Introduction: Navigating the Global Market for how do i know if it’s my starter or alternator

When troubleshooting automotive electrical issues, understanding how to determine whether it’s your starter or alternator causing the problem is critical for B2B buyers in the automotive sector. This guide aims to equip international purchasers with the knowledge necessary to identify, source, and procure the right components for optimal vehicle performance. With a focus on the intricate relationship between starters, alternators, and batteries, we delve into their functions, common failure signs, and the diagnostics needed to pinpoint the exact issue.

This comprehensive resource covers various types of starters and alternators, their specific applications across different vehicle models, and essential criteria for supplier vetting. Given the diverse automotive landscapes in regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Nigeria—it’s crucial for buyers to grasp the nuances that affect performance and durability in different climates and driving conditions.

By leveraging this guide, businesses can make informed purchasing decisions, ensuring they acquire high-quality parts that align with their operational needs and customer expectations. Furthermore, understanding cost implications and sourcing strategies will help optimize budgets while maintaining vehicle reliability, ultimately contributing to a more efficient supply chain in the automotive sector.

Índice

- Top 2 How Do I Know If It’S My Starter Or Alternator Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do i know if it’s my starter or alternator

- Understanding how do i know if it’s my starter or alternator Types and Variations

- Key Industrial Applications of how do i know if it’s my starter or alternator

- 3 Common User Pain Points for ‘how do i know if it’s my starter or alternator’ & Their Solutions

- Strategic Material Selection Guide for how do i know if it’s my starter or alternator

- In-depth Look: Manufacturing Processes and Quality Assurance for how do i know if it’s my starter or alternator

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do i know if it’s my starter or alternator’

- Comprehensive Cost and Pricing Analysis for how do i know if it’s my starter or alternator Sourcing

- Alternatives Analysis: Comparing how do i know if it’s my starter or alternator With Other Solutions

- Essential Technical Properties and Trade Terminology for how do i know if it’s my starter or alternator

- Navigating Market Dynamics and Sourcing Trends in the how do i know if it’s my starter or alternator Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do i know if it’s my starter or alternator

- Strategic Sourcing Conclusion and Outlook for how do i know if it’s my starter or alternator

- Aviso legal importante e termos de utilização

Understanding how do i know if it’s my starter or alternator Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Battery Testing | Slow cranking, dim lights, bloated battery case | Oficinas de reparação automóvel | Pros: Quick diagnosis; Cons: Requires additional tools. |

| Alternator Voltage Check | Fluctuating voltage gauge, dimming lights, grinding noises | Fleet management, transportation | Pros: Identifies power issues; Cons: May need specialized equipment. |

| Starter Performance Assessment | Whirring or grinding noises, single click, no engine crank | Serviços de manutenção de veículos | Pros: Clear indicators of failure; Cons: Labor-intensive diagnostics. |

| Jump-Start Diagnostic Method | Behavior of the vehicle during jump-starting | Centros de serviço automóvel | Pros: Simple and effective; Cons: Temporary solution. |

| Comprehensive Electrical System Check | Evaluates all components working together | Automotive manufacturing, dealerships | Pros: Holistic view of vehicle health; Cons: Time-consuming. |

What are the Characteristics of Battery Testing for B2B Buyers?

Battery testing is essential for identifying issues related to power supply in vehicles. Key indicators include slow engine cranking, dim interior lights, and physical signs like a bloated battery case. This type of testing is particularly valuable for automotive repair shops that need to quickly diagnose battery issues to provide timely service. Buyers should consider the cost of necessary tools and training for staff, as effective battery testing can lead to higher customer satisfaction and repeat business.

How to Conduct an Alternator Voltage Check?

An alternator voltage check is critical for ensuring that the vehicle’s electrical system is functioning correctly. Symptoms include fluctuating voltage readings and unusual noises from the engine bay. This method is especially relevant for fleet management and transportation companies that rely on multiple vehicles. Buyers should weigh the benefits of investing in specialized diagnostic equipment against the potential downtime caused by alternator issues, which can affect operational efficiency.

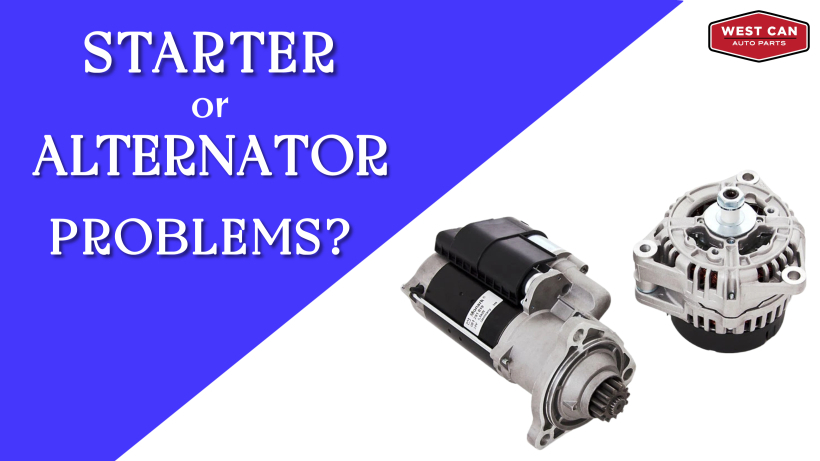

Why is Starter Performance Assessment Important for Vehicle Maintenance?

Starter performance assessments help pinpoint issues like whirring or grinding sounds when starting the vehicle. For vehicle maintenance services, understanding starter functionality is crucial, as this component is vital for vehicle operation. Buyers should assess the labor costs associated with diagnosing starter problems, as thorough inspections can be time-consuming but necessary for ensuring vehicle reliability.

How Does the Jump-Start Diagnostic Method Work?

The jump-start diagnostic method allows technicians to identify whether the battery, starter, or alternator is at fault based on how the vehicle reacts during a jump start. It’s a straightforward approach often utilized in automotive service centers. While it offers a quick solution, buyers should recognize that this method only temporarily addresses the issue and may not reveal underlying problems.

