Introduction: Navigating the Global Market for bad starter symptoms

In the intricate landscape of automotive maintenance, recognizing the symptoms of a bad starter is crucial for international B2B buyers. Many businesses, particularly those operating in Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—face challenges in sourcing reliable starter components. A malfunctioning starter can disrupt operations, lead to costly downtimes, and affect overall productivity. This guide offers a comprehensive exploration of bad starter symptoms, providing actionable insights on identifying issues, understanding the underlying causes, and evaluating potential solutions.

The content delves into various types of starter symptoms, their applications in different vehicle models, and crucial aspects of supplier vetting. Furthermore, it addresses cost considerations and best practices for maintaining starter systems to enhance longevity and performance. By equipping B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to mitigate risks associated with starter failures and streamline procurement processes. Whether you are seeking to enhance your fleet’s reliability or ensure that your automotive service offerings meet customer expectations, understanding bad starter symptoms is an essential step toward operational excellence.

جدول المحتويات

- Top 3 Bad Starter Symptoms Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for bad starter symptoms

- Understanding bad starter symptoms Types and Variations

- Key Industrial Applications of bad starter symptoms

- 3 Common User Pain Points for ‘bad starter symptoms’ & Their Solutions

- Strategic Material Selection Guide for bad starter symptoms

- In-depth Look: Manufacturing Processes and Quality Assurance for bad starter symptoms

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘bad starter symptoms’

- Comprehensive Cost and Pricing Analysis for bad starter symptoms Sourcing

- Alternatives Analysis: Comparing bad starter symptoms With Other Solutions

- Essential Technical Properties and Trade Terminology for bad starter symptoms

- Navigating Market Dynamics and Sourcing Trends in the bad starter symptoms Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bad starter symptoms

- Strategic Sourcing Conclusion and Outlook for bad starter symptoms

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding bad starter symptoms Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| صوت النقر | A distinct clicking noise when turning the ignition. | إدارة الأسطول، شركات الخدمات اللوجستية | الإيجابيات: سهل التشخيص؛ وغالباً ما يشير إلى وجود مشاكل في البطارية. السلبيات: May require further inspection if persistent. |

| لا يوجد رد | Dashboard lights illuminate, but the engine fails to crank. | Construction, agriculture vehicles | الإيجابيات: Clear indicator of starter failure; actionable. السلبيات: May be confused with battery or electrical issues. |

| Grinding Noises | Unusual grinding sounds during starting attempts. | Transportation services, delivery fleets | الإيجابيات: Signals mechanical issues needing immediate attention. السلبيات: Could lead to further damage if ignored. |

| انبعاث الدخان | Visible smoke from the starter or electrical components. | الآلات الثقيلة وإصلاح السيارات | الإيجابيات: Immediate visual cue of failure; prompts urgent action. السلبيات: Indicates severe damage, requiring costly repairs. |

| Oil Soaking | Starter components covered in engine oil. | ورش إصلاح السيارات، خدمات الأساطيل | الإيجابيات: Identifies oil leaks that can affect starter longevity. السلبيات: يتطلب إصلاحات إضافية بخلاف استبدال المُشغّل. |

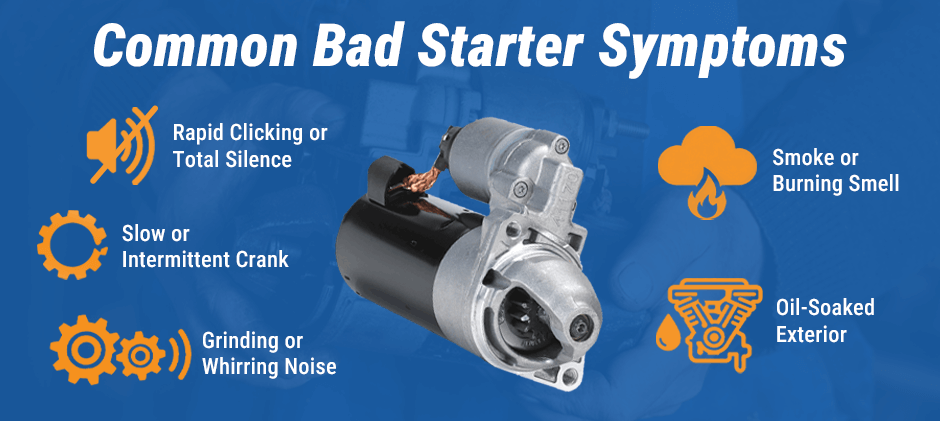

What are the characteristics of the Clicking Sound symptom in starters?

The clicking sound is often the first sign of starter issues, typically indicating a weak battery or poor connection. When the ignition key is turned, the starter solenoid engages but fails to crank the engine, resulting in a series of clicks. This symptom is particularly relevant for businesses with fleets, as it allows for quick identification and troubleshooting, minimizing downtime. B2B buyers should consider the ease of diagnosing this issue and the relatively low cost of battery replacement versus a full starter replacement.

How does the No Response symptom affect B2B applications?

When a vehicle’s dashboard lights up but the engine does not crank, it signifies a potential starter failure. This symptom is crucial for industries relying on operational vehicles, such as construction or agriculture. Understanding this symptom can help businesses develop preventive maintenance schedules. B2B buyers should prioritize sourcing reliable starters and consider the total cost of ownership, including potential labor costs for diagnostics.

What should businesses know about Grinding Noises from starters?

Grinding noises during starting attempts usually indicate that the starter gear is failing to engage properly with the flywheel. This can lead to further mechanical issues if not addressed promptly. For transportation services and delivery fleets, recognizing this symptom can prevent extensive repairs and operational delays. Buyers should evaluate the quality and warranty of starter components to ensure long-term reliability and avoid frequent replacements.

Illustrative image related to bad starter symptoms

Why is Smoke Emission a critical warning sign for B2B buyers?

Smoke emission from the starter or electrical components is a severe indicator of failure, often resulting from overheating or electrical shorts. This symptom necessitates immediate attention, especially in industries that rely on heavy machinery or automotive repairs. B2B buyers should understand the implications of smoke signals as they often lead to costly repairs and extended downtime. Investing in high-quality starters can mitigate these risks and enhance operational efficiency.

