Introduction: Navigating the Global Market for symptoms of bad starter

In the competitive landscape of automotive parts sourcing, understanding the symptoms of a bad starter is crucial for international B2B buyers. A malfunctioning starter can lead to costly downtime and disruptions in operations, making it imperative to recognize early warning signs. This guide serves as a comprehensive resource, detailing the various types of starters, their applications across different vehicle models, and the importance of proper supplier vetting to ensure quality and reliability.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Vietnam, will find valuable insights into the typical symptoms that indicate starter issues, such as unusual noises, slow cranking, and intermittent starting failures. Moreover, we explore common causes of starter problems, ranging from wear and tear to electrical failures, and offer actionable strategies to mitigate these issues.

By equipping buyers with knowledge on how to identify starter symptoms, evaluate supplier capabilities, and understand cost implications, this guide empowers informed purchasing decisions. Navigating the global market for automotive starters becomes less daunting, enabling businesses to maintain operational efficiency and enhance their supply chain management.

جدول المحتويات

- Top 3 Symptoms Of Bad Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for symptoms of bad starter

- Understanding symptoms of bad starter Types and Variations

- Key Industrial Applications of symptoms of bad starter

- 3 Common User Pain Points for ‘symptoms of bad starter’ & Their Solutions

- Strategic Material Selection Guide for symptoms of bad starter

- In-depth Look: Manufacturing Processes and Quality Assurance for symptoms of bad starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘symptoms of bad starter’

- Comprehensive Cost and Pricing Analysis for symptoms of bad starter Sourcing

- Alternatives Analysis: Comparing symptoms of bad starter With Other Solutions

- Essential Technical Properties and Trade Terminology for symptoms of bad starter

- Navigating Market Dynamics and Sourcing Trends in the symptoms of bad starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of symptoms of bad starter

- Strategic Sourcing Conclusion and Outlook for symptoms of bad starter

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding symptoms of bad starter Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| ضوضاء غير عادية | Grinding or clicking sounds when starting the vehicle. | Automotive repair services, fleet management | الإيجابيات: Early identification of issues; السلبيات: قد يتطلب الاستبدال الفوري. |

| Slow Cranking | Engine cranks slowly or sluggishly despite adequate battery power. | Vehicle maintenance, logistics companies | الإيجابيات: Indicates potential electrical issues; السلبيات: Can lead to complete failure if ignored. |

| مشاكل بدء التشغيل المتقطع | Inconsistent starting behavior; sometimes starts, sometimes doesn’t. | Rental services, transportation companies | الإيجابيات: Highlights potential electrical faults; السلبيات: Difficult to diagnose without testing. |

| Dashboard Lights Without Start | Dashboard lights illuminate, but the engine fails to crank. | Automotive diagnostics, service centers | الإيجابيات: Confirms starter issues; السلبيات: May be confused with battery problems. |

| Faulty Solenoid Symptoms | Single loud click when attempting to start; solenoid failure. | Automotive parts suppliers, repair workshops | الإيجابيات: Specific indication of solenoid issues; السلبيات: Requires additional testing for confirmation. |

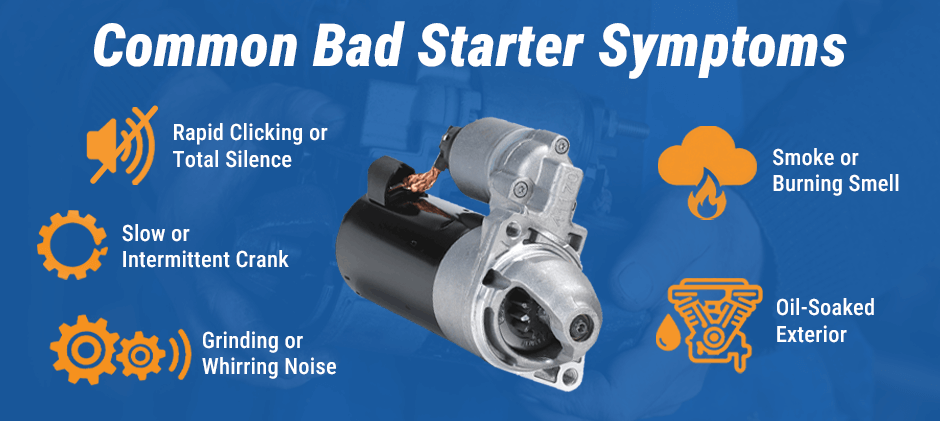

What Are the Key Characteristics of Unusual Noises in Starters?

Unusual noises such as grinding or clicking when attempting to start the vehicle are often the first indicators of a failing starter. These sounds can suggest that the starter gear is not engaging properly with the flywheel, leading to potential damage if not addressed. For B2B buyers, recognizing these symptoms early can prevent more extensive repairs and downtime, making it crucial for automotive repair services and fleet management companies to monitor this closely.

How Does Slow Cranking Indicate Starter Problems?

Slow cranking occurs when the engine takes longer than usual to start, despite having a charged battery. This symptom can signal internal wear or electrical issues within the starter. Businesses involved in vehicle maintenance or logistics should prioritize regular checks for this symptom, as it can lead to complete starter failure if neglected, resulting in costly delays and repairs.

