مقدمة: الإبحار في السوق العالمية لمولدات المولدات الصينية

مع تزايد بحث المشترين الدوليين من الشركات عن حلول موثوقة في قطاع السيارات، فإن الحصول على مولدات كهربائية عالية الجودة من الصين يمثل فرصًا وتحديات في آن واحد. يستلزم الطلب العالمي على الأنظمة الكهربائية الفعالة في المركبات فهمًا عميقًا لمختلف أنواع المولدات المتاحة وتطبيقاتها وتعقيدات فحص الموردين. يهدف هذا الدليل إلى إلقاء الضوء على المشهد العام لسوق المولدات الكهربائية الصينية، وتقديم رؤى حول عروض المنتجات المتنوعة، من السيارات إلى التطبيقات الصناعية.

لا يتطلب الإبحار في هذه السوق معرفة مواصفات المنتج فحسب، بل يتطلب أيضًا الوعي بمعايير التصنيع الإقليمية وديناميكيات التسعير. بالنسبة للمشترين من أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا - خاصة في بلدان مثل البرازيل والمملكة العربية السعودية - فإن اتخاذ قرارات الشراء المستنيرة يمكن أن يؤثر بشكل كبير على الكفاءة التشغيلية وفعالية التكلفة.

في هذا الدليل الشامل، ستجد في هذا الدليل الشامل معلومات مفصلة عن الأنواع المختلفة لمولدات الكهرباء، وتطبيقاتها في مختلف الصناعات، واستراتيجيات فحص الموردين، وتحليل اتجاهات التسعير. من خلال تجهيز نفسك بالمعرفة والأدوات المناسبة، يمكنك بثقة التنقل في تعقيدات توريد المولدات من الصين، مما يضمن لك اختيار الشركاء الذين يتوافقون مع احتياجات عملك وتوقعات الجودة. سواء كنت تتطلع إلى تعزيز سلسلة التوريد الخاصة بك أو تحسين أداء المنتج، فإن هذا الدليل هو مصدرك الأساسي للنجاح في سوق المولدات الكهربائية العالمية.

جدول المحتويات

- قائمة المصنعين والموردين 4 أعلى 4 المولد الصينية قائمة المصنعين والموردين

- مقدمة: الإبحار في السوق العالمية لمولدات المولدات الصينية

- فهم أنواع المولدات الصينية واختلافاتها

- التطبيقات الصناعية الرئيسية لمولد التيار المتردد الصيني

- 3 نقاط ألم شائعة لدى المستخدمين لـ ‘المولدات الصينية’ وحلولها

- دليل اختيار المواد الاستراتيجية لمولد التيار المتردد الصيني

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لمولدات المولدات الصينية

- دليل عملي للمصادر: قائمة تدقيق خطوة بخطوة لـ ‘المولد الصيني’

- تحليل شامل للتكاليف والتسعير لمصادر المولدات الصينية للمولدات الكهربائية

- تحليل البدائل: مقارنة المولد الصيني بالحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية لمولد المولدات الصينية

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع المولدات الكهربائية الصينية

- الأسئلة المتداولة (FAQs) لمشتري B2B لمولد المولد الصيني

- استنتاج وتوقعات التوريد الاستراتيجي لمولدات المولدات الصينية الاستراتيجية

- إخلاء مسؤولية هام وشروط الاستخدام

فهم أنواع المولدات الصينية واختلافاتها

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| مولدات السيارات | مصممة للمركبات، عادةً أنظمة 12 فولت أو 24 فولت | تصنيع السيارات وإصلاحها | الإيجابيات: ارتفاع الطلب، والتوافق مع مختلف المركبات. السلبيات: تقلبات الأسعار بناءً على اتجاهات السيارات. |

| المولدات الصناعية | خرج طاقة أعلى، وتصميم متين، وغالبًا ما يكون 3 مراحل | مصانع التصنيع، وتوليد الطاقة | الإيجابيات: متينة ومناسبة للاستخدامات الشاقة. السلبيات: استثمار أولي أعلى مطلوب. |

| مولدات كهربائية بحرية | مواد مقاومة للتآكل، مخصصة للاستخدام البحري | القوارب والسفن والمعدات البحرية | الإيجابيات: مصممة للبيئات القاسية والأداء الموثوق به. السلبيات: محدودة للتطبيقات البحرية، مع احتمال ارتفاع التكاليف. |

| مولدات التوربينات الريحية | مُحسَّن لإنتاج الطاقة المتجددة، والإنتاج المتغير | مشاريع الطاقة المتجددة ومزارع الرياح | الإيجابيات: يدعم المبادرات الخضراء وتوفير التكاليف على المدى الطويل. السلبيات: يتطلب خبرة محددة في التركيب. |

| المولدات الكهربائية المحمولة | خفيفة الوزن وسهلة النقل، وغالباً ما تعمل بالغاز | مواقع البناء، والفعاليات الخارجية | الإيجابيات: استخدام متعدد الاستخدامات، وإمداد فوري بالطاقة. السلبيات: خرج طاقة محدود، غير مناسب للإعدادات الدائمة. |

ما هي خصائص مولدات السيارات ومدى ملاءمتها للمشترين بين الشركات؟

صُممت مولدات السيارات خصيصًا للمركبات وتعمل عادةً على أنظمة 12 فولت أو 24 فولت. وهي تلعب دورًا حاسمًا في إعادة شحن البطاريات وتشغيل إلكترونيات السيارة. يجب على مشتري B2B في قطاع السيارات مراعاة التوافق مع مختلف موديلات السيارات وطرازاتها، بالإضافة إلى اتجاهات الطلب في تصنيع السيارات. في حين أنها مطلوبة على نطاق واسع، يمكن أن تحدث تقلبات في الأسعار بسبب التحولات في صناعة السيارات، مما يجعل من الضروري للمشترين الحفاظ على علاقات قوية مع الموردين.

كيف تختلف المولدات الصناعية في التصميم والتطبيق؟

صُممت المولدات الكهربائية الصناعية لإنتاج طاقة أعلى وغالبًا ما تكون مصممة بطريقة متينة لتحمل البيئات الصعبة. تُستخدم هذه المولدات بشكل شائع في مصانع التصنيع وتوليد الطاقة، وعادةً ما تتميز هذه المولدات بمخرجات ثلاثية الطور. بالنسبة لمشتري B2B، فإن متانة وأداء المولدات الصناعية تجعلها خيارًا موثوقًا به للتطبيقات الشاقة. ومع ذلك، يمكن أن يكون الاستثمار الأولي المرتفع عائقًا، لذا يجب على المشترين أن يوازنوا بين الفوائد طويلة الأجل مقابل التكاليف الأولية.

ما الذي يجعل المولدات البحرية فريدة من نوعها وكيف ينبغي للمشترين التعامل معها؟

تم تصميم المولدات الكهربائية البحرية بمواد مقاومة للتآكل لتحمل الظروف القاسية للبيئات البحرية. وهي ضرورية للقوارب والسفن لضمان إمدادات الطاقة الموثوقة للأنظمة الموجودة على متن السفن. يجب على مشتري الأعمال التجارية في القطاع البحري إعطاء الأولوية لمتانة وأداء هذه المولدات. على الرغم من أنها مصممة لتطبيقات محددة، إلا أن التكاليف المرتفعة المرتبطة بالمكونات البحرية قد تتطلب وضع ميزانية وتخطيط دقيقين للمشتريات.

لماذا تعتبر مولدات توربينات الرياح مهمة لمشاريع الطاقة المتجددة؟

تم تحسين مولدات التوربينات الريحية لتوليد الكهرباء من طاقة الرياح، مما يجعلها عنصراً حيوياً في مبادرات الطاقة المتجددة. ويمكنها التعامل مع الإنتاج المتغير حسب ظروف الرياح، وهو أمر بالغ الأهمية لكفاءة إنتاج الطاقة. يجب على مشتري B2B المشاركين في مشاريع الطاقة المتجددة أن يأخذوا في الاعتبار وفورات التكلفة طويلة الأجل والفوائد البيئية لهذه المولدات. ومع ذلك، فإنها تتطلب أيضًا خبرة متخصصة في التركيب، مما قد يزيد من التكلفة الإجمالية للمشروع وتعقيده.

ما المزايا التي تقدمها المولدات المحمولة للمشترين من الشركات؟

تم تصميم المولدات الكهربائية المحمولة لسهولة النقل والإمداد الفوري بالطاقة، وغالباً ما تعمل بالبنزين. وتجد تطبيقاتها في مواقع البناء والفعاليات الخارجية التي تحتاج إلى طاقة مؤقتة. سوف يقدّر المشترون من الشركات الذين يبحثون عن المرونة تعدد استخدامات المولدات المحمولة. ومع ذلك، فإنها عادةً ما تكون ذات خرج طاقة محدود وليست مناسبة للتركيبات الدائمة، مما يجعل من الضروري للمشترين تقييم احتياجاتهم المحددة من الطاقة قبل إجراء عملية الشراء.

