مقدمة: الإبحار في السوق العالمية لكيفية عمل محرك بدء تشغيل السيارة

في المشهد الديناميكي لمكونات السيارات، يعد فهم كيفية عمل محرك بدء تشغيل السيارة أمرًا بالغ الأهمية بالنسبة للمشترين الدوليين بين الشركات الذين يتطلعون إلى تعزيز استراتيجيات الشراء الخاصة بهم. يعد محرك بدء التشغيل عنصراً محورياً في عملية الإشعال، وهو مسؤول عن بدء تشغيل المحرك من خلال توفير عزم الدوران اللازم لتشغيل المحرك. نظرًا لأن المشترين يبحثون عن مكونات موثوقة وفعالة، يتعمق هذا الدليل في وظائف وأنواع وتطبيقات محركات بدء التشغيل، مما يزود أصحاب المصلحة بالمعرفة اللازمة لاتخاذ قرارات شراء مستنيرة.

قد يكون الإبحار في السوق العالمية أمرًا صعبًا، خاصةً عند الحصول على قطع غيار السيارات عالية الجودة من مناطق متنوعة مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. لا يحدد هذا الدليل الشامل الأنواع المختلفة لمحركات بدء التشغيل المتاحة فحسب، بل يتناول أيضًا الاعتبارات الأساسية مثل فحص الموردين وتحليل التكلفة ومقاييس الأداء. من خلال فهم هذه العوامل، يمكن للمشترين التخفيف من المخاطر المرتبطة بالتوريد وضمان حصولهم على المنتجات التي تلبي احتياجاتهم التشغيلية المحددة.

علاوةً على ذلك، يُمكّن هذا الدليل المشترين بين الشركات من تحديد الموردين ذوي السمعة الطيبة والتفاوض على شروط مواتية، مما يؤدي في النهاية إلى اتخاذ قرارات شراء أكثر استراتيجية. مع رؤى مصممة خصيصًا لأسواق مثل البرازيل ونيجيريا، تم تصميم هذا المورد لتعزيز كفاءة وموثوقية عملياتك في مجال السيارات، مما يضمن لك الحفاظ على قدرتك التنافسية في صناعة دائمة التطور.

جدول المحتويات

- قائمة المصنعين والموردين لأفضل 3 كيف يعمل محرك بدء تشغيل السيارة

- مقدمة: الإبحار في السوق العالمية لكيفية عمل محرك بدء تشغيل السيارة

- فهم كيفية عمل محرك بدء تشغيل السيارة أنواعه واختلافاته

- التطبيقات الصناعية الرئيسية لكيفية عمل محرك بدء تشغيل السيارة

- 3 نقاط ألم شائعة للمستخدمين حول ‘كيفية عمل محرك تشغيل السيارة’ وحلولها

- دليل اختيار المواد الاستراتيجية لكيفية عمل محرك بدء تشغيل السيارة

- نظرة متعمقة: عمليات التصنيع وضمان الجودة لكيفية عمل محرك بدء تشغيل السيارة

- دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘كيف يعمل محرك تشغيل السيارة’

- تحليل شامل للتكلفة والتسعير لكيفية عمل محرك بدء تشغيل السيارة Sourcing

- تحليل البدائل: مقارنة كيفية عمل محرك بدء تشغيل السيارة مع الحلول الأخرى

- الخصائص التقنية والمصطلحات التجارية الأساسية لكيفية عمل محرك تشغيل السيارة

- الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع كيفية عمل محرك تشغيل السيارة

- الأسئلة المتداولة (FAQs) لمشتري B2B حول كيفية عمل محرك بدء تشغيل السيارة

- خاتمة المصادر الاستراتيجية والتوقعات الخاصة بكيفية عمل محرك تشغيل السيارة

- إخلاء مسؤولية هام وشروط الاستخدام

فهم كيفية عمل محرك بدء تشغيل السيارة أنواعه واختلافاته

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| محركات بدء التشغيل بالتيار المستمر | تعمل باستخدام التيار المباشر؛ تصميم بسيط؛ عزم دوران عالٍ. | السيارات، والآلات الثقيلة، والبحرية. | الإيجابيات: موثوقية عالية؛ صيانة منخفضة. السلبيات: يمكن أن تكون أقل كفاءة من البدائل. |

| محركات تخفيض التروس | استخدام التروس لتكبير عزم الدوران؛ حجم صغير؛ خفيف الوزن. | السيارات عالية الأداء، والدراجات النارية. | الإيجابيات: ناتج عزم دوران محسّن؛ تصميم موفر للمساحة. السلبيات: أكثر تعقيداً؛ احتمال تآكل التروس. |

| المحركات المغناطيسية الدائمة | استخدام مغناطيس دائم لوظيفة المحرك؛ خفيف الوزن. | السيارات الكهربائية والأنظمة الهجينة. | الإيجابيات: كفاءة عالية؛ مدمجة. السلبيات: تكلفة أعلى؛ عزم دوران محدود مقارنة بمحركات التيار المستمر. |

| محركات تشغيل الملف اللولبي | ملف لولبي متكامل للتعشيق؛ تشغيل سريع. | المركبات القياسية والأساطيل التجارية. | الإيجابيات: مشاركة سريعة؛ موثوقة. السلبيات: عرضة للسخونة الزائدة في حالة الاستخدام المستمر. |

| محركات بنديكس درايف موتورز | تتميز بنظام دفع فريد من نوعه للتعشيق التلقائي. | السيارات الكلاسيكية وعمليات الترميمات القديمة. | الإيجابيات: تشغيل سلس؛ يمنع تلف البادئ. السلبيات: تصميم معقد؛ من الصعب الحصول على قطع غيار معقدة؛. |

ما هي الخصائص الرئيسية لمحركات بدء التشغيل بالتيار المستمر؟

محركات بدء التشغيل بالتيار المستمر هي أكثر الأنواع شيوعاً المستخدمة في المركبات اليوم. وهي تعمل بالتيار المباشر، وتوفر عزم دوران عالٍ لتشغيل المحرك بسرعة. هذه البساطة تجعلها موثوقة للغاية ومنخفضة الصيانة، مما يجعلها مناسبة لمختلف تطبيقات B2B، بما في ذلك السيارات والآلات الثقيلة. يجب أن يأخذ المشترون في الاعتبار موثوقيتها وسهولة تركيبها، ولكن يجب أن يلاحظوا أيضاً أنها قد تكون أقل كفاءة من التقنيات الأحدث.

كيف تعمل محركات تخفيض التروس على تحسين الأداء؟

تستخدم محركات اختزال التروس نظام تروس لزيادة ناتج عزم الدوران، مما يجعلها مثالية للمركبات عالية الأداء والدراجات النارية حيث تكون المساحة محدودة. يسمح تصميمها المدمج بتضخيم عزم الدوران بشكل كبير دون زيادة متناسبة في الحجم. في حين أنها توفر مزايا في الأداء، يجب أن يكون المشترون على دراية بالتعقيد المحتمل في التركيب وخطر تآكل التروس مع مرور الوقت.

ما هي مزايا المحركات المغناطيسية الدائمة؟

تحظى المحركات المغناطيسية الدائمة بشعبية متزايدة في السيارات الكهربائية والهجينة نظراً لخصائصها الخفيفة الوزن وعالية الكفاءة. وهي تستخدم مغناطيسات دائمة لتوليد المجال المغناطيسي، مما يؤدي إلى تقليل استهلاك الطاقة. وعلى الرغم من أنها توفر أداءً ممتازًا، إلا أن تكلفتها المرتفعة يمكن أن تكون عائقًا أمام بعض المشترين من الشركات وخاصة في الأسواق الحساسة للميزانية.

لماذا تختار محركات بداية الملف اللولبي لتطبيقات الأساطيل؟

تشتهر محركات بدء التشغيل ذات الملف اللولبي بملفها اللولبي المدمج الذي يسمح بالتشغيل السريع، مما يجعلها خياراً موثوقاً للمركبات القياسية والأساطيل التجارية. يقلل تشغيلها السريع من خطر استنزاف البطارية ويضمن التشغيل الفعال. ومع ذلك، يجب أن يتوخى المشترون الحذر من مشاكل السخونة الزائدة المحتملة مع الاستخدام المطول، مما قد يؤثر على الموثوقية.

ما الذي يجعل محركات بنديكس درايف موتورز فريدة من نوعها؟

تتميز محركات الدفع من بنديكس بنظام تعشيق فريد من نوعه يقوم تلقائياً بتوصيل البادئ بالحذافة عند الحاجة، مما يمنع تلف البادئ أثناء التشغيل. ويحظى هذا التصميم بتقدير خاص في السيارات الكلاسيكية وعمليات الترميم القديمة حيث تكون القطع الأصلية ضرورية. وعلى الرغم من أنها توفر تشغيلًا سلسًا، إلا أن الحصول على قطع الغيار قد يكون صعبًا، كما أن تعقيد التصميم قد يثني بعض المشترين عن الشراء.

التطبيقات الصناعية الرئيسية لكيفية عمل محرك بدء تشغيل السيارة

| الصناعة/القطاع | التطبيق المحدد لكيفية عمل محرك بدء تشغيل السيارة | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| تصنيع السيارات | إنتاج المركبات التي تتطلب أنظمة تشغيل موثوقة | يضمن كفاءة تجميع السيارة وفعاليتها الوظيفية | ضمان الجودة، ومواصفات الشركة المصنعة للمعدات الأصلية واللوائح المحلية |

| النقل واللوجستيات | إدارة الأسطول للمركبات التجارية التي تعتمد على التشغيل الفعال | يقلل من وقت التعطل وتكاليف الصيانة | توافر قطع الغيار، وموثوقية المورد، وشروط الضمان |

| معدات زراعية | محركات بدء التشغيل في الجرارات والآلات الزراعية للعمليات الميدانية | يعزز الكفاءة التشغيلية أثناء المهام الحرجة | التوافق مع مختلف طرازات الماكينات ودعم ما بعد البيع |

| ماكينات البناء | معدات ثقيلة تتطلب حلول تشغيل قوية | يحسن الإنتاجية في مواقع الإنشاءات | الأداء في ظل الظروف القاسية وتحديد مصادر مراكز الخدمة المحلية |

| مركبات الطاقة المتجددة | التكامل في السيارات الكهربائية والهجينة للتصاميم المبتكرة | تدعم حلول النقل المستدام | الامتثال للمعايير البيئية والتوافق التكنولوجي |

كيف يتم استخدام محرك بدء تشغيل السيارة في صناعة السيارات؟

في قطاع تصنيع السيارات، يعتبر محرك بدء التشغيل أمراً بالغ الأهمية لضمان تشغيل السيارات بشكل موثوق. يتم دمج هذا المكون أثناء عملية التجميع، حيث يجب على المصنعين الالتزام بمعايير الجودة الصارمة لضمان تشغيل كل سيارة بسلاسة. بالنسبة للمشترين الدوليين، ولا سيما في الأسواق الناشئة، يعد الحصول على محركات بدء التشغيل التي تلبي مواصفات مصنعي المعدات الأصلية أمرًا ضروريًا للحفاظ على الجودة والأداء. بالإضافة إلى ذلك، يمكن أن يؤثر فهم اللوائح المحلية المتعلقة بمكونات السيارات على قرارات الشراء.