Why Are Intermittent Starting Issues Critical to Diagnose?

Intermittent starting issues, where the vehicle sometimes starts and sometimes does not, can complicate diagnosis. This inconsistency may stem from a failing starter or electrical system problems. For rental services and transportation companies, addressing these issues promptly can enhance reliability and customer satisfaction, reducing the risk of vehicle downtime.

What Does It Mean When Dashboard Lights Illuminate But the Engine Doesn’t Start?

When dashboard lights illuminate but the engine fails to crank, it typically indicates a problem with the starter rather than the battery. This symptom is particularly relevant for automotive diagnostics and service centers, as it can streamline troubleshooting processes. Understanding this distinction allows for more efficient repairs and better inventory management for parts suppliers.

How to Identify Faulty Solenoid Symptoms in Starters?

A single loud click when attempting to start the vehicle often indicates a faulty solenoid, which is crucial for engaging the starter motor. For automotive parts suppliers and repair workshops, recognizing this symptom can lead to targeted solutions and faster service. Proper training and tools for technicians to diagnose solenoid issues can enhance service quality and customer trust.

Key Industrial Applications of symptoms of bad starter

| الصناعة/القطاع | Specific Application of symptoms of bad starter | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| إصلاح السيارات | Diagnosing vehicle starting issues through symptoms of bad starter | Reduces downtime and repair costs by enabling quick diagnosis | Quality of diagnostic tools, availability of replacement parts, and technical support |

| النقل واللوجستيات | Ensuring fleet reliability by monitoring starter performance | Minimizes breakdowns and enhances operational efficiency | Compatibility with various vehicle models, bulk purchasing options, and warranty terms |

| الزراعة | Maintenance of agricultural machinery’s starting systems | Ensures timely operations during critical planting and harvest seasons | Durability of components in harsh environments, supplier reliability, and lead times |

| البناء | Ensuring the functionality of heavy machinery and equipment | Prevents project delays and enhances productivity | Availability of service technicians, equipment compatibility, and after-sales support |

| التعدين | Monitoring starter systems in heavy mining equipment | Enhances safety by reducing the risk of equipment failure | Robustness of components, sourcing from reputable manufacturers, and compliance with industry standards |

How Can Automotive Repair Benefit from Understanding Symptoms of Bad Starters?

In the automotive repair industry, understanding the symptoms of a bad starter is crucial for diagnosing vehicle starting issues efficiently. Mechanics can quickly identify whether a starter is malfunctioning by recognizing signs such as unusual noises or slow cranking. This knowledge helps reduce vehicle downtime and repair costs, ultimately improving customer satisfaction. B2B buyers in this sector should prioritize high-quality diagnostic tools and reliable replacement parts to ensure effective repairs.

Why is Monitoring Starter Performance Essential for Transportation & Logistics?

For businesses in transportation and logistics, monitoring starter performance is essential to maintain fleet reliability. Symptoms of a bad starter can lead to unexpected breakdowns, which disrupt schedules and reduce operational efficiency. By implementing a proactive maintenance strategy based on these symptoms, companies can minimize the risk of vehicle failure. Buyers should consider compatibility with various vehicle models and bulk purchasing options to optimize their fleet management.

How Do Symptoms of Bad Starters Impact Agricultural Operations?

In agriculture, timely operations during critical planting and harvest seasons are vital. Recognizing symptoms of a bad starter can prevent machinery breakdowns that could delay these operations. Farmers benefit from ensuring that their equipment starts reliably, which directly impacts productivity and profitability. Sourcing durable components that can withstand harsh environmental conditions is essential for B2B buyers in this sector.

What Role Do Starters Play in Construction Project Efficiency?

In the construction industry, the functionality of heavy machinery and equipment is paramount. Understanding the symptoms of a bad starter can help prevent project delays caused by equipment failure. By recognizing issues early, construction companies can maintain productivity on-site. B2B buyers should focus on sourcing components that are compatible with their equipment and consider the availability of service technicians for ongoing support.

How Can Mining Operations Enhance Safety by Monitoring Starter Systems?

Mining operations rely heavily on heavy equipment, where monitoring starter systems is critical for safety and efficiency. Symptoms of a bad starter can indicate potential equipment failure, which poses significant safety risks in hazardous environments. By proactively addressing these symptoms, mining companies can mitigate risks and enhance operational reliability. Buyers should prioritize sourcing robust components from reputable manufacturers that comply with industry standards.

3 Common User Pain Points for ‘symptoms of bad starter’ & Their Solutions

Scenario 1: Difficulty Diagnosing Starter Problems in Remote Areas

المشكلة:

B2B buyers operating in remote regions often face significant challenges when diagnosing vehicle issues, particularly with starter problems. Limited access to diagnostic tools and expertise can lead to prolonged downtime and increased operational costs. For instance, a logistics company in Africa may have a fleet of vehicles that frequently experience starting issues, yet the nearest service center is hundreds of kilometers away. This situation not only affects their delivery schedules but also strains their budget due to potential emergency repairs and vehicle replacements.

