Introdução: Navegar no mercado global para saber como testar um solenoide de motor de arranque

No mundo acelerado da reparação e manutenção automóvel, compreender como testar um solenoide do motor de arranque é crucial para garantir a eficiência operacional e minimizar o tempo de inatividade. Um solenoide de arranque defeituoso pode levar a falhas no veículo, afectando a logística e a produtividade de empresas de diversos sectores. Este guia abrangente irá aprofundar vários métodos de teste, incluindo inspecções visuais e medições eléctricas, fornecendo aos compradores B2B conhecimentos práticos para identificar e resolver problemas de solenóides de forma eficaz.

O guia abrange uma vasta gama de tópicos, desde os diferentes tipos de solenóides de arranque e as suas aplicações específicas em vários modelos de veículos até às considerações essenciais para a verificação de fornecedores e avaliações de custos. Ao equipar os compradores B2B internacionais - especialmente os de África, América do Sul, Médio Oriente e Europa, incluindo o Brasil e a Arábia Saudita - com conhecimentos aprofundados, este recurso permite tomar decisões de compra informadas.

Compreender as nuances do teste do solenoide do motor de arranque não só ajuda a selecionar os componentes certos, como também aumenta a fiabilidade geral das operações automóveis. À medida que as empresas navegam pelas complexidades do mercado global, este guia serve como uma ferramenta indispensável, assegurando que os compradores podem obter com confiança peças e serviços de qualidade, conduzindo assim ao sucesso das suas operações.

Índice

- Lista dos 2 principais fabricantes e fornecedores de Como testar um solenoide de motor de arranque

- Introdução: Navegar no mercado global para saber como testar um solenoide de motor de arranque

- Compreender como testar um solenoide do motor de arranque Tipos e variações

- Principais aplicações industriais de como testar um solenoide de motor de arranque

- 3 Pontos de dor comuns do utilizador para ‘como testar um solenoide do motor de arranque’ e as suas soluções

- Guia de Seleção de Material Estratégico para saber como testar um solenoide de motor de arranque

- Análise aprofundada: Processos de fabrico e garantia de qualidade para saber como testar um solenoide de motor de arranque

- Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘como testar um solenoide de motor de arranque’

- Análise abrangente de custos e preços para como testar um solenoide de motor de arranque Sourcing

- Análise de alternativas: Comparação de como testar um solenoide de motor de arranque com outras soluções

- Propriedades técnicas essenciais e terminologia comercial para saber como testar um solenoide do motor de arranque

- Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector de como testar um solenoide de motor de arranque

- Perguntas frequentes (FAQs) para compradores B2B sobre como testar um solenoide do motor de arranque

- Strategic Sourcing Conclusion and Outlook for how to test a starter motor solenoid

- Aviso legal importante e termos de utilização

Compreender como testar um solenoide do motor de arranque Tipos e variações

| Nome do tipo | Principais características distintivas | Aplicações B2B primárias | Breves prós e contras para compradores |

|---|---|---|---|

| Inspeção visual | Verificações simples de danos físicos e ligações | Oficinas de reparação automóvel, manutenção de frotas | Prós: Rápido e fácil; não são necessárias ferramentas. Contras: Podem faltar problemas eléctricos. |

| Teste de tensão | Utiliza um multímetro para verificar a tensão nos terminais do solenoide | Fornecedores de peças para automóveis, mecânicos | Prós: Preciso; identifica as falhas eléctricas. Contras: Requer ferramentas e conhecimentos específicos. |

| Teste de carga | Avalia o solenoide sob carga para determinar a sua funcionalidade | Máquinas pesadas, centros de serviços para automóveis | Prós: Abrangente; revela o desempenho sob stress. Contras: Mais complexo; requer equipamento especializado. |

| Medição da resistência | Mede a resistência para identificar falhas internas | Serviços de reparação eléctrica, técnicos de automóveis | Prós: Detecta problemas ocultos; resultados fiáveis. Contras: Técnica; pode exigir conhecimentos avançados. |

| Clique em Testar | Ouve o som de um estalido ao engatar o solenoide | Mecânica de bricolage, serviços de assistência rodoviária | Prós: Simples; é necessário um mínimo de equipamento. Contras: Não é definitivo; os resultados podem ser mal interpretados. |

Quais são as principais caraterísticas da inspeção visual para testar um solenoide de motor de arranque?

A inspeção visual é o método mais simples para avaliar um solenoide do motor de arranque. Envolve a verificação de quaisquer sinais visíveis de desgaste, danos ou ligações soltas. Este método é particularmente adequado para oficinas de reparação automóvel e operações de manutenção de frotas, onde avaliações rápidas podem poupar tempo. Embora seja fácil e não exija ferramentas especializadas, pode não ter em conta problemas eléctricos subjacentes que podem afetar o desempenho.

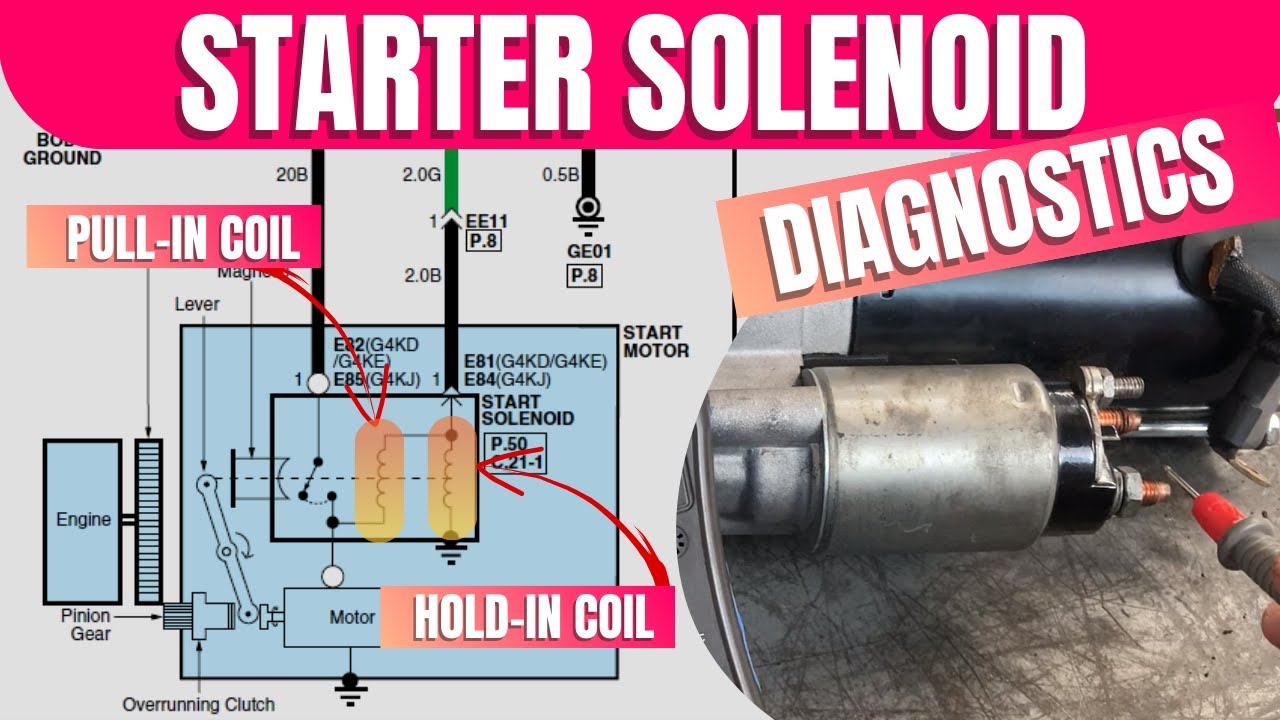

Como é que o teste de tensão fornece informações sobre a funcionalidade do solenoide?

O teste de tensão emprega um multímetro para medir a tensão nos terminais do solenoide, assegurando que a tensão correta está a ser fornecida pela bateria. Este método é vital para os fornecedores de peças automóveis e para os mecânicos, uma vez que identifica com precisão as falhas eléctricas. No entanto, requer ferramentas específicas e um certo nível de conhecimento técnico, o que pode ser um obstáculo para alguns compradores.

