Introduction: Navigating the Global Market for how do you tap a starter

When faced with the challenge of ensuring vehicle reliability across diverse markets, understanding how to tap a starter becomes crucial for international B2B buyers. This guide delves into the intricacies of sourcing, maintaining, and troubleshooting starter systems, specifically designed for those operating in regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Nigeria. As businesses increasingly rely on transportation to facilitate trade and logistics, the ability to quickly diagnose and address starter issues can significantly reduce downtime and enhance operational efficiency.

In the following sections, we will explore various types of starters, their applications in different vehicle models, and the common problems associated with them. We will also provide insights on effective supplier vetting processes to ensure quality components and services. Additionally, an overview of cost considerations will be included, enabling informed purchasing decisions that align with your budgetary constraints and operational needs.

This comprehensive guide empowers B2B buyers by equipping them with the knowledge necessary to navigate the global market confidently, ensuring that they can maintain their fleets in optimal condition while minimizing disruptions. By understanding how to effectively address starter issues, businesses can enhance their service delivery and maintain a competitive edge in their respective industries.

Table Of Contents

- Top 2 How Do You Tap A Starter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do you tap a starter

- Understanding how do you tap a starter Types and Variations

- Key Industrial Applications of how do you tap a starter

- 3 Common User Pain Points for ‘how do you tap a starter’ & Their Solutions

- Strategic Material Selection Guide for how do you tap a starter

- In-depth Look: Manufacturing Processes and Quality Assurance for how do you tap a starter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you tap a starter’

- Comprehensive Cost and Pricing Analysis for how do you tap a starter Sourcing

- Alternatives Analysis: Comparing how do you tap a starter With Other Solutions

- Essential Technical Properties and Trade Terminology for how do you tap a starter

- Navigating Market Dynamics and Sourcing Trends in the how do you tap a starter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do you tap a starter

- Strategic Sourcing Conclusion and Outlook for how do you tap a starter

- Important Disclaimer & Terms of Use

Understanding how do you tap a starter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gentle Tapping | Light taps on the solenoid area to dislodge stuck gears. | Emergency vehicle repairs | Pros: Quick fix; minimal tools needed. Cons: Temporary solution; may require replacement soon. |

| Firm Tapping | More pronounced hits on the starter motor casing. | Fleet maintenance and repair shops | Pros: Can provide a longer-lasting temporary fix. Cons: Risk of damaging components if too forceful. |

| Electrical Connection Jarring | Tapping while attempting to start the engine to create a connection. | Automotive troubleshooting | Pros: Can restore functionality briefly. Cons: Requires coordination; not a permanent fix. |

| Corrosion Cleaning | Using tapping along with cleaning terminals to improve contact. | Routine maintenance for older vehicles | Pros: Improves connections; prolongs starter life. Cons: Labor-intensive; may need professional help. |

| Diagnostic Tapping | Tapping to diagnose issues by observing starter response. | Automotive diagnostics and repair | Pros: Helps identify specific problems. Cons: Requires experience to interpret results accurately. |

What Are the Characteristics of Gentle Tapping for Starters?

Gentle tapping is a quick and effective method often used in emergencies to temporarily revive a failing starter motor. This technique involves lightly tapping the solenoid area with a tool, such as a tire iron or hammer, to dislodge any stuck gears. It is particularly suitable for B2B applications in emergency vehicle repairs, as it requires minimal tools and can be performed quickly. Buyers should consider that while this method is effective in the short term, it is not a permanent solution, and the starter may need replacement soon thereafter.

How Does Firm Tapping Differ and When Is It Used?

Firm tapping involves applying more pronounced hits to the starter motor casing, which can help if the starter is more severely stuck. This technique is often used in fleet maintenance and repair shops, where quick fixes are necessary to minimize downtime. While this method can provide a longer-lasting temporary fix compared to gentle tapping, buyers should be cautious, as excessive force may lead to damage to the starter or surrounding components.

What Is the Purpose of Electrical Connection Jarring?

Electrical connection jarring is a technique where tapping occurs while attempting to start the engine. This method is often employed in automotive troubleshooting to create a temporary electrical connection when the starter solenoid is malfunctioning. It is particularly useful for mechanics and technicians looking to diagnose starter issues in a quick and efficient manner. However, this approach requires coordination and may not yield a permanent fix, making it essential for buyers to have a backup plan for repairs.

How Can Corrosion Cleaning Enhance Starter Performance?

Corrosion cleaning involves tapping the starter while simultaneously cleaning the connection terminals, which can significantly improve electrical contact. This method is especially relevant for routine maintenance of older vehicles that may have accumulated corrosion over time. While it can prolong the starter’s life and enhance performance, this approach may be labor-intensive and could require professional assistance, which buyers should factor into their maintenance budgets.

What Insights Can Be Gained from Diagnostic Tapping?

Diagnostic tapping is a technique used to diagnose specific issues with a starter by observing its response to taps. This method is valuable for automotive diagnostics and repair, allowing technicians to identify whether the problem lies with the starter itself or other components. While it offers insights into the starter’s condition, it requires experience and expertise to interpret the results accurately, making it more suitable for professional mechanics and repair shops rather than casual users.