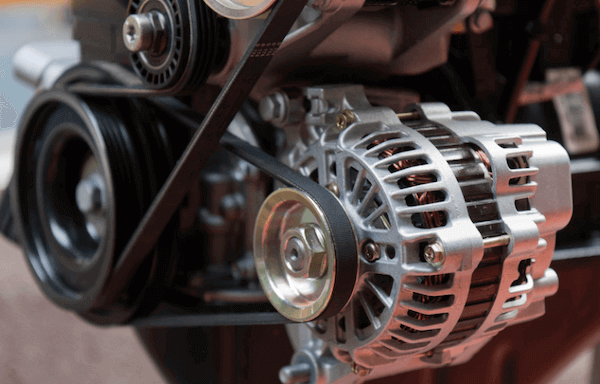

Illustrative image related to how do i know if it’s my starter or alternator

What is Involved in a Comprehensive Electrical System Check?

A comprehensive electrical system check evaluates the synergy between the battery, alternator, and starter, providing a complete picture of the vehicle’s electrical health. This method is particularly beneficial for automotive manufacturers and dealerships that prioritize quality assurance. While it offers the most thorough diagnostics, buyers must consider the time and resources required to perform such an extensive check, weighing it against the long-term benefits of maintaining vehicle reliability.

Key Industrial Applications of how do i know if it’s my starter or alternator

| Indústria/Setor | Specific Application of how do i know if it’s my starter or alternator | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Diagnostic services to determine starter or alternator issues | Increases customer satisfaction and repeat business | Quality of diagnostic tools, technician expertise |

| Gestão de frotas | Regular checks to prevent vehicle downtime due to electrical failures | Reduces operational costs and enhances fleet reliability | Availability of parts, supplier reliability |

| Equipamento de construção | Assessing machinery starting issues in heavy-duty vehicles | Minimizes project delays and equipment downtime | Compatibilidade com várias marcas de máquinas |

| Transporte e Logística | Ensuring the reliability of delivery vehicles | Ensures timely deliveries and maintains client trust | Quick access to parts, service agreements with suppliers |

| Operações mineiras | Troubleshooting electrical issues in mining trucks and equipment | Aumenta a eficiência operacional e a segurança | Availability of specialized parts for harsh environments |

How Do Automotive Repair Shops Utilize Starter and Alternator Diagnostics?

Automotive repair shops often face challenges when diagnosing electrical issues in vehicles. By implementing effective diagnostic services that identify whether the problem lies with the starter or alternator, these businesses can enhance customer satisfaction and loyalty. The ability to quickly and accurately troubleshoot these components reduces repair times, allowing for more vehicles to be serviced. For international buyers, sourcing high-quality diagnostic tools and ensuring technicians are well-trained are critical for maintaining service standards.

What Are the Benefits of Regular Checks for Fleet Management?

In fleet management, regular checks for starter and alternator functionality are essential to prevent unexpected vehicle downtime. By proactively identifying issues, businesses can reduce operational costs and enhance fleet reliability. This is especially important in regions with challenging climates, such as Africa and South America, where extreme temperatures can affect battery and alternator performance. Key considerations include having reliable suppliers for parts and ensuring that maintenance schedules are adhered to.

How Do Construction Companies Address Machinery Starting Issues?

Construction companies rely heavily on their machinery, and any starting issues can lead to costly project delays. By utilizing diagnostic services to determine whether problems stem from starters or alternators, these businesses can minimize equipment downtime. Given the diverse range of machinery used in construction, buyers should focus on sourcing compatible parts and ensuring that suppliers understand the specific needs of heavy-duty vehicles.

Illustrative image related to how do i know if it’s my starter or alternator

Why Is Reliability Crucial for Transportation and Logistics?

In the transportation and logistics sector, the reliability of delivery vehicles is paramount. Any electrical failure can disrupt the supply chain and affect client trust. By regularly assessing the condition of starters and alternators, companies can ensure timely deliveries and maintain a competitive edge. Key sourcing considerations include quick access to replacement parts and establishing service agreements with trusted suppliers to minimize downtime.

How Do Mining Operations Benefit from Electrical Troubleshooting?

Mining operations often utilize heavy-duty trucks and machinery that require consistent performance. Troubleshooting electrical issues related to starters and alternators ensures that equipment operates efficiently and safely. This is particularly important in harsh environments where equipment is subjected to extreme conditions. For international buyers, sourcing specialized parts and ensuring suppliers can meet the demands of mining operations are essential for maintaining productivity.

3 Common User Pain Points for ‘how do i know if it’s my starter or alternator’ & Their Solutions

Scenario 1: Difficulty Diagnosing Electrical Failures in Vehicles

O problema: A fleet manager overseeing a diverse range of vehicles frequently faces challenges when diagnosing electrical failures. When a vehicle won’t start, the manager is left guessing whether the issue is with the starter, alternator, or battery. This uncertainty leads to unnecessary downtime, delays in operations, and increased maintenance costs. Furthermore, without proper diagnostic tools, the manager often relies on trial and error, which can further complicate the issue and strain relationships with drivers who depend on their vehicles.

