Introdução: Navegando no mercado global para quais são os sinais de que um starter está indo mal

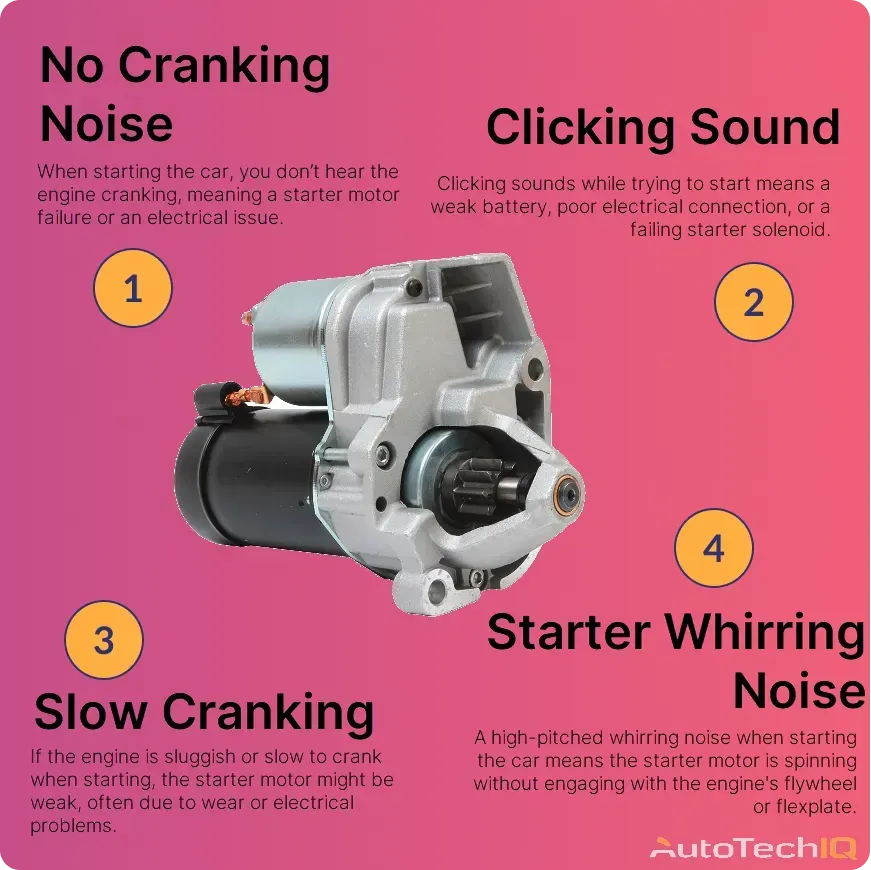

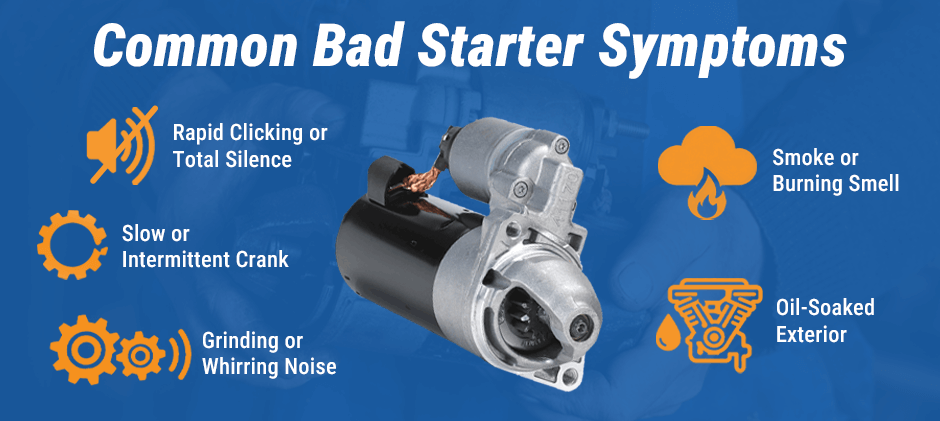

No atual mercado global de ritmo acelerado, compreender os sinais de avaria de um motor de arranque é crucial para as empresas que dependem de equipamento automóvel e de transporte. Quer esteja a operar uma empresa de logística na América do Sul ou a gerir uma frota na Europa, reconhecer os primeiros indicadores de falha do motor de arranque pode poupar custos significativos associados ao tempo de inatividade e às reparações. Este guia abrangente não só descreve os sinais comuns de um motor de arranque avariado - tais como ruídos invulgares, luzes de aviso no painel de instrumentos e arranque lento - mas também aprofunda as complexidades dos sistemas de motor de arranque, as melhores práticas de manutenção e as implicações dos vários problemas do motor de arranque no desempenho geral do veículo.

O guia foi concebido especificamente para compradores B2B internacionais, particularmente os de regiões como África, Médio Oriente e Vietname, que enfrentam desafios únicos no fornecimento de componentes automóveis fiáveis. Ao abordar aspectos críticos como a verificação do fornecedor, considerações de custo e requisitos específicos da aplicação, este recurso permite-lhe tomar decisões de compra informadas que se alinham com as suas necessidades operacionais. Com informações sobre as implicações das falhas dos motores de arranque na eficiência da logística e do transporte, pode melhorar as suas estratégias de aquisição e garantir que a sua frota se mantém operacional e competitiva no panorama global. Aproveite os conhecimentos fornecidos neste guia para navegar pelas complexidades da manutenção e substituição de motores de arranque, conduzindo a sua empresa a uma maior fiabilidade e sucesso.

Índice

- Top 2 Quais são os sinais de que um motor de arranque está a ficar estragado Lista de fabricantes e fornecedores

- Introdução: Navegando no mercado global para quais são os sinais de que um starter está indo mal

- Compreender quais são os sinais de avaria do motor de arranque Tipos e variações

- Principais aplicações industriais de quais são os sinais de avaria de um motor de arranque

- 3 Pontos de dor comuns dos utilizadores para ‘quais são os sinais de um arrancador que está a ficar mau’ e as suas soluções

- Guia de seleção de materiais estratégicos para quais são os sinais de avaria de um motor de arranque

- Análise aprofundada: Processos de fabrico e garantia de qualidade para quais são os sinais de avaria de um arrancador

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘quais são os sinais de que um arrancador está a estragar-se’

- Análise exaustiva dos custos e dos preços para quais são os sinais de um arranque em mau estado Sourcing

- Análise de alternativas: Comparação de quais são os sinais de avaria de um motor de arranque com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para quais são os sinais de avaria de um motor de arranque

- Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector Quais são os sinais de que um arranque está a correr mal?

- Perguntas frequentes (FAQs) para compradores B2B sobre quais são os sinais de avaria de um motor de arranque

- Strategic Sourcing Conclusion and Outlook for quais são os sinais de um arranque que está a correr mal

- Aviso legal importante e termos de utilização

Compreender quais são os sinais de avaria do motor de arranque Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Indicadores luminosos do painel de instrumentos | As luzes do painel de instrumentos acendem-se sem que o motor dê a partida. | Gestão de frotas, serviços de transporte | Prós: Alerta visual imediato; fácil de diagnosticar. Contras: Pode indicar vários problemas. |

| Ruído de clique | Ouvem-se cliques simples ou múltiplos quando se roda a ignição. | Oficinas de reparação automóvel, fornecedores de peças | Prós: Identificação rápida de problemas no arranque. Contras: Também pode indicar problemas na bateria. |

| Arranque lento | O motor arranca lentamente ou tem dificuldade em arrancar. | Serviços de manutenção de veículos | Prós: Indica uma potencial falha do motor de arranque numa fase precoce. Contras: Pode exigir diagnósticos adicionais. |

| Emissão de fumo | Fumo visível quando se tenta ligar o veículo. | Serviços de emergência automóvel | Prós: Indicação clara de falha grave. Contras: É necessária uma ação imediata para evitar mais danos. |

| Arrancador embebido em óleo | O motor de arranque apresenta sinais de fuga de óleo ou danos. | Fabricação automóvel, oficinas de reparação | Prós: Destaca a necessidade de manutenção; protege contra futuras falhas. Contras: Reparações dispendiosas devido a problemas subjacentes. |

Quais são as principais caraterísticas dos indicadores luminosos do painel de instrumentos para iniciantes?