ما الدور الذي يلعبه المحرك البادئ في النقل والخدمات اللوجستية؟

بالنسبة للشركات العاملة في مجال النقل والخدمات اللوجستية، تُعد موثوقية محرك بدء التشغيل أمرًا بالغ الأهمية لعمليات الأسطول. يقلل محرك بدء التشغيل الذي يعمل بشكل جيد من وقت تعطل المركبة، مما قد يؤثر بشكل كبير على جداول التسليم والإنتاجية الإجمالية. يجب على الشركات التفكير في توفير محركات بدء التشغيل التي توفر المتانة وسهولة الصيانة. من المهم أيضًا ضمان توفير إمدادات ثابتة من قطع الغيار من موردين موثوقين، حيث يمكن أن يقلل ذلك من الاضطرابات التشغيلية ويقلل من تكاليف الصيانة الإجمالية.

كيف يكون محرك بدء التشغيل ضرورياً في المعدات الزراعية؟

في البيئات الزراعية، تعتبر محركات بدء التشغيل جزءًا لا يتجزأ من تشغيل الجرارات والآلات الأخرى. تضمن هذه المحركات تشغيل المعدات بكفاءة، خاصة خلال فترات الزراعة والحصاد الحرجة. يحتاج المشترون في هذا القطاع إلى التركيز على المحركات البادئة المتوافقة مع مجموعة متنوعة من طرازات الآلات، بالإضافة إلى تلك التي يمكنها تحمل الظروف البيئية القاسية. كما يعد دعم ما بعد البيع وتوافر قطع الغيار من الاعتبارات الحيوية لضمان استمرار العمليات في الحقل.

لماذا يعتبر محرك بدء التشغيل مهمًا لآلات البناء؟

في صناعة البناء والتشييد، تعتمد المعدات الثقيلة اعتمادًا كبيرًا على محركات التشغيل القوية لتعمل بفعالية. يجب أن تعمل هذه المحركات بشكل موثوق في ظل ظروف صعبة، والتي يمكن أن تشمل درجات الحرارة القصوى والأحمال الثقيلة. يجب على الشركات التي تبحث عن محركات بادئ الحركة لآلات الإنشاءات أن تعطي الأولوية لمواصفات الأداء والقدرة على توفير الخدمة في المواقع البعيدة. علاوة على ذلك، يمكن أن يؤدي فهم شروط الضمان وتوافر مراكز الخدمة المحلية إلى تعزيز الكفاءة التشغيلية في مواقع العمل.

كيف يدعم محرك بدء التشغيل مركبات الطاقة المتجددة؟

مع تحول مشهد السيارات نحو الاستدامة، تلعب محركات بدء التشغيل دوراً محورياً في السيارات الكهربائية والهجينة. يجب أن تتكامل هذه المحركات بسلاسة مع التقنيات المتقدمة لضمان الأداء الأمثل. بالنسبة للمشترين الدوليين، وخاصة في المناطق التي تركز على حلول الطاقة الخضراء، فإن الحصول على محركات بدء التشغيل التي تتوافق مع المعايير البيئية أمر بالغ الأهمية. بالإضافة إلى ذلك، يمكن أن يؤثر التوافق مع تصميمات وتقنيات السيارات المختلفة على استراتيجيات الشراء، مما يجعل من الضروري التعاون مع الموردين المبتكرين.

3 نقاط ألم شائعة للمستخدمين حول ‘كيفية عمل محرك تشغيل السيارة’ وحلولها

السيناريو 1: فهم وظائف محرك بدء التشغيل لصيانة الأسطول

المشكلة:

غالبًا ما يواجه المشترون من الشركات وخاصةً مديري أساطيل السيارات في مناطق مثل إفريقيا وأمريكا الجنوبية صعوبة في فهم تعقيدات كيفية عمل محركات بدء التشغيل. يمكن أن تؤدي هذه الفجوة المعرفية إلى تشخيص خاطئ لمشاكل المركبات، مما يؤدي إلى إصلاحات أو استبدال غير ضروري. على سبيل المثال، إذا فشلت إحدى مركبات الأسطول في بدء التشغيل، فقد يعزو المدير المشكلة بشكل غير صحيح إلى محرك بدء التشغيل دون النظر إلى حالة البطارية أو المكونات الكهربائية الأخرى. يمكن أن يتسبب ذلك في وقت تعطل كبير وتكاليف غير متوقعة، مما يعيق الكفاءة التشغيلية.

الحل:

للتخفيف من حدة هذه المشكلة، يجب أن يستثمر المشترون من الشركات في تدريب شامل لفرق الصيانة لديهم على وظائف محرك بدء التشغيل. وينبغي أن يغطي هذا التدريب دور المكونات الرئيسية، مثل الملف اللولبي وحديد التسليح وترس الترس وتفاعلاتها أثناء عملية بدء التشغيل. بالإضافة إلى ذلك، يمكن أن يساعد تنفيذ نهج تشخيصي منهجي الفنيين على تحديد ما إذا كان محرك البادئ معطلاً بدقة أو إذا كانت المشكلة تكمن في مكان آخر، مثل البطارية أو الأسلاك. كما يمكن أن يؤدي توفير إمكانية الوصول إلى أدوات التشخيص أو الشراكة مع مزودي خدمة السيارات الموثوق بهم إلى تعزيز القدرة على استكشاف مشاكل بدء التشغيل بسرعة ودقة، مما يقلل من وقت تعطل السيارة والتكاليف المرتبطة بها.

السيناريو 2: توفير محركات بدء التشغيل عالية الجودة لأنواع المركبات المتنوعة

المشكلة:

في المناطق ذات الأنواع المتنوعة من المركبات، مثل الشرق الأوسط وأوروبا، قد يكون الحصول على محركات بدء التشغيل عالية الجودة مهمة شاقة للمشترين من الشركات. قد تتطلب المركبات المختلفة تصميمات ومواصفات محددة لمحركات بدء التشغيل، مما يؤدي إلى تحديات في إدارة المخزون والتوافق. وقد يؤدي ذلك إلى تأخيرات في الشراء أو زيادة التكاليف إذا تم طلب قطع غيار غير صحيحة.

الحل:

لتبسيط عملية التوريد، يجب على المشترين بين الشركات إقامة علاقات مع الموردين ذوي السمعة الطيبة المتخصصين في قطع غيار السيارات، وخاصة محركات بدء التشغيل. من الضروري إنشاء قائمة جرد مفصلة تتضمن طرازات السيارات وموديلاتها ومواصفات محرك البادئ المقابلة. من خلال الاستفادة من المنصات الرقمية التي توفر كتالوجات شاملة لقطع غيار السيارات، يمكن للمشترين ضمان طلب المكونات الصحيحة. وعلاوة على ذلك، يمكن أن يؤدي التفكير في الموردين الذين يقدمون ضمانات وسياسات إرجاع إلى الحماية من مشاكل التوافق المحتملة، مما يسمح بعملية شراء أكثر كفاءة.

السيناريو 3: معالجة أعطال محرك البادئ في ظروف التشغيل القاسية

المشكلة:

في مناطق مثل نيجيريا والبرازيل، حيث تعمل المركبات غالبًا في بيئات قاسية، يمكن أن تتكرر أعطال محركات بدء التشغيل بسبب درجات الحرارة والرطوبة والغبار الشديدة. قد يجد المشترون من الشركات الذين يديرون أساطيل أو محطات الخدمة أنفسهم يتعاملون مع معدلات أعلى من المتوقع لاستبدال محرك البادئ مما يؤثر على ميزانيات الصيانة الإجمالية وموثوقية السيارة.

الحل:

لمكافحة أعطال محركات بدء التشغيل في الظروف الصعبة، من الضروري اختيار محركات بدء التشغيل المصممة لقوة التحمل والمرونة. يجب أن يركز المشترون على الحصول على محركات بادئ الحركة شديدة التحمل التي يمكنها تحمل العوامل البيئية القاسية. بالإضافة إلى ذلك، يمكن أن يساعد تنفيذ جدول زمني للصيانة الوقائية في تحديد علامات التآكل والتلف المبكرة. يمكن أن تؤدي عمليات الفحص المنتظمة وتنظيف التوصيلات الكهربائية، إلى جانب التأكد من أن البطارية في حالة جيدة، إلى إطالة عمر محركات بدء التشغيل. ومن شأن التعاون مع الشركات المصنعة لفهم أفضل الممارسات للتركيب والصيانة في الظروف المحلية أن يعزز طول عمر هذه المكونات المهمة وأدائها.

دليل اختيار المواد الاستراتيجية لكيفية عمل محرك بدء تشغيل السيارة

ما هي المواد المستخدمة عادةً في محركات تشغيل السيارات؟

عند اختيار المواد المستخدمة في محركات بدء تشغيل السيارات، يجب مراعاة عدة عوامل رئيسية، بما في ذلك الأداء الحراري والكهربائي، والمتانة، والفعالية من حيث التكلفة. تؤثر المواد المستخدمة في بناء المحركات البادئة بشكل كبير على موثوقيتها وكفاءتها، خاصة في المناخات والظروف التشغيلية المتنوعة الموجودة في مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا. فيما يلي، نحلل أربع مواد شائعة مستخدمة في المحركات البادئة: النحاس والصلب والألومنيوم والمركبات البلاستيكية.

كيف يساهم النحاس في أداء محرك البادئ؟

الخصائص الرئيسية: النحاس معروف بتوصيله الكهربائي الممتاز وأدائه الحراري الممتاز. ويمكنه تحمل درجات الحرارة المرتفعة ومقاوم للتآكل، مما يجعله مناسباً للمكونات الكهربائية لمحرك بدء التشغيل.

إيجابيات وسلبيات: الميزة الأساسية للنحاس هي موصلية النحاس الفائقة، مما يسمح بنقل الطاقة بكفاءة. ومع ذلك، فإن النحاس باهظ الثمن نسبياً مقارنةً بالمعادن الأخرى، مما قد يزيد من تكاليف الإنتاج. بالإضافة إلى ذلك، على الرغم من أن النحاس متين، إلا أنه يمكن أن يكون عرضة للأكسدة إذا لم يتم طلاؤه بشكل صحيح.

التأثير على التطبيق: إن الموصلية العالية للنحاس تجعله مثاليًا للاستخدام في اللفات والوصلات داخل محرك بدء التشغيل. ومع ذلك، فإن تكلفته قد تكون عاملاً مقيداً للمشاريع الحساسة للميزانية، خاصة في الأسواق النامية.

