Introduction: Navigating the Global Market for where to get your alternator tested

In the ever-evolving landscape of automotive maintenance, sourcing reliable locations for where to get your alternator tested can be a daunting challenge for B2B buyers. Whether you’re managing a fleet in Africa, overseeing vehicle maintenance in South America, or facilitating automotive services in Europe, understanding the nuances of alternator testing is critical for optimizing performance and minimizing downtime. This comprehensive guide delves into the various types of alternator testing services available, the applications suited to different markets, and the essential criteria for vetting suppliers.

By exploring the intricacies of alternator functionality and the common signs of failure, this guide empowers international B2B buyers to make informed purchasing decisions. We cover the costs associated with testing, the technology behind testing equipment, and the geographic considerations that may impact your sourcing strategies. Furthermore, we provide insights into building relationships with trustworthy suppliers, ensuring that your business is equipped with the knowledge needed to secure high-quality testing services.

Navigating this global market requires not only an understanding of the technical aspects but also a strategic approach to supplier engagement. With this guide, you can confidently enhance your operational efficiency and ensure your vehicles are always ready to perform at their best.

جدول المحتويات

- Top 3 Where To Get Your Alternator Tested Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for where to get your alternator tested

- Understanding where to get your alternator tested Types and Variations

- Key Industrial Applications of where to get your alternator tested

- 3 Common User Pain Points for ‘where to get your alternator tested’ & Their Solutions

- Strategic Material Selection Guide for where to get your alternator tested

- In-depth Look: Manufacturing Processes and Quality Assurance for where to get your alternator tested

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘where to get your alternator tested’

- Comprehensive Cost and Pricing Analysis for where to get your alternator tested Sourcing

- Alternatives Analysis: Comparing where to get your alternator tested With Other Solutions

- Essential Technical Properties and Trade Terminology for where to get your alternator tested

- Navigating Market Dynamics and Sourcing Trends in the where to get your alternator tested Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of where to get your alternator tested

- Strategic Sourcing Conclusion and Outlook for where to get your alternator tested

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding where to get your alternator tested Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| Auto Parts Retail Chains | Free testing services, convenient locations, additional services offered | Fleet management, repair shops | الإيجابيات: No cost, easy access. السلبيات: Limited expertise on specific vehicle types. |

| Independent Auto Repair Shops | Personalized service, diagnostic expertise, often specialized | Small businesses, local fleets | الإيجابيات: Tailored diagnostics, local knowledge. السلبيات: Potentially higher costs. |

| Mobile Mechanics | On-site testing, convenience, flexible scheduling | Busy fleets, remote operations | الإيجابيات: Saves time, immediate service. السلبيات: Limited equipment compared to fixed shops. |

| Dealership Service Centers | Manufacturer-trained technicians, OEM parts availability | High-end vehicles, warranty repairs | الإيجابيات: High-quality service, original parts. السلبيات: Higher prices, longer wait times. |

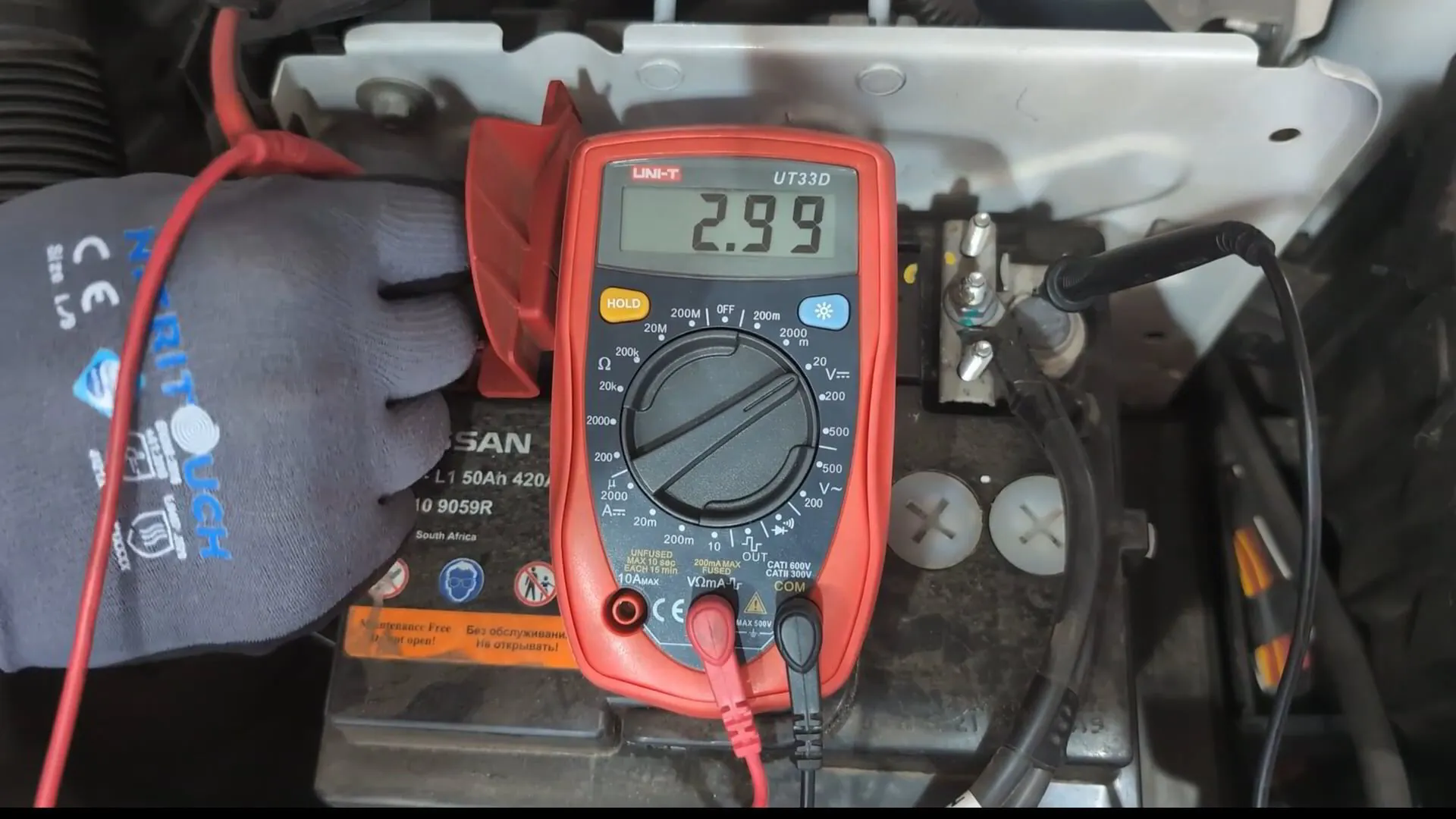

| DIY Testing Kits | Cost-effective, hands-on approach, educational | Small businesses with technical staff | الإيجابيات: Low investment, fosters learning. السلبيات: Requires technical knowledge, time-consuming. |

What Are the Advantages of Using Auto Parts Retail Chains for Alternator Testing?