How can Oil Soaking impact starter performance in vehicles?

Oil soaking occurs when engine oil leaks onto the starter, significantly impairing its performance and lifespan. This symptom is particularly relevant for automotive repair shops and fleet services, where timely maintenance can prevent starter failure. B2B buyers should consider the implications of oil leaks in their purchasing decisions and factor in the need for additional repairs. Regular inspections and quality starter components can help maintain optimal performance and reduce long-term costs.

Key Industrial Applications of bad starter symptoms

| الصناعة/القطاع | Specific Application of bad starter symptoms | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| إصلاح السيارات | تشخيص مشاكل بدء التشغيل في المركبات | Reduces downtime and repair costs, enhancing service efficiency | Quality of replacement parts, warranty terms, and supplier reliability |

| النقل واللوجستيات | صيانة أسطول المركبات التجارية | Ensures operational reliability, minimizing delays and enhancing delivery efficiency | Bulk purchasing options, after-sales support, and technical assistance |

| الزراعة | تشغيل الآلات الزراعية | Ensures timely planting and harvesting, directly impacting yield | Compatibility with various machinery models and parts availability |

| البناء | Heavy machinery and equipment diagnostics | Prevents project delays by ensuring machinery uptime and reliability | Sourcing from trusted manufacturers and availability of technical support |

| التعدين | Maintenance of mining vehicles and equipment | Enhances safety and operational efficiency, reducing the risk of accidents | Compliance with industry standards, sourcing durable components, and supplier certifications |

How Are Bad Starter Symptoms Applied in the Automotive Repair Industry?

In the automotive repair industry, diagnosing bad starter symptoms is crucial for ensuring vehicles are operational. Mechanics often encounter issues such as clicking sounds or unresponsive engines, which can lead to misdiagnosis if not correctly assessed. By identifying these symptoms early, repair shops can reduce downtime and repair costs, ultimately improving customer satisfaction. For international B2B buyers, sourcing high-quality replacement starters and components that meet regional standards is essential to maintain reliability and performance.

What Role Do Bad Starter Symptoms Play in Transportation & Logistics?

In the transportation and logistics sector, fleet maintenance hinges on the ability to quickly identify and resolve starter issues in commercial vehicles. A malfunctioning starter can lead to significant delays, impacting delivery schedules and operational costs. By recognizing symptoms like unusual noises or failure to start, fleet managers can ensure that vehicles remain in service. Buyers in this sector should focus on suppliers that offer bulk purchasing options and robust after-sales support to maintain fleet efficiency across diverse geographical regions.

Illustrative image related to bad starter symptoms

How Do Bad Starter Symptoms Impact Agricultural Operations?

Agricultural machinery is vital for timely planting and harvesting, making the identification of bad starter symptoms critical. Farmers often face challenges with starting equipment, which can lead to lost productivity during peak seasons. Symptoms such as grinding sounds or engine failure to crank can signal a need for immediate repairs or replacements. Buyers in the agricultural sector should prioritize sourcing parts that are compatible with a variety of machinery models, ensuring minimal disruption to operations during critical farming periods.

Why Are Bad Starter Symptoms Important in Construction?

In the construction industry, heavy machinery and equipment must operate reliably to avoid project delays. Diagnosing bad starter symptoms—like failure to start or unusual sounds—can prevent costly downtime. Identifying these issues early allows construction managers to maintain equipment effectively, ensuring projects remain on schedule. Buyers should consider sourcing from reputable manufacturers who can provide durable components and technical support, ensuring compliance with safety and operational standards.

How Do Bad Starter Symptoms Affect Mining Operations?

Mining operations rely heavily on the functionality of vehicles and equipment, making the identification of bad starter symptoms crucial for safety and efficiency. Symptoms such as smoke from the starter or a non-responsive engine can indicate potential failures that could lead to hazardous situations. Timely diagnosis and repair can enhance operational efficiency and reduce the risk of accidents. Buyers in the mining sector should focus on sourcing components that meet industry standards, ensuring durability and reliability in challenging environments.

3 Common User Pain Points for ‘bad starter symptoms’ & Their Solutions

Scenario 1: Unexpected Vehicle Downtime Due to Starter Issues

المشكلة: For fleet managers operating in regions with challenging climates, such as the extremes found in parts of Africa or the Middle East, a faulty starter can lead to significant operational disruptions. Imagine a delivery truck failing to start early in the morning due to a worn-out starter, causing delays and potentially losing business to competitors. This situation not only affects logistics but also impacts customer satisfaction and trust, which are critical in maintaining a competitive edge.

الحل: To mitigate these risks, fleet managers should implement a proactive maintenance schedule that includes regular inspections of the starter system. Specifically, they should focus on identifying common signs of starter failure, such as unusual noises or dashboard warning lights, and address them before they escalate. Moreover, sourcing high-quality starter components from reputable suppliers ensures better durability and performance. When ordering replacements, provide detailed specifications to your supplier to ensure compatibility with your fleet’s vehicles. Engaging a certified technician for periodic checks can also help diagnose underlying issues before they lead to vehicle downtime.

Scenario 2: Misdiagnosis Leading to Increased Repair Costs

المشكلة: A common challenge faced by automotive repair shops is the misdiagnosis of issues related to vehicle starting problems. For instance, if a technician assumes that a faulty battery is the sole cause of a no-start condition, they may replace it only to find that the starter was the real culprit. This not only leads to unnecessary expenses for the customer but also erodes the shop’s reputation for reliable service.

الحل: To avoid misdiagnosis, repair shops should invest in diagnostic tools that can accurately test the battery, alternator, and starter as a system. Training technicians to recognize the interconnectedness of these components is essential. When diagnosing a vehicle, they should follow a systematic approach, starting with the simplest checks, such as the battery’s state of charge and connections, before proceeding to test the starter. Additionally, workshops can develop a checklist for common symptoms associated with starter issues, allowing technicians to quickly narrow down the problem and avoid costly mistakes. Partnering with reliable parts suppliers can also streamline the process of sourcing the right replacement parts once a diagnosis is confirmed.