Os indicadores luminosos do painel de instrumentos funcionam como um sistema de alerta essencial para potenciais problemas com o motor de arranque. Quando as luzes do painel de instrumentos se acendem mas o motor não arranca, isso sugere normalmente um mau funcionamento do motor de arranque ou dos componentes relacionados. Este sintoma é particularmente relevante para as empresas de gestão de frotas, uma vez que permite uma programação proactiva da manutenção. No entanto, é importante notar que este sinal também pode indicar outros problemas eléctricos, necessitando de mais diagnósticos.

Como é que um ruído de clique indica problemas no motor de arranque?

Um ruído de clique ao rodar a chave da ignição é um sintoma clássico de falha do motor de arranque. Este ruído ocorre devido à insuficiência de energia que chega ao motor de arranque ou a problemas mecânicos no próprio motor de arranque. As oficinas de reparação automóvel podem beneficiar com o reconhecimento deste sinal, uma vez que ajuda a simplificar o processo de diagnóstico. Embora seja um indicador claro de problemas no motor de arranque, os compradores também devem considerar que podem surgir sintomas semelhantes devido a problemas na bateria, o que exige um exame minucioso.

Porque é que o arranque lento é um sinal crítico de problemas com o motor de arranque?

O arranque lento é um indicador significativo de uma falha no motor de arranque, em que o motor se esforça por virar. Este sintoma é crucial para os serviços de manutenção de veículos, uma vez que permite uma intervenção precoce antes de ocorrer uma falha completa. A resolução do problema do arranque lento pode evitar reparações mais extensas e períodos de inatividade. No entanto, é essencial que os compradores efectuem diagnósticos adicionais, uma vez que o arranque lento também pode resultar de deficiências da bateria ou de outros problemas mecânicos.

O que deve fazer se vir emissões de fumo?

A emissão de fumo durante as tentativas de ignição é um sinal grave de falha do motor de arranque, indicando frequentemente sobreaquecimento ou curto-circuitos eléctricos. Esta situação exige a atenção imediata dos serviços de emergência automóvel para evitar danos adicionais no veículo. Embora forneça uma indicação clara de uma avaria, os compradores devem estar preparados para potenciais reparações dispendiosas. Uma ação imediata pode atenuar os danos e poupar em custos de reparação futuros.

Como é que um motor de arranque embebido em óleo afecta o desempenho?

Um motor de arranque encharcado de óleo resulta de fugas no motor, comprometendo a funcionalidade do motor de arranque. Esta questão é especialmente relevante nos sectores de fabrico e reparação automóvel, uma vez que realça a necessidade de verificações de manutenção regulares. A resolução das fugas de óleo não só protege o motor de arranque como também evita falhas prematuras. No entanto, esta situação pode levar a reparações dispendiosas, uma vez que requer a substituição do motor de arranque e a resolução do problema subjacente de fuga de óleo.

Principais aplicações industriais de quais são os sinais de avaria de um motor de arranque

| Indústria/Setor | Aplicação específica de quais são os sinais de avaria do motor de arranque | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Diagnosticar problemas no motor de arranque de veículos durante a manutenção de rotina | Reduz o tempo de inatividade e os custos de reparação, resolvendo os problemas atempadamente | Acesso a ferramentas de diagnóstico e a técnicos especializados |

| Transporte e Logística | Avaliar os motores de arranque dos veículos da frota para garantir a fiabilidade | Aumenta a eficiência da frota e minimiza as avarias inesperadas | Qualidade dos componentes do motor de arranque e disponibilidade de peças de substituição |

| Equipamento de construção | Monitorização do desempenho do motor de arranque em máquinas pesadas | Evita atrasos dispendiosos nos projectos e períodos de inatividade do equipamento | Compatibilidade com vários tipos de máquinas e garantias robustas |

| Agricultura | Avaliação da funcionalidade do arrancador no equipamento agrícola | Assegura a plantação e a colheita atempadas, maximizando o rendimento | Fiabilidade do fornecedor e apoio à expedição internacional |

| Mineração | Identificação de falhas do motor de arranque em veículos mineiros | Mantém a continuidade operacional e a segurança dos trabalhadores | Conformidade com os regulamentos locais e disponibilidade de peças em áreas remotas |

Como é que ‘quais são os sinais de avaria de um motor de arranque’ é aplicado na indústria de reparação automóvel?

No sector da reparação automóvel, identificar os sinais de um mau motor de arranque é crucial para manter o desempenho do veículo. Os mecânicos utilizam ferramentas de diagnóstico para detetar problemas como ruídos de clique ou arranque lento, que podem indicar uma falha do motor de arranque. Ao resolver estes problemas atempadamente, as oficinas de reparação podem reduzir o tempo de inatividade do veículo e minimizar os custos de reparação para os seus clientes. Os compradores internacionais devem considerar a aquisição de equipamento de diagnóstico de qualidade e garantir que os seus técnicos têm formação em sistemas de arranque para aumentar a fiabilidade do serviço.

Qual é a importância de monitorizar as questões de arranque nos transportes e na logística?

No sector dos transportes e da logística, a gestão de frotas depende fortemente da fiabilidade dos veículos. A avaliação regular do desempenho do motor de arranque ajuda a garantir que os veículos da frota estão operacionais e prontos para serem utilizados. A identificação precoce de problemas nos motores de arranque pode evitar avarias inesperadas, conduzindo a uma maior eficiência e a custos reduzidos associados a reparações e atrasos logísticos. Os compradores deste sector devem dar prioridade ao fornecimento de componentes de arranque de alta qualidade e considerar parcerias com fornecedores fiáveis que possam prestar apoio atempado.

Porque é que a funcionalidade do motor de arranque é fundamental no equipamento de construção?

Os projectos de construção dependem frequentemente de maquinaria pesada que requer sistemas de arranque fiáveis. A monitorização da funcionalidade do arrancador no equipamento de construção é vital para evitar atrasos dispendiosos. Um motor de arranque avariado pode interromper as operações, afectando os prazos e os custos do projeto. As empresas devem concentrar-se no fornecimento de motores de arranque duradouros que sejam compatíveis com vários tipos de maquinaria, juntamente com garantias robustas para proteger o seu investimento. Além disso, o acesso a técnicos qualificados para manutenção pode aumentar a fiabilidade do equipamento.

Qual o impacto da avaliação do desempenho dos arrancadores na agricultura?

Na agricultura, a funcionalidade do equipamento agrícola está diretamente ligada à produtividade. A identificação de sinais de falha do arrancador em tractores e ceifeiras é essencial para garantir a plantação e a colheita atempadas. Os atrasos causados por problemas no arrancador podem afetar significativamente o rendimento e a rentabilidade. Os compradores deste sector devem procurar fornecedores que ofereçam motores de arranque fiáveis com um bom suporte para envios internacionais, assegurando que podem substituir rapidamente os componentes avariados durante as épocas altas.

Quais são as implicações das falhas do arrancador nas operações mineiras?

As operações mineiras dependem de veículos pesados que têm de funcionar de forma fiável em ambientes difíceis. Identificar prontamente as falhas dos motores de arranque é crucial para manter a continuidade operacional e garantir a segurança dos trabalhadores. Um motor de arranque avariado pode levar a um tempo de inatividade significativo, o que é dispendioso no sector mineiro. Os compradores internacionais precisam de garantir que as suas estratégias de fornecimento cumprem os regulamentos locais e que podem aceder rapidamente às peças, mesmo em áreas remotas, para minimizar as interrupções nas suas operações.

3 Pontos de dor comuns dos utilizadores para ‘quais são os sinais de um arrancador que está a ficar mau’ e as suas soluções

Cenário 1: Tempo de inatividade inesperado devido a falha do arrancador

O problema: Muitos compradores B2B nos sectores automóvel ou dos transportes experimentam uma paragem súbita do veículo devido a uma avaria no motor de arranque. Esta falha inesperada pode levar à interrupção das operações, atrasos nas entregas e aumento dos custos, especialmente para as empresas que dependem de frotas de veículos. Quando um veículo não arranca, não só afecta a tarefa imediata em mãos, como também tem impacto na produtividade geral, potencialmente prejudicando as relações com os clientes e diminuindo a confiança. Os compradores têm frequentemente dificuldade em identificar se o motor de arranque é a causa principal, o que leva a atrasos de diagnóstico dispendiosos.