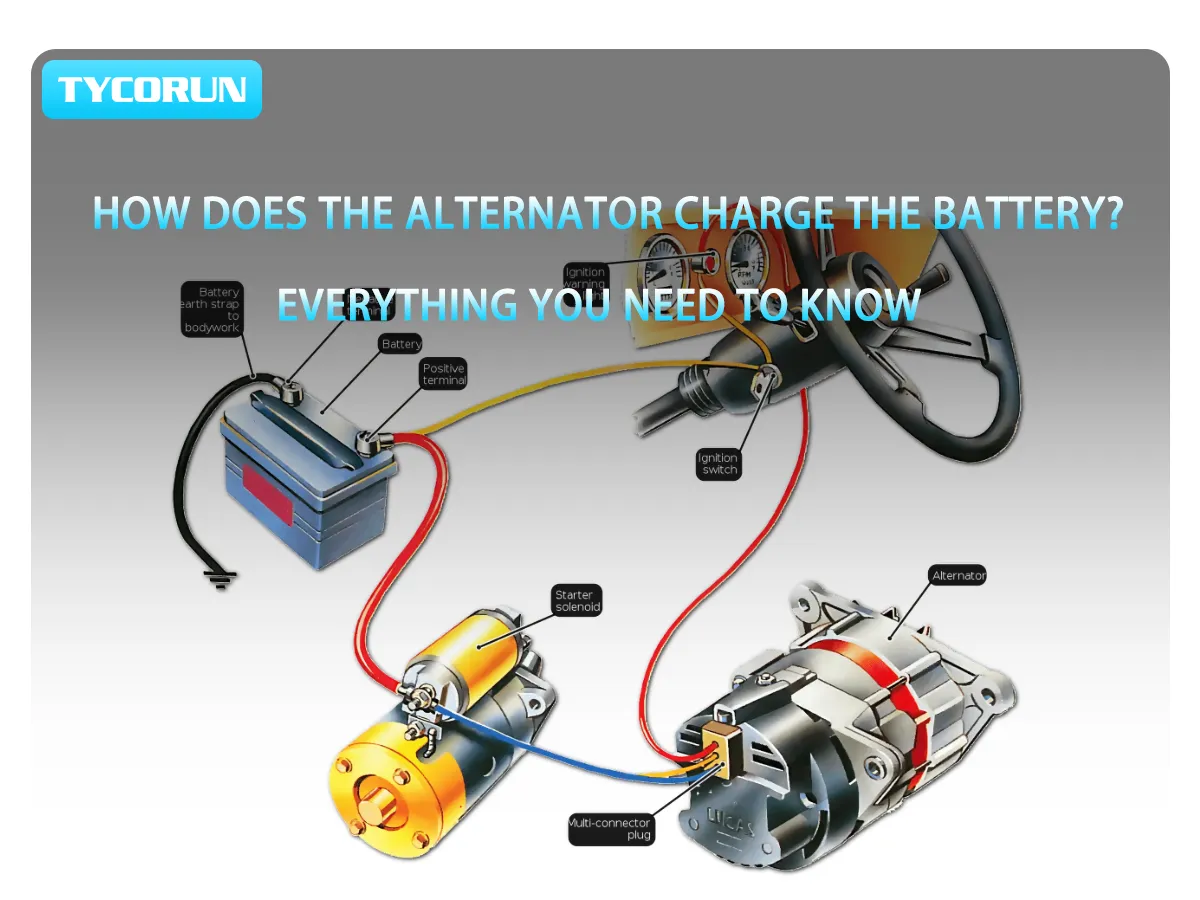

A solução: To overcome this challenge, fleet managers should invest in diagnostic tools that can accurately assess the health of the starter, alternator, and battery. For instance, using a multimeter to measure voltage output can help determine if the alternator is functioning correctly. When the vehicle is running, the voltage should ideally be between 13.7 and 14.7 volts. If the reading is below this range, the alternator may need attention. Additionally, conducting a “jump-start test” can help isolate the problem: if the vehicle starts with a jump but fails afterward, the alternator might be at fault. Training staff on these diagnostic methods will enhance their troubleshooting skills and minimize unnecessary repairs, ultimately improving operational efficiency.

Scenario 2: Managing Component Lifespan and Preventive Maintenance

O problema: In regions with extreme temperatures, such as Africa and South America, the lifespan of starters and alternators can be significantly impacted. A B2B buyer in the automotive maintenance industry often struggles with the challenge of managing the longevity of these components. Harsh environmental conditions lead to frequent breakdowns, resulting in costly replacements and customer dissatisfaction. This creates a pressing need for effective preventive maintenance strategies to extend component life and reduce unplanned repairs.

A solução: To address this issue, B2B buyers should implement a comprehensive preventive maintenance program tailored to their operational environment. Regularly scheduled inspections should focus on the electrical system, including checks for corrosion, loose connections, and signs of wear on belts. Additionally, educating vehicle operators about the importance of monitoring dashboard warning lights can help catch issues early. Establishing partnerships with reliable parts suppliers can ensure access to high-quality starters and alternators, specifically designed for durability in extreme conditions. By prioritizing these practices, businesses can significantly reduce the frequency of component failures and enhance overall fleet reliability.

Illustrative image related to how do i know if it’s my starter or alternator

Scenario 3: Cost Management in Vehicle Repairs

O problema: A logistics company experiences frequent electrical issues with its fleet, leading to costly repairs and unexpected downtime. As a B2B buyer, the procurement officer is tasked with managing repair costs while ensuring that the fleet remains operational. The challenge lies in accurately diagnosing whether the issue stems from the starter, alternator, or battery to avoid unnecessary expenses on parts and labor.

A solução: To effectively manage repair costs, the procurement officer should establish a clear protocol for diagnosing electrical issues. This includes training maintenance staff on how to identify specific symptoms associated with each component. For instance, understanding that a clicking sound may indicate a starter problem, while flickering lights can point to an alternator issue. Implementing a standardized troubleshooting guide can streamline the diagnostic process and reduce reliance on external mechanics, saving time and money. Furthermore, negotiating service contracts with local repair shops can provide access to competitive rates for necessary repairs. By fostering a culture of proactive maintenance and informed decision-making, the logistics company can mitigate repair costs and enhance fleet performance.

Strategic Material Selection Guide for how do i know if it’s my starter or alternator

Que materiais são normalmente utilizados em arrancadores e alternadores?

When diagnosing issues with starters and alternators, understanding the materials used in their construction can significantly impact performance, durability, and cost-effectiveness. Here are some of the most common materials utilized in these critical automotive components, along with their properties, advantages, disadvantages, and considerations for international buyers.

Quais são as principais propriedades do cobre em arrancadores e alternadores?

Copper is widely used in electrical components due to its excellent conductivity. It has a high melting point of about 1,984°F (1,085°C) and is resistant to corrosion, making it ideal for use in starters and alternators that require reliable electrical connections.

Prós e contras: Copper’s high conductivity translates to efficient energy transfer, which is crucial for starters and alternators. However, it is relatively expensive compared to other materials and can be prone to oxidation if not properly coated.

Impacto na aplicação: Copper is compatible with various media, including electrical currents and mechanical stress. Its ability to withstand high temperatures makes it suitable for automotive applications.