اعتبارات للمشترين الدوليين: يجب على المشترين من مناطق مثل البرازيل ونيجيريا التأكد من الامتثال للمعايير المحلية للمكونات الكهربائية، مثل IEC أو NEMA، والتي غالبًا ما تحدد استخدام مواد موصلة عالية الجودة.

ما هو دور الفولاذ في تصنيع محرك التشغيل؟

الخصائص الرئيسية: يشتهر الفولاذ بقوته ومتانته، مع مقاومة جيدة للتآكل والتشوه تحت الضغط. كما يمكن معالجته لمقاومة التآكل، مما يعزز من طول عمره في البيئات القاسية.

إيجابيات وسلبيات: تتمثل الميزة الأساسية للفولاذ في متانته، مما يجعله مناسبًا للمكونات الهيكلية مثل مبيت المحرك وأقواس التثبيت. ومع ذلك، يمكن أن يكون الفولاذ أثقل من المواد الأخرى، مما قد يؤثر على الوزن الإجمالي للمحرك البادئ. بالإضافة إلى ذلك، إذا لم تتم معالجته بشكل صحيح، يمكن أن يتآكل بمرور الوقت.

التأثير على التطبيق: تعتبر قوة الفولاذ ضرورية للمكونات التي تتعرض لإجهاد ميكانيكي أثناء التشغيل. وقد يكون وزنه عاملاً مهماً للتطبيقات التي تركز على الأداء، خاصة في المناطق ذات التضاريس المتفاوتة.