A solução: Para reduzir o tempo de inatividade inesperado, é essencial que as empresas implementem um programa de manutenção proactivo que inclua inspecções regulares do sistema de arranque. Os compradores devem formar o seu pessoal para reconhecer os primeiros sinais de falha do motor de arranque, tais como sons de clique invulgares, arranque lento ou luzes de aviso no painel de instrumentos. O investimento em ferramentas de diagnóstico, como um voltímetro, pode ajudar a determinar se o problema está no motor de arranque ou na bateria. Além disso, estabelecer relações com fornecedores fiáveis de peças e serviços de qualidade para o motor de arranque pode garantir substituições rápidas, minimizando o tempo de inatividade do veículo. A criação de uma lista de verificação para inspecções regulares do veículo também pode ajudar a identificar sinais de alerta precoce, permitindo intervenções atempadas.

Cenário 2: Custos de reparação elevados devido ao facto de se ignorarem os problemas do motor de arranque

O problema: Muitas empresas ignoram a importância dos primeiros sinais que indicam um mau arranque, o que conduz a problemas mais graves e a custos de reparação mais elevados. Ignorar sintomas como arranque lento ou alertas no painel de instrumentos pode resultar numa falha completa do motor de arranque, necessitando não só de uma substituição do motor de arranque, mas também de reparações nos sistemas eléctricos associados. Para os compradores B2B que gerem orçamentos apertados, estas despesas inesperadas podem sobrecarregar os recursos financeiros e afetar o fluxo de caixa.

A solução: Os compradores B2B devem dar prioridade à manutenção e ao diagnóstico regulares para evitar que pequenos problemas se transformem em reparações dispendiosas. Ao implementar um procedimento normalizado para monitorizar o desempenho do veículo, incluindo verificações do motor de arranque, as empresas podem detetar os problemas atempadamente. A formação do pessoal sobre os sinais comuns de falha do motor de arranque e a integração destas verificações na manutenção de rotina podem reduzir significativamente a probabilidade de falhas graves. Além disso, as empresas devem considerar o estabelecimento de um orçamento para manutenção preventiva que inclua inspecções periódicas ao motor de arranque e potenciais substituições, o que pode poupar dinheiro a longo prazo ao evitar reparações de emergência.

Cenário 3: Dificuldade em obter componentes de arranque fiáveis

O problema: Os compradores em mercados emergentes enfrentam frequentemente desafios no fornecimento de componentes de arranque fiáveis, o que leva a atrasos e a reparações de qualidade inferior que podem comprometer o desempenho do veículo. Este problema é particularmente grave em regiões onde a disponibilidade de peças de qualidade é inconsistente, o que faz com que as empresas tenham de se contentar com produtos de qualidade inferior ou enfrentem tempos de inatividade prolongados enquanto procuram os componentes certos. Este cenário não só afecta a eficiência operacional, como também suscita preocupações quanto à fiabilidade e segurança dos veículos.

A solução: Para enfrentar os desafios de sourcing, os compradores B2B devem cultivar relações com fornecedores de renome especializados em componentes automóveis, particularmente em sistemas de arranque. O envolvimento com fornecedores que compreendem as necessidades específicas da sua região pode levar a um melhor acesso a peças de qualidade. Os compradores também devem considerar o aproveitamento de plataformas e mercados online que os ligam a fabricantes e distribuidores que oferecem componentes de arranque verificados. O estabelecimento de uma rede de partilha de informações sobre fornecedores e produtos de renome pode aumentar ainda mais a eficiência do aprovisionamento. Além disso, as empresas podem investir em acordos de compra a granel com fornecedores fiáveis para garantir uma qualidade consistente e custos potencialmente mais baixos ao longo do tempo.

Guia de seleção de materiais estratégicos para quais são os sinais de avaria de um motor de arranque

Que materiais são normalmente utilizados na identificação de sinais de avaria de um motor de arranque?

Ao avaliar os sinais de mau funcionamento de um motor de arranque, vários materiais desempenham um papel crucial nos componentes e diagnósticos envolvidos. A compreensão das propriedades, vantagens, desvantagens e considerações internacionais destes materiais pode beneficiar significativamente os compradores B2B na tomada de decisões informadas.

1. Cobre

Propriedades principais: O cobre é conhecido pela sua excelente condutividade eléctrica, condutividade térmica e resistência à corrosão. Funciona normalmente de forma eficaz a temperaturas que variam entre -200°C e 200°C.

Prós e contras: A principal vantagem do cobre é a sua condutividade superior, tornando-o ideal para ligações eléctricas em motores de arranque. No entanto, o cobre pode ser relativamente caro em comparação com outros metais e pode exigir revestimentos protectores para evitar a corrosão, especialmente em ambientes húmidos ou salinos.

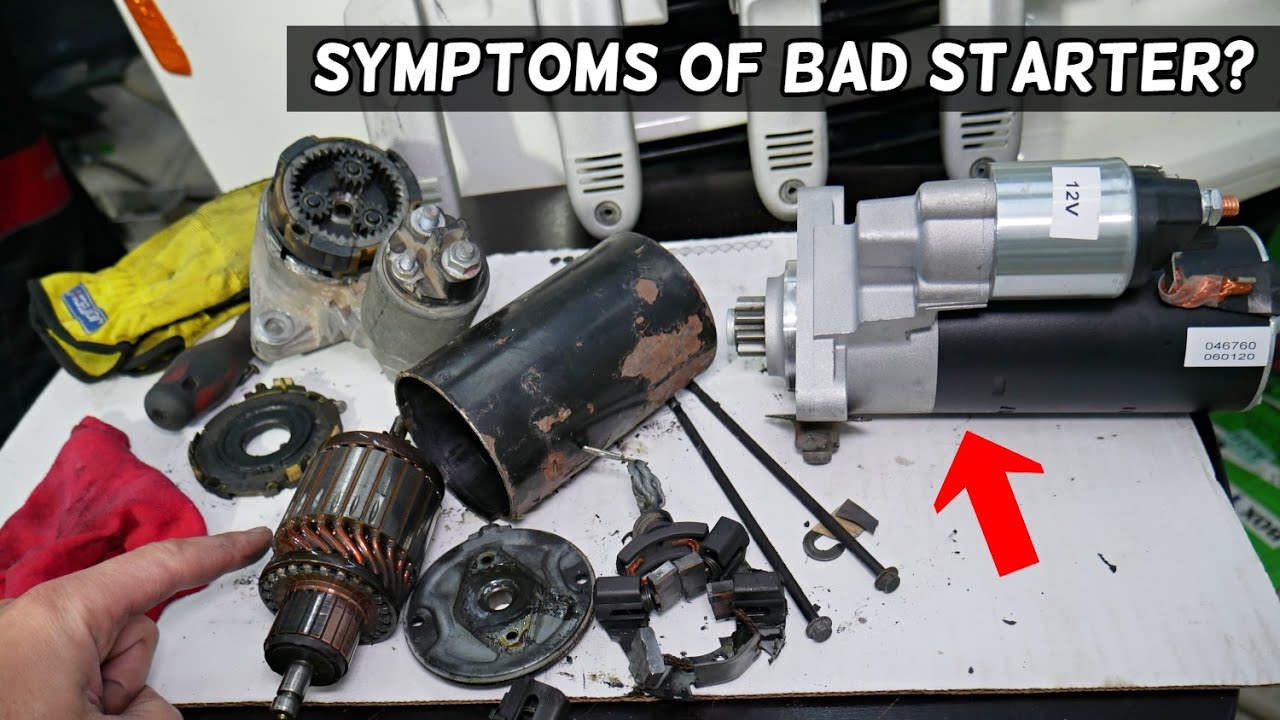

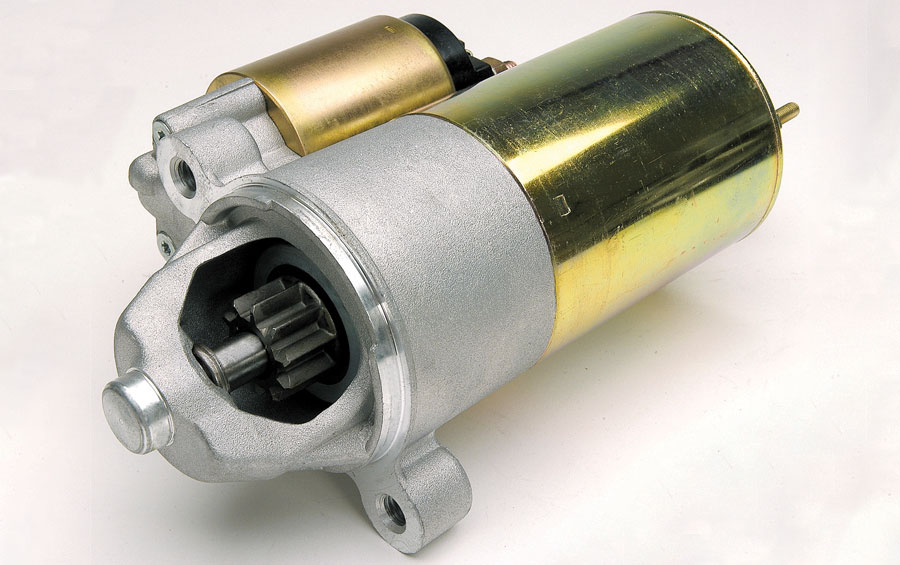

Imagem ilustrativa relacionada com os sinais de avaria do motor de arranque

Impacto na aplicação: A elevada condutividade do cobre é essencial para garantir que os sinais eléctricos são transmitidos de forma eficiente, o que é fundamental para o diagnóstico de problemas no motor de arranque. No entanto, a sua suscetibilidade à corrosão pode afetar a sua longevidade em determinados climas.