Auto parts retail chains like O’Reilly Auto Parts provide a convenient option for businesses seeking free alternator testing. These chains typically have numerous locations, making it easy for fleet managers and repair shops to access services without significant downtime. The primary drawback is that while staff are trained in general automotive knowledge, they may lack specific expertise for specialized or high-performance vehicles.

Why Choose Independent Auto Repair Shops for Alternator Testing?

Independent auto repair shops offer a more personalized service that can be crucial for businesses managing diverse vehicle fleets. These shops often have technicians with extensive experience in diagnosing a wide range of issues, including alternator problems. However, they may charge higher fees compared to retail chains, so businesses should weigh the benefits of specialized service against potential costs.

How Do Mobile Mechanics Enhance the Alternator Testing Experience?

Mobile mechanics bring the service directly to the business, making it a highly convenient option for companies with busy schedules or remote operations. This flexibility can significantly reduce downtime, as tests can be conducted on-site. The downside is that mobile mechanics may have less access to advanced diagnostic equipment compared to traditional shops, which could limit their testing capabilities.

What Are the Benefits of Using Dealership Service Centers for Alternator Testing?

Dealership service centers employ technicians trained specifically on their brand’s vehicles and often utilize OEM parts for repairs. This ensures high-quality service and accurate diagnostics. However, the costs associated with dealership services can be significantly higher, and businesses might experience longer wait times due to high demand.

Why Consider DIY Testing Kits for Alternator Assessment?

For businesses with technically proficient staff, DIY testing kits offer a cost-effective and educational approach to alternator testing. These kits empower teams to conduct their own assessments, fostering a deeper understanding of vehicle maintenance. However, this method requires a certain level of expertise and can be time-consuming, which may not be ideal for all businesses.

Key Industrial Applications of where to get your alternator tested

| الصناعة/القطاع | Specific Application of where to get your alternator tested | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | Routine alternator testing for customer vehicles | Enhances service reliability and customer satisfaction | Access to advanced testing equipment and trained technicians |

| النقل واللوجستيات | صيانة الأنظمة الكهربائية لمركبات الأسطول | تقليل وقت التعطل وضمان الكفاءة التشغيلية | Availability of quick turnaround testing services |

| معدات البناء | Testing alternators in heavy machinery | منع الأعطال المكلفة وإطالة عمر المعدات | Need for specialized testing services tailored for industrial equipment |

| الطاقة المتجددة | Testing alternators in wind turbines and solar power systems | Ensures optimal energy generation and system reliability | Compatibility with diverse energy solutions and international standards |

| الآلات الزراعية | Alternator testing in tractors and harvesters | زيادة الإنتاجية من خلال تقليل أعطال المعدات إلى الحد الأدنى | Availability of local service centers and parts for specific machinery |

How is ‘where to get your alternator tested’ utilized in Automotive Repair Shops?

In automotive repair shops, regular alternator testing is essential for diagnosing electrical issues in customer vehicles. This service helps mechanics identify failing alternators before they lead to more significant problems, thereby enhancing service reliability. For international B2B buyers, sourcing testing equipment that meets local regulations and standards is critical, ensuring that technicians are well-trained and equipped to provide accurate results. Additionally, establishing relationships with suppliers who offer reliable parts for replacements can enhance customer satisfaction.

Why is alternator testing crucial for Transportation & Logistics?

In the transportation and logistics sector, maintaining the electrical systems of fleet vehicles is vital for operational efficiency. Regular alternator testing helps prevent unexpected breakdowns, which can lead to significant delays and increased operational costs. International buyers must consider sourcing testing services that provide quick turnarounds, as vehicle downtime can severely impact logistics operations. Additionally, understanding local regulations regarding vehicle maintenance can guide sourcing decisions.

What role does alternator testing play in Construction Equipment maintenance?

For construction equipment, testing alternators is a proactive measure to prevent costly breakdowns of heavy machinery. Construction companies depend on these machines for productivity, and a failure in the electrical system can halt operations. B2B buyers in this sector should seek specialized testing services that cater to industrial equipment, ensuring that the testing process is efficient and minimizes downtime. Additionally, sourcing local service providers can facilitate quicker repairs and parts replacements.

How does alternator testing benefit Renewable Energy applications?

In renewable energy systems, such as wind turbines and solar power installations, alternator testing is crucial for ensuring optimal performance and reliability. Regular testing helps identify issues that could affect energy generation, allowing for timely interventions. For international buyers, it’s essential to partner with testing service providers that comply with international standards and can accommodate diverse energy solutions. This ensures the longevity and efficiency of renewable energy systems.

Why is testing alternators important in Agricultural Machinery?

In the agricultural sector, alternator testing in tractors and harvesters is vital for maintaining productivity during critical farming seasons. Regular testing minimizes the risk of equipment failure, which can lead to significant financial losses. Buyers in this sector should focus on sourcing local service centers that understand the specific needs of agricultural machinery. Availability of parts and service tailored to these machines is also a key consideration to ensure minimal disruption during peak operational times.

3 Common User Pain Points for ‘where to get your alternator tested’ & Their Solutions

Scenario 1: Difficulty Finding Reliable Testing Locations

المشكلة: For B2B buyers managing vehicle fleets, sourcing reliable alternator testing services can be a significant challenge, especially in regions with limited access to automotive service facilities. This often leads to uncertainty about whether the service providers are qualified to conduct accurate tests. Additionally, buyers may face difficulties in ensuring that testing facilities are equipped with the latest technology and expertise to handle various alternator types, especially if they operate a diverse fleet with different vehicle models.

الحل: To overcome this challenge, B2B buyers should conduct thorough research to identify reputable automotive service providers in their area. Start by utilizing online platforms and industry forums to gather feedback and reviews about local alternator testing services. When contacting potential service providers, inquire about their qualifications, certifications, and the technology they use for testing. It’s also beneficial to establish partnerships with automotive parts suppliers who may offer testing services as part of their support. This not only ensures reliability but can also lead to better pricing and service arrangements for bulk testing needs.

Scenario 2: Unclear Testing Procedures and Results Interpretation

المشكلة: B2B buyers often struggle with understanding the testing procedures and interpreting the results of alternator tests. This lack of clarity can lead to confusion regarding whether an alternator needs replacement or if it can be repaired. The technical jargon used in reports can be particularly daunting for fleet managers who may not have a strong automotive background. As a result, they may make uninformed decisions that could lead to increased operational costs and downtime.

الحل: To address this issue, B2B buyers should seek out service providers that offer comprehensive explanations of their testing procedures and results. Before conducting the tests, ask for a detailed overview of what the testing entails and what specific metrics will be evaluated. After receiving the results, request a consultation to discuss the findings in layman’s terms. This can help clarify whether the alternator is functioning optimally or if there are signs of potential failure. Additionally, consider investing in training sessions for your team on basic automotive knowledge, particularly focusing on alternator functions and diagnostics, to empower them to make informed decisions.

