Introduction: Navigating the Global Market for good alternator brands

In today’s global marketplace, sourcing good alternator brands can be a daunting task for B2B buyers. With a myriad of options available across different regions, understanding which brands offer the best reliability, performance, and value is crucial. This guide delves into the intricacies of selecting the right alternators, addressing vital considerations such as product types, specific applications, and the importance of thorough supplier vetting. It also examines cost implications, including total cost of ownership and potential savings from aftermarket alternatives.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including key markets such as Germany and Brazil—face unique challenges in ensuring they receive quality products that meet their diverse needs. This comprehensive resource empowers decision-makers by providing insights into the most trusted brands, their features, and the warranties they offer. Additionally, it highlights the significance of understanding local regulations and market dynamics, enabling buyers to navigate the complexities of global sourcing effectively.

By equipping B2B buyers with actionable information and expert recommendations, this guide serves as a vital tool for making informed purchasing decisions. Whether you are looking to enhance your fleet’s reliability or ensure your automotive business remains competitive, understanding the landscape of good alternator brands is essential for your success.

Índice

- Top 1 Good Alternator Brands Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for good alternator brands

- Understanding good alternator brands Types and Variations

- Key Industrial Applications of good alternator brands

- 3 Common User Pain Points for ‘good alternator brands’ & Their Solutions

- Strategic Material Selection Guide for good alternator brands

- In-depth Look: Manufacturing Processes and Quality Assurance for good alternator brands

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘good alternator brands’

- Comprehensive Cost and Pricing Analysis for good alternator brands Sourcing

- Alternatives Analysis: Comparing good alternator brands With Other Solutions

- Essential Technical Properties and Trade Terminology for good alternator brands

- Navigating Market Dynamics and Sourcing Trends in the good alternator brands Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of good alternator brands

- Strategic Sourcing Conclusion and Outlook for good alternator brands

- Aviso legal importante e termos de utilização

Understanding good alternator brands Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Alternadores OEM | Manufactured to original equipment specifications. | Automotive manufacturers, fleet services. | Prós: Perfect fit, high reliability. Contras: Custo mais elevado. |

| Alternadores para o mercado de reposição | Cost-effective alternatives often remanufactured or new. | Independent auto repair shops, retailers. | Prós: Affordable, wide selection. Contras: Variable quality. |

| Alternadores de alta potência | Designed for vehicles with increased electrical demands. | Performance vehicles, off-road vehicles. | Prós: Enhanced performance, supports additional accessories. Contras: More expensive, larger size. |

| Alternadores remanufaturados | Rebuilt to original specs, often with a warranty. | Budget-conscious buyers, small repair shops. | Prós: Cost-effective, environmentally friendly. Contras: Vida útil mais curta do que a de um novo. |

| Alternadores especiais | Tailored for specific applications (e.g., agricultural, marine). | Niche markets, specialized vehicle repair. | Prós: Optimized for specific use cases. Contras: Limited availability. |

What are OEM Alternators and Their Benefits for B2B Buyers?

OEM (Original Equipment Manufacturer) alternators are designed to meet the exact specifications of the vehicle manufacturer. These alternators ensure optimal performance and reliability, making them ideal for automotive manufacturers and fleet services that prioritize quality and longevity. When purchasing OEM alternators, B2B buyers should consider factors such as warranty coverage, availability, and pricing, as these can significantly impact total cost of ownership.

How Do Aftermarket Alternators Serve B2B Markets?

Aftermarket alternators provide a cost-effective solution for independent auto repair shops and retailers. They offer a diverse range of options, including both new and remanufactured units, allowing businesses to cater to various customer needs and budgets. While aftermarket options can be more affordable, it is crucial for buyers to assess the quality and compatibility of these products to avoid potential installation issues.

Why Choose High-Output Alternators for Specialized Applications?

High-output alternators are specifically designed to support vehicles with increased electrical demands, such as those equipped with advanced audio systems or additional lighting. B2B buyers in performance automotive or off-road vehicle markets will find these alternators essential for ensuring reliable power delivery. However, they typically come at a higher price point and may require more space, so compatibility with the vehicle’s design should be a key consideration.

What Are the Advantages of Remanufactured Alternators?

Remanufactured alternators offer a balance between cost and performance, making them an attractive option for budget-conscious buyers and small repair shops. These products are rebuilt to meet original specifications and often come with warranties, providing buyers with peace of mind. However, B2B buyers should be aware that remanufactured units may have a shorter lifespan compared to new alternatives, so evaluating the warranty terms and service history is vital.

How Do Specialty Alternators Meet Niche Market Needs?

Specialty alternators are designed for specific applications, such as agricultural equipment or marine vehicles. These tailored products ensure optimal performance in unique operating conditions, making them valuable for niche markets. B2B buyers should consider the specific requirements of their applications when sourcing specialty alternators, as availability may be limited and pricing can vary significantly based on the customization involved.

Key Industrial Applications of good alternator brands

| Indústria/Setor | Specific Application of good alternator brands | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Automotivo | Replacement parts for vehicles | Assegura o funcionamento fiável do veículo e a satisfação do cliente | Compatibility with various vehicle models and OEM standards |

| Agricultura | Alternators for farming equipment | Enhances productivity by ensuring equipment reliability | Resistance to environmental factors and heavy-duty performance |

| Construção | Power generation for machinery | Guarantees consistent power supply for construction sites | Durability under harsh conditions and ease of installation |

| Energia renovável | Wind turbine and solar panel systems | Supports sustainable energy initiatives and reduces costs | Efficiency ratings and compatibility with existing systems |

| Marinha | Power systems for boats and ships | Provides reliable power for navigation and onboard systems | Resistência à corrosão e conformidade com as normas marítimas |

How Are Good Alternator Brands Used in the Automotive Sector?