O que torna o teste de carga um método abrangente para avaliar solenóides?

O teste de carga avalia o desempenho do solenoide em condições reais de funcionamento, simulando o stress que sofreria durante o arranque do motor. Este método é ideal para maquinaria pesada e centros de serviço automóvel onde a fiabilidade é crítica. Embora forneça uma visão abrangente da funcionalidade do solenoide, é mais complexo e necessita de equipamento especializado, o que pode ser uma consideração para os compradores B2B.

Porque é que a medição da resistência é importante no teste de solenóides?

A medição da resistência envolve a verificação da resistência interna do solenoide para identificar quaisquer falhas que possam não ser aparentes através de outros métodos de teste. Esta técnica é essencial para serviços de reparação eléctrica e técnicos de automóveis que necessitam de resultados fiáveis. Embora possa detetar problemas ocultos, requer um conhecimento mais avançado dos sistemas eléctricos, o que pode ser uma desvantagem para os compradores menos experientes.

Como é que o teste de clique pode ajudar na avaliação rápida do estado do solenoide?

O teste de clique é um método simples em que o técnico ouve um som de clique quando a ignição é ligada, indicando que o solenoide está a tentar engatar. Este método é particularmente útil para os mecânicos de bricolage e para os serviços de assistência rodoviária devido aos seus requisitos mínimos de equipamento. No entanto, embora ofereça uma avaliação rápida, não é definitivo e pode levar a interpretações erradas relativamente à funcionalidade do solenoide.

Principais aplicações industriais de como testar um solenoide de motor de arranque

| Indústria/Setor | Aplicação específica de como testar um solenoide do motor de arranque | Valor/benefício para a empresa | Considerações importantes sobre o fornecimento para esta aplicação |

|---|---|---|---|

| Reparação automóvel | Diagnosticar problemas de arranque em veículos | Reduz o tempo de inatividade e os custos de reparação, assegurando aos clientes uma rápida recuperação do veículo. | Fornecimento de ferramentas de diagnóstico fiáveis e de componentes compatíveis com vários modelos de veículos. |

| Fabrico de equipamento pesado | Garantir a fiabilidade dos sistemas de arranque das máquinas | Evita atrasos operacionais, mantendo a produtividade nos locais de construção e exploração mineira. | Necessidade de equipamento de teste duradouro que possa suportar ambientes adversos e utilização frequente. |

| Gestão de frotas | Controlos de manutenção de rotina dos veículos da frota | Aumenta a fiabilidade da frota e prolonga a vida útil dos veículos, conduzindo a custos operacionais mais baixos. | Importância da compra a granel e da compatibilidade entre os diversos tipos de veículos da frota. |

| Máquinas agrícolas | Ensaio de solenóides de arranque em tractores e ceifeiras-debulhadoras | Assegura a plantação e a colheita atempadas, minimizando os atrasos devidos a falhas do equipamento. | Consideração de adaptações específicas para a agricultura e disponibilidade de peças em áreas remotas. |

| Transporte e Logística | Verificação da funcionalidade do motor de arranque em veículos comerciais | Melhora a eficiência da entrega e reduz as avarias inesperadas durante o transporte. | Necessidade de acesso rápido a peças e equipamento de ensaio para prestar assistência eficiente a uma frota diversificada. |

Como é que ‘como testar um solenoide do motor de arranque’ é aplicado na indústria de reparação automóvel?

No sector da reparação automóvel, testar um solenoide do motor de arranque é crucial para diagnosticar problemas de arranque nos veículos. Os mecânicos utilizam ferramentas específicas para verificar a continuidade eléctrica e o funcionamento correto do solenoide. Ao identificar com precisão se o solenoide ou outros componentes estão em falta, as oficinas podem reduzir as reparações desnecessárias, poupando assim tempo e custos aos seus clientes. Para os compradores internacionais, o aprovisionamento de ferramentas de diagnóstico de alta qualidade que satisfaçam vários modelos de veículos é essencial para manter os padrões de serviço.

Que papel desempenha o ensaio de um solenoide de motor de arranque no fabrico de equipamento pesado?

No fabrico de equipamento pesado, os sistemas de arranque fiáveis são vitais para as máquinas utilizadas na construção e na exploração mineira. O teste regular dos solenóides do motor de arranque assegura que as máquinas arrancam de forma fiável, evitando atrasos operacionais dispendiosos. Para os fabricantes, é fundamental investir em equipamento de teste duradouro capaz de suportar condições de trabalho difíceis. Os compradores internacionais devem considerar a disponibilidade de componentes e ferramentas especializados que possam ser utilizados eficazmente em diversos ambientes.

Como é que o ensaio de solenóides beneficia as operações de gestão de frotas?

A gestão de frotas depende fortemente da funcionalidade dos veículos, tornando o teste dos solenóides do motor de arranque uma tarefa de manutenção de rotina. As verificações regulares ajudam a identificar potenciais falhas antes que estas conduzam a avarias, aumentando a fiabilidade da frota e prolongando a vida útil dos veículos. Para as empresas que operam em várias regiões, a aquisição de equipamento de teste e peças compatíveis a granel pode simplificar os processos de manutenção e reduzir o tempo de inatividade, optimizando assim a eficiência operacional.

Porque é que o ensaio dos solenóides do motor de arranque é crucial nas máquinas agrícolas?

A maquinaria agrícola, como tractores e ceifeiras, depende de sistemas de arranque funcionais para operações atempadas. O teste dos solenóides do motor de arranque garante que estas máquinas arrancam sem atrasos, o que é vital durante as épocas de plantação e colheita. As empresas agrícolas devem considerar a disponibilidade de peças e ferramentas de teste que possam ser facilmente acedidas em áreas remotas. Isto assegura que o equipamento permanece operacional, apoiando, em última análise, a produtividade e a rentabilidade.

Como é que o teste de um solenoide de motor de arranque afecta o transporte e a logística?

No sector dos transportes e da logística, a funcionalidade dos veículos comerciais é fundamental para as entregas atempadas. O teste dos solenóides do motor de arranque ajuda a evitar avarias inesperadas que podem perturbar os horários. As empresas têm de garantir um acesso rápido a equipamento de teste e a peças de substituição, especialmente para frotas diversificadas. Esta capacidade não só aumenta a eficiência como também contribui para a satisfação do cliente, mantendo prazos de entrega fiáveis.

3 Pontos de dor comuns do utilizador para ‘como testar um solenoide do motor de arranque’ e as suas soluções

Cenário 1: Dificuldade em diagnosticar problemas com o solenoide de arranque

O problema: Muitos compradores B2B, especialmente os da indústria de reparação automóvel, enfrentam frequentemente desafios ao diagnosticar se um solenoide de arranque defeituoso é a causa principal de um veículo não arrancar. Esta situação é exacerbada pelo acesso limitado a ferramentas de diagnóstico e pelos diferentes níveis de especialização dos técnicos. Em regiões com menos apoio técnico, como partes de África e da América do Sul, estes compradores podem ter dificuldade em identificar se o problema está no solenoide, na bateria ou no próprio motor de arranque. Esta incerteza pode levar à perda de tempo, ao aumento dos custos de mão de obra e à insatisfação do cliente.