Considerações para compradores internacionais: Buyers from regions like Africa and South America should consider local availability and pricing fluctuations. Compliance with international standards such as ASTM B170 for copper wire may also be necessary.

How Does Aluminum Perform in Starters and Alternators?

Aluminum is another common material, particularly for housings and structural components of starters and alternators. It has a lower density than copper, making it lighter, and it also exhibits good corrosion resistance.

Prós e contras: Aluminum is less expensive than copper and is easier to manufacture due to its malleability. However, its conductivity is lower, which can affect performance in high-demand applications.

Impacto na aplicação: Aluminum’s lightweight nature can enhance fuel efficiency in vehicles, while its corrosion resistance helps prolong the lifespan of components exposed to harsh environments.

Considerações para compradores internacionais: In regions like Europe and the Middle East, buyers should ensure that aluminum components meet standards such as DIN 1725 for aluminum alloys.

Qual é o papel do aço nos arrancadores e alternadores?

Steel is often used in the construction of starter motors and alternators, particularly for their casings and internal components. It offers high strength and durability, with a melting point of approximately 2,500°F (1,370°C).

Prós e contras: Steel’s robustness makes it suitable for heavy-duty applications. However, it is heavier than aluminum and can be susceptible to rust if not properly treated.

Impacto na aplicação: Steel components can withstand significant mechanical stress, making them ideal for high-performance vehicles. However, their weight can negatively affect fuel efficiency.

Considerações para compradores internacionais: Buyers should be aware of local regulations regarding steel quality, such as compliance with JIS G3101 in Japan or ASTM A36 in the U.S., especially in regions like Vietnam and Nigeria.

How Is Plastic Used in Starters and Alternators?

Plastic is increasingly utilized in starters and alternators, particularly for insulation and housing components. It is lightweight, has good electrical insulating properties, and can withstand moderate temperatures.

Prós e contras: The use of plastic can reduce overall weight and manufacturing costs. However, it may not be suitable for high-temperature applications and can degrade over time when exposed to UV light.

Illustrative image related to how do i know if it’s my starter or alternator

Impacto na aplicação: Plastic components can help in reducing the overall weight of the assembly, contributing to improved fuel efficiency. However, their longevity may be compromised in extreme conditions.

Considerações para compradores internacionais: Buyers should ensure that plastic materials comply with international standards such as ISO 9001 for quality management systems, particularly in regions with stringent regulations.

Quadro resumo da seleção de materiais para arrancadores e alternadores

| Material | Typical Use Case for how do i know if it’s my starter or alternator | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Ligações eléctricas e cablagem | Excelente condutividade | Custo elevado e risco de oxidação | Alto |

| Alumínio | Caixas e componentes estruturais | Leve e resistente à corrosão | Condutividade inferior à do cobre | Médio |

| Aço | Casings and internal components | Alta resistência e durabilidade | Mais pesado e com tendência para a ferrugem | Médio |

| Plástico | Componentes de isolamento e habitação | Leve e económico | Not suitable for high temperatures | Baixo |

This guide provides a comprehensive overview of the materials used in starters and alternators, equipping international B2B buyers with the insights needed for informed decision-making.

In-depth Look: Manufacturing Processes and Quality Assurance for how do i know if it’s my starter or alternator

What Are the Main Stages in the Manufacturing Process for Starters and Alternators?

The manufacturing process of starters and alternators involves several critical stages that ensure the final product meets quality standards and performs reliably.

-

Preparação do material:

The initial stage focuses on sourcing high-quality materials, including metals such as aluminum and copper, which are essential for electrical conductivity and durability. Suppliers must adhere to strict specifications to ensure the materials can withstand harsh automotive environments. Material testing, including chemical composition analysis and tensile strength tests, is often conducted to verify quality. -

Formação:

This stage involves shaping the prepared materials into the required components. Techniques like stamping, machining, and casting are commonly employed. Stamping is often used for creating metal parts such as housings and brackets, while precision machining is applied to components requiring tight tolerances, such as rotor shafts. Advanced technologies, such as CNC machining, enhance accuracy and consistency in forming processes. -

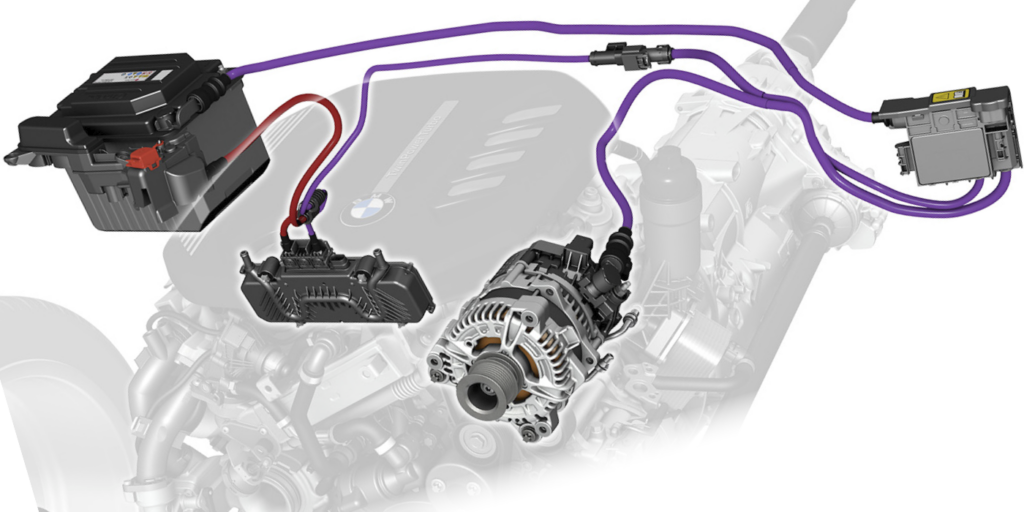

Montagem:

The assembly process integrates various components, including stators, rotors, and brushes for alternators, and armatures and solenoids for starters. This stage often employs automated assembly lines to enhance efficiency and reduce human error. Each assembly line must be meticulously designed to ensure proper alignment and fit of components, which is crucial for the functionality of the final product. -

Acabamento:

After assembly, the products undergo finishing processes, including painting, coating, and polishing, to enhance durability and aesthetic appeal. These treatments also help prevent corrosion, which is vital for components exposed to environmental elements. Quality checks during this phase ensure that the finishing meets industry standards.