Scenario 3: Poor Customer Experience Due to Delayed Repairs

المشكلة: For businesses that rely on customer-facing vehicles, such as taxis or car rentals, a vehicle that won’t start can lead to a poor customer experience and lost revenue. When customers are stranded due to a bad starter, it reflects poorly on the business and can lead to negative reviews, impacting future sales.

الحل: To enhance customer satisfaction and reduce the likelihood of starter-related issues, businesses should implement a comprehensive vehicle maintenance program. This program should include regular inspections of the starter system, including checking for signs of wear such as corrosion on terminals or frayed wiring. Establishing a relationship with a local automotive service provider can ensure quick access to expert diagnostics and repairs. Additionally, offering customers a reliable means of transportation while their vehicle is being serviced can greatly improve their overall experience. Consider providing shuttle services or loaner vehicles to keep customers satisfied and maintain trust in your brand.

Strategic Material Selection Guide for bad starter symptoms

What Materials Are Commonly Used for Bad Starter Symptoms?

When addressing bad starter symptoms, the materials used in the starter system components play a crucial role in performance and reliability. Below, we analyze four common materials used in starters and their associated components, focusing on key properties, pros and cons, and considerations for international B2B buyers.

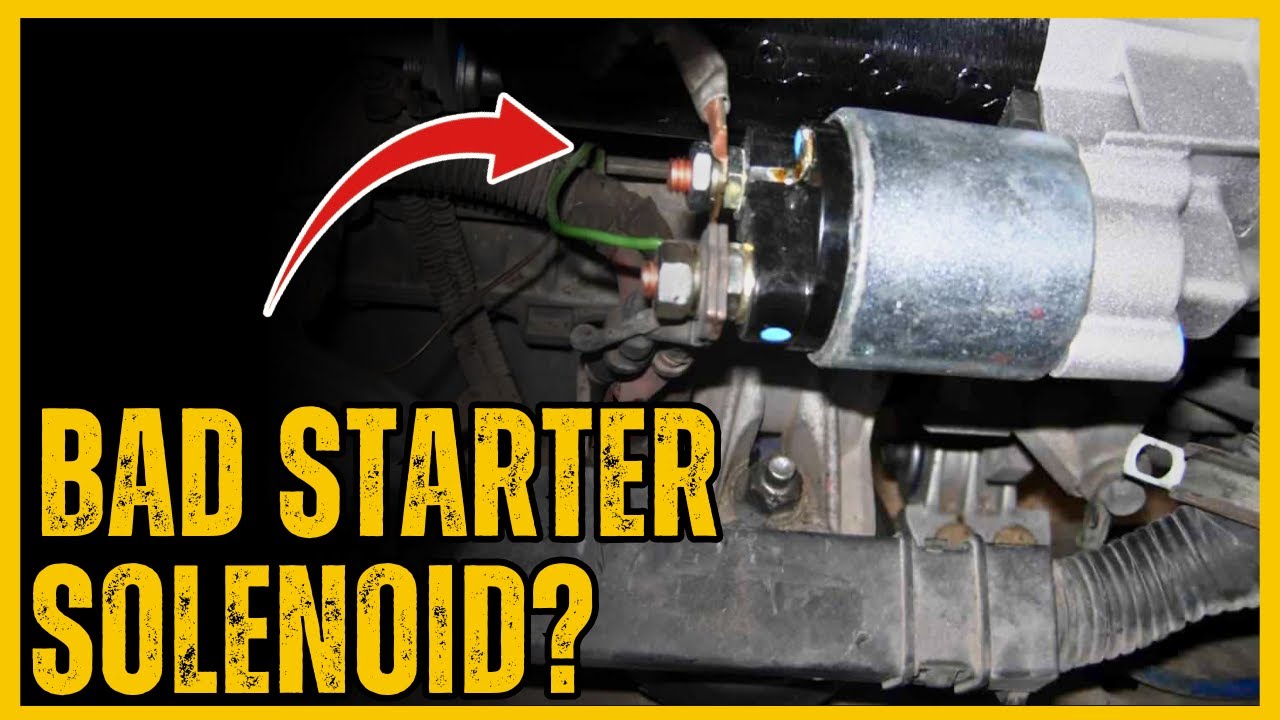

Illustrative image related to bad starter symptoms

How Do Copper and Aluminum Compare for Electrical Connections?

النحاس is a favored material for electrical connections due to its excellent conductivity and thermal properties. It typically features a high temperature rating and is resistant to corrosion when properly treated. However, copper can be more expensive than alternatives like aluminum, and its weight can be a drawback in applications where reducing mass is essential.

الإيجابيات: High conductivity, good thermal performance, and durability make copper a reliable choice for electrical connections in starters.

سلبيات: Higher cost and weight compared to aluminum can limit its use in certain applications.

بالنسبة لـ الألومنيوم, while it has lower conductivity than copper, it is lightweight and more cost-effective. It is also resistant to corrosion, especially when anodized. However, aluminum connections may require larger cross-sectional areas to match copper’s conductivity, potentially complicating design and installation.

الإيجابيات: Lightweight, cost-effective, and corrosion-resistant, making it suitable for various automotive applications.

سلبيات: Lower conductivity than copper and potential for increased installation complexity.

ما هو الدور الذي يلعبه الفولاذ في مكونات المبتدئين؟

الصلب, particularly high-strength steel alloys, is commonly used in the structural components of starters, such as housings and mounting brackets. Steel’s high tensile strength and durability make it suitable for withstanding mechanical stresses. However, steel is prone to corrosion if not properly coated or treated, which can lead to premature failure in harsh environments.

الإيجابيات: Excellent strength and durability, making it ideal for structural components in starters.

سلبيات: Susceptibility to corrosion and heavier weight compared to alternative materials can be limiting factors.

How Effective Are Plastics in Starter Systems?

بلاستيك, such as polyamide (nylon) and polycarbonate, are often used for non-structural components like housings and insulators in starters. They offer good electrical insulation properties and are lightweight, which can enhance overall system efficiency. However, plastics may not withstand high temperatures as well as metals, and their mechanical properties can degrade over time, especially in extreme conditions.

