Introduction: Navigating the Global Market for autotech alternator

In today’s dynamic automotive landscape, sourcing high-performance autotech alternators is crucial for businesses aiming to meet the increasing demands of diverse applications—from car audio systems to marine and racing environments. However, international B2B buyers often grapple with challenges such as identifying reliable suppliers, understanding product specifications, and ensuring compatibility with various vehicle models. This comprehensive guide addresses these concerns by delving into the multifaceted world of autotech alternators.

We explore the different types of alternators available, their specific applications, and how to effectively vet suppliers to ensure quality and reliability. Additionally, we provide insights into cost considerations and the importance of understanding amperage ratings to match your operational needs. With a focus on international markets, particularly in regions like Africa, South America, the Middle East, and Europe, this guide empowers buyers to make informed purchasing decisions. By equipping you with the knowledge to navigate supplier options and technical specifications, we aim to enhance your procurement strategy, ultimately ensuring that your operations run smoothly and efficiently.

As the global market for automotive components continues to evolve, leveraging the insights presented here will be invaluable in securing the right autotech alternators for your business needs.

جدول المحتويات

- Top 4 Autotech Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for autotech alternator

- Understanding autotech alternator Types and Variations

- Key Industrial Applications of autotech alternator

- 3 Common User Pain Points for ‘autotech alternator’ & Their Solutions

- Strategic Material Selection Guide for autotech alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for autotech alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘autotech alternator’

- Comprehensive Cost and Pricing Analysis for autotech alternator Sourcing

- Alternatives Analysis: Comparing autotech alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for autotech alternator

- Navigating Market Dynamics and Sourcing Trends in the autotech alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of autotech alternator

- Strategic Sourcing Conclusion and Outlook for autotech alternator

- إخلاء مسؤولية هام وشروط الاستخدام

Understanding autotech alternator Types and Variations

| اسم النوع | السمات المميزة الرئيسية | التطبيقات الأساسية بين الشركات (B2B) | مزايا وعيوب موجزة للمشترين |

|---|---|---|---|

| المولدات عالية الإنتاجية | Ranges from 130 to 500 amps; designed for performance applications | Automotive aftermarket, racing, marine | الإيجابيات: High amperage output; customizable options. السلبيات: Longer lead times for custom builds. |

| Denso Hairpin Alternators | Compact design with enhanced heat dissipation; available in various amperage ratings | Heavy-duty vehicles, off-road applications | الإيجابيات: Efficient cooling; suitable for extreme conditions. السلبيات: May require specific installation adjustments. |

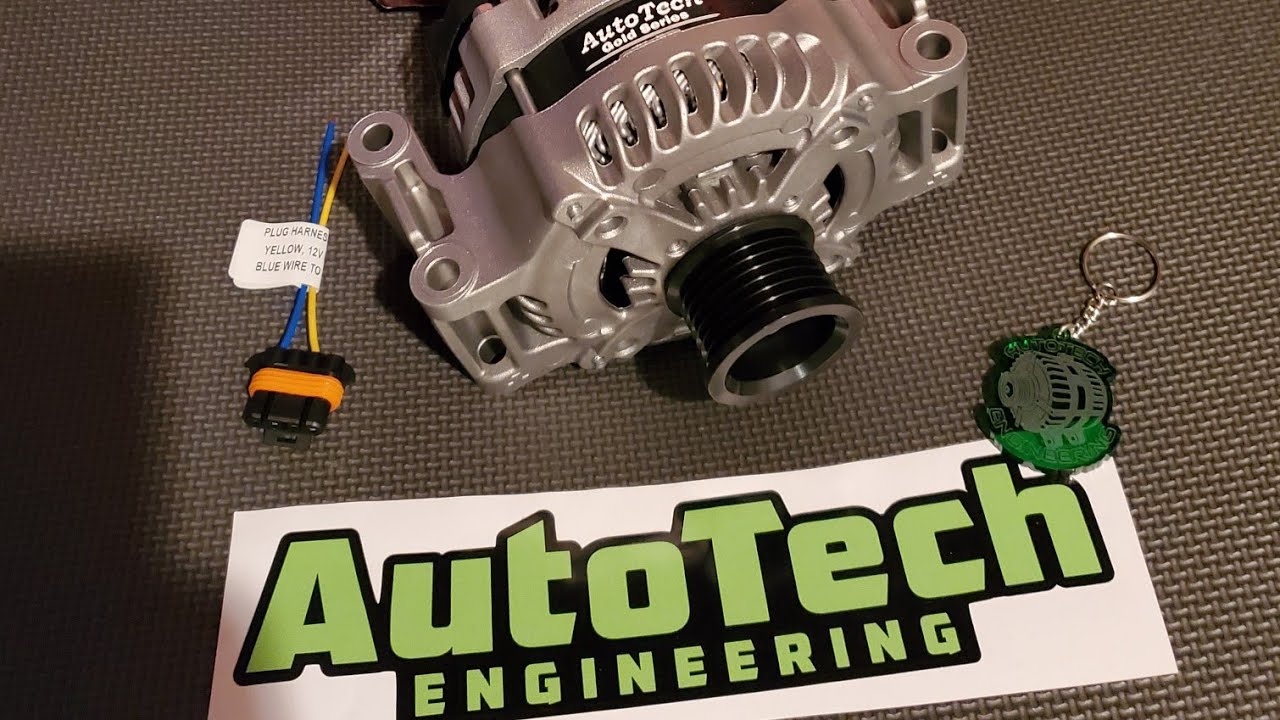

| Gold Series Alternators | Premium components; higher idle output; proven performance metrics | Audio systems, performance vehicles | الإيجابيات: Reliable under load; extensive testing for quality. السلبيات: Higher price point compared to standard models. |

| Competition Series Alternators | Optimized for high performance; robust build with advanced diodes | Motorsports, competitive racing | الإيجابيات: Exceptional output at low RPM; designed for maximum durability. السلبيات: Limited applications; may not fit all vehicle types. |

| Custom Alternators | Tailored solutions for specific vehicle needs; built to order | Specialty vehicles, unique applications | الإيجابيات: Exact fit for unique requirements; high adaptability. السلبيات: Non-refundable; longer production times. |