التطبيقات الصناعية الرئيسية لمولد التيار المتردد الصيني

| الصناعة/القطاع | التطبيق المحدد لمولد المولد الصيني | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | توليد الطاقة لأنظمة الكهرباء في المركبات | ضمان الموثوقية والكفاءة في عمليات المركبات | معايير الجودة، والتوافق مع طرازات السيارات، وشروط الضمان |

| الطاقة المتجددة | التكامل في أنظمة طاقة الرياح والطاقة الشمسية | يعزز قدرات تحويل الطاقة وتخزينها | اعتماد للتطبيقات المتجددة والمتانة ودعم الصيانة |

| معدات البناء | إمدادات الطاقة للآلات الثقيلة | يدعم التشغيل المستمر في المواقع البعيدة | سعة التحميل، ومقاومة الظروف البيئية، وخدمة ما بعد البيع |

| التطبيقات البحرية | الطاقة الكهربائية للقوارب والسفن | طاقة موثوقة للملاحة والأنظمة الموجودة على متن الطائرة | مقاومة التآكل، ومواصفات الحجم والوزن، والامتثال للمعايير البحرية |

| الاتصالات السلكية واللاسلكية | أنظمة الطاقة الاحتياطية للأبراج الخلوية | ضمان عدم انقطاع الخدمة والموثوقية دون انقطاع | متطلبات الجهد، وكفاءة الطاقة، وسهولة التكامل |

كيف يتم استخدام ‘المولد الصيني’ في قطاع السيارات؟

في صناعة السيارات، يلعب ‘المولد الصيني المولد’ دورًا حاسمًا في توليد الطاقة الكهربائية للمركبات. فهو يشحن البطارية ويشغل المكونات الأساسية مثل نظام الإشعال وتكييف الهواء وأنظمة الصوت. بالنسبة للمشترين الدوليين، لا سيما في مناطق مثل البرازيل والمملكة العربية السعودية، يعد الحصول على مولدات عالية الجودة أمرًا حيويًا لضمان الموثوقية والأداء. يجب على المشترين إعطاء الأولوية للتوافق مع طرازات السيارات المختلفة والنظر في الموردين الذين يقدمون ضمانات شاملة وشهادات جودة.

ما الدور الذي يلعبه ‘المولد الصيني’ في أنظمة الطاقة المتجددة؟

في مجال الطاقة المتجددة، يعد ‘المولد الصيني المولد’ ضروريًا لتحويل الطاقة الميكانيكية من توربينات الرياح أو الألواح الشمسية إلى طاقة كهربائية. عملية التحويل هذه ضرورية لتعزيز قدرات تخزين الطاقة وتوزيعها. يجب على المشترين في أفريقيا وأمريكا الجنوبية البحث عن مولدات تفي بمعايير الاعتماد لتطبيقات الطاقة المتجددة، مما يضمن المتانة والكفاءة. من المهم أيضًا تقييم قدرة المورد على توفير دعم الصيانة المستمرة، والتي يمكن أن تؤثر بشكل كبير على الكفاءة التشغيلية.

كيف يتم استخدام ‘المولد الصيني المولد’ في معدات البناء؟

في مجال البناء، يُستخدم ‘المولد الصيني المولد’ لتزويد الآلات الثقيلة بالطاقة الكهربائية، مما يضمن التشغيل المستمر حتى في مواقع العمل البعيدة. هذا التطبيق مفيد بشكل خاص في المناطق ذات الوصول المحدود إلى مصادر الطاقة المستقرة. يجب على المشترين مراعاة سعة حمل المولد ومقاومته للظروف البيئية القاسية. بالإضافة إلى ذلك، يمكن أن يساعد التوريد من الشركات المصنعة التي توفر خدمة قوية لما بعد البيع في تخفيف وقت التعطل وتعزيز الإنتاجية في مواقع البناء.

ما أهمية ‘المولد الصيني’ في التطبيقات البحرية؟

في التطبيقات البحرية، يوفر ‘المولد الصيني المولد’ الطاقة الكهربائية الأساسية لأنظمة الملاحة والمعدات على متن القوارب والسفن. تُعد الموثوقية في توليد الطاقة أمرًا بالغ الأهمية، حيث يمكن أن يؤدي الفشل إلى مخاطر كبيرة تتعلق بالسلامة. يجب أن يركز المشترون على تحديد مصادر المولدات المقاومة للتآكل والمتوافقة مع المعايير البحرية لضمان طول العمر والأداء في البيئات الصعبة. يعد فهم مواصفات الحجم والوزن أمرًا بالغ الأهمية أيضًا، حيث أن المساحة غالبًا ما تكون محدودة على متن السفن.

كيف يدعم ‘المولد الصيني’ الاتصالات السلكية واللاسلكية؟

بالنسبة للاتصالات السلكية واللاسلكية، فإن ‘المولدات الكهربائية الصينية’ جزء لا يتجزأ من أنظمة الطاقة الاحتياطية للأبراج الخلوية، مما يضمن عدم انقطاع الخدمة أثناء انقطاع التيار الكهربائي. هذه الموثوقية أمر بالغ الأهمية للحفاظ على شبكات الاتصالات، خاصة في المناطق النائية. يجب على المشترين تقييم متطلبات الجهد وكفاءة الطاقة عند تحديد مصادر المولدات، حيث تؤثر هذه العوامل بشكل مباشر على التكاليف التشغيلية. كما أن سهولة الاندماج في الأنظمة الحالية من الاعتبارات الرئيسية أيضًا، حيث يمكن أن تؤثر على وقت التركيب والتكاليف الإجمالية للمشروع.

3 نقاط ألم شائعة لدى المستخدمين لـ ‘المولدات الصينية’ وحلولها

السيناريو 1: توريد مولدات عالية الجودة لأسواق متنوعة

المشكلة: غالبًا ما يواجه المشترون بين الشركات تحديات في الحصول على مولدات كهربائية صينية عالية الجودة تفي بالمعايير الدولية. قد لا توفر العديد من الشركات المصنعة مواصفات شاملة، مما يؤدي إلى تباينات في الأداء والتوافق مع المركبات المحلية. في مناطق مثل أفريقيا وأمريكا الجنوبية، حيث يمكن أن تكون البنية التحتية غير متناسقة، تزداد مخاطر شراء منتجات دون المستوى بشكل كبير. وقد يؤدي ذلك إلى تأخيرات تشغيلية وزيادة تكاليف الصيانة وعدم رضا العملاء.

الحل: وللتخفيف من هذه المخاطر، يجب على المشترين إقامة علاقات قوية مع المصنعين ذوي السمعة الطيبة وإجراء العناية الواجبة الشاملة. ابدأ بطلب شهادات المنتج وتقارير الاختبار للتحقق من الامتثال للمعايير الدولية. انخرط في التواصل المباشر مع المصنعين لتوضيح المواصفات والتوافق مع طرازات معينة من المركبات. بالإضافة إلى ذلك، ضع في اعتبارك المشاركة في المعارض التجارية أو معارض الصناعة في الصين لبناء شبكات العلاقات وتقييم جودة المنتج بشكل مباشر. يمكن أن يضمن أيضًا استخدام خدمات الفحص من طرف ثالث قبل الشحن أن تفي المولدات بمعايير الجودة المطلوبة، مما يقلل في النهاية من مخاطر المرتجعات ويعزز ثقة العملاء.

السيناريو 2: تجاوز العوائق اللغوية في المواصفات الفنية

المشكلة: يمكن أن تشكل الحواجز اللغوية تحديات كبيرة عند التعامل مع الموردين الصينيين، خاصة فيما يتعلق بالمواصفات الفنية لمولدات التيار المتردد. يمكن أن تؤدي التفسيرات الخاطئة إلى طلبات لا تفي بالمعايير المطلوبة أو غير متوافقة مع الأنظمة الحالية. وتنتشر هذه المشكلة بشكل خاص بالنسبة للمشترين في الشرق الأوسط وأوروبا، حيث يعد التواصل التقني الدقيق أمرًا بالغ الأهمية لنجاح عملية الشراء.

الحل: للتغلب على العوائق اللغوية، يجب على المشترين من الشركات الاستثمار في خدمات الترجمة الاحترافية أو الاستعانة بموظفين ثنائيي اللغة يفهمون المصطلحات التقنية واللغة المحلية. عند صياغة المواصفات، من المفيد استخدام الوسائل البصرية مثل الرسوم البيانية أو الصور لنقل الأفكار المعقدة بشكل أوضح. بالإضافة إلى ذلك، فإن الاستفادة من منصات التكنولوجيا التي تسهل الترجمة في الوقت الحقيقي يمكن أن تعزز كفاءة التواصل. يمكن أن يؤدي تشجيع الموردين على توفير الوثائق والدعم بلغتين إلى سد الفجوة بشكل أكبر، مما يضمن أن يكون لدى جميع الأطراف فهم واضح لمتطلبات المنتج ويقلل من احتمالية حدوث أخطاء مكلفة.

السيناريو 3: التعامل مع دعم ما بعد البيع ومشاكل الضمان

المشكلة: يواجه العديد من المشترين بين الشركات صعوبات في الحصول على دعم ما بعد البيع وخدمات الضمان الموثوق بها لمولدات الكهرباء التي يتم توريدها من الصين. يمكن أن تؤدي شروط الضمان غير المتسقة أو ضعف الدعم إلى فترات تعطل طويلة وزيادة تكاليف التشغيل، خاصة في المناطق التي يصعب فيها الحصول على المساعدة الفنية. وغالبًا ما يجد المشترون في أوروبا وأمريكا الجنوبية أنفسهم عالقين دون الحصول على الدعم الكافي في حالة تعطل المنتج، مما يسبب الإحباط والخسارة المالية.

