مقدمة: الإبحار في السوق العالمية للملف اللولبي البادئ هو جزء من مشغل المحرك

في المشهد المعقد لمكونات السيارات، يعد فهم ما إذا كان الملف اللولبي لبادئ التشغيل جزءًا من نظام بدء التشغيل أمرًا بالغ الأهمية لمشتري B2B. يعمل الملف اللولبي لبدء التشغيل كوسيط محوري يضمن اتصال نظام الإشعال بفعالية مع محرك بدء التشغيل لبدء تشغيل المحرك. ومع ذلك، يمكن أن يشكل الحصول على الملف اللولبي المناسب تحديات، خاصة في الأسواق المتنوعة في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، حيث قد يؤدي اختلاف المعايير وموثوقية الموردين إلى تعقيد قرارات الشراء.

سوف يتعمق هذا الدليل الشامل في تعقيدات الملف اللولبي لبادئ التشغيل، حيث يغطي أنواعه وتطبيقاته والدور الحاسم الذي يلعبه في نظام بادئ التشغيل بشكل عام. سيجد المشترون رؤى قيمة حول كيفية فحص الموردين بشكل فعال، وتقييم التكاليف، والتعرف على علامات فشل الملف اللولبي، مما يضمن اتخاذ خيارات مستنيرة تعزز استراتيجيات الشراء الخاصة بهم. من خلال تزويد المشترين الدوليين بالمعرفة اللازمة للتغلب على هذه التعقيدات، يمكّنهم هذا الدليل من تأمين مكونات السيارات الموثوقة التي تلبي احتياجاتهم التشغيلية المحددة.

مع التركيز على التطبيقات العملية والتوريد الاستراتيجي، تم تصميم هذا المورد لمساعدة المشترين من الشركات على تبسيط عمليات الشراء وتخفيف المخاطر، مما يؤدي في النهاية إلى تعزيز الأداء والموثوقية في عملياتهم في مجال السيارات.

جدول المحتويات

- أعلى 1 هل الملف اللولبي البادئ جزء من قائمة المصنعين والموردين للمبتدئين

- مقدمة: الإبحار في السوق العالمية للملف اللولبي البادئ هو جزء من مشغل المحرك

- فهم هل الملف اللولبي البادئ جزء من بادئ التشغيل أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية للملف اللولبي البادئ هو جزء الملف اللولبي لبادئ التشغيل

- 3 نقاط ألم شائعة لدى المستخدمين حول ‘هل الملف اللولبي لبدء التشغيل جزء من بادئ التشغيل’ وحلولها

- دليل اختيار المواد الاستراتيجية لـ هو الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

- نظرة متعمقة: عمليات التصنيع وضمان الجودة للملف اللولبي البادئ هو جزء من بادئ التشغيل

- دليل عملي للمصادر: قائمة تدقيق خطوة بخطوة لـ ‘هل الملف اللولبي المبدئ جزء من المبدئ’

- تحليل شامل للتكاليف والتسعير للملف اللولبي لبادئ التشغيل جزء من مصدر بادئ التشغيل

- تحليل البدائل: مقارنة هل الملف اللولبي البادئ جزء من البادئ مع الحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية للملف اللولبي لبدء التشغيل هو جزء من بادئ التشغيل

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع بادئ التشغيل هو جزء من الملف اللولبي لبادئ التشغيل

- الأسئلة المتداولة (FAQs) لمشتري B2B من هل الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

- استنتاج المصادر الاستراتيجية والتوقعات الخاصة بـ هو الملف اللولبي لبدء التشغيل جزء من بادئ التشغيل

- إخلاء مسؤولية هام وشروط الاستخدام

فهم هل الملف اللولبي البادئ جزء من بادئ التشغيل أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| الملف اللولبي التقليدي | مفتاح كهروميكانيكي، يُستخدم عادةً في السيارات القديمة. | ورش تصليح السيارات | الإيجابيات: فعالة من حيث التكلفة ومتوفرة على نطاق واسع. السلبيات: توافق محدود مع المركبات الحديثة. |

| ملف لولبي متكامل | مدمجة مع محرك بدء التشغيل، مما يقلل من مساحة التركيب. | الشركات المصنعة للمعدات الأصلية وتجميع السيارات | الإيجابيات: كفاءة في المساحة وسهولة التركيب. السلبيات: تكلفة أولية أعلى، ومرونة أقل في الترقيات. |

| الملف اللولبي عن بُعد | يسمح بالتفعيل عن بُعد، وغالباً ما يُستخدم في تطبيقات السباقات. | قطاعات السيارات عالية الأداء | الإيجابيات: تحكم محسّن، مناسب للتركيبات المخصصة. السلبيات: التعقيد في التركيب، قد يتطلب مكونات إضافية. |

| ملف لولبي عالي العزم | مصممة للمحركات عالية الأداء، قادرة على التعامل مع التيار المتزايد. | المركبات الثقيلة وفرق السباقات | الإيجابيات: موثوقة في الظروف القاسية، وقوة تشغيل محسّنة. السلبيات: أكثر تكلفة، ويتطلب فحوصات توافق دقيقة. |

| الملف اللولبي الذكي | تتميز بأدوات تحكم إلكترونية لتحسين الأداء. | أنظمة السيارات المتقدمة | الإيجابيات: تشخيصات محسّنة وموفرة للطاقة. السلبيات: تكلفة أعلى، واحتمال حدوث أعطال إلكترونية. |

ما هي خصائص الملفات اللولبية التقليدية؟

تعمل الملفات اللولبية التقليدية كمفاتيح تبديل كهروميكانيكية موثوق بها، وتوجد عادةً في طرازات السيارات القديمة. وتتميز بتصميمها المباشر وسهولة استبدالها، مما يجعلها خياراً مفضلاً للعديد من ورش إصلاح السيارات. يجب على مشتري B2B النظر في مدى توافقها مع طرازات معينة من المركبات، حيث أن هذه الملفات اللولبية قد لا تلبي متطلبات المركبات الأحدث التي تستخدم أنظمة تشغيل أكثر تقدماً.

كيف تعمل الملفات اللولبية المدمجة على تحسين التركيب؟

تدمج الملفات اللولبية المدمجة الملف اللولبي ومحرك بدء التشغيل في وحدة واحدة، مما يوفر توفيرًا كبيرًا في المساحة في مقصورات المحرك. هذا التصميم مفيد بشكل خاص لمصنعي المعدات الأصلية وخطوط تجميع السيارات، حيث تكون الكفاءة أمرًا بالغ الأهمية. في حين أنها تبسط عملية التركيب، يجب على المشترين أن يوازنوا بين التكاليف الأولية المرتفعة مقابل الفوائد المحتملة للتجميع المبسط وتقليل مخزون القطع.

ما المزايا التي تقدمها الملفات اللولبية عن بُعد؟

توفر الملفات اللولبية عن بُعد القدرة على التنشيط من مسافة بعيدة، مما يجعلها شائعة بشكل خاص في قطاعات السيارات عالية الأداء، مثل السباقات. ويسمح التحكم المحسّن فيها بالتركيبات المخصصة وتكوينات التشغيل الفريدة. ومع ذلك، يجب على مشتري B2B أن يكونوا على دراية بالتعقيدات التي ينطوي عليها التركيب، حيث قد تتطلب هذه الأنظمة مكونات وخبرات إضافية.

لماذا تختار الملفات اللولبية عالية العزم للتطبيقات الشاقة؟

صُممت الملفات اللولبية ذات عزم الدوران العالي للمحركات عالية الأداء، القادرة على التعامل مع متطلبات التيار المتزايدة. وهي ضرورية لمركبات الخدمة الشاقة وفرق السباقات التي تتطلب طاقة بدء تشغيل موثوقة في ظل الظروف القاسية. في حين أنها توفر مزايا أداء كبيرة، يجب على المشترين مراعاة التكاليف المرتفعة والتأكد من توافقها مع تطبيقاتهم الخاصة لتجنب المشاكل.

ما هي فوائد الملفات اللولبية الذكية؟

تشتمل الملفات اللولبية الذكية على عناصر تحكم إلكترونية تعزز الأداء من خلال تحسين الوظائف والتشخيصات. تزداد أهمية هذه المكونات في أنظمة السيارات المتقدمة، مما يجذب المصنعين الذين يركزون على الابتكار. على الرغم من ارتفاع تكاليفها واحتمال حدوث أعطال إلكترونية، فإن كفاءة الطاقة وقدرات التشخيص تجعلها خيارًا جذابًا للمشترين من الشركات الذين يتطلعون إلى الاستثمار في التكنولوجيا المتطورة.

التطبيقات الصناعية الرئيسية للملف اللولبي البادئ هو جزء الملف اللولبي لبادئ التشغيل

| الصناعة/القطاع | التطبيق المحدد لـ هو الملف اللولبي لبدء التشغيل جزء من بادئ التشغيل | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | التكامل في خطوط تجميع المركبات لأنظمة بدء التشغيل | يضمن تشغيل المحرك بشكل موثوق، مما يقلل من وقت التعطل | ضمان الجودة، والتوافق مع طرازات السيارات المختلفة |

| الآلات الثقيلة | الاستخدام في معدات البناء مثل الحفارات والجرافات | يعزز الكفاءة التشغيلية ويقلل من تكاليف الصيانة | المتانة في ظل الظروف القاسية، والتوريد من موردين موثوق بهم |

| الصناعة البحرية | التطبيق في محركات القوارب لأنظمة الإشعال | زيادة الموثوقية في البيئات البحرية القاسية | مقاومة التآكل، والامتثال للمعايير البحرية |

| معدات زراعية | الاستخدام في الجرارات والحصادات لبدء تشغيل المحرك | يدعم العمليات الزراعية في الوقت المناسب، مما يعزز الإنتاجية | القدرة على التكيف مع الظروف الجوية المتنوعة، والموثوقية على المدى الطويل |

| قطاع الطاقة المتجددة | التنفيذ في مولدات توربينات الرياح للتشغيل الأولي للطاقة | يسهل توليد الطاقة بكفاءة، وتحسين الإنتاجية | المواصفات الفنية لأنظمة الجهد العالي، التوريد من الشركات المصنعة المتخصصة |

كيف يتم استخدام الملف اللولبي لبدء التشغيل في صناعة السيارات؟

في قطاع تصنيع السيارات، تُعد الملفات اللولبية لبادئ التشغيل جزءًا لا يتجزأ من تجميع أنظمة بدء تشغيل السيارة. فهي تعمل كحلقة وصل حاسمة بين نظام الإشعال ومحرك بدء التشغيل، مما يضمن تشغيل المركبات بشكل موثوق. بالنسبة لمشتري B2B في هذه الصناعة، يعد الحصول على ملفات لولبية لبدء التشغيل عالية الجودة أمرًا ضروريًا لتقليل وقت تعطل الإنتاج وضمان موثوقية السيارة. وتشمل الاعتبارات الرئيسية التوافق مع طرازات المركبات المختلفة والالتزام بمعايير الصناعة لضمان الجودة.