In the automotive industry, good alternator brands provide essential replacement parts for a wide range of vehicles, including cars, trucks, and buses. These alternators are crucial for maintaining the electrical system, powering everything from headlights to infotainment systems. B2B buyers in this sector must ensure compatibility with various vehicle models, focusing on OEM standards to avoid installation issues and ensure reliability. Additionally, a warranty can be a significant factor, providing reassurance about the product’s longevity and performance.

What Role Do Good Alternator Brands Play in Agriculture?

In agriculture, good alternator brands are integral to the functionality of farming equipment such as tractors and harvesters. These alternators ensure that machinery operates efficiently, which is vital for maximizing productivity during critical planting and harvesting seasons. Buyers must consider the alternator’s resistance to environmental factors like dust and moisture, as well as its ability to handle heavy-duty performance. Sourcing from reputable brands can help mitigate downtime and enhance operational efficiency in agricultural settings.

How Are Good Alternator Brands Beneficial in Construction?

In the construction industry, good alternator brands are used in power generation for heavy machinery and equipment. These alternators ensure a consistent power supply, which is crucial for the operation of tools and equipment on construction sites. Buyers should prioritize durability under harsh conditions and ease of installation when sourcing alternators for construction applications. This focus helps reduce downtime and enhances the overall productivity of construction projects, making it a critical consideration for B2B buyers.

How Do Good Alternator Brands Support Renewable Energy Initiatives?

Good alternator brands play a pivotal role in renewable energy applications, particularly in wind turbines and solar panel systems. They ensure efficient energy conversion and reliable performance, which are essential for supporting sustainable energy initiatives. B2B buyers must evaluate the efficiency ratings of alternators and their compatibility with existing renewable energy systems to ensure optimal performance. This consideration is particularly important for international buyers looking to invest in eco-friendly energy solutions.

Why Are Good Alternator Brands Important in Marine Applications?

In the marine sector, good alternator brands are vital for providing power to navigation systems and onboard electronics in boats and ships. These alternators must be corrosion-resistant and compliant with marine standards to withstand harsh marine environments. B2B buyers should focus on sourcing alternators that meet these specific requirements, ensuring reliable power supply and safety during maritime operations. This attention to detail is essential for maintaining operational efficiency and compliance in the marine industry.

3 Common User Pain Points for ‘good alternator brands’ & Their Solutions

Scenario 1: Difficulty in Ensuring Compatibility with Existing Systems

O problema: B2B buyers often face challenges when sourcing alternators that are compatible with specific vehicle models or existing electrical systems. The risk of purchasing the wrong alternator can lead to significant downtime and financial loss, particularly for businesses relying on a fleet of vehicles. Misalignment in specifications such as amperage, fitment, or mounting points can result in costly errors, frustrating installation processes, and ultimately, reduced operational efficiency.

A solução: To mitigate compatibility issues, B2B buyers should begin by conducting thorough research on the specific requirements for their vehicles or equipment. Utilizing VIN (Vehicle Identification Number) to cross-reference with manufacturer specifications can ensure the selected alternator matches the necessary parameters. Additionally, collaborating closely with suppliers who offer detailed product catalogs and technical support can facilitate better decision-making. It’s also advisable to invest in alternators from reputable brands known for their precision manufacturing and extensive testing, such as Denso or Bosch. These brands often provide comprehensive fitment guides and customer support, which can significantly reduce the risk of compatibility issues.