Scenario 3: Cost Concerns Related to Testing and Repairs

المشكلة: Budget constraints are a common concern for B2B buyers, particularly for small to medium-sized enterprises managing fleets. The costs associated with alternator testing and subsequent repairs or replacements can add up quickly, leading to anxiety over maintaining fleet budgets while ensuring vehicle reliability. Buyers may also be hesitant to invest in testing services without a clear understanding of the return on investment (ROI) and how it impacts overall fleet performance.

الحل: To mitigate cost concerns, B2B buyers should implement a proactive maintenance strategy that includes regular alternator testing as part of their fleet management routine. This can help catch potential issues early, reducing the likelihood of more expensive repairs down the line. Consider negotiating service contracts with automotive providers that include bundled testing and repair services at a discounted rate. Additionally, track the performance of your alternators and any related expenditures to develop a clearer picture of the ROI associated with regular testing. By demonstrating that early detection of alternator issues can lead to substantial cost savings, you can justify the investment in testing services to stakeholders.

Strategic Material Selection Guide for where to get your alternator tested

What Materials Are Commonly Used for Testing Alternators in B2B Applications?

When considering where to get alternators tested, the choice of materials for testing equipment and facilities plays a crucial role in ensuring accurate results and long-term durability. Below, we analyze four common materials used in the context of alternator testing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. فولاذ

الخصائص الرئيسية: Steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It typically has good temperature resistance, withstanding high operational temperatures without significant deformation.

الإيجابيات والسلبيات: The primary advantage of steel is its robustness, which allows it to endure rigorous testing environments. However, steel is prone to corrosion if not properly treated, which can be a significant drawback in humid or corrosive environments. Additionally, the manufacturing complexity can be higher due to the need for protective coatings.

التأثير على التطبيق: Steel structures can support heavy testing equipment, ensuring stability during alternator tests. However, in regions with high humidity or exposure to chemicals, corrosion resistance becomes a critical factor.

اعتبارات للمشترين الدوليين: Buyers from Africa and South America should ensure that the steel used complies with local standards for corrosion resistance, such as ASTM A123 for hot-dip galvanized steel. In Europe, compliance with EN standards is essential.

2. الألومنيوم

الخصائص الرئيسية: Aluminum is lightweight and has excellent corrosion resistance, making it ideal for portable testing equipment. It also has good thermal conductivity, which is beneficial for dissipating heat during testing.

الإيجابيات والسلبيات: The lightweight nature of aluminum allows for easy transport and setup of testing equipment. However, it is less durable than steel and may not withstand heavy loads or impacts as effectively. The cost of aluminum can also be higher than that of steel, depending on market fluctuations.

التأثير على التطبيق: Aluminum’s corrosion resistance makes it suitable for outdoor testing environments, especially in coastal areas. However, its lower strength limits its use in high-stress applications.

اعتبارات للمشترين الدوليين: Buyers in the Middle East and Europe may prefer aluminum for its lightweight properties, but they should ensure that it meets relevant standards such as DIN EN 573 for aluminum alloys.

3. Composite Materials

الخصائص الرئيسية: Composites, such as fiberglass or carbon fiber, offer a unique combination of lightweight properties and high strength. They are also resistant to corrosion and can be engineered for specific performance characteristics.

الإيجابيات والسلبيات: The primary advantage of composites is their versatility and resistance to environmental factors. However, they can be more expensive to manufacture and may require specialized processes for repair or modification.

التأثير على التطبيق: Composites can be particularly useful in creating lightweight, portable testing rigs that do not compromise on strength. Their resistance to environmental degradation makes them ideal for various climates.

اعتبارات للمشترين الدوليين: Buyers should be aware of the specific composite standards in their regions, such as ASTM D3039 for tensile properties, which can vary significantly between countries.

4. Plastic

الخصائص الرئيسية: Plastics are lightweight and resistant to corrosion, making them a popular choice for non-structural components in testing equipment. They can also be molded into complex shapes, allowing for innovative designs.

الإيجابيات والسلبيات: The low cost and ease of manufacturing are significant advantages of plastics. However, they may not withstand high temperatures or mechanical stresses, limiting their application in more demanding environments.

التأثير على التطبيق: Plastics can be used effectively for housing and protective covers for testing equipment, but their limitations in strength and temperature resistance must be considered.

