Introduction: Navigating the Global Market for que es el alternador

In an increasingly interconnected world, understanding the role and function of the alternator is crucial for international B2B buyers seeking reliable energy solutions. The alternator, a key component in both automotive and industrial applications, is essential for converting mechanical energy into electrical energy. This guide aims to demystify the complexities of sourcing alternators by providing insights into various types, applications, and the intricacies of supplier vetting.

With a focus on empowering B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—this comprehensive resource will address the critical factors influencing purchasing decisions. From understanding the different types of alternators available to evaluating their performance, efficiency, and cost-effectiveness, our guide serves as a roadmap for making informed choices.

Additionally, we will cover essential topics such as the importance of quality assurance in supplier selection and potential challenges faced in global markets. By leveraging this guide, buyers can confidently navigate the complexities of sourcing alternators, ensuring they meet their operational needs while optimizing their investments. Whether you’re in Brazil, Germany, or elsewhere, this guide is designed to facilitate successful procurement strategies in the competitive landscape of alternator sourcing.

جدول المحتويات

- Top 4 Que Es El Alternador Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for que es el alternador

- Understanding que es el alternador Types and Variations

- Key Industrial Applications of que es el alternador

- 3 Common User Pain Points for ‘que es el alternador’ & Their Solutions

- Strategic Material Selection Guide for que es el alternador

- In-depth Look: Manufacturing Processes and Quality Assurance for que es el alternador

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘que es el alternador’

- Comprehensive Cost and Pricing Analysis for que es el alternador Sourcing

- Alternatives Analysis: Comparing que es el alternador With Other Solutions

- Essential Technical Properties and Trade Terminology for que es el alternador

- Navigating Market Dynamics and Sourcing Trends in the que es el alternador Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of que es el alternador

- Strategic Sourcing Conclusion and Outlook for que es el alternador

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding que es el alternador Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| مولدات السيارات | Designed for vehicles; compact and lightweight. | تصنيع وإصلاح السيارات. | الإيجابيات: Essential for vehicle operation; reliable. السلبيات: يقتصر على تطبيقات السيارات. |

| المولدات الصناعية | Larger, robust design; high power output. | Manufacturing plants, heavy machinery. | الإيجابيات: High efficiency; suitable for continuous operation. السلبيات: تكلفة أولية أعلى؛ تركيب معقد. |

| مولدات كهربائية بحرية | Corrosion-resistant materials; designed for marine environments. | Shipping, fishing, and recreational vessels. | الإيجابيات: Durability in harsh conditions; reliable power supply. السلبيات: Specialized maintenance may be required. |

| المولدات الكهربائية المحمولة | Lightweight and mobile; often gas-powered. | Construction sites, outdoor events. | الإيجابيات: Versatile and easy to transport; immediate power supply. السلبيات: Limited run time; fuel dependency. |

| Renewable Energy Alternators | Integrated with solar or wind systems; eco-friendly. | Renewable energy projects, off-grid systems. | الإيجابيات: Sustainable energy source; reduced operational costs. السلبيات: Initial setup can be costly; variable energy output. |

What Are the Characteristics and Suitability of Automotive Alternators?

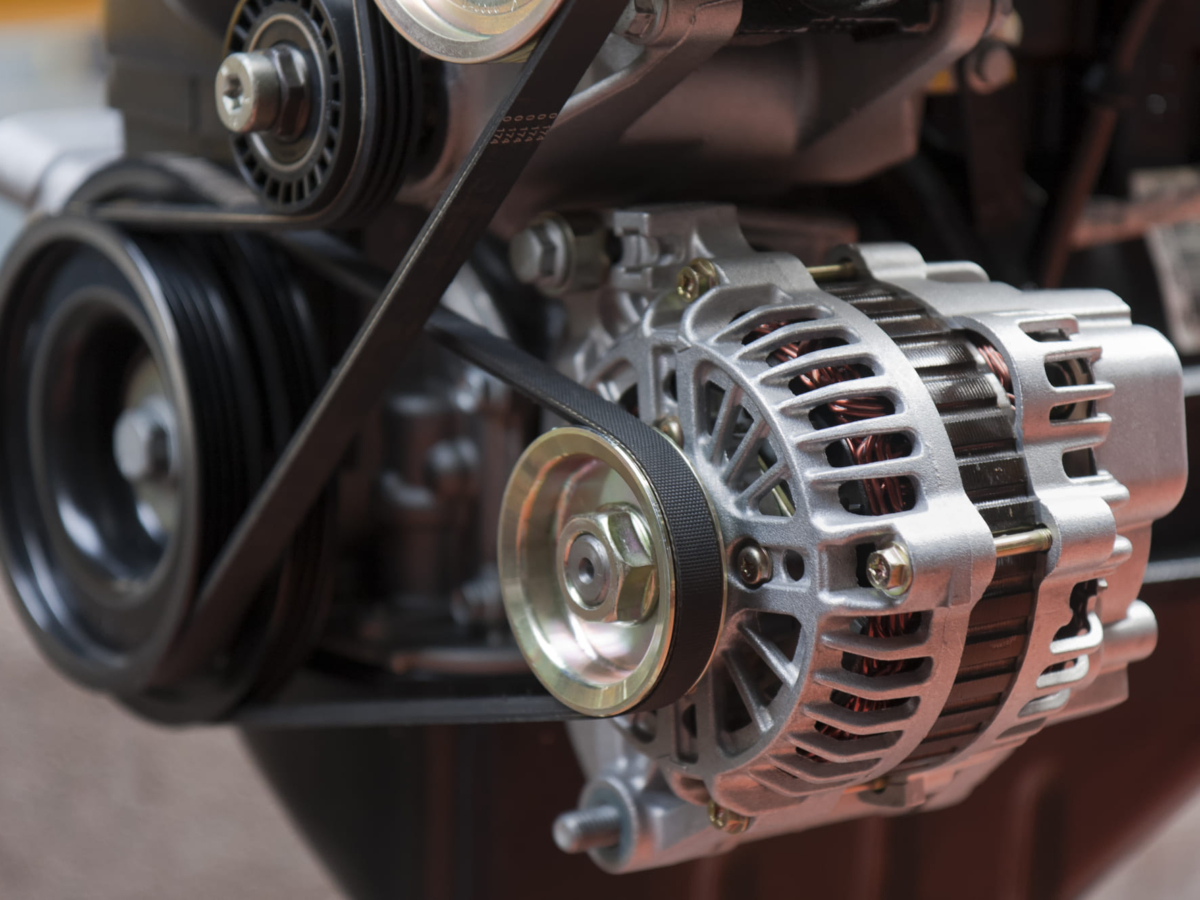

Automotive alternators are specifically engineered for vehicles, providing essential electrical power for ignition, lighting, and other electrical systems when the engine is running. They are compact and lightweight, making them suitable for various vehicle types, from passenger cars to heavy-duty trucks. B2B buyers in the automotive sector should consider the compatibility of these alternators with specific vehicle models, as well as the warranty and service support offered by manufacturers.

