Introdução: Navegar no mercado global de como funciona um motor de arranque

No competitivo mercado global de hoje, compreender o funcionamento de um motor de arranque é crucial para as empresas envolvidas no fabrico, reparação e manutenção de automóveis. As complexidades deste componente essencial podem ter um impacto significativo no desempenho e na fiabilidade dos veículos, tornando imperativo que os compradores B2B internacionais, especialmente os de regiões como África, América do Sul, Médio Oriente e Europa, tenham uma compreensão abrangente da sua funcionalidade. Este guia aprofunda a mecânica dos motores de arranque, explorando vários tipos, as suas aplicações em diferentes modelos de veículos e os factores críticos a ter em conta ao adquiri-los.

Navegar pelas complexidades das especificações dos motores de arranque pode ser assustador, especialmente quando se tem em conta as variações regionais nas normas de fabrico e na fiabilidade dos fornecedores. Este guia fornece informações práticas sobre como examinar os fornecedores de forma eficaz, compreender as implicações de custos e avaliar a qualidade dos motores de arranque para garantir que as suas decisões de compra são informadas e estratégicas. Ao equipar os compradores B2B com os conhecimentos necessários para avaliar as métricas de desempenho, a compatibilidade e a durabilidade, este recurso permite que as empresas optimizem os seus processos de aquisição, melhorem a eficiência operacional e, em última análise, obtenham sucesso nos seus mercados. Quer esteja na Nigéria à procura de componentes robustos para terrenos acidentados ou na Alemanha à procura de motores de arranque de elevada eficiência para veículos eléctricos, este guia é o seu recurso de referência para tomar decisões de compra informadas no mercado dos motores de arranque.

Índice

- Lista dos 4 principais fabricantes e fornecedores de Como funciona um motor de arranque

- Introdução: Navegar no mercado global de como funciona um motor de arranque

- Compreender o funcionamento de um motor de arranque Tipos e variações

- Principais aplicações industriais de como funciona um motor de arranque

- 3 Pontos de dor comuns dos utilizadores para ‘como funciona um motor de arranque’ e as suas soluções

- Guia de seleção de materiais estratégicos para o funcionamento de um motor de arranque

- Análise aprofundada: Processos de fabrico e garantia de qualidade para como funciona um motor de arranque

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘como funciona um motor de arranque’

- Análise exaustiva dos custos e dos preços para o fornecimento de produtos e serviços para o funcionamento de um motor de arranque

- Análise de alternativas: Comparação de como funciona um motor de arranque com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para o funcionamento de um motor de arranque

- Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector do funcionamento de um motor de arranque

- Perguntas frequentes (FAQs) para compradores B2B de como funciona um motor de arranque

- Conclusão e Perspectivas do Sourcing Estratégico para o funcionamento de um motor de arranque

- Aviso legal importante e termos de utilização

Compreender o funcionamento de um motor de arranque Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Arrancador convencional | Utiliza um solenoide e um mecanismo de engrenagem de pinhão para engatar o volante do motor. | Automotivo, Máquinas Pesadas | Prós: Fiável e económico. Contras: Binário limitado para motores maiores. |

| Motor de arranque com redução de engrenagem | Incorpora um sistema de redução de engrenagens para aumentar o binário de saída. | Veículos de alto desempenho, Camiões | Prós: Binário mais elevado, design compacto. Contras: Mais caro do que os arrancadores convencionais. |

| Arrancador de Íman Permanente | Utiliza ímanes permanentes em vez de bobinas de campo. | Veículos eléctricos, motociclos | Prós: Leve, eficiente. Contras: Binário limitado para aplicações maiores. |

| Arrancador de binário elevado | Concebido para aplicações de elevado desempenho com binário melhorado. | Corridas, Camiões pesados | Prós: Excelente para ambientes de elevado stress. Contras: Custo e consumo de energia mais elevados. |

| Gerador de arranque integrado (ISG) | Combina as funções de arranque e gerador numa única unidade. | Híbridos suaves, veículos avançados | Prós: Eficiência melhorada, peso reduzido. Contras: A conceção complexa pode conduzir a custos de reparação mais elevados. |

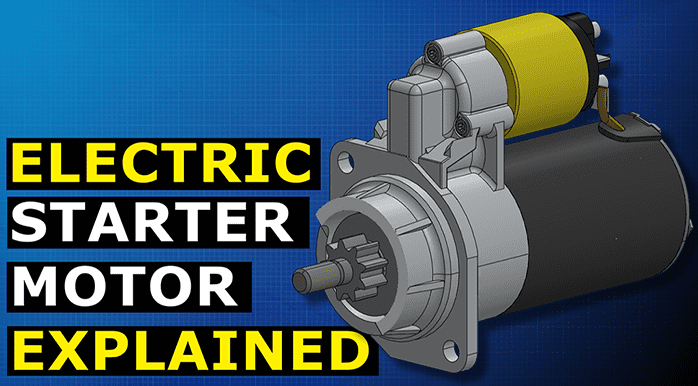

Quais são as caraterísticas de um motor de arranque convencional?

Os motores de arranque convencionais são o tipo mais utilizado, caracterizado por um design simples que inclui um solenoide e uma engrenagem de pinhão. Engatam o volante do motor para o fazer girar, o que os torna um elemento básico em aplicações automóveis e de maquinaria pesada. Os compradores B2B apreciam a sua fiabilidade e acessibilidade, especialmente para veículos de série. No entanto, podem não fornecer binário suficiente para motores maiores, o que pode ser uma consideração para empresas que lidam com maquinaria pesada ou veículos especializados.

Como é que um arrancador de redução de engrenagens difere de outros tipos?

Os motores de arranque com redução de engrenagens utilizam um sistema de engrenagens para multiplicar o binário de saída, tornando-os adequados para veículos e camiões de elevado desempenho. Este design permite um motor de arranque mais compacto, ao mesmo tempo que fornece a potência necessária para fazer rodar motores maiores. Os compradores B2B em sectores como os transportes e as corridas consideram estes motores de arranque vantajosos devido às suas capacidades de desempenho melhoradas. A contrapartida é um preço mais elevado, que pode afetar as considerações orçamentais de algumas empresas.

Que vantagens oferecem os arrancadores de ímanes permanentes?

Os motores de arranque de ímanes permanentes distinguem-se pela utilização de ímanes permanentes em vez das tradicionais bobinas de campo. Este design resulta num arrancador mais leve e mais eficiente, tornando-o ideal para veículos eléctricos e motociclos. Os compradores B2B focados na inovação e sustentabilidade podem achar estes motores de arranque particularmente apelativos. No entanto, o seu binário de saída limitado significa que podem não ser adequados para aplicações maiores, o que é uma consideração importante para as empresas que exigem um desempenho robusto.

Porquê escolher um motor de arranque de binário elevado para aplicações pesadas?

Os arrancadores de binário elevado são especificamente concebidos para ambientes exigentes, oferecendo um binário melhorado para lidar com aplicações de elevado desempenho. Indústrias como as das corridas de automóveis e dos camiões pesados beneficiam destes motores de arranque devido à sua capacidade de funcionar sob tensão. Embora ofereçam um excelente desempenho, os compradores devem estar cientes do seu custo mais elevado e do aumento do consumo de energia, que podem afetar os orçamentos operacionais.

Quais são as vantagens dos geradores de arranque integrados (ISG)?

Os geradores de arranque integrados combinam as funções de um motor de arranque e de um gerador numa única unidade, oferecendo maior eficiência e peso reduzido. Esta tecnologia é particularmente relevante para veículos híbridos suaves e avançados, apelando aos compradores B2B interessados em soluções automóveis de vanguarda. No entanto, a complexidade dos sistemas ISG pode levar a custos de reparação mais elevados, que devem ser tidos em conta nas decisões de compra.

Principais aplicações industriais de como funciona um motor de arranque

| Indústria/Setor | Aplicação específica de Como funciona um motor de arranque | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Fabricação Automotiva | Motores de arranque em linhas de montagem de veículos para ensaio de motores | Assegura um arranque fiável do motor para garantir a qualidade | Fiabilidade do fornecedor, conformidade com as normas do sector automóvel, condições de garantia |

| Agricultura | Motores de arranque em máquinas agrícolas, como tractores e ceifeiras | Facilita o funcionamento eficiente de máquinas pesadas | Durabilidade em ambientes agressivos, disponibilidade de peças para manutenção |

| Construção | Motores de arranque em equipamento pesado de construção, como escavadoras e gruas | Aumenta a produtividade assegurando a prontidão do equipamento | Compatibilidade com as máquinas existentes, assistência técnica e disponibilidade de peças |

| Marinha | Motores de arranque em motores marítimos para barcos e navios | Crítico para um arranque fiável do motor em operações marítimas | Resistência à corrosão, requisitos de potência específicos para aplicações marítimas |

| Energia renovável | Motores de arranque em turbinas eólicas e seguidores solares | Apoia a eficiência e a fiabilidade da produção de energia | Especificações técnicas, eficiência energética e certificações de fornecedores |

Como são utilizados os motores de arranque no fabrico de automóveis?

