Introduction: Navigating the Global Market for how long do alternators last

In the dynamic landscape of the automotive industry, understanding how long alternators last is crucial for B2B buyers who are tasked with sourcing reliable components for vehicles across various markets. With an average lifespan of around seven years or 150,000 miles, alternators are vital for maintaining the electrical systems of vehicles. However, factors such as vehicle type, usage patterns, and regional electrical demands can significantly influence their longevity. This guide comprehensively examines the nuances of alternator lifespan, exploring different types, applications, and the implications of quality on performance and reliability.

International buyers from Africa, South America, the Middle East, and Europe face unique challenges when sourcing automotive parts, including the need for quality assurance and cost-effectiveness. By delving into supplier vetting processes, cost considerations, and maintenance practices, this guide equips decision-makers with the insights necessary to make informed purchasing decisions. Understanding the intricacies of alternator functionality and longevity not only aids in reducing operational disruptions but also enhances the overall efficiency of fleet management.

Ultimately, this resource aims to empower B2B buyers with the knowledge to navigate the global market effectively, ensuring they select the right alternators that meet their specific requirements while optimizing their procurement strategies.

جدول المحتويات

- Top 3 How Long Do Alternators Last Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how long do alternators last

- Understanding how long do alternators last Types and Variations

- Key Industrial Applications of how long do alternators last

- 3 Common User Pain Points for ‘how long do alternators last’ & Their Solutions

- Strategic Material Selection Guide for how long do alternators last

- In-depth Look: Manufacturing Processes and Quality Assurance for how long do alternators last

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long do alternators last’

- Comprehensive Cost and Pricing Analysis for how long do alternators last Sourcing

- Alternatives Analysis: Comparing how long do alternators last With Other Solutions

- Essential Technical Properties and Trade Terminology for how long do alternators last

- Navigating Market Dynamics and Sourcing Trends in the how long do alternators last Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how long do alternators last

- Strategic Sourcing Conclusion and Outlook for how long do alternators last

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding how long do alternators last Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولدات القياسية | تدوم عادةً من 5 إلى 7 سنوات أو 100,000 إلى 150,000 ميل. | General automotive applications. | Pros: Cost-effective; Cons: May require frequent replacement. |

| المولدات عالية الأداء | Designed for vehicles with high electrical demands; often more durable. | Racing and performance vehicles. | Pros: Enhanced power output; Cons: Higher initial investment. |

| المولدات المعاد تصنيعها | Rebuilt from used parts, usually more affordable than new. | Budget-conscious businesses. | Pros: Cost savings; Cons: Potential variability in quality. |

| مولدات التيار المتردد OEM | Original equipment manufacturer parts; designed specifically for a vehicle model. | Fleet management and vehicle maintenance. | Pros: Guaranteed compatibility; Cons: Premium pricing. |

| مولدات ما بعد البيع | Third-party alternatives; may offer better performance or warranty options. | Independent repair shops and aftermarket retailers. | Pros: Variety of options; Cons: Quality can vary widely. |

ما هي خصائص المولدات القياسية؟

Standard alternators are the most common type found in vehicles, designed to last approximately 5-7 years or 100,000-150,000 miles under normal operating conditions. They are suitable for general automotive applications where electrical demands are moderate. For B2B buyers, these alternators are often the most cost-effective choice, but they may require more frequent replacements, leading to increased long-term maintenance costs.

Why Choose High-Performance Alternators?

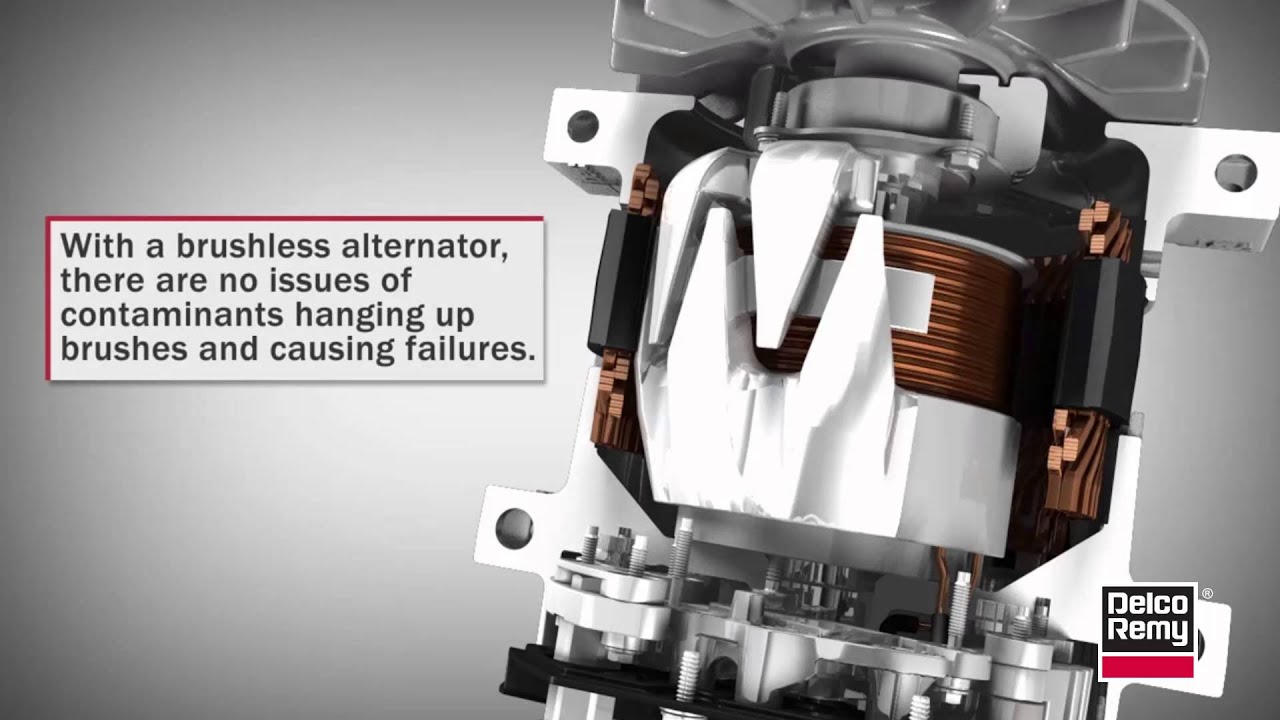

High-performance alternators are specifically engineered to handle the electrical demands of racing or performance vehicles. These units typically offer a longer lifespan due to their robust design and are ideal for businesses involved in motorsports or high-performance automotive applications. While they come with a higher initial investment, the enhanced power output and reliability can justify the cost for businesses that require superior performance.

What Should You Know About Remanufactured Alternators?

Remanufactured alternators are rebuilt from used components, making them a more affordable option for businesses looking to save costs. While these alternators can be a viable choice for budget-conscious buyers, there is variability in quality depending on the remanufacturing process. It is crucial for B2B buyers to evaluate the reputation of the remanufacturer to ensure reliability.

How Do OEM Alternators Benefit Businesses?

OEM (Original Equipment Manufacturer) alternators are designed specifically for a particular vehicle model, ensuring perfect compatibility and performance. Businesses managing fleets or conducting regular vehicle maintenance often prefer OEM parts to minimize downtime and ensure reliability. However, the premium pricing associated with OEM parts can be a consideration for budget-sensitive buyers.

What Are the Advantages of Aftermarket Alternators?

Aftermarket alternators provide a wide variety of options, allowing businesses to select parts that may offer better performance or warranty terms compared to OEM units. These alternators are often used by independent repair shops and aftermarket retailers. While the variety can be advantageous, B2B buyers should be cautious, as the quality of aftermarket parts can vary significantly, necessitating thorough research and supplier vetting.