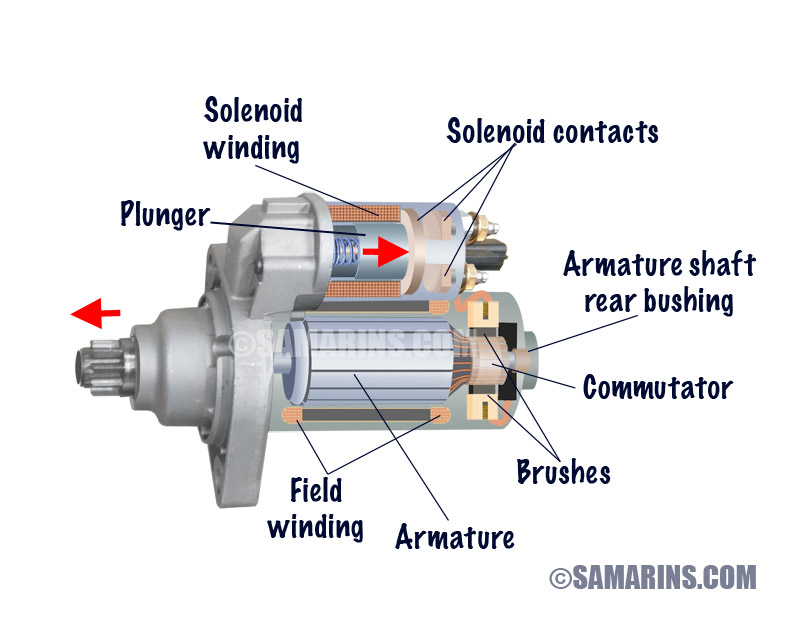

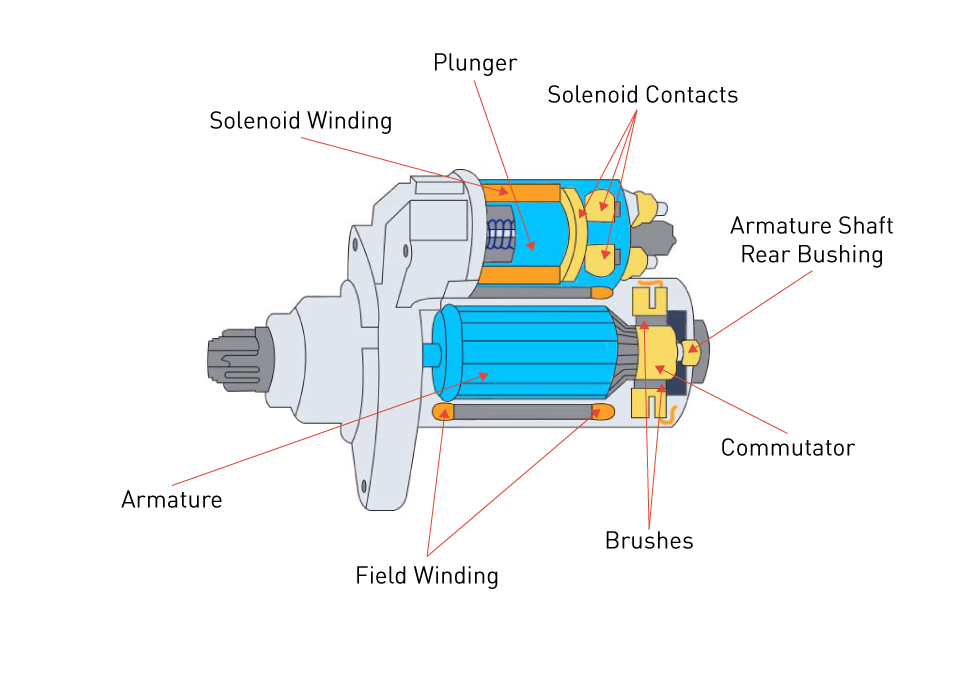

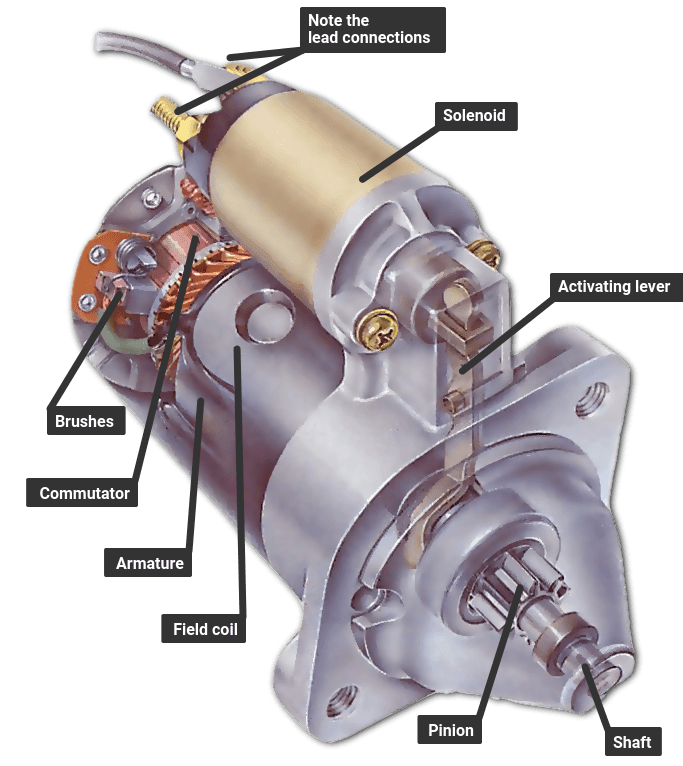

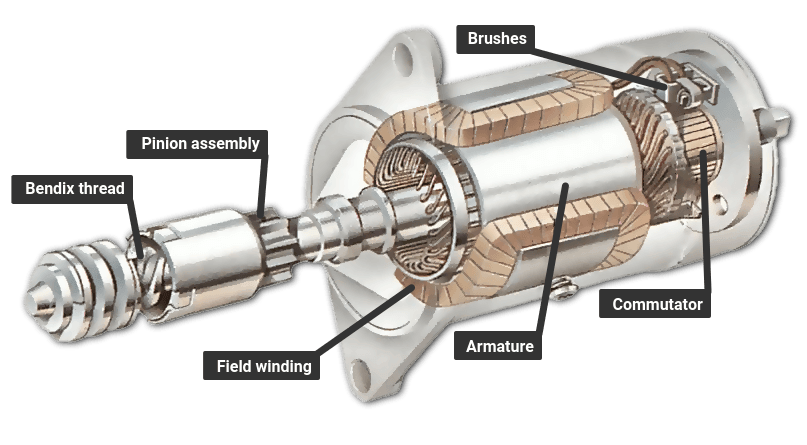

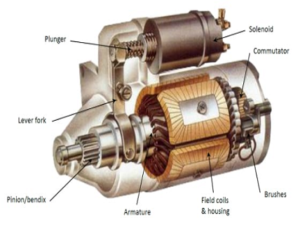

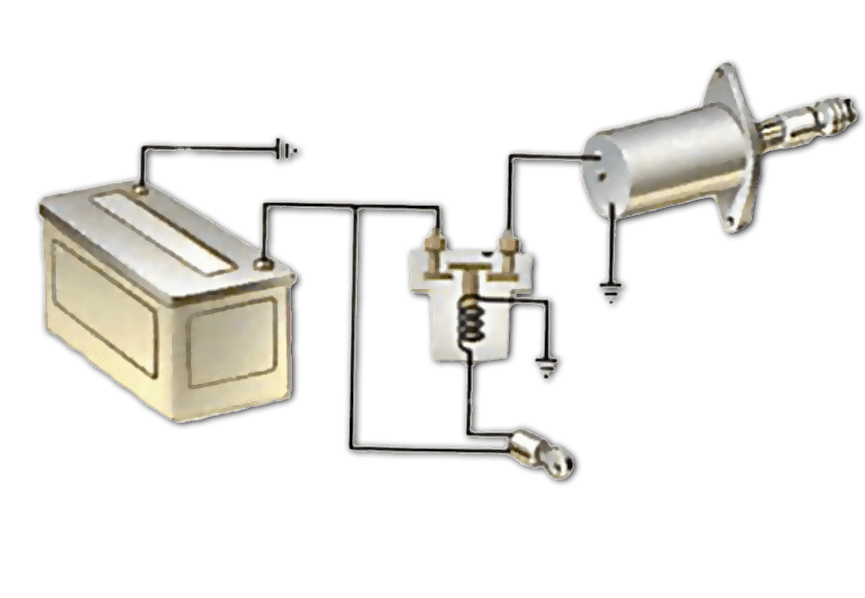

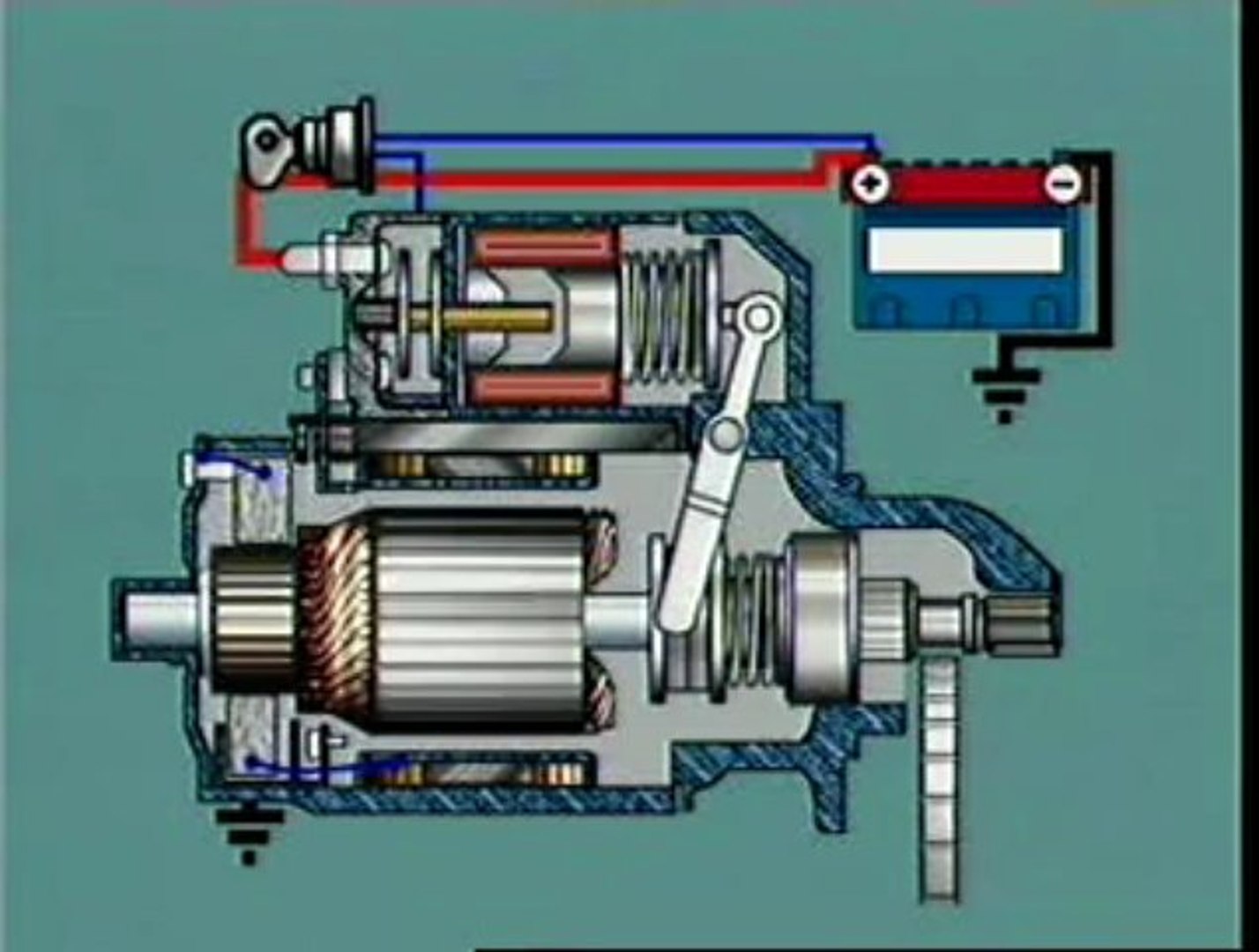

صورة توضيحية تتعلق بكيفية عمل محرك تشغيل السيارة

اعتبارات للمشترين الدوليين: من الضروري الامتثال لمعايير مثل ASTM A36 للفولاذ الإنشائي ASTM A36. يجب على المشترين أيضًا مراعاة توافر الفولاذ المعالج لمنع التآكل في البيئات الرطبة أو الساحلية.

كيف يعزز الألومنيوم كفاءة محرك البادئ؟

الخصائص الرئيسية: الألومنيوم خفيف الوزن ومقاوم للتآكل ويتمتع بتوصيل حراري جيد. وهذه الخصائص تجعله خيارًا جذابًا للمكونات التي تتطلب توازنًا بين القوة والوزن.

إيجابيات وسلبيات: الميزة الرئيسية للألومنيوم هي وزنه المنخفض، الأمر الذي يمكن أن يحسّن الكفاءة الإجمالية للمركبة. ومع ذلك، فإن الألمنيوم أقل قوة من الفولاذ، مما قد يحد من استخدامه في المكونات عالية الضغط. بالإضافة إلى ذلك، يمكن أن يكون أغلى من الفولاذ.

التأثير على التطبيق: غالبًا ما يُستخدم الألومنيوم في الغلاف وبعض المكونات الداخلية لمحركات بدء التشغيل، حيث يكون تقليل الوزن مفيدًا. وتعتبر مقاومته للتآكل ذات قيمة خاصة في المناطق ذات الرطوبة العالية.

صورة توضيحية تتعلق بكيفية عمل محرك تشغيل السيارة

اعتبارات للمشترين الدوليين: يجب على المشترين التأكد من أن مكونات الألومنيوم تفي بمعايير مثل ASTM B221 لسبائك الألومنيوم. من المهم أيضًا فهم قدرات إعادة التدوير المحلية، حيث يمكن إعادة تدوير الألومنيوم بكفاءة.

ما المزايا التي تقدمها المركبات البلاستيكية في محركات التشغيل؟

الخصائص الرئيسية: المركبات البلاستيكية خفيفة الوزن ومقاومة للتآكل ويمكن تشكيلها في أشكال معقدة. كما أنها توفر عزلًا كهربائيًا جيدًا، وهو أمر مفيد لبعض المكونات.

إيجابيات وسلبيات: تتمثل الميزة الأساسية للمركبات البلاستيكية في تعدد استخداماتها ووزنها المنخفض، وهو ما يمكن أن يعزز الكفاءة الكلية لمحركات بدء التشغيل. غير أنها قد لا تتحمل درجات الحرارة العالية مثل المعادن ويمكن أن تكون عرضة للتآكل بمرور الوقت.

التأثير على التطبيق: غالبًا ما تستخدم المركبات البلاستيكية في المكونات غير الهيكلية، مثل أغطية التوصيلات الكهربائية. وتساعد خواصها العازلة على منع التقصير الكهربائي.

اعتبارات للمشترين الدوليين: يجب أن يبحث المشترون عن الامتثال للمعايير الدولية مثل ISO 9001 لإدارة الجودة. كما أن الوعي بالأنظمة المحلية المتعلقة بالمواد البلاستيكية أمر بالغ الأهمية أيضاً، خاصة في المناطق التي تركز على الاستدامة.

جدول ملخص لاختيار المواد لمحركات التشغيل

| المواد | حالة الاستخدام النموذجية لكيفية عمل محرك تشغيل السيارة | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | اللفات والتوصيلات الكهربائية | موصلية كهربائية ممتازة | أعلى تكلفة، عرضة للأكسدة | عالية |

| الصلب | المكونات الهيكلية (المبيت والأقواس) | قوة ومتانة عالية | أثقل وزناً، احتمال التآكل | متوسط |

| الألومنيوم | الغلاف والمكونات الداخلية | خفيف الوزن ومقاوم للتآكل | أقل قوة من الفولاذ | متوسط |

| المركبات البلاستيكية | المكونات غير الهيكلية (العلب) | خفيف الوزن ومتعدد الاستخدامات وعزل جيد | مقاومة محدودة لدرجات الحرارة | منخفض |

يوفر هذا الدليل الاستراتيجي لاختيار المواد للمشترين من الشركات رؤى أساسية حول المواد المستخدمة في محركات بدء تشغيل السيارات، مما يتيح اتخاذ قرارات مستنيرة تتماشى مع متطلبات الأداء والتكلفة والامتثال في أسواقهم.

نظرة متعمقة: عمليات التصنيع وضمان الجودة لكيفية عمل محرك بدء تشغيل السيارة

ما هي المراحل الرئيسية لتصنيع محرك تشغيل السيارة؟

تتسم عملية تصنيع محرك بدء تشغيل السيارة بالتعقيد، حيث تتضمن عدة مراحل رئيسية تضمن أن المنتج النهائي يلبي معايير الأداء والجودة. يعد فهم هذه المراحل أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات الذين يتطلعون إلى الحصول على محركات بدء تشغيل موثوقة.

1. تحضير المواد: ما هي المواد المستخدمة؟

تبدأ العملية بالاختيار الدقيق للمواد وتحضيرها. وتشمل المواد الشائعة ما يلي:

- أسلاك نحاسية: تستخدم لملفات المحرك والفرش بسبب توصيلها الممتاز.

- الفولاذ أو الحديد: وعادة ما يتم استخدام هذه المعادن في المبيت وقلب المحرك وترس الترس الصغير، مما يوفر المتانة والقوة.

- البلاستيك: غالبًا ما تستخدم للمكونات غير الموصلة للكهرباء، مثل أجزاء السكن والعزل.

وبمجرد اختيار هذه المواد، تخضع هذه المواد لمعالجات مثل التلدين للمعادن لتعزيز خواصها وضمان استيفائها للمواصفات المطلوبة.

2. كيف يتم تشكيل محرك بدء التشغيل؟

تتضمن مرحلة التشكيل عدة تقنيات:

- الختم والتشكيل: يتم تشكيل المكونات المعدنية باستخدام ماكينات الختم أو تشكيلها لصنع الأجزاء الضرورية مثل المبيت والحذافة.

- اللف: يتم لف الأسلاك النحاسية حول قلب المحرك لتكوين المغناطيس الكهربائي، وهو أمر ضروري لتوليد عزم الدوران.

- التصنيع الآلي: يتم استخدام التصنيع الآلي الدقيق لإنشاء المبدل والتأكد من أن جميع الأجزاء المتحركة تتناسب مع بعضها البعض بسلاسة.

تتطلب كل عملية من هذه العمليات عمالة ماهرة وآلات متطورة للحفاظ على الدقة والاتساق.

3. ما الذي تنطوي عليه عملية التجميع؟

مرحلة التجميع هي المرحلة التي تجتمع فيها جميع المكونات معًا:

- التجميع الفرعي للمكونات: يتم تجميع المكونات المنفردة، مثل الملف اللولبي وحديد التسليح وترس الترس في وحدات فرعية.

- التجميع النهائي: يتم بعد ذلك تجميع الوحدات الفرعية في محرك التشغيل النهائي. ويتضمن ذلك محاذاة دقيقة وتكامل التوصيلات الكهربائية.

- التشحيم: يتم تطبيق التشحيم المناسب على الأجزاء المتحركة لتقليل الاحتكاك والتآكل أثناء التشغيل.

يعد الاهتمام بالتفاصيل أثناء التجميع أمرًا بالغ الأهمية، حيث يمكن أن يؤدي عدم المحاذاة الخاطئة إلى فشل سابق لأوانه أو مشاكل في الأداء.

4. ما هي تقنيات التشطيب المستخدمة؟

تعمل عمليات التشطيب على تعزيز متانة وجمالية محرك بدء التشغيل:

- طلاء: يمكن طلاء المكونات بتشطيبات واقية لمقاومة التآكل والتآكل. وهذا مهم بشكل خاص للأجزاء المعرضة للبيئات القاسية في تطبيقات السيارات.