Considerações internacionais: Os compradores B2B devem estar cientes de normas como a ASTM B170 para o fio de cobre e das implicações dos requisitos locais de resistência à corrosão em regiões como o Médio Oriente e a América do Sul, onde os factores ambientais podem variar significativamente.

2. Aço

Propriedades principais: O aço é um material forte e duradouro, com boa resistência à tração e à deformação. Pode suportar temperaturas e pressões elevadas, o que o torna adequado para várias aplicações automóveis.

Prós e contras: A durabilidade e a relação custo-eficácia do aço são vantagens significativas. No entanto, é propenso à ferrugem e à corrosão se não for corretamente tratado, o que pode levar a falhas nos sistemas de arranque ao longo do tempo.

Impacto na aplicação: O aço é frequentemente utilizado em caixas de arrancadores e componentes que requerem integridade estrutural. A sua robustez garante que o arrancador pode suportar as tensões mecânicas durante o funcionamento, mas a corrosão pode comprometer a sua funcionalidade.

Considerações internacionais: O cumprimento de normas como a DIN 17100 para o aço estrutural é essencial para os compradores na Europa. Além disso, os compradores na América do Sul e em África devem considerar a disponibilidade de revestimentos resistentes à corrosão para aumentar a longevidade do aço.

3. Alumínio

Propriedades principais: O alumínio é leve, resistente à corrosão e tem boa condutividade térmica. Funciona normalmente com eficácia a temperaturas até 400°C.

Prós e contras: A principal vantagem do alumínio é a sua natureza leve, que pode levar a uma maior eficiência de combustível nos veículos. No entanto, é menos condutor do que o cobre e pode não ser tão durável em condições extremas.

Impacto na aplicação: O alumínio é frequentemente utilizado nos invólucros e componentes do motor de arranque quando a redução de peso é benéfica. Embora ofereça uma boa resistência à corrosão, a sua menor resistência em comparação com o aço pode exigir componentes mais espessos, aumentando potencialmente os custos.

Imagem ilustrativa relacionada com os sinais de avaria do motor de arranque

Considerações internacionais: Os compradores devem estar cientes de normas como a JIS H4000 para ligas de alumínio em aplicações automóveis, particularmente em regiões como a Ásia e o Médio Oriente, onde o alumínio é amplamente utilizado.

4. Compósitos plásticos

Propriedades principais: Os compósitos plásticos são leves, resistentes à corrosão e podem ser moldados em formas complexas. Normalmente, têm uma temperatura nominal de até 120°C.

Prós e contras: A principal vantagem dos compósitos plásticos é a sua versatilidade e baixo peso, o que pode aumentar a eficiência global do veículo. No entanto, podem não suportar temperaturas elevadas ou tensões mecânicas tão bem como os metais, levando a potenciais falhas.

Impacto na aplicação: Os compósitos plásticos são frequentemente utilizados em componentes não estruturais de arrancadores, tais como caixas ou isoladores. A sua resistência à corrosão é benéfica, mas podem exigir uma análise cuidadosa em ambientes de alta temperatura.

Considerações internacionais: A conformidade com normas como a ASTM D638 para materiais plásticos é crucial para os compradores na Europa e na América do Norte. Os compradores em África e na América do Sul devem ter em conta os regulamentos locais relativos à segurança dos materiais e ao impacto ambiental.

Tabela resumida

| Material | Caso de utilização típico para saber quais são os sinais de avaria de um motor de arranque | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Ligações eléctricas nos motores de arranque | Condutividade elétrica superior | Caro, propenso à corrosão | Alto |

| Aço | Componentes estruturais dos motores de arranque | Durável e económico | propensão para enferrujar sem tratamento | Médio |

| Alumínio | Carcaças e componentes leves | Leve, resistente à corrosão | Menos condutor, menor resistência | Médio |

| Compósitos plásticos | Componentes não estruturais como caixas | Versátil e leve | Resistência limitada a altas temperaturas | Baixo |

Este guia estratégico de seleção de materiais fornece informações valiosas aos compradores B2B, permitindo-lhes tomar decisões informadas com base nas necessidades específicas das suas aplicações e considerações regionais.

Análise aprofundada: Processos de fabrico e garantia de qualidade para quais são os sinais de avaria de um arrancador

Quais são as principais etapas do processo de fabrico de arrancadores?

O processo de fabrico de motores de arranque envolve várias fases críticas que garantem que o produto final cumpre as normas de qualidade e desempenho. Para os compradores B2B, a compreensão destas fases pode fornecer informações sobre a fiabilidade e a durabilidade dos motores de arranque que adquirem.

Preparação de materiais: Que materiais são utilizados no fabrico de arrancadores?

A primeira fase é a preparação do material, onde são selecionadas matérias-primas de alta qualidade. Os materiais comuns para os arrancadores incluem metais como o aço e o alumínio para a caixa, cobre para a cablagem e várias ligas para os componentes internos. Estes materiais são escolhidos pela sua força, condutividade e resistência ao calor e à corrosão. A garantia de qualidade começa aqui, uma vez que o aprovisionamento de fornecedores reputados pode afetar significativamente o desempenho do produto acabado.

Conformação: Como são moldados os arrancadores?

Na fase de conformação, as matérias-primas são submetidas a processos como a maquinagem, a fundição e a estampagem para criar componentes específicos do motor de arranque. A maquinagem envolve o corte e a moldagem de peças metálicas de acordo com especificações precisas, assegurando o seu encaixe perfeito durante a montagem. A fundição permite a criação de formas complexas, nomeadamente para a caixa do motor de arranque. A estampagem é frequentemente utilizada para produzir peças mais pequenas, como suportes e terminais. Esta fase exige tecnologia avançada e mão de obra especializada para manter a precisão e a consistência, que são vitais para um desempenho ótimo.

Montagem: Que técnicas são utilizadas para montar os arrancadores?

A fase de montagem combina todos os componentes formados num arrancador completo. Este processo pode incluir técnicas como a soldadura, a soldadura e a cravação para assegurar as ligações. As linhas de montagem automatizadas são normalmente utilizadas para aumentar a eficiência e reduzir os erros humanos. Os controlos de qualidade durante esta fase são cruciais, uma vez que mesmo pequenos desalinhamentos podem levar à falha do motor de arranque. Os fabricantes utilizam frequentemente especificações de binário e inspecções visuais para garantir que os componentes são montados corretamente.

Acabamento: Como é que o produto final é preparado para distribuição?

O acabamento envolve processos que melhoram a durabilidade e o aspeto estético do arrancador. Isto pode incluir a aplicação de revestimentos protectores para evitar a corrosão, bem como o teste do arrancador em várias condições para garantir que cumpre as normas de desempenho. São realizadas inspecções finais para verificar se existem defeitos ou inconsistências antes de o produto ser embalado para distribuição.

Que normas de controlo de qualidade são essenciais no fabrico de arrancadores?

O controlo de qualidade (CQ) é fundamental no fabrico de motores de arranque, garantindo que cada unidade cumpre as normas internacionais e as expectativas dos clientes. Os compradores B2B devem estar cientes das principais normas e pontos de controlo envolvidos neste processo.

Que normas internacionais devem os compradores B2B procurar?

Uma das normas internacionais mais reconhecidas é a ISO 9001, que define os requisitos para um sistema de gestão da qualidade. A conformidade com a norma ISO 9001 indica que um fabricante implementou processos para fornecer consistentemente produtos que cumprem os requisitos regulamentares e do cliente.