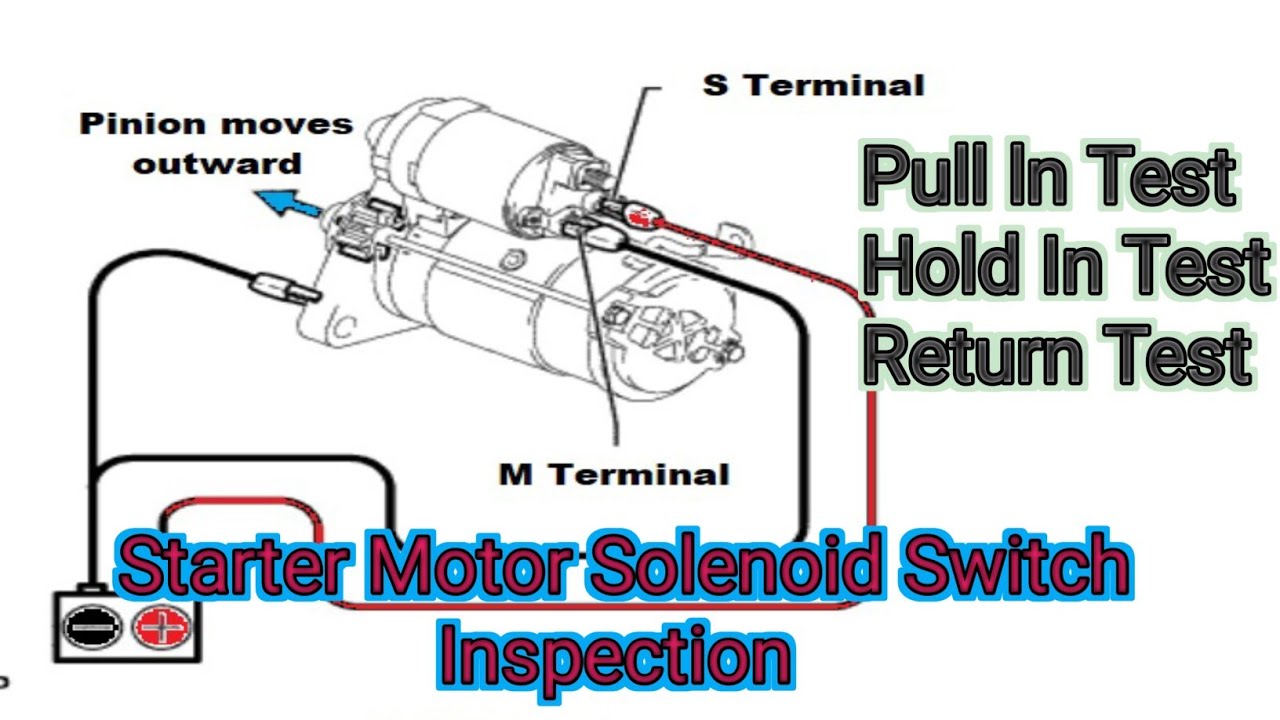

A solução: Para diagnosticar eficazmente um problema no solenoide de arranque, os compradores devem implementar uma abordagem de teste sistemática que minimize as conjecturas. Comece por se certificar de que a bateria está totalmente carregada; uma bateria fraca pode imitar uma falha do solenoide. Em seguida, utilize um voltímetro simples para verificar se há energia no terminal de entrada do solenoide. Se houver energia mas não houver som de clique do solenoide, isso indica uma potencial falha no próprio solenoide. Os compradores podem investir em multímetros de qualidade e proporcionar sessões de formação aos seus técnicos para melhorar as capacidades de diagnóstico. Além disso, a aquisição de kits de teste de solenoide de arranque que incluam instruções claras pode permitir aos técnicos avaliar rapidamente a funcionalidade do solenoide e reduzir o tempo gasto na resolução de problemas.

Cenário 2: Disponibilidade limitada de peças de substituição de qualidade

O problema: Os compradores B2B, particularmente os que operam em áreas remotas ou em mercados emergentes, deparam-se frequentemente com dificuldades no fornecimento de peças de substituição fiáveis para solenóides de arranque. Este desafio pode ser agravado pela prevalência de componentes contrafeitos ou de qualidade inferior no mercado, o que leva a mais complicações e custos a longo prazo. Uma peça de substituição defeituosa pode não só levar a problemas recorrentes, mas também danificar o motor de arranque do veículo, resultando numa reparação mais dispendiosa.

A solução: Para reduzir o risco de aquisição de peças de baixa qualidade, os compradores devem estabelecer relações com fornecedores reputados, conhecidos pela sua autenticidade e fiabilidade. A realização de uma pesquisa exaustiva sobre os fabricantes e a procura de recomendações de colegas de confiança do sector podem ajudar a identificar fontes de qualidade. Além disso, os compradores devem considerar investir num sistema de gestão de inventário robusto que monitorize a qualidade das peças e o desempenho dos fornecedores. A formação do pessoal para reconhecer as peças genuínas e compreender as especificações necessárias para os diferentes modelos de veículos é crucial. Esta abordagem não só garante que são fornecidas as peças corretas, como também cria confiança junto dos clientes que esperam reparações duradouras.

Cenário 3: Falta de conhecimentos sobre os procedimentos de ensaio

O problema: Para muitas empresas de reparação automóvel, particularmente as operações mais pequenas ou os novos operadores, pode haver uma lacuna significativa de conhecimento relativamente aos procedimentos de teste adequados para solenóides de arranque. Sem uma compreensão clara de como executar estes testes de forma eficaz, os técnicos podem sobrestimar o problema, levando a substituições desnecessárias de peças, ou subestimá-lo, resultando em problemas não resolvidos. Esta falta de conhecimento pode comprometer a qualidade do serviço e a eficiência operacional, especialmente em mercados competitivos.

A solução: Para colmatar esta lacuna de conhecimentos, as empresas devem investir em programas de formação centrados nos sistemas eléctricos e no diagnóstico do solenoide de arranque. A colaboração com organizações de formação ou especialistas do sector para realizar workshops pode equipar os técnicos com as competências e a confiança necessárias. Além disso, a criação de guias ou listas de verificação fáceis de seguir para procedimentos de teste pode ajudar a normalizar as práticas em toda a equipa. Os recursos online, como vídeos instrutivos e webinars, também podem servir como materiais suplementares valiosos. Ao promover uma cultura de aprendizagem contínua e de proficiência técnica, as empresas podem melhorar as suas ofertas de serviços e garantir diagnósticos mais exactos, conduzindo, em última análise, a uma maior satisfação do cliente.

Guia de Seleção de Material Estratégico para saber como testar um solenoide de motor de arranque

Que materiais são normalmente utilizados no teste de solenóides de motores de arranque?

No processo de teste dos solenóides do motor de arranque, a seleção dos materiais desempenha um papel crucial para garantir resultados precisos e durabilidade. Aqui, analisamos quatro materiais comuns utilizados nos componentes e ferramentas necessários para testar solenóides de motores de arranque.

1. Cobre

Propriedades principais: O cobre é conhecido pela sua excelente condutividade eléctrica, o que faz dele a escolha preferida para a cablagem e terminais em testes de solenóides. Tem também um ponto de fusão elevado (cerca de 1.984°F ou 1.085°C) e uma boa resistência à corrosão, especialmente quando revestido.

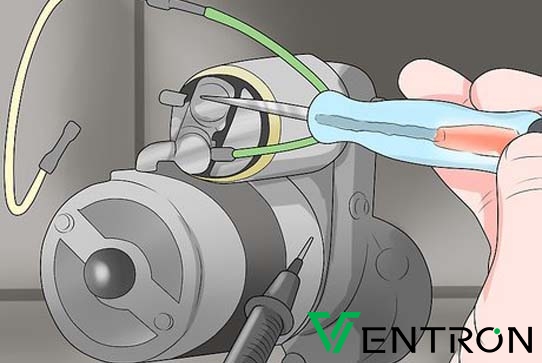

Imagem ilustrativa relacionada com a forma de testar um solenoide do motor de arranque

Prós e contras: A principal vantagem do cobre é a sua condutividade superior, que garante uma queda de tensão mínima durante os testes. No entanto, o cobre pode ser mais caro do que alternativas como o alumínio e é propenso à corrosão se não for devidamente revestido, o que pode afetar o desempenho ao longo do tempo.

Impacto na aplicação: A compatibilidade do cobre com vários meios eléctricos torna-o ideal para o teste de solenóides. No entanto, em ambientes húmidos ou corrosivos, deve ser considerada a necessidade de revestimentos protectores para manter a integridade.

Considerações para compradores internacionais: Os compradores em regiões como a África e a América do Sul devem garantir a conformidade com as normas eléctricas locais, uma vez que a cablagem de cobre obedece frequentemente às normas ASTM. Na Europa, é essencial cumprir os regulamentos da UE relativos à segurança dos materiais.