ما الدور الذي يلعبه الملف اللولبي لبدء التشغيل في الآلات الثقيلة؟

في الماكينات الثقيلة، مثل الحفارات والجرافات، يعد الملف اللولبي لبدء التشغيل أمرًا حيويًا لبدء عمل المحرك. تم تصميم هذه المكونات لتتحمل الظروف القاسية والاستخدام المتكرر، مما يضمن استمرار تشغيل الآلات في البيئات الصعبة. بالنسبة للشركات العاملة في هذا القطاع، تؤثر متانة وموثوقية الملفات اللولبية لبادئ التشغيل بشكل مباشر على الكفاءة التشغيلية وتكاليف الصيانة. يجب أن يركز المشترون على الحصول على المنتجات التي تلبي معايير المتانة الصارمة والمدعومة من قبل موردين ذوي سمعة طيبة.

كيف يكون الملف اللولبي البادئ مفيداً في الصناعة البحرية؟

في الصناعة البحرية، تعتبر ملفات لولبية بادئ التشغيل ضرورية لأنظمة الإشعال في محركات القوارب. وبالنظر إلى البيئات البحرية القاسية، يجب أن تكون هذه الملفات اللولبية مقاومة للتآكل والرطوبة. تعد أنظمة بدء التشغيل الموثوقة ضرورية للسلامة والأداء على الماء. يجب على مشتري B2B في هذا القطاع إعطاء الأولوية للحصول على ملفات لولبية لبدء التشغيل التي تتوافق مع المعايير البحرية وتقدم أداءً مثبتًا في الظروف المعاكسة، مما يضمن السلامة والكفاءة التشغيلية.

ما أهمية الملف اللولبي لبادئ الحركة للمعدات الزراعية؟

بالنسبة للمعدات الزراعية مثل الجرارات والحصادات، يلعب الملف اللولبي لبدء التشغيل دورًا محوريًا في إشعال المحرك. يعد التشغيل في الوقت المناسب والموثوق به أمرًا بالغ الأهمية للعمليات الزراعية الفعالة، خاصة خلال مواسم الزراعة والحصاد الحرجة. يحتاج المشترون في هذه الصناعة إلى التأكد من أن الملفات اللولبية لبادئ التشغيل التي يحصلون عليها يمكن أن تتحمل الظروف الجوية المتنوعة وتوفر موثوقية طويلة الأجل. يمكن أن يؤدي هذا التركيز على الجودة إلى زيادة الإنتاجية وتقليل وقت التعطل أثناء العمليات.

كيف يتم استخدام الملف اللولبي لبدء التشغيل في قطاع الطاقة المتجددة؟

في قطاع الطاقة المتجددة، ولا سيما في مولدات توربينات الرياح، تسهل الملفات اللولبية لبدء التشغيل التشغيل الأولي للنظام. هذه الوظيفة ضرورية لتحسين توليد الطاقة وضمان تشغيل التوربينات بكفاءة. يجب على مشتري B2B النظر في المواصفات الفنية التي تستوعب أنظمة الجهد العالي والبحث عن الشركات المصنعة المتخصصة التي يمكنها توفير ملفات لولبية بادئ التشغيل المصممة خصيصًا لتطبيقات الطاقة المتجددة. هذا الاهتمام بالتفاصيل يمكن أن يعزز الأداء العام للنظام وموثوقيته.

3 نقاط ألم شائعة لدى المستخدمين حول ‘هل الملف اللولبي لبدء التشغيل جزء من بادئ التشغيل’ وحلولها

السيناريو 1: سوء فهم دور الملف اللولبي لبدء التشغيل

المشكلة: غالبًا ما يخلط العديد من مشتري B2B، وخاصة أولئك الذين يشاركون في صيانة السيارات وإصلاحها، بين الملف اللولبي لبدء التشغيل ومحرك بدء التشغيل نفسه. يمكن أن يؤدي سوء الفهم هذا إلى تشخيص خاطئ لمشكلات بدء التشغيل، مما يؤدي إلى عمليات استبدال غير ضرورية وزيادة تكاليف التشغيل. على سبيل المثال، إذا افترض المشتري أن محرك البادئ المعطل هو المشكلة الوحيدة دون النظر إلى دور الملف اللولبي، فقد لا يعالج المشكلة الأساسية، مما يطيل من فترة تعطل السيارة ويؤدي إلى خسائر محتملة في الإنتاجية.

الحل: وللتغلب على هذه المشكلة، يجب على مشتري B2B إعطاء الأولوية للتدريب الشامل للفنيين على وظائف مكونات السيارة وعلاقاتها المتبادلة، وخاصة الملف اللولبي لبدء التشغيل ومحرك بدء التشغيل. ويشمل ذلك الاستثمار في كتيبات تقنية مفصلة أو برامج تدريب عبر الإنترنت تشرح طريقة عمل نظام البادئ. بالإضافة إلى ذلك، يمكن أن يساعد وضع قائمة مرجعية تشخيصية قياسية تتضمن اختبار الملف اللولبي الفنيين على تحديد السبب الجذري لمشاكل بدء التشغيل بدقة. كما يمكن أن يؤدي تشجيع الفنيين على إجراء فحوصات الجهد في الملف اللولبي إلى منع التشخيص الخاطئ والإصلاحات غير الضرورية، وبالتالي توفير التكاليف وتحسين كفاءة الخدمة.

السيناريو 2: توريد ملفات لولبية لبدء التشغيل عالية الجودة

المشكلة: يمكن أن يكون الحصول على ملفات لولبية لبدء التشغيل عالية الجودة مهمة شاقة للمشترين من الشركات B2B، خاصةً عندما يواجهون عددًا كبيرًا من الموردين الذين يقدمون درجات متفاوتة من الجودة والأسعار. ويواجه العديد من المشترين صعوبة في تحديد الموردين الذين يوفرون مكونات موثوقة ومتينة من شأنها تقليل الإصلاحات المستقبلية ومطالبات الضمان. ويزداد هذا التحدي تعقيدًا في الأسواق الدولية، حيث قد يواجه المشترون مشكلات تتعلق بالخدمات اللوجستية ولوائح الاستيراد.

الحل: يجب على المشترين بين الشركات تطوير عملية تقييم قوية للموردين تتضمن معايير مثل جودة المنتج وشروط الضمان واستجابة خدمة العملاء. يمكن أن يؤدي الدخول في شراكات مع موردين مرموقين معروفين بمراقبة الجودة إلى تعزيز موثوقية القطع التي يتم توريدها بشكل كبير. كما يُنصح أيضاً بطلب عينات أو إجراء اختبارات أداء على الملفات اللولبية لبداية التشغيل قبل الالتزام بطلبات الشراء بالجملة. وعلاوة على ذلك، يمكن أن يساعد استخدام المنصات التي تجمع مراجعات الموردين المشترين على قياس تجارب الآخرين في الصناعة، مما يمكنهم من اتخاذ قرارات مستنيرة وتجنب الأخطاء المكلفة.

السيناريو 3: نقص الوعي بالصيانة

المشكلة: من النقاط المهمة التي يعاني منها المشترون من الشركات في قطاع السيارات نقص الوعي بأهمية الصيانة الدورية للملفات اللولبية لبادئ التشغيل. تعمل العديد من الشركات في ظل الاعتقاد الخاطئ بأن الملفات اللولبية هي مكونات قليلة الصيانة، مما يؤدي إلى إهمال الفحوصات الروتينية. يمكن أن يؤدي هذا الإهمال إلى أعطال غير متوقعة، وزيادة تكاليف الإصلاح، ووقت تعطل السيارة الطويل، مما يؤثر سلبًا على العمليات التجارية.

الحل: لمكافحة هذه المشكلة، يجب على المشترين في قطاع الأعمال تنفيذ جدول صيانة استباقي يتضمن فحوصات منتظمة للملف اللولبي لبدء التشغيل والمكونات المرتبطة به. يمكن أن يؤدي تثقيف الموظفين حول علامات تعطل الملف اللولبي - مثل أصوات النقر غير المعتادة أو التشغيل المتقطع - إلى تمكينهم من تحديد المشاكل في وقت مبكر. بالإضافة إلى ذلك، فإن دمج التكنولوجيا مثل أدوات التشخيص التي يمكنها مراقبة أداء الملف اللولبي البادئ في الوقت الفعلي سيوفر المزيد من المعلومات حول حالته. من خلال تعزيز ثقافة الصيانة الوقائية والوعي، يمكن للشركات أن تقلل بشكل كبير من احتمالية حدوث أعطال غير متوقعة وضمان عمليات أكثر سلاسة.

دليل اختيار المواد الاستراتيجية لـ هو الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

ما هي المواد المستخدمة عادةً في الملفات اللولبية لبدء التشغيل؟

عند اختيار المواد اللازمة للملفات اللولبية لبادئ التشغيل، من الضروري مراعاة خصائص أدائها وكيفية توافقها مع المتطلبات المحددة لتطبيقات السيارات. نحلل هنا أربع مواد شائعة مستخدمة في إنتاج الملفات اللولبية لبادئ التشغيل، مع التركيز على خصائصها ومزاياها وعيوبها واعتباراتها للمشترين الدوليين من الشركات.

1. النحاس

الخصائص الرئيسية:

يشتهر النحاس بموصلية كهربائية ممتازة، مما يجعله مثاليًا للمكونات الكهربائية. كما أن له موصلية حرارية جيدة ويمكنه تحمل التقلبات المعتدلة في درجات الحرارة.

الإيجابيات والسلبيات:

تضمن الموصلية العالية للنحاس نقل الطاقة بكفاءة، وهو أمر ضروري لوظيفة الملف اللولبي لبادئ التشغيل. ومع ذلك، فهو عرضة للتآكل، خاصة في البيئات الرطبة، مما قد يؤدي إلى تدهور الأداء بمرور الوقت. كما يمكن أن تكون تكلفته مرتفعة نسبياً مقارنة بالمواد الأخرى.