Key Industrial Applications of how long do alternators last

| الصناعة/القطاع | Specific Application of how long do alternators last | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | إنتاج المركبات والآلات الثقيلة | Ensures reliability and reduces downtime in production | Quality of alternators, compatibility with vehicle systems |

| الطاقة المتجددة | Wind and solar energy systems integration | Enhances energy storage efficiency and system reliability | Environmental compliance, durability under harsh conditions |

| النقل واللوجستيات | Fleet management for trucks and commercial vehicles | Minimizes operational disruptions and maintenance costs | Availability of replacement parts, service agreements |

| التعدين | Equipment powering in remote locations | Reduces operational delays and enhances productivity | Robustness of alternators, performance in extreme conditions |

| الزراعة | Agricultural machinery and irrigation systems | Increases efficiency and reliability of operations | Compatibility with existing machinery, maintenance support |

How Do Alternators Impact the Automotive Manufacturing Sector?

In the automotive manufacturing sector, understanding the lifespan of alternators is crucial for production efficiency. Manufacturers rely on high-quality alternators to ensure that vehicles are assembled with reliable electrical systems. If alternators fail prematurely, it can lead to production delays and increased costs associated with warranty claims. Key sourcing considerations include ensuring that the alternators meet stringent quality standards and are compatible with a wide range of vehicle models to minimize the need for multiple parts.

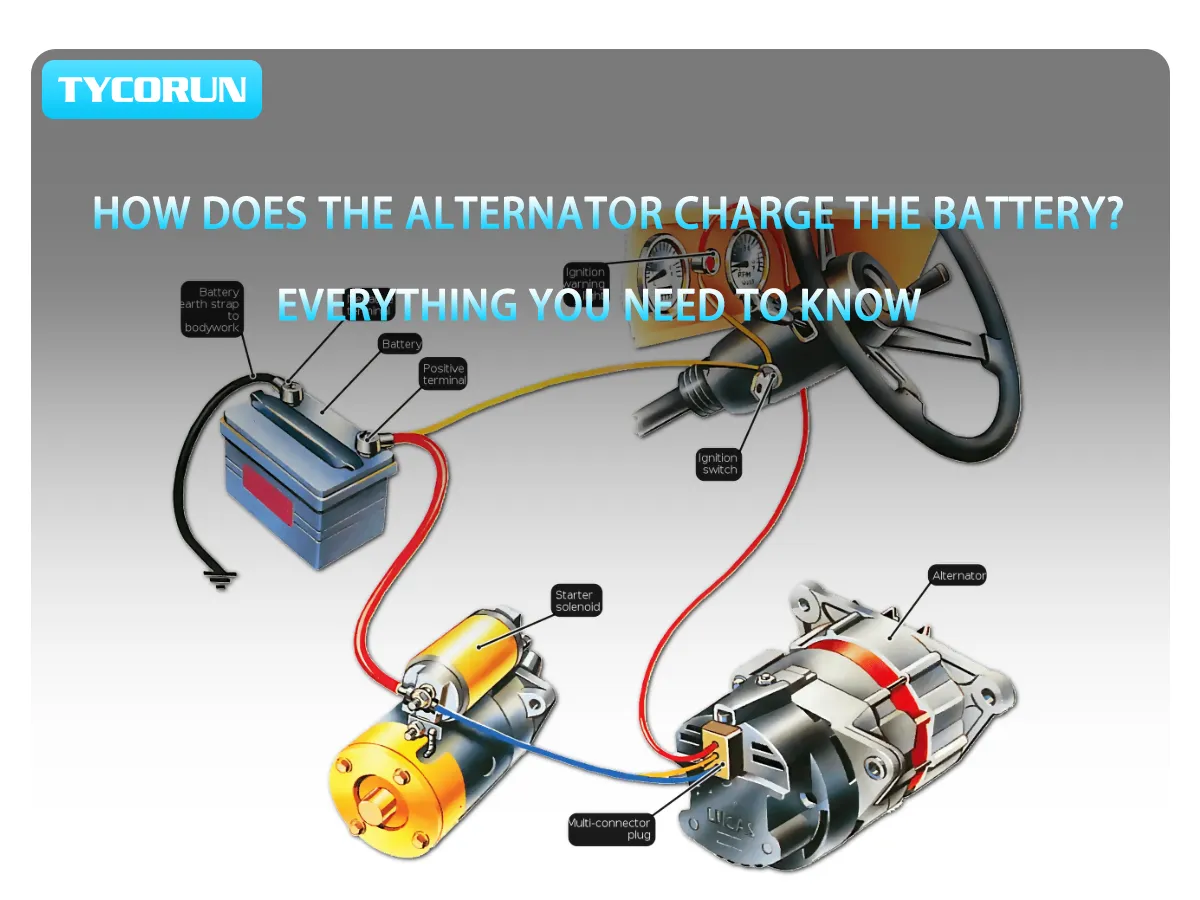

What Role Do Alternators Play in Renewable Energy Systems?

In renewable energy applications, such as wind and solar systems, alternators are vital for converting mechanical energy into electrical energy. Their lifespan affects the overall efficiency of energy storage systems. A failing alternator can lead to energy losses and increased operational costs. Buyers in this sector must consider sourcing alternators that can withstand environmental challenges, such as extreme temperatures and humidity, to ensure long-term reliability and compliance with environmental regulations.

How Are Alternators Utilized in Transportation and Logistics?

In the transportation and logistics industry, particularly for fleets of trucks and commercial vehicles, the longevity of alternators directly impacts operational efficiency. A reliable alternator ensures that vehicles can perform consistently, minimizing downtime due to electrical failures. Businesses must focus on sourcing alternators that not only meet the power demands of their vehicles but also have strong support for maintenance and replacement parts to reduce the total cost of ownership.

ما أهمية المولدات في صناعة التعدين؟

Mining operations often take place in remote locations where equipment reliability is paramount. Alternators power essential machinery, and their failure can result in significant operational delays. Therefore, understanding how long alternators last helps mining companies plan for maintenance and replacement effectively. Buyers should prioritize sourcing robust alternators capable of performing under extreme conditions, ensuring they can withstand dust, moisture, and heavy vibrations common in mining environments.

كيف تعزز المولدات العمليات الزراعية؟

In agriculture, alternators are crucial for powering machinery and irrigation systems. The lifespan of these components can greatly influence the efficiency of farming operations. A failing alternator can disrupt the operation of essential equipment, leading to reduced productivity and increased costs. Buyers in this sector need to ensure that the alternators they source are compatible with existing machinery and come with reliable maintenance support to avoid unexpected downtime during critical farming periods.