2. Alumínio

Propriedades principais: O alumínio é leve e tem uma boa condutividade eléctrica, embora inferior à do cobre. Tem um ponto de fusão de cerca de 660°C (1.221°F) e é naturalmente resistente à corrosão devido à sua camada de óxido.

Imagem ilustrativa relacionada com a forma de testar um solenoide do motor de arranque

Prós e contras: A principal vantagem do alumínio é o seu baixo custo e peso, tornando-o mais fácil de manusear e instalar. No entanto, a sua condutividade não é tão elevada como a do cobre, o que pode levar a ligeiras ineficiências nos ensaios.

Impacto na aplicação: O alumínio é adequado para aplicações em que o peso é uma preocupação, mas pode não ter um desempenho tão bom em ambientes de alta temperatura. A sua utilização em conectores e terminais deve ser cuidadosamente avaliada com base nas condições de teste específicas.

Considerações para compradores internacionais: Os compradores devem estar cientes da variação das normas para componentes de alumínio nas diferentes regiões. Por exemplo, no Brasil, a conformidade com as normas do INMETRO é crucial, enquanto na Europa é necessária a adesão às normas EN.

3. Aço

Propriedades principais: O aço é um material forte e duradouro com elevada resistência à tração. Normalmente, tem um ponto de fusão de cerca de 1.370°C (2.500°F) e pode ser tratado para resistência à corrosão através de galvanização ou revestimento.

Prós e contras: A durabilidade do aço torna-o adequado para componentes estruturais em configurações de teste. No entanto, o seu peso pode ser uma desvantagem e pode exigir tratamentos adicionais para evitar a ferrugem e a corrosão, o que pode aumentar a complexidade do fabrico.

Impacto na aplicação: Os componentes de aço podem suportar pressões e temperaturas elevadas, o que os torna ideais para ambientes de teste pesados. No entanto, é necessário ter cuidado para garantir que os revestimentos utilizados não interferem com a condutividade eléctrica.

Considerações para compradores internacionais: Em regiões como o Médio Oriente, onde a humidade pode ser elevada, os compradores devem ter em conta a resistência à corrosão dos componentes de aço. A conformidade com as normas locais, como ASTM ou JIS, também é importante.

4. Plástico (polímero)

Propriedades principais: Os plásticos, particularmente os polímeros de alta qualidade, oferecem excelentes propriedades de isolamento e podem suportar temperaturas moderadas (até cerca de 300°F ou 150°C). São leves e resistentes a muitos produtos químicos.

Prós e contras: A principal vantagem do plástico é a sua capacidade de isolamento, que é essencial em aplicações eléctricas. No entanto, os plásticos podem não ser adequados para aplicações a altas temperaturas e podem degradar-se com o tempo sob exposição aos raios UV.

Impacto na aplicação: O plástico é ideal para componentes não condutores, tais como caixas e isoladores em ferramentas de teste. No entanto, a escolha do plástico deve ter em conta as condições ambientais específicas a que estará sujeito.

Considerações para compradores internacionais: Os compradores devem certificar-se de que os plásticos utilizados cumprem as normas de segurança e ambientais das suas regiões, como o REACH na Europa ou a ANVISA no Brasil.

Tabela resumida da seleção de materiais para testar solenóides do motor de arranque

| Material | Caso de utilização típico de como testar um solenoide de motor de arranque | Vantagem principal | Principal desvantagem/limitação | Custo relativo (baixo/médio/alto) |

|---|---|---|---|---|

| Cobre | Cablagem e terminais para ligações eléctricas | Excelente condutividade | Custo mais elevado, propenso à corrosão | Alto |

| Alumínio | Conectores e componentes leves | Económica e leve | Condutividade inferior à do cobre | Médio |

| Aço | Componentes estruturais e suportes | Alta resistência e durabilidade | Mais pesado, pode necessitar de tratamento anticorrosivo | Médio |

| Plástico | Isoladores e caixas não condutoras | Excelentes propriedades de isolamento | Resistência limitada à temperatura, degradação UV | Baixo |

Esta análise fornece aos compradores B2B uma compreensão abrangente das opções de materiais para testar solenóides de motores de arranque, considerando o desempenho, o custo e os requisitos de conformidade regionais.

Análise aprofundada: Processos de fabrico e garantia de qualidade para saber como testar um solenoide de motor de arranque

Quais são as principais fases do processo de fabrico de um solenoide de motor de arranque?

O processo de fabrico de um solenoide de motor de arranque envolve várias fases críticas, cada uma concebida para garantir que o produto cumpre as normas de desempenho necessárias. Estas fases incluem a preparação do material, a moldagem, a montagem e o acabamento.

-

Preparação do material

- O primeiro passo envolve a seleção de matérias-primas de alta qualidade, como o cobre para componentes eléctricos e plásticos ou metais duráveis para a caixa. Os fornecedores realizam frequentemente testes a estes materiais para garantir que cumprem propriedades eléctricas e mecânicas específicas.

- A certificação de materiais é essencial, especialmente para os compradores internacionais, uma vez que garante a conformidade com as normas globais. Por exemplo, a aquisição de materiais que cumpram as normas ASTM ou ISO pode afetar significativamente o desempenho e a longevidade do solenoide. -

Formando

- As técnicas de conformação variam consoante o componente que está a ser fabricado. No caso dos solenóides, a maquinagem de precisão e a estampagem são normalmente utilizadas para criar o núcleo e o invólucro.

- Tecnologias avançadas como a maquinagem CNC (Controlo Numérico Computadorizado) permitem uma elevada precisão e repetibilidade, essenciais para garantir que os componentes se encaixam corretamente durante a montagem. -

Montagem

- O processo de montagem envolve normalmente vários subconjuntos, incluindo a bobina do solenoide, o êmbolo e o invólucro. As linhas de montagem automatizadas são frequentemente utilizadas para aumentar a eficiência e reduzir o erro humano.

- Durante esta fase, é crucial assegurar que as ligações eléctricas estão seguras e que o solenoide está corretamente calibrado para funcionar com a tensão e amperagem especificadas. -

Acabamento

- A fase de acabamento pode envolver processos de tratamento de superfície, como o revestimento, a pintura ou a galvanização, para melhorar a resistência à corrosão e o aspeto estético.

- As verificações de controlo de qualidade durante esta fase asseguram que todos os componentes cumprem as especificações de conceção e estão isentos de defeitos.

Que medidas de controlo de qualidade são essenciais para os solenóides do motor de arranque?

A garantia de qualidade é vital na produção de solenóides para motores de arranque, particularmente para compradores B2B que exigem fiabilidade e desempenho. A implementação de medidas robustas de controlo de qualidade (CQ) é essencial para garantir que o produto final cumpre as normas internacionais.

-

Conformidade com normas internacionais

- A adesão à norma ISO 9001, que define os critérios para um sistema de gestão da qualidade, é crucial para os fabricantes. Esta certificação demonstra um compromisso com a qualidade e a melhoria contínua.

- As normas específicas da indústria, como a CE (Conformité Européenne) para produtos vendidos no Espaço Económico Europeu e a API (American Petroleum Institute) para componentes automóveis, garantem ainda que os solenóides são seguros e eficazes. -

Pontos de verificação do controlo de qualidade

– Controlo de Qualidade de Entrada (IQC): Nesta fase, as matérias-primas são inspeccionadas à chegada para garantir que cumprem as normas especificadas. Isto inclui a verificação das certificações dos materiais e a realização de testes iniciais.

– Controlo de qualidade em processo (IPQC): Durante o processo de fabrico, são recolhidas amostras aleatórias em várias fases para garantir o cumprimento das normas de qualidade. Isto pode implicar o controlo do desempenho das máquinas e a realização de verificações regulares da precisão da montagem.

– Controlo de Qualidade Final (FQC): Antes da expedição, cada solenoide é submetido a uma inspeção final. Isto inclui testes de funcionalidade, como a verificação da resistência eléctrica adequada e a garantia de que o solenoide engata corretamente sob carga. -

Métodos de teste comuns

- O teste elétrico é crucial e normalmente envolve a verificação da continuidade, resistência e queda de tensão. Os testes funcionais asseguram que o solenoide funciona corretamente quando está sob tensão.

