Introduction: Navigating the Global Market for parts of an alternator diagram

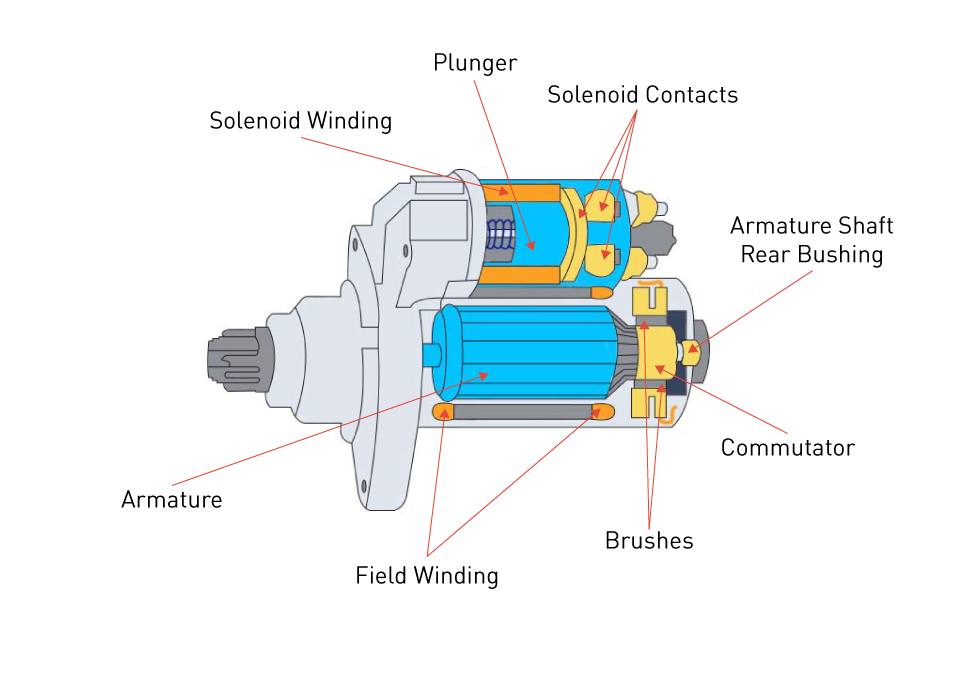

In today’s global marketplace, navigating the intricacies of sourcing parts of an alternator diagram can be a daunting task for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. With a myriad of components such as rotors, stators, rectifiers, and voltage regulators, understanding the essential parts of an alternator is critical for ensuring optimal performance in automotive applications. This comprehensive guide is designed to demystify these components, providing insights into their functions, applications, and the intricacies of their interconnections.

Throughout this guide, you will find valuable information on various types of alternators, their specific uses across different industries, and best practices for vetting suppliers. We delve into the cost considerations associated with sourcing these parts, helping you make informed decisions that align with your budget and operational needs. By equipping you with the knowledge to identify quality components and reliable suppliers, this guide empowers international B2B buyers to streamline their procurement processes and enhance their operational efficiency.

As you explore the components of an alternator, you will gain not only technical understanding but also strategic insights that can lead to more effective purchasing decisions. This is particularly vital in diverse markets such as Brazil and Nigeria, where local conditions and regulations can impact the sourcing landscape. Let this guide be your roadmap to successfully navigate the global market for alternator parts.

جدول المحتويات

- Top 5 Parts Of An Alternator Diagram Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for parts of an alternator diagram

- Understanding parts of an alternator diagram Types and Variations

- Key Industrial Applications of parts of an alternator diagram

- 3 Common User Pain Points for ‘parts of an alternator diagram’ & Their Solutions

- Strategic Material Selection Guide for parts of an alternator diagram

- In-depth Look: Manufacturing Processes and Quality Assurance for parts of an alternator diagram

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of an alternator diagram’

- Comprehensive Cost and Pricing Analysis for parts of an alternator diagram Sourcing

- Alternatives Analysis: Comparing parts of an alternator diagram With Other Solutions

- Essential Technical Properties and Trade Terminology for parts of an alternator diagram

- Navigating Market Dynamics and Sourcing Trends in the parts of an alternator diagram Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of parts of an alternator diagram

- Strategic Sourcing Conclusion and Outlook for parts of an alternator diagram

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding parts of an alternator diagram Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| Basic Alternator Diagram | Shows essential components like rotor, stator, and rectifier | Automotive repair shops, educational use | الإيجابيات: Simple, easy to understand; السلبيات: Lacks detail for advanced users. |

| Electrical Circuit Diagram | Includes connections and wiring layout | Electrical engineering, automotive design | الإيجابيات: شامل; السلبيات: Can be complex for beginners. |

| Functional Flow Diagram | Illustrates the operational sequence of the alternator | Technical training, automotive diagnostics | الإيجابيات: Great for understanding processes; السلبيات: May require prior knowledge. |

| Schematic Diagram | Detailed representation of electrical components and their interactions | OEMs, engineering firms | الإيجابيات: Highly detailed; السلبيات: Not user-friendly for non-technical buyers. |

| 3D Alternator Visualization | Three-dimensional models of alternator components | Product development, marketing | الإيجابيات: Engaging and informative; السلبيات: Requires advanced software for access. |

What are the Characteristics of a Basic Alternator Diagram?

