مقدمة: الإبحار في السوق العالمية لمعرفة تكلفة مولد التيار المتردد

في المشهد الديناميكي لسوق السيارات العالمي، يعد فهم تكلفة مولد التيار المتردد أمرًا بالغ الأهمية بالنسبة للمشترين الدوليين بين الشركات. لا يؤثر الحصول على المولد المناسب على الأداء العام للمركبات فحسب، بل يؤثر أيضًا على الكفاءة التشغيلية وتكاليف الصيانة. يُعد هذا الدليل بمثابة مورد شامل، حيث يتعمق في الأنواع المختلفة لمولدات التيار المتردد وتطبيقاتها عبر طرازات السيارات المختلفة والعوامل الأساسية التي تؤثر على الأسعار.

يواجه المشترون من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، بما في ذلك بلدان مثل نيجيريا وفيتنام، تحديات فريدة من نوعها في الحصول على قطع غيار السيارات عالية الجودة. وتشمل هذه التحديات التعامل مع موثوقية الموردين، وفهم ظروف السوق المحلية، وضمان الامتثال للمعايير الدولية. من خلال تقديم رؤى حول عمليات فحص الموردين والمواصفات الرئيسية التي يجب مراعاتها والتفاصيل التفصيلية للتكاليف، يمكّن هذا الدليل صانعي القرار من اتخاذ خيارات شراء مستنيرة.

من خلال التركيز على تقديم معلومات قابلة للتنفيذ، نهدف إلى إزالة الغموض عن تعقيدات تسعير المولدات وتوافرها. لا يزود هذا المورد المشترين بين الشركات بالمعرفة اللازمة للتفاوض بفعالية فحسب، بل يساعدهم أيضًا على تأمين مولدات كهربائية موثوقة تلبي احتياجاتهم التشغيلية المحددة. سواء كنت مدير أسطول سيارات أو تاجر تجزئة للسيارات، فإن فهم هذه التعقيدات سيمكنك من تحسين استراتيجية الشراء الخاصة بك وتعزيز ميزتك التنافسية في السوق.

جدول المحتويات

- أعلى 1 أعلى 1 كم تكلفة المولد قائمة المصنعين والموردين قائمة الموردين

- مقدمة: الإبحار في السوق العالمية لمعرفة تكلفة مولد التيار المتردد

- فهم مقدار تكلفة مولد التيار المتردد أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لكمية تكلفة مولد التيار المتردد

- 3 نقاط ألم شائعة للمستخدمين حول ‘كم تكلفة المولد’ وحلولها

- دليل اختيار المواد الاستراتيجية لمعرفة تكلفة مولد التيار المتردد

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لكمية تكلفة مولد التيار المتردد

- دليل عملي للمصادر: قائمة تدقيق خطوة بخطوة لـ ‘كم تبلغ تكلفة المولد’

- تحليل شامل للتكلفة والتسعير لمصادر التكلفة والتسعير لمقدار تكلفة المولد المولد

- تحليل البدائل: مقارنة كم تكلفة المولد مع الحلول الأخرى

- الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية لكمية تكلفة المولد الكهربائي

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع كم يكلف مولد التيار المتردد

- الأسئلة المتداولة (FAQs) لمشتري B2B عن تكلفة مولد التيار المتردد

- استنتاج المصادر الاستراتيجية والتوقعات بشأن تكلفة مولد التيار المتردد

- إخلاء مسؤولية هام وشروط الاستخدام

فهم مقدار تكلفة مولد التيار المتردد أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولدات الجديدة | مواصفات جديدة تماماً، وبمواصفات OEM، وموثوقية عالية عادةً | ورش تصليح السيارات والوكلاء | الإيجابيات: موثوقية عالية وتغطية ضمان عالية. السلبيات: تكلفة مقدمة أعلى. |

| المولدات المعاد تصنيعها | أعيد بناؤها من قطع مستعملة، وتم اختبارها للتأكد من جودتها وانخفاض تكلفتها | ورشات مستقلة، تجار قطع غيار | الإيجابيات: فعالة من حيث التكلفة والأداء الجيد. السلبيات: ضمان أقصر، وتباين محتمل في الجودة. |

| المولدات عالية الأداء | إنتاجية أعلى، مصممة للمركبات المعدلة، ومواد محسنة | فرق السباقات ومتاجر الأداء | الإيجابيات: زيادة إنتاجية الطاقة، ومتانة أفضل. السلبيات: سعر أعلى، قد يتطلب تعديلات. |

| المولدات أحادية السلك | أسلاك مبسطة وسهلة التركيب ومناسبة للمركبات القديمة | مرممو السيارات الكلاسيكية والميكانيكيون الذين يصنعون السيارات الكلاسيكية بأنفسهم | الإيجابيات: سهلة التركيب، منخفضة التكلفة. السلبيات: توافق محدود مع الأنظمة الحديثة. |

| المولدات ذات القدرة العالية | مصممة للمركبات ذات المتطلبات الكهربائية العالية | الشاحنات الثقيلة والمركبات التجارية | الإيجابيات: يدعم إلكترونيات متعددة وموثوقة تحت الحمل. السلبيات: عادةً ما تكون أثقل وأكثر تكلفة. |

ما هي المولدات الجديدة ومدى ملاءمتها للمشترين بين الشركات؟

يتم تصنيع مولدات المولدات الجديدة لتلبية مواصفات الشركة المصنعة للمعدات الأصلية (OEM)، مما يضمن موثوقية وأداءً عاليًا. وهي مثالية لورش إصلاح السيارات والوكلاء الذين يعطون الأولوية للجودة وتغطية الضمان لعملائهم. على الرغم من أن التكلفة الأولية أعلى، إلا أن الموثوقية طويلة الأجل ودعم الضمان يجعل من المولدات الجديدة خيارًا مفضلاً للعديد من مشتري الأعمال التجارية الذين يبحثون عن قطع غيار يمكن الاعتماد عليها لصيانة السيارة.

لماذا تختار المولدات المعاد تصنيعها للحصول على حلول فعالة من حيث التكلفة؟

يتم إعادة تصنيع مولدات المولدات المعاد تصنيعها من قطع مستعملة وتخضع لاختبارات صارمة لضمان الجودة. وهي تعتبر بديلاً فعالاً من حيث التكلفة بالنسبة للكراجات المستقلة وتجار قطع الغيار الذين يتطلعون إلى تقديم أسعار تنافسية دون التضحية بالأداء. ومع ذلك، يجب على المشترين الأخذ بعين الاعتبار أن هذه الوحدات قد تأتي مع ضمانات أقصر وتباين محتمل في الجودة، مما يجعل من الضروري الحصول عليها من موردين ذوي سمعة جيدة.

ما الذي يجعل المولدات عالية الأداء مثالية للتطبيقات المتخصصة؟

تم تصميم مولدات المولدات عالية الأداء للمركبات التي تتطلب خرجاً أعلى بسبب التعديلات أو الأنظمة الكهربائية المحسنة. وتستخدم هذه الوحدات عادةً من قبل فرق السباقات ومحلات الأداء العالي التي تحتاج إلى توصيل طاقة موثوقة في ظل ظروف صعبة. وعلى الرغم من أنها توفر متانة وإنتاج طاقة أكبر، يجب أن يكون المشترون مستعدين لسعر أعلى وتعديلات محتملة لتناسب مركباتهم.

كيف يعمل المولد أحادي السلك على تبسيط عملية تركيب السيارات الكلاسيكية؟

تم تصميم المولدات ذات السلك الواحد لسهولة التركيب، خاصةً في السيارات القديمة حيث تكون الأسلاك المبسطة مفيدة. وهي تحظى بشعبية بين مرممي السيارات الكلاسيكية والميكانيكيين الذين يقومون بأعمالهم بأنفسهم والذين يقدرون إعدادها المباشر. على الرغم من أنها أقل تكلفة بشكل عام، إلا أنه يجب أن يكون المشترون على دراية بتوافقها المحدود مع الأنظمة الكهربائية الحديثة، مما قد يحد من استخدامها في السيارات الأحدث.

ما هي فوائد المولدات عالية القدرة للتطبيقات الشاقة؟

تم تصميم المولدات عالية القدرة خصيصًا للمركبات ذات المتطلبات الكهربائية الكبيرة، مثل الشاحنات الثقيلة والمركبات التجارية. توفر هذه المولدات طاقة موثوقة لأنظمة إلكترونية متعددة، مما يجعلها ضرورية للشركات التي تعتمد على الآلات الثقيلة. على الرغم من أنها تميل إلى أن تكون أثقل وأكثر تكلفة من المولدات العادية، إلا أن قدرتها على دعم الأحمال الكهربائية الكبيرة تجعلها استثمارًا مهمًا للمشترين من الشركات في القطاع التجاري.

التطبيقات الصناعية الرئيسية لكمية تكلفة مولد التيار المتردد

| الصناعة/القطاع | التطبيق المحدد لتكلفة مولد التيار المتردد | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| ورش تصليح السيارات | تحليل تكلفة استبدال مولد التيار المتردد | وضع ميزانية دقيقة للإصلاحات وتعزيز رضا العملاء | النظر في خيارات الضمان ومواصفات القطعة |

| خدمات الأسطول التجاري | تقييم تكاليف المولدات المتحركة لصيانة الأسطول | تحسين الكفاءة التشغيلية وتقليل وقت التوقف عن العمل | اتفاقيات الشراء بالجملة وموثوقية الموردين |

| الطاقة المتجددة | توريد مولدات التيار المتردد للسيارات الهجينة أو الكهربائية | زيادة الاستدامة والامتثال للوائح التنظيمية | التوافق مع مواصفات السيارة ومعايير الأداء |

| معدات البناء | فهم تكاليف مولد التيار المتردد للآلات الثقيلة | تحسين موثوقية المعدات وخفض التكاليف التشغيلية | توافر قطع الغيار لماركات معينة من الماكينات |

| الصناعة البحرية | تقييم تكلفة المولدات المترددة في التطبيقات البحرية | تعزيز السلامة والكفاءة التشغيلية على متن السفن | الامتثال للوائح التنظيمية البحرية والمعايير البيئية |

كيف تستفيد ورش إصلاح السيارات من فهم تكاليف المولد؟

غالبًا ما تواجه ورش إصلاح السيارات تحديات في تقديم أسعار شفافة للعملاء، خاصةً عندما يتعلق الأمر باستبدال المولدات. من خلال فهم تكلفة المولدات، يمكن للمحلات التجارية وضع تقديرات دقيقة، مما يؤدي إلى تحسين ثقة العملاء ورضاهم. بالإضافة إلى ذلك، يمكن أن يؤدي الحصول على مولدات عالية الجودة مع ضمانات قوية إلى تقليل معدلات الإرجاع وتعزيز سمعة المتجر. يجب على المشترين الدوليين، خاصة من مناطق مثل إفريقيا وأمريكا الجنوبية، مراعاة أسعار السوق المحلية وموثوقية الموردين عند الحصول على هذه المكونات.