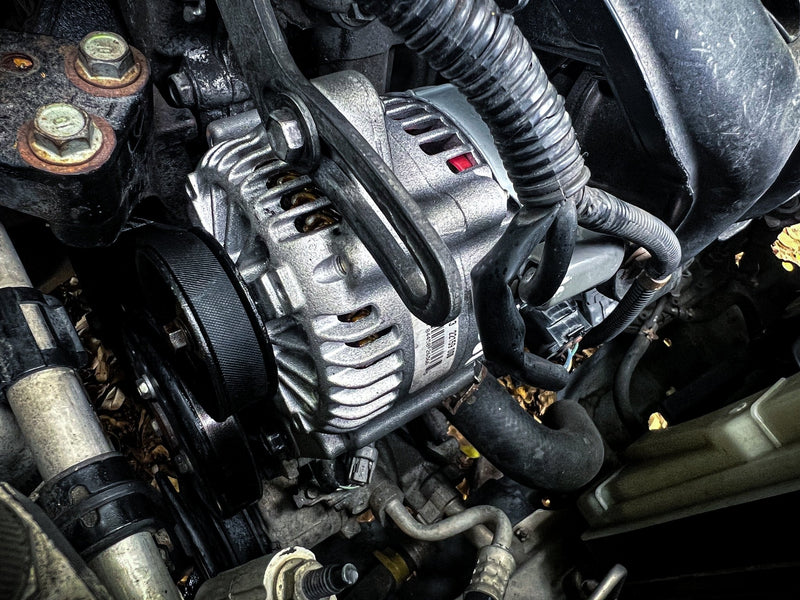

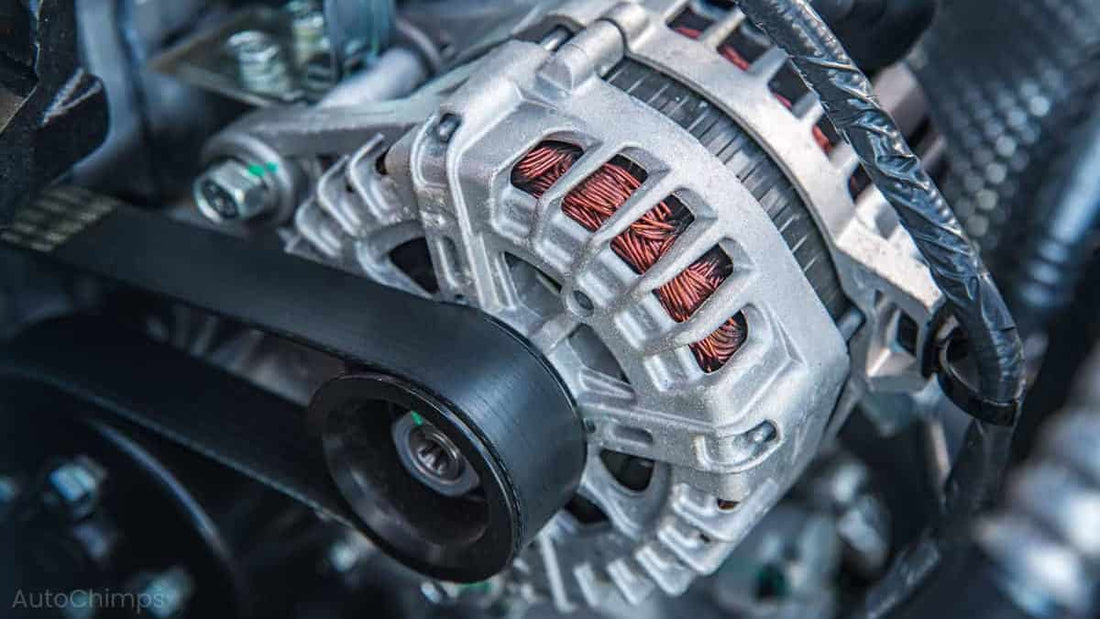

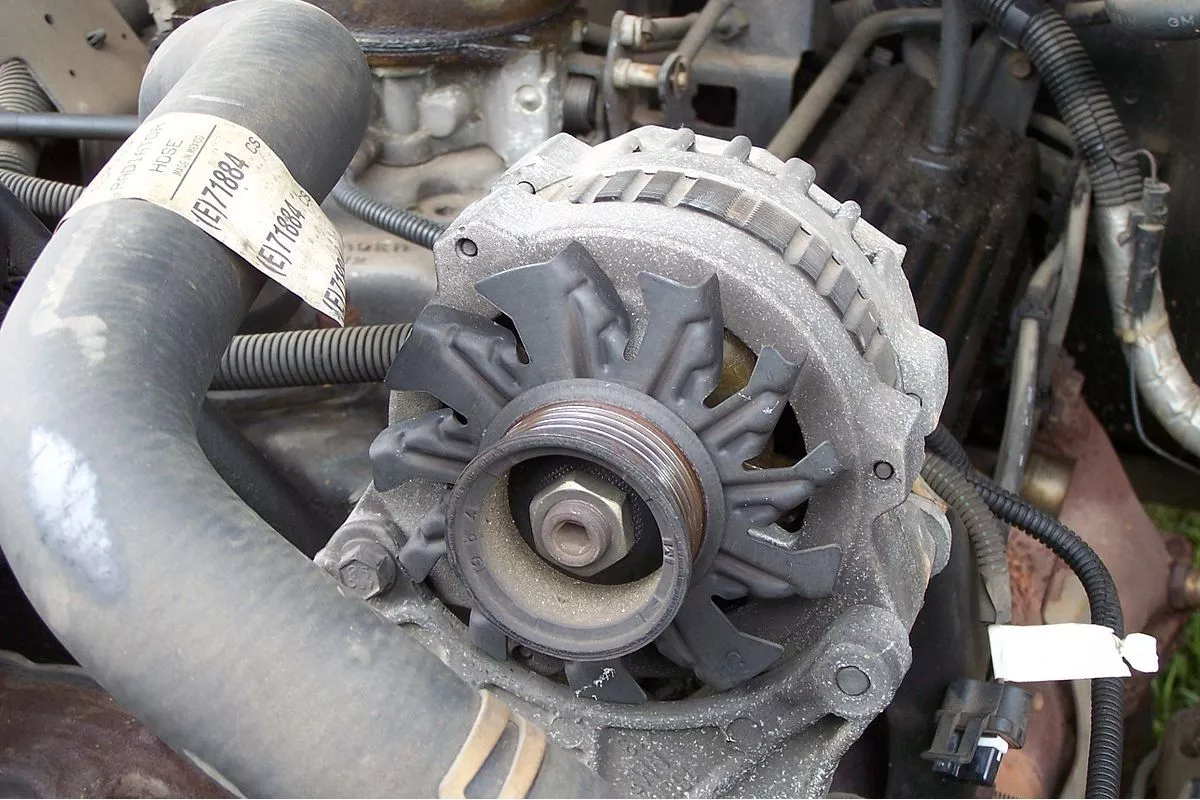

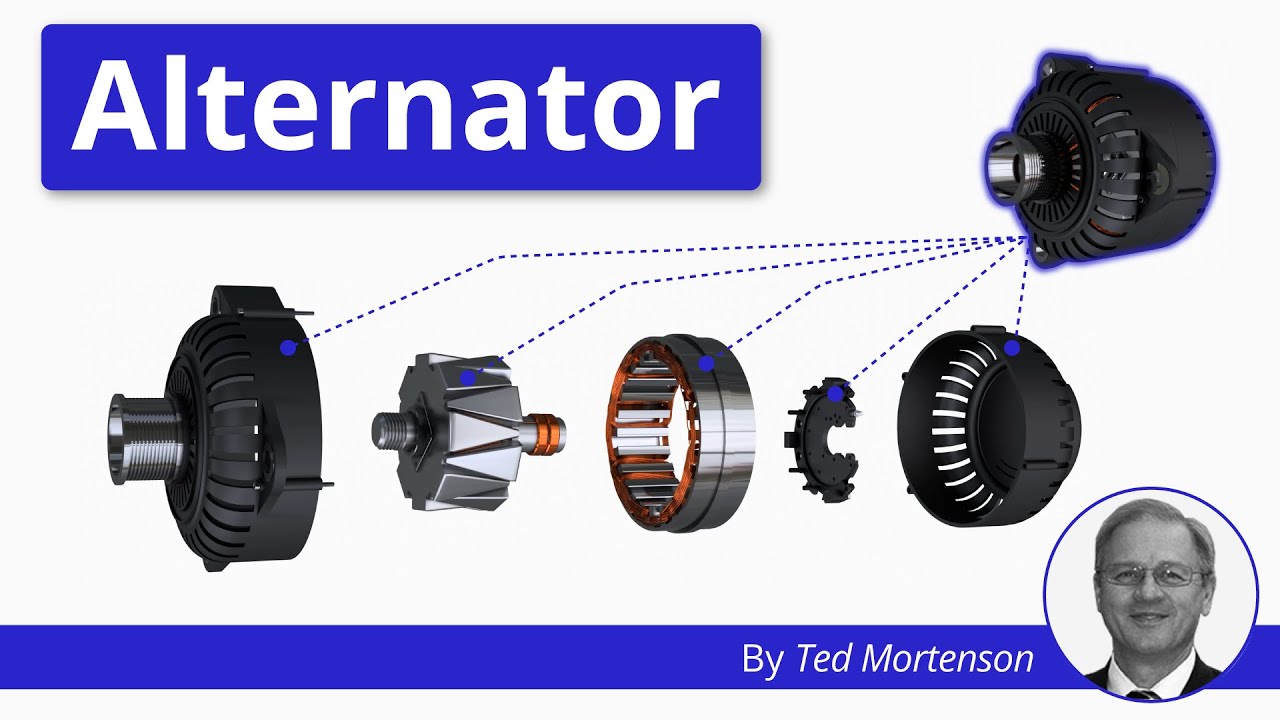

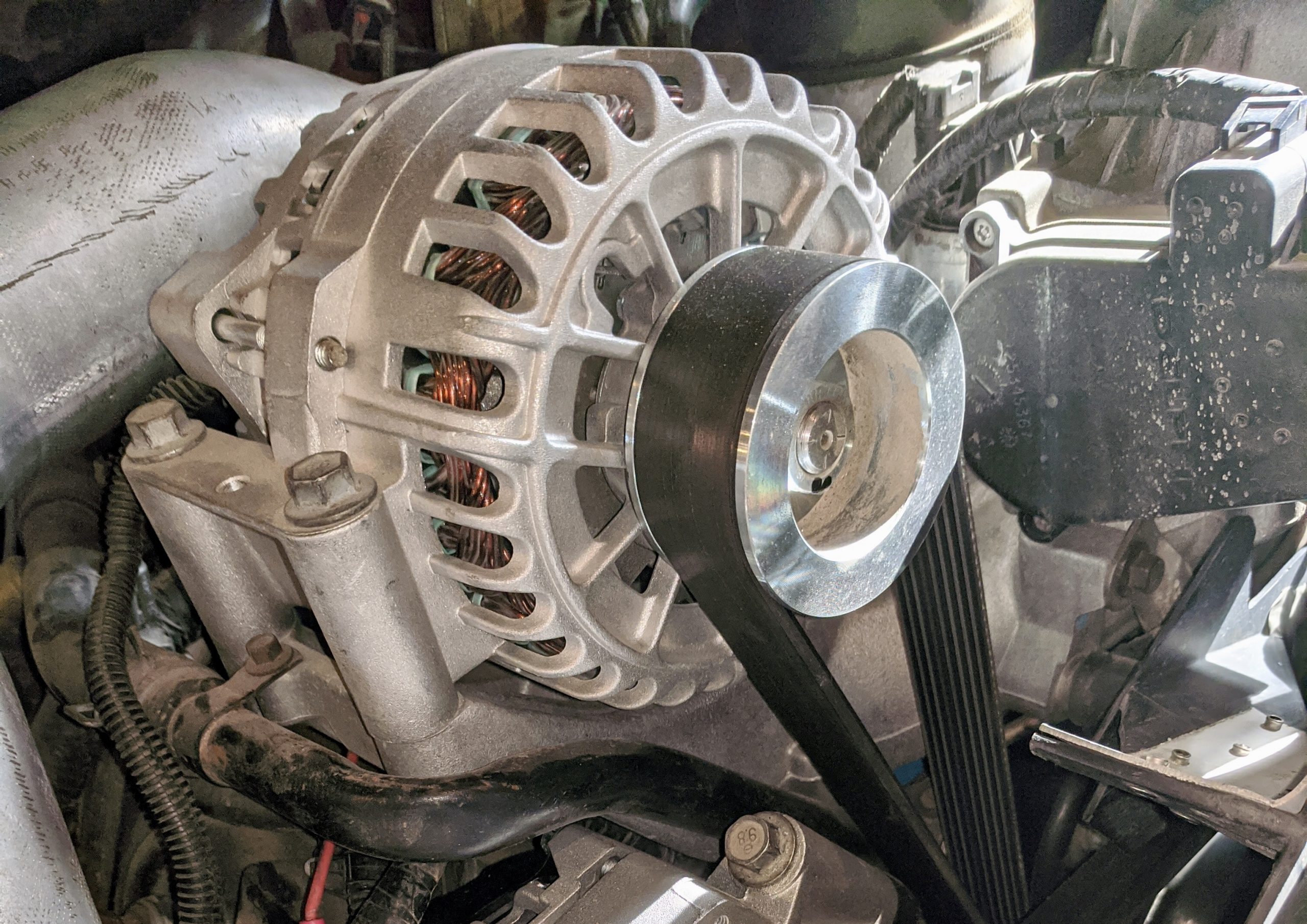

Illustrative image related to how long do alternators last

3 Common User Pain Points for ‘how long do alternators last’ & Their Solutions

Scenario 1: Understanding Alternator Lifespan for Fleet Management

المشكلة: B2B buyers managing fleets often struggle with the unpredictability of alternator lifespan. With vehicles operating under various conditions, from urban traffic to rough terrains, knowing when to replace alternators can be challenging. This unpredictability can lead to unexpected vehicle downtime, impacting operational efficiency and increasing maintenance costs. Furthermore, with a lack of consistent performance data on alternators across different vehicle models, fleet managers may find it difficult to develop a reliable maintenance schedule.

الحل: To overcome this issue, fleet managers should implement a systematic approach to monitor alternator performance and longevity. Start by establishing a baseline for alternator lifespan specific to each vehicle type within the fleet. This can be achieved through detailed record-keeping of maintenance activities, including the age of the alternator, mileage, and any previous issues. Additionally, investing in telematics systems can provide real-time data on vehicle performance and alert managers to any electrical anomalies that may indicate alternator failure. Regular training for maintenance staff on the signs of alternator issues can also enhance early detection, ensuring timely replacements and minimizing downtime.

السيناريو 2: توريد مولدات عالية الجودة لتطبيقات متنوعة

المشكلة: Many B2B buyers face difficulties in sourcing high-quality alternators that meet the specific needs of their vehicles, especially when dealing with diverse applications. For instance, companies that operate in regions with extreme weather conditions may require alternators that can withstand higher thermal loads. However, the market is flooded with options, and distinguishing between reliable and subpar products can be daunting. This can lead to costly mistakes, such as purchasing alternators that fail prematurely or are incompatible with existing systems.

الحل: To effectively source alternators, buyers should prioritize working with reputable suppliers who provide detailed specifications and performance data for their products. Request comprehensive documentation that includes expected lifespan, load capacity, and environmental tolerances. Establish relationships with manufacturers that offer warranties and post-purchase support, as this can be an indicator of product quality. Additionally, consider leveraging feedback from other businesses in your industry to identify trusted brands and models. Conducting small-scale trials with new alternators in controlled environments can also help assess performance before committing to larger purchases.

Illustrative image related to how long do alternators last