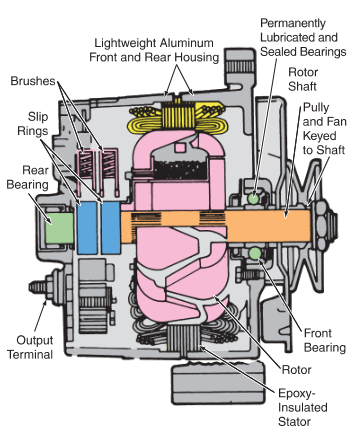

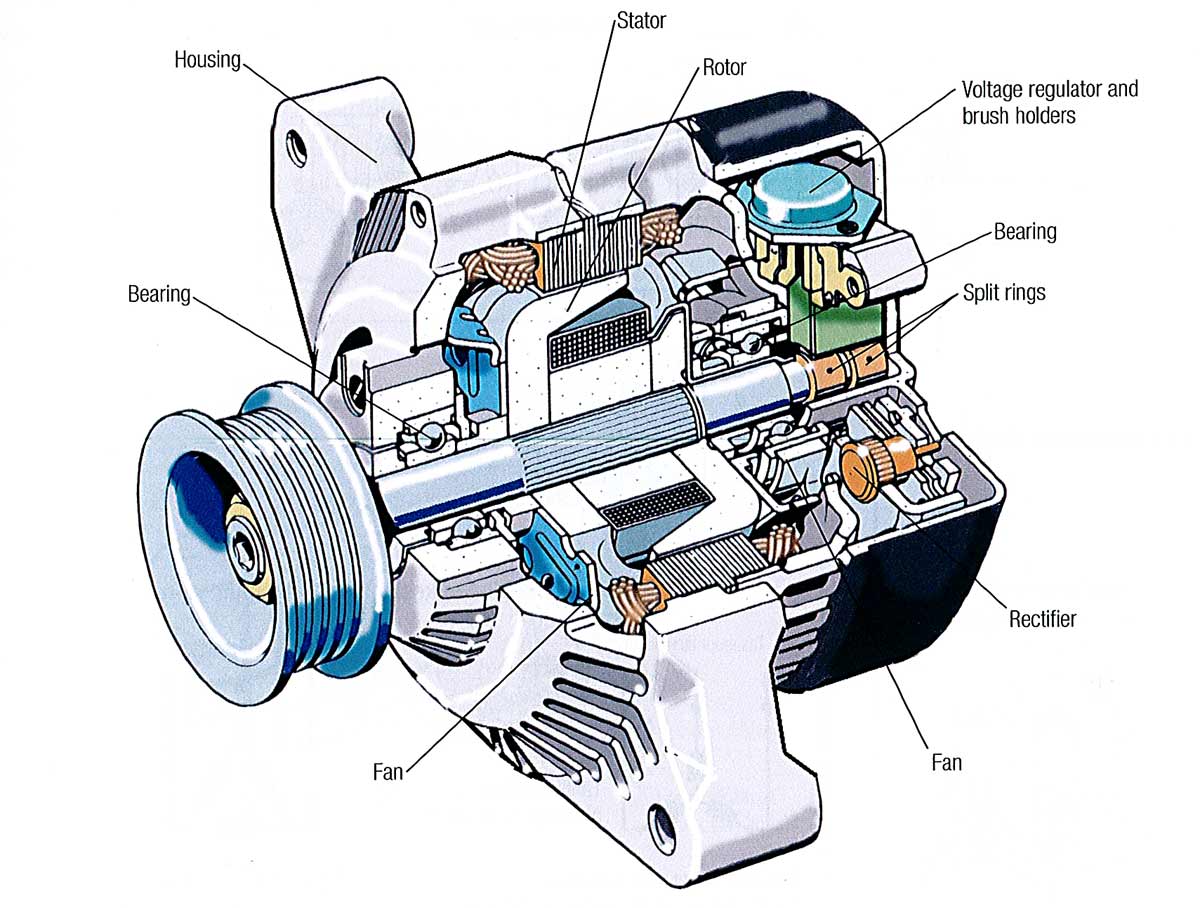

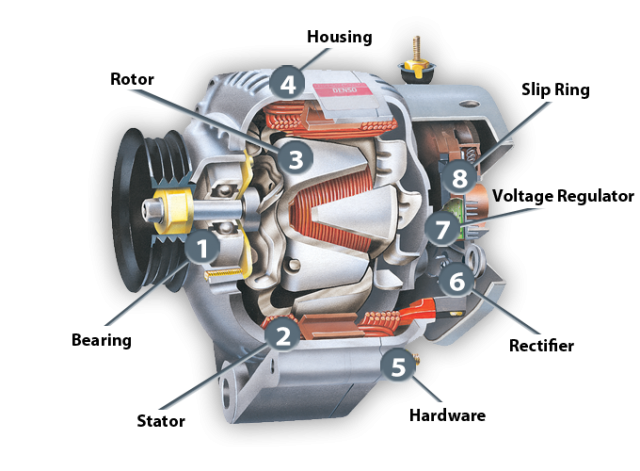

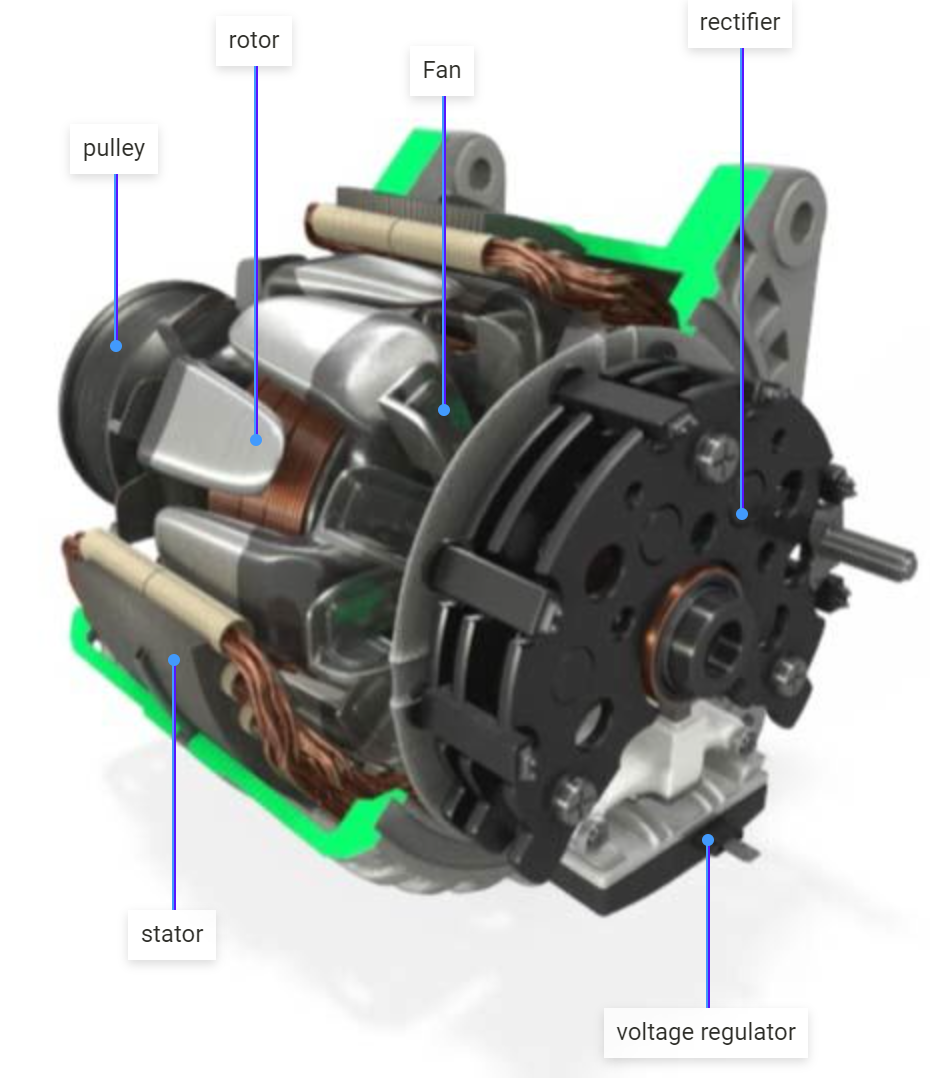

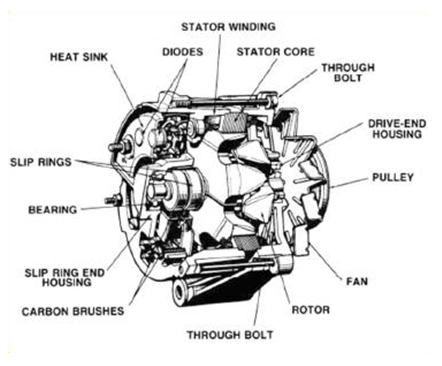

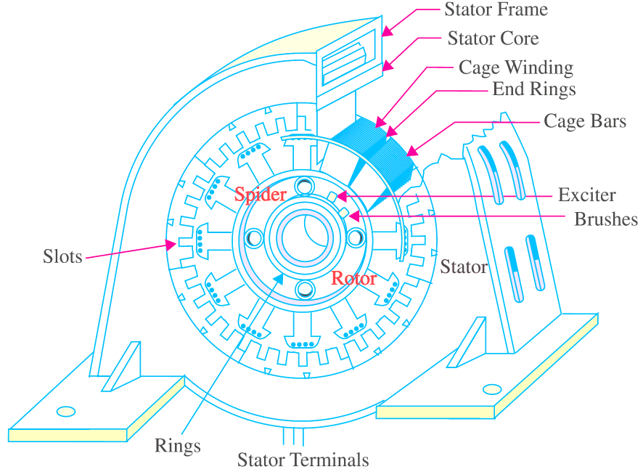

The Basic Alternator Diagram is designed to provide a straightforward representation of an alternator’s core components, including the rotor, stator, rectifier, and voltage regulator. This type of diagram is particularly useful for automotive repair shops and educational institutions where foundational knowledge is essential. When purchasing, consider the clarity of the diagram and its alignment with the technical expertise of your team, as a simple diagram can facilitate quicker learning and troubleshooting.

How Does an Electrical Circuit Diagram Benefit B2B Buyers?

An Electrical Circuit Diagram offers a detailed view of the wiring and connections within the alternator, making it invaluable for electrical engineers and automotive designers. This type of diagram is particularly beneficial in complex projects where precise electrical configurations are critical. Buyers should assess the diagram’s accuracy and comprehensiveness, as a well-structured circuit diagram can prevent costly errors in installation and maintenance.

Why Choose a Functional Flow Diagram?

The Functional Flow Diagram focuses on the operational processes of the alternator, detailing how mechanical energy is converted into electrical energy. This type of diagram is excellent for technical training and automotive diagnostics, helping teams understand the sequence of operations. When purchasing this type of diagram, consider its applicability in training sessions, as a clear flow can enhance learning outcomes.

What Makes a Schematic Diagram Essential for OEMs?

Schematic Diagrams provide a thorough representation of the electrical components and their interactions within the alternator. This type of diagram is crucial for original equipment manufacturers (OEMs) and engineering firms involved in product development. Buyers should prioritize diagrams that offer high levels of detail and accuracy, as these can significantly impact the design and functionality of new products.

How Can 3D Alternator Visualizations Enhance Marketing Efforts?

3D Alternator Visualizations create an engaging representation of alternator components, making them effective for product development and marketing strategies. These models provide a dynamic view that can help stakeholders visualize the product’s functionality and design. When considering a 3D visualization, assess the technology required to access and utilize these models, as well as their effectiveness in conveying complex information to potential clients.

Key Industrial Applications of parts of an alternator diagram

| الصناعة/القطاع | Specific Application of parts of an alternator diagram | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | توليد الطاقة لأنظمة الكهرباء في المركبات | Reliable vehicle operation and enhanced customer satisfaction | Quality of components, compatibility with vehicle models, and local regulations |

| الطاقة المتجددة | التكامل في أنظمة طاقة الرياح والطاقة الشمسية | Efficient energy conversion and storage capabilities | Durability in harsh environments, scalability, and technical support |

| بحري | إمداد الطاقة للأنظمة الكهربائية على متن الطائرة | Ensures functionality of navigation and communication tools | Corrosion resistance, compliance with maritime standards, and serviceability |