الحل: ولمعالجة هذه المشكلة، يجب على المشترين إعطاء الأولوية للموردين الذين يقدمون دعمًا قويًا لما بعد البيع وشروط ضمان واضحة. قبل إبرام العقود النهائية، من الضروري توضيح فترة الضمان والتغطية وعملية التعامل مع المطالبات. كما يمكن أن يساعد إنشاء قناة اتصال واضحة لدعم ما بعد البيع في حل المشكلات بسرعة. يجب على المشترين الاستفسار عما إذا كان لدى المورّد ممثلون أو شركاء محليون يمكنهم تقديم الخدمة والدعم في الوقت المناسب. بالإضافة إلى ذلك، فإن وضع خطة طوارئ تتضمن موردين أو خدمات إصلاح بديلة يمكن أن يساعد في تخفيف المخاطر المرتبطة بأعطال المنتج، مما يضمن سلاسة العمليات ورضا العملاء بشكل مستدام.

دليل اختيار المواد الاستراتيجية لمولد التيار المتردد الصيني

ما هي المواد الشائعة المستخدمة في المولدات الكهربائية الصينية؟

عند اختيار المواد اللازمة لمولدات التيار المتردد المصنعة في الصين، تدخل عدة عوامل في الاعتبار، بما في ذلك الأداء والتكلفة والامتثال للمعايير الدولية. فيما يلي تحليل لأربع مواد شائعة مستخدمة في إنتاج مولدات الكهرباء، مع التركيز على خصائصها ومزاياها وعيوبها واعتباراتها للمشترين الدوليين من الشركات.

1. ألومنيوم

الخصائص الرئيسية:

الألومنيوم خفيف الوزن ويتميز بتوصيل حراري وكهربائي ممتاز، مما يجعله مثاليًا لمكونات المولد. وتصل درجة انصهاره إلى 660 درجة مئوية تقريبًا ويتميز بمقاومة جيدة للتآكل، خاصةً عندما يكون مؤكسدًا.

الإيجابيات والسلبيات:

يتميز الألومنيوم بالمتانة والفعالية من حيث التكلفة، مما يجعله خيارًا شائعًا للعديد من المصنعين. ومع ذلك، يمكن أن يكون أقل متانة من المعادن الأخرى في ظل الظروف القاسية، وقد تتطلب عمليات تصنيعه تقنيات متخصصة، مما يزيد من التعقيد.

التأثير على التطبيق:

تعزز طبيعة الألومنيوم خفيفة الوزن من كفاءة استهلاك الوقود في المركبات، مما يجعله مناسبًا لتطبيقات السيارات. ومع ذلك، قد لا يكون مثاليًا للبيئات ذات درجات الحرارة العالية دون طلاء مناسب.

اعتبارات للمشترين الدوليين:

يجب على المشترين من مناطق مثل أفريقيا والشرق الأوسط ضمان الامتثال للوائح البيئية المحلية المتعلقة بإعادة تدوير الألومنيوم. كما قد تكون معايير مثل ASTM B221 لبثق الألومنيوم ذات صلة أيضاً.

2. نحاس

الخصائص الرئيسية:

يشتهر النحاس بخصائص التوصيل الكهربائي والحراري الممتازة. وله درجة انصهار عالية تبلغ حوالي 1,085 درجة مئوية وهو مقاوم للتآكل، خاصة في البيئات الجافة.

الإيجابيات والسلبيات:

وعلى الرغم من أن النحاس يوفر توصيلًا فائقًا، مما يجعله مثاليًا للملفات والتوصيلات في المولدات، إلا أنه أغلى من الألومنيوم. ويمكن أن يكون وزنه أيضاً عيباً في تطبيقات السيارات حيث يكون توفير الوزن أمراً بالغ الأهمية.

التأثير على التطبيق:

النحاس ضروري لمولدات المولدات عالية الأداء، خاصة في التطبيقات التي تتطلب نقل الطاقة بكفاءة. ومع ذلك، فإن تكلفته المرتفعة قد تحد من استخدامه في الأسواق الحساسة للميزانية.

اعتبارات للمشترين الدوليين:

يجب أن يكون المشترون بين الشركات على دراية بتقلبات أسعار النحاس في السوق والتعريفات المحتملة. وقد يكون من الضروري أيضًا الامتثال لمعايير مثل JIS H 3100 لسبائك النحاس، خاصة في اليابان والأسواق الآسيوية الأخرى.

3. الفولاذ

الخصائص الرئيسية:

يتميز الفولاذ بقوة الشد العالية والمتانة. ويمكنه تحمل درجات الحرارة والضغوط العالية، مما يجعله مناسبًا لمختلف المكونات الميكانيكية في المولدات.

الإيجابيات والسلبيات:

الفولاذ غير مكلف نسبيًا وسهل التصنيع، ولكنه أثقل من الألومنيوم ويمكن أن يكون عرضة للتآكل إذا لم تتم معالجته بشكل صحيح. وقد يؤثر ذلك على طول عمر المكونات المعرضة للبيئات القاسية.

التأثير على التطبيق:

وغالبًا ما يستخدم الفولاذ في المكونات الهيكلية لمولدات الكهرباء، مثل العلب والأقواس. يمكن أن يكون وزنه عيبًا في تطبيقات السيارات، حيث يكون تقليل وزن السيارة أولوية.

اعتبارات للمشترين الدوليين:

يجب على المشترين الدوليين النظر في الامتثال لمعايير مثل ASTM A36 للصلب الهيكلي. قد يحتاج المشترون من أوروبا أيضًا إلى الالتزام بلوائح الاتحاد الأوروبي فيما يتعلق بسلامة المواد والأثر البيئي.

4. المركبات البلاستيكية

الخصائص الرئيسية:

المركبات البلاستيكية خفيفة الوزن ومقاومة للتآكل ويمكن تشكيلها في أشكال معقدة. وعادةً ما يكون لها توصيل حراري وكهربائي أقل مقارنةً بالمعادن.

الإيجابيات والسلبيات:

هذه المواد فعالة من حيث التكلفة ويمكن أن تقلل من الوزن الإجمالي، ولكنها قد لا تتحمل درجات الحرارة العالية مثل المعادن. يمكن أن تختلف خواصها الميكانيكية بشكل كبير بناءً على التركيبة.

التأثير على التطبيق:

وغالبًا ما تستخدم المركبات البلاستيكية في المكونات غير الهيكلية لمولدات الكهرباء، مثل الأغطية والعوازل. وهي مناسبة للتطبيقات التي يكون فيها تقليل الوزن أمرًا بالغ الأهمية، ولكن يجب مراعاة محدوديتها في مقاومة الحرارة.

اعتبارات للمشترين الدوليين:

يجب على المشترين التأكد من امتثال المواد البلاستيكية للمعايير الدولية مثل ISO 9001 لإدارة الجودة. بالإضافة إلى ذلك، فإن فهم اللوائح البيئية المتعلقة باستخدام البلاستيك في مناطقهم أمر بالغ الأهمية.

جدول ملخص لاختيار المواد للمولدات الكهربائية الصينية

| المواد | حالة الاستخدام النموذجي لمولد المولد الصيني | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | السكن، الأقواس | خفيف الوزن وموصلية جيدة | أقل قوة في الظروف القاسية | متوسط |

| النحاس | اللفات والتوصيلات الكهربائية | توصيلية فائقة | تكلفة أعلى، أثقل | عالية |

| الصلب | المكونات الهيكلية | قوة عالية وفعالة من حيث التكلفة | أثقل وزناً، وعرضة للتآكل | منخفض |

| المركبات البلاستيكية | الأغطية والعوازل | خفيف الوزن ومقاوم للتآكل | مقاومة محدودة للحرارة | متوسط |

يقدم هذا الدليل نظرة عامة شاملة على اختيار المواد اللازمة لمولدات الكهرباء، مما يساعد المشترين الدوليين من الشركات على اتخاذ قرارات مستنيرة مع مراعاة المتطلبات والمعايير الإقليمية الخاصة بهم.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لمولدات المولدات الصينية

ما هي المراحل الرئيسية في عملية تصنيع المولدات الصينية؟

تنطوي عملية تصنيع المولدات الكهربائية في الصين على عدة مراحل حاسمة، كل منها مصممة لضمان إنتاج عالي الجودة. ويمكن أن يساعد فهم هذه المراحل المشترين الدوليين على تقييم موثوقية مورديهم.

تحضير المواد: ما هي المواد المستخدمة؟

الخطوة الأولى في تصنيع المولدات هي إعداد المواد الخام. وغالبًا ما يُستخدم النحاس عالي الجودة في اللفات نظرًا لتوصيلها الممتاز، بينما يُستخدم الفولاذ عادةً لمكونات الدوار والجزء الثابت. يجب على الموردين التأكد من أن المواد تفي بمعايير الجودة العالمية لتجنب المشاكل في الأداء والمتانة.