Scenario 3: Managing Cost Implications of Alternator Failure

المشكلة: For businesses reliant on vehicle operations, unexpected alternator failure can lead to significant financial strain. Beyond the immediate costs of repairs or replacements, businesses may incur additional expenses due to lost productivity, emergency towing, and potential damage to electrical systems caused by a failing alternator. This scenario is particularly concerning for companies in regions where repair services are limited or costly, making it crucial to manage the risks associated with alternator lifespan effectively.

الحل: Implementing a proactive maintenance strategy is essential for minimizing the cost implications of alternator failures. Regular inspections and diagnostics should be part of the vehicle maintenance schedule, focusing specifically on alternator performance. Use predictive maintenance techniques, such as monitoring voltage output and checking for unusual noises, to identify potential issues before they escalate. Additionally, educate drivers on the signs of alternator problems, such as dimming lights or electrical malfunctions, to encourage timely reporting. Budgeting for routine alternator replacements based on average lifespans can also help businesses allocate funds more effectively and avoid the financial shock of unexpected repairs.

Strategic Material Selection Guide for how long do alternators last

What Materials are Commonly Used in Alternators and How Do They Affect Lifespan?

When considering the longevity of alternators, the materials used in their construction play a critical role. Below, we analyze four common materials found in alternators, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

ما هي الخصائص الرئيسية للألومنيوم في المولدات الكهربائية؟

Aluminum is widely used in alternator housings and components due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of around 150°C and offers good corrosion resistance, particularly when anodized.

الإيجابيات: Aluminum is durable, lightweight, and cost-effective, making it suitable for automotive applications where weight reduction is crucial for fuel efficiency.

السلبيات: However, its mechanical strength is lower than that of other metals like steel, which may limit its use in high-stress components. Additionally, aluminum can be more prone to wear over time, especially in harsh environments.

التأثير على التطبيق: Aluminum’s compatibility with various automotive fluids is generally good, but it may not perform as well in extreme conditions, such as high humidity or salt exposure, which are common in coastal regions of Africa and South America.

اعتبارات للمشترين الدوليين: Compliance with international standards like ASTM and DIN is essential. Buyers should also consider the availability of aluminum components in their region, as supply chain issues may arise, particularly in developing markets.

كيف يعزز النحاس من أداء المولد؟

Copper is primarily used in the windings of alternators due to its superior electrical conductivity. It can handle high current loads and has a temperature rating of around 200°C.