Para além disso, as certificações específicas do sector, como a CE (Conformité Européenne) e a API (American Petroleum Institute), podem fornecer uma garantia adicional da qualidade e segurança do produto. Estas certificações implicam frequentemente testes rigorosos e o cumprimento de critérios de desempenho específicos relevantes para a indústria automóvel.

Quais são os principais pontos de controlo de CQ durante o fabrico?

São estabelecidos pontos de controlo de qualidade em várias fases do processo de fabrico para detetar precocemente quaisquer defeitos.

- Controlo de Qualidade de Entrada (IQC): Este ponto de controlo inicial envolve a inspeção das matérias-primas à chegada para garantir que cumprem as normas de qualidade especificadas.

- Controlo de qualidade em processo (IPQC): Durante o processo de fabrico, o IPQC monitoriza a produção para detetar quaisquer desvios às normas de qualidade. Isto pode incluir a recolha regular de amostras e o ensaio de componentes.

- Controlo de Qualidade Final (FQC): A inspeção final assegura que os arrancadores concluídos funcionam corretamente e cumprem todas as especificações antes de serem expedidos. Isto pode envolver testes de desempenho e inspecções visuais para detetar quaisquer defeitos de superfície.

Que métodos de ensaio são normalmente utilizados no fabrico de arrancadores?

Os fabricantes utilizam vários métodos de teste para verificar a funcionalidade e a fiabilidade dos arrancadores. Os testes mais comuns incluem:

- Testes elétricos: Isto verifica se o motor de arranque funciona corretamente em condições de carga, verificando se existem problemas como consumo excessivo de corrente ou queda de tensão.

- Teste de durabilidade: Os motores de arranque podem ser submetidos a ensaios de desgaste simulado para avaliar a sua longevidade e desempenho ao longo do tempo.

- Ensaios ambientais: Estes testes avaliam a capacidade de resistência do motor de arranque a temperaturas extremas, humidade e vibração, que são factores críticos em aplicações automóveis.

Como os compradores B2B podem verificar as práticas de controlo de qualidade dos fornecedores?

Para os compradores internacionais, particularmente os de África, América do Sul, Médio Oriente e Europa, a verificação das práticas de controlo de qualidade de um fornecedor é essencial para garantir a fiabilidade do produto.

Imagem ilustrativa relacionada com os sinais de avaria do motor de arranque

Que práticas de auditoria devem os compradores implementar?

A realização de auditorias regulares aos fornecedores pode fornecer informações valiosas sobre os seus processos de fabrico e medidas de controlo de qualidade. Os compradores devem considerar a implementação:

- Auditorias a fornecedores: Estas envolvem avaliações no local das instalações de fabrico para avaliar a conformidade com as normas e práticas de qualidade.

- Revisão da documentação: Solicitar o acesso a relatórios de garantia de qualidade, registos de inspeção e certificações pode ajudar a verificar o empenho do fornecedor na qualidade.

Como podem as inspecções por terceiros aumentar a confiança na qualidade?

A contratação de agências de inspeção de terceiros pode garantir que os produtos cumprem as normas de qualidade especificadas. Estas agências podem realizar avaliações independentes e fornecer relatórios objectivos sobre os processos de fabrico e os produtos finais. Esta camada adicional de verificação é particularmente importante para transacções internacionais, onde podem existir barreiras de comunicação.

Que nuances devem os compradores B2B internacionais ter em conta?

Ao adquirir entradas de fornecedores internacionais, os compradores devem estar cientes das potenciais nuances do controlo de qualidade. As diferenças nas normas de fabrico, os requisitos regulamentares e as práticas culturais podem ter impacto na qualidade do produto.

- Conformidade regulamentar: Certifique-se de que os fornecedores cumprem os regulamentos locais e as normas internacionais relevantes para o seu mercado. Isto pode incluir a compreensão de regulamentos específicos do sector automóvel em regiões como a Europa ou o Médio Oriente.

- Considerações culturais: As diferentes regiões podem ter abordagens diferentes em matéria de gestão da qualidade e de serviço ao cliente. Estabelecer uma comunicação e expectativas claras pode ajudar a atenuar os mal-entendidos e garantir um processo de aquisição mais fluido.

Ao compreenderem os processos de fabrico e as medidas de garantia de qualidade envolvidas na produção de starters, os compradores B2B podem tomar decisões mais informadas, assegurando que adquirem produtos fiáveis e de alta qualidade para as suas operações.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘quais são os sinais de que um arrancador está a estragar-se’

Para ajudar os compradores B2B a identificar os sinais de avaria de um motor de arranque, este guia prático de fornecimento fornece uma lista de verificação passo a passo. Compreender estes sinais é crucial para manter a fiabilidade do veículo e minimizar o tempo de inatividade, especialmente nas indústrias que dependem do transporte e da logística.

Imagem ilustrativa relacionada com os sinais de avaria do motor de arranque

Passo 1: Identificar os principais sintomas de falha do motor de arranque

Comece por se familiarizar com os indicadores comuns de uma falha no motor de arranque. Sintomas como um ruído de estalido ao rodar a chave, luzes do painel de instrumentos acesas sem atividade do motor ou arranque lento podem assinalar problemas. O reconhecimento precoce destes sinais pode evitar avarias inesperadas e reparações dispendiosas.

Passo 2: Avaliar o sistema elétrico do veículo

O mau funcionamento do motor de arranque resulta frequentemente de problemas no sistema elétrico. Verifique o estado da bateria, assegurando que está totalmente carregada e sem corrosão. As más ligações podem conduzir a um fornecimento de energia inadequado, agravando os problemas do motor de arranque. A manutenção regular dos componentes eléctricos é essencial para um desempenho ótimo.

Passo 3: Monitorização de ruídos invulgares

Preste atenção a quaisquer sons anómalos durante o processo de arranque. Ruídos de moagem ou estalidos podem indicar que a engrenagem de arranque não está a engatar corretamente ou que existe uma falha interna. A documentação destes ruídos pode fornecer informações valiosas aquando da discussão de problemas com mecânicos ou fornecedores.

Passo 4: Inspecionar o motor de arranque quanto a danos físicos

Efectue uma inspeção visual do motor de arranque. Procure sinais de fugas de óleo, corrosão ou danos físicos na própria unidade. Os motores de arranque encharcados de óleo podem levar a falhas eléctricas e a identificação precoce de fugas pode poupar custos em reparações extensas. Certifique-se de que a área em redor do motor de arranque permanece limpa e sem detritos.

Passo 5: Avaliar as opções de reparação e substituição

Uma vez identificados os sinais de falha do motor de arranque, considere as suas opções de reparação ou substituição. Avalie se o problema pode ser resolvido através de reparações simples ou se é necessária uma substituição completa. Avalie as implicações de custo e o potencial tempo de inatividade associado a cada opção e dê prioridade a soluções que minimizem as interrupções operacionais.

Passo 6: Consultar técnicos qualificados

Recorra a técnicos automóveis certificados, especializados em sistemas de arranque. A sua experiência pode fornecer informações sobre as causas da falha e recomendar soluções adequadas. Esteja preparado para partilhar observações detalhadas sobre os sintomas e qualquer historial de manutenção para facilitar um diagnóstico preciso.

Passo 7: Peças de substituição de qualidade

Se for necessária uma substituição, certifique-se de que obtém peças de arranque de alta qualidade de fornecedores reputados. Verifique as certificações dos fornecedores e as garantias das peças para garantir a fiabilidade e o desempenho. Considere fornecedores com um historial comprovado na sua região para garantir uma entrega e apoio atempados.

Imagem ilustrativa relacionada com os sinais de avaria do motor de arranque

Seguindo esta lista de verificação, os compradores B2B podem identificar eficazmente os sinais de avaria de um motor de arranque, levando a decisões informadas que aumentam a fiabilidade do veículo e a eficiência operacional.

Análise exaustiva dos custos e dos preços para quais são os sinais de um arranque em mau estado Sourcing

Quais são os principais componentes de custo no fornecimento de starters?

Ao adquirir componentes como os motores de arranque, compreender a estrutura de custos é crucial para os compradores B2B internacionais. Os principais componentes de custo incluem:

-

Materiais: As matérias-primas utilizadas no fabrico de motores de arranque, como os metais (cobre, alumínio, aço) e os plásticos, têm um impacto significativo nos preços. Os materiais de maior qualidade que oferecem uma melhor durabilidade e desempenho podem aumentar os custos, mas podem conduzir a um Custo Total de Propriedade (TCO) mais baixo ao longo do tempo.