| الآلات الثقيلة | المولدات في معدات البناء والتعدين | Improved operational efficiency and reduced downtime | Robustness, maintenance requirements, and local service availability |

| الاتصالات السلكية واللاسلكية | أنظمة الطاقة الاحتياطية لأبراج الاتصالات | ضمان عدم انقطاع الخدمة والموثوقية دون انقطاع | Voltage stability, cooling efficiency, and ease of installation |

How Are Parts of an Alternator Diagram Used in the Automotive Industry?

In the automotive sector, the parts of an alternator diagram are critical for understanding how alternators generate power for electrical systems, such as lights, infotainment, and battery charging. Reliable power generation is essential for vehicle performance and customer satisfaction. International buyers, particularly from regions like Africa and South America, must ensure compatibility with various vehicle models and adhere to local regulations regarding emissions and safety.

ما الدور الذي تلعبه مكونات المولد في تطبيقات الطاقة المتجددة؟

In renewable energy systems, such as wind and solar, alternators convert mechanical energy into electrical energy, which is then stored or fed into the grid. The parts of an alternator diagram help engineers design systems that optimize energy efficiency. Buyers in this sector should prioritize durability and performance under harsh environmental conditions, as well as scalability for future energy demands.

How Are Alternators Utilized in Marine Applications?

Marine vessels rely on alternators to power essential onboard systems, including navigation and communication tools. The alternator’s diagram provides insights into the cooling mechanisms and electrical connections necessary for reliable operation in a marine environment. Buyers must consider corrosion resistance and compliance with maritime safety standards when sourcing alternator components.

Why Are Alternators Important for Heavy Machinery?

In heavy machinery, such as construction and mining equipment, alternators ensure that all electrical systems function smoothly, which is vital for operational efficiency. The parts of an alternator diagram illustrate how these components work together to minimize downtime. Buyers should focus on the robustness of alternators and the availability of maintenance services, particularly in remote areas.

كيف تدعم المولدات البنية التحتية للاتصالات السلكية واللاسلكية؟

Telecommunications towers use alternators as backup power sources to maintain service continuity during outages. Understanding the parts of an alternator diagram allows for the design of reliable systems that ensure uninterrupted communication. Buyers in this field should emphasize voltage stability and cooling efficiency to ensure optimal performance in diverse climates.

3 Common User Pain Points for ‘parts of an alternator diagram’ & Their Solutions

Scenario 1: Misunderstanding the Functionality of Alternator Parts

المشكلة: Many B2B buyers, particularly in regions with less access to technical education, face significant challenges in understanding the specific functions of each part of an alternator as illustrated in diagrams. This lack of clarity can lead to improper sourcing of components, increased downtime in operations, and ultimately, financial losses. For example, a buyer may not realize the critical role of the voltage regulator in maintaining consistent output, leading to the purchase of incorrect or incompatible parts.