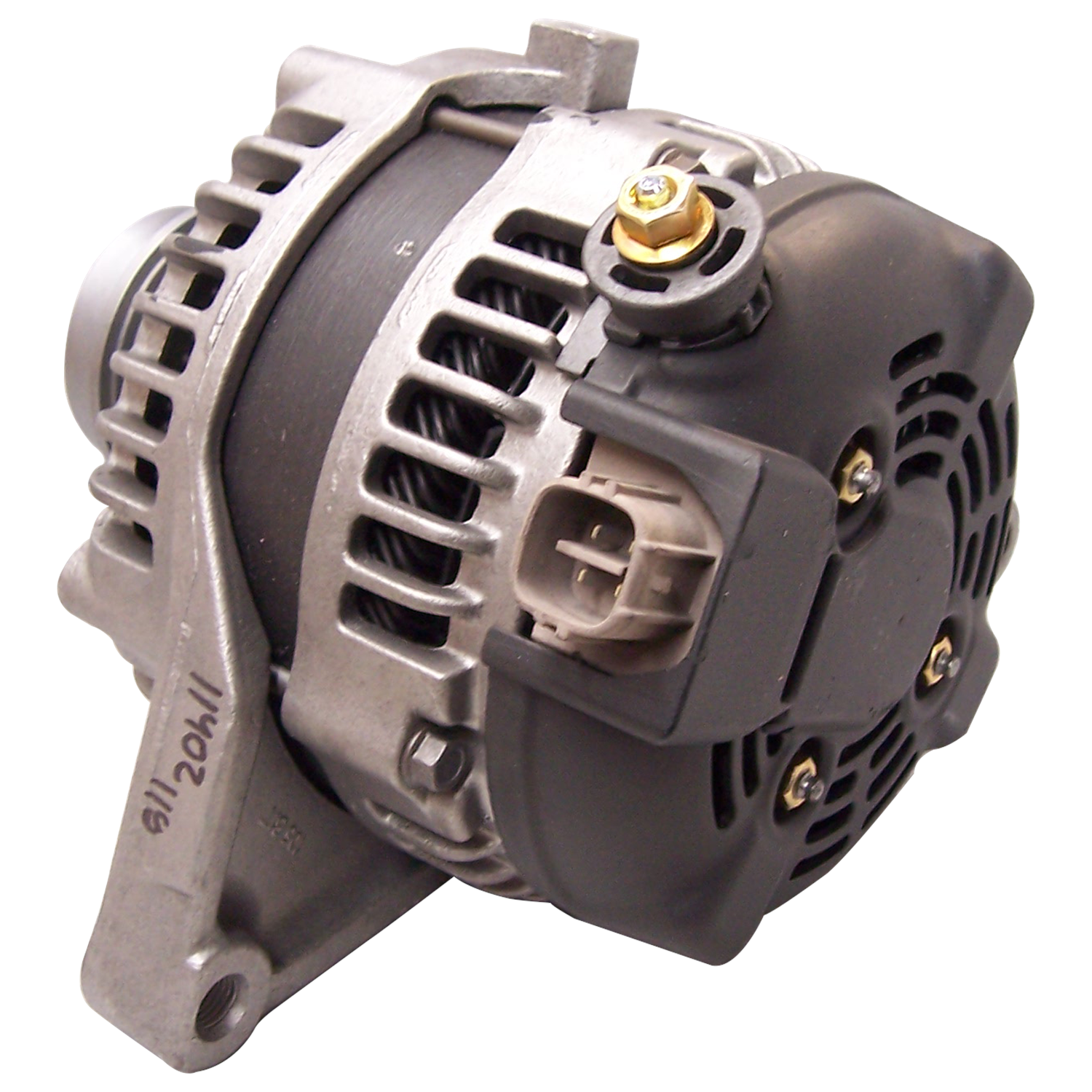

What are High Output Alternators and Their Key Applications?

High Output Alternators are designed to provide significant amperage, ranging from 130 to 500 amps, making them ideal for vehicles with high electrical demands, such as those equipped with advanced audio systems or additional lighting. They are commonly used in the automotive aftermarket, racing, and marine applications. Buyers should consider the lead time for custom orders and the specific amperage requirements of their vehicles.

How Do Denso Hairpin Alternators Stand Out?

Denso Hairpin Alternators feature a compact design that enhances heat dissipation, allowing them to perform efficiently in heavy-duty and off-road environments. With various amperage ratings available, these alternators are suitable for heavy-duty vehicles that require reliable power under challenging conditions. B2B buyers should evaluate installation requirements, as these units may necessitate specific adjustments for optimal performance.

What Makes Gold Series Alternators a Premium Choice?

Gold Series Alternators are engineered with premium components and have higher idle output ratings, making them a reliable choice for performance vehicles and audio systems. Their proven performance metrics, supported by extensive testing, assure buyers of their durability and functionality. However, the higher price point may be a consideration for budget-conscious buyers.

Why Choose Competition Series Alternators for Motorsports?

Competition Series Alternators are optimized for high-performance applications, featuring robust builds and advanced diodes that ensure exceptional output even at low RPMs. These units are primarily used in motorsports and competitive racing, where reliability and performance are critical. Buyers should note that these alternators may have limited applications and may not be compatible with all vehicle types.

How Can Custom Alternators Meet Unique Needs?

Custom Alternators provide tailored solutions for specific vehicle requirements, allowing businesses to get exactly what they need for specialty vehicles. While they offer high adaptability, buyers should be aware of the non-refundable nature of these units and the longer production times associated with custom builds. This option is ideal for businesses needing specific configurations that standard models cannot fulfill.

Key Industrial Applications of autotech alternator

| الصناعة/القطاع | Specific Application of autotech alternator | القيمة/الفائدة للأعمال | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| السيارات | High-performance vehicles and racing | Enhanced power supply for audio and performance systems | Ensure compatibility with vehicle models and amperage needs |

| بحري | Boats and personal watercraft | طاقة موثوقة للملاحة والأنظمة الموجودة على متن الطائرة | Consider marine-grade materials for corrosion resistance |

| Off-Road Vehicles | 4x4s and utility terrain vehicles | Consistent power for winches and auxiliary lighting | Evaluate ruggedness and durability under extreme conditions |

| الآلات الثقيلة | معدات البناء والزراعة | Sustained energy for heavy-duty operations | Focus on high amperage outputs for demanding applications |

| الطاقة المتجددة | Electric vehicles and solar-powered systems | Efficient energy management and storage capabilities | Check for compatibility with battery types and charging systems |

How is the Autotech Alternator Used in High-Performance Vehicles and Racing?

In the automotive industry, particularly for high-performance vehicles and racing applications, the Autotech alternator serves a critical role in powering advanced audio systems and performance-enhancing components. These vehicles often require a higher amperage to support multiple electronic systems, especially during high-demand scenarios like racing. Autotech’s high-output alternators, ranging from 130 to 500 amps, ensure that these vehicles maintain consistent power, even under extreme conditions. Buyers in this sector must prioritize compatibility with specific vehicle models and ensure the alternator can meet their amperage requirements.