- تنظيف عالي الجودة: يتم تنظيف أي بقايا من عملية التصنيع لضمان الأداء الأمثل وطول العمر الافتراضي.

- وضع العلامات: وغالبًا ما يتم تمييز المنتجات النهائية بأرقام تسلسلية أو رموز شريطية للتتبع والتعرف عليها.

لا تعمل هذه اللمسات النهائية على تحسين عمر المنتج فحسب، بل تضمن أيضًا الامتثال لمعايير الصناعة.

كيف يتم تنفيذ ضمان الجودة في تصنيع المحركات البادئة؟

يعد ضمان الجودة (QA) جزءًا لا يتجزأ من ضمان أداء محركات بدء التشغيل بشكل موثوق وآمن. يجب أن يكون مشترو B2B على دراية بالمعايير والعمليات المختلفة المعنية.

ما هي المعايير الدولية التي يجب على المشترين البحث عنها؟

غالبًا ما يلتزم ضمان الجودة في تصنيع محركات بدء التشغيل بالعديد من المعايير الدولية:

- ISO 9001: يركز هذا المعيار على أنظمة إدارة الجودة وهو قابل للتطبيق في مختلف الصناعات، بما في ذلك صناعة السيارات. يشير الامتثال إلى أن الشركة المصنعة لديها عمليات فعالة مطبقة.

- علامة CE: بالنسبة للمنتجات التي تباع في أوروبا، تشير علامة CE إلى الامتثال لمعايير الصحة والسلامة وحماية البيئة.

- معايير واجهة برمجة التطبيقات: بالنسبة للمصنعين الذين يعملون في مناطق معينة، مثل الشرق الأوسط، قد يكون الالتزام بمعايير معهد البترول الأمريكي مناسبًا أيضًا.

توفر هذه الشهادات للمشترين الثقة في جودة وسلامة المنتجات التي يشترونها.

ما هي نقاط التحقق الرئيسية لمراقبة الجودة؟

تُعد نقاط فحص مراقبة الجودة (QC) أمرًا بالغ الأهمية في عملية التصنيع. وتشمل نقاط التفتيش الشائعة ما يلي:

- مراقبة الجودة الواردة (IQC): يتم فحص المواد عند وصولها للتأكد من مطابقتها للمواصفات قبل بدء الإنتاج.

- مراقبة الجودة أثناء الإنتاج (IPQC): طوال عملية التصنيع، يتم إجراء فحوصات عشوائية لمراقبة جودة المكونات والتركيبات.

- مراقبة الجودة النهائية (FQC): وتخضع محركات بدء التشغيل المكتملة لاختبارات صارمة للأداء، بما في ذلك ناتج عزم الدوران والمقاومة الكهربائية والأداء الحراري.

وتساعد نقاط الفحص هذه في تحديد العيوب في وقت مبكر من العملية، مما يقلل من الهدر ويحسن جودة المنتج بشكل عام.

كيف يمكن للمشترين B2B التحقق من مراقبة جودة الموردين؟

بالنسبة للمشترين بين الشركات B2B، فإن التحقق من عمليات مراقبة الجودة لدى الموردين أمر ضروري لضمان الموثوقية وتقليل المخاطر.

ما هي الطرق التي يمكن استخدامها في عمليات تدقيق الموردين؟

يمكن للمشترين إجراء عدة طرق لتقييم جودة الموردين:

- التدقيق في الموقع: يتيح القيام بزيارات إلى منشآت التصنيع للمشترين تقييم عمليات الإنتاج والآلات وظروف العمل بشكل مباشر.

- طلب تقارير الجودة: يجب أن يكون الموردون قادرين على تقديم الوثائق، بما في ذلك تقارير مراقبة الجودة والشهادات، لإثبات الامتثال للمعايير الدولية.

- عمليات التفتيش من طرف ثالث: يمكن أن يوفر إشراك وكالات التفتيش التابعة لجهة خارجية تقييمًا غير متحيز لعمليات مراقبة الجودة وجودة المنتج الخاصة بالمورد.

وتساعد هذه الخطوات المشترين على التأكد من أنهم يتعاونون مع مصنعين ذوي سمعة طيبة يضعون الجودة على رأس أولوياتهم.

ما هي الفروق الدقيقة في مراقبة الجودة والشهادات بالنسبة للمشترين الدوليين؟

عند الحصول على محركات بدء التشغيل على المستوى الدولي، يجب على المشترين بين الشركات من مناطق مثل أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا مراعاة الفروق الدقيقة المختلفة:

- الامتثال التنظيمي: لدى المناطق المختلفة لوائح محددة يجب الالتزام بها، مثل المعايير البيئية أو لوائح السلامة.

- الاختلافات الثقافية: يمكن أن يساعد فهم ممارسات التصنيع الإقليمية وتوقعات الجودة في إقامة تواصل فعال مع الموردين.

- الخدمات اللوجستية وسلسلة التوريد: إن ضمان قوة سلسلة التوريد وقدرة الموردين على الوفاء بالجداول الزمنية للتسليم دون المساس بالجودة أمر بالغ الأهمية للمعاملات الدولية.

من خلال معالجة هذه الفروق الدقيقة، يمكن للمشترين التأكد من أنهم يحصلون على محركات بدء التشغيل عالية الجودة التي تلبي احتياجاتهم التشغيلية والمتطلبات التنظيمية.

دليل عملي للمصادر: قائمة مرجعية خطوة بخطوة لـ ‘كيف يعمل محرك تشغيل السيارة’

يهدف هذا الدليل إلى تزويد المشترين بين الشركات بقائمة مراجعة شاملة للحصول على معلومات حول كيفية عمل محرك بدء تشغيل السيارة. يعد فهم الآليات الكامنة وراء محركات بدء التشغيل أمرًا بالغ الأهمية لاتخاذ قرارات شراء مستنيرة، خاصةً عند التفكير في المكونات التي تلبي معايير تشغيلية ومتطلبات إقليمية محددة. اتبع الخطوات الموضحة أدناه لضمان فهم شامل وعملية توريد فعالة.

الخطوة 1: حدد المواصفات الفنية الخاصة بك

يعد وضع مواصفات فنية واضحة أمرًا أساسيًا في عملية التوريد. حدد النوع المحدد من محرك بدء التشغيل المطلوب لتطبيقك، بما في ذلك تصنيفات الجهد ومتطلبات عزم الدوران والتوافق مع أنواع المحركات المختلفة. سيساعدك هذا الوضوح على تضييق نطاق الموردين الذين يقدمون منتجات تتماشى مع احتياجاتك التشغيلية.

الخطوة 2: البحث في آلية عمل محركات التشغيل

يعد فهم الأداء الأساسي لمحركات بدء التشغيل أمرًا ضروريًا للتواصل الفعال مع الموردين. تعرّف على المكونات الرئيسية مثل المحرك والملف اللولبي وترس الترس الصغير، وكيفية عملها معًا لتدوير المحرك. ستمكنك هذه المعرفة من الدخول في المزيد من المناقشات التقنية وتقييم جودة المنتجات المعروضة.

صورة توضيحية تتعلق بكيفية عمل محرك تشغيل السيارة

الخطوة 3: تقييم الموردين المحتملين

قبل الالتزام، من الأهمية بمكان فحص الموردين بدقة. اطلب ملفات تعريف الشركة، ودراسات الحالة، والمراجع من المشترين في صناعة أو منطقة مماثلة. ركز على خبراتهم في مجال المحركات البادئة واستفسر عن عمليات ضمان الجودة لديهم لضمان موثوقية منتجاتهم.

- تحقق من الشهادات: ابحث عن موردين حاصلين على شهادات ISO أو معايير خاصة بالصناعة لضمان جودة المنتج.

- تقييم قدرات الإنتاج: تأكد من أن لديهم القدرة على تلبية متطلباتك من حيث الحجم دون المساس بالجودة.

الخطوة 4: طلب عينات للاختبار

قبل الانتهاء من عملية الشراء، اطلب عينات من محركات بدء التشغيل التي تفكر فيها. سيساعدك اختبار هذه العينات في ظروف العالم الحقيقي على تقييم الأداء والتوافق والمتانة. هذه الخطوة ضرورية لتجنب المشاكل المحتملة بعد الشراء على نطاق واسع.

الخطوة 5: مراجعة الضمان ودعم ما بعد البيع

يعتبر الضمان القوي ودعم ما بعد البيع من العوامل الحاسمة في عملية اتخاذ القرار. تأكد من أن الموردين يقدمون فترة ضمان معقولة ولديهم عملية واضحة لمعالجة العيوب أو الأعطال. يمكن أن يوفر هذا الضمان التكاليف والوقت على المدى الطويل.

الخطوة 6: التفاوض على الأسعار والشروط

بمجرد تحديد المورد المناسب، ادخل في مفاوضات بشأن الأسعار والشروط. ضع في اعتبارك خصومات الطلبات بالجملة وشروط الدفع وترتيبات الشحن. هذه الخطوة ضرورية لضمان حصولك على صفقة مواتية تتماشى مع ميزانيتك ومتطلباتك التشغيلية.

الخطوة 7: إنهاء عملية الشراء

بعد إجراء جميع التقييمات والمفاوضات، قم بإنهاء عملية الشراء عن طريق تقديم طلب الشراء. تأكد من توثيق جميع الالتزامات التعاقدية، بما في ذلك الجداول الزمنية للتسليم وجداول الدفع. سيساعد هذا الوضوح في الحفاظ على سلاسة الصفقة وإدارة التوقعات من كلا الجانبين.

من خلال اتباع قائمة المراجعة هذه، يمكن للمشترين بين الشركات التعامل بفعالية مع تعقيدات الحصول على معلومات حول كيفية عمل محرك تشغيل السيارة، مما يضمن اتخاذ قرارات مستنيرة واستراتيجية تتماشى مع احتياجات أعمالهم.

تحليل شامل للتكلفة والتسعير لكيفية عمل محرك بدء تشغيل السيارة Sourcing

ما هي مكونات التكلفة الرئيسية في الحصول على محرك تشغيل السيارة؟

عند التزود بمحركات بدء تشغيل السيارات، يُعد فهم هيكل التكلفة أمرًا بالغ الأهمية بالنسبة للمشترين بين الشركات. وتشمل المكونات الرئيسية التي تؤثر على التكلفة الإجمالية المواد، والعمالة، ونفقات التصنيع، والأدوات، ومراقبة الجودة، والخدمات اللوجستية، وهوامش الربح.

صورة توضيحية تتعلق بكيفية عمل محرك تشغيل السيارة

-

المواد: تشمل المواد الأساسية لمحركات بدء التشغيل النحاس للملفات، والصلب للغلاف، وسبائك مختلفة للمكونات مثل المحرك ومبدل التيار. يمكن أن تتقلب تكلفة هذه المواد الخام بناءً على طلب السوق وتوافرها، مما يؤثر على السعر الإجمالي.