Key Industrial Applications of how do you tap a starter

| Industry/Sector | Specific Application of how do you tap a starter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Emergency starter activation during repairs | Reduces downtime for vehicle repairs, enhancing service efficiency | Availability of tools and expertise; sourcing local mechanics or tools. |

| Transportation & Logistics | Quick fixes for fleet vehicles in transit | Minimizes delays and costs associated with vehicle breakdowns | Reliable access to tools and training for staff; stock of spare parts. |

| Agriculture | Restarting farm equipment during critical operations | Ensures continuous operation during peak seasons, reducing loss | Need for durable tools that withstand harsh environments; training for operators. |

| Construction | Tapping starters on heavy machinery for immediate use | Enhances productivity by reducing equipment downtime on site | Access to specialized tools and training; consideration for safety protocols. |

| Mining | Quick troubleshooting of machinery in remote locations | Maintains operational efficiency and reduces lost production time | Sourcing robust tools; ensuring availability of replacement parts in remote areas. |

How is Tapping a Starter Used in the Automotive Repair Industry?

In the automotive repair sector, tapping a starter serves as an immediate troubleshooting technique for vehicles that fail to start. Mechanics often utilize this method as a temporary solution to dislodge a stuck starter solenoid, particularly in cold weather or after prolonged inactivity. This approach not only allows for quick diagnostics but also minimizes service time, ultimately improving customer satisfaction. For international B2B buyers, sourcing reliable tools and ensuring mechanics are trained in this technique can enhance repair shop efficiency and customer trust.

What Role Does Tapping a Starter Play in Transportation and Logistics?

In the transportation and logistics industry, tapping a starter can be crucial for fleet management. When vehicles experience starting issues during transit, a quick tap can temporarily resolve the problem, allowing drivers to continue their route without significant delays. This practice helps companies avoid costly downtime and maintain schedules. For businesses operating in regions like Africa and South America, it is vital to ensure that drivers are trained in basic mechanical troubleshooting and that tools are readily available for quick fixes.

How is Tapping a Starter Applied in Agriculture?

In agriculture, tapping a starter can be a lifesaver for essential machinery like tractors and harvesters, especially during critical planting or harvesting seasons. When equipment fails to start, a simple tap can often get it running again, preventing costly delays in production. For agricultural businesses, sourcing durable tools that can withstand outdoor conditions and training operators on quick fixes is essential to ensure uninterrupted operations.

Why is Tapping a Starter Important in Construction?

Construction sites often rely on heavy machinery that can be prone to starting issues. Tapping a starter can provide a quick workaround to get machinery operational without waiting for repairs, thus enhancing overall productivity. For construction companies, ensuring that operators are equipped with the right tools and knowledge to perform these quick fixes can lead to significant time and cost savings. Buyers should consider the availability of robust tools and appropriate safety training for their workforce.

How Does Tapping a Starter Benefit the Mining Industry?

In the mining industry, where equipment is frequently used in remote locations, tapping a starter can help troubleshoot machinery failures that could otherwise halt production. This quick fix can be essential for maintaining operational efficiency, especially when waiting for professional repairs is not feasible. For international buyers, sourcing rugged tools that can withstand harsh mining environments, along with ensuring a supply of spare parts, is crucial for minimizing downtime and maintaining productivity.

3 Common User Pain Points for ‘how do you tap a starter’ & Their Solutions

Scenario 1: Difficulty Diagnosing Starter Issues in Cold Weather

The Problem: As a B2B buyer operating in regions with extreme weather conditions, such as parts of Europe and North America, diagnosing starter issues can be particularly challenging. Cold temperatures often exacerbate starter malfunctions, leading to misdiagnosis. Buyers may face a scenario where their fleet of vehicles exhibits intermittent starting issues, and the pressure to maintain operational efficiency can result in hasty decisions that overlook the underlying problem. This situation is not only frustrating but can also lead to costly repairs if the root cause is not correctly identified.

The Solution: To effectively address starting issues during cold weather, B2B buyers should implement a systematic diagnostic approach. Begin by educating your maintenance team on the symptoms of a failing starter, such as a single click or dimming interior lights when attempting to start the vehicle. Encourage them to perform regular inspections of the starter solenoid and electrical connections, particularly during seasonal transitions. A practical step involves using a multimeter to check voltage levels at the battery and starter terminals. If low voltage is detected, consider tapping the starter gently with a rubber mallet to dislodge any stuck components, which can sometimes restore functionality temporarily. However, emphasize the importance of scheduling a thorough inspection and potential replacement of the starter as a long-term solution.

Scenario 2: Managing Fleet Maintenance Costs with Starter Repairs

The Problem: B2B buyers managing fleets often struggle with balancing maintenance costs and vehicle uptime. A common pain point arises when multiple vehicles experience starter problems, leading to downtime and repair expenses that can quickly escalate. The challenge is further complicated by the need to source quality replacement parts without inflating the budget, especially for companies operating in emerging markets where parts availability may be limited or expensive.

The Solution: To mitigate costs while ensuring reliable fleet operation, B2B buyers should establish partnerships with reputable suppliers of automotive parts who can provide quality starters at competitive prices. Develop a proactive maintenance schedule that includes regular checks of the starter systems to catch issues before they escalate. When a starter issue is identified, consider employing the temporary tapping method as a diagnostic tool to assess if the problem is a quick fix or indicative of a more significant issue. This allows for immediate action while waiting for parts, reducing downtime. Additionally, consider investing in training for your maintenance staff on identifying early signs of starter failure and the appropriate methods to tap starters safely. This not only empowers your team but can also lead to substantial savings in repair costs over time.