No fabrico de automóveis, os motores de arranque desempenham um papel crucial nas linhas de montagem de veículos, especialmente durante os testes de motores. Estes motores asseguram que os motores podem arrancar de forma fiável, o que é vital para os processos de garantia de qualidade. Para os compradores B2B neste sector, é essencial obter motores de arranque que cumpram as rigorosas normas do sector automóvel e que ofereçam garantias sólidas. A fiabilidade do fornecedor também é fundamental, uma vez que quaisquer atrasos ou falhas podem perturbar os calendários de produção.

Qual o papel dos motores de arranque na agricultura?

No sector agrícola, os motores de arranque são essenciais para o funcionamento de máquinas como tractores e ceifeiras. Estes motores permitem um arranque eficiente do motor, o que é essencial para manter a produtividade durante as épocas críticas de plantação e colheita. Os compradores deste sector devem ter em conta a durabilidade dos motores de arranque, uma vez que estes funcionam frequentemente em ambientes adversos. Além disso, ter acesso a peças de substituição e serviços de manutenção é crucial para minimizar o tempo de inatividade.

Como é que os motores de arranque são essenciais para o equipamento de construção?

Os motores de arranque são componentes vitais no equipamento pesado de construção, incluindo escavadoras e gruas. Garantem que estas máquinas estão prontas a funcionar a qualquer momento, aumentando a produtividade geral nos estaleiros de construção. Para os compradores B2B no sector da construção, a compatibilidade com a maquinaria existente é uma consideração fundamental para o aprovisionamento. Além disso, os fornecedores devem fornecer um forte apoio de serviço e um fornecimento fiável de peças para manter o equipamento operacional.

Porque é que os motores de arranque são importantes nas aplicações marítimas?

Na indústria marítima, os motores de arranque são essenciais para o arranque fiável dos motores de barcos e navios. Dados os desafios únicos colocados pelos ambientes marítimos, como a exposição à água salgada e à humidade, estes motores têm de ser resistentes à corrosão. Os compradores B2B neste sector devem concentrar-se no fornecimento de motores de arranque que satisfaçam requisitos de potência específicos e que tenham certificações para aplicações marítimas, garantindo que podem suportar os rigores das operações marítimas.

Como é que os motores de arranque contribuem para os sistemas de energias renováveis?

Os motores de arranque encontram aplicações em sistemas de energias renováveis, como turbinas eólicas e seguidores solares, onde são essenciais para iniciar o movimento e otimizar a produção de energia. A fiabilidade destes motores tem um impacto direto na eficiência da produção de energia. Os compradores do sector das energias renováveis devem dar prioridade ao fornecimento de motores com elevadas classificações de eficiência energética e especificações técnicas detalhadas, garantindo que estão em conformidade com os mais recentes avanços tecnológicos e objectivos de sustentabilidade.

3 Pontos de dor comuns dos utilizadores para ‘como funciona um motor de arranque’ e as suas soluções

Cenário 1: Compreender a funcionalidade do motor de arranque para uma manutenção eficaz

O problema: Os compradores B2B enfrentam frequentemente desafios quando se trata de compreender o funcionamento dos motores de arranque, especialmente em máquinas complexas ou veículos de frota. Muitas empresas dependem de uma mistura de veículos mais antigos e mais recentes, o que dificulta a padronização das práticas de manutenção. Sem um conhecimento sólido do funcionamento de um motor de arranque, as equipas de manutenção podem ignorar componentes críticos, o que leva a falhas inesperadas e a períodos de inatividade dispendiosos.

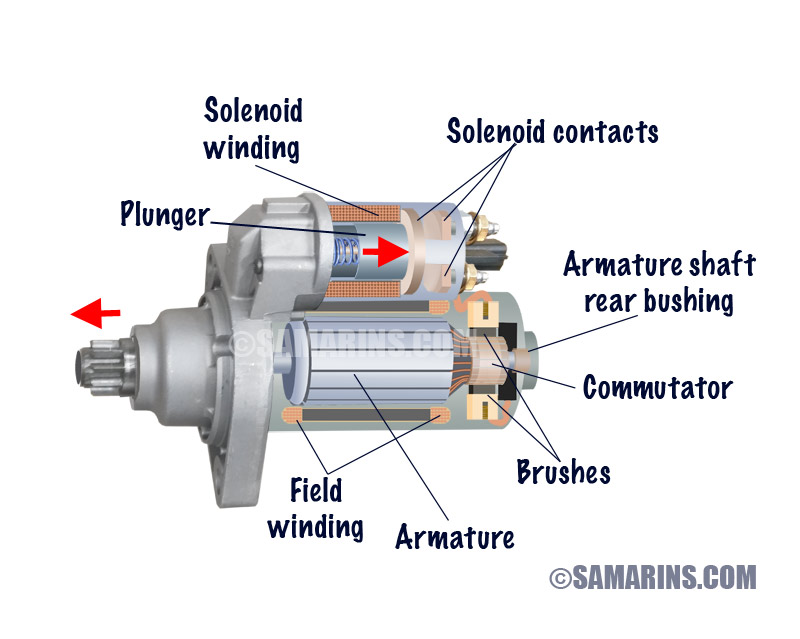

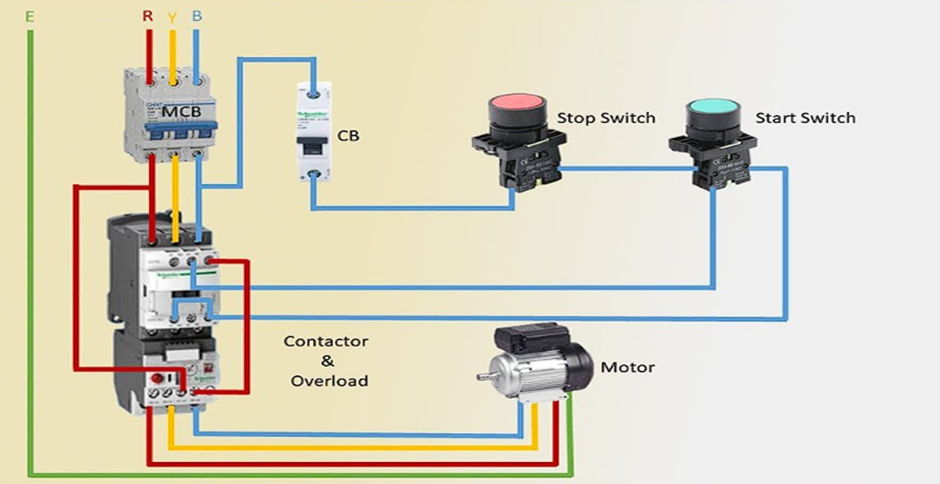

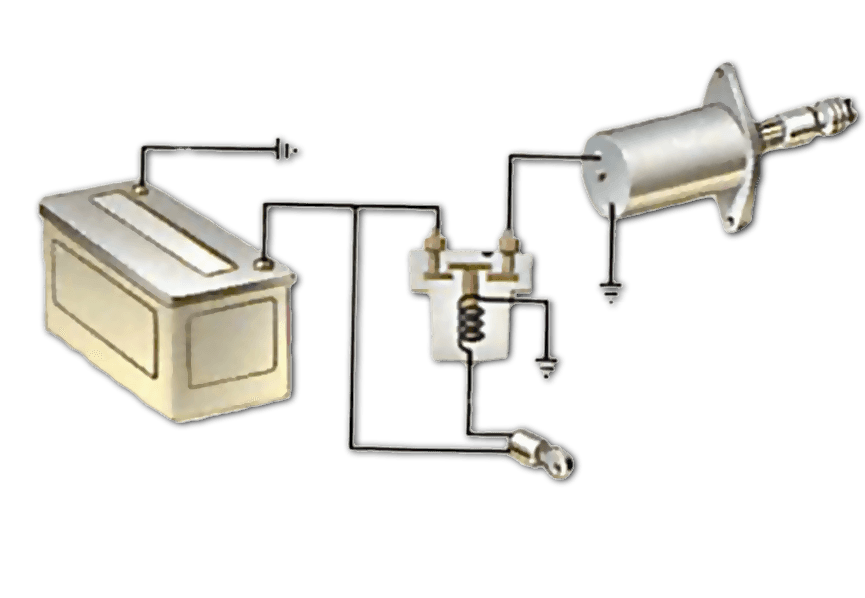

A solução: Para uma manutenção eficaz dos motores de arranque, é essencial que os compradores invistam em formação abrangente para as suas equipas de manutenção. Esta formação deve abranger a anatomia dos motores de arranque - incluindo o solenoide, a armadura e a engrenagem do pinhão - e a mecânica da forma como estes componentes interagem durante a ignição do motor. Além disso, considere a possibilidade de obter manuais detalhados ou recursos de formação que expliquem problemas comuns e técnicas de resolução de problemas. O estabelecimento de um procedimento padronizado para inspecções regulares também pode ajudar a identificar potenciais problemas antes que estes conduzam a falhas. Ao dar prioridade à formação e a práticas de manutenção consistentes, as empresas podem melhorar a sua eficiência operacional e reduzir o risco de avarias inesperadas.