Illustrative image related to autotech alternator

What Role Does the Autotech Alternator Play in Marine Applications?

In marine environments, Autotech alternators are essential for providing reliable power to navigation equipment, lighting, and other onboard systems in boats and personal watercraft. The harsh marine conditions necessitate alternators designed with corrosion-resistant materials and robust construction. This ensures longevity and reliability, which are critical for safety and performance on water. Buyers should consider sourcing products that are explicitly designed for marine use, focusing on durability and resistance to saltwater damage.

How Does the Autotech Alternator Enhance Off-Road Vehicles?

Off-road vehicles, such as 4x4s and utility terrain vehicles, benefit significantly from the Autotech alternator due to its ability to deliver consistent power for winches, auxiliary lighting, and other critical accessories. These vehicles often operate in rugged terrains where traditional alternators may fail. Autotech’s high-output units provide the necessary amperage to power additional equipment without straining the vehicle’s electrical system. Buyers should evaluate the alternator’s ruggedness and durability to ensure it can withstand extreme off-road conditions.

In What Ways Do Heavy Machinery Operations Rely on Autotech Alternators?

Heavy machinery used in construction and agriculture requires dependable energy sources to operate effectively. Autotech alternators provide sustained energy for high-demand applications, ensuring that equipment runs smoothly and efficiently. The high amperage outputs are particularly beneficial for machines that operate multiple systems simultaneously, such as hydraulic systems and power tools. Businesses should focus on sourcing alternators with the capacity to meet the specific energy needs of their machinery, taking into account the demanding nature of their operations.

How is the Autotech Alternator Used in Renewable Energy Solutions?

In the realm of renewable energy, particularly with electric vehicles and solar-powered systems, the Autotech alternator plays a pivotal role in managing energy supply and storage. It ensures that the battery systems receive adequate charging while optimizing performance across various energy-consuming devices. Buyers should ensure compatibility with different battery types, such as AGM and lithium, to maximize efficiency. Sourcing considerations should include the alternator’s ability to handle varying energy demands and its integration with existing energy systems.

3 Common User Pain Points for ‘autotech alternator’ & Their Solutions

Scenario 1: Difficulty in Finding Compatible Alternators for Specific Vehicles

المشكلة: Many B2B buyers face significant challenges in sourcing high-output alternators that are compatible with specific vehicle models. This is particularly prevalent in markets like Africa and South America, where a diverse range of vehicle types may not be well-documented in catalogs. Buyers often encounter frustration when their vehicle specifications do not match available models, leading to delays in procurement and potential losses in operational efficiency.

Illustrative image related to autotech alternator

الحل: To mitigate this issue, it is crucial for buyers to engage directly with manufacturers who specialize in custom solutions. For example, AutoTech Engineering encourages customers to contact them directly if their vehicle is not listed in the online catalog. Buyers should prepare detailed information about their vehicle, including make, model, and any specific electrical requirements. This proactive approach enables manufacturers to provide tailored solutions, ensuring that the right alternator is sourced for the specific application. Additionally, maintaining clear communication throughout the ordering process can help streamline lead times and avoid potential misfits.

Scenario 2: Concerns Over Performance Under Varied Conditions

المشكلة: B2B buyers often worry about the performance reliability of alternators, especially under diverse operating conditions such as extreme temperatures or heavy loads. For instance, in regions with high ambient temperatures, such as the Middle East, the durability and efficiency of an alternator can be severely tested. Buyers may fear that subpar products could lead to unexpected failures, impacting their business operations and client satisfaction.

الحل: To address these concerns, it is essential to choose alternators that have been rigorously tested for performance under varied conditions. AutoTech Engineering utilizes multiple testing methods to validate the performance of their alternators, ensuring that they meet or exceed industry standards. Buyers should prioritize suppliers who provide “Proof in Performance” videos and detailed specifications about the alternators’ capabilities at both idle and operational speeds. This not only builds confidence in the product but also allows buyers to make informed decisions based on actual performance data. Furthermore, conducting regular maintenance checks can help ensure the longevity of alternators, particularly in harsh environments.

Illustrative image related to autotech alternator

Scenario 3: Managing Warranty and Return Policy Confusion

المشكلة: Many B2B buyers are often confused about warranty coverage and return policies, especially when dealing with custom-built alternators. In markets with varying consumer protection laws, such as Europe and Africa, the implications of warranty terms can be significant. Buyers may hesitate to invest in high-output alternators if they are uncertain about what is covered, leading to potential financial risk.

الحل: To alleviate these concerns, buyers should thoroughly review the warranty and return policies before making a purchase. AutoTech Engineering offers a comprehensive warranty that covers labor and parts, but it is crucial for buyers to understand the limitations, such as exclusions for improper installation. Establishing clear communication with the supplier regarding any uncertainties can clarify what to expect in terms of service and support. Buyers should also consider documenting the installation process and any potential issues that arise to ensure they have the necessary evidence should a warranty claim be needed. Investing in quality alternators with transparent policies not only reduces risk but also enhances long-term operational reliability.

Strategic Material Selection Guide for autotech alternator

What Are the Key Materials Used in Autotech Alternators?

When selecting materials for autotech alternators, several factors must be considered, including performance, durability, and cost. Here, we analyze four common materials used in the manufacturing of alternators, focusing on their properties, pros and cons, and implications for international B2B buyers.

How Does Aluminum Benefit Autotech Alternators?

Aluminum is a prevalent choice for the casing and some internal components of alternators due to its lightweight and excellent thermal conductivity. It typically has a temperature rating of up to 150°C and offers good resistance to corrosion, especially when anodized.

الإيجابيات: Aluminum is lightweight, which contributes to better fuel efficiency in vehicles. It is also relatively inexpensive and easy to machine, making it suitable for high-volume production.

السلبيات: While aluminum is resistant to corrosion, it can be less durable than other metals under extreme mechanical stress. It may also require additional coatings for enhanced corrosion resistance in harsh environments.

التأثير على التطبيق: Aluminum’s lightweight nature makes it ideal for automotive applications where weight reduction is crucial. However, in regions with high humidity or saline environments, such as coastal areas in Africa or the Middle East, additional protective measures may be necessary.

ما الدور الذي يلعبه النحاس في أداء المولد؟

Copper is primarily used in the windings of alternators due to its excellent electrical conductivity, which is essential for efficient power generation. It can handle high temperatures and has a melting point of around 1,085°C.