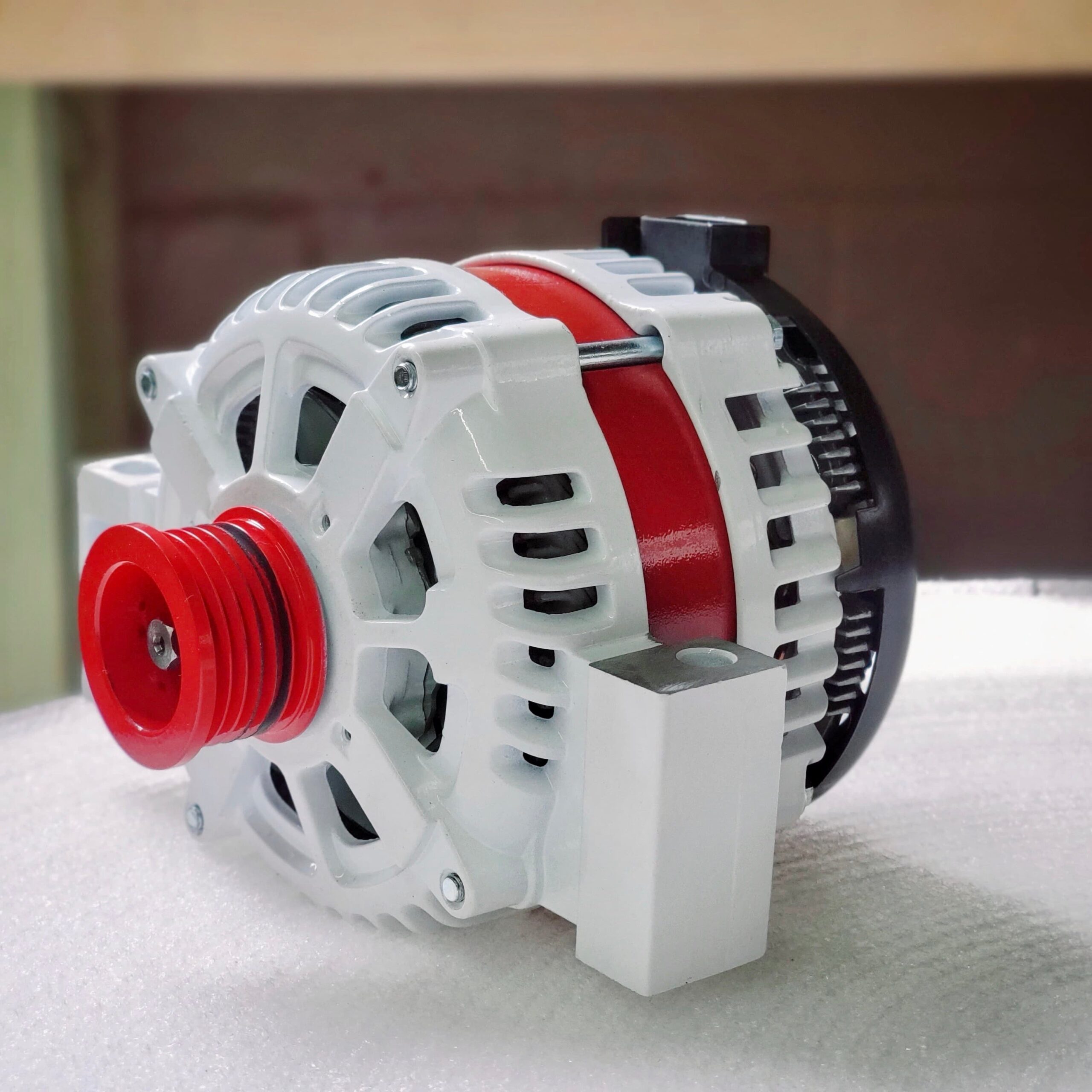

Illustrative image related to good alternator brands

Scenario 2: Managing Cost vs. Quality Dilemmas in Alternator Purchases

O problema: B2B buyers frequently grapple with the dilemma of balancing cost and quality when purchasing alternators. With a wide range of prices in the market, it can be tempting to opt for cheaper options to save on upfront costs. However, lower-quality alternators may lead to higher long-term expenses due to frequent replacements, downtime, and potential damage to other vehicle components. This situation is especially critical for businesses operating in regions like Africa or South America, where sourcing replacements can be challenging and costly.

A solução: To navigate this cost-quality conundrum, buyers should adopt a total cost of ownership approach. This involves evaluating not just the initial purchase price but also the expected lifespan, warranty terms, and the reliability of the alternator. Opting for brands like AC Delco or WAI, which offer robust warranties and are known for their durability, can provide peace of mind. Furthermore, buyers should consider leveraging bulk purchasing options or establishing long-term relationships with suppliers to negotiate better pricing on high-quality alternators. Regularly reviewing performance data and customer feedback can also guide purchasing decisions and ensure that the chosen alternators meet the demands of the business without compromising quality.

Scenario 3: Difficulty in Obtaining Reliable After-Sales Support

O problema: After-sales support is a critical consideration for B2B buyers, yet it is often overlooked. Buyers may find themselves stranded with malfunctioning alternators and inadequate support from manufacturers or suppliers. This lack of reliable after-sales service can lead to extended downtimes, especially in regions where technical assistance is scarce. For businesses that depend on the operational reliability of their vehicles, such gaps in service can be detrimental.

Illustrative image related to good alternator brands

A solução: To ensure access to dependable after-sales support, buyers should prioritize suppliers and brands that are well-regarded for their customer service and warranty offerings. It is beneficial to choose alternator brands that provide extensive technical assistance and have a reputation for honoring warranties without hassle. Buyers can also seek suppliers that offer training sessions or resources on installation and maintenance, enabling their teams to troubleshoot issues effectively. Establishing a communication channel for post-purchase inquiries can further enhance support. Regularly engaging with suppliers for updates on product performance and potential recalls can also foster a proactive approach to maintenance and support, ensuring smoother operations.

Strategic Material Selection Guide for good alternator brands

What Materials are Commonly Used in Good Alternator Brands?

When selecting alternators for various applications, the materials used in their construction play a significant role in performance, durability, and overall value. Below, we analyze four common materials used in good alternator brands and their implications for international B2B buyers.

Quais são as principais propriedades do alumínio nos alternadores?

Aluminum is widely used in alternator housings and components due to its lightweight nature and excellent thermal conductivity. It typically has a temperature rating of around 150°C and is resistant to corrosion, making it suitable for various environmental conditions.

Prós: Aluminum is lightweight, which helps reduce the overall weight of the vehicle, improving fuel efficiency. It also offers good corrosion resistance, which is critical for applications in humid or coastal environments.

Contras: While aluminum is durable, it can be less robust than other materials like steel, particularly under high-stress conditions. Additionally, its manufacturing process can be more complex, potentially increasing production costs.

Illustrative image related to good alternator brands

Impacto na aplicação: Aluminum’s compatibility with electrical systems is critical, as it minimizes the risk of electrical interference. However, it may not be suitable for extreme temperature applications without additional thermal management.

Considerações para compradores internacionais: Buyers from regions with high humidity, such as parts of Africa and South America, may prefer aluminum for its corrosion resistance. Compliance with international standards like ASTM and DIN is crucial to ensure quality and performance.