الحل:

To mitigate these challenges, businesses should invest in portable diagnostic tools that can help identify starter problems on-site. Tools such as multimeters and portable jump-starters can provide immediate feedback on battery and starter functionality. Training staff to recognize symptoms of bad starters—like unusual noises, intermittent starting, and slow cranking—can empower them to troubleshoot effectively. Additionally, establishing partnerships with local mechanics who can provide mobile services can enhance support and reduce downtime. By creating a systematic approach to diagnosing and addressing starter issues, companies can maintain fleet reliability even in remote locations.

Scenario 2: Increased Maintenance Costs Due to Undiagnosed Starter Issues

المشكلة:

Many businesses underestimate the cost implications of undiagnosed starter problems, leading to a cycle of increased maintenance expenses. For example, a transportation company in South America may experience frequent vehicle breakdowns due to faulty starters, which are misattributed to battery failures or alternator issues. This misdiagnosis can lead to unnecessary repairs and part replacements, resulting in inflated maintenance budgets and lost revenue due to vehicle inoperability.

الحل:

To tackle this issue, companies should implement a proactive maintenance strategy that includes regular inspections of starter systems. Utilizing a comprehensive checklist that focuses on the symptoms of bad starters—such as listening for strange sounds or monitoring cranking speed—can help identify potential failures before they escalate. Investing in staff training to enhance their understanding of starter operation and maintenance can also reduce misdiagnosis. Furthermore, leveraging data analytics to track vehicle performance over time will allow businesses to anticipate starter-related issues and schedule maintenance proactively, ultimately reducing costs and improving fleet efficiency.

Scenario 3: Inconsistent Supplier Quality and Reliability

المشكلة:

B2B buyers often struggle with inconsistent quality and reliability when sourcing starter components. A manufacturing company in Europe might find that different suppliers provide starters with varying performance levels, leading to inconsistent vehicle performance and reliability issues. This inconsistency can result in production delays and a lack of trust in the supply chain, complicating operational logistics and increasing overall costs.

الحل:

To address supplier quality concerns, companies should establish a rigorous supplier evaluation and selection process. This includes assessing supplier capabilities, reviewing product specifications, and requesting samples for testing. Engaging in long-term partnerships with reputable manufacturers known for high-quality starter components can also enhance reliability. Additionally, implementing a quality control system that includes regular testing of starter performance can help maintain standards. By focusing on sourcing practices and building strong relationships with dependable suppliers, businesses can ensure consistent quality and minimize the risk of operational disruptions caused by starter failures.

Strategic Material Selection Guide for symptoms of bad starter

What Materials Are Commonly Used in Components Related to Symptoms of Bad Starters?

When diagnosing issues related to bad starters, it is essential to consider the materials used in the components that comprise the starter system. The choice of material can significantly influence performance, durability, and overall reliability. Below, we analyze four common materials used in starter components, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. فولاذ

الخصائص الرئيسية: Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for various automotive applications.

Illustrative image related to symptoms of bad starter

الإيجابيات والسلبيات: Steel is relatively inexpensive and widely available, which makes it a popular choice for manufacturing starter components. However, it is prone to corrosion if not properly coated, which can lead to premature failure in harsh environments. Additionally, the weight of steel can be a disadvantage in applications where weight reduction is critical.

التأثير على التطبيق: Steel components can handle the mechanical stresses involved in starter operation but may require protective coatings to enhance corrosion resistance, especially in humid or coastal regions.

اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM A36 for structural steel is essential. Buyers from regions with high humidity, like parts of Africa and South America, should prioritize corrosion-resistant coatings.

2. الألومنيوم

الخصائص الرئيسية: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is often used in applications where weight reduction is a priority.

Illustrative image related to symptoms of bad starter

الإيجابيات والسلبيات: The lightweight nature of aluminum makes it ideal for automotive applications, enhancing fuel efficiency. However, it is generally more expensive than steel and may not provide the same level of strength under extreme conditions. Additionally, aluminum components can be more complex to manufacture, requiring specialized processes.

التأثير على التطبيق: Aluminum components can improve the overall performance of starters by reducing weight, but they must be designed to withstand the mechanical stresses of operation.

اعتبارات للمشترين الدوليين: Buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions. In Europe, DIN standards may apply, and it is crucial to consider the availability of aluminum alloys that meet specific performance requirements.

3. نحاس

الخصائص الرئيسية: Copper is an excellent conductor of electricity and has good thermal conductivity. It is often used in electrical connections within starter systems.

Illustrative image related to symptoms of bad starter

الإيجابيات والسلبيات: Copper’s superior conductivity makes it ideal for electrical components, ensuring efficient power transfer. However, it is more expensive than steel and aluminum and can be prone to corrosion if not properly insulated.

التأثير على التطبيق: The use of copper in starter systems enhances performance by ensuring reliable electrical connections. However, its susceptibility to corrosion necessitates protective measures, especially in environments with high moisture.

اعتبارات للمشترين الدوليين: Compliance with electrical standards such as IEC 60228 for conductors is crucial. Buyers in the Middle East and Africa should consider the impact of local environmental conditions on copper’s longevity.

4. المركبات البلاستيكية

الخصائص الرئيسية: Plastic composites are lightweight, corrosion-resistant, and can be molded into complex shapes. They offer good electrical insulation properties.

الإيجابيات والسلبيات: The use of plastic composites can significantly reduce weight and manufacturing costs. However, they may not be as durable as metal options and can degrade under high temperatures or exposure to certain chemicals.