Illustrative image related to autotech alternator

الإيجابيات: Copper’s high conductivity ensures minimal energy loss, enhancing the overall efficiency of the alternator. It is also highly durable and resistant to corrosion, particularly when coated.

السلبيات: The primary drawback of copper is its cost, which is higher than aluminum. Additionally, its weight can contribute to the overall weight of the alternator, potentially impacting vehicle performance.

التأثير على التطبيق: In markets where electrical efficiency is a priority, such as in Europe, copper is often preferred. However, buyers in regions with budget constraints may find the cost of copper prohibitive.

لماذا يستخدم الفولاذ في مكونات المولد؟

Steel is commonly used for structural components and brackets in alternators due to its strength and durability. It can withstand high mechanical loads and has a temperature rating that varies based on the alloy used, typically around 300°C.

الإيجابيات: Steel’s high tensile strength makes it ideal for components that require robustness. It is also relatively inexpensive and widely available, making it a cost-effective choice for manufacturers.

السلبيات: Steel is heavier than aluminum and copper, which can negatively affect vehicle performance. It is also prone to rust if not properly coated or treated.

التأثير على التطبيق: In regions with high mechanical stress or where durability is critical, such as in off-road applications common in South America, steel components are advantageous. However, buyers in coastal areas need to consider corrosion-resistant coatings.

How Does Plastic Contribute to Alternator Design?

Plastics, particularly high-performance thermoplastics, are increasingly used for insulation and housing components in alternators. They can withstand temperatures up to 120°C and offer good electrical insulation properties.

الإيجابيات: Plastics are lightweight and can be molded into complex shapes, allowing for design flexibility. They are also resistant to corrosion and can be less expensive than metals.

السلبيات: While plastics are durable, they may not withstand extreme temperatures or mechanical stress as well as metals. Additionally, they may degrade over time when exposed to UV light.

التأثير على التطبيق: In regions with moderate climates, plastics can be an excellent choice for weight reduction. However, in extreme environments, such as high-temperature areas in Africa or the Middle East, careful selection of plastic types is necessary.

Illustrative image related to autotech alternator

Summary Table of Material Selection for Autotech Alternators

| المواد | Typical Use Case for autotech alternator | الميزة الرئيسية | العيب/القيود الرئيسية | التكلفة النسبية (منخفضة/متوسطة/عالية) |

|---|---|---|---|---|

| الألومنيوم | الغلاف والمكونات الداخلية | Lightweight and good thermal conductivity | أقل متانة في ظل الضغط الشديد | متوسط |

| النحاس | Windings | موصلية كهربائية ممتازة | Higher cost and added weight | عالية |

| الصلب | المكونات الهيكلية والأقواس الهيكلية | High tensile strength and cost-effective | أثقل وزناً وعرضة للصدأ | منخفض |

| بلاستيك | العزل والإسكان | خفة الوزن ومرونة التصميم | Limited temperature and mechanical stress resistance | متوسط |

This strategic material selection guide provides insights into the various materials used in autotech alternators, helping international B2B buyers make informed decisions based on performance requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for autotech alternator

What Are the Key Stages in the Manufacturing Process of Autotech Alternators?

The manufacturing of autotech alternators involves several critical stages designed to ensure high performance and reliability. These stages include material preparation, forming, assembly, and finishing.

تحضير المواد

The process begins with the selection of high-quality raw materials such as copper for windings, aluminum or steel for housings, and durable plastic for internal components. Each material undergoes rigorous quality checks to ensure they meet industry standards. Suppliers are often evaluated based on their compliance with international standards like ISO 9001, ensuring that only the best materials are utilized.

Illustrative image related to autotech alternator

Forming Techniques

Once the materials are prepared, they undergo forming processes. This stage often involves precision machining and stamping to create the alternator’s components, including the rotor, stator, and housing. Advanced techniques such as CNC machining are employed to achieve exact specifications, ensuring that parts fit together seamlessly.

Assembly Procedures

In the assembly phase, components are meticulously put together in a clean environment to prevent contamination. Skilled technicians use specialized tools to ensure that each unit is assembled to meet the defined specifications. This stage often includes the installation of internal voltage regulators and diodes, which are critical for the alternator’s performance.

Finishing Touches

The final stage of manufacturing involves applying protective coatings and conducting final inspections. Finishing touches may include anodizing aluminum parts or applying paint to enhance durability and aesthetics. Once the alternators are completed, they undergo a series of tests to verify their performance metrics.

How is Quality Assurance Integrated into the Production of Autotech Alternators?

Quality assurance (QA) is paramount in the manufacturing of autotech alternators, ensuring that each unit meets stringent performance standards. The QA process is typically aligned with international standards such as ISO 9001 and industry-specific certifications like CE and API.

نقاط مراقبة الجودة

Quality control is integrated at multiple checkpoints throughout the manufacturing process:

-

مراقبة الجودة الواردة (IQC): Materials are inspected upon arrival to ensure they meet predefined specifications. This step is crucial for preventing defects in the final product.

-

مراقبة الجودة أثناء الإنتاج (IPQC): During the assembly phase, technicians conduct ongoing checks to monitor adherence to manufacturing standards. This includes verifying the accuracy of machining and assembly.

-

مراقبة الجودة النهائية (FQC): After assembly, each alternator undergoes a comprehensive testing process to ensure it meets performance specifications. This includes testing for voltage output, ripple current, and overall functionality.

What Testing Methods Are Commonly Used for Autotech Alternators?

Various testing methods are employed to validate the performance and durability of autotech alternators.

Load Bank Testing

Load bank testers simulate real-world conditions to evaluate how alternators perform under different loads. This method helps identify any potential failures or inefficiencies.

Computerized Testing

Advanced computerized testers are utilized to assess parameters such as ripple current and voltage set points. These tests ensure that the alternators perform optimally at various RPMs, reflecting actual vehicle conditions.

Stator and Rotor Testing

Stator and rotor components are individually tested to verify their integrity and performance. This step ensures that each part meets the rigorous standards set forth by the manufacturer.

كيف يمكن للمشترين B2B التحقق من عمليات مراقبة الجودة لدى الموردين؟

B2B buyers must be proactive in verifying the quality control processes of their suppliers to ensure reliability and performance. Here are several methods to achieve this:

Illustrative image related to autotech alternator

إجراء عمليات التدقيق

Buyers can conduct audits of the manufacturing facility to assess the quality control measures in place. This can include reviewing documentation, inspecting the production line, and observing testing procedures.

طلب تقارير الجودة

Suppliers should be able to provide detailed quality reports that outline their testing procedures, results, and any certifications obtained. These documents serve as proof of compliance with industry standards.