-

العمل: تشمل تكاليف العمالة أجور عمال خطوط التجميع والمهندسين وموظفي ضمان الجودة. وتختلف هذه التكاليف حسب المنطقة؛ على سبيل المثال، قد تختلف معدلات العمالة في أفريقيا اختلافًا كبيرًا عن تلك الموجودة في أوروبا أو أمريكا الجنوبية، مما يؤثر على السعر النهائي.

-

تكاليف التصنيع العامة: يشمل ذلك التكاليف المتعلقة بعمليات المصنع مثل المرافق والإيجار واستهلاك المعدات. ويمكن لعمليات التصنيع الفعالة أن تساعد في تقليل النفقات العامة، وهو أمر بالغ الأهمية في الحفاظ على الأسعار التنافسية.

-

الأدوات: يمكن أن تكون تكاليف الإعداد الأولي لتصنيع محركات بدء التشغيل، بما في ذلك القوالب والقوالب، كبيرة. غالبًا ما يتم إطفاء هذه التكاليف على حجم إنتاج أكبر، لذلك يمكن أن تؤدي الكميات الكبيرة من الطلبات إلى انخفاض تكاليف الوحدة.

-

مراقبة الجودة (QC): يتطلب ضمان استيفاء المحركات البادئة لمعايير الصناعة الاستثمار في عمليات مراقبة الجودة ومعدات الاختبار. ويمكن أن تؤدي الشهادات مثل ISO 9001 إلى زيادة التكاليف ولكنها غالباً ما تكون ضرورية للتجارة الدولية.

-

اللوجستيات: تلعب تكاليف الشحن، بما في ذلك تكاليف النقل والرسوم الجمركية، دورًا مهمًا، لا سيما بالنسبة للمشترين الدوليين. ويمكن أن تؤثر المصطلحات التجارية الدولية المختلفة (الشروط التجارية الدولية) على من يتحمل هذه التكاليف، مما يؤثر على السعر الإجمالي.

-

الهامش: يضيف الموردون عادةً هامش ربح لتغطية المخاطر والنفقات التجارية. ويمكن أن يساعد فهم المشهد التنافسي المشترين على التفاوض على شروط أفضل.

كيف تؤثر العوامل المؤثرة في الأسعار على توريد محركات بدء التشغيل؟

هناك عدة عوامل تؤثر على تسعير محركات بدء التشغيل، بما في ذلك حجم الطلب، والمواصفات، والمواد، وشهادات الجودة، وعلاقات الموردين.

-

الحجم/الحد الأدنى للطلب: يمكن أن يؤثر الحد الأدنى لكميات الطلبات (MOQs) بشكل كبير على التسعير. وغالبًا ما تؤدي الطلبات الأكبر حجمًا إلى وفورات الحجم، مما يقلل من تكلفة الوحدة. يجب على المشترين بين الشركات تقييم احتياجاتهم بعناية لتحسين حجم الطلبات.

-

المواصفات/التخصيص: يمكن أن تؤدي التصميمات المخصصة أو متطلبات الأداء المحددة إلى زيادة التكاليف بسبب التعقيدات الهندسية والإنتاجية الإضافية. وينبغي على المشترين تحديد مواصفاتهم بوضوح لتجنب التكاليف غير المتوقعة.

-

المواد: لا يؤثر اختيار المواد على الأداء فحسب بل على التكلفة أيضاً. وقد تؤدي المواد عالية الجودة إلى زيادة التكاليف الأولية ولكنها قد تؤدي إلى انخفاض التكلفة الإجمالية للملكية من خلال تحسين المتانة وانخفاض معدلات الفشل.

-

الجودة/الشهادات: المنتجات التي تفي بمعايير الجودة الصارمة والشهادات غالباً ما تتطلب أسعاراً أعلى. وفي حين أن ذلك يمكن أن يزيد من التكاليف الأولية، إلا أنه قد يقلل من نفقات الصيانة على المدى الطويل، وهو اعتبار حاسم بالنسبة للمشترين من الشركات.

-

عوامل الموردين: يمكن أن تؤثر سمعة المورد وموثوقيته أيضًا على السعر. فقد يتقاضى الموردون الراسخون أسعاراً أعلى لمنتجاتهم، لكنهم غالباً ما يقدمون دعماً وشروط ضمان أفضل، وهو ما يمكن أن يكون مفيداً على المدى الطويل.

-

مصطلحات التجارة الدولية: إن فهم شروط التجارة الدولية المختلفة أمر حيوي للمعاملات الدولية. فهي تملي مسؤوليات المشترين والبائعين فيما يتعلق بتكاليف الشحن والتأمين والمسؤولية، مما يؤثر على التسعير الإجمالي.

ما هي النصائح التي يمكن أن تساعد مشتري B2B في التفاوض على أسعار أفضل لمحركات بدء التشغيل؟

لتأمين أفضل الأسعار والشروط الممكنة، يجب على المشترين بين الشركات النظر في الاستراتيجيات التالية:

-

التفاوض بفعالية: إشراك الموردين في مناقشات حول هياكل التسعير والاستعداد للتفاوض على أساس الحجم والعقود طويلة الأجل. وقد يقدم الموردون خصومات مقابل الالتزام بالطلبات المستقبلية.

-

التركيز على التكلفة الإجمالية للملكية: قم بتقييم ليس فقط سعر الشراء ولكن تكلفة دورة الحياة بأكملها، بما في ذلك الصيانة ومعدلات الأعطال المحتملة. قد يؤدي الاستثمار في محركات بدء التشغيل الأعلى جودة إلى خفض التكاليف الإجمالية.

-

كن على دراية بالفروق الدقيقة في التسعير: قد يكون للمناطق المختلفة هياكل تسعير مختلفة بناءً على ظروف السوق المحلية وتقلبات العملة وتكاليف الشحن. يمكن أن يساعد فهم هذه الفروق الدقيقة المشترين على اتخاذ قرارات أكثر استنارة.

-

البحث والمقارنة بين الموردين: قم بإجراء بحث شامل لمقارنة العديد من الموردين، مع التركيز على موثوقيتهم وجودتهم واستراتيجيات التسعير الخاصة بهم. ويمكن الاستفادة من هذه المعلومات أثناء المفاوضات.

-

ضع في اعتبارك التوريد المحلي: بالنسبة للمشترين في مناطق مثل أفريقيا وأمريكا الجنوبية، قد يقدم الموردون المحليون تكاليف شحن وتعريفات مخفضة مما يجعلها خيارات أكثر فعالية من حيث التكلفة.

إخلاء المسؤولية بشأن الأسعار الإرشادية

يمكن أن تختلف أسعار المحركات البادئة اختلافاً كبيراً بناءً على العوامل المذكورة أعلاه وظروف السوق. ويُنصح المشترون بالحصول على عروض أسعار متعددة وإجراء العناية الواجبة لضمان اتخاذ قرارات شراء مدروسة.

تحليل البدائل: مقارنة كيفية عمل محرك بدء تشغيل السيارة مع الحلول الأخرى

استكشاف بدائل محركات تشغيل السيارات: تحليل مقارن

في صناعة السيارات، يعتبر محرك بدء تشغيل السيارة مكونًا أساسيًا مسؤولاً عن بدء تشغيل المحرك. ولكن مع تطور التكنولوجيا، بدأت تظهر طرق وحلول بديلة تقدم مزايا ووظائف مختلفة. سيقارن هذا التحليل بين محرك بدء تشغيل السيارة التقليدي وبديلين قابلين للتطبيق: مولد بدء التشغيل المتكامل (ISG) وبادئ التشغيل اليدوي.

جدول المقارنة

| جانب المقارنة | كيف يعمل محرك بدء تشغيل السيارة | مولد بدء التشغيل المدمج (ISG) | مشغّل الكرنك اليدوي |

|---|---|---|---|

| الأداء | عزم دوران عالٍ لبدء تشغيل المحرك بسرعة | كفاءة مع الأنظمة الهجينة؛ تشغيل سلس | يقتصر على التشغيل الأولي للمحرك؛ يتطلب عمالة مكثفة |

| التكلفة | تكلفة أولية معتدلة؛ شائعة في المركبات | تكلفة أعلى بسبب التكنولوجيا المتقدمة | تكلفة أولية منخفضة؛ الحد الأدنى من التكنولوجيا |

| سهولة التنفيذ | تركيب قياسي في معظم السيارات | يتطلب تكامل التصميم المحدد | تركيب بسيط؛ لا توجد أنظمة معقدة |

| الصيانة | يلزم إجراء فحوصات منتظمة؛ يمكن أن تفشل مع مرور الوقت | صيانة منخفضة؛ مدمجة في نظام السيارة | الحد الأدنى من الصيانة؛ جهد يدوي مطلوب |

| أفضل حالة استخدام | مركبات تقليدية؛ أداء موثوق به | السيارات الهجينة والكهربائية؛ كفاءة استخدام الطاقة | السيارات القديمة أو الطوارئ؛ التشغيل اليدوي |

تفصيل البدائل

مولد بدء التشغيل المدمج (ISG)

يجمع مولد بدء التشغيل المدمج بين وظائف محرك بدء التشغيل ومولد المولد في وحدة واحدة، وهو مفيد بشكل خاص في السيارات الهجينة والكهربائية. يوفر هذا النظام بدء تشغيل المحرك بسلاسة ويمكنه أيضاً استعادة الطاقة أثناء الكبح، مما يعزز كفاءة استهلاك الوقود بشكل عام. ويُعدّ نظام ISG مفيداً للمشترين من الشركات الذين يركّزون على حلول السيارات الحديثة الصديقة للبيئة. ومع ذلك، فإن التكلفة الأولية أعلى بكثير من محركات بدء التشغيل التقليدية، وتتطلب دمج التصميم بعناية في النظام الكهربائي للسيارة.

صورة توضيحية تتعلق بكيفية عمل محرك تشغيل السيارة

مشغّل الكرنك اليدوي

إن مشغّل الكرنك اليدوي هو حل قديم يعتمد على الجهد البدني لتشغيل المحرك. على الرغم من أنها طريقة بسيطة ومنخفضة التكلفة، إلا أنها مناسبة في المقام الأول للمركبات القديمة أو كاحتياطي للطوارئ. إن عدم تعقيدها يعني الحاجة إلى الحد الأدنى من الصيانة، مما يجعلها جذابة للأسواق المتخصصة. ومع ذلك، فإن طبيعته التي تتطلب جهداً كثيفاً في العمل وقلة قابليته العملية في المركبات الحديثة تقلل بشكل كبير من جاذبيته لمعظم مشتري B2B اليوم.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

عند اختيار حل بدء التشغيل لتطبيقات السيارات، يجب على مشتري B2B مراعاة عوامل مختلفة مثل نوع السيارة والميزانية والاستخدام المقصود. توفر محركات بدء تشغيل السيارات التقليدية الموثوقية والأداء للمركبات التقليدية، بينما توفر مولدات بدء التشغيل المدمجة كفاءة متقدمة للطرازات الهجينة والكهربائية. وعلى النقيض من ذلك، تخدم بادئات التشغيل اليدوية دورًا متخصصًا، في المقام الأول في السيناريوهات القديمة أو الطارئة. سيساعد تقييم هذه البدائل مقابل احتياجات العمل المحددة على ضمان توافق التقنية المختارة مع الأهداف التشغيلية ومتطلبات السوق.