Illustrative image related to symptoms of bad starter

التأثير على التطبيق: While plastic composites can be used for non-structural components, their limitations in high-stress applications must be considered. They are ideal for insulating components but may not be suitable for load-bearing parts.

اعتبارات للمشترين الدوليين: Compliance with standards such as ASTM D638 for tensile properties of plastics is important. Buyers should evaluate the thermal and chemical resistance of plastic composites based on local conditions in regions like Europe and South America.

جدول ملخص

| المواد | Typical Use Case for symptoms of bad starter | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الصلب | Starter housing and gears | قوة ومتانة عالية | عرضة للتآكل | منخفض |

| الألومنيوم | غلاف محرك بدء التشغيل | خفيف الوزن ومقاوم للتآكل | More expensive and complex to manufacture | Med |

| النحاس | التوصيلات الكهربائية في المبتدئين | موصلية ممتازة | باهظة الثمن ومعرضة للتآكل | عالية |

| المركبات البلاستيكية | المكونات العازلة | خفيف الوزن وقابل للتشكيل | أقل متانة تحت الضغط | Med |

This material selection guide provides B2B buyers with essential insights into the properties and applications of various materials used in starter components, helping them make informed purchasing decisions tailored to their specific operational environments.

In-depth Look: Manufacturing Processes and Quality Assurance for symptoms of bad starter

ما هي المراحل الرئيسية لتصنيع محرك التشغيل؟

Manufacturing a starter motor involves several critical stages, each designed to ensure the final product meets performance and reliability standards. Understanding these stages is essential for B2B buyers looking to procure high-quality starter motors.

How is Material Prepared for Starter Motor Manufacturing?

The first stage of manufacturing involves material preparation, where raw materials such as steel, copper, and plastic are sourced. The selection of these materials is crucial, as they directly impact the durability and efficiency of the starter motor. For instance, high-grade steel is often used for the housing to withstand mechanical stresses, while copper is favored for electrical components due to its excellent conductivity.

Once sourced, the materials undergo rigorous quality checks to ensure they meet the necessary specifications. This may include chemical analysis and dimensional checks, ensuring that the materials are free from defects that could compromise performance.

ما هي التقنيات المستخدمة في تشكيل مكونات محرك التشغيل؟

After material preparation, the forming process begins. This stage typically includes several techniques such as forging, machining, and stamping.

- تزوير is often used to create the motor housing, where heated metal is shaped using compressive forces, resulting in a strong and lightweight structure.

- التصنيع الآلي processes, like CNC (Computer Numerical Control) turning and milling, are employed to achieve precise dimensions for components such as the rotor and stator.

- الختم is used to produce flat components quickly, such as brackets and covers, ensuring consistency in shape and size.

Each of these forming techniques requires skilled labor and advanced machinery to maintain high production standards.

كيف يتم تجميع وتشطيب محركات بدء التشغيل؟

ما الذي تنطوي عليه عملية التجميع؟

The assembly of starter motors involves the integration of various components, including the armature, field windings, solenoid, and housing. Skilled technicians often perform this stage, ensuring that each part is correctly aligned and securely fastened.

During assembly, quality control checkpoints are implemented. For instance, torque specifications for fastening components are strictly adhered to, and electrical connections are tested for continuity to prevent future failures.

ما هي تقنيات التشطيب المطبقة؟

Finishing processes include surface treatments such as coating and painting to prevent corrosion and enhance aesthetic appeal. Techniques like powder coating are common, as they provide a durable finish that can withstand harsh environments.

Additionally, performance testing is conducted during this phase to ensure that the starter motor meets operational standards. This may involve bench testing under various load conditions to simulate real-world performance.

What Are the Quality Control Measures for Starter Motors?

Quality control (QC) is an integral part of the manufacturing process, especially for components like starter motors that are critical to vehicle operation.

Which International Standards Are Relevant to Starter Motor Manufacturing?

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that the manufacturing process is consistently monitored and improved, leading to higher-quality products.

Illustrative image related to symptoms of bad starter

In addition to ISO standards, industry-specific certifications such as CE (European Conformity) for the European market and API (American Petroleum Institute) standards for specific applications may also be relevant. These certifications can help international buyers verify the quality and safety of the starter motors.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control is monitored at multiple checkpoints during the manufacturing process:

-

مراقبة الجودة الواردة (IQC): This stage checks raw materials for quality before they are used in production. This includes verifying specifications and inspecting for defects.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During the manufacturing process, ongoing inspections are conducted to ensure that components meet quality standards and specifications. This can include monitoring tolerances and testing for functionality at various stages of assembly.

-

مراقبة الجودة النهائية (FQC): Before shipping, the finished starter motors undergo thorough testing to confirm they meet performance criteria. This may include electrical testing, load testing, and visual inspections for cosmetic defects.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

What Methods Are Available for Conducting Supplier Audits?

B2B buyers can ensure the reliability of their suppliers by conducting audits. These audits can assess compliance with international standards, evaluate manufacturing processes, and review quality control practices. Buyers may choose to perform these audits themselves or hire third-party inspection services for an unbiased evaluation.

What Documentation Should Buyers Request from Suppliers?