عمليات التفتيش من قبل أطراف ثالثة

Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s quality control processes. These agencies often have established protocols to assess manufacturing facilities comprehensively.

ما هي الفروق الدقيقة في مراقبة الجودة والشهادات بالنسبة للمشترين الدوليين من الشركات إلى الشركات (B2B)؟

When engaging with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of several nuances in quality control and certification:

Understanding Local Standards

Different countries may have varying standards and certifications. Buyers should ensure that the products meet the requirements of their local markets, which may include additional testing or certifications beyond international standards.

Illustrative image related to autotech alternator

Navigating Import Regulations

Import regulations can impact the acceptance of certain products. B2B buyers must familiarize themselves with any specific requirements that may apply when importing alternators into their respective countries.

Cultural and Communication Considerations

Effective communication is vital in international transactions. Buyers should establish clear lines of communication with suppliers to address any quality concerns or specifications, ensuring that both parties have aligned expectations.

Conclusion: Importance of Quality in Autotech Alternators for B2B Buyers

For B2B buyers in various regions, understanding the manufacturing processes and quality assurance measures for autotech alternators is essential. Not only does this knowledge help in selecting reliable suppliers, but it also ensures that the products meet the rigorous demands of automotive applications. By prioritizing quality and leveraging thorough verification processes, buyers can confidently invest in high-performance alternators that enhance their operational capabilities.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘autotech alternator’

This guide serves as a comprehensive checklist for B2B buyers seeking to procure Autotech alternators. By following these steps, you can ensure that your sourcing process is efficient, effective, and results in high-quality products that meet your specific needs.

-

تحديد متطلباتك التقنية

Clearly defining your technical specifications is crucial before reaching out to suppliers. Consider factors such as amperage ratings, compatibility with vehicle models, and any specific features required for your application (e.g., marine, racing, or off-road use). This clarity will help you communicate your needs effectively and streamline the procurement process. -

البحث عن الموردين ذوي السمعة الطيبة

Conduct thorough research to identify suppliers with a strong reputation in the industry. Look for companies that have been in business for several years and have positive reviews from other B2B buyers. Pay attention to their product offerings, including the range of amperage options and custom solutions available. A well-established supplier is more likely to provide reliable products and support. -

التحقق من شهادات الموردين ومعايير الجودة

It’s essential to ensure that the supplier adheres to quality control standards. Request information on their certifications, such as ISO or other relevant quality standards. Additionally, inquire about their testing processes to confirm that they conduct thorough quality checks, including performance testing at various RPMs, to ensure that the alternators meet or exceed OEM specifications. -

Request Samples or Performance Proof

Before placing a bulk order, request samples or performance proof of the alternators. This could include performance videos or data sheets demonstrating the product’s output at specified RPMs. Evaluating samples allows you to assess the product’s build quality and performance in real-world conditions, ensuring it meets your expectations. -

Assess Warranty and Support Policies

Review the supplier’s warranty and support policies carefully. A robust warranty indicates confidence in the product quality and provides peace of mind for your investment. Look for details on warranty coverage, such as what is included and the process for claiming warranty support in case of defects or issues. This can save you from potential losses down the line. -

Evaluate Shipping and Delivery Terms

Clarify the shipping options, lead times, and delivery terms with the supplier. Understanding these logistics is vital for planning your inventory and ensuring timely availability of products. Be aware of any additional costs related to shipping, especially if you are sourcing from international suppliers, to avoid unexpected expenses. -

التفاوض على شروط الدفع

Establishing favorable payment terms can significantly impact your cash flow. Discuss options such as credit terms or financing plans, especially for larger orders. Be sure to understand any associated fees or penalties, and negotiate terms that allow you to manage your financial resources effectively while ensuring a steady supply of alternators.

By following these steps, you can optimize your sourcing process for Autotech alternators, ensuring that you find the right products for your business needs while minimizing risks and maximizing quality.

Comprehensive Cost and Pricing Analysis for autotech alternator Sourcing

What Are the Key Cost Components in Autotech Alternator Sourcing?

When sourcing autotech alternators, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

المواد: The quality of materials used in manufacturing alternators significantly impacts cost. High-grade components such as OEM bearings and press-fit avalanche diodes are essential for durability and performance. Custom specifications can lead to variations in material costs.

-

العمل: Skilled labor is required for assembly and testing, particularly for custom units. Labor costs can vary based on the region, with higher wages typically seen in developed countries.

-

تكاليف التصنيع العامة: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient production processes can help minimize overhead costs.

-

الأدوات: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider these costs in their total sourcing budget, particularly for low-volume orders.

-

مراقبة الجودة (QC): Rigorous testing and quality assurance processes are vital to ensure alternators meet performance standards. Investments in advanced testing equipment can add to costs but are essential for reducing returns and warranty claims.

-

اللوجستيات: Shipping costs can vary widely based on destination, mode of transport, and packaging requirements. For international buyers, understanding Incoterms is crucial to determine who bears the shipping and insurance costs.

-

الهامش: Manufacturers typically add a profit margin to their costs. This margin can fluctuate based on market demand, competition, and the perceived value of the product.

What Influences Pricing for Autotech Alternators?

Several factors influence the pricing of autotech alternators, making it essential for buyers to conduct thorough market research.

Illustrative image related to autotech alternator

-

الحجم/الحد الأدنى للطلب: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often lead to discounts, while smaller orders may incur higher per-unit costs due to setup and production inefficiencies.

-

المواصفات والتخصيص: Custom specifications can increase costs due to the need for specialized materials and additional labor. However, these customizations may be necessary to meet specific performance requirements.

-

شهادات المواد والجودة: Alternators made from high-quality materials with relevant certifications (e.g., ISO, CE) may command higher prices but offer better reliability and performance. Buyers should weigh the benefits of quality against cost.

-

عوامل الموردين: Supplier reputation, reliability, and financial stability can influence pricing. A well-established supplier may charge a premium for their products due to their proven track record.

-

مصطلحات التجارة الدولية: Understanding Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect the total landed cost of the product and should be clarified before finalizing orders.

How Can Buyers Negotiate for Better Pricing on Autotech Alternators?

Effective negotiation strategies can help buyers secure better pricing and terms when sourcing autotech alternators.

-

حجم الرافعة المالية: Buyers should consider consolidating orders to achieve volume discounts. Engaging in long-term contracts can also provide negotiating power.

-

فهم التكلفة الإجمالية للملكية (TCO): Buyers should assess the long-term costs associated with alternators, including installation, maintenance, and potential downtime. Highlighting TCO can strengthen a negotiation position.