الإيجابيات: The high conductivity of copper allows for efficient energy transfer, which is vital for the performance of alternators. Its durability also ensures a longer lifespan under normal operating conditions.

السلبيات: The main drawback is its cost, as copper is more expensive than aluminum. Additionally, copper can corrode if not properly insulated, leading to potential failures.

التأثير على التطبيق: Copper is highly compatible with automotive electrical systems, but its susceptibility to corrosion means that protective coatings are often necessary in humid or corrosive environments.

اعتبارات للمشترين الدوليين: Buyers should ensure that copper components meet local and international standards. In regions like the Middle East, where high temperatures can affect performance, selecting high-quality copper with appropriate insulation is crucial.

What Role Does Steel Play in Alternator Durability?

Steel is often used for structural components of alternators, such as the frame and rotor. It has a high tensile strength and can withstand significant mechanical stress, with a temperature rating typically around 300°C.

الإيجابيات: The strength and durability of steel make it ideal for high-load applications, ensuring that the alternator can withstand vibrations and shocks commonly encountered in automotive environments.

السلبيات: However, steel is heavier than aluminum and can be prone to rust if not properly treated, which can lead to premature failure in humid or corrosive conditions.

التأثير على التطبيق: Steel’s durability makes it suitable for heavy-duty applications, but its weight can negatively impact overall vehicle efficiency.

اعتبارات للمشترين الدوليين: Buyers in regions with high humidity or salt exposure, such as coastal areas, should prioritize galvanized or stainless steel options to prevent corrosion.

How Does Plastic Contribute to Alternator Functionality?

Plastic is often used for non-structural components, such as covers and insulators. It offers good electrical insulation properties and can withstand temperatures up to 100°C.

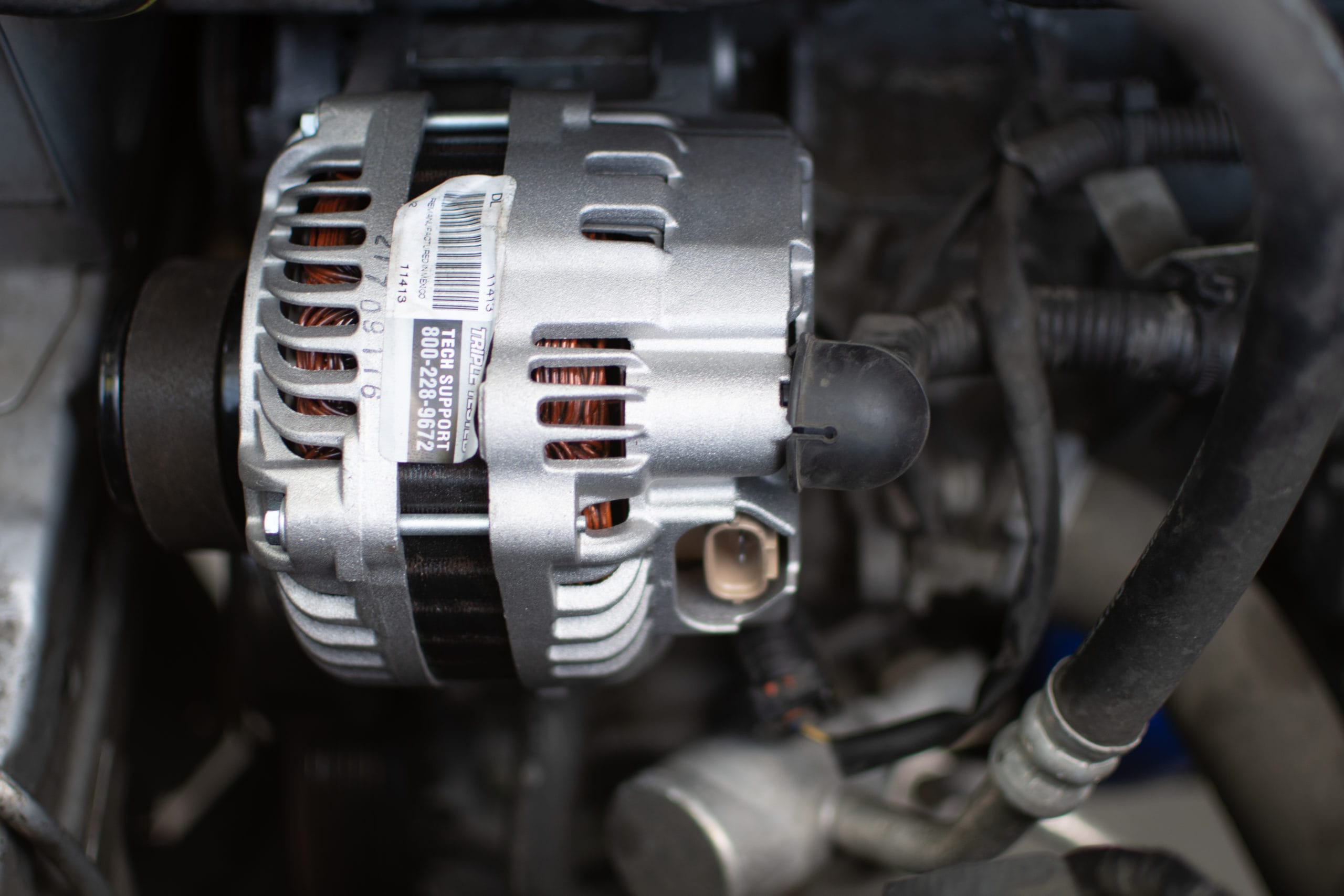

Illustrative image related to how long do alternators last

الإيجابيات: The lightweight nature of plastic helps reduce overall alternator weight, while its insulation properties prevent electrical shorts.

السلبيات: Plastics can degrade over time, especially when exposed to UV light or extreme temperatures, which may lead to failures.

التأثير على التطبيق: Plastic components are generally compatible with automotive fluids, but their longevity can be a concern in harsh environments.

اعتبارات للمشترين الدوليين: Buyers should ensure that plastic components meet relevant standards and are suitable for the climate and conditions in their region.

جدول ملخص لاختيار المواد للمولدات الكهربائية

| المواد | Typical Use Case for how long do alternators last | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | العلب والمكونات خفيفة الوزن | خفيفة الوزن وفعالة من حيث التكلفة | Lower mechanical strength than steel | متوسط |

| النحاس | الملفات والتوصيلات الكهربائية | موصلية كهربائية ممتازة | ارتفاع التكلفة وقابلية التآكل | عالية |

| الصلب | Structural components and rotors | متانة وقوة عالية | أثقل وزناً وعرضة للصدأ | متوسط |

| بلاستيك | الأغطية والعوازل | خفيف الوزن وعزل جيد | Degrades over time under harsh conditions | منخفض |

This analysis provides valuable insights for international B2B buyers, helping them make informed decisions about material selection for alternators, ultimately impacting their longevity and performance.

Illustrative image related to how long do alternators last

In-depth Look: Manufacturing Processes and Quality Assurance for how long do alternators last

ما هي المراحل الرئيسية في عملية تصنيع المولدات الكهربائية؟

The manufacturing of alternators is a complex process involving multiple stages to ensure quality and longevity. The main stages include material preparation, forming, assembly, and finishing.

كيف يتم تحضير المواد لتصنيع المولد؟

The first step in alternator manufacturing involves sourcing high-quality materials such as aluminum for the housing, copper for the windings, and steel for the rotor and stator components. The preparation phase may include processes like cutting, machining, and casting, where raw materials are shaped into components that meet the specific requirements of alternator design.

ما هي تقنيات التشكيل المستخدمة في إنتاج المولد؟

Once materials are prepared, forming techniques come into play. This stage often employs die casting for the aluminum housing, which ensures durability and optimal weight. Stamping is commonly used for metal components, while winding processes are critical for creating the stator and rotor coils. Advanced manufacturing techniques, such as CNC machining, may also be utilized to achieve precise dimensions, which is essential for the alternator’s performance and longevity.