ما المزايا التي تحققها خدمات الأسطول التجاري من خلال تقييم تكاليف المولد؟

بالنسبة لخدمات الأساطيل التجارية، يُعد تقييم تكاليف مولد التيار المتردد أمرًا بالغ الأهمية للحفاظ على الكفاءة التشغيلية. يضمن المولد الذي تتم صيانته بشكل جيد تشغيل المركبات بسلاسة، مما يقلل من مخاطر الأعطال غير المتوقعة ووقت التعطل المكلف. من خلال إبرام اتفاقيات الشراء بالجملة مع موردين موثوقين، يمكن لمديري الأساطيل التفاوض على أسعار أفضل وضمان توافر قطع الغيار بشكل ثابت. كما يجب على الشركات العاملة في الشرق الأوسط وأوروبا أن تأخذ في الحسبان رسوم الاستيراد وديناميكيات سلسلة التوريد المحلية عند الحصول على مولدات التيار المتردد.

كيف يستفيد قطاع الطاقة المتجددة من رؤى تكلفة المولدات؟

في قطاع الطاقة المتجددة، خاصةً مع ظهور السيارات الهجينة والكهربائية، فإن فهم تكاليف المولدات أمر ضروري للمصنعين والموردين. تُعد هذه المكونات جزءًا لا يتجزأ من تحويل الطاقة الميكانيكية إلى طاقة كهربائية، مما يجعل موثوقيتها أمرًا حاسمًا للأداء. يجب أن يتأكد المشترون من أن المولدات تفي بمعايير التوافق والأداء المحددة، خاصة في مناطق مثل أفريقيا حيث يتزايد اعتماد السيارات الكهربائية. وهذا يتطلب الحصول على مصادر من الشركات المصنعة التي يمكنها تقديم مواصفات وشهادات مفصلة.

لماذا يعتبر فهم تكاليف المولد مهمًا لمعدات البناء؟

تعتمد معدات البناء اعتمادًا كبيرًا على أنظمة كهربائية قوية، مما يجعل تكلفة المولدات عاملاً مهمًا في ميزانيات الصيانة الإجمالية. إن فهم هذه التكاليف يسمح لشركات الإنشاءات بالتخطيط للإصلاحات والاستبدال بفعالية، مما يضمن في النهاية موثوقية المعدات. يجب على المشترين في أمريكا الجنوبية وأفريقيا النظر في مدى توافر المولدات لعلامات تجارية محددة من الماكينات لتجنب التأخير في العمليات. وعلاوة على ذلك، فإن تقييم الموردين على أساس قدرتهم على توفير الدعم وقطع الغيار في الوقت المناسب أمر حيوي لتقليل وقت التعطل إلى أدنى حد ممكن.

كيف تستفيد الصناعة البحرية من تقييمات تكلفة المولدات؟

في الصناعة البحرية، تلعب مولدات التيار المتردد دورًا حاسمًا في تشغيل الأنظمة الأساسية على متن السفن. يمكن أن يؤدي فهم التكاليف المرتبطة بهذه المكونات إلى وضع ميزانية أفضل للصيانة والإصلاحات، مما يعزز السلامة العامة والكفاءة التشغيلية. يجب على المشترين الدوليين، خاصةً في المناطق ذات اللوائح البحرية الصارمة، التأكد من أن المولدات التي يتم الحصول عليها تتوافق مع المعايير البيئية ومتطلبات الأداء. يساعد هذا الاعتبار الدقيق في الحفاظ على موثوقية السفينة والامتثال للوائح الصناعة.

3 نقاط ألم شائعة للمستخدمين حول ‘كم تكلفة المولد’ وحلولها

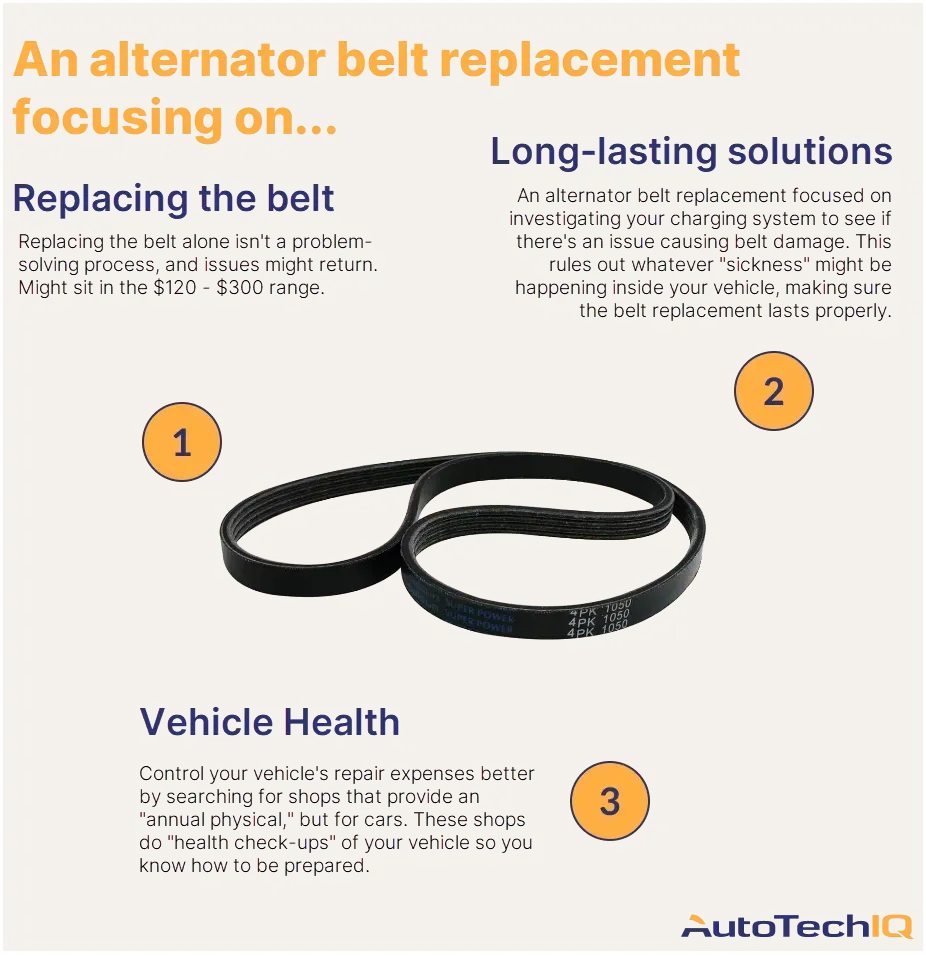

السيناريو 1: التكاليف المرتفعة غير المتوقعة لاستبدال المولد

المشكلة: قد يواجه المشتري من شركة إلى أخرى في قطاع السيارات تكاليف عالية غير متوقعة مرتبطة باستبدال المولد بسبب عدم فهم العوامل المؤثرة في الأسعار. هذا الوضع شائع بشكل خاص عندما تقوم الشركات بشراء قطع الغيار دون مراعاة مواصفات السيارة بشكل كامل مثل الطراز والطراز والسنة. ونتيجة لذلك، قد تتلقى هذه الشركات عروض أسعار للموديلات المتطورة أو المولدات المتخصصة التي تتجاوز ميزانيتها، مما يؤدي إلى تجاوز الميزانية والتأخير في التشغيل.

الحل: لإدارة التكاليف بفعالية، يجب على المشترين استثمار الوقت في فهم المتطلبات المحددة للمركبات التي يقومون بصيانتها. ويشمل ذلك البحث عن متوسط النطاق السعري لمولدات التيار المتردد في مختلف الماركات والموديلات. يمكن أن يوفر استخدام موارد مثل قواعد بيانات قطع غيار السيارات عبر الإنترنت رؤى حول مقارنات الأسعار. بالإضافة إلى ذلك، فإن إقامة علاقات مع العديد من الموردين يمكن أن يساعد المشترين على التفاوض على أسعار أفضل. يجب على الشركات أيضاً أن تأخذ بعين الاعتبار شروط الضمان، حيث أن الضمانات الأطول قد تكلف أكثر في البداية ولكنها قد توفر قيمة أفضل على المدى الطويل. من خلال مواءمة قرارات الشراء مع مواصفات السيارة الدقيقة، يمكن للمشترين تقليل التكاليف غير المتوقعة والحفاظ على سلامة الميزانية.

السيناريو 2: صعوبة في الحصول على المولد المناسب

المشكلة: يواجه العديد من المشترين بين الشركات تحديات عند الحصول على المولد الصحيح لطرازات السيارات القديمة أو الأقل شيوعًا. ويمكن أن يؤدي ذلك إلى فترات تعطل طويلة حيث يكافحون للعثور على قطع غيار متوافقة، مما يؤدي إلى خسارة الإيرادات وعدم رضا العملاء. تتفاقم هذه المشكلة في المناطق ذات الوصول المحدود إلى موردي السيارات، مما يجعل من الضروري للمشترين العثور على مصادر موثوقة بسرعة.