بالإضافة إلى ذلك، فإن استخدام المواد المتقدمة، مثل الألومنيوم عالي الجودة والسبائك الخاصة، يمكن أن يعزز الكفاءة وطول العمر. يجب على المشترين الاستفسار عن مصادر هذه المواد وما إذا كان الموردون يجرون اختبارات شاملة للمواد قبل الاستخدام.

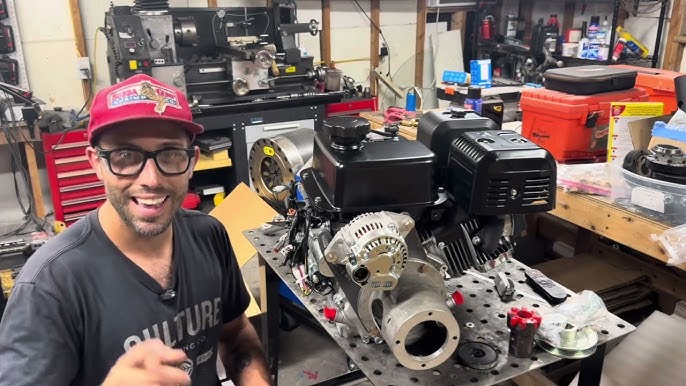

كيف يتم تشكيل المولدات أثناء التصنيع؟

بمجرد تحضير المواد، تكون المرحلة التالية هي التشكيل. وهذا ينطوي على تقنيات مختلفة مثل الختم والتشكيل والتشكيل الآلي لإنشاء المكونات الأساسية للمولد. على سبيل المثال، غالبًا ما يتم إنتاج الجزء الثابت والدوّار باستخدام الآلات الدقيقة لضمان الأبعاد الدقيقة وتقليل مخاطر الأعطال التشغيلية.

صورة توضيحية متعلقة بمولد المولد الصيني

كثيرًا ما يتم استخدام تقنيات متقدمة مثل التصنيع باستخدام الحاسب الآلي (التحكم العددي الحاسوبي) لتحقيق دقة عالية وإمكانية التكرار في الإنتاج. يجب على المشترين البحث عن المصنعين الذين يستخدمون هذه التقنيات لضمان جودة متسقة في منتجاتهم.

ما الذي تنطوي عليه عملية التجميع؟

يعد تجميع المولدات مرحلة حرجة تتطلب عمالة ماهرة ودقة. خلال هذه المرحلة، يتم تجميع جميع المكونات - بما في ذلك الدوار والجزء الثابت والثنائيات والمبيت. تعتبر المحاذاة الصحيحة أمرًا بالغ الأهمية، حيث يمكن أن يؤدي عدم المحاذاة الصحيحة إلى عدم الكفاءة والأعطال المحتملة في تشغيل المولد.

يمكن أن يشمل ضمان الجودة في هذه المرحلة اختبار عزم الدوران على أدوات التثبيت الحرجة وعمليات الفحص البصري لضمان التجميع السليم. يجب على المشترين بين الشركات النظر في سؤال الموردين عن بروتوكولات التجميع الخاصة بهم وما إذا كانوا يدمجون أنظمة آلية لتعزيز الاتساق.

ما هي تقنيات التشطيب المطبقة؟

تُعد عمليات التشطيب ضرورية لتحسين كل من جماليات ووظائف المولدات الكهربائية. وعادةً ما يتم استخدام تقنيات مثل الطلاء والطلاء والطلاء لحماية المكونات من التآكل والتآكل. تتضمن عملية التشطيب أيضًا فحوصات الجودة لضمان سلاسة جميع الأسطح وخلوها من العيوب.

يجب على المشترين الاستفسار عن أنواع الطلاءات المستخدمة ومقاومتها للعوامل البيئية، حيث يمكن أن يؤثر ذلك بشكل كبير على طول عمر المولد في مختلف المناخات.

صورة توضيحية متعلقة بمولد المولد الصيني

ما هي المعايير الدولية التي تحكم ضمان جودة المولدات الكهربائية الصينية؟

يعد ضمان الجودة أمرًا بالغ الأهمية في تصنيع المولدات الكهربائية، خاصةً بالنسبة للمشترين الدوليين من الشركات. وتحكم العديد من المعايير الدولية هذه العمليات، مما يضمن استيفاء المنتجات لمعايير الأداء والسلامة المحددة.

ما هي معايير ISO التي يجب أن يكون المشترون على دراية بها؟

ISO 9001 هو أكثر معايير إدارة الجودة المعترف بها التي تنطبق على المصنعين في جميع أنحاء العالم، بما في ذلك إنتاج المولدات الكهربائية في الصين. يركز هذا المعيار على الجودة المتسقة ورضا العملاء من خلال نهج منظم للإدارة والتحسين المستمر.

يمكن للمصنعين أيضًا الالتزام بمعيار ISO/TS 16949، الذي يستهدف تحديدًا صناعة السيارات ويركز على منع العيوب والحد من التباين والهدر في سلسلة التوريد.

هل هناك شهادات خاصة بالصناعة يجب أخذها في الاعتبار؟

وبالإضافة إلى معايير الجودة العامة، قد تكون الشهادات المحددة مثل شهادة المطابقة الأوروبية (CE) وشهادة معهد البترول الأمريكي (API) ذات صلة اعتمادًا على الاستخدام المقصود لمولدات التيار المتردد. تشير شهادة CE إلى أن المنتج يفي بمتطلبات السلامة والصحة والبيئة الخاصة بالاتحاد الأوروبي، بينما تضمن شهادة API أن المنتجات تفي بمعايير الصناعة للأداء والموثوقية.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في التصنيع؟

تعتبر نقاط التحقق من مراقبة الجودة (QC) ضرورية للحفاظ على سلامة عملية التصنيع. وتشمل المراحل الرئيسية ما يلي:

-

مراقبة الجودة الواردة (IQC): وتتضمن نقطة الفحص الأولية هذه فحص المواد الخام للتأكد من مطابقتها للمواصفات قبل دخولها في عملية الإنتاج.

-

مراقبة الجودة أثناء الإنتاج (IPQC): أثناء التصنيع، يتم إجراء فحوصات منتظمة لضمان التزام الإنتاج بمعايير الجودة. وقد يشمل ذلك مراقبة التفاوتات المسموح بها وإجراء اختبارات وظيفية على المكونات.

-

مراقبة الجودة النهائية (FQC): بعد التجميع، يتم إجراء فحص شامل للتحقق من أن المنتج النهائي يفي بجميع المواصفات ومعايير الجودة قبل الشحن.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

بالنسبة للمشترين الدوليين، يعد التحقق من عمليات مراقبة الجودة لدى الموردين أمرًا حيويًا لضمان موثوقية المنتج والامتثال للمعايير. وفيما يلي بعض الاستراتيجيات:

ما الدور الذي تلعبه عمليات التدقيق في التحقق من الموردين؟

يمكن أن يوفر إجراء عمليات التدقيق للموردين المحتملين رؤى قيمة حول عمليات التصنيع وتدابير مراقبة الجودة الخاصة بهم. وينبغي للمشترين النظر في جدولة عمليات التدقيق في الموقع أو طلب تقارير تدقيق مفصلة لتقييم مدى الامتثال للمعايير الدولية.

ما مدى أهمية عمليات التفتيش من قبل طرف ثالث؟

يمكن أن يؤدي استخدام خدمات التفتيش من طرف ثالث إلى زيادة التحقق من صحة ادعاءات المورد فيما يتعلق بعمليات مراقبة الجودة الخاصة به. ويمكن لهذه المنظمات المستقلة إجراء عمليات تفتيش شاملة في مختلف مراحل التصنيع، مما يوفر تقييمًا غير متحيز لجودة المنتج.

ما هي اعتبارات مراقبة الجودة الفريدة للأسواق الدولية؟

يجب أن يكون المشترون بين الشركات من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا على دراية بالفروق الدقيقة في مراقبة الجودة التي قد تؤثر على قرارات الشراء الخاصة بهم.

كيف تؤثر الاختلافات الثقافية على توقعات الجودة؟

يمكن أن تؤثر الاختلافات الثقافية على توقعات الجودة والتواصل فيما يتعلق بمواصفات المنتج. يجب على المشترين تحديد متطلباتهم بوضوح والتأكد من أن الموردين يفهمون هذه التوقعات بشكل كامل لتجنب التناقضات.

ما هي التحديات اللوجستية وتحديات الامتثال؟

كما أن التعامل مع الخدمات اللوجستية والامتثال للوائح التنظيمية المحلية يمكن أن يشكل تحديات أيضاً. يجب على المشترين التحقق من أن الموردين على دراية بالمشهد التنظيمي في الأسواق المستهدفة والتأكد من أن المنتجات متوافقة مع المعايير المحلية.

من خلال فهم عمليات التصنيع وممارسات ضمان الجودة الخاصة بمولدات الطاقة الكهربائية الصينية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة تتماشى مع احتياجاتهم التشغيلية وتوقعات الجودة.