Scenario 3: Ensuring Quality Control in Starter Replacement Processes

The Problem: For B2B buyers involved in automotive services or repair shops, ensuring quality control during starter replacements can be a significant concern. Inadequate or incorrect installation of starters can lead to recurring issues, frustrated customers, and damage to the vehicle’s electrical system. This scenario is particularly pressing for businesses that pride themselves on delivering high-quality service and maintaining a solid reputation.

The Solution: To enhance quality control in starter replacement, develop a comprehensive checklist for your technicians to follow during the installation process. This should include verifying the compatibility of the new starter with the vehicle model, inspecting all electrical connections for corrosion, and ensuring that the battery voltage is adequate before the installation. Encourage the practice of performing a “tap test” on the old starter before removal to confirm if it was indeed the source of the issue. If the vehicle starts after a few taps, it may indicate a need for additional troubleshooting rather than a simple replacement. Implementing a feedback loop where technicians document and share their experiences with starter replacements can also foster continuous improvement and knowledge sharing within your team. By prioritizing thorough installation practices, you can significantly reduce the risk of future issues and enhance customer satisfaction.

Strategic Material Selection Guide for how do you tap a starter

What Materials Are Commonly Used for Tapping Starters?

When considering how to tap a starter effectively, the choice of materials for the tools used can significantly influence performance and durability. Here, we analyze four common materials: steel, aluminum, brass, and composite materials. Each has distinct properties, advantages, and disadvantages that can affect their suitability for this specific automotive task.

1. Steel: The Traditional Choice for Durability

Key Properties: Steel is known for its high tensile strength and durability, making it resistant to deformation under pressure. It typically has a temperature rating that can withstand extreme conditions, which is beneficial in automotive applications.

Pros & Cons: Steel tools are generally more durable and can handle repeated impacts without significant wear. However, they are heavier than other materials, which may affect maneuverability. The cost of steel tools can vary, but they are often more affordable than specialized alloys.

Impact on Application: Steel’s corrosion resistance can be a concern, especially in humid or salty environments. Proper maintenance and coatings can mitigate these issues, but international buyers should be aware of local conditions that may accelerate corrosion.

Specific Considerations for International Buyers: Compliance with standards such as ASTM A36 for structural steel is crucial. Buyers in regions like Germany and Nigeria should ensure that the steel tools meet local regulations and quality standards.

2. Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight and has excellent corrosion resistance, making it suitable for various environments. It can withstand moderate temperatures but may not perform well under extreme conditions compared to steel.