الإيجابيات: Lightweight, good electrical insulation, and cost-effective for non-structural components.

سلبيات: Limited temperature resistance and potential degradation in harsh environments.

What Considerations Should International Buyers Keep in Mind?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local standards such as ASTM, DIN, and JIS when selecting materials for starters. In regions with extreme climates, such as high humidity or temperature variations, choosing materials with superior corrosion resistance and durability is essential. Additionally, understanding the supply chain dynamics and availability of these materials in local markets can significantly impact procurement strategies.

Summary Table of Material Selection for Bad Starter Symptoms

| المواد | Typical Use Case for bad starter symptoms | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| النحاس | التوصيلات الكهربائية في المبتدئين | High conductivity and thermal performance | تكلفة ووزن أعلى | عالية |

| الألومنيوم | Electrical connections and structural parts | خفيفة الوزن وفعالة من حيث التكلفة | Lower conductivity and installation complexity | متوسط |

| الصلب | Structural components like housings | Excellent strength and durability | Susceptible to corrosion and heavier | متوسط |

| بلاستيك | المكونات غير الهيكلية والعوازل غير الهيكلية | خفيف الوزن وعزل كهربائي جيد | Limited temperature resistance and degradation | منخفض |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for starters, enabling informed decisions that enhance product performance and reliability in various operating environments.

In-depth Look: Manufacturing Processes and Quality Assurance for bad starter symptoms

What Are the Main Stages of Manufacturing Processes for Starters?

Understanding the manufacturing process of starter motors is essential for B2B buyers seeking reliable components. The production typically involves several key stages: material preparation, forming, assembly, and finishing.

كيف يتم تحضير المواد لإنتاج المواد الأولية؟

The manufacturing process begins with selecting high-quality materials. Key components include copper for windings, steel for the housing, and various alloys for gears and other mechanical parts. Quality assurance starts with Incoming Quality Control (IQC), where materials are inspected for defects, dimensions, and compliance with specifications. This step ensures that only suitable materials enter the production line, reducing the risk of faults in the final product.

ما هي تقنيات التشكيل المستخدمة في تصنيع البادئات؟

Once materials are approved, the next stage is forming. Techniques such as stamping, forging, and machining are commonly employed. Stamping is often used for producing the metal housing, while precision machining is essential for components like the armature and commutator. During this stage, In-Process Quality Control (IPQC) is critical, as it involves monitoring the manufacturing process to detect any deviations from standards early on. Regular checks can prevent costly rework and ensure the dimensional accuracy of parts.

How Is Assembly Conducted in Starter Manufacturing?

Assembly is a vital phase where various components are brought together to create the finished starter motor. This stage typically involves:

-

تكامل المكونات: The assembly line integrates all the parts, including the motor, solenoid, and gear assembly. Skilled technicians or automated systems ensure that components fit correctly.

-

التوصيلات الكهربائية: Careful attention is paid to electrical connections, ensuring that soldering and wiring meet stringent electrical standards to prevent failures.

-

الاختبار: Each starter undergoes initial testing to ensure it meets operational specifications before moving to the final quality check.

ما هي عمليات التشطيب التي يتم تطبيقها على المبتدئين؟

The finishing stage involves processes like painting, coating, and final inspection. A protective coating is often applied to prevent corrosion and wear. This is particularly important for components that may be exposed to various environmental conditions, especially in markets like Africa and South America, where humidity and temperature variations can be extreme.

The final inspection at this stage is crucial and forms part of the Final Quality Control (FQC). This involves rigorous testing of the starter motor’s performance, including cranking tests, load tests, and electrical output verification.

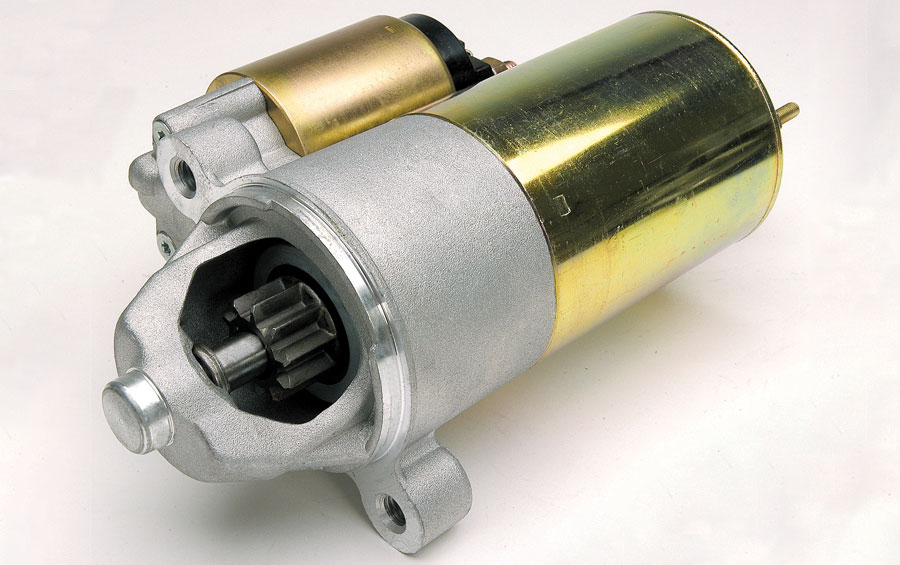

Illustrative image related to bad starter symptoms

What Quality Assurance Standards Are Relevant for Starters?

Quality assurance is paramount in the manufacturing of starter motors. International standards such as ISO 9001 establish guidelines for quality management systems, ensuring that manufacturers consistently produce high-quality products. Additionally, industry-specific certifications like CE marking for European markets and API standards for automotive components may also apply.

كيف يتم إنشاء نقاط التحقق من مراقبة الجودة؟

Quality control checkpoints are integral throughout the manufacturing process:

-

مراقبة الجودة الواردة (IQC): Ensures that raw materials meet specified quality standards before production begins.

-

مراقبة الجودة أثناء الإنتاج (IPQC): Monitors production processes to maintain quality standards, including dimensional checks and operational testing of components during assembly.

-

مراقبة الجودة النهائية (FQC): Conducts comprehensive testing of the finished product to confirm that it operates effectively and meets all specifications.