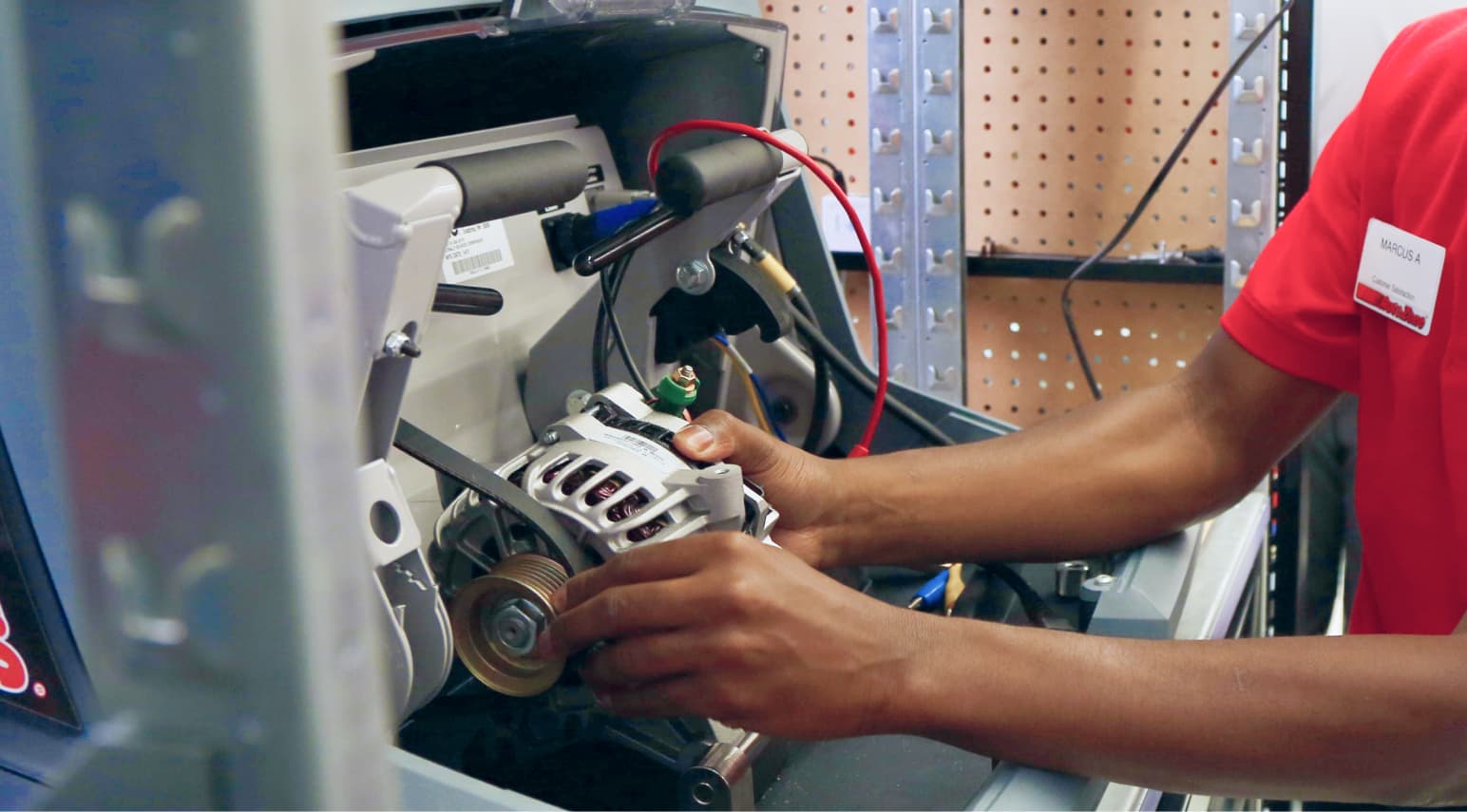

Illustrative image related to where to get your alternator tested

اعتبارات للمشترين الدوليين: Compliance with safety and environmental regulations, such as REACH in Europe, is essential when selecting plastics for testing equipment.

Summary Table of Material Selection for Alternator Testing

| المواد | Typical Use Case for where to get your alternator tested | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الصلب | Heavy-duty testing rigs and frames | متانة وقوة عالية | عرضة للتآكل دون معالجة | متوسط |

| الألومنيوم | Portable testing equipment | خفيف الوزن ومقاوم للتآكل | أقل متانة من الفولاذ | عالية |

| مركب | Lightweight, high-strength testing structures | Versatile and resistant to degradation | ارتفاع تكاليف التصنيع | عالية |

| بلاستيك | Housing for testing equipment | منخفضة التكلفة وسهلة التصنيع | Limited temperature and strength | منخفض |

This analysis provides a comprehensive overview of the materials used in alternator testing, allowing international B2B buyers to make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for where to get your alternator tested

ما هي المراحل الرئيسية لعملية تصنيع المولدات الكهربائية؟

The manufacturing process of alternators is intricate, involving several key stages that ensure the final product meets the high standards required for automotive applications. Understanding these stages can help B2B buyers identify quality suppliers for alternator testing services.

تحضير المواد: ما هي المواد المستخدمة في تصنيع المولد؟

The first stage involves selecting and preparing raw materials. Key materials typically include copper for winding, aluminum for the housing, and various types of plastics for insulation. These materials must be sourced from reputable suppliers who adhere to international quality standards. Buyers should inquire about the origin and certification of these materials to ensure compliance with standards such as ISO 9001.

Forming: How Are Components Shaped and Machined?

Once materials are prepared, the next step is forming. This includes processes such as stamping, casting, and machining to create individual components like the rotor, stator, and housing. High-precision techniques like CNC machining are often employed to ensure the components fit together seamlessly. B2B buyers should look for manufacturers that utilize advanced forming technologies to guarantee dimensional accuracy and reduce waste.

Illustrative image related to where to get your alternator tested

Assembly: How Are Alternators Assembled?

After component formation, the assembly stage begins. This involves integrating the rotor and stator, installing bearings, and attaching the voltage regulator. Automated assembly lines are commonly used to enhance efficiency and consistency. B2B buyers should assess whether the assembly process is automated or manual, as automation often leads to higher precision and lower defect rates.

Finishing: What Processes Ensure a Quality Finish?

The final stage of manufacturing is finishing, which may include processes like painting, coating, or surface treatment to enhance durability and resistance to environmental factors. This is crucial, especially in regions with extreme weather conditions. Buyers should verify if the manufacturer follows specific finishing protocols that meet international standards.

What Quality Control Measures Are Essential for Alternator Testing Services?

Quality control (QC) is vital in ensuring the reliability and performance of alternators. It encompasses various checkpoints and testing methods throughout the manufacturing process.

Illustrative image related to where to get your alternator tested

What International Standards Should Be Considered?

B2B buyers should ensure that their suppliers adhere to recognized international standards such as ISO 9001, which focuses on quality management systems. Additionally, specific automotive standards like IATF 16949 can provide further assurance of quality in the automotive supply chain. These certifications indicate that the manufacturer has established a robust QC system, reducing the risk of defects.

ما هي نقاط التفتيش الرئيسية لمراقبة الجودة في عملية التصنيع؟

تتضمن مراقبة الجودة في تصنيع مولد التيار المتردد عادةً العديد من نقاط الفحص:

-

مراقبة الجودة الواردة (IQC): This stage assesses the quality of raw materials before they enter the production line. Suppliers must provide documentation proving that materials meet specified standards.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During manufacturing, various tests are performed to monitor the production process. This may include dimensional checks and functional tests to ensure components meet design specifications.

-

مراقبة الجودة النهائية (FQC): Once assembly is complete, the alternator undergoes rigorous testing to ensure it functions correctly. This includes electrical testing, load testing, and thermal testing to simulate real-world conditions.

كيف يتم اختبار المولدات لضمان الجودة؟

Testing methods are critical for verifying the functionality and reliability of alternators. B2B buyers should be aware of the various testing procedures that manufacturers might employ.

