Introduction: Navigating the Global Market for testing starter solenoid

In the increasingly competitive landscape of automotive components, effectively testing starter solenoids poses a significant challenge for international B2B buyers. As the heart of a vehicle’s starting system, a reliable starter solenoid ensures seamless engine ignition, and understanding how to accurately assess its functionality is crucial for operational success. This guide will explore the various testing methodologies, including the use of multimeters and manual jump-start techniques, providing insights into different types of solenoids, their applications across diverse vehicle models, and the importance of quality assurance.

The comprehensive scope of this guide extends beyond mere testing techniques; it encompasses critical aspects such as supplier vetting, cost considerations, and market trends specific to regions like Africa, South America, the Middle East, and Europe, including countries like Vietnam and Nigeria. By delving into the nuances of sourcing and evaluating starter solenoids, this guide empowers B2B buyers to make informed purchasing decisions that not only enhance their operational efficiency but also foster long-term supplier relationships.

Armed with actionable insights and expert recommendations, readers will be better positioned to navigate the global market for testing starter solenoids, ensuring they procure high-quality components that meet their unique business needs. With this knowledge, buyers can mitigate risks associated with subpar products and align their purchasing strategies with industry best practices.

Índice

- Top 4 Testing Starter Solenoid Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for testing starter solenoid

- Understanding testing starter solenoid Types and Variations

- Key Industrial Applications of testing starter solenoid

- 3 Common User Pain Points for ‘testing starter solenoid’ & Their Solutions

- Strategic Material Selection Guide for testing starter solenoid

- In-depth Look: Manufacturing Processes and Quality Assurance for testing starter solenoid

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘testing starter solenoid’

- Comprehensive Cost and Pricing Analysis for testing starter solenoid Sourcing

- Alternatives Analysis: Comparing testing starter solenoid With Other Solutions

- Essential Technical Properties and Trade Terminology for testing starter solenoid

- Navigating Market Dynamics and Sourcing Trends in the testing starter solenoid Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of testing starter solenoid

- Strategic Sourcing Conclusion and Outlook for testing starter solenoid

- Aviso legal importante e termos de utilização

Understanding testing starter solenoid Types and Variations

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Teste com multímetro | Measures voltage and resistance, requires technical skill | Automotive repair shops, electronics suppliers | Prós: Accurate diagnostics; Contras: Requires expertise and proper tools. |

| Jump Start Method | Directly connects terminals to bypass solenoid function | Automotive troubleshooting, field repairs | Prós: Quick assessment; Contras: Risk of short circuits if not done carefully. |

| Solenoid Bench Testing | Tests solenoid outside the vehicle using a power source | Equipment manufacturers, automotive service centers | Prós: Isolates solenoid issues; Contras: Requires additional equipment and time. |

| Inspeção visual | Checks for physical damage or corrosion | Vehicle maintenance, fleet services | Prós: Simple and no tools needed; Contras: Pode não detetar problemas subjacentes. |

| Teste de carga | Assesses solenoid performance under operational conditions | Heavy machinery, commercial vehicle servicing | Prós: Real-world performance evaluation; Contras: May require specialized equipment. |

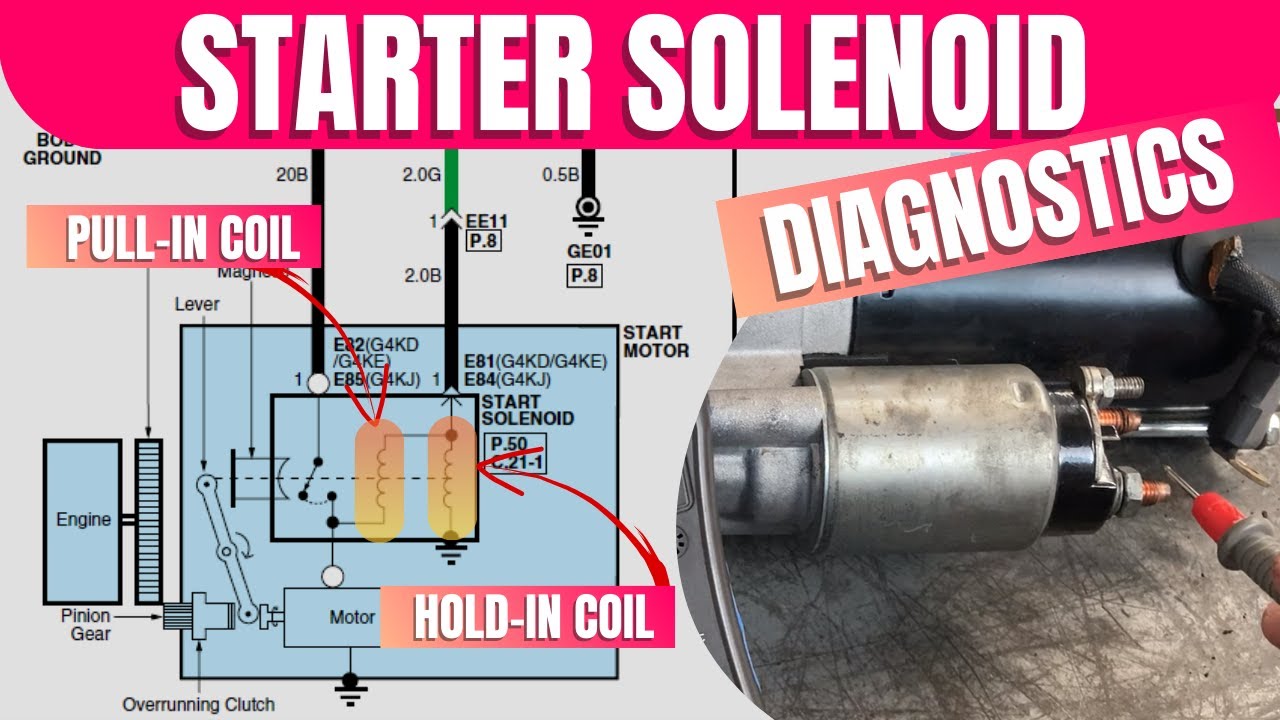

What is Multimeter Testing and When Should It Be Used?