Cenário 2: Fornecimento de motores de arranque de qualidade para minimizar as falhas

O problema: Muitos compradores B2B têm dificuldade em obter motores de arranque fiáveis que satisfaçam os requisitos específicos dos seus veículos ou máquinas. O mercado está inundado de vários fabricantes, o que torna difícil distinguir entre produtos de alta qualidade e produtos de qualidade inferior. A utilização de motores de arranque de qualidade inferior pode levar a falhas frequentes, ao aumento dos custos operacionais e à perda de confiança dos clientes.

A solução: Para minimizar as falhas, os compradores devem concentrar-se na construção de relações com fornecedores reputados, especializados em motores de arranque. Efetuar uma pesquisa exaustiva para verificar os padrões de qualidade e as certificações dos potenciais fornecedores. Solicite amostras para avaliar o desempenho e a fiabilidade antes de efetuar compras em grandes quantidades. Além disso, aproveite as análises dos clientes e os estudos de caso da indústria para avaliar a fiabilidade de marcas específicas de motores de arranque. A implementação de um período experimental com novos fornecedores também pode garantir que os seus produtos satisfazem as suas necessidades operacionais sem comprometer a qualidade. Ao serem diligentes no aprovisionamento, as empresas podem reduzir significativamente o risco de falhas no motor de arranque.

Cenário 3: Diagnosticar eficazmente os problemas do motor de arranque

O problema: Em muitos casos, os compradores B2B têm dificuldade em diagnosticar com rapidez e exatidão os problemas do motor de arranque. Sintomas como um ruído de clique ou arranque lento podem ser indicativos de vários problemas subjacentes, desde problemas com a bateria a componentes defeituosos no próprio motor de arranque. Esta incerteza pode levar a substituições desnecessárias de peças, ao desperdício de recursos e a um tempo de inatividade prolongado para as operações.

A solução: Para melhorar a eficiência do diagnóstico, as empresas devem implementar um protocolo estruturado de resolução de problemas. Comece por formar os técnicos sobre os principais indicadores de problemas no motor de arranque e os passos para os diagnosticar, tais como verificar a tensão da bateria, inspecionar as ligações e testar o solenoide. Investir em ferramentas de diagnóstico que possam analisar sistemas eléctricos também proporcionará avaliações mais precisas. Além disso, a criação de uma base de conhecimentos partilhada dentro da organização que documente os problemas comuns do motor de arranque e as suas resoluções pode servir como uma referência valiosa para os técnicos. Ao equipar as equipas com os conhecimentos e as ferramentas certas, as empresas podem simplificar os seus processos de diagnóstico e minimizar o tempo de inatividade desnecessário.

Guia de seleção de materiais estratégicos para o funcionamento de um motor de arranque

Quais materiais são normalmente usados em motores de arranque?

Ao selecionar materiais para motores de arranque, é essencial considerar as suas propriedades, desempenho e adequação a aplicações específicas. A análise que se segue centra-se em quatro materiais comuns utilizados em motores de arranque: cobre, alumínio, aço e compósitos plásticos.

Quais são as principais propriedades do cobre nos motores de arranque?

O cobre é amplamente utilizado em motores de arranque, particularmente em componentes eléctricos como enrolamentos e escovas. A sua excelente condutividade eléctrica (aproximadamente 58% IACS), a elevada condutividade térmica e a resistência à corrosão fazem dele a escolha ideal para uma transferência de energia eficiente. O cobre pode funcionar eficazmente a temperaturas até 200°C, o que é crucial para as exigências de binário elevado dos motores de arranque.

Prós e contras do cobre:

– Prós: A elevada condutividade assegura uma transferência de energia eficiente, reduzindo a perda de energia e melhorando o desempenho. Tem também uma boa resistência à oxidação.

– Contras: O cobre é relativamente caro e pode ser pesado, o que pode afetar o peso total do motor de arranque. Além disso, pode necessitar de revestimentos protectores para aumentar a resistência à corrosão em determinados ambientes.

Impacto na aplicação:

A compatibilidade do cobre com cargas eléctricas elevadas torna-o adequado para motores de arranque, onde o rápido engate e desengate são cruciais. No entanto, em ambientes húmidos ou corrosivos, podem ser necessárias medidas de proteção adicionais.

Considerações para compradores internacionais:

Os compradores internacionais devem considerar as flutuações de custo do cobre, a conformidade com as normas eléctricas e a potencial necessidade de revestimentos protectores com base nas condições ambientais regionais.

Como o alumínio beneficia o design do motor de arranque?

O alumínio é frequentemente utilizado na carcaça e nos componentes estruturais dos motores de arranque devido às suas propriedades de leveza e resistência à corrosão. Com um ponto de fusão de cerca de 660°C, o alumínio pode suportar as tensões térmicas encontradas durante o funcionamento.

Prós e contras do alumínio:

– Prós: A natureza leve melhora a eficiência do combustível nos veículos e a sua resistência à corrosão prolonga o tempo de vida dos motores de arranque.

– Contras: O alumínio tem uma resistência à tração inferior à do aço, o que pode limitar a sua utilização em aplicações de elevada tensão. Também pode ser mais caro do que algumas opções de aço.

Impacto na aplicação:

As propriedades de leveza do alumínio são particularmente benéficas para as aplicações automóveis, onde a redução do peso pode melhorar o desempenho do veículo. No entanto, a sua menor resistência pode exigir considerações de conceção cuidadosas para evitar falhas estruturais.

Considerações para compradores internacionais:

Os compradores devem assegurar o cumprimento das normas regionais para as ligas de alumínio e considerar a disponibilidade de graus específicos nos seus mercados.

Qual o papel do aço na durabilidade do motor de arranque?

O aço é normalmente utilizado para componentes que requerem elevada resistência e durabilidade, como o induzido e a caixa. A sua elevada resistência à tração e a capacidade de suportar tensões mecânicas significativas fazem dele uma escolha fiável para motores de arranque.

Prós e contras do aço:

– Prós: Excelente relação resistência/peso e durabilidade, tornando-o adequado para aplicações pesadas. O aço é também relativamente económico em comparação com outros metais.

– Contras: O aço é propenso à corrosão se não for corretamente tratado, e o seu peso pode ser uma desvantagem em aplicações sensíveis ao desempenho.

Impacto na aplicação:

A robustez do aço é fundamental para os motores de arranque sujeitos a um binário elevado e a esforços mecânicos. No entanto, as medidas de proteção contra a corrosão são essenciais para garantir a longevidade, especialmente em ambientes agressivos.

Imagem ilustrativa relacionada com o funcionamento de um motor de arranque

Considerações para compradores internacionais:

Os compradores internacionais devem verificar a conformidade com as normas ASTM ou DIN para os tipos de aço e considerar as implicações do peso no desempenho global do veículo.

Como é que os compósitos plásticos são utilizados nos componentes do motor de arranque?

Os compósitos plásticos estão a ser cada vez mais utilizados em componentes não estruturais de motores de arranque, tais como caixas e materiais de isolamento. As suas propriedades de leveza e isolamento tornam-nos adequados para aplicações específicas.

Prós e contras dos compósitos plásticos:

– Prós: São leves, resistentes à corrosão e excelentes isolantes eléctricos, reduzindo o risco de curto-circuitos.

– Contras: Resistência mecânica limitada em comparação com os metais, o que pode restringir a sua utilização em aplicações de alta tensão. Podem também ser sensíveis a temperaturas elevadas.

Imagem ilustrativa relacionada com o funcionamento de um motor de arranque

Impacto na aplicação:

Os compósitos plásticos podem ajudar a reduzir o peso total dos motores de arranque, ao mesmo tempo que fornecem o isolamento necessário. No entanto, a sua utilização deve ser limitada a componentes que não suportem carga.

Considerações para compradores internacionais:

Os compradores devem certificar-se de que os compósitos plásticos utilizados cumprem os regulamentos e normas ambientais relevantes, nomeadamente no que respeita à inflamabilidade e à resistência química.