ما هي طرق الاختبار الشائعة المستخدمة؟

-

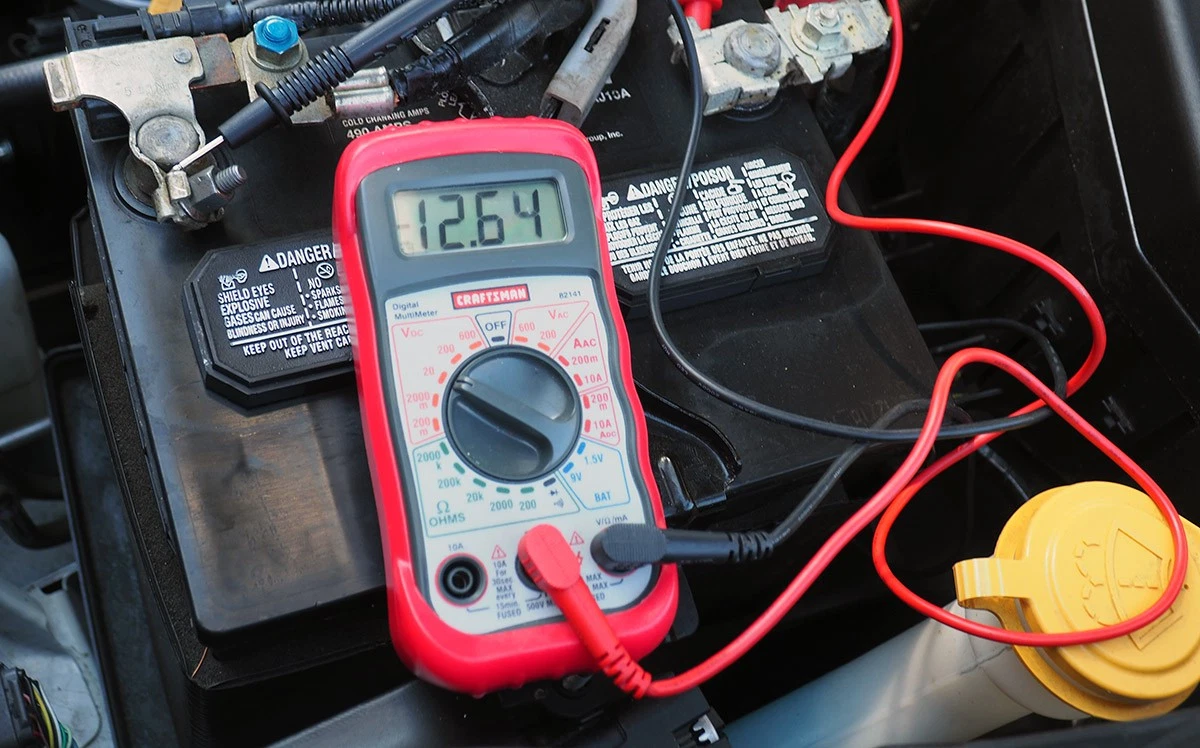

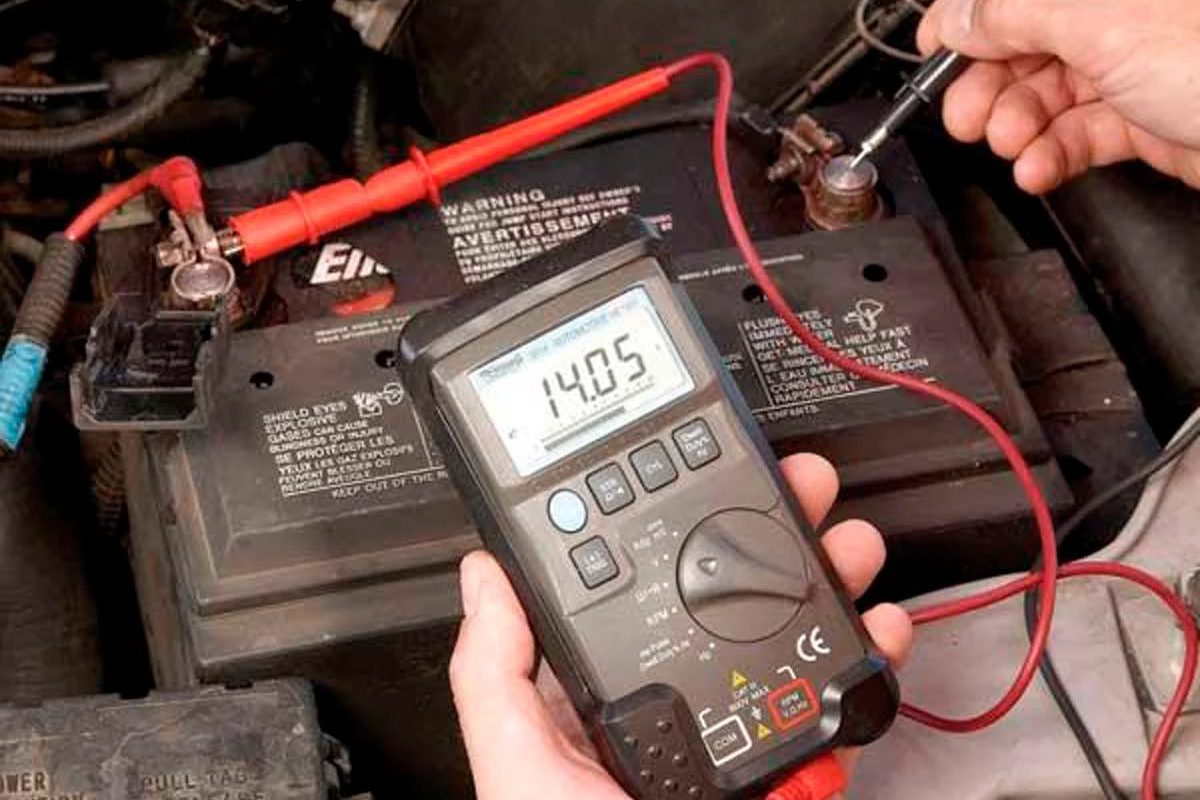

الاختبارات الكهربائية: This is essential to verify that the alternator produces the correct voltage and current. Manufacturers often use multimeters and oscilloscopes to check output under various load conditions.

-

اختبار الحمل: This method simulates the alternator’s performance under real-world conditions. It helps determine if the alternator can sustain its output while powering multiple electrical accessories.

-

اختبار الاهتزازات: This assesses how well the alternator withstands vibrations during operation. It is crucial for ensuring longevity and reliability, especially in vehicles operating in rugged environments.

-

الاختبار الحراري: Alternators should be able to dissipate heat effectively. Thermal tests evaluate how well the alternator performs under high-temperature conditions, which can affect its lifespan.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

B2B buyers looking to source alternator testing services should take proactive steps to verify the QC processes of potential suppliers.

What Are Effective Strategies for Supplier Audits?

-

عمليات تدقيق الموردين: Conducting regular audits of suppliers can help assess their compliance with quality standards. Audits should review manufacturing processes, QC checkpoints, and testing methods to ensure adherence to international standards.

-

طلب تقارير الجودة: Buyers should ask for detailed quality reports that document testing results and QC procedures. These reports provide insight into the supplier’s commitment to quality.

-

عمليات التفتيش من طرف ثالث: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s manufacturing and QC processes. This is especially valuable for international buyers who may face challenges in verifying local suppliers.

ما هي الفروق الدقيقة في مراقبة الجودة والاعتماد للمشترين الدوليين بين الشركات؟

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific QC and certification nuances when sourcing alternators.

Illustrative image related to where to get your alternator tested

How Does Regional Regulation Affect Quality Assurance?

Different regions may have varying regulations regarding automotive components. For instance, European manufacturers might need to comply with CE marking requirements, which indicate conformity with health, safety, and environmental protection standards. Understanding these regional regulations is essential for ensuring compliance and avoiding potential import/export issues.

What Should Buyers Know About Cultural and Operational Differences?

Cultural differences can also impact quality assurance practices. For example, some regions may place a higher emphasis on personal relationships in business, which can influence how QC processes are implemented. B2B buyers should consider these cultural factors when evaluating suppliers and establishing partnerships.