How Does Copper Contribute to Alternator Performance?

Copper is primarily used in the windings and connectors of alternators due to its excellent electrical conductivity and thermal properties. It can handle high temperatures, typically rated up to 200°C, and has a high resistance to oxidation.

Prós: Copper’s superior conductivity ensures efficient power generation and transmission, which is essential for modern vehicles with high electrical demands. Its durability also supports long service life.

Contras: The primary drawback is cost; copper is more expensive than alternatives like aluminum. Additionally, its weight can contribute to increased overall vehicle weight, which may not be desirable for fuel efficiency.

Impacto na aplicação: Copper is particularly advantageous in applications requiring high amperage and rapid electrical response, making it ideal for vehicles with advanced electronic systems.

Considerações para compradores internacionais: Buyers in Europe, especially Germany, may prioritize copper for its performance benefits, while also needing to consider the environmental impact of copper mining and production.

Qual o papel do aço na construção de alternadores?

Steel is often used in the structural components of alternators, including the rotor and stator frames. It offers high strength and durability, with a temperature rating typically around 300°C.

Illustrative image related to good alternator brands

Prós: Steel’s robustness makes it suitable for heavy-duty applications, and it can withstand significant mechanical stress. It is also relatively inexpensive compared to aluminum and copper.

Contras: The main disadvantage of steel is its susceptibility to corrosion, requiring protective coatings to enhance longevity. Additionally, its weight can negatively impact vehicle performance.

Impacto na aplicação: Steel is ideal for applications where mechanical strength is paramount, such as in commercial vehicles or heavy machinery.

Illustrative image related to good alternator brands

Considerações para compradores internacionais: Buyers from the Middle East may favor steel for its strength, but they should be aware of the need for corrosion protection in harsh environments. Compliance with local standards is essential for quality assurance.

How Does Plastic Affect Alternator Design?

Plastic is increasingly used in non-structural components of alternators, such as housings and insulation. It offers a temperature resistance typically up to 100°C and is lightweight.

Prós: Plastic is cost-effective and can be molded into complex shapes, allowing for innovative designs. Its lightweight nature can contribute to overall vehicle efficiency.

Contras: Plastic is less durable than metals and can degrade under high temperatures or exposure to certain chemicals. This limits its application in critical components.

Impacto na aplicação: Plastic can be suitable for low-stress components, but its use in high-temperature areas should be carefully considered.

Considerações para compradores internacionais: Buyers in regions with varying climates should assess plastic’s suitability based on environmental conditions. Compliance with material safety standards is crucial to ensure reliability.

Summary Table of Material Properties for Good Alternator Brands

| Material | Typical Use Case for good alternator brands | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Alumínio | Caixas e componentes estruturais | Leve e resistente à corrosão | Less robust under high stress | Médio |

| Cobre | Enrolamentos e conectores | Condutividade elétrica superior | Custo e peso mais elevados | Alto |

| Aço | Estruturas do rotor e do estator | Alta resistência e durabilidade | Suscetível à corrosão | Baixo |

| Plástico | Componentes não estruturais | Económica e leve | Menos durável sob tensão | Baixo |

This analysis provides B2B buyers with essential insights into the materials used in good alternator brands, helping them make informed purchasing decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for good alternator brands

What Are the Main Stages of Manufacturing Processes for Good Alternator Brands?

The manufacturing of high-quality alternators involves several key stages, each critical to ensuring the final product meets the rigorous demands of performance and reliability. Understanding these processes helps B2B buyers appreciate the craftsmanship involved and the standards upheld by reputable brands.

Illustrative image related to good alternator brands

Como é que o material é preparado para o fabrico de alternadores?

The first step in the manufacturing process is material preparation, where high-quality raw materials are sourced. Common materials include copper for windings, steel for frames, and various polymers for insulation. Suppliers of good alternator brands often conduct thorough audits of their material suppliers to ensure compliance with international standards like ISO 9001. This compliance guarantees that only materials free from defects and suitable for automotive applications are used.

Que técnicas de conformação são utilizadas na produção de alternadores?

Once materials are prepared, the forming stage begins. This often involves processes such as stamping, machining, and casting. For instance, the rotor and stator components are typically stamped from metal sheets and then machined to precise specifications. Good brands may employ techniques like die-casting for parts that require complex shapes, ensuring high dimensional accuracy. Advanced forming technologies, such as CNC machining, further enhance precision and repeatability, critical for performance.

How Is Assembly Conducted in Quality Alternator Manufacturing?

The assembly process is where the individual components come together to form the final alternator. Skilled technicians or automated systems typically carry out this process in a cleanroom environment to prevent contamination. Good alternator brands often implement lean manufacturing principles to minimize waste and optimize efficiency. Key components, such as the rotor, stator, bearings, and voltage regulators, are assembled with precision, ensuring each unit is built to meet specific performance standards.

Que processos de acabamento são importantes para os alternadores?

Finishing processes enhance the durability and aesthetic appeal of alternators. These can include surface treatments, such as anodizing or powder coating, to prevent corrosion and wear. Additionally, proper balancing of the rotor is crucial to ensure smooth operation and minimize vibration during use. Quality brands often perform rigorous inspections during this stage to ensure that all components meet their specifications before moving to quality control checks.

Illustrative image related to good alternator brands

What Quality Assurance Measures Are Standard for Good Alternator Brands?

Quality assurance (QA) is essential in the alternator manufacturing process. It encompasses various methods and standards that guarantee each product’s reliability and performance.