-

أسعار سوق الأبحاث: Conducting competitive analysis to understand market pricing can provide leverage during negotiations. Buyers should be prepared to share this information to justify their pricing requests.

-

Be Open to Flexible Terms: Offering to adjust payment terms or delivery schedules can create mutually beneficial arrangements that may result in better pricing.

-

بناء العلاقات: Establishing a strong relationship with suppliers can lead to better terms over time. Suppliers are more likely to offer favorable conditions to trusted partners.

إخلاء المسؤولية بشأن الأسعار الإرشادية

Prices for autotech alternators can vary significantly based on the factors discussed above. It is advisable for buyers to request quotes tailored to their specific requirements and to consider all associated costs to ensure a comprehensive understanding of pricing dynamics.

Alternatives Analysis: Comparing autotech alternator With Other Solutions

Introduction: Evaluating Alternatives to Autotech Alternators

In the competitive landscape of automotive electrical solutions, businesses often seek the most efficient and cost-effective options for high-output alternators. While the Autotech alternator is known for its superior performance and reliability, it is essential for B2B buyers to explore viable alternatives that may cater to specific operational needs or budget constraints. This analysis will compare the Autotech alternator with two prominent alternatives: the Denso Alternator و المولد الميكانيكي, focusing on key aspects such as performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to autotech alternator

جدول المقارنة

| جانب المقارنة | Autotech Alternator | Denso Alternator | المولد الميكانيكي |

|---|---|---|---|

| الأداء | Up to 500 amps at 1800 RPM | Up to 200 amps | Up to 370 amps |

| التكلفة | Moderate to High | معتدل | عالية |

| سهولة التنفيذ | Requires spacers/brackets | Direct fit for many models | Custom fit options available |

| الصيانة | Low (Lifetime labor warranty) | Moderate (OEM parts) | Low (High-quality components) |

| أفضل حالة استخدام | مركبات عالية الأداء | Standard and OEM vehicles | Audio systems and racing |

تفصيل البدائل

Denso Alternator

The Denso alternator is a widely recognized option in the automotive industry, particularly for its compatibility with various OEM vehicles. It typically offers a maximum output of up to 200 amps, making it suitable for standard applications. The main advantage of Denso alternators is their ease of installation, as they often fit directly into existing setups without the need for additional modifications. However, they may not deliver the high output required for specialized applications such as competitive racing or high-demand audio systems. Thus, while cost-effective and reliable, they may fall short for buyers needing high-performance solutions.

المولد الميكانيكي

Mechman alternators are another strong contender in the high-output segment, capable of delivering up to 370 amps. They are particularly favored by audio enthusiasts and racers due to their robust design and high amperage capabilities. These alternators are built with high-quality components, ensuring durability and longevity. However, they tend to be on the higher end of the price spectrum, which may deter budget-conscious buyers. Additionally, installation may require custom fittings, which could complicate the process for some users. Despite these challenges, Mechman alternators excel in scenarios where maximum power output is crucial.

الخلاصة: اختيار الحل المناسب لاحتياجاتك

When evaluating alternator solutions, B2B buyers should consider their specific application requirements, budget constraints, and installation capabilities. The Autotech alternator stands out for high-performance applications, particularly where significant power output is essential. However, for businesses focused on standard vehicle applications or those with tighter budgets, alternatives like the Denso and Mechman alternators offer viable solutions. Careful consideration of performance needs, installation ease, and long-term maintenance will guide buyers in selecting the best alternator for their operational demands.

Essential Technical Properties and Trade Terminology for autotech alternator

What Are the Essential Technical Properties of Autotech Alternators?

When considering the purchase of autotech alternators, understanding key technical properties is crucial for making informed decisions. Here are some of the most important specifications:

Illustrative image related to autotech alternator

1. تصنيف الأمبيرية

Amperage ratings define the maximum electrical output of an alternator. Autotech offers a range from 130 Amps to 500 Amps, allowing buyers to select a unit that meets specific power needs. This is particularly important for applications requiring high energy, such as car audio systems or racing vehicles. Selecting the right amperage ensures that the alternator can support the electrical load without failure.

2. Voltage Setpoints

Voltage setpoints indicate the predetermined voltage output of the alternator, typically aligned with OEM specifications. For instance, Autotech’s alternators have a setpoint of 15V cold. This is vital for ensuring compatibility with various battery types and preventing damage due to over-voltage, which can lead to premature battery failure.

3. نوع المنظم

Alternators can feature internal or external voltage regulators. Autotech’s units come with internally regulated systems that meet or exceed OEM standards. This specification is critical as it affects the alternator’s efficiency, longevity, and ability to maintain stable voltage outputs across different operating conditions.

Illustrative image related to autotech alternator

4. Diode Configuration

Diodes are essential for converting AC current generated by the alternator into usable DC current. Autotech uses 12-80 Amp Avalanche diodes, known for their durability and efficiency. The quality and configuration of diodes impact the alternator’s overall performance and reliability, making it a key consideration for buyers in high-demand applications.

5. معايير الاختبار

Autotech employs rigorous testing protocols, utilizing multiple test benches to ensure each unit meets specified performance standards. This includes testing under actual vehicle RPM conditions. Understanding the testing procedures is crucial for B2B buyers, as it assures them of the alternator’s reliability and performance capabilities.

6. الضمان والدعم

A robust warranty policy, such as Autotech’s lifetime labor and one-year parts limited warranty, indicates the manufacturer’s confidence in their product. This is an essential aspect for B2B buyers as it minimizes the risk associated with investment and ensures support in case of manufacturing defects.

What Are Common Trade Terms Related to Autotech Alternators?

Familiarity with industry terminology can streamline communication and enhance understanding during negotiations. Here are some essential trade terms:

1. OEM (الشركة المصنعة للمعدات الأصلية)

OEM refers to the original manufacturer of a component that is sold as part of a vehicle. In the context of alternators, knowing whether a product is OEM can assure buyers of quality and compatibility with their vehicles.

2. MOQ (الحد الأدنى لكمية الطلب)

MOQ is the smallest number of units a supplier is willing to sell. Understanding this term is vital for B2B buyers to negotiate better pricing and ensure they are ordering enough units to meet their needs without excess inventory.

3. طلب عرض أسعار (RFQ)

An RFQ is a document sent to suppliers to obtain pricing and other details about a product or service. For buyers, submitting an RFQ for autotech alternators can help clarify costs and lead times, making the purchasing process more efficient.

4. شروط التجارة الدولية (Incoterms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping costs, insurance, and delivery points. Familiarity with these terms is crucial for buyers, especially in global markets, to avoid misunderstandings and unexpected expenses.

