مقدمة: التنقل في السوق العالمية لقطع غيار المولدات الكهربائية

في مشهد التجارة العالمية المتطور باستمرار، يمكن أن يكون الحصول على قطع غيار المولدات عالية الجودة تحديًا شاقًا للمشترين بين الشركات، خاصةً أولئك الذين يعملون في أسواق متنوعة مثل إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. تعد موثوقية مولدات التيار المتردد أمرًا بالغ الأهمية لأداء المركبات والآلات، مما يجعل من الضروري تحديد الموردين الذين لا يقدمون حلولاً عالية الجودة فحسب، بل حلولاً فعالة من حيث التكلفة أيضًا. يعالج هذا الدليل الشامل تعقيدات سوق قطع غيار المولدات الكهربائية، ويقدم رؤى حول الأنواع المختلفة من المولدات، وتطبيقاتها في مختلف الصناعات، والاستراتيجيات الفعالة لفحص الموردين.

من خلال استكشاف الموضوعات الأساسية مثل اعتبارات التكلفة، والتوافق مع معايير مصنعي المعدات الأصلية، وأحدث الابتكارات في تكنولوجيا المولدات، يمكّن هذا الدليل المشترين الدوليين من اتخاذ قرارات شراء مستنيرة. سواء أكنت في البرازيل تبحث عن مكونات قوية للآلات الزراعية أو في المملكة العربية السعودية تبحث عن مولدات كهربائية موثوقة للسيارات، فإن الأفكار التي يتم مشاركتها هنا ستساعدك على تبسيط عملية التوريد الخاصة بك. صُمم هذا المورد لتعزيز فهمك لديناميكيات السوق، مما يمكّنك من الإبحار في تعقيدات التجارة الدولية بثقة ودقة. في نهاية المطاف، هدفنا هو تزويدك بالمعرفة اللازمة لتأمين أفضل قطع غيار المولدات لتلبية احتياجاتك التشغيلية، مما يضمن لك تحقيق أقصى عائدات من استثماراتك.

جدول المحتويات

- قائمة المصنعين والموردين لأعلى 3 قطع غيار المولدات 3

- مقدمة: التنقل في السوق العالمية لقطع غيار المولدات الكهربائية

- فهم أنواع أجزاء المولدات وأنواعها واختلافاتها

- التطبيقات الصناعية الرئيسية لقطع غيار المولدات الكهربائية

- 3 نقاط ألم شائعة لدى المستخدمين لـ ‘أجزاء المولدات’ وحلولها

- دليل اختيار المواد الاستراتيجية لأجزاء المولدات الكهربائية

- نظرة متعمقة: عمليات التصنيع وضمان جودة قطع غيار المولدات الكهربائية

- دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘قطع غيار المولدات’

- التحليل الشامل للتكلفة والتسعير الشامل لمصادر قطع غيار المولدات الكهربائية

- تحليل البدائل: مقارنة أجزاء المولدات بالحلول الأخرى

- الخواص الفنية الأساسية والمصطلحات التجارية لأجزاء المولدات الكهربائية

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع قطع غيار المولدات الكهربائية

- الأسئلة المتداولة (FAQs) لمشتري قطع غيار مولدات التيار المتردد B2B

- استنتاجات وتوقعات التوريد الاستراتيجي لقطع غيار المولدات الكهربائية

- إخلاء مسؤولية هام وشروط الاستخدام

فهم أنواع أجزاء المولدات وأنواعها واختلافاتها

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولدات القياسية | تصميم تقليدي، عادةً 12 فولت، وأداء موثوق به | السيارات، الشاحنات الخفيفة | الإيجابيات: فعالة من حيث التكلفة ومتوفرة على نطاق واسع. السلبيات: مخرجات محدودة للتطبيقات عالية الطلب. |

| المولدات عالية الإنتاجية | زيادة خرج التيار الكهربائي وأنظمة التبريد المتخصصة | المركبات عالية الأداء، الشاحنات التجارية | الإيجابيات: تدعم الأحمال الكهربائية العالية، وهي مثالية لتحديثات ما بعد البيع. السلبيات: تكلفة أعلى، قد تتطلب تركيباً محدداً. |

| مولدات كهربائية بحرية | مواد مقاومة للتآكل، مصممة للبيئات الرطبة | القوارب والمركبات البحرية | الإيجابيات: متانة في الظروف القاسية وإمداد طاقة موثوق به. السلبيات: أكثر تكلفة، وتقتصر على التطبيقات البحرية. |

| المولدات الصناعية | هيكل متين وخيارات الجهد العالي | الآلات الثقيلة والمولدات والمعدات الصناعية | الإيجابيات: مصمم للظروف القاسية وعمر افتراضي طويل. السلبيات: استثمار أولي أكبر وأكثر ضخامة. |

| المولدات ذات المغناطيس الدائم | تستخدم مغناطيسات دائمة لتحقيق الكفاءة والحجم الصغير | المحركات الصغيرة وأنظمة الطاقة المتجددة | الإيجابيات: خفيفة الوزن وعالية الكفاءة. السلبيات: إخراج محدود للتطبيقات الأكبر حجماً. |

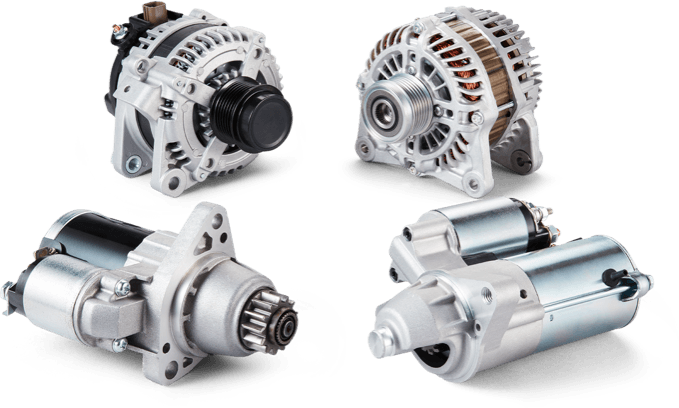

ما هي المولدات القياسية وميزاتها الرئيسية؟

المولدات القياسية هي النوع الأكثر شيوعًا المستخدم في المركبات اليومية، وتعمل عادةً بقوة 12 فولت. وهي مصممة لتحقيق الموثوقية والكفاءة، مما يجعلها مناسبة لتطبيقات السيارات والشاحنات الخفيفة. عند التفكير في الشراء، يجب على مشتري B2B التركيز على معايير OEM والتوافق مع طرازات المركبات المختلفة. على الرغم من أنها فعالة من حيث التكلفة ومتوفرة على نطاق واسع، إلا أن إنتاجها قد لا يلبي متطلبات المركبات عالية الأداء أو المركبات الكهربائية الثقيلة.

كيف تختلف المولدات عالية الإنتاجية عن الخيارات القياسية؟

تم تصميم مولدات المولدات عالية الخرج لتوليد أمبيرات متزايدة، مما يجعلها مثالية للمركبات عالية الأداء والشاحنات التجارية التي تتطلب المزيد من الطاقة الكهربائية. غالبًا ما تتضمن هذه المولدات أنظمة تبريد متخصصة للتعامل مع الحمل الإضافي. بالنسبة لمشتري B2B، فإن الاعتبار الرئيسي هو الاحتياجات الكهربائية المحددة للمركبات التي تخدمها. وعلى الرغم من أنها توفر فوائد كبيرة في دعم الأحمال الكهربائية العالية، إلا أنها عادةً ما تكون بسعر أعلى وقد تتطلب متطلبات تركيب محددة.

ما الذي يجعل المولدات البحرية فريدة من نوعها؟

تم تصميم المولدات الكهربائية البحرية خصيصًا لتحمل البيئات المسببة للتآكل في التطبيقات البحرية. وهي تتميز بمواد مقاومة للتآكل ومصممة للعمل بفعالية في الظروف الرطبة. يجب على المشترين في قطاع الأعمال التجارية في القطاع البحري إعطاء الأولوية للمتانة والموثوقية عند الحصول على هذه المولدات. على الرغم من أنها تقدم أداءً فائقًا في الظروف القاسية، إلا أن المولدات البحرية أغلى ثمنًا بشكل عام وتقتصر على الاستخدام في القوارب والمركبات البحرية الأخرى.

لماذا تختار المولدات الصناعية للتطبيقات الشاقة؟

تم تصميم المولدات الكهربائية الصناعية للتعامل مع المتطلبات الصارمة للآلات الثقيلة والمعدات الصناعية. وهي عادةً ما تتميز ببنية قوية وخيارات جهد أعلى، مما يجعلها مناسبة للمولدات وغيرها من التطبيقات الشاقة. بالنسبة لمشتري B2B، يعد فهم متطلبات الطاقة المحددة والظروف البيئية لتطبيقاتهم أمرًا بالغ الأهمية. في حين أن هذه المولدات توفر متانة استثنائية وعمر افتراضي طويل، إلا أنها قد تنطوي على استثمارات أولية أعلى ويمكن أن تكون أضخم من الخيارات القياسية.

ما هي مزايا المولدات ذات المغناطيس الدائم؟

تستخدم المولدات الكهربائية ذات المغناطيس الدائم مغناطيسات دائمة لتوليد الكهرباء، مما يؤدي إلى تصميم مدمج وفعال. وهي تستخدم عادة في المحركات الصغيرة وأنظمة الطاقة المتجددة. يجب على مشتري B2B مراعاة كفاءتها وحجمها عند اختيار هذه المولدات. على الرغم من أنها خفيفة الوزن وذات كفاءة عالية، إلا أن إنتاجها قد لا يكفي للتطبيقات الأكبر حجمًا، مما يجعلها أقل تنوعًا في بعض السياقات الصناعية أو سياقات السيارات.