Which International Standards Are Relevant to Alternator Quality Control?

Good alternator brands adhere to international quality standards such as ISO 9001, which outlines a framework for quality management systems. Compliance with these standards demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are critical for specific markets, particularly in Europe and the Americas, respectively.

Quais são os principais pontos de verificação do controlo de qualidade na fabricação de alternadores?

Quality control occurs at various checkpoints throughout the manufacturing process. The main checkpoints include:

- Controlo de Qualidade de Entrada (IQC): This initial stage verifies the quality of incoming materials and components before production begins.

- Controlo de qualidade em processo (IPQC): During assembly, random samples are taken to ensure that the assembly process adheres to quality standards. This step may include functional testing of components as they are assembled.

- Controlo de Qualidade Final (FQC): Once the alternator is fully assembled, it undergoes extensive testing to ensure it meets performance specifications. This includes electrical tests for voltage output, thermal testing, and vibration analysis.

Como os compradores B2B podem verificar as práticas de controlo de qualidade dos fornecedores?

B2B buyers can take several actions to verify the quality control practices of their suppliers:

-

Auditorias: Conducting supplier audits helps assess adherence to quality standards and manufacturing processes. These audits can be scheduled or surprise inspections, providing an accurate picture of the supplier’s operations.

-

Relatórios de qualidade: Requesting detailed quality reports and certifications can offer insight into the manufacturer’s compliance with international standards. This documentation should include records of IQC, IPQC, and FQC results.

-

Inspeções por terceiros: Engaging third-party inspection services can further validate the quality of the alternators. These inspections can provide an unbiased assessment of the manufacturing processes and end products.

-

Customer Reviews and Testimonials: Researching customer feedback and testimonials can provide insights into the supplier’s reliability and the performance of their products in real-world applications.

Que nuances devem os compradores internacionais B2B ter em conta relativamente ao controlo de qualidade?

Os compradores internacionais, especialmente de regiões como a África, a América do Sul, o Médio Oriente e a Europa, devem estar cientes das nuances específicas do controlo de qualidade:

-

Conformidade regulamentar: Different regions may have varying regulatory requirements for automotive components. It is essential to ensure that the alternators comply with local regulations in the buyer’s region, which may involve additional certifications or testing.

-

Considerações culturais: Understanding cultural differences in business practices can facilitate smoother negotiations and collaborations with suppliers. Building strong relationships often leads to better communication regarding quality expectations.

-

Logística e cadeia de abastecimento: International shipping can impact the quality of products. Buyers should inquire about how suppliers handle packaging and transportation to mitigate risks of damage during transit.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when selecting alternator brands, ensuring they partner with reliable manufacturers committed to quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘good alternator brands’

To assist B2B buyers in procuring quality alternators, this guide outlines essential steps for sourcing reliable brands. It is designed to streamline the purchasing process, ensuring that buyers select products that meet their operational needs while maintaining cost-effectiveness and reliability.

Passo 1: Defina as suas especificações técnicas

Establishing clear technical requirements is critical. Consider the specific vehicle models you are servicing, the required amperage, and whether you need new or remanufactured units. Detailing these specifications will help you target the right alternator brands that align with your operational demands.

Passo 2: Research Reputable Brands

Familiarize yourself with leading alternator brands known for their reliability and performance. Brands such as Denso, Bosch, and AC Delco are widely recognized for their quality. Look for brands that offer extensive warranties and have a proven track record in the market, ensuring you invest in products that reduce the risk of failure.

Illustrative image related to good alternator brands

Passo 3: Avaliar as certificações dos fornecedores

Before committing to a supplier, verify their industry certifications and quality assurance processes. Certifications such as IATF-16949 indicate adherence to high manufacturing standards. This step ensures that you are sourcing from reputable suppliers who prioritize quality and reliability in their products.

Passo 4: Solicitar amostras para teste

Whenever possible, request samples of the alternators you are considering. Testing samples allows you to evaluate their performance and compatibility with your applications. Look for performance indicators such as voltage stability and durability under load, which are crucial for operational efficiency.

Passo 5: Assess Pricing Structures and Total Cost of Ownership

Analyze the pricing of the alternators in relation to their features and warranties. Consider not just the initial purchase price but also the total cost of ownership, which includes potential shipping fees, installation costs, and expected lifespan. A slightly higher upfront cost may lead to significant savings in maintenance and replacements over time.

Passo 6: Review Supplier Support and Warranty Policies

Evaluate the level of customer support provided by potential suppliers. A robust support system can assist with installation issues and warranty claims. Ensure that warranty policies are clear and favorable, ideally offering coverage for at least one to two years, which reflects the supplier’s confidence in their product.

Passo 7: Gather Feedback from Existing Customers

Reach out to other businesses that have experience with the brands and suppliers you are considering. Gathering testimonials and reviews can provide valuable insights into product performance and supplier reliability. This firsthand information can guide your decision-making process and help mitigate risks associated with new suppliers.

Illustrative image related to good alternator brands

By following these steps, B2B buyers can confidently navigate the procurement process for alternators, ensuring they select high-quality products that meet their specific needs and contribute to operational success.

Comprehensive Cost and Pricing Analysis for good alternator brands Sourcing

What Are the Key Cost Components in Sourcing Good Alternator Brands?

When sourcing alternators, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materiais: The quality of raw materials directly affects the durability and efficiency of alternators. High-quality copper windings, for instance, can increase costs but also enhance performance and longevity.