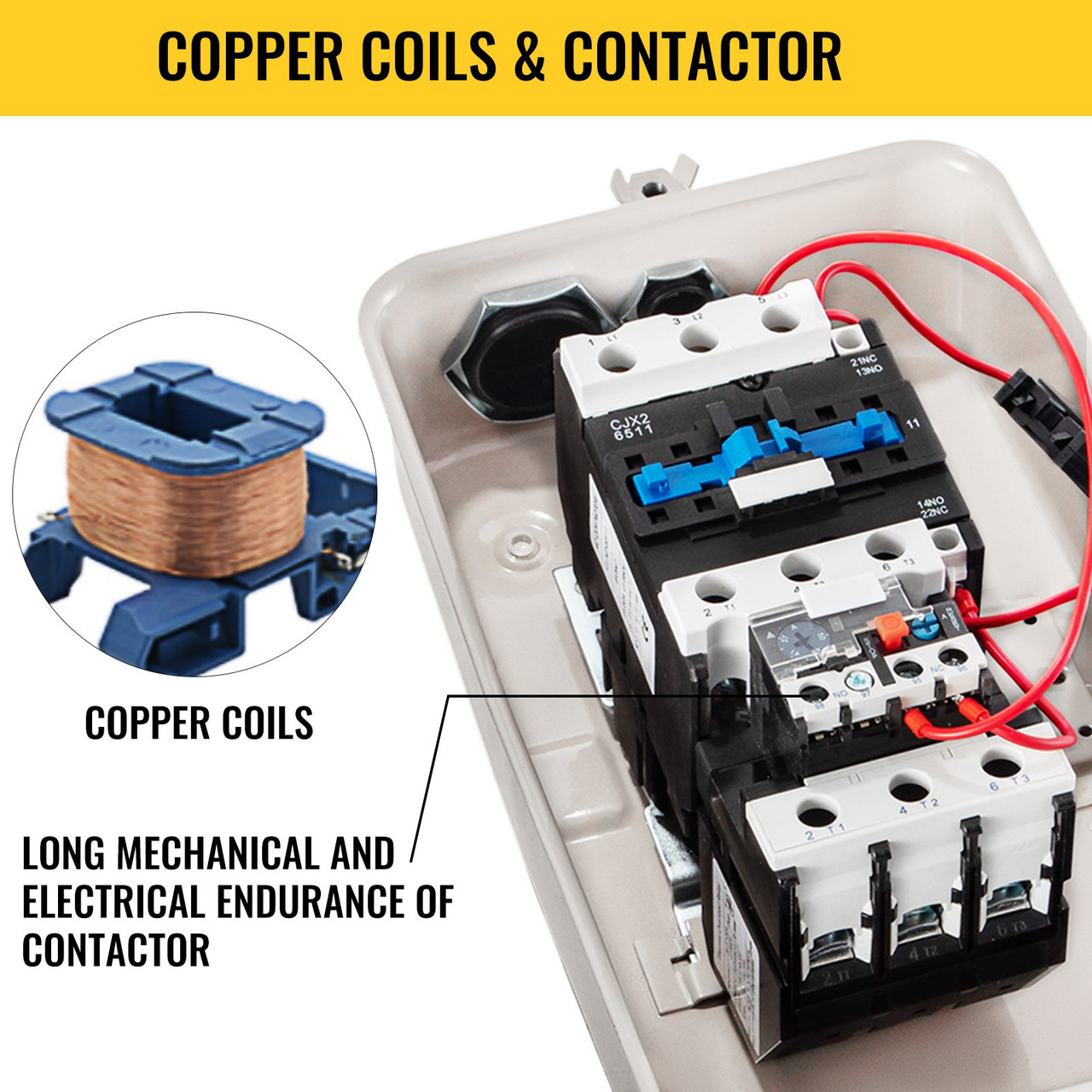

Illustrative image related to how do you tap a starter

Pros & Cons: The primary advantage of aluminum tools is their lightweight nature, making them easier to handle. However, they are less durable than steel and can deform under heavy impact. The cost is generally higher than steel, which can be a factor for budget-conscious buyers.

Impact on Application: Aluminum’s compatibility with electrical components is beneficial, as it doesn’t create magnetic interference. However, its lower strength means that it may not be suitable for heavy-duty applications.

Specific Considerations for International Buyers: Buyers should look for compliance with standards like ASTM B221 for aluminum extrusions. In regions like South America, where humidity levels can be high, aluminum’s corrosion resistance can be a significant advantage.

3. Brass: A Unique Option with Electrical Properties

Key Properties: Brass is an alloy of copper and zinc, known for its excellent electrical conductivity and corrosion resistance. It can handle moderate temperatures and is often used in electrical applications.

Pros & Cons: The key advantage of brass is its resistance to corrosion, particularly in marine environments. However, it is softer than steel and can wear out more quickly under heavy use. Brass tools tend to be more expensive due to the cost of raw materials.

Impact on Application: Brass’s conductivity makes it suitable for tapping starters, especially in applications where electrical connections are crucial. However, its softness can limit its use in high-impact scenarios.

Specific Considerations for International Buyers: Compliance with standards such as ASTM B36 for brass is essential. Buyers in the Middle East should consider the environmental conditions that could affect brass’s longevity.

4. Composite Materials: The Modern Alternative

Key Properties: Composite materials are engineered for specific properties, such as lightweight construction and high strength-to-weight ratios. They often have excellent corrosion resistance and can withstand a range of temperatures.

Pros & Cons: The primary advantage of composites is their versatility and lightweight nature. However, they can be more expensive to manufacture and may not be as widely available as traditional materials.

Impact on Application: Composites can be designed to meet specific media compatibility requirements, making them suitable for various automotive applications. However, their performance under heavy impact may not match that of metal tools.

Specific Considerations for International Buyers: Buyers should ensure that composite tools meet relevant standards, such as ASTM D638 for tensile properties. In Europe, the preference for innovative materials may favor the adoption of composites.

Summary Table of Material Selection for Tapping Starters

| Material | Typical Use Case for how do you tap a starter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General tapping and automotive repairs | High durability and strength | Heavier, potential corrosion | Low |

| Aluminum | Lightweight applications and ease of use | Excellent corrosion resistance | Less durable under heavy impact | Medium |

| Brass | Electrical applications and corrosion-prone areas | Good conductivity and corrosion resistance | Softer, wears out faster | High |

| Composite | Versatile applications with specific needs | Lightweight and customizable properties | Higher manufacturing costs | Medium to High |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their tool choices for tapping starters, considering the unique demands of their regional markets.

Illustrative image related to how do you tap a starter

In-depth Look: Manufacturing Processes and Quality Assurance for how do you tap a starter

What Are the Key Manufacturing Processes for Tapping a Starter?

Manufacturing a starter involves several critical stages that ensure the final product is reliable and effective. Understanding these processes can help B2B buyers from regions such as Africa, South America, the Middle East, and Europe make informed decisions when sourcing starters for their businesses.

What Are the Main Stages of Starter Manufacturing?

-

Material Preparation: The first stage involves selecting high-quality materials, typically metals such as steel and copper, which are essential for durability and conductivity. Suppliers must ensure that raw materials meet international standards, as the quality of materials directly impacts the performance and longevity of the starter.

-

Forming: In this phase, materials undergo various forming processes such as stamping, machining, and casting. Stamping is often used to create the outer casing and internal components, while precision machining is employed for parts like the armature and commutator. This stage is crucial as it defines the dimensional accuracy of components, which is vital for the starter’s functionality.

-

Assembly: Once the components are formed, they are assembled into the final product. This process may involve manual assembly or automated systems, depending on the manufacturer. Key components like the starter motor, solenoid, and wiring harness are integrated during this stage. The assembly process must be executed with precision to ensure that all parts fit and function correctly.

-

Finishing: After assembly, starters undergo finishing processes such as painting, plating, or coating. These processes not only enhance the aesthetic appeal but also provide protection against corrosion and wear. Quality control measures during finishing are essential to ensure that the coatings are applied uniformly and effectively.

What Key Techniques Are Used in Starter Manufacturing?

Manufacturers employ various techniques to enhance efficiency and quality in starter production. Automation plays a significant role in processes like forming and assembly, reducing human error and increasing throughput. Additionally, techniques such as lean manufacturing and Six Sigma are often implemented to streamline operations and minimize waste.

How Is Quality Assurance Managed in Starter Production?