الخلاصة

By understanding the manufacturing processes and quality assurance measures involved in alternator testing services, B2B buyers can make informed decisions when selecting suppliers. Emphasizing quality control, adherence to international standards, and verification through audits and third-party inspections can ensure that buyers secure reliable and high-performing alternators for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘where to get your alternator tested’

مقدمة

Finding a reliable service to test your alternator is essential for maintaining the efficiency of your vehicle’s electrical system. This guide provides a structured checklist for B2B buyers seeking to identify suitable testing services, ensuring that their vehicles operate smoothly and efficiently. By following these steps, you can streamline the sourcing process and make informed decisions.

الخطوة 1: تحديد متطلبات الاختبار الخاصة بك

Begin by clarifying what you need from an alternator testing service. Consider factors such as the type of vehicles you manage and the specific issues you are encountering. This step is crucial to ensure that the service provider can meet your technical needs effectively.

Illustrative image related to where to get your alternator tested

- Types of Testing: Determine whether you need basic functionality tests or more detailed diagnostics.

- Volume of Testing: Assess how many alternators you need to test regularly to gauge the service capacity required.

الخطوة 2: Research Local and International Service Providers

Conduct thorough research to find potential service providers both locally and internationally. This expands your options and allows you to compare services.

- Online Directories: Utilize platforms like Yellow Pages or local business directories to find established testing centers.

- Industry Forums: Engage with industry forums and networks to get recommendations from peers who have used similar services.

الخطوة 3: تقييم شهادات الموردين

Before making a commitment, verify that the suppliers have the necessary certifications and qualifications. This step ensures that you are dealing with reputable providers who adhere to industry standards.

- ضمان الجودة: Look for certifications such as ISO 9001, which indicate a commitment to quality management practices.

- Technical Proficiency: Ensure technicians are certified to handle the specific types of alternators relevant to your fleet.

الخطوة 4: Request Detailed Service Proposals

Once you have shortlisted potential suppliers, request detailed proposals outlining their services. This information will help you compare offerings and pricing effectively.

- Scope of Services: Ensure the proposal includes a comprehensive list of services, such as diagnostics, repairs, and testing equipment used.

- Pricing Structure: Look for transparency in pricing, including any additional fees for expedited services or repairs.

الخطوة 5: Assess Turnaround Times

Understanding the turnaround time for testing services is vital to minimize downtime for your vehicles. Make sure to inquire about average testing durations and any factors that could affect these times.

Illustrative image related to where to get your alternator tested

- Service Levels: Check if they offer express services for urgent needs.

- Historical Performance: Ask for past performance metrics to evaluate their reliability.

الخطوة 6: Check Customer Reviews and References

Review customer feedback and request references from previous clients. This step helps you gauge the reliability and quality of service provided by potential suppliers.

- Online Reviews: Look for reviews on platforms like Google, Yelp, or specialized automotive forums.

- Direct References: Speak to former clients about their experiences, focusing on service quality and responsiveness.

الخطوة 7: Establish a Clear Communication Channel

Effective communication is essential for a successful partnership. Ensure that the service provider has a reliable method for updates and inquiries.

- Dedicated Account Manager: Check if they assign a dedicated contact person for your account.

- Response Times: Evaluate their responsiveness to queries during the initial communication to set expectations for future interactions.

By following this checklist, B2B buyers can confidently identify and select a reliable service provider for alternator testing, ensuring their fleet operates efficiently and minimizes unexpected downtime.

Illustrative image related to where to get your alternator tested

Comprehensive Cost and Pricing Analysis for where to get your alternator tested Sourcing

When sourcing services for alternator testing, understanding the cost structure and pricing nuances is crucial for B2B buyers. This analysis delves into the various components that contribute to the overall cost, as well as factors influencing pricing and tips for securing the best deals.

What are the Key Cost Components in Alternator Testing Services?

-

المواد: The primary materials involved in alternator testing include diagnostic equipment and replacement parts if necessary. High-quality diagnostic tools, such as multimeters and oscilloscopes, are essential for accurate testing and can represent a significant upfront investment for service providers.

-

العمل: Skilled technicians are needed to perform alternator testing. The labor cost varies based on geographical location, with higher rates in developed regions like Europe compared to developing regions. Technicians must be trained to use testing equipment properly and interpret results accurately, which adds to labor costs.

-

تكاليف التصنيع العامة: This includes the costs associated with maintaining the facilities, utilities, and administrative expenses of the testing service provider. Overhead can fluctuate based on the location and scale of operations.

-

الأدوات: Specialized tools for testing alternators contribute to the cost structure. These tools require regular maintenance and calibration, further influencing overall pricing.

-

مراقبة الجودة (QC): Implementing a robust QC process is vital for ensuring accurate and reliable testing results. Costs here can include training, certifications, and compliance with industry standards, which may vary by region.

-

اللوجستيات: For service providers that offer mobile testing or pickup and delivery services, logistics costs can significantly impact pricing. Factors such as distance, transportation mode, and fuel prices are critical considerations.

-

الهامش: Service providers typically include a profit margin in their pricing, which can vary widely based on market competition and perceived service value.

How Do Price Influencers Affect Alternator Testing Costs?

-

الحجم/الحد الأدنى لكمية الطلب: Larger orders or contracts for alternator testing can lead to bulk pricing discounts. Buyers should consider consolidating their needs to achieve better rates.

-

المواصفات والتخصيص: Custom testing services or specifications may increase costs. Buyers should clearly define their testing requirements to avoid unexpected charges.

-

جودة المواد والشهادات: Services that use higher-quality materials or are certified by recognized organizations may charge more. Buyers should weigh the benefits of quality against cost.

-

عوامل الموردين: The reputation and experience of the supplier can significantly influence pricing. Established suppliers may charge a premium for their services due to their reliability and expertise.

-

مصطلحات التجارة الدولية: Understanding shipping terms is essential, especially for international buyers. Costs can vary based on whether the buyer or seller is responsible for shipping and insurance, which can affect the final price.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing Alternator Testing Services?

-

التفاوض: Always negotiate pricing and terms with suppliers. Establishing a good relationship can lead to better deals, especially for repeat business.

-

التكلفة الإجمالية للملكية (TCO): Consider the TCO rather than just the upfront price. Assess the long-term implications of service quality, reliability, and potential costs associated with poor testing outcomes.

-

الفروق الدقيقة في الأسعار للمشترين الدوليين: Buyers from regions like Africa and South America may face additional challenges, such as fluctuating exchange rates and import duties. It’s essential to factor these into the total cost when sourcing from international suppliers.

-

Research Local Alternatives: Investigate local service providers who may offer competitive pricing without the added costs of international logistics. This can be particularly beneficial in regions with developing automotive services.

-

ابق على اطلاع على اتجاهات السوق: Understanding market dynamics and service trends can empower buyers to make informed decisions and identify when pricing is favorable.

الخلاصة

Navigating the cost and pricing landscape for alternator testing services involves a thorough understanding of various components and influencers. By applying strategic negotiation tactics and considering the total cost of ownership, B2B buyers can achieve cost-efficient solutions tailored to their specific needs. Always remember that prices can vary significantly based on location and service quality, so conducting comprehensive research is essential for making sound procurement decisions.