دليل عملي للمصادر: قائمة تدقيق خطوة بخطوة لـ ‘المولد الصيني’

لمساعدة المشترين الدوليين بين الشركات في الحصول على مصادر المولدات الكهربائية الصينية بفعالية، يحدد هذا الدليل قائمة مرجعية عملية. باتباع هذه الخطوات، يمكنك ضمان عملية شراء مبسطة وتأمين منتجات عالية الجودة تلبي احتياجات عملك.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

حدد بوضوح المتطلبات الفنية للمولدات التي تحتاجها. وهذا يشمل خرج الطاقة والحجم والتوافق مع الأنظمة الحالية وأي شهادات محددة مطلوبة. سيساعد وجود مواصفات دقيقة في التواصل الفعال مع الموردين وضمان أن المنتجات تلبي احتياجاتك التشغيلية.

- متطلبات الطاقة: حدد معدلات الجهد والتيار.

- سياق التطبيق: حدِّد ما إذا كانت المولدات مخصصة للسيارات أو للاستخدامات الصناعية أو غيرها من الاستخدامات.

الخطوة 2: البحث عن الموردين المحتملين

قم بإجراء بحث شامل لتحديد الموردين ذوي السمعة الطيبة في الصين. استخدم المنصات الإلكترونية والأدلة التجارية ومنتديات الصناعة لتجميع قائمة بالمصنعين المحتملين. هذه الخطوة ضرورية للتأكد من أنك تتعامل مع شركات راسخة قادرة على تقديم منتجات عالية الجودة.

- سمعة الصناعة: ابحث عن المراجعات والشهادات من العملاء السابقين.

- التواجد في السوق: ضع في اعتبارك الموردين الذين لهم حضور طويل الأمد في السوق.

الخطوة 3: تقييم شهادات الموردين

قبل وضع اللمسات الأخيرة على المورّد، تحقق من امتلاكه للشهادات ومعايير الجودة اللازمة. تشير الشهادات مثل ISO 9001 أو TS16949 إلى أن الشركة المصنعة تلتزم بمعايير إدارة الجودة الدولية، وهو أمر حيوي لضمان موثوقية المنتج وأدائه.

- ضمان الجودة: اطلب توثيق عمليات مراقبة الجودة الخاصة بهم.

- الامتثال: التأكد من أن المنتجات تفي بلوائح السلامة والبيئة الإقليمية.

الخطوة 4: طلب عينات من المنتجات

اطلب دائمًا عينات من المولدات قبل تقديم طلب بالجملة. يتيح لك ذلك تقييم جودة المنتجات وأدائها بشكل مباشر. يساعد اختبار العينات على تخفيف المخاطر المرتبطة بعمليات الشراء على نطاق واسع.

صورة توضيحية متعلقة بمولد المولد الصيني

- اختبار الأداء: تحقق من خرج الطاقة والكفاءة في ظل ظروف واقعية.

- تقييم المتانة: قم بتقييم المواد والبناء من حيث طول العمر الافتراضي.

الخطوة 5: التفاوض على الشروط والأسعار

بمجرد تحديد المورد المناسب، ادخل في مفاوضات بشأن الأسعار وشروط الدفع وجداول التسليم. يمكن للاتفاقات الواضحة بشأن هذه الجوانب أن تمنع سوء الفهم وتضمن سلاسة الصفقة.

- خصومات على الكميات الكبيرة: استفسر عن مستويات الأسعار بناءً على حجم الطلب.

- ضمان الدفع: ضع في اعتبارك استخدام طرق دفع آمنة لحماية معاملتك.

الخطوة 6: إنشاء قنوات الاتصال

التواصل الفعال هو المفتاح طوال عملية التوريد. تأكد من إنشاء قنوات موثوقة للحوار المستمر مع المورد الخاص بك. وهذا أمر مهم لمعالجة أي مخاوف قد تنشأ أثناء الإنتاج أو الشحن.

- دعم اللغة: إذا لزم الأمر، فكر في الاستعانة بمترجم أو الاستعانة بموظفين يتحدثون لغتين لتسهيل المناقشات.

- تحديثات منتظمة: اطلب تحديثات منتظمة عن حالة الإنتاج والجداول الزمنية للشحن.

الخطوة 7: خطة الخدمات اللوجستية والجمارك

وأخيراً، استعد للخدمات اللوجستية التي ينطوي عليها استيراد مولدات الكهرباء من الصين. وهذا يشمل ترتيب الشحن وفهم اللوائح الجمركية والتخطيط للتعريفات المحتملة. يمكن للإدارة اللوجستية السليمة توفير الوقت وتقليل التكاليف.

- خيارات الشحن: تقييم طرق الشحن المختلفة من حيث فعالية التكلفة وسرعة التسليم.

- الامتثال الجمركي: تعرّف على لوائح الاستيراد في بلدك لتجنب التأخير.

من خلال اتباع قائمة المراجعة هذه، يمكن للمشترين بين الشركات التعامل مع تعقيدات توريد مولدات الكهرباء من الصين بمزيد من الثقة والكفاءة.

تحليل شامل للتكاليف والتسعير لمصادر المولدات الصينية للمولدات الكهربائية

ما هي مكونات التكلفة الرئيسية في توريد المولدات الصينية؟

عند توريد مولدات الكهرباء من الصين، يعد فهم هيكل التكلفة أمرًا ضروريًا لوضع ميزانية فعالة. وتشمل مكونات التكلفة الأساسية ما يلي:

-

المواد: يؤثر اختيار المواد بشكل مباشر على جودة وتكلفة المولدات الكهربائية. وتشمل المواد الشائعة النحاس والألومنيوم ومختلف المواد البلاستيكية، والتي يمكن أن تتقلب أسعارها حسب ظروف السوق.

-

العمل: تكاليف العمالة في الصين أقل بشكل عام من العديد من الدول الغربية، ولكنها تختلف حسب المنطقة ونوع المصنع. يمكن أن تضيف العمالة الماهرة للتجميع ومراقبة الجودة إلى التكلفة.

-

تكاليف التصنيع العامة: يشمل ذلك التكاليف غير المباشرة المرتبطة بالإنتاج، مثل مرافق المصنع واستهلاك المعدات والمصروفات الإدارية. وعادةً ما يكون للمصانع ذات الكفاءة نفقات عامة أقل، مما قد يؤثر إيجابًا على التسعير.

-

الأدوات: يمكن أن تكون تكاليف الأدوات كبيرة، خاصة بالنسبة للمولدات المخصصة. فالقوالب والقوالب عالية الجودة مطلوبة للإنتاج بكميات كبيرة، وينبغي أخذ هذه التكاليف في الحسبان في السعر الإجمالي.

-

مراقبة الجودة (QC): يضمن تنفيذ عمليات مراقبة الجودة القوية استيفاء المولدات للمعايير الدولية، وهو ما قد يضيف إلى التكاليف الأولية ولكنه أمر بالغ الأهمية للحفاظ على موثوقية المنتج.

-

اللوجستيات: يمكن أن تختلف تكاليف الشحن من الصين إلى بلد المقصد اختلافًا كبيرًا بناءً على المسافة وطريقة الشحن وأسعار الشحن الحالية. يُنصح بالنظر في كل من خيارات الشحن الجوي والبحري.

-

الهامش: يقوم الموردون عادةً بتضمين هامش ربح في تسعيرهم، والذي يمكن أن يختلف بناءً على وضعهم في السوق والمنافسة والعلاقة مع المشتري.

كيف تؤثر العوامل المؤثرة في الأسعار على تكلفة المولدات؟

هناك عدة عوامل تؤثر على أسعار مولدات التيار المتردد التي يتم توريدها من الصين:

-

الحجم/الحد الأدنى للطلب: يمكن أن يؤثر الحد الأدنى لكميات الطلبات (MOQs) بشكل كبير على الأسعار. فغالباً ما تؤدي الطلبات الأكبر حجماً إلى تخفيضات حيث يستفيد الموردون من وفورات الحجم.

-

المواصفات والتخصيص: عادةً ما تتكبد مولدات المولدات المصممة خصيصًا أو تلك التي لها متطلبات تقنية محددة تكاليف أعلى بسبب زيادة التعقيدات الهندسية والإنتاجية.

-

المواد: لا يؤثر اختيار المواد على التكلفة فحسب، بل يؤثر أيضًا على أداء المولد ومتانته. وقد تؤدي المواد الممتازة إلى ارتفاع التكاليف الأولية ولكنها يمكن أن تقلل من إجمالي تكاليف الملكية مع مرور الوقت.

-

شهادات الجودة: يمكن أن يؤدي الامتثال لمعايير الجودة الدولية (مثل ISO، CE) إلى زيادة تكاليف الإنتاج ولكنه ضروري للمشترين في الأسواق المنظمة.

-

عوامل الموردين: تلعب سمعة المورد وموثوقيته دوراً حاسماً في التسعير. وقد يتقاضى الموردون الراسخون ذوو السجل الحافل أسعاراً أعلى ولكنهم غالباً ما يقدمون ضماناً أفضل للجودة والخدمة.

-

مصطلحات التجارة الدولية: يمكن أن تؤثر شروط التجارة الدولية المتفق عليها على التكلفة النهائية، حيث أنها تحدد من يتحمل مسؤولية الشحن والتأمين والتعريفات.

ما هي نصائح المشتري الفعالة لتوريد المولدات الكهربائية من الصين؟

بالنسبة للمشترين الدوليين بين الشركات، لا سيما من أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، إليك بعض النصائح العملية:

-

التفاوض على الأسعار: لا تتردد في التفاوض على الشروط مع الموردين. ففهم ظروف السوق وتقديم عروض تنافسية يمكن أن يؤدي إلى تسعير أفضل.