الحل: للتغلب على صعوبات التوريد، يجب على المشترين إقامة شراكات مع الموردين المتخصصين الذين يركزون على القطع التي يصعب العثور عليها. كما يمكن أن يؤدي استخدام الأسواق الإلكترونية التي تلبي احتياجات مكونات السيارات على وجه التحديد إلى نتائج مثمرة. يمكن أن يساعد تنفيذ نظام إدارة المخزون في تتبع المولدات المتاحة وتبسيط عملية التوريد، مما يضمن الوصول إلى المكونات المناسبة دائمًا. بالإضافة إلى ذلك، يمكن للمشترين المشاركة في المنتديات أو شبكات الصناعة حيث يمكنهم تبادل المعلومات حول الموردين الموثوق بهم وتوافر القطع. من خلال بناء شبكة من الموردين الموثوق بهم بشكل استباقي، يمكن للمشترين تقليل المهل الزمنية وضمان حصولهم على القطع المناسبة عند الحاجة.

السيناريو 3: الارتباك بشأن أنواع المولدات ومواصفاتها

المشكلة: غالبًا ما يواجه المشترون بين الشركات ارتباكًا فيما يتعلق بالأنواع المختلفة لمولدات التيار المتردد ومواصفاتها، مما قد يؤدي إلى عمليات شراء غير صحيحة. وينتشر هذا الالتباس بشكل خاص عند التعامل مع المركبات المتطورة التي قد تتطلب مولدات كهربائية متخصصة. ونتيجة لذلك، قد ينتهي الأمر بالمشترين بمكونات لا تفي بمتطلبات التيار أو التركيب اللازمة، مما يستلزم المزيد من عمليات الشراء ومضاعفة التكاليف.

الحل: ولمعالجة هذه المشكلة، يجب على المشترين إعطاء الأولوية للتثقيف حول الأنواع المختلفة من المولدات ومواصفاتها. يمكنهم إجراء دورات تدريبية لفرق الشراء لديهم أو الاستفادة من الموارد عبر الإنترنت لتعزيز فهمهم. يمكن أن يساعد إنشاء قائمة مرجعية مفصلة بالمواصفات، بما في ذلك متطلبات التيار الكهربائي وأنماط التركيب، في تبسيط عملية اتخاذ القرار. بالإضافة إلى ذلك، فإن الاستفادة من خبرات الموردين الذين يمكنهم تقديم رؤى حول أنسب مولد كهربائي لتطبيقات محددة يمكن أن يمنع حدوث أخطاء مكلفة. من خلال التزود بالمعرفة والموارد، يمكن للمشترين اتخاذ قرارات مستنيرة، مما يضمن لهم شراء المولد الصحيح في كل مرة.

دليل اختيار المواد الاستراتيجية لمعرفة تكلفة مولد التيار المتردد

ما هي المواد الرئيسية التي تؤثر على تكاليف المولد؟

عند النظر في تكلفة المولدات الكهربائية، تلعب المواد المستخدمة في بنائها دورًا حاسمًا في تحديد كل من الأداء والسعر. ونقوم هنا بتحليل أربع مواد شائعة مستخدمة في المولدات، مع التركيز على خصائصها ومزاياها وعيوبها وآثارها على المشترين الدوليين من الشركات على مستوى العالم، خاصة في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا.

كيف يؤثر النحاس على أداء المولد وتكلفته؟

يُعد النحاس مادة أساسية تُستخدم في لفات المولدات الكهربائية نظراً لخصائصه الممتازة في التوصيل الكهربائي والحراري. وتشمل الخصائص الرئيسية للنحاس نقطة انصهار عالية (حوالي 1,984 درجة فهرنهايت أو 1,085 درجة مئوية) ومقاومة ملحوظة للتآكل، مما يجعله مناسباً لمختلف الظروف البيئية.

الإيجابيات: تضمن الموصلية العالية للنحاس نقل الطاقة بكفاءة، مما يؤدي إلى أداء أفضل وطول عمر المولد. كما أنه سهل الاستخدام نسبياً أثناء التصنيع.

السلبيات: العيب الرئيسي للنحاس هو تكلفته، والتي يمكن أن تكون مرتفعة، خاصة خلال فترات تقلبات السوق. بالإضافة إلى ذلك، يمكن أن يساهم وزنه في الكتلة الإجمالية لمولد التيار المتردد، مما يؤثر على كفاءة استهلاك الوقود في تطبيقات السيارات.

التأثير على التطبيق: إن توافق النحاس مع البيئات ذات درجات الحرارة المرتفعة يجعله مثاليًا لتطبيقات السيارات حيث يكون توليد الحرارة شائعًا.

اعتبارات للمشترين الدوليين: يجب أن يكون المشترون على دراية بتفاوت أسعار النحاس والتعريفات المحتملة التي قد تؤثر على التكاليف. ومن الضروري أيضاً الامتثال للمعايير الدولية (مثل ASTM B170 للنحاس).

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

ما الدور الذي يلعبه الألومنيوم في تصنيع المولد؟

يتم استخدام الألومنيوم بشكل متزايد في علب المولدات وبعض تطبيقات اللف بسبب خفة وزنه وخصائصه المقاومة للتآكل. وتبلغ درجة انصهاره حوالي 1,221 درجة فهرنهايت (660 درجة مئوية) وهو معروف بنسبة قوته إلى وزنه الممتازة.

الإيجابيات: تساعد الطبيعة خفيفة الوزن للألومنيوم على تقليل الوزن الإجمالي للمولد، مما يمكن أن يحسن من كفاءة استهلاك السيارة للوقود. بالإضافة إلى ذلك، فإن الألومنيوم أقل تكلفة بشكل عام من النحاس.

السلبيات: وعلى الرغم من أن الألومنيوم يتمتع بموصلية جيدة، إلا أنه ليس بفعالية النحاس، مما قد يؤدي إلى انخفاض كفاءة نقل الطاقة بشكل طفيف. علاوة على ذلك، يمكن أن يكون التعامل مع الألومنيوم أكثر صعوبة من حيث اللحام والتشغيل الآلي.

التأثير على التطبيق: يعد الألومنيوم مناسبًا للتطبيقات التي يكون فيها توفير الوزن أمرًا بالغ الأهمية، ولكنه قد لا يعمل بشكل جيد في السيناريوهات الكهربائية عالية الطلب.

اعتبارات للمشترين الدوليين: يجب على المشترين التأكد من أن مكونات الألومنيوم تتوافق مع المعايير ذات الصلة، مثل ISO 9001 لأنظمة إدارة الجودة، والتي يمكن أن تختلف حسب المنطقة.

كيف تؤثر مكونات الصلب والحديد على وظيفة المولد؟

غالباً ما يستخدم الفولاذ والحديد في المكونات الهيكلية للمولدات، مثل الدوار والجزء الثابت. تبلغ درجة انصهار الفولاذ حوالي 2500 درجة فهرنهايت (1370 درجة مئوية)، بينما تبلغ درجة انصهار الحديد حوالي 2800 درجة فهرنهايت (1538 درجة مئوية).

الإيجابيات: يوفر الفولاذ والحديد المتانة والقوة، وهما ضروريان للمكونات الميكانيكية للمولد. كما أنها غير مكلفة نسبيًا مقارنة بالمواد الأخرى.

السلبيات: الجانب السلبي الرئيسي هو أن الفولاذ والحديد عرضة للتآكل ما لم تتم معالجته بشكل مناسب، مما قد يؤدي إلى فشل سابق لأوانه. بالإضافة إلى ذلك، يمكن أن يساهم وزنهما في ثقل المولد بشكل عام.

التأثير على التطبيق: إن متانة الفولاذ والحديد تجعلهما مناسبين للتطبيقات عالية الإجهاد، ولكن قد يكون وزنهما عيباً في المركبات ذات الأداء العالي.

اعتبارات للمشترين الدوليين: يجب على المشترين البحث عن الطلاءات المقاومة للتآكل والتأكد من توافقها مع معايير المواد المحلية، مثل DIN للأسواق الألمانية.

ماذا عن المواد البلاستيكية والمركبة في المولدات الكهربائية؟

يتم استخدام المواد البلاستيكية والمواد المركبة بشكل متزايد في المكونات غير الهيكلية لمولدات الكهرباء، مثل العلب والعوازل. وتتراوح درجة انصهار هذه المواد عادةً ما بين 300 درجة فهرنهايت و500 درجة فهرنهايت (149 درجة مئوية إلى 260 درجة مئوية)، اعتمادًا على النوع المحدد.

الإيجابيات: الميزة الأساسية للبلاستيك هي طبيعته خفيفة الوزن ومقاومته للتآكل. كما أنه يسمح بأشكال وتصميمات أكثر تعقيداً، مما يعزز الأداء.

السلبيات: قد لا تتحمل المواد البلاستيكية درجات الحرارة المرتفعة بنفس فعالية المعادن، مما قد يحد من استخدامها في تطبيقات معينة. كما يمكن أن تكون أقل تحملاً بمرور الوقت عند تعرضها لظروف بيئية قاسية.

التأثير على التطبيق: البلاستيك مناسب للأجزاء التي لا تتعرض لإجهاد ميكانيكي أو درجة حرارة عالية، مما يجعله مثاليًا للأجزاء العازلة والعازلات.

اعتبارات للمشترين الدوليين: يجب أن يتأكد المشترون من أن المكونات البلاستيكية تفي بمعايير السلامة والأداء ذات الصلة، مثل UL 94 لقابلية الاشتعال.