-

Trabalho: Os custos de mão de obra variam consoante a região e podem afetar o preço global. Em países com custos de mão de obra mais elevados, como partes da Europa, pode verificar-se um aumento dos preços. Por outro lado, o abastecimento em regiões com custos de mão de obra mais baixos pode ser mais económico, mas pode afetar a qualidade.

-

Custos indiretos de produção: Inclui os custos relacionados com as instalações, os serviços públicos e as despesas administrativas. Processos de fabrico eficientes podem ajudar a reduzir os custos gerais, permitindo preços mais competitivos.

-

Ferramentas: Os custos de configuração dos moldes e das ferramentas podem ser significativos, especialmente no caso de arrancadores personalizados. O investimento em ferramentas de alta qualidade pode melhorar a eficiência do fabrico e a qualidade do produto.

-

Controlo de Qualidade (QC): A implementação de medidas rigorosas de controlo de qualidade pode implicar custos adicionais, mas garante que as entradas cumprem as normas de desempenho e segurança necessárias. As certificações (por exemplo, ISO, CE) também podem aumentar o custo, mas são essenciais para garantir a fiabilidade e ganhar a confiança do comprador.

-

Logística: Os custos de envio e de manuseamento são críticos, especialmente para as transacções internacionais. Factores como a distância, o método de envio e os direitos aduaneiros devem ser considerados no preço total.

-

Margem: Os fornecedores acrescentam normalmente uma margem para cobrir os seus riscos e garantir a rentabilidade. Compreender as margens típicas da indústria pode ajudar os compradores a avaliar se estão a receber um preço justo.

Como é que os influenciadores de preços afectam os custos iniciais?

Vários factores influenciam o preço das entradas no mercado B2B:

-

Volume/MOQ: A compra em grandes quantidades conduz frequentemente a custos unitários mais baixos. Os fornecedores podem oferecer descontos com base em quantidades mínimas de encomenda (MOQs), o que pode ser vantajoso para os compradores a granel.

-

Especificações e personalização: Os motores de arranque personalizados, concebidos para aplicações ou veículos específicos, podem aumentar significativamente os custos. Os compradores devem pesar os benefícios da personalização contra a despesa adicional.

-

Materiais e certificações de qualidade: Tal como referido, a escolha dos materiais e a presença de certificações de qualidade podem afetar os preços. Os compradores devem dar prioridade à qualidade para garantir a longevidade e a fiabilidade.

-

Fatores relacionados ao fornecedor: A reputação e a fiabilidade do fornecedor também podem influenciar os preços. Os fornecedores estabelecidos podem cobrar mais devido ao seu historial comprovado, enquanto os fornecedores mais recentes podem oferecer preços competitivos para entrar no mercado.

-

Incoterms: É essencial compreender as condições de envio. Os custos podem variar consoante o comprador ou o vendedor sejam responsáveis pelo envio, seguro e taxas. O conhecimento dos Incoterms pode ajudar os compradores a negociar melhores condições.

Que sugestões do comprador podem melhorar a eficiência de custos no aprovisionamento de entradas?

Para maximizar a relação custo-eficácia na aquisição de entradas, considere as seguintes estratégias:

-

Negociar eficazmente: Estabelecer uma boa relação com os fornecedores pode levar a melhores preços e condições. Não hesite em negociar o preço, especialmente no caso de encomendas em massa ou de contratos a longo prazo.

-

Foco no custo total de propriedade (TCO): Considere não só o custo inicial, mas também as implicações a longo prazo da sua compra. Um motor de arranque de qualidade superior pode custar mais inicialmente, mas pode poupar dinheiro em reparações e substituições.

-

Pesquisar as nuances dos preços regionais: Os preços podem variar significativamente entre regiões devido às condições do mercado local, custos de mão de obra e disponibilidade de materiais. Compreender estas nuances pode ajudar os compradores a tomar decisões informadas.

-

Avaliar a fiabilidade do fornecedor: Avalie sempre a fiabilidade dos potenciais fornecedores. Um preço ligeiramente mais elevado de um fornecedor de confiança pode valer a pena para evitar potenciais problemas de qualidade ou de entrega.

-

Mantenha-se informado sobre as tendências do mercado: Manter-se a par das tendências do sector, como os avanços na tecnologia de arranque ou as alterações nos custos dos materiais, pode ajudar os compradores a tomar decisões de compra estratégicas e atempadas.

Isenção de responsabilidade sobre preços indicativos

Os preços das entradas podem flutuar com base nas condições do mercado, nas negociações com os fornecedores e em factores regionais. É essencial que os compradores efectuem uma pesquisa exaustiva e obtenham várias cotações para garantir preços competitivos.

Análise de alternativas: Comparação de quais são os sinais de avaria de um motor de arranque com outras soluções

Introdução: Compreender as alternativas à identificação de problemas iniciais

Quando se lida com problemas automóveis, particularmente com motores de arranque, é crucial reconhecer os sinais de uma falha no motor de arranque. No entanto, existem métodos e tecnologias alternativas que podem ajudar a diagnosticar ou resolver estes problemas. Esta análise irá comparar os sinais tradicionais de avaria de um motor de arranque com duas soluções alternativas: ferramentas de diagnóstico avançadas e serviços de mecânica móvel. Ao compreender estas alternativas, os compradores B2B podem tomar decisões informadas que se adequem às suas necessidades operacionais.

Tabela comparativa

| Aspecto comparativo | Quais são os sinais de que o motor de arranque está a funcionar mal? | Ferramentas de diagnóstico avançadas | Serviços de mecânica móvel |

|---|---|---|---|

| Desempenho | Identifica sintomas como estalidos ou arranque lento | Fornece diagnósticos precisos através de análise eletrónica | Oferece avaliação e reparações no local |

| Custo | Sem custos diretos; baseia-se na observação | Investimento inicial elevado, mas rentável ao longo do tempo | As taxas de serviço variam; muitas vezes mais caras do que a bricolage |

| Facilidade de implementação | Requer conhecimentos básicos de funcionamento do veículo | Requer formação para interpretar os dados | Cómodo, sem necessidade de transporte |

| Manutenção | Sem manutenção; observacional | Requer calibração e actualizações de software | Custos contínuos das chamadas de serviço |

| Melhor caso de uso | Identificação rápida de problemas no arranque | Diagnóstico abrangente para vários sistemas do veículo | Reparações imediatas sem reboque |

Discriminação detalhada das alternativas

1. Ferramentas de diagnóstico avançadas

As ferramentas de diagnóstico avançadas utilizam software sofisticado para analisar os sistemas electrónicos de um veículo, fornecendo informações precisas sobre potenciais problemas com o motor de arranque. Estas ferramentas ligam-se frequentemente ao computador de bordo do veículo, oferecendo informações que vão para além do desempenho do motor de arranque.

Imagem ilustrativa relacionada com os sinais de avaria do motor de arranque

Prós: Podem diagnosticar vários problemas em vários sistemas, e não apenas no motor de arranque, o que os torna versáteis. Podem poupar tempo e reduzir os erros de diagnóstico.

Contras: O custo inicial de aquisição de ferramentas de diagnóstico pode ser elevado e, muitas vezes, requerem pessoal com formação para funcionar eficazmente. Além disso, a manutenção do software e do hardware pode implicar custos adicionais.

2. Serviços de mecânica móvel

Os serviços de mecânica móvel proporcionam a conveniência de inspecções e reparações no local. Estes profissionais estão equipados para resolver problemas de arranque diretamente no local onde se encontra o veículo, o que pode poupar tempo e eliminar a necessidade de reboque.

Prós: Este serviço é cómodo e pode fornecer soluções imediatas sem que seja necessário deslocar o veículo. É particularmente vantajoso para as empresas com uma frota que requer um tempo de inatividade mínimo.

Contras: O custo dos serviços móveis pode ser mais elevado do que o das reparações tradicionais devido às taxas de deslocação e conveniência. Além disso, a qualidade do serviço pode variar significativamente entre fornecedores, o que pode levar a resultados inconsistentes.