Alternatives Analysis: Comparing where to get your alternator tested With Other Solutions

Exploring Alternatives for Alternator Testing

When it comes to ensuring the reliability of your vehicle’s electrical system, knowing where to get your alternator tested is crucial. However, businesses in diverse markets may encounter various alternatives that can also serve the purpose of testing alternators. Understanding these options can help B2B buyers make informed decisions based on their specific operational needs and resources.

Illustrative image related to where to get your alternator tested

| جانب المقارنة | Where To Get Your Alternator Tested | DIY Testing with Multimeter | الخدمات الميكانيكية المتنقلة |

|---|---|---|---|

| الأداء | Accurate diagnostics with professional tools. | Can provide basic voltage readings but lacks comprehensive analysis. | Offers thorough checks with professional-grade equipment on-site. |

| التكلفة | Typically free or low-cost at auto parts stores. | Minimal cost for purchasing a multimeter (if not already owned). | Higher cost due to service fees and travel. |

| سهولة التنفيذ | Requires a visit to a location or removal of the alternator. | Simple to use for those familiar with electrical systems. | Convenient as it brings the service to your location. |

| الصيانة | No maintenance required from the customer. | Requires knowledge and occasional calibration of the multimeter. | Minimal; the mechanic handles all equipment maintenance. |

| أفضل حالة استخدام | Ideal for comprehensive testing and professional advice. | Suitable for tech-savvy individuals or small businesses with limited needs. | Best for businesses needing on-site services or with limited access to facilities. |

What Are the Pros and Cons of DIY Testing with a Multimeter?

DIY testing with a multimeter can be a cost-effective alternative for businesses that have employees with electrical knowledge. The primary advantage is the low upfront cost, particularly if a multimeter is already available. It allows for basic voltage checks to determine if the alternator is functioning within the normal range. However, this method lacks the depth of analysis that professional testing provides, as it may not detect underlying issues that require specialized equipment. Moreover, improper use of the multimeter can lead to inaccurate readings, potentially resulting in misguided troubleshooting.

كيف تقارن خدمات الميكانيكي المتنقلة؟

Mobile mechanic services represent a convenient alternative for B2B buyers who require immediate support without the need to transport the vehicle. This service can deliver professional diagnostics directly at the business site, minimizing downtime. The mechanics typically come equipped with advanced tools that allow for thorough testing and repairs. However, this option may come at a higher cost due to service fees and travel expenses. Businesses with multiple vehicles may find this option more expensive than traditional testing methods, especially if frequent visits are necessary.

Conclusion: How to Choose the Right Alternator Testing Solution

Selecting the right solution for alternator testing depends on various factors, including budget constraints, accessibility, and the level of expertise available within your organization. For businesses looking for thorough diagnostics without incurring significant costs, utilizing local automotive parts stores for free testing is often the best choice. Alternatively, companies with employees skilled in electrical systems may benefit from DIY testing methods. For those needing immediate and comprehensive service, mobile mechanic options can provide the necessary support, albeit at a higher price point. Evaluating these alternatives against your operational needs will guide you in making the most effective decision for your business.

Essential Technical Properties and Trade Terminology for where to get your alternator tested

What Are the Key Technical Properties to Consider When Getting Your Alternator Tested?

Understanding the technical properties of alternators is crucial for B2B buyers, especially when selecting a service provider for testing. Here are essential specifications to keep in mind:

Illustrative image related to where to get your alternator tested

-

ناتج الجهد

Alternators typically produce between 13.5 to 14.8 volts when the engine is running. This range is critical for ensuring that the electrical system and battery receive adequate power. When sourcing testing services, confirm that the provider can accurately measure voltage output to determine alternator health. -

التصنيف الحالي (التيار الكهربائي)

The amperage rating indicates the maximum current the alternator can supply. It varies based on the vehicle’s electrical demands. A higher rating is essential for modern vehicles equipped with advanced electrical systems. When assessing testing services, ensure they can evaluate the alternator’s current output against the manufacturer’s specifications. -

تركيب المواد

The materials used in the alternator, such as the housing and internal components, affect durability and performance. For example, aluminum housings are lighter and more resistant to corrosion compared to steel. Understanding material properties helps in assessing the longevity and reliability of the alternator being tested. -

نوع المحمل

Alternators use either ball or roller bearings, which significantly influence their efficiency and lifespan. High-quality bearings reduce friction, leading to better performance and reduced wear. Inquire if the testing service can evaluate bearing condition, as this can indicate potential failure. -

تصنيفات درجة الحرارة

Alternators operate in various temperature conditions, and their components must withstand these extremes. Knowing the maximum operating temperature can help gauge whether an alternator is suitable for specific environments. Testing services should be able to simulate or measure operational conditions to ensure reliability.

What Are Common Trade Terms Related to Alternator Testing?

Familiarity with industry jargon is beneficial for B2B buyers when discussing services and specifications. Here are some common terms:

-

OEM (الشركة المصنعة للمعدات الأصلية)

This term refers to parts made by the manufacturer of the vehicle. When testing an alternator, knowing whether it is OEM or aftermarket can influence your decision on replacement parts or services. OEM parts generally ensure compatibility and reliability. -

MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest quantity of a product that a supplier is willing to sell. When sourcing alternators or parts for testing, understanding the MOQ can help in budgeting and inventory management, especially for international buyers. -

طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. When seeking alternator testing services, issuing an RFQ can help compare offers and negotiate better terms. -

شروط التجارة الدولية (Incoterms)

These are pre-defined commercial terms published by the International Chamber of Commerce relating to international shipping. Understanding Incoterms is essential for international buyers to clarify responsibilities regarding shipping costs, risk, and insurance when sending alternators for testing. -

اختبار المقعد

This is a method where the alternator is tested outside of the vehicle, allowing for a thorough examination of its performance. Ensure that the testing facility provides bench testing services to accurately diagnose issues. -

اختبار الحمل

Load testing measures how well the alternator performs under specific electrical loads. This is vital for understanding whether the alternator can handle the demands of modern vehicles. Verify if the testing service includes load testing to ensure comprehensive evaluation.

By understanding these critical properties and trade terms, B2B buyers can make informed decisions when selecting a provider for alternator testing, ensuring optimal performance and reliability for their vehicles.

Navigating Market Dynamics and Sourcing Trends in the where to get your alternator tested Sector

What Are the Current Market Dynamics Influencing Where to Get Your Alternator Tested?

The global market for alternator testing services is increasingly shaped by a combination of technological advancements, growing vehicle complexity, and shifting consumer expectations. One significant driver is the rise of electric and hybrid vehicles, which necessitate specialized testing services to address unique electrical system requirements. As a result, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are seeking reliable partners capable of offering comprehensive diagnostics and testing solutions.