How Do Industrial Alternators Stand Out in Power Generation?

Industrial alternators are characterized by their robust design and high power output, making them ideal for large-scale applications such as manufacturing plants and heavy machinery. These alternators are built for continuous operation and high efficiency, ensuring minimal downtime. For B2B buyers, key considerations include the alternator’s power rating, operational efficiency, and the availability of technical support for installation and maintenance.

What Makes Marine Alternators Unique for Maritime Applications?

Marine alternators are specially designed to withstand harsh marine environments, featuring corrosion-resistant materials and robust construction. They provide reliable power to ships, fishing boats, and recreational vessels. For businesses in the maritime industry, purchasing considerations should include the alternator’s ability to operate under varying sea conditions and the availability of marine-grade components for maintenance.

Why Choose Portable Alternators for On-the-Go Power Needs?

Portable alternators are lightweight and easily transportable, often powered by gasoline, making them ideal for construction sites, outdoor events, and emergency power needs. Their versatility allows businesses to generate immediate power in remote locations. Buyers should evaluate the run time, fuel efficiency, and ease of use when selecting portable alternators, as these factors directly impact operational effectiveness.

How Do Renewable Energy Alternators Contribute to Sustainable Practices?

Renewable energy alternators are designed to integrate seamlessly with solar or wind energy systems, providing an eco-friendly power solution for off-grid applications. They help businesses reduce operational costs and reliance on fossil fuels. B2B buyers should consider the initial investment and the potential return on investment through energy savings, as well as the alternator’s efficiency in variable weather conditions.

Key Industrial Applications of que es el alternador

| الصناعة/القطاع | Specific Application of que es el alternador | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | Power generation in vehicles | Ensures reliable operation of electrical components, enhancing vehicle performance and safety. | Quality assurance of parts, compatibility with vehicle models, and adherence to local regulations. |

| الطاقة المتجددة | Integration with wind turbines | Converts mechanical energy into electricity, supporting sustainable energy initiatives. | Reliability under varying environmental conditions and compliance with energy standards. |

| الآلات الصناعية | إمدادات الطاقة للآلات الثقيلة | Maintains operational efficiency and reduces downtime in manufacturing processes. | Durability of components, availability of spare parts, and service support. |

| التطبيقات البحرية | Electrical generation in boats and ships | Powers navigation and communication systems, crucial for safety at sea. | Marine-grade materials to withstand harsh conditions and regulatory compliance for marine equipment. |

| معدات البناء | Energy generation for construction machinery | Enhances productivity by ensuring machinery operates without electrical failures. | Robustness against heavy use, ease of maintenance, and supplier reliability. |

How is ‘que es el alternador’ Used in the Automotive Industry?

In the automotive sector, the alternator is crucial for generating electrical power while the vehicle is running. It recharges the battery and powers essential electrical systems, such as lights, infotainment, and safety features. This reliability is vital for ensuring vehicle performance and safety. International buyers, particularly in regions like Africa and South America, should consider sourcing alternators that meet local vehicle specifications and environmental conditions, ensuring compatibility and compliance with safety standards.

What Role Does ‘que es el alternador’ Play in Renewable Energy?

In renewable energy, particularly with wind turbines, the alternator converts mechanical energy from the turbine into electrical energy. This conversion is essential for integrating wind energy into the power grid, promoting sustainability. Buyers in this sector must prioritize sourcing alternators that demonstrate high efficiency and reliability, especially in varying weather conditions. Compliance with international energy standards is also critical to ensure the longevity and effectiveness of these systems.

How is ‘que es el alternador’ Beneficial for Industrial Machinery?

In industrial machinery, alternators provide a stable power supply, essential for maintaining operational efficiency. They help reduce downtime caused by electrical failures, thereby enhancing productivity. For businesses sourcing alternators for machinery, durability and the availability of spare parts are key considerations. Ensuring the alternator can withstand heavy-duty use and is supported by reliable service is crucial for minimizing operational disruptions.

Why is ‘que es el alternador’ Important for Marine Applications?

In marine applications, alternators generate electricity for navigation and communication systems, which are vital for safety at sea. The harsh marine environment necessitates the use of marine-grade alternators, resistant to corrosion and wear. Buyers must ensure that the alternators comply with maritime regulations and are built to endure the unique challenges of marine operations, thereby ensuring safety and reliability.

How Does ‘que es el alternador’ Enhance Construction Equipment?

In the construction industry, alternators are integral to powering heavy machinery, ensuring continuous operation on job sites. This reliability enhances productivity and reduces the risk of electrical failures that can lead to costly delays. When sourcing alternators for construction equipment, businesses should focus on robustness, ease of maintenance, and the reliability of suppliers to ensure that machinery remains operational under demanding conditions.

3 Common User Pain Points for ‘que es el alternador’ & Their Solutions

Scenario 1: Navigating Alternator Specifications for Diverse Applications

المشكلة: B2B buyers often face the challenge of selecting the correct alternator specifications for various applications, ranging from automotive to industrial uses. Misunderstanding the electrical requirements can lead to operational inefficiencies or equipment failures. For instance, a buyer may need an alternator that supports a specific voltage output to power machinery in a manufacturing plant but struggles to identify the right model from numerous options in the market.