ملخص الاعتبارات المادية لتكاليف المولدات الكهربائية

| المواد | حالة الاستخدام النموذجية لمقدار تكلفة المولدات الكهربائية | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | الملفات والتوصيلات الكهربائية | موصلية ممتازة | تكلفة عالية | عالية |

| الألومنيوم | العلب وبعض اللفات | خفيف الوزن ومقاوم للتآكل | موصلية أقل من النحاس | متوسط |

| فولاذ/حديد | المكونات الهيكلية مثل الدوار والجزء الثابت | متين وقوي | عرضة للتآكل | منخفض |

| بلاستيك | المكونات غير الهيكلية مثل العلب والعوازل | خفة الوزن ومرونة التصميم | مقاومة محدودة لدرجات الحرارة | متوسط |

يوفر هذا التحليل نظرة ثاقبة على المواد التي تؤثر بشكل كبير على تكاليف المولدات، مما يساعد المشترين الدوليين بين الشركات على اتخاذ قرارات مستنيرة بناءً على متطلبات الأداء والاعتبارات الإقليمية.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

نظرة متعمقة: عمليات التصنيع وضمان الجودة لكمية تكلفة مولد التيار المتردد

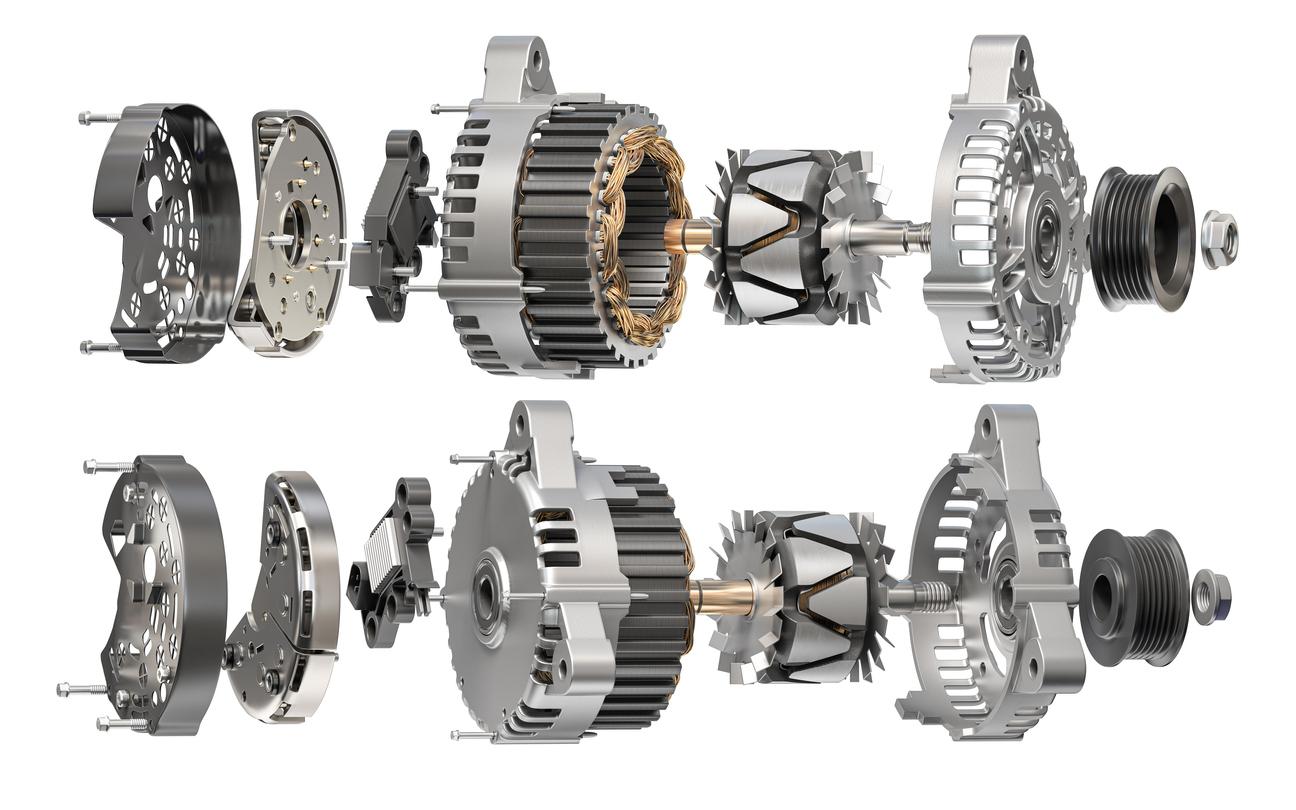

ما هي المراحل الرئيسية لعملية تصنيع المولدات الكهربائية؟

تتضمن عملية تصنيع مولدات التيار المتردد عدة مراحل حاسمة تضمن أن المنتج النهائي يفي بمعايير الأداء والجودة. يعد فهم هذه المراحل أمرًا حيويًا بالنسبة للمشترين بين الشركات حيث يمكن أن تؤثر على التكلفة الإجمالية والموثوقية والضمان لمولدات التيار المتردد التي يتم الحصول عليها.

تحضير المواد: ما هي المواد المستخدمة في تصنيع المولد؟

الخطوة الأولى في عملية التصنيع هي إعداد المواد الخام. وتشمل المواد الأولية المستخدمة في المولدات الكهربائية الفولاذ عالي الجودة والأسلاك النحاسية والسبائك المختلفة التي تعزز الأداء. وغالبًا ما يحصل المصنعون على هذه المواد من موردين معتمدين لضمان مطابقتها للمعايير الدولية.

تبدأ مراقبة الجودة في هذه المرحلة، مع فحوصات مراقبة الجودة الواردة (IQC) للتحقق من مطابقة المواد للمواصفات. ويمكن أن تتضمن هذه الخطوة اختبارات لتركيب المواد وقوة الشد والتوصيل الكهربائي، وهي أمور حاسمة لكفاءة المولد وطول عمره.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

كيف يتم تشكيل المولدات وتشكيلها أثناء التصنيع؟

بعد إعداد المواد، تكون المرحلة التالية هي التشكيل. ويشمل ذلك عمليات مثل الختم والصب والتشغيل الآلي للمكونات المختلفة للمولّد، بما في ذلك الجزء الثابت والدوّار والمبيت. ويمكن استخدام تقنيات متقدمة مثل التصنيع الآلي باستخدام الحاسب الآلي والقطع بالليزر لتحقيق أبعاد وتفاوتات دقيقة.

خلال هذه المرحلة، يتم إجراء فحوصات مراقبة الجودة أثناء العملية (IPQC) لضمان تصنيع كل مكون بشكل صحيح. وقد يشمل ذلك فحوصات الأبعاد والاختبارات الوظيفية للتحقق من أن الأجزاء تتوافق مع بعضها البعض بسلاسة.

ما هي تقنيات التجميع المستخدمة في تصنيع المولد؟

بمجرد تشكيل جميع المكونات، يتم الانتقال إلى مرحلة التجميع. هذا هو المكان الذي يتم فيه تجميع المولد معًا، بما في ذلك تركيب الدوار والجزء الثابت والتوصيلات الكهربائية. يمكن استخدام خطوط التجميع الآلية لتعزيز الكفاءة، ولكن التجميع اليدوي شائع أيضًا للمكونات الحساسة للجودة.

تشمل نقاط التحقق من الجودة الرئيسية أثناء التجميع فحوصات عزم الدوران على أدوات التثبيت والفحص البصري بحثًا عن أي علامات تلف أو اختلال في المحاذاة. تستخدم بعض الشركات المصنعة تقنيات متقدمة، مثل الأذرع الروبوتية، لضمان التجميع المتسق والدقيق.

ما هي عمليات التشطيب التي يتم تطبيقها على المولدات؟

المرحلة الأخيرة في عملية التصنيع هي التشطيب، والتي قد تشمل المعالجات السطحية والطلاء والطلاء لتعزيز المتانة ومقاومة التآكل. هذه العمليات حيوية، خاصة في المناطق ذات الظروف البيئية القاسية، حيث يمكن أن تؤثر بشكل كبير على عمر المولد.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

يتم إجراء مراقبة الجودة النهائية (FQC) في هذه المرحلة، مع إجراء اختبار شامل للمنتج النهائي للتأكد من أنه يفي بمواصفات الأداء. ويمكن أن يشمل ذلك الاختبارات الكهربائية للتحقق من خرج الجهد واختبارات التدوير الحراري لتقييم الأداء تحت درجات حرارة مختلفة.

ما هي المعايير الدولية وإجراءات ضمان الجودة ذات الصلة بالمولدات؟

يجب أن يكون المشترون بين الشركات على دراية بالمعايير الدولية المختلفة التي تحكم تصنيع وضمان جودة المولدات الكهربائية. لا يضمن الامتثال لهذه المعايير جودة المنتج فحسب، بل يسهل أيضًا التجارة الدولية بشكل أكثر سلاسة.

كيف تؤثر معايير ISO على تصنيع المولدات؟

ISO 9001 هي واحدة من أكثر معايير إدارة الجودة المعترف بها وتنطبق على تصنيع المولدات الكهربائية. ويدل الامتثال لمعيار الأيزو 9001 على أن الشركة المصنعة قد أنشأت نظامًا لإدارة الجودة يركز على تلبية متطلبات العملاء وتعزيز رضاهم.

بالإضافة إلى معايير ISO، قد تنطبق الشهادات الخاصة بالصناعة مثل CE (المطابقة الأوروبية) وAPI (معهد البترول الأمريكي)، خاصةً بالنسبة لمولدات التيار المتردد المستخدمة في تطبيقات محددة مثل القطاعات الصناعية أو قطاعات السيارات. وغالبًا ما تتطلب هذه الشهادات اختبارات ووثائق صارمة، مما يضمن للمشترين سلامة المنتج وموثوقيته.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

ما هي نقاط التحقق الرئيسية لمراقبة الجودة في تصنيع المولدات؟

للتأكد من أن المولدات تفي بالمواصفات المطلوبة، يقوم المصنعون بتنفيذ العديد من نقاط فحص مراقبة الجودة خلال عملية الإنتاج.

ما هي مراقبة الجودة الواردة (IQC)؟

يتم إجراء مراقبة الجودة الشاملة على المواد الخام قبل دخولها خط الإنتاج. وتتحقق هذه المرحلة من خلو المواد من العيوب واستيفائها للمواصفات المطلوبة. وقد تشمل الاختبارات الشائعة تحليل تركيب المواد وفحص الأبعاد.

كيف تعمل مراقبة الجودة أثناء العملية (IPQC)؟

تحدث مراقبة الجودة المتكاملة أثناء عملية التصنيع وتتضمن المراقبة المستمرة للإنتاج. ويشمل ذلك التحقق من أبعاد المكونات والتأكد من اتباع عمليات التجميع بشكل صحيح وإجراء الاختبارات الوظيفية على التجميعات الفرعية.