- Podem também ser realizados testes ambientais, como ciclos de temperatura e exposição à humidade, para simular condições reais e garantir a durabilidade.

Como os compradores B2B podem verificar o controlo de qualidade dos fornecedores?

Para os compradores B2B internacionais, especialmente os de regiões como África, América do Sul, Médio Oriente e Europa, é essencial verificar os processos de controlo de qualidade de um fornecedor. Aqui estão estratégias acionáveis para garantir a qualidade:

-

Auditorias a fornecedores

- A realização de auditorias no local permite aos compradores avaliar os processos de fabrico, as medidas de controlo de qualidade e as capacidades operacionais gerais dos potenciais fornecedores. Esta experiência em primeira mão pode revelar o empenhamento na qualidade e a conformidade com as normas internacionais. -

Relatórios e certificações de qualidade

- A solicitação de documentação, como relatórios de controlo de qualidade, certificações de materiais e certificados de conformidade, pode fornecer informações sobre a adesão do fornecedor às normas da indústria. As actualizações regulares destes documentos devem fazer parte do processo de aquisição. -

Inspeções por terceiros

- A contratação de agências de inspeção de terceiros pode fornecer uma avaliação imparcial dos processos de fabrico e da qualidade do produto. Estas agências podem realizar inspecções aleatórias durante várias fases da produção e fornecer relatórios detalhados.

Quais são as nuances do controlo de qualidade para compradores B2B internacionais?

A navegação no panorama do controlo de qualidade pode ser complexa para os compradores internacionais. É essencial compreender os regulamentos e normas regionais.

-

Requisitos de conformidade regionais

- Os compradores têm de estar cientes dos requisitos de conformidade específicos das suas respectivas regiões. Por exemplo, os compradores da UE podem exigir a marcação CE, enquanto os do Médio Oriente podem procurar a certificação G-mark.

- Além disso, o conhecimento da legislação local relativa às importações e à segurança dos produtos pode evitar atrasos dispendiosos e problemas de conformidade. -

Considerações culturais e logísticas

- As diferentes regiões podem ter diferentes abordagens ao controlo de qualidade e às práticas de fabrico. Estabelecer relações com fornecedores que compreendam estas nuances pode conduzir a melhores resultados.

- Os desafios logísticos, como os regulamentos de expedição e aduaneiros, podem afetar a entrega atempada dos produtos. É essencial trabalhar com fornecedores que tenham experiência em comércio internacional e que saibam lidar com estas complexidades. -

Melhoria contínua e ciclos de feedback

- O estabelecimento de ciclos de feedback com os fornecedores pode promover uma cultura de melhoria contínua. A comunicação regular sobre o desempenho do produto e as questões de qualidade pode ajudar a resolver as preocupações de forma proactiva e a reforçar as parcerias.

Ao centrarem-se nestes aspectos dos processos de fabrico e da garantia de qualidade dos solenóides para motores de arranque, os compradores B2B podem tomar decisões informadas, assegurando que adquirem componentes fiáveis e de alta qualidade para as suas necessidades no sector automóvel.

Guia prático de abastecimento: Uma lista de verificação passo-a-passo para ‘como testar um solenoide de motor de arranque’

Para garantir a eficácia dos testes e da aquisição de um solenoide de motor de arranque, este guia fornece uma lista de verificação estruturada que os compradores B2B podem seguir. Ao seguir estes passos, as empresas podem otimizar as suas decisões de compra, garantindo que adquirem componentes de alta qualidade que satisfazem as suas necessidades operacionais.

Passo 1: Identificar os seus requisitos de teste

É fundamental compreender os requisitos específicos para testar um solenoide do motor de arranque. Determine os tipos de veículos ou máquinas que irá reparar, uma vez que modelos diferentes podem exigir protocolos de teste únicos. Esta clareza ajudará a simplificar o seu processo de aprovisionamento, permitindo-lhe concentrar-se nos fornecedores que fornecem componentes compatíveis com as suas necessidades.

Imagem ilustrativa relacionada com a forma de testar um solenoide do motor de arranque

Passo 2: Pesquisar potenciais fornecedores

Faça uma pesquisa exaustiva para identificar fornecedores especializados em componentes eléctricos para automóveis. Procure empresas com uma sólida reputação no sector, bem como críticas positivas de clientes anteriores. Utilize plataformas como feiras comerciais, publicações do sector e mercados online para reunir uma lista abrangente de potenciais fornecedores.

Passo 3: Avaliar as certificações dos fornecedores

Antes de assumir um compromisso, verifique se os potenciais fornecedores possuem certificações relevantes. Certificações como a ISO 9001 podem indicar que o fornecedor cumpre as normas de gestão da qualidade. Além disso, verifique se existem certificações específicas do sector que possam ser necessárias para a sua região, especialmente se estiver a abastecer-se em mercados internacionais.

Passo 4: Solicitar amostras de produtos

Para garantir a qualidade do solenoide do motor de arranque, solicitar amostras aos fornecedores selecionados. Testar amostras antes de efetuar uma compra a granel permite-lhe avaliar o seu desempenho e compatibilidade com o seu equipamento. Preste atenção aos materiais utilizados, ao design e à qualidade geral da construção, uma vez que estes factores influenciam significativamente a fiabilidade.

Passo 5: Rever as políticas de garantia e devolução

Compreender a garantia e as políticas de devolução é essencial para mitigar o risco. Informe-se sobre o período de garantia dos solenóides do motor de arranque e as condições em que as devoluções são aceites. Uma garantia robusta pode indicar a confiança do fornecedor no seu produto, enquanto as políticas de devolução flexíveis proporcionam segurança no caso de os componentes não corresponderem às suas expectativas.

Passo 6: Avaliar os serviços de apoio técnico

Avalie o nível de suporte técnico que os fornecedores oferecem. Os fornecedores fiáveis devem fornecer documentação abrangente, incluindo guias de instalação e sugestões de resolução de problemas. Além disso, considere se eles oferecem suporte ou consultoria contínua, que pode ser inestimável para resolver problemas que possam surgir durante o teste e a implementação.

Passo 7: Negociar preços e condições

Depois de ter selecionado um fornecedor preferencial, inicie negociações para estabelecer preços e condições de pagamento favoráveis. Considere descontos para compras a granel ou opções de contrato a longo prazo, especialmente se prevê uma procura consistente de solenóides para motores de arranque. Uma comunicação clara sobre o seu orçamento e requisitos promoverá uma relação mutuamente benéfica.

Ao seguir esta lista de verificação, os compradores B2B podem navegar no processo de aquisição com confiança, garantindo que obtêm solenóides de motor de arranque de alta qualidade que satisfazem as suas necessidades operacionais, minimizando os riscos associados ao desempenho do produto e à fiabilidade do fornecedor.

Análise abrangente de custos e preços para como testar um solenoide de motor de arranque Sourcing

Quais são os principais componentes de custo para testar um solenoide de motor de arranque?

Ao analisar a estrutura de custos para testar um solenoide de motor de arranque, entram em jogo vários componentes-chave:

Imagem ilustrativa relacionada com a forma de testar um solenoide do motor de arranque

-

Materiais: Os principais materiais envolvidos incluem o próprio solenoide do motor de arranque, a cablagem, os conectores e o equipamento de teste, como voltímetros e luzes de teste. Dependendo da qualidade e das especificações, os preços destes materiais podem variar significativamente. Os componentes de alta qualidade resultam frequentemente num melhor desempenho e numa vida útil mais longa, o que é crucial para os utilizadores finais.

-

Trabalho: São necessários técnicos qualificados para efetuar os testes com precisão. Os custos de mão de obra podem variar consoante a localização geográfica e o nível de especialização do pessoal. Em regiões com escassez de mão de obra especializada, como certas zonas de África e da América do Sul, os custos de mão de obra podem ser mais elevados devido à procura.

-

Custos indiretos de produção: Inclui os custos associados a instalações, serviços públicos e despesas administrativas que apoiam a produção de solenóides para motores de arranque. Uma gestão eficaz das despesas gerais pode afetar significativamente os preços globais.