Tabela resumida da seleção de materiais para motores de arranque

| Material | Caso de utilização típico de como funciona um motor de arranque | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Enrolamentos eléctricos e escovas | Elevada condutividade elétrica | Caro e pesado | Alto |

| Alumínio | Componentes estruturais e de alojamento | Leve e resistente à corrosão | Menor resistência à tração em comparação com o aço | Médio |

| Aço | Armadura e caixa | Excelente resistência e durabilidade | Sujeito a corrosão sem tratamento | Baixo |

| Compósitos plásticos | Componentes não-estruturais e isolamento | Leve e com bom isolamento elétrico | Resistência mecânica limitada | Médio |

Este guia estratégico de seleção de materiais fornece informações essenciais aos compradores internacionais B2B que procuram otimizar o desempenho e a fiabilidade dos motores de arranque em várias aplicações.

Análise aprofundada: Processos de fabrico e garantia de qualidade para como funciona um motor de arranque

Quais são as principais fases do fabrico de motores de arranque?

O processo de fabrico de motores de arranque envolve várias fases críticas que garantem que o produto final é fiável e eficiente. A compreensão destas fases pode ajudar os compradores B2B a avaliar a qualidade e a adequação dos potenciais fornecedores.

Como é que o material é preparado para a produção de motores de arranque?

A primeira fase do processo de fabrico é a preparação do material. São obtidas matérias-primas de alta qualidade, como o cobre para os enrolamentos, o ferro macio para a armadura e os plásticos duráveis para a caixa. Estes materiais devem cumprir normas específicas para garantir um desempenho ótimo. Por exemplo, o cobre deve ter uma elevada taxa de condutividade, enquanto os plásticos devem ser resistentes ao calor e à exposição a produtos químicos.

Uma vez adquiridos os materiais, estes são submetidos a testes para verificar as suas propriedades. Este controlo de qualidade inicial é crucial para evitar defeitos em fases posteriores. Os fornecedores utilizam frequentemente análises espectrométricas e outros métodos de ensaio para confirmar a integridade dos materiais.

Que técnicas de conformação são utilizadas no fabrico de motores de arranque?

Após a preparação do material, o passo seguinte é a formação dos vários componentes do motor de arranque. Normalmente, isto inclui processos como a estampagem, a moldagem e a maquinagem.

-

Estampagem: Os componentes metálicos, como o induzido e a caixa, são frequentemente produzidos por estampagem. Isto envolve a utilização de matrizes para cortar e moldar folhas de metal nas formas pretendidas. A precisão é vital neste passo para garantir que todas as peças se encaixam perfeitamente.

-

Moldagem: Os componentes de plástico são criados utilizando técnicas de moldagem por injeção. Este método permite a criação de formas complexas e a produção de grandes volumes. As peças moldadas devem ser inspeccionadas quanto à precisão dimensional e ao acabamento da superfície.

-

Maquinação: Alguns componentes, como o comutador e o pinhão, requerem maquinação para obter dimensões precisas. As máquinas CNC (Controlo Numérico Computadorizado) são frequentemente utilizadas para este fim, proporcionando uma elevada precisão e repetibilidade.

Como são montados os componentes do motor de arranque?

A fase de montagem combina os componentes previamente formados num motor de arranque completo. Este processo envolve normalmente os seguintes passos:

-

Subconjunto: Os componentes individuais, como a armadura, as bobinas de campo e o solenoide, são montados separadamente. Este passo permite controlos de qualidade mais fáceis antes da montagem final.

-

Montagem final: Os subconjuntos são então combinados. O induzido é colocado na caixa e o solenoide é montado. Deve-se ter o cuidado de assegurar que todas as ligações eléctricas estão seguras.

-

Controlo de qualidade durante a montagem: Ao longo do processo de montagem, os operadores efectuam verificações para garantir que os componentes estão corretamente alinhados e que não existem defeitos. Isto inclui inspecções visuais e testes operacionais.

Que processos de acabamento são aplicados aos motores de arranque?

Uma vez montados, os motores de arranque são submetidos a processos de acabamento para aumentar a sua durabilidade e desempenho. Estes processos podem incluir:

-

Tratamento de superfície: Os componentes podem ser revestidos com acabamentos de proteção para evitar a corrosão. A galvanoplastia é um método comum utilizado para peças metálicas.

-

Testes: Após o acabamento, cada motor de arranque é submetido a um teste de funcionamento. Isto garante que o motor funciona corretamente em condições de carga. Os testes podem envolver a simulação de condições reais do veículo para verificar o desempenho.

Que medidas de garantia de qualidade são implementadas na fabricação de motores de arranque?

A garantia de qualidade é fundamental no fabrico de motores de arranque para assegurar a fiabilidade e o desempenho. São relevantes várias normas internacionais e certificações específicas do sector.

Que normas internacionais se aplicam ao fabrico de motores de arranque?

A ISO 9001 é uma das normas de gestão da qualidade mais reconhecidas a nível mundial. Define critérios para o estabelecimento de um sistema de gestão da qualidade (QMS). Os fabricantes de motores de arranque procuram frequentemente esta certificação para demonstrar o seu empenhamento na qualidade. Outras certificações específicas da indústria podem incluir a marcação CE para conformidade com as normas de segurança europeias e a certificação API para componentes automóveis.

Quais são os principais pontos de controlo de qualidade na produção?

Os pontos de verificação do controlo de qualidade (CQ) são implementados ao longo do processo de fabrico. Estes incluem normalmente:

-

Controlo de Qualidade de Entrada (IQC): As matérias-primas são inspeccionadas à chegada para garantir que cumprem as normas de qualidade especificadas.

-

Controlo de qualidade em processo (IPQC): Durante o processo de fabrico, os operadores realizam inspecções em várias fases para detetar defeitos precocemente.

-

Controlo de Qualidade Final (FQC): Após a montagem, cada motor de arranque é submetido a testes exaustivos para confirmar que cumpre as normas de funcionamento. Isto inclui testes eléctricos e avaliações de desempenho.

Como os compradores B2B podem verificar as práticas de controlo de qualidade dos fornecedores?

Os compradores B2B devem tomar medidas proactivas para verificar as práticas de controlo de qualidade dos potenciais fornecedores. Eis alguns passos a seguir:

-

Auditorias: A realização de auditorias a fornecedores pode fornecer informações sobre os seus processos de fabrico e medidas de garantia de qualidade. Isto é particularmente importante para os fornecedores internacionais, onde as normas podem variar.

-

Relatórios de qualidade: Solicitar relatórios de qualidade pormenorizados pode ajudar os compradores a compreender o historial de CQ do fornecedor, incluindo quaisquer desvios às normas e a forma como foram resolvidos.

-

Inspeções por terceiros: A contratação de serviços de inspeção por terceiros pode proporcionar uma avaliação imparcial das práticas de gestão da qualidade de um fornecedor. Estas organizações podem efetuar auditorias e testes para garantir a conformidade com as normas internacionais.

Quais são as nuances do controlo de qualidade e da certificação para os compradores internacionais B2B?

Os compradores B2B internacionais, especialmente os de regiões como África, América do Sul, Médio Oriente e Europa, têm de navegar por várias nuances de controlo de qualidade. Os diferentes mercados podem ter normas e regulamentos únicos que afectam a aceitação do produto.

-

Normas regionais: Os compradores devem estar cientes das normas regionais específicas que se podem aplicar aos componentes automóveis. Por exemplo, a União Europeia tem regulamentos rigorosos relativamente à segurança automóvel e às emissões que têm de ser cumpridos.

-

Documentação: A documentação adequada, incluindo certificados de conformidade e relatórios de ensaio, é essencial para um desalfandegamento sem problemas e para a entrada no mercado. Os compradores devem certificar-se de que os fornecedores podem fornecer a documentação necessária.

-

Considerações culturais: A compreensão das diferenças culturais nas práticas comerciais pode facilitar as negociações e promover relações mais fortes com os fornecedores. Isto inclui o reconhecimento da importância da confiança e das parcerias a longo prazo em muitas regiões.

Em conclusão, os processos de fabrico e as medidas de garantia de qualidade para motores de arranque são abrangentes e fundamentais para garantir a fiabilidade do produto. Ao compreender estes aspectos, os compradores B2B podem tomar decisões informadas ao selecionar os fornecedores, o que conduzirá, em última análise, a uma maior eficiência operacional e à satisfação do cliente.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘como funciona um motor de arranque’

Para compreender e adquirir efetivamente motores de arranque, é essencial ter um roteiro claro. Este guia descreve os passos necessários para os compradores B2B, especialmente os que operam em diversos mercados em África, na América do Sul, no Médio Oriente e na Europa. Ao seguir esta lista de verificação, irá garantir que o seu processo de aprovisionamento é eficiente e cumpre os seus requisitos técnicos.