Quality assurance is a crucial component of starter manufacturing. It ensures that products meet both industry and international standards, which is vital for building trust with B2B buyers.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards, such as:

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization, regardless of size or industry. It emphasizes continuous improvement and customer satisfaction.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with safety, health, and environmental protection standards.

- API Standards: For starters used in the automotive and industrial sectors, compliance with American Petroleum Institute (API) standards is often required.

Understanding these standards helps buyers assess the reliability and safety of the products they are sourcing.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to ensuring that starters meet the required specifications. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials and components before they enter the production process. Rigorous testing and documentation are essential at this stage to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC monitors key parameters such as dimensions, assembly accuracy, and functional testing. This ensures that any defects are identified and rectified early in the process.

-

Final Quality Control (FQC): Before the starters are packaged and shipped, FQC involves comprehensive testing of the final product. This includes performance tests, visual inspections, and compliance checks against relevant standards.

What Testing Methods Are Commonly Used in Starter Quality Control?

Several testing methods are employed to ensure that starters perform reliably:

- Functional Testing: This involves testing the starter under conditions that simulate real-world usage to ensure it engages and disengages properly.

- Electrical Testing: Measuring the electrical resistance and current draw helps identify issues related to the solenoid and motor.

- Durability Testing: Starters may undergo cycling tests to assess their performance under repeated use, simulating wear over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, ensuring that suppliers adhere to stringent quality control measures is paramount. Here are ways to verify supplier QC:

Illustrative image related to how do you tap a starter

-

Audits: Conducting regular audits of suppliers can help buyers assess their manufacturing processes and quality control systems. This includes reviewing documentation related to quality standards and testing results.

-

Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes and the results of their testing. This documentation should be transparent and readily available.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s quality control measures. These inspections can be particularly beneficial for buyers in regions where local standards may differ from international norms.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from diverse regions may encounter specific challenges related to quality control. For instance:

-

Cultural Differences: Understanding the local manufacturing culture is crucial. Some regions may prioritize speed over quality, leading to potential issues in product reliability.

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers should be aware of local standards and ensure that suppliers comply with both local and international regulations.

-

Logistical Challenges: Importing products across borders can introduce additional quality risks, including damage during transit. Establishing clear quality expectations and inspection protocols can mitigate these risks.

In conclusion, understanding the manufacturing processes and quality assurance protocols for starters is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside stringent quality control measures, buyers can ensure they are sourcing reliable products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you tap a starter’

Introduction

This guide serves as a practical checklist for B2B buyers who are looking to understand the process of tapping a starter in automotive contexts. Whether you’re in the automotive parts supply chain or managing a fleet, knowing how to effectively tap a starter can save time and resources, especially in emergency situations. This step-by-step approach will help you identify the necessary tools, understand the techniques, and ensure safety during the process.

Step 1: Understand the Functionality of the Starter

Before attempting to tap a starter, it’s essential to understand its role in the vehicle. The starter is responsible for initiating the engine’s combustion process by cranking the engine. Familiarizing yourself with how the starter works will help in identifying issues and knowing when tapping might be a viable solution.

- Key Elements to Consider:

- Familiarize yourself with the starter motor and solenoid components.

- Understand the signs indicating a starter issue, such as clicking sounds or dimming lights.

Step 2: Gather Necessary Tools

Having the right tools at hand is critical for the tapping process. Typically, a hammer or a suitable tool for tapping, such as a tire iron, is required. Ensuring you have the correct tools will facilitate a smoother operation and reduce the risk of damaging components.

- Recommended Tools:

- A rubber mallet or hammer to minimize damage.

- A flashlight for visibility, especially in low-light conditions.

Step 3: Assess the Vehicle’s Condition

Before proceeding, evaluate the vehicle’s overall condition. A thorough assessment will help determine whether tapping the starter is the appropriate response or if other issues, such as a dead battery or corroded connections, are at play.

- Points to Check:

- Inspect battery connections for corrosion.

- Listen for any unusual sounds that could indicate further mechanical issues.

Step 4: Locate the Starter and Solenoid

Identifying the exact location of the starter and solenoid is crucial for effective tapping. Typically, the starter is situated at the bottom of the engine. Knowing where to tap can make the difference between a successful start and potential damage.

Illustrative image related to how do you tap a starter

- Tips for Locating:

- Refer to the vehicle’s service manual for specific diagrams.

- Ensure that you have clear access to the starter without any obstructions.

Step 5: Perform the Tapping Technique

Once you have everything in place, carefully tap the starter solenoid. This technique can sometimes dislodge stuck components and help the starter engage. However, caution is necessary to avoid causing damage.

- Tapping Guidelines:

- Use gentle taps—aim for 3-4 light strikes on the solenoid.

- If necessary, increase the force gradually, but avoid excessive force.

Step 6: Test the Starter

After tapping, it’s time to test the starter by attempting to crank the engine. This step will help determine whether the tapping was effective or if further action is needed.

- What to Look For:

- Listen for any changes in sound when attempting to start.

- Observe if the engine cranks smoothly or if additional troubleshooting is required.

Step 7: Plan for Professional Assistance

Regardless of the outcome, it’s advisable to consult a professional mechanic if the starter continues to malfunction. Tapping may provide a temporary fix, but ongoing issues typically indicate that replacement or repair is necessary.

Illustrative image related to how do you tap a starter

- Next Steps:

- Schedule an appointment with a qualified technician.

- Keep records of the vehicle’s issues for future reference.

By following this checklist, B2B buyers can effectively manage starter issues, ensuring better vehicle reliability and minimizing downtime.