-

التركيز على كفاءة التكلفة: تقييم ليس فقط سعر الوحدة ولكن أيضًا التكلفة الإجمالية للملكية، والتي تشمل تكاليف الصيانة والاستبدال. وفي بعض الأحيان، يمكن أن يؤدي الاستثمار الأولي الأعلى إلى وفورات طويلة الأجل.

-

فهم الفروق الدقيقة في الأسعار: يمكن أن تختلف الأسعار بشكل كبير بناءً على طلب السوق وجداول الإنتاج. ويمكن أن تساعد مواكبة هذه الاتجاهات في توقيت عمليات الشراء للحصول على أفضل الأسعار.

-

تقييم علاقات الموردين: يمكن أن يؤدي بناء علاقات قوية مع الموردين إلى تسعير أفضل، وأولوية في جدولة الإنتاج، وتحسين التواصل أثناء عملية التوريد.

-

إجراء بحث شامل: تحقق من خلفيات الموردين المحتملين ومراجعاتهم وأدائهم السابق لضمان الموثوقية. فكر في زيارة المصانع أو إجراء عمليات تدقيق إن أمكن.

إخلاء المسؤولية بشأن الأسعار الإرشادية

يمكن أن تتقلب أسعار المولدات التي يتم توريدها من الصين بناءً على عوامل مختلفة، بما في ذلك اتجاهات السوق وتكاليف المواد واستراتيجيات تسعير الموردين. لذلك، من الضروري أن يقوم المشترون بإجراء بحث شامل والحصول على عروض أسعار محدثة لضمان وضع ميزانية دقيقة.

تحليل البدائل: مقارنة المولد الصيني بالحلول الأخرى

فهم البدائل في حلول المولدات

في المشهد التنافسي للمكونات الكهربائية، لا سيما للمركبات، فإن الحاجة إلى حلول توليد الطاقة الفعالة والموثوقة أمر بالغ الأهمية. في حين أن منتجات ‘المولدات الصينية’ توفر خيارًا مقنعًا، إلا أنه من المفيد للمشترين الدوليين من الشركات النظر في حلول بديلة قد توفر أداءً محسنًا أو فعالية من حيث التكلفة أو سهولة التنفيذ. يقارن هذا التحليل ‘المولد الصيني’ مع بديلين بارزين: ‘المولدات المحلية’ و‘المولدات الهجينة’.’

صورة توضيحية متعلقة بمولد المولد الصيني

جدول المقارنة

| جانب المقارنة | المولد صيني | المولدات المحلية | المولدات الهجينة |

|---|---|---|---|

| الأداء | كفاءة عالية؛ خرج تيار متردد | كفاءة قابلة للمقارنة؛ خرج تيار متردد | متعدد الاستخدامات؛ مخرج تيار متردد ومخرج تيار مستمر |

| التكلفة | تكلفة أقل بشكل عام | متوسطة إلى عالية التكلفة | استثمار أولي أعلى |

| سهولة التنفيذ | التثبيت البسيط | يمكن أن يكون التثبيت معقداً | تتطلب معرفة متخصصة |

| الصيانة | صيانة منخفضة مطلوبة | احتياجات صيانة معتدلة | الصيانة الدورية المطلوبة |

| أفضل حالة استخدام | الاستخدام القياسي للسيارات | مركبات عالية الأداء | تطبيقات خارج الشبكة أو متنقلة |

تفصيل البدائل

المولدات المحلية

توفر المولدات المحلية، التي غالباً ما تنتجها الشركات المصنعة المحلية في مختلف البلدان، بديلاً تنافسياً لنظيراتها الصينية. وعادةً ما تقدم مستويات أداء مماثلة ولكنها قد تكون مصممة مع مراعاة الظروف المحلية، مما قد يؤدي إلى تعزيز الموثوقية. ومع ذلك، يمكن أن تكون التكلفة أعلى بسبب نفقات الإنتاج المحلية والتعريفات الجمركية، مما قد يؤثر على المشترين المهتمين بالميزانية. وقد يتطلب تركيبها أيضاً خبرة محددة، مما يجعلها أقل متاحة لجميع المستخدمين.

المولدات الهجينة

تمثل المولدات الهجينة حلاً حديثًا يجمع بين تقنيات المولدات التقليدية ومصادر الطاقة المتجددة. وهي مصممة لتوفير كل من مخرجات التيار المتردد والتيار المستمر، مما يجعلها متعددة الاستخدامات لمختلف التطبيقات، من الاستخدام السكني إلى الاستخدام الصناعي. وعادةً ما يكون الاستثمار الأولي أعلى من الاستثمار في المولدات التقليدية، كما أنها تتطلب صيانة دورية لضمان الأداء الأمثل. ومع ذلك، فإن قدرتها على العمل في حالات خارج الشبكة وتقليل استهلاك الوقود تجعلها خياراً جذاباً للمشترين الذين يبحثون عن حلول مستدامة.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

عند تقييم بدائل ‘مولد المولد الصيني’، يجب على المشترين بين الشركات النظر في متطلباتهم المحددة، بما في ذلك قيود الميزانية، وقدرات التركيب، والاستخدام المقصود لمولد المولد. في حين أن منتجات ‘المولد الصيني المولد’ تقدم حلاً فعالاً من حيث التكلفة وفعالاً لاحتياجات السيارات القياسية، قد توفر المولدات المحلية والمولدات الهجينة مزايا إضافية للتطبيقات المتخصصة أو المشاريع الموجهة نحو الأداء. وفي النهاية، سيعتمد الاختيار الصحيح على الموازنة بين الأداء والتكلفة وسهولة التنفيذ لتلبية المتطلبات الفريدة للبيئة التشغيلية لكل مشترٍ.

الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية لمولد المولدات الصينية

ما هي الخصائص التقنية الرئيسية للمولدات الكهربائية من الصين؟

عند التفكير في شراء مولدات التيار المتردد من الشركات المصنعة الصينية، من الضروري فهم المواصفات الفنية الهامة. فيما يلي بعض أهم الخصائص التي يجب تقييمها:

-

درجة المواد

يتم تصنيع المولدات عادةً من مواد عالية الجودة مثل الألومنيوم والنحاس. تؤثر درجة المواد على المتانة والوزن والكفاءة. ويضمن استخدام مواد عالية الجودة طول العمر والأداء الأمثل، وهو أمر بالغ الأهمية للاستخدامات الشاقة مثل المركبات التجارية. -

ناتج الطاقة (القوة الكهربائية)

يشير تصنيف خرج الطاقة لمولد المولد إلى قدرته على توليد الكهرباء، ويقاس بالواط أو الأمبير. هذه المواصفات ضرورية لمطابقة المولد مع متطلبات السيارة الكهربائية. يجب أن يتأكد المشترون من أن خرج المولد متوافق مع بطارية السيارة ونظامها الكهربائي لتجنب ضعف الأداء. -

مستويات التسامح

يشير التفاوت المسموح به إلى الحد المسموح به من التباين في بُعد مادي أو قيمة مقيسة. تعتبر مستويات التفاوت المسموح بها في مكونات المولد (مثل المحامل واللفات) ضرورية لضمان التشغيل السلس وتقليل البلى والتلف. وهذا مهم بشكل خاص في التطبيقات عالية الأداء حيث تؤثر الدقة على الكفاءة والموثوقية. -

تصنيف الكفاءة

تشير تصنيفات الكفاءة إلى مدى فعالية المولد في تحويل الطاقة الميكانيكية إلى طاقة كهربائية. ويعني ارتفاع معدل الكفاءة تقليل الطاقة المهدرة، مما يعني توفيرًا أفضل في استهلاك الوقود وخفض التكاليف التشغيلية. وهذا أمر جذاب بشكل خاص للمشترين من الشركات الذين يتطلعون إلى تحسين أداء أسطولهم. -

آلية التبريد

يمكن لآلية التبريد المستخدمة في المولد أن تؤثر بشكل كبير على أدائه وعمره الافتراضي. قد تحتوي المولدات على أنظمة تبريد بالهواء أو أنظمة تبريد بالسائل. يعد فهم طريقة التبريد أمرًا بالغ الأهمية للتطبيقات التي سيعمل فيها المولد في بيئات ذات درجة حرارة عالية، حيث إنها تؤثر بشكل مباشر على الموثوقية وفترات الصيانة. -

مواصفات التركيب

للمركبات المختلفة متطلبات تركيب محددة لمولدات التيار المتردد. يجب على المشترين التحقق من مواصفات التركيب لضمان التوافق مع طراز المركبة المقصودة. ويشمل ذلك الأبعاد وأنماط البراغي وأنواع التوصيلات، والتي يمكن أن تختلف بشكل كبير بين الشركات المصنعة.