التطبيقات الصناعية الرئيسية لقطع غيار المولدات الكهربائية

| الصناعة/القطاع | التطبيق المحدد لقطع غيار المولدات | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | قطع الغيار لمركبات الركاب | ضمان التشغيل الموثوق للمركبة ورضا العملاء | التوافق مع المعدات الأصلية والمتانة تحت درجات الحرارة المرتفعة |

| الآلات الصناعية | توليد الطاقة في المعدات الثقيلة | زيادة وقت التشغيل والكفاءة في عمليات الإنتاج إلى أقصى حد ممكن | قدرة إخراج عالية، مقاومة للبيئات القاسية |

| الزراعة | مولدات المولدات للآلات الزراعية | يعزز الإنتاجية والموثوقية أثناء الحصاد | توافر قطع غيار متخصصة لماكينات معينة |

| بحري | مولدات المولدات للقوارب والمعدات البحرية | يوفر طاقة ثابتة للملاحة والأنظمة الموجودة على متن الطائرة | مقاومة التآكل، والامتثال للمعايير البحرية |

| الطاقة المتجددة | التكامل في أنظمة طاقة الرياح والطاقة الشمسية | يدعم حلول الطاقة المستدامة ويقلل التكاليف | التوافق مع تقنيات الطاقة المتجددة |

كيف تُستخدم قطع غيار المولدات في قطاع السيارات؟

في صناعة السيارات، تُعد قطع غيار المولدات ضرورية للحفاظ على الأنظمة الكهربائية لسيارات الركاب. تضمن هذه المكونات، بما في ذلك المُنظِّمات والمُقوِّمات، بقاء البطارية مشحونة وأن تعمل الأنظمة الأساسية مثل المصابيح وأجهزة المعلومات والترفيه بسلاسة. بالنسبة للمشترين بين الشركات، يعد الحصول على قطع غيار عالية الجودة ومتوافقة مع المعدات الأصلية أمراً بالغ الأهمية لتجنب الأعطال التي يمكن أن تؤدي إلى تعطل مكلف وعدم رضا العملاء. بالإضافة إلى ذلك، يجب أن تتحمل القطع درجات الحرارة المرتفعة والاهتزازات المعتادة في مقصورات المحرك، مما يؤكد الحاجة إلى المتانة والموثوقية.

ما الدور الذي تلعبه أجزاء المولدات في الآلات الصناعية؟

في قطاع الآلات الصناعية، تُعد المولدات الكهربائية جزءًا لا يتجزأ من توليد الطاقة للمعدات الثقيلة مثل الرافعات والحفارات. تضمن المولدات عالية الإنتاجية تشغيل هذه الماكينات بكفاءة، مما يزيد من الإنتاجية في مواقع البناء. يجب على المشترين النظر في توفير قطع الغيار التي يمكنها التعامل مع الأحمال الثقيلة والظروف القاسية، وهو أمر حيوي للحفاظ على وقت التشغيل. كما يُعد التوافق مع الأنظمة الحالية والامتثال للمعايير الدولية من العوامل الأساسية للشركات في مناطق مثل أفريقيا وأمريكا الجنوبية، حيث تُعد موثوقية المعدات أمرًا بالغ الأهمية.

كيف تفيد قطع غيار المولدات الآلات الزراعية؟

تعتمد الآلات الزراعية اعتمادًا كبيرًا على المولدات الكهربائية لتوليد الطاقة بكفاءة أثناء العمليات الحرجة مثل الزراعة والحصاد. تضمن المولدات عالية الجودة أن تعمل المعدات بشكل موثوق، خاصة في المناطق النائية حيث يمكن أن يؤدي تعطلها إلى خسائر مالية كبيرة. يجب أن يركز المشترون بين الشركات على توفير قطع الغيار المصممة خصيصًا للتطبيقات الزراعية، مما يضمن تلبية المتطلبات الفريدة لهذا القطاع. يمكن أن يؤدي توافر المكونات المتخصصة أيضًا إلى تعزيز طول عمر الآلات وأدائها، مما يجعل من الضروري للموردين تقديم حلول مصممة خصيصًا.

لماذا تعتبر أجزاء المولدات مهمة في التطبيقات البحرية؟

في الصناعة البحرية، تُعد المولدات الكهربائية ضرورية لتشغيل أنظمة الملاحة والإلكترونيات على متن السفن. تتطلب البيئة البحرية القاسية قطعًا مقاومة للتآكل ويمكن أن تعمل بشكل موثوق في ظروف مختلفة. يجب على مشتري B2B إعطاء الأولوية لتوريد قطع غيار المولدات التي تتوافق مع معايير الصناعة البحرية لضمان السلامة والموثوقية. بالإضافة إلى ذلك، تُعد القدرة على توفير الدعم السريع وقطع الغيار أمرًا بالغ الأهمية لتقليل وقت التعطل، خاصة في المناطق ذات الأنشطة البحرية الكبيرة، مثل الشرق الأوسط وأوروبا.

كيف تُستخدم أجزاء المولدات في أنظمة الطاقة المتجددة؟

تلعب المولدات دورًا محوريًا في أنظمة الطاقة المتجددة، لا سيما في توربينات الرياح وتطبيقات الطاقة الشمسية. فهي تحول الطاقة الميكانيكية إلى طاقة كهربائية، مما يجعلها ضرورية لإنتاج الطاقة المستدامة. يجب أن يبحث المشترون في هذا القطاع عن أجزاء المولدات المتوافقة مع تقنيات الطاقة المتجددة والمصممة لتحقيق كفاءة عالية وصيانة منخفضة. إن الطلب المتزايد على الحلول المستدامة في مناطق مثل أمريكا الجنوبية وأفريقيا يسلط الضوء على أهمية الحصول على مكونات موثوقة يمكنها دعم الانتقال إلى مصادر الطاقة المتجددة.

3 نقاط ألم شائعة لدى المستخدمين لـ ‘أجزاء المولدات’ وحلولها

السيناريو 1: صعوبة العثور على قطع غيار المولد المتوافقة

المشكلة: غالبًا ما يواجه المشترون بين الشركات تحديات عند محاولة الحصول على قطع غيار المولدات المتوافقة مع مركبات أو آلات معينة. وتتفاقم هذه المشكلة في المناطق ذات الطرازات والتعديلات المتنوعة للمركبات، كما هو الحال في أفريقيا وأمريكا الجنوبية. قد يقضي المشترون وقتًا طويلاً وموارد كبيرة في البحث عن القطع المناسبة، ليجدوا أنها غير متوافقة أو ذات جودة رديئة، مما يؤدي إلى التأخير في الصيانة والإصلاحات.

الحل: للتغلب على مشكلة التوافق هذه، من الضروري الحفاظ على نظام منظم لإدارة المخزون يتتبع مواصفات كل مركبة ومتطلبات مولد التيار المتردد الخاصة بها. يجب على المشترين الاستفادة من الكتالوجات الشاملة عبر الإنترنت التي تسمح بالتصفية حسب الطراز والطراز والسنة للعثور على قطع غيار المولد التي يحتاجون إليها بالضبط. يمكن أن تضمن إقامة علاقات مع الموردين الموثوق بهم الذين يقدمون قطع غيار مصنعي المعدات الأصلية (OEM) الجودة والملاءمة. بالإضافة إلى ذلك، يمكن أن يؤدي الاستثمار في أدوات أو برامج متقدمة للعثور على القطع إلى تبسيط عملية البحث عن المصادر، مما يقلل من الوقت الضائع على المكونات غير المتطابقة. تحقق دائمًا من رقم القطعة ومواصفاتها قبل تقديم الطلب، وفكر في طلب عينات أو مواصفات تفصيلية للمنتج لضمان التوافق.

السيناريو 2: مخاوف بشأن جودة وموثوقية قطع غيار المولدات

المشكلة: تُعد الجودة والموثوقية أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات، خاصةً في الصناعات التي يمكن أن يؤدي فيها تعطل المعدات إلى خسائر مالية كبيرة. قد يواجه المشترون قلقًا بشأن متانة قطع غيار المولدات التي يتم الحصول عليها من موردين أقل شهرة، خاصة عند التشغيل في البيئات القاسية أو تحت أحمال ثقيلة. يمكن أن تؤدي القطع رديئة الجودة إلى أعطال متكررة وزيادة تكاليف الصيانة وتشويه السمعة بين العملاء.

الحل: ولمعالجة هذه المخاوف، يجب على المشترين بين الشركات إعطاء الأولوية للمشترين من الشركات التي لديها موردين معروفين بالتزامهم بالجودة. ابحث عن الموردين الذين يقدمون نتائج الاختبارات التفصيلية والشهادات والضمانات لأجزاء المولدات الخاصة بهم. يمكن أن يؤدي التعامل مع الموردين الذين يجرون عمليات صارمة لضمان الجودة إلى التخفيف من المخاطر المرتبطة بالمكونات دون المستوى المطلوب. بالإضافة إلى ذلك، يجب على المشترين النظر في تنفيذ عملية تقييم قوية للموردين تتضمن تقييم ممارسات التصنيع لدى المورد ومراجعة شهادات العملاء. لمزيد من الضمان، يمكن أن يساعد إجراء تقييمات الأداء المنتظمة للأجزاء المركبة في تحديد المشكلات المحتملة قبل أن تؤدي إلى أعطال، مما يسمح بإجراء الصيانة والاستبدال الاستباقي.

صورة توضيحية متعلقة بأجزاء المولدات

السيناريو 3: ارتفاع التكاليف المرتبطة باستبدال أجزاء المولد

المشكلة: تُعد إدارة التكاليف مصدر قلق كبير للمشترين بين الشركات، خاصةً عندما يتعلق الأمر باستبدال قطع غيار المولدات. في المناطق ذات الضرائب المرتفعة على الواردات أو الموردين المحليين المحدودين، يمكن أن تتصاعد الأسعار بسرعة، مما يؤثر على الميزانيات التشغيلية الإجمالية. بالإضافة إلى ذلك، قد يعاني المشترون من التكاليف غير المتوقعة الناشئة عن الاستبدال المتكرر بسبب عدم كفاية الجودة أو التركيب غير المناسب.

الحل: للتحكم في التكاليف بفعالية، يجب على المشترين النظر في إقامة شراكات استراتيجية مع الموردين الذين يقدمون أسعاراً تنافسية وخيارات شراء بالجملة. كما يمكن أن يؤدي التفاوض على عقود طويلة الأجل إلى الحصول على أسعار أفضل وضمان إمدادات ثابتة من قطع الغيار عالية الجودة. يجب على المشترين مراجعة استراتيجيات الشراء بانتظام والبحث عن موردين بديلين قد يقدمون أسعاراً أقل دون المساس بالجودة. يمكن أن يقلل تنفيذ برنامج الصيانة الوقائية بشكل كبير من الحاجة إلى الاستبدال المتكرر من خلال ضمان صيانة المولدات بشكل صحيح، وبالتالي إطالة عمرها التشغيلي. يمكن أن يؤدي تثقيف الموظفين حول تقنيات التركيب السليمة وأهمية استخدام قطع غيار عالية الجودة إلى تقليل التكاليف غير المتوقعة وتعزيز الكفاءة التشغيلية الإجمالية.