التأثير على التطبيق:

النحاس مناسب للتطبيقات التي تتطلب أداءً كهربائيًا عاليًا. ومع ذلك، فإن قابليته للتآكل تعني أن الطلاءات أو المعالجات الإضافية قد تكون ضرورية في بيئات معينة.

اعتبارات للمشترين الدوليين:

في مناطق مثل أفريقيا وأمريكا الجنوبية، حيث تشكل الرطوبة والتآكل مخاوف كبيرة، يجب على المشترين التأكد من أن المكونات النحاسية معالجة أو مطلية بشكل كافٍ. كما يمكن أن يكون الامتثال للمعايير الدولية مثل ASTM B187 للنحاس عاملاً في قرارات الشراء.

2. الألومنيوم

الخصائص الرئيسية:

يتميز الألومنيوم بخفة وزنه ومقاومته للتآكل، كما يتميز بتوصيل كهربائي معتدل مقارنةً بالنحاس.

الإيجابيات والسلبيات:

إن طبيعة الألومنيوم خفيفة الوزن تجعله خياراً مفضلاً لتطبيقات السيارات، مما يساهم في كفاءة السيارة بشكل عام. ومع ذلك، يمكن أن يؤدي انخفاض موصلية الألمنيوم إلى زيادة المقاومة، مما قد يؤثر على الأداء. بالإضافة إلى ذلك، يمكن أن يكون تصنيع الألومنيوم أكثر تكلفة بسبب الحاجة إلى تقنيات معالجة متخصصة.

التأثير على التطبيق:

الألومنيوم مناسب بشكل خاص للتطبيقات التي يكون فيها تقليل الوزن أمرًا بالغ الأهمية. ومع ذلك، فإن انخفاض الموصلية يعني أن اعتبارات التصميم الدقيقة ضرورية لضمان أداء موثوق به.

اعتبارات للمشترين الدوليين:

يجب على المشترين الدوليين أن يكونوا على دراية بدرجات الألومنيوم المحددة وامتثالها لمعايير مثل DIN EN 573. في أسواق مثل أوروبا والشرق الأوسط، قد تميل التفضيلات في أسواق مثل أوروبا والشرق الأوسط إلى الألومنيوم لخصائصه خفيفة الوزن.

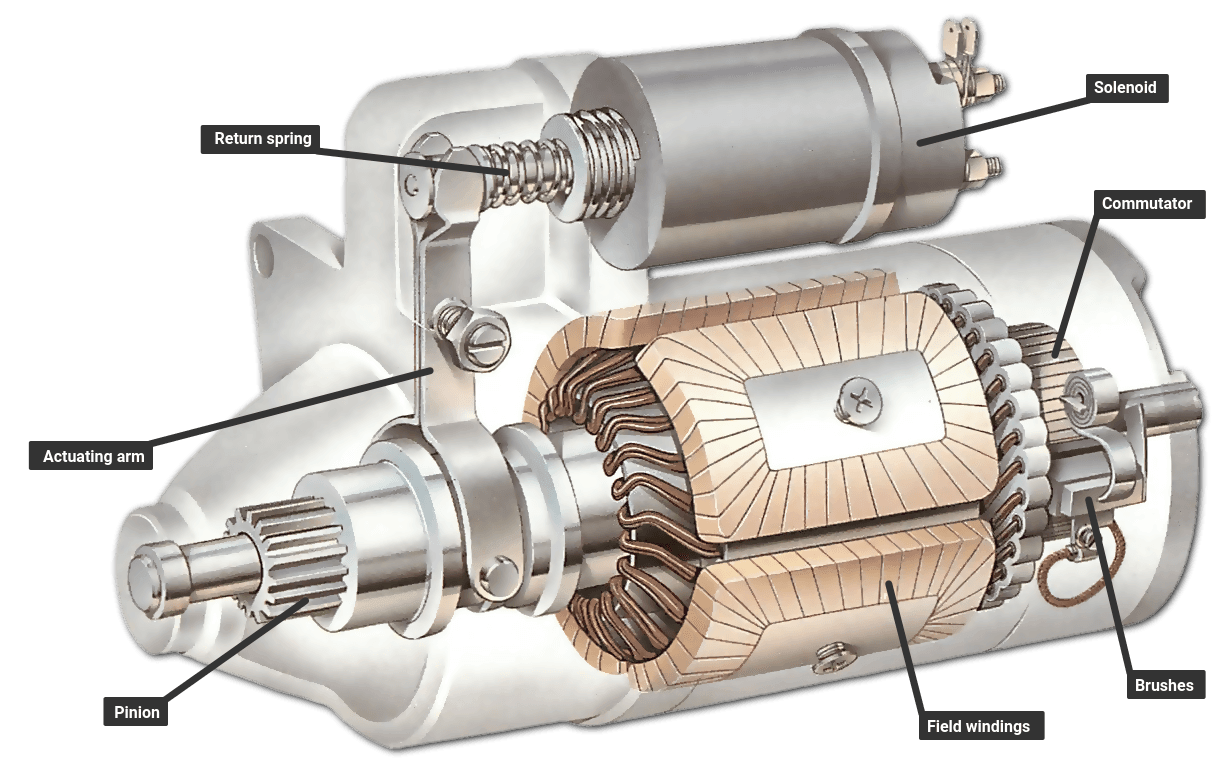

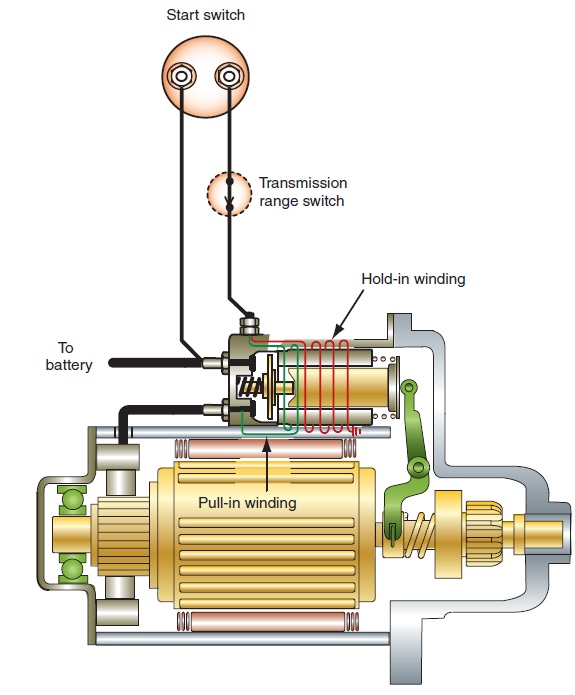

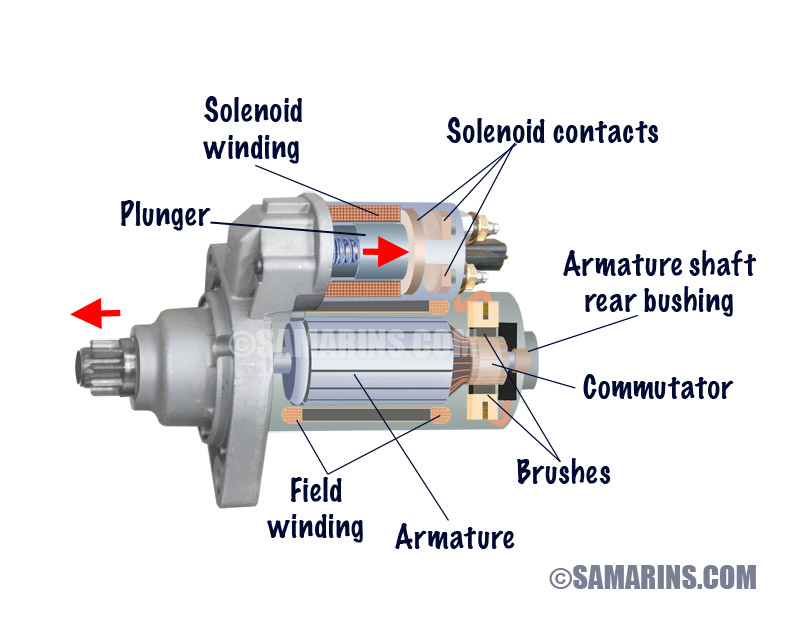

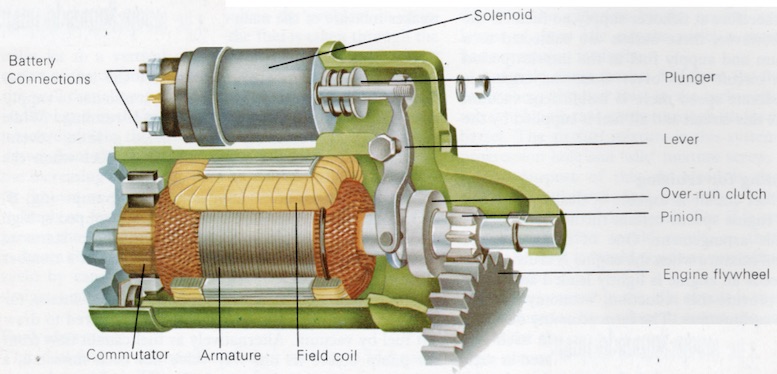

صورة توضيحية متعلقة بـ هو الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

3. الفولاذ

الخصائص الرئيسية:

يشتهر الفولاذ بقوته ومتانته العالية، ومقاومته الجيدة للتشوه تحت الضغط.

الإيجابيات والسلبيات:

متانة الفولاذ تجعله خيارًا ممتازًا للمكونات التي تتطلب قوة ميكانيكية عالية. ومع ذلك، فهو أثقل من الألومنيوم والنحاس، مما قد يكون عيباً في التطبيقات الحساسة للوزن. كما أن الصلب عرضة للصدأ إذا لم تتم معالجته بشكل صحيح.

التأثير على التطبيق:

الصلب مناسب للتطبيقات التي تكون فيها القوة الميكانيكية ذات أهمية قصوى. إلا أن وزنه قد يؤثر على الكفاءة الإجمالية للمركبة، كما أن معالجات مقاومة التآكل ضرورية لطول العمر الافتراضي.

اعتبارات للمشترين الدوليين:

يجب على المشترين في المناطق ذات الرطوبة العالية أو البيئات المالحة، مثل المناطق الساحلية في أمريكا الجنوبية أو الشرق الأوسط، أن يأخذوا بعين الاعتبار مكونات الصلب ذات الطلاء المقاوم للتآكل. كما يمكن أن يؤثر الامتثال لمعايير مثل ASTM A36 على قرارات الشراء.