Multimeter testing is a highly precise method for evaluating starter solenoids. By measuring voltage and resistance, technicians can determine whether the solenoid is functioning correctly. This method is particularly suitable for automotive repair shops and electronics suppliers that require accurate diagnostics. However, it necessitates a certain level of technical skill and familiarity with multimeter usage, which may not be available in all settings.

How Does the Jump Start Method Work and What Are Its Benefits?

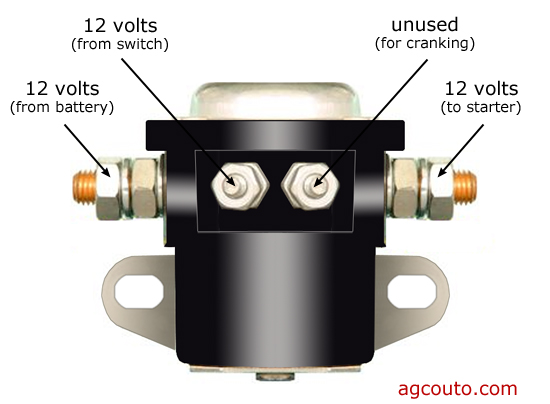

The jump start method involves directly connecting the solenoid terminals to bypass its functionality temporarily. This method allows technicians to quickly assess whether the solenoid is the source of starting issues. It’s commonly used in automotive troubleshooting and field repairs due to its immediacy. However, caution is necessary to avoid short circuits, making it less ideal for inexperienced personnel.

What is Solenoid Bench Testing and Its Applications?

Solenoid bench testing is conducted outside the vehicle, where the solenoid is powered separately to evaluate its performance. This method is ideal for equipment manufacturers and automotive service centers looking to isolate solenoid issues without the influence of other vehicle components. While it provides a clear picture of solenoid functionality, it requires additional equipment and can be time-consuming.

Why Consider Visual Inspection for Solenoid Issues?

Visual inspection is the simplest form of testing, where technicians look for signs of physical damage, corrosion, or loose connections. This method is often employed in vehicle maintenance and fleet services, as it requires no special tools or equipment. However, while it can quickly identify obvious issues, it may overlook more subtle, underlying problems that could affect performance.

What is Load Testing and How Can It Benefit Your Operations?

Load testing assesses the starter solenoid’s performance under operational conditions, making it especially useful for heavy machinery and commercial vehicle servicing. This method simulates real-world usage, providing insights into how the solenoid will perform under stress. However, it may require specialized equipment, which could be a consideration for smaller operations or those with budget constraints.

Key Industrial Applications of testing starter solenoid

| Indústria/Setor | Specific Application of Testing Starter Solenoid | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Testing starter solenoids in vehicles for maintenance and repairs | Reduces vehicle downtime and enhances repair efficiency | Quality of components, local availability, warranty terms |

| Máquinas agrícolas | Ensuring reliable operation of starter solenoids in farm equipment | Increases productivity by minimizing equipment failures | Supplier reliability, compatibility with equipment models |

| Equipamento de construção | Testing solenoids in heavy machinery for construction sites | Enhances operational efficiency and safety on-site | Compliance with safety standards, support services |

| Transporte e Logística | Verifying solenoid functionality in fleet vehicles | Reduces maintenance costs and improves fleet reliability | Bulk purchasing options, service agreements |

| Equipamento industrial | Testing solenoids in generators and machinery | Ensures uninterrupted operations and power reliability | Technical support, sourcing from reputable manufacturers |

How is Testing Starter Solenoid Applied in the Automotive Repair Industry?

In the automotive repair sector, testing starter solenoids is crucial for diagnosing starting issues in vehicles. Mechanics often encounter problems where vehicles fail to start due to faulty solenoids. By conducting tests, technicians can quickly identify whether the issue lies with the solenoid or the starter motor itself, thus streamlining the repair process. International buyers in this sector should prioritize sourcing high-quality solenoids that comply with local regulations to ensure reliability and safety.

What Role Does Testing Starter Solenoid Play in Agriculture Machinery?

Agricultural machinery relies heavily on starter solenoids for starting engines in tractors and harvesters. Testing these components ensures that farmers can depend on their equipment during critical harvesting seasons. A malfunctioning solenoid can lead to significant downtime, impacting productivity. Buyers should consider suppliers who offer durable solenoids specifically designed for harsh agricultural environments, ensuring longevity and performance in varying conditions.

How is Testing Starter Solenoid Important for Construction Equipment?

In the construction industry, testing starter solenoids in heavy machinery, such as excavators and bulldozers, is essential for maintaining operational efficiency. A faulty solenoid can cause machinery to fail at crucial moments, leading to project delays and increased costs. Buyers should focus on sourcing solenoids that meet rigorous safety and performance standards, as well as those that provide technical support and servicing options to minimize operational disruptions.

Illustrative image related to testing starter solenoid

Why is Testing Starter Solenoid Critical for Transportation and Logistics?

In the transportation and logistics sector, where fleet reliability is paramount, testing starter solenoids helps ensure that vehicles are always operational. Regular testing can prevent unexpected breakdowns, thus reducing maintenance costs and improving overall fleet reliability. B2B buyers in this sector should seek suppliers that offer bulk purchasing options and service agreements to facilitate ongoing maintenance and support.

How Does Testing Starter Solenoid Benefit Industrial Equipment Operations?

Testing starter solenoids in industrial equipment, such as generators and manufacturing machines, is vital for ensuring uninterrupted operations. A malfunctioning solenoid can lead to power failures, affecting production lines. Buyers should prioritize sourcing from reputable manufacturers that provide comprehensive technical support and warranty services, ensuring that their operations remain efficient and reliable.

3 Common User Pain Points for ‘testing starter solenoid’ & Their Solutions

Scenario 1: Difficulty Identifying Solenoid Issues

O problema: B2B buyers often encounter challenges in diagnosing whether the issue lies with the starter solenoid or the starter itself. This confusion can lead to unnecessary purchases and increased downtime for vehicles. For instance, a fleet manager may receive reports of vehicles failing to start but lacks the technical expertise to discern whether the solenoid is the culprit. This situation is particularly prevalent in regions where mechanical expertise may be limited, leading to reliance on trial and error rather than accurate diagnostics.