-

Trabalho: Skilled labor is required for assembly, particularly in manufacturing facilities that prioritize quality control. Labor costs can vary significantly by region, impacting overall pricing.

-

Custos indiretos de produção: This encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Ferramentas: The investment in specialized machinery and tools for manufacturing specific alternator models can influence pricing. Custom tooling may lead to higher initial costs but can lower per-unit costs for larger production runs.

-

Controlo de Qualidade (QC): Rigorous testing and quality assurance processes are essential to ensure product reliability. Brands that invest in comprehensive QC may have higher upfront costs but can offer better warranties and customer satisfaction.

-

Logística: Shipping costs can fluctuate based on distance, mode of transport, and volume. Efficient logistics strategies can reduce costs and improve delivery times.

-

Margem: Supplier margins vary, impacting the final price. Established brands with strong market presence may command higher prices due to brand equity and perceived reliability.

What Price Influencers Should International Buyers Consider?

Several factors can influence the pricing of alternators in the B2B market:

-

Volume/MOQ (Quantidade mínima de encomenda): Suppliers often provide better pricing for larger orders. Buyers should assess their needs to maximize cost savings through bulk purchasing.

-

Especificações e personalização: Custom requirements may increase production costs. Buyers should evaluate whether standard models meet their needs to avoid unnecessary expenses.

-

Materiais e certificações de qualidade: Alternators with premium materials and certifications (e.g., ISO, IATF-16949) may have higher costs but offer long-term reliability, which can justify the investment.

-

Fatores relacionados ao fornecedor: Supplier reputation and stability can influence pricing. Established suppliers may charge more but provide better quality assurance and support.

-

Incoterms: Understanding shipping terms is essential. The choice between FOB (Free on Board) and CIF (Cost, Insurance, and Freight) can significantly impact total costs, including insurance and tariffs.

What Buyer Tips Can Help Ensure Cost-Efficiency?

For B2B buyers, especially from diverse markets such as Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negociação: Engage suppliers in discussions regarding pricing, especially for bulk orders. Leverage competition among suppliers to negotiate better terms.

-

Custo total de propriedade (TCO): Consider not just the initial purchase price but also maintenance, potential downtime, and shipping costs. Higher-quality alternators may save money in the long run by reducing failures and associated costs.

-

Nuances de preços para transacções internacionais: Be aware of currency fluctuations, tariffs, and taxes that may affect the final cost. Establishing relationships with local suppliers can mitigate some of these risks.

-

Garantia e assistência pós-venda: Evaluate warranty offerings and the supplier’s ability to provide timely after-sales support. A strong warranty can reduce long-term costs associated with replacements and repairs.

Isenção de responsabilidade sobre preços indicativos

While this analysis provides a framework for understanding the cost and pricing dynamics of good alternator brands, actual prices may vary based on market conditions, specific supplier agreements, and regional factors. Always consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing good alternator brands With Other Solutions

Introduction: Exploring Alternatives to Good Alternator Brands

In the automotive industry, selecting the right components is crucial for ensuring the reliability and performance of vehicles. While good alternator brands like Denso and Bosch are popular choices due to their proven quality and reliability, it’s essential to consider alternatives that may offer different benefits or better suit specific needs. This section compares established alternator brands with alternative solutions, including refurbished units and aftermarket substitutes, providing insights to help B2B buyers make informed decisions.

Illustrative image related to good alternator brands

Tabela comparativa

| Aspecto comparativo | Good Alternator Brands | Refurbished Alternators | Alternadores para o mercado de reposição |

|---|---|---|---|

| Desempenho | High-quality, OE-compliant | Variable; depends on refurbishment quality | Generally reliable, but may not match OEM standards |

| Custo | Moderate to high (e.g., $130 – $860) | Lower (e.g., $50 – $300) | Competitive (e.g., $40 – $640) |

| Facilidade de implementação | Direct-fit options available | Requires verification of quality | Usually direct-fit, easy installation |

| Manutenção | Low; designed for long life | Potential for early failure | Generally low; depends on brand |

| Melhor caso de uso | Fleet vehicles, premium cars | Cost-sensitive buyers | Everyday vehicles, DIY projects |

Discriminação detalhada das alternativas

1. Refurbished Alternators

Refurbished alternators present a cost-effective alternative for businesses looking to minimize expenses. These units are often sourced from old or damaged alternators that have been repaired and restored to working condition. While they can provide significant savings, the performance may be inconsistent. The quality of refurbishment varies widely among suppliers, making it essential for buyers to choose reputable vendors. This option is best for cost-sensitive buyers who prioritize budget over guaranteed performance.

2. Aftermarket Alternators

Aftermarket alternators are designed to be compatible with a wide range of vehicles, often at a lower price point than OE brands. They can provide reliable performance, particularly from reputable manufacturers, but may not always meet the same standards as original equipment. Buyers should evaluate the specifications, warranty, and reviews to ensure they select high-quality products. This solution is ideal for everyday vehicles and DIY enthusiasts who appreciate a balance of cost and performance.

Conclusão: Fazendo a escolha certa para as suas necessidades

When deciding between good alternator brands and alternative solutions, B2B buyers should consider factors such as performance reliability, cost-effectiveness, and the specific requirements of their fleet or vehicles. Good alternator brands like Denso and Bosch offer assurance of quality and performance, making them suitable for high-demand applications. In contrast, refurbished and aftermarket options may provide significant cost savings for businesses with different priorities. Ultimately, the right choice will depend on individual needs, budget constraints, and the intended use of the vehicles involved. Conducting thorough research and considering long-term implications will enable buyers to make informed, strategic decisions.