Illustrative image related to how long do alternators last

كيف يتم التجميع في تصنيع المولدات الكهربائية؟

The assembly stage is where all the prepared components come together. This process typically involves integrating the rotor and stator, connecting the electrical windings, and installing the voltage regulator. Automated assembly lines are often employed to enhance efficiency and ensure consistency. Quality checks during assembly are crucial, as any misalignment or improper connection can lead to premature failure.

What Finishing Processes Ensure the Quality of Alternators?

Finishing processes include applying protective coatings to prevent corrosion and enhance durability. Components may undergo surface treatments, such as anodizing or powder coating, to improve their resistance to environmental factors. Additionally, final inspections for aesthetic quality and dimensional accuracy are performed before the alternators are packaged for distribution.

What Are the Quality Control Measures in Alternator Manufacturing?

Quality control (QC) is a critical aspect of alternator manufacturing, ensuring that products meet international standards and customer expectations.

Which International Standards Guide Alternator Quality Assurance?

Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems, ensuring that processes consistently meet customer and regulatory requirements. Additionally, industry-specific certifications, such as CE marking for products sold in Europe and API standards for automotive components, may be relevant depending on the market.

What Are the Key QC Checkpoints During Alternator Production?

Quality control checkpoints are strategically placed throughout the manufacturing process, including:

-

مراقبة الجودة الواردة (IQC): This checkpoint verifies the quality of raw materials before production begins. Suppliers must provide documentation proving that materials meet specified standards.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During manufacturing, regular inspections ensure that processes are being followed correctly. This may include dimensional checks and testing electrical components for performance.

-

مراقبة الجودة النهائية (FQC): Before shipping, finished alternators undergo comprehensive testing to confirm functionality and performance. Common tests include electrical output tests, thermal imaging to check for overheating, and vibration analysis to ensure the alternator operates smoothly.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

B2B buyers must take proactive measures to ensure they are sourcing high-quality alternators. Here are some actionable strategies:

What Auditing and Reporting Mechanisms Should Buyers Consider?

Buyers should request detailed quality assurance reports from suppliers that outline their QC processes, including any certifications they hold. Regular audits of the manufacturing facilities can provide insights into the operational standards and adherence to quality protocols.

كيف يمكن لعمليات التفتيش التي تجريها أطراف ثالثة أن تعزز ضمان الجودة؟

Engaging third-party inspection services can serve as an additional layer of assurance. These independent entities can conduct thorough evaluations of manufacturing practices, material quality, and final products, ensuring compliance with international standards. This is particularly important for international buyers from regions like Africa, South America, the Middle East, and Europe, where local regulations may vary.

ما هي الفروق الدقيقة في مراقبة الجودة وإصدار الشهادات للمشترين الدوليين؟

B2B buyers in different regions must navigate various regulations and quality standards. For instance, buyers in Europe may require CE marking, while those in the Middle East might focus on GCC standards. Understanding these nuances is crucial for ensuring compliance and avoiding potential legal issues.

How Can Buyers Stay Informed About Manufacturing Trends and Quality Standards?

To maintain a competitive edge, B2B buyers should stay informed about the latest manufacturing trends and quality standards relevant to alternators. Regular participation in industry conferences, workshops, and webinars can provide valuable insights into best practices, emerging technologies, and evolving regulations. Collaborating with local industry associations can also enhance understanding of regional requirements.

الخلاصة

In summary, understanding the manufacturing processes and quality assurance measures for alternators is essential for B2B buyers looking to make informed purchasing decisions. By focusing on the key stages of manufacturing and the rigorous QC protocols in place, buyers can ensure that they are sourcing reliable products that meet their operational needs. Engaging in thorough supplier verification and staying updated on industry standards will further bolster their purchasing strategy, ultimately leading to enhanced product longevity and performance.

Illustrative image related to how long do alternators last

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how long do alternators last’

مقدمة

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in understanding the lifespan of alternators, crucial components in automotive and industrial applications. By following these steps, buyers can make informed decisions when sourcing alternators, ensuring they select quality products that meet their operational needs.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Before starting your procurement process, it’s essential to clearly define the technical specifications of the alternators you require. Consider factors such as voltage output, amperage, and compatibility with existing systems. A well-defined specification will streamline your sourcing process and help you communicate effectively with potential suppliers.

- الجهد والأمبيرية: Ensure you understand the electrical requirements of your application.

- التوافق: Verify that the alternator will work with the specific vehicle or machinery models in use.

الخطوة 2: Research Market Standards

Understanding the market standards for alternators is vital for identifying reliable suppliers. Research typical lifespans, which generally range from 7 to 10 years or 150,000 miles, depending on usage and maintenance. This knowledge will help you assess whether suppliers meet industry benchmarks.

- Lifespan Expectations: Familiarize yourself with what constitutes a good lifespan for alternators in your specific application.

- Quality Indicators: Look for manufacturers that provide warranties or guarantees on their products.

الخطوة 3: تقييم الموردين المحتملين

Thoroughly vet potential suppliers to ensure they can meet your specifications and quality standards. Request detailed company profiles, case studies, and references from other businesses in similar industries or regions. This step minimizes risks and builds confidence in your supplier selection.

Illustrative image related to how long do alternators last

- Supplier Experience: Assess how long the supplier has been in the alternator market and their reputation.

- آراء العملاء: Look for testimonials or case studies that illustrate successful partnerships.

الخطوة 4: Check for Certifications and Compliance

Verify that suppliers comply with international quality standards and regulations relevant to your industry. Certifications such as ISO 9001 or automotive-specific standards demonstrate a commitment to quality and reliability.

- ضمان الجودة: Ensure the alternators have undergone rigorous testing to meet safety and performance standards.

- الامتثال التنظيمي: Confirm that the products adhere to the regulations applicable in your target markets, particularly if you are sourcing from different regions.

الخطوة 5: طلب عينات وإجراء الاختبارات

Before making a bulk purchase, request samples of the alternators to conduct thorough testing. Testing samples in real-world conditions will help you assess performance and compatibility with your systems.

- Performance Assessment: Evaluate the alternator’s efficiency and reliability under operational conditions.

- Failure Analysis: Monitor how the alternator performs over time to anticipate potential issues.

الخطوة 6: التفاوض على الشروط والأحكام

Once you’ve identified a suitable supplier, it’s crucial to negotiate favorable terms and conditions. This includes pricing, delivery timelines, warranty provisions, and after-sales support. Clear agreements will help mitigate risks and ensure a smooth transaction.

- Pricing Structure: Discuss bulk purchase discounts or long-term partnership pricing.

- الضمان والدعم: Ensure you have a clear understanding of the warranty terms and what after-sales support is available.

الخطوة 7: Establish a Maintenance Plan

After procurement, create a maintenance plan to ensure the longevity of your alternators. Regular inspections and maintenance can significantly extend their operational lifespan, aligning with the average expectations.

- Scheduled Inspections: Develop a routine check-up schedule to catch potential issues early.

- Maintenance Documentation: Keep records of inspections and repairs to track performance trends over time.

By following this practical sourcing guide, B2B buyers can effectively navigate the complexities of procuring alternators, ensuring they make informed choices that enhance their operational efficiency.

Comprehensive Cost and Pricing Analysis for how long do alternators last Sourcing

What Are the Key Cost Components Involved in Sourcing Alternators?

When considering the sourcing of alternators, it’s crucial to understand the various cost components that contribute to the overall price. These include:

-

المواد: The primary materials used in alternator manufacturing, such as copper for windings, aluminum for casings, and various plastics, significantly influence costs. Fluctuations in material prices can directly affect the final pricing of alternators.

-

العمل: Labor costs vary by region and can be influenced by the skill level required for assembly. In regions with higher labor costs, such as Europe, the total cost of production may increase, impacting pricing for international buyers.

-

تكاليف التصنيع العامة: This includes expenses related to utilities, facility maintenance, and administrative costs. Efficient manufacturing processes can help minimize these overheads, thereby lowering prices.

-

الأدوات: The initial investment in tooling for production can be substantial, especially for custom alternators. Buyers may need to consider these costs when negotiating prices, as they can be amortized over larger production runs.

-

مراقبة الجودة (QC): Ensuring that alternators meet specific quality standards is vital for performance and reliability. Implementing rigorous QC processes can add to the overall cost but ultimately benefits the buyer by reducing failure rates.