صورة توضيحية متعلقة بـ هو الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

4. المركبات البلاستيكية

الخصائص الرئيسية:

المركبات البلاستيكية خفيفة الوزن ويمكن تصميمها هندسيًا للحصول على خصائص حرارية وكهربائية محددة.

الإيجابيات والسلبيات:

يمكن تصميم هذه المواد لتوفر مقاومة ممتازة للتآكل وخفض الوزن. ومع ذلك، عادةً ما يكون لها توصيل حراري وكهربائي أقل مقارنةً بالمعادن، مما قد يحد من استخدامها في التطبيقات عالية الأداء.

التأثير على التطبيق:

تعتبر المواد البلاستيكية المركبة مناسبة للمكونات غير الحاملة للملف اللولبي لبادئ التشغيل، خاصةً في البيئات التي يمثل فيها التآكل مصدر قلق. إلا أن أداءها في التطبيقات ذات درجات الحرارة العالية قد يكون محدوداً.

اعتبارات للمشترين الدوليين:

في مناطق مثل أفريقيا وأوروبا، حيث تكون مقاومة التآكل أمرًا بالغ الأهمية، قد تكون المواد البلاستيكية المركبة هي المفضلة. يجب على المشترين التأكد من أن هذه المواد تفي بالمعايير ذات الصلة مثل ISO 9001 لضمان الجودة.

جدول ملخص

| المواد | حالة الاستخدام النموذجية لـ هو الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | التوصيلات الكهربائية والمحطات الطرفية | موصلية كهربائية ممتازة | عرضة للتآكل | عالية |

| الألومنيوم | علب ومكونات الملف اللولبي خفيفة الوزن | خفيف الوزن ومقاوم للتآكل | موصلية أقل من النحاس | متوسط |

| الصلب | المكونات الهيكلية التي تتطلب قوة عالية | متانة وقوة عالية | أثقل وزناً وعرضة للصدأ | متوسط |

| المركبات البلاستيكية | المكونات غير الحاملة | مقاومة التآكل وخفة الوزن | توصيل حراري وكهربائي أقل | منخفض |

يقدم هذا التحليل نظرة عامة شاملة لخيارات المواد الخاصة بالملفات اللولبية لبداية التشغيل، مما يتيح للمشترين الدوليين من الشركات اتخاذ قرارات مستنيرة بناءً على الأداء والتكلفة والاعتبارات البيئية.

صورة توضيحية متعلقة بـ هو الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

نظرة متعمقة: عمليات التصنيع وضمان الجودة للملف اللولبي البادئ هو جزء من بادئ التشغيل

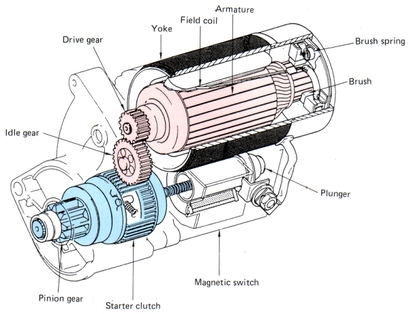

ما هي المراحل الرئيسية لتصنيع الملف اللولبي لبدء التشغيل؟

تتسم عملية تصنيع الملف اللولبي لبادئ التشغيل بالتعقيد، وتتكون من عدة مراحل رئيسية تضمن أن المنتج النهائي يلبي معايير الأداء الصارمة. وتعد كل مرحلة من هذه المراحل ضرورية لضمان عمل الملف اللولبي بشكل موثوق داخل النظام الكهربائي للسيارة.

كيف يتم تحضير المواد لإنتاج الملف اللولبي لبدء التشغيل؟

الخطوة الأولى في عملية التصنيع هي إعداد المواد. حيث يتم الحصول على المواد عالية الجودة، بما في ذلك النحاس للمكونات الكهربائية والمواد البلاستيكية أو المعادن القوية للغطاء، من موردين مرموقين. وتخضع هذه المواد لفحص شامل للتحقق من جودتها، مما يضمن استيفاءها للمواصفات المطلوبة للمتانة والتوصيل.

وبمجرد قبول المواد، يتم تقطيعها وتشكيلها إلى المكونات اللازمة. وقد يتضمن ذلك عمليات تصنيع آلي تضمن أبعادًا دقيقة لأطراف الملف اللولبي ومبيته ومكوناته الداخلية.

ما هي تقنيات التشكيل المستخدمة في تصنيع الملف اللولبي لبدء التشغيل؟

تتضمن المرحلة التالية تشكيل المكونات الفردية. يتم استخدام تقنيات مثل الختم والقولبة بشكل شائع. على سبيل المثال، قد يتم إنتاج مبيت الملف اللولبي من خلال القولبة بالحقن، في حين يمكن إنشاء المكبس الداخلي ونقاط التلامس باستخدام عمليات ختم دقيقة.

بعد التشكيل، تخضع المكونات لمزيد من فحوصات الجودة، مثل فحوصات الأبعاد، لضمان مطابقتها لمواصفات التصميم. هذه المرحلة حيوية، لأن أي اختلافات قد تؤدي إلى مشاكل في الأداء في التجميع النهائي.

كيف يتم تجميع ملفات لولبية بادئ الحركة وتشطيبها؟

ما هي عمليات التجميع المتضمنة في صنع الملف اللولبي لبدء التشغيل؟

يتضمن تجميع الملف اللولبي لبادئ التشغيل دمج المكونات المشكلة في وحدة واحدة. وتتضمن هذه العملية عادةً إدخال المكبس في مبيت الملف اللولبي وتوصيل الأطراف الكهربائية. وغالبًا ما يتم استخدام خطوط التجميع الآلية لتعزيز الكفاءة والاتساق، على الرغم من أن الفنيين المهرة قد يقومون أيضًا بالتجميع النهائي لضمان الجودة.

أثناء التجميع، يتم فحص كل وصلة بدقة لمنع حدوث أعطال كهربائية. يتم التقيد بمواصفات عزم الدوران المناسبة، مما يضمن تأمين المكونات دون التسبب في تلفها.

صورة توضيحية متعلقة بـ هو الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

ما هي تقنيات التشطيب المطبقة لضمان الجودة؟

وبمجرد التجميع، تخضع الملفات اللولبية لبادئ التشغيل لعمليات تشطيب قد تشمل معالجات سطحية لتعزيز مقاومة التآكل. وتساعد تقنيات التشطيب مثل الطلاء أو الطلاء على حماية الملف اللولبي من العوامل البيئية، وهو أمر مهم بشكل خاص للملفات اللولبية المستخدمة في المناخات المتنوعة الموجودة في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط.

يتم إجراء عمليات الفحص النهائي للتأكد من أن مظهر المنتج ووظائفه يفي بالمعايير المطلوبة قبل التعبئة والتغليف والتوزيع.

ما هي إجراءات مراقبة الجودة الضرورية للملفات اللولبية البادئة؟

يعد ضمان الجودة أمرًا بالغ الأهمية في تصنيع الملفات اللولبية لبادئ التشغيل، حيث يمكن أن تؤدي العيوب إلى تعطل السيارة. ويضمن الالتزام بالمعايير الدولية مثل ISO 9001 أن يحافظ المصنعون على مستوى عالٍ من الجودة طوال عملية الإنتاج.

ما هي المعايير الدولية ذات الصلة بجودة الملف اللولبي لبدء التشغيل؟

ISO 9001 هو معيار معترف به على نطاق واسع يحدد معايير نظام إدارة الجودة. ويشير الامتثال لهذا المعيار إلى أن الشركة المصنعة قد أنشأت عمليات لمراقبة الجودة المتسقة والتحسين المستمر. وبالإضافة إلى ذلك، قد تكون الشهادات الخاصة بالصناعة مثل شهادة المطابقة الأوروبية (CE) ومعهد البترول الأمريكي (API) قابلة للتطبيق، اعتمادًا على الاستخدام المقصود للملف اللولبي.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في التصنيع؟

يتم دمج نقاط فحص مراقبة الجودة في مراحل مختلفة من عملية التصنيع. وتشمل عادةً ما يلي:

- مراقبة الجودة الواردة (IQC): تتضمن هذه المرحلة فحص المواد الخام عند وصولها للتأكد من استيفائها للمعايير المحددة.

- مراقبة الجودة أثناء الإنتاج (IPQC): أثناء التصنيع، يتم إجراء فحوصات للتحقق من أن المكونات يتم إنتاجها بشكل صحيح ومطابقة لمواصفات التصميم.

- مراقبة الجودة النهائية (FQC): قبل التغليف، يتم إجراء تقييم شامل للملفات اللولبية المجمّعة، بما في ذلك اختبارات الأداء الوظيفي والفحص البصري.

ما هي طرق الاختبار الشائعة الاستخدام للملفات اللولبية البادئة؟

لضمان الموثوقية والأداء، يتم استخدام العديد من طرق الاختبار خلال عملية التصنيع. وتشمل هذه الطرق ما يلي:

- الاختبارات الكهربائية: يضمن قدرة الملف اللولبي على التعامل مع الجهد والتيار المطلوبين دون عطل.

- الاختبار الوظيفي: يحاكي تشغيل الملف اللولبي داخل دائرة مركبة فعلية للتأكد من أنه يتم تعشيقه وفصله بشكل صحيح.

- اختبار المتانة: تقييم أداء الملف اللولبي في ظل الظروف القاسية، مثل التقلبات في درجات الحرارة والاهتزازات، لضمان طول العمر الافتراضي.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

بالنسبة للمشترين الدوليين بين الشركات B2B، فإن التحقق من عمليات مراقبة الجودة للموردين المحتملين أمر بالغ الأهمية. ويمكن تحقيق ذلك من خلال عدة طرق:

- عمليات التدقيق: يسمح إجراء عمليات تدقيق الموردين للمشترين بفحص مرافق التصنيع وعمليات مراقبة الجودة بشكل مباشر.

- تقارير الجودة: يمكن أن يوفر طلب تقارير الجودة التفصيلية من الموردين رؤى حول ممارسات التصنيع والالتزام بالمعايير.