الحل: To overcome this challenge, buyers should begin by conducting a thorough analysis of their power requirements, including voltage, amperage, and load characteristics. Engaging with manufacturers or suppliers who specialize in alternators can provide insights into which models best suit particular applications. Furthermore, utilizing online tools or resources that offer detailed specifications and comparison features can help streamline the selection process. Buyers should also consider future scalability; selecting an alternator that not only meets current needs but can adapt to potential increases in load will ultimately save costs in the long run.

Scenario 2: Identifying Signs of Alternator Failure in Critical Operations

المشكلة: In many industries, the alternator is crucial for maintaining operational continuity, yet many B2B buyers lack the technical expertise to identify early signs of alternator failure. For example, a logistics company may find that its fleet vehicles experience frequent electrical issues, leading to unexpected downtimes and increased maintenance costs. This situation is exacerbated when buyers do not recognize that the root cause could be a failing alternator.

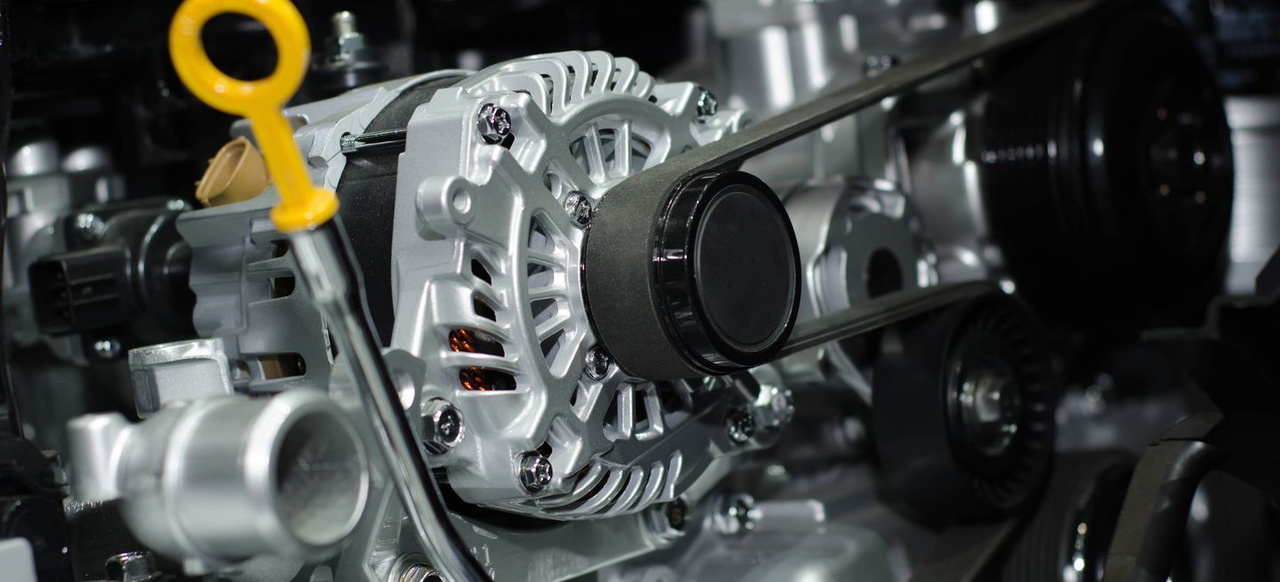

Illustrative image related to que es el alternador

الحل: Establishing a proactive maintenance schedule that includes regular inspections of the alternator can significantly mitigate the risk of failure. Buyers should train their technical staff to recognize common indicators of alternator problems, such as unusual noises, fluctuating electrical outputs, or warning lights on vehicle dashboards. Additionally, investing in diagnostic tools can help monitor alternator performance in real-time, allowing for early detection of issues. Partnering with a reliable service provider for routine check-ups and maintenance can also ensure that the alternators are functioning optimally, thus reducing the likelihood of costly downtimes.

Scenario 3: Sourcing Quality Alternators Amidst a Saturated Market

المشكلة: In a saturated market, B2B buyers often struggle to source high-quality alternators that meet industry standards without compromising on cost. The proliferation of low-cost alternatives may tempt buyers, but these products can lead to long-term failures and increased replacement costs. For instance, a construction firm may purchase cheaper alternators that do not withstand the heavy demands of their equipment, resulting in frequent breakdowns and project delays.

الحل: Buyers should prioritize sourcing alternators from reputable manufacturers who provide warranties and certifications that guarantee quality and performance. Engaging in industry networks or forums can help buyers gather recommendations and reviews on suppliers. Additionally, conducting a cost-benefit analysis that considers not only the initial purchase price but also the long-term performance and reliability of the alternator will lead to more informed decision-making. Establishing long-term relationships with trusted suppliers can also yield advantages, such as better pricing and exclusive access to new technologies. By focusing on quality over cost, buyers can ensure that their operations run smoothly and efficiently, ultimately driving profitability.

Strategic Material Selection Guide for que es el alternador

ما هي المواد التي تستخدم عادة في المولدات الكهربائية؟

When selecting materials for alternators, several options are commonly considered, each with unique properties and implications for performance, durability, and cost. Below are analyses of four prevalent materials used in the construction of alternators, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

كيف يساهم النحاس في أداء المولد؟

Copper is widely used in alternators for windings due to its excellent electrical conductivity. It can handle high temperatures, making it suitable for the heat generated during operation. Copper also has a high tensile strength, which contributes to the durability of the alternator.

Illustrative image related to que es el alternador

الإيجابيات: Copper’s high conductivity ensures efficient energy transfer, reducing energy losses. It is also relatively easy to work with during manufacturing, allowing for complex winding designs.

السلبيات: The primary drawback of copper is its cost, which is higher than many alternatives. Additionally, copper is susceptible to corrosion, especially in humid environments, which may require protective coatings.

التأثير على التطبيق: Copper’s compatibility with high-frequency currents makes it ideal for automotive applications, where rapid energy fluctuations occur.

اعتبارات للمشترين الدوليين: Buyers from regions like Africa and South America should consider the availability of copper and its cost fluctuations. Compliance with international standards such as ASTM B170 for copper wire may also be relevant.