الحل: To effectively address this issue, buyers should invest in comprehensive training resources that include detailed diagrams and explanations of each component’s function. Partnering with suppliers who offer educational materials or webinars can provide valuable insights into the workings of alternators. Additionally, using interactive tools that allow for a virtual dissection of an alternator can aid in visualizing how each part interacts. Buyers should also consider engaging with technical support from manufacturers to clarify any doubts about component functionalities before making purchasing decisions. This proactive approach will ensure that they source the right parts, ultimately improving operational efficiency.

Scenario 2: Difficulty in Identifying Quality Components

المشكلة: In international markets, especially in regions like Africa and South America, B2B buyers often struggle with identifying high-quality alternator parts due to the prevalence of counterfeit or substandard components. This challenge is exacerbated when parts are purchased based solely on diagrams without thorough vetting of the suppliers. Consequently, buyers may end up with parts that lead to frequent failures, repair costs, and a damaged reputation with their clients.

الحل: To mitigate the risk of acquiring low-quality components, buyers should utilize detailed parts diagrams as reference points for verification. They should establish relationships with reputable manufacturers and distributors who provide guarantees on the quality of their products. Additionally, buyers can leverage certification marks or industry standards as benchmarks for quality assurance. It is advisable to request samples or trial orders to evaluate the performance of parts before committing to larger purchases. Networking with industry peers for recommendations on trusted suppliers can also be an invaluable resource in this quest for quality.

Scenario 3: Inadequate Knowledge of Installation and Maintenance

المشكلة: Another common pain point for B2B buyers is the lack of knowledge regarding the proper installation and maintenance of alternator parts, which can lead to improper functionality and accelerated wear. This issue is particularly pressing in regions where technical expertise is limited, and buyers may rely on basic diagrams that do not provide enough detail on the installation process. Such oversights can result in costly repairs and increased operational downtime.

الحل: To overcome this challenge, buyers should seek out comprehensive installation manuals and maintenance guides that accompany parts diagrams. Investing in training sessions for their technical staff, whether through online courses or hands-on workshops, can significantly enhance their understanding of installation procedures. Additionally, establishing a partnership with suppliers who offer technical support or installation services can ensure that parts are installed correctly the first time. Encouraging a culture of continuous learning within the organization will help staff stay updated on best practices in maintenance, thus prolonging the lifespan of the alternator and its components. By prioritizing education and support, buyers can effectively maintain their systems and avoid unnecessary costs.

Strategic Material Selection Guide for parts of an alternator diagram

What Are the Key Materials Used in Alternator Components?

When selecting materials for alternator components, several factors must be considered, including performance characteristics, cost-effectiveness, and compliance with international standards. Below, we analyze four common materials used in alternator parts, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

How Does Aluminum Benefit Alternator Housing and Components?

Aluminum is widely used for the outer housing of alternators due to its lightweight nature and excellent heat dissipation properties. With a high strength-to-weight ratio, aluminum can withstand the mechanical stresses involved in alternator operation while preventing magnetization, which is crucial for maintaining efficiency.

الإيجابيات: Aluminum is durable and corrosion-resistant, making it suitable for various environmental conditions. It is also relatively inexpensive and easy to manufacture, which contributes to lower production costs.

السلبيات: While aluminum is strong, it may not be as robust as some steel alloys in extreme conditions. Additionally, its thermal expansion can be a consideration in high-temperature applications.

التأثير على التطبيق: Aluminum’s compatibility with high temperatures and electrical conductivity makes it ideal for housing and structural components. However, care must be taken to ensure that any coatings or treatments used do not interfere with its thermal properties.

اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM and ISO is essential. In regions like Africa and South America, where environmental conditions may vary, selecting high-quality aluminum that meets local regulations is crucial.

Illustrative image related to parts of an alternator diagram

Why Is Copper Essential for Electrical Components in Alternators?

Copper is the preferred material for electrical windings and connections in alternators due to its excellent electrical conductivity. This property allows for efficient energy transfer, which is vital for the performance of the alternator.

الإيجابيات: Copper’s high conductivity ensures minimal energy loss, enhancing overall efficiency. It is also highly ductile, allowing for easy shaping into wires and terminals.

السلبيات: Copper is heavier than aluminum and can be more expensive. Additionally, it is prone to corrosion if not properly insulated or treated.

التأثير على التطبيق: Copper’s compatibility with high electrical loads makes it essential for components like the rotor and stator windings. However, its weight may impact the overall design of lightweight vehicles.

اعتبارات للمشترين الدوليين: Buyers should ensure that copper components comply with international standards, such as IEC or JIS, especially in regions where electrical safety is a concern.

Illustrative image related to parts of an alternator diagram

How Do Steel Alloys Enhance the Durability of Alternator Components?

Steel alloys are often used in the construction of the rotor and stator cores due to their strength and magnetic properties. These materials can withstand significant mechanical stress and provide the necessary magnetic characteristics for efficient operation.

الإيجابيات: Steel alloys are highly durable and can withstand high temperatures and mechanical fatigue, making them suitable for demanding applications.

السلبيات: The weight of steel can be a disadvantage in applications where weight savings are critical. Additionally, steel is susceptible to corrosion unless properly treated.

التأثير على التطبيق: Steel’s magnetic properties enhance the efficiency of the rotor and stator, making it a critical component in power generation. However, its weight may necessitate design considerations in lightweight vehicles.

اعتبارات للمشترين الدوليين: Compliance with standards like ASTM A36 or DIN 17100 is essential. Buyers in regions with high humidity, such as parts of the Middle East, should consider corrosion-resistant coatings.

What Role Does Plastic Play in Alternator Components?

Plastics, particularly engineering thermoplastics, are increasingly used in alternator components like housings, insulators, and covers due to their lightweight and non-conductive properties.

Illustrative image related to parts of an alternator diagram

الإيجابيات: Plastics are lightweight and can be molded into complex shapes, which can reduce manufacturing costs. They also provide excellent electrical insulation.

السلبيات: Plastics may not withstand high temperatures as effectively as metals and can degrade over time when exposed to certain chemicals.

التأثير على التطبيق: The use of plastics can enhance the overall efficiency of the alternator by reducing weight. However, care must be taken to select plastics that can withstand the operational environment.

اعتبارات للمشترين الدوليين: Buyers should ensure that the plastics used comply with relevant standards, such as ASTM D638 for tensile properties, and consider local climate conditions that may affect material performance.

جدول تلخيصي لاختيار المواد لأجزاء المولدات

| المواد | Typical Use Case for parts of an alternator diagram | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | Outer housing and structural components | خفيف الوزن ومقاوم للتآكل | Less robust than some alloys | منخفض |

| النحاس | اللفات والتوصيلات الكهربائية | موصلية كهربائية عالية | أثقل وأكثر تكلفة | عالية |

| Steel Alloys | أنوية الدوار والجزء الثابت | High durability and magnetic properties | أثقل وزناً وعرضة للتآكل | متوسط |

| بلاستيك | Housings, insulators, and covers | خفيف الوزن وقابل للتشكيل | مقاومة محدودة للحرارة العالية | منخفض |

In-depth Look: Manufacturing Processes and Quality Assurance for parts of an alternator diagram

What Are the Key Stages of Manufacturing Parts of an Alternator?