- عمليات التفتيش من قبل أطراف ثالثة: يمكن أن يوفر إشراك خدمات التفتيش من طرف ثالث تقييماً غير متحيز لتدابير مراقبة الجودة لدى المورد.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

يجب أن يكون المشترون بين الشركات من مناطق متنوعة مثل أفريقيا وأمريكا الجنوبية وأوروبا على دراية بالفروق الدقيقة المحددة في مراقبة الجودة. قد يكون لدى الأسواق المختلفة معايير مختلفة للجودة والسلامة، مما يستلزم أن يكون المشترون على دراية باللوائح والتوقعات المحلية.

علاوة على ذلك، قد تؤثر الحواجز اللغوية والاختلافات الثقافية على التواصل فيما يتعلق بتوقعات الجودة. وينبغي على المشترين وضع مواصفات واضحة والحفاظ على خطوط اتصال مفتوحة لضمان فهم الموردين لمتطلباتهم بشكل كامل.

الخاتمة: ضمان الجودة في تصنيع الملف اللولبي للمبتدئين

وباختصار، فإن عمليات التصنيع وضمان الجودة للملفات اللولبية لبادئ التشغيل متعددة الأوجه وحاسمة لتقديم مكونات سيارات موثوقة. من خلال فهم هذه العمليات، يمكن للمشترين الدوليين بين الشركات اتخاذ قرارات مستنيرة عند توريد الملفات اللولبية، مما يضمن لهم الشراكة مع المصنعين الذين يعطون الأولوية للجودة والامتثال للمعايير الدولية. وهذا لا يعزز موثوقية المنتجات فحسب، بل يعزز أيضًا العلاقات التجارية طويلة الأجل المبنية على الثقة والشفافية.

دليل عملي للمصادر: قائمة تدقيق خطوة بخطوة لـ ‘هل الملف اللولبي المبدئ جزء من المبدئ’

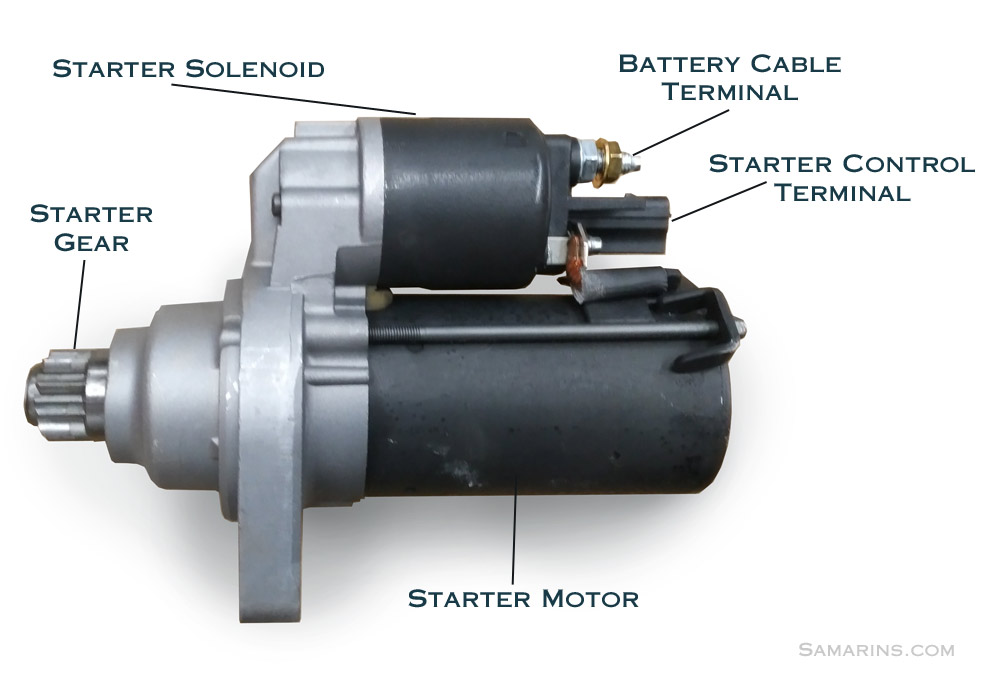

لمساعدة مشتري B2B في فهم عملية شراء ملفات لولبية بادئ التشغيل، يوفر هذا الدليل قائمة مراجعة منظمة. يعد الملف اللولبي لبادئ التشغيل مكونًا مهمًا في نظام تشغيل السيارات، حيث يعمل كمفتاح يربط البطارية بمحرك بدء التشغيل. يوجز هذا الدليل الخطوات الأساسية لضمان التوريد الفعال لهذا المكون، المصمم خصيصًا للمشترين الدوليين.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

ابدأ بتحديد المتطلبات الفنية للملف اللولبي لبدء التشغيل الذي تحتاجه بوضوح. ويشمل ذلك مواصفات مثل تصنيفات الجهد، وتكوينات الأطراف، والتوافق مع طرازات معينة من المركبات.

– تصنيفات الجهد الكهربائي: تأكد من تطابق الملف اللولبي مع النظام الكهربائي للمركبات في أسطولك.

– تكوينات المحطات الطرفية: تحقق من محاذاة أطراف التوصيل مع محركات التشغيل الموجودة لديك لتجنب مشاكل التركيب.

الخطوة 2: البحث عن الموردين المحتملين

قم بإجراء بحث شامل لتحديد الموردين ذوي السمعة الطيبة المتخصصين في مكونات السيارات، وخاصة الملفات اللولبية لبدء التشغيل. ابحث عن المصنعين الذين لديهم سجل حافل في الأسواق المستهدفة، مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

– مراجعات الموردين: تحقق من المنصات الإلكترونية بحثاً عن المراجعات والشهادات من المشترين الآخرين من الشركات.

– الخبرة في المجال: أعط الأولوية للموردين الذين يتمتعون بخبرة واسعة في منطقتك أو قطاع السوق الخاص بك.

الخطوة 3: التحقق من شهادات الموردين

تأكد من حصول الموردين الذين اخترتهم على الشهادات اللازمة لضمان الجودة. تشير شهادات مثل ISO 9001 إلى الالتزام بمعايير الجودة العالمية.

– أنظمة إدارة الجودة: التأكد من أن المورد ينفذ عمليات قوية لمراقبة الجودة للحفاظ على معايير المنتج.

– الامتثال للوائح: تحقق من الامتثال للوائح المحلية في مناطق التشغيل الخاصة بك للتخفيف من المخاطر.

الخطوة 4: طلب عينات للاختبار

قبل إجراء عمليات الشراء بالجملة، اطلب عينات من الملفات اللولبية لبدء التشغيل لاختبارها. هذه الخطوة ضرورية لتقييم جودة المنتجات وأدائها.

– الاختبارات الوظيفية: قم بإجراء اختبارات للتأكد من أن الملفات اللولبية تعمل بشكل صحيح تحت ظروف مختلفة.

– جودة المواد: افحص المواد المستخدمة للتأكد من أنها تفي بمتطلبات المتانة لتطبيقاتك.

الخطوة 5: مقارنة هياكل التسعير

اجمع معلومات التسعير من عدة موردين لمقارنة التكاليف بفعالية. انظر إلى ما هو أبعد من السعر المبدئي؛ ضع في اعتبارك التكلفة الإجمالية للملكية، بما في ذلك الشحن والرسوم الجمركية والتعريفات المحتملة.

– خصومات على الحجم: استفسر عن الخصومات على الطلبيات بالجملة، والتي يمكن أن تقلل من التكاليف الإجمالية بشكل كبير.

– الرسوم المخفية: كن على علم بأي رسوم إضافية قد يتم تطبيقها أثناء عملية الشراء.

الخطوة 6: تقييم خدمة ما بعد البيع والضمان

قم بتقييم مستوى دعم ما بعد البيع الذي يقدمه الموردون لك. يمكن أن يوفر لك الضمان الموثوق به وخدمة العملاء المتجاوبة الوقت والمال على المدى الطويل.

– شروط الضمان: فهم تغطية الضمان للملفات اللولبية لبادئ التشغيل، بما في ذلك المدة والشروط.

– الدعم الفني: تحقق مما إذا كان المورد يقدم المساعدة الفنية أو دعم استكشاف الأخطاء وإصلاحها لمعالجة أي مشاكل قد تنشأ بعد الشراء.

الخطوة 7: وضع اللمسات الأخيرة على اتفاقية المشتريات

بمجرد اختيار المورد، قم بوضع اللمسات الأخيرة على اتفاقية الشراء. تأكد من تحديد جميع الشروط بوضوح، بما في ذلك الجداول الزمنية للتسليم وجداول الدفع ومواصفات المنتج.

– التواصل الواضح: حافظ على خطوط اتصال مفتوحة لمعالجة أي مخاوف أثناء عملية الشراء.

– الوثائق: احتفظ بجميع الوثائق ذات الصلة للرجوع إليها في المستقبل ولأغراض الامتثال.

من خلال اتباع قائمة المراجعة هذه، يمكن للمشترين بين الشركات التنقل في شراء الملفات اللولبية لبدء التشغيل بشكل أكثر فعالية، مما يضمن حصولهم على مكونات عالية الجودة تلبي احتياجاتهم التشغيلية.

صورة توضيحية متعلقة بـ هو الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

تحليل شامل للتكاليف والتسعير للملف اللولبي لبادئ التشغيل جزء من مصدر بادئ التشغيل

ما هي مكونات التكلفة الرئيسية لتوريد الملفات اللولبية لبدء التشغيل؟

عند توريد ملفات لولبية لبدء التشغيل، يعد فهم هيكل التكلفة أمرًا بالغ الأهمية للمشترين بين الشركات. تشمل المكونات الأساسية للتكلفة المواد، والعمالة، ونفقات التصنيع العامة، والأدوات، ومراقبة الجودة، والخدمات اللوجستية، وهامش المورد.

-

المواد: تشمل المواد الخام المستخدمة في الملفات اللولبية لبدء التشغيل عادةً النحاس للأسلاك، والصلب للغلاف، ومواد بلاستيكية مختلفة للعزل. يمكن أن تتقلب أسعار هذه المواد بناءً على ظروف السوق، مما يؤثر على التكلفة الإجمالية.

-

العمل: تختلف تكاليف العمالة بشكل كبير حسب منطقة الإنتاج. ففي المناطق التي تنخفض فيها تكلفة المعيشة، مثل أجزاء من أمريكا الجنوبية وأفريقيا، قد تكون تكاليف العمالة أقل، مما قد يسمح بتسعير أكثر تنافسية.

-

تكاليف التصنيع العامة: يشمل ذلك جميع التكاليف غير المباشرة المرتبطة بالإنتاج، بما في ذلك المرافق وصيانة المرافق واستهلاك المعدات. ويمكن أن تساعد عمليات التصنيع الفعالة في تقليل هذه التكاليف.