Why is Aluminum Becoming Popular in Alternator Manufacturing?

Aluminum is increasingly used in alternators, particularly for the rotor and housing. It is lighter than copper, which can enhance the overall efficiency of the vehicle by reducing weight.

الإيجابيات: The lightweight nature of aluminum improves fuel efficiency and performance. It also offers good corrosion resistance, especially when anodized, making it suitable for various environments.

السلبيات: While aluminum is less expensive than copper, it has lower electrical conductivity, which can lead to higher energy losses. Additionally, aluminum’s mechanical strength is not as high as copper, which may affect durability under extreme conditions.

التأثير على التطبيق: Aluminum is particularly suitable for applications requiring lightweight components, such as in modern electric vehicles.

اعتبارات للمشترين الدوليين: Buyers should be aware of the specific aluminum grades that meet international standards, such as DIN 1725, to ensure quality and performance.

What Role Does Steel Play in Alternator Design?

Steel is often used for the structural components of alternators, including the frame and mounting brackets. Its strength and durability make it an ideal choice for these applications.

الإيجابيات: Steel provides excellent mechanical strength and can withstand high pressure and temperature conditions. It is also relatively low-cost compared to other metals.

السلبيات: Steel is heavier than aluminum and copper, which may negatively impact the overall weight of the alternator. It is also prone to rust and corrosion, necessitating protective coatings.

التأثير على التطبيق: Steel’s strength is particularly beneficial in heavy-duty applications, such as industrial generators.

اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM A36 for structural steel is essential. Buyers should also consider the availability of corrosion-resistant coatings suitable for their specific environments.

How Does Plastic Enhance Alternator Functionality?

Plastic components are increasingly utilized in alternators, particularly for insulators and housings. Materials like polycarbonate and nylon are common choices.

الإيجابيات: Plastics are lightweight, which contributes to overall efficiency. They are also resistant to corrosion and can be molded into complex shapes, enhancing design flexibility.

Illustrative image related to que es el alternador

السلبيات: Plastics generally have lower thermal and mechanical strength compared to metals, which may limit their use in high-stress applications. They can also degrade under prolonged exposure to high temperatures.

التأثير على التطبيق: Plastic is suitable for non-load-bearing components, where weight reduction is crucial.

اعتبارات للمشترين الدوليين: Buyers should ensure that the plastics used comply with international standards like ISO 9001 for quality management systems.

جدول ملخص لاختيار المواد للمولدات الكهربائية

| المواد | Typical Use Case for que es el alternador | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | Windings in alternators | موصلية كهربائية ممتازة | ارتفاع التكلفة وقابلية التآكل | عالية |

| الألومنيوم | الدوار والمبيت | خفيفة الوزن ومقاومة جيدة للتآكل | موصلية أقل من النحاس | متوسط |

| الصلب | المكونات الهيكلية | High mechanical strength | أثقل وزناً وعرضة للتآكل | منخفض |

| بلاستيك | Insulators and housings | خفة الوزن ومرونة التصميم | قوة حرارية/ميكانيكية أقل | متوسط |

This comprehensive material selection guide provides valuable insights for B2B buyers looking to optimize alternator performance while considering cost, durability, and compliance with international standards.

Illustrative image related to que es el alternador

In-depth Look: Manufacturing Processes and Quality Assurance for que es el alternador

ما هي المراحل الرئيسية في عملية تصنيع المولدات الكهربائية؟

The manufacturing process of alternators involves several critical stages, each essential for ensuring the final product meets industry standards and customer expectations. Understanding these stages is vital for B2B buyers seeking reliable suppliers.

How Are Raw Materials Prepared for Alternator Manufacturing?

The manufacturing journey begins with material preparation. High-quality raw materials, such as copper for winding, steel for the rotor and stator, and various plastics for insulation, are sourced. Suppliers often provide certificates of compliance to verify the quality of these materials. Rigorous testing is conducted to ensure that these materials meet specific mechanical and electrical standards, such as conductivity and tensile strength.

ما هي تقنيات التشكيل المستخدمة في إنتاج المولد؟

Once materials are prepared, the next stage is forming. Techniques such as stamping and machining are employed to create the rotor, stator, and other key components. Stamping involves using dies to cut and shape metal sheets, while machining allows for precise shaping of components to exact specifications. Advanced CNC (Computer Numerical Control) technology is commonly used to enhance precision and reduce waste, ensuring each part fits together perfectly.

Illustrative image related to que es el alternador

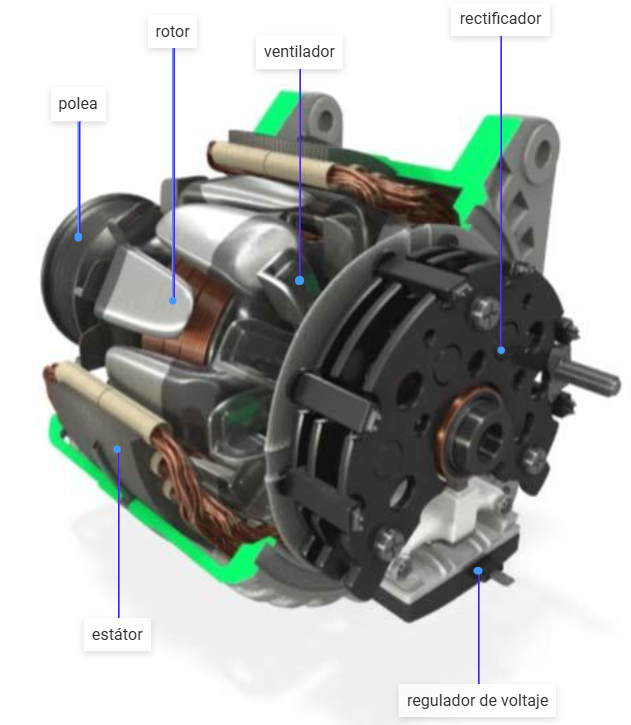

كيف يتم تجميع المولدات الكهربائية؟

After forming, the components move into the assembly phase. This stage requires meticulous attention to detail, as the alternator consists of multiple parts, including the rotor, stator, rectifier, and regulator. Each component is assembled in a clean environment to prevent contamination. Automation plays a significant role in this phase, with robotic arms often used for tasks that require high precision, such as inserting bearings and securing screws.