Requesting documentation is crucial for verifying a supplier’s commitment to quality. Key documents include:

- Certificates of Compliance: These indicate that products meet specific standards and regulations.

- تقارير مراقبة الجودة: These provide insight into the QC measures taken during production and any issues encountered.

- Test Reports: Detailed testing results can help buyers understand the performance and reliability of the starter motors.

What Are the Nuances for International B2B Buyers in Quality Control?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local regulations and standards is vital. Certain regions may have unique requirements regarding safety and environmental impact that must be met.

Additionally, language barriers and differing quality expectations can complicate supplier relationships. Establishing clear communication and understanding the local market can help mitigate these challenges.

In summary, a thorough understanding of the manufacturing processes and quality assurance measures for starter motors not only enhances procurement strategies but also ensures that buyers can source reliable, high-quality products tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘symptoms of bad starter’

مقدمة

This guide provides a comprehensive checklist for B2B buyers who are looking to procure components related to the symptoms of a bad starter motor. Understanding these symptoms is vital for ensuring vehicle reliability and performance, especially in industries reliant on transportation and logistics. By following these steps, buyers can make informed decisions that enhance operational efficiency and reduce downtime.

الخطوة 1: Identify Key Symptoms of a Bad Starter

Before sourcing any components, familiarize yourself with the primary symptoms indicating a bad starter. Common signs include unusual noises like grinding or clicking, slow engine cranking, and intermittent starting issues. Recognizing these symptoms early can help mitigate more significant issues and reduce costs associated with unexpected breakdowns.

Illustrative image related to symptoms of bad starter

الخطوة 2: حدد المواصفات الفنية الخاصة بك

Clearly outline the technical requirements for the starter components you need. This may include voltage ratings, size, compatibility with specific vehicle models, and operational conditions. Providing detailed specifications will help suppliers understand your needs and ensure you receive the correct components that meet your operational requirements.

الخطوة 3: البحث والتحقق من أوراق اعتماد الموردين

It’s crucial to vet potential suppliers thoroughly. Look for certifications such as ISO or industry-specific standards that indicate quality assurance. Additionally, investigate their track record by requesting references or case studies from clients in similar sectors. This step ensures you partner with reputable suppliers who can deliver reliable products.

الخطوة 4: Evaluate Product Quality and Performance

Request samples or product specifications to assess the quality of the starter components. Look for details regarding materials used, manufacturing processes, and performance testing. High-quality components can significantly impact the longevity and efficiency of your vehicles, minimizing the risk of future starter issues.

الخطوة 5: Assess Warranty and Support Services

Inquire about warranty terms and the availability of after-sales support. A robust warranty indicates the supplier’s confidence in their product, while effective support services can be invaluable if issues arise post-purchase. Understanding these terms can help you avoid future liabilities and ensure your investment is protected.

الخطوة 6: Consider Supply Chain Reliability

Evaluate the supplier’s logistics capabilities and delivery timelines. A reliable supply chain is essential to avoid delays that could impact your operations. Assess their ability to meet your volume needs and ensure they can provide timely delivery, especially if you operate in regions with logistical challenges.

الخطوة 7: التفاوض على الأسعار وشروط الدفع

Engage in discussions about pricing, discounts for bulk orders, and payment terms. Understanding the total cost of ownership, including shipping and handling, will help you budget effectively. Negotiating favorable terms can enhance your cash flow and improve overall procurement efficiency.

By following this checklist, B2B buyers can make informed decisions when sourcing components related to symptoms of a bad starter, ultimately enhancing their operational efficiency and reducing costs associated with vehicle downtimes.

Comprehensive Cost and Pricing Analysis for symptoms of bad starter Sourcing

What Are the Key Cost Components for Sourcing Solutions Related to Bad Starter Symptoms?

When sourcing components related to bad starter symptoms, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

المواد: The quality and type of materials used can significantly influence costs. For starters, high-grade metals and electrical components can enhance performance but may raise initial costs. Assessing the balance between quality and price is essential for long-term reliability.

-

العمل: Skilled labor is often required for the assembly and installation of starter components. Labor costs can vary widely based on geographical location, with regions like Europe and North America generally experiencing higher labor rates compared to parts of Africa or South America.

-

تكاليف التصنيع العامة: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, allowing for more competitive pricing.

-

الأدوات: The initial investment in tooling for producing starter components can be significant, especially for custom solutions. Buyers should consider whether the tooling costs are amortized over large production runs to lower per-unit costs.

-

مراقبة الجودة: Ensuring that products meet quality standards involves additional costs. Investing in robust QC processes can prevent costly returns and enhance customer satisfaction.

-

اللوجستيات: Transportation and handling costs are vital, especially for international shipping. Different Incoterms can affect who bears these costs and should be considered when negotiating terms with suppliers.

-

الهامش: Supplier profit margins can vary based on market demand, competition, and the complexity of the product. Understanding the typical margins in the industry can aid in negotiations.

How Do Price Influencers Impact the Sourcing of Starter Components?

Several factors can influence the pricing of starter components, impacting the overall cost to buyers.

-

الحجم/الحد الأدنى للطلب: Minimum order quantities (MOQs) can dictate pricing structures. Higher order volumes typically yield better pricing due to economies of scale. International buyers should negotiate MOQs to ensure cost-effectiveness.