Comprehensive Cost and Pricing Analysis for how do you tap a starter Sourcing

What Are the Key Cost Components for Tapping a Starter Sourcing?

When analyzing the cost structure for sourcing solutions related to tapping a starter, it is essential to break down the various cost components involved. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The materials used in the production of starters typically include metals such as copper and aluminum, as well as various plastics and composites for housing. The quality of these materials can significantly affect both performance and price. For instance, using higher-grade materials may increase the initial cost but can lead to longer-lasting products, ultimately reducing the Total Cost of Ownership (TCO).

-

Labor: Labor costs encompass the wages paid to skilled workers who manufacture and assemble starters. Regions with lower labor costs may provide competitive pricing, but it’s crucial to assess the skill level and experience of the workforce to ensure quality.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs, which can be a point of negotiation when sourcing.

-

Tooling: Initial tooling costs can be significant, especially for custom starter designs. Buyers should consider the potential for economies of scale; larger orders may justify these upfront costs by spreading them over a greater number of units.

-

Quality Control: Implementing rigorous QC measures ensures that the starters meet industry standards and customer specifications. While this may add to costs, it can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, mode of transportation, and Incoterms will influence these costs. Buyers should evaluate logistics providers and consider local suppliers to reduce shipping expenses.

-

Margin: Suppliers will typically add a profit margin to their costs, which can vary widely based on market demand, competition, and the supplier’s position in the supply chain.

How Do Price Influencers Affect Sourcing of Tapping Starters?

Several factors influence pricing when sourcing starters, particularly for international buyers from diverse markets such as Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly impact pricing. Higher volume purchases often come with bulk discounts, making it essential for buyers to consolidate orders where feasible.

-

Specifications and Customization: Customized starters may incur additional costs due to unique design requirements or specialized materials. Buyers should evaluate the necessity of customization against potential added expenses.

-

Materials and Quality Certifications: The choice of materials and adherence to quality certifications can affect both the cost and reliability of the starters. Certifications may also be a requirement in certain markets, influencing sourcing decisions.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can impact pricing. Established suppliers with a proven track record may charge a premium, but this can often be justified through consistent quality and performance.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect overall costs.

What Are the Best Negotiation Tips for B2B Buyers in Tapping Starter Sourcing?

B2B buyers should employ strategic negotiation techniques to optimize their sourcing of tapping starters:

-

Research and Benchmarking: Conduct thorough market research to understand pricing trends and benchmarks. This knowledge empowers buyers to negotiate effectively and identify fair pricing.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield benefits such as improved service and preferential pricing.

-

Focus on Total Cost of Ownership: When negotiating, emphasize the TCO rather than just the initial price. Highlight how quality and reliability can lead to lower long-term costs, thus justifying a higher upfront investment.

-

Be Open to Alternative Suppliers: Diversifying supplier options can foster competitive pricing. Engaging multiple suppliers allows for better negotiation leverage.

-

Understand Cultural Nuances: For international buyers, being aware of cultural differences in negotiation styles can enhance communication and lead to more favorable outcomes.

Conclusion

Understanding the cost structure and pricing nuances of sourcing tapping starters is vital for international B2B buyers. By considering key cost components, price influencers, and negotiation strategies, buyers can make informed decisions that align with their operational needs and budget constraints. This approach not only enhances purchasing efficiency but also contributes to the overall success of their business operations.

Alternatives Analysis: Comparing how do you tap a starter With Other Solutions

Exploring Alternatives to Tapping a Starter

When dealing with a non-starting vehicle, tapping the starter is a well-known technique that can temporarily resolve the issue. However, it’s essential for B2B buyers, particularly those in automotive services, to be aware of other viable solutions that can either complement or replace this method. In this section, we will explore alternative techniques to get a vehicle started, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

Illustrative image related to how do you tap a starter

| Comparison Aspect | How Do You Tap A Starter | Jump Starting the Battery | Replacing the Starter Motor |

|---|---|---|---|

| Performance | Temporary fix; may last weeks | Immediate start if battery is the issue | Long-term solution; restores full functionality |

| Cost | Low (tools on hand) | Moderate (cables if not owned) | High (cost of part + labor) |

| Ease of Implementation | Simple, requires minimal skill | Easy with basic knowledge; requires jumper cables | Requires mechanical expertise; more time-consuming |

| Maintenance | Minimal; no ongoing upkeep | No maintenance needed; just cables | Regular checks recommended; part replacement required |

| Best Use Case | Emergency situations | When battery is drained or weak | Persistent starter issues; vehicle reliability is crucial |

What Are the Pros and Cons of Jump Starting the Battery?

Jump starting the battery is a common solution when a vehicle fails to start. This method involves connecting jumper cables from a functioning battery to the dead battery, allowing the vehicle to start.

Pros:

– Quick and effective if the battery is the issue.

– Cost-effective if cables are already owned.

– Can be performed by anyone with basic knowledge.

Cons:

– Only useful if the battery is the root cause; won’t help if the starter is faulty.

– Requires access to another vehicle or a portable jump starter.

– Potential for errors in connection can lead to further electrical issues.

Illustrative image related to how do you tap a starter

How Does Replacing the Starter Motor Compare?

Replacing the starter motor is a more permanent solution for persistent starting issues. It involves removing the old starter and installing a new one, usually requiring professional assistance.

Pros:

– Restores full functionality and reliability to the vehicle.

– Eliminates the need for repeated emergency fixes.

– New starters often come with warranties.