ما هي مراقبة الجودة النهائية (FQC)؟

تتم مراقبة الجودة النوعية بعد تجميع المولد بالكامل وتتضمن اختبارًا شاملاً للمنتج النهائي. ويمكن أن يشمل ذلك اختبارات الأداء الكهربائي والتدوير الحراري والفحص البصري لضمان خلو المنتج من العيوب.

كيف يمكن للمشترين B2B التحقق من ممارسات مراقبة الجودة لدى الموردين؟

بالنسبة للمشترين الدوليين بين الشركات، فإن التحقق من ممارسات مراقبة الجودة للموردين المحتملين أمر ضروري.

ما هي أفضل الممارسات لإجراء عمليات تدقيق الموردين؟

يعد إجراء عمليات تدقيق الموردين أحد أكثر الطرق فعالية لتقييم تدابير مراقبة الجودة الخاصة بالشركة المصنعة. يجب أن يبحث المشترون عن تقارير تدقيق مفصلة توضح الامتثال لمعايير المنظمة الدولية لتوحيد المقاييس والعمليات الداخلية وأي إجراءات تصحيحية تم اتخاذها في الماضي.

كيف يمكن لعمليات التفتيش من طرف ثالث تعزيز الثقة في جودة الموردين؟

يمكن أن يوفر إشراك خدمات التفتيش من طرف ثالث مستوى إضافي من الضمان. يمكن لهذه الكيانات المستقلة إجراء عمليات التفتيش في مراحل مختلفة من عملية التصنيع وتقديم تقارير غير متحيزة عن الالتزام بالجودة.

ما هي الفروق الدقيقة في مراقبة الجودة والاعتماد للمشترين الدوليين بين الشركات؟

يجب على المشترين بين الشركات من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا أن يكونوا على دراية بالفروق الدقيقة المحددة المتعلقة بمراقبة الجودة والاعتماد.

كيف تؤثر المعايير الإقليمية على توقعات الجودة؟

قد تختلف توقعات الجودة والمتطلبات التنظيمية باختلاف المناطق. على سبيل المثال، قد تفرض لوائح الاتحاد الأوروبي إرشادات أكثر صرامة مقارنةً بتلك الموجودة في مناطق أخرى. يجب على المشترين التعرف على المعايير المحلية لضمان الامتثال.

ما الدور الذي تلعبه شهادات الامتثال في التجارة الدولية؟

تعمل شهادات الامتثال كدليل على أن المنتج يفي بمعايير ولوائح محددة. يمكن أن تكون هذه المستندات ضرورية للتخليص الجمركي ويمكن أن تساعد في تسهيل العلاقات التجارية بشكل أكثر سلاسة. يجب أن يطلب المشترون دائمًا هذه الشهادات من الموردين للتأكد من أن المنتجات تفي بمعايير منطقتهم.

في الختام، يُعد فهم عمليات التصنيع ومقاييس ضمان الجودة لمولدات التيار المتردد أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات. من خلال الاطلاع على مراحل الإنتاج والمعايير ذات الصلة وممارسات مراقبة الجودة، يمكن للمشترين اتخاذ قرارات شراء أكثر استنارة وتعزيز موثوقية سلاسل التوريد الخاصة بهم.

دليل عملي للمصادر: قائمة تدقيق خطوة بخطوة لـ ‘كم تبلغ تكلفة المولد’

مقدمة

يوفر دليل التوريد العملي هذا للمشترين بين الشركات قائمة مرجعية شاملة لشراء مولدات التيار المتردد بفعالية وفهم التكاليف المرتبطة بها. مع اختلاف المواصفات وظروف السوق عبر مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، سيساعدك هذا الدليل في اتخاذ قرارات شراء مستنيرة.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

يعد تحديد متطلباتك الفنية بوضوح أمرًا ضروريًا للحصول على المولد المناسب. ضع في اعتبارك عوامل مثل سنة السيارة وطرازها وطرازها وحجم محركها. يجب أيضًا مراعاة الاحتياجات المحددة للتيار الكهربائي وأنماط التركيب لضمان التوافق والكفاءة في التشغيل.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

- متطلبات الأمبيرية: تحتاج المركبات المختلفة إلى مولدات كهربائية ذات معدلات أمبيرية متفاوتة. تأكد من فهمك للحمل الكهربائي الذي ستتطلبه سيارتك.

- التوافق: تحقق من مطابقة المولد للمواصفات المطلوبة لسيارتك لتجنب الأخطاء المكلفة.

الخطوة 2: تسعير السوق البحثية

يعد فهم النطاق السعري لمولدات التيار المتردد أمرًا بالغ الأهمية لتجنب الدفع الزائد. يمكن أن تتفاوت الأسعار بشكل كبير بناءً على العلامة التجارية والجودة والمنطقة، وعادةً ما تتراوح بين $100 و$1000.

- اتجاهات السوق المحلية: ابحث في اتجاهات الأسعار في منطقتك المحددة لتحديد ميزانية واقعية.

- التحليل المقارن: قارن الأسعار من موردين متعددين لتحديد الأسعار التنافسية والخصومات المحتملة لعمليات الشراء بالجملة.

الخطوة 3: تقييم شهادات الموردين

قبل الالتزام بأي مورد، من الضروري التحقق من شهاداته ومعايير الصناعة الخاصة به. يجب أن يلتزم الموردون ذوو السمعة الحسنة بتدابير مراقبة الجودة وأن يمتلكوا الشهادات ذات الصلة.

- شهادات ISO: ابحث عن الموردين الحاصلين على شهادة ISO 9001، مما يشير إلى التزامهم بإدارة الجودة.

- معلومات الضمان: قم بتقييم الضمان المقدم على مولدات الكهرباء، حيث يعكس ذلك ثقة الشركة المصنعة في منتجاتها.

الخطوة 4: تحقق من توفر المنتج وأوقات الانتظار

تأكد من توفر المولدات المحددة التي تحتاجها وتأكد من توفر المولدات التي تحتاجها وافهم المهل الزمنية للتسليم. هذا مهم بشكل خاص للشركات التي تعتمد على الإصلاحات أو الاستبدال في الوقت المناسب.

- مستويات المخزون: تأكد من أن المورد لديه مخزون كافٍ لتلبية احتياجاتك دون تأخير.

- خيارات الشحن: استفسر عن طرق الشحن وأوقات التسليم المقدرة لتخطيط عملياتك بفعالية.

الخطوة 5: طلب عينات ومواصفات المنتج

قبل الانتهاء من عملية الشراء، اطلب عينات أو مواصفات تفصيلية للمنتج. سيسمح لك ذلك بتقييم جودة وتوافق المولدات مع مركباتك.

- تقييم الجودة: افحص العينات للتحقق من جودة التصنيع والمواد المستخدمة، وتأكد من أنها تفي بمعاييرك.

- الوثائق الفنية: راجع أوراق بيانات المنتج لفهم المواصفات الكهربائية والمعلمات التشغيلية.

الخطوة 6: التفاوض على الشروط وخيارات الدفع

يمكن أن يساعد الدخول في مفاوضات في تأمين أسعار أفضل وشروط مواتية. ناقش خيارات السداد، بما في ذلك الخصومات بالجملة وشروط الائتمان التي يمكن أن تفيد التدفق النقدي لديك.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

- شروط دفع مرنة: استكشف خيارات تمديد شروط السداد أو التمويل، خاصةً للطلبات الكبيرة.

- فرص الخصم: استفسر عن الخصومات على المدفوعات المبكرة أو تكرار العمل لزيادة قوتك الشرائية.

الخطوة 7: تأسيس علاقة طويلة الأمد

يمكن أن يؤدي بناء علاقة قوية مع مورد مولد التيار المتردد الخاص بك إلى خدمة وأسعار أفضل في المستقبل. فكر في الموردين الذين يثبتون الموثوقية وسرعة الاستجابة.

- حلقة التغذية الراجعة: تقديم ملاحظات حول أداء المنتج والخدمة لتعزيز العلاقة التعاونية.

- الاحتياجات المستقبلية: ناقش متطلباتك المستقبلية لضمان قدرة المورد على تلبية احتياجاتك المتطورة مع نمو أعمالك.

سيمكّنك اتباع قائمة المراجعة هذه من التنقل في عملية شراء مولدات التيار المتردد بفعالية، مما يضمن لك الحصول على أفضل المنتجات بأسعار تنافسية.

تحليل شامل للتكلفة والتسعير لمصادر التكلفة والتسعير لمقدار تكلفة المولد المولد

ما هي مكونات التكلفة الرئيسية لتوريد المولدات؟

يشتمل هيكل تكلفة توريد المولدات على العديد من المكونات الهامة. وتشمل هذه المكونات المواد، والعمالة، ونفقات التصنيع العامة، والأدوات، ومراقبة الجودة، والخدمات اللوجستية، وهوامش الربح.

-

المواد: تشمل المواد الأساسية لمولدات التيار المتردد النحاس للملفات، والصلب للدوار والجزء الثابت، ومواد بلاستيكية مختلفة للمبيت والموصلات. يمكن أن تؤثر جودة هذه المواد ومصدرها بشكل كبير على التكلفة. على سبيل المثال، يمكن أن يؤدي استخدام النحاس عالي الجودة إلى تحسين الأداء وطول العمر، ولكنه قد يرفع السعر.

-

العمل: تختلف تكاليف العمالة حسب منطقة التصنيع. فالبلدان ذات الأجور المرتفعة، مثل تلك الموجودة في أوروبا، ستشهد عادةً زيادة في تكاليف العمالة مقارنةً بالمناطق في أفريقيا أو أمريكا الجنوبية حيث قد تكون العمالة أرخص.

-

تكاليف التصنيع العامة: يشمل ذلك المرافق وصيانة المعدات ومساحة المصنع، والتي تساهم في التكلفة الإجمالية للإنتاج. يمكن أن تساعد عمليات التصنيع الفعالة في تقليل هذه التكاليف.

-

الأدوات: يمكن أن تتطلب الأدوات المتخصصة لإنتاج المولدات الكهربائية استثمارات كبيرة، مما يؤثر على الأسعار الأولية. ويمكن للأدوات المخصصة لطرازات معينة من المركبات أن تزيد من التكاليف.