دليل اختيار المواد الاستراتيجية لأجزاء المولدات الكهربائية

ما هي المواد الرئيسية المستخدمة في أجزاء المولد وخصائصها؟

عند اختيار مواد لأجزاء مولد التيار المتردد، من الضروري مراعاة خصائصها وأدائها وملاءمتها لتطبيقات محددة. فيما يلي أربع مواد شائعة مستخدمة في مكونات مولد التيار المتردد، تم تحليلها من منظور B2B.

كيف يفيد الألومنيوم أجزاء المولد؟

يُستخدم الألومنيوم على نطاق واسع في علب وأقواس المولدات بسبب طبيعته الخفيفة الوزن وتوصيله الحراري الممتاز. وعادةً ما تصل درجة حرارته إلى 150 درجة مئوية ويتميز بمقاومة جيدة للتآكل، خاصةً عندما يكون مؤكسداً.

الإيجابيات: تقلل الكثافة المنخفضة للألومنيوم من الوزن الإجمالي لمولد التيار المتردد، مما يعزز كفاءة استهلاك الوقود في تطبيقات السيارات. وتساعد قدرته على تبديد الحرارة بفعالية في الحفاظ على درجات حرارة التشغيل المثلى، وهو أمر حيوي للأداء وطول العمر.

السلبيات: على الرغم من أن الألومنيوم متين، إلا أنه قد يكون عرضة للإجهاد في ظروف الإجهاد العالي، خاصةً في التطبيقات الشاقة. وبالإضافة إلى ذلك، يمكن أن تكون تكلفته أعلى من بعض المعادن الأخرى، مما قد يؤثر على المشاريع الحساسة للميزانية.

التأثير على التطبيق: الألومنيوم متوافق مع مختلف الوسائط، بما في ذلك سوائل السيارات، ولكن يجب توخي الحذر لتجنب التآكل الجلفاني عند اقترانه مع معادن غير متشابهة.

اعتبارات للمشترين الدوليين: يجب على المشترين من مناطق مثل أفريقيا وأمريكا الجنوبية التأكد من الامتثال للوائح المحلية المتعلقة باستخدام الألومنيوم في مكونات السيارات. قد تنطبق معايير مثل ASTM و JIS، مما يؤثر على اختيار المواد.

ما الدور الذي يلعبه الفولاذ في مكونات المولد؟

وغالبًا ما يستخدم الفولاذ، وخاصة الفولاذ عالي الكربون، في أعمدة المولد والمكونات الداخلية نظرًا لقوته ومقاومته للتآكل. ويمكنه تحمل الضغوط العالية وتصل درجة حرارته إلى 300 درجة مئوية تقريباً.

الإيجابيات: قوة الشد العالية للصلب تجعله مناسبًا للتطبيقات ذات الأحمال العالية، مما يضمن المتانة والموثوقية. كما أنه فعّال من حيث التكلفة مقارنةً بالمواد الأخرى، مما يجعله خياراً شائعاً للمصنعين.

صورة توضيحية متعلقة بأجزاء المولدات

السلبيات: الفولاذ أثقل من الألومنيوم ويمكن أن يتآكل إذا لم تتم معالجته أو تغليفه بشكل صحيح. ويمكن أن يؤدي ذلك إلى زيادة تكاليف الصيانة بمرور الوقت، خاصةً في البيئات الرطبة أو المسببة للتآكل.

التأثير على التطبيق: يتوافق الفولاذ مع مجموعة واسعة من سوائل السيارات، ولكن قابليته للصدأ تستلزم طلاءات واقية في البيئات ذات مستويات الرطوبة العالية.

اعتبارات للمشترين الدوليين: يجب أن يكون المشترون في الشرق الأوسط وأوروبا على دراية بمعايير مقاومة التآكل وقد يفضلون خيارات الفولاذ المقاوم للصدأ لتعزيز المتانة في البيئات القاسية.

كيف يعزز النحاس وسبائكه التوصيلية الكهربائية؟

يُعد النحاس مادة أساسية في لفات المولدات والتوصيلات الكهربائية نظرًا لتوصيلها الكهربائي الفائق، حيث تبلغ درجة توصيلها 59.6 × 10^6 S/م. ويمكن أن يعمل بفعالية في درجات حرارة تصل إلى 200 درجة مئوية.

صورة توضيحية متعلقة بأجزاء المولدات

الإيجابيات: تضمن الموصلية الممتازة للنحاس نقل الطاقة بكفاءة، مما يؤدي إلى أداء أفضل وتقليل فقد الطاقة. تسمح قابليته للتشكيل بسهولة في الأسلاك والموصلات.

السلبيات: النحاس مكلف نسبيًا مقارنةً بالألومنيوم ويمكن أن يكون عرضة للأكسدة، مما قد يؤثر على التوصيلية بمرور الوقت. بالإضافة إلى ذلك، فهو أثقل وزنًا، وهو ما يمكن أن يكون أحد الاعتبارات في التطبيقات الحساسة للوزن.

التأثير على التطبيق: النحاس متوافق مع مختلف الوسائط الكهربائية، ولكن الأكسدة يمكن أن تؤدي إلى زيادة المقاومة، مما يستلزم صيانة دورية.

اعتبارات للمشترين الدوليين: يعد الامتثال للمعايير الكهربائية، مثل IEC و UL، أمرًا حيويًا للمشترين الدوليين، خاصة في البرازيل والمملكة العربية السعودية، حيث قد تكون هناك حاجة إلى شهادات محددة.

صورة توضيحية متعلقة بأجزاء المولدات

ما المزايا التي يقدمها البلاستيك في عزل المولد؟

غالبًا ما تُستخدم المواد البلاستيكية، وخاصة البوليمرات عالية الأداء، للعزل ومكونات التغطية في المولدات الكهربائية. ويمكنها تحمل درجات حرارة تصل إلى 120 درجة مئوية وتوفر خصائص عزل كهربائية ممتازة.

الإيجابيات: البلاستيك خفيف الوزن، ومقاوم للتآكل، ويمكن تشكيله في أشكال معقدة، مما يجعله مثاليًا للتصميمات المعقدة. كما أنها توفر عزلاً حرارياً جيداً، مما يعزز السلامة.

السلبيات: وعلى الرغم من متانة المواد البلاستيكية بشكل عام، إلا أنها يمكن أن تتحلل تحت الحرارة الشديدة أو التعرض للأشعة فوق البنفسجية، مما يحد من استخدامها في التطبيقات ذات درجات الحرارة العالية. كما أنها قد تكون أقل ملاءمة للبيئة مقارنةً بالمعادن.

التأثير على التطبيق: تعتبر المواد البلاستيكية مناسبة للمكونات غير الإنشائية والعزل الكهربائي، ولكن يجب مراعاة محدوديتها في البيئات عالية الإجهاد.

صورة توضيحية متعلقة بأجزاء المولدات

اعتبارات للمشترين الدوليين: يجب على المشترين أن يكونوا على دراية باللوائح البيئية المتعلقة باستخدام البلاستيك، خاصة في أوروبا، حيث قد يكون من الضروري الامتثال لتوجيهات مثل REACH.

جدول تلخيصي لاختيار المواد لأجزاء المولدات

| المواد | حالة الاستخدام النموذجية لقطع غيار المولدات | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | العلب، الأقواس | خفيفة الوزن وممتازة في تبديد الحرارة | عرضة للإجهاد تحت الضغط | متوسط |

| الصلب | الأعمدة، والمكونات الداخلية | قوة عالية وفعالة من حيث التكلفة | أثقل وزناً وعرضة للتآكل | منخفض |

| النحاس | اللفات والتوصيلات الكهربائية | موصلية كهربائية فائقة | باهظة الثمن وعرضة للأكسدة | عالية |

| بلاستيك | العزل، والمكونات غير الهيكلية | خفيف الوزن ومقاوم للتآكل | أداء محدود في درجات الحرارة العالية | متوسط |

يوفر دليل الاختيار الاستراتيجي للمواد هذا للمشترين من الشركات رؤى أساسية حول المواد المستخدمة في أجزاء المولدات الكهربائية، مما يتيح اتخاذ قرارات مستنيرة تتماشى مع احتياجات الأداء ومعايير الامتثال الإقليمية.