The manufacturing of alternator components is a complex process that involves several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers seeking reliable suppliers, particularly in regions like Africa, South America, the Middle East, and Europe.

كيف يتم تحضير المواد لمكونات المولد؟

Material preparation is the first stage in the manufacturing process. For alternator components, the primary materials include aluminum for the housing, copper for windings, and specialized alloys for other parts like the rotor and stator.

-

اختيار المواد: Buyers should ensure that suppliers use high-grade materials that meet international standards. For example, aluminum’s lightweight nature and heat dissipation properties make it ideal for alternator housings.

-

ضمان الجودة: Suppliers often conduct chemical composition tests to verify material quality. Certifications from recognized bodies can be requested to ensure compliance with international standards.

What Techniques Are Used in Forming Alternator Parts?

Once the materials are prepared, the next step is forming, which involves shaping the materials into specific components of the alternator.

-

Casting and Machining: For components like the housing and rotor, casting techniques are commonly employed. The aluminum is melted and poured into molds, where it takes shape. After cooling, machining processes such as CNC milling are used to achieve precise dimensions.

-

Winding and Assembly: The stator windings are created by wrapping copper wire around the stator core. This process is critical for generating the magnetic field necessary for the alternator’s operation. Automated winding machines can enhance precision and reduce labor costs.

كيف يتم تجميع أجزاء المولد؟

Assembly is a critical stage where individual components are brought together to create the final product.

-

تكامل المكونات: The assembly process involves fitting the rotor into the stator, connecting the rectifier, voltage regulator, and other parts. Precision is essential at this stage to ensure proper functionality.

-

Use of Jigs and Fixtures: To maintain alignment and tolerances, manufacturers often use jigs and fixtures during assembly. This equipment ensures that all components fit perfectly, reducing the risk of defects.

What Are the Finishing Processes for Alternator Parts?

Finishing processes are essential to enhance the durability and performance of alternator components.

-

معالجة السطح: Components may undergo anodizing or painting to improve corrosion resistance and appearance. This is particularly important for parts exposed to harsh environmental conditions.

-

Quality Checks Post-Finishing: After finishing, components undergo visual inspections and measurements to ensure they meet specifications.

كيف يتم تنفيذ ضمان الجودة في تصنيع المولدات؟

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each component meets the required standards before reaching the customer.

What International Standards Are Relevant to Alternator Manufacturing?

For international B2B buyers, understanding the standards applicable to alternator manufacturing is crucial.

-

آيزو 9001: This standard outlines the requirements for a quality management system and is widely recognized across industries. Suppliers certified to ISO 9001 demonstrate a commitment to quality and continuous improvement.

-

الشهادات الخاصة بالصناعة: Depending on the market, additional certifications such as CE (European Conformity) for safety and environmental standards may be applicable. Buyers should inquire about these certifications to ensure compliance with local regulations.

What Quality Control Checkpoints Should B2B Buyers Be Aware Of?

Quality control (QC) checkpoints are vital for identifying defects early in the manufacturing process.

Illustrative image related to parts of an alternator diagram

-

مراقبة الجودة الواردة (IQC): This checkpoint involves inspecting raw materials upon arrival to verify that they meet specifications.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During manufacturing, IPQC ensures that each stage adheres to quality standards. This might include dimensional checks and functional testing.

-

مراقبة الجودة النهائية (FQC): Before shipping, a final inspection ensures that all components are defect-free and meet performance criteria. This includes electrical testing for components like the rectifier and voltage regulator.

What Common Testing Methods Are Employed in Quality Assurance?

Various testing methods are utilized to verify the quality of alternator components:

-

الاختبارات الكهربائية: This includes testing the output voltage and current of the alternator components to ensure they meet design specifications.

-

اختبارات التدوير الحراري: These tests simulate the operating conditions of an alternator to assess its durability and performance under heat stress.

-

اختبار الاهتزازات: This is crucial to ensure that the alternator can withstand the vibrations it will encounter in real-world applications.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

يمكن للمشترين بين الشركات اتخاذ عدة خطوات للتحقق من عمليات مراقبة الجودة للموردين المحتملين:

-

تدقيق الموردين: Conducting regular audits of suppliers can provide insights into their manufacturing and QC processes. This can include reviewing their quality management systems and production facilities.

-

طلب تقارير الجودة: Suppliers should be able to provide documentation detailing their quality control processes, test results, and any certifications.

-

عمليات التفتيش من قبل أطراف ثالثة: Engaging third-party inspectors can provide an unbiased assessment of a supplier’s quality management practices. This is especially useful for buyers in regions where they may not have direct access to suppliers.

ما هي الفروق الدقيقة في مراقبة الجودة وإصدار الشهادات للمشترين الدوليين؟

When sourcing alternator components internationally, buyers must be aware of specific nuances:

-

المعايير الإقليمية: Different regions may have unique quality standards and certifications. Understanding these can help buyers avoid compliance issues.

-

التواصل والشفافية: Clear communication regarding quality expectations and standards is vital. Buyers should ensure that suppliers understand and can meet their specific requirements.

-

الاعتبارات الثقافية: Cultural differences may influence quality perceptions and practices. Building strong relationships with suppliers can facilitate better communication and understanding.

الخلاصة

Understanding the manufacturing processes and quality assurance practices for alternator components is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly, finishing, and quality control, buyers can ensure they source high-quality products that meet their needs. Moreover, being aware of international standards and conducting thorough supplier evaluations can significantly enhance the procurement process, ultimately leading to better performance and reliability in their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of an alternator diagram’

In the competitive landscape of automotive components, sourcing parts of an alternator diagram requires meticulous planning and execution. This guide offers a step-by-step checklist to aid B2B buyers in identifying, evaluating, and procuring the essential components effectively.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Establishing clear technical specifications is the foundation of successful sourcing. Outline the specific parts of the alternator diagram you require, such as the rotor, stator, rectifier, and voltage regulator. Consider factors like size, material composition, and voltage ratings to ensure compatibility with your existing systems.

Illustrative image related to parts of an alternator diagram

الخطوة 2: البحث وتحديد الموردين ذوي السمعة الطيبة

Conduct thorough research to identify suppliers with a strong reputation in the automotive parts industry. Use online platforms, industry publications, and trade associations to compile a list of potential vendors. Focus on those who specialize in alternator components and have a proven track record of quality and reliability.

الخطوة 3: تقييم الموردين المحتملين

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who can provide evidence of their expertise in alternator parts and assess their responsiveness and customer service through initial communications.