-

المواصفات/التخصيص: Customized starter solutions often incur additional costs. Buyers should clearly define specifications to avoid unexpected price escalations.

-

شهادات المواد والجودة: The choice of materials and the presence of quality certifications (e.g., ISO, TS) can significantly affect pricing. Products with higher certifications may come at a premium but can ensure reliability and compliance.

-

عوامل الموردين: Supplier reputation, reliability, and market positioning can impact pricing. Established suppliers may charge more due to their brand value and assurance of quality.

-

مصطلحات التجارة الدولية: The choice of Incoterms can influence the final price by determining shipping responsibilities and cost liabilities. Familiarity with Incoterms can help buyers negotiate better terms and reduce hidden costs.

What Are Some Effective Buyer Tips for Negotiating Costs in International Markets?

When navigating the complexities of international B2B sourcing, particularly in regions such as Africa, South America, the Middle East, and Europe, it’s essential to adopt strategic approaches.

-

التفاوض: Leverage multiple supplier quotes to create a competitive bidding environment. Don’t hesitate to negotiate on terms, especially regarding MOQ and payment terms.

-

الفعالية من حيث التكلفة: Always consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. TCO includes maintenance, operational efficiency, and potential downtime costs associated with poor-quality components.

-

الفروق الدقيقة في التسعير: Be aware of regional pricing differences and currency fluctuations. Establishing contracts in stable currencies can mitigate risks associated with exchange rate volatility.

-

Due Diligence: Conduct thorough research on suppliers, including their financial stability, production capabilities, and customer reviews. This helps ensure long-term partnerships that are beneficial for both parties.

In conclusion, a comprehensive understanding of cost components and pricing influencers, alongside strategic negotiation and due diligence, can significantly enhance the sourcing process for components related to bad starter symptoms. Buyers should remain informed and proactive to ensure they receive the best value in their international transactions.

Alternatives Analysis: Comparing symptoms of bad starter With Other Solutions

Understanding Alternatives to Diagnosing Starter Issues

In the automotive sector, accurately diagnosing issues with a vehicle’s starter system is crucial for ensuring operational efficiency. While the symptoms of a bad starter are essential indicators, alternative diagnostic methods and solutions can provide additional insights and reliability in identifying the root cause of starting problems. This analysis will compare the traditional method of observing symptoms of a bad starter with two viable alternatives: using advanced diagnostic tools and employing mobile diagnostic services.

جدول المقارنة

| جانب المقارنة | Symptoms Of Bad Starter | أدوات التشخيص المتقدمة | Mobile Diagnostic Services |

|---|---|---|---|

| الأداء | Relies on observable signs; can be misleading if other components fail. | High accuracy in identifying issues; provides detailed diagnostics. | Good for on-site assessments; combines various diagnostic methods. |

| التكلفة | Low cost, as it requires minimal investment. | Moderate to high cost for tools and software. | Varies based on service and location; can be more expensive than DIY. |

| سهولة التنفيذ | Simple and requires no special training; can be done by anyone. | Requires technical expertise to operate effectively. | Convenient as it brings services directly to the vehicle, but may require scheduling. |

| الصيانة | No ongoing costs; relies on user knowledge. | Tools require calibration and updates; ongoing costs for software. | Regular service fees; potential for subscription models. |

| أفضل حالة استخدام | Useful for quick, basic assessments and initial troubleshooting. | Ideal for in-depth analysis and professional workshops. | Excellent for fleet management or remote diagnostics in various locations. |

تفصيل البدائل

أدوات التشخيص المتقدمة

These tools leverage sophisticated technology, such as OBD-II scanners and software, to provide comprehensive diagnostics for a vehicle’s electrical system. The primary advantage of using advanced diagnostic tools is their ability to accurately pinpoint issues beyond just starter problems, including alternator and battery failures. However, these tools require technical expertise to interpret the data effectively, which can be a barrier for smaller businesses or individual mechanics. Additionally, the initial investment can be significant, but the long-term benefits of precise diagnostics can outweigh the costs.

Mobile Diagnostic Services

Mobile diagnostic services provide the convenience of on-site evaluations, allowing technicians to assess a vehicle’s starting issues directly at the location of the vehicle. This approach combines various diagnostic methods, often utilizing both manual observation and advanced technology. The primary advantage is the reduced downtime for businesses, especially those with a fleet of vehicles. However, the cost may vary widely depending on the service provider and location, and scheduling can sometimes be less flexible than DIY methods. Despite these drawbacks, mobile services offer an excellent solution for businesses that prioritize operational efficiency.

Illustrative image related to symptoms of bad starter

الخلاصة: اختيار الحل المناسب لاحتياجاتك

When selecting the appropriate diagnostic method for starter issues, B2B buyers should consider their specific operational requirements and resources. For businesses seeking cost-effective, straightforward assessments, relying on observable symptoms can be sufficient. However, for those requiring precision and detailed analysis, investing in advanced diagnostic tools or mobile services may be more beneficial. Ultimately, the choice will depend on the balance between budget constraints, the complexity of the vehicle’s electrical systems, and the need for rapid resolution to minimize downtime. By carefully evaluating these factors, buyers can ensure they select the most suitable diagnostic solution for their needs.