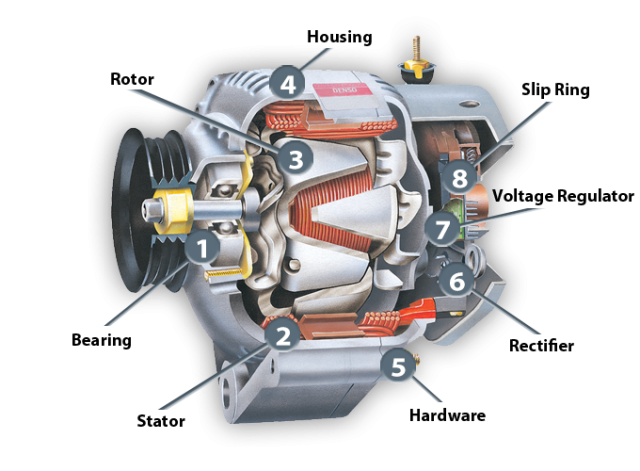

نظرة متعمقة: عمليات التصنيع وضمان جودة قطع غيار المولدات الكهربائية

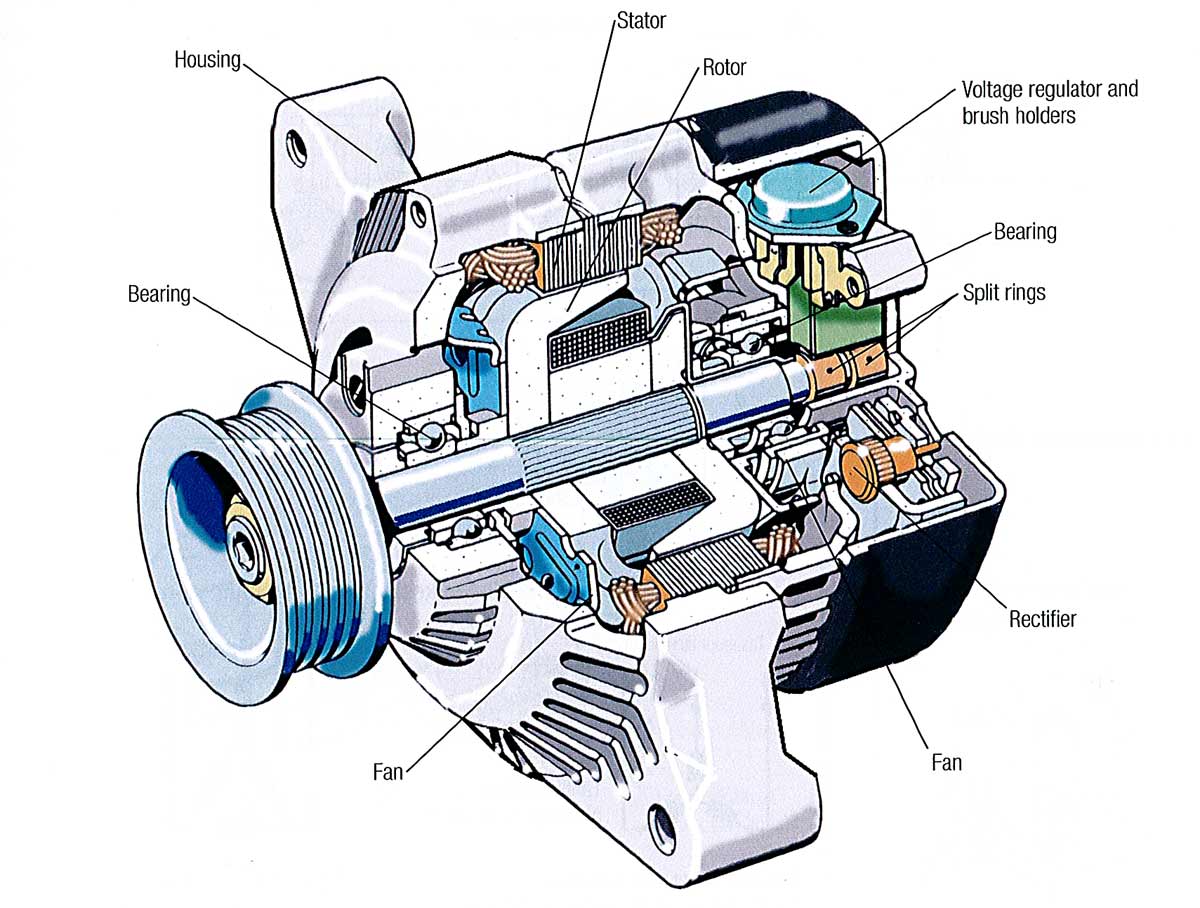

ما هي المراحل الرئيسية في عملية تصنيع أجزاء المولد؟

تتضمن عملية تصنيع أجزاء مولد التيار المتردد عدة مراحل حاسمة، كل منها مصمم لضمان إنتاج عالي الجودة يفي بالمعايير الدولية. يمكن أن يؤدي فهم هذه المراحل إلى تمكين المشترين بين الشركات من اتخاذ قرارات مستنيرة عند الحصول على مكونات المولد.

1. تحضير المواد

المرحلة الأولى في تصنيع أجزاء المولد هي إعداد المواد. يتم اختيار المواد الخام عالية الجودة، مثل النحاس للملفات، والألومنيوم أو الفولاذ للعلب والعلب الفولاذية واللدائن للعوازل، بعناية. وغالبًا ما يقوم الموردون بإجراء تقييمات شاملة لموادهم للتأكد من أنها تلبي الخصائص الميكانيكية والكهربائية المحددة. ويمكن أن تشمل مرحلة التحضير هذه أيضًا عمليات مثل تقطيع المواد وتشكيلها حسب الأبعاد المطلوبة.

صورة توضيحية متعلقة بأجزاء المولدات

2. تقنيات التشكيل

بمجرد تحضير المواد، تتضمن الخطوة التالية التشكيل. تُستخدم تقنيات مثل الختم والصب والتشغيل الآلي بشكل شائع. على سبيل المثال، يمكن أن يؤدي الختم إلى إنشاء المكونات المعدنية للمولّد، في حين يمكن استخدام الصب للأشكال الأكثر تعقيدًا. وغالبًا ما يتم استخدام التصنيع الآلي الدقيق لضمان ملاءمة المكونات معًا بشكل مثالي، وهو أمر بالغ الأهمية للأداء. هذه المرحلة جزء لا يتجزأ من تحقيق المواصفات والتفاوتات المطلوبة.

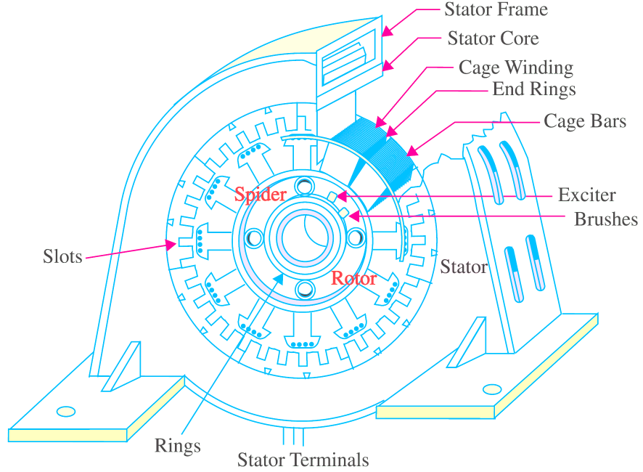

3. تجميع المكونات

مرحلة التجميع حيث يتم تجميع الأجزاء الفردية معًا لتشكيل المولد. وغالبًا ما تتضمن هذه العملية عمالة ماهرة وأنظمة آلية لضمان الدقة والكفاءة. ويتم تجميع المكونات الرئيسية، مثل الثوابت والدوارات والمنظمات، بعناية فائقة. خلال هذه المرحلة، قد يستخدم المصنعون أيضًا تقنيات مثل اللحام والعقص لتأمين التوصيلات الكهربائية، مما يضمن أداء المولد بشكل موثوق.

4. عمليات التشطيب

بعد التجميع، يتم تطبيق عمليات التشطيب لتعزيز المتانة والمظهر الجمالي لأجزاء المولد. وقد يشمل ذلك المعالجات السطحية مثل الطلاء بأكسيد الألومنيوم أو الطلاء بالمسحوق، الذي يحمي من التآكل والتآكل. وبالإضافة إلى ذلك، يتم إجراء فحوصات الموازنة والمحاذاة لضمان التشغيل السلس. هذه المرحلة ضرورية لضمان عمل المولد بكفاءة في ظل ظروف التشغيل المختلفة.

كيف يتم تنفيذ ضمان الجودة في تصنيع قطع غيار المولدات؟

يعد ضمان الجودة أمرًا بالغ الأهمية في تصنيع قطع غيار المولدات، خاصة في المعاملات الدولية بين الشركات. يحتاج المشترون إلى فهم تدابير مراقبة الجودة المختلفة المعمول بها لضمان موثوقية المنتج والامتثال لمعايير الصناعة.

المعايير الدولية والشهادات الخاصة بالصناعة

تلتزم الشركات المصنعة لقطع غيار المولدات عادةً بمعايير إدارة الجودة الدولية مثل ISO 9001. وتدل هذه الشهادة على أن الشركة قد أنشأت نظامًا قويًا لإدارة الجودة يلبي باستمرار متطلبات العملاء والمتطلبات التنظيمية. وبالإضافة إلى ذلك، قد تكون الشهادات الخاصة بالصناعة مثل شهادة المطابقة الأوروبية (CE) للأسواق الأوروبية أو معهد البترول الأمريكي (API) لتطبيقات محددة ذات صلة أيضًا. هذه الشهادات هي مؤشرات على التزام الشركة المصنعة بالجودة والسلامة.

صورة توضيحية متعلقة بأجزاء المولدات

نقاط التحقق الرئيسية لمراقبة الجودة

وعادةً ما يتم تقسيم مراقبة الجودة في عملية التصنيع إلى عدة نقاط تفتيش:

-

مراقبة الجودة الواردة (IQC): تتضمن نقطة الفحص الأولية هذه فحص المواد الخام والمكونات عند وصولها. ويجب على الموردين تقديم وثائق تثبت استيفاء المواد للمعايير المحددة.

-

مراقبة الجودة أثناء الإنتاج (IPQC): أثناء عملية التصنيع، تُتخذ تدابير مراقبة الجودة المتكاملة لمراقبة الإنتاج في مراحل مختلفة. ويشمل ذلك التحقق من الأبعاد، والتفاوتات المسموح بها، والاختبارات الوظيفية لاكتشاف العيوب مبكرًا.

-

مراقبة الجودة النهائية (FQC): بمجرد تجميع أجزاء مولد التيار المتردد بالكامل، تتضمن مراقبة الجودة النوعية اختبارًا صارمًا لضمان استيفاء المنتج لمواصفات الأداء. وتشمل الاختبارات الشائعة اختبار الأداء الكهربائي، والتدوير الحراري، واختبارات الإجهاد الميكانيكي.

ما هي طرق الاختبار الشائعة المستخدمة لأجزاء المولد؟

تلعب طرق الاختبار دورًا حاسمًا في ضمان جودة وموثوقية أجزاء المولد. تم تصميم هذه الطرق للتحقق من أن المكونات ستعمل كما هو متوقع في ظل ظروف العالم الحقيقي.

-

الاختبارات الكهربائية: تقوم هذه الطريقة بتقييم الخرج الكهربائي للمولّد، بما في ذلك تصنيفات الجهد والأمبيرية. وهي تضمن قدرة المولد على إنتاج طاقة كافية للاستخدام المقصود.

-

الاختبار الحراري: يجب أن تعمل المولدات بفعالية في البيئات ذات درجات الحرارة العالية. يقيم الاختبار الحراري كيفية تحمل المكونات للحرارة ويضمن عدم تدهور المواد بمرور الوقت.

-

الاختبارات الميكانيكية: ويتضمن ذلك تقييم السلامة الميكانيكية لأجزاء المولد بما في ذلك اختبارات الاهتزاز واختبارات قوة الشد. تضمن هذه الاختبارات قدرة المكونات على تحمل الضغوط التي ستواجهها أثناء التشغيل.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

بالنسبة للمشترين الدوليين بين الشركات (B2B)، فإن التحقق من عمليات مراقبة الجودة لدى الموردين أمر بالغ الأهمية. وفيما يلي عدة استراتيجيات للتأكد من أنك تتعامل مع مُصنِّع موثوق به:

إجراء عمليات التدقيق

يمكن أن توفر عمليات التدقيق المنتظمة لمنشأة التصنيع نظرة ثاقبة على ممارسات مراقبة الجودة لدى المورد. يمكن للمشترين طلب رؤية خطوط الإنتاج ومرافق الاختبار وأنظمة إدارة الجودة المعمول بها. يمكن أن تساعد هذه الملاحظة المباشرة في تقييم ما إذا كانت الشركة المصنعة تفي بمعايير الجودة اللازمة.