-

مراقبة الجودة (QC): تضمن عمليات الاختبار الصارمة وعمليات ضمان الجودة الصارمة أن يفي كل مولد بمعايير الأداء. قد تؤدي عمليات مراقبة الجودة المحسنة إلى زيادة التكاليف ولكنها ضرورية لمنع العيوب وضمان رضا العملاء.

-

اللوجستيات: يمكن أن تختلف تكاليف الشحن بناءً على المسافة من موقع التصنيع إلى موقع المشتري، وطرق النقل، وأي تعريفات أو رسوم جمركية أو رسوم متضمنة في التجارة الدولية.

-

الهامش: يضيف الموردون عادةً هامش ربح لتغطية المخاطر وضمان استدامة العمليات التجارية. ويمكن أن يتقلب الهامش بناءً على طلب السوق والمنافسة.

كيف تؤثر العوامل المؤثرة في الأسعار على تكاليف المولد؟

هناك عدة عوامل تؤثر على أسعار المولدات في سوق B2B:

-

الحجم/الحد الأدنى لكمية الطلب: غالباً ما تؤدي المشتريات بالجملة إلى انخفاض تكاليف الوحدة الواحدة. ويكون الموردون أكثر استعداداً للتفاوض على أسعار الطلبيات الكبيرة بسبب انخفاض تكاليف المناولة والشحن.

-

المواصفات والتخصيص: يمكن أن تؤدي المولدات المخصصة المصممة خصيصاً لتلبية متطلبات محددة للمركبة أو تحسينات الأداء إلى زيادة التكاليف. يجب على المشترين تحديد احتياجاتهم بوضوح لتجنب التكاليف غير المتوقعة.

-

المواد: يؤثر اختيار المواد، مثل درجة النحاس أو نوع الغلاف، تأثيراً مباشراً على التكلفة. وعادة ما تؤدي المواد الأعلى جودة إلى أداء أفضل ولكن بسعر أعلى.

-

الجودة والشهادات: قد تأتي المولدات الحاصلة على شهادات صناعية محددة أو تلك التي تلتزم بمعايير جودة صارمة بسعر أعلى ولكنها توفر موثوقية أكبر ودعم ضمان أكبر.

-

عوامل الموردين: يمكن أن تؤثر سمعة المورد وموثوقيته على التكاليف. وقد يفرض الموردون الراسخون أسعاراً أعلى نظراً لسجلهم الحافل بالإنجازات، بينما قد يعرض الموردون الجدد أسعاراً أقل لكسب حصة في السوق.

-

مصطلحات التجارة الدولية: يمكن أن تؤثر شروط الشحن والمسؤولية عن الخدمات اللوجستية على التكلفة الإجمالية. ومن الضروري فهم شروط التجارة الدولية لتجنب التكاليف الخفية المتعلقة بالشحن والجمارك والتأمين.

ما هي النصائح الفعالة للمشتري فيما يتعلق بمصادر المولد؟

يجب على المشترين بين الشركات الذين يتطلعون إلى الحصول على مصادر المولدات الكهربائية أن يضعوا في اعتبارهم الاستراتيجيات التالية لتعزيز كفاءة التكلفة:

-

التفاوض: إشراك الموردين في المفاوضات لتأمين أفضل الأسعار، خاصة بالنسبة لطلبات الشراء بالجملة. فوجود عروض أسعار متعددة يمكن أن يعزز موقفك التفاوضي.

-

التكلفة الإجمالية للملكية (TCO): قم بتقييم التكلفة الإجمالية، بما في ذلك الصيانة المحتملة وتغطية الضمان والأداء بمرور الوقت، بدلاً من التركيز فقط على التكاليف الأولية. قد يؤدي المولد الأرخص إلى نفقات أعلى على المدى الطويل إذا تعطل قبل الأوان.

-

الفروق الدقيقة في الأسعار للمشترين الدوليين: يجب على المشترين من مناطق مثل أفريقيا أو أمريكا الجنوبية أن يأخذوا في الحسبان التكاليف الإضافية مثل التعريفات الجمركية ورسوم الاستيراد والخدمات اللوجستية المحلية عند مقارنة الأسعار. كما يمكن أن يؤثر فهم ظروف السوق المحلية على استراتيجيات التفاوض.

-

علاقات الموردين: يمكن أن يؤدي بناء علاقات قوية مع الموردين إلى تحسين الأسعار، والأولوية في الإنتاج، وتحسين الخدمة. كما أن إقامة شراكات طويلة الأجل يمكن أن توفر أيضاً رؤى متعمقة في اتجاهات السوق وفرص تحقيق وفورات في المستقبل.

إخلاء المسؤولية عن الأسعار الإرشادية

يمكن أن تتقلب أسعار المولدات الكهربائية على نطاق واسع بناءً على عوامل مختلفة، بما في ذلك ظروف السوق واستراتيجيات تسعير الموردين والتأثيرات الجيوسياسية. ابحث دائمًا عن عروض أسعار حالية ومحددة من الموردين لضمان وضع ميزانية دقيقة لاحتياجاتك من المصادر.

تحليل البدائل: مقارنة كم تكلفة المولد مع الحلول الأخرى

فهم بدائل تكاليف المولدات

عند النظر في التكاليف المرتبطة بمولدات التوليد، يجب على مشتري B2B أيضًا تقييم الحلول البديلة التي يمكن أن تحقق أهدافًا مماثلة في أداء السيارة والموثوقية الكهربائية. في حين أن مولد التيار المتردد هو مكون أساسي لتوليد الطاقة الكهربائية في المركبات، توجد بدائل أو أنظمة تكميلية مختلفة قد تقدم فوائد مختلفة اعتمادًا على التطبيق المحدد والميزانية والمتطلبات التشغيلية.

جدول المقارنة

| جانب المقارنة | كم تبلغ تكلفة المولد | استبدال البطارية | أنظمة الطاقة الشمسية |

|---|---|---|---|

| الأداء | ضروري لعمليات المحرك؛ عادةً ما تكون المخرجات 13.8-14.6 فولت | توفر طاقة محدودة؛ تتطلب شحنًا منتظمًا | يمكن أن توفر طاقة مستمرة ولكن تعتمد على توفر ضوء الشمس |

| التكلفة | $100 - $1000 | $50 - $300 | $1,000 - $3,000 للإعداد |

| سهولة التنفيذ | معتدل؛ يتطلب تركيباً احترافياً | سهل؛ يمكن للمستخدمين القيام به | معقدة؛ تتطلب تركيب وفهم تكنولوجيا الطاقة الشمسية |

| الصيانة | منخفضة؛ تدوم عادةً من 7 إلى 10 سنوات | معتدلة؛ تحتاج البطاريات إلى فحوصات دورية واستبدالها | عالية؛ تتطلب صيانة الألواح والبطاريات |

| أفضل حالة استخدام | تطبيقات السيارات القياسية | النسخ الاحتياطي لاحتياجات الطاقة على المدى القصير | التطبيقات خارج الشبكة أو الطاقة التكميلية للمركبات الكهربائية |

تفصيل البدائل

استبدال البطارية

يعمل استبدال البطارية كبديل مباشر لاستبدال المولد. في حين أن البطاريات يمكن أن توفر الطاقة اللازمة لتشغيل السيارة وتشغيل الأنظمة الكهربائية، إلا أنها ليست حلاً طويل الأجل لتوليد الطاقة. وتتراوح تكلفة استبدال البطارية عادةً من $50 إلى $300، اعتماداً على النوع والسعة. الميزة الأساسية لهذا الحل هي سهولة تنفيذه؛ حيث يمكن للعديد من المستخدمين استبدال البطاريات دون مساعدة مهنية. ومع ذلك، تتطلب البطاريات شحنًا منتظمًا وقد لا توفر طاقة كافية لجميع أنظمة المركبات، خاصة في حالات ارتفاع الطلب.

أنظمة الطاقة الشمسية

تمثل أنظمة الطاقة الشمسية بديلاً أكثر ابتكاراً، خاصة بالنسبة للمركبات الكهربائية أو التطبيقات خارج الشبكة. يمكن لهذه الأنظمة توفير طاقة مستمرة وتقليل الاعتماد على مصادر الطاقة التقليدية. يمكن أن تكون تكلفة الإعداد الأولي كبيرة، حيث تتراوح بين $1,000 إلى $3,000، اعتمادًا على حجم وتعقيد التركيب. ومع ذلك، يمكن لأنظمة الطاقة الشمسية أن تخفض التكاليف التشغيلية على المدى الطويل كما أنها صديقة للبيئة. يمكن أن تكون صيانة أنظمة الطاقة الشمسية عالية، لأنها تتطلب فحوصات منتظمة للألواح الشمسية وأنظمة تخزين البطاريات. بالإضافة إلى ذلك، يعتمد أداؤها بشكل كبير على توافر أشعة الشمس، مما يجعلها أقل موثوقية في المناطق ذات أنماط الطقس غير المتناسقة.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

عند الاختيار بين المولد والحلول البديلة مثل بدائل البطاريات أو أنظمة الطاقة الشمسية، يجب على مشتري B2B تقييم احتياجاتهم التشغيلية المحددة وقيود الميزانية والأهداف طويلة الأجل بعناية. في حين أن مولد التيار المتردد غالبًا ما يكون الخيار الأكثر موثوقية وفعالية للمركبات التقليدية، قد تكون البدائل مناسبة للتطبيقات المتخصصة أو في المناطق التي تختلف فيها احتياجات توليد الطاقة. سيؤدي فهم إيجابيات وسلبيات كل خيار إلى تمكين المشترين من اتخاذ قرارات مستنيرة تتماشى مع متطلبات أعمالهم وكفاءتهم التشغيلية.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

الخصائص التقنية الأساسية والمصطلحات التجارية الأساسية لكمية تكلفة المولد الكهربائي

ما هي المواصفات الفنية الرئيسية للمولدات التي تؤثر على تكلفتها؟

يعد فهم المواصفات الفنية لمولدات التيار المتردد أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات في اتخاذ قرارات شراء مستنيرة. فيما يلي بعض الخصائص الأساسية التي تؤثر على أسعار المولدات وأدائها:

1. تصنيف الأمبيرية

تشير الأمبيرية إلى التيار الكهربائي الذي يمكن لمولد المولد توليده. وهي مواصفات بالغة الأهمية لأنها تحدد قدرة المولد على تشغيل المكونات الكهربائية المختلفة في السيارة. على سبيل المثال، تتطلب السيارات ذات المتطلبات الكهربائية العالية، مثل تلك المجهزة بأنظمة معلومات وترفيه متقدمة أو ملحقات إلكترونية متعددة، مولدات ذات معدلات أمبيرية أعلى. عند البحث عن مصادر لمولدات التيار المتردد، تأكد من توافق الأمبيرية مع متطلبات السيارة لتجنب ضعف الأداء أو التلف المحتمل.