ما هي عمليات التشطيب الضرورية للمولدات عالية الجودة؟

Finishing processes are critical for enhancing the durability and aesthetic appeal of the alternator. Techniques such as surface treatment, painting, and coating are applied to protect against corrosion and wear. Additionally, balancing the rotor is crucial to minimize vibrations during operation, thereby extending the lifespan of the alternator. Manufacturers may also apply insulation to electrical components to prevent short circuits.

What International Quality Standards Are Relevant to Alternator Manufacturing?

Quality assurance is paramount in alternator production. International standards such as ISO 9001 set the framework for quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements. For alternators, compliance with CE marking regulations ensures that products meet European safety, health, and environmental protection standards. In regions like Africa and South America, adherence to local regulations is equally important for market entry.

كيف يتم دمج نقاط التحقق من مراقبة الجودة في عملية التصنيع؟

Quality control (QC) is integrated throughout the manufacturing process, with several key checkpoints:

-

مراقبة الجودة الواردة (IQC): This initial checkpoint ensures that raw materials meet specified standards before they enter production. Suppliers must provide documentation, including material certificates and test reports, which B2B buyers should review.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During assembly, continuous monitoring of processes is conducted to identify any deviations from established standards. This may involve visual inspections, measurements, and functional tests to ensure components meet specifications.

-

مراقبة الجودة النهائية (FQC): Before shipment, finished alternators undergo comprehensive testing. This includes electrical testing to verify voltage output, load testing to assess performance under operational conditions, and visual inspections for any cosmetic defects.

ما هي طرق الاختبار الشائعة المستخدمة للمولدات الكهربائية؟

Testing methods are crucial for validating the performance and safety of alternators. Common methods include:

-

الاختبارات الكهربائية: Measures output voltage and current under various load conditions to ensure the alternator operates efficiently.

-

الاختبار الحراري: Assesses the alternator’s ability to dissipate heat during operation, preventing overheating and potential failure.

-

اختبار الاهتزازات: Evaluates the performance of the alternator under operational conditions to identify any issues that may lead to premature wear.

-

اختبار المتانة: Simulates long-term usage to ensure the alternator can withstand the rigors of daily operation.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers. Here are some actionable insights:

-

إجراء عمليات تدقيق للموردين: Regular audits allow buyers to assess the manufacturing processes, quality management systems, and adherence to international standards. This can include reviewing documentation, observing processes, and evaluating the training of personnel.

-

Request Quality Assurance Reports: Suppliers should provide detailed reports on their quality control measures, including results from IQC, IPQC, and FQC stages. These documents should outline testing methods and results, along with any corrective actions taken for non-conformities.

-

Engage Third-Party Inspection Services: Independent inspection agencies can provide unbiased assessments of the manufacturing processes and quality assurance practices. This is particularly valuable for international buyers looking to establish trust with suppliers across different regions.

ما هي اعتبارات مراقبة الجودة الفريدة للمشترين الدوليين؟

When sourcing alternators internationally, buyers must be aware of specific quality control nuances. Different regions may have varying standards and regulations, affecting product compliance. For example, while CE marking is crucial for European markets, compliance with local regulations is essential in Africa and South America. Buyers should thoroughly research and understand these requirements to ensure smooth importation and market acceptance.

In summary, the manufacturing processes and quality assurance for alternators are intricate and require stringent adherence to standards. By understanding these processes and actively verifying supplier practices, B2B buyers can ensure they procure high-quality alternators that meet their operational needs and market regulations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘que es el alternador’

When sourcing alternators for your business needs, it’s essential to follow a structured approach to ensure you select the right products and suppliers. This guide provides a step-by-step checklist tailored for B2B buyers, helping you navigate the procurement process efficiently.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

Establishing clear technical specifications is vital for ensuring the alternators meet your operational requirements. Consider factors such as voltage output, size, weight, and compatibility with existing systems. Ensure you also include any certifications or standards specific to your industry, such as ISO or CE markings.

Illustrative image related to que es el alternador

الخطوة 2: البحث عن الموردين المحتملين

Conduct thorough research to identify reliable suppliers who specialize in alternators. Look for companies with a solid reputation in the market, particularly those that cater to your geographical region. Utilize online platforms, industry directories, and trade associations to compile a list of potential suppliers.

الخطوة 3: Evaluate Supplier Certifications and Compliance

Before moving forward with any supplier, verify their certifications and compliance with industry standards. This step is crucial for ensuring product quality and safety. Key certifications to look for include:

– آيزو 9001 for quality management systems.

– ISO 14001 for environmental management.

– ROHS compliance for hazardous substances.

الخطوة 4: طلب عينات أو نماذج أولية

Once you’ve shortlisted potential suppliers, request samples or prototypes of the alternators. This allows you to assess the quality and performance firsthand. Evaluate the samples based on your technical specifications and any additional requirements you may have, such as testing for durability or efficiency.

الخطوة 5: تقييم الأسعار وشروط الدفع

Compare pricing among your shortlisted suppliers while considering the total cost of ownership, which includes shipping, import duties, and potential tariffs. Inquire about payment terms, including discounts for bulk orders or extended payment plans. Understanding the financial implications will help you make an informed decision.

الخطوة 6: تحقق من المراجع وملاحظات العملاء

Gather references and seek feedback from other customers who have purchased from your potential suppliers. This step can provide insights into the supplier’s reliability, customer service, and product performance. Look for reviews on third-party platforms to get an unbiased perspective.

الخطوة 7: وضع اللمسات الأخيرة على اتفاقية الشراء

Once you have evaluated all aspects, it’s time to negotiate and finalize the purchase agreement. Ensure that the contract includes clear terms regarding delivery timelines, warranty conditions, and return policies. A well-defined agreement will protect your interests and facilitate a smoother transaction.