طلب تقارير الجودة

يجب أن يكون الموردون قادرين على تقديم تقارير الجودة ونتائج الاختبارات لمنتجاتهم. يجب أن توضح هذه المستندات بالتفصيل نتائج فحوصات مراقبة الجودة المتكاملة ومراقبة الجودة الشاملة ومراقبة الجودة المالية. إن فهم عدد مرات إجراء هذه الاختبارات ومعايير الاجتياز يمكن أن يوفر المزيد من راحة البال.

إشراك جهات خارجية في عمليات التفتيش

يمكن أن يوفر استخدام خدمات الفحص من طرف ثالث تقييمًا غير متحيز لعمليات التصنيع الخاصة بالمورد. ويمكن لهذه الخدمات التحقق من الامتثال للمعايير الدولية وضمان استيفاء المنتجات للمواصفات المطلوبة قبل الشحن.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين؟

بالنسبة للمشترين بين الشركات من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، فإن فهم الفروق الدقيقة في مراقبة الجودة أمر ضروري. يمكن أن تؤثر عوامل مثل اختلاف اللوائح التنظيمية ولوجستيات سلسلة التوريد والاختلافات الثقافية على عمليات ضمان الجودة.

-

الامتثال التنظيمي: قد يكون للمناطق المختلفة متطلبات امتثال محددة يجب على المصنعين الوفاء بها. يجب على المشترين أن يتعرفوا على هذه اللوائح لضمان امتثال المنتجات للقوانين المحلية.

-

اعتبارات سلسلة التوريد: يمكن أن تؤثر الخدمات اللوجستية على جودة المنتج، خاصة أثناء النقل. إن التأكد من أن المورد لديه عمليات تغليف وشحن قوية يمكن أن يخفف من التلف أثناء النقل.

-

الاختلافات الثقافية: قد تختلف أساليب التواصل وممارسات العمل عبر الثقافات. ويمكن أن يؤدي وضع توقعات واضحة والحفاظ على خطوط اتصال مفتوحة إلى تعزيز التعاون وضمان فهم معايير الجودة والوفاء بها.

من خلال الفهم الشامل لعمليات التصنيع وتدابير ضمان الجودة المعمول بها لقطع غيار المولدات الكهربائية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة تعزز موثوقية سلسلة التوريد وأداء المنتج.

دليل عملي للمصادر: قائمة مراجعة خطوة بخطوة لـ ‘قطع غيار المولدات’

يعمل هذا الدليل كقائمة مراجعة شاملة للمشترين بين الشركات الذين يسعون لشراء قطع غيار المولدات، مما يضمن لك اتخاذ قرارات مستنيرة تتماشى مع احتياجاتك التشغيلية وميزانيتك. من خلال اتباع هذه الخطوات، يمكنك تبسيط عملية التوريد وتقليل المخاطر وتعزيز كفاءة سلسلة التوريد لديك في نهاية المطاف.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

يعد وضع مواصفات فنية واضحة الخطوة الأولى في تحديد مصادر قطع غيار المولدات. ويشمل ذلك فهم متطلبات الجهد والأمبيرية والتوافق مع الأنظمة الموجودة. تساعد المواصفات التفصيلية على ضمان أن القطع التي تشتريها ستلبي المتطلبات التشغيلية لمركباتك أو ماكيناتك.

صورة توضيحية متعلقة بأجزاء المولدات

- النظر في التطبيق: قد تتطلب الاستخدامات المختلفة، مثل السيارات أو البحرية أو الصناعية، أنواعًا محددة من المولدات.

- مراجعة معايير تصنيع المعدات الأصلية: تأكد من أن القطع التي تبحث عنها تفي بمعايير الشركة المصنعة للمعدات الأصلية (OEM) من حيث الجودة والتركيب.

الخطوة 2: البحث وتحديد الموردين ذوي السمعة الطيبة

قم بإجراء بحث شامل لتحديد الموردين ذوي السمعة القوية في سوق قطع غيار المولدات. ابحث عن الشركات التي أثبتت خبرتها وتجربتها، لا سيما تلك التي تلبي احتياجات السوق الجغرافي الذي تتعامل معه.

- تحقق من المراجعات عبر الإنترنت: استخدم منصات مثل Trustpilot أو المنتديات الخاصة بالصناعة لقياس موثوقية الموردين.

- تقييم التواجد في الصناعة: غالبًا ما يكون الموردون الذين يتمتعون بحضور طويل الأمد ومجموعة واسعة من المنتجات أكثر جدارة بالثقة.

الخطوة 3: تقييم الموردين المحتملين

قبل الالتزام، من الأهمية بمكان فحص الموردين المحتملين بدقة. اطلب ملفات تعريف الشركة ودراسات الحالة والمراجع من المشترين في صناعة أو منطقة مماثلة لتقييم مصداقيتهم.

- اطلب الشهادات: التأكد من التزام المورد بمعايير الجودة ذات الصلة، مثل شهادات الأيزو.

- استفسر عن الضمانات: يمكن أن توفر سياسة الضمان القوية ضمانًا فيما يتعلق بجودة القطع وطول عمرها الافتراضي.

الخطوة 4: طلب العينات والمواصفات

قبل تقديم طلب بالجملة، اطلب عينات من أجزاء المولد. يتيح لك ذلك تقييم جودة المنتجات وتوافقها وأدائها بشكل مباشر.

- إجراء اختبارات الأداء: إذا كان ذلك ممكنًا، اختبر العينات في ظروف التشغيل الفعلية للتأكد من أنها تفي بمواصفاتك.

- مراجعة الوثائق الفنية: تأكد من حصولك على المواصفات الفنية التفصيلية وأدلة التركيب مع العينات.

الخطوة 5: التفاوض على الأسعار والشروط

بمجرد تحديد المورد المناسب، ادخل في مفاوضات بشأن الأسعار وشروط الدفع. سيساعدك فهم هيكل التكلفة على زيادة ميزانيتك إلى أقصى حد مع تأمين قطع غيار عالية الجودة.

- ضع في اعتبارك خصومات الطلبات بالجملة: قد يقدم الموردون أسعارًا أفضل للطلبات الأكبر حجمًا، مما قد يقلل من التكاليف الإجمالية بشكل كبير.

- توضيح شروط الدفع: تأكد من توافق شروط الدفع مع ممارسات إدارة التدفق النقدي لديك.

الخطوة 6: تحديد الخدمات اللوجستية وتوقعات التسليم

ناقش الخدمات اللوجستية لضمان تسليم قطع غيار المولدات في الوقت المناسب. يعد التواصل الواضح بشأن طرق الشحن ومهل التسليم ومواقع التسليم أمرًا ضروريًا لتجنب حدوث أي خلل في عملياتك.

- تحديد تكاليف الشحن: ضع في اعتبارك تكاليف الشحن عند تقييم السعر الإجمالي للقطع.

- وضع جداول زمنية محددة للتسليم: الاتفاق على جداول زمنية واقعية للتسليم لضمان تخطيط عملياتك وفقًا لذلك.

الخطوة 7: تنفيذ تدابير مراقبة الجودة

بعد استلام قطع غيار المولدات، قم بتنفيذ إجراءات مراقبة الجودة للتحقق من حالتها ووظائفها. هذه الخطوة بالغة الأهمية للتأكد من أن المنتجات تفي بمعاييرك التشغيلية.

- الفحص بحثًا عن الأضرار: إجراء فحص شامل عند الوصول لتحديد أي أضرار أثناء الشحن.

- اختبار الوظائف: إذا كان ذلك ممكنًا، اختبر الأجزاء قبل دمجها في أنظمتك للتأكد من أدائها كما هو متوقع.

من خلال اتباع قائمة المراجعة هذه، يمكنك التنقل بفعالية في عملية توريد قطع غيار المولدات، مما يضمن أن تكون استراتيجية الشراء الخاصة بك فعالة ومتوافقة مع احتياجات عملك.

التحليل الشامل للتكلفة والتسعير الشامل لمصادر قطع غيار المولدات الكهربائية

ما هي مكونات التكلفة الرئيسية لتوريد قطع غيار المولد؟

عند الحصول على قطع غيار المولدات، من الضروري فهم مكونات التكلفة المختلفة التي تساهم في السعر النهائي. وتشمل هذه المكونات عادةً ما يلي:

-

المواد: تعتبر تكلفة المواد الخام، مثل المعادن والبلاستيك، عاملاً مهماً. وتؤثر جودة هذه المواد بشكل مباشر على متانة وأداء المولدات. وغالبًا ما يوفر الموردون مجموعة من خيارات المواد لتلبية مستويات الميزانية المختلفة.

-

العمل: يمكن أن تختلف تكاليف العمالة بشكل كبير بناءً على موقع التصنيع. قد تقدم المناطق ذات تكاليف العمالة المنخفضة أسعاراً أكثر تنافسية، ولكن هذا قد يأتي أحياناً على حساب الجودة.

-

تكاليف التصنيع العامة: يشمل ذلك التكاليف المرتبطة بعمليات المصنع، مثل المرافق والصيانة والنفقات الإدارية. ويمكن أن تساعد عمليات التصنيع الفعالة في تقليل هذه التكاليف.

-

الأدوات: يمكن أن تكون تكاليف الإعداد الأولي للمعدات المتخصصة كبيرة، لا سيما بالنسبة للمولدات المخصصة أو ذات الإنتاجية العالية. وفهم هذه التكاليف أمر بالغ الأهمية لتقييم السعر الإجمالي.

-

مراقبة الجودة (QC): تضمن الاختبارات الصارمة وعمليات ضمان الجودة الصارمة أن أجزاء المولدات تفي بالمعايير المحددة. قد تأتي الأجزاء عالية الجودة بتكاليف أعلى لمراقبة الجودة، مما قد يؤثر على السعر النهائي.

-

اللوجستيات: تلعب رسوم الشحن والمناولة دورًا حاسمًا، خاصة بالنسبة للمعاملات الدولية. قد تختلف التكاليف بناءً على المسافة وطريقة الشحن واللوائح المحلية.

-

الهامش: يضيف الموردون عادةً هامش ربح يمكن أن يختلف بناءً على طلب السوق والمنافسة. ويمكن أن يساعد فهم هذا الجانب في المفاوضات.