Passo 1: Defina as suas especificações técnicas

Comece por delinear os requisitos técnicos para os motores de arranque de que necessita. Isto inclui tensão, especificações de binário e compatibilidade com os sistemas de motor existentes. Compreender as suas especificações ajuda a restringir os potenciais fornecedores e garante que os produtos satisfazem as suas necessidades operacionais.

- Requisitos de tensão: Determine se necessita de motores de arranque de 12V ou 24V com base nas especificações do seu veículo ou máquina.

- Necessidades de binário: Avalie o binário necessário para pôr o motor a trabalhar eficazmente, que varia consoante o tamanho e a conceção do motor.

Passo 2: Pesquisa e identificação de fornecedores fiáveis

Efectue uma pesquisa exaustiva para compilar uma lista de potenciais fornecedores. Procure fabricantes com um historial comprovado e feedback positivo dos clientes, especialmente os que estão familiarizados com as necessidades específicas da sua região.

Imagem ilustrativa relacionada com o funcionamento de um motor de arranque

- Comentários de fornecedores: Verifique as críticas e os testemunhos em linha para avaliar a fiabilidade e a qualidade dos produtos do fornecedor.

- Experiência no sector: Dê prioridade aos fornecedores com experiência no seu sector, uma vez que estes compreenderão melhor as suas necessidades.

Passo 3: Avaliar as certificações dos fornecedores

Antes de proceder a qualquer fornecedor, verificar as suas certificações. Este passo é crucial para garantir que os motores de arranque cumprem as normas internacionais de qualidade e segurança.

- Certificações ISO: Procure a certificação ISO 9001 ou outras certificações relevantes que indiquem um compromisso com a gestão da qualidade.

- Conformidade com as normas locais: Certifique-se de que os produtos cumprem as regulamentações específicas dos seus mercados-alvo, nomeadamente na Europa ou na América do Sul.

Passo 4: Solicitar amostras para teste

Depois de ter selecionado os potenciais fornecedores, solicite amostras dos seus motores de arranque. Este passo permite-lhe avaliar a qualidade e o desempenho dos produtos antes de efetuar uma compra a granel.

- Teste de desempenho: Teste as amostras em condições semelhantes às do seu ambiente operacional para garantir que cumprem as suas especificações.

- Avaliação da durabilidade: Verificar o desgaste após uma série de testes para avaliar a fiabilidade a longo prazo dos motores de arranque.

Passo 5: Negociar condições e preços

Depois de selecionar um fornecedor preferencial, inicie negociações sobre preços, prazos de entrega e condições de pagamento. Uma negociação eficaz pode levar a melhores preços e condições favoráveis.

- Descontos por atacado: Informe-se sobre descontos para encomendas em grandes quantidades, o que pode reduzir significativamente os seus custos.

- Flexibilidade de pagamento: Discuta as condições de pagamento que se alinham com os seus requisitos de fluxo de caixa, tais como pagamentos parciais ou condições de crédito.

Passo 6: Estabelecer um processo de garantia de qualidade

Implemente um processo de garantia de qualidade para assegurar que os motores de arranque que recebe cumprem as suas normas. Este processo pode ajudar a reduzir os riscos associados a produtos defeituosos.

- Controlo de qualidade de entrada: Organizar inspecções após a entrega para verificar eventuais discrepâncias ou defeitos.

- Monitorização do desempenho dos fornecedores: Monitorizar continuamente o desempenho dos fornecedores com base na qualidade, no prazo de entrega e na capacidade de resposta a problemas.

Passo 7: Desenvolver uma relação a longo prazo

Construir uma relação forte com o seu fornecedor pode levar a um melhor serviço e apoio a longo prazo. Estabeleça uma comunicação regular para resolver quaisquer preocupações e explorar futuras oportunidades de colaboração.

- Mecanismo de feedback: Dê feedback construtivo ao seu fornecedor para o ajudar a melhorar as suas ofertas.

- Oportunidades de desenvolvimento conjunto: Explore oportunidades de co-desenvolvimento de motores de arranque adaptados às suas necessidades específicas.

Ao seguir esta lista de verificação, os compradores B2B podem simplificar o processo de aprovisionamento de motores de arranque, garantindo que obtêm produtos de alta qualidade que se alinham com as suas necessidades operacionais, ao mesmo tempo que promovem fortes relações com os fornecedores.

Imagem ilustrativa relacionada com o funcionamento de um motor de arranque

Análise exaustiva dos custos e dos preços para o fornecimento de produtos e serviços para o funcionamento de um motor de arranque

Quais são os principais componentes de custo na produção de motores de arranque?

Ao adquirir motores de arranque, compreender a estrutura de custos é essencial para os compradores B2B. O custo total de um motor de arranque pode ser dividido em vários componentes:

-

Materiais: Os principais materiais para os motores de arranque incluem o cobre para os enrolamentos, o aço para a caixa e ligas especializadas para as engrenagens. A escolha dos materiais tem um impacto significativo tanto no desempenho como no custo. Materiais de alta qualidade podem levar a custos iniciais mais elevados, mas podem reduzir as taxas de falha a longo prazo.

-

Trabalho: Os custos de mão de obra englobam os salários dos trabalhadores envolvidos na montagem, no controlo de qualidade e nos testes. As regiões com custos de mão de obra mais baixos, como partes de África e da América do Sul, podem oferecer preços competitivos, mas podem comprometer a qualidade se não forem geridas corretamente.

-

Custos indiretos de produção: Inclui os custos associados às instalações de produção, serviços públicos e despesas administrativas. Processos de fabrico eficientes podem reduzir as despesas gerais, permitindo aos fornecedores oferecer preços mais competitivos.

-

Ferramentas: O investimento inicial em ferramentas para a produção de motores de arranque pode ser substancial, especialmente para projectos personalizados. Os compradores devem considerar se precisam de produtos prontos a usar ou se precisam de ferramentas especializadas para especificações únicas.

-

Controlo de Qualidade (QC): A implementação de medidas rigorosas de controlo de qualidade garante que os motores de arranque cumprem as normas internacionais. No entanto, os processos de CQ reforçados podem aumentar os custos. Os compradores devem avaliar a importância das certificações e das garantias de qualidade em relação ao seu orçamento.

-

Logística: Os custos de envio podem variar significativamente consoante o destino, o modo de transporte e o volume. Compreender os Incoterms é crucial para calcular os custos logísticos totais, especialmente para os compradores internacionais.

-

Margem: As margens dos fornecedores variam consoante a concorrência no mercado, a procura e a singularidade da sua oferta. Os compradores devem estar cientes de que as margens mais elevadas estão frequentemente associadas a um melhor serviço e apoio.

Como é que os influenciadores de preços afectam os custos do motor de arranque?

Vários factores podem influenciar o preço dos motores de arranque, incluindo

-

Volume e quantidade mínima de encomenda (MOQ): Os volumes de encomenda mais elevados podem conduzir a descontos significativos. Os compradores devem negociar MOQs que estejam de acordo com as suas necessidades, maximizando a relação custo-eficácia.

-

Especificações e personalização: Os projectos personalizados podem aumentar os custos devido à necessidade de ferramentas e materiais especializados. Os compradores devem avaliar se as opções disponíveis no mercado podem satisfazer as suas necessidades para evitar despesas desnecessárias.

-

Qualidade dos materiais e certificações: A utilização de materiais de qualidade superior e a conformidade com certificações internacionais (por exemplo, ISO) podem aumentar os custos, mas proporcionam fiabilidade a longo prazo. Os compradores devem ponderar a importância destes factores em função das suas restrições orçamentais.

-

Fatores relacionados ao fornecedor: A reputação e a fiabilidade do fornecedor podem afetar os preços. Os fornecedores estabelecidos podem cobrar um prémio pelos seus produtos, mas muitas vezes prestam um melhor apoio ao cliente e serviços de garantia.

-

Incoterms: Compreender as implicações dos Incoterms é vital para as transacções internacionais. Estes determinam quem assume a responsabilidade pelos custos e riscos de transporte, afectando o preço global.

Que dicas para o comprador podem melhorar a eficiência de custos no fornecimento de motores de arranque?

Para navegar nas complexidades do aprovisionamento de motores de arranque, os compradores devem considerar as seguintes sugestões:

-

Negociação: Envolver os fornecedores em discussões sobre preços, especialmente se puder comprometer-se com volumes maiores. Utilize cotações competitivas de vários fornecedores para melhorar a sua posição negocial.

-

Custo total de propriedade (TCO): Para além do preço de compra inicial, considere o TCO, que inclui manutenção, potenciais falhas e eficiência energética. O investimento em motores de arranque de maior qualidade pode levar a um TCO mais baixo a longo prazo.

-

Nuances de preços para compradores internacionais: Tenha em atenção as flutuações cambiais, os direitos de importação e os impostos que podem afetar o custo final. Familiarize-se com as tendências do mercado regional em África, na América do Sul, no Médio Oriente e na Europa para tomar decisões de compra informadas.