ما هي المصطلحات التجارية الشائعة في صناعة المولدات؟

يعد فهم المصطلحات الصناعية أمرًا ضروريًا للتواصل والتفاوض الفعال مع الموردين. فيما يلي بعض المصطلحات التجارية الشائعة المرتبطة بمولدات التيار المتردد:

-

OEM (الشركة المصنعة للمعدات الأصلية)

يشير مصطلح OEM إلى الشركات التي تنتج المكونات التي يتم بيعها إلى شركة أخرى، والتي تقوم بعد ذلك ببيعها تحت علامتها التجارية الخاصة. في سوق المولدات الكهربائية، غالبًا ما يتم تفضيل قطع غيار مصنعي المعدات الأصلية لتوافقها المضمون وضمان جودتها. -

MOQ (الحد الأدنى لكمية الطلب)

موك هو أصغر عدد من الوحدات التي يرغب المورد في بيعها في طلب واحد. ويعد فهم موك أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات لضمان قدرتهم على تلبية متطلبات الموردين مع الاستمرار في إدارة المخزون بفعالية. -

طلب عرض أسعار (RFQ)

طلب عرض الأسعار هو مستند يتم إرساله إلى الموردين لطلب تسعير وشروط لمنتجات محددة، وهي في هذه الحالة مولدات الكهرباء. يمكن أن تساعد صياغة طلب عرض أسعار شامل المشترين في الحصول على أسعار تنافسية وفهم شروط البيع. -

مصطلحات التجارة الدولية

تحدد شروط التجارة الدولية أو الشروط التجارية الدولية مسؤوليات المشترين والبائعين في المعاملات الدولية. بالنسبة لمشتريات المولدات الكهربائية، يساعد فهم شروط التجارة الدولية مثل FOB (مجاناً على متن السفينة) أو CIF (تكلفة التأمين والشحن) على توضيح تكاليف الشحن والمخاطر ومسؤوليات التسليم. -

المهلة الزمنية

تشير المهلة الزمنية إلى الوقت المستغرق من تقديم الطلب إلى استلام المنتج. وهذا مهم بشكل خاص في سوق المولدات الكهربائية، حيث يمكن أن يؤثر التسليم في الوقت المناسب على جداول الإنتاج والكفاءة التشغيلية. -

شروط الضمان

توضح شروط الضمان بالتفصيل الشروط التي يمكن بموجبها إصلاح المنتج أو استبداله في حالة تعطله. يعد فهم تغطية الضمان لمولدات التيار المتردد أمرًا ضروريًا لتخفيف المخاطر وضمان الرضا عن الشراء على المدى الطويل.

من خلال فهم هذه الخصائص التقنية والشروط التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة عند الحصول على مولدات الكهرباء من الشركات المصنعة الصينية، مما يضمن تلبية احتياجاتهم التشغيلية وأهدافهم التجارية.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع المولدات الكهربائية الصينية

ما هي ديناميكيات السوق الحالية والاتجاهات الرئيسية في قطاع المولدات الصينية؟

تشهد السوق العالمية لمولدات التيار المتردد نموًا قويًا مدفوعًا بالطلب المتزايد من مختلف القطاعات، لا سيما قطاع السيارات والطاقة المتجددة. في الأسواق الناشئة مثل أفريقيا وأمريكا الجنوبية، تتوسع صناعة السيارات بسرعة، مما يتطلب إمدادات ثابتة من المولدات الكهربائية الموثوقة. وبالمثل، تشهد منطقة الشرق الأوسط وأوروبا انتعاشًا في إنتاج السيارات واعتماد السيارات الكهربائية (EV)، مما يزيد من الطلب على مولدات الطاقة المتجددة عالية الجودة.

تشمل الاتجاهات الرئيسية ظهور السيارات الكهربائية والهجينة، والتي تتطلب تكنولوجيا المولدات المتقدمة لإدارة الطاقة بكفاءة. بالإضافة إلى ذلك، تركز الشركات المصنعة بشكل متزايد على التصاميم المدمجة خفيفة الوزن التي تعزز كفاءة استهلاك الوقود مع الحفاظ على الأداء. وتكتسب الابتكارات في المواد، مثل استخدام الألومنيوم والمواد المركبة، زخماً متزايداً، مما يسمح بإدارة حرارية ومتانة أفضل.

يجب أن يكون المشترون الدوليون بين الشركات على دراية بالمشهد التنافسي في الصين، التي تعد موطنًا للعديد من المصنعين المتخصصين في مولدات الكهرباء. من الضروري الحصول على مصادر استراتيجية من موردين موثوقين، حيث يمكن أن تؤثر الاختلافات في الجودة بشكل كبير على أداء المنتج. يجب على المشترين أيضاً أن يفكروا في الاستفادة من المنصات التكنولوجية لتعزيز الشفافية في سلسلة التوريد، مما يتيح تحسين التفاوض وإدارة المخاطر.

كيف يمكن أن تؤثر الاستدامة والتوريد الأخلاقي على الشراء بين الشركات في قطاع المولدات الكهربائية؟

أصبحت الاستدامة اعتبارًا محوريًا في سوق المولدات الكهربائية العالمية. ويخضع التأثير البيئي لعمليات التصنيع، لا سيما فيما يتعلق بالنفايات والانبعاثات، للتدقيق. ويعطي المشترون الدوليون الأولوية بشكل متزايد للموردين الذين يظهرون التزامًا بالممارسات المستدامة. ويشمل ذلك استخدام مواد صديقة للبيئة، وتحسين استهلاك الطاقة أثناء الإنتاج، وتقليل النفايات إلى الحد الأدنى.

كما أن التوريد الأخلاقي مهم بنفس القدر، خاصة بالنسبة للشركات التي تتطلع إلى تأسيس سمعة قوية لعلامتها التجارية. فالمورّدون الذين يلتزمون بممارسات العمل الأخلاقية ويحافظون على الشفافية في عملياتهم من المرجح أن يعززوا الشراكات طويلة الأجل. تُعد شهادات مثل ISO 14001 (الإدارة البيئية) وISO 45001 (الصحة والسلامة المهنية) مؤشرات قيّمة على التزام المورد بالاستدامة والممارسات الأخلاقية.

وبالإضافة إلى ذلك، يكتسب اعتماد المواد ‘الخضراء’، مثل المكونات القابلة لإعادة التدوير والمواد غير السامة، زخمًا في تصنيع مولدات التيار المتردد. يجب أن يبحث المشترون بنشاط عن الموردين الذين يمكنهم تقديم شهادات لهذه المواد، مما يضمن توافق عمليات الشراء الخاصة بهم مع أهداف الاستدامة الأوسع نطاقاً.

ما هو تطور سوق المولدات الصينية وأهميتها بالنسبة للمشترين بين الشركات؟

تطورت سوق مولدات التيار المتردد الصينية بشكل كبير على مدى العقود القليلة الماضية، بالتوازي مع التصنيع السريع وازدهار السيارات في البلاد. وقد تحول القطاع الذي كان يركز في البداية على التصنيع الأساسي، نحو التكنولوجيا المتقدمة والابتكار، حيث ينتج المصنعون الصينيون الآن مولدات كهربائية عالية الجودة تلبي المعايير الدولية.

ويكتسب هذا التطور أهمية خاصة بالنسبة للمشترين بين الشركات، حيث يشير إلى الانتقال من مجرد التوريد القائم على التكلفة إلى نهج أكثر دقة يقدّر الجودة والابتكار والاستدامة. ومع استمرار المصنعين الصينيين في الاستثمار في البحث والتطوير، تزداد قدرتهم على تقديم حلول مخصصة تلبي احتياجات السوق المحددة. يمثل هذا الاتجاه فرصة للمشترين الدوليين للاستفادة من قدرات التصنيع الصينية مع ضمان توافقها مع معاييرهم التشغيلية والأخلاقية.

باختصار، يمكن أن يؤدي فهم ديناميكيات سوق المولدات الكهربائية الصينية، إلى جانب التركيز على الاستدامة والتوريد الأخلاقي، إلى تعزيز استراتيجيات الشراء للمشترين الدوليين بين الشركات بشكل كبير.

الأسئلة المتداولة (FAQs) لمشتري B2B لمولد المولد الصيني

1. كيف أختار مورد مولد التيار المتردد المناسب في الصين؟

يتضمن اختيار مورد المولد المناسب إجراء بحث وتقييم شاملين. ابدأ بمراجعة أوراق اعتماد المورد، مثل شهادات الاعتماد (ISO، CE) والخبرة في المجال. تحقق من مراجعات العملاء ودراسات الحالة لقياس موثوقيتها. بالإضافة إلى ذلك، اطلب عينات لتقييم جودة المنتج وأدائه. قم بإجراء اتصالات مباشرة لمناقشة احتياجاتك المحددة، بما في ذلك خيارات التخصيص والمهل الزمنية ودعم ما بعد البيع. يجب أن يتحلى المورد حسن السمعة بالشفافية بشأن عمليات التصنيع وبروتوكولات ضمان الجودة.

2. ما هي المواصفات الشائعة التي يجب أخذها في الاعتبار عند الحصول على مولدات المولدات؟

عند الحصول على مولدات التوليد، ضع في اعتبارك مواصفات مثل خرج الجهد (عادةً 12 فولت أو 24 فولت)، وتصنيف الأمبير، والحجم، والوزن. بالإضافة إلى ذلك، تحقق من توافق المولد مع التطبيق المقصود، سواء كان للاستخدام في السيارات أو الصناعة أو الاستخدام البحري. ابحث عن ميزات مثل معدلات الكفاءة والمتانة في ظل الظروف البيئية المختلفة. إذا كان التخصيص مطلوبًا، ناقش التعديلات لتلبية متطلبات تشغيلية محددة، مثل تكوينات التركيب أو التوصيلات الكهربائية.