كيف تؤثر العوامل المؤثرة في الأسعار على تكلفة أجزاء المولد؟

هناك عدة عوامل يمكن أن تؤثر على سعر قطع غيار المولدات، خاصةً بالنسبة للمشترين بين الشركات في مناطق مختلفة:

-

الحجم/الحد الأدنى للطلب: يمكن أن يؤدي الشراء بالجملة إلى تخفيضات كبيرة. وغالباً ما يحدد الموردون كميات الطلبات الدنيا (MOQ) لتحسين الإنتاج وخفض التكاليف.

-

المواصفات والتخصيص: يمكن أن تؤدي المواصفات المخصصة، مثل وحدات الإنتاجية العالية أو ميزات التصميم المحددة، إلى زيادة التكاليف. ويجب على المشترين أن يوازنوا بين فوائد التخصيص وقيود الميزانية.

-

جودة المواد والشهادات: القطع التي تفي بمعايير أو شهادات صناعية محددة (على سبيل المثال، ISO، OEM) عادةً ما تكون أسعارها أعلى. وقد يقلل الاستثمار في قطع الغيار المعتمدة من تكاليف الصيانة على المدى الطويل.

-

عوامل الموردين: يمكن أن تؤثر سمعة الموردين وموثوقيتهم على الأسعار. فقد يتقاضى الموردون الراسخون ذوو السجلات المثبتة أسعاراً أعلى بسبب عمليات ضمان الجودة التي يتبعونها.

-

مصطلحات التجارة الدولية: يعد فهم المصطلحات التجارية الدولية أمرًا حيويًا لضبط التكاليف. يمكن أن تؤثر شروط مثل فوب (مجاناً على ظهر السفينة) أو سيف (التكلفة والتأمين والشحن) على التكلفة الإجمالية للرسو.

ما هي استراتيجيات التفاوض التي يمكن للمشترين استخدامها لتحسين التكاليف؟

يمكن للمشترين الدوليين بين الشركات الاستفادة من العديد من الاستراتيجيات لتعزيز كفاءة التكلفة:

-

إجراء أبحاث السوق: يمكن أن يؤدي فهم أسعار السوق واتجاهاته إلى تمكين المشترين أثناء المفاوضات. ويمكن أن يؤدي جمع عروض أسعار متعددة من موردين مختلفين إلى توفير النفوذ.

-

التفاوض بشأن خصومات الحجم: يمكن أن يؤدي التأكيد على الشراكات طويلة الأجل والحجم الكبير إلى إقناع الموردين بتقديم أسعار أفضل.

-

تقييم التكلفة الإجمالية للملكية (TCO): ضع في اعتبارك ليس فقط سعر الشراء ولكن أيضًا التكاليف طويلة الأجل، بما في ذلك الصيانة والضمان ووقت التعطل المحتمل. وقد يؤدي الاستثمار الأولي الأعلى في الأجزاء عالية الجودة إلى انخفاض التكلفة الإجمالية للملكية.

-

استكشف الموردين المحليين: بالنسبة للمشترين في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، قد يقدم الموردون المحليون تكاليف شحن مخفضة ومهل زمنية أقصر.

-

كن على دراية بالفروق الدقيقة في التسعير: قد تختلف ديناميكيات السوق وتقلبات العملة والاعتبارات التنظيمية التي يمكن أن تؤثر على الأسعار باختلاف المناطق. ويمكن أن يساعد البقاء على اطلاع على هذه العوامل في اتخاذ قرارات استراتيجية بشأن التوريد.

في الختام، يعد الفهم الشامل لمكونات التكلفة والعوامل المؤثرة في الأسعار واستراتيجيات التفاوض الفعالة أمرًا ضروريًا للمشترين الدوليين من الشركات الذين يقومون بتوريد قطع غيار المولدات. في حين أن الأسعار يمكن أن تتباين على نطاق واسع، يمكن أن يؤدي اتخاذ القرارات المستنيرة إلى قيمة أفضل وشراكات طويلة الأجل. ضع في اعتبارك دائمًا الأسعار الإرشادية وتحقق من التفاصيل مع الموردين للحصول على أدق عروض الأسعار.

تحليل البدائل: مقارنة أجزاء المولدات بالحلول الأخرى

فهم البدائل في حلول المولدات

في مجال السيارات والآلات الصناعية، يمكن أن يؤثر اختيار المكونات بشكل كبير على الكفاءة التشغيلية وفعالية التكلفة. عند التفكير في قطع غيار المولدات، من الضروري استكشاف البدائل القابلة للتطبيق التي يمكن أن تؤدي أدوارًا مماثلة في صيانة الأنظمة الكهربائية. سيقارن هذا التحليل أجزاء المولدات التقليدية مع حلين بديلين: أنظمة إدارة البطاريات وحلول الطاقة الشمسية.

صورة توضيحية متعلقة بأجزاء المولدات

جدول المقارنة

| جانب المقارنة | قطع غيار المولدات | أنظمة إدارة البطاريات | حلول الطاقة الشمسية |

|---|---|---|---|

| الأداء | توليد جهد كهربائي موثوق لشحن وتشغيل الأنظمة الكهربائية. | تحسين أداء البطارية وإطالة عمرها الافتراضي. | يوفر طاقة متجددة لشحن الأنظمة وتشغيلها. |

| التكلفة | منخفضة التكلفة بشكل عام مع مجموعة من خيارات التسعير. | استثمار أولي أعلى؛ توفير على المدى الطويل بسبب طول عمر البطارية. | يمكن أن تكون تكاليف التركيب مرتفعة؛ وفورات محتملة على المدى الطويل في تكاليف الطاقة. |

| سهولة التنفيذ | سهلة التركيب مع تكوينات السيارة القياسية. | يتطلب خبرة في التثبيت والتهيئة. | قد تكون عملية التركيب معقدة، خاصة في تطبيقات التعديل التحديثي. |

| الصيانة | يلزم إجراء فحوصات منتظمة للتحقق من البلى والتلف، ولكن الصيانة منخفضة بشكل عام. | يتطلب مراقبة حالة البطارية وإدارتها. | الحد الأدنى من الصيانة بمجرد تركيبها ولكن ذلك يعتمد على الظروف الجوية. |

| أفضل حالة استخدام | مثالية لمركبات محركات الاحتراق التقليدية والآلات الثقيلة. | ممتازة للمركبات الكهربائية وأنظمة تخزين الطاقة. | مناسبة للتطبيقات خارج الشبكة والمناطق التي تتوافر فيها أشعة الشمس بكثرة. |

تفصيل البدائل

أنظمة إدارة البطاريات

أنظمة إدارة البطاريات (BMS) هي أنظمة إلكترونية متطورة تراقب أداء البطارية وتديرها، مما يضمن الشحن والتفريغ الأمثل. يمكن لهذه الأنظمة إطالة عمر البطاريات بشكل كبير، مما يجعلها خياراً جذاباً للسيارات الكهربائية وحلول تخزين الطاقة المتجددة. ومع ذلك، يمكن أن يكون الاستثمار الأولي لنظام إدارة البطاريات أعلى مقارنةً بأجزاء المولدات التقليدية. بالإضافة إلى ذلك، فإنها تتطلب مستوى من الخبرة للتركيب والإدارة المستمرة، مما قد يعقد اعتمادها في بعض الأسواق.

حلول الطاقة الشمسية

تعمل حلول الطاقة الشمسية على تسخير الطاقة المتجددة لشحن البطاريات وتشغيل الأنظمة الكهربائية. وهي مفيدة بشكل خاص في المناطق التي تتمتع بأشعة الشمس الوفيرة، حيث توفر مصدر طاقة مستدام وفعال من حيث التكلفة. وفي حين أن تكلفة الإعداد الأولية يمكن أن تكون كبيرة، إلا أن التوفير في فواتير الطاقة على المدى الطويل والفوائد البيئية يمكن أن تفوق هذه النفقات. ومع ذلك، يمكن أن تكون تركيبات الطاقة الشمسية معقدة وقد تتطلب تعديلات كبيرة على الأنظمة القائمة، مما قد يثني بعض الشركات عن اعتماد هذه التكنولوجيا.

الخلاصة: كيفية اختيار الحل المناسب لاحتياجاتك

عند الاختيار بين قطع غيار المولدات والحلول البديلة، يجب على المشترين من الشركات النظر في احتياجاتهم التشغيلية المحددة وقيود الميزانية وجدوى التنفيذ. إذا كانت الموثوقية وسهولة الاستبدال من الأولويات، فقد تكون قطع غيار المولدات التقليدية هي الخيار الأفضل. ومع ذلك، بالنسبة للشركات التي تتطلع إلى الاستثمار في الاستدامة والتوفير على المدى الطويل، فإن استكشاف أنظمة إدارة البطاريات أو حلول الطاقة الشمسية يمكن أن يحقق فوائد كبيرة. في نهاية المطاف، يجب أن يتماشى القرار مع الأهداف الاستراتيجية للشركة ومتطلباتها التشغيلية، مما يضمن أن الحل المختار يعزز الأداء والكفاءة بشكل عام.

الخواص الفنية الأساسية والمصطلحات التجارية لأجزاء المولدات الكهربائية

ما هي الخصائص التقنية الرئيسية لأجزاء المولد؟

يعد فهم الخصائص التقنية الأساسية لقطع غيار المولدات أمرًا بالغ الأهمية لمشتري B2B لضمان الأداء الأمثل وطول العمر الافتراضي. فيما يلي بعض المواصفات الهامة التي يجب مراعاتها:

صورة توضيحية متعلقة بأجزاء المولدات

1. درجة جودة المواد

تُصنع أجزاء المولد عادةً من مواد عالية الجودة مثل الألومنيوم والنحاس والسبائك المختلفة. لا تؤثر درجة هذه المواد على الأداء فحسب، بل تؤثر أيضًا على متانة المكونات ومقاومتها للحرارة. على سبيل المثال، الألومنيوم عالي الجودة خفيف الوزن ولكنه قوي، مما يجعله مثاليًا لمبيت المولد. يجب على المشترين بين الشركات إعطاء الأولوية للموردين الذين يقدمون مواصفات المواد التفصيلية لضمان الامتثال لمعايير الصناعة.

2. مستويات التحمل

يشير التفاوت المسموح به إلى الحد المسموح به من التباين في بُعد مادي أو قيمة مقيسة. بالنسبة لأجزاء مولد التيار المتردد، تعتبر التفاوتات المسموح بها الدقيقة أمرًا حيويًا لضمان الملاءمة والوظيفة المناسبة. وتقلل المكونات المصنعة بمستويات تفاوت تحمل صارمة من مخاطر الأعطال الميكانيكية وتزيد من الكفاءة. يجب على المشترين الاستفسار عن مواصفات التفاوت المسموح به لتجنب مشاكل التوافق في تطبيقاتهم.