الخطوة 4: Check for Certifications and Compliance

Verify that your chosen suppliers possess relevant certifications and comply with international quality standards, such as ISO 9001 or specific automotive industry standards. Compliance ensures that the components meet safety and performance requirements, reducing the risk of failures in your applications.

الخطوة 5: طلب عينات للاختبار

Before placing a large order, request samples of the alternator components you plan to purchase. Testing these samples allows you to evaluate their quality, durability, and compatibility with your systems. This step is essential to ensure that the parts function as intended and meet your performance criteria.

الخطوة 6: التفاوض على الشروط والأسعار

Engage in discussions with your selected suppliers to negotiate pricing, payment terms, and delivery schedules. Be transparent about your budget and timeline while seeking competitive pricing. Consider the total cost of ownership, including shipping and potential tariffs, to make an informed decision.

الخطوة 7: إنشاء علاقة للطلبات المستقبلية

After successfully procuring the necessary alternator parts, focus on building a long-term relationship with your suppliers. Regular communication and feedback can lead to better pricing, priority service, and access to new products in the future. A strong partnership can enhance your supply chain efficiency and reliability.

By following these steps, B2B buyers can navigate the complexities of sourcing alternator parts effectively, ensuring they acquire high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for parts of an alternator diagram Sourcing

Analyzing the cost structure and pricing for parts of an alternator diagram is crucial for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. Understanding these elements will empower buyers to make informed purchasing decisions while maximizing their cost efficiency.

What Are the Key Cost Components for Alternator Parts?

The cost of alternator parts can be broken down into several key components:

-

المواد: The choice of materials significantly impacts costs. Common materials include aluminum for the housing, copper for windings, and various plastics for insulation and components. The prices of these materials can fluctuate based on global supply chains and market demand.

-

العمل: Labor costs vary by region and can influence the overall price. Skilled labor is essential for precision manufacturing of alternator components, and this cost can differ significantly between countries. For instance, labor costs in South America may be lower than in Europe, affecting the pricing strategy.

-

تكاليف التصنيع العامة: This encompasses all indirect costs related to production, such as utilities, rent, and equipment maintenance. Efficient operations can reduce overhead, allowing suppliers to offer competitive prices.

-

الأدوات: The initial investment in tooling can be substantial, especially for customized parts. Buyers should inquire about tooling costs and whether these are included in the quoted prices or charged separately.

-

مراقبة الجودة (QC): Ensuring that alternator parts meet specified standards is crucial. QC processes add to manufacturing costs but are necessary to maintain reliability and compliance with international quality certifications.

-

اللوجستيات: Transportation costs can vary widely based on shipping methods, distances, and tariffs. These logistics costs must be factored into the total pricing, particularly for international shipments.

-

الهامش: Suppliers will include a profit margin in their pricing. Understanding the typical margins in the industry can help buyers gauge whether they are receiving a fair price.

What Factors Influence Pricing for Alternator Parts?

Several price influencers can affect the final cost of alternator parts:

-

الحجم/الحد الأدنى للطلب: Minimum Order Quantities (MOQ) can lead to bulk pricing discounts. Buyers looking to purchase larger quantities should negotiate terms that reduce the per-unit cost.

-

المواصفات والتخصيص: Custom parts or specific design requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

جودة المواد والشهادات: Higher-quality materials or those with specific certifications (like ISO or TS) will generally come at a premium. Buyers should assess whether the additional cost aligns with their performance requirements.

-

عوامل الموردين: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers may charge more for their experience and quality assurance, while newer suppliers might offer lower prices to gain market share.

-

مصطلحات التجارة الدولية: Understanding Incoterms is essential for international buyers. These terms define the responsibilities of buyers and sellers in the shipping process and can significantly affect the total landed cost.

ما هي النصائح التي يمكن أن تساعد المشترين على التفاوض للحصول على أسعار أفضل؟

-

Leverage Negotiation: Engage suppliers in discussions about pricing. Highlighting the potential for long-term partnerships or bulk orders can yield better pricing.

-

التركيز على كفاءة التكلفة: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, maintenance, and potential downtime. A lower initial price may not always equate to lower overall costs.

-

فهم الفروق الدقيقة في الأسعار: International buyers should be aware of currency fluctuations, local economic conditions, and trade regulations that could affect pricing. This knowledge can enhance negotiation power.

إخلاء المسؤولية عن الأسعار الإرشادية

It is important to note that the prices for alternator parts can vary widely based on the factors mentioned above. Buyers should seek quotes from multiple suppliers to ensure they are getting competitive pricing tailored to their specific needs and circumstances.

Illustrative image related to parts of an alternator diagram

Alternatives Analysis: Comparing parts of an alternator diagram With Other Solutions

Exploring Alternatives to Parts of an Alternator Diagram

In the realm of automotive and electrical engineering, understanding the components and functioning of an alternator is vital for maintenance and repair. While the traditional parts of an alternator diagram provide a comprehensive overview of how these components interact, there are alternative solutions that can also aid in understanding and application. This analysis compares the conventional diagram against two viable alternatives: 3D modeling software and augmented reality (AR) applications.

| جانب المقارنة | Parts Of An Alternator Diagram | 3D Modeling Software | Augmented Reality (AR) Applications |

|---|---|---|---|

| الأداء | Provides a clear, static view of components and their functions. | Offers dynamic visualization, allowing for interactive exploration of components. | Delivers immersive experiences, enabling users to visualize components in real-world settings. |

| التكلفة | Generally low-cost or free resources available. | Requires investment in software licenses and potentially high-spec hardware. | Costs can vary significantly, often requiring both software and hardware investments. |

| سهولة التنفيذ | Simple to create and share, widely understood. | Requires training and familiarity with software tools. | Implementation can be complex, needing AR-compatible devices and potentially extensive user training. |

| الصيانة | Minimal; only needs updates if components change. | Software updates necessary; hardware may require maintenance. | High maintenance due to software updates and the need for compatible hardware. |

| أفضل حالة استخدام | Ideal for educational purposes and quick reference. | Best for detailed design work and simulations in engineering. | Excellent for training scenarios and hands-on learning experiences. |

What Are the Advantages and Disadvantages of 3D Modeling Software?

3D modeling software provides a more dynamic representation of alternator components, allowing users to manipulate and interact with the model. This method excels in detailed design work, where engineers can simulate different scenarios and conduct virtual testing. However, the cost and complexity of these tools can be a barrier for smaller companies or those without specialized staff. Training is often required to maximize the software’s potential, which can add to the overall expense and time investment.

How Do Augmented Reality (AR) Applications Enhance Understanding of Alternators?

AR applications represent the cutting edge of educational tools, allowing users to visualize alternator components in their actual environment. This immersive approach can significantly enhance learning and retention, making it particularly beneficial for training new technicians. The downside, however, is the high cost associated with AR technology, which includes both software and compatible devices. Additionally, the learning curve can be steep, as users must become accustomed to new interfaces and functionalities.