5. المهلة الزمنية

Lead time refers to the duration from placing an order to the delivery of the product. Understanding lead times for custom-built alternators, such as those offered by Autotech, can help businesses plan their inventory and project timelines effectively.

Illustrative image related to autotech alternator

6. سوق ما بعد البيع

The aftermarket refers to parts and accessories that are not supplied by the vehicle’s original manufacturer. For buyers looking for high-performance alternators, knowing the distinction between OEM and aftermarket can influence their purchasing decisions based on quality and performance expectations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing autotech alternators, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the autotech alternator Sector

What Are the Key Drivers and Trends Shaping the Autotech Alternator Market?

The global autotech alternator market is experiencing significant transformation driven by several key factors. The increasing demand for high-performance vehicles, particularly in emerging markets like Africa and South America, is propelling growth in this sector. Buyers are increasingly focused on sourcing alternators that offer enhanced output capabilities, with specifications ranging from 130 amps to over 500 amps. Additionally, the rise of electric and hybrid vehicles is pushing manufacturers to innovate, leading to a surge in demand for specialized alternators that accommodate advanced battery technologies.

Illustrative image related to autotech alternator

Emerging technologies, such as IoT and smart vehicle integration, are also reshaping sourcing trends. B2B buyers are now prioritizing suppliers who can provide not just high-quality products but also advanced connectivity features that enhance vehicle performance. This shift requires suppliers to invest in R&D and adopt agile manufacturing processes to meet the fast-evolving needs of the market. Furthermore, a growing emphasis on performance verification through “Proof in Performance” videos allows buyers to make informed decisions, ensuring that the products they source deliver as promised.

In regions like the Middle East and Europe, regulatory frameworks are becoming stricter regarding emissions and vehicle efficiency. This regulatory environment is driving demand for alternators that not only meet performance standards but are also compatible with eco-friendly technologies. As a result, international B2B buyers are advised to seek suppliers that demonstrate compliance with these regulations while offering customizable solutions tailored to specific vehicle applications.

How Are Sustainability and Ethical Sourcing Influencing B2B Practices in the Autotech Sector?

As sustainability becomes a cornerstone of modern business practices, the autotech alternator sector is not immune to these pressures. B2B buyers are increasingly scrutinizing their supply chains, seeking partners committed to environmental stewardship. The production of high-output alternators can have significant environmental impacts, including energy consumption and waste generation. Thus, manufacturers are encouraged to adopt greener production methods, such as utilizing energy-efficient machinery and recycling materials whenever possible.

Ethical sourcing is also gaining traction among international buyers. This involves ensuring that raw materials and components are sourced from suppliers who adhere to fair labor practices and sustainable environmental policies. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming essential credentials for suppliers looking to attract conscientious buyers.

In addition, the use of eco-friendly materials in alternator production, such as recyclable metals and biodegradable components, is increasingly appealing to buyers focused on sustainability. This trend not only helps companies enhance their brand image but also aligns with the growing consumer demand for environmentally responsible products. By prioritizing sustainability and ethical sourcing, B2B buyers can differentiate themselves in a competitive market and contribute positively to global sustainability goals.

What Is the Historical Context of the Autotech Alternator Market?

The autotech alternator market has evolved significantly since its inception in the early 20th century. Initially, alternators were primarily designed for basic functionality, providing electrical power to ignition systems and vehicle lighting. However, as automotive technology advanced, the need for more robust electrical systems became apparent. This led to the development of high-output alternators that could support the growing number of electronic components in vehicles.

In the late 1980s, companies like AutoTech Engineering began specializing in high-performance alternators, focusing on applications in racing, marine, and off-road vehicles. This specialization allowed manufacturers to cater to niche markets that demanded higher amperage outputs and greater reliability under extreme conditions. Over the decades, advancements in materials science and manufacturing techniques have further enhanced the performance and durability of alternators, making them integral to modern vehicle design.

Today, as the automotive industry shifts towards electrification and sustainability, the autotech alternator market continues to adapt, offering solutions that meet both performance and environmental standards. This historical context highlights the importance of innovation and adaptability in a sector that remains essential to vehicle functionality and performance.

Frequently Asked Questions (FAQs) for B2B Buyers of autotech alternator

-

How do I select the right autotech alternator for my vehicle?

Choosing the right autotech alternator involves considering your vehicle’s specific requirements. Factors include the amperage needed for your electrical systems, compatibility with your vehicle model, and any performance enhancements you desire, such as improved sound systems or additional lighting. If your vehicle is not listed in the catalog, reach out directly for custom solutions. Our team can assist in determining the appropriate model based on your vehicle’s specifications and intended use. -

What are the benefits of high output alternators for commercial applications?

High output alternators provide significant advantages for commercial applications, particularly in vehicles with high electrical demands. They ensure consistent power delivery, which is crucial for running additional equipment like audio systems, lighting, and other electronics. This reliability minimizes the risk of battery drain and system failures, enhancing operational efficiency. Additionally, they are designed to perform well under various conditions, making them suitable for demanding environments. -

What customization options are available for autotech alternators?

Autotech offers a range of customization options to meet specific client needs. You can choose from various amperage ratings, voltage set points, and design features tailored to your vehicle’s requirements. If you have unique specifications or need a specific design that isn’t listed, our team can create a custom alternator just for you. Contact us to discuss your requirements, and we will provide a tailored quote. -

What is the minimum order quantity (MOQ) for purchasing autotech alternators?

The minimum order quantity can vary based on the specific alternator model and customization options. Generally, we cater to both small-scale and large-scale orders, making it accessible for various business needs. For bulk orders, discounts may apply, and we encourage you to contact our sales team to discuss your needs and explore pricing options. -

What payment terms do you offer for international buyers?

We provide flexible payment terms to accommodate international buyers, including options for credit and financing. Typically, payments can be made via bank transfer, credit card, or through financing plans that offer up to 100 days with no interest. It’s advisable to discuss payment terms directly with our sales team to align with your financial processes and ensure a smooth transaction. -

How do you ensure the quality of your alternators?

Quality assurance is a top priority at Autotech. Each alternator undergoes rigorous testing using three different machines to verify its performance under real vehicle conditions. We assess parameters such as ripple current, voltage set points, and output at various RPMs. Additionally, all components are pre-qualified and tested before assembly, ensuring that our products meet or exceed industry standards. -

What logistics and shipping options are available for international orders?

For international orders, we offer various shipping options tailored to your needs. We work with reliable logistics partners to ensure timely delivery while maintaining cost-effectiveness. Depending on your location, shipping times and costs may vary. Our team can provide detailed shipping estimates and help you choose the best option for your business. -

What should I do if I encounter a problem with my autotech alternator?