-

Avaliação de fornecedores: Dar prioridade aos fornecedores com um historial de fiabilidade e qualidade. A realização de diligências adequadas pode evitar erros dispendiosos no aprovisionamento.

Isenção de responsabilidade sobre preços indicativos

Os preços dos motores de arranque podem variar muito em função dos factores acima mencionados e das condições de mercado. É aconselhável que os compradores efectuem uma pesquisa de mercado exaustiva e obtenham vários orçamentos para garantir que recebem preços competitivos adaptados às suas necessidades específicas.

Análise de alternativas: Comparação de como funciona um motor de arranque com outras soluções

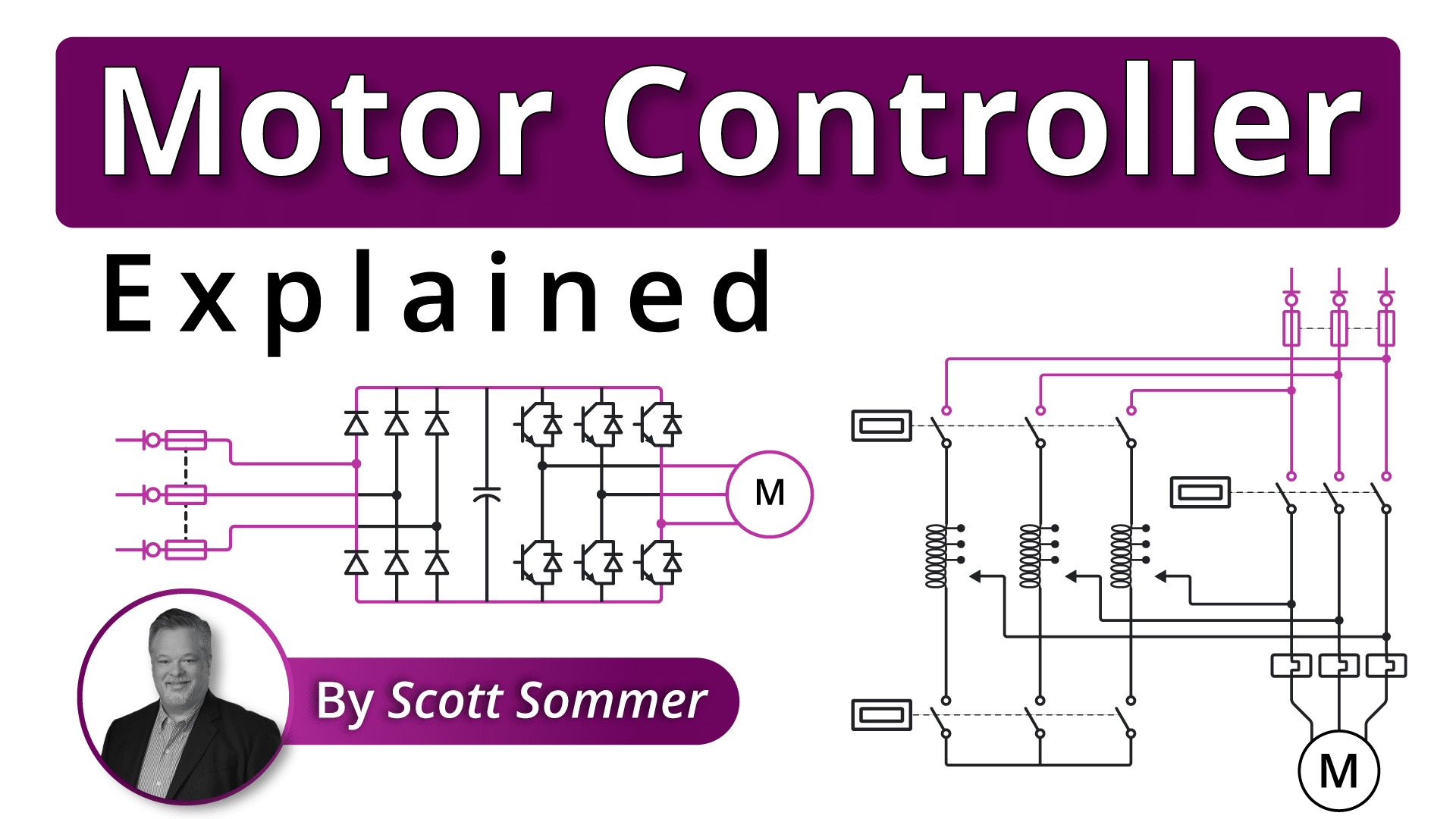

Compreender as alternativas aos motores de arranque em aplicações automóveis

Na indústria automóvel, o motor de arranque desempenha um papel crucial na ignição do motor. No entanto, com a evolução da tecnologia, surgiram soluções alternativas que podem atingir objectivos semelhantes. Esta análise irá comparar o motor de arranque tradicional com duas alternativas viáveis: o Gerador de Arranque Integrado (ISG) e o Sistema de Arranque Pneumático. Cada opção apresenta vantagens e desvantagens únicas que podem influenciar as decisões de compra dos compradores B2B em várias regiões, incluindo África, América do Sul, Médio Oriente e Europa.

| Aspecto comparativo | Como funciona um motor de arranque | Gerador de arranque integrado (ISG) | Sistema de arranque pneumático |

|---|---|---|---|

| Desempenho | Binário elevado para rajadas curtas; fiável para a maioria dos veículos | Oferece um funcionamento contínuo; aumenta a eficiência do combustível | Arranque rápido do motor com binário elevado |

| Custo | Custos de instalação e manutenção geralmente baixos a moderados | Custo inicial mais elevado devido à complexidade | Custos moderados; depende da configuração do compressor de ar |

| Facilidade de implementação | Instalação de série na maioria dos veículos; fácil de substituir | Instalação mais complexa; requer integração com sistemas eléctricos | Necessita de equipamento adicional (compressor de ar) |

| Manutenção | Necessidade de controlos regulares; potencial de desgaste ao longo do tempo | Manutenção mínima; geralmente mais durável | Manutenção de rotina do compressor de ar necessária |

| Melhor caso de uso | Veículos convencionais; fiável para motores tradicionais | Veículos híbridos e eléctricos; melhora a eficiência | Veículos pesados; ideal para condições extremas |

Análise aprofundada das alternativas

Quais são as vantagens e desvantagens dos geradores de arranque integrados (ISG)?

O Gerador de Arranque Integrado (ISG) combina a funcionalidade de um motor de arranque e de um alternador, proporcionando o arranque do motor e a produção de eletricidade. Este sistema é particularmente vantajoso para veículos híbridos e eléctricos, uma vez que aumenta a eficiência do combustível ao permitir a travagem regenerativa. No entanto, a complexidade do ISG implica custos iniciais mais elevados e requer uma instalação especializada, o que pode constituir um obstáculo para alguns compradores. A manutenção é geralmente mínima, uma vez que estes sistemas são concebidos para serem duradouros.

Como é que um sistema de arranque pneumático se compara aos motores de arranque tradicionais?

Os sistemas de arranque pneumático utilizam ar comprimido para arrancar o motor, o que os torna adequados para aplicações pesadas, como equipamento de construção e exploração mineira. Estes sistemas fornecem um binário elevado e podem arrancar motores em condições extremas, onde os sistemas eléctricos podem falhar. No entanto, a necessidade de um compressor de ar aumenta o custo e a complexidade geral da instalação. A manutenção também é um fator a considerar, uma vez que o compressor de ar requer verificações regulares para garantir um desempenho ótimo.

Conclusão: escolhendo a solução certa para as suas necessidades

Para os compradores B2B que avaliam os motores de arranque e as suas alternativas, a decisão deve depender de requisitos operacionais específicos e de considerações de custo. Os motores de arranque convencionais continuam a ser uma escolha fiável para os veículos tradicionais, enquanto os geradores de arranque integrados são ideais para os híbridos modernos centrados na eficiência. Os sistemas pneumáticos destacam-se em aplicações para veículos pesados, proporcionando um desempenho robusto em ambientes difíceis. A compreensão destas opções permitirá aos compradores selecionar a solução que melhor se adapta aos seus objectivos operacionais e restrições orçamentais.

Propriedades técnicas essenciais e terminologia comercial para o funcionamento de um motor de arranque

Quais são as principais propriedades técnicas de um motor de arranque?