-

اللوجستيات: Shipping costs, which can vary widely based on distance and chosen Incoterms, play a significant role in the total cost. Buyers should factor in these expenses when calculating the total landed cost.

-

الهامش: Suppliers will typically add a margin on top of their costs to ensure profitability. Understanding market dynamics and competitor pricing can help buyers negotiate better deals.

What Factors Influence the Pricing of Alternators?

Several factors can influence the pricing of alternators beyond the basic cost components:

-

الحجم والحد الأدنى لكمية الطلب (MOQ): Larger orders often lead to discounts, making it economically viable for buyers to procure in bulk. Understanding the MOQ from suppliers can help buyers optimize their purchasing strategy.

-

المواصفات والتخصيص: Custom alternators designed for specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

شهادات المواد والجودة: Alternators made from high-quality materials or those that meet specific certifications (such as ISO standards) can command higher prices. Buyers need to balance quality with cost to ensure they receive value.

-

عوامل الموردين: The reliability and reputation of the supplier can impact pricing. Established suppliers with a proven track record may charge more due to their quality assurance and customer service.

-

مصطلحات التجارة الدولية: The choice of Incoterms can significantly affect the total cost, as they define the responsibilities of buyers and sellers in shipping. Understanding these terms can help buyers negotiate better shipping agreements.

What Are the Best Buyer Tips for Sourcing Alternators?

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, here are some actionable tips to enhance cost-efficiency in sourcing alternators:

-

التفاوض: Engage in open discussions with suppliers about pricing, especially for bulk orders. Leveraging competitive quotes can lead to better deals.

-

التكلفة الإجمالية للملكية (TCO): Evaluate the total cost of ownership, which includes purchase price, maintenance, and expected lifespan of the alternator. A lower upfront cost may not always equate to better value if the product has a shorter lifespan.

-

فهم الفروق الدقيقة في الأسعار: Be aware of regional pricing differences influenced by local market conditions, tariffs, and taxes. This understanding can help in making informed purchasing decisions.

-

Supplier Relationship Management: Build long-term relationships with suppliers to gain insights into pricing trends and potential discounts. Reliable suppliers may offer better terms to loyal customers.

-

البحث والمقارنة المعيارية: Conduct thorough market research to compare prices and specifications from various suppliers. This benchmarking can provide leverage in negotiations and help identify fair pricing.

الخلاصة

Sourcing alternators involves a complex interplay of various cost components and pricing influences. By understanding these factors and applying strategic purchasing techniques, international buyers can optimize their sourcing processes, ensuring they receive quality products at competitive prices. Always consider the total cost of ownership and maintain strong supplier relationships to enhance your procurement strategy.

Illustrative image related to how long do alternators last

Alternatives Analysis: Comparing how long do alternators last With Other Solutions

Exploring Alternatives to Alternators: A Comparative Analysis

In the automotive industry, understanding the longevity of components such as alternators is crucial for maintenance and operational efficiency. However, there are alternative technologies and methods that can also fulfill the electrical power needs of vehicles. This section presents a comparative analysis of how long alternators last against other viable solutions, such as direct battery systems and hybrid energy solutions.

| جانب المقارنة | How Long Do Alternators Last | Direct Battery Systems | Hybrid Energy Solutions |

|---|---|---|---|

| الأداء | 7 سنوات / 150,000 ميل | Limited by battery capacity | High efficiency, reduced emissions |

| التكلفة | استثمار أولي معتدل | High initial cost | Higher upfront, potential savings on fuel |

| سهولة التنفيذ | التركيب القياسي | Complex integration | تتطلب معرفة متخصصة |

| الصيانة | Moderate (routine checks) | Low (battery replacement) | Moderate (depends on system) |

| أفضل حالة استخدام | المركبات التقليدية | Electric vehicles (EVs) | Performance vehicles, urban transport |

What Are the Advantages and Disadvantages of Direct Battery Systems?

Direct battery systems are increasingly popular, especially in electric vehicles. These systems store electrical energy directly and power the vehicle’s systems without the need for an alternator. The major advantage of direct battery systems is their simplicity and reduced mechanical complexity. However, they have limitations, including a finite charge capacity and the need for frequent recharging, which can be a drawback in long-distance travel or in regions with limited charging infrastructure.

How Do Hybrid Energy Solutions Compare to Traditional Alternators?

Hybrid energy solutions combine both traditional fuel engines and electric power systems, optimizing performance and reducing emissions. These systems can achieve superior efficiency and power management, particularly in urban environments where stop-and-go traffic is common. However, the integration of hybrid systems can be complex and expensive, requiring specialized knowledge for maintenance and repair. While they offer significant advantages in fuel savings and environmental impact, the initial investment can be a barrier for some businesses.

الخاتمة: كيف يمكن لمشتري B2B اختيار الحل المناسب؟

For B2B buyers evaluating the best power solutions for their vehicles, the choice between traditional alternators and alternatives like direct battery systems or hybrid energy solutions will depend on several factors. Considerations include the typical usage patterns of the vehicles, the infrastructure available for maintenance and recharging, and the overall cost of ownership. Each solution has its unique strengths and challenges, and understanding these nuances will enable buyers to make informed decisions that align with their operational needs and sustainability goals. As the automotive landscape evolves, staying informed about these alternatives can lead to significant operational advantages.

Essential Technical Properties and Trade Terminology for how long do alternators last

ما هي الخصائص التقنية الرئيسية للمولدات؟

Understanding the technical specifications of alternators is crucial for B2B buyers looking to make informed purchasing decisions. Here are several critical properties:

Illustrative image related to how long do alternators last

1. درجة المواد

The materials used in alternator construction, such as copper for windings and aluminum for casings, impact durability and performance. Higher-grade materials can enhance resistance to corrosion and heat, prolonging the alternator’s lifespan. For buyers, selecting alternators made from high-quality materials can reduce maintenance costs and improve reliability, especially in regions with harsh environmental conditions.

2. Ampere Rating

The ampere rating indicates the alternator’s maximum electrical output. Most standard alternators range from 40 to 200 amps. Understanding this specification is vital for buyers, as it determines the alternator’s ability to support a vehicle’s electrical needs, particularly when additional electronic accessories are installed. Choosing the right ampere rating ensures that the vehicle’s battery remains charged and that all electrical components function efficiently.

3. تنظيم الجهد

Alternators typically operate at a voltage output of 12 to 14.5 volts. A well-functioning voltage regulator ensures that the electrical system remains stable, preventing damage to sensitive electronics. B2B buyers should consider the quality of voltage regulation, as poor regulation can lead to fluctuations that affect battery life and the longevity of other electronic components.

4. نوع المحمل

Alternators use either ball or roller bearings for support and rotation. Ball bearings are commonly used for their ability to handle both radial and axial loads, while roller bearings provide lower friction. The choice of bearing type can influence the alternator’s noise levels and operational lifespan. Buyers should assess the bearing type based on the expected operating conditions and desired longevity.

Illustrative image related to how long do alternators last

5. نمط التركيب

Different vehicles require specific mounting styles for alternators, such as side-mounted or front-mounted configurations. The mounting style affects installation ease and compatibility with various vehicle models. Understanding the mounting requirements is essential for B2B buyers to ensure that the alternator can be installed without modifications, saving time and costs.

What Are the Common Trade Terms Related to Alternator Lifespan?

Familiarity with industry terminology can aid B2B buyers in negotiations and procurement processes. Here are several essential terms:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to components made by the same manufacturer that produced the original parts for a vehicle. Purchasing OEM alternators often guarantees compatibility and quality, as these components are designed to meet specific manufacturer standards. B2B buyers should weigh the benefits of OEM parts against cost considerations.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for businesses planning inventory, as it can impact cash flow and storage requirements. Buyers should negotiate MOQs that align with their purchasing capabilities to avoid excess inventory.

3. طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It allows buyers to compare costs and conditions from multiple vendors. Crafting a clear RFQ can streamline the procurement process and ensure that all necessary specifications are included.

4. مصطلحات التجارة الدولية

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers engaged in cross-border transactions, as they directly affect cost and risk management.