Imagem ilustrativa relacionada com os sinais de avaria do motor de arranque

Conclusão: escolhendo a solução certa para as suas necessidades

Ao selecionar um método para diagnosticar problemas no arranque, os compradores B2B devem considerar o seu contexto operacional específico. Se as soluções imediatas e no local forem cruciais, os serviços de mecânica móvel podem ser a melhor escolha, apesar dos potenciais custos mais elevados. Para as empresas que dão prioridade a diagnósticos abrangentes e têm a capacidade de investir em tecnologia, as ferramentas de diagnóstico avançadas oferecem uma solução sólida a longo prazo. Em última análise, a compreensão dos sinais de avaria de um motor de arranque continua a ser essencial, mas a integração destas soluções alternativas pode aumentar a eficiência operacional e a fiabilidade do veículo.

Propriedades técnicas essenciais e terminologia comercial para quais são os sinais de avaria de um motor de arranque

Quais são as principais propriedades técnicas dos arrancadores em aplicações automóveis?

Ao avaliar os motores de arranque em aplicações automóveis, certas propriedades técnicas são fundamentais para compreender o seu desempenho e fiabilidade. Eis algumas especificações essenciais que os compradores devem considerar:

-

Grau do material

Os arrancadores são normalmente fabricados em aço de alta qualidade ou ligas de alumínio. O grau do material afecta a durabilidade, o peso e a resistência à corrosão do motor de arranque. Por exemplo, um motor de arranque feito de aço de alta qualidade pode suportar melhor as condições adversas sob o capô, garantindo uma vida útil mais longa e menos falhas. -

Tensão nominal

A maioria dos arrancadores para automóveis funciona a 12 volts, mas é essencial confirmar esta especificação em relação ao sistema elétrico do veículo. Uma incompatibilidade pode levar a ineficiências ou a uma falha total. Compreender a classificação da tensão ajuda a garantir a compatibilidade com a bateria e os componentes eléctricos do veículo, crucial para o desempenho e a segurança. -

Especificações de binário

As classificações de binário indicam a capacidade do motor de arranque para fazer arrancar o motor. São necessárias classificações de binário mais elevadas para motores maiores ou com taxas de compressão mais elevadas. Os compradores devem fazer corresponder as especificações de binário do motor de arranque aos requisitos do motor para evitar desgaste prematuro ou avaria. -

Consumo de corrente

Esta especificação refere-se à quantidade de corrente eléctrica que o motor de arranque consome durante o funcionamento, normalmente medida em amperes. Um consumo de corrente elevado pode indicar ineficiências ou problemas subjacentes, tais como um motor de arranque ou uma bateria avariados. A monitorização do consumo de corrente é crucial para diagnosticar precocemente potenciais problemas e garantir um desempenho ótimo. -

Classificação de temperatura

Os arrancadores são concebidos para funcionar dentro de intervalos de temperatura específicos. Uma classificação de alta temperatura garante que o motor de arranque pode funcionar eficazmente em condições extremas, como em regiões com temperaturas ambiente elevadas. A compreensão desta classificação ajuda os compradores a selecionar motores de arranque que possam suportar o ambiente operacional dos seus veículos. -

Tempo de vida (classificação de ciclo)

Esta propriedade estima o número de ciclos de arranque que um arrancador pode suportar antes de falhar. Uma classificação de ciclo mais elevada significa um produto mais fiável que pode suportar uma utilização frequente. Os compradores em ambientes B2B devem dar prioridade a arrancadores com classificações de vida útil comprovadas para minimizar os custos de manutenção e o tempo de inatividade.

Quais são os termos comerciais comuns relacionados com os arrancadores?

Compreender o jargão da indústria é vital para uma comunicação e negociação eficazes no sector automóvel B2B. Aqui estão alguns termos comerciais comuns com os quais os compradores devem estar familiarizados:

Imagem ilustrativa relacionada com os sinais de avaria do motor de arranque

-

OEM (Fabricante de Equipamento Original)

Este termo refere-se a peças fabricadas pelo fabricante original do veículo. Os motores de arranque OEM são frequentemente preferidos devido à sua compatibilidade e qualidade garantidas. A compreensão das normas OEM ajuda os compradores a tomar decisões informadas sobre a fiabilidade e o desempenho das peças que estão a adquirir. -

MOQ (Quantidade mínima de encomenda)

É a quantidade mais pequena de um produto que um fornecedor está disposto a vender. Conhecer o MOQ é crucial para que os compradores possam gerir eficazmente os níveis de inventário e garantir que estão a comprar quantidades suficientes para satisfazer a procura sem excesso de stock. -

RFQ (Pedido de Orçamento)

Um pedido de cotação é um documento enviado aos fornecedores solicitando cotações de preços para produtos específicos. O envio de RFQs permite aos compradores comparar preços e condições de diferentes fornecedores, ajudando na seleção das melhores opções de fornecimento. -

Incoterms (Termos Comerciais Internacionais)

Trata-se de termos comerciais padronizados que definem as responsabilidades de compradores e vendedores em transacções internacionais. A familiaridade com os Incoterms ajuda os compradores a compreender os custos de envio, a transferência de riscos e as responsabilidades de entrega, cruciais para o planeamento orçamental e logístico. -

Mercado pós-venda

Este termo refere-se a peças e acessórios não fabricados pelo OEM, mas concebidos para se adaptarem e funcionarem no veículo. Os motores de arranque do mercado de substituição podem oferecer alternativas económicas, mas podem variar em termos de qualidade e desempenho. Os compradores devem avaliar as vantagens e desvantagens ao considerarem as opções do mercado de substituição. -

Garantia

Trata-se de uma garantia fornecida pelo fabricante relativamente à qualidade e durabilidade do produto. Compreender os termos da garantia é essencial para que os compradores protejam o seu investimento e possam resolver os problemas que possam surgir.

Ao compreenderem estas propriedades técnicas e termos comerciais, os compradores B2B podem tomar decisões informadas relativamente às compras de starters, garantindo que selecionam os produtos certos para as suas necessidades específicas e contextos operacionais.

Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector Quais são os sinais de que um arranque está a correr mal?

Quais são as actuais dinâmicas de mercado e as principais tendências para os compradores B2B que se concentram em questões de arranque?

No sector automóvel, em particular no que diz respeito aos motores de arranque, o mercado está a assistir a transformações significativas impulsionadas pelos avanços tecnológicos e pela evolução das expectativas dos consumidores. Os compradores B2B internacionais, especialmente de regiões como a África, a América do Sul, o Médio Oriente e a Europa, dão cada vez mais prioridade ao fornecimento fiável de componentes automóveis. As principais tendências incluem o surgimento de plataformas digitais que facilitam a compra direta aos fabricantes, permitindo aos compradores aceder a uma gama mais vasta de produtos e comparar preços de forma eficaz. Além disso, a integração da análise de dados e da tecnologia IoT está a melhorar as capacidades de diagnóstico dos sistemas de arranque, permitindo uma melhor identificação de potenciais falhas antes de estas ocorrerem.

As tecnologias emergentes, como as ferramentas de manutenção preditiva, estão a tornar-se cada vez mais relevantes, ajudando as empresas a antecipar problemas relacionados com os motores de arranque e a reduzir o tempo de inatividade. Isto é particularmente crucial em regiões onde a fiabilidade dos veículos é essencial para as actividades económicas. Além disso, a sustentabilidade está a moldar as estratégias de abastecimento, com os compradores a favorecerem os fabricantes que aderem a práticas ecológicas na produção e na logística. A crescente procura de veículos eléctricos (EVs) também influencia o mercado de motores de arranque, uma vez que os sistemas de arranque tradicionais estão a evoluir para acomodar novas tecnologias, apresentando oportunidades para parcerias B2B na cadeia de fornecimento.

Como é que a sustentabilidade e o fornecimento ético podem afetar os compradores B2B no sector de arranque?

A sustentabilidade e o abastecimento ético tornaram-se primordiais na indústria automóvel, com implicações significativas para os compradores B2B que lidam com componentes de arranque. O impacto ambiental dos processos de fabrico, incluindo o consumo de energia e a produção de resíduos, está a ser analisado. Os compradores estão a procurar cada vez mais fornecedores que implementem práticas sustentáveis, como a utilização de materiais reciclados ou a minimização das emissões durante a produção. Esta mudança não só beneficia o planeta, como também melhora a reputação da marca e alinha-se com as preferências dos consumidores por produtos ambientalmente responsáveis.

Para além disso, as cadeias de abastecimento éticas são fundamentais para garantir práticas laborais justas ao longo do processo de produção. Os compradores são encorajados a estabelecer parcerias com fabricantes que ofereçam transparência relativamente às suas práticas de abastecimento, condições de trabalho e envolvimento da comunidade. Certificações como a ISO 14001 para gestão ambiental e comércio justo podem servir como indicadores do compromisso de um fornecedor com práticas sustentáveis. Ao dar prioridade a parceiros com estas certificações, os compradores B2B podem mitigar os riscos associados ao fornecimento não ético e contribuir para uma indústria automóvel mais sustentável.