Cons:

– Higher upfront cost due to parts and labor.

– More complex process requiring mechanical skills.

– Time-consuming compared to quick fixes like tapping or jump starting.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When choosing the right method for addressing starting issues, B2B buyers should assess their specific needs and circumstances. For quick fixes or in emergency situations, tapping the starter or jump starting the battery may be sufficient. However, for long-term reliability and performance, investing in a new starter motor is often the best course of action. Evaluating factors such as cost, ease of implementation, and the urgency of the situation can guide buyers in selecting the most effective solution for their automotive needs.

Essential Technical Properties and Trade Terminology for how do you tap a starter

What Are the Key Technical Properties to Consider When Tapping a Starter?

When addressing the issue of tapping a starter, particularly in the context of automotive repair and maintenance, several technical properties are critical for B2B buyers to understand. These properties directly influence the performance and longevity of starter motors in vehicles.

1. Material Grade

The materials used in starter construction, such as copper for electrical connections and high-grade steel for the housing, are essential for durability and conductivity. Higher-grade materials resist wear and corrosion, which is particularly important for vehicles operating in harsh climates, such as those found in parts of Africa or South America. Opting for starters made from superior materials can reduce downtime and maintenance costs.

2. Electrical Resistance

Electrical resistance in the starter’s wiring and connections affects its efficiency. Low-resistance materials ensure that the starter receives adequate power from the battery, enhancing performance. In B2B contexts, understanding the specifications for resistance can help buyers choose starters that minimize energy loss, ultimately leading to better fuel efficiency and lower operational costs.

3. Tolerance Levels

Tolerance levels refer to the allowable variations in the dimensions of starter components, such as the solenoid and gear. High precision in these components ensures proper engagement with the engine’s flywheel. For businesses, selecting starters with tight tolerances can prevent premature wear and potential failures, thereby enhancing reliability.

Illustrative image related to how do you tap a starter

4. Weight Specifications

The weight of a starter motor can impact its installation and overall vehicle performance. Lighter starters can improve fuel efficiency and reduce strain on the vehicle’s electrical system. For B2B buyers, understanding weight specifications is crucial for ensuring compatibility with vehicle models and meeting performance expectations.

5. Operating Temperature Range

The operating temperature range indicates the conditions under which a starter motor can function effectively. Starters designed to withstand extreme temperatures are essential for vehicles operating in regions with harsh climates. B2B buyers should consider this property to ensure that the starter will perform reliably in their specific operational environments.

Which Trade Terms Are Essential for Understanding Starter Motors?

Familiarity with industry jargon can significantly enhance communication and decision-making in the procurement of starter motors. Here are key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. Choosing OEM starters ensures compatibility and performance standards are met. For businesses, sourcing OEM parts can lead to enhanced reliability and warranty support.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for businesses looking to manage inventory and budget effectively. It can influence purchasing decisions, especially for smaller companies that may not require large quantities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes for specific products or services. Utilizing RFQs helps B2B buyers compare offers from different suppliers, ensuring they secure the best pricing and terms for starter motors.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, insurance, and liability, which are critical when importing starter motors from different regions.

5. Aftermarket

Aftermarket refers to parts and accessories made by companies other than the original manufacturer. For B2B buyers, aftermarket starters can offer cost-effective alternatives to OEM products, but understanding quality and compatibility is essential to avoid potential issues.

Understanding these technical properties and trade terms is essential for B2B buyers engaged in the automotive sector. By making informed decisions based on this knowledge, businesses can enhance their operational efficiency and reduce long-term costs.

Navigating Market Dynamics and Sourcing Trends in the how do you tap a starter Sector

What are the Key Market Trends in the Starter Sector?

The starter sector, essential for automotive functionality, is experiencing notable changes driven by technological advancements and evolving consumer preferences. Global demand for reliable and efficient starter systems is rising, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key drivers include the growth of the automotive industry, increasing vehicle ownership, and the shift towards electric vehicles (EVs). As manufacturers pivot to cater to EV markets, innovations in starter technology, such as advanced solenoid designs and integration with smart vehicle systems, are becoming crucial.

Additionally, the trend towards digitalization in the supply chain is reshaping how international B2B buyers source starters. Technologies like blockchain are enhancing transparency and traceability, allowing buyers to verify the quality and origin of components. Furthermore, partnerships with local suppliers are gaining traction, as companies seek to mitigate risks associated with global sourcing disruptions. Understanding these dynamics is vital for B2B buyers to make informed purchasing decisions that align with their operational needs and market conditions.

How Does Sustainability Impact Sourcing in the Starter Sector?

Sustainability is increasingly influencing the sourcing strategies of B2B buyers in the starter sector. The environmental impact of manufacturing processes, particularly concerning waste management and resource usage, is a growing concern among companies worldwide. As regulations tighten and consumer awareness rises, businesses are prioritizing ethical supply chains that minimize their carbon footprint.

Incorporating ‘green’ certifications, such as ISO 14001, into sourcing practices ensures compliance with environmental standards. Buyers are also exploring materials that are recyclable or sourced from sustainable practices, such as aluminum and certain polymers that can reduce waste during production. By investing in sustainable practices, companies not only meet regulatory requirements but also enhance their brand reputation and attract environmentally-conscious customers. This commitment to sustainability is becoming a competitive differentiator in the global marketplace.

What is the Historical Context of the Starter Sector’s Evolution?