-

الأدوات: ترتبط تكاليف الأدوات بتصميم وإنشاء القوالب وأدوات التصنيع الأخرى اللازمة للإنتاج. وقد تكون الأدوات المخصصة ضرورية لتصميمات الملفات اللولبية المتخصصة، مما قد يزيد من التكاليف.

-

مراقبة الجودة (QC): تضمن عمليات مراقبة الجودة الصارمة أن كل ملف لولبي يفي بمعايير ومواصفات الصناعة. ويمكن أن يؤدي الاستثمار في مراقبة الجودة إلى التخفيف من المخاطر المرتبطة بالمنتجات المعيبة، على الرغم من أنه يضيف إلى التكلفة الإجمالية.

-

اللوجستيات: يمكن أن تختلف تكاليف الشحن اختلافًا كبيرًا بناءً على المسافة من المورد إلى المشتري، ووسيلة النقل، وأي رسوم جمركية أو رسوم استيراد قد تُطبّق. يجب على المشترين الدوليين مراعاة هذه العوامل عند تقييم التكاليف الإجمالية.

-

الهامش: يضيف الموردون عادةً هامشاً لتغطية تكاليفهم وأرباحهم. ويمكن أن يختلف الهامش حسب موقع المورد في السوق وكفاءته التشغيلية.

ما هي العوامل المؤثرة في الأسعار التي يجب على المشترين أخذها في الاعتبار عند شراء ملفات لولبية لبدء التشغيل؟

هناك عدة عوامل تؤثر على أسعار الملفات اللولبية لبدء التشغيل، وهي عوامل ضرورية للمشترين بين الشركات:

-

الحجم/الحد الأدنى للطلب: يمكن أن يؤثر الحد الأدنى لكمية الطلب (MOQ) بشكل كبير على التسعير. وغالباً ما تؤدي الكميات الكبيرة إلى تخفيضات في الأسعار، لذا يجب على المشترين تقييم احتياجاتهم بعناية للاستفادة من وفورات الحجم.

-

المواصفات/التخصيص: يمكن أن تؤدي المواصفات المخصصة إلى زيادة التكاليف. يجب على المشترين الإبلاغ عن متطلباتهم بوضوح لتجنب النفقات غير المتوقعة المتعلقة بالتصاميم أو المواد المخصصة.

-

المواد: يؤثر اختيار المواد على كل من الأداء والتكلفة. قد تعزز المواد الممتازة المتانة ولكنها تزيد أيضاً من السعر. يجب أن يوازن المشترون بين الفوائد مقابل التكاليف.

-

الجودة/الشهادات: قد تتطلب المنتجات الحاصلة على شهادات جودة معترف بها أسعارًا أعلى. ومع ذلك، فإن الاستثمار في المنتجات المعتمدة يمكن أن يؤدي إلى تحقيق وفورات طويلة الأجل من خلال تقليل معدلات الأعطال ومطالبات الضمان.

-

عوامل الموردين: يمكن أن تؤثر سمعة المورد وموثوقيته على الأسعار. وقد يتقاضى الموردون الراسخون الذين يتمتعون بسجل حافل بالجودة رسوماً أعلى ولكن يمكن أن يوفروا راحة البال.

-

مصطلحات التجارة الدولية: تحدد شروط التجارة الدولية المختارة مسؤوليات المشترين والبائعين في الشحن. ويمكن أن يساعد فهم هذه الشروط المشترين على وضع ميزانية دقيقة لتكاليف الشحن والمناولة.

كيف يمكن للمشترين التفاوض على أسعار أفضل للملفات اللولبية لبدء التشغيل؟

يمكن لاستراتيجيات التفاوض الفعالة أن تؤدي إلى تحقيق وفورات كبيرة للمشترين الدوليين بين الشركات:

-

البحث والمقارنة المعيارية: يجب على المشترين إجراء بحث شامل للسوق لفهم متوسط الأسعار والتفاوض من موقع المعرفة.

-

التزامات الحجم: يمكن أن يوفر الالتزام بطلبات أكبر حجماً نفوذاً في المفاوضات. وغالباً ما يكون الموردون على استعداد لتقديم أسعار أفضل مقابل حجم مضمون.

-

العلاقات طويلة الأمد: يمكن أن يؤدي بناء علاقات طويلة الأجل مع الموردين إلى تحسين الأسعار والشروط بمرور الوقت مع تطور الثقة.

-

التكلفة الإجمالية للملكية (TCO): يجب على المشترين النظر في التكلفة الإجمالية للملكية بدلاً من التكاليف الأولية فقط. قد ينتهي الأمر بالملف اللولبي المنخفض السعر الذي يتعطل بشكل متكرر إلى تكلفة أكبر على المدى الطويل بسبب تكاليف الاستبدال والعمالة.

-

الحساسية الثقافية: إن فهم الفروق الثقافية في أساليب التفاوض يمكن أن يساعد المشترين على التواصل بشكل أكثر فعالية وتعزيز علاقات أفضل مع الموردين، لا سيما في مناطق مثل أفريقيا وأمريكا الجنوبية.

ما هي الفروق الدقيقة في الأسعار بالنسبة للمشترين الدوليين من الشركات إلى الشركات؟

يجب على المشترين الدوليين التعامل مع تعقيدات إضافية عند توريد الملفات اللولبية البادئة. يمكن أن تؤثر تقلبات العملة على الأسعار بشكل كبير، لذلك يجب على المشترين النظر في استراتيجيات التحوط. بالإضافة إلى ذلك، فإن فهم اللوائح المحلية ورسوم الاستيراد أمر بالغ الأهمية لتجنب التكاليف غير المتوقعة.

قد يواجه المشترون في مناطق مثل أوروبا وأفريقيا والشرق الأوسط تعريفات استيراد متفاوتة يمكن أن تؤثر على الأسعار الإجمالية. يُنصح بالعمل مع الخبراء أو الاستشاريين المحليين لتجاوز هذه التعقيدات بفعالية.

إخلاء المسؤولية

الأسعار المذكورة في هذا التحليل إرشادية وقد تختلف بناءً على ظروف السوق ومفاوضات الموردين ومتطلبات المشتري المحددة. احصل دائماً على عروض أسعار متعددة وقم بإجراء العناية الواجبة قبل اتخاذ قرارات الشراء.

صورة توضيحية متعلقة بـ هو الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

تحليل البدائل: مقارنة هل الملف اللولبي البادئ جزء من البادئ مع الحلول الأخرى

استكشاف بدائل لحلول بدء تشغيل المركبات

عند تقييم دور الملف اللولبي لبدء التشغيل داخل نظام بدء تشغيل السيارة، من الضروري النظر في التقنيات البديلة التي تقدم وظائف مماثلة. إن فهم هذه البدائل يمكّن مشتري B2B من اتخاذ قرارات مستنيرة، مما يضمن اختيار الحل الأكثر فعالية وفعالية من حيث التكلفة لاحتياجاتهم الخاصة.

جدول المقارنة

| جانب المقارنة | هل الملف اللولبي لبدء التشغيل جزء من المشغل | البديل 1: البديل 1: مرحل البادئ | البديل 2: نظام التشغيل بالضغط على الزر |

|---|---|---|---|

| الأداء | موثوقية وكفاءة عالية في تشغيل المحركات | موثوقية معتدلة، تعتمد على جودة الملف اللولبي | راحة عالية مع إمكانية التشغيل الفوري |

| التكلفة | منخفضة إلى معتدلة بشكل عام، حسب طراز السيارة | منخفضة التكلفة، وبأسعار معقولة لمعظم السيارات | استثمار أولي أعلى، ولكن قد يوفر في الصيانة |

| سهولة التنفيذ | يتطلب معرفة خاصة بالتركيب والكهرباء | تركيب بسيط، وغالباً ما يتم التوصيل والتشغيل | تركيب أكثر تعقيداً، قد يتطلب مساعدة احترافية |

| الصيانة | احتياجات صيانة منخفضة، ولكنها تتطلب فحوصات منتظمة | الحد الأدنى من الصيانة اللازمة | يمكن أن تكون الصيانة أعلى بسبب المكونات الإضافية |

| أفضل حالة استخدام | الأفضل لأنظمة الإشعال التقليدية | مثالية للمركبات القديمة أو الأبسط | مثالية للسيارات الحديثة ذات الميزات المتقدمة |

تفصيل البدائل

ما هو مرحل بدء التشغيل ومتى يجب استخدامه؟

يعمل مرحل بدء التشغيل كمفتاح يقوم بتشغيل الملف اللولبي لبدء التشغيل عند تنشيط الإشعال. إنه حل اقتصادي، وغالباً ما يستخدم مع الملف اللولبي لبدء التشغيل في السيارات القديمة. تتيح بساطة المرحل سهولة التركيب، مما يجعله خياراً شائعاً بين عشاق السيارات التي تعمل بنفسك. ومع ذلك، فإن أداءه يعتمد بشكل كبير على جودة الملف اللولبي الذي يتم تنشيطه. بالنسبة للسيارات التي تتطلب الحد الأدنى من المتطلبات الكهربائية، يمكن أن يكون مرحل بادئ التشغيل حلاً فعالاً من حيث التكلفة وفعالاً.

كيف يمكن مقارنة نظام التشغيل بالضغط على الزر؟

يوفر نظام التشغيل بضغطة زر بديلاً حديثاً وسهل الاستخدام لطرق الإشعال التقليدية. يسمح هذا النظام للسائقين بتشغيل مركباتهم بضغطة زر بسيطة، مما يعزز الراحة. على الرغم من أن التكلفة الأولية قد تكون أعلى بسبب تعقيد التركيب والتكامل مع النظام الكهربائي للسيارة، إلا أنه غالباً ما يؤدي إلى انخفاض تكاليف الصيانة على المدى الطويل. ومع ذلك، يمكن أن يكون هذا النظام أكثر عرضة للفشل بسبب اعتماده على مكونات إلكترونية متعددة، الأمر الذي قد يتطلب المزيد من الفحوصات والصيانة المتكررة.