ما هي طرق الاختبار الشائعة الاستخدام في ضمان جودة المبتدئين؟

Testing methods for starters can include:

- الاختبارات الكهربائية: Verifying that the starter engages and disengages correctly under load.

- الاختبارات الميكانيكية: Ensuring that all moving parts operate smoothly without excessive friction or noise.

- الاختبار الحراري: Assessing how the starter performs under various temperature conditions, simulating real-world usage scenarios.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

For B2B buyers, particularly in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are several approaches:

-

تدقيق الموردين: Conducting on-site audits can provide insight into the manufacturer’s processes and quality control measures. This firsthand examination can reveal the reliability of their production practices.

-

تقارير الجودة: Requesting detailed quality reports and certifications can help assess a supplier’s adherence to international standards. Look for ISO certifications, compliance with CE marking, and any other relevant industry-specific certifications.

-

عمليات التفتيش من قبل أطراف ثالثة: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality practices. These services can conduct tests and inspections at various stages of production to ensure compliance.

ما هي الفروق الدقيقة في مراقبة الجودة للمشترين الدوليين؟

International buyers should be aware of specific nuances when dealing with quality control. Variations in standards and regulations across countries can impact the quality assurance processes. For instance, European standards may be stricter compared to those in some African or South American countries. Additionally, language barriers can complicate communication regarding quality expectations.

Illustrative image related to bad starter symptoms

B2B buyers should also consider the logistics of shipping and handling, as components must withstand transportation conditions. Ensuring that suppliers have robust packaging and handling protocols can mitigate risks associated with damage during transit.

الخلاصة

For B2B buyers sourcing starter motors, understanding the manufacturing processes and quality assurance practices is essential. By familiarizing themselves with these elements, buyers can make informed decisions, ensuring they procure reliable components that meet their operational needs. Prioritizing suppliers who adhere to international quality standards and demonstrating robust quality control practices will ultimately lead to better performance and reliability in their automotive applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bad starter symptoms’

مقدمة

This guide aims to equip B2B buyers with a practical checklist for identifying and addressing bad starter symptoms in automotive applications. Understanding these symptoms is crucial for maintaining vehicle performance and ensuring operational efficiency. By following this checklist, buyers can make informed decisions and avoid costly repairs.

الخطوة 1: Identify Common Bad Starter Symptoms

Recognizing the signs of a failing starter is the first step towards effective troubleshooting. Look for indicators such as unusual sounds (clicking or grinding), unresponsive engines despite dashboard lights illuminating, or smoke emerging from the starter area. These symptoms often suggest underlying issues that need immediate attention.

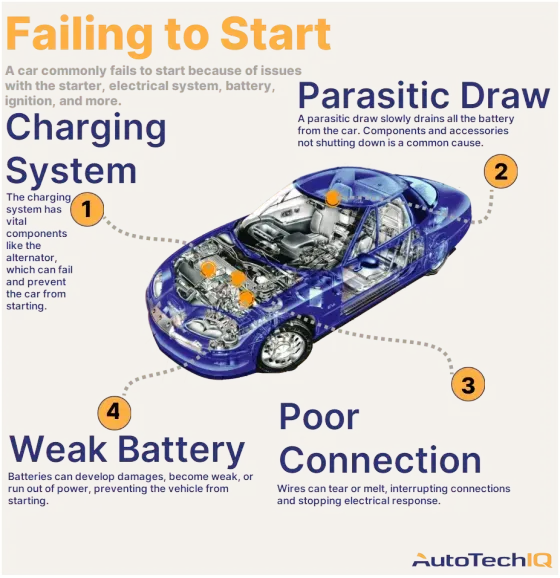

الخطوة 2: إجراء تشخيص أولي

Before sourcing new components, perform a basic diagnosis to rule out other potential problems. Check the battery’s charge and connections, as a weak battery can often mimic starter issues. Additionally, consider testing the alternator to ensure it’s supplying adequate voltage, which is vital for the starter’s operation.

الخطوة 3: حدد المواصفات الفنية الخاصة بك

Establish clear technical specifications for the starter components you require. This includes voltage ratings, physical dimensions, and compatibility with existing systems. Knowing these specifications will help you narrow down suppliers who can meet your exact needs and prevent future compatibility issues.

الخطوة 4: Research and Vet Potential Suppliers

Thoroughly evaluate potential suppliers for their reliability and quality of products. Look for established companies with a proven track record in the automotive sector. Request company profiles, client testimonials, and references to gauge their reputation, especially from buyers in similar regions or industries.

الخطوة 5: التحقق من شهادات الجودة

Ensure that the suppliers you consider have relevant quality certifications, such as ISO or other industry-specific standards. These certifications are indicators of a supplier’s commitment to quality control and adherence to manufacturing regulations, which can significantly affect the longevity and performance of starter components.

الخطوة 6: طلب عينات أو نماذج أولية

Before making a bulk purchase, request samples or prototypes of the starter components. This allows you to evaluate the quality and performance firsthand, ensuring they meet your specifications and expectations. Testing samples can help identify any potential issues before committing to larger orders.

الخطوة 7: Establish a Clear Return Policy

Finally, ensure that you have a clear return policy in place with your supplier. This is crucial for mitigating risks associated with defective or incompatible parts. Understand the terms of returns, warranties, and support services available, which will provide peace of mind and protect your investment.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing components related to bad starter symptoms, ensuring they make informed and strategic decisions.

Comprehensive Cost and Pricing Analysis for bad starter symptoms Sourcing

What Are the Key Cost Components for Sourcing Starter Components?

When sourcing parts related to bad starter symptoms, several cost components play a crucial role in determining the overall pricing structure. Understanding these components can help B2B buyers make informed purchasing decisions.

Illustrative image related to bad starter symptoms

-

المواد: The primary materials used in starter motors include copper for windings, steel for housings, and various plastics for insulation and casings. The quality of these materials significantly affects the cost. High-grade materials may lead to better performance and longevity, but they will also increase the initial purchase price.