By following this checklist, B2B buyers can make informed decisions when sourcing alternators, ensuring that they select the best products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for que es el alternador Sourcing

ما هي مكونات التكلفة الرئيسية في توريد المولدات الكهربائية؟

Understanding the cost structure associated with sourcing alternators is crucial for B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe. The primary cost components include:

-

المواد: The raw materials for alternators primarily consist of copper, steel, and various types of electrical components. The quality of these materials directly impacts performance and longevity, affecting both initial costs and Total Cost of Ownership (TCO).

-

العمل: Labor costs vary significantly by region and can influence pricing. Skilled labor is essential for the assembly and quality control processes, and labor rates can fluctuate based on local economic conditions.

-

تكاليف التصنيع العامة: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thus impacting overall pricing.

-

الأدوات: Custom tooling may be required for specific alternator designs or specifications, which can add to upfront costs. Buyers should consider whether existing tooling can be utilized to minimize expenses.

-

مراقبة الجودة (QC): Rigorous QC processes ensure that the alternators meet industry standards and certifications. While these processes may add to the cost, they are crucial for maintaining product reliability and reducing warranty claims.

-

اللوجستيات: Transportation and shipping costs can vary widely, especially for international buyers. Factors such as distance, shipping method, and import/export regulations play a significant role in logistics expenses.

-

الهامش: Suppliers typically include a margin to cover risks and ensure profitability. Understanding the margin structure can help buyers identify opportunities for negotiation.

كيف تؤثر العوامل المؤثرة في الأسعار على قرارات توريد المولدات؟

Several factors can influence the pricing of alternators, which buyers should consider during procurement:

-

الحجم/الحد الأدنى لكمية الطلب: Larger orders often lead to discounts due to economies of scale. B2B buyers should evaluate their purchasing strategy to maximize volume discounts.

-

المواصفات والتخصيص: Custom alternators designed for specific applications may incur additional costs. Buyers should assess whether standard models meet their needs or if customization is necessary.

-

جودة المواد والشهادات: Higher-quality materials and certifications (such as ISO standards) typically command higher prices. Buyers must balance the need for quality with budget constraints.

-

عوامل الموردين: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers may offer better warranties and support, justifying a higher price point.

-

مصطلحات التجارة الدولية: The choice of Incoterms affects the allocation of costs and responsibilities between buyers and suppliers. Understanding these terms is essential for budgeting total costs accurately.

What Tips Can Help Buyers Negotiate Better Prices for Alternators?

B2B buyers can adopt several strategies to enhance their purchasing outcomes:

-

التفاوض على الشروط: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Building a good relationship may lead to more favorable terms.

-

التركيز على كفاءة التكلفة: Evaluate the TCO rather than just the initial purchase price. Consider factors such as energy efficiency, maintenance costs, and lifespan when assessing the value of an alternator.

-

البحث عن ظروف السوق المحلية: Understanding regional economic factors can help buyers make informed decisions. For instance, currency fluctuations can affect pricing in international transactions.

-

Leverage Group Purchasing: Consider joining or forming buying groups with other businesses to increase purchasing power and negotiate better pricing.

-

ابق على اطلاع على اتجاهات الأسعار: Regularly monitor market trends and material costs to anticipate changes in pricing. This knowledge can empower buyers during negotiations.

الخلاصة

In conclusion, sourcing alternators involves a complex interplay of cost components and price influencers. For international B2B buyers, particularly those operating in diverse markets, understanding these factors is vital for achieving cost-effective and reliable procurement. While indicative pricing can provide a starting point, thorough analysis and strategic negotiation will ultimately lead to more favorable purchasing outcomes.

Alternatives Analysis: Comparing que es el alternador With Other Solutions

Understanding Alternative Solutions to ‘Que Es El Alternador’

When evaluating energy generation solutions for vehicles or machinery, understanding the alternatives to traditional alternators can be crucial for B2B buyers. These alternatives may offer different benefits in terms of efficiency, cost, and functionality. In this section, we will compare ‘que es el alternador’ with two viable alternatives: مولدات التيار المستمر و أنظمة إدارة البطاريات (BMS).

جدول المقارنة

| جانب المقارنة | Que Es El Alternador | مولد التيار المستمر | نظام إدارة البطارية (BMS) |

|---|---|---|---|

| الأداء | Efficient at converting mechanical energy to electrical energy, particularly in vehicles. | Provides steady DC output but less efficient at varying loads. | Optimizes battery usage and extends battery life, but does not generate energy. |

| التكلفة | Moderate initial cost with long-term savings through efficiency. | Generally lower upfront cost, but may require more maintenance. | Higher initial investment due to advanced technology. |

| سهولة التنفيذ | Relatively easy to install in vehicles and machinery. | Simple installation but may require specific configurations. | Complex implementation requiring integration with existing systems. |

| الصيانة | Requires periodic checks and replacements of components like brushes. | Needs regular maintenance for optimal performance and longevity. | Minimal maintenance but requires software updates and monitoring. |

| أفضل حالة استخدام | Ideal for automotive applications and systems requiring reliable power generation. | Suitable for simple applications where DC power is needed without fluctuations. | Best for systems focused on battery health and efficiency, like electric vehicles and renewable energy systems. |

تفصيل البدائل

مولدات التيار المستمر

DC generators convert mechanical energy into direct current electricity and are commonly used in applications requiring a stable power source. They are cost-effective and simpler to install compared to alternators. However, their performance is less efficient when dealing with variable loads, which can lead to energy waste. Moreover, they require consistent maintenance to ensure they operate efficiently over time.

أنظمة إدارة البطاريات (BMS)

A Battery Management System is an advanced technology designed to monitor and manage battery performance, ensuring optimal usage and longevity. BMS is particularly beneficial for electric vehicles and renewable energy applications where battery health is critical. While it offers sophisticated management capabilities and can extend battery life, the initial investment is usually higher than that of an alternator or DC generator. Additionally, integrating a BMS can be complex, requiring expertise in both hardware and software.

الخلاصة

Selecting the right energy solution depends on specific operational requirements and budget constraints. For B2B buyers, understanding the unique advantages and limitations of each alternative is essential. If reliability and consistent power generation are the priorities, ‘que es el alternador’ remains a strong choice, especially in automotive contexts. However, if the focus is on battery longevity and efficiency, investing in a Battery Management System may yield better long-term benefits. Ultimately, careful consideration of the application, performance needs, and cost will guide buyers toward the most suitable solution for their energy generation requirements.