-

Ferramentas: Podem ser necessárias ferramentas especializadas para testar e fabricar solenóides, o que contribui para o investimento inicial. As empresas devem avaliar se devem alugar ou comprar estas ferramentas com base no seu volume de testes projetado.

-

Controlo de Qualidade (QC): Garantir que os produtos cumprem as normas de qualidade é essencial para minimizar as devoluções e manter a satisfação do cliente. A implementação de medidas robustas de controlo de qualidade pode aumentar os custos iniciais, mas reduzirá os custos a longo prazo associados a defeitos e falhas.

-

Logística: Os custos de envio e de manuseamento podem aumentar a despesa total. Factores como a distância, o modo de transporte e o peso da remessa podem influenciar estes custos.

-

Margem: Os fornecedores incluem normalmente uma margem de lucro na sua estrutura de preços, que pode variar em função da concorrência e da procura no mercado.

Como é que os influenciadores de preços afectam os custos de teste do solenoide do motor de arranque?

Vários fatores influenciam o preço dos serviços de teste do solenóide do motor de arranque:

-

Volume/MOQ: As quantidades mínimas de encomenda (MOQ) podem afetar significativamente os preços. Volumes mais elevados conduzem frequentemente a uma redução dos custos por unidade, o que torna essencial que os compradores tenham em conta o seu poder de compra.

-

Especificações e personalização: As soluções personalizadas adaptadas a tipos de veículos específicos ou a requisitos de teste podem implicar custos adicionais. Os compradores devem equilibrar a necessidade de personalização com as restrições orçamentais.

-

Materiais e certificações de qualidade: A escolha dos materiais tem um impacto direto na durabilidade e no desempenho. Além disso, os produtos com certificações industriais podem ter preços mais elevados, mas oferecem garantia de qualidade, o que pode ser um fator crítico para os compradores internacionais.

-

Fatores relacionados ao fornecedor: A reputação e a fiabilidade dos fornecedores podem afetar os preços. Os fornecedores estabelecidos com um historial comprovado podem cobrar mais, mas muitas vezes oferecem um melhor apoio e fiabilidade.

-

Incoterms: A compreensão das condições de envio é vital para as transacções internacionais. Os Incoterms ditam as responsabilidades relativas ao transporte, seguro e tarifas, o que pode influenciar o custo total de propriedade para os compradores.

Que dicas podem os compradores utilizar para negociar os custos de forma eficaz?

Os compradores B2B internacionais podem utilizar várias estratégias para melhorar a relação custo-eficácia:

-

Negociação: Envolver os fornecedores em discussões sobre estruturas de preços, especialmente para encomendas em massa. O estabelecimento de relações a longo prazo pode também conduzir a melhores condições.

-

Relação custo-benefício: Analise o custo total de propriedade e não apenas o preço de compra. Considere factores como a manutenção, a garantia e as potenciais devoluções ao avaliar as opções.

-

Compreender as nuances da fixação de preços: As diferentes regiões podem ter uma dinâmica de preços única. Por exemplo, os compradores do Brasil podem ser confrontados com tarifas que afectam os custos totais, enquanto os da Arábia Saudita podem beneficiar de incentivos ao abastecimento local.

-

Pesquisar e comparar: Recolher cotações de vários fornecedores para conhecer os preços de mercado. Este conhecimento proporciona uma vantagem nas negociações.

-

Foco na qualidade: Embora seja importante procurar preços mais baixos, comprometer a qualidade pode levar a custos mais elevados a longo prazo devido a falhas ou ineficiências.

Isenção de responsabilidade sobre preços indicativos

O preço para testar os solenóides do motor de arranque pode variar muito com base nos factores discutidos. É aconselhável que os compradores efectuem uma pesquisa exaustiva e obtenham orçamentos específicos adaptados às suas necessidades e circunstâncias.

Análise de alternativas: Comparação de como testar um solenoide de motor de arranque com outras soluções

Introdução: Avaliação de alternativas para o teste de solenóides de motores de arranque

Quando se trata de garantir a integridade operacional dos solenóides do motor de arranque, compreender os vários métodos de teste disponíveis é crucial para os compradores B2B, especialmente os dos sectores da reparação e manutenção automóvel. Embora o método tradicional de testar um solenoide de motor de arranque se tenha revelado eficaz, as soluções alternativas podem oferecer diferentes vantagens. Esta secção avalia como testar um solenoide de motor de arranque em relação a outros métodos viáveis, ajudando as empresas a tomar decisões informadas e adaptadas às suas necessidades operacionais.

Tabela comparativa

| Aspecto comparativo | Como testar um solenoide de motor de arranque | Teste de queda de tensão | Testes em bancada |

|---|---|---|---|

| Desempenho | Fiável para identificar problemas nos solenóides | Eficaz no diagnóstico de falhas eléctricas | Avaliação exaustiva da funcionalidade do solenoide |

| Custo | Ferramentas de baixo custo (multímetro/lâmpada de teste) | Custo mínimo, requer um multímetro | Custo moderado (montagem em banco de ensaio) |

| Facilidade de implementação | Requer conhecimentos e ferramentas básicos | Simples, mas requer conhecimentos de princípios eléctricos | Requer equipamento e competências especializadas |

| Manutenção | Manutenção reduzida; as ferramentas são duradouras | Manutenção reduzida; os multímetros são robustos | Moderado; os bancos de ensaio podem necessitar de calibração |

| Melhor caso de uso | Diagnóstico rápido no local | Identificação de problemas de tensão em circuitos complexos | Avaliação pormenorizada para remodelação ou substituição |

Discriminação detalhada das alternativas

Teste de queda de tensão: Uma alternativa eficaz

O teste de queda de tensão é um método simples que avalia a integridade eléctrica de um solenoide do motor de arranque, medindo a perda de tensão através do componente quando a corrente flui. Esta técnica é vantajosa para diagnosticar não só problemas com o solenoide, mas também potenciais problemas de cablagem no circuito de arranque. É relativamente barata, uma vez que requer principalmente um multímetro, que é uma ferramenta comum em muitas oficinas de reparação automóvel. No entanto, exige uma compreensão básica dos princípios eléctricos e pode não ser tão fácil de utilizar por técnicos menos experientes.

Teste de bancada: Avaliação exaustiva

O teste em banco de ensaio oferece uma avaliação mais completa de um solenoide do motor de arranque, retirando-o do veículo e testando-o em condições controladas. Este método permite aos técnicos avaliar o desempenho do solenoide isoladamente, tornando-o ideal para cenários de renovação ou substituição. Embora esta abordagem forneça informações detalhadas sobre a funcionalidade do componente, requer uma bancada de testes e possivelmente formação especializada, o que pode aumentar os custos iniciais de instalação. Além disso, pode não ser prático para diagnósticos rápidos num ambiente de oficina movimentado, onde a eficiência do tempo é crítica.

Conclusão: escolhendo a solução certa para as suas necessidades

A seleção do método adequado para testar um solenoide de motor de arranque depende, em última análise, das necessidades e recursos específicos da sua empresa. Para diagnósticos rápidos, no local, o método tradicional de testar o solenoide continua a ser uma escolha fiável. Por outro lado, se as suas operações exigirem uma análise aprofundada ou uma remodelação, o teste de bancada pode revelar-se mais vantajoso, apesar dos seus custos de instalação mais elevados. O teste de queda de tensão atinge um equilíbrio entre custo e eficácia, tornando-o uma alternativa valiosa para quem procura diagnosticar problemas eléctricos de forma eficiente. Em última análise, os compradores B2B devem avaliar os seus requisitos operacionais, os níveis de competências dos técnicos e as restrições orçamentais para determinar a melhor solução para as suas necessidades.

Propriedades técnicas essenciais e terminologia comercial para saber como testar um solenoide do motor de arranque

Quais são as propriedades técnicas essenciais ao testar um solenoide de motor de arranque?

Ao testar um solenoide de motor de arranque, várias propriedades técnicas são cruciais para garantir um desempenho e fiabilidade óptimos. A compreensão destas especificações pode ajudar os compradores B2B a tomar decisões informadas relativamente à qualidade e compatibilidade do produto.