Essential Technical Properties and Trade Terminology for symptoms of bad starter

What Are the Key Technical Properties of Starters That Indicate Symptoms of Failure?

Understanding the critical technical properties associated with starter motors can help B2B buyers make informed decisions regarding replacement parts and maintenance. Here are some essential specifications:

-

درجة المواد

The materials used in a starter motor, such as high-grade steel for the housing and copper for windings, impact durability and performance. High-quality materials resist corrosion and wear, leading to longer service life, which is crucial for reducing operational costs in commercial fleets. -

تصنيف الجهد الكهربائي

Standard automotive starters typically operate at 12 volts. Knowing the voltage requirement is essential for ensuring compatibility with the vehicle’s electrical system. A mismatch can lead to failure, necessitating costly repairs and downtime. -

Torque Specification

The torque rating of a starter motor indicates its ability to crank the engine effectively. A higher torque rating is beneficial for vehicles with larger engines or those operating in extreme conditions. This is particularly important for B2B buyers involved in industries such as transportation or construction, where equipment reliability is critical. -

التيار المستهلك

Measured in amperes, the current draw of a starter motor is a vital specification. A starter that draws excessive current may indicate internal failure, leading to battery drain and operational inefficiencies. Understanding current draw helps in selecting starters that optimize energy consumption. -

Engagement and Disengagement Mechanism

Starters employ solenoids to engage and disengage the starter gear with the engine’s flywheel. The reliability of this mechanism is crucial; a malfunction can prevent the engine from starting or cause damage to both the starter and engine. B2B buyers should look for starters with robust solenoid designs to minimize failure risks.

What Are Common Trade Terms Relevant to Starters?

Familiarity with industry terminology is vital for effective communication and negotiation in the B2B sector. Here are some key terms related to starters:

Illustrative image related to symptoms of bad starter

-

OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the original manufacturer of the vehicle. These parts often provide the best fit and performance, making them a preferred choice for businesses focused on quality and reliability. -

MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest amount of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it affects inventory management and cash flow. Buyers should negotiate favorable MOQs to align with their operational needs. -

طلب عرض أسعار (RFQ)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. Crafting a detailed RFQ can help businesses receive competitive quotes for starter motors, ensuring they secure the best deals. -

شروط التجارة الدولية (Incoterms)

Incoterms are standardized trade terms used in international shipping that define the responsibilities of buyers and sellers. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery timelines associated with starter purchases. -

فترة الضمان

The warranty period is the time frame during which the manufacturer guarantees the performance of the starter. Understanding warranty terms can provide insight into the expected longevity and reliability of the product, which is essential for making cost-effective purchasing decisions.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the complexities of starter motor procurement with greater confidence, ensuring they choose the right components for their needs while optimizing operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the symptoms of bad starter Sector

What Are the Global Drivers Influencing the Symptoms of Bad Starter Sector?

The global market for automotive components, including starter motors, is shaped by a confluence of factors including technological advancements, evolving consumer preferences, and regulatory changes. As vehicles increasingly incorporate advanced electronics and connectivity features, the demand for reliable starter systems has surged. Key trends include the integration of smart technology in starters that can diagnose issues in real-time, which is particularly appealing to B2B buyers looking for enhanced reliability and performance.

Internationally, regions such as Africa and South America are witnessing a growing middle class that is investing in vehicle ownership, thereby increasing the demand for quality automotive parts. In contrast, Europe, particularly in markets like Germany, is focusing on sustainability and efficiency, leading to a preference for parts that offer longevity and lower failure rates. Additionally, the rise of electric vehicles (EVs) is prompting a shift in starter technology, as traditional starter systems may be replaced or adapted to fit new powertrains. B2B buyers must stay abreast of these trends to align their sourcing strategies accordingly, ensuring they meet the evolving demands of their customer base.

How Can B2B Buyers Address Sustainability and Ethical Sourcing in the Symptoms of Bad Starter Sector?

Sustainability is becoming a focal point in the automotive parts industry, particularly for B2B buyers. The environmental impact of manufacturing and disposing of automotive components like starters can be significant, leading to increased scrutiny from consumers and regulatory bodies. Ethical sourcing practices are essential in mitigating these impacts. Buyers should prioritize suppliers that demonstrate transparency in their supply chains, employ sustainable manufacturing processes, and utilize recyclable materials.

Illustrative image related to symptoms of bad starter

Additionally, certifications such as ISO 14001 for environmental management can provide assurance that suppliers are committed to reducing their ecological footprint. As the automotive industry moves toward greener technologies, sourcing components that are not only efficient but also produced with minimal environmental impact will enhance brand reputation and customer loyalty. B2B buyers are encouraged to seek out manufacturers who integrate sustainability into their design and production processes, ensuring that their purchases contribute positively to environmental goals.

What Is the Historical Context of the Symptoms of Bad Starter Sector?

The evolution of the starter motor can be traced back to the early 20th century when vehicles primarily relied on hand cranking. The introduction of the electric starter motor in the 1910s revolutionized the automotive industry, offering convenience and reliability. Over the decades, advancements in materials and technology have significantly improved the durability and performance of starters.