Essential Technical Properties and Trade Terminology for que es el alternador

ما هي الخصائص التقنية الرئيسية للمولد الكهربائي؟

Understanding the technical specifications of an alternator is essential for B2B buyers, particularly in sectors like automotive, renewable energy, and industrial applications. Here are some critical specifications to consider:

-

Output Voltage and Current

The output voltage of an alternator typically ranges from 12V to 48V for automotive applications. Current output can vary from 30A to over 200A, depending on the vehicle’s power requirements. This specification is crucial for ensuring that the alternator can meet the energy demands of the electrical systems in vehicles or machinery. -

تصنيف الكفاءة

Efficiency ratings usually range from 60% to 90%. A higher efficiency rating indicates that more mechanical energy is converted into electrical energy, which is vital for reducing fuel consumption and enhancing overall performance. This property is particularly important for B2B buyers looking to improve the sustainability of their operations. -

تركيب المواد

Alternators are often made from materials like aluminum and copper. The rotor and stator are typically constructed from high-grade steel or aluminum for durability and optimal conductivity. Understanding material grades can help buyers ensure they are purchasing high-quality components that will withstand operational stresses. -

تحمل درجات الحرارة

Alternators must operate effectively across a range of temperatures, typically between -40°C to +125°C. This tolerance is essential for ensuring reliability in various climates, particularly in regions with extreme weather conditions. Buyers should look for alternators that can maintain performance under high thermal stress. -

Regulation Mechanism

The voltage regulation mechanism is a critical component, often using either a mechanical or electronic regulator. It ensures that the output voltage remains stable, which is vital for protecting sensitive electronic components. A reliable regulation system is a key selling point for B2B buyers focused on quality and performance.

ما هي المصطلحات التجارية الشائعة المتعلقة بالمولدات الكهربائية؟

Familiarity with industry terminology is essential for effective communication and decision-making in B2B transactions. Here are some common terms:

-

OEM (الشركة المصنعة للمعدات الأصلية)

This refers to companies that produce parts that may be marketed by another manufacturer. For alternators, OEM parts are often preferred for their quality and compatibility with specific vehicle models. Buyers should verify whether the alternators they consider are OEM to ensure reliability. -

MOQ (الحد الأدنى لكمية الطلب)

This term defines the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses to manage inventory effectively and negotiate better pricing. Buyers should inquire about MOQs to optimize procurement strategies. -

طلب عرض أسعار (RFQ)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. This document typically includes specifications, quantities, and delivery requirements. B2B buyers should utilize RFQs to gather competitive bids and ensure they receive the best value for their purchases. -

شروط التجارة الدولية (Incoterms)

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Knowing the relevant Incoterms can help B2B buyers navigate logistics and shipping responsibilities more effectively. -

سوق ما بعد البيع

This term refers to parts and accessories that are not sourced from the original manufacturer. Aftermarket alternators can be a cost-effective alternative, but buyers should ensure compatibility and performance standards to avoid potential issues.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions when sourcing alternators for their operations, enhancing both efficiency and reliability in their applications.

Navigating Market Dynamics and Sourcing Trends in the que es el alternador Sector

What Are the Current Market Dynamics and Sourcing Trends for Alternators?

The global alternator market is experiencing notable growth driven by increasing demand for electric and hybrid vehicles, advancements in automotive technology, and a rising focus on energy efficiency. In regions such as Africa and South America, rapid urbanization and population growth are leading to a surge in vehicle ownership, thus boosting the demand for reliable alternators. Meanwhile, Europe, particularly Germany, is at the forefront of technological innovation, with a strong emphasis on integrating advanced alternator systems that enhance vehicle performance and energy efficiency.

Emerging B2B tech trends include the adoption of smart alternators equipped with sensors that monitor performance and optimize energy output. This shift towards smart technology is particularly appealing to international buyers looking to improve operational efficiency and reduce maintenance costs. Additionally, the rise of e-commerce platforms is transforming sourcing strategies, enabling buyers to access a wider range of suppliers and products, thereby facilitating competitive pricing and quicker delivery times.

Key market dynamics also include the growing importance of local sourcing in response to global supply chain disruptions. For international B2B buyers, establishing relationships with local manufacturers not only ensures a more resilient supply chain but also reduces lead times and shipping costs. As the market evolves, buyers must stay informed about these trends to make strategic sourcing decisions.

How Is Sustainability and Ethical Sourcing Addressed in the Alternator Sector?

Sustainability is becoming a central concern in the alternator industry, with increasing awareness of its environmental impact. The production of alternators often involves the use of metals and other materials that can have adverse effects on the environment if not sourced responsibly. Ethical sourcing practices are essential for ensuring that materials are obtained from suppliers who adhere to environmental regulations and labor standards.

The importance of transparent supply chains cannot be overstated. International B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to ethical practices, including the use of recycled materials and adherence to sustainability certifications. Certifications such as ISO 14001 for environmental management and various green labels help buyers identify suppliers that are serious about reducing their ecological footprint.

Moreover, companies are exploring innovative materials for alternators, such as lightweight composites and recyclable components, which can significantly reduce energy consumption during manufacturing. By prioritizing sustainable sourcing, businesses not only enhance their brand reputation but also align with the growing consumer demand for environmentally friendly products.

ما هو تطور المولد وأثره على التوريد بين الشركات؟

The alternator has evolved significantly since its inception in the early 20th century. Originally designed to generate electricity for early automobiles, modern alternators are now sophisticated devices capable of efficiently converting mechanical energy into electrical energy, thanks to advancements in materials and technology. This evolution has led to the development of high-performance alternators that are integral to the functionality of contemporary vehicles, particularly electric and hybrid models.

For B2B buyers, understanding this evolution is crucial. It highlights the importance of sourcing from suppliers who not only provide traditional alternators but also innovate with new technologies. The shift towards hybrid and electric vehicles necessitates a focus on advanced alternator designs that cater to the specific needs of these vehicles, influencing sourcing decisions and supplier partnerships. As the market continues to evolve, buyers must remain agile, adapting their sourcing strategies to align with technological advancements and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of que es el alternador

-

How do I determine if an alternator is suitable for my vehicle?