What Quality Control Measures Are in Place for Starters and Alternators?

Quality control (QC) is paramount in the manufacturing of starters and alternators, ensuring that each unit meets rigorous performance and safety standards.

-

International Standards Compliance:

Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with such standards ensures that manufacturers have established processes for continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for specific automotive components further validate quality assurance. -

Quality Control Checkpoints:

The QC process typically includes several key checkpoints:

– Controlo de Qualidade de Entrada (IQC): This initial stage examines raw materials and components upon receipt, ensuring they meet specified requirements before production begins.

– Controlo de qualidade em processo (IPQC): Throughout the manufacturing process, periodic inspections are conducted to monitor production quality, verifying that components are being assembled correctly and consistently.

– Controlo de Qualidade Final (FQC): After assembly, final inspections are performed to ensure the completed starters and alternators meet performance specifications, including electrical testing, durability assessments, and functional checks. -

Common Testing Methods:

Manufacturers utilize various testing methods to verify product quality. Electrical testing checks the performance of the alternator and starter under load conditions, while mechanical testing assesses structural integrity. Vibration and thermal testing are also employed to simulate real-world operating conditions, ensuring reliability in diverse environments.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring product reliability and performance.

-

Auditorias a fornecedores:

Conducting supplier audits is an effective way for buyers to assess manufacturing capabilities and QC processes. Audits should evaluate compliance with international standards, manufacturing practices, and the effectiveness of quality management systems. This on-site assessment can reveal insights into the supplier’s commitment to quality. -

Relatórios de controlo de qualidade:

Suppliers should provide detailed QC reports that outline testing results, compliance with standards, and any corrective actions taken. These reports serve as documentation of the supplier’s quality assurance efforts and can help buyers make informed decisions. -

Inspeções por terceiros:

Engaging third-party inspection agencies can offer an additional layer of assurance. These independent organizations can verify that the manufacturing processes and quality control measures meet international standards and the specific needs of the buyer.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

International buyers must navigate various quality control nuances that can impact sourcing decisions.

-

Regional Standards Variability:

Different regions may have specific regulations and quality standards that suppliers must adhere to. For instance, automotive components sold in Europe may require compliance with stringent CE regulations, while those in the Middle East may need to meet local standards. Buyers should familiarize themselves with these regional requirements to ensure compliance. -

Barreiras culturais e de comunicação:

Cultural differences can influence manufacturing practices and quality perceptions. Establishing clear communication channels and expectations with suppliers is essential. Regular updates and feedback loops can help bridge these gaps and ensure alignment on quality standards. -

Considerações logísticas:

Quality control does not end at the factory gate. Buyers must consider the logistics of transporting products across borders, which can introduce risks such as damage or tampering. Implementing robust logistics and handling protocols can mitigate these risks and ensure that products arrive in optimal condition.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed sourcing decisions, ensuring they acquire reliable starters and alternators that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do i know if it’s my starter or alternator’

In the automotive sector, understanding the distinctions between a faulty starter and a malfunctioning alternator is crucial for effective troubleshooting and procurement strategies. This guide provides a structured checklist to help international B2B buyers navigate the complexities of sourcing components related to these critical vehicle systems.

Passo 1: Identify Key Symptoms of Failure

Before sourcing parts, it’s essential to recognize the signs of failure for both starters and alternators. Common indicators include slow engine cranking, unusual noises, and electrical issues like dimming lights. Documenting these symptoms can help you communicate effectively with suppliers and technicians, ensuring you receive the right components for your needs.

Passo 2: Defina as suas especificações técnicas

Clearly outline the technical requirements for the components you need. This includes specifications such as voltage ratings, compatibility with vehicle models, and performance metrics. Precise specifications help avoid mismatches and ensure that the parts sourced will function correctly within the intended application.

Passo 3: Avalie potenciais fornecedores

Thoroughly vet suppliers to ensure they meet your quality and reliability standards. Look for company profiles, customer testimonials, and case studies relevant to your industry. Engaging suppliers who have experience with your specific vehicle types can lead to better support and more suitable products.

- Request Certifications: Ensure suppliers have necessary industry certifications, such as ISO standards, which indicate adherence to quality management practices.

- Check References: Reach out to other businesses in your region that have sourced similar components for feedback on their experiences.

Passo 4: Avaliar as opções de garantia e suporte

Understanding warranty terms and after-sales support is critical in the procurement process. A solid warranty can protect your investment, while responsive customer support can assist in troubleshooting and resolving issues that may arise post-purchase.

- Inquire About Coverage: Ask about the length and terms of the warranty, including what parts are covered and any exclusions.

- Serviços de apoio: Determine if the supplier offers technical support or installation services, which can be invaluable for complex systems.

Passo 5: Conduct Cost-Benefit Analysis

Evaluate the cost of components against their quality and supplier reliability. Cheaper options may seem appealing, but they can lead to higher long-term costs due to frequent replacements or inadequate performance.

- Compare Prices: Gather quotes from multiple suppliers to understand the market rate for the components you need.

- Considerar o custo total de propriedade: Factor in potential maintenance costs, downtime, and the longevity of the parts when making your decision.

Passo 6: Planear a logística e a entrega

Ensure your sourcing strategy includes considerations for logistics and delivery timelines. Import regulations, shipping times, and customs clearance can impact your procurement process, especially when dealing with international suppliers.

- Opções de envio: Discuss available shipping methods and their associated costs with suppliers.

- Tempos de espera: Ask about expected delivery times to align your procurement with operational needs.

Passo 7: Finalizar a sua estratégia de aprovisionamento

Once you’ve evaluated suppliers and defined your requirements, finalize your procurement strategy. Document all decisions and agreements to ensure clarity and accountability.

- Create Purchase Orders: Prepare detailed purchase orders that include all specifications, pricing, and delivery terms.

- Maintain Open Communication: Establish a communication plan with your supplier to address any potential issues during the procurement process.

By following this checklist, B2B buyers can make informed decisions that lead to successful sourcing of components necessary for diagnosing and resolving starter and alternator issues in vehicles.