3. ما هو الحد الأدنى لكمية الطلب (موك) الذي يجب أن أتوقعه عند شراء مولدات التيار المتردد؟

يمكن أن تتباين موك لمولدات التيار المتردد تباينًا كبيرًا اعتمادًا على المورد والمنتج المحدد. عادة، قد يحدد المصنعون الصينيون عادةً موكوك تتراوح بين 50 إلى 500 وحدة. ومع ذلك، قد يقدم بعض الموردين مرونة للمشترين لأول مرة أو الشركات الصغيرة. يُنصح بالإبلاغ عن احتياجاتك مقدمًا والتفاوض على موك على أساس قدرتك الشرائية. ضع في اعتبارك أن انخفاض موك قد يؤدي إلى ارتفاع تكاليف الوحدة الواحدة، لذا ضع في اعتبارك ميزانيتك واستراتيجية الشراء طويلة الأجل.

4. كيف يمكنني ضمان جودة المولدات التي أطلبها من الصين؟

لضمان الجودة، اطلب مواصفات وشهادات مفصلة من المورد الخاص بك. تنفيذ عملية ضمان الجودة (QA) التي تشمل عمليات التفتيش قبل الشحن واختبارات الطرف الثالث إذا لزم الأمر. ضع معايير جودة واضحة في اتفاقية الشراء الخاصة بك، بما في ذلك مقاييس الأداء وشروط الضمان. النظر في زيارة المصنع أو استخدام خدمات التفتيش للتحقق من ممارسات الإنتاج. يمكن أن يساعد الحفاظ على التواصل المفتوح طوال عملية التصنيع في معالجة أي مخاوف تتعلق بالجودة في وقت مبكر.

5. ما هي شروط الدفع التي يقدمها عادةً موردو المولدات الكهربائية الصينية؟

يمكن أن تختلف شروط الدفع، ولكن العديد من الموردين الصينيين يقدمون خيارات مثل T/T (التحويل البرقي) أو خطاب الاعتماد أو PayPal. تتضمن الممارسة الشائعة إيداع 30% مقدمًا مع دفع الرصيد المستحق قبل الشحن. بالنسبة للطلبيات الأكبر، تفاوض على شروط مواتية قد تشمل فترات سداد ممتدة أو دفعات بالتقسيط. تأكد دائمًا من أن شروط الدفع محددة بوضوح في العقد لتجنب سوء الفهم وضمان الحماية من المخاطر المحتملة.

6. ما هو متوسط المهلة الزمنية اللازمة لاستلام المولدات الكهربائية من الصين؟

يمكن أن تختلف المهل الزمنية اللازمة لمولدات التيار المتردد بناءً على عوامل مثل حجم الطلب، وطلبات التخصيص، والقدرة الإنتاجية للمورد. بشكل عام، توقع مهلة تتراوح من 30 إلى 90 يومًا. إذا كنت تحتاج إلى تسليم أسرع، ناقش خيارات الشحن السريع مع المورد الخاص بك. بالإضافة إلى ذلك، ضع في اعتبارك الوقت اللازم لفحص الجودة ولوجستيات الشحن. يمكن أن يساعد التخطيط المسبق والحفاظ على التواصل المفتوح مع المورد الخاص بك في الحد من التأخير.

7. كيف أتعامل مع الشحن والخدمات اللوجستية لطلبات المولدات الخاصة بي؟

عند التعامل مع الشحن والخدمات اللوجستية، اعمل عن كثب مع المورد الخاص بك لتحديد طريقة الشحن الأكثر كفاءة بناءً على التكلفة والسرعة والموثوقية. تشمل الخيارات الشائعة الشحن البحري للطلبيات الكبيرة والشحن الجوي للشحنات الأصغر حجماً والحساسة من حيث الوقت. تأكد من أن المورد يقدم جميع الوثائق اللازمة، بما في ذلك الفواتير وقوائم التعبئة والإقرارات الجمركية. تعاون مع وكيل شحن موثوق به للتغلب على لوائح الشحن الدولي وضمان التسليم في الوقت المناسب.

8. هل هناك خيارات تخصيص متاحة لمولدات التيار المتردد من الموردين الصينيين؟

نعم، يقدم العديد من موردي المولدات الصينية خيارات التخصيص لتلبية متطلبات محددة. يمكن أن تشمل التخصيصات تعديلات على الجهد والأمبير وتكوينات التركيب وحتى وضع علامتك التجارية بشعارك. عند مناقشة الطلبات المخصصة، كن واضحًا بشأن مواصفاتك والنتائج المتوقعة. يُنصح بطلب نماذج أولية أو عينات قبل الالتزام بطلب أكبر، مما يسمح لك باختبار أداء المنتج وتوافقه مع استخدامك.

قائمة المصنعين والموردين 4 أعلى 4 المولد الصينية قائمة المصنعين والموردين

1. الجسر الأصفر - المولدات الكهربائية

المجال: موقع yellowbridge.com

تاريخ التسجيل: 2003 (22 عامًا)

مقدمة: المولد: مصطلح قديم لمولد كهربائي ينتج تياراً متردداً (خاصة في السيارات).

2. ريفيرسو - أسلاك المولد

المجال: context.reverso.net

مسجل: 2000 (25 سنة)

مقدمة: هذه الشركة، ريفيرسو - رصاصات المولدات، هي كيان بارز في السوق. للحصول على تفاصيل محددة عن المنتج، يُنصح بزيارة موقعها الإلكتروني مباشرةً.

3. DB Electronics - مراجعة المولدات ذات الميزانية المحدودة

المجال: community.cartalk.com

تاريخ التسجيل: 1995 (30 عامًا)

مقدمة: مولد كهربائي اقتصادي من الصين، العلامة التجارية: DB Electronics، تم شراؤها من أمازون مقابل $101 (بما في ذلك الضريبة)، بحالة جديدة، يشبه ظاهرياً مولد التيار المتردد المصنّع من قبل OEM، قلب سلك نحاسي أرق، خرج الجهد المقاس عند منتصف 14 فولت، الضمان: سنة واحدة من أمازون، مخاوف بشأن الجودة وطول العمر مقارنة بالخيارات المحلية أو المعاد تصنيعها.

4. B Buckeye Auto Electric - مولد 28 فولت معاد التصنيع

المجال: ebay.com

تاريخ التسجيل: 1995 (30 عامًا)

مقدمة: {“رقم القطعة”:”S00012966″،”النوع”:”مولد”،”الجهد”:”28 فولت”،”الأمبيرية”:”55 أمبير”،”الحالة”:”معاد التصنيع”،”البائع”:”B Buckeye Auto Electric”،”تقييم البائع”:”100% إيجابي”،”السعر”:”US $100.00″،”تكلفة الشحن”:”$25.00 دولار أمريكي”،”وقت الشحن”:”2-4 أيام”،”الإرجاع”:”14 يوم إرجاع، المشتري يدفع ثمن إعادة الشحن”،”بلد المنشأ”:”الولايات المتحدة”،”الطلاء”:”مطلي، طبيعي”،”تم اختباره”:”نعم"}

استنتاج وتوقعات التوريد الاستراتيجي لمولدات المولدات الصينية الاستراتيجية

كيف يمكن للمصادر الاستراتيجية تعزيز مشترياتك من المولدات الصينية؟

مع زيادة الطلب العالمي على مكونات السيارات الموثوقة، برز التوريد الاستراتيجي لمولدات التيار المتردد الصينية كاستراتيجية محورية للمشترين الدوليين بين الشركات. ويوفر المشهد التنافسي للسوق الصينية مجموعة متنوعة من المصنعين، مما يضمن للشركات العثور على منتجات عالية الجودة بأسعار تنافسية. من خلال إقامة علاقات متينة مع الموردين، لا يمكن للمشترين تأمين شروط مواتية فحسب، بل يمكنهم أيضًا الوصول إلى التقنيات المبتكرة وممارسات التصنيع التي يمكن أن تعزز الكفاءة التشغيلية.

وعلاوة على ذلك، فإن فهم الفروق الدقيقة في السوق الصينية، بما في ذلك معايير الجودة ومتطلبات الامتثال، سيمكن المشترين من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا من اتخاذ قرارات مستنيرة. يخفف هذا النهج الاستراتيجي من المخاطر المرتبطة باضطرابات سلسلة التوريد ويساعد في الحفاظ على تدفق ثابت لمولدات الطاقة المتجددة عالية الأداء.

وبالنظر إلى المستقبل، ومع استمرار تطور قطاع السيارات، سيكون تبني التوريد الاستراتيجي أمرًا ضروريًا للبقاء في صدارة المنافسة. نحن نشجع المشترين الدوليين بين الشركات على الانخراط بنشاط مع المصنعين الصينيين، وتعزيز الشراكات التي يمكن أن تؤدي إلى نجاح طويل الأجل. من خلال القيام بذلك، فإنك لن تعزز استراتيجية المشتريات الخاصة بك فحسب، بل ستعزز أيضاً من نمو أعمالك لتحقيق النمو المستدام في سوق ديناميكية متزايدة.

صورة توضيحية متعلقة بمولد المولد الصيني

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.