Emerging technologies, such as cloud-based diagnostic tools and mobile applications, are transforming how testing services are delivered. These innovations enable real-time data collection and analysis, allowing businesses to streamline operations and enhance customer service. For instance, companies can now offer remote testing services, making it easier for clients to access testing facilities without the need for physical visits. Additionally, the proliferation of data analytics is enabling businesses to predict alternator failures before they occur, providing a significant value-add for B2B buyers.

Furthermore, sustainability is becoming a critical consideration in sourcing decisions. Companies are increasingly focusing on suppliers who not only provide quality testing services but also adhere to eco-friendly practices. This trend is particularly pronounced in regions like Europe, where stringent regulations around environmental impact are shaping procurement strategies.

How Is Sustainability and Ethical Sourcing Shaping the Alternator Testing Market?

As global awareness of environmental issues grows, B2B buyers are prioritizing sustainability and ethical sourcing in their procurement processes. The alternator testing sector is no exception, with companies increasingly recognizing the importance of minimizing their environmental footprint. This shift is driven by both regulatory pressures and a demand from consumers for greener practices.

Businesses are actively seeking partners that demonstrate a commitment to sustainable practices, including responsible waste management and energy-efficient operations. For example, testing facilities that utilize renewable energy sources or have implemented recycling programs for old components are becoming more attractive to buyers. Additionally, certifications such as ISO 14001 for environmental management systems can serve as a critical differentiator in the market.

Incorporating sustainable materials in the manufacturing of testing equipment is also gaining traction. B2B buyers are now more inclined to choose suppliers that offer products made from recycled or environmentally friendly materials. This commitment not only enhances a company’s brand image but also aligns with the growing consumer preference for environmentally responsible businesses.

What Historical Factors Have Influenced the Alternator Testing Sector?

The evolution of the alternator testing market can be traced back to the advancement of automotive technology itself. Initially, alternators were relatively simple devices, but as vehicles became more complex, the need for specialized testing services emerged. The introduction of electronic components in vehicles in the late 20th century marked a significant turning point. This complexity required more sophisticated testing methods to ensure that all electrical systems functioned correctly.

Illustrative image related to where to get your alternator tested

In the early 2000s, the rise of diagnostic tools and software allowed for more accurate and efficient testing processes, paving the way for a more service-oriented approach in the market. The growth of e-commerce has also transformed how testing services are marketed and delivered, enabling businesses to reach a broader audience and streamline operations. As the industry continues to evolve, these historical developments will play a crucial role in shaping future trends in alternator testing services.

Frequently Asked Questions (FAQs) for B2B Buyers of where to get your alternator tested

-

How do I identify a reliable service provider for alternator testing?

When sourcing a service provider for alternator testing, consider their reputation and experience in the industry. Look for reviews and testimonials from other B2B buyers, and check if they offer certifications or guarantees on their services. Additionally, inquire about their testing equipment and methodologies to ensure they meet international standards. Establishing communication and asking for references can also help gauge their reliability. -

What is the best way to ensure quality when testing alternators?

To ensure quality in alternator testing, choose a service provider that utilizes advanced diagnostic tools and adheres to industry standards. Request a detailed report of the testing process, including voltage output and any identified issues. It’s beneficial to work with providers who offer warranties on their testing results, as this adds an extra layer of quality assurance. -

What factors should I consider when selecting a supplier for alternator testing services?

Consider the supplier’s location, service capacity, and specialization in alternator testing. Evaluate their ability to handle your specific volume needs and whether they can accommodate custom requirements. Additionally, assess their response time for inquiries and the efficiency of their logistics, as these factors can significantly impact your operational timelines. -

What are common payment terms for B2B services in alternator testing?

Payment terms for alternator testing services can vary by supplier. Typical arrangements include upfront payments, net 30 or net 60 days, and sometimes pay-per-test models. It’s advisable to clarify these terms during initial discussions and ensure they align with your budget and cash flow management strategies. Establishing clear terms in a contract can help prevent misunderstandings later. -

What is the minimum order quantity (MOQ) for alternator testing services?

The minimum order quantity for alternator testing services can differ based on the supplier’s policies and capabilities. Some may not have a strict MOQ, while others may require a minimum number of alternators to be tested per order. Discuss your requirements upfront to find a supplier that can accommodate your needs, especially if you are a smaller business or a new market entrant. -

How can I ensure compliance with international trade regulations when sourcing alternator testing services?

To ensure compliance with international trade regulations, familiarize yourself with the import/export laws of both your country and that of the service provider. Request documentation proving compliance with safety and quality standards, such as ISO certifications. Engaging a legal advisor or trade compliance expert can also help navigate complex regulations and mitigate risks associated with international transactions. -

What logistics considerations should I keep in mind when arranging alternator testing?

Logistics considerations include the shipping method, transit times, and costs associated with sending alternators to the testing facility. Assess whether the supplier offers collection services or if you need to handle transportation. Additionally, inquire about the turnaround time for testing and the process for returning tested alternators, as delays can impact your supply chain. -

How can I customize testing services for my specific business needs?

To customize testing services, communicate your specific requirements to potential suppliers. Discuss any particular tests or metrics you need, such as load testing or environmental conditions. Many suppliers are willing to tailor their services to meet client needs, so establishing a clear dialogue about your expectations and operational requirements can lead to a more beneficial partnership.

Top 3 Where To Get Your Alternator Tested Manufacturers & Suppliers List

1. AutoZone – Alternator Testing

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: This company, AutoZone – Alternator Testing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Firestone – Alternator Inspection

المجال: firestonecompleteautocare.com

تاريخ التسجيل: 2004 (21 عامًا)

مقدمة: Alternator inspection is crucial for vehicle performance. It is responsible for charging the battery and powering electrical systems. Signs of a failing alternator include dimming lights, electrical issues, and a dead battery. Regular inspections can help prevent breakdowns and ensure reliable vehicle operation.

3. Alternator Depot – Free Alternator and Starter Testing

المجال: alternatordepot.com

مسجل: 2012 (13 سنة)

مقدمة: This company, Alternator Depot – Free Alternator and Starter Testing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for where to get your alternator tested

In the realm of strategic sourcing for alternator testing, understanding the landscape of available services is crucial for international B2B buyers. Establishing partnerships with trusted service providers, such as O’Reilly Auto Parts, offers not only complimentary testing but also expert guidance on maintaining critical vehicle components. This approach reduces downtime and enhances operational efficiency, particularly important for businesses operating in regions like Africa, South America, the Middle East, and Europe.

Investing in reliable testing services ensures that alternators are functioning optimally, directly impacting vehicle performance and longevity. With fluctuating supply chain dynamics and varying regional capabilities, leveraging local expertise can lead to significant cost savings and improved service quality.

Illustrative image related to where to get your alternator tested

As you navigate the complexities of sourcing alternator testing, consider the long-term relationships you can build with service providers who understand your unique market needs. By prioritizing strategic sourcing, you position your business for sustained success in an increasingly competitive environment. Explore local options and take proactive steps to ensure your fleet remains in peak condition—your operational efficiency will thank you.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

Illustrative image related to where to get your alternator tested

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.