Comprehensive Cost and Pricing Analysis for how do i know if it’s my starter or alternator Sourcing

What Are the Key Cost Components for Identifying Starter or Alternator Issues?

Understanding the cost structure involved in diagnosing whether a starter or alternator issue is present is crucial for B2B buyers, particularly those sourcing automotive components. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier margin.

Illustrative image related to how do i know if it’s my starter or alternator

-

Materiais: The cost of materials will vary based on the quality and specifications required for the starter or alternator. Common materials include copper for windings, steel for housings, and various plastics for insulation. Higher quality materials can enhance durability and performance, which may justify a higher price.

-

Trabalho: Labor costs encompass the wages of skilled technicians needed for assembly and testing. Labor rates can fluctuate significantly based on geographic location and local labor market conditions. For international buyers, understanding these rates in the context of their local markets is essential.

-

Custos indiretos de produção: This includes the expenses related to the production facility, utilities, and administrative costs. Efficient manufacturing processes can help lower overhead costs, which can be reflected in pricing.

-

Ferramentas: Investment in specialized tools for assembly or testing can add to the initial cost. However, suppliers with advanced tooling capabilities may offer better pricing structures over time due to increased efficiency.

-

Controlo de qualidade: Rigorous QC processes ensure that parts meet safety and performance standards, which can increase costs but ultimately lead to lower failure rates. Certifications such as ISO or OEM specifications can also influence pricing.

-

Logística: Shipping and handling costs must be factored in, especially for international transactions. Incoterms can significantly affect logistics costs, including responsibilities for duties, insurance, and freight.

-

Margem: Suppliers will typically add a margin to cover their costs and profit. Understanding the typical margins in your specific market can aid in negotiation.

What Factors Influence Pricing for Starters and Alternators?

Several factors can influence the pricing of starters and alternators, particularly in international markets:

-

Volume/MOQ: The quantity of parts ordered often affects unit pricing. Larger volumes typically result in lower per-unit costs due to economies of scale.

-

Especificações e personalização: Custom designs or specifications can increase costs. It is essential to clearly define requirements to avoid unexpected expenses.

-

Materiais e qualidade: Higher quality components will naturally come at a premium. Buyers should assess the trade-offs between cost and reliability.

-

Fatores relacionados ao fornecedor: The supplier’s reputation, reliability, and geographic location can affect pricing. Engaging with reputable suppliers can reduce risks and enhance supply chain stability.

-

Incoterms: Understanding Incoterms is vital for determining who is responsible for shipping costs, risks, and customs duties. This knowledge can help buyers negotiate better terms and avoid hidden costs.

What Are Effective Buyer Tips for Sourcing Starters and Alternators?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negociar termos: Always negotiate pricing, terms, and conditions. Building a relationship with suppliers can lead to better deals and flexibility in future orders.

-

Foco no custo total de propriedade (TCO): Consider not just the upfront costs but also the long-term expenses associated with maintenance, warranty claims, and replacement parts.

-

Compreender as nuances dos preços: Be aware of the pricing dynamics in different regions. Factors such as local demand, currency fluctuations, and import tariffs can significantly affect costs.

-

Assess Supplier Capabilities: Evaluate the supplier’s ability to meet your quality and delivery requirements. A reliable supplier can mitigate risks associated with poor-quality components.

Conclusão

While diagnosing issues related to starters and alternators involves various cost components and pricing influencers, a thorough understanding of these aspects can help B2B buyers make informed purchasing decisions. By focusing on negotiation, total cost of ownership, and supplier relationships, buyers can enhance their sourcing strategies and ultimately improve their operational efficiency. Always remember that the prices provided are indicative and can vary based on market conditions and specific supplier negotiations.

Illustrative image related to how do i know if it’s my starter or alternator

Alternatives Analysis: Comparing how do i know if it’s my starter or alternator With Other Solutions

Exploring Alternatives to Diagnose Starter or Alternator Issues

When it comes to diagnosing whether a vehicle’s issues stem from the starter or the alternator, there are several methods available. Understanding these alternatives can help businesses make informed decisions regarding vehicle maintenance and repairs. This comparison will highlight the traditional diagnostic method alongside two viable alternatives: the use of diagnostic tools and mobile mechanic services.

Tabela comparativa

| Aspecto comparativo | How Do I Know If It’s My Starter Or Alternator | Ferramentas de diagnóstico | Serviços de mecânica móvel |

|---|---|---|---|

| Desempenho | Effective for basic troubleshooting | High accuracy in diagnostics | Quick diagnosis on-site |

| Custo | Low (DIY method) | Moderado (compra de ferramentas) | High (service fees apply) |

| Facilidade de implementação | Requires some mechanical knowledge | Requires training to use | Convenient, no tools needed |

| Manutenção | N/A | Tools require upkeep | Regular service scheduling |

| Melhor caso de uso | For basic vehicle owners | Professional workshops or fleets | For busy individuals or businesses needing quick service |

Discriminação detalhada das alternativas

1. Diagnostic Tools

Diagnostic tools, such as OBD-II scanners, provide a systematic approach to vehicle diagnostics. These tools connect to the vehicle’s onboard computer to retrieve error codes that can indicate whether the starter or alternator is malfunctioning.

Prós:

– High accuracy and reliability, reducing guesswork.

– Can diagnose multiple systems beyond just the starter and alternator, making them versatile.

– Ideal for professional workshops where multiple vehicles are serviced regularly.

Contras:

– Requires initial investment in the tools, which may be a barrier for smaller businesses.

– Staff may need training to interpret the diagnostic codes effectively.

– Not suitable for DIY mechanics without technical knowledge.

2. Serviços de mecânica móvel

Mobile mechanic services bring the expertise directly to the vehicle’s location, providing convenience for businesses or individuals with tight schedules. These professionals can perform diagnostics and repairs on-site, eliminating the need for towing or waiting at a garage.

Prós:

– Quick and convenient, especially for businesses that cannot afford vehicle downtime.

– Mechanics are typically well-trained, ensuring reliable diagnostics and repairs.

– Can handle a range of issues, making them versatile.

Contras:

– Generally more expensive due to travel and service fees.