-

العمل: Labor costs encompass the wages paid to skilled technicians who manufacture and assemble starters. In regions with higher labor costs, such as Europe, these expenses can be substantial. Conversely, sourcing from areas with lower labor costs may offer savings but could compromise quality if not managed properly.

-

تكاليف التصنيع العامة: This includes expenses related to factory operations, such as utilities, rent, and administrative costs. Buyers should consider suppliers that effectively manage overhead to offer competitive pricing without sacrificing quality.

-

الأدوات: The cost of specialized tools and machinery required for manufacturing starters can be significant. Custom tooling may lead to higher upfront costs, but it can also enhance production efficiency and product quality, impacting long-term pricing.

-

مراقبة الجودة (QC): Rigorous QC processes are essential to ensure reliability and performance. Suppliers with stringent QC protocols may charge higher prices but can provide added assurance of product durability, reducing the risk of failures associated with bad starter symptoms.

-

اللوجستيات: Shipping and handling costs vary based on distance, shipping method, and the volume of the order. International buyers must account for potential tariffs and customs duties, which can significantly affect the total cost.

-

الهامش: Suppliers typically include a profit margin in their pricing. Understanding the standard margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Starters?

Several factors can influence the pricing of starter components, and recognizing these can help buyers strategize their procurement effectively.

-

الحجم/الحد الأدنى للطلب: Bulk purchasing often leads to lower unit costs. Establishing a minimum order quantity (MOQ) with suppliers can help secure better pricing, particularly for high-demand regions.

-

المواصفات والتخصيص: Customized starters designed for specific applications may incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

الجودة والشهادات: Products that meet international quality standards or certifications (such as ISO) may be priced higher due to the assurance of performance and reliability. Buyers should assess whether the added cost aligns with their operational needs.

-

عوامل الموردين: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge more, but they often provide better after-sales support and warranty options.

-

مصطلحات التجارة الدولية: Understanding the shipping terms (Incoterms) is critical for international buyers. These terms dictate who is responsible for shipping costs, insurance, and customs duties, which can affect the overall pricing structure.

What Are Some Negotiation Tips for B2B Buyers in Different Regions?

Navigating the purchasing process in international markets requires strategic negotiation to ensure cost-efficiency. Here are some actionable tips:

-

الاستفادة من خصومات الحجم الكبير: When possible, consolidate orders to meet MOQs and negotiate bulk pricing. This can lead to significant savings, particularly for high-demand markets in Africa and South America.

-

تقييم التكلفة الإجمالية للملكية (TCO): Consider not just the purchase price but also the potential costs associated with maintenance, downtime, and replacements. A higher-quality starter may have a higher upfront cost but lower TCO due to fewer failures.

-

فهم ظروف السوق المحلية: Buyers in different regions, such as Germany or Nigeria, should familiarize themselves with local market dynamics, including currency fluctuations and economic conditions, to negotiate effectively.

-

بناء علاقات مع الموردين: Establishing long-term partnerships with reliable suppliers can lead to better pricing and terms over time. Open communication can facilitate smoother negotiations and foster trust.

-

ابق على اطلاع على الفروق الدقيقة في التسعير: Keep abreast of industry trends and pricing changes. This knowledge can provide leverage during negotiations and help buyers make more informed decisions.

إخلاء المسؤولية بشأن الأسعار

The prices and cost structures outlined in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing information tailored to your specific needs.

Alternatives Analysis: Comparing bad starter symptoms With Other Solutions

Understanding Alternatives for Diagnosing Automotive Issues

When it comes to diagnosing automotive problems, particularly issues related to starting a vehicle, understanding the symptoms of a bad starter is crucial. However, there are alternative methods and technologies that can also help identify and resolve these issues. This section compares the traditional identification of bad starter symptoms against other diagnostic solutions, empowering B2B buyers to make informed decisions.

| جانب المقارنة | Bad Starter Symptoms | الماسحات الضوئية التشخيصية | Mobile Mechanics |

|---|---|---|---|

| الأداء | Effective in identifying starter issues through symptoms | Provides comprehensive diagnostics of all vehicle systems | Can offer hands-on diagnostics and repairs on-site |

| التكلفة | Low (requires basic knowledge) | Medium to high (varies by brand) | High (service fees included) |

| سهولة التنفيذ | Requires familiarity with symptoms | Requires training to interpret codes | Convenient, but may require scheduling |

| الصيانة | No ongoing maintenance required | Regular updates needed for software | Dependent on technician’s skills |

| أفضل حالة استخدام | Basic troubleshooting for DIY enthusiasts | Professional diagnostics for complex issues | Quick solutions for on-the-go repairs |

What Are the Advantages and Disadvantages of Diagnostic Scanners?

Diagnostic scanners are a powerful tool for automotive troubleshooting. They connect to a vehicle’s onboard computer system to retrieve error codes that indicate issues across various components, including the starter.

الإيجابيات:

– Comprehensive diagnostics beyond just starter issues.

– Ability to identify problems before they escalate.

– User-friendly interface for those trained in automotive technology.

السلبيات:

– Higher initial investment and potential software update costs.

– Requires technical knowledge to interpret the codes accurately.

– May not provide immediate solutions; often requires further inspection.

How Do Mobile Mechanics Provide a Competitive Edge?

Mobile mechanics bring the repair shop to the customer’s location, providing convenience and immediate service. They often carry diagnostic tools and can directly assess and repair starter issues on-site.

الإيجابيات:

– Convenience of service without needing to tow the vehicle.

– Hands-on assessment can lead to quicker resolutions.

– Personalized service often results in better customer satisfaction.

السلبيات:

– Service fees can be higher than traditional repair shops.

– Availability may vary based on location and demand.

– Limited to the tools they can carry, which may restrict complex diagnostics.

Making the Right Choice for Your Automotive Diagnostic Needs

B2B buyers must consider several factors when choosing between diagnosing bad starter symptoms and alternative solutions. If your team has the expertise and prefers a hands-on approach, recognizing bad starter symptoms might be the most cost-effective method. For more complex diagnostics or if your team lacks the technical know-how, investing in a diagnostic scanner could enhance your troubleshooting capabilities.