2. نمط التركيب

يعد نمط تركيب المولد ضروريًا للتوافق مع طرازات معينة من المركبات. تحتوي المركبات المختلفة على تكوينات تركيب فريدة من نوعها، والتي يمكن أن تؤثر على عملية التركيب والوظائف العامة. يجب على مشتري B2B التحقق من أن نمط تركيب المولد يتطابق مع مواصفات السيارة لضمان الملاءمة والوظيفة المناسبة. يمكن أن يؤدي عدم التوافق إلى تكاليف إضافية في العمالة وقطع الغيار.

3. ناتج الجهد

عادةً ما تنتج المولدات الحديثة جهداً يتراوح بين 13.5 و14.5 فولت، وهو أمر ضروري لشحن بطارية السيارة وتشغيل الأنظمة الكهربائية. يمكن أن يؤدي المولد الذي يفشل في الحفاظ على هذا الجهد إلى استنزاف البطارية والأعطال الكهربائية. من الضروري للمشترين فهم متطلبات الجهد الكهربائي لسياراتهم واختيار المولدات التي تلبي هذه المواصفات أو تتجاوزها لضمان التشغيل الموثوق.

4. فترة الضمان

تعتبر فترة الضمان لمولد المولد من الاعتبارات الرئيسية التي يمكن أن تؤثر على التكاليف الإجمالية. فغالبًا ما يشير الضمان الأطول إلى جودة ومتانة أعلى، وهو ما يمكن أن يُترجم إلى تكاليف أقل على المدى الطويل بسبب انخفاض معدلات الأعطال. يجب على المشترين تقييم شروط الضمان التي يقدمها المصنعون أو الموردون ومراعاتها في تحليل التكلفة الإجمالية. يمكن أن يوفر الضمان القوي أيضًا راحة البال وضمان موثوقية المنتج.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

5. تركيب المواد

وتلعب المواد المستخدمة في تصنيع المولدات، مثل النحاس للملفات والصلب عالي الجودة للمبيت دورًا مهمًا في الأداء وطول العمر. يمكن للمواد عالية الجودة أن تزيد من التكلفة الأولية ولكنها غالبًا ما تؤدي إلى متانة وكفاءة أفضل، وهو أمر بالغ الأهمية للتطبيقات عالية الطلب. يجب على مشتري B2B تقييم مواصفات المواد للتأكد من أنهم يستثمرون في المولدات التي ستتحمل الضغوط التشغيلية ولها عمر افتراضي أطول.

ما هي المصطلحات التجارية الشائعة المستخدمة في معاملات المولدات؟

يمكن أن يؤدي التنقل بين المصطلحات المرتبطة بمولدات الكهرباء إلى تبسيط عملية الشراء. فيما يلي بعض المصطلحات الشائعة في هذا المجال التي يجب أن يكون المشترون من الشركات على دراية بها:

1. OEM (الشركة المصنعة للمعدات الأصلية)

تُصنع قطع غيار OEM من قبل نفس الشركة المصنعة التي أنتجت المكون الأصلي للسيارة. وغالباً ما تكون هذه القطع مفضلة لتوافقها المضمون وموثوقيتها. يجب على مشتري B2B أن يأخذوا بعين الاعتبار مولدات المولدات الأصلية لمركبات الأسطول أو التطبيقات عالية الأداء، حيث أنها تضمن نفس جودة ومواصفات المعدات الأصلية.

2. MOQ (الحد الأدنى لكمية الطلب)

يشير مصطلح "موك" إلى أصغر كمية من المنتج الذي يرغب المورد في بيعه. ويُعد فهم موك أمرًا ضروريًا للمشترين بين الشركات (B2B)، حيث يمكن أن يؤثر على إدارة المخزون والتدفق النقدي. يجب أن يتفاوض المشترون على موك الذي يتماشى مع استراتيجية الشراء والاحتياجات التشغيلية.

3. طلب عرض أسعار (RFQ)

طلب عرض الأسعار هو مستند رسمي يتم إرساله إلى الموردين لطلب التسعير وتفاصيل أخرى لمنتجات محددة. وفي سياق المولدات الكهربائية، يمكن أن يساعد طلب عرض الأسعار المنظم جيدًا المشترين في الحصول على عروض أسعار وشروط تنافسية من موردين متعددين، مما يسهل عملية اتخاذ القرار بشكل أفضل.

4. شروط التجارة الدولية (Incoterms)

إنكوترمز هي مجموعة من القواعد المعترف بها دوليًا والتي تحدد مسؤوليات المشترين والبائعين في عملية الشحن. وبالنسبة للمعاملات بين الشركات التي تشمل المولدات الكهربائية، فإن فهم شروط إنكوترمز أمر بالغ الأهمية لتوضيح تكاليف الشحن وإدارة المخاطر والجداول الزمنية للتسليم، والتي يمكن أن تؤثر بشكل كبير على التكلفة الإجمالية للمشتريات.

من خلال فهم هذه الخصائص التقنية والمصطلحات التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات أكثر استنارة عند الحصول على مصادر المولدات، مما يؤدي في النهاية إلى نتائج شراء أفضل وكفاءة تشغيلية أفضل.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع كم يكلف مولد التيار المتردد

نظرة عامة على السوق والاتجاهات الرئيسية في قطاع المولدات الكهربائية

يشهد سوق المولدات الكهربائية العالمية تحولاً كبيرًا مدفوعًا بعوامل مختلفة. يؤدي الطلب المتزايد على السيارات الكهربائية (EVs) والسيارات الهجينة إلى إعادة تشكيل المشهد، مع تركيز الشركات المصنعة على تصميمات أكثر كفاءة لمولدات التيار المتردد لدعم الأنظمة الكهربائية المتقدمة. ويعطي المشترون من الشركات وخاصة من مناطق مثل إفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا الأولوية بشكل متزايد لمولدات التيار المتردد التي توفر أداءً محسنًا ومتانة. ويأتي هذا التحول مدفوعًا بالحاجة إلى الموثوقية في ظروف التشغيل القاسية ونمو سوق خدمات ما بعد البيع للسيارات.

تكتسب التقنيات الناشئة، مثل المولدات الرقمية وأنظمة الشحن الذكية، زخماً متزايداً. وتوفر هذه الابتكارات مراقبة البيانات في الوقت الفعلي وتحسين كفاءة الطاقة، والتي يمكن أن تكون مفيدة بشكل خاص لمشغلي الأساطيل الذين يتطلعون إلى تحسين أداء المركبات وتقليل التكاليف التشغيلية. بالإضافة إلى ذلك، يتزايد الاتجاه نحو إعادة تصنيع المولدات الكهربائية المعاد تصنيعها، مما يوفر خيارًا فعالاً من حيث التكلفة وصديقًا للبيئة للمشترين. هذا الاتجاه مهم بشكل خاص للأسواق التي تمثل فيها قيود الميزانية مصدر قلق رئيسي.

يتأثر المشترون الدوليون أيضًا بتقلبات تكاليف المواد الخام، لا سيما النحاس، وهو عنصر أساسي في تصنيع مولدات الكهرباء. ومع ارتفاع الطلب على السيارات الكهربائية، تزداد المنافسة على هذه المواد، مما يؤدي إلى تقلب الأسعار. يحتاج المشترون إلى البقاء على اطلاع على ديناميكيات السوق والنظر في إقامة شراكات طويلة الأجل مع الموردين للتخفيف من المخاطر المرتبطة بتقلبات الأسعار.

كيف يمكن أن تؤثر الاستدامة والتوريد الأخلاقي على سوق المولدات الكهربائية؟

أصبحت الاستدامة اعتبارًا أساسيًا للمشترين بين الشركات في قطاع المولدات الكهربائية. لا يمكن المبالغة في التأثير البيئي لعمليات التصنيع وأهمية سلاسل التوريد الأخلاقية. تبحث الشركات بشكل متزايد عن الموردين الذين يلتزمون بالممارسات المستدامة، مثل الحد من انبعاثات الكربون وتقليل النفايات. وهذا مهم بشكل خاص في المناطق التي يتم فيها تشديد اللوائح البيئية.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

ويكتسب استخدام الشهادات ‘الخضراء’ والمواد المستدامة في إنتاج المولدات الكهربائية زخمًا متزايدًا. يتم تشجيع المشترين على الاستفسار عن مصادر المواد، وخاصة النحاس والمعادن الأخرى، وعمليات التصنيع التي يستخدمها الموردون. لا يمكن للاستثمار في المولدات الكهربائية المصنوعة من مواد معاد تدويرها أو تلك المنتجة بأقل تأثير بيئي ممكن أن يعزز مسؤولية الشركات فحسب، بل يجذب أيضًا قاعدة متنامية من المستهلكين المهتمين بالبيئة.

علاوة على ذلك، يمكن أن يؤدي تطبيق الممارسات المستدامة إلى تحقيق وفورات في التكاليف على المدى الطويل. فمن خلال اعتماد عمليات التصنيع الموفرة للطاقة واستراتيجيات التوريد المستدامة، يمكن للشركات خفض تكاليفها التشغيلية وتحسين قدرتها التنافسية في السوق. ومع اشتداد التركيز العالمي على الاستدامة، يجب على المشترين بين الشركات في سوق المولدات الكهربائية إعطاء الأولوية للموردين الذين يظهرون التزامًا بالتوريد الأخلاقي والإشراف البيئي.