If you experience issues with your autotech alternator, please contact our customer service team immediately. We offer a lifetime labor warranty and a one-year parts warranty covering premature failures. Be prepared to provide details about the installation and usage, as our warranty does not cover damage due to improper installation or misuse. Our team is committed to resolving any concerns and ensuring your satisfaction with our products.

Top 4 Autotech Alternator Manufacturers & Suppliers List

1. AutoTech Engineering – High Output Alternators

المجال: autotechengineeringusa.com

مسجل: 2018 (7 سنوات)

مقدمة: High Output Alternators for Cars, Trucks, Marine, Racing, Offroad, Overlanding, SXS, and UTV. Amperage ratings range from 130 Amp to 500 Amp. Custom-built options available with an average lead time of 1-2 weeks. All units are tested twice before shipping. Internal voltage regulators meet or exceed OEM specifications. Heavy-duty dual bridge rectifiers and premium high-temperature bearings included…

2. Facebook – Auto Tech Alternators

3. AUTOTECH – 370 AMP ALTERNATOR

المجال: smscaraudio.com

مسجل: 2018 (7 سنوات)

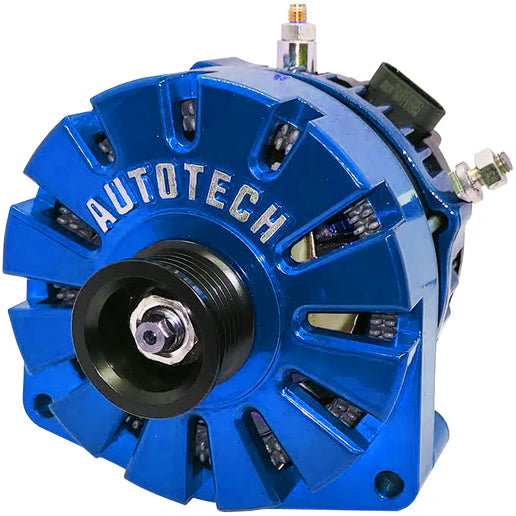

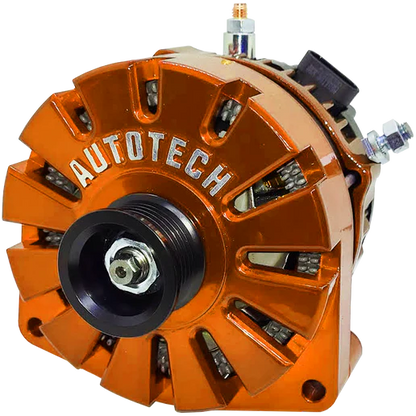

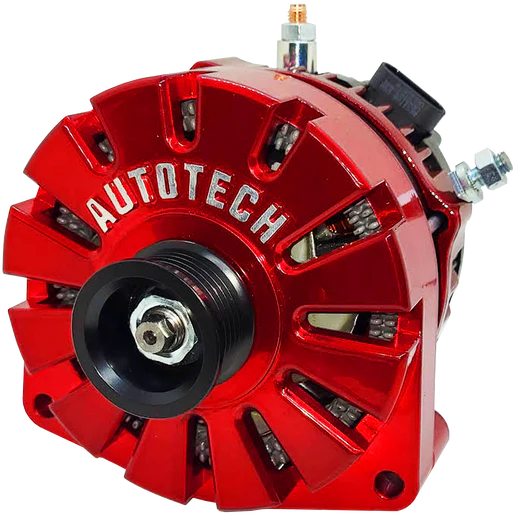

مقدمة: [{‘name’: ‘AUTOTECH 370 AMP ALTERNATOR 8237-370 KANDY BLUE’, ‘price’: ‘$425.00’, ‘status’: ‘Sold out’}, {‘name’: ‘AUTOTECH 370 AMP ALTERNATOR 8237-370 GLOSS BLACK’, ‘price’: ‘$425.00’, ‘status’: ‘Sold out’}, {‘name’: ‘AUTOTECH 320 AMP 2020 – CURRENT POLARIS SLINGSHOT ALTERNATORS | HP-4017547-320 AMP’, ‘price’: ‘$549.99’, ‘status’: ‘Sold out’}, {‘name’: ‘AUTOTECH 370 AMP ALTERNATORS | HP-8112-370A’…

4. AutoTech – 400 Amp High Output Alternator

المجال: eliteautogear.com

مسجل: 2019 (6 سنوات)

مقدمة: AutoTech Alternator for Chevy/GM 400 Amp High Output Alternator 4.3L–8.1L Engines (2005–2024) | Upgrade for Car Audio, Trucks & SUVs | REALLY RED (BREMBO RED) – Model AT-HP-8301-400A-RD | Price: $550.00 USD | Availability: Only 2 left

AutoTech Alternator for Chevy/GM 400 Amp High Output Alternator 4.3L–8.1L Engines (2005–2024) | Upgrade for Car Audio, Trucks & SUVs | INTENSE BLUE/BLUEPLE Model AT-…

Strategic Sourcing Conclusion and Outlook for autotech alternator

As the demand for high-output alternators continues to rise globally, strategic sourcing becomes paramount for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe. Key takeaways from this guide highlight the importance of selecting suppliers like AutoTech Engineering, which offers a comprehensive range of high-quality alternators tailored for various applications, including automotive, marine, and racing. Their commitment to rigorous testing and quality assurance ensures that buyers receive reliable and efficient products that enhance vehicle performance.

Investing in high-output alternators not only improves operational efficiency but also provides significant long-term value. With options ranging from 130 to 500 amps and customized solutions available, buyers can find the perfect fit for their specific needs.

Looking ahead, businesses in emerging markets should prioritize partnerships with reputable manufacturers who can meet their unique requirements and adapt to evolving industry standards. By leveraging strategic sourcing practices, international buyers can enhance their operational capabilities and drive success in their respective sectors. Now is the time to explore opportunities with trusted suppliers and invest in high-performance solutions that will propel your business forward.

إخلاء مسؤولية هام وشروط الاستخدام

⚠️ تنويه هام

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. ولا تشكل هذه المعلومات مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

Illustrative image related to autotech alternator

على الرغم من أننا بذلنا قصارى جهدنا لضمان دقة المعلومات وحداثتها، فإننا لا نتحمل أي مسؤولية عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين من الشركات (B2B) إجراء عمليات التحقق المستقلة والشاملة الخاصة بهم. قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، والبحث عن استشارة مهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.