Ao adquirir motores de arranque para aplicações automóveis, compreender as propriedades técnicas é crucial para tomar decisões de compra informadas. Aqui estão algumas especificações críticas que os compradores B2B devem considerar:

Imagem ilustrativa relacionada com o funcionamento de um motor de arranque

-

Grau do material

Os materiais utilizados nos motores de arranque, como o cobre para os enrolamentos e o aço de alta qualidade para a caixa, afectam significativamente o desempenho e a durabilidade. O cobre é preferido pela sua excelente condutividade, que assegura uma transferência de energia eficiente. O aço de alta qualidade melhora a integridade estrutural do motor de arranque, permitindo-lhe suportar condições de funcionamento difíceis. A seleção do tipo de material correto é essencial para garantir um desempenho e uma fiabilidade duradouros. -

Classificação de binário

O binário é uma medida da força de rotação e um motor de arranque tem de fornecer uma quantidade de binário suficiente para pôr o motor a trabalhar eficazmente. Este é normalmente medido em Newton-metros (Nm). Uma classificação de binário mais elevada é essencial para motores maiores ou em condições extremas, como altitudes elevadas ou tempo frio. Os compradores devem fazer corresponder a classificação do binário às especificações do seu motor para garantir um desempenho ótimo. -

Consumo de corrente

O consumo de corrente, medido em amperes (A), indica a quantidade de corrente eléctrica que o motor de arranque consome durante o funcionamento. Um motor de arranque com um consumo de corrente elevado pode exigir uma bateria e um sistema de cablagem mais robustos. Compreender o consumo de corrente é vital para garantir a compatibilidade com os sistemas eléctricos existentes, evitando potenciais falhas ou ineficiências. -

Gama de temperaturas operacionais

Os motores de arranque estão frequentemente expostos a temperaturas extremas. A gama de temperaturas operacionais define as condições em que o motor pode funcionar efetivamente sem falhas. Os motores concebidos para ambientes de alta temperatura (por exemplo, aplicações sob o capot) devem utilizar materiais e isolamento resistentes ao calor. A seleção de um motor de arranque dentro da gama de temperaturas adequada é fundamental para manter a fiabilidade e o desempenho. -

Peso e tamanho

As dimensões e o peso do motor de arranque podem afetar a instalação e o desempenho geral do veículo. Um design compacto e leve pode contribuir para melhorar a eficiência do combustível e facilitar a instalação. Os compradores B2B devem considerar estes factores, especialmente quando trabalham com espaço limitado no compartimento do motor ou quando a redução de peso é uma prioridade.

Quais são os termos comerciais comuns relacionados com motores de arranque?

Compreender a terminologia do sector pode melhorar a comunicação e a negociação com os fornecedores. Eis alguns termos comerciais essenciais frequentemente utilizados no sector automóvel:

-

OEM (Fabricante de Equipamento Original)

OEM refere-se a produtos fabricados pela mesma empresa que produziu as peças originais para um veículo. Os motores de arranque OEM são concebidos para cumprir as especificações exactas do fabricante do veículo, garantindo a compatibilidade e o desempenho. Os compradores B2B preferem frequentemente peças OEM pela sua fiabilidade, embora possam ter um preço mais elevado em comparação com as alternativas do mercado de substituição. -

MOQ (Quantidade mínima de encomenda)

O MOQ é o número mais pequeno de unidades que um fornecedor está disposto a vender. Este termo é crucial para as transacções B2B, uma vez que afecta a gestão do inventário e a eficiência dos custos. Compreender o MOQ ajuda os compradores a planear as suas compras e a negociar melhores condições com os fornecedores. -

RFQ (Pedido de Orçamento)

Um pedido de cotação é um documento enviado por um comprador aos fornecedores solicitando preços e outros pormenores para produtos específicos. No contexto dos motores de arranque, um pedido de cotação pode ajudar os compradores a comparar as ofertas de diferentes fabricantes, assegurando-lhes o melhor negócio com base no preço, qualidade e condições de entrega. -

Incoterms (Termos Comerciais Internacionais)

Os Incoterms são termos comerciais internacionais padronizados que definem as responsabilidades dos compradores e vendedores no envio e entrega. A compreensão destes termos é essencial para que os compradores B2B possam gerir a logística de forma eficaz, incluindo os custos de envio, o seguro e o risco durante o trânsito. -

Peças de reposição

As peças de substituição são componentes fabricados por outros fabricantes que não o OEM. Embora frequentemente menos dispendiosos, a qualidade e a compatibilidade dos motores de arranque do mercado de substituição podem variar. Os compradores B2B devem pesar as potenciais poupanças contra os riscos de qualidade e desempenho quando consideram as opções do mercado de substituição.

Ao familiarizarem-se com estas propriedades e termos essenciais, os compradores internacionais B2B podem tomar decisões informadas que melhoram a eficiência operacional e garantem a satisfação a longo prazo com as suas compras de motores de arranque.

Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector do funcionamento de um motor de arranque

Quais são as principais dinâmicas e tendências do mercado que afectam os motores de arranque?

O mercado dos motores de arranque é atualmente influenciado por uma confluência de avanços tecnológicos, alterações nas preferências dos consumidores e factores económicos regionais. Os impulsionadores globais incluem a procura crescente de veículos eléctricos (EVs) e híbridos, que necessitam de sistemas de motores de arranque mais sofisticados. À medida que os fabricantes mudam para sistemas integrados de motor de arranque-gerador, os compradores B2B têm de se adaptar ao aprovisionamento de componentes que não só satisfaçam as necessidades tradicionais, como também respondam a estas tecnologias emergentes.

Em regiões como a África, a América do Sul, o Médio Oriente e a Europa, existe um grande interesse em motores de arranque modulares e personalizáveis que possam ser adaptados a vários tipos de motores. Esta tendência é particularmente proeminente em mercados como a Nigéria e a Alemanha, onde os fabricantes locais se esforçam por melhorar o desempenho dos veículos, reduzindo simultaneamente os custos. Além disso, os avanços na ciência dos materiais, incluindo compósitos leves e ímanes avançados, estão a impulsionar a inovação na conceção dos motores de arranque, permitindo uma maior eficiência e um menor consumo de energia.

Outra tendência notável é o aumento das soluções digitais da cadeia de abastecimento. Os compradores B2B internacionais estão a utilizar cada vez mais a análise de dados e as tecnologias IoT para simplificar os processos de aprovisionamento, melhorar a gestão de inventário e melhorar as relações com os fornecedores. Esta transformação digital é essencial para manter a vantagem competitiva num cenário de mercado em rápida evolução.

Como é que a sustentabilidade influencia as decisões de abastecimento no sector dos motores de arranque?

A sustentabilidade tornou-se uma consideração crítica no fornecimento e produção de motores de arranque. Com a crescente consciencialização dos impactos ambientais, os compradores B2B estão a dar prioridade aos fornecedores que demonstram um compromisso com práticas sustentáveis. O sector automóvel, em particular, enfrenta pressões para reduzir as pegadas de carbono e minimizar os resíduos durante a produção.

O fornecimento ético é atualmente uma expetativa básica entre os compradores internacionais, especialmente em regiões como a Europa, onde os regulamentos relativos às normas ambientais são rigorosos. Os compradores estão cada vez mais à procura de fornecedores que possam oferecer transparência nas suas cadeias de fornecimento, incluindo certificações para materiais e práticas sustentáveis. Isto inclui a utilização de materiais reciclados na produção de motores de arranque e a adesão a processos de fabrico amigos do ambiente.

Além disso, as certificações como a ISO 14001 (Gestão Ambiental) e outros rótulos ‘verdes’ estão a tornar-se critérios essenciais para a avaliação dos fornecedores. Os compradores também estão a explorar opções para motores de arranque remanufaturados, que não só reduzem os resíduos como também apresentam uma solução económica, mantendo os padrões de desempenho. Ao dar prioridade à sustentabilidade, os compradores B2B podem alinhar as suas estratégias de aprovisionamento com os objectivos ambientais globais, melhorar a reputação da marca e satisfazer as exigências dos consumidores em matéria de fabrico responsável.

Qual é o contexto histórico do desenvolvimento do motor de arranque relevante para o mercado atual?

A evolução dos motores de arranque pode ser rastreada até à sua invenção por Charles Kettering em 1911, que revolucionou a indústria automóvel ao eliminar a necessidade de motores de manivela manual. Esta inovação lançou as bases para os veículos modernos, integrando motores eléctricos e sistemas de ignição para simplificar o processo de arranque.

Ao longo das décadas, os motores de arranque sofreram avanços significativos, passando de sistemas mecânicos para concepções electromagnéticas altamente sofisticadas que aumentam a fiabilidade e a eficiência. A introdução de solenóides e de sistemas de engrenagens de pinhão melhorou o processo de engate e desengate, permitindo um arranque sem falhas e reduzindo o risco de danos.

Atualmente, à medida que o panorama automóvel se desloca para a eletrificação, o contexto histórico do desenvolvimento do motor de arranque serve como um lembrete da rápida progressão tecnológica na indústria. Compreender esta evolução permite que os compradores B2B apreciem as complexidades e os avanços nas actuais tecnologias de motores de arranque, assegurando decisões de aprovisionamento informadas que se alinham com as futuras exigências do mercado.