Illustrative image related to bad starter symptoms

On the other hand, if immediate service is essential, especially in remote areas, mobile mechanics provide an invaluable resource. Ultimately, the right choice depends on your specific operational needs, budget constraints, and the level of expertise available within your team.

Essential Technical Properties and Trade Terminology for bad starter symptoms

What Are the Essential Technical Properties of Starters with Bad Symptoms?

When diagnosing starter problems, several critical technical specifications come into play. Understanding these properties is vital for B2B buyers, as they impact product quality, reliability, and performance.

1. درجة المواد

The materials used in starter construction significantly affect durability and performance. High-grade metals, such as stainless steel or specific alloys, resist corrosion and wear. For B2B buyers, investing in starters made from superior materials ensures longevity and reduces the need for frequent replacements, thereby lowering overall maintenance costs.

Illustrative image related to bad starter symptoms

2. المقاومة الكهربائية

Electrical resistance in starter components (like windings and terminals) can impact performance. A lower resistance typically means better conductivity and efficiency. Understanding this property helps buyers select starters that will function optimally in various environmental conditions, reducing the risk of failure and ensuring reliable vehicle operation.

3. عزم الدوران الناتج

Torque output refers to the rotational force the starter can produce when engaging the engine. This is crucial for starting larger engines, especially in commercial vehicles. Buyers must consider torque ratings to ensure the starter can handle the specific demands of their vehicles, leading to better performance and reduced wear on the starter and engine.

4. مقاومة الحرارة

Starters are often exposed to high temperatures, particularly in harsh operating environments. A starter’s ability to withstand heat without degrading is essential for reliability. B2B buyers should prioritize starters with high heat resistance ratings to minimize the risk of overheating, which can lead to premature failure.

5. متوسط العمر المتوقع

Lifecycle expectancy indicates how long a starter is expected to function before requiring replacement. This metric is vital for budgeting and planning maintenance schedules. Buyers should look for starters with extended lifecycle expectancies to enhance operational efficiency and minimize downtime.

6. توافق الجهد

Most starters operate within specific voltage ranges, typically 12V or 24V. Understanding voltage compatibility ensures that the starter will function correctly within the electrical system of the vehicle. Selecting the right voltage starter is critical for preventing electrical issues and ensuring proper functionality.

What Common Trade Terms Should B2B Buyers Know Regarding Starters?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms related to starter components and their procurement.

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to parts made by the original manufacturer of the vehicle. These components typically meet the manufacturer’s specifications, ensuring compatibility and quality. For B2B buyers, choosing OEM starters can provide peace of mind regarding performance and reliability.

Illustrative image related to bad starter symptoms

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ represents the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, especially when planning inventory and managing costs. Negotiating favorable MOQs can lead to better pricing and more efficient supply chain management.

3. طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. For B2B buyers, issuing an RFQ allows for competitive bidding and helps identify the best options available in the market.

4. شروط التجارة الدولية (Incoterms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international trade. Understanding these terms is essential for B2B transactions, as they clarify shipping responsibilities, risk management, and cost allocation.

Illustrative image related to bad starter symptoms

5. المهلة الزمنية

Lead time refers to the time between placing an order and receiving the goods. In the automotive industry, understanding lead times is crucial for planning maintenance and ensuring timely availability of starters, thus minimizing downtime.

6. فترة الضمان

The warranty period is the duration during which the manufacturer guarantees the product against defects. For B2B buyers, a longer warranty period can indicate product reliability and reduce the risk of unexpected costs due to failures.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding starters, ensuring they select products that meet their operational needs while also optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the bad starter symptoms Sector

What Are the Current Market Dynamics and Key Trends Affecting the Bad Starter Symptoms Sector?

The global automotive industry is witnessing significant shifts that impact the bad starter symptoms sector, driven by technological advancements, evolving consumer expectations, and economic factors. One of the primary drivers is the increasing complexity of vehicle electrical systems. As vehicles become more sophisticated, the interplay between batteries, starters, and alternators has grown more intricate. This complexity necessitates enhanced diagnostic tools and solutions, creating opportunities for B2B suppliers who can offer advanced technologies, such as predictive analytics and IoT-enabled monitoring systems.

Illustrative image related to bad starter symptoms

Moreover, the rise of electric vehicles (EVs) is reshaping the landscape. While traditional starters may see a decline in demand, the need for robust support systems for EV components presents a new market avenue. B2B buyers, particularly in emerging markets like Africa and South America, should consider investing in suppliers who are pivoting to offer parts and services compatible with hybrid and electric vehicles.

Another notable trend is the growing demand for aftermarket services. As vehicles age, the likelihood of starter and battery failures increases, prompting consumers to seek reliable replacement parts and professional services. This trend is pronounced in Europe, where vehicle longevity is emphasized, and in regions with harsh climates, such as the Middle East and parts of Africa. B2B buyers should focus on sourcing high-quality components that ensure vehicle reliability and longevity.

How Are Sustainability and Ethical Sourcing Influencing the Bad Starter Symptoms Sector?

Sustainability and ethical sourcing are becoming pivotal in the automotive parts industry, including the bad starter symptoms sector. The environmental impact of automotive manufacturing is under scrutiny, pushing B2B buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes the use of recycled materials, reduced emissions during production, and responsible waste management.

Ethical supply chains are not just a trend; they are increasingly becoming a consumer requirement. Buyers in regions such as Europe are particularly sensitive to the ethical implications of their purchasing decisions. Companies that can provide certifications for green materials or demonstrate compliance with environmental regulations will have a competitive edge. Sourcing from manufacturers who adhere to international environmental standards, such as ISO 14001, can also enhance a buyer’s reputation and marketability.

Furthermore, as the automotive industry shifts toward electrification, the demand for sustainable components is likely to rise. B2B buyers should consider suppliers who are innovating in this space, offering eco-friendly alternatives that align with the future of automotive technology. This trend not only addresses environmental concerns but also appeals to a growing segment of consumers who prioritize sustainability in their purchasing decisions.

What is the Historical Context of the Bad Starter Symptoms Sector for B2B Buyers?