Illustrative image related to good alternator brands

Essential Technical Properties and Trade Terminology for good alternator brands

What Are the Key Technical Properties of Reliable Alternator Brands?

When evaluating alternator brands for procurement, understanding critical technical properties is essential for ensuring product performance and longevity. Here are some key specifications that B2B buyers should consider:

1. Classificação da amperagem

The amperage rating indicates the maximum electrical output an alternator can provide. It is crucial for determining whether the alternator can meet the electrical demands of a vehicle, especially when additional accessories like high-powered sound systems or lighting are added. Choosing an alternator with an appropriate amperage rating prevents electrical failures and enhances vehicle performance.

2. Material Grade

Alternators are typically made from materials like aluminum, copper, and high-grade plastics. The material grade affects durability, weight, and heat resistance. For instance, a high-grade aluminum housing provides better heat dissipation and corrosion resistance, which is vital in harsh operating conditions. Buyers should prioritize alternators with robust material construction to ensure reliability and reduce maintenance costs.

Illustrative image related to good alternator brands

3. Design and Configuration

The design includes the alternator’s physical dimensions, mounting points, and pulley system. A direct-fit design ensures compatibility with the specific vehicle model, simplifying installation. Understanding the configuration helps avoid costly installation errors and downtime, making it a key consideration for B2B buyers.

4. Classificação da eficiência

The efficiency rating reflects how effectively an alternator converts mechanical energy into electrical energy. Higher efficiency ratings translate into better fuel economy and lower emissions, which are increasingly important in global markets focused on sustainability. Buyers should seek alternators with high efficiency to align with environmental standards and reduce operational costs.

5. Warranty and Support

A robust warranty indicates the manufacturer’s confidence in their product’s quality. Warranties often cover defects and performance issues, providing peace of mind for buyers. Strong technical support also enhances the buyer’s experience, especially when dealing with installation or troubleshooting. Ensure to assess warranty terms and support availability as part of the purchasing decision.

Quais são os termos comerciais comuns utilizados na indústria de alternadores?

Familiarizing oneself with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should know:

1. OEM (Fabricante de Equipamento Original)

OEM refers to parts made by the original manufacturer of a vehicle. In the context of alternators, OEM parts are designed to meet the exact specifications of the vehicle they are intended for. Buyers often prefer OEM alternators for their guaranteed compatibility and reliability, especially in high-performance applications.

2. MOQ (Quantidade mínima de encomenda)

MOQ is the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory and cash flow effectively. Suppliers may set MOQs based on production costs or to ensure profitability, making it essential to negotiate favorable terms.

3. RFQ (Pedido de Cotação)

An RFQ is a document issued by a buyer to solicit price proposals from suppliers for specific products. It outlines the buyer’s requirements and helps in comparing different suppliers based on price, terms, and specifications. Crafting a detailed RFQ can lead to better pricing and service agreements.

4. Incoterms (Termos Comerciais Internacionais)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers involved in global procurement, as they clarify shipping costs and risk transfer points, helping to avoid misunderstandings.

5. Carga de base

A core charge is an additional fee applied when purchasing a remanufactured alternator, which is refunded upon returning the old unit. This practice encourages recycling and ensures that suppliers have the necessary components for future remanufacturing. Buyers should be aware of core charges to factor them into their overall cost calculations.

Illustrative image related to good alternator brands

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when selecting high-quality alternators that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the good alternator brands Sector

What Are the Current Market Dynamics Affecting Good Alternator Brands?

The global alternator market is witnessing a significant shift driven by several factors including technological advancements, increasing demand for electric vehicles (EVs), and the need for efficient energy management systems. With the rise of EVs, traditional alternator manufacturers are adapting by innovating products that cater to hybrid and electric applications. In regions such as Africa and South America, where vehicle ownership is rapidly increasing, the demand for reliable and cost-effective alternators is soaring. Buyers from these regions are particularly focused on finding brands that offer durability and performance at competitive prices.

Furthermore, B2B buyers are leveraging digital platforms for sourcing, enhancing their ability to compare products and manufacturers globally. The trend towards online procurement is accompanied by the use of data analytics and supply chain management software, allowing businesses to make informed purchasing decisions based on real-time market insights. Companies are also increasingly valuing suppliers that provide comprehensive support and warranty options, as these factors significantly influence total cost of ownership.

How Is Sustainability and Ethical Sourcing Reshaping the Good Alternator Brands Market?

Sustainability has become a critical factor in the sourcing decisions of B2B buyers, particularly in Europe and North America. The environmental impact of automotive components, including alternators, has led to a heightened awareness of ethical sourcing practices. Buyers are increasingly prioritizing brands that demonstrate a commitment to sustainability through the use of recycled materials and environmentally friendly manufacturing processes. Certifications such as ISO 14001 (Environmental Management) and adherence to the REACH regulation (Registration, Evaluation, Authorisation, and Restriction of Chemicals) are becoming prerequisites for supplier selection.

Moreover, the demand for ‘green’ products is not only a regulatory compliance issue but also a competitive advantage. Brands that can showcase their sustainability credentials are more likely to attract buyers looking to enhance their corporate social responsibility (CSR) profiles. This trend is particularly relevant in regions like Europe, where consumers and businesses alike are advocating for cleaner, greener alternatives. As a result, good alternator brands are increasingly investing in research and development to create products that meet both performance and environmental standards.