To determine if an alternator is suitable for your vehicle, check the specifications outlined in your vehicle’s manual, including voltage, amperage output, and physical dimensions. Ensure that the alternator matches or exceeds the power requirements of your vehicle’s electrical system. Collaborating with suppliers who can provide detailed product specifications and compatibility information is essential, especially when sourcing from international manufacturers. -

What are the key components of an alternator that I should consider?

When evaluating alternators, focus on components such as the rotor, stator, rectifier, and voltage regulator. Each component plays a critical role in the alternator’s performance and reliability. Additionally, consider the materials used in construction, as high-quality materials can enhance durability and efficiency, particularly in demanding applications or environments prevalent in markets like Africa and South America. -

What are common signs that an alternator may be failing?

Common signs of a failing alternator include dimming headlights, electrical system malfunctions, unusual noises (such as grinding or whining), and warning lights on the dashboard. In a B2B context, it’s crucial to communicate these signs to your maintenance teams to ensure timely interventions and reduce downtime for vehicles or equipment that rely on these components. -

ما هي المهلة الزمنية المعتادة للحصول على مصادر المولدات على المستوى الدولي؟

Lead times for sourcing alternators can vary widely based on the supplier’s location, production capacity, and shipping methods. Generally, you can expect lead times ranging from 4 to 12 weeks. For international buyers, consider establishing relationships with suppliers who offer expedited shipping options and clear communication regarding timelines to enhance your supply chain efficiency. -

What minimum order quantities (MOQ) should I expect when purchasing alternators?

Minimum order quantities can vary significantly based on the supplier and the type of alternator. Typically, MOQs can range from 50 to several hundred units. When negotiating with suppliers, inquire about flexibility in MOQs, especially if you are testing a new market or product line, as some manufacturers may offer smaller batches for initial orders. -

How do I vet suppliers for alternators to ensure quality?

To vet suppliers, conduct thorough background checks that include reviewing certifications, customer feedback, and industry reputation. Request samples to assess product quality and performance. Additionally, consider suppliers with established quality assurance processes and compliance with international standards, particularly if you are sourcing from regions with varying manufacturing practices. -

ما هي شروط الدفع التي يقدمها عادةً مورّدو مولدات التيار المتردد؟

Payment terms can vary widely among suppliers, but common practices include upfront payments, partial payments, or payment upon delivery. Establishing clear payment terms in your contracts is crucial to avoid misunderstandings. Additionally, consider suppliers who offer secure payment options and flexible terms to accommodate your cash flow needs, especially in international transactions. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد المولدات الكهربائية؟

When importing alternators, consider factors such as shipping methods, customs regulations, and import duties. Collaborate with logistics partners who have experience in handling automotive parts to ensure compliance with all regulations. Additionally, factor in the costs of insurance and storage to avoid unexpected expenses and ensure timely delivery to your operations.

Top 4 Que Es El Alternador Manufacturers & Suppliers List

1. Infinity Auto - Alternadores

المجال: infinityauto.com

تاريخ التسجيل: 2002 (23 عامًا)

مقدمة: El alternador es un generador que distribuye electricidad al auto y recarga la batería. Funciona convirtiendo energía mecánica en energía eléctrica, impulsado por el cigüeñal del motor a través de una correa serpentina. Sus componentes principales incluyen: 1. Rotor: gira dentro del estator y crea electricidad mediante imanes. 2. Estator: parte fija que trabaja con el rotor para generar electricid…

2. EMSA – Alternadores

المجال: emsa.gen.tr

مقدمة: Un alternador es un dispositivo mecánico que convierte la energía mecánica en energía eléctrica. Es un componente clave en sistemas de generación de energía eléctrica, como generadores diésel, motores de combustión interna y turbinas de viento. Se compone de un rotor, que gira y está conectado al motor o turbina, y un estator, que es fijo y contiene los bobinados de la bobina del alternador. Su fu…

3. Sadi Transmisiones – Alternadores

المجال: saditransmisiones.com

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: Un alternador es un dispositivo electromecánico que convierte energía mecánica en energía eléctrica, utilizado en vehículos y maquinaria como automóviles, camiones, generadores y motores industriales. Sus partes principales incluyen un rotor, un estator y un sistema de excitación. El rotor, impulsado por una correa del motor, gira dentro del estator, induciendo corriente eléctrica en las bobinas d…

4. Mercedes-Benz – Alternador

المجال: mercedes-benzdimovil.com

مسجل: 2016 (9 سنوات)

مقدمة: El alternador es un componente esencial del vehículo que genera energía eléctrica para mantener la batería cargada y alimentar los sistemas eléctricos del coche. Funciona convirtiendo la energía mecánica del cigüeñal en electricidad a través de la inducción. Contiene varias partes clave: polea, estator, rotor, diodos, regulador de voltaje y ventilador de enfriamiento. Los síntomas de un alternador…

Strategic Sourcing Conclusion and Outlook for que es el alternador

As businesses across Africa, South America, the Middle East, and Europe seek to optimize their operations, understanding the pivotal role of the alternator in various applications becomes increasingly important. The alternator not only serves as a crucial component in vehicles, ensuring the smooth functioning of electrical systems, but also plays a significant role in larger energy generation contexts, from diesel generators to renewable energy sources.

Strategic sourcing of high-quality alternators can lead to reduced operational costs, improved efficiency, and enhanced reliability of electrical systems. By partnering with reputable manufacturers and suppliers, businesses can ensure they are equipped with the latest advancements in alternator technology, which is essential for maintaining competitive advantage in a rapidly evolving market.

Looking ahead, international B2B buyers should prioritize sourcing strategies that emphasize quality, sustainability, and technological innovation. By investing in reliable alternator solutions, companies can not only secure their operational needs but also contribute to a greener future. Engage with trusted suppliers and explore new opportunities to enhance your sourcing strategy today—your business’s success depends on it.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.

Illustrative image related to que es el alternador