تشمل العوامل التي تؤثر على التكلفة العلامة التجارية للمحرك البادئ سواء كان جديداً أو معاد التصنيع وأي إصلاحات إضافية تحتاجها السيارة.

3. كارباز - تكاليف استبدال محرك بدء التشغيل

المجال: carbuzz.com

تاريخ التسجيل: 2003 (22 عامًا)

مقدمة: تتراوح تكلفة استبدال محرك بدء التشغيل بين $450 و$600 في المتوسط. ومن الأمثلة المحددة على السيارات تويوتا تندرا (2000-2005) بتكلفة تتراوح بين $650 و$900 بسبب التركيب المعقد، وهوندا سيفيك بتكلفة تتراوح بين $490 و$760. يستغرق وقت العمل لمعظم عمليات الاستبدال من 1.5 إلى 2.5 ساعة، بينما قد تستغرق عمليات التركيب المعقدة ما يصل إلى أربع ساعات. تتراوح تكاليف بادئ تشغيل ما بعد البيع من $120 إلى $200، ...

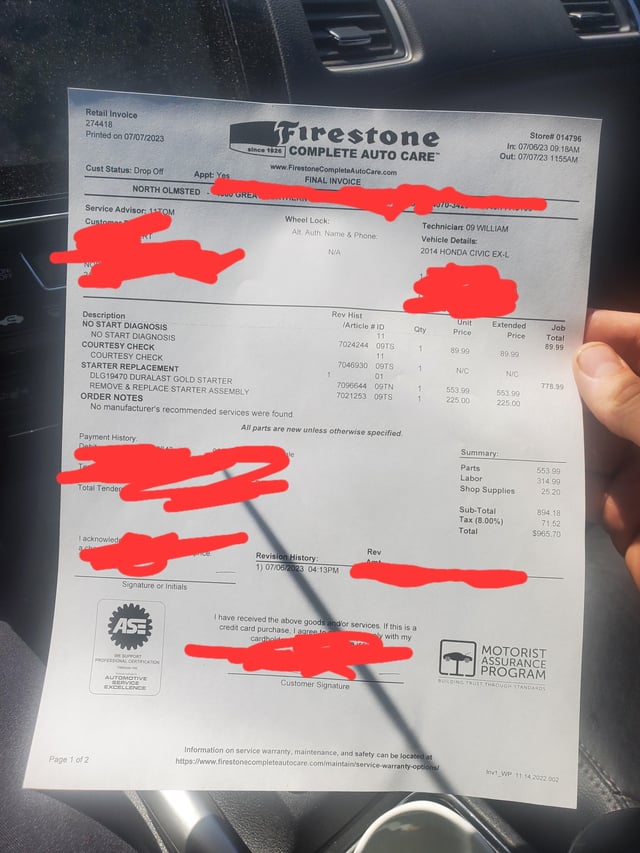

4. استبدال البادئ - التكلفة والاعتبارات

المجال: forum.ih8mud.com

مسجل: 2000 (25 سنة)

مقدمة: تكلفة العمالة لاستبدال البادئ: $200 (متجر مستقل)؛ تكلفة استبدال بادئ التشغيل OEM من جديد: $120؛ الوقت المقدر للحجز: 5 ساعات (5.5 ساعات لمحرك VVT)؛ اعتبارات إضافية: تنظيف منطقة المحرك، وتغطية منافذ السحب، ومنافذ السحب والتفريغ، واستبدال سدادات مخمد حاقن الوقود، والتأكد من جودة بادئ التشغيل المعاد بناؤه.

استنتاج المصادر الاستراتيجية والتوقعات لتكلفة استبدال محرك بدء التشغيل

باختصار، يعد التوريد الاستراتيجي لبدائل المحركات البادئة أمرًا ضروريًا للمشترين الدوليين بين الشركات بهدف تحسين التكاليف وضمان الموثوقية. إن فهم التباين في تكاليف الاستبدال - التي تتراوح من $50 لقطع الغيار إلى أكثر من $1100 للعمالة المحترفة - يمكّن الشركات من اتخاذ قرارات مستنيرة تتماشى مع ميزانياتها التشغيلية. تؤثر عوامل مثل نوع السيارة وإمكانية الوصول إلى البادئ وظروف السوق المحلية بشكل كبير على الأسعار، مما يجعل من الضروري تقييم هذه العناصر قبل الشراء.

يمكن أن يؤدي الاستثمار في المكونات عالية الجودة والموردين الموثوق بهم إلى تحقيق وفورات طويلة الأجل، مما يقلل من وقت التعطل ويعزز كفاءة الأسطول. من خلال تطوير علاقات قوية مع المصنعين والموزعين، يمكن للشركات أيضًا الحصول على أسعار أفضل، وعمليات تسليم في الوقت المناسب، ورؤى الخبراء في اتجاهات السوق.

بينما تتنقل بين تعقيدات عمليات استبدال المحركات البادئة، ضع في اعتبارك الاستفادة من الشراكات الاستراتيجية وتقنيات التوريد المتقدمة لتأمين أفضل النتائج الممكنة. يتطور المشهد بسرعة، خاصة في الأسواق الناشئة في أفريقيا وأمريكا الجنوبية والشرق الأوسط. استفد من هذه الفرص لابتكار استراتيجيات التوريد الخاصة بك وتهيئة أعمالك للنجاح في المستقبل.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.