الخصائص التقنية والمصطلحات التجارية الأساسية لكيفية عمل محرك تشغيل السيارة

ما هي الخصائص التقنية الرئيسية لمحرك تشغيل السيارة؟

يعد فهم الخصائص التقنية الأساسية لمحرك بدء تشغيل السيارة أمرًا بالغ الأهمية بالنسبة للمشترين في قطاع السيارات. لا تؤثر هذه المواصفات على أداء محرك بدء التشغيل وطول عمره فحسب، بل تؤثر أيضًا على قرارات الشراء بناءً على الجودة والتوافق.

صورة توضيحية تتعلق بكيفية عمل محرك تشغيل السيارة

1. تصنيف عزم الدوران

يشير تصنيف عزم الدوران لمحرك البادئ إلى مقدار قوة الدوران التي يمكن أن يولدها لقلب المحرك. يقاس عادةً بوحدة النيوتن-متر (نيوتن-متر)، ويعد تصنيف عزم الدوران الأعلى ضروريًا للمحركات الأكبر حجمًا أو تلك التي تعمل في ظروف أكثر قسوة. بالنسبة للمشترين من B2B، يضمن اختيار محرك بادئ الحركة مع تصنيف عزم دوران مناسب بدء تشغيل المحرك بشكل موثوق، مما يقلل من مخاطر الفشل ووقت التعطل المكلف.

2. مواصفات الجهد والتيار

تعمل معظم محركات البادئ عند 12 فولت، ولكن فهم السحب الحالي (مقيساً بالأمبير) مهم بنفس القدر. قد يتطلب محرك بدء التشغيل ما بين 100 إلى 200 أمبير أثناء التشغيل. يجب على المشترين مراعاة هذه المواصفات لضمان التوافق مع النظام الكهربائي للسيارة وتجنب مشاكل استنزاف البطارية، والتي تعتبر ضرورية للحفاظ على الكفاءة التشغيلية.

3. تركيب المواد

تلعب المواد المستخدمة في بناء محرك بدء التشغيل، مثل الفولاذ عالي الجودة للغلاف والنحاس للملفات، دورًا مهمًا في المتانة والأداء. يمكن أن تتحمل تركيبة المواد القوية الضغوطات الحرارية والميكانيكية أثناء التشغيل، وهو أمر بالغ الأهمية لمشتري B2B الذين يبحثون عن طول العمر والموثوقية في منتجاتهم.

4. نطاق درجة حرارة التشغيل

يجب أن تعمل المحركات البادئة بفعالية عبر نطاق من درجات الحرارة، من البرد الشديد إلى الحرارة العالية. يمكن أن يختلف نطاق درجات الحرارة التشغيلية بشكل كبير حسب التصميم، وفهم ذلك أمر حيوي للمشترين في المناطق ذات المناخات القاسية. إن اختيار محرك بادئ الحركة الذي يمكنه تحمل الظروف البيئية المحلية سيعزز الأداء ويقلل من تكرار الاستبدال.

5. نسبة التروس

تؤثر نسبة تروس محرك البادئ على تعشيقه مع دولاب الموازنة. تسمح نسبة التروس الأعلى بميزة ميكانيكية أكبر، والتي يمكن أن تكون حاسمة في بدء تشغيل المحركات الأكبر حجمًا. يجب على مشتري B2B الانتباه إلى هذه المواصفات لضمان التوافق مع المركبات في أسطولهم أو قطاع السوق.

ما هي المصطلحات التجارية الشائعة المستخدمة في صناعة المحركات المبتدئة؟

يعد الإلمام بالمصطلحات الصناعية أمرًا ضروريًا للتواصل والتفاوض الفعال في سوق B2B. فيما يلي بعض المصطلحات الشائعة المتعلقة بمحركات بدء التشغيل.

1. OEM (الشركة المصنعة للمعدات الأصلية)

يشير مصطلح OEM إلى القطع المصنوعة من قبل الشركة المصنعة للسيارة، مما يضمن التوافق والجودة. عند الحصول على محركات بادئ التشغيل، غالباً ما يفضل المشترون قطع غيار OEM لضمان الموثوقية وتغطية الضمان، مما قد يؤثر على قرارات الشراء.

2. MOQ (الحد الأدنى لكمية الطلب)

يشير موك إلى أصغر كمية من المنتج الذي يرغب المورد في بيعه. وبالنسبة للمشترين في مجال الأعمال التجارية بين الشركات، فإن فهم موك أمر بالغ الأهمية لوضع الميزانية وإدارة المخزون، حيث أن الطلبات الأكبر يمكن أن تقلل في كثير من الأحيان من تكاليف الوحدة.

3. طلب عرض أسعار (RFQ)

طلب عرض الأسعار هو مستند يتم إرساله إلى الموردين لطلب عرض أسعار لمنتجات محددة. وهذه ممارسة شائعة في المعاملات بين الشركات، مما يسمح للمشترين بمقارنة الأسعار والشروط بفعالية قبل اتخاذ قرارات الشراء.

صورة توضيحية تتعلق بكيفية عمل محرك تشغيل السيارة

4. شروط التجارة الدولية (Incoterms)

إن شروط التجارة الدولية هي قواعد معترف بها دوليًا تحدد مسؤوليات المشترين والبائعين في المعاملات الدولية. ويمكن لفهم هذه الشروط أن يساعد المشترين بين الشركات في التعامل مع التزامات الشحن والتأمين والتسليم، مما يضمن سلاسة المعاملات.

5. سوق ما بعد البيع

يشير مصطلح ما بعد البيع إلى القطع التي تصنعها شركات أخرى غير الشركة المصنعة الأصلية. قد يفكر المشترون من الشركات في محركات بدء التشغيل ما بعد البيع كبديل فعال من حيث التكلفة، ولكن يجب عليهم أن يوازنوا بين المفاضلة المحتملة في الجودة وتغطية الضمان.

من خلال فهم هذه الخصائص التقنية والمصطلحات التجارية، يمكن للمشترين بين الشركات اتخاذ قرارات مستنيرة عند الحصول على محركات بدء التشغيل، مما يضمن اختيار المنتجات التي تلبي احتياجاتهم التشغيلية ومعاييرهم.

الإبحار في ديناميكيات السوق واتجاهات التوريد في قطاع كيفية عمل محرك تشغيل السيارة

ما هي ديناميكيات السوق الحالية والاتجاهات الرئيسية التي تؤثر على صناعة المحركات البادئة؟

يشهد قطاع محركات بدء التشغيل تحولات كبيرة مدفوعة بالتطورات التكنولوجية وتطور تفضيلات المستهلكين والتغيرات التنظيمية. على الصعيد العالمي، تركز صناعة السيارات بشكل متزايد على تعزيز كفاءة السيارة وأدائها، مما يؤدي إلى زيادة الطلب على محركات بدء التشغيل ذات عزم الدوران العالي التي يمكن أن تسهل الإشعال السريع للمحرك. في مناطق مثل أفريقيا وأمريكا الجنوبية، حيث يزداد الاعتماد على السيارات ويزداد تطوير البنية التحتية بشكل كبير، يصبح الطلب على محركات بدء التشغيل الموثوقة أمرًا بالغ الأهمية.

تشمل الاتجاهات الناشئة دمج محركات بدء التشغيل مع الأنظمة المتقدمة مثل السيارات الهجينة والكهربائية (EVs)، حيث يعمل محرك بدء التشغيل كجزء من نظام أكثر تعقيدًا. بالنسبة للمشترين بين الشركات، يعد فهم هذه التطورات التكنولوجية أمرًا ضروريًا لتوريد المنتجات التي تتماشى مع أحدث تصميمات السيارات. بالإضافة إلى ذلك، يؤدي ظهور منصات التجارة الإلكترونية وحلول سلسلة التوريد الرقمية إلى إعادة تشكيل كيفية حصول المشترين الدوليين على محركات بدء التشغيل. يسمح هذا التحول بمزيد من الشفافية والوصول إلى مجموعة أوسع من الموردين، مما يعزز المنافسة والابتكار في هذا القطاع.

كيف تؤثر الاستدامة والتوريد الأخلاقي على سلسلة توريد المحركات المبتدئة؟

لقد أصبحت الاستدامة حجر الزاوية في ممارسات سلسلة التوريد في قطاع السيارات، ومحركات بدء التشغيل ليست استثناءً. يشكل التأثير البيئي لعمليات التصنيع، خاصة في المناطق ذات اللوائح التنظيمية المتساهلة، تحديًا للمشترين الدوليين. هناك تركيز متزايد على التوريد الأخلاقي، حيث يُتوقع من الموردين الالتزام بالمعايير البيئية وإظهار المسؤولية في عمليات التصنيع الخاصة بهم.

يبحث المشترون بين الشركات على نحو متزايد عن شركاء يعطون الأولوية للاستدامة، ويستخدمون المواد ‘الخضراء’ والشهادات التي تشير إلى ممارسات التوريد المسؤولة. ويشمل ذلك استخدام المواد القابلة لإعادة التدوير في إنتاج محركات بدء التشغيل والالتزام بالمعايير البيئية الدولية. فالشركات التي تستطيع إثبات التزامها بالاستدامة لا تعزز سمعة علامتها التجارية فحسب، بل تجذب أيضًا شريحة متنامية من السوق التي تقدر الممارسات الصديقة للبيئة.

كيف تطور محرك بدء التشغيل مع مرور الوقت؟

شهد محرك بدء التشغيل تطوراً كبيراً منذ اختراعه على يد تشارلز كيترينج في عام 1911، والذي أحدث ثورة في أنظمة إشعال السيارات. وقد تم دمج محرك بدء التشغيل في البداية مع أنظمة الإشعال والمولد، ومنذ ذلك الحين تطور ليصبح وحدة مخصصة تعتبر حاسمة بالنسبة للسيارات الحديثة. وقد تحول التركيز من أنظمة التعشيق الميكانيكية إلى أنظمة كهربائية متطورة تعزز الموثوقية والكفاءة.

مع استمرار تطور صناعة السيارات، لا سيما مع ظهور السيارات الكهربائية والهجينة، يتوسع دور محرك بدء التشغيل. وغالبًا ما يتم دمجها الآن مع أنظمة الكبح المتجددة وغيرها من التقنيات المتقدمة، مما يعكس اتجاهًا أوسع نحو المكونات متعددة الوظائف في تصميم السيارات. إن فهم هذا السياق التاريخي ضروري للمشترين من الشركات الذين يسعون إلى شراء محركات بادئ الحركة التي تلبي متطلبات تطبيقات السيارات المعاصرة.