الخاتمة: اتخاذ الاختيار الصحيح لنظام تشغيل سيارتك

عند اختيار الحل الأنسب لبدء التشغيل، يجب على مشتري B2B تقييم متطلباتهم التشغيلية المحددة وقيود الميزانية والقدرات التكنولوجية لمركباتهم. في حين أن الملف اللولبي لبدء التشغيل هو خيار يمكن الاعتماد عليه للأنظمة التقليدية، فإن البدائل مثل مرحلات بدء التشغيل وأنظمة التشغيل بالضغط على الزر تقدم مزايا مميزة وقد تتماشى بشكل أفضل مع تصميمات المركبات الحديثة أو سياقات تشغيلية محددة. وفي النهاية، فإن فهم المزايا والقيود الفريدة لكل خيار سيمكن المشترين من اتخاذ قرارات مستنيرة تعزز كفاءة وموثوقية أنظمة بدء تشغيل مركباتهم.

الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية للملف اللولبي لبدء التشغيل هو جزء من بادئ التشغيل

ما هي الخصائص التقنية الرئيسية للملف اللولبي البادئ؟

يعد فهم المواصفات الفنية للملف اللولبي لبادئ التشغيل أمرًا بالغ الأهمية لمشتري B2B الذين يتطلعون إلى شراء مكونات سيارات موثوقة. فيما يلي بعض الخصائص الأساسية التي يجب مراعاتها:

-

درجة المواد

عادةً ما يتم تصنيع الملف اللولبي لبادئ التشغيل من مواد عالية الجودة مثل النحاس للملفات والبلاستيك المتين أو المعادن للغلاف. يؤثر اختيار المواد على التوصيل ومقاومة الحرارة وطول العمر الإجمالي. يجب على المشترين البحث عن ملفات لولبية تفي بمعايير الصناعة أو تتجاوزها لضمان الموثوقية في ظل ظروف التشغيل المختلفة. -

تصنيف الجهد الكهربائي

تعمل معظم ملفات لولبية بادئ تشغيل السيارات بجهد قياسي 12 فولت، ولكن قد يكون بعضها مصممًا لأنظمة 24 فولت في السيارات الأكبر حجمًا. إن فهم تصنيف الجهد أمر بالغ الأهمية للتوافق مع النظام الكهربائي للسيارة. يمكن أن يؤدي عدم تطابق الجهد الكهربائي إلى تعطل الملف اللولبي أو ضعف الأداء، مما يجعل هذه المواصفات ضرورية لمشتريات B2B. -

القدرة الاستيعابية الحالية

تشير سعة حمل التيار، التي تقاس عادةً بالأمبير (A)، إلى مقدار التيار الكهربائي الذي يمكن للملف اللولبي التعامل معه دون ارتفاع درجة الحرارة. يضمن التصنيف الأعلى للتيار قدرة الملف اللولبي على إدارة الطاقة المطلوبة لتشغيل محرك بدء التشغيل بفعالية. يجب أن يتأكد المشترون من أن مواصفات الملف اللولبي تتماشى مع متطلبات نظام بدء تشغيل السيارة. -

نطاق درجة حرارة التشغيل

يحدد نطاق درجة حرارة التشغيل الظروف البيئية التي يمكن للملف اللولبي أن يعمل في ظلها على النحو الأمثل. يجب أن تكون الملفات اللولبية قادرة على العمل بفعالية في درجات حرارة تتراوح من -40 درجة مئوية إلى +85 درجة مئوية. هذا النطاق مهم بشكل خاص للمناطق ذات المناخ القاسي، مثل أجزاء من أفريقيا وأمريكا الجنوبية، حيث قد تتعرض المركبات لظروف قاسية. -

قياس المقاومة

المقاومة، التي تقاس بوحدة الأوم، عامل حاسم بالنسبة للملفات اللولبية لأنها تؤثر على كفاءتها وزمن استجابتها. تشير قيم المقاومة المنخفضة بشكل عام إلى توصيل أفضل وتفعيل أسرع. يجب على المشترين مراعاة مواصفات المقاومة عند تقييم الملفات اللولبية لضمان أداء سريع وموثوق. -

تكوين التثبيت

يعد تكوين التركيب، بما في ذلك الأبعاد وأنواع المحطات الطرفية، أمرًا حيويًا لضمان التوافق مع طرازات معينة من السيارات. يقلل التركيب الصحيح من مشاكل التركيب ويضمن الأداء الأمثل. يجب على المشترين التحقق من هذه المواصفات مقابل متطلبات السيارة قبل إجراء عملية الشراء.

ما هي المصطلحات التجارية الشائعة المتعلقة بالملفات اللولبية لبدء التشغيل؟

إن الإلمام بمصطلحات الصناعة أمر ضروري للتواصل والتفاوض الفعال في سوق B2B. وفيما يلي بعض المصطلحات الرئيسية:

-

OEM (الشركة المصنعة للمعدات الأصلية)

يشير مصطلح OEM إلى المنتجات المصنوعة من قبل الشركة المصنعة الأصلية للسيارة. تم تصميم الملفات اللولبية لبادئ التشغيل من OEM لتلبية المواصفات الدقيقة للسيارة، مما يضمن التوافق والموثوقية. غالباً ما يفضل المشترون بين الشركات قطع غيار OEM لضمان جودتها. -

MOQ (الحد الأدنى لكمية الطلب)

موك هو أصغر كمية من المنتج يرغب المورد في بيعها. ويعد فهم موك ضرورياً للمشترين لقياس جدوى الشراء، خاصة عند النظر في مستويات المخزون أو احتياجات المشروع المحددة. -

طلب عرض أسعار (RFQ)

طلب عروض الأسعار هو عملية رسمية يطلب فيها المشتري عروض أسعار من الموردين لمنتجات أو خدمات محددة. وهذه خطوة بالغة الأهمية في عملية الشراء، حيث تسمح للمشترين بمقارنة التكاليف والشروط قبل اتخاذ القرار. -

شروط التجارة الدولية (Incoterms)

تحدد شروط التجارة الدولية مسؤوليات المشترين والبائعين في المعاملات الدولية، بما في ذلك نقاط التسليم وتكاليف الشحن. يساعد الإلمام بهذه المصطلحات المشترين بين الشركات على تجنب سوء الفهم وضمان سلاسة المعاملات، خاصة عند التوريد من قارات مختلفة. -

المهلة الزمنية

مهلة التسليم هي المدة الزمنية من تقديم الطلب إلى استلام المنتج. إن فهم المهل الزمنية أمر بالغ الأهمية بالنسبة للمشترين بين الشركات لتخطيط مخزونهم وضمان توفر المكونات الضرورية عند الحاجة. -

فترة الضمان

فترة الضمان هي الإطار الزمني الذي تضمن فيه الشركة المصنعة المنتج ضد العيوب. إن معرفة شروط الضمان أمر حيوي بالنسبة للمشترين لتقييم الموثوقية والدعم طويل الأجل للمكونات التي يقومون بشرائها.

من خلال فهم هذه الخصائص التقنية والشروط التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة عند الحصول على الملفات اللولبية لبدء التشغيل، مما يضمن اختيار المكونات التي تلبي متطلباتهم التشغيلية ومعاييرهم.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع بادئ التشغيل هو جزء من الملف اللولبي لبادئ التشغيل

ما هي ديناميكيات السوق الحالية التي تؤثر على قطاع الملف اللولبي لبدء التشغيل؟

يشهد سوق الملف اللولبي لبدء التشغيل نموًا كبيرًا، مدفوعًا في المقام الأول بالطلب المتزايد على السيارات في الاقتصادات الناشئة مثل فيتنام والبرازيل ومختلف البلدان في أفريقيا والشرق الأوسط. تؤدي الزيادة الكبيرة في ملكية السيارات، لا سيما بين الطبقة المتوسطة، إلى زيادة الحاجة إلى مكونات بادئ تشغيل موثوقة. بالإضافة إلى ذلك، يعمل التحول نحو السيارات الكهربائية (EVs) على إعادة تشكيل قطاع الملف اللولبي لبادئ التشغيل، حيث يقوم المصنعون بتكييف عروضهم لتلبية احتياجات الطرازات الهجينة والكهربائية بالكامل، والتي قد تستخدم أنواعًا مختلفة من الملفات اللولبية أو تدمجها في أنظمة أكثر تعقيدًا.

تعمل التقنيات الناشئة، مثل تقنيات التصنيع المتقدمة والتشخيص الذكي، على تعزيز مشهد التوريد. على سبيل المثال، يتيح تكامل إنترنت الأشياء (إنترنت الأشياء) في مكونات السيارات الصيانة التنبؤية، مما يسمح للشركات بتوقع أعطال الملف اللولبي قبل حدوثها. هذا النهج الاستباقي جذاب للمشترين من الشركات الذين يبحثون عن شراكات طويلة الأجل مع الشركات المصنعة التي تقدم حلولاً مبتكرة ومنتجات موثوقة.

بينما يتنقل المشترون الدوليون بين الشركات في هذه السوق الديناميكية، يصبح فهم الاختلافات الإقليمية في لوجستيات سلسلة التوريد والأطر التنظيمية أمرًا بالغ الأهمية. قد تواجه البلدان في أفريقيا وأمريكا الجنوبية تحديات فريدة من نوعها تتعلق بالبنية التحتية ولوائح الاستيراد، والتي يمكن أن تؤثر على توريد الملفات اللولبية البادئة. وبالتالي، يجب على المشترين تقييم موثوقية الموردين وقدرتهم على تلبية معايير الامتثال المحلية مع الحفاظ على أسعار تنافسية.

كيف تؤثر الاستدامة والتوريد الأخلاقي على قطاع الملف اللولبي لبدء التشغيل؟

أصبحت الاستدامة أولوية متزايدة بالنسبة للشركات في قطاع قطع غيار السيارات، بما في ذلك الملفات اللولبية لبدء التشغيل. مع تزايد المخاوف بشأن التأثير البيئي، أصبح المشترون من الشركات أكثر ميلًا الآن إلى الشراكة مع الموردين الذين يلتزمون بالممارسات المستدامة. ويشمل ذلك توريد المواد الخام القابلة لإعادة التدوير أو المشتقة من مصادر مستدامة. على سبيل المثال، يمكن للشركات التي تستخدم مواد صديقة للبيئة في الملفات اللولبية الخاصة بها أن تميز نفسها في سوق تنافسية.

كما أن التوريد الأخلاقي أمر بالغ الأهمية، حيث يطالب المستهلكون والشركات على حد سواء بالشفافية في سلاسل التوريد. ويتم تشجيع المشترين على البحث عن الموردين الذين يمكنهم تقديم شهادات تثبت الامتثال لممارسات العمل الأخلاقية والمعايير البيئية. أصبحت الشهادات الخضراء، مثل ISO 14001 للإدارة البيئية وISO 50001 لإدارة الطاقة، ضرورية للمصنعين الذين يهدفون إلى جذب المشترين المهتمين بالبيئة.