Perguntas frequentes (FAQs) para compradores B2B de como funciona um motor de arranque

-

Como posso resolver os problemas de avaria do motor de arranque na minha frota?

Para resolver a falha do motor de arranque, certifique-se primeiro de que a bateria está totalmente carregada e que as ligações estão seguras. Os sinais comuns de avaria incluem sons de estalidos sem rotação do motor ou arranque lento. Se estes sintomas ocorrerem, inspeccione o motor de arranque para verificar se existem componentes desgastados, como o solenoide, as escovas ou a armadura. Considere a implementação de um programa de manutenção regular para testar e substituir proactivamente os motores de arranque avariados. O estabelecimento de relações com fornecedores fiáveis de peças de substituição também pode agilizar as reparações e minimizar o tempo de inatividade do veículo. -

Qual é o melhor motor de arranque para veículos de alto desempenho?

Para veículos de alto desempenho, procure motores de arranque que ofereçam valores de binário mais elevados e maior durabilidade. As marcas especializadas em peças automóveis de alto desempenho fornecem frequentemente motores de arranque concebidos para suportar cargas mais elevadas. Considere factores como o peso, o tamanho e a resistência ao calor do motor, uma vez que as aplicações de alto desempenho podem gerar mais calor. Certifique-se de que o motor de arranque é compatível com as especificações do seu veículo. Consultar os fabricantes ou distribuidores sobre as suas necessidades específicas também pode produzir recomendações personalizadas. -

Como escolher um fornecedor fiável de motores de arranque?

Ao selecionar um fornecedor de motores de arranque, dê prioridade aos que têm um historial comprovado na indústria automóvel. Procure certificações e conformidade com normas de qualidade internacionais, como a ISO 9001. Solicite amostras para avaliar a qualidade e o desempenho do produto. Além disso, avalie o serviço ao cliente, as políticas de garantia e os prazos de entrega. A criação de uma parceria a longo prazo com um fornecedor que compreenda a dinâmica do mercado regional pode melhorar a sua estratégia de aprovisionamento e garantir um fornecimento consistente. -

Quais são as quantidades mínimas de encomenda (MOQ) típicas para motores de arranque?

As quantidades mínimas de encomenda (MOQ) para motores de arranque podem variar muito consoante o fabricante e o modelo específico. Geralmente, as MOQs podem variar de 50 a 500 unidades, dependendo das capacidades de produção e das políticas de inventário do fornecedor. É aconselhável negociar os MOQs, especialmente se for um novo comprador ou estiver a testar uma nova linha de produtos. Os fornecedores podem oferecer flexibilidade nos MOQs para relações estabelecidas, permitindo encomendas iniciais mais pequenas para avaliar a procura do mercado. -

Que condições de pagamento são comuns nas transacções internacionais B2B para motores de arranque?

As condições de pagamento comuns nas transacções B2B internacionais incluem frequentemente opções como cartas de crédito, transferências electrónicas e condições de conta aberta. As cartas de crédito oferecem segurança a ambas as partes, garantindo o pagamento após a confirmação do envio. As transferências electrónicas são simples, mas exigem confiança no fornecedor. As condições de conta aberta podem ser oferecidas a compradores estabelecidos com um bom historial de crédito. Esclareça sempre as condições de pagamento antes de finalizar os contratos para evitar mal-entendidos e garantir transacções sem problemas. -

Como posso assegurar a garantia de qualidade (QA) dos motores de arranque adquiridos?

Para garantir a qualidade dos motores de arranque, estabeleça especificações e normas claras antes da compra. Solicitar certificações de qualidade aos fornecedores, tais como certificações ISO ou TS, que indicam a adesão às normas de fabrico. Considere a implementação de um serviço de inspeção por terceiros para avaliar os produtos antes da expedição. Auditorias regulares aos processos de produção dos seus fornecedores também podem ajudar a manter a qualidade ao longo do tempo. A criação de um ciclo de feedback com as suas equipas de compras e manutenção pode melhorar ainda mais a gestão da qualidade. -

Que considerações logísticas devo ter em conta ao importar motores de arranque?

Ao importar motores de arranque, considere factores como os custos de envio, os regulamentos aduaneiros e os direitos de importação. Avalie os melhores métodos de envio com base no custo e nos prazos de entrega; o frete aéreo é mais rápido mas mais caro do que o frete marítimo. Certifique-se de que o seu fornecedor fornece toda a documentação necessária para o desalfandegamento. Trabalhar com um parceiro logístico com experiência em peças para automóveis pode simplificar o processo e ajudar a ultrapassar quaisquer potenciais desafios durante o trânsito. -

Quais são as causas mais comuns de avaria do motor de arranque?

As causas comuns de avaria do motor de arranque incluem problemas eléctricos, como problemas na bateria, ligações deficientes ou componentes desgastados, como escovas e solenóides. As falhas mecânicas podem resultar de calor excessivo ou de desgaste das peças internas. As verificações de manutenção regulares podem ajudar a identificar sinais precoces de desgaste e evitar avarias inesperadas. A formação da sua equipa em técnicas de resolução de problemas pode minimizar ainda mais o tempo de inatividade e garantir operações eficientes da frota.

Lista dos 4 principais fabricantes e fornecedores de Como funciona um motor de arranque

1. Motores de arranque eléctricos para automóveis

Domínio: autoelectro.pt

Registado: 1999 (26 anos)

Introdução: Os motores de arranque são responsáveis por virar o motor durante a ignição, permitindo a entrada de ar e combustível para a combustão. Os principais componentes incluem:

- Armadura: Um eletroíman montado no eixo de transmissão, envolvido por laços condutores.

- Comutador: Uma secção do veio que conduz a eletricidade através de escovas.

- Escovas: Conduzem eletricidade ao entrarem em contacto com o comutador.

- Solenoide: Actua...

2. Haynes - Motores de arranque

Domínio: us.haynes.com

Registado: 1996 (29 anos)

Introdução: Um motor de arranque é um componente essencial do sistema de arranque de um veículo, responsável pela rotação do motor para iniciar o processo de combustão. Normalmente, é composto por um motor elétrico, um solenoide e uma engrenagem de pinhão. O motor de arranque engata quando se roda a chave da ignição, extraindo energia da bateria para dar partida no motor. Se o motor de arranque falhar, o motor não arranca, o que indica...

3. Reddit - O arranque do carro explicado

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: O motor de arranque do automóvel é alimentado pela bateria e engata uma engrenagem mais pequena para rodar rapidamente e engatar a engrenagem principal, ligando o motor. Quando o motor atinge uma velocidade suficiente, o motor de arranque desengata-se, permitindo que o motor funcione independentemente através de uma sequência de ignição do combustível nos cilindros.

4. Como funciona um automóvel - Sistema de arranque

Domínio: howacarworks.com

Registado: 2011 (14 anos)

Introdução: O sistema de arranque inclui um motor de arranque pré-engatado que utiliza um solenoide para mover o pinhão, permitindo um engate suave com o volante do motor. O motor de arranque necessita de uma forte corrente eléctrica da bateria, activada por um grande interrutor controlado pela chave de ignição. O sistema dispõe de uma mola de retorno para evitar o engate excessivo e o desgaste da bateria. O motor de arranque utiliza uma curva...

Conclusão e Perspectivas do Sourcing Estratégico para o funcionamento de um motor de arranque

Em conclusão, compreender como funciona um motor de arranque é crucial para os compradores B2B internacionais envolvidos na aquisição de peças automóveis. O design complexo do motor de arranque - que inclui componentes como o solenoide, a armadura e o pinhão - desempenha um papel vital na ignição do motor e na funcionalidade geral do veículo. Para empresas em regiões como África, América do Sul, Médio Oriente e Europa, o fornecimento estratégico de motores de arranque de alta qualidade pode aumentar a eficiência operacional e reduzir os custos a longo prazo.

Investir em componentes fiáveis não só garante operações mais suaves, como também promove a confiança dos utilizadores finais, levando a uma maior satisfação do cliente. À medida que a indústria automóvel continua a evoluir, particularmente com o aumento dos veículos eléctricos e das tecnologias híbridas, manter-se informado sobre os avanços na tecnologia dos motores de arranque será essencial para manter uma vantagem competitiva.

Imagem ilustrativa relacionada com o funcionamento de um motor de arranque

Incentivamos os compradores B2B a envolverem-se com fornecedores de renome que dão prioridade à qualidade e à inovação nas suas ofertas de motores de arranque. Ao fazê-lo, pode assegurar os melhores produtos para a sua frota, garantindo fiabilidade e desempenho no panorama automóvel em constante mudança.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.