الأسئلة المتداولة (FAQs) لمشتري B2B حول كيفية عمل محرك بدء تشغيل السيارة

-

كيف يمكنني استكشاف أخطاء محرك تشغيل السيارة الذي لا يعمل؟

لاستكشاف أعطال محرك بادئ التشغيل غير القابل للتشغيل وإصلاحها، افحص أولاً جهد البطارية؛ فغالباً ما تكون البطارية الضعيفة هي السبب. تأكد من أن جميع التوصيلات الكهربائية نظيفة وآمنة، خاصة عند أطراف البطارية وتوصيلات بادئ التشغيل. افحص الملف اللولبي للتأكد من عمله، حيث يمكن أن يمنع الملف اللولبي المعيب وصول الطاقة إلى بادئ التشغيل. إذا تم فحص هذه المكونات، ففحص محرك البادئ نفسه للتأكد من عدم وجود أعطال داخلية. بالنسبة لمشتري B2B، يمكن أن يؤدي وجود ميكانيكي أو فني محلي موثوق به إلى تسريع عملية التشخيص، مما يقلل من وقت تعطل أسطولك. -

ما هو أفضل محرك تشغيل للمركبات الثقيلة؟

يجب أن يوفر أفضل محرك بادئ تشغيل للمركبات الثقيلة عزم دوران عالٍ ومتانة في ظل الظروف القاسية. ابحث عن الموديلات ذات الملفات الميدانية القوية وآلية الملف اللولبي الموثوق بها، حيث أن ذلك يعزز الأداء وطول العمر. غالبًا ما تقدم العلامات التجارية المتخصصة في تطبيقات الخدمة الشاقة مشغلات مصممة لموديلات وطرازات محددة من المركبات، مما يضمن الملاءمة والوظيفة المثلى. يمكن أن يساعدك التعاون مع الموردين الذين يفهمون احتياجاتك الإقليمية - مثل درجات الحرارة القصوى في أفريقيا أو ظروف الارتفاعات العالية في أمريكا الجنوبية - في الحصول على أنسب محركات التشغيل لأسطولك. -

كيف يمكنني تقييم مورد محركات بدء تشغيل السيارة؟

عند تقييم أحد مورِّدي محركات بدء تشغيل السيارات، ضع في اعتبارك سمعة الشركة في هذا المجال، وجودة المنتج وخدمة العملاء. اطلب عيّنات لتقييم جودة التصنيع وأداء محركات التشغيل الخاصة بهم. من المهم أيضًا التحقق من شهاداتهم وامتثالهم للمعايير الدولية. راجع خبرتهم في سوقك المحدد، خاصةً إذا كنت تقوم بالتوريد من مناطق مثل أوروبا أو الشرق الأوسط. كما أن إنشاء خط اتصال واضح وفهم قدراتهم اللوجستية يمكن أن يضمن لك التسليم والدعم في الوقت المناسب. -

ما هي شروط الدفع الشائعة في معاملات B2B الدولية لقطع غيار السيارات؟

عادةً ما تتضمن شروط الدفع الشائعة في المعاملات الدولية بين الشركات لقطع غيار السيارات إيداع مبلغ عند تأكيد الطلب، على أن يكون الرصيد مستحق الدفع قبل الشحن. قد يقدم بعض الموردين خطابات اعتماد أو الدفع عند التسليم لتخفيف المخاطر. تأكد من مناقشة الشروط التي تتماشى مع التدفق النقدي وتحمل المخاطر والتفاوض بشأنها. من الضروري أيضاً فهم الآثار المترتبة على صرف العملات والتعريفات الجمركية المحتملة، خاصةً عند التعامل مع موردين من مناطق متنوعة مثل أفريقيا وأمريكا الجنوبية. -

ما هو الحد الأدنى لكميات الطلب (MOQs) لمحركات بدء التشغيل؟

يمكن أن يختلف الحد الأدنى لكميات الطلبات (MOQs) لمحركات بدء التشغيل اختلافًا كبيرًا بناءً على المورد والمنتج المحدد. وعادةً ما يتراوح الحد الأدنى للكميات المطلوبة من 50 إلى 500 وحدة، اعتمادًا على قدرات الإنتاج لدى المُصنِّع ونفوذ التفاوض لديك. بالنسبة للمشترين بين الشركات B2B، من المفيد الاستفسار عن المرونة في موكس، خاصةً إذا كنت تختبر أسواقًا أو خطوط إنتاج جديدة. قد يقدم بعض الموردين أسعارًا متدرجة بناءً على الحجم، مما قد يساعدك على إدارة تكاليف المخزون بفعالية. -

كيف يمكنني تخصيص محركات بدء التشغيل لتناسب طرازات معينة من السيارات؟

غالبًا ما ينطوي تخصيص محركات بدء التشغيل لتلائم طرازات معينة من المركبات على تعديل الأبعاد أو تكوينات التروس أو المواصفات الكهربائية. تعاون بشكل وثيق مع المورد الخاص بك لتوصيل متطلباتك الدقيقة، بما في ذلك أي ميزات فريدة مطلوبة للتوافق مع مركباتك. يمكن أن يساعد توفير المواصفات التفصيلية والنماذج الأولية في عملية التصميم. تأكد من أن المورد لديه خبرة في الحلول المخصصة ويمكنه تلبية معايير ضمان الجودة الخاصة بك في جميع مراحل الإنتاج. -

ما هي تدابير ضمان الجودة التي يجب أن أضعها في الاعتبار عند الحصول على محركات بدء التشغيل؟

عند توريد محركات بدء التشغيل، يجب أن تشمل إجراءات ضمان الجودة شهادات الموردين (مثل ISO 9001)، وبروتوكولات الاختبار الداخلية، وعمليات التفتيش من طرف ثالث. اطلب توثيق عمليات مراقبة الجودة وأي ضمانات مقدمة على منتجاتهم. يمكن أن يساعد إنشاء فهم واضح لطرق الاختبار المستخدمة، مثل اختبارات عزم الدوران والمتانة، في ضمان موثوقية محركات البادئ التي تشتريها. كما يمكن أن تؤدي عمليات التدقيق المنتظمة أو الزيارات المنتظمة لمنشأة التصنيع إلى تعزيز الثقة والشفافية في علاقتك مع الموردين. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في اعتباري عند استيراد محركات بدء التشغيل؟

تشمل الاعتبارات اللوجستية عند استيراد المحركات البادئة فهم تكاليف الشحن، والمهل الزمنية واللوائح الجمركية في منطقتك. تعامل مع مزودي الخدمات اللوجستية الذين لديهم خبرة في مجال قطع غيار السيارات للتغلب على التحديات المحتملة بفعالية. من الضروري مراعاة متطلبات التعبئة والتغليف لمنع التلف أثناء النقل، ولضمان الامتثال لرسوم الاستيراد والضرائب. يمكن أن يساعدك وضع جدول زمني واضح للتسليم على مواءمة احتياجات مخزونك مع طلب السوق، خاصةً في المناطق ذات دورات المبيعات المتقلبة.

قائمة المصنعين والموردين لأفضل 3 كيف يعمل محرك بدء تشغيل السيارة

1. أوتوإلكترو - محركات بدء التشغيل

المجال: autoelectro.co.uk

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: محركات البادئ مسؤولة عن قلب المحرك أثناء الاشتعال، مما يسمح بدخول الهواء والوقود للاحتراق. تشمل المكونات الرئيسية ما يلي:

- حديد التسليح: مغناطيس كهرومغناطيسي مركب على عمود الإدارة، مصنوع من قلب حديد لين مصفح مع حلقات موصل.

- مقوم التيار: جزء من العمود مع لوحين يوفران وصلات لملف المغناطيس الكهربائي.

- الفرش: توصيل الكهرباء عن طريق...

2. هاينز – دليل نظام الإشعال

المجال: us.haynes.com

تاريخ التسجيل: 1996 (29 عامًا)

مقدمة: هذه الشركة، Haynes – Ignition System Guide، هي كيان بارز في السوق. للحصول على تفاصيل محددة عن المنتجات، يوصى بزيارة موقعها الإلكتروني مباشرة.

3. كيف تعمل السيارة - شرح نظام التشغيل - شرح نظام التشغيل

المجال: howacarworks.com

مسجل: 2011 (14 سنة)

مقدمة: يتكون نظام بدء التشغيل من محرك بادئ تشغيل مسبق التشغيل يستخدم ملفاً لولبياً لتعشيق ترس مع حلقة تروس على دولاب الموازنة للمحرك. ويتطلب محرك بدء التشغيل تياراً كهربائياً قوياً من البطارية، يتم تنشيطه بواسطة مفتاح كبير يتم التحكم به بواسطة مفتاح الإشعال. يجذب الملف اللولبي قضيباً حديدياً لإغلاق التلامسات وإكمال الدائرة. يحتوي محرك البادئ على ترس بنديكس يتم تعشيقه على...

خاتمة المصادر الاستراتيجية والتوقعات الخاصة بكيفية عمل محرك تشغيل السيارة

كيف يمكن للمصادر الاستراتيجية تعزيز فهمك لمحركات التشغيل؟

باختصار، يعد فهم تعقيدات كيفية عمل محرك بدء تشغيل السيارة أمرًا ضروريًا للمشترين بين الشركات في قطاع السيارات. من خلال فهم الميكانيكيات - من دور الملف اللولبي إلى تعشيق ترس الترس - يمكن للشركات اتخاذ قرارات أكثر استنارة بشأن الحصول على محركات ومكونات بادئ الحركة عالية الجودة.

لا يضمن التوريد الاستراتيجي الوصول إلى موردين موثوقين فحسب، بل يؤكد أيضًا على أهمية الجودة والأداء في قطع غيار السيارات. ويكتسب هذا الأمر أهمية خاصة في الأسواق الناشئة في أفريقيا وأمريكا الجنوبية والشرق الأوسط وأوروبا، حيث يتزايد الطلب على حلول السيارات التي يمكن الاعتماد عليها.

يمكن أن يؤدي الاستثمار في محركات بدء التشغيل عالية الجودة إلى تحسين أداء السيارة ورضا العملاء، مما يؤدي في النهاية إلى نجاح شركتك. أثناء تنقلك في استراتيجيات التوريد الخاصة بك، ضع في اعتبارك إقامة شراكات مع الشركات المصنعة التي تعطي الأولوية للابتكار ومراقبة الجودة.

بينما تتطلع إلى المستقبل، اغتنم الفرصة للاستفادة من هذه المعرفة في عمليات الشراء الخاصة بك. استكشف الموردين العالميين الذين يمكنهم تلبية احتياجاتك والمساهمة في استدامة سلسلة التوريد الخاصة بك. يمكننا معاً أن ندفع بمستقبل صناعة السيارات إلى الأمام.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.

صورة توضيحية تتعلق بكيفية عمل محرك تشغيل السيارة