كيف يمكن للمشترين B2B اختيار الحل المناسب لاحتياجاتهم؟

When selecting between a traditional parts of an alternator diagram and alternative solutions like 3D modeling or AR applications, B2B buyers should carefully consider their specific requirements. Factors such as budget, the intended use of the technology, and the level of technical expertise within their organization will play significant roles in the decision-making process. For companies focused on education and quick reference, diagrams may suffice. However, for those looking to invest in detailed design or immersive training, exploring 3D modeling or AR could yield substantial long-term benefits. Ultimately, aligning the chosen solution with the organization’s goals will ensure optimal investment in understanding and utilizing alternator technology.

Illustrative image related to parts of an alternator diagram

Essential Technical Properties and Trade Terminology for parts of an alternator diagram

What are the Key Technical Properties of Alternator Parts?

When sourcing components for alternators, understanding the technical properties is crucial for ensuring quality and performance. Here are some of the critical specifications to consider:

-

درجة المواد

The materials used in alternator components, such as aluminum for the housing and copper for windings, significantly affect performance and durability. Aluminum is lightweight and dissipates heat effectively, while copper offers excellent conductivity. Selecting the right material grade ensures that the alternator can withstand operational stresses, particularly in diverse climatic conditions encountered in regions like Africa and South America. -

مستويات التسامح

Tolerance refers to the allowable deviation from specified dimensions in alternator components, such as the rotor and stator. Precise tolerances are essential for maintaining the efficiency of the magnetic field and ensuring that moving parts do not interfere with one another. High tolerance levels are particularly important in high-speed applications, as they reduce the risk of mechanical failure and enhance the longevity of the alternator. -

التصنيفات الكهربائية

Key electrical specifications include voltage output (typically between 12V and 14.5V for automotive applications) and current capacity (measured in amps). These ratings determine the alternator’s ability to meet the electrical demands of various vehicle systems. Understanding these ratings is vital for B2B buyers to match alternators to specific vehicle requirements, ensuring optimal performance and reliability. -

آلية التبريد

The cooling system, whether it involves external fans or internal cooling channels, plays a critical role in maintaining optimal operating temperatures. Efficient cooling prevents overheating, which can degrade performance and reduce the lifespan of the alternator. Buyers should consider the cooling design based on the anticipated operational environment, particularly in regions with high ambient temperatures. -

مواصفات التركيب

Proper mounting dimensions and configurations are essential for seamless integration into the vehicle engine. Understanding the mounting specifications helps buyers ensure compatibility with various vehicle models and reduces installation challenges. It is especially important for international buyers to consider local vehicle designs when sourcing alternators.

What are Common Trade Terms in the Alternator Supply Chain?

Navigating the procurement process requires familiarity with specific trade terminology. Here are some key terms that B2B buyers should know:

-

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to companies that produce parts that are sold to vehicle manufacturers as original components. Purchasing OEM alternators ensures compatibility and reliability, as these parts are designed to meet the specific standards of vehicle makers. -

MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and negotiate better pricing, particularly in bulk purchases. -

طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Issuing an RFQ allows buyers to compare prices and terms from different suppliers, ensuring they secure the best deal for alternators and components. -

شروط التجارة الدولية (Incoterms)

Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand shipping costs and risks, especially when importing alternators from different regions, such as Europe or the Middle East. -

المهلة الزمنية

Lead time refers to the time it takes from placing an order until the goods are delivered. Understanding lead times is essential for buyers to manage project timelines and ensure that alternators are available when needed, particularly in industries where downtime can result in significant losses. -

شروط الضمان

Warranty terms outline the conditions under which a product is covered for defects or failures. Knowing the warranty conditions for alternators is important for buyers to assess the risk of failure and the potential costs associated with replacements or repairs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing alternator components, ensuring optimal performance and compatibility for their applications.

Illustrative image related to parts of an alternator diagram

Navigating Market Dynamics and Sourcing Trends in the parts of an alternator diagram Sector

What Are the Current Market Trends for Parts of an Alternator Diagram?

The global alternator market is experiencing significant growth, driven by the increasing demand for efficient and reliable automotive electrical systems. Factors such as the rising production of electric and hybrid vehicles, particularly in regions like Africa, South America, the Middle East, and Europe, are reshaping the sourcing landscape. B2B buyers in these regions should note the growing emphasis on advanced alternator technologies, including smart voltage regulators and lightweight materials that enhance efficiency and performance.

Emerging trends in sourcing include the integration of digital technologies such as IoT and AI, which allow for real-time monitoring and diagnostics of alternator performance. This shift not only improves operational efficiency but also helps in predictive maintenance, reducing downtime and costs for end-users. Additionally, the rise of e-commerce platforms is making it easier for international buyers to source parts directly from manufacturers, thus facilitating competitive pricing and access to a broader range of products.

Another significant trend is the movement towards modular designs that allow for easier assembly and maintenance. This is particularly relevant for B2B buyers who prioritize ease of integration and adaptability in their supply chains. As the market continues to evolve, staying informed about these trends will be crucial for buyers looking to optimize their sourcing strategies.

How Can Sustainability and Ethical Sourcing Impact B2B Buyers in the Alternator Sector?

In an increasingly eco-conscious market, sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the alternator parts sector. The environmental impact of manufacturing processes, particularly concerning raw material extraction and waste generation, is under scrutiny. Buyers are encouraged to prioritize suppliers who demonstrate commitment to reducing their carbon footprint and adopting sustainable practices in their operations.

The use of ‘green’ certifications, such as ISO 14001 for environmental management and other eco-labels, can serve as indicators of a supplier’s dedication to sustainability. Additionally, sourcing materials that are recycled or derived from renewable resources can significantly reduce the overall environmental impact of alternator components. As a result, B2B buyers who integrate sustainability into their sourcing strategies can not only enhance their brand reputation but also align with the growing consumer demand for environmentally friendly products.

Moreover, ethical supply chains are essential in ensuring that the materials used in alternator production do not contribute to social injustices, such as labor exploitation or environmental degradation. By partnering with suppliers who uphold ethical labor practices and transparency, buyers can mitigate risks associated with their supply chains while fostering long-term partnerships built on trust and integrity.

What Is the Historical Context of Alternator Development Relevant to B2B Buyers?

The alternator has evolved significantly since its inception, transitioning from basic mechanical generators to complex electrical systems integral to modern vehicles. Initially developed in the early 20th century, alternators were relatively simple devices that provided limited power. However, advancements in technology have led to the development of more efficient and compact designs, such as the introduction of the diode bridge in the 1960s, which enabled the conversion of AC to DC more effectively.