In recent years, the emergence of smart technologies and the integration of starters with vehicle diagnostics systems have transformed how B2B buyers approach sourcing. The shift towards electric vehicles also marks a significant turning point, as traditional starter designs adapt to meet new energy demands. Understanding this historical context is crucial for B2B buyers, as it informs their sourcing decisions and helps them anticipate future trends in the automotive components market.

Frequently Asked Questions (FAQs) for B2B Buyers of symptoms of bad starter

-

How do I identify the symptoms of a bad starter?

To identify the symptoms of a bad starter, look for signs such as unusual noises (grinding or clicking), slow engine cranking, intermittent starting issues, or dashboard lights illuminating without the engine turning over. Each of these symptoms can indicate a failing starter motor. For a more accurate diagnosis, consider using a voltmeter to check the voltage during starting attempts, and ensure the battery is in good condition, as it can often be mistaken for starter issues. -

What is the best way to troubleshoot starter problems?

The best way to troubleshoot starter problems is to perform a systematic check of the starter system. Start with the battery; ensure it is fully charged and in good condition. Next, inspect the starter connections for corrosion or loose wires. If the battery and connections are fine, attempt a jump-start. If the vehicle starts, the issue may be with the battery or alternator. If it doesn’t, the starter itself may need replacement. Document your findings for discussions with suppliers. -

What are common causes of starter failure in vehicles?

Common causes of starter failure include wear and tear over time, electrical issues such as faulty wiring or corroded connections, and problems with the starter relay or solenoid. Environmental factors, such as exposure to extreme temperatures or moisture, can also contribute to starter issues. Regular maintenance and inspections can help identify potential problems early, reducing the risk of sudden failures. -

How can I evaluate potential suppliers for starter components?

When evaluating suppliers for starter components, consider their industry reputation, years of experience, and customer testimonials. Request samples to assess the quality of their products and inquire about their manufacturing processes. Additionally, check if they comply with international quality standards, such as ISO certifications. Establish clear communication regarding lead times, payment terms, and return policies to ensure a smooth transaction. -

What minimum order quantities (MOQ) should I expect when sourcing starters?

Minimum order quantities (MOQ) for starters can vary significantly by supplier, typically ranging from 50 to 500 units, depending on the manufacturer’s production capabilities and your specific requirements. When negotiating with suppliers, discuss your needs and explore options for lower MOQs, especially if you’re just starting or testing a new market. Some suppliers may offer flexibility or tiered pricing based on order size. -

How do I ensure quality assurance (QA) when sourcing starters internationally?

To ensure quality assurance when sourcing starters internationally, establish a clear QA process that includes pre-shipment inspections and quality control checks at the supplier’s facility. Consider hiring a third-party inspection service to verify product specifications and compliance with industry standards. Additionally, maintain open communication with your supplier throughout the production process to address any issues promptly. -

What payment terms should I negotiate with international suppliers?

When negotiating payment terms with international suppliers, consider terms that protect your investment while ensuring timely delivery. Common options include letters of credit, advance payments, or net payment terms (e.g., 30, 60, or 90 days). Discuss the potential for partial payments upon order confirmation and final payment upon delivery to balance risk. Always review the terms carefully and ensure they align with your cash flow management. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد البادئات؟

When importing starters, consider logistics factors such as shipping methods, customs regulations, and transit times. Choose a reliable freight forwarder familiar with automotive parts to navigate the complexities of international shipping. Ensure that all necessary documentation (e.g., invoices, packing lists, certificates of origin) is prepared to facilitate customs clearance. Additionally, plan for potential delays and have contingency plans in place to maintain your supply chain continuity.

Top 3 Symptoms Of Bad Starter Manufacturers & Suppliers List

1. Reddit – Starter Troubleshooting Guide

المجال: reddit.com

تاريخ التسجيل: 2005 (20 عامًا)

مقدمة: This company, Reddit – Starter Troubleshooting Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Facebook – Starter Issues

المجال: facebook.com

تاريخ التسجيل: 1997 (28 عامًا)

مقدمة: This company, Facebook – Starter Issues, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Subaru WRX – Starter Motor Concerns

المجال: mechanics.stackexchange.com

تاريخ التسجيل: 2009 (16 عامًا)

مقدمة: 2004 Subaru WRX, 110000 miles, audible symptoms of failing starter motor include grinding screech on cold starts, low amplitude grinding squeal even on warm days, no problems starting the car yet, concerns about original equipment starter motor.

Strategic Sourcing Conclusion and Outlook for symptoms of bad starter

In conclusion, understanding the symptoms of a bad starter is crucial for international B2B buyers in the automotive sector, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Recognizing early signs such as unusual noises, slow cranking, and intermittent starting issues can prevent costly downtime and improve operational efficiency.

Strategic sourcing of quality starter components from reputable suppliers ensures reliability and longevity, reducing the likelihood of future failures. Buyers should prioritize partnerships with manufacturers who emphasize quality control and provide comprehensive warranties, thereby safeguarding their investments.

As the automotive industry continues to evolve, staying informed about advancements in starter technology and sourcing practices will be essential for maintaining competitive advantage. We encourage buyers to engage with trusted suppliers, attend industry expos, and invest in ongoing training for their teams. By doing so, you can enhance your procurement strategies and ensure your fleet remains operational and efficient. Embrace the future of automotive sourcing with confidence, knowing that informed decisions today will drive success tomorrow.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.