3. تصنيفات الجهد والأمبيرية

يحتوي كل جزء من أجزاء المولد على تصنيفات محددة للجهد والأمبيرية التي تحدد حدوده التشغيلية. من الضروري فهم هذه التصنيفات لأنها تؤثر على قدرة المولد على توليد الطاقة الكهربائية وإدارتها بفعالية. على سبيل المثال، تتطلب المولدات عالية الإنتاجية المصممة لتطبيقات الخدمة الشاقة تصنيفات أمبيرية أعلى. يجب على مشتري B2B تقييم احتياجاتهم ومطابقتها مع مواصفات المولد المناسبة لضمان الموثوقية.

4. مقاومة الحرارة

تعمل المولدات في بيئات ذات درجات حرارة عالية، مما يجعل مقاومة الحرارة خاصية بالغة الأهمية. يجب أن تكون المكونات قادرة على تحمل درجات الحرارة المرتفعة دون أن تتدهور. تعمل مواد مثل الإيبوكسي عالي الحرارة والشحوم المصممة خصيصًا على تحسين الأداء الحراري لأجزاء المولد. يجب على المشترين البحث عن المنتجات التي تنص صراحةً على قدراتها على مقاومة الحرارة، خاصةً للتطبيقات في الظروف القاسية.

5. تقييمات الكفاءة

تشير تصنيفات الكفاءة إلى مدى فعالية المولد في تحويل الطاقة الميكانيكية إلى طاقة كهربائية. لا يؤدي تصنيف الكفاءة الأعلى إلى أداء أفضل فحسب، بل يساهم أيضًا في توفير الوقود وتقليل الانبعاثات في المركبات. يجب على مشتري B2B البحث عن المولدات ذات تصنيفات الكفاءة العالية لتحسين الاستدامة الإجمالية لعملياتهم.

صورة توضيحية متعلقة بأجزاء المولدات

ما هي المصطلحات والمصطلحات التجارية الشائعة المستخدمة في أجزاء المولد؟

يمكن أن يؤدي التعرف على المصطلحات الخاصة بالصناعة إلى تعزيز عمليات التواصل والتفاوض في سوق B2B بشكل كبير. إليك بعض المصطلحات الأساسية:

1. OEM (الشركة المصنعة للمعدات الأصلية)

يشير المصنعون الأصليون إلى الشركات المصنعة التي تنتج قطع غيار مطابقة لتلك المثبتة أصلاً في السيارة أو الماكينة. وغالباً ما يفضل المشترون بين الشركات قطع الغيار المصنعة للمعدات الأصلية لجودتها المضمونة وتوافقها. يمكن أن يساعد فهم الفرق بين قطع غيار المعدات الأصلية وقطع ما بعد البيع المشترين على اتخاذ قرارات مستنيرة فيما يتعلق بالأداء واعتبارات الضمان.

2. MOQ (الحد الأدنى لكمية الطلب)

يشير موك إلى أصغر كمية من المنتج الذي يرغب المورد في بيعه. هذا المصطلح مهم بشكل خاص للمشترين بين الشركات الذين يتطلعون إلى تحسين تكاليف المخزون. يمكن أن يؤدي التفاوض على موك إلى تحسين التسعير وكفاءة سلسلة التوريد، خاصةً بالنسبة للعمليات واسعة النطاق.

3. طلب عرض أسعار (RFQ)

طلب عرض الأسعار هو عملية رسمية يستخدمها المشترون لطلب الأسعار والشروط من الموردين. ويتضمن عادةً مواصفات الأجزاء المطلوبة والكميات والجداول الزمنية للتسليم. يمكن أن يؤدي تقديم طلب عرض أسعار إلى تبسيط عمليات الشراء وضمان حصول المشترين على أسعار تنافسية.

4. شروط التجارة الدولية (Incoterms)

شروط التجارة الدولية هي شروط تجارية موحدة توضح مسؤوليات المشترين والبائعين في المعاملات الدولية. إن فهم هذه الشروط أمر بالغ الأهمية بالنسبة للمشترين بين الشركات المشاركين في توريد قطع غيار المولدات عبر الحدود، حيث إنها تحدد تكاليف الشحن وإدارة المخاطر ومسؤوليات التأمين.

5. ما بعد البيع

يشير سوق ما بعد البيع إلى القطع والملحقات التي لا يتم الحصول عليها من الشركة المصنعة للمعدات الأصلية. وعلى الرغم من أن قطع ما بعد البيع يمكن أن تكون أقل تكلفة، إلا أن جودتها وتوافقها يمكن أن يتفاوت. يجب على المشترين الموازنة بين إيجابيات وسلبيات خيارات ما بعد البيع، خاصةً عند النظر في الآثار المترتبة على الضمان.

من خلال فهم هذه الخصائص التقنية والمصطلحات التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات أكثر استنارة عند الحصول على قطع غيار المولدات، مما يؤدي في النهاية إلى تحسين الكفاءة التشغيلية وفعالية التكلفة.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع قطع غيار المولدات الكهربائية

ما هي المحركات الرئيسية لسوق قطع غيار المولدات؟

يشهد سوق قطع غيار المولدات الكهربائية نموًا قويًا مدفوعًا بعوامل عالمية مختلفة. وتعد زيادة إنتاج السيارات، لا سيما في الأسواق الناشئة مثل البرازيل والمملكة العربية السعودية، حافزًا مهمًا. ومع تسارع وتيرة التحضر في هذه المناطق، ارتفع الطلب على مكونات السيارات الموثوقة، بما في ذلك مولدات التيار المتردد. بالإضافة إلى ذلك، يؤدي ارتفاع عدد السيارات الكهربائية (EVs) والأنظمة الهجينة إلى تغيير المشهد، مما يستلزم تصميمات مبتكرة لمولدات التيار المتردد التي تلبي احتياجات الكفاءة العالية وإنتاج الطاقة. ويتضح هذا الاتجاه بشكل خاص في أوروبا، حيث تدفع الضغوط التنظيمية الشركات المصنعة نحو الممارسات المستدامة.

كما يشهد المشترون بين الشركات تحولاً نحو منصات التوريد الرقمية. يؤدي اعتماد التقنيات المتقدمة، مثل إدارة المخزون القائمة على الذكاء الاصطناعي والتحليلات التنبؤية، إلى تبسيط عمليات الشراء. يمكن للمشترين الآن الاستفادة من الأسواق عبر الإنترنت لمقارنة الأسعار وتقييم موثوقية الموردين وتتبع حالات الشحن في الوقت الفعلي. علاوة على ذلك، تسهل اتفاقيات التجارة عبر الحدود الوصول بسهولة إلى موردين متنوعين، مما يتيح للمشترين الحصول على قطع غيار المولدات عالية الجودة بأسعار تنافسية.

ما مدى أهمية الاستدامة والتوريد الأخلاقي في قطاع قطع غيار المولدات؟

أصبحت الاستدامة والمصادر الأخلاقية محورية في سوق قطع غيار المولدات الكهربائية. وقد دفعت المخاوف البيئية المحيطة بعمليات التصنيع الشركات إلى تبني ممارسات أكثر مراعاة للبيئة. بالنسبة للمشترين بين الشركات، فإن التوريد من الموردين الذين يستخدمون المواد القابلة لإعادة التدوير وتقنيات الإنتاج الموفرة للطاقة ليس مجرد اتجاه بل ضرورة. يمكن لهذا الالتزام بالاستدامة أن يقلل بشكل كبير من البصمة الكربونية المرتبطة بإنتاج وتوزيع مولدات التيار المتردد.

وعلاوة على ذلك، تتزايد أهمية سلاسل التوريد الأخلاقية مع تزايد طلب المستهلكين على الشفافية. يجب على المشترين إعطاء الأولوية للموردين الحاصلين على شهادات تثبت امتثالهم لمعايير الحوكمة البيئية والاجتماعية. وقد يشمل ذلك شهادات الأيزو لإدارة الجودة والتأثير البيئي، بالإضافة إلى الالتزام بممارسات العمل العادلة. من خلال التوافق مع الموردين الأخلاقيين، يمكن للشركات تعزيز سمعة علامتها التجارية مع تلبية المتطلبات التنظيمية في مختلف المناطق، خاصة في أوروبا حيث لوائح الاستدامة صارمة.

كيف تطور سوق قطع غيار المولدات بمرور الوقت؟

يعكس تطور سوق قطع غيار المولدات التطورات التكنولوجية الأوسع نطاقاً وتغير طلبات المستهلكين. في البداية، كانت المولدات في الغالب أجهزة ميكانيكية ذات كفاءة محدودة. ومع ذلك، مع تقدم تكنولوجيا السيارات، أدى إدخال المكونات الإلكترونية إلى تحسين الأداء والموثوقية بشكل كبير.

في أواخر القرن العشرين، أصبح التحول نحو المولدات عالية الإنتاجية واضحًا، مدفوعًا بالطلبات الكهربائية المتزايدة من السيارات الحديثة المزودة بأنظمة معلومات وترفيه متقدمة وميزات السلامة. أما اليوم، فقد اتسع نطاق التركيز ليشمل ليس فقط الأداء ولكن أيضًا الاستدامة، حيث يستكشف العديد من المصنّعين طرقًا لإنتاج مولدات لا تتسم بالكفاءة فحسب، بل أيضًا صديقة للبيئة. وقد وضع هذا التطور قطع غيار المولدات كمكونات أساسية في سلسلة توريد السيارات، مما يؤكد أهميتها لكل من المصنعين والمشترين من الشركات في السوق العالمية.

من خلال فهم هذه الديناميكيات، يمكن للمشترين الدوليين اتخاذ قرارات مستنيرة، مما يضمن حصولهم على قطع غيار مولدات الطاقة المترددة عالية الجودة التي تلبي المتطلبات الحالية وأهداف الاستدامة المستقبلية.

الأسئلة المتداولة (FAQs) لمشتري قطع غيار مولدات التيار المتردد B2B

1. كيف يمكنني حل مشكلات التوافق عند تحديد مصادر قطع مولد التيار المتردد؟

لمعالجة مشكلات التوافق، ابدأ بتحديد طراز السيارة أو الماكينة المحددة التي تم تصميم قطع غيار المولد من أجلها. استخدم أرقام قطع الشركة المصنعة ومواصفاتها، مع التأكد من مطابقتها لمعايير الشركة المصنعة للمعدات الأصلية. تعاون بشكل وثيق مع الموردين الذين يقدمون كتالوجات مفصلة للمنتجات ومخططات التوافق. النظر في طلب عينات أو نماذج أولية لاختبار التوافق قبل تقديم طلبات كبيرة. كما يمكن أن يساعد التعامل مع الموردين الذين يقدمون الدعم الفني في توضيح أي شكوك تتعلق بالتوافق.