-

Grau do material

– Definição: O tipo de material refere-se ao tipo específico de metal utilizado no fabrico do solenoide, frequentemente cobre ou alumínio para componentes eléctricos.

– Importância: Os materiais de alta qualidade são essenciais para a durabilidade e a condutividade eléctrica. Em regiões com temperaturas extremas ou condições adversas, um material robusto pode evitar falhas prematuras, reduzindo assim os custos de manutenção. -

Classificação atual

– Definição: Esta propriedade indica a corrente máxima que o solenoide pode suportar sem sobreaquecer.

– Importância: Um solenoide com uma corrente nominal mais elevada é necessário para veículos de alto desempenho ou aplicações com requisitos eléctricos exigentes. Correntes nominais adequadas podem evitar o sobreaquecimento e a avaria, garantindo a longevidade. -

Tolerância de resistência

– Definição: A tolerância da resistência especifica a gama aceitável de resistência em ohms dentro da bobina do solenoide.

– Importância: A manutenção de níveis de resistência corretos é crucial para um funcionamento eficiente. Uma resistência demasiado elevada pode indicar uma avaria, enquanto uma resistência demasiado baixa pode sugerir um curto-circuito. Compreender isto pode ajudar na resolução de problemas e garantir que o solenoide funciona eficazmente. -

Tensão de funcionamento

– Definição: Este é o nível de tensão a que o solenoide foi concebido para funcionar, normalmente 12V em aplicações automóveis.

– Importância: A compatibilidade com o sistema elétrico do veículo é essencial. A utilização de um solenoide com uma tensão de funcionamento incorrecta pode provocar falhas ou danos no solenoide e no motor de arranque. -

Tempo de envolvimento

– Definição: O tempo de arranque refere-se ao tempo que o solenoide demora a ativar o motor de arranque quando a ignição é ligada.

– Importância: O engate rápido é essencial para um arranque fiável do veículo. Um solenoide com um tempo de engate prolongado pode indicar desgaste ou mau funcionamento, levando a problemas de arranque. -

Classificação de temperatura

– Definição: Esta propriedade define a gama de temperaturas em que o solenoide pode funcionar eficazmente.

– Importância: Para os compradores B2B em regiões com climas extremos, a seleção de solenóides com classificações de temperatura adequadas garante um desempenho fiável e evita falhas devido ao stress térmico.

Qual a terminologia comercial comum que os compradores B2B devem conhecer?

Compreender o jargão do sector é essencial para uma comunicação e negociação eficazes no espaço B2B. Eis alguns termos-chave relacionados com os solenóides para motores de arranque:

-

OEM (Fabricante de Equipamento Original)

– Definição: OEM refere-se a empresas que produzem peças que são utilizadas no fabrico de veículos ou máquinas.

– Importância: A compra de peças OEM pode garantir a compatibilidade e o desempenho, o que é especialmente importante para as empresas que procuram manter padrões de qualidade nas reparações ou substituições. -

MOQ (Quantidade mínima de encomenda)

– Definição: É a quantidade mais pequena de um produto que um fornecedor está disposto a vender.

– Importância: Compreender o MOQ é vital para a gestão de stocks. Os compradores devem assegurar-se de que podem cumprir o MOQ sem excesso de stock, o que pode imobilizar capital. -

RFQ (Pedido de Orçamento)

– Definição: Um pedido de cotação é um documento enviado aos fornecedores solicitando uma cotação para produtos ou serviços específicos.

– Importância: A utilização de RFQs pode simplificar o processo de compra e promover preços competitivos, permitindo aos compradores tomar decisões rentáveis. -

Incoterms (Termos Comerciais Internacionais)

– Definição: Trata-se de termos de envio normalizados que definem as responsabilidades dos compradores e vendedores nas transacções internacionais.

– Importância: A familiaridade com os Incoterms ajuda a compreender os custos de envio, os riscos e as responsabilidades de entrega, o que é crucial para as transacções B2B internacionais. -

Prazo de entrega

– Definição: O prazo de entrega é o período de tempo que decorre entre a encomenda e a receção do produto.

– Importância: O conhecimento dos prazos de entrega é essencial para o planeamento de projectos e a gestão de stocks, ajudando as empresas a evitar atrasos nas operações. -

Garantia

– Definição: Uma garantia é uma garantia fornecida pelo fabricante relativamente ao estado do produto e às condições de reparação ou substituição.

– Importância: Uma garantia sólida pode oferecer tranquilidade aos compradores, indicando a confiança do fabricante na qualidade do seu produto e proporcionando proteção contra defeitos.

Ao compreender estas propriedades técnicas e termos da indústria, os compradores B2B podem tomar decisões mais informadas, garantindo que selecionam o solenoide de motor de arranque adequado às suas necessidades.

Navegar na dinâmica do mercado e nas tendências de aprovisionamento no sector de como testar um solenoide de motor de arranque

Quais são as actuais dinâmicas de mercado para o teste de um solenoide de motor de arranque?

O mercado do ensaio de solenóides de motores de arranque é influenciado por vários factores a nível mundial. À medida que a tecnologia automóvel avança, há uma procura crescente de métodos de teste eficientes para garantir a fiabilidade do veículo. Isto é particularmente relevante para os compradores B2B internacionais em regiões como a África, a América do Sul, o Médio Oriente e a Europa, onde a manutenção dos veículos é crucial para a eficiência operacional. As tecnologias emergentes, como as ferramentas de diagnóstico digital e as aplicações móveis, estão a moldar o panorama, permitindo que os mecânicos e os técnicos automóveis realizem testes com maior precisão e rapidez.

Além disso, a mudança para os veículos eléctricos (VE) está a provocar uma reavaliação dos sistemas de arranque tradicionais, incluindo os solenóides. À medida que os fabricantes se adaptam para apoiar as infra-estruturas de EV, os compradores B2B têm de se adaptar a estas mudanças, adquirindo componentes que cumpram as novas especificações. Além disso, o aumento das plataformas de comércio eletrónico está a transformar as práticas de aquisição, permitindo aos compradores internacionais aceder a uma gama mais vasta de ferramentas e equipamentos de teste, muitas vezes a preços competitivos. O foco também está a mudar para a automação e o diagnóstico remoto, simplificando o processo de teste e reduzindo o tempo de inatividade.

Como a sustentabilidade e o fornecimento ético estão impactando o mercado de solenóides de motor de partida?

A sustentabilidade está a tornar-se cada vez mais uma prioridade no sector automóvel, incluindo os ensaios e o fornecimento de solenóides para motores de arranque. O impacto ambiental dos componentes automóveis, desde a produção até à eliminação, levou a uma procura de alternativas mais ecológicas. Os compradores B2B estão agora à procura de fornecedores que dêem prioridade ao fornecimento ético e à sustentabilidade nos seus processos de fabrico. Isto inclui a utilização de materiais reciclados, a redução de resíduos e a garantia de conformidade com os regulamentos ambientais.

Além disso, certificações como a ISO 14001 (Gestão Ambiental) e a utilização de materiais ‘verdes’ estão a tornar-se essenciais para os fornecedores que pretendem diferenciar-se no mercado. Os compradores são incentivados a avaliar as suas cadeias de abastecimento em termos de sustentabilidade, uma vez que tal não só reflecte a responsabilidade social das empresas, como também pode melhorar a reputação da marca e a fidelidade dos clientes. Ao alinhar as estratégias de aprovisionamento com práticas sustentáveis, as empresas podem reduzir a sua pegada de carbono e contribuir para um planeta mais saudável, sem deixar de cumprir as normas de desempenho e qualidade.

Como é que o teste dos solenóides do motor de arranque evoluiu ao longo do tempo?

A evolução dos métodos de teste para solenóides de motores de arranque pode ser rastreada até ao surgimento da tecnologia automóvel no início do século XX. Inicialmente, os testes envolviam verificações manuais básicas, muitas vezes baseadas em medidores mecânicos e ferramentas rudimentares. À medida que os sistemas automóveis se tornaram mais complexos, o mesmo aconteceu com as metodologias de ensaio, levando à introdução de dispositivos de diagnóstico eléctricos no final do século XX.