ما هي التطورات الرئيسية التي شهدتها تقنية المولدات الكهربائية؟

لقد تطور المولد بشكل كبير منذ نشأته، حيث تحول من أجهزة ميكانيكية بسيطة إلى أنظمة إلكترونية متطورة جزء لا يتجزأ من السيارات الحديثة. تم تصميم مولدات التيار المتردد في الأصل لتوفير الطاقة الكهربائية الأساسية، إلا أن المولدات المعاصرة مزودة بتكنولوجيا متقدمة تعزز كفاءتها وموثوقيتها. ويمثل إدخال المولدات الرقمية علامة فارقة رئيسية، مما يسمح بتحسين إدارة الأداء والتكامل مع أنظمة السيارة.

وعلى مر العقود، أدت التطورات في المواد وتقنيات التصنيع أيضًا إلى تحسين متانة مولدات التيار المتردد وعمرها الافتراضي. ويدفع التحول نحو السيارات الكهربائية والهجينة إلى مزيد من الابتكار، حيث يعمل المصنعون على تطوير مولدات كهربائية يمكنها التعامل مع المتطلبات الكهربائية المتزايدة لهذه السيارات. ويعكس هذا التطور الاتجاهات الأوسع نطاقًا في صناعة السيارات، حيث أصبحت الكفاءة والاستدامة والتكنولوجيا المتقدمة ذات أهمية قصوى. يجب على المشترين بين الشركات مواكبة هذه التطورات لاتخاذ قرارات مستنيرة بشأن التوريد تتماشى مع مستقبل تكنولوجيا السيارات.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

الأسئلة المتداولة (FAQs) لمشتري B2B عن تكلفة مولد التيار المتردد

-

كيف يمكنني تحديد تكلفة مولد التيار المتردد لأسطولي؟

لتحديد تكلفة مولد التيار المتردد لأسطولك، ضع في اعتبارك عوامل مثل طراز كل مركبة وطرازها وسنتها، بالإضافة إلى متطلبات التيار المحددة. يمكن أن يتراوح سعر المولدات من $100 إلى $1000، اعتمادًا على هذه المواصفات. بالإضافة إلى ذلك، استفسر عن أي ضمانات معروضة، حيث يمكن أن تؤثر على السعر الأولي. من الحكمة أيضًا مقارنة عروض الأسعار من عدة موردين لضمان حصولك على أسعار تنافسية، خاصةً إذا كنت تبحث عن مصادر لأسطول كبير. -

ما هي العوامل التي تؤثر على سعر المولد في الأسواق الدولية؟

يتأثر سعر المولد في الأسواق الدولية بعوامل مثل رسوم الاستيراد وتكاليف الشحن والضرائب المحلية. بالإضافة إلى ذلك، يمكن أن تؤثر أسعار الصرف بشكل كبير على الأسعار. كما يمكن أن تؤثر الاختلافات في معايير التصنيع وتوافر المواد في مناطق مختلفة على التكاليف. سيساعدك فهم ظروف السوق المحلية واستراتيجيات تسعير الموردين على اتخاذ قرارات شراء مستنيرة. -

ما الذي يجب أن أبحث عنه عند فحص مورِّدي مولدات التيار المتردد؟

عند التدقيق في مورّدي المولدات الكهربائية، يجب إعطاء الأولوية لسمعتهم وقدراتهم الإنتاجية وامتثالهم لمعايير الجودة العالمية. تحقق من وجود شهادات مثل ISO للتأكد من استيفائهم لمعايير الجودة. اطلب مراجع من العملاء السابقين، وقم بتقييم قدرتهم على توفير دعم ما بعد البيع والضمانات والحلول المخصصة. كما يمكن للمورّد الذي لديه شبكة لوجستية قوية أن يضمن أيضاً التسليم في الوقت المناسب والتوريد المتسق. -

ما هو الحد الأدنى لكمية الطلب (MOQ) لشراء مولدات التيار المتردد؟

يمكن أن يختلف الحد الأدنى لكميات الطلبات (موك) لمولدات التيار المتردد اختلافًا كبيرًا بين الموردين. قد يسمح البعض بطلبات منخفضة تصل إلى 10 وحدات، بينما قد يطلب منك البعض الآخر الشراء بكميات كبيرة، مثل 50 وحدة أو أكثر. من المهم الإبلاغ عن احتياجاتك مقدمًا والتفاوض بشأن الشروط التي تناسب نموذج عملك، خاصةً إذا كنت مشترٍ أصغر أو بدأت للتو في الحصول على مولدات المولدات لعملياتك. -

كيف يمكنني التأكد من ضمان جودة المولدات التي أشتريها؟

لضمان ضمان الجودة لمولدات المولدات الخاصة بك، ضع في اعتبارك وضع بروتوكول واضح لمراقبة الجودة مع المورد الخاص بك. قد يشمل ذلك عمليات الفحص قبل الشحن، وشهادات الجودة، واتفاقيات الضمان. اطلب عينات قبل إجراء عمليات شراء كبيرة، وفكر في خدمات الفحص من طرف ثالث للتحقق من أن المولدات تفي بمواصفاتك. يمكن أيضًا أن يؤدي إنشاء علاقة جيدة مع المورد إلى تسهيل إدارة الجودة بشكل أفضل. -

ما هي شروط الدفع التي يجب أن أتفاوض بشأنها عند الحصول على مولدات التيار المتردد؟

عند توريد المولدات، تفاوض على شروط الدفع التي تتماشى مع التدفق النقدي واستراتيجية عملك. تتضمن الشروط الشائعة 30 أو 60 أو 90 يومًا بعد التسليم، أو حتى الدفع الجزئي مقدمًا مع دفع الرصيد عند الاستلام. ضع في اعتبارك استخدام طرق دفع آمنة للتخفيف من المخاطر، ووضح أي غرامات على المدفوعات المتأخرة أو خصومات على المدفوعات المبكرة. يمكن أن يساعد ذلك في الحفاظ على علاقة إيجابية مع المورد الخاص بك. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد المولدات الكهربائية؟

عند استيراد مولدات الكهرباء، ضع في اعتبارك العوامل اللوجستية مثل طرق الشحن وأوقات العبور وإجراءات التخليص الجمركي. حدد خيارات الشحن الأكثر فعالية من حيث التكلفة التي توازن بين السرعة والسعر، وتأكد من حصولك على جميع الوثائق اللازمة للجمارك لتجنب التأخير. بالإضافة إلى ذلك، ضع في الحسبان حلول التخزين إذا كنت تشتري بكميات كبيرة، بالإضافة إلى الحاجة المحتملة للتوزيع المحلي بمجرد وصول المولدات. -

هل يمكنني تخصيص مولدات المولدات لتلبية متطلبات محددة لسياراتي؟

نعم، يقدم العديد من الموردين خيارات تخصيص لمولدات المولدات لتلبية متطلبات محددة. قد يشمل ذلك اختلافات في الأمبير أو أنماط التركيب أو التوصيلات الكهربائية. عند مناقشة التخصيص، حدد بوضوح مواصفاتك والاستخدام المقصود لضمان التوافق مع مركباتك. كن مستعدًا لمناقشة المهل الزمنية اللازمة للطلبات المخصصة، حيث يمكن أن تختلف بناءً على مدى تعقيد التعديلات.

أعلى 1 أعلى 1 كم تكلفة المولد قائمة المصنعين والموردين قائمة الموردين

1. J.D. Power - تكاليف استبدال المولدات

المجال: jdpower.com

تاريخ التسجيل: 1995 (30 عامًا)

مقدمة: تتراوح تكاليف استبدال المولد من $350 إلى $900، اعتماداً على طراز السيارة وما إذا كانت هناك حاجة إلى استبدال قطع إضافية. تتراوح تكلفة المولد نفسه عادةً ما بين $100 إلى $350، مع تكلفة الطرازات الفاخرة من $500 إلى $700. يمكن أن تضيف تكاليف العمالة من $350 إلى $500 أخرى إذا تم إجراؤها لدى أحد الوكلاء. تتوفر المولدات المعاد بناؤها وعادة ما تأتي مع ضمان، في حين أن التركيب الذاتي...

استنتاج المصادر الاستراتيجية والتوقعات بشأن تكلفة مولد التيار المتردد

باختصار، يعد فهم عوامل التكلفة المرتبطة بمولدات المولدات أمرًا بالغ الأهمية لمشتري B2B الذين يتطلعون إلى اتخاذ قرارات شراء مستنيرة. يمكن أن يختلف سعر مولد التيار المتردد اختلافًا كبيرًا بناءً على طراز السيارة وطرازها ومتطلباتها المحددة، حيث تتراوح التكاليف من $100 إلى $1000. تشمل الاعتبارات الرئيسية نوع مولد التيار المتردد المطلوب، وقوته، وخيارات الضمان، وما إذا كان يجب اختيار قطع غيار جديدة أو معاد تصنيعها.

يلعب التوريد الاستراتيجي دورًا حيويًا في ضمان حصول الشركات ليس فقط على أفضل الأسعار ولكن أيضًا الحفاظ على الجودة والموثوقية في مكونات السيارات الخاصة بها. من خلال الشراكة مع موردين موثوق بهم والاستفادة من الرؤى المحلية، يمكن للمشترين تحسين استراتيجيات الشراء الخاصة بهم وتخفيف المخاطر المرتبطة بأعطال المولدات.

واستشرافًا للمستقبل، ينبغي على المشترين الدوليين بين الشركات من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا إعطاء الأولوية لبناء علاقات قوية مع الموردين الذين يفهمون ديناميكيات السوق المحلية. لن يؤدي هذا النهج الاستباقي إلى تبسيط عمليات التوريد فحسب، بل سيعزز أيضًا الكفاءة التشغيلية ويدعم النمو المستدام. اتخذ الخطوة التالية في رحلة التوريد الإستراتيجية الخاصة بك من خلال التعامل مع الموردين ذوي السمعة الطيبة والبقاء على اطلاع بأحدث الاتجاهات في تكنولوجيا المولدات والتسعير.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

صورة توضيحية متعلقة بتكلفة مولد التيار المتردد

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.