2. ما هو أفضل نوع من مولد التيار المتردد للاستخدامات الشاقة؟

بالنسبة لتطبيقات الخدمة الشاقة، مثل الآلات الصناعية أو المركبات التجارية، عادةً ما تكون المولدات عالية الإنتاجية هي الخيار الأفضل. هذه الوحدات مصممة للتعامل مع الأحمال الكهربائية المتزايدة وغالبًا ما تأتي مع ميزات مثل أنظمة التبريد المحسنة والبنية القوية لتحمل البيئات القاسية. ابحث عن المولدات ذات الحد الأدنى من تصنيف التيار الكهربائي الذي يلبي متطلباتك الكهربائية. بالإضافة إلى ذلك، ضع في اعتبارك الموردين المتخصصين في الاستخدامات الشاقة لضمان حصولك على منتجات عالية الجودة مصممة خصيصًا لتلبية احتياجاتك.

3. ما هي العوامل التي يجب مراعاتها عند فحص موردي مولدات التيار المتردد؟

عند التدقيق في موردي المولدات الكهربائية، يجب إعطاء الأولوية لخبرتهم في المجال وسمعتهم وجودة منتجاتهم. اطلب مراجع أو دراسات حالة من عملاء سابقين وتحقق من امتثالهم لمعايير الجودة العالمية، مثل شهادات ISO. افحص عمليات التصنيع الخاصة بهم واستفسر عن سياسات الضمان ودعم ما بعد البيع. بالإضافة إلى ذلك، قم بتقييم قدراتها اللوجستية، بما في ذلك خيارات الشحن وأوقات التسليم، للتأكد من قدرتها على تلبية احتياجات سلسلة التوريد الخاصة بك بفعالية.

4. كيف يمكنني تخصيص أجزاء المولد لتطبيقات محددة؟

لتخصيص أجزاء مولد التيار المتردد حسب الطلب، ابدأ مناقشة مع المورد الخاص بك حول متطلباتك المحددة، مثل تصنيفات الجهد أو الأمبيرية أو الأبعاد المادية. يقدم العديد من الموردين حلولاً مصممة خصيصًا ويمكنهم تعديل التصميمات الحالية لتناسب التطبيقات الفريدة. قدم المواصفات التفصيلية، وإن أمكن، أمثلة على التخصيصات المماثلة التي أنجزوها في الماضي. كن مستعدًا للمناقشات حول الحد الأدنى لكميات الطلبات (موك) والمهل الزمنية المحتملة للطلبات المخصصة.

5. ما هو الحد الأدنى المعتاد لكميات الطلبات (MOQ) لقطع غيار المولدات؟

يمكن أن يختلف الحد الأدنى لكميات الطلبات (MOQ) لقطع غيار المولدات اختلافًا كبيرًا بين الموردين، حيث يتراوح عادةً بين 10 و100 وحدة، اعتمادًا على نوع القطع ومستوى تخصيصها. من الضروري التأكد من موك مع الموردين المحتملين قبل تقديم الطلبات، حيث يمكن أن يؤثر ذلك على استراتيجية الشراء الإجمالية الخاصة بك. إذا كنت تختبر خط إنتاج جديد، ناقش خيارات الطلبات التجريبية الأصغر أو شراء عينات لتقليل المخاطر.

6. ما هي شروط الدفع التي يجب أن أتوقعها عند الحصول على قطع غيار المولدات على المستوى الدولي؟

عادةً ما تتضمن شروط الدفع للمشتريات الدولية لقطع غيار المولدات خيارات مثل الدفع مقدمًا أو خطاب الاعتماد أو شروط الحساب المفتوح. قد تعتمد الشروط على علاقتك مع المورد وحجم الطلب وبلد المنشأ. يُنصح بالتفاوض على الشروط التي توازن بين التدفق النقدي وإدارة المخاطر. تأكد من وضوح أسعار تحويل العملات، والرسوم المصرفية المحتملة، وأي ودائع مقدمة مطلوبة قبل الإنتاج.

7. كيف يمكنني ضمان ضمان الجودة (QA) لأجزاء المولد؟

لضمان ضمان جودة قطع غيار المولدات، اطلب وثائق مفصلة من الموردين، بما في ذلك عمليات مراقبة الجودة وطرق الاختبار والشهادات. الانخراط في التواصل المنتظم فيما يتعلق بمعايير الجودة والتوقعات. قد يكون من المفيد إجراء عمليات تدقيق أو تفتيش في الموقع لمرافق التصنيع إن أمكن. بالإضافة إلى ذلك، ضع في اعتبارك الموردين الذين يقدمون ضمانات أو كفالات على منتجاتهم، والتي يمكن أن تكون بمثابة طبقة إضافية لضمان الجودة.

8. ما هي الاعتبارات اللوجستية المهمة عند استيراد قطع غيار المولدات؟

عند استيراد قطع غيار المولدات، ضع في اعتبارك عوامل مثل طرق الشحن واللوائح الجمركية والتعريفات المحتملة. ابحث عن أكثر طرق الشحن والجداول الزمنية كفاءة لتقليل التأخير. تعاون مع شركاء الخدمات اللوجستية ذوي الخبرة في الشحن الدولي لضمان الامتثال للقوانين المحلية والوثائق المناسبة للتخليص الجمركي. بالإضافة إلى ذلك، ضع في اعتبارك حلول التخزين وممارسات إدارة المخزون للتعامل مع الشحنات الواردة بفعالية.

قائمة المصنعين والموردين لأعلى 3 قطع غيار المولدات 3

1. DB Electrical - مولدات كهربائية عالية الإنتاجية

المجال: dbelectrical.com

مسجل: 2000 (25 سنة)

مقدمة: مولدات كهربائية وقطع غيار للبيع |مولدات عالية الإنتاجية. شحن مجاني في نفس اليوم لأكثر من $50* الولايات المتحدة الأمريكية/48 فقط. مولدات عالية الجودة بأسعار منخفضة. تتميز مولدات المولدات الكهربائية DB الكهربائية بإيبوكسي عالي الحرارة، ومقومات للخدمة الشاقة، ومنظمات عالية الجودة، ومحامل مصممة جيدًا، وشحم عالي الحرارة. يفي بمعايير OEM للجودة والتركيب. يخضع كل مولد مولد لعمليات فحص صارمة...

2. قطع غيار BNR - المولدات والمشغلات

المجال: ebay.com

تاريخ التسجيل: 1995 (30 عامًا)

مقدمة: اسم المتجر: BNR قطع غيار المولدات والمبدلات

تقييم الملاحظات 100% ردود فعل إيجابية

إجمالي العناصر المباعة: 89 ألف عنصر

المتابعون 5.5K

الفئات: أكيورا، ألفا روميو، أودي، أودي، بي إم دبليو، كاديلاك، كاديلاك، شيفروليه، دودج، دودج، فيراري، فورد، هوندا، جيب، جيب ، لكزس، مازدا، مرسيدس، نيسان، بورش، تويوتا، فولكس واجن، وغيرها.

عينة من المنتجات:

1. مولد مولد مرسيدس 150 أمبير W116 W116 W123 W115 W125 W126 R107 مولد عالي الإنتاجية - $27...

3. شفروليه بيرفورما - المولدات والملحقات

المجال: proformparts.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: {“الفئة”: ”المولدات والملحقات”، ”أنواع المنتجات”: [“المولد”، ”حامل المولد”، ”طقم تركيب المولد”، ”مباعد تركيب المولد”، ”بكرة المولد”]، ”مخرجات_مولدات_أمبيراج”:[“160 أمبير أمبير”، ”140 أمبير”، ”120 أمبير”، ”110 أمبير”، ”100 أمبير”، ”80 أمبير”، ”70 أمبير”، ”60 أمبير”، ”50 أمبير”]، ”العلامات التجارية”: [“شفروليه بيرفورمانس”، ”موبار”، ”موبار”، ”بروفورم المحرك”، ”كرايسلر بيغ بلوك”، ”كرايسلر سمول بلوك”، "شفروليه SB الجيل 1″، "شفروليه SB...

استنتاجات وتوقعات التوريد الاستراتيجي لقطع غيار المولدات الكهربائية

في المشهد التنافسي لتوريد قطع غيار المولدات، يجب على المشترين الدوليين بين الشركات إعطاء الأولوية للجودة والموثوقية والفعالية من حيث التكلفة. من خلال التوريد الاستراتيجي للمولدات والمكونات عالية الجودة، يمكن للشركات تحسين أداء مركباتها وطول عمرها بشكل كبير مع تقليل الأعطال التشغيلية إلى الحد الأدنى. من خلال فهم الدور الحاسم الذي تلعبه مولدات التيار المتردد في الأنظمة الكهربائية، يجب على المشترين التركيز على الموردين الذين يلتزمون بمعايير مصنعي المعدات الأصلية ويقدمون اختبارات صارمة لمنتجاتهم، مما يضمن الأداء الأمثل في ظل ظروف مختلفة.

صورة توضيحية متعلقة بأجزاء المولدات

وعلاوة على ذلك، يمكن أن تؤدي الاستفادة من العلاقات مع الشركات المصنعة ذات السمعة الطيبة إلى تحقيق وفورات كبيرة، غالبًا ما تصل إلى 301 تيرابايت و3 تيرابايت من أسعار التجزئة، دون المساومة على الجودة. مع استمرار توسع الأسواق الناشئة في إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، هناك طلب متزايد على قطع غيار المولدات الموثوقة التي يمكنها تحمل بيئات وسيناريوهات استخدام متنوعة.

بالنظر إلى المستقبل، من الضروري أن يظل المشترون من الشركات على اطلاع دائم بالتطورات في تكنولوجيا المولدات وممارسات الصيانة. من خلال الاستثمار في مصادر عالية الجودة وبناء شراكات قوية مع الموردين، يمكن للشركات أن تضع نفسها في وضع يمكنها من تحقيق النمو المستدام والنجاح في سوق ديناميكي. تواصل مع الموردين الموثوق بهم اليوم لتأمين أفضل الحلول لاحتياجاتك من مولدات التيار المتردد ودفع أعمالك إلى الأمام.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.