Atualmente, o panorama transformou-se com a integração de eletrónica avançada e diagnósticos orientados por software. O equipamento de teste moderno permite a análise em tempo real e a elaboração de relatórios pormenorizados, permitindo aos técnicos identificar as falhas com precisão. Esta evolução é particularmente significativa para os compradores B2B em diversos mercados, onde a eficiência e a fiabilidade dos métodos de teste têm um impacto direto nos custos operacionais e no desempenho dos veículos. À medida que a indústria continua a inovar, compreender estas mudanças é crucial para tomar decisões de compra informadas e manter-se competitivo no sector da reparação automóvel.

Imagem ilustrativa relacionada com a forma de testar um solenoide do motor de arranque

Perguntas frequentes (FAQs) para compradores B2B sobre como testar um solenoide do motor de arranque

-

Como testar eficazmente um solenoide do motor de arranque?

Para testar um solenoide do motor de arranque, comece por localizar o solenoide perto do motor de arranque do seu veículo. Certifique-se de que a bateria está carregada e utilize uma luz de teste para verificar se há energia nos terminais do solenoide. Ligue a luz de teste ao terminal de saída e ligue o outro fio à terra. Peça a alguém que ligue a ignição; se a luz se acender, o solenoide está a funcionar. Se o motor de arranque não engatar, o solenoide pode necessitar de ser substituído. Consulte sempre o manual de serviço do veículo para obter instruções específicas. -

Quais são os sinais comuns de um solenoide de arranque avariado?

Os sinais comuns de um solenoide de arranque avariado incluem um som de estalido ao rodar a ignição, o motor de arranque não engata ou problemas de arranque intermitentes. Se notar estes sintomas, isso pode indicar que o solenoide está a funcionar mal ou que existe um problema com a bateria ou com o motor de arranque. Efectue um teste completo para isolar o problema antes de proceder a reparações ou substituições. -

Como posso garantir a qualidade dos solenóides para motores de arranque dos fornecedores?

Para garantir a qualidade, solicite amostras e certificações aos fornecedores, verificando se cumprem as normas internacionais, como as especificações ISO ou OEM. Efectue verificações dos antecedentes do fornecedor, incluindo críticas e classificações de clientes anteriores. Também é aconselhável procurar referências e, se possível, visitar as instalações de fabrico para avaliar os seus processos de controlo de qualidade. -

Que opções de personalização estão disponíveis para os solenóides do motor de arranque?

Muitos fabricantes oferecem opções de personalização para solenóides de motores de arranque, incluindo variações de tensão, tamanho e configurações de terminais. Quando estiver a fazer compras, discuta os seus requisitos específicos com potenciais fornecedores para ver se podem satisfazer as suas necessidades. Seja claro sobre a sua aplicação para garantir que os solenóides cumprem as especificações técnicas necessárias para um desempenho ótimo. -

Qual é a quantidade mínima de encomenda (MOQ) típica para solenóides de motores de arranque?

O MOQ para solenóides de motor de arranque pode variar significativamente entre fornecedores, geralmente entre 50 e 500 unidades. Os factores que influenciam o MOQ incluem a capacidade de produção do fornecedor, a complexidade do produto e os seus pedidos de personalização específicos. Negocie sempre os termos e explore possíveis descontos para encomendas maiores para otimizar a sua estratégia de aquisição. -

Que condições de pagamento devo esperar quando forneço solenóides para motores de arranque a nível internacional?

As condições de pagamento podem variar, mas as opções comuns incluem pagamento adiantado, pagamento parcial antes da expedição ou cartas de crédito. Estabeleça antecipadamente condições claras com os fornecedores, tendo em conta factores como o seu fluxo de caixa e a fiabilidade do fornecedor. É prudente utilizar métodos de pagamento seguros para proteger os seus interesses financeiros em transacções internacionais. -

Como posso simplificar a logística de importação de solenóides para motores de arranque?

Para agilizar a logística, trabalhe em estreita colaboração com um transitário de renome com experiência em envios internacionais. Eles podem ajudar a navegar pelas regulamentações alfandegárias, otimizar as rotas de remessa e gerenciar a documentação. Certifique-se de que tem um conhecimento claro dos custos de envio, dos prazos de entrega e de quaisquer tarifas ou direitos potenciais que possam ser aplicados às suas importações. -

Que práticas de garantia de qualidade devo implementar quando forneço solenóides?

A implementação de práticas robustas de garantia de qualidade inclui a realização de inspecções antes da expedição, a exigência de especificações detalhadas dos produtos e o estabelecimento de uma comunicação clara com os fornecedores relativamente às normas de qualidade. Utilize serviços de inspeção de terceiros para verificar a conformidade com os seus requisitos antes da expedição. As auditorias regulares às instalações dos fornecedores também podem ajudar a garantir o controlo de qualidade contínuo e a reduzir os riscos associados ao aprovisionamento.

Lista dos 2 principais fabricantes e fornecedores de Como testar um solenoide de motor de arranque

1. Reddit - Cabo de arranque do solenoide

Domínio: reddit.com

Registado: 2005 (20 anos)

Introdução: cabo de arranque solenóide, multímetro, bateria, solenóide de arranque

2. WikiHow - Guia do solenoide de arranque

Domínio: wikihow.com

Registado: 2004 (21 anos)

Introdução: O solenoide do motor de arranque é um mecanismo que transmite a corrente eléctrica da bateria para o motor de arranque, accionando o motor elétrico para ligar o motor. Tem normalmente uma forma cilíndrica com um cilindro mais pequeno acoplado, localizado perto do local onde o motor e a transmissão se encontram. O solenoide tem dois terminais, um ligado à bateria. Quando se roda a chave da ignição, deve ouvir-se um estalido ...

Strategic Sourcing Conclusion and Outlook for how to test a starter motor solenoid

Em conclusão, testar eficazmente um solenoide do motor de arranque é crucial para garantir um desempenho fiável do veículo, particularmente em mercados diversos como África, América do Sul, Médio Oriente e Europa. Ao seguir métodos sistemáticos - localizar o solenoide, verificar a corrente e avaliar a resistência - os compradores B2B podem melhorar significativamente as suas capacidades de resolução de problemas. Isto não só poupa tempo e reduz os custos de reparação, como também promove relações mais fortes com os clientes que dependem da funcionalidade consistente do veículo.

O aprovisionamento estratégico desempenha um papel fundamental neste processo. Ao estabelecer parcerias com fornecedores de renome que fornecem motores de arranque e solenóides de alta qualidade, as empresas podem garantir que têm acesso a componentes fiáveis que cumprem as normas internacionais. O envolvimento em sourcing estratégico permite que as empresas aproveitem os preços competitivos e a garantia de qualidade, que são essenciais nos mercados emergentes.

Ao navegar pelas complexidades do aprovisionamento e dos testes, considere estabelecer relações com fornecedores de confiança que compreendam as necessidades específicas da sua região. Ao fazê-lo, pode aumentar a eficiência operacional e posicionar a sua empresa para o sucesso a longo prazo. Comece hoje a explorar as suas opções de fornecimento para garantir os melhores componentes para as suas necessidades automóveis e assegurar que os seus veículos estão sempre prontos a funcionar.

Aviso legal importante e termos de utilização

⚠️ Aviso importante

As informações fornecidas neste guia, incluindo conteúdo sobre fabricantes, especificações técnicas e análises de mercado, têm fins meramente informativos e educativos. Não constituem aconselhamento profissional sobre aquisições, aconselhamento financeiro ou aconselhamento jurídico.

Embora tenhamos envidado todos os esforços para garantir a precisão e atualidade das informações, não nos responsabilizamos por quaisquer erros, omissões ou informações desatualizadas. As condições de mercado, os detalhes da empresa e os padrões técnicos estão sujeitos a alterações.

Imagem ilustrativa relacionada com a forma de testar um solenoide do motor de arranque

Os compradores B2B devem realizar a sua própria diligência prévia independente e minuciosa. antes de tomar qualquer decisão de compra. Isso inclui entrar em contacto diretamente com os fornecedores, verificar certificações, solicitar amostras e procurar aconselhamento profissional. O risco de confiar em qualquer informação contida neste guia é assumido exclusivamente pelo leitor.