Qual é a evolução dos sistemas de arranque no sector automóvel?

A evolução dos sistemas de arranque no sector automóvel reflecte avanços significativos em termos de tecnologia e engenharia. Inicialmente, os motores de arranque eram simples motores eléctricos concebidos para ligar o motor. No entanto, à medida que os veículos se tornaram mais sofisticados, os motores de arranque evoluíram para se integrarem em sistemas electrónicos mais amplos, incluindo a gestão e o diagnóstico do motor. Esta transição tem sido particularmente evidente no surgimento de motores de arranque de alto desempenho concebidos para veículos modernos, incluindo híbridos e veículos eléctricos.

A introdução da tecnologia inteligente também transformou os sistemas de arranque, permitindo funcionalidades como o arranque remoto e mecanismos de segurança melhorados. Estes desenvolvimentos não só melhoram a experiência do utilizador, como também exigem uma mudança nas estratégias de abastecimento dos compradores B2B. Compreender estas mudanças é crucial para as empresas que procuram manter-se competitivas num mercado em rápida evolução, uma vez que têm de adaptar as suas práticas de compra para se alinharem com as mais recentes tecnologias e exigências dos consumidores.

Ao manterem-se informados sobre estas tendências, os compradores podem tomar decisões estratégicas que melhorem as suas operações e se alinhem com as expectativas do mercado, garantindo que se mantêm na vanguarda da indústria automóvel.

Imagem ilustrativa relacionada com os sinais de avaria do motor de arranque

Perguntas frequentes (FAQs) para compradores B2B sobre quais são os sinais de avaria de um motor de arranque

-

Quais são os sinais mais comuns de avaria do motor de arranque?

Os sinais típicos de um motor de arranque avariado incluem um som de clique quando a ignição é ligada, o motor não arranca ou problemas de arranque intermitentes. Uma manivela lenta também pode indicar que o motor de arranque está a ter dificuldades em funcionar corretamente. Além disso, o fumo ou as fugas de óleo em redor da área do motor de arranque podem indicar problemas graves que podem levar a reparações dispendiosas se não forem resolvidos de imediato. A monitorização destes sinais pode ajudar a evitar avarias inesperadas e facilitar reparações atempadas. -

Posso dar o arranque ao meu veículo se o motor de arranque estiver a funcionar mal?

O arranque por ressalto de um veículo com um motor de arranque avariado é geralmente ineficaz, uma vez que este método fornece principalmente energia à bateria e não ao motor de arranque propriamente dito. Se o motor de arranque estiver a falhar, pode não engatar mesmo com um arranque auxiliar. Nestes casos, é aconselhável diagnosticar o problema do motor de arranque antes de tentar efetuar qualquer arranque assistido para evitar potenciais complicações ou danos adicionais no sistema elétrico do veículo. -

Como posso determinar se o problema é o motor de arranque ou a bateria?

Para distinguir entre um problema de arranque e um problema de bateria, utilize um voltímetro para verificar a tensão da bateria. Uma bateria totalmente carregada deve ter pelo menos 12,6 volts. Se a bateria estiver forte mas o motor não arrancar, isso indica provavelmente uma falha no motor de arranque. Além disso, procure sons de clique; um ruído de clique aponta frequentemente para um problema no motor de arranque, enquanto um arranque lento pode sugerir uma bateria fraca. -

O que devo procurar ao selecionar fornecedores para iniciantes?

Ao adquirir entradas, é essencial avaliar os potenciais fornecedores com base na sua reputação, qualidade do produto e conformidade com as normas internacionais. Procure fornecedores com críticas positivas, certificações e um historial de fiabilidade. Além disso, informe-se sobre os seus processos de garantia de qualidade, políticas de garantia e apoio pós-venda para garantir que está a fazer um bom investimento. -

Que opções de personalização devo ter em conta quando forneço entradas?

A personalização pode desempenhar um papel vital para garantir que os motores de arranque cumprem os requisitos específicos do veículo ou as normas de desempenho. Discuta com o seu fornecedor opções como diferentes tamanhos, tensões nominais e materiais. Além disso, informe-se sobre a possibilidade de marca ou embalagem que se alinhe com as necessidades da sua empresa, uma vez que estes factores podem melhorar as ofertas de produtos e a sua comercialização. -

Qual é a quantidade mínima de encomenda (MOQ) para as entradas dos fornecedores?

O MOQ para iniciantes pode variar significativamente entre fornecedores, muitas vezes dependendo das suas capacidades de fabrico e níveis de inventário. É aconselhável discutir antecipadamente as suas necessidades com os potenciais fornecedores para negociar condições favoráveis. Alguns fornecedores podem ser flexíveis com os MOQs para as primeiras encomendas, especialmente se estiver a estabelecer uma relação comercial a longo prazo. -

Que condições de pagamento devo esperar quando forneço entradas a nível internacional?

As condições de pagamento podem variar muito entre fornecedores internacionais. As opções mais comuns incluem pagamento antecipado, cartas de crédito e pagamento aquando da entrega. Discutir estas condições durante as negociações iniciais é crucial para garantir clareza e compreensão mútua. Além disso, considere o impacto das taxas de câmbio e das taxas de transação nos seus custos globais quando se envolver no comércio internacional. -

Como é que a logística afecta a aquisição de entradas para a minha empresa?

A logística desempenha um papel fundamental na entrega atempada de entradas. Factores como os métodos de envio, o desalfandegamento e os prazos de entrega podem afetar a eficiência da sua cadeia de abastecimento. Certifique-se de que o seu fornecedor tem um parceiro logístico fiável e que pode fornecer informações de seguimento transparentes. É também vantajoso discutir as políticas de devolução e o tratamento de potenciais danos durante o transporte para salvaguardar o seu investimento.

Top 2 Quais são os sinais de que um motor de arranque está a ficar estragado Lista de fabricantes e fornecedores

1. Reddit - Problemas com o motor de arranque

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: Esta empresa, Reddit - Starter Issues, é uma entidade notável no mercado. Para obter detalhes específicos do produto, recomenda-se que visite diretamente o seu sítio Web.

2. Northrich Automotive - Serviços de reparação de motores de arranque de automóveis

Domínio: northrichauto.com

Registada: 2001 (24 anos)

Introdução: A Northrich Automotive oferece serviços de reparação automóvel, incluindo diagnósticos e reparações relacionadas com motores de arranque avariados. Os principais sinais de um motor de arranque avariado incluem arranque lento, recusa de arranque, problemas de arranque intermitente, luzes interiores fracas, ruídos de trituração, sons de choramingos, funcionamento contínuo após o arranque, cheiro a queimado e fugas de óleo no sistema de arranque. Se estes problemas estiverem presentes, é...

Strategic Sourcing Conclusion and Outlook for quais são os sinais de um arranque que está a correr mal

Em conclusão, reconhecer os sinais de uma falha do motor de arranque é essencial para manter a eficiência operacional na gestão da sua frota ou veículo. Indicadores-chave como luzes de aviso no painel de instrumentos, ruídos de clique, arranque lento ou fugas de óleo visíveis podem sinalizar uma falha iminente do motor de arranque. Ao compreender estes sintomas, as empresas podem obter estrategicamente peças de substituição ou serviços antes de ocorrer uma avaria completa, minimizando o tempo de inatividade e os custos de reparação.

O sourcing estratégico não só aumenta a eficiência da cadeia de fornecimento, como também promove relações com fornecedores fiáveis que podem fornecer componentes de qualidade adaptados às suas necessidades específicas. À medida que os compradores B2B internacionais de regiões como África, América do Sul, Médio Oriente e Europa navegam pelas complexidades da aquisição de peças para automóveis, é imperativo dar prioridade a parcerias que garantam uma entrega atempada e apoio especializado.

Olhando para o futuro, considere a integração de verificações de manutenção regulares nos seus protocolos operacionais. Esta abordagem proactiva não só prolongará a vida útil dos seus motores de arranque, como também melhorará a fiabilidade geral do veículo. Recorra a fornecedores de confiança que compreendam as exigências específicas do seu mercado e se mantenham à frente de potenciais problemas. A adoção destas medidas permitirá à sua empresa funcionar sem problemas e de forma eficaz num cenário cada vez mais competitivo.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.