– Availability can vary, especially in remote areas.

– Limited by the tools and equipment they can bring to the job site.

Conclusion: Choosing the Right Solution for Vehicle Diagnostics

When deciding on the best method to determine whether the starter or alternator is at fault, B2B buyers should consider their specific needs, budget, and technical capabilities. For businesses with technical expertise and a focus on cost-effectiveness, the traditional diagnostic method may be sufficient. However, for organizations that prioritize speed and convenience, investing in diagnostic tools or utilizing mobile mechanic services may provide the best return on investment. Ultimately, the right choice will depend on the operational context, the volume of vehicles serviced, and the urgency of repairs needed.

Essential Technical Properties and Trade Terminology for how do i know if it’s my starter or alternator

What Are the Key Technical Properties to Consider When Diagnosing Starter or Alternator Issues?

When faced with potential issues regarding a vehicle’s starter or alternator, understanding certain technical properties can significantly aid in diagnosing problems. Here are some critical specifications to consider:

-

Grau do material

– Definição: Refers to the quality and type of materials used in manufacturing starters and alternators. Common materials include high-grade aluminum for housings and copper for windings.

– Importância do B2B: Higher material grades often lead to enhanced durability and performance. Suppliers must ensure that components meet industry standards to minimize failure rates and maximize the lifespan of the part. -

Corrente nominal (amperagem)

– Definição: The maximum current that a starter or alternator can handle, typically expressed in amps (A). For instance, starters may range from 150 to 300 amps.

– Importância do B2B: Understanding the current rating is essential when selecting components that align with the vehicle’s power requirements. Inadequate ratings can lead to overheating and premature failure. -

Especificações de binário

– Definição: The amount of rotational force that a starter motor can exert to crank the engine, measured in foot-pounds (ft-lbs).

– Importância do B2B: Proper torque specifications ensure that the starter engages effectively with the engine. This is crucial for preventing mechanical failures and ensuring optimal performance, particularly in heavy-duty applications. -

Saída de tensão

– Definição: The voltage produced by the alternator to recharge the battery and power the electrical system, usually around 13.5 to 14.5 volts while the engine is running.

– Importância do B2B: A consistent voltage output is vital for the health of the battery and electrical systems. Buyers need to ensure that the alternator meets the voltage requirements specified by the vehicle manufacturer. -

Níveis de tolerância

– Definição: The allowable deviation from specified dimensions in the manufacturing process, often expressed in millimeters (mm) or inches.

– Importância do B2B: Precise tolerances are critical in ensuring that parts fit together correctly and function as intended. Variations can lead to operational inefficiencies and increased wear.

What Are Common Trade Terms Relevant to Starter and Alternator Diagnosis?

Familiarizing oneself with industry jargon can enhance communication and streamline procurement processes. Here are several common terms:

-

OEM (Fabricante de Equipamento Original)

– Definição: Refers to companies that produce parts that are used in the assembly of vehicles. OEM parts are made to the exact specifications of the original components.

– Importância do B2B: Purchasing OEM parts ensures compatibility and reliability, which can be crucial for maintaining vehicle performance and warranty compliance. -

MOQ (Quantidade mínima de encomenda)

– Definição: The smallest quantity of a product that a supplier is willing to sell. This can vary significantly between manufacturers.

– Importância do B2B: Understanding MOQ is essential for inventory management and cost control. Businesses must align their purchasing strategies with supplier requirements to avoid excess inventory. -

RFQ (Pedido de Orçamento)

– Definição: A formal process where buyers request price quotes from suppliers for specific products or services.

– Importância do B2B: An RFQ helps buyers assess pricing, availability, and terms from multiple suppliers, enabling informed decision-making and cost savings. -

Incoterms (Termos Comerciais Internacionais)

– Definição: A set of international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Importância do B2B: Understanding Incoterms is crucial for international transactions, as they define risk transfer and cost responsibilities, helping to avoid disputes. -

Prazo de entrega

– Definição: The time taken from placing an order to its delivery. This can include manufacturing time, shipping, and handling.

– Importância do B2B: Knowing lead times is vital for planning and inventory management. Businesses must ensure that they have the necessary parts on hand to avoid downtime in operations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when diagnosing and purchasing components related to starters and alternators, ultimately enhancing operational efficiency and vehicle reliability.

Navigating Market Dynamics and Sourcing Trends in the how do i know if it’s my starter or alternator Sector

What Are the Global Drivers Impacting the Starter and Alternator Market?

The market for automotive starters and alternators is influenced by several global drivers. Firstly, the growing vehicle ownership rates, especially in emerging markets like Nigeria and Vietnam, are creating a higher demand for reliable automotive components. Additionally, advancements in automotive technology, such as the integration of smart features and electric vehicles (EVs), are reshaping consumer expectations for performance and efficiency. As a result, there is a noticeable shift towards sourcing high-quality, durable starters and alternators that can withstand diverse climatic conditions, particularly in regions with extreme weather.

Emerging B2B tech trends are also reshaping the sourcing landscape. Digital platforms and e-commerce solutions are facilitating easier access to suppliers, enabling international buyers to compare products, prices, and reviews effortlessly. Furthermore, the adoption of data analytics is helping manufacturers and suppliers optimize their inventory management and forecast demand more accurately. This trend is particularly relevant for B2B buyers looking to streamline their procurement processes and ensure they have the right components in stock to meet customer needs.

How Are Sustainability and Ethical Sourcing Influencing the Starter and Alternator Sector?

Sustainability has become a crucial consideration for B2B buyers in the automotive components market. The environmental impact of production processes, particularly in terms of energy consumption and waste generation, is under scrutiny. Buyers are increasingly seeking suppliers that demonstrate a commitment to sustainable practices, such as using recyclable materials and reducing carbon footprints in manufacturing. This trend is especially pertinent in regions like Europe, where regulatory frameworks are stringent.

Ethical sourcing is another vital aspect, as buyers are more aware of the conditions under which components are produced. Companies are expected to ensure that their supply chains adhere to fair labor practices and environmental standards. Certifications like ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers aiming to attract conscientious buyers. By prioritizing sustainability and ethical sourcing, international buyers not only mitigate risks but also enhance their brand reputation in an increasingly eco-conscious marketplace.