The starter sector has evolved significantly since the introduction of the first electric starters in the early 20th century. Initially, hand-cranking engines posed safety and usability challenges, prompting the development of electric starters that revolutionized vehicle operation. Over the decades, advancements in electrical engineering and materials science have led to more compact, reliable, and efficient starter systems.

In recent years, the sector has seen a shift towards integrating smart technologies, such as sensors and connectivity features, aligning with the broader automotive industry’s move towards automation and electrification. This evolution reflects the changing demands of consumers and the need for manufacturers to innovate continuously. Understanding this historical context is essential for B2B buyers, as it provides insights into the reliability and technological capabilities of current starter systems.

Frequently Asked Questions (FAQs) for B2B Buyers of how do you tap a starter

-

How do I solve a starter issue in my vehicle?

To address a starter problem, first, ensure the battery is fully charged and connections are secure. If the starter is still unresponsive, a gentle tap with a hammer on the starter solenoid may help dislodge any stuck components. This method can temporarily restore functionality, but it’s crucial to have the starter inspected and replaced by a professional to avoid further issues. Regular maintenance can prevent such failures, particularly in harsh environments where corrosion is prevalent. -

What is the best method to test a starter before purchasing?

The most effective way to test a starter is to perform a voltage drop test. Use a multimeter to check the voltage at the starter while attempting to start the engine. A significant drop indicates a problem with the starter or its connections. Additionally, listen for clicking sounds or dimming lights when the ignition is turned on, as these can signal a failing starter. Ensuring thorough testing can help prevent sourcing faulty products. -

How can I identify a reliable supplier for starters?

When sourcing starters, prioritize suppliers with a proven track record in your target market. Look for certifications and customer reviews that validate their quality standards. Engage in direct communication to assess their responsiveness and willingness to provide product samples. Establishing relationships with local distributors can also enhance trust and facilitate smoother transactions. Verify their compliance with international trade regulations to ensure seamless importation. -

What customization options are available for starters?

Many manufacturers offer customization options for starters, including variations in voltage, size, and mounting configurations. When discussing customization, provide detailed specifications regarding your vehicle models and any performance enhancements desired. Collaborate closely with suppliers to ensure that the modified products meet your operational needs while adhering to industry standards. This can also influence lead times and pricing, so factor those into your negotiations. -

What is the minimum order quantity (MOQ) for starters?

MOQs for starters can vary significantly depending on the supplier and the type of starter. Typically, manufacturers may set an MOQ ranging from 50 to 500 units. When negotiating, consider your market demand and storage capabilities to avoid overcommitting. Some suppliers may be flexible with MOQs for first-time orders or establish tiered pricing based on order volume, which can be beneficial for building a long-term partnership. -

What payment terms should I expect when sourcing starters internationally?

Payment terms can differ based on the supplier’s location and your established relationship. Common terms include upfront payment, 30-60 days net, or a letter of credit for larger transactions. Always clarify payment methods accepted (e.g., wire transfers, credit cards) and ensure that they offer secure options. It’s advisable to negotiate favorable terms that accommodate your cash flow while still providing the supplier with assurance. -

How can I ensure quality assurance (QA) for starters sourced internationally?

Implement a robust QA process by requiring suppliers to provide documentation of their quality standards and testing procedures. Consider third-party inspections before shipment to verify that the starters meet your specifications. Request samples for testing in your applications to assess performance. Establish clear communication channels for reporting defects and addressing quality issues promptly, ensuring both parties understand expectations for product performance. -

What logistics considerations should I keep in mind when importing starters?

When importing starters, consider shipping methods, customs regulations, and potential tariffs that may affect cost and delivery timelines. Work with logistics partners experienced in handling automotive parts to navigate international shipping complexities. Ensure proper packaging to prevent damage during transit, and plan for potential delays in customs clearance. Having a comprehensive logistics strategy will help streamline the process and minimize disruptions to your supply chain.

Top 2 How Do You Tap A Starter Manufacturers & Suppliers List

1. Reddit – Car Starter Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Tapping on a car starter with a hammer while turning the ignition may help start the car, but it should be done gently to avoid damage. This method is typically a last resort before repairing or replacing the starter.

2. Tool Tally – Starter Solenoid Fix

Domain: tooltally.com

Registered: 2018 (7 years)

Introduction: The article discusses how to temporarily fix a bad starter solenoid by tapping it with a hammer. It describes the symptoms of a bad starter solenoid, which include hearing a single weak click or no sound when trying to start the car. The starter solenoid is an electromagnet relay that engages the starter with the flywheel. The article provides tips on identifying other potential issues such as a d…

Strategic Sourcing Conclusion and Outlook for how do you tap a starter

How Can You Optimize Your Strategic Sourcing for Starter Solutions?

In conclusion, tapping a starter is not just about immediate fixes; it reflects the broader strategic sourcing practices essential for B2B buyers. Understanding the nuances of starter functionality, from recognizing symptoms of failure to knowing when to intervene, empowers businesses to make informed decisions that enhance operational efficiency.

Illustrative image related to how do you tap a starter

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to significant cost savings and improved supply chain resilience. By establishing strong relationships with reliable suppliers, businesses can ensure they have access to quality components and services that minimize downtime.

Looking ahead, the automotive industry is poised for technological advancements that will influence starter systems and their maintenance. Buyers should remain proactive, staying informed about emerging trends and best practices in sourcing. Engage with local suppliers, explore innovative solutions, and prioritize quality to ensure your operations run smoothly. Start your journey today towards a more robust and efficient sourcing strategy, and keep your business moving forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how do you tap a starter