علاوة على ذلك، يمثل التحول نحو السيارات الكهربائية فرصة للشركات التي يمكنها تقديم حلول مستدامة. فمع ارتفاع اعتماد السيارات الكهربائية، من المرجح أن يزداد الطلب على المكونات التي تقلل من التأثير البيئي، مثل الملفات اللولبية منخفضة الطاقة. يجب على المشترين بين الشركات إعطاء الأولوية للموردين الذين يعملون بشكل استباقي على تقليل بصمتهم الكربونية والمساهمة في الاقتصاد الدائري.

كيف تطور قطاع الملف اللولبي لبدء التشغيل بمرور الوقت؟

شهد الملف اللولبي لبدء التشغيل تطوراً كبيراً منذ نشأته في أوائل القرن العشرين. وقد تم تصميمه في البداية كمفتاح بسيط لتوصيل البطارية بمحرك بدء التشغيل، إلا أن التطورات التكنولوجية حولته إلى مكون متطور يلعب دوراً حاسماً في أداء السيارة. وقد أدى ظهور أنظمة الإشعال الإلكترونية ودمج المواد المتقدمة إلى تعزيز متانة وكفاءة الملفات اللولبية.

في السنوات الأخيرة، أثّر ظهور السيارات الكهربائية والهجينة بشكل أكبر على تصميم ووظائف الملفات اللولبية لبادئ التشغيل. يقوم المصنعون الآن بتطوير ملفات لولبية يمكنها تحمل أحمال كهربائية أعلى وتعمل بسلاسة داخل أنظمة السيارات المعقدة. ولا يعكس هذا التطور التقدم التكنولوجي فحسب، بل يعكس أيضًا متطلبات المستهلكين المتغيرة للحصول على حلول سيارات أكثر موثوقية وكفاءة. مع استمرار تحول مشهد السيارات، سيظل الملف اللولبي لبادئ الحركة مكونًا حيويًا يتكيف لتلبية احتياجات السيارات الحديثة مع توفير فرص لشراكات مبتكرة بين الشركات.

الأسئلة المتداولة (FAQs) لمشتري B2B من هل الملف اللولبي لبادئ التشغيل جزء من بادئ التشغيل

-

كيف يمكنني تحديد ما إذا كان الملف اللولبي لبدء التشغيل جزءًا من نظام بدء التشغيل؟

الملف اللولبي لبدء التشغيل هو بالفعل مكون مهم في نظام بدء التشغيل. فهو يعمل كمفتاح كهربائي يقوم بتوصيل البطارية بمحرك بدء التشغيل عند تشغيل مفتاح الإشعال. للتأكد من دوره، يمكنك الرجوع إلى دليل خدمة السيارة، والذي يتضمن عادةً مخططاً تخطيطياً لنظام بدء التشغيل. بالإضافة إلى ذلك، يمكن أن يساعدك فحص المكونات المادية في توضيح موضع الملف اللولبي وتوصيله داخل مجموعة بادئ التشغيل. -

ما هي العلامات الشائعة لفشل الملف اللولبي لبدء التشغيل؟

قد يظهر على الملف اللولبي لبادئ التشغيل المعطوب العديد من الأعراض، بما في ذلك صوت طقطقة عند محاولة تشغيل المحرك، أو عدم استجابة المحرك، أو مشاكل في التشغيل المتقطع، أو فشل المحرك في التدوير تماماً. في حالة ظهور هذه المشاكل، من الضروري إجراء فحص شامل للملف اللولبي والمكونات ذات الصلة لتحديد السبب الجذري للمشكلة قبل الشروع في الإصلاحات. -

كيف يمكنني ضمان الجودة عند الحصول على ملفات لولبية لبدء التشغيل على المستوى الدولي؟

لضمان الجودة عند الحصول على ملفات لولبية لبادئ التشغيل، قم بإجراء فحص شامل للموردين من خلال التحقق من شهاداتهم وعمليات الإنتاج ومراجعات العملاء. اطلب عينات لتقييم الجودة بشكل مباشر واستفسر عن إجراءات ضمان الجودة الخاصة بهم، بما في ذلك بروتوكولات اختبار الملفات اللولبية. يمكن أن يساعد أيضًا وضع اتفاقية جودة تحدد المواصفات والتفاوتات ومتطلبات الاختبار في الحفاظ على المعايير. -

ما هي خيارات التخصيص المتوفرة عادةً لملفات لولبية بادئ التشغيل؟

تقدم العديد من الشركات المصنعة خيارات تخصيص للملفات اللولبية لبادئ التشغيل، بما في ذلك الاختلافات في تصنيفات الجهد، وتكوينات الأطراف، ومواد التبييت. عند مناقشة التخصيص، قدم المواصفات الخاصة بك فيما يتعلق بالحجم ومتطلبات الطاقة والتوافق مع طرازات معينة من المركبات. سيساعد ذلك على ضمان أن الملف اللولبي يلبي احتياجاتك التشغيلية ويتكامل بسلاسة مع أنظمتك الحالية. -

ما هو الحد الأدنى لكمية الطلب (MOQ) للملفات اللولبية لبداية التشغيل؟

يختلف الحد الأدنى لكمية الطلب لملفات لولبية بادئ التشغيل حسب المورد ويمكن أن يعتمد على عوامل مثل قدرات الإنتاج ومتطلباتك الخاصة. وبوجه عام، يمكن أن يتراوح الحد الأدنى للكميات المطلوبة من 50 وحدة إلى عدة مئات. يُنصح بمناقشة الحد الأدنى للكميات المطلوبة مباشرةً مع الموردين المحتملين واستكشاف خيارات الطلبات الأصغر إذا كانت احتياجاتك الأولية متواضعة. -

ما هي شروط الدفع التي يجب أن أضعها في الاعتبار عند الحصول على ملفات لولبية لبدء التشغيل؟

عند الحصول على ملفات لولبية لبدء التشغيل، ضع في اعتبارك شروط الدفع التي تتماشى مع التدفق النقدي وتحمل المخاطر. تشمل الخيارات الشائعة صافي 30 أو صافي 60 يومًا، مما يتيح وقتًا للفحص وفحص الجودة قبل السداد الكامل. بالإضافة إلى ذلك، ضع في اعتبارك استخدام خدمات الضمان أو خطابات الاعتماد للمعاملات الكبيرة لحماية استثمارك وضمان امتثال المورد للشروط المتفق عليها. -

كيف يمكنني التعامل مع الخدمات اللوجستية للشحن الدولي للملفات اللولبية لبادئات التشغيل؟

لإدارة الخدمات اللوجستية للشحن الدولي، تعاون مع وكيل شحن موثوق به من ذوي الخبرة في مجال قطع غيار السيارات. تأكد من أنهم يفهمون اللوائح والوثائق المطلوبة لبلدان وجهتك. ضع في اعتبارك عوامل مثل أوقات الشحن والتكاليف والرسوم الجمركية. يمكن أن يساعد تتبع الشحنات والحفاظ على التواصل الواضح مع المورد الخاص بك في منع التأخير وضمان التسليم السلس. -

ما هي عمليات ضمان الجودة التي يجب أن تكون موجودة للملفات اللولبية البادئة؟

يجب أن تشمل عمليات ضمان الجودة للملفات اللولبية البادئة عمليات فحص المواد الواردة، وفحوصات الجودة أثناء العملية، واختبار المنتج النهائي. يمكن أن يساعد تنفيذ نظام قوي لإدارة الجودة (QMS) في ضمان الامتثال لمعايير الصناعة. بالإضافة إلى ذلك، ضع في اعتبارك إجراء عمليات تدقيق دورية للموردين لديك للتحقق من التزامهم بممارسات الجودة وتعزيز التحسين المستمر في عمليات التصنيع الخاصة بهم.

أعلى 1 هل الملف اللولبي البادئ جزء من قائمة المصنعين والموردين للمبتدئين

1. محترفي تريسي للإطارات - الملف اللولبي لبدء التشغيل

المجال: tracystirepros.com

مسجل: 2011 (14 سنة)

مقدمة: الملف اللولبي لبدء التشغيل هو مكون أساسي في نظام بدء تشغيل السيارة، حيث يعمل كجسر يسمح للتيار الكهربائي بالتدفق من البطارية إلى محرك بدء التشغيل. يقوم بتعشيق محرك بدء التشغيل عند تنشيط الإشعال، مما يؤدي إلى تشغيل المحرك لتشغيل السيارة. تتضمن علامات وجود خلل في الملف اللولبي لبدء التشغيل صوت نقر، أو عدم وجود صوت عند بدء التشغيل، أو مشاكل متقطعة في بدء التشغيل، أو عدم وجود صوت عند تشغيل المحرك.

استنتاج المصادر الاستراتيجية والتوقعات الخاصة بـ هو الملف اللولبي لبدء التشغيل جزء من بادئ التشغيل

باختصار، يعد فهم دور الملف اللولبي لبادئ التشغيل كمكون أساسي في نظام بادئ التشغيل أمرًا ضروريًا لمشتري B2B في صناعة قطع غيار السيارات. وتسلط وظيفته كمفتاح يربط نظام الإشعال بمحرك البادئ الضوء على أهمية الحصول على ملفات لولبية عالية الجودة لضمان موثوقية السيارة. يمكن أن يؤدي التعرف على علامات تعطل الملف اللولبي وتنفيذ الصيانة الدورية إلى منع حدوث أعطال مكلفة، مما يجعل التوريد الاستراتيجي ليس خيارًا ذكيًا فحسب، بل خيارًا ضروريًا لتحقيق الكفاءة التشغيلية.

بالنسبة للمشترين الدوليين، لا سيما في الأسواق الناشئة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، لا يمكن المبالغة في أهمية إقامة علاقات مع موردين موثوقين. فالاستثمار في مكونات عالية الجودة مثل الملفات اللولبية لبدء التشغيل يمكن أن يعزز بشكل كبير عروض منتجاتك ورضا العملاء.

مع استمرار تطور صناعة السيارات، فإن البقاء على اطلاع على التطورات في تكنولوجيا البادئ وممارسات التوريد سيكون أمراً بالغ الأهمية. تواصل مع الموردين الموثوق بهم واستكشف الحلول المبتكرة للبقاء في المقدمة في سوق تنافسية. أعط الأولوية للتوريد الاستراتيجي اليوم لتأمين مستقبل مستدام ومربح لأعمالك.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.