What Is the Historical Context of Good Alternator Brands in the B2B Landscape?

The alternator industry has evolved significantly over the past few decades. Initially, alternators were primarily developed for internal combustion engine vehicles, focusing on mechanical efficiency and reliability. However, with the advent of electronic vehicles and the increasing demand for advanced automotive technologies, manufacturers began diversifying their product offerings. Companies like Bosch and Denso, which have a long history in the automotive sector, have adapted their designs to meet the requirements of modern vehicles, including those with high electrical loads from infotainment systems and advanced driver assistance systems.

This evolution has not only broadened the scope of alternator applications but has also raised the bar for quality and performance standards. As international B2B buyers navigate this landscape, understanding the historical context and technological advancements in alternators can provide valuable insights into making informed purchasing decisions that align with current market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of good alternator brands

-

How can I identify a reliable alternator supplier?

To identify a reliable alternator supplier, start by researching their reputation in the industry. Look for customer reviews, testimonials, and case studies. Verify their certifications, such as ISO or IATF, which indicate adherence to quality standards. Additionally, request samples to assess product quality and consistency. Engaging in direct communication with the supplier can also provide insights into their customer service, responsiveness, and support capabilities. -

What are the key features to consider when sourcing alternators?

When sourcing alternators, consider the brand reputation, product specifications (like amperage and fitment), warranty terms, and whether they offer new or remanufactured units. It’s important to ensure compatibility with your specific vehicle models and applications. Additionally, evaluate the supplier’s ability to provide technical support and after-sales service, which can be crucial for troubleshooting and maintenance. -

What is the best alternator brand for heavy-duty vehicles?

For heavy-duty vehicles, brands like Bosch and Denso are often recommended due to their durability and performance under high loads. Bosch alternators are known for their robust construction and extensive range, while Denso provides high-quality units that meet OEM specifications. Always ensure that the selected brand meets the specific amperage and electrical requirements of your heavy-duty applications. -

What should I know about minimum order quantities (MOQs) for alternators?

Minimum order quantities (MOQs) can vary significantly between suppliers. Some may have low MOQs to accommodate smaller businesses, while others might require larger orders to offer competitive pricing. It’s essential to discuss MOQs upfront and consider how they align with your inventory management and cash flow needs. Additionally, inquire about pricing tiers based on volume to potentially reduce costs with larger orders. -

How can I ensure the quality of alternators before purchasing?

To ensure quality, request product samples for testing before making a bulk purchase. Look for alternators that come with comprehensive warranties and quality assurance certifications. Additionally, consider suppliers who provide detailed testing reports for their products, as this demonstrates their commitment to quality control. Building a relationship with the supplier can also help facilitate transparency regarding quality assurance processes. -

Que condições de pagamento são normalmente oferecidas pelos fornecedores de alternadores?

Payment terms can vary widely among suppliers. Common options include upfront payments, net 30/60/90 days, or payment upon delivery. Always clarify the terms before finalizing an order and consider negotiating terms that align with your cash flow cycle. Additionally, check if suppliers offer discounts for early payments or bulk orders, which can enhance your overall cost-effectiveness. -

Que considerações logísticas devo ter em conta quando forneço alternadores a nível internacional?

When sourcing alternators internationally, consider shipping methods, lead times, and customs regulations. Understand the total landed cost, which includes shipping, duties, and taxes. It’s advisable to partner with logistics companies experienced in international trade to navigate potential challenges. Additionally, ensure that your supplier can provide the necessary documentation for customs clearance, which can prevent delays in delivery. -

How do I manage supplier relationships for long-term success?

Managing supplier relationships involves regular communication, feedback, and performance reviews. Establish clear expectations regarding quality, delivery timelines, and service levels. Building a partnership mentality can lead to better pricing, flexibility in orders, and priority service. Schedule periodic reviews to discuss performance and explore opportunities for collaboration, such as joint development of new products or services tailored to your market needs.

Top 1 Good Alternator Brands Manufacturers & Suppliers List

1. Alternators – Top Brands Reviewed

Domínio: grassrootsmotorsports.com

Registado: 1999 (26 anos)

Introdução: Alternators discussed include: 1. Nippodenso (available at Napa, comes with a limited 3-year warranty) 2. OEM rebuilt alternators (recommended by users for reliability) 3. Bosch (mentioned as a good option from Auto Zone) 4. Autozone reman alternators (some users report good experiences) 5. Local rebuilders (recommended for quality over store-bought options)

Strategic Sourcing Conclusion and Outlook for good alternator brands

In conclusion, strategic sourcing of high-quality alternators is essential for international B2B buyers aiming to enhance their automotive offerings. By focusing on reputable brands like Denso, Bosch, and AC Delco, companies can ensure reliability, performance, and customer satisfaction. These brands not only provide strong warranties and support but also cater to a wide range of vehicle applications, making them suitable for diverse markets across Africa, South America, the Middle East, and Europe.

Illustrative image related to good alternator brands

Buyers should prioritize factors such as fitment, electrical load requirements, and total cost of ownership when selecting alternators. This approach not only mitigates risks associated with product failures but also fosters long-term partnerships with manufacturers known for their quality and service.

As the automotive market continues to evolve, leveraging strategic sourcing can lead to significant competitive advantages. By investing in dependable alternators today, businesses can position themselves for success and resilience in an ever-changing global marketplace. Engage with trusted suppliers now to secure the best options for your operational needs and drive your business forward with confidence.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.

Illustrative image related to good alternator brands