This evolution has been driven largely by the growing demands for vehicle reliability and the need for efficient power management systems. Understanding this historical context can provide B2B buyers with insights into the technological advancements that inform current sourcing decisions. By recognizing the trajectory of alternator technology, buyers can better assess the capabilities and innovations of modern suppliers, ensuring they choose partners who are aligned with the future of automotive power solutions.

In conclusion, as the alternator market continues to innovate, B2B buyers must stay informed about emerging trends and sustainability practices to enhance their sourcing strategies and meet the demands of a changing automotive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of an alternator diagram

-

How do I identify the key components in an alternator diagram?

To effectively identify the components in an alternator diagram, focus on the labeled sections that highlight each part’s function. Key components include the rotor, stator, rectifier, and voltage regulator. Understanding how these parts interact is crucial; the rotor generates a magnetic field, while the stator converts this into electrical energy. Familiarizing yourself with the diagram’s legend can also aid in quickly pinpointing components, which is essential for sourcing replacement parts or for training purposes. -

What is the best way to source quality alternator parts for international trade?

Sourcing quality alternator parts for international trade involves selecting suppliers with a proven track record. Look for manufacturers that comply with international quality standards such as ISO 9001. Conducting thorough background checks and seeking certifications can help ensure reliability. Additionally, utilizing platforms that specialize in B2B trade can provide access to verified suppliers. Request samples to assess quality before committing to larger orders. -

How can I ensure the customization of alternator parts meets my specific requirements?

To ensure customization of alternator parts meets your needs, communicate your specifications clearly to potential suppliers. Provide detailed technical drawings, material requirements, and performance standards. It’s beneficial to work with suppliers who have experience in custom manufacturing and can offer design assistance. Request prototypes before full-scale production to verify that the customizations function as intended. Establishing a close partnership with the supplier can also facilitate smoother adjustments during the design process. -

ما هو الحد الأدنى المعتاد لكميات الطلبات (MOQs) لقطع غيار المولدات؟

Minimum order quantities (MOQs) for alternator parts can vary significantly based on the supplier and the type of part. Generally, MOQs can range from 50 to several hundred units for standard components. For custom parts, the MOQ might be higher due to initial setup costs. It’s advisable to discuss MOQs directly with suppliers and explore options for lower quantities, especially if you’re testing a new market or product line. -

ما هي شروط الدفع التي يجب أن أتوقعها عند الحصول على قطع غيار المولدات على المستوى الدولي؟

Payment terms for international sourcing can vary widely among suppliers. Common terms include upfront payments, partial payments, or letter of credit arrangements. It’s essential to clarify these terms before finalizing any agreements. Some suppliers may offer flexible payment options based on your purchasing history or creditworthiness. Ensure that the payment method chosen provides adequate protection against fraud and aligns with your cash flow needs. -

How can I effectively vet suppliers of alternator parts?

Effective vetting of suppliers involves several steps: check their business credentials, request references, and review customer feedback. Conduct site visits if possible or use third-party inspection services to assess their manufacturing capabilities. Additionally, inquire about their compliance with industry standards and quality assurance processes. Establishing clear communication and asking for samples can also provide insight into their reliability and product quality. -

What quality assurance practices should I look for in alternator parts suppliers?

When evaluating suppliers for alternator parts, look for established quality assurance practices such as regular inspections, testing protocols, and certifications. Suppliers should follow industry standards like ISO 9001 and have documented processes for quality control. Ask about their approach to handling defective products and their return policy. A robust QA process not only ensures the quality of the parts but also mitigates risks associated with international procurement. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في الحسبان عند استيراد قطع غيار المولدات؟

Logistics plays a crucial role in importing alternator parts. Consider factors such as shipping methods, lead times, and customs regulations in your destination country. Work with freight forwarders experienced in automotive parts to navigate import duties and tariffs effectively. Ensure that the packaging is suitable for international transport to prevent damage. Establishing a reliable logistics plan will help streamline the import process and reduce potential delays.

Top 5 Parts Of An Alternator Diagram Manufacturers & Suppliers List

1. Electude – Alternator Components

المجال: electude.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: المولد هو مكوّن أساسي في السيارات يقوم بتحويل الطاقة الميكانيكية إلى طاقة كهربائية، مما يولد الطاقة لوحدات الاستهلاك الكهربائية والبطارية في السيارة. وتشمل المكونات الرئيسية ما يلي:

- بكرة: تنقل الطاقة الميكانيكية من المحرك.

– Rotor: Creates the magnetic field for generating alternating current.

- الجزء الثابت: الجزء الثابت حيث يتم توليد الجهد الكهربائي.

- المقوم: ...

2. HowStuffWorks - المولدات

المجال: auto.howstuffuffworks.com

مسجل: 1998 (27 سنة)

مقدمة: المولدات صغيرة الحجم وخفيفة الوزن، بحجم حبة جوز الهند تقريباً، وهي مصنوعة من غلاف خارجي من الألومنيوم لتبديد الحرارة. تشمل المكونات الرئيسية ما يلي:

- بكرة دفع متصلة بعمود الدوران لتحويل الطاقة الميكانيكية إلى طاقة كهربائية.

– Terminals: S terminal (senses battery voltage), IG terminal (ignition switch for voltage regulator), L terminal (closes circuit to warning lamp…

3. Pinterest – Exploded View of an Alternator

4. Facebook – Car Alternator Diagram

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: A detailed diagram showing the internal structure of a car alternator, with labeled components such as the rotor, stator windings, brushes, rectifier.

5. Scribd – Alternator Components & Functions

المجال: scribd.com

مسجل: 2006 (19 سنة)

مقدمة: The document describes the parts, connections, and functions of an alternator. It lists 15 main parts of the alternator including the pulley, fan, rotor, stator, and voltage regulator. It shows diagrams of the alternator’s connections to the main circuit and regulator. The alternator’s function is to recharge the battery after use and power other equipment while spinning.

Strategic Sourcing Conclusion and Outlook for parts of an alternator diagram

How Can Strategic Sourcing Enhance Your Alternator Component Procurement?

In conclusion, understanding the intricacies of alternator components is essential for international B2B buyers looking to optimize their sourcing strategies. Key takeaways highlight the critical roles of each part, from the rotor and stator to the voltage regulator and rectifier. These components not only influence the performance and reliability of alternators but also affect overall vehicle efficiency and operational costs.

Strategic sourcing allows businesses to identify high-quality suppliers who can provide reliable alternator parts, ensuring compliance with regional standards while maximizing value. By fostering strong relationships with manufacturers across Africa, South America, the Middle East, and Europe, buyers can leverage local insights and innovations that enhance their supply chain resilience.

Looking ahead, the global automotive market is evolving rapidly, emphasizing sustainability and technological advancements. Now is the time for B2B buyers to act—evaluate your sourcing strategies, engage with trusted suppliers, and invest in high-performance alternator components that meet the demands of tomorrow’s vehicles. By doing so, you position your business to thrive in an increasingly competitive landscape.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.