The bad starter symptoms sector has evolved significantly over the past few decades. Initially, starters were relatively straightforward components with limited technology. However, as automotive engineering advanced, starters became more complex, integrating electronics and requiring greater precision. This evolution has been accompanied by an increase in diagnostic capabilities, enabling technicians to identify issues more effectively.

In the past, the relationship between manufacturers and B2B buyers was predominantly transactional. Today, there is a shift towards strategic partnerships, where buyers seek suppliers who can provide comprehensive solutions, including diagnostics, support, and training. This historical evolution reflects a broader trend in the automotive industry toward collaboration and innovation, which is essential for navigating the complexities of modern vehicle systems.

As the sector continues to evolve, B2B buyers must stay informed about technological advancements and market dynamics to make informed sourcing decisions that align with their operational goals and customer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of bad starter symptoms

-

How do I identify bad starter symptoms in vehicles?

To identify bad starter symptoms, look for common signs such as unusual sounds (clicking or grinding) when attempting to start the vehicle, a dashboard that lights up without engine response, or repeated jump-start failures. If the starter is overheating, it may emit smoke or a burning smell. Inspect the starter for oil leaks or corrosion, as these can impede its functionality. Conducting a thorough visual inspection and listening for abnormal sounds can help pinpoint starter issues. -

What are the most common causes of starter failure?

Common causes of starter failure include loose or corroded electrical connections, worn-out internal components, oil leaks, and faulty relays or fuses. Environmental factors, such as extreme temperatures and moisture, can also accelerate wear. Regular maintenance and prompt attention to warning signs can mitigate these issues, ensuring the longevity of your starter and overall vehicle performance. -

What should I look for when sourcing starter parts from international suppliers?

When sourcing starter parts internationally, prioritize suppliers with a proven track record in quality and reliability. Look for certifications that ensure compliance with industry standards. Assess their ability to provide documentation for traceability and quality assurance. Furthermore, inquire about their experience with shipping logistics, especially in your target region, to ensure timely delivery and minimize disruptions. -

كيف يمكنني فحص الموردين للمكونات الأولية؟

To vet suppliers, conduct thorough research by checking their online presence, customer reviews, and ratings. Request references from other businesses that have sourced similar components. Evaluate their response times and willingness to provide samples or detailed product specifications. Additionally, consider visiting their facilities if feasible, or using third-party inspection services to verify their capabilities and quality control processes. -

What customization options are available for starter systems?

Many suppliers offer customization options for starter systems, including variations in voltage, size, and performance specifications. Discuss your specific requirements with potential suppliers to determine their flexibility in accommodating custom designs. Ensure that any modifications adhere to industry standards and that the supplier can provide necessary documentation and support for these custom products. -

What is the minimum order quantity (MOQ) for starter components?

The minimum order quantity for starter components varies by supplier and is influenced by factors such as production capabilities and material availability. Typically, MOQs range from a few units to several hundred. When negotiating with suppliers, clarify your needs and inquire about options for lower MOQs, especially if you are a smaller business or testing new products in your market. -

ما هي شروط الدفع التي يجب أن أتوقعها عند شراء قطع الغيار المبتدئة دولياً؟

Payment terms can vary significantly between suppliers. Common arrangements include upfront payments, deposits, or payment upon delivery. It’s essential to discuss and agree on terms that are mutually beneficial while ensuring security for both parties. Consider using escrow services or letters of credit to mitigate risks associated with international transactions, especially in new supplier relationships. -

How can I ensure quality assurance when sourcing starter components?

To ensure quality assurance, establish clear specifications and standards before placing orders. Request samples for testing before bulk purchases, and inquire about the supplier’s quality control processes. Regular audits and inspections during production can also help maintain quality. Finally, consider implementing a return policy for defective parts to protect your investment and maintain operational efficiency.

Top 3 Bad Starter Symptoms Manufacturers & Suppliers List

1. Corvette – Starter Symptoms

المجال: corvetteforum.com

تاريخ التسجيل: 1999 (26 عامًا)

مقدمة: Symptoms of a bad starter include: 1. A single click sound when attempting to start the vehicle. 2. Occasional successful starts after multiple attempts. 3. Potential grounding issues if the starter connections are not clean. 4. Possible solenoid failure, which may allow for replacement of just that part. 5. Worn commutator or brushes in the starter, requiring a new starter if they do not make goo…

2. Subaru – WRX Starter Motor Issues

المجال: mechanics.stackexchange.com

تاريخ التسجيل: 2009 (16 عامًا)

مقدمة: 2004 Subaru WRX, original equipment starter motor, symptoms include grinding screech on cold starts, low amplitude grinding squeal on warm days, concerns about battery and alternator, no starting problems yet, potential issues with starter gears, clutch in starter, gears binding due to worn bushings, common issue with lubrication of pinion gear.

3. IH8MUD – Starter Symptoms Guide

المجال: forum.ih8mud.com

مسجل: 2000 (25 سنة)

مقدمة: Symptoms of a bad starter include grinding or rattling noises, metal-on-metal grinding sounds when the key is released, and occasional failure to spin. A bad drive may be a likely cause of these symptoms. Inspection of the flywheel and cleaning of the engine components are recommended maintenance tips.

Strategic Sourcing Conclusion and Outlook for bad starter symptoms

In summary, recognizing the symptoms of a bad starter is crucial for maintaining vehicle reliability and avoiding costly downtime. Key indicators such as unusual sounds, dashboard warning lights, and unresponsive engines can signal underlying issues that may stem from various causes, including corroded connections or oil leaks. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these symptoms not only aids in effective troubleshooting but also emphasizes the importance of sourcing high-quality starter components and services.

Strategic sourcing is essential for ensuring that your fleet remains operational and efficient. By partnering with reliable suppliers and service providers, businesses can mitigate risks associated with starter failures and enhance overall vehicle performance. This proactive approach not only reduces maintenance costs but also contributes to improved customer satisfaction and loyalty.

Looking ahead, we encourage B2B buyers to invest in robust supply chains and engage with knowledgeable technicians to address starter issues promptly. By doing so, you can secure a competitive advantage in your market while ensuring that your vehicles are always ready to perform. Prioritize quality and reliability in your sourcing strategies, and watch your business thrive.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.