5. فترة الضمان

The warranty period specifies the duration during which the manufacturer will repair or replace a defective alternator. A longer warranty can indicate greater confidence in product durability. Buyers should consider warranty terms when evaluating suppliers to ensure they are protected against potential defects.

Illustrative image related to how long do alternators last

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding alternators, ultimately leading to better procurement strategies and improved vehicle performance.

Navigating Market Dynamics and Sourcing Trends in the how long do alternators last Sector

What Are the Key Market Dynamics Affecting Alternator Lifespan?

The alternator market is currently influenced by a variety of global drivers, including the increasing demand for electric vehicles (EVs) and the growing emphasis on vehicle efficiency. As manufacturers innovate to produce longer-lasting and more efficient alternators, B2B buyers must stay informed about the latest developments. The average lifespan of an alternator is typically around seven years or 150,000 miles, but this can vary based on factors such as vehicle usage, climate conditions, and quality of the components used. For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding local market conditions—such as vehicle maintenance practices and the prevalence of electronic systems in vehicles—is crucial for sourcing decisions.

Emerging B2B technologies, such as predictive maintenance tools and data analytics, are transforming how companies manage their vehicle fleets. These technologies enable buyers to monitor the health of alternators in real time, thus extending their lifespan through timely interventions. Furthermore, the rise of e-commerce platforms and digital marketplaces is facilitating easier access to high-quality alternators and components, allowing B2B buyers to make informed decisions based on reviews, ratings, and supply chain transparency.

How Is Sustainability Shaping the Alternator Supply Chain?

Sustainability has become a pivotal consideration in the alternator industry, as B2B buyers increasingly prioritize environmentally responsible sourcing. The production of alternators can have significant environmental impacts, from resource extraction to manufacturing processes. Therefore, understanding the lifecycle of alternators is essential for making sustainable purchasing decisions.

Ethical sourcing practices are gaining traction, with manufacturers seeking to obtain materials from suppliers who adhere to environmental and labor standards. Certifications such as ISO 14001 for environmental management and the use of recycled materials are becoming benchmarks for sustainable practices. For international buyers, especially in regions with stringent regulations, ensuring that suppliers maintain these certifications can mitigate risks and enhance brand reputation.

Moreover, adopting greener technologies, such as energy-efficient manufacturing processes and recyclable materials, is not just a trend but a necessity in meeting consumer expectations and regulatory requirements. By aligning their procurement strategies with sustainable practices, B2B buyers can contribute to a circular economy, thereby reducing waste and promoting resource efficiency.

What Is the Historical Context of Alternators in Automotive Engineering?

The evolution of alternators has significantly influenced their lifespan and performance in modern vehicles. Initially, vehicles utilized DC generators, which were less efficient and prone to failure. The introduction of the alternator in the 1960s marked a turning point, as it offered a more reliable and efficient method of charging the battery and powering electrical components.

Over the decades, advancements in materials and technology have led to the development of more durable alternators, capable of withstanding the increasing electrical demands of modern vehicles equipped with advanced electronic systems. The integration of smart technologies, such as onboard diagnostics, has further improved the ability to monitor alternator performance, allowing for proactive maintenance strategies that can extend the lifespan of this critical component.

Understanding this historical context not only informs B2B buyers about the evolution of alternators but also highlights the importance of investing in high-quality, technologically advanced products that are likely to deliver better performance and longevity in the field.

Illustrative image related to how long do alternators last

Frequently Asked Questions (FAQs) for B2B Buyers of how long do alternators last

-

How long do alternators typically last?

On average, alternators can last about seven years or up to 150,000 miles, depending on various factors such as the quality of the part, vehicle condition, and usage of electrical systems. Regular maintenance and inspection can extend this lifespan. For businesses, understanding these metrics is crucial when planning for vehicle fleet maintenance and budgeting for potential replacements. -

What are the signs that indicate an alternator is failing?

Common signs of a failing alternator include difficulty starting the vehicle, dim or fluctuating headlights, unusual noises like squealing, and dashboard warning lights. For B2B buyers, being aware of these symptoms can aid in timely replacement, minimizing downtime and ensuring operational efficiency. -

Can I drive a vehicle with a bad alternator?

It is not advisable to drive a vehicle with a faulty alternator, as it can lead to a complete vehicle shutdown and damage to other electrical components. For businesses, this could result in unexpected repair costs and operational disruptions. It’s best to arrange for immediate inspection and repair. -

ما الذي يجب أن آخذه في الاعتبار عند شراء المولدات الكهربائية من الموردين الدوليين؟

When sourcing alternators internationally, consider the supplier’s reputation, product quality, and compliance with international standards. Verify certifications and request samples if possible. Additionally, assess their logistical capabilities and delivery times to ensure timely availability for your operations. -

ما هو الحد الأدنى لكمية الطلب (MOQ) للمولدات؟

Minimum order quantities can vary widely based on the supplier and the type of alternators being sourced. Some suppliers may have a MOQ of 50 units, while others may offer flexibility for smaller orders. It’s important to discuss your specific needs with suppliers to find the best arrangement that suits your business model. -

How do I ensure quality assurance when purchasing alternators?

To ensure quality assurance, request detailed product specifications, and certifications, and ask for quality control processes from the supplier. Consider conducting third-party inspections or audits before shipment. Establishing a strong relationship with the supplier can also help ensure that quality standards are consistently met. -

What payment terms are typically offered by international alternator suppliers?

Payment terms can vary significantly among suppliers, but common practices include net 30 or net 60 days, advance payments, or letters of credit. It’s essential to negotiate terms that align with your cash flow needs while ensuring the supplier feels secure in the transaction. Always review payment terms carefully to avoid unexpected costs. -

How can I manage logistics when importing alternators?

Effective logistics management involves coordinating with freight forwarders for shipping and customs clearance, ensuring that all documentation is in order. Consider the shipping method (air vs. sea) based on urgency and cost-effectiveness. Additionally, understanding local regulations and tariffs in your destination country is crucial for smooth importation and budgeting.

Top 3 How Long Do Alternators Last Manufacturers & Suppliers List

1. فورد فيوجن - عمر المولد

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: Alternator average lifespan for Ford Fusion is generally around 180,000 miles, with some users reporting up to 200,000 kilometers (approximately 124,274 miles) before issues arise. The original alternator on a 2011 Ford Fusion with a 2.5L engine was still functioning at 180,000 miles without electrical issues. Common failure points include worn brushes in the voltage regulator, which can be replac…

2. Pilots of America – Alternator Lifespan Insights

المجال: pilotsofamerica.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: Alternators typically last around 20 years or 1400 hours of operation. However, their lifespan can vary based on usage, with some users reporting an average lifespan of 5-800 hours for specific aircraft models. Regular inspections are recommended, with a 500-hour internal inspection suggested by manufacturers like Cessna. Brushes within the alternator, which are made of graphite, can wear out fast…

3. Savannah Toyota – Alternator Replacement

المجال: savannahtoyota.com

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: The alternator powers all electronics in a vehicle while the engine is running, functioning as a generator using the gas engine as its energy source. It typically lasts between 80,000 and 150,000 miles (about seven years). The average cost of a new alternator ranges from $500 to $1,000, depending on the vehicle type. Signs of a failing alternator include a battery warning light, dim headlights, bu…

Strategic Sourcing Conclusion and Outlook for how long do alternators last

In conclusion, understanding the lifespan of alternators—averaging seven years or 150,000 miles—is essential for B2B buyers in the automotive sector. Recognizing the factors that influence this lifespan, such as quality, vehicle condition, and electrical load, allows businesses to make informed purchasing decisions. Strategic sourcing of high-quality alternators can prevent unexpected failures and costly repairs, ensuring operational efficiency.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, prioritizing reliable suppliers and manufacturers is critical. Building strong relationships with reputable partners not only enhances product quality but also fosters trust and long-term collaboration.

As you navigate the complexities of sourcing automotive components, consider leveraging insights from industry experts and investing in preventive maintenance strategies. This proactive approach will not only extend the life of your alternators but also optimize your overall vehicle performance. Embrace the future of strategic sourcing by aligning with partners that share your commitment to quality and reliability, ensuring that your fleet remains operational and efficient for years to come.

Illustrative image related to how long do alternators last

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.