How Has the Starter and Alternator Market Evolved Over Time?

The evolution of the starter and alternator market can be traced back to the early 20th century when vehicles relied on manual cranking to start engines. The introduction of electric starters in the 1910s revolutionized vehicle operation, making it more accessible for the general public. Over the decades, advancements in technology have led to the development of more efficient and reliable starters and alternators, incorporating features like regenerative braking and smart charging systems.

In recent years, the push towards electric and hybrid vehicles has further transformed the market, as traditional starters and alternators adapt to new automotive technologies. Today, the focus is on creating components that not only perform well under various conditions but also align with global trends in sustainability and ethical production. As the automotive landscape continues to evolve, so too will the demands and expectations placed on these essential components, making it crucial for B2B buyers to stay informed and agile in their sourcing strategies.

Illustrative image related to how do i know if it’s my starter or alternator

Frequently Asked Questions (FAQs) for B2B Buyers of how do i know if it’s my starter or alternator

-

How do I diagnose whether my vehicle issue is related to the starter or alternator?

To diagnose the issue, begin with a visual inspection for signs of damage or corrosion on the battery terminals. Listen for sounds when attempting to start the vehicle; a clicking noise often indicates a starter issue, while dimming lights and dashboard warnings suggest alternator problems. Conducting a jump-start test can also help determine the culprit: if the vehicle starts with a jump but dies after disconnecting, it may point to a failing alternator. Engaging a professional technician for a thorough assessment is advisable for accurate diagnosis. -

What are the common symptoms of a failing starter or alternator?

Common symptoms of a failing starter include whirring or grinding noises when trying to start the vehicle, a single click without engine crank, or electrical components working while the engine does not. For a failing alternator, watch for dimming or flickering lights, strange noises from the engine compartment, and persistent battery warning lights. These symptoms can guide you in identifying the problematic component, allowing for timely repairs and reduced downtime. -

What is the best way to source quality starters and alternators for international trade?

When sourcing starters and alternators internationally, prioritize suppliers with established reputations for quality. Look for manufacturers that adhere to international quality standards, such as ISO certifications. Request samples to assess the product quality firsthand, and consider their warranty and return policies. Building relationships with suppliers who offer comprehensive support and transparent communication can also enhance your sourcing experience. -

How can I vet suppliers for automotive parts like starters and alternators?

To vet suppliers, start by researching their industry reputation and customer reviews. Evaluate their production capabilities, certifications, and compliance with international standards. Request references from other businesses that have sourced from them. Additionally, consider conducting factory visits or audits if possible, as this can provide insights into their operational practices and quality control measures. -

What customization options should I consider when sourcing automotive starters and alternators?

Customization options can include specific voltage ratings, design modifications for unique vehicle applications, and branding requirements. Discuss your needs with suppliers early in the negotiation process to ensure they can accommodate your specifications. Additionally, inquire about minimum order quantities (MOQ) for custom parts, as this can impact your budget and inventory management. -

What payment terms are typical for international suppliers of automotive components?

Payment terms can vary significantly among suppliers. Common practices include upfront deposits, letter of credit, or payment upon delivery. It’s crucial to negotiate terms that protect both parties, ensuring that you receive quality products while providing the supplier with financial security. Always clarify the terms in your contract to avoid misunderstandings later. -

How do I ensure quality assurance when importing starters and alternators?

Implement a quality assurance (QA) plan that includes detailed inspections at various stages of the supply chain. Request quality certifications from suppliers and consider third-party inspection services before shipment. Establish clear quality benchmarks and communicate these to your suppliers, ensuring they understand your expectations for product performance and reliability. -

Que considerações logísticas devo ter em conta ao importar peças para automóveis?

When importing starters and alternators, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner experienced in handling automotive parts to ensure timely delivery. Factor in lead times for production and shipping, and maintain open communication with suppliers regarding any delays or changes in shipping schedules to mitigate disruptions to your supply chain.

Top 2 How Do I Know If It’S My Starter Or Alternator Manufacturers & Suppliers List

1. Capitol Chevy – Battery, Starter, Alternator Diagnostics

Domínio: capitol-chevy.com

Registado: 1999 (26 anos)

Introdução: This page provides information on diagnosing issues related to the battery, starter, or alternator in vehicles. It outlines symptoms and likely culprits for starting problems: 1. Dim or flickering lights indicate a failing alternator. 2. Dash lights on but car won’t start suggest a faulty starter. 3. Successful jump start points to a weak battery. 4. Jump start fails may indicate a bad starter or …

2. Honda Civic – Starting Issues Diagnosis

Domínio: mechanics.stackexchange.com

Registado: 2009 (16 anos)

Introdução: Vehicle: 2006 Honda Civic EX 1.8L 4 Cylinder; Symptoms: Car won’t start, weak cranking, single click sound; Battery: New battery installed, tested good; Possible issues: Starter failure, alternator failure, battery cable issues; Diagnosis steps: Check battery voltage (12.6V off, 13.5-14.2V running), perform voltage drop test on cables.

Strategic Sourcing Conclusion and Outlook for how do i know if it’s my starter or alternator

In the quest to determine whether your vehicle’s issues stem from the starter or alternator, understanding the interplay between these crucial components is vital. Key indicators, such as slow engine cranking, dim lights, or unusual noises, can help you pinpoint the problem efficiently. For B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe, sourcing high-quality automotive parts is essential for maintaining operational reliability and minimizing downtime.

Strategic sourcing plays a pivotal role in ensuring that you procure the right components at competitive prices. By establishing strong relationships with trusted suppliers and manufacturers, you can enhance your supply chain resilience and access the latest technologies. This proactive approach not only reduces costs but also positions your business to respond swiftly to market demands.

As you move forward, consider investing in comprehensive diagnostics and maintenance solutions to streamline your operations. Engaging with reputable service providers can further bolster your strategy, ensuring that your fleet remains in peak condition. Embrace the opportunity to enhance your sourcing strategy today, and secure a competitive edge in the evolving automotive landscape.

Illustrative image related to how do i know if it’s my starter or alternator

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.