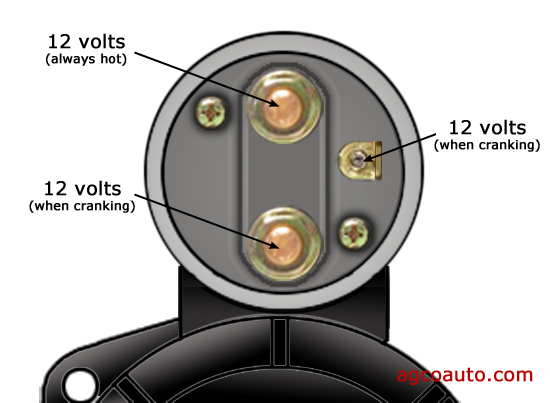

A solução: Implementing a systematic testing approach can streamline the identification process. Buyers should invest in a reliable multimeter to test the solenoid’s functionality. Begin by disconnecting the battery to ensure safety, then locate the solenoid. Use the multimeter to check for continuity by placing the probes on the solenoid terminals. A reading of zero or close to it indicates a faulty solenoid. Providing training sessions for staff on how to use this equipment effectively can enhance their diagnostic capabilities, reducing misdiagnosis and preventing unnecessary expenditures on parts that do not need replacement.

Cenário 2: Aquisição de peças de substituição de qualidade

O problema: Another significant pain point for B2B buyers is sourcing high-quality replacement solenoids. Many businesses face issues with substandard parts that fail prematurely, leading to repeated repairs and increased operational costs. For instance, a construction company in Nigeria may find that the solenoids they purchase from local suppliers do not meet international quality standards, resulting in frequent breakdowns of their machinery.

A solução: To mitigate this risk, buyers should establish relationships with reputable suppliers who can guarantee the quality of their products. Conduct thorough research to identify manufacturers with a proven track record in the industry. Request certifications and customer testimonials to validate the quality of their components. Additionally, consider forming partnerships with suppliers who offer warranties or return policies on their parts. This approach not only ensures that you receive reliable products but also provides peace of mind that you can return faulty items without incurring additional costs.

Scenario 3: Ensuring Correct Installation and Maintenance

O problema: Improper installation and maintenance of starter solenoids can lead to further complications, including misalignment and electrical failures. This is a common issue for businesses that may not have dedicated automotive technicians. For example, a logistics company in South America may have various personnel handling vehicle maintenance, resulting in inconsistent installation practices and ultimately affecting vehicle reliability.

A solução: To address installation challenges, B2B buyers should develop comprehensive training programs for their maintenance teams. Providing detailed manuals or visual aids that outline the correct installation procedures for starter solenoids can significantly reduce the likelihood of errors. Additionally, regular maintenance schedules should be instituted, including checks on the solenoid connections and overall system performance. Encouraging feedback from technicians on the installation process can lead to continuous improvements in practices and help standardize procedures across the organization. By prioritizing training and maintenance, businesses can enhance the longevity and performance of their starter systems, thereby reducing overall operational disruptions.

Strategic Material Selection Guide for testing starter solenoid

What Materials Are Commonly Used for Testing Starter Solenoids?

When considering materials for testing starter solenoids, it is essential to evaluate options that align with performance requirements and regional standards. Here, we analyze four common materials: copper, aluminum, plastic, and steel.

How Does Copper Perform in Starter Solenoid Testing?

Copper is frequently used in electrical applications due to its excellent conductivity. It has a high melting point (approximately 1,984°F or 1,085°C) and provides good corrosion resistance, especially when coated. The primary advantage of copper is its superior electrical conductivity, which ensures efficient current flow during testing.

Prós: Copper is highly durable, has a long lifespan, and is relatively easy to work with in manufacturing processes. It is also widely available, making it a cost-effective choice for many applications.

Illustrative image related to testing starter solenoid

Contras: The primary drawback is its susceptibility to oxidation, which can affect performance if not properly maintained. Additionally, copper can be more expensive than other materials, which may impact budget considerations for some buyers.

Impacto na aplicação: Copper’s high conductivity makes it ideal for applications requiring rapid response times in solenoid testing. However, it may not be suitable for environments with high humidity unless adequately protected.

Considerações para compradores internacionais: Buyers in regions like Africa and South America should ensure compliance with local electrical standards and consider the availability of copper in their markets. Compliance with international standards such as ASTM is crucial for ensuring quality.

What Role Does Aluminum Play in Testing Starter Solenoids?

Aluminum is another common material used in electrical components, including starter solenoids. It has a lower melting point (approximately 1,221°F or 660°C) than copper but offers good corrosion resistance and is lightweight.

Prós: Aluminum is less expensive than copper and is easier to fabricate, making it a popular choice for manufacturers. Its lightweight nature also reduces overall product weight, which can be beneficial in automotive applications.

Contras: While aluminum has decent conductivity, it is not as effective as copper. It can also be prone to galvanic corrosion when in contact with other metals, which may limit its use in certain environments.

Impacto na aplicação: Aluminum’s lightweight and corrosion-resistant properties make it suitable for various applications, but its lower conductivity may affect performance in high-demand scenarios.

Considerações para compradores internacionais: Buyers should be aware of regional preferences for materials and ensure that aluminum components meet local and international standards.

Why Choose Plastic for Testing Starter Solenoids?

Plastic materials, particularly thermoplastics, are increasingly used in various electrical applications due to their insulating properties and resistance to corrosion.

Prós: Plastics are lightweight, cost-effective, and can be molded into complex shapes, making them versatile for various applications. They also provide excellent insulation, reducing the risk of electrical shorts.

Contras: The primary limitation of plastic is its lower thermal and mechanical strength compared to metals. High temperatures can lead to deformation, which may not be suitable for all testing environments.

Impacto na aplicação: Plastic is ideal for non-conductive components in solenoid testing but may not be suitable for high-stress applications.

Considerações para compradores internacionais: Buyers must ensure that the plastics used comply with relevant safety and environmental regulations, particularly in regions with stringent compliance requirements.

How Does Steel Compare for Testing Starter Solenoids?

Steel, particularly stainless steel, is often used in the construction of solenoid housings due to its strength and durability.

Prós: Steel offers high tensile strength and excellent resistance to wear and tear, making it suitable for heavy-duty applications. Stainless steel also provides good corrosion resistance.

Contras: The weight of steel can be a disadvantage in applications where weight reduction is critical. Additionally, it is more expensive than aluminum and plastic.

Impacto na aplicação: Steel’s durability makes it ideal for environments with high mechanical stress, but its weight may limit its use in lightweight applications.

Considerações para compradores internacionais: Buyers should consider the cost implications of using steel and ensure compliance with local manufacturing standards, especially in regions with specific material requirements.

Summary Table of Material Selection for Testing Starter Solenoids

| Material | Typical Use Case for testing starter solenoid | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Ligações eléctricas e cablagem | Condutividade elétrica superior | Suscetível à oxidação | Alto |

| Alumínio | Componentes leves em solenóides | Cost-effective and easy to fabricate | Condutividade inferior à do cobre | Médio |

| Plástico | Componentes de isolamento | Excelentes propriedades de isolamento | Lower thermal/mechanical strength | Baixo |

| Aço | Componentes estruturais e de alojamento | Alta resistência à tração | Mais pesado e mais caro | Médio |

This analysis provides a comprehensive overview of the materials commonly used for testing starter solenoids, highlighting their advantages and limitations, as well as considerations for international buyers. Understanding these factors is essential for making informed purchasing decisions in the B2B market.

Illustrative image related to testing starter solenoid

In-depth Look: Manufacturing Processes and Quality Assurance for testing starter solenoid

What Are the Key Stages in the Manufacturing Process for Starter Solenoids?

The manufacturing of starter solenoids involves several crucial stages, each contributing to the overall quality and functionality of the final product. Understanding these stages can help international B2B buyers assess potential suppliers and their capabilities.

1. Material Preparation: What Materials Are Used in Starter Solenoid Manufacturing?

The first step in the manufacturing process is the preparation of raw materials. High-quality materials such as copper, steel, and specialized plastics are commonly used. Copper is utilized for electrical connections due to its excellent conductivity, while steel is often employed for the solenoid casing to provide structural integrity. The materials must meet specific standards to ensure durability and performance, particularly under varying environmental conditions.

2. Forming: How Are Starter Solenoid Components Shaped?

The forming process includes several techniques such as stamping, molding, and machining. Stamping is often used to create the solenoid’s metal components, while plastic injection molding is typically employed for the casing. Precision machining is essential for parts that require tight tolerances, ensuring that all components fit together seamlessly. B2B buyers should inquire about the machinery used and the capabilities of the manufacturer to ensure they can meet specific design requirements.

3. Assembly: What Assembly Techniques Are Commonly Used?

Once the components are prepared, the assembly process begins. This typically involves the integration of the solenoid coil, plunger, and housing. Automated assembly lines are increasingly common, allowing for higher efficiency and consistency. Hand assembly may also be used for more intricate components. Quality control during assembly is critical; thus, buyers should seek manufacturers that employ well-defined assembly protocols to minimize defects.

4. Finishing: How Are Starter Solenoids Finished for Optimal Performance?

The finishing stage includes processes such as coating, painting, and quality checks. Coatings may be applied to protect against corrosion, while painting may be used for aesthetic purposes. Additional quality checks are performed to ensure that the product meets operational specifications. Buyers should verify that manufacturers have a robust finishing process that adheres to international standards.

Illustrative image related to testing starter solenoid

What Quality Assurance Practices Are Essential for Starter Solenoids?

Quality assurance is vital in the manufacturing process of starter solenoids to ensure reliability and safety. Understanding the relevant standards and checkpoints can guide B2B buyers in selecting the right suppliers.

Relevant International Standards: Which Certifications Should Buyers Look For?

Manufacturers should comply with international quality standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for those in the oil and gas sector may be relevant. Buyers should request documentation that verifies compliance with these standards.

Quais são os principais pontos de verificação do controlo de qualidade no processo de fabrico?

Quality control (QC) should be integrated at various stages of the manufacturing process, including:

- Controlo de Qualidade de Entrada (IQC): This involves the inspection of raw materials to ensure they meet specified standards before production begins.

- Controlo de qualidade em processo (IPQC): During manufacturing, continuous monitoring is essential to catch defects early. This can include checks on dimensions, electrical performance, and assembly integrity.

- Controlo de Qualidade Final (FQC): Before products are shipped, a final inspection should be conducted to verify that each unit meets all operational and safety standards.

B2B buyers should ensure that potential suppliers have well-defined QC checkpoints in place.

What Common Testing Methods Are Used to Ensure Starter Solenoid Quality?

Testing methods play a crucial role in ensuring the performance and safety of starter solenoids. Understanding these methods can provide buyers with insights into the supplier’s commitment to quality.

How Is Electrical Testing Conducted for Starter Solenoids?

Electrical testing is fundamental for verifying the operational effectiveness of starter solenoids. This can include:

Illustrative image related to testing starter solenoid

- Ensaios de resistência: Measuring the electrical resistance to ensure proper conductivity.

- Teste de carga: Assessing how well the solenoid performs under actual load conditions.

- Testes funcionais: Checking the solenoid’s engagement and disengagement mechanisms to ensure reliable operation.

Buyers should inquire about the specific testing methods employed and request test reports to validate the performance of the products.

Como podem os compradores B2B verificar os processos de controlo de qualidade dos fornecedores?

To ensure that a supplier adheres to robust quality control processes, B2B buyers can take several steps:

What Audit Procedures Should Buyers Implement?

Conducting regular audits of suppliers can help verify compliance with quality standards. Buyers should develop a checklist that includes:

- Verification of certifications and compliance with international standards.

- Review of the supplier’s QC processes and documentation.

- Assessment of their testing methods and results.

Qual a importância das inspecções por terceiros?

Engaging a third-party inspection service can provide an unbiased evaluation of a supplier’s quality assurance practices. This can be particularly beneficial for international buyers who may not have the capacity to conduct on-site audits. Third-party inspections can cover material quality, manufacturing processes, and final product testing.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of several nuances in the QC process:

How Do Cultural and Regulatory Differences Impact Quality Standards?

Cultural attitudes toward quality and regulatory compliance can vary significantly by region. It is essential for buyers to understand the local regulations and standards applicable to their markets. Engaging with suppliers familiar with these nuances can facilitate smoother transactions and ensure compliance.

What Role Does Communication Play in Quality Assurance?

Effective communication is crucial in ensuring that quality expectations are clearly understood and met. Buyers should establish clear lines of communication with suppliers to discuss quality requirements, timelines, and any potential issues that may arise during the manufacturing process.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting suppliers for starter solenoids, ultimately ensuring that they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘testing starter solenoid’

When considering the procurement of testing equipment for starter solenoids, it’s essential to have a structured approach. This guide offers a step-by-step checklist designed for B2B buyers looking to source reliable and efficient testing solutions. By following these steps, you can ensure that your investment aligns with your operational needs and standards.

Passo 1: Defina as suas especificações técnicas

Establishing clear technical specifications is crucial for sourcing the right testing equipment. Determine the voltage, amperage, and compatibility requirements based on the types of starter solenoids you will be testing. This clarity will help you communicate effectively with potential suppliers and ensure you receive appropriate products.

- Voltage Requirements: Identify the voltage levels for the solenoids in your fleet.

- Amperage Ratings: Understand the typical amperage to ensure your testing equipment can handle the load.

Passo 2: Pesquisar potenciais fornecedores

Conduct thorough research to identify potential suppliers who specialize in automotive testing equipment. Look for companies with a solid reputation in your region, particularly those that cater to markets in Africa, South America, the Middle East, and Europe.

- Supplier Reviews: Check online reviews and ratings from other businesses.

- Experiência no sector: Prefer suppliers with a proven track record in providing automotive solutions.

Passo 3: Avaliar as certificações dos fornecedores

Before proceeding with any supplier, verify their certifications to ensure compliance with international standards. This step is vital for quality assurance and can prevent future operational issues.

- ISO Certifications: Look for ISO 9001 or equivalent standards, indicating quality management systems.

- Conformidade local: Ensure that the products meet local regulations in your target markets.

Passo 4: Solicitar amostras de produtos

Don’t hesitate to request samples of the testing equipment before making a bulk purchase. This allows you to assess the quality and performance of the products firsthand.

Illustrative image related to testing starter solenoid

- Test Performance: Evaluate how well the equipment performs under real-world conditions.

- User-Friendliness: Ensure that the equipment is easy to use and comes with adequate documentation.

Passo 5: Avaliar o suporte pós-venda

Quality after-sales support is critical for the longevity of your investment. Inquire about warranty policies, technical support, and training for your staff on how to use the equipment effectively.

- Período de garantia: Confirm the length and terms of the warranty offered.

- Technical Assistance: Check if the supplier provides ongoing support and maintenance services.

Passo 6: Compare preços e condições

Once you have shortlisted potential suppliers, compare their pricing structures and terms of sale. Look beyond just the price; consider total cost of ownership, including shipping, duties, and potential tariffs.

- Bulk Purchase Discounts: Ask if there are discounts for larger orders.

- Payment Terms: Ensure the payment terms are favorable and align with your cash flow needs.

Passo 7: Finalize the Order

After thorough evaluation, finalize your order with the chosen supplier. Ensure that you have clear agreements regarding delivery timelines, payment schedules, and any additional services included.

- Delivery Schedule: Confirm the expected delivery date and logistics.

- Documentação: Ensure all necessary documentation is in place for customs clearance if applicable.

By following these steps, B2B buyers can make informed decisions when sourcing testing equipment for starter solenoids, ensuring that they select the best products for their operational needs.

Comprehensive Cost and Pricing Analysis for testing starter solenoid Sourcing

What Are the Key Cost Components for Testing Starter Solenoids?

In the B2B landscape of starter solenoid testing, understanding the cost structure is paramount. The primary components influencing costs include:

-

Materiais: The quality of materials used in manufacturing solenoids significantly impacts costs. Premium materials like high-grade copper for wiring and corrosion-resistant metals can enhance performance but increase expenses.

-

Trabalho: Skilled labor is essential for both manufacturing and testing processes. The cost of labor can vary widely based on geographical location, with skilled workers in Europe generally commanding higher wages than those in regions such as Africa or South America.

-

Custos indiretos de produção: This encompasses utilities, rent, equipment maintenance, and other operational costs. Efficient manufacturing processes can reduce overhead, leading to lower prices for buyers.

-

Ferramentas: Specialized tools and machinery for producing solenoids add to the initial setup costs. The complexity of the solenoid design can necessitate more advanced tooling, impacting overall expenses.

-

Controlo de Qualidade (QC): Implementing rigorous QC processes ensures reliability and performance, which may lead to higher costs. However, investing in QC can reduce long-term warranty claims and enhance customer satisfaction.

-

Logística: Shipping costs can vary depending on the distance from the manufacturing site to the buyer. International shipments may incur additional tariffs and customs fees, which should be factored into the total cost.

-

Margem: Suppliers typically add a profit margin to cover their risks and ensure sustainable operations. Understanding typical margins in your supplier’s region can aid in negotiating better terms.

How Do Price Influencers Affect the Cost of Testing Starter Solenoids?

Several factors can influence the pricing of starter solenoid testing:

-

Volume/MOQ (Quantidade mínima de encomenda): Higher order volumes often lead to discounts due to economies of scale. B2B buyers should consider bulk purchasing to achieve lower per-unit costs.

-

Especificações e personalização: Custom solenoids tailored to specific applications may incur additional costs. Buyers should clearly define their requirements to receive accurate quotes.

-

Materiais e certificações de qualidade: Premium materials and compliance with international quality standards (such as ISO certifications) can elevate costs but ensure better performance and reliability.

-

Fatores relacionados ao fornecedor: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding international shipping terms is crucial. Different Incoterms can affect responsibility for shipping costs and risk, impacting the overall price.

What Are Some Effective Buyer Tips for Sourcing Testing Services?

-

Negotiate Smartly: Always negotiate terms and prices. Suppliers may have room to adjust pricing based on your order size or long-term partnership potential.

-

Foco na eficiência de custos: Evaluate the total cost of ownership (TCO), not just the initial purchase price. Consider maintenance, warranty, and performance reliability when assessing cost-effectiveness.

-

Compreender as nuances dos preços para os compradores internacionais: International buyers should be aware of currency fluctuations, customs duties, and local taxes that can affect pricing. It’s advisable to work with suppliers who have experience in your target market.

-

Pesquisar e comparar: Gather quotes from multiple suppliers and compare not just prices but also the quality of materials and services offered. Ensure that all potential suppliers provide detailed breakdowns of their costs.

-

Mantenha-se informado sobre as tendências do mercado: Keeping abreast of changes in material costs, labor rates, and technological advancements can provide leverage during negotiations and help in making informed purchasing decisions.

Isenção de responsabilidade para preços indicativos

Prices for testing starter solenoids can vary significantly based on the factors mentioned above. The information provided here serves as a general guide, and actual costs may differ based on specific buyer needs, supplier capabilities, and market conditions. Always conduct thorough due diligence and request detailed quotations from suppliers to ensure accurate pricing.

Alternatives Analysis: Comparing testing starter solenoid With Other Solutions

Exploring Alternatives for Testing Starter Solenoids

In the world of automotive maintenance and repair, understanding the various methods available for diagnosing starter issues is crucial. While testing a starter solenoid is a common approach, several alternative solutions can achieve similar outcomes, each with its own set of advantages and limitations. This analysis will compare the traditional method of testing a starter solenoid against two viable alternatives: using a multimeter and employing a professional diagnostic tool.

| Aspecto comparativo | Testing Starter Solenoid | Using a Multimeter | Professional Diagnostic Tool |

|---|---|---|---|

| Desempenho | Effective for direct solenoid issues, but limited in scope. | Offers precise readings and broader electrical diagnostics. | Comprehensive, multi-system diagnostics with higher accuracy. |

| Custo | Generally low cost for parts and tools. | Low-cost solution if the multimeter is already owned. | Higher initial investment, but can save costs in the long run. |

| Facilidade de implementação | Requires basic mechanical skills; straightforward for experienced users. | Requires understanding of multimeter use; may be complex for novices. | User-friendly interface; however, training may be needed for effective use. |

| Manutenção | Minimal; replace solenoid as needed. | Requires periodic calibration of the multimeter. | Regular software updates and maintenance for accuracy. |

| Melhor caso de uso | Ideal for quick checks in fieldwork or for DIY enthusiasts. | Best for detailed electrical system analysis. | Recommended for professional garages and workshops needing detailed diagnostics. |

What Are the Advantages and Disadvantages of Using a Multimeter?

Using a multimeter to test a starter solenoid provides a more comprehensive view of the electrical system. This method allows technicians to assess voltage and resistance, offering insights into the solenoid’s functionality and the overall health of the electrical circuit. The primary advantage is the precision of readings, which can identify issues beyond the solenoid itself. However, it requires a certain level of expertise to interpret the results correctly, making it less accessible for those without technical training.

How Does a Professional Diagnostic Tool Compare?

Professional diagnostic tools offer a sophisticated solution for assessing starter solenoids and other vehicle components. These devices provide a user-friendly interface and can run extensive diagnostics across multiple systems in a vehicle. Their ability to deliver comprehensive reports and pinpoint issues quickly is a significant advantage for automotive professionals. The downside is the higher cost, which may be prohibitive for smaller shops or individual mechanics. Additionally, operators may need training to utilize these tools effectively.

Conclusão: Que solução devem os compradores B2B escolher?

When selecting the right solution for testing starter solenoids, B2B buyers should consider their specific needs and resources. For quick, straightforward checks, testing the starter solenoid directly remains a reliable method. However, for detailed diagnostics and a broader understanding of vehicle health, investing in a multimeter or professional diagnostic tool could provide greater value. Assessing the balance between initial investment, ease of use, and the depth of analysis required will guide buyers toward the most suitable option for their operational context.

Essential Technical Properties and Trade Terminology for testing starter solenoid

What Are the Key Technical Properties to Consider When Testing Starter Solenoids?

When evaluating starter solenoids for automotive applications, understanding critical technical specifications is vital. Here are some essential properties to consider:

Illustrative image related to testing starter solenoid

-

Grau do material

– Definição: This refers to the type and quality of materials used in the construction of the solenoid, commonly copper for electrical contacts and high-grade steel or aluminum for housing.

– Importância do B2B: High-quality materials ensure durability and reliable performance, which is crucial in preventing premature failures that could disrupt operations. Buyers should prioritize solenoids made from materials that can withstand high temperatures and resist corrosion, particularly in regions with extreme weather conditions. -

Resistência da bobina

– Definição: This is the electrical resistance of the solenoid’s coil, typically measured in ohms.

– Importância do B2B: Proper coil resistance is critical for efficient operation. Too high or too low resistance can indicate potential issues like short circuits or inefficient power usage, leading to increased operational costs. Ensuring the correct resistance can prevent unnecessary repairs and downtime. -

Tensão de funcionamento

– Definição: The voltage at which the solenoid is designed to operate, commonly 12V or 24V in automotive applications.

– Importância do B2B: Selecting a solenoid with the correct operating voltage is essential for compatibility with the vehicle’s electrical system. Mismatched voltage can lead to solenoid failure or malfunction, impacting vehicle reliability and performance. -

Força de acionamento

– Definição: The force required to activate the solenoid, usually measured in pounds or newtons.

– Importância do B2B: Adequate actuation force is necessary for engaging the starter motor effectively. Insufficient force can lead to incomplete engagement, resulting in grinding or failure to start. Understanding actuation force helps buyers choose the right solenoid for their specific engine configurations. -

Níveis de tolerância

– Definição: The acceptable range of deviation from specified dimensions, often critical for the fit and function of the solenoid.

– Importância do B2B: Tighter tolerances ensure better performance and longevity. Parts that do not fit properly can lead to mechanical failures, increased wear, and operational inefficiencies. Buyers should inquire about tolerance specifications to ensure compatibility with existing systems.

What Are Common Trade Terms Related to Starter Solenoid Testing?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B sector. Here are some common terms:

-

OEM (Fabricante de Equipamento Original)

– Definição: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importância: Purchasing OEM parts guarantees compatibility and quality, as they are designed to meet the specific requirements of the vehicle manufacturer. This can be a deciding factor for businesses looking to ensure reliability in their fleet operations. -

MOQ (Quantidade mínima de encomenda)

– Definição: A quantidade mais pequena de um produto que um fornecedor está disposto a vender.

– Importância: Understanding MOQ is essential for budget planning and inventory management. Buyers must ensure that their order meets the supplier’s MOQ to avoid additional costs or delays. -

RFQ (Pedido de Orçamento)

– Definição: A document issued to suppliers asking for a price quote for specific products or services.

– Importância: An RFQ allows buyers to compare pricing, terms, and conditions from multiple suppliers, facilitating informed decision-making and negotiation. -

Incoterms (Termos Comerciais Internacionais)

– Definição: A set of international rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts.

– Importância: Familiarity with Incoterms helps businesses understand shipping responsibilities, costs, and risks, which is critical for international transactions, especially when sourcing components from global suppliers. -

Peças de reposição

– Definição: Components made by companies other than the original manufacturer, intended as replacements.

– Importância: While often cheaper, aftermarket parts may vary in quality. Businesses need to weigh the cost savings against potential risks of performance issues when selecting these components.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing and testing starter solenoids, ultimately enhancing their operational efficiency and reliability.

Navigating Market Dynamics and Sourcing Trends in the testing starter solenoid Sector

What Are the Current Market Dynamics and Key Trends in the Testing Starter Solenoid Sector?

The global market for testing starter solenoids is witnessing significant shifts driven by technological advancements, increasing vehicle electrification, and a growing emphasis on quality assurance. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly focused on sourcing high-quality, durable solenoids that meet rigorous testing standards. This trend is fueled by the rising demand for reliable automotive components, particularly as vehicles become more complex and integrated with advanced electronics.

Emerging technologies, such as IoT and AI, are revolutionizing how starter solenoids are tested and monitored. Automated testing systems equipped with AI algorithms can provide real-time diagnostics, improving efficiency and accuracy in evaluating solenoid performance. Additionally, the increasing adoption of electric vehicles (EVs) is reshaping sourcing strategies, as solenoids specifically designed for EV applications are becoming essential. Buyers are encouraged to stay informed about these advancements to ensure they are sourcing the most effective and up-to-date components.

Market dynamics are also influenced by the need for transparency in the supply chain. International buyers are prioritizing suppliers who can provide detailed information about their sourcing processes, materials used, and testing methodologies. This shift towards transparency not only enhances trust but also aligns with the growing demand for sustainable practices in sourcing.

How Important Is Sustainability and Ethical Sourcing in the Testing Starter Solenoid Sector?

As global awareness of environmental issues increases, sustainability and ethical sourcing have become paramount considerations for B2B buyers in the testing starter solenoid sector. The environmental impact of manufacturing processes, particularly in developing regions, has prompted buyers to seek out suppliers that adhere to sustainable practices. This includes the use of eco-friendly materials, waste reduction strategies, and energy-efficient manufacturing processes.

Ethical supply chains are crucial for maintaining brand reputation and customer loyalty. Buyers are now more inclined to partner with manufacturers that prioritize fair labor practices and transparent sourcing. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential benchmarks for evaluating suppliers.

Furthermore, the shift towards greener technologies is influencing material selection. Manufacturers are increasingly utilizing recyclable and biodegradable materials in solenoid production, responding to the demand for “green” certifications. Buyers who prioritize these materials not only contribute to environmental sustainability but also enhance their own market positioning in an increasingly eco-conscious consumer landscape.

Illustrative image related to testing starter solenoid

What Is the Brief Evolution and History of Testing Starter Solenoids?

The evolution of testing starter solenoids has been marked by significant technological advancements and changes in automotive design. Initially, testing methods were rudimentary, relying on basic electrical tests to determine functionality. Over the decades, as automotive technology evolved, so did the complexity of solenoid systems, necessitating more sophisticated testing techniques.

The introduction of electronic testing equipment in the late 20th century revolutionized the industry, enabling precise diagnostics and improved quality control. This shift laid the groundwork for the integration of IoT technologies in modern testing protocols, allowing for real-time monitoring and data analytics. Today, as the automotive industry pivots towards electrification and automation, the testing of starter solenoids continues to evolve, emphasizing the need for buyers to stay updated on the latest innovations to maintain competitive advantage.

In summary, understanding the current market dynamics, prioritizing sustainability, and recognizing the evolution of testing technologies are vital for B2B buyers in the testing starter solenoid sector. By aligning sourcing strategies with these insights, buyers can enhance operational efficiency and contribute positively to their respective markets.

Illustrative image related to testing starter solenoid

Frequently Asked Questions (FAQs) for B2B Buyers of testing starter solenoid

-

How do I test a starter solenoid effectively?

To test a starter solenoid, first ensure safety by disconnecting the battery. Then, use a multimeter to check for continuity across the solenoid terminals. Connect the multimeter probes to the two large terminals; a reading of zero ohms indicates a good solenoid. If the reading is infinite or very high, the solenoid is faulty. Additionally, you can bypass the solenoid by jumping the terminals with a screwdriver; if the starter engages, the solenoid is likely defective. Always consult your vehicle’s manual for specific instructions related to your model. -

What should I consider when sourcing starter solenoids for international trade?

When sourcing starter solenoids internationally, consider factors such as supplier reliability, product certifications, and compliance with local regulations. Investigate the supplier’s production capabilities, lead times, and quality assurance processes. It’s also crucial to evaluate shipping logistics, including customs duties and import regulations in your country. Establish clear communication regarding payment terms and delivery schedules to avoid misunderstandings. Engaging with suppliers who have a proven track record in international B2B transactions can mitigate risks significantly. -

What are the best practices for vetting suppliers of starter solenoids?

Vetting suppliers involves several steps: first, check their business credentials and years of experience in the industry. Request references from other clients to gauge their reliability and product quality. Analyze their manufacturing processes and certifications, such as ISO standards, to ensure compliance with international quality benchmarks. Additionally, consider requesting samples to assess product quality firsthand. Utilize platforms like Alibaba or Global Sources for supplier reviews and ratings, which can provide insights into their reputation in the market. -

What customization options are available for starter solenoids?

Customization options for starter solenoids can vary widely depending on the manufacturer. Common customizations include variations in voltage ratings, terminal configurations, and housing materials to suit specific environmental conditions. Some suppliers may also offer tailored solutions for unique applications, such as high-performance vehicles or specific industrial machinery. When discussing customization, provide detailed specifications and use cases to ensure the supplier can meet your requirements effectively. -

What are the typical minimum order quantities (MOQs) for starter solenoids?

Minimum order quantities for starter solenoids can vary by supplier and depend on factors such as the complexity of the product and manufacturing processes. Generally, MOQs can range from 100 to 1,000 units for standard models. However, some suppliers may accommodate smaller orders, particularly if they are trying to establish a relationship with a new customer. It’s advisable to negotiate MOQs based on your specific needs and explore options for bulk purchasing to secure better pricing. -

What payment terms are common for international transactions of starter solenoids?

Common payment terms in international transactions typically include options like advance payment, Letter of Credit (LC), or payment upon delivery. Advance payment is often required for smaller orders, while LCs provide security for both parties in larger transactions. Some suppliers may offer net terms, allowing payment within a set period after delivery. It’s crucial to clearly outline payment terms in the contract and consider using escrow services for added security, particularly with new suppliers. -

How can I ensure quality assurance (QA) for the starter solenoids I purchase?

To ensure quality assurance for starter solenoids, request detailed documentation of the supplier’s QA processes, including testing protocols and inspection criteria. Many reputable manufacturers will conduct rigorous testing at various stages of production, from raw material inspection to final product testing. Consider implementing a third-party inspection service to validate product quality before shipment. Establishing clear specifications and performance benchmarks in your purchase agreement can also help maintain quality standards. -

Que considerações logísticas devo ter em conta ao importar solenóides de arranque?

When importing starter solenoids, logistics considerations include shipping methods, transit times, and customs clearance procedures. Choose a reliable freight forwarder who can navigate the complexities of international shipping and provide insights into duties and taxes applicable to your shipments. Ensure proper documentation is prepared, including commercial invoices and packing lists, to facilitate smooth customs clearance. Planning for potential delays and having contingency plans in place can help minimize disruptions in your supply chain.

Top 4 Testing Starter Solenoid Manufacturers & Suppliers List

1. Reddit - Cabo de arranque do solenoide

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: cabo de arranque solenóide, multímetro, bateria, solenóide de arranque

2. Starter Solenoid – Electromagnetic Switch

Domínio: linkedin.com

Registado: 2002 (23 anos)

Introdução: Starter solenoid is an electromagnetic switch that engages the starter motor when the ignition key is turned to the ‘start’ position. It controls the high current needed to operate the starter motor, ensuring safe engagement and disengagement. Symptoms of a bad starter solenoid include clicking noises, failure to crank, difficulty starting the engine, decreased acceleration performance, automatic …

3. F150 Forum – Starter & Solenoid Testing Guide

Domínio: f150forum.com

Registado: 2004 (21 anos)

Introdução: The discussion revolves around testing the starter and solenoid for a 1989 Ford F150 Supercab with a 5.0 engine. Key points include: 1. Testing the solenoid by jumping the two large terminals to bypass it. 2. If the truck cranks, the solenoid is likely bad; if not, the starter should be tested. 3. The user experienced issues with the starter making grinding noises and not engaging properly. 4. Rec…

4. WikiHow – Starter Solenoid Guide

Domínio: wikihow.com

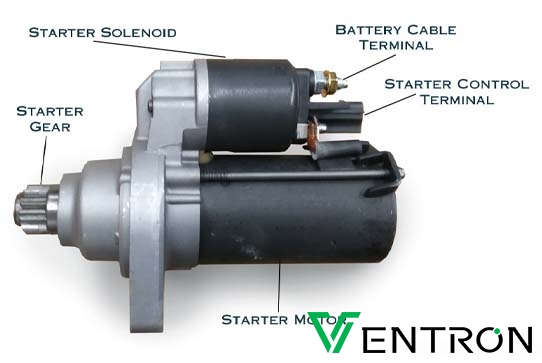

Registado: 2004 (21 anos)

Introdução: The starter solenoid is an electrical mechanism that transmits current from the battery to the starter, engaging the starter motor to start the engine. It is typically cylindrical in shape with a smaller cylinder attached, and has two terminals. The solenoid engages when the ignition key is turned, and a clicking sound indicates it is functioning. If there is no clicking, the solenoid may be fault…

Strategic Sourcing Conclusion and Outlook for testing starter solenoid

In the realm of automotive components, understanding the intricacies of testing starter solenoids is paramount for international B2B buyers. The significance of strategic sourcing cannot be overstated; selecting high-quality parts from reputable suppliers ensures reliability and performance in vehicle operations. As we’ve explored, employing methods such as multimeter testing and bypass techniques can effectively diagnose solenoid issues, ultimately leading to informed purchasing decisions.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize sourcing durable and reliable solenoids. The experiences shared by automotive communities underscore the importance of investing in quality over cost, as subpar components can lead to recurring failures and increased operational downtime. Furthermore, establishing strong relationships with trusted manufacturers will facilitate access to superior products and technical support.

Looking ahead, the automotive sector is poised for innovation, making it essential for buyers to stay informed about advancements in starter technology. By focusing on quality sourcing and fostering partnerships with reputable suppliers, businesses can enhance their operational efficiency and ensure customer satisfaction. Engage with trusted distributors today to secure the best starter